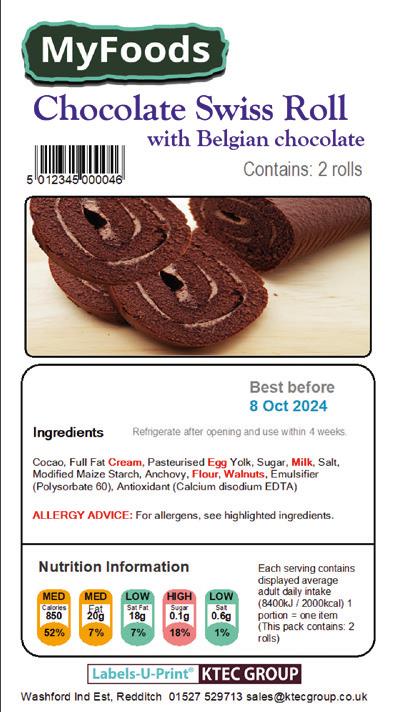

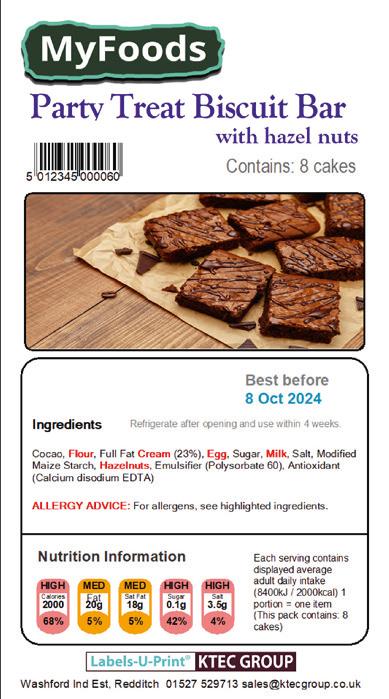

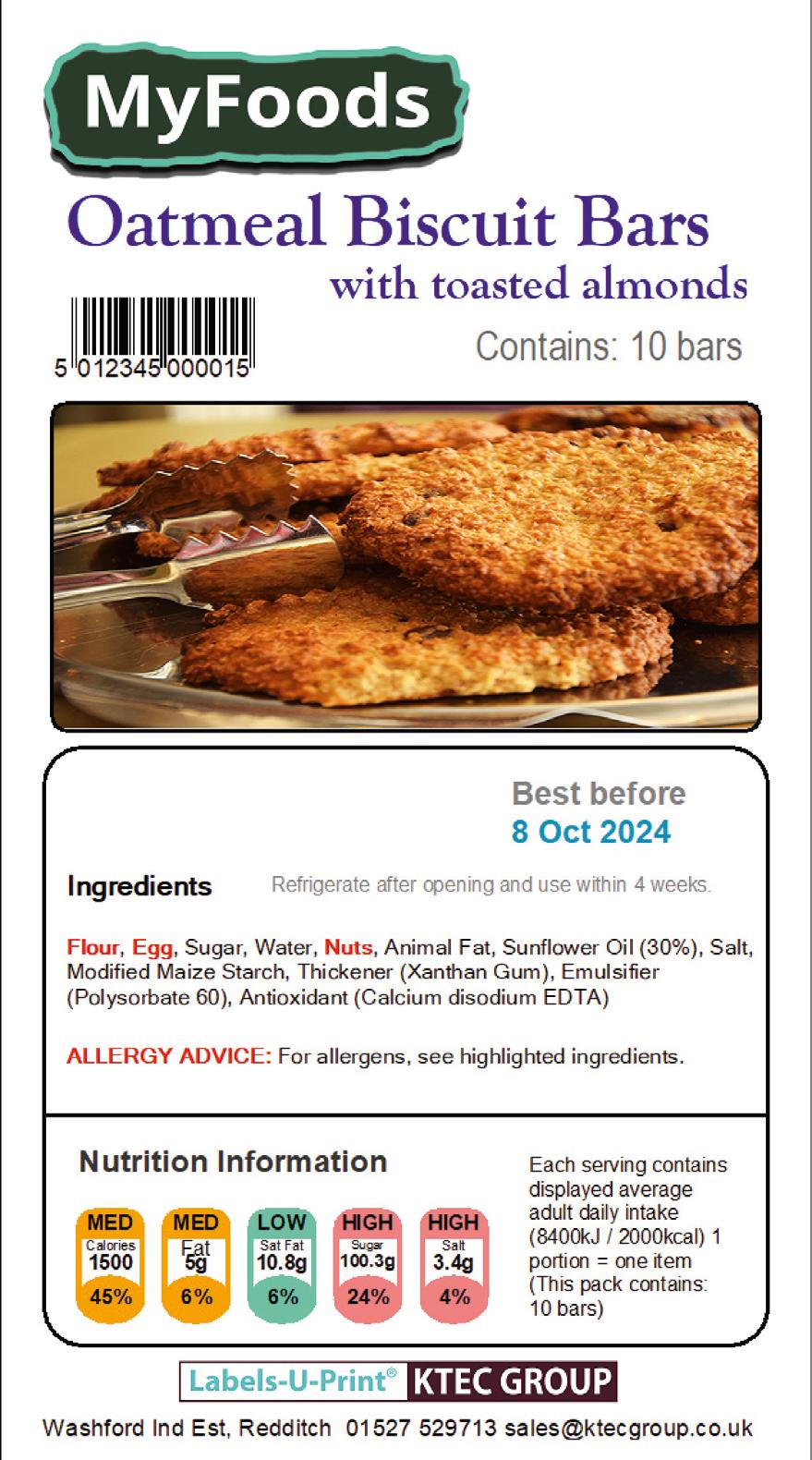

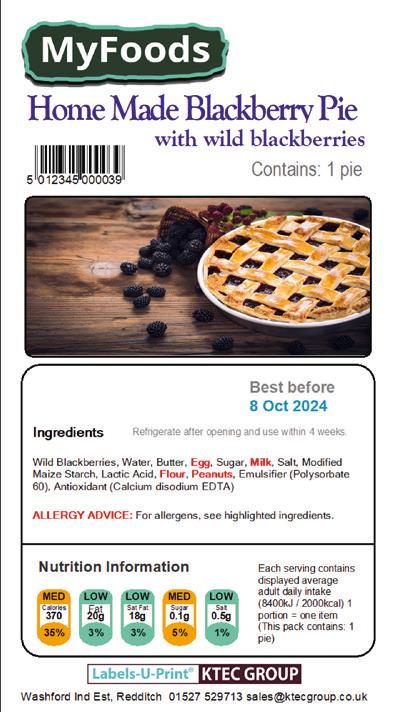

Stay compliant with UK regulations, including Natasha’s Law, by printing clear allergen and nutrition information.

Editor Paul Attwood editor@fdm-uk.co.uk

Editorial Assistant Sophie Weir editorial@fdm-uk.co.uk

Features Editor

Henry Peters editorial@fdm-uk.co.uk

Production/Design

Laura Whitehead laura@lapthornmedia.co.uk

Sales Manager Holly Jones sales@fdm-uk.co.uk

Publishing Director

Maria Lapthorn maria@lapthornmedia.co.uk

Lapthorn Media Ltd 5-7 Ozengell Place, Eurokent Business Park, Ramsgate, Kent, CT12 6PB

UK’s first fairtrade fonio grain beer hits the shelves at Co-op, Sainsbury’s and Waitrose EcoClarity and Yorkshire Water join forces in fight against fatbergs

Interview with Mark Norton, Prima Bakeries Group’s Managing Director Logistics UK Virtual Transport Manager returns in November IoT technology takes sustainable cheese-making from gouda to grate

With the evenings drawing in, it is a clear indication that 2025 is on the horizon and with it a whole new set of rules and regulations for the food and drink manufacturing industry to become familiar with, so are you prepared?

In this issue, we have a piece by Mark Ross, the Global Brand Manager for Titan Containers Arctic store, about the need for cold storage solutions for the modern-day e-commerce food market.

We also have a piece by Michael Laurier, Chief Executive Officer at Symphony Environmental, who is at the forefront of packaging technology. He lists five key trends for the plastics sector to look out for in 2025.

We hope you enjoy this issue and as always, if you have any news that you would like to feature, please email details to editorial@fdm-uk.co.uk

A new set of animated videos following the Welsh farm to fork journey, produced by Hybu Cig Cymru – Meat Promotion Wales (HCC), has been launched to help educate the next generation and promote PGI Welsh Lamb, PGI Welsh Beef and Pork from Wales.

The Journey from Farm to Food animated video series aims to educate children on farming in Wales and how red meat is produced. The videos are narrated by popular Welsh television presenter and author Mari Lovgreen,

who is known for presenting children’s television programmes on S4C as well as Cefn Gwlad, the Urdd Eisteddfod and the Royal Welsh Show coverage. Mari also lives on a beef and sheep farm with her young family in mid Wales.

There are two sets of videos, one suited for 5-7 year olds and another for 8-11 year olds, each available in English and Welsh. The videos are approximately 4 minutes long and have been created with school lessons in mind.

The videos focus on Wales’ sustainable farming methods, highlighting how the weather and natural grasslands in Wales create the ideal conditions to produce delicious and sustainable Welsh Lamb, Welsh Beef and Pork from Wales.

The videos are being shared with schools and teachers at the start of the new school year in HCC’s new

New commercial food waste legislation in the UK will come into force at the end of March 2025.

The new law means that most businesses will have to separate food waste from other waste streams. Companies must store waste food in separate bins and arrange for its collection by licensed waste carriers.

This is part of Defra’s simpler recycling plans that aim to improve recycling rates, simplify waste

management, and benefit the environment. Mandatory food waste separation should ensure less waste food makes its way to landfill sites and is instead disposed of responsibly.

The new food waste legislation in the UK is part of a legal statutory instrument to standardise recycling across England. This is the Environment Act 2021 (Commencement No. 9 and Transitional Provisions) Regulations 2024. It focuses on changing waste separation and collection requirements for domestic and non-domestic premises. Put simply –most businesses will have to arrange separate food waste collections.

Any business in England that produces more than 5kg of food waste per week must arrange separate collections by licensed waste carriers. This includes any biodegradable

material waste produced from processing or preparing food –including inedible parts like bones, eggshells, fruit and vegetable skins, tea bags, and coffee grounds.

According to the official government response, the preference is for food waste to go for anaerobic digestion treatment. This is because it generates biofuel and digestate from unavoidable waste food. Biofuel can be used for energy while digestate is spread on land to recycle nutrients and help form a circular economy.

The new food waste law requiring businesses to separate waste food comes into effect on 31 March 2025 in the UK. This includes for public and third-sector organisations like schools, prisons, and hospitals.

For micro businesses (firms with fewer than 10 full-time employees),

teacher-focused newsletter The Kitchen Classroom / Gwersi o’r Gegin which launched earlier this year. The newsletter covers a range of food and farming topics and is tailored to primary and secondary school teachers as well as being available in English and Welsh.

The new Journey from Farm to Food videos will be featured and available to download for those signed up to the newsletter as well as on HCC’s dedicated site: redmeathub.wales.

they must comply with the new food waste law by 31 March 2027.

Mandatory food waste separation will apply to all non-domestic properties in England such as care homes, offices, schools, garages, and transport hubs. It’s especially relevant for restaurants, cafes, pubs, takeaways, bakeries, and butchers.

Micro businesses are exempt from the new food waste regulation for a couple of years. Any firm with fewer than ten full-time employees can still dispose of food scraps and leftovers in general waste bins. However, separating food waste is advisable where possible for companies of any size and industry.

The UK government aims to eliminate food waste from landfill by 2030. It’s hoped that this new legislation can drive England towards that target, as it also covers changes to food waste collections from homes. Wales and Scotland already have their own food waste legislation in place.

Supermarket carrot Prices have soared by nearly 40% following a “disastrous” year marked by widespread flooding.

The price of own-label carrots has jumped by an average of 38% year on year to 69p per 800g-1kg pack in Aldi, Asda, Lidl, Morrisons, Sainsbury’s and Tesco, according to The Grocer’s analysis of Assosia’s Key Value Items tracker. In the past month alone, prices have risen by 6%. Waitrose has also hiked prices to a lesser extent: by 7% to 75p per pack in the past month, and 25% in the past year.

The upward price movement follows an “undoubtedly disastrous” year that “really stung” the industry, according to Rodger Hobson, chair of the British Carrot Growers Association.

The past 12 months have been the “toughest year I’ve ever known”

due to flooding that wiped out thousands of tonnes of crops, he said.

The Weather resulted in a higher level of imported carrots, which are typically two to three times more expensive than those grown in the UK, he revealed.

One industry expert also suggested the higher prices reflected retailers “getting tired” of the price war, which had led to many carrots being sold below the cost of production.

This summer’s weather had been more predictable, making it a “nice carrot year,” Hobson said.

“I don’t think it’s going to be a massive year from a yield point of view, but I don’t think it’s going to be a disaster either,” he forecast.

“Supply should be steady, but I don’t think there’s going to be a big surplus.”

Supermarkets are lining up to stock the UK’s first Fairtrade Fonio grain beer as shoppers increasingly switch to Fairtrade.

Brewgooder Fairtrade Fonio Session IPA is now available at Co-op, Sainsbury’s and Waitrose, as well as on British Airways flights. It comes as research reveals around 80% of consumers have chosen Fairtrade products over an alternative.

The delicious, crisp and hoppy 4.3% Session IPA is packaged in colourful cans urging shoppers to ‘Fairtrade up your beer’.

The new beer was recently recognised with a Great Taste Award – dubbed the ‘Oscars of the food and drink world’ – after a blind taste testing by more than 500 critics, chefs, recipe creators, buyers, retailers, and other specialists in the field.

Fonio is a climate-resilient super grain native to West Africa which is quick to harvest, doesn’t

require fertilisers, and uses much less water to grow than barley. In a world first, Scotland’s first B-Corp certified brewer is using a Fairtrade-certified supply chain, ethically sourcing the grain from smallholder farmers.

Brewgooder, whose turnover increased 74% to £3.7m last year, predicts the new beer will add more than £2 million in retail sales to the UK’s Fairtrade market annually, with the potential to grow.

Farmers in Guinea, West Africa typically face significant challenges – from a lack of infrastructure and access to markets, to lack of investment and the low productivity of traditional farming methods.

Representatives in the region have described the ‘transformational’ potential the new supply chain could have on West African communities. So far, 67 farmers have signed up and it’s hoped hundreds could benefit in future.

A cheese manufacturer has secured £1 million in debt funding from the Midlands Engine Investment Fund II, through its appointed fund manager Frontier Development Capital (FDC), to help it fulfil its fast-growing order book.

Nantwich Cheese Company supplies the catering and hospitality industries, schools, hospitals and

Specialist ice cream manufacturer gg’s is set to provide even more customers with a taste of Italy after purchasing state-of-the-art machinery to slash production times and boost output.

Local business owner Keith Jones opened the original gg’s parlour in 2019 from a pub they had recently purchased in Penclawdd after spotting a gap in the market for ice cream shops in the idyllic seaside peninsula of Gower.

gg’s subsequent success pushed the team to grow their operations, moving to an off-site production unit. From here, the business decided it needed to progress to a continuous production model and bought four new specialist machines with a £70,000 hire purchase funding facility from Lloyds Bank.

The new machinery set, which includes an ingredient feeder and ripple pump, has slashed production times while improving the quality.

food manufacturers and also makes products for retailers including Aldi’s ‘own label’ range of waxed cheeses.

The company sources cheese from British and continental producers then processes and packs it at its Whitchurch plant.

It offers a full range of formats including sliced, diced, grated and crumbed and block cheese, along with blended cheeses ranging from traditional favourites to more novel varieties.

Nantwich Cheese Company was founded in 2009 by Wayne Morgan, who has over 40 years’ experience and

is well known in the industry. He was later joined by his son Luke who had previously held senior positions in Nando’s grocery business, and who took over as CEO five years ago. Since then, turnover has climbed steadily, from £5m in 2019 to £12m in 2023 and is on course to reach £17m in the current year following a number of major new contract wins.

The company currently employs 31 people, having recently taken on eight new recruits, and expects to create five more jobs in the year ahead.

The £400m Midlands Engine Investment Fund II covers the entire Midlands region and provides debt

The same amount of gelato it used to take gg’s a day to produce, now takes just one hour.

The set up ensures a consistent quality of output by uniformly distributing toppings and sauces throughout the ice cream – all so that customers can have a great experience.

The company already supplies around 200 small businesses in South Wales – including CK’s convenience shops and restaurants – but is currently in the process of securing a SALSA (Safe and Local Supplier Approval) certification so that it can distribute its products to larger customers and even supermarkets.

To enable the dramatic increase of its production speed, gg has recently hired two new staff for its sales and marketing team with an aim of building brand awareness and attracting household name clients.

finance from £25k to £2m and equity investment up to £5m to help a range of small and medium sized businesses to start up, scale up or stay ahead.

The purpose of the Midlands Engine Investment Fund II is to drive sustainable economic growth by supporting innovation and creating local opportunity for new and growing businesses across the Midlands.

The Midlands Engine Investment Fund II will increase the supply and diversity of early-stage finance for smaller businesses in the Midlands, providing funds to firms that might otherwise not receive investment and help to break down barriers in access to finance.

Colpac has launched Stagione® Light, a new line of paperboard food packaging as part of its successful Stagione® range.

Stagione® Light showcases the iconic shape and roll top design of Colpac’s original range, whilst offering customers lighter products

that are manufactured from one piece of paperboard. The new packs are made from FSC® certified*, recyclable paperboard in accordance with UK and European recycling guidelines.

Stagione® Light has three size variants: 500ml and 750ml rectangular, and 1000ml square.

Colpac commissioned new machinery to develop its Stagione® Light products and has extended its Stagione® range to provide a wider choice and lower cost entry points, broadening its appeal.

This versatile new line can be used to serve hot or chilled dishes in

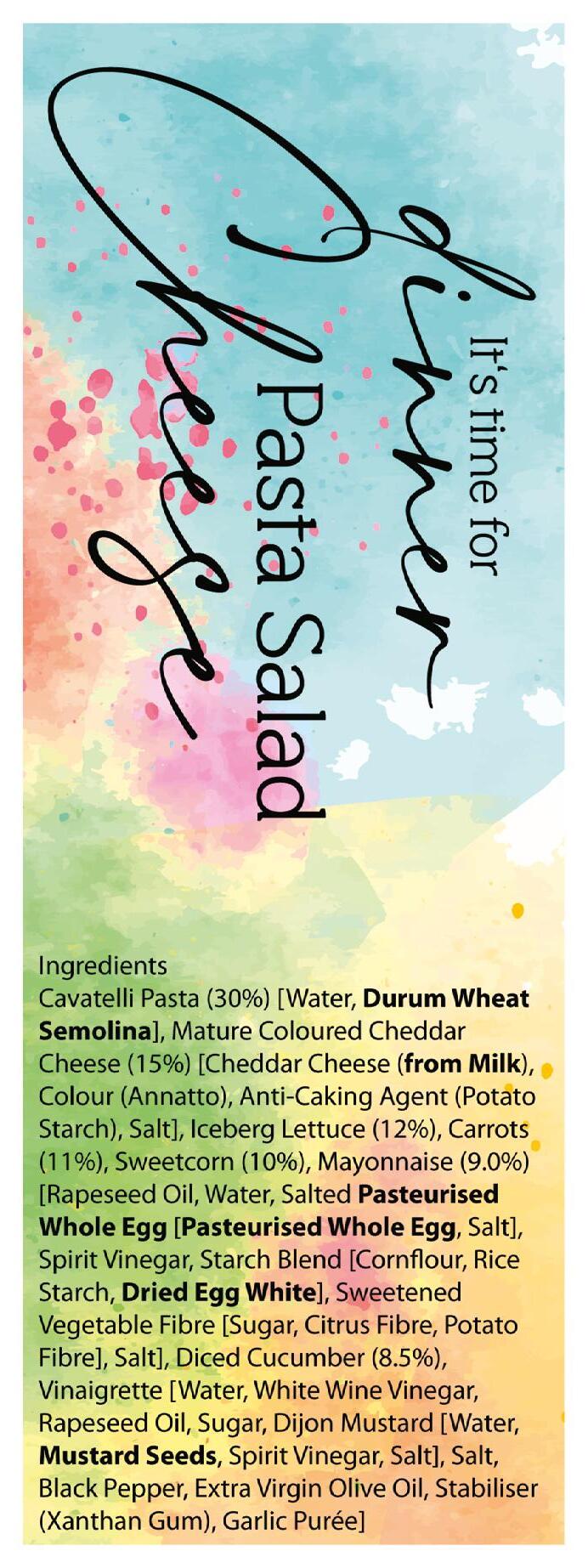

Pick any can of beans or box of cereal off the supermarket shelf and you’ll find a swathe of food information and symbols on the label. But who decides what’s included on that food label and what are the legal requirements?

and PP

foodservice environments; the grease resistant barrier and webbed design makes the packs leakproof when filled with wet, instant eat foods. Stagione® Light can also be utilised to package chilled food-to-go such as salads or baked goods in foodservice or retail environments.

To reduce complexity for customers and align with the current range, the new bases fit the current wide selection of lid options that Colpac offers. Lid options include rPET and PP clear lids, and PP and PE coated paperboard lids.

Family-owned business Invopak has over 50 years of experience as a leading packaging supplier and is here to decode the wealth of information on food packaging symbols.

The FSA (Food Standards Agency) regulates the food packaging industry to ensure labels are clear and not misleading.

The FSA regulates what and how nutritional information is displayed on food packaging:

• Ingredients (listed in order of weight)

• Energy in kilojoules (kj) and kilocalories (kcal)

• Information on fat, saturates, carbohydrates, sugars, protein and salt content

In 2014, a voluntary traffic light labelling system was introduced to highlight key nutritional information (graded red, amber or green) depending on how healthy the product is and is displayed on the front of packaging.

As the World Health Organisation highlighted numerous health and well-being benefits on eating five

Tight fitting lids provide a leakproof seal for transport and display and maintain food freshness. To further extend shelf-life, Stagione® Light can also be film sealed thanks to the packs’ roll top construction.

To maximise brand opportunities, the packs offer all over printing as they are formed from a single piece of paperboard. This includes printing on the base which is perfect for ingredient information.

Stagione® Light is exclusively available from Colpac and can be preordered now.

portions of fruit and vegetables daily, the ‘five a day’ campaign was launched in 2003. As a result, companies use this as selling point and label pre-packaged foods in this way.

Food packaging symbols change often because of new legislation, customer demand or fresh initiatives on health and the environment. Failure to comply can lead to prosecution under Food Law, so it is essential to keep labels up to date.

Food packaging symbols are also about opportunity, enabling food businesses to showcase the benefits of their products, ecocredentials, or a specific dietary requirement.

Diageo announced a first-of-itskind 90% paper-based bottle trial for Johnnie Walker Black Label exclusively at Johnnie Walker Princes Street’s 1820 bar, in Edinburgh.

Created in partnership with PA Consulting, as part of the Bottle Collective with PA and PulPac, this will be the second paper-based bottle trial from Diageo and PA, following the success of the Baileys paperbased bottle mini format (80ml) trial, using a similar Dry Molded Fiber innovation.

The trial bottle is made from 90% paper and a very thin plastic liner. The innovative technology makes the paper-based bottle approximately 60% lighter, with initial external life cycle analysis on the prototype showing an up to 47% potential reduction in carbon

The trial bottle is made from 90% paper and a very thin plastic liner.

emissions, compared to the Johnnie Walker Black Label glass bottle equivalent. The bottle closure was developed in collaboration with PulPac, Setop DIAM and PA and is made from a unique combination of cork and similar Dry Molded Fiber paper technology as the bottle.

The Johnnie Walker Black Label paper-based bottle for this test is designed considering recyclability among other aspects. The plastic liner is designed to not require consumer or bartender disassembly, as it is not attached or bonded to the outer paper layer, assisting recycling facilities to separate without disrupting the recycling process. The stopper used for trial purposes is not recyclable, however alternative solutions are in development.

Diageo continue to explore paper formats across the wider portfolio as a means to reduce carbon emissions. This includes an ongoing partnership with Pulpex as they continue to develop and internally test their initial concept paperbased bottle, which is currently in feasibility testing.

These latest innovations form part of Diageo’s ambition to reduce its carbon footprint by exploring new packaging formats.

It’s time to work with plastic manufacturers instead of confronting them with bans.

The plastics industry has for many years been at the forefront of innovation as the sector has become a lightning rod in the debate over our environment. But according to Symphony Environmental, a company at the forefront of packaging technology, the plastics sector is leading the charge when it comes to a transformative shift towards sustainability.

Driven by environmental concerns and regulatory pressures these are some of latest trends steering the course of plastics technology.

1. The Circular Economy: By adopting a circular economy approach, businesses are not only contributing to reducing the environmental impact of plastics but also fostering a more sustainable and resource-efficient model. Central to this is the goal of minimising waste and promoting the recycling and reuse of plastics. Companies are now designing products with recycling in mind, opting for materials that can be efficiently processed through recycling systems or indeed biodegrade. This shift means that the industry as a whole is moving towards a future where

the life cycle of plastic is carefully managed to minimise its impact on the environment. However, for the foreseeable future a significant amount of plastic will still get into the open environment where it can lie or float around for decades, and this is why our d2w biodegradable plastic has been invented.

2. Biodegradable plastics: Biodegradable plastics are becoming central to the ongoing efforts to mitigate the environmental impact of traditional plastic materials. Ordinary polyethylene and polypropylene products can be made to biodegrade much more quickly if they get into the environment, leaving no microplastics behind, simply by making them with a d2w masterbatch at little or no extra cost. This concerted push toward a more sustainable and environmentally aware approach to plastic manufacturing reflects a commitment to balancing the functional advantages of plastics with a conscientious approach to ecological sustainability.

3. Regulatory framework: Many governments and international organisations are driving major

change in the regulatory landscape to strengthen and enforce responsible plastic management. A central part of this has been the increase in restrictions on singleuse plastics, but restrictions on plastic can steer people toward less sustainable materials such as paper. In the Middle East governments have required a wide range of packaging and other products to be made with d2w or equivalent biodegradable technology.

4. Smart Plastics: We provide a range of these plastics, which can protect people against insects, rodents and fire, and can reduce the deterioration of food. The largest bakery in the western world has started to use d2p technology for its bread-packaging and has been using d2w for more than 15 years.

5. Anti-Microbial Plastics: The development of anti-microbial plastics has emerged as a significant and timely trend. As a direct result of the heightened emphasis on hygiene, particularly within healthcare environments, this innovative approach involves the integration of substances with inherent anti-microbial or antiviral qualities into the plastic manufacturing process. As the demand for heightened hygiene persists, the development and use of anti-microbial plastics such as Symphony’s d2p underscores a commitment to advancing public health measures through innovative material solutions.

It was the missing piece of the puzzle needed to complete a modernization process lasting many years, with Hell Brauerei KG in Altötting, Bavaria, the first customer in the world to opt for the Innokeg X. With this semiautomatic module that washes and racks kegs in just one operating step, KHS provides a space-saving system for the low-capacity range and thus for quality-conscious family firms such as Hell Brauerei.

Not only are operating processes much simpler and faster since installation of the new technology: the brewery also appreciates the simple operation and flexibility they now have, enabling them to react accordingly to short-term orders and produce seasonal beers efficiently, for instance.

In Altötting, approximately 80 kilometers east of Munich not far from the Austrian border, tradition is writ large. Hell Brauerei, founded in 1890, still racks beer into wooden barrels that are expertly pitched every two years. However, for the brewing process itself state-of-the-art technology is now increasingly being used, with the brewery gradually having renewed its equipment over a prolonged period, starting with the fermentation cellar, then moving on to the bright beer tank cellar and finally the piping and filling. KHS has been largely instrumental in helping to bring these modernization measures to a close.

Georg Hell, who now runs the brewery in its fifth generation, recently invested in a second-hand machine for glass

The KHS Innokeg X can process up to 25 returnable kegs or barrels an hour holding up to 58 liters.

filling as his output is still too low for a new one. However, with the Innokeg X the systems provider has now developed a system for barrels and kegs that is perfectly tailored to the requirements of craft beer producers and small and medium-sized companies such as Hell.

The new setup provides clear benefits when it comes to investment and overall costs compared to the use of separate modules for washing and racking. The KHS Innokeg X can process up to 25 returnable kegs or

barrels an hour holding up to 58 liters. The brewery boss is particularly enthusiastic about the multiple processing head that washes and racks his containers in a single step. Moreover, the experienced master brewer appreciates the compactness of the Innokeg X – it fits onto a single euro pallet – and thus the small space needed to accommodate it. This allowed the system to be quickly and easily installed in the production shop without any constructional changes having to be made.

Further pluses of the Innokeg X are its simple operation and universally logical design. KHS has integrated an HMI panel with a touch screen display for operators at eye level and equipped the machine with sensors and actuators for measuring pressure, for example. At the same time, the cost of investment is lower than that for larger or specialized modules and less maintenance and fewer spare parts are required.

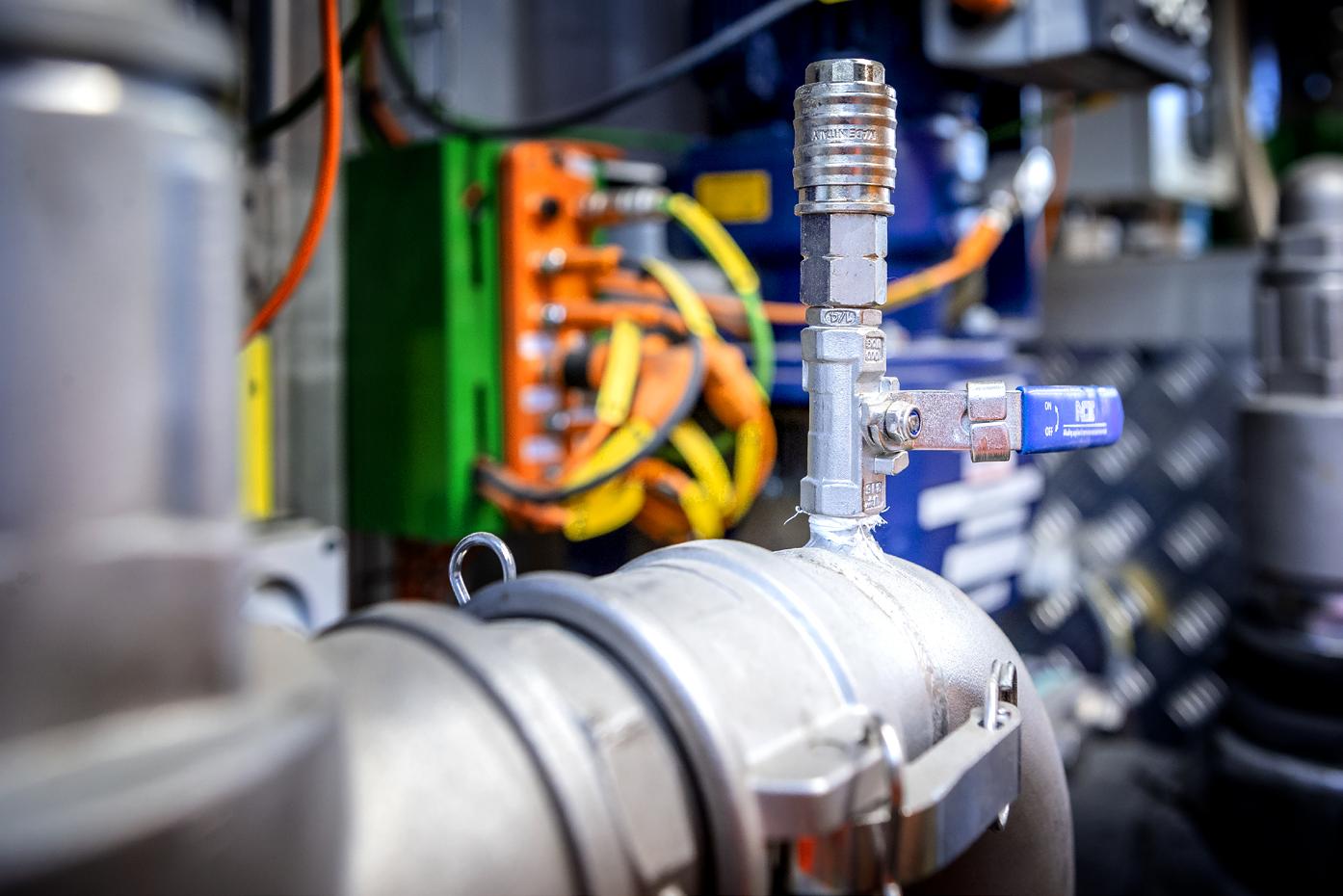

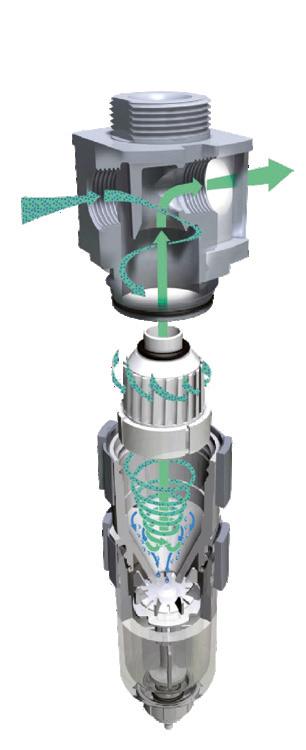

Trials of a cutting-edge fats, oils and grease (FOG) Recovery Hub at Yorkshire Water’s wastewater treatment works in Hull, UK, are helping the utility improve environmental performance while lowering costs, says Chris Clemes, chief executive of engineering technology company EcoClarity.

Sewer blockages are a major concern in the UK, with an estimated 200,000 occurring annually, and FOG – fat, oil and grease - cited as the cause in around 75% of cases.

A build-up of FOG hinders the smooth operation of sewer systems and wastewater treatment works (WwTW), shortens the lifespan of critical assets and increases maintenance costs. This burden ultimately falls on water companies.

“As a water company, we suffer from thousands of preventable blockages each year from fats going down sewers. FOG blockages, or fatbergs impair the performance

of wastewater assets which can cause sewer overflows, that can impact the environment,” explains Yorkshire Water’s waste services manager James Gudgeon.

“Water companies can spend a significant amount of money on staff and equipment costs to remove FOG from our sewers and send it to landfill – which also has an environmental impact. Additionally, network failures caused by FOG blockages carry the risk of costly environmental performance fines.”

As part of Yorkshire Water’s drive to increase efficiency within its operations, the water utility works alongside technology consultancy Isle to identify

the latest technologies and innovations in clean and wastewater.

“In 2021, Isle suggested working with EcoClarity on our wastewater site, at a time we were looking to grow our imported waste business. The EcoClarity proposition gives us the ability to import different types of waste that we would not normally be able to treat.”

Yorkshire Water is the first UK water utility to install EcoClarity’s patented technology - located at its Hull wastewater treatment site. The modular, containerised EcoClarity system was introduced in February 2024 and will be used to treat FOG wastewater generated onsite during cleaning and maintenance procedures, as well as loads from waste management companies.

The process separates problematic FOG from wastewater and recovers a valuable energy resource for biodiesel production, while returning safe water

FOG blockages, or fatbergs impair the performance of wastewater assets which can cause sewer overflows, that can impact the environment.

to the environment. The operational model involves installing a network of FOG Recovery Hubs at wastewater treatment works and other sites suitable for liquid waste tankers to offload grease trap waste.

“We’re turning FOG waste into a valuable resource,” says Chris Febrey, EcoClarity’s operations manager. “By accurately measuring and verifying the composition of waste, we can verify reductions in greenhouse gas emissions for businesses and promote a circular economy. Our collaboration with Yorkshire Water highlights the importance of proper FOG management.”

The installation has a myriad of benefits for Yorkshire Water. Alongside the environmental and financial rewards of safely removing the FOG from the environment.

“Working in partnership is a significant commitment, but it was an easy decision once we looked at the holistic benefits of EcoClarity’s hubs,” says Gudgeon. “It brings us another avenue of engagement with the food industry and the FSEs [food service establishments] out there; it reduces the amount FOG going into sewers at source – preventing sewer blockages and protecting the environment, ultimately resulting in protecting our people not having to do high risk jobs.

“It also enables us to bring in new waste streams and new revenue streams into Yorkshire Water and ultimately that money is reinvested into the business and goes towards helping keep customer bills low - it is a true circular economy in action,” he adds.

FOG is a common byproduct of commercial kitchens and food processing facilities, but its disposal has long posed a challenge to the water sector. Currently, too much FOG enters the sewers and drains, causing blockages, which significantly impact the public, the environment, and are costly for water companies to clear.

The alternative is landfill disposal, which fails to capitalise on the value of FOG as a potential renewable fuel source. The patented EcoClarity system efficiently separates fat, oils and grease from wastewater, resulting in a 98% concentration of oil suitable for biodiesel production, which could ultimately be used to power the trucks transporting the FOG.

As EcoClarity sites are registered with Argent Energy’s Carbon Certification Scheme, the company can track the volume of greenhouse gas (GHG) emissions saved by the biodiesel produced from its FOG feedstock. This allows third-party companies, disposing of their waste in this way, to demonstrate their commitment to sustainability with transparency.

Long travel distances, slow offloading times, limited data on waste content, and a lack of transparency in pricing have historically led to frustration and a drain on profits for liquid waste operators. Thanks to EcoClarity’s highly efficient disposal opportunities, first at Argent Energy’s refinery in Stanlow, Cheshire, and now at Hull wastewater treatment works, travel distances for hauliers are minimised, along with fuel consumption.

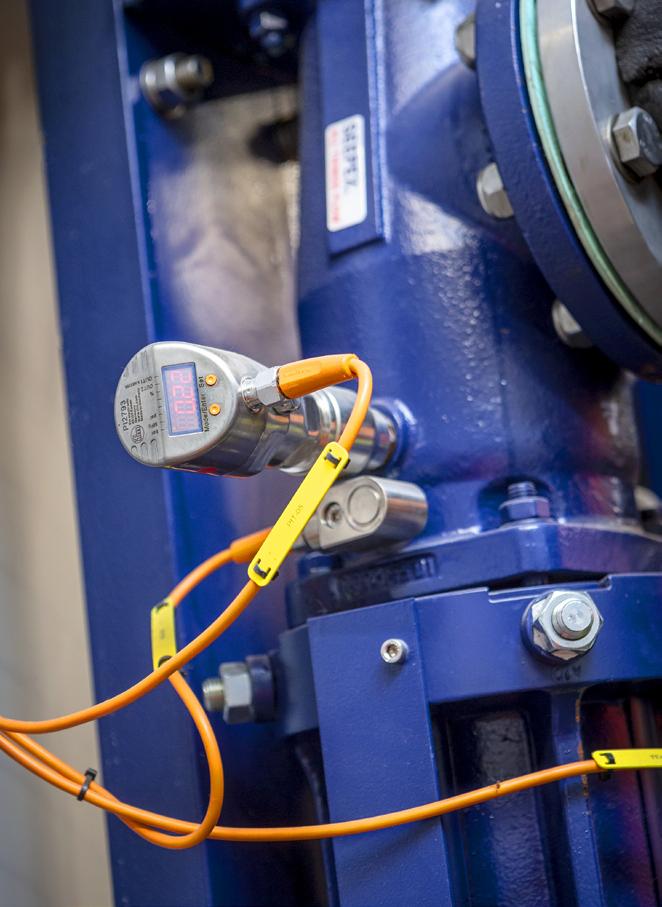

EcoClarity’s FOG Recovery Hubs analyse the precise mass and FOG content of every load that comes in. As the FOG-rich waste goes through a mass meter, it is quantified and the data shared with the client - supporting their green credentials.

This also translates to quicker turnarounds for tankers, lower operating costs, and more time spent serving customers. Boasting up to a 87% reduction in greenhouse gases, biodiesel contributes to climate change mitigation and could be used to power tankers transporting wastewatercreating a tight circular economy of value.

“We are working with EcoClarity towards the potential nirvana of being able to harvest the FOG from our sewer network and turn it into biodiesel that fuels our vans. That’s the end goal,” added Gudgeon.

Further EcoClarity hubs are being planned by Yorkshire Water, with Knostrop wastewater treatment works in Leeds next on the list. Sites belonging to United Utilities and Southern Water, as well as two large entertainment venues in London and Cornwall, are also in the pipeline.

The Schmersal Group has designed a new safety light barrier especially for hygiene-sensitive uses in the food processing industry, such as milk and meat processing.

This version has evolved with the demands of standard cleaning operations in the industry as the sophisticated design helps to ensure IP69 degree of protection (protection against the ingress of water from high-pressure of steam cleaning).

The protective enclosure with external gaskets satisfies stringent standards and is designed to cope with frequent cleaning with water, foam, lyes, high-pressure or hot steam.

SCHMERSAL | Enigma Business Park Malvern, Worcestershire, WR14 1GL

www.schmersal.co.uk

uksupport@schmersal.com

Integrating IoT technologies throughout supply chains enforces the rigorous quality control of food products from food to fork, mitigating the risk of contamination and illness.

Hospital admissions from food poisoning from salmonella and E coli have reached their highest level in decades in the UK. Hospital admissions for salmonella infections reached 1,468 in England between April 2022 and March 2023, according to NHS data. And hospital admissions for E coli reached over 4,340, equivalent to nine in 100,000 people in 2023, up from three in 100,000 people in 2000, according to recent reports.

In December last year, 30 people were hospitalised with E coli, with the outbreak resulting in one death. Further tragic cases include paralympic hopeful Lizzi Jordan, who lost her sight to

Titan is a leading design and manufacturer of innovative end user and OEM high-performance flow meters, used within a wide range of environments and applications.

• Compact, robust, reliable

• Excellent accuracy and repeatability

• Measure low to high flow ranges

• High chemical resistance

• OEM bespoke design capability

+44 (0)1935 812790

E coli after eating a fastfood meal in 2017, which left her in a coma. With new cases continuing to emerge, food businesses are being pressed to do more to safeguard the public and minimise contamination.

Food businesses undoubtedly have a responsibility to ensure food safety regulations and protocols are followed in-house, but food contamination can happen at any point in the production chain. In many cases, business owners have limited control over the storage, transportation and packaging process of their imported produce, it is nearly impossible for them to guarantee food safety standards have been met from beginning to end. This risk has been recognised by the UK government rating supply contamination as four out of five for likelihood in the 2023 national risk register. However, as businesses increasingly embrace digitisation, the implementation of IoT technologies promotes confidence, compliance and thus protection for the whole supply chain.

According to Ruby Whipp, Vice President of Product at mpro5: “The most important step in ensuring food safety is preventing the occurrence of foodborne illness in the first instant. By leveraging IoT technologies, food companies will benefit from improved supply chain visibility and end-to-end traceability. Radiofrequency identification (RFID) tags, for example, document the complete journey from origin to destination by transmitting location and sourcing data to companies, updating them on the exact whereabouts of each product throughout its journey to them. This way, any issues relating to product recall or batch contamination can be traced back through the chain, identifying locations of potential food safety breaches, such as a facility also handling nut products.”

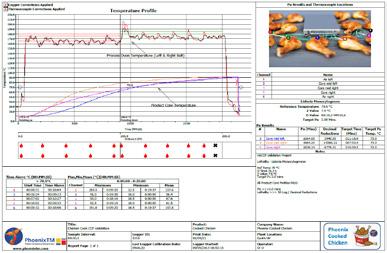

Good food safety starts with temperature data.

Accurate and reliable temperature data is essential for the integrity of the food industry and the safety of consumers.

Tinytag Data Loggers are robust, reliable and highly accurate measuring devices for monitoring temperature and humidity during food processing, storage and cold chain distribution.

Tinytag use simple technology that’s easy-to-use, easy-to-manage and conveniently versatile to help businesses gather vital temperature data at every stage of the food supply chain.

Improve temperature management

Tinytags can aid quality and food safety inspections (including compliance with HACCP regulations) by providing evidence of conditions that’s easyto-read and readily available in userfriendly data logging software, Tinytag Explorer.

Monitoring with data loggers can indicate the need to replace old or faulty equipment, stabilise temperature conditions in refrigerated areas or improve insulation in packaging, helping you to streamline product storage.

Save energy, save money

Temperature data loggers can help to identify the efficiency of heating and cooling equipment, helping businesses to pinpoint where to save energy and save money across their operation.

Data you can trust

Tinytag data loggers bring over three decades of manufacturing experience from an ISO 9001 and ISO 14001 accredited UK manufacturer, Gemini Data Loggers UK Ltd.

Certifiable instrument accuracy through our in-house Calibration Service that’s traceable to National Standards means you can put extra trust in the reliability of your data – and prove it to auditors.

Versatile data logging: portable data loggers

Compact, portable and easy-to-use Tinytag data loggers (temperature, relative humidity and energy consumption) provide a flexible solution for monitoring food processing and cold chain compliance. Tinytags are battery-powered, self-contained devices and have configurable LED alarms for notifying temperature breaches.

The Tinytag Connect system of Radio and LAN (Ethernet) data loggers brings you convenient wireless temperature and relative humidity monitoring at an affordable price and is ideal for use in warehouses and refrigerated storage and distribution, where central data management presents a significant –time-saving – advantage. Mix-and-match Radio and LAN loggers according to infrastructure requirements, get real-time data access and receive email alerts when temperatures are out of range to take fast corrective actions.

Tinytag DI is the secure software for Tinytag data loggers. With Tinytag DI, you can control who has access to your data loggers by managing user access levels. You may also set up groups according to location or department to assign data loggers to the relevant teams. An audit log ensures accurate and consistent data, providing a record of critical events and any changes made to the loggers.

Further information: www.geminidataloggers.com

Food safety specialist Fortress Technology explores the benefits of staying ahead of an unannounced inspection by an external party, and the value of monitoring everyday risks by performing regular internal and external audit reviews.

The distinction between a food inspection and a food safety audit can get clouded. In food safety circles especially, the two terms are frequently interchangeable. They both help to improve operational performance. And they both assess conformance to set standards. There are, however, subtle differences.

A food safety audit is a systematic evaluation of food factory documentation to determine if food safety practices, programmes and related activities, including procedures and record keeping, are meeting expectations. Generally, an auditor looks at data over a period of time to see if positive or negative trends are developing.

Food safety inspections, on the other hand, provide a thorough physical review of a food facility to assess what is actually happening in production during a precise moment in time. This snapshot – typically lasting between two and four days – gives a realistic assessment of conditions. These can be both positive and negative.

When inspecting a Critical Control Point (CCP), an inspector may look for any potential contaminant events that if left unaddressed could prompt an investigation. When conducting an audit, qualified personnel will review the effectiveness of a HACCP plan and ensure it is being implemented correctly.

The Food Standards Agency evaluates the effectiveness of the official audit controls systems managed by enforcement officers and local authorities in England, Wales and Northern Ireland. Although food safety audits are not a legal requirement, by conducting internal or external audits, food processors can be assured their processes are conforming to these defined food safety standards.

Any failure can feel like the end of the road. However, in audit terms, a nonconformance issue simply notifies a food processor that something needs to be addressed in order to comply with food safety rules, regulations and supplier contractual obligations.

Poor record-keeping and noncompliance with established Food Safety Plans are some of the top reasons that food and beverage manufacturers fail their audits. When equipment and surfaces deteriorate, they can present a possible contamination risk. Auditing highlights these issue and ensures they are resolved before an inspection. Additionally, end-of-line inspection equipment can expedite the process of tracing a contaminant entry-point and correcting the non- conformance.

In order to assess performance and knowledge of good manufacturing practices, a Traceability Performance Assessment can also be conducted. This timed traceability recall exercise can be added to any GMP inspection and helps to promote food safety compliance amongst staff, highlights Phil Brown, Sales Director of Fortress Technology Europe.

An audit checklist should cover all aspects of production that affect food safety practices and HACCP compliance. Most auditors will expect to examine documentation, records, premises, practices, equipment, and processes. Signs of pest infestation,

hygiene protocols, temperature control, and food handler and machine operative training and competence will all be scrutinised.

To assist food manufacturers, Fortress published a typical audit-conformance checklist in its latest Food Equipment Audits Whitepaper. Download a free copy from https://fortresstechnology. co.uk/food-equipment-audits/.

Post-audit, the successes and non-compliances flagged by the investigation should be examined by the relevant staff and auditing personnel. Once a course of action to address and prevent future nonconformances is established, food processors can implement these changes.

For inspection equipment, specific GFSI standards should be followed. Particularly the testing of industrial food metal detectors.

Food safety audits play an essential role in supporting safe food consumption, brand integrity, regulatory compliance, supply chain management, risk assessment and prevention, and promoting operational excellence. Given the numerous critical control points in a processing plant, Fortress advises routinely and systematically revisiting potential hygiene and contamination hazards as part of a regular risk assessment and food safety programme.

What motivated Prima Bakeries Group to acquire Furniss of Cornwall, and how do you see this acquisition complementing your existing brands, Prima Bakeries and Cornish Premier Pasties?

The brands have complementary product ranges, with sweet and savoury goods that are all made to an incredibly high-quality standard. Having three heritage Cornish brands, under one roof feels synonymous. The businesses have complementary customer bases allowing significant cross-selling opportunities. The purchase will also allow Furniss to source raw materials sharing the wider group’s buying power.

With Prima Bakeries Group transitioning to an Employee Ownership Trust earlier this year,

how has this shift impacted the team’s morale and the overall growth trajectory of the company, particularly with record-breaking sales and the acquisition of Furniss?

The group has always recruited motivated and capable staff and has been proud to be one of the leading bakery businesses in the West Country in terms of training bakery colleagues. The EOT has built on this further and consolidated staff involvement and morale. The acquisition will strengthen the group further to the benefit of all staff members.

You mentioned plans to invest in the production facilities at Redruth to help Furniss reach its full potential. Can you share more about the specific improvements or expansions that are planned?

The equipment that we are investing in will allow us to meet increasing demand, as well as having more temperature-controlled space within our facilities.

At the moment, we’re looking at how Furniss operates and will make improvements and expansions when the time is right. Having the resources and knowledge from Prima Bakeries and Cornish Premier Pasties allows us to be flexible with our approach and ensure any changes are beneficial to both Furniss and the wider group.

As Prima Bakeries Group prepares to open a new 20,000 sq. ft. production facility in St Columb, doubling pasty production, how do you plan to balance scaling up with maintaining the authenticity and quality that Cornish food products are known for?

We’re committed to only producing the very best products, using the very best ingredients. Our recipes have been crafted to taste great, which takes years of perfecting, and this isn’t about to change! The equipment that we are investing in will allow us to meet increasing demand, as well as having more temperature-controlled space within our facilities.

Furniss of Cornwall has a rich heritage, being the only company licensed to make The Original Cornish Fairing™. How do you plan to honour this legacy while integrating the brand under the Prima Bakeries Group’s broader vision?

Furniss’s heritage is well established with time-honoured recipes dating back to 1886. We intend to build on that legacy by staying true to the company’s history of making great-tasting biscuits while expanding operations to meet customer demand. The same staff and production methods that have served the company so well will be maintained and built on by being part of the wider group.

Iconic biscuit manufacturer, Furniss of Cornwall, has been acquired by Redruth-based Prima Bakeries Group.

Prima Bakeries Group, which incorporates Redruth-based Prima Bakeries and St Columb-based Cornish Premier Pasties, has announced its purchase of Cornish biscuit maker Furniss of Cornwall, for an undisclosed sum. Furniss of Cornwall will now operate under the Prima Bakeries Group with all staff joining the Employee Ownership Trust.

The acquisition comes as Prima Bakeries Group announces record years for both Cornish Premier Pasties and Prima Bakeries, with sales growing by £2 million year-onyear and the turnover of the Group expected to reach £15 million per annum, by the end of 2024.

Commenting on the acquisition, Mark Norton, Managing Director of Prima Bakeries Group said:

“Earlier in the year we announced the Group’s transition to an Employee Ownership Trust, so it feels extra special to report these figures following the end of our financial year. It’s proof that we’re supporting both our local people and the wider economy, whilst also reinforcing Prima Bakeries Group’s position of a truly Cornish company as we continue to go from strength to strength.”

As well as the purchase of Furniss of Cornwall, the Group will be opening a new 20,000 sq. ft. production facility in St Columb later in the year, doubling production capacity for their awardwinning pasties.

Furniss Of Cornwall was started by John Cooper Furniss in 1886 and is best known for being the only company in the world licensed to make The Original Cornish Fairing™. It operates from Redruth and employs 30 full-time staff. The deal was supported by Mark Champion of Exeter-based ISCA Ventures, corporate finance specialists and Tim Jackman of Plymouth-based solicitors Whyte Jackman.

Leading glass packaging company, Croxsons, has recently made changes to its management structure. Tracey Kendall, formerly business development manager - export, has been appointed as the new warehouse & logistics manager, while Justin Giddings, previously the area sales manager covering the southeast, has taken on the new role of commercial manager.

Tracey, who has been an integral part of Croxsons for the past nine years, will now be responsible for overseeing the logistical operations within the UK.

Her new role includes managing stock, determining optimal stock levels and understanding client requirements to ensure efficient

stock management. The position reports directly to commercial director, George O’Brien. Tracey will still be taking and managing Export enquiries and accounts.

With seven years of service at Croxsons, Justin will be focusing on evaluating and improving the current supply chain to enhance cost efficiency and operational effectiveness, ensuring the company’s long-term strategic goals are met. He will also be identifying new initiatives to drive business growth, while continuing his sales responsibilities in the southeast. He will still report to sales director, Paul McGrane.

Croxsons CEO, Tim Croxson, commented on the appointments: “We have an incredible team and are proud of our track record of staff retention.

“We are pleased that both Tracey and Justin have committed to the Croxsons family and look forward to our continued growth.”

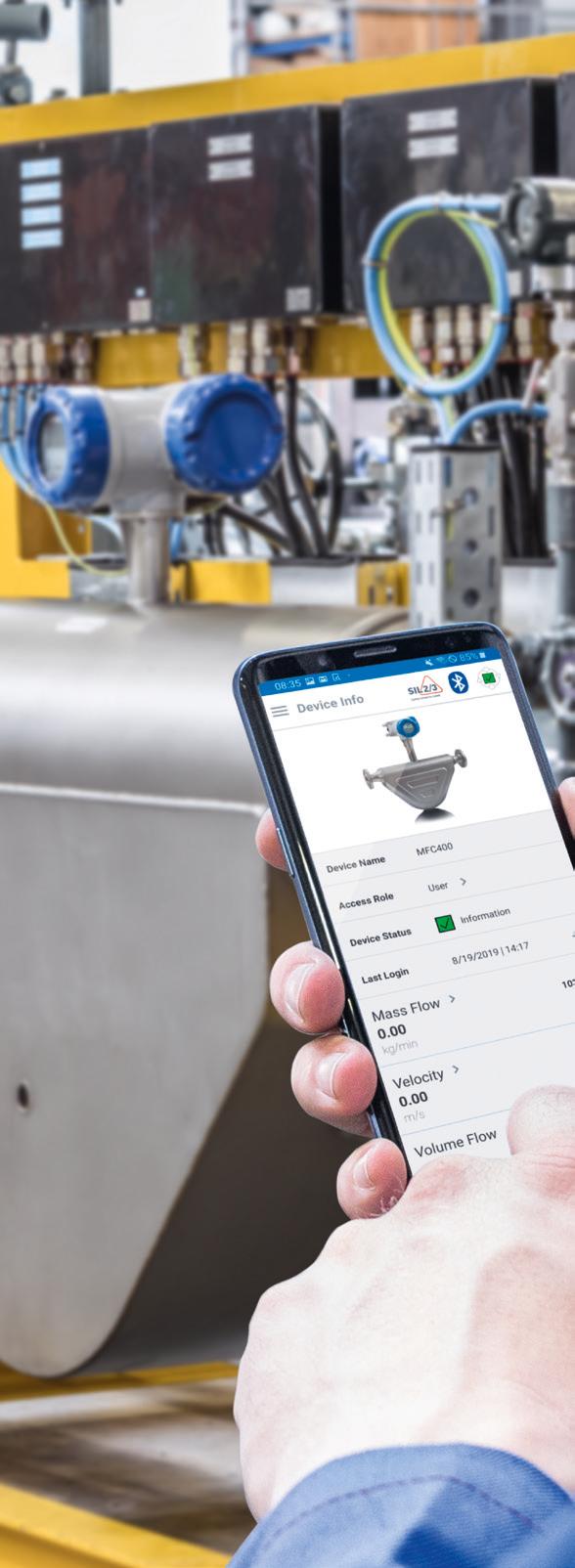

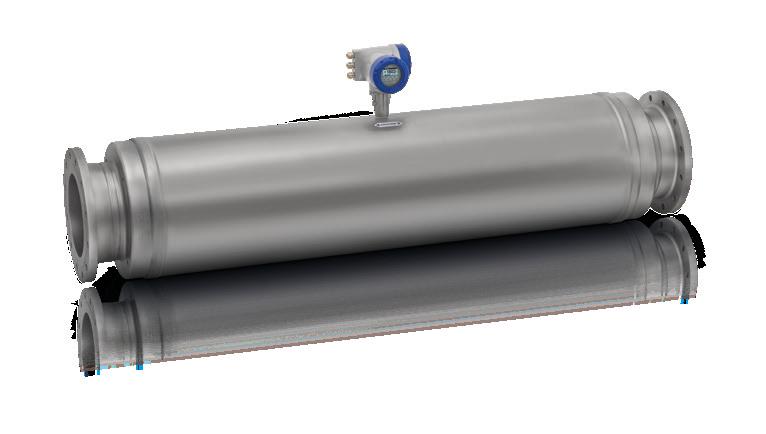

OPTIMASS series – Coriolis mass flowmeters with Bluetooth® communication

• The outstanding features of OPTIMASS flowmeters such as continuous operation even with entrained gas of up to 100%, have now been extended by easy wireless operation

Ash Corbett-Collins has been elected to lead the UK beer drinkers’ group.

The Campaign for Real Ale (CAMRA) is pleased to announce Ash Corbett-Collins has been appointed as its new Chairman.

An election took place at a meeting of the Campaign’s National Executive in Cumbria over the weekend.

Vice Chairman since last November, Ash Corbett-Collins is a long-standing National Executive member who was first elected to the Board of the Campaign in 2018.

The process to elect a new Vice Chair is now underway, with the result expected in the autumn.

Mr Corbett-Collins thanked previous Chairman, Nik Antona, for his hard work and dedication. Nik Antona stood down due to ill health after a five-and-a-half-year tenure.

Nik has been a CAMRA volunteer for more than 20 years, including holding roles within branches, as a Regional Director and a longstanding National Executive member holding key positions including Finance Director before his time as Chairman.

Vice Chairman since last November, Ash Corbett-Collins is a long-standing National Executive member who was first elected to the Board of the Campaign in 2018.

Leading manufacturer of industrial lubricants, cutting fluids, and line marking systems ROCOL has announced it has bolstered its senior leadership team with a new Head of Technical and two Product Managers.

Egidio D’Antona joins ROCOL as the new Head of Technical having joined from Swedish electric car manufacturer, Polestar.

Kelly Dougill and Matthew Broderick are named as two new Product Managers, overseeing plant, facilities and maintenance fluids, and process lubricants respectively.

According to ROCOL, all three new hires underscore the company’s continued commitment to advancing its product offerings and maintaining its position as a market leader in industrial lubricants.

With a focus on driving growth and innovation, Mr D’Antona has outlined that one of his priorities will be to concentrate on highimpact research projects that align with current and future market trends.

All three members of staff joined the company as part of a strategic hiring drive in August 2024.

ROCOL says it has experienced a “significant increase” in demand in 2024 compared to last year and expects to see a “stronger level of growth” for the rest of the year.

Gerard McCargo, Human Resources Business Partner at ITW Fluids Europe, said: “Our new experts will now support ROCOL in its mission to serve our global customer base and capitalise on new market opportunities, providing fresh ideas and approaches to sit alongside our high-quality products and services.”

By Mark Ross, Global Brand Manager, TITAN Containers ArcticStore

The vast UK food and beverage sector touches on multiple industries, from hospitality to breweries and dairies.

The rise in online food orders and meal kit subscriptions are causing shifts in the marketplace and increasing the demand for more agile cold-storage solutions. The UK grocery delivery market is estimated to be worth over £20 billion this year, with a further £10 billion growth predicted over the next five years.

In response, how can businesses use effective cold storage management to capitalise on changing consumer trends and stay competitive?

Cold storage and delivery in the food industry involve a carefully controlled supply chain known as the “cold chain.” This system ensures perishable food items are stored, transported, and delivered at specific low temperatures to maintain freshness, safety, and quality.

Cold storage specifically refers to facilities where food products are kept at a regulated temperature to prevent spoilage before or during transit.

Cold delivery refers to transportation of perishable goods under controlled temperature conditions by road, sea or air.

In today’s market, speed is everything.

Together, these processes are crucial for the food industry, enabling the safe distribution of products like dairy, meat, seafood, and produce across long distances without compromising quality.

The UK has strict regulations in place for businesses selling food online. These regulations require food to be stored in a hygienic location and at precise temperatures to prevent foodborne illnesses like e-coli and salmonella and uphold the highest quality standards.

In today’s market, speed is everything. Having agile cold storage capacity and solutions which allows businesses to scale up and down in response to surges in demand and seasonal shifts is key to success.

Seasonal shifts and sudden demand spikes can strain conventional cold storage systems, leading to inefficiencies or product loss. An agile cold storage solution allows businesses to quickly adjust storage capacity, ensuring they can meet customer needs without overextending resources or facing shortages.

Maintaining a large cold storage facility year-round can be prohibitively expensive, especially when demand is low. Agile systems enable businesses to optimise their operations by scaling down during off-peak times, reducing energy costs and operational expenses without compromising product quality.

Advanced automation and robotics are increasingly being used to streamline operations. These reduce the need for manual labour in harsh, lowtemperature environments, improving productivity and ensuring consistent quality control.

Modern cold storage facilities leverage smart monitoring systems to maintain optimal conditions and provide full traceability. These systems track temperature, humidity, and other critical parameters in real-time, ensuring food products remain within safe limits at every stage.

According to a recent study, 60 percent of consumers purchase their food products from companies with sustainable business practices. And this environmental consciousness is only going to become more important over time.

Many types of traditional refrigeration and air conditioning equipment require the use of F-gas. When mishandled, these gases can contribute to the greenhouse effect. It’s vital firms ensure they partner with F-gas-certified businesses to limit the potential harm of these gases.

In the drive for sustainability and efficiency, the food and drink industry is turning towards technologies that support environmental stewardship and offer operational cost savings. Breezair Evaporative Cooling stands out as a leading solution, harnessing natural evaporation principles to deliver effective cooling with minimal energy consumption.

Why Breezair is the Smart Choice:

• Energy Efficiency: Utilising the natural process of water evaporation, Breezair Evaporative Cooling significantly lowers energy consumption compared to traditional cooling methods, and is recognised as the world’s coolest, quietest, and most energyefficient evaporative cooler.

• Eco-Friendly Cooling: Unlike conventional air conditioning systems that use refrigerants, Breezair Evaporative Cooling uses water exclusively to cool the air, positioning it as an environmentally friendly choice.

• Spot Cooling: Targets hot spots with cool, fresh air, designed to enhance conditions for workers in those warmer areas.

• Enhanced Workplace Comfort: By sustaining optimal conditions, Breezair fosters a healthier, more productive workplace.

• Industrial Cooling Solution: Designed for a wide range of industrial and commercial environments, offering an efficient, low-maintenance adiabatic cooling system with minimal carbon impact, ensuring optimal conditions for the food & drink industry.

Understanding The Technology:

Breezair Evaporative Cooling uses evaporation—drawing outside air through water-soaked pads, where it becomes cooler as water evaporates and absorbs the heat. This cooled air is then distributed throughout the premises via ducts by a fan and motor system tailored to ensure consistent cooling.

Choosing Breezair Evaporative Cooling signifies a commitment to sustainability and efficiency.

The system’s effectiveness hinges on fully saturated cooling pads and accurately sized fans and motors, ensuring appropriate airflow for the intended space.

Leading the Way in Sustainable Cooling:

Breezair represents more than just a cooling system; it’s a testament to innovative, environmentally responsible technology that combines business efficiency with ecological sustainability. This strategy not only enhances workplace environments but also furthers broader environmental objectives.

Choosing Breezair Evaporative Cooling signifies a commitment to sustainability and efficiency. It reflects a dedication to both environmental stewardship and workforce productivity, advocating sustainable practices that contribute to a greener industrial future.

Advance towards a cooler, greener future by contacting us at sales@cpa-group.com, and discover more about Breezair Evaporative Cooling at www.cpa-group.com/product/ breezair-evaporative-cooling.

Food allergens can be life threatening and the only way people can manage a food allergy is to avoid the foods that make them ill. In the UK, it is estimated that 1-2% of adults and 5-8% of children have a food allergy. This equates to around 2 million people living in the UK with a food allergy, this figure does not include those with food intolerances. Considering that, there are actually even more people living with a food allergy or food intolerance. An allergic reaction can be produced by a tiny amount of a food ingredient that a person is sensitive to (for example a teaspoon of milk powder, a fragment of peanut or just one or two sesame seeds). Symptoms of an allergic reaction can range from mild symptoms such as itching around the mouth and rashes or can progress to more severe symptoms such as vomiting, diarrhoea, wheezing and on occasion anaphylaxis shock. It even can cause, like in the tragic case of Natasha Ednan-Laperouse, death.

Food producers face the challenge to design a product label, which on the one hand contains all information required by the authorities but is on the other hand attractive for the customers.

Printing labels in-house gives them flexibility to react to market changes and to changes in their ingredients list.

A product label is the first source of information for people with food allergy or food intolerance to help them decide if they can buy and eat that product without risking an allergic reaction. And studies have shown that the readability of information is a key factor to the consumer’s purchasing decision, making food safer as required by the UK Food Information Amendment, also known as Natasha’s Law, and require food businesses to provide full ingredient lists and allergen labelling on foods pre-packaged for direct sale on the premises. The legislation is introduced to protect allergy sufferers

and give them confidence in the food they buy. PPDS (Prepacked for Direct Sale) food has to clearly display the name of the food and a full ingredients list, with allergenic ingredients emphasised (for example in bold, italics or a different colour) on the packaging.

Food producers face the challenge to design a product label, which on the one hand contains all information required by the authorities but is on the other hand attractive for the customers. To capture all ingredients listed on a product label at a glance could be quite difficult, especially when the product and its packaging is rather small. For the production of these labels manufacturers need a printing process, which guarantees razor-sharp printouts even with a very small font size on a small label. In all of these cases, the printed quality and appearance of these labels are extremely important. Providing a professional appearance on packages can easily make the difference between a product selling well or simply sitting on the retail shelf.

DTM Print, international OEM and solution provider for specialty printing systems, offers label printers that give food businesses the opportunity to print their own labels. Printing labels in-house gives them flexibility to react to market changes and to changes in their ingredients list. When the printer is then also connected with a database that contains all the current ingredients of each product it’s easy to print labels on-demand the day the food is packed.

When the printer is then also connected with a database that contains all the current ingredients of each product it’s easy to print labels on-demand the day the food is packed.

The product portfolio of DTM Print includes label printers using either inkjet or dry toner LED laser printer. Advantages of colour inkjet and colour laser label printing over other label printing technologies are:

1. Lower Cost per Label = Higher Profits. Printing only the required number of labels is always a better choice and will cost less. Why order thousands or even tens of thousands of labels from an outside vendor when only 500 are needed? By eliminating obsolete label inventory additional money is saved.

2. Time Savings. Production efficiency is increased as labels can be printed on-demand and in-house.

3. Fast Adaption. Since ingredients or legal requirements can change manufacturers have to be able to adapt their product labels immediately without additional costs for new printing plates or cutting dies.

Depending on the number of labels needed per day, DTM Print has the perfect printer model to offer. One of them is the DTM CX86e Colour Tag Printer, that allows producers to print food labels in full colour and on demand. The printed labels are very water-resistant, UV-resistant, warm food counter and fridge resistant, with pin-sharp, small legible text down to 2pt size if needed. With the CX86e it’s easy to include best before dates, lot numbers and highlight allergens ensuring food labels always meet UK Government and FSA requirements.

Because of its small size and low weight of just 9.5 kg the printer can be placed almost anywhere, is easy to transport and produces labels within seconds directly in production, at the counter or at any other the point-of-sale. Special attention was paid to a simple operation not only when printing labels but also when maintaining the printer or replacing consumables.

To guarantee the best print results DTM Print recommends its Genuine DTM Dry Toner Label Stock. A wide range of approved matte, semi-gloss and high-gloss materials are available, allowing product owners to precisely match their substrate requirements.

DTM Print has many standard sizes available and any material is available as custom made size.

The DTM CX86e is the world’s smallest LED dry toner colour label printer and helps food and drink manufacturers to produce professional full-colour food labels that are compliant with UK food regulations, such as Natasha’s Law, while also reducing wastage as labels are produced on-demand.

For more information visit: https://dtm-print.eu

Rushlift, the national fullservice provider of materials handling equipment (MHE), has won the UK Material Handling Association’s prestigious Dealer Member of The Year Award at the Archies 2024, an industry accolade that recognises Rushlift’s commitment to excellence in service, innovation and customer satisfaction.

The trophy was presented to Jason McNally, Director Rushlift MHE, at a major gala awards dinner held at the Hilton Metropole, Birmingham, in front of an audience of industry

leaders. The UKMHA Dealer Member of The Year Award is one of the most coveted accolades in the material handling industry.

As a national full-service provider of MHE Rushlift is free to source from any supplier of industrial equipment, acting as a ‘one stop’ point of contact for all equipment needs, from counterbalanced forklift trucks, warehouse trucks, cherry pickers and access equipment, to ride-on cleaning machines, sideloaders, racking and conveyor systems.

Rushlift has six national depots located strategically across the UK and over 150 highly qualified field engineers on the road at any one time, enabling the company to issue a guarantee that an engineer will be on site within four hours.

For further information on Rushlift go to https://www. rushlift.co.uk

Lineage announces a grand prize of $50,000 for the Food Chain Innovation Challenge

The global winner will receive substantial prize from Lineage and invite to a six-month, executive-led incubator program to help kick start their business.

Lineage, Inc., the world’s largest global temperature-controlled warehouse REIT, today announced additional details of its flagship competition, the Food Chain Innovation Challenge, including members of the judging panels as well as the grand prize.

The challenge of creating impactful solutions for food waste comes at a critical time, as the severely foodinsecure population is expected to hit nearly a billion people by 2028. Lineage’s global competition invites students and startups to pitch

their innovative technologies or data solutions that address postharvest food waste.

The Food Chain Innovation Challenge will take place in three major locations: London on November 14, and Amsterdam and San Francisco both on November 19.

During each event, participants will present solutions aimed at mitigating food waste to an esteemed regional

judging panel. Judges will select a regional winner, who will be awarded a $5,000 cash prize and a spot in the grand final event on December 2. One winner will then be chosen to receive the $50,000 grand prize and an invite into a six-month, executive-led incubator program tailored to their unique business goals.

The London event will take place on November 14, 2024, at The Science Museum. At the events, participants

will be asked to pitch their existing ideas across four specific areas: reducing food waste, food preservation techniques, access to nutritious food and data-driven insights and analytics.

For a glimpse into the 2023 Hackathon, the predecessor to The Food Chain Innovation Challenge held in Amsterdam, watch this video. Also, hear insights from last year’s winner to get inspired and understand the impact of winning this prestigious challenge.

Logistics UK’s Transport Manager 2024, sponsored by Brigade Electronics, got under way in September in Yeovil, with 1,500 delegates booked onto the conference series and three of the venues full. To enable transport managers across the country to take advantage of the information and guidance, even if they are unable to attend in person, there will once again be a virtual version of Transport Manager, to take place on Friday 29 November 2024.

Virtual Transport Manager will cater for those who cannot travel to an in-person event, whether due to location, time or business pressures, or who don’t have time for all the sessions in one go. The virtual one-

day conference will follow the same format as the in-person events to be held around the country and will provide the information and guidance on legislation which the industryleading conferences are renowned for.

Transport Manager is a recognised Continuing Professional Development (CPD) event, and attendees will receive a certificate evidencing their attendance, whether they attend in-person or virtually. CPD is a term used to describe the learning activities professionals engage in to develop, enhance and maintain their abilities.

Logistics UK is delighted to have secured the involvement of the Traffic Commissioners for the

whole series, both virtual and live, and other sessions will include the Transport Manager calendar, a compliance update, GSR and ADAS systems, the legal responsibilities of a transport manager, revision of the Transport Manager CPC syllabus, transport managers in a connected and autonomous world, driver focus: finding and keeping the best, and a session by the Metropolitan Police on dealing with fatal incidents and collision investigation.

Transport Manager is also supported by bronze sponsors BP, r2c, Weightmans, WTW and a plethora of regional exhibitors. For further information, or to book a place, please visit: https://logistics. org.uk/transport-manager

The banana inspection and packing lines within Primafruit at their Evesham facility were heavily reliant on manual labour. Imported produce, cardboard trays filled with bananas, were received stacked on pallets, typically to a height nearing 2.5m. The operation for Primafruit was to de-stack the cardboard trays, inspect the produce and re-pack the fruit into either cardboard trays or collapsible, returnable plastic crates prior to re-palletising and despatch to their retail customer. Primafruit wanted to automate the process at their state-of-the-art facility which is perfectly located in a central hub for agriculture and have a dedicated pack house, chilled storage, and ripening chambers. The new system was another important step in their automation journey creating a more efficient and safe working environment.

CKF has vast experience, designing and building robotic palletising systems for a wide range of industries. This application demanded that the CKF team fully understood the challenges such that customised solutions could be developed to provide Primafruit with an efficient automated process.

For the automation

to be cost effective CKF proposed a single robot for de-stacking and re-stacking.

For the automation to be cost effective CKF proposed a single robot for destacking and re-stacking. Searches, tolerances, case quality and stack profile are all key elements to the success of any robot palletisation. To undertake the de-stacking and restacking utilising a single tool would require a bespoke design. The CKF Engineering team also understood the demands on the tool to handle two differing containers i.e. cardboard trays and plastic collapsible, reuseable crates. It was vital that the tooling developed would maintain the integrity of the bananas, without marking or causing any damage.

By using a single robot cell, the system would maximise the floor space available to ensure that designated access routes for personnel and the movement of materials would be maintained.

CKF utilised an ABB IRB 660 industrial robot system in the solution design - this dedicated palletising robot is designed to handle a load of up to 180kg at a reach of up to 3.15m. Its low weight upper arm, 4 axis design and parallel rod system means it delivers optimised speed, reach and payload. This robot is exceptionally fast making it ideal for palletising bags, boxes, crates, bottles and more.

The CKF Engineering team developed the bespoke gripper to pick either two or three cases at a time (dependent on stack orientation.).

The single tool was designed to suit both de-stacking and re-stacking, together with handling two case variants of differing dimensions, location points and material. Based on an anodised aluminium framework to reduce weight, the tool utilises pneumatically actuated side grippers and base slide plate for transfer of the multiple case format, additionally, a vacuum assist is required to enable lifting of the product trays prior to separation from the stack. Due to the lack of conformity of the pallet stack from the suppliers to Primafruit, the CKF team developed the Robot positioning for de-palletising using an onboard sensor array to determine the coordinates of height and stack position prior to the pick operation.

Once transferred from the pallet, stack cases are transferred to and from the inspection cells on the CKF range of ZPA conveyor sections which utilises the Interroll DC platform. This perfectly matched range of controls, motor rollers and power units enable the provision of a unique combination of conveyors for this system. This includes CKF accumulation conveyors configured to provide individually controlled zones, allowing zero pressure accumulation of the product trays and the flexibility to be configured to different sizes.

Get in touch with CKF today to discuss your palletising requirements: www.ckf.co.uk info@ckf.co.uk

Roll out of IoT technology showcases huge potential benefits to dairy supply chain.

Appleby Creamery, an awardwinning, small-batch cheese producer based in the Lake District, is aiming to support its traditional manufacturing processes and make its products even more sustainable through the use of Internet of Things (IoT) technology.

In collaboration with CENSIS – the innovation delivery organisation for digitalisation and enabling technologies – the system has been designed and deployed to monitor energy use and temperatures across the creamery’s Eden Valley site.

The initiative – delivered via CENSIS’s Milk Round technology accelerator – is part of the Digital Dairy Chain, a multipartner project led by Scotland’s Rural College, which aims to transform the dairy processing supply chain in south and west Scotland, and Cumbria. The project is funded by UK Research and Innovation’s flagship Strength in Places Fund.

Producing cheese requires consistent temperatures and humidity levels at different stages of the process to

maintain product quality and safety. Prior to the installation of the IoT system, conditions in fridges and ripening rooms were checked and recorded manually during working hours.

The new system allows the Appleby Creamery team to monitor conditions remotely every 15 minutes, 24 hours per day, and sends real-time alerts if anomalies occur, allowing for a prompt response to prevent the risk of product spoilage.

The system also tracks the energy use of equipment throughout the cheesemaking process – from fridges to pasteurisers – with the data displayed on a dashboard developed by CENSIS. This helps the creamery team to make decisions that could save energy and make better use of its on-site renewable sources.

Rolled out over two phases, the project will soon include the installation of sensors to track fuel gas usage and hot and cold water consumption. The data collected will not only enhance cost savings and sustainability, but also automate compliance reporting for metrics such as the creamery’s temperate and humidity.

Additionally, it will provide insights for scaling operations and attracting new investment. The sensing system is low-cost, easy to maintain, and can be readily relocated to monitor different areas of the site.

Founded in 2007 by three former colleagues from Express Dairies, Appleby Creamery has grown to a team of 12, with plans for further expansion into Scotland and the south of England. Sourcing its milk from Crofthead Dairy Farm in Dumfries and Galloway, the creamery’s variety of cheeses –including brie, blue, and cheddar – can be purchased from a range of retailers including Booth’s and Tebay Services Farm Shop.

Four Speedor high-speed doors have been installed by Hart Door Systems at a major frozen and cooked meat manufacturing in northern England. The doors, at just 1.5m wide and 1.95m high, are the second smallest Speedors ever manufactured by Hart.

“The contract demonstrates two things,” says Gordon Kipling, regional sales manager for Hart. “Not only is our Speedor range available in distinctly different types of doors but where applicable the doors can be available in reduced sizes for precise requirements.

“In this case there was a need to protect the production environment against drafts, humidity, dust and dirt by installing our Speedor Cleanroom with its fast opening and closing speed. Our pharmaceutical standard Cleanroom Speedors control airflow thus reducing contaminants.”

Designed specifically for manufacturing and research facilities, Speedor Cleanroom works in strictly controlled environments where hygiene standards are high, such as pharmaceuticals, food processing, electronics and micro-mechanics industries.

The main features of Speedor Cleanroom include maintaining strict air leakage requirements over specified pressure differentials. Complete with an intelligent control panel with digital display each Cleanroom has a reliable and clean in-line drive system complete with an integral safety brake and a non-touch safety light curtain ensures maximum protection to personnel. Seals minimise pressure drops and protect the manufacturing environment against drafts, humidity, dust and dirt.

www.hartdoors.com sales: +44 (0)191 214 0404

British design and manufacture, wide range of models covering high security, large doors with high wind resistance (3,000 to 5,000 pascals), fire and high speed automation with systems’ interface.

Abbey’s silo evacuation services are available at short notice, with our team of professionals operating nationwide. We respond quickly to ensure your products keep flowing and your sites remain fully operational.

Our focus is on minimising disruption to your business. We remove contaminated products, blockages, or spillages without delay, getting sites up and running in no time. You can call our team to perform silo-to-silo transfers and remove products from tanker trailers or any other vessels that need materials removed.

Abbey Warehouse, which specialises in handling a wide range of products both food and non-food, can help reformat all your products.

Abbey Logistics is the UK’s largest bulk powder road tanker company for food-grade products. We have extensive experience in sugar, flour, salt, starch, and most other powdered and granulated products.

In addition to food products, Abbey works with some of the UK’s largest polymer, cement, lime, and ash