EXHIBITION FOODEX MANUFACTURING SOLUTIONS 2023 AUTOMATION

March 2023 fdm-uk.co.uk

A SMOOTHER TRANSITION TO AUTOMATION SUCCESS

Features Editor Henry Peters editorial@fdm-uk.co.uk

Production/Design Laura Whitehead laura@lapthornmedia.co.uk

Sales Manager Holly Jones sales@fdm-uk.co.uk

Sales Executive Alex Costa alex@fdm-uk.co.uk

Publishing Director Maria Lapthorn maria@lapthornmedia.co.uk

Don’t Wait for Compulsory Food Traceability, by Adem Kulauzovic Brillopak accelerates packing efficiency at Morrisons fresh-produce operations 2023 and packaging: What have we seen so far, by Elena Rotzokou

The UK’s dedicated food & drink manufacturing event returns this March AB Agri Chooses Infor to Drive Digital Strategy for Growth

Editors Note

Welcome to the latest issue of Food & Drink Manufacturing UK Magazine.

We are always thrilled to hear of new and innovative ways to tackle plastic pollution and with the increasing demands for sustainable food packing, we bring news that climate tech innovator, Kelpi, has secured £3 million fundraising to advance technology, creating biomaterial coatings from seaweed.

Paul Attwood Editor

Paul Attwood Editor

We bring news of the upcoming exhibitions, the IFE Manufacturing event at the ExCEl, London on 20-22nd March and Foodex Manufacturing Solutions event at the NEC, Birmingham on 24-26th April.

We also feature an interview with Rasmus Mortenson, CEO at Lyras, who addresses the need for energy-efficient technology in the dairy sector in order to improve sustainability.

We hope you enjoy this issue and as always, if you have any news that you would like to feature, please email details to editorial@fdm-uk.co.uk.

CONTENTS Editor

Assistant

Amato

Paul Attwood editor@fdm-uk.co.uk Editorial

Francesca

editorial@fdm-uk.co.uk

Lapthorn Media Ltd 5-7 Ozengell Place, Eurokent Business Park, Ramsgate, Kent, CT12 6PB 16 30 36 38 46

16

Every effort is made to ensure the accuracy and reliability of material published in Food & Drink Manufacturing UK however, the publishers accept no responsibility for the claims or opinions made by advertisers, manufactures or contributors. No part of this publication may be reproduced or transmitted in any form or by any means, mechanical, electronic (including photocopying) or stored in any information retrieval system without the prior consent of the publisher. 03 36 46 30 38

808 117 www.fdm-uk.co.uk @fdmanufacturing

01843

Finsbury

Food Group acquires Lees Foods

The specialist bakery business, Finsbury Food Group has acquired Lees Foods in a cash deal reported to be worth £5.7 million.

Renowned for its snowballs, teacakes and meringues Lees Foods has been in business since 1931 and has a workforce of around 200, based in Lanarkshire.

Finsbury Food Group has said it believes the deal will consolidate its position in the sweets sector and means it now has a growing manufacturing presence in Scotland.

CEO at Finsbury, John Duffy is said to believe the sale will mean it can explore further commercial opportunism including out-of-home eating.

Welsh Government considering banning meal deals

The Welsh Government has been urged not to ban meal deals following the consultation document to make Wales a ‘healthier’ food environment.’

The consultation document, published back in June 2022, looked at ways to ‘make the food environment in Wales healthier’ including banning meal deals.

Whilst the consultation came to an end in September nothing has yet been published. However, The Welsh Retail Consortium has written to ministers explaining that the move would as its head, Sara Jones explained: “Just lead to restrictions in terms of availability and affordability in terms of the consumer.”

She added: “With inflation running at an 18-year high it would be regressive and irresponsible to put up costs in this manner with no evidence

at this time that it would significantly improve public health.”

David Thomson, of the Food and Drink Federation Cymru told the BBC: “The Welsh government must ensure that any policy does not increase the cost of food for the people of Wales at a time when households across the country are struggling to make ends meet. In addition, it is critical that Welsh food and drink manufacturers have a level playing field with their competitors in other parts of the UK.”

A Welsh Government spokesperson said: “We are considering the next steps on price promotions and locations and no final position has been made following the pubic consultation.

“We are not proposing to ban meal deals themselves but to consider whether there should be restrictions on high fat, salt and sugar products that may be part of a meal deal.”

04 Industry News

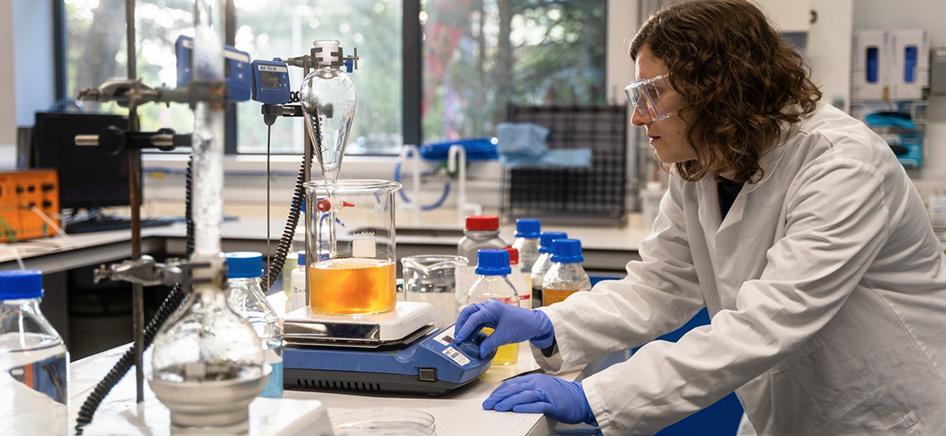

£3 million funding to advance the science of sustainable food packaging

Climate tech innovator Kelpi has secured more than £3 million fundraising to advance its technology creating biomaterial coatings from seaweed. It is working with the food industry to bring sustainable packaging a step closer to supermarket shelves.

“This landmark investment enables Kelpi to scale up our pioneering work using seaweed to create bioplastic packaging with the barrier properties required by clients,” said Kelpi CEO and co-founder Neil Morris.

Kelpi’s seed round was led by Science Creates Ventures and Green Angel Syndicate, with funding from One Planet Capital and follow-on investment from Bristol Private Equity Club (BPEC), together with private angel investors. The round includes £665,000 of grant funding from Innovate UK’s Combined Investor Partnership.

Morris continued: “Kelpi can now play a key role in eliminating plastic pollution and ending our dependence on fossil fuels to create single-use packaging.

“We’re delighted to receive this backing from specialist deep science and sustainability investors like Science Creates Ventures and Green Angel Syndicate to allow us to accelerate our pioneering work with major food and drink companies worldwide to prove our materials at scale.”

Kelpi said in its annoucement that seaweed provides a particularly valuable source of carbohydrates for biomaterials. It grows prolifically without need for fertilisers, nor land nor fresh water – offering benefits

over alternative plants from which bioplastics can be made. It soaks up carbon as it grows, de-acidifying and re-oxygenating the ocean.

Grocery price inflation rises to record 16.7%, says Kantar

Grocery price inflation hit a record 16.7% in the four weeks to 22nd January 2023 according to Kantar, the highest level since it started tracking the figure in 2008. Overall take-home grocery sales rose by 5.7% during the four week period and by 7.6% over the 12 weeks.

Fraser McKevitt, head of retail and consumer insight at Kantar, commented: “Late last year, we saw the rate of grocery price inflation dip slightly, but that small sign of relief for consumers has been short-lived.

“Grocery price inflation jumped a staggering 2.3 percentage points this

month to 16.7%, flying past the previous high we recorded in October 2022.

“Households will now face an extra £788 on their annual shopping bills if they don’t change their behaviour to cut costs.”

Aldi was the fastest growing grocer for the fourth month in a row this period, with sales 26.9% higher year on year. It now holds 9.2% of the market. Lidl’s sales jumped by 24.1%, putting its market share at 7.1%.

There was little to split Britain’s three largest retailers. Sainsbury’s sales increased by 6.1%, just 0.1 percentage point higher than Asda and Tesco, giving it 15.4% of the market. Tesco

remains the largest British retailer with a 27.5% market share while Asda holds 14.2%. Although its sales fell by 1.9%, Morrisons’ performance has continued to improve for the eleventh month in a row and its market share now stands at 9.1%.

Iceland’s share increased by 0.1 percentage point to 2.5%, driven by an annual sales rise of 10.6%. Ocado matched the market’s growth rate at 7.6%, well above overall online sales which were down 0.7%. Convenience specialist Co-op has a 5.5% share of the market and Waitrose accounts for 4.7% of total sales.

05 Industry News

This landmark investment enables Kelpi to scale up our pioneering work using seaweed to create bioplastic packaging with the barrier properties required by clients.

- Neil Morris

Princes Group reports global food waste progress

International food and drink group, Princes, has published food waste data for its global operations, reporting a 27% reduction against the Group’s 2018/2019 baseline, marking progress towards the company’s 2030 goal to halve food waste.

Of the 69,141 tonnes of food waste generated across Princes’ global operations, it reported 19,130 tonnes were sent to anaerobic digestion plants to be converted into energy, while 40,879 tonnes were recycled into biobased materials and 4,897 tonnes were used as animal feed.

Additionally, 507 tonnes were redistributed to charities including FareShare, a UK food waste and hunger charity. Since 2013, Princes has donated

all food and drink that cannot be sold to FareShare.

In 2021/2022, over 105,000 cases of food and drink (475 tonnes) were donated to FareShare, and the Group established a food bank partnership in Italy for excess stock at its Princes Industrie Alimentari operation in Foggia, donating 32 tonnes to date.

Over the past two years, Princes has supported WRAP’s annual UK Food Waste Action Week to highlight the role that preventing food waste plays in tackling climate change.

Continued progress to reduce waste and reuse materials is key to Princes’ 2030GreenGoals initiative, which outlines the Group’s ambition to become a carbon neutral manufacturing business across its UK and international operations by 2030.

The business claims it has been reducing emissions through site upgrades and investments for many years, but reset its base level in 2018/19. Since then, Princes has reduced its operational carbon emissions by 10.5%, with further projects planned to achieve the Group’s 2030 target.

Iceland Seafood UK continues operations as part of the Iceland Seafood Group

Having previously announced its intention to exit the UK market from a value-added perspective Seafood International (ISI) is to review its UK strategy and plans to continue operations here.

In December 2022, two Letters of Intent (LOI) were signed with prospective buyers to sell the business, but neither negotiation turned out to be successful. After careful considerations the board of Iceland Seafood said it had decided to put the sale process on hold and continue to operate the UK subsidiary.

Iceland Seafood said it is to review its strategy on an ongoing basis and remains interested to support further consolidation of the UK business at the right time and terms.

In an industry where consolidation is needed, Iceland Seafood made it public late last year it was interested in selling the UK business.

It is however the conclusion of the board of directors that the proposals received didn’t reflect the value of the company, as external conditions for the industry have been challenging.

Recently, Iceland Seafood UK (IS UK) is reported to have made significant progress with its strategic partners recovering unprecedented inflationary cost and adding a significant new business. Therefore, the company said it foresees better results, driven by the above, in

addition to returns on investments in equipment, that will increase its ability to grow and reduce unit costs.

Markets are said to be stabilising, after the high volatility and constant upward cost pressure experienced throughout last year, which severely impacted the results of IS UK in 2022.

IS UK said it will continue to cooperate closely with its loyal customers and suppliers.

Iceland Seafood said it is to review its strategy on an ongoing basis and remains interested to support further consolidation of the UK business at the right time and terms.

06 Industry News

Domestic food and drink exports at an all-time high

The Food and Drink Federation (FDF) has compiled the latest export figures released by His Majesty’s Customs and Excise, and UK-grown food and drink exports have reached a record high.

“Despite the turbulence of the past few years, it is great to see the appetite for UK produce remains as strong as ever,” said FDF’s head of international trade Dominic Goudie.

Dairy exports have reached £2 billion, up 36% from 2021. Beef grossed £648.9 million (up 44.9%) and vegetables totalling £442.4 million (up 42%).

This growth has coincided with an increase in volume of sales in most categories over the last 12 months.

Goudie continued: “Our products, which are trusted for their worldleading quality, safety, animal welfare and sustainability credentials, can be found in shops, restaurants, bars, cafes and along high streets around the world every day.

“As demand for UK exports returns to pre-Covid levels, it is vital that the Government ensures pragmatic solutions are in place to facilitate sustainable growth of UK food and drink exports, supported by a border that prioritises the efficient movement of short shelf-life products, while protecting our vital trade with EU partners and beyond.”

World’s first 100% cultivated meat steak is produced in the UK

A team of scientists at 3D BioTissues (3DBT), a Newcastle-based tissue engineering company have produced the first-ever steak fillet of cultivated meat.

The fillet is made from solely pork cells, was made to be the same size and shape as a traditional piece of pork and is reported to have also replicated the flavour and texture of a pork steak too.

The fillet was produced using 3DBT’s patented, serum-free and animal-free cell booster, City-mix, a patented media supplement which eliminates the requirement of conventional plantbased scaffolds, blends or fillers, as have been universally adopted by the industry to date to ensure structural integrity of cultivated meat products. 3DBT’s fillet is therefore 100% meat, leading 3DBT to believe that this is the world’s first 100% cultivated pork steak to be produced and tasted.

Che Connon, chief executive of 3DBT, said: “This is a significant scientific breakthrough which has very positive implications not just for BSF and 3DBT but also for the UK and the cultivated meat industry as a whole. We are absolutely delighted with the appearance, taste, aroma, and texture of our cultivated pork, which is the first time we have fully sampled our product. Our cruelty-free fillet has exceeded our expectations in all respects, and we are extremely excited about the technological progress we are making and the impact this could have on our industry.

“City-mix, our serum-free media supplement in which we cultivated the fillet, is helping to greatly reduce the cost of cultivated meat such that it may become economically viable in the near future. At the same time, our ‘structure without scaffold’ technology is helping to make cultivated meat that more closely resembles traditional meat in every respect without the need for plantbased additives. We look forward to taking the findings through to the next stage of development, focused on producing a chefready product for public consumption.”

The company is also looking to work with manufacturers and supermarkets to sell cultivated meat and separately with fashion companies to produce cultivated leather using the same tissue-templating process but with skin cells. The company believes this has the potential to significantly reduce livestock farming, cutting the greenhouse gases, water and energy used in meat production.

07 Industry News

This is a significant scientific breakthrough which has very positive implications not just for BSF and 3DBT but also for the UK and the cultivated meat industry as a whole.

- Che Connon

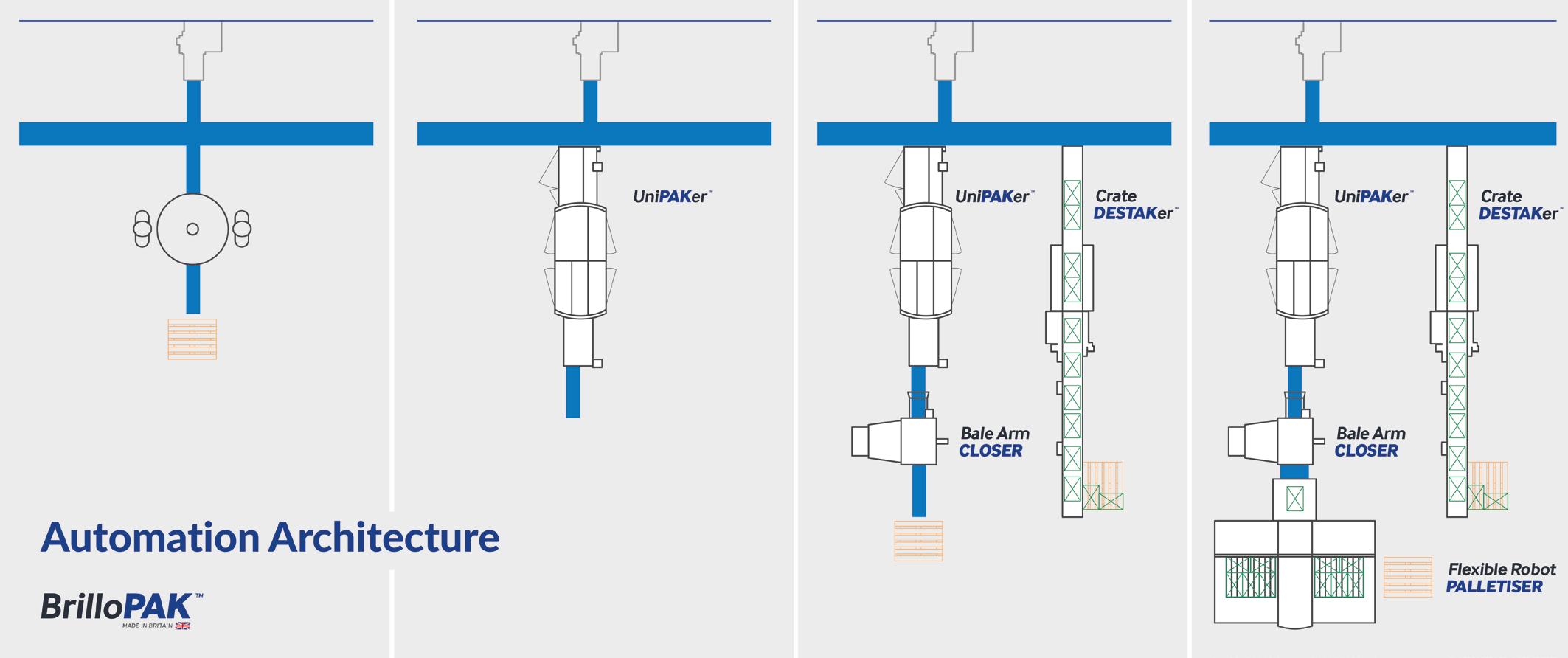

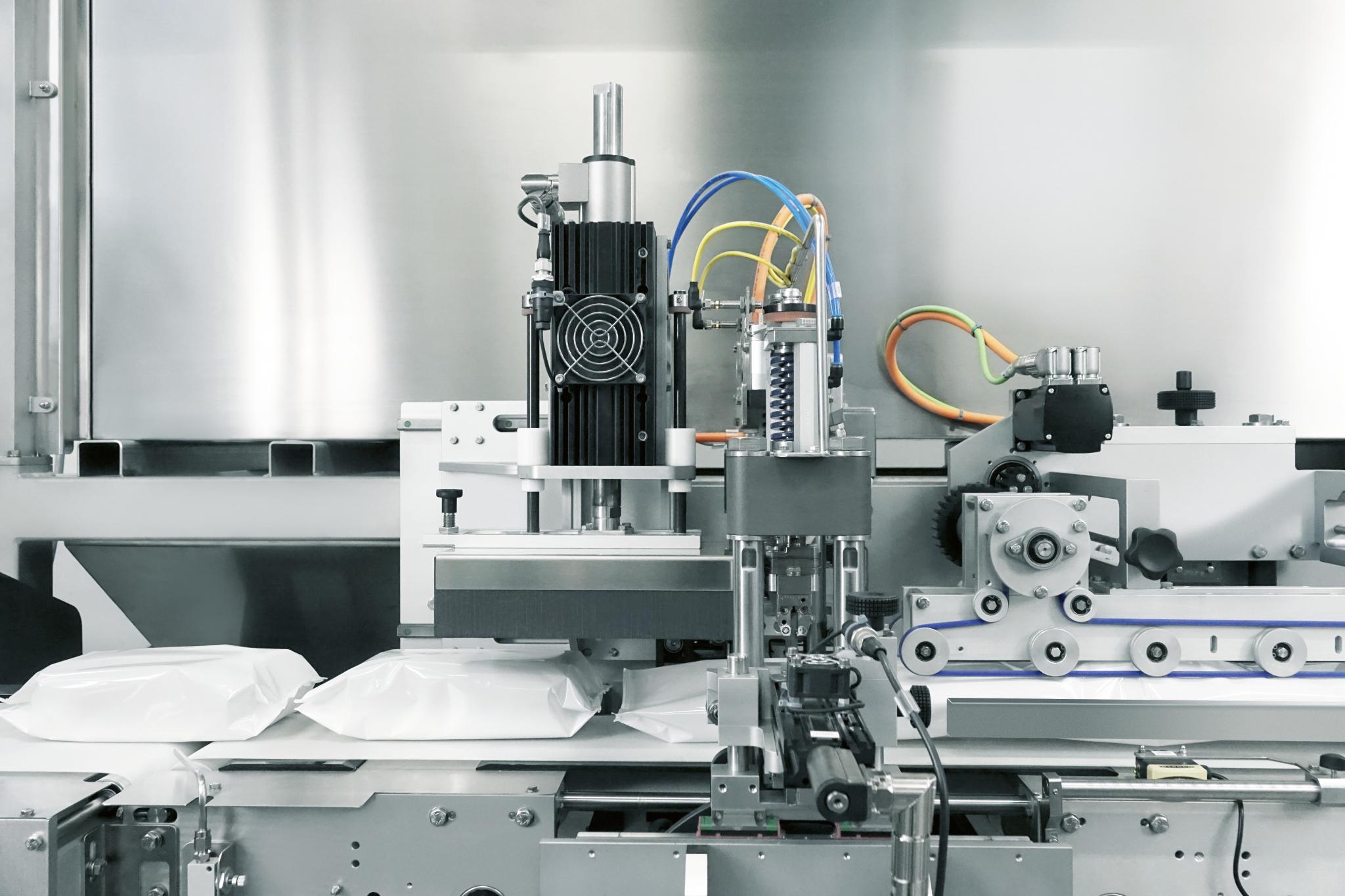

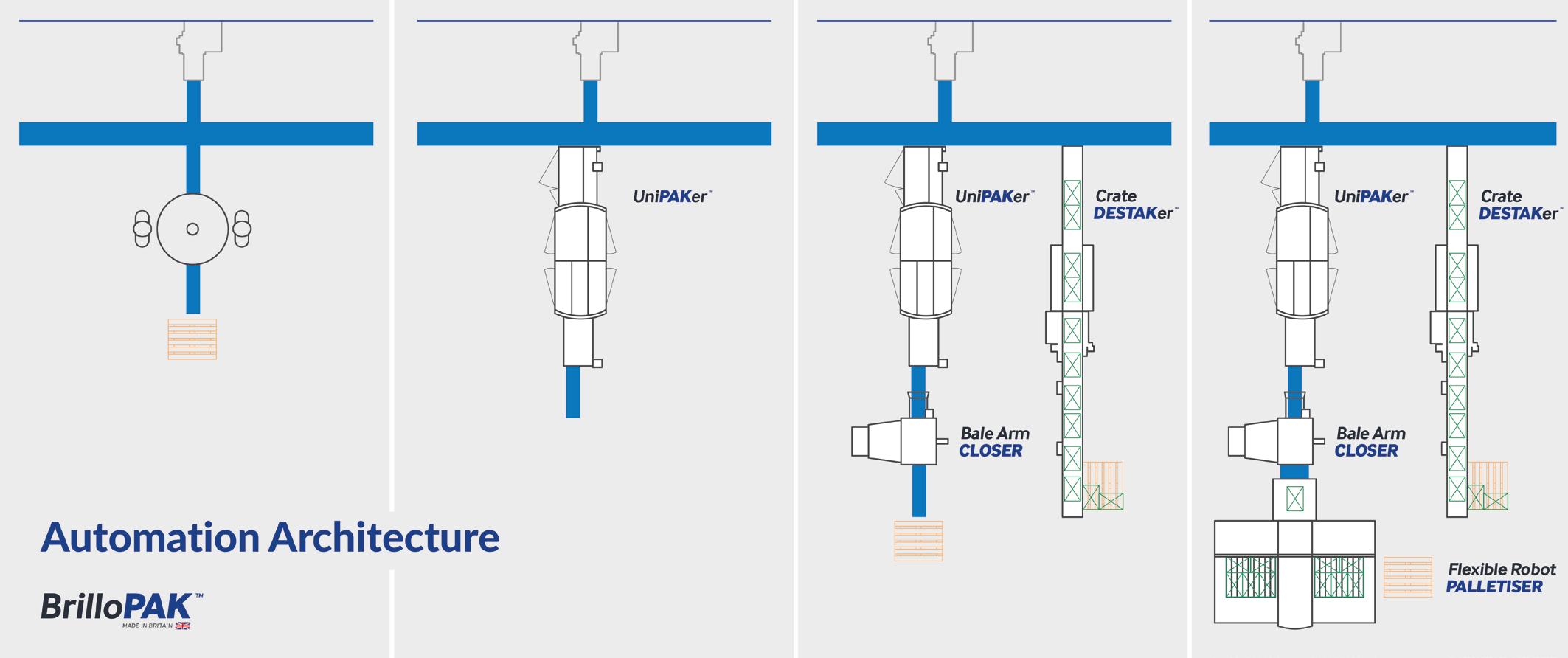

A smoother transition to automation success

Your investment in end-of-line automation in food packing is no longer a medium-term aspiration, it is now a short-term business imperative. And with an optimum combination of classleading technology and a partner that understands every facet of the evolutionary process, you can quickly reap the throughput rewards and avoid all the planning, architectural and logistical pitfalls.

This push to automate is being driven by your end users; the proliferation of digital supply chains, which thrive on end-to-end operational data; labour market shortages, evolution and migration; and efficiency, agility & speed of response becoming ever-more essential metrics for your customers.

But we know that deploying automation is a big step as it can be very different to manual operations. There is also an element of perceived risk. Indeed, we’ve heard from many

food processors and packers who are not fully utilising their new automation equipment, often for simple reasons that were overlooked at the planning stage.

These can include simply not asking “why are we automating?”, a failure to create forward-looking requirements plans, engineers and operators being reluctant to use more complex technology, failure to consider future business when planning and failure to involve all stakeholders.

To prevent these issues, we highly recommend you partner with a manufacturer that can act as an expert guide, as you prepare and transition into automation - from planning through design, deployment, evaluation and enhancement, and onto carefully phased and fully scaled operations. There’s a lot to consider.

By taking a holistic view of your requirements, your facilities, your business plan, your customers’ needs and your plant capabilities, Brillopak can help you create an automation action plan that delivers your desired improvements in operations efficiency and a quick payback.

08

Automation in Food Packing

David Jahn, sales director at Brillopak explains why automation should not be feared and that proper planning can prevent myriad issues, while delivering significant performance increases. We’ve created a multi-stage agenda that captures all plant, project and business requirements and addresses many of the issues before they can even appear.

- David Jahn

We’ve created a multi-stage agenda that captures all plant, project and business requirements and addresses many of the issues before they can even appear. These steps help users to much better understand our process.

Step one is a full plant audit and requirements capture, where we ask the questions ‘why are you automating?’ and ‘what are your business goals, drivers and needs?’ In step 2 we look at the plant architecture to assess space, utilities, flow and potential. We then look at your packaging, in terms of the product, the package types, the primary materials and the desired throughput. We need to look at this to define the robotic systems.

End-of-line packaging machine design is next, where we examine any unique product/plant/customer factors that could influence design/operation? At this and every stage the devil is always in the detail. We mustn’t forget your people. Here we will look at workforce preparation, especially at skill and staffing levels. Following this we look a little to the future and discuss what you will need in terms of maintenance and service.

Once this has all been finalised we

Automation in Food Packing

can examine the installation, test and commissioning of your new automation solutions, where we will minimise downtime and ensure your engineering team is part of the process as early as possible.

The final step is to study your future requirements and how a phased approach can take you onto the next evolutionary steps. We can look at how we can help you to enhance and grow your initial installation. Maybe add a second packer and additional conveyors and then copy this three-machine format and co-locate. At each phase we will examine the lessons learnt to define best practice for the next stage. You can grow and expand at your own pace and set operational and financial stage gates to suit your precise needs.

Our award-winning robotic caseloading systems include single-system solutions and everything for end-toend packing lines, including packmanagement conveyor systems, robotic product loaders, crate de-stackers, bale arm closers and palletisers.

Our team has installed over 200 systems, helping transform manual packing halls into semi or fully automated operations.

Ultimately you don’t know what you don’t know. Our systems are designed with the flexibility to handle multiple product types now and into the future, to ensure that your investment today is still generating payback in 10 years’ time.

If you’d like to discuss a project, please contact us at technicalsales@brillopak. co.uk or phone us on 01622 872 907 for a free consultation.

09

We can look at how we can help you to enhance and grow your initial installation.

- David Jahn

NFU says Government must commit to domestic food production

“There are three cornerstones on which a prosperous farming sector must be built and which any government should use to underpin its farming policy. They are boosting productivity, protecting the environment and managing volatility,” was the message from NFU president, Minette Batters speaking at the NFU’s annual conference.

Delivering the opening address at NFU Conference, NFU President Minette Batters laid out the three cornerstones needed to ensure a prosperous food and farming sector; one that delivers a secure, safe and affordable supply of British food, for both home markets and overseas, and recognises that farmers are the nation’s working conservationists in protecting and enhancing the environment.

“There are three key lessons we can take from this extraordinary year,” she will say. “As the global population continues to rise, and parts of the planet become less suited to producing the food we eat, we have an opportunity, and a duty, to get the best out of our maritime climate.

“Secondly, in the face of climate change, we should be unwavering in our commitment to achieving net zero and contributing to our energy security through on-farm renewables generation. And thirdly, we should nevertake our food security for granted.

“But the fact remains, volatility, uncertainty and instability are the greatest risks to farm businesses in England and Wales today. Critically, those consequences will be felt far beyond farming, they will be felt across the natural environment, and in struggling households across the country.

Shortages

“Labour shortages and soaring energy prices are hitting the poultry industry, already reeling from avian influenza, as well as horticultural businesses and pig farms.

“Meanwhile, other sectors are facing an uncertain future as direct payments are

phased out against a backdrop of huge cost inflation, with agricultural inputs having risen almost 50% since 2019. And the impact of this? UK egg production has fallen to its lowest level in nine years. In 2022, UK egg packers packed almost a billion fewer eggs than they did in 2019.

“This was also the year that the potential impact of climate change really hit home. The extraordinary temperatures we experienced in July topped the previous record by almost a degree and a half. While many parts of the country have experienced huge amounts of rainfall recently, impacting farming operations over autumn and winter, some counties still remain in official drought status.

“Despite all this, NFU members and the farmers and growers of Britain continued to bring in the harvest, to produce the nation’s food and to keep the country fed through tough times. We have seen progress; with the publication of the prospectus for the new Environmental Land Management Schemes; with increases to the Seasonal Agricultural Workers schemes; and in securing the establishment of the Trade and Agriculture Commission, leading to the Food and Drink Export Council and the placement of eight new agriculture attachés to sell British food overseas.”

10 Industry News

Rittal_ The System_ 2022_ EN_MPE_Oct 2022.indd 1

Enclosures from the smallest to the largest.

Breakthrough on food checks welcomed as Protocol agreement edges closer

The Chartered Institute of Environmental Health (CIEH) has welcomed reports that a breakthrough has almost been reached between UK and EU negotiators regarding checks on goods moving between Great Britain (GB) and Northern Ireland (NI) but has demanded clarity on how this will work in practice.

CIEH has already highlighted the possibility of deploying Environmental Health Officers (EHOs) to help support port authorities responsible for conducting food and animal health checks on such goods. This goes hand in hand with the need for greater funding of in-land local authority food safety teams who will be placed under greater pressure to monitor such goods to ensure food safety standards are being maintained.

The reported breakthrough, which suggests that there will be the creation of a new ‘green and red lane’ system of checks on goods moving between

GB and NI, potentially removes one of the last major stumbling blocks in the ongoing dispute between the UK and the EU with regards to the operation of the Northern Ireland Protocol.

Goods moving from GB destined to stay within NI would go through a ‘green lane’ and be subject to lighter checks at Northern Ireland’s ports compared to goods that are destined to make their way south to the Republic of Ireland going through the ‘red lane’ which would require much stricter checks.

Such a move would require products moving between GB and NI to be appropriately labelled as suitable for NI only, will require appropriate monitoring by NI officials to ensure goods intended solely for the NI market remain there to prevent food crime, and will also require appropriate checks to be made by local authority food safety teams to ensure that such goods adhere to EU food safety standards.

Ross Matthewman, Head of Policy and Campaigns at CIEH, said: “We at CIEH cautiously welcome the news that a resolution to this ongoing dispute over the Protocol is one step closer with this breakthrough on food and animal checks. The creation of a ‘green and red lane’ system of checks is a sensible and pragmatic approach that both reduces needless friction on the movement of goods whilst ensuring standards are being maintained.

However, as is always the case with these matters, we await to see the fine print as to the precise nature of these checks, and seek assurances that local authorities will be appropriately resourced to ensure they are equipped to enforce any new regulations.

“Finally, CIEH wish to highlight the role that EHOs have historically played in conducting food and animal health checks at border control posts in the past, and to suggest that EHOs stand ready to fulfil this role once more in supporting port authorities with this vital work.”

11 Industry News

www.rittal.co.uk 31-Oct-22 4:00:01 PM

Switch to automated lift trucks brings a host of benefits to fresh fruit specialist

As part of its strategy to streamline intralogistics processes and reduce the impact of the labour crisis on its business, Primafruit – a leading name in the fresh produce industry - has introduced a fleet of fully automated counterbalanced trucks from Toyota Material Handling’s Autopilot range at its Vale of Evesham-based production and storage facility.

The Toyota automated guided vehicles (AGVs) are utilised at every stage of Primafruit’s mission critical storing and packing operation.

Fresh fruit arrives at the 41,000 square metre site from Primafruit’s suppliers and grower partners across Europe and South America and is taken by the automated trucks from the goods-in bay to the chilled very narrow aisle storage area.

The AGVs are then deployed to transfer palletised loads of fruit from the chilled storage system to the facility’s packhouse area where two production lines - one for packaging citrus fruits and another dedicated to processing berries, such as grapes, strawberries etc – are in operation.

We chose to work with Toyota because of their reputation in the industry and the comprehensive package they offered to us.

- Jordan Beckley

From the packhouse the automated trucks take palletised loads of individually packaged fruits to the building’s despatch bay where orders are loaded into vehicles by manual trucks for onward delivery.

In all Primafruit operate seven Toyota Autopilot OAE120CB counterbalanced

Lobo System Solves Safe Access Issues For Overhead Conveyors In Automated Logistics Industry

The LOBO System, a leading provider of modular access solutions, has recently supported KNAPP, a global automation and logistics company, with a safe access issue for overhead conveyors.

The LOBO System provided a customized bespoke solution that addressed safety concerns and increased the efficiency of the conveyor systems.

KNAPP faced the challenge of providing safe access for maintenance and inspection of their overhead conveyors. The LOBO System provided a modular access solution that allowed for safe and easy access to the conveyors without disrupting the flow of operations. In addition, the solution included customizable and long staging platforms, making it easy for engineers to access the conveyors.

The LOBO System’s solution not only

trucks at the Vale of Evesham site. The models specified have a 1.2 tonne load capacity and a lift height of 4.15 metres.

All models in the Toyota Autopilot range are programmed to complete tasks and work alongside manual operators in total safety. The trucks use built-in safety scanners and obstacle detection units to negotiate obstructions, while load sensors and multiple sensor devices further ensure accurate and safe load handling.

The trucks are controlled by Toyota’s in-house T-ONE automation software. Capable of working as a standalone system or as a communications layer in tandem with the client’s warehouse management and production systems, T-ONE tracks goods storage, orders, traffic and flow thanks to its intelligent fleet control functionality and its ability to integrate with the user’s ERP/WMS if required to do so.

Since switching to automated forklift technology, Primafruit report that the Vale of Evesham facility has become a more serene working environment, as the company’s general manager, Jordan Beckley, explains: “The implementation of the Toyota Autopilot AGVs has certainly had

addressed the safety concerns but also increased the efficiency of the conveyor systems. The modular design allowed for quick and easy installation, reducing downtime and increasing productivity. The solution was also designed to be easily reconfigurable, allowing for future changes to the conveyor systems.

The product is designed to improve safety, reduce labour costs, and increase efficiency for businesses in the automated distribution industry. It is the perfect solution as the system is lightweight, easy to transport and can be assembled by just one person with no tools required.

“We are thrilled to have supported KNAPP in resolving their access issue. Our modular access platform solutions are designed to meet each customer’s specific needs, making it easy to address safety concerns while

12 Automation

a calming effect on our operational areas due to the controlled manner in which they complete the work,” he says.

“We have also seen the system reduce a huge amount of manual pallet movements around the site, which has allowed our teams to focus on other more profitable tasks,” Jordan continues.

Automated pallet handling equipment has been shown to consume less energy than driver-operated forklifts – a benefit which, along with the other advantages that the technology brings, contributes to a typical return-on-investment time of less than two years.

Toyota provided the automated counterbalanced trucks on a rental package with full ongoing service back-up and technical support included in the monthly fee.

“We chose to work with Toyota because of their reputation in the industry and the comprehensive package they offered to us.

“The Toyota team worked closely with us to implement a flexible solution which can adapt to the constantly changing challenges that our industry presents,” adds Jordan Beckley.

A short film showing Toyota’s automated forklift technology in operation at Primafruit’s Vale of Evesham site can be viewed online here: https://oc.toyota-industries. eu/owncloud/index.php/s/ xg6evfvQOajPhMK

GenerationJuice transforms sales process with support from Made Smarter’s North West Adoption programme A manufacturer of juice dispensers is using augmented reality to transform its sales process, drive productivity and create new jobs.

GenerationJuice, based in Bromborough, Liverpool City Region, makes app-driven drink dispensers, or drink hubs, designed to serve natural juice drinks from concentrate into reusable bottles, as an alternative to single use plastic and aluminium cans.

After success in the leisure and hospitality industry the business, which launched in 2019, has started to target emerging markets such as education and healthcare.

tasting samples of the drinks at the same time.

The app-based solution eliminates the time-consuming and inefficient face-to-face demonstration process which typically ties up two sales staff for half a day.

GenerationJuice estimates that with new marketing activity to generate demo leads, productivity will increase by 600% and turnover by 50%. The technology investment has also created two new jobs.

By using the app and sending tasting samples of its 180-drink portfolio by courier, GenerationJuice will cut its annual mileage by 20,000, reducing its own carbon footprint.

With sustainability high on the agenda, GenerationJuice estimates its products can offer resource efficiency for its customers in terms of waste reduction, energy savings, and environmental impact.

increasing efficiency,” said Tom Bokros, Senior Technical Sales Engineer at LOBO Systems.

It worked with Made Smarter’s Adoption Programme in the North West to develop a digital demo experience using augmented reality to enable customers to visualise the dispenser on their site while

It estimates that an average customer can expect to save one ton of plastic or aluminium waste based on an average consumption of 75-90,000 plastic bottles or cans - potentially reducing the company’s energy consumption by up to 63%.

For more information, visit www.madesmarter.uk/ adoption

13 Automation

Our modular access platform solutions are designed to meet each customer’s specific needs, making it easy to address safety concerns while increasing efficiency.

- Tom Bokros

Juice dispenser manufacturer embraces augmented reality to accelerate growth

Specialist food manufacturer boosts productivity and turnover following Made Smarter support

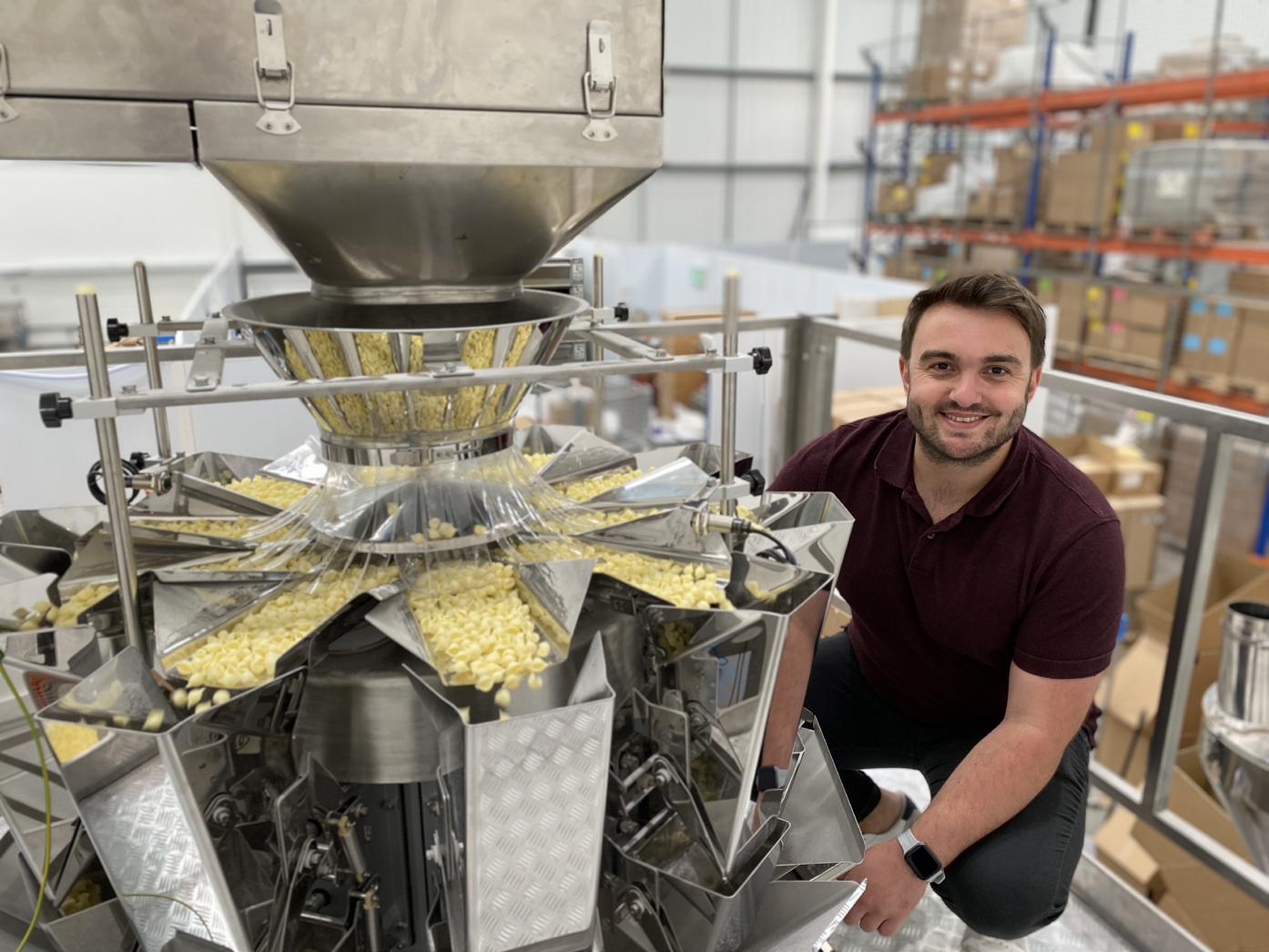

Firstplay Dietary Foods is adding digitalisation to the menu with automation investment

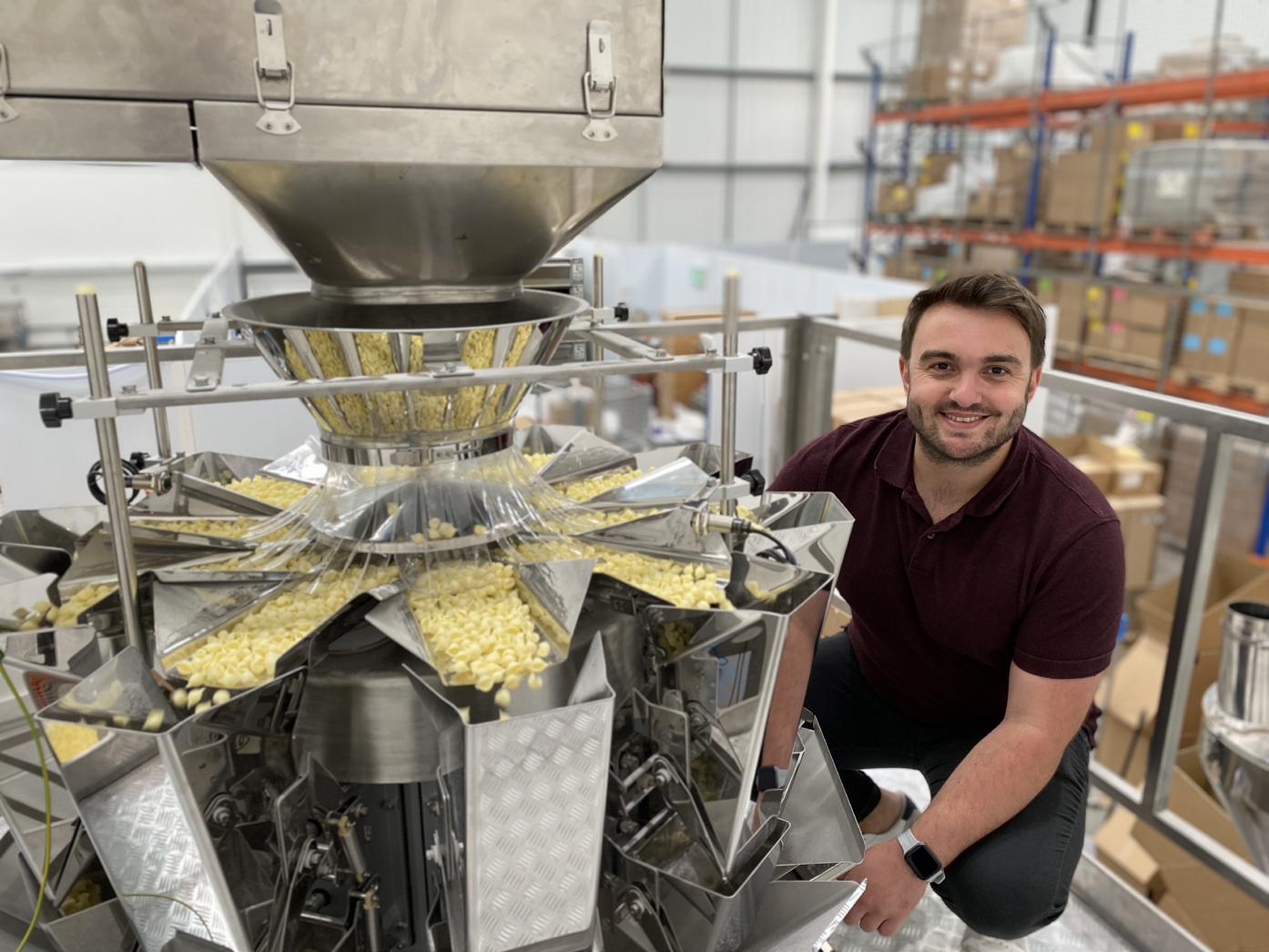

A specialist food manufacturer has experienced a 10-boost in productivity and is forecasting a 30% increase in turnover after investing in automation technology with the support of Made Smarter.

Firstplay Dietary Foods, based in Stockport, makes a range of low protein products for people with metabolic conditions like Phenylketonuria (PKU) which leave people unable to eat protein without risking brain damage.

With a growing international demand from patients and dieticians, due to the increased number of countries delivering newborn screening, the business has invested £120,000 in new digital machinery, increasing its blending capacity, while replacing a manual weighing and packing process with automation.

As a result, the business has increased production capacity 10-fold, reduced human error and waste, and is forecast to increase turnover by 30%.

In addition, two operators are now focussed on more value-add activities

such as sales and complex packing tasks.

Tom Fletcher, Managing Director, said: “Our growth has been organic with only occasional investment to update our production processes. Our partnership with Made Smarter changes that. We have a longterm strategy and a digital roadmap to follow to achieve those goals. My only wish is that we had done it sooner.By replacing a manual low-skilled task with automation, we are able to do much more with the resources we have, as well as upskilling our existing staff, which to a small business is extremely valuable.”

Firstplay was established in 1993 by Steve and Linda Fletcher to help people living with PKU, an inborn error of metabolism which affects roughly 1 in 10,000 people in the UK.

Over the decades the business has grown steadily, innovating its product range to include dried pasta, flavoured pasta sachets, breads, baking mixes, snacks and soups, for an increasing global market.

With ambitions to target emerging markets in China, the Middle East and

America, Firstplay needed to address its manufacturing productivity and efficiency challenges.

But a key bottleneck in the production process was the manual weighing and packing of certain products which had a limited capacity of about 600 packets per day, and was open to errors and waste.

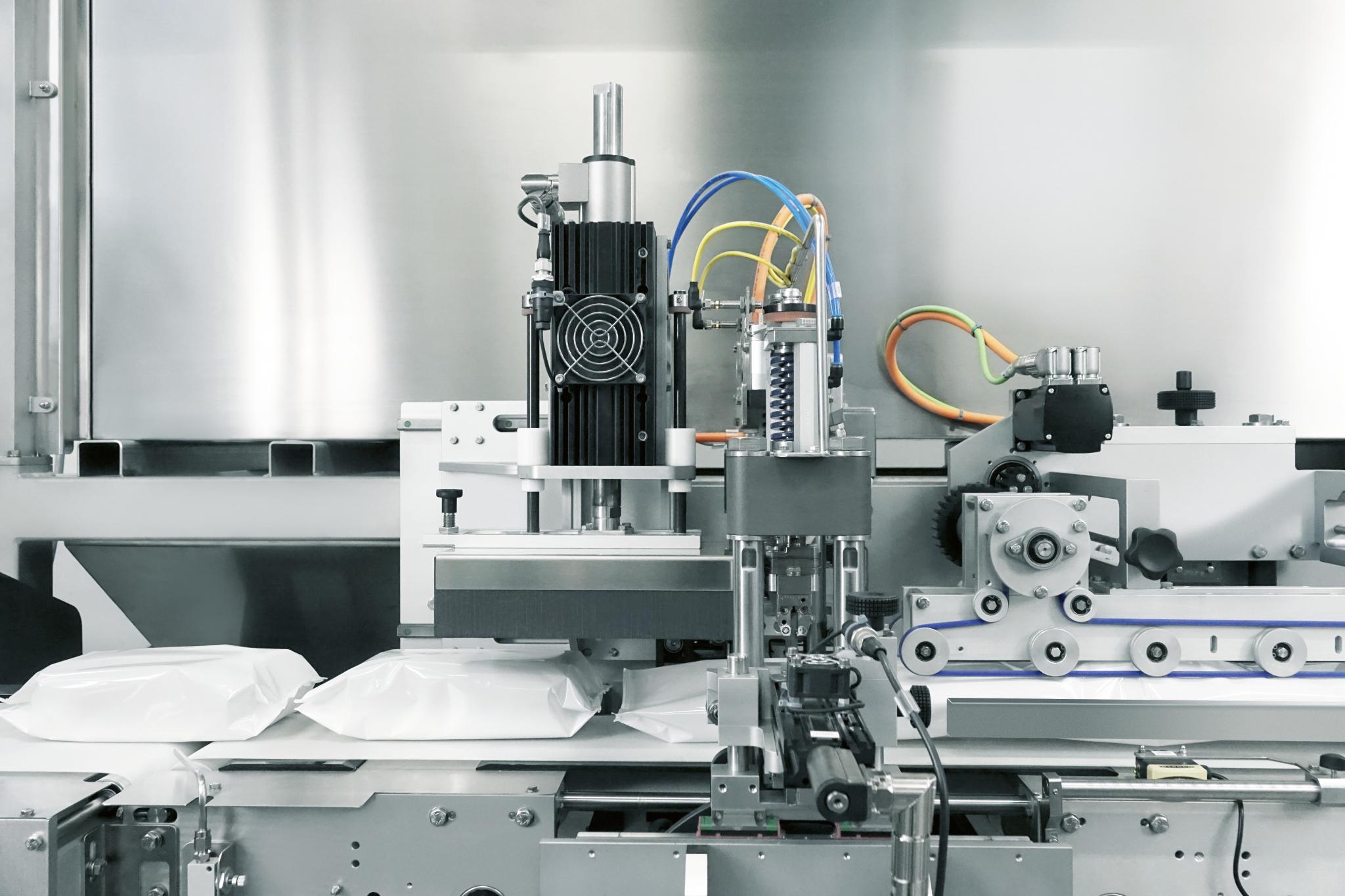

With grant support from Made Smarter, Firstplay invested in a powder packaging machine, which includes an automated multi-head weigher and powder filler. It works by loading the product through a hopper, digitally weighs and corrects the amount of product, and then dispenses and seals it into a bag before delivering it for boxing.

The new equipment also introduced a live data feed, giving management realtime overview of variables such as the running speed of the equipment, total giveaway, and average weights over the course of a shift.

The outcome has been transformative, increasing the number of sachets it can produce from 600 per day to 6,000 sachets per day.

Digital process control means that packets are more consistently filled, improving quality and reducing waste, both in time and in packaging materials.

With a roadmap to digital transformation in hand, Firstplay is now exploring a series of projects including data and systems integration technology to link its new machinery with a barcode scanning system for stock control, and implementing business and production software for better data analytics to improve production efficiency.

For more information, visit www.madesmarter.uk

14

Automation

+44 (0)1427 614 222 sales@cwm-automation.com North Warren Rd, Gainsborough, Lincs, DN21 2TU CWM AUTOMATION'S ROBOT TEST CELL CWM's brand new robot test cell allows customers from a wide range of industries to see proof of concept for all of their pick & place solutions. The test cell can be quickly configured to prove operational repeatability and speeds for picking and placing of all different types of products. Book a visit to trial your products on CWM's robot test cell today!

Don’t Wait for Compulsory Food Traceability

It seems that compulsory product traceability may be imminent for food and beverage manufacturers as global efforts to facilitate recalls and protect consumer safety increase following several consumer safety scandals in recent years.

16

Food Traceability

So, what would compulsory traceability mean? How might traceability record keeping, and in particular batch-level coding, play a crucial role in the swift and accurate withdrawal of unsafe food?

Adem Kulauzovic, Director of Automation, Domino Printing Sciences, explores these questions and highlights why food and beverage manufacturers should adopt traceability solutions today to protect their consumers, brand image, and bottom line.

Understanding the impact of food safety incidents

The last decade has seen a marked increase in regulatory traceability requirements aimed at protecting consumers. Item-level serialisation for patient safety is now a regulatory requirement in many industries, including medical devices, pharmaceuticals, and tobacco products. As global focus on consumer health and safety increases, manufacturers in all sectors should prepare for further regulations necessitating item- and batch-level traceability.

The food industry, in particular, is a prime candidate for regulation. Consumer safety is one of the driving forces behind product traceability, with the need to recall products from sale quickly and accurately following a food safety incident. Incidents necessitating recalls could include the presence of undeclared allergens or additives in packaged foodstuffs or contamination of raw produce.

Product traceability via coding and marking can provide a method for keeping track of food in the supply chain to support the quick and efficient recall of affected products when required. If a situation necessitates a product recall, growers, processors, and manufacturers can utilise product codes to identify which products or batches have been affected and track where items have been sent. This helps limit the scope of a recall, minimises waste, and reduces the time it takes to resolve the issue without compromising consumer safety.

Without traceability records, food safety incidents may necessitate nationwide recalls ensuring that all affected products are withdrawn from sale. Such was the case in the US in 2018 with an outbreak of E. coli linked to the sale of romaine lettuce. At the time, FDA attempts to trace the source of the E. coli outbreak were hampered by poor traceability records, leading to nationwide recalls. The repercussions from the recall were far-reaching, affecting supermarkets, hospitality venues, and food manufacturers handling romaine lettuce for further processing into packaged goods.

Indeed, a 2021 report on the economic impact of the E. coli outbreak estimated that the total cost of pulling

all harvested romaine from the supply chain was approximately USD 20.6 million, with additional costs of USD 37.3 million from wasted stock that could not be harvested or sold.

Food recalls can also cause serious harm to a brand’s image, leading to lost sales long after a food safety incident has passed. The indirect impacts of the romaine lettuce recall are an example of the damage that may be incurred at a brand level. Many hospitality venues and packaged goods providers found themselves unable to provide their standard products, leading to an inevitable loss of custom.

Batch-level traceability for food and beverage

The prospect of implementing additional manufacturing processes to enable traceability might sound costly. Indeed, item-level serialisation, such as that required in the pharmaceutical sector in many countries, has come at a high cost to businesses, but not all traceability measures have to cost the earth.

Continued >>> 17 Food Traceability

Without traceability records, food safety incidents may necessitate nationwide recalls ensuring that all affected products are withdrawn from sale. Such was the case in the US in 2018 with an outbreak of E. coli linked to the sale of romaine lettuce.

- Adem Kulauzovic

Food Traceability

For low-value, high-yield food products, including fresh fruit and vegetables, traceability can be facilitated at the batch level using unique labels on cases and pallets. This batch-level labelling provides a chain of custody, trackable forwards to the exact retailer or food processor receiving a shipment and back to the field where the produce was grown – and at all the steps in between.

In a food safety incident, batch-level traceability allows farms to precisely identify which suppliers have received their stock. It also enables retailers and processors to determine from where a compromised product may have come.

The batch-level traceability requirements described above are expected to be introduced for certain fresh produce as part of the US’s next update to the Food Safety Modernization Act. The new requirements, which aim to make it easier to track the movement of food and prevent or mitigate foodborne illnesses, will apply to all organisations that manufacture, process, pack, or hold foods deemed as ‘high risk’.

Combatting food fraud with traceability

Implementing batch-level traceability for fresh food can also help protect brands and consumers from the risk of food fraud – specifically foods contaminated with undeclared additives, also known as ‘food adulteration’. Food adulteration can emerge when fraudulent raw materials contaminate legitimate supply chains, putting both businesses and consumers at risk.

The risk of food adulteration is particularly prevalent today, with widespread supply chain issues and raw materials shortages. When raw materials are in short supply, brands may look beyond their regular approved suppliers to complete their supply chain, making them a prime target for substandard or fake alternatives. Indeed, the Food Authenticity Network reports that global food fraud has substantially increased since COVID-19 struck in 2020, with cases of food adulteration growing globally by 30%.

As with all counterfeit products, counterfeit raw materials can lead to

loss of brand revenue and consumer trust if their use results in a noticeably substandard final product, but the issue can result in much more than consumers paying extra for cheap products. Fraudulent foodstuffs can pose a serious health risk if unidentified allergens or hazardous materials are inadvertently added to food products.

Some of the most counterfeited products include:

• Olive oil – fraudulent oil products diluted with substandard or lower value oil may contain hidden allergens (for example, nut oils) or oils that are not fit for human consumption.

• Milk – watered down, substandard milk products have been found to contain melamine, a high-protein compound known to cause kidney problems.

• Honey – illicitly produced honey may be diluted with refined sugar or syrups. Adulterated honey has also been found to contain potentially harmful antibiotics.

• Wine and spirits – counterfeit alcohol products often contain substances that can be highly detrimental to human health –including methanol and antifreeze.

• Seafood – expensive varieties of fish can be substituted for lower-value products. A frequent substitute for some varieties of tuna is escolar, an oily, hard-to-digest fish known to cause mild to severe stomach upset.

Batch-level traceability can help brands mitigate some of the risk of counterfeits and food adulteration, as it requires suppliers to provide supply chain data on individual batches of ingredients at the point of supply and delivery. This information can then be aggregated into each additional step of the supply chain to give a muchneeded audit trail of individual batches of ingredients and provide a necessary deterrent to any party seeking to contaminate a product or ingredient –be that deliberate or by accident.

Embracing traceability in the food supply chain

Food safety incidents and adulterated and counterfeit food products can be just as dangerous as fake pharmaceuticals, and as such, the food industry is a prime candidate for regulatory traceability. That said, those without a current traceability solution should not wait for regulation – the time to act is now.

Beyond compliance and consumer safety, the end-to-end traceability of food and beverage products also presents an opportunity for brands to enable greater data exchange with retailers, suppliers, and consumers. Such data will offer new opportunities for food businesses to address risks and operational challenges and provide the transparency needed to run supply chains more efficiently. The information can also be passed on to the consumer via scannable 2D codes, for improved engagement and brand positioning.

Conclusion

As we move further into the era of big data, traceability solutions will become a crucial part of day-to-day business. All brands working within the food and beverage sector need to be ready to adopt them in due course.

However, those food and drink manufacturers who embrace traceability ahead of the curve will not only reap the benefits of implementing it without regulatory and time pressures but could also gain significant competitive differentiation through optimised supply chains, improved consumer experience, and preparedness to weather whatever challenges may yet get thrown in their path.

18

Food safety incidents and adulterated and counterfeit food products can be just as dangerous as fake pharmaceuticals, and as such, the food industry is a prime candidate for regulatory traceability.

- Adem Kulauzovic

The cost of not cooling your greatest assets – your people!

There is wide misconception that cooling large spaces like factories and warehouses is so expensive it is not viable. While there is of course a cost, it may not be as great as initially considered and the benefits of providing a comfortable environment for staff is not only beneficial to the employees in the space but can also reduce absenteeism and promote longevity of employment.

We were really alerted to such benefits by a large retail end-user who installed our product recently in a large

warehouse. Making changes to their building by installing another floor closer to the roof, they knew would create an even greater problem of heat than already existed and already having to pay their staff extra money to carry on working over a certain temperature. Despite there being no legal upper limit currently in the UK, the enduser anticipated if they worsened conditions their staff would be ‘down the road’ to go and work in neighboring warehouses. Like many buildings situated in industrial / commercial areas, the competition in the local employment market is very high and in times of low unemployment, staff can take advantage to pick and choose the best companies.

In which case, can you afford not to provide the best environment for your staff? The beauty of choosing evaporative cooling solutions by Seeley International is not just about reducing temperatures because our coolers supply 100% outdoor air which creates a very comfortable environment,

unlike traditional air-conditioning that recycles air that gets stale. With high IAQ you can be certain of health benefits for your staff, leading to reduced headaches & fatigue associated with low IAQ. Purging the space will also reduce the risk of airborne viruses and ultimately increase production. With low running costs and using only water as a cooling medium, Seeley International can provide you with solutions to promote staff wellbeing which in turn encourages long term staff retention, reducing recruitment and the time & costs associated.

19 Facilities Management

With high IAQ you can be certain of health benefits for your staff, leading to reduced headaches & fatigue associated with low IAQ.

Affordable cooling with no chemical refrigerants Low running costs giving high Indoor Air Quality (IAQ) www.seeleyinternational.com uksales@seeleyinternational.com +44 (0)115 9635630 Healthy building, productive people!

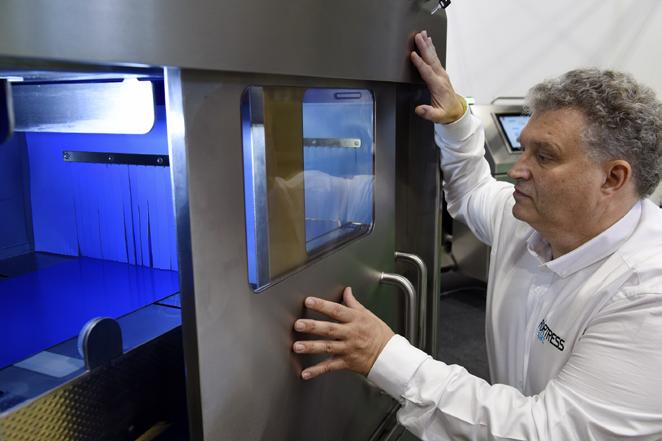

Hygienic X-Ray for High Care Food Environments

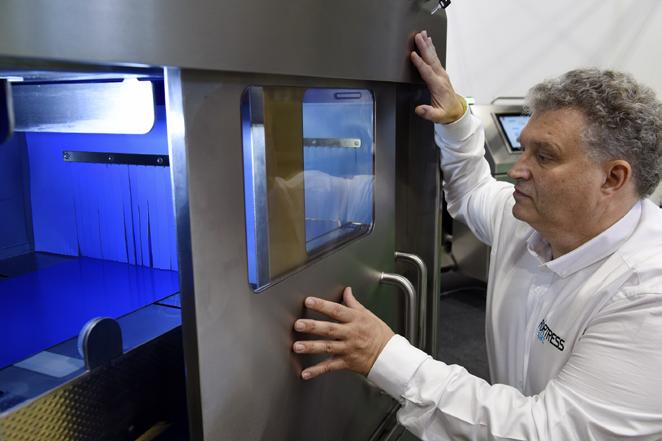

Having engineered some of the most reliable x-rays on the market, the newest inline Raptor X-Ray, Pipeline X-Ray and Apollo machines from Fortress Technology Europe all deliver cleanability, supreme hygiene standards and food protection assurance in bucket loads. With not a loose wire or hanging cable in sight!

Utilising the highest-spec food x-ray technologies, all three machines within the Fortress X-Ray range minimise cleaning and set up times to increase plant productivity. Yet, also give producers of fresh, chilled and frozen wrapped and unpackaged products the added assurance of exceptional brand safety by ensuring cross contact contaminations are tightly controlled.

Reassuringly, the frameworks on all Fortress X-Ray inspection systems are IP69k rated. With no trailing cables, they are fully protected against dust and other particulates, to withstand high-pressure, high-temperature jet sprays, wash-downs or steam-cleaning procedures.

Fortress x-ray electrical panels are all IP65k-rated. This means they are all dust tight and are protected against low-pressure water jets when using a nozzle.

Carefree duty of care

Providing reliable and fool-proof in-line inspection and detection of metal, glass, mineral stone, rubber compounds and calcified bone in a wide variety of high care food applications, the Fortress x-ray conveyor range simultaneously inspects fill levels, topping coverage, for example pastry, and can measure mass and count components.

This x-ray technology will also detect any product defects, process and packaging problems with 100 percent accuracy. Ensuring full compliance with all major food industry guidelines, including IFS, BRC, HACCP and GFSI, giving food manufacturers more

reliable protection against consumer complaints and retailer recalls.

Created for quality checking sliced meats, cheese, ready meal and wrapped raw meat applications, the Apollo X-Ray can accommodate lower pack formats measuring 300mm by 300mm and 100mm deep, inspecting and rejecting 200ppm.

In comparison, the Raptor X-Ray was designed to target contaminants present in slightly longer and higher packs, up to 400mm in length by 150mm deep, and inspecting at speeds of up to 100ppm.

Both machines monitor fill levels, spot damaged packaging and can reliably identify ingredient clumps and broken or missing product. The Apollo X-ray is also available in an ‘XL’ size to accommodate packs up to 300mm x 300mm x 200mm if needed.

Windows of opportunity

Another unique feature on the conveyor x-ray range is the protective acrylic window. With the radiography beams fully contained, food operatives can work alongside the machines and see packs travelling through the system. Users can instantly spot product spillages and action accordingly, without feeling like their personal safety is being compromised.

Fortress Commercial Manager Jodie Curry explains: “Having a clear side removes the mystery and fear factor, especially when there’s a stainless steel box with a big radiation sign on the side.”

An extra benefit of this visibility is it removes the need for bulky safety guards.

20

Food Safety

Removing these to access machines can add another layer of complexity for machine cleaning notes Jodie.

Magnetic x-ray curtains, the easy clean tight fitting conveyor, IP69k sensors and bevelled surfaces further speeds up repeatable cleaning and sanitation tasks, highlights Jodie.

Describing in more detail the easyclean conveyor concept, Jodie adds: “Our unique conveyor features a quick release for disassembly of the deck, belt, motor and rollers, saving valuable time, money and labour to provide the ultimate in hygiene peace of mind. During the sanitisation process, machine operators simply unclip and disconnect the conveyor motor and lift out the entire assembly.”

The ‘no tool’ maintenance innovation, which features on all three models, including the X-Ray Pipeline, is another massive time-saver. As well as stopping operatives fiddling with screws, nuts, bolts etc. and using incompatible tools that could damage the machine, it eliminates the risk of accidently

contaminating food with a stray component.

Rather than using unhygienic stickers and labels, all safety symbols, industryapproved markings and the machine nameplate are laser-etched directly onto every Fortress X-Ray steel cabinet.

Average clean times on all machines should now take a matter of minutes, suggests Jodie. “When sanitation employees have open areas and smooth surfaces to work with, they can more efficiently access and clean equipment to reduce machine downtime and prevent cross contact contamination.”

Rather than air conditioning, passive airflow technology is used maintain a regulated filament temperature in the X-Ray cabinet, never exceeding the constant 30°C. Additionally, an electric servo driven reject system eliminates the used of compressed air. All of which can help to reduce running costs and maximise efficiency.

Modular by design and automatically incorporating every retailer COP that exists, the Raptor X-Ray and Apollo X-Ray machines can be integrated with a Checkweigher to create a high performance x-ray combination inspection system. The electronics can also be fully integrated with upstream flow wrapping or packaging machines and controlled via a single HMI.

21 Food Safety

During the sanitisation process, machine operators simply unclip and disconnect the conveyor motor and lift out the entire assembly.

Expert Partner in Hygienic Solutions CalL: 01603 788 833 EmaIl: maIl@tekNomek.co.uk Web: wWw.tekNomek.co.uk

- Jodie Curry

Poly Top TabLes

Tote BinS

for

tHe besT in hygiEnic, sTaInLesS sTeEl furNiture & equIpMenT, calL tHe…

Delfin ATEX VacuUm

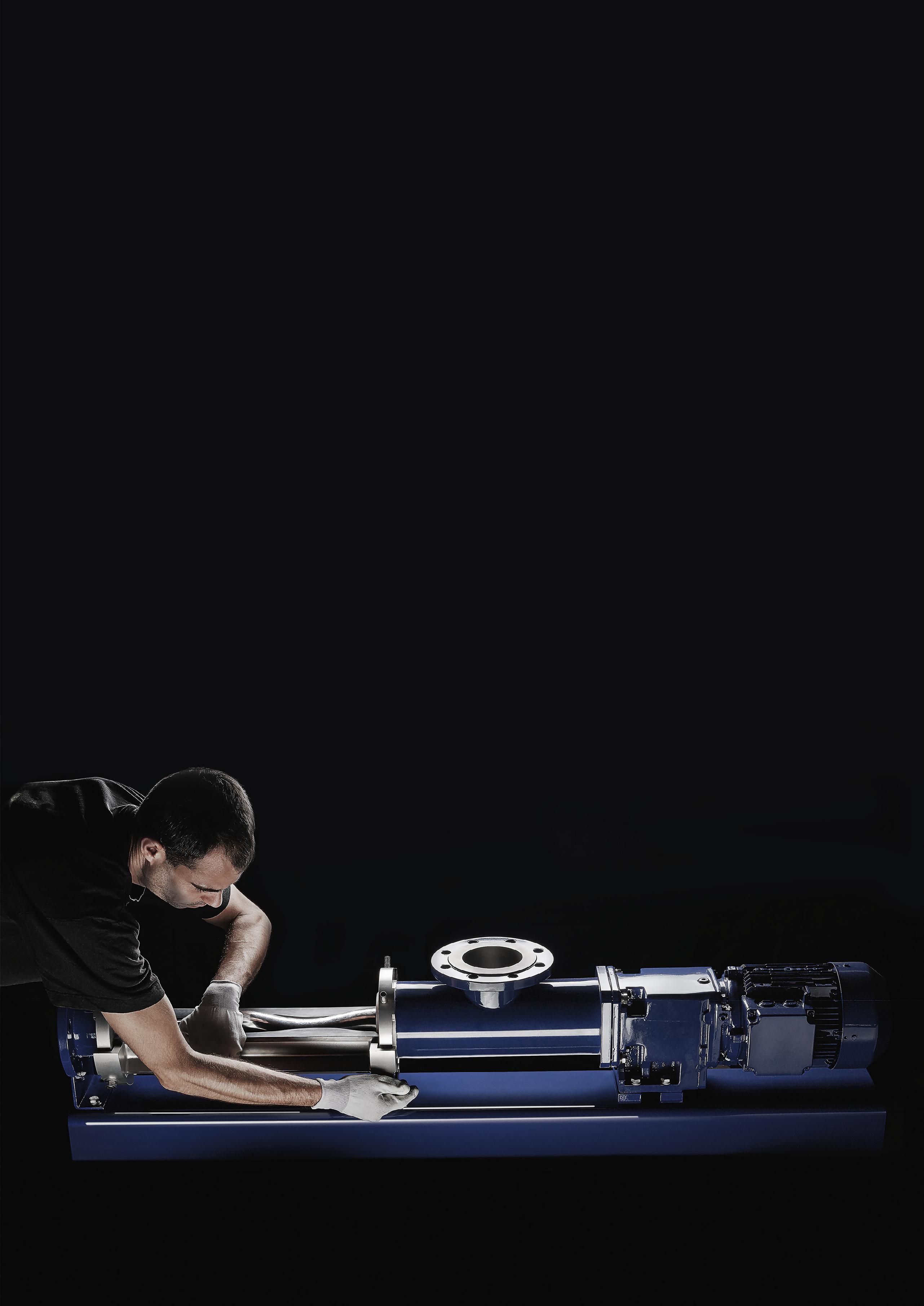

Food safety takes priority in design

By Matt Hale, International Sales & Marketing Manager, HRS Heat Exchangers

Modern food production systems have reduced the cost of foods and made them more available, but general trends towards the centralisation of food supply also increases the opportunity that food safety issues, such as contamination with pathogens or toxins will affect large numbers of people1. To prevent this, food producers implement strict systems such as Hazard Analysis Critical Control Points (HACCP), but the design and manufacturing standards of food processing equipment are also of vital importance.

Types of contamination

The contamination of food and drink products can cause anything from minor quality issues to severe health outcomes and even death. There are four main types of contamination which can affect food and drink products: microbial, chemical, physical and allergenic.

Microbial contamination is caused by microorganisms such as bacteria, viruses, mould, fungi and toxins like campylobacter, salmonella and E. coli, and microbial contamination

is the most common source of food poisoning. Control measures include strict hygiene measures, ensuring separation between raw and cooked ingredients, and the use of techniques to reduce the microbial load in the product, such as pasteurisation or sterilisation.

22

Food Safety

Chemical contamination often arises from the poor control of products used for cleaning and disinfection. If chemical residues remain on food preparation or contact surfaces, or if chemicals are used in the vicinity of food and drink products, then contamination can occur. Another source of chemical contamination may be the production of primary food ingredients such as the incorrect use of pesticides and medicines on farms.

As the name suggests, physical contamination is caused by foreign objects, and can include anything from stones and pest bodies through to items of plastic or metal. Within food processing facilities, poorly maintained or badly designed equipment can itself become a source of physical contamination in the form of items such as flaking paint or loose screws. Physical contaminants may also carry harmful bacteria, increasing the overall contamination risk.

The final source of contamination is allergenic contamination, which occurs when a food which causes an allergic reaction comes into contact with another food. There are 14 recognised allergens2, including gluten, peanuts, eggs, mustard, soy, and fish, and

the reactions caused can range from mild discomfort through to fatal anaphylactic shock.

The importance of design

Food processing business adopt a range of processes and procedures to prevent these forms of contamination from

occurring. These measures may include cleaning and maintenance procedures, pest control, personal hygiene, protective clothing, dress codes, etc. Many of these procedures will have been implemented as a result of Hazard Analysis Critical Control Points (HACCP) assessment of the facility and the production methods employed, but there is another equally important aspect of avoiding contamination which is not always given such a high profile: the design and construction of the food processing equipment itself.

Hygienic equipment design enhances cleanability, decreasing the risk of biological, physical and chemical contamination. In addition, equipment that is designed and constructed to meet hygienic principles is easier to maintain and reduces the risk of physical hazards3.

Hygienic design principles encompass a range of different factors, including material choice, surface finish, and construction methods, as well as the physical design of the product – for example avoiding lips, crevices and sharp angles where cleaning chemicals or product may build up or remain after cleaning.

Continued >>> 23 Food Safety

Control measures include strict hygiene measures, ensuring separation between raw and cooked ingredients, and the use of techniques to reduce the microbial load in the product, such as pasteurisation or sterilisation.

- Matt Hale

Food Safety

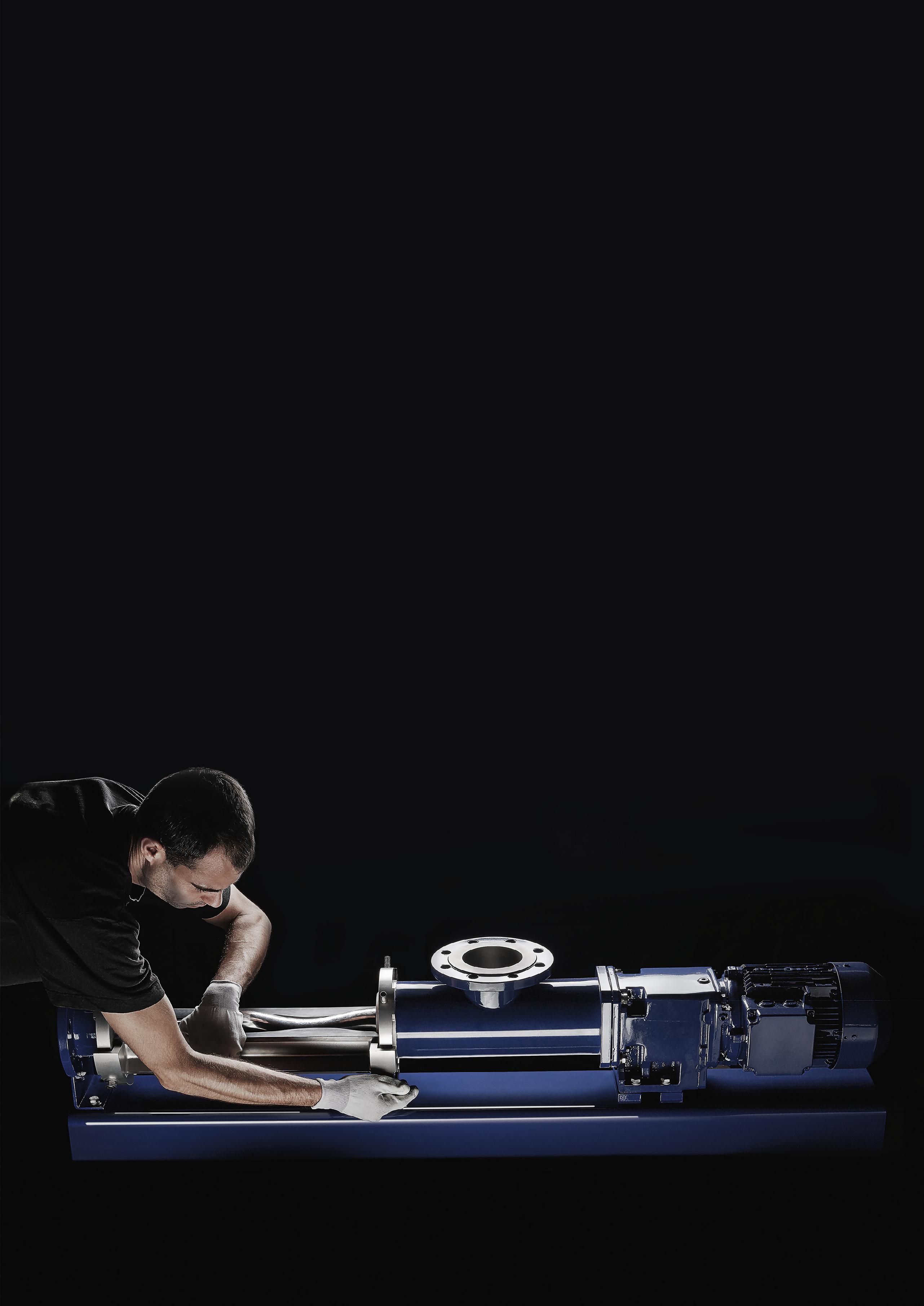

To facilitate cleaning underneath and around equipment, it should be elevated above the floor on legs or mounted in a frame (as is the case with HRS’s skid-mounted systems).

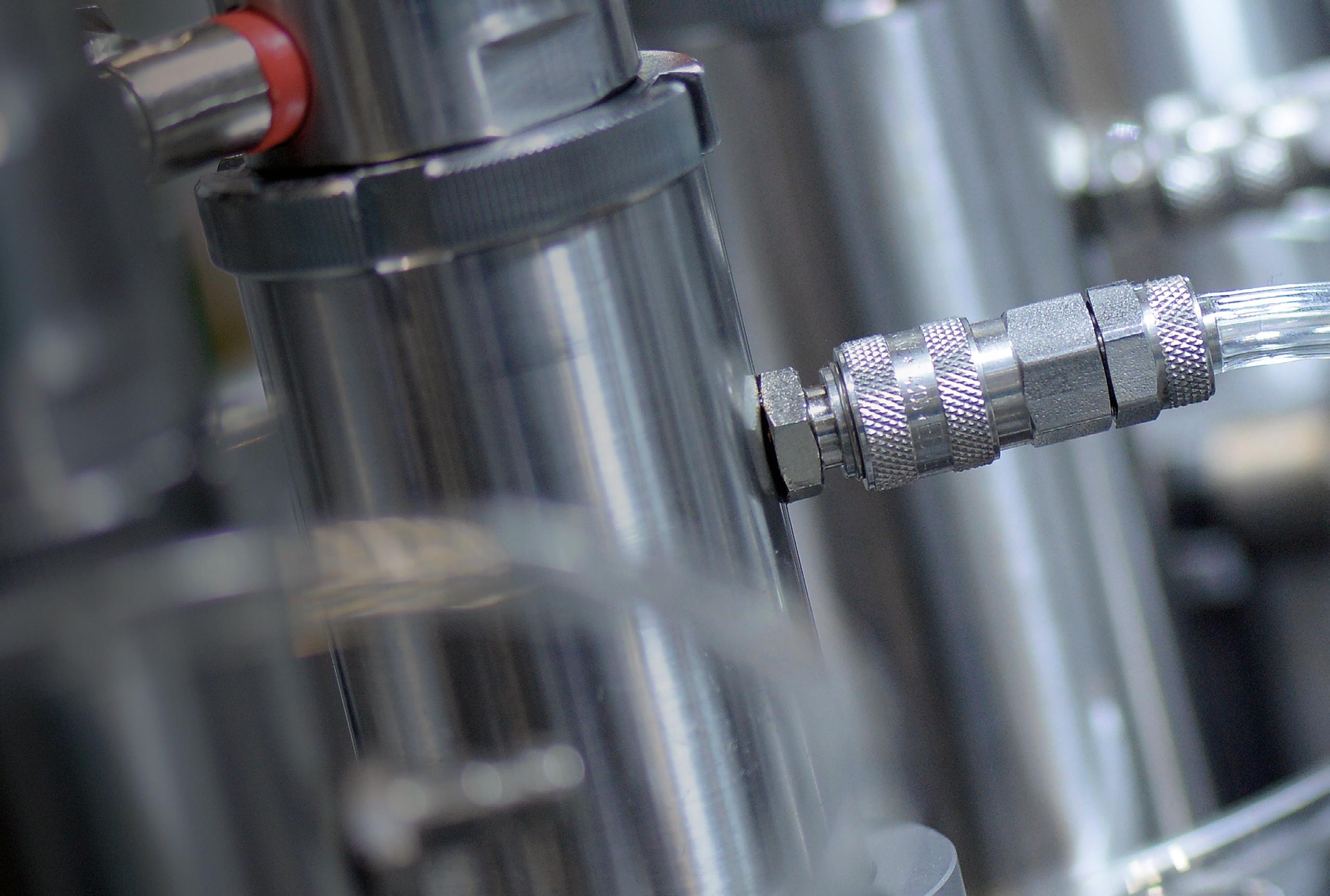

When designing equipment, different standards may be applied to foodcontact and non-contact surfaces, and surfaces which come into contact with product must generally be smooth, non-toxic, non-absorbent and resistant to corrosion. For this reason, stainless steel is a popular choice and AISI 300-series stainless steel (as specified by 3A Sanitary Standards) is used as a key material by HRS Heat Exchangers. Welding and joints are also important; continuous butt welds should be used and ground to a smooth surface, while bolts and threads used within the food contact zone must be of a hygienic design.

It is also important to maintain the movement of fluids and materials within the equipment and connecting pipework. Maintaining flow and preventing fouling is also a key priority in heat exchanger design and is why HRS Heat Exchangers produce corrugated tube or scraped surface designs. It is also important to use closed coupled connections to equipment in order to prevent the creation of dead spots, and to ensure that where necessary, equipment can be fully drained or emptied for cleaning or product changeover.

Other considerations include avoiding the use of O-ring seals in grooves, avoiding ledges around top rims, and ensuring that shafts are suitably sealed with double seals where necessary.

Reducing waste while maintaining safety

HRS Heat Exchangers produces a wide range of equipment for use in the food and beverage sectors, from basic tubular heat exchangers to fully integrated pasteurisation/sterilisation and aseptic filler systems, as well as a number of specialist products such as evaporators, ice crushers and melters, direct steam injection systems, air removal systems and pumps.

All of these are hygienically designed from the start to facilitate clean operation and prevent the types of product contamination discussed above. All HRS products designed for food use meet 3A Sanitary Standards.

Furthermore, HRS equipment is particularly designed to facilitate product removal and subsequent cleaning. It has always been a challenge for food and drink businesses to implement effective and rigorous CIP regimes which meet the necessary standards in a way which minimises the loss or degradation of saleable or useful product. One example is the HRS R Series of rotating scraped surface heat exchangers which can physically remove product without the need for traditional pigging or flushing systems.

The R Series is suitable for a range of heat transfer applications and its unique design enables high viscosity products to be pumped with reduced back pressure and lower energy use. The helical spiral is fitted with scrapers – which scrape the surface of the tubes to prevent fouling in normal use – can also be run in reverse; thereby enabling valuable product to be recovered prior to routine cleaning or product changeover. This design feature means that much of the product can be removed from the HRS R Series without the need for additional pumps or pressure systems, reducing both CAPEX and OPEX.

HRS also produces a Product Recovery System, which combines continual monitoring of a set parameter (for example Brix, pH or viscosity) with the three-way valve technology employed in every HRS pasteuriser or steriliser. Working together, these two systems ensure that all product which meets the set parameters is utilised and only that which falls outside (for example, that diluted prior to or during CIP) is discarded. Furthermore, such monitoring helps to validate the effectiveness of CIP and ensures that following a cleaning cycle, only product that meets specification is allowed to proceed.

The hygienic design and construction of food processing equipment is an essential but often overlooked aspect of controlling the safety and quality of food and drink products, playing a crucial role in preventing contamination and allowing other food safety procedures to be carried out.

24

When designing equipment, different standards may be applied to food-contact and non-contact surfaces, and surfaces which come into contact with product must generally be smooth, non-toxic, non-absorbent and resistant to corrosion.

- Matt Hale

0026

Foodex Manufacturing Solutions 2023

“After a five-year hiatus, Foodex Manufacturing Solutions returns to the NEC, Birmingham this April (24th – 26th), as part of the UK Food & Drink Shows.

Bringing together the very best of the hospitality, manufacturing and grocery, speciality & convenience retail sectors, the shows are set to showcase the very latest products, big thinking, key insights and address key trends through the lens of the developing cost-of-living crisis.

“The must-attend event unites Foodex Manufacturing Solutions (incorporating Ingredients), National Convenience Show, Farm Shop & Deli Show and Food & Drink Expo under one roof, giving food and drink professionals 2023’s most comprehensive snapshot of the latest developments across multiple industries. Register for a free pass here

“The three-day event is well known for its ability to bring together the great and the good from the industry’s diverse sectors with innovative exhibitors, hot-topic seminars and business-changing awards central to the shows’ unparalleled line-up.

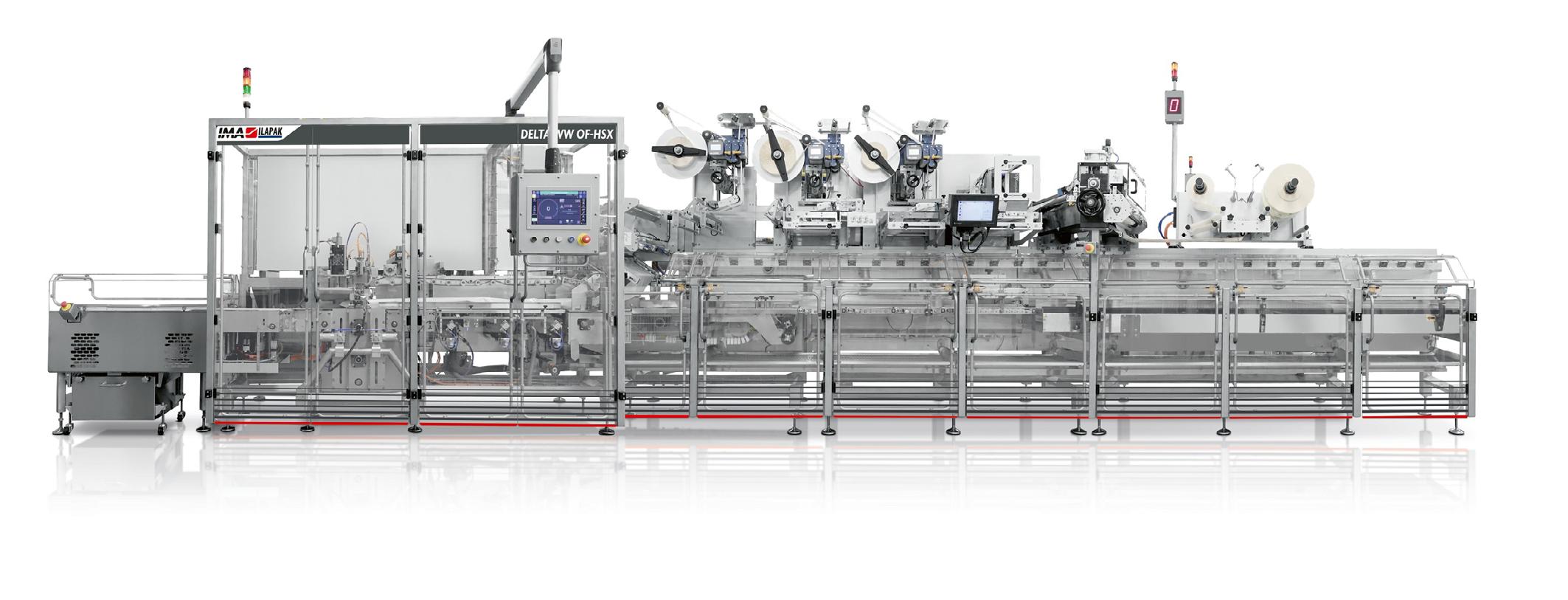

“Visitors to Foodex Manufacturing Solutions, the UK’s premier trade event for food and drink manufacturing, processing, packaging and logistics, will leave with heightened awareness of the sector’s technology, automation and sustainability capabilities. A jam-packed show floor will be showcasing the latest products and services to improve

operational efficiency, with exhibitors such as Busch Vacuum Solutions – specialists in vacuum packaging, pneumatic conveying, degassing, and bottling (Stand H161); Rotech Machines – experts in quality, costeffective coding equipment (Stand P141); and Autopak Machinery Limited (Stand K151), who design, build, programme and service machinery across most UK industries, showcasing their wares.

“For the full list of exhibitors and products on show, visit www.foodex.co.uk

“Meanwhile, on a central stage, expert panels will be discussing some of the biggest issues facing the sector. Industry heavyweights such as Kate Nicholls from UKHospitality, Katie Prowse from Lumina Intelligence and chemical engineer at the University of Birmingham, Dr Taghi Miri, are just some of the names that have been lined up to tackle hot-topic issues such as sustainability and technology.”

Key highlights of the programme’s schedule include:

• The next generation of manufacturing (Food Manufacture Live, Tuesday 25th April, 2.15pm)

• Does sustainability come at a cost? (Education Hub, Tuesday 25th April, 12.30pm)

• The challenges and opportunities of innovative foods (Education Hub, Monday 24th April, 12.30pm)

“With face-to-face business back in full swing, buyers will once more have the opportunity to connect with potential suppliers and troubleshoot problems through various interactive events and discussions. The knock-on effect of the pandemic has meant that the manufacturing sector has not been able to come together in person in five years. When it returns to the NEC in April some of the incredible developments that have been made in this specialist sector will be plain to see. Whether you’re looking for a simple solution to an existing problem or a product at the vanguard of innovation, there’ll be an answer for you at Foodex.

“The UK Food & Drink Shows are historically an event in which industry professionals can regroup, dissect problems, and share ideas. Our industry’s spirit was laid bare throughout the Coronavirus pandemic, as we face yet further challenges, I have no doubt that we will unite once again in April to prove our resilience. Register for your pass today for free: https://foodex-2023.reg.buzz/

“Encompassing the entire industry, the UK Food & Drink Shows are unrivalled in their ability to bring people together, build and foster better relationships, discover business building insight and celebrate innovation, all with the support of the multi-award-winning William Reed brand.”

By Andrew Reed, Managing Director – Wine & Exhibitions, William Reed

26

Foodex Preview

FEATURING:

Where the processing, packaging & logistics sectors meet

Informing, inspiring and connecting the industry

DOORS OPEN NEXT MONTH

After a five-year hiatus, Foodex Manufacturing Solutions will return to the NEC, Birmingham next month (24th – 26th), as part of the UK Food & Drink Shows.

The must-attend event unites Foodex Manufacturing Solutions (incorporating Ingredients), National Convenience Show, Farm Shop & Deli Show and Food & Drink Expo under one roof, giving food and drink professionals 2023’s most comprehensive snapshot of the latest products, key insights and developments across multiple industries.

Register for FREE: foodex.co.uk

This is a trade event. No under-18s will be admitted.

Ending non-compliant food label EPWs

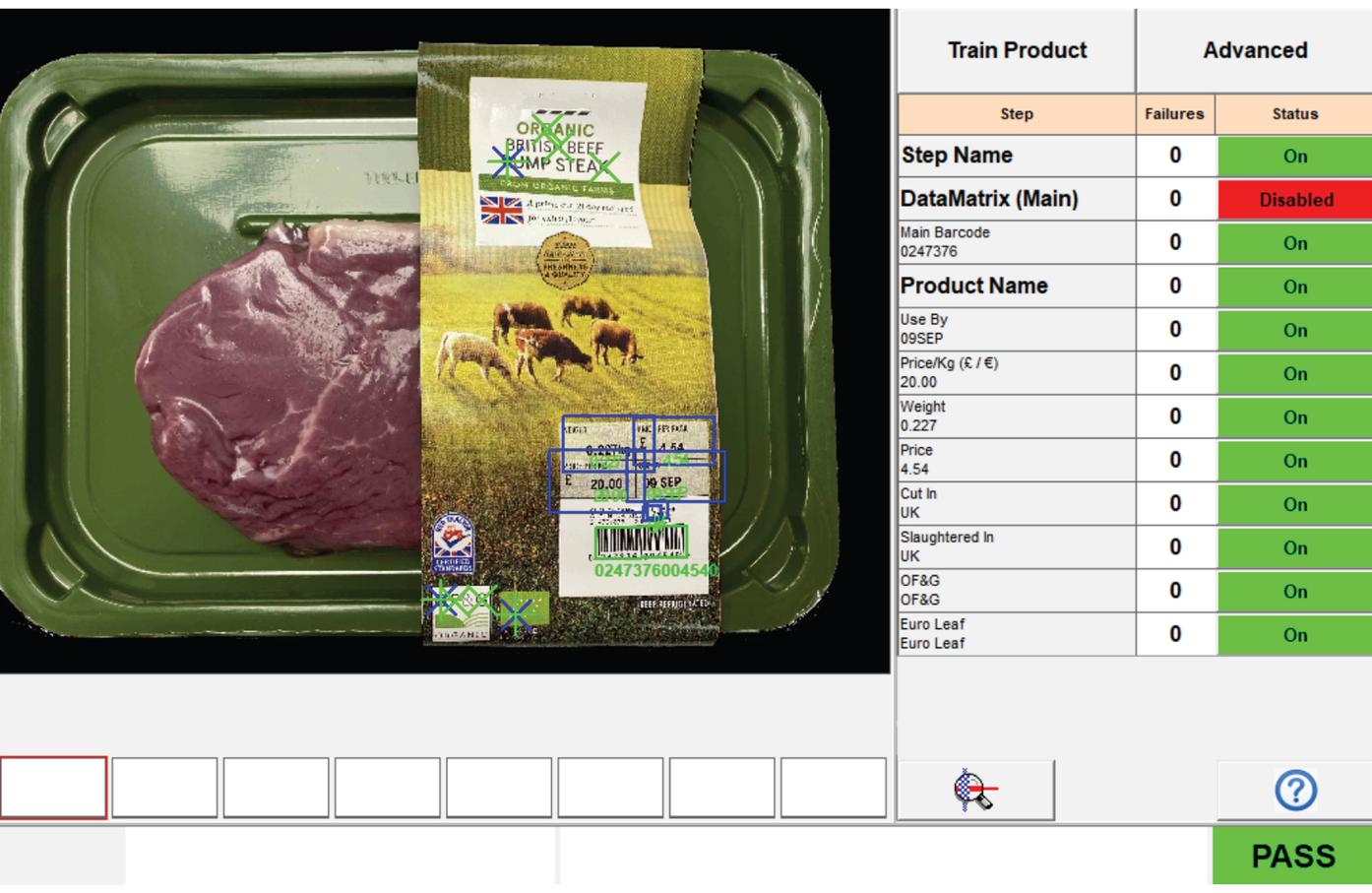

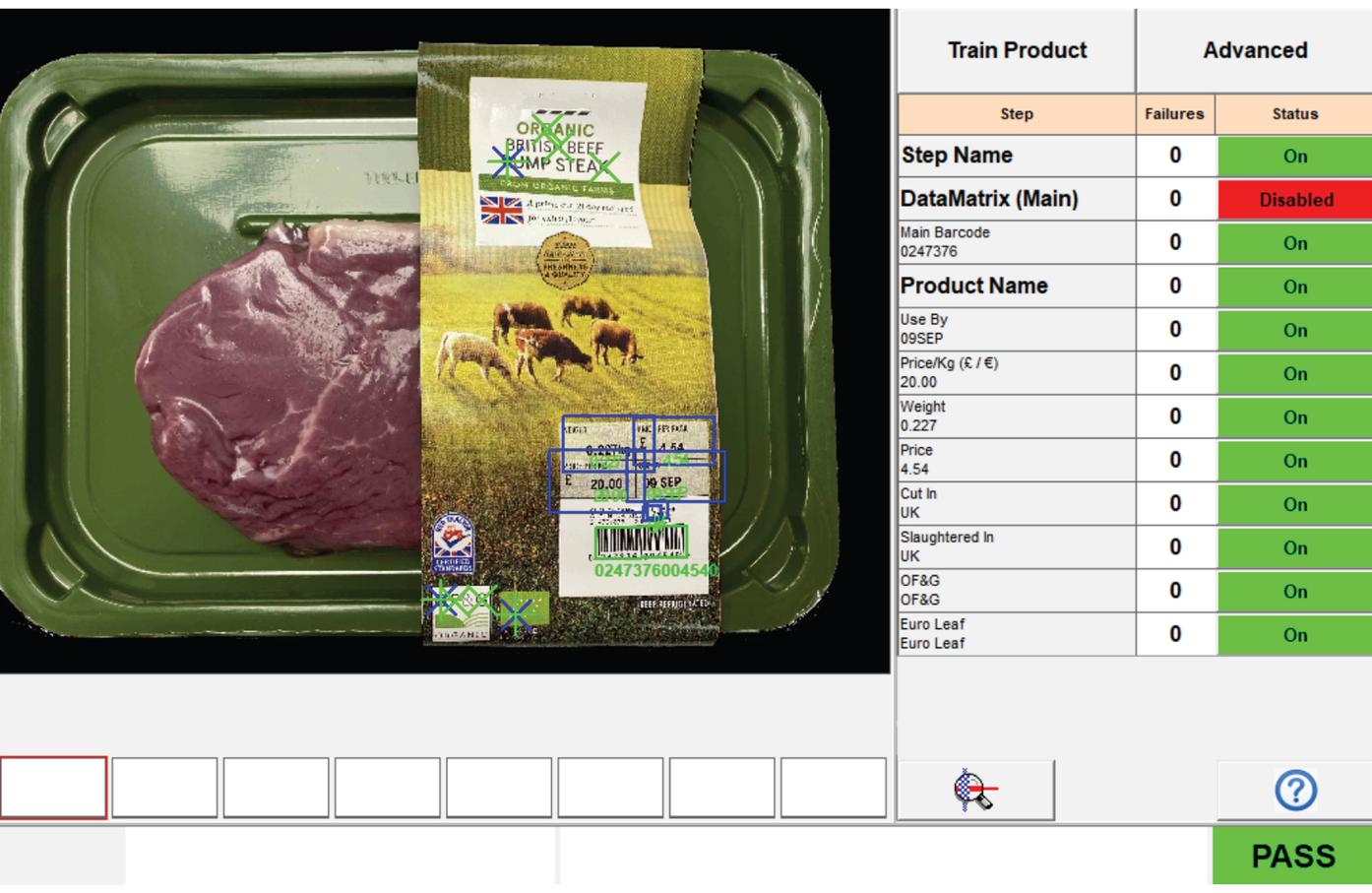

At FoodEx 2023, Stand G100, JentonDimaco will showcase its latest Veri-VIEW software that checks food labels against robust source data before any food packs leave the factory floor.

JentonDimaco will explain to visitors how this ‘belts & braces’ automated approach to label verification can accelerate the verification process, catch mislabelled products early, enable product to be reworked and re-labelled, resulting in fewer costly and brand-damaging food Emergency Product Withdrawals (EPWs).

“Checking the image quality and presence of a printed label is essentially only half the story and could be futile and non-compliant. Particularly if the production and retailer source data that food labels are being checked against isn’t correct or the most up-to-date version,” emphasises Managing Director Dr Russell Sion.

Mitigating the risk of human errors, the addition of Veri-VIEW software helps to ensure that all of the variable and non-variable label data matches up. Providing an instant overview of label integrity, Veri-VIEW captures in real-time, all the data generated by every Dimaco Veri-PACK system on

the factory floor. Providing a complete overview from one convenient central display. Production and technical personnel get to see what’s happening as new data is issued, with the assurance that all actions are automatically recorded.

Putting this into context, this means that when a supermarket makes a label adjustment during the production run, for example to a price, the JentonDimaco Veri-CENTRAL server will pick this up instantly.

LEFT: Veri-VIEW from JentonDimaco offers real-time viewing of all data generated by every Veri-PACK system on the factory floor, from one convenient central display.

This information is then automatically relayed to every Veri-PACK labelling system within seconds and the action taken documented on Veri-VIEW.

Russ expands:

JentonDimaco label verification systems are the most efficient way to authenticate all aspects of data and artwork on retail labels including price, barcodes, use-by dates, promotional labels and artwork revisions. All of this data is verified against a master specification held on the JentonDimaco Veri-CENTRAL server, which sources data from each food manufacturer’s MRP server or production spreadsheets.

After biological contamination, label related defects are cited as the second most common cause behind costly and brand-damaging recalls and retailer returns.

Exceeding the label verification standards set by all UK retailers, come and learn how your food production site can introduce a more robust label verification system, reduce waste, address costly EPWs and meet future label compliance standards at FoodEx 2023, Stand G100.

LEFT: A robust and compliant label verification system should be able to verify 100% of the data on 100% of the products against validated source production data.

28

Foodex Preview

Small, Sustainable & Sensitive

Fortress bigs up its small-footprint inspection systems at FoodEx 2023, stand K41

For many logistical reasons, ingredient lines and food SMEs are increasingly seeking compact, high performance, and energy efficient contaminant detection equipment. Catering to this trend, at FoodEx 2023, stand K41 Fortress Technology will showcase several of its small footprint solutions, intentionally designed to save processors valuable production space without compromising on metal detection sensitivity.

Offering best-in-class detection of magnetic and non-magnetic metals in flour, rice, cereal, corn, grains, sugar, seeds and spices, the Fortress Mini Gravity Metal Detector, featuring a 75mm anti-static in-feed pipe with a high speed reject valve, was created specifically for busy ingredient lines where space is limited. The smaller pipe quickly separates metal contaminants from the good product flow. Resulting in less product rework and consequently waste.

Made to accommodate smaller food factory layouts, including tightly packed production facilities, low ceiling heights and for insertion between product chutes and hoppers, this Mini Gravity Metal Detector is also packed full of useful labour

and time saving features. Including optional automatic testing to eliminate production downtime, reduce waste and product rework. The metal detector is also built to withstand vibrations and temperature changes without compromising performance, and can be supplied to meet hazardous location standards.

Scanning raw materials using a Mini Gravity Metal Detector as ingredients come into a factory is prudent for many reasons. “In most instances, ingredients are inspected by suppliers before delivery using a bulk inspection machine. However, a reinspection will help processors to doubly ensure that suppliers are complying and hold them accountable for ingredient quality,” emphasises commercial manager Jodie Curry.

On conveyor inspection lines, a retailspec combination metal detection and checkweighing system provides an alternative space-saver. Mounting these systems on the same conveyor results in a far smaller footprint than stand-alone units would occupy. At FoodEx 2023, Fortress presents its most compact - the 100mm belt width Raptor Combi.

Designed for high care confectionery, chocolate, bakery, packaged meats and fish, cheeses and prepared food manufacturers, this award-winning Raptor Combi accurately inspects and weight checks products and pack formats weighing from 50 grams up to 8kg and measuring up to 400mm in length.

Several innovative design features minimise this Raptor Combi’s footprint. Clever configuration of the reject mechanisms, for example, means that they occupy 50% less space than a conventional design.

For optimal sensitivity, aperture size is one of the most critical decisions. Too small and there’s a risk the product won’t pass through. Too large in relation to the product being inspected can limit the inspection performance. The Fortress team will be on hand throughout FoodEx 2023 to advise food processors on how to achieve the best performance, functionality and ROI relative to each product being quality checked for contaminants. Visit Stand K41 for some impartial guidance.

29 Foodex Preview

A reinspection will help processors to doubly ensure that suppliers are complying and hold them accountable for ingredient quality.

- Jodie Curry

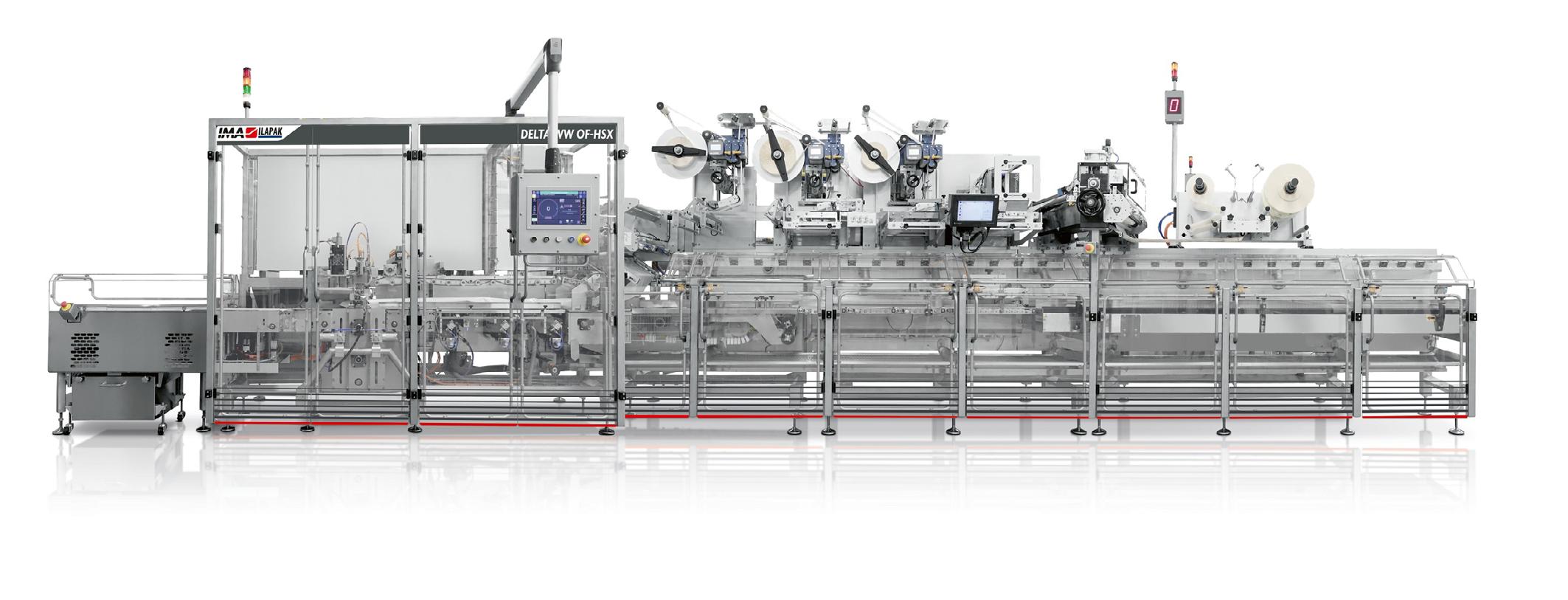

Brillopak’s five-year phased automation roadmap accelerates packing efficiency at Morrisons freshproduce operations in Thrapston

Packing automation success is all in the planning. Embarking on a mission to reconfigure its fresh-produce packing hall at Thrapston, the Morrisons Centre of Excellence - which prepares and delivers 130 million packs of fruit every year to 82 stores - has succeeded in its automation vision and ambition.

British automation specialist Brillopak supported Thrapston at every phase of the five-year programme. In total, Brillopak installed 11 fully integrated freshproduce packing lines comprising around 40 machines, with equipment and capital investments split across three defined phases.

Rather than piecemeal different technologies together, Thrapston’s site manager at the time, Matthew Peczek, sought a cohesive automation investment approach to increase efficiency, achieve packing consistency and optimise produce quality.

Taking the decision to completely redevelop the factory layout in 2017, Matthew was resolute that all machinery would be designed and placed linearly, with everything coming

from the chillers and out to the back end for distribution, in one continuous flow. His linear vision has since been realised. Now, every part of the line faces in the same direction throughout the packing hall.