The Schmersal Group has designed a new safety light barrier especially for hygiene-sensitive uses in the food processing industry, such as milk and meat processing.

This version has evolved with the demands of standard cleaning operations in the industry as the sophisticated design helps to ensure IP69 degree of protection (protection against the ingress of water from high-pressure of steam cleaning).

The protective enclosure with external gaskets satisfies stringent standards and is designed to cope with frequent cleaning with water, foam, lyes, high-pressure or hot steam.

SCHMERSAL | Enigma Business Park Malvern, Worcestershire, WR14 1GL

www.schmersal.co.uk

uksupport@schmersal.com

Editor Paul Attwood editor@fdm-uk.co.uk

Editorial Assistant Anna Startin editorial@fdm-uk.co.uk

Features Editor Henry Peters editorial@fdm-uk.co.uk

Production/Design

Laura Whitehead laura@lapthornmedia.co.uk

Sales Manager Holly Jones sales@fdm-uk.co.uk

Publishing Director Maria Lapthorn maria@lapthornmedia.co.uk

Lapthorn Media Ltd 5-7 Ozengell Place, Eurokent Business Park, Ramsgate, Kent, CT12 6PB

BCMPA helps to open doors for US trade partnerships

FANUC robot eases palletising bottleneck for salad dressing producer Brunos

9 Questions to Ask Your Heat Exchanger Supplier

Preventative measures to protect your food & beverage business from pest infestation

Get smart: how digital innovation could remodel a more sustainable food industry

Welcome to the latest issue of Food & Drink Manufacturing UK Magazine.

In this issue, we have an interesting piece from Harford Control, who produces software to optimize production and efficiency, highlighting the cost of overfilling and under filling in the industry and the strategies which can be used to tackle the problem.

We also hear from John Stewart, technical training manager at Pelsis Group, a leading pest control training facility. John speaks about protecting your food and beverage business from the risk of pest infestation and the preventative measures that can be implemented.

We hope you enjoy this issue and as always, if you have any news that you would like to feature, please email details to editorial@fdm-uk.co.uk.

Proofworks launches today with a proprietary SaaS solution to digitalise the entire spirits supply chain, from production, maturation and bottling, to customer engagement and digital ownership.

Combining user-friendly solutions with the latest in powerful Web3 technologies, the Proofworks platform surfaces previously unseen data and insights, allowing for optimisation and transparency at every stage of the product journey.

This is a key time for the spirits industry, as visibility of channel inventory becomes critical with category growth changes, and as increasing costs and supply chain disruption drive the need for greater efficiency. We’re also seeing changing consumer behaviours with an increased desire to connect in new, authentic and more meaningful ways.

Proofworks is enabling the connectivity of distilleries and warehouses through technologies such as NFC, RFID, QR codes

and smart sensors. All this data is stored securely on blockchain and made accessible via the Proofworks platform.

As well as this powerful data being used to inform and optimise production, meet emerging compliance requirements and achieve sustainability goals, it is also empowering the end consumer experience.

A fundamental principle is that users don’t need to be familiar with blockchain concepts or Web3 technologies to engage with the tools and services. As broader adoption continues and valuable use-cases emerge, Proofworks believe these technologies provide spirits companies with a unique competitive advantage.

Images: © Will Ireland

kp highlights need for better compliance with ban on EPS/XPS single use, foodservice packaging

Months after the UK’s ban on singleuse EPS/XPS foodservice packaging, Klöckner Pentaplast (kp) believes there’s still work to do in educating foodservice businesses about the differences between now-banned EPS/ XPS packaging and the recyclable alternatives that are legal for use.

Despite the ban, implemented in October 2023, reports have revealed that some customers are still unknowingly being sold packaging that is no longer legal. kp, an innovator in thermoformed trays and rigid films for form, fill and seal applications, as well as flexible barrier and stretch films, calls on the food and packaging industries to improve awareness in this area, to support the fight against linear packaging waste streams.

Sally Molyneux, Regional Sales Director UK & Ireland at kp, emphasised the ongoing need for foodservice industry awareness, stating, “While the ban has been rolled out, the market has seen reports of some wholesalers continuing to sell outlawed EPS/XPS packaging. In many cases, the food business using these may not even be aware of the issue, and the bottom line is that both they and the consumers they sell to are being misled.”

kp remains committed to championing sustainability-focused design in the food packaging industry, designing packaging to fit into a closed loop system, and advocating for informed consumer choices and stringent regulatory enforcement.

Parkside has used its unique flexible packaging capabilities to support a collaboration between Beavertown Brewery, artisanal crisp brand SMUG, manufacturer Yorkshire Crisp Company, and the Campaign Against Living Miserably (CALM), as part of an innovative campaign to start conversations around mental health.

The campaign sees Beavertown offering a free packet of SMUG’s delicious Cheddar & Jalapeño crisps, produced by Yorkshire Crisp Company and packed in Parkside’s compostable packaging - with the purchase of a pint of Beavertown

beer at participating pubs across the UK. The limited edition crisps will feature messaging to raise awareness of the importance of protecting mental health. The inside of the pack is printed with conversation starters that are visible when the pack is opened up, prompting consumers to discuss their mental health.

“It’s crucial to start conversations about mental health, now more than ever,” said Mark Shaw, Sales Account Manager at Parkside. “Something as simple as a quick chat with a friend over a pint can make all the difference to someone who may be experiencing mental health difficulties. We’re privileged to be able to play a small part in the Open

Up campaign through our compostable packaging, which can help to turn a quick pint and snack break into a meaningful moment.”

Every day, 18 people in the UK take their own lives. And over half of adults in the UK have pretended to be ‘okay’ to avoid talking about their mental health. These facts can change, and all partners in the collaboration are doing their bit to help create that change as part of CALM and Beavertown’s campaign to unite the nation against suicide and end the stigma surrounding mental health.

OPTIMASS series – Complete portfolio of Coriolis mass flowmeters for the food and beverage industry

• Entrained Gas Management (EGMTM): meter maintains operation over a wide range of gas fractions and complex flow conditions

• Single or double straight tubes for shear-sensitive and high-viscosity media. Integral heating jacket as optional

• FDA, EC1935/2004 conform; 3A, EHEDG certified

krohne.link/coriolis-microsite

Fresh Direct, the UK’s leading foodservice fresh produce provider, has launched mushroom ‘meat’, an innovative, new product that provides a healthy centre of plate alternative to meat.

Mushroom meat is made from the stalks of mushrooms that would otherwise be discarded, as only the caps are required for standard mushroom products. Rather than waste the stalks, Fresh Direct has partnered with specialist Irish mushroom grower, Umi Foods to harvest, cook and shred the surplus products.

Ian Nottage, Head of Food Development at Fresh Direct, said: “The texture of the mushroom meat provides a fantastic alternative to more traditional centre of plate options.

“It also has the benefit of avoiding food waste, as it’s made from the unused stalk of the mushroom when it’s harvested.

“With the fibrous root of the mushroom there is a natural texture, which gives a satisfying eating appeal.

“It’s also suitable for vegans as only soya protein, tapioca flour and coconut oil are added to make this really innovative product.”

Based on projected sales, the launch of mushroom meat is expected to save around 80 tonnes of food waste every year.

Wincanton, a leading supply chain partner to UK business, has achieved a five-year extension to its supply chain partnership with Fentimans, the Botanically Brewed premium soft drinks brand.

The contract sees Wincanton as Fentimans’ dedicated warehouse and transport partner, managing operations from Wincanton’s shared-user distribution centre in Middlewich, Cheshire. The service includes warehouse and distribution to Fentimans’ UK domestic market, including the retail and hospitality sectors, and the assembly and preparation of export loads for onward shipping to global markets, delivering circa 5m products annually.

Fentimans will continue to benefit from Wincanton’s flagship transport technology EyeQ. This innovation, unique to Wincanton, will help deliver accurate, realtime visibility on the location of Fentimans’ stock, proof of delivery, and optimisation of

delivery routes; reducing waste and carbon emissions, ensuring a sustainable transport offering and improving customer experience as a result.

Ian Vaughan, Logistics Manager at Fentimans, commented:

“Fentimans are delighted to be extending our long standing and fruitful partnership with Wincanton for a further five years. The quality of our working relationship and agility of the service provision will position us very positively in driving our longerterm growth strategy.”

TAILORED SOLUTIONS AND SOLID SUPPORT FOR VARIOUS INDUSTRIES WORLDWIDE

Whatever industry you are in, from plastics to pharmaceuticals and from dairy to aquaculture, you wouldn’t want your production compromised by faltering input of raw materials.

Let DMN-WESTINGHOUSE add reliability to your dry bulk handling processes. Since 1950, we have excelled in designing and manufacturing high-end rotary valves and diverter valves with a stark focus on durability, cleanability and compliance.

Discover your future-proof solution at dmnwestinghouse.com

Packaging materials have a relatively short lifespan. They are generally disposed of immediately after use, and hence a source of waste. Recycling of plastics, and especially paper, is resourceintensive, which is why innovative manufacturers look for more sustainable alternatives.

The most eco-friendly packaging materials are those that are fully plantbased and compostable. In other words, those that do not require any industrial recycling. Materials that fully degrade in soil and/or aqueous environments. Such compounds can consist of a binder (e.g., a bio-resin) and a solid fibre or reinforcing filler.

BioPowder is an innovative manufacturer of powders made exclusively from upcycled by-products such as olive stones. The company makes functional fillers, texturizers and reinforcing particles that have proven effective in biodegradable packaging compounds. Bio-sourced resins as well as protein films are examples of possible applications. The powder particles, marketed under the name Olea FP (Functional Powder) is suited for a wide range of packaging products: transparent films, solid containers, barrier coatings, and biobased adhesives.

“Bio-based innovation includes anything from conventional, fossil-based polymers reinforced or filled with a natural particle up to 100% compostable films that leave no trace. Our goal is to assist material scientists in their developments, wherever they are standing in their journey towards a reduced environmental impact”, says Kathrin

Schilling, founder and director of BioPowder.

“Sustainability sure is high up in the agenda of most packaging manufacturers. The route to implementation, however, can look very different across companies. Our goal is to encourage material scientists to think outside of the box and experiment with innovative raw material options”, Schilling adds.

Olive stone powders are made from olive stones, a side-stream of the olive oil production, whose processing is purely mechanical and resourceefficient. Upcycling of olive stones reduces waste, promotes rural development in the Mediterranean region and is the backbone of other circular business ventures. The low emissions associated with powder manufacturing are offset through carbon capture by the olive tree.

Given the above, Olea FP can reduce the overall carbon footprint of packaging materials. It is a truly circular solution, which works both as a substitute for conventional raw materials (e.g., of fossil or mineral origin) and a catalyst of disruptive innovation.

Looking at the functional properties, olive stone powders add value in the following ways:

• Proven aptitude for packaging compounds undergoing different processing steps such as injection moulding, extrusion, film blowing and filament creation.

• Variable water and oil absorption capabilities: surface-treated (e.g., hydrophobic) product grades are available.

• Customized micron ranges for texture effects, viscosity control and easy dispersion in different polymer chemistries.

• Particle stability and hardness ensure reinforcement and durability of packaging materials such as reusable cosmetic containers.

• Low density: ideal for lightweight applications such as compostable food packaging films.

In a world where the sustainability narrative can no longer be ignored, the use of olive stone powders in packaging is a promising option for eco-conscious manufacturers. Olive stone powders prove their worth through diverse functional properties, making them a valuable addition to the arsenal of sustainable packaging materials, promising a greener and more ecoconscious future for the industry.

Macsa id UK – leading manufacturer of high performance coding and marking systems for the global food industry – is highlighting the suitability of its modular SPA2 CO2 laser coding systems for marking the printed cardboard pots that are increasingly popular for packaging dairy products such as spreadable cheeses.

Cardboard is widely used by dairy processors and manufacturers due to its effective thermal insulation, light protection and recyclability – ensuring the quality of products throughout the supply chain. Board is also sustainable, light weight and versatile which makes it particularly suitable for bespoke designs in a range of shapes and styles.

In line with food safety requirements, laser marking surpasses traditional ink methods by providing accurate and durable markings whilst ensuring traceability.

Laser marking on cardboard offers significant advantages, such as precise coding on high speed production lines, accurate reproduction of details, durability of the marking and the ability to handle various types of board, including coated or specially finished ones.

Additionally, laser coding technology is fume free, does not require consumables and generates zero waste, making it environmentally friendly, eco-conscious and more efficient. Plus, the non-contact marking process prevents wear and deterioration of the pack.

Macsa id’s SPA2 laser coders are available with a comprehensive range of software, accessories and services.

European steel for packaging manufacturing remains assured during transition to chrome free passivation alternative

APEAL, the Association of European Producers of Steel for Packaging, is pleased to confirm its members have all successfully completed the REACH Authorisation process for the use of chromium trioxide and sodium dichromate in the passivation of electrolytic tinplate (ETP) and the manufacture of electrolytic chromium coated steel (ECCS).

This is an important milestone for the packaging manufacturing landscape during the active development and qualification of the alternative technologies for our uses and will ensure the continued supply of European steel for packaging.

APEAL members have timelimited Authorisation to use these substances in the passivation of ETP until the end of 2027 and, where relevant, in the manufacture of ECCS until the end of 2028.

There will be no further possibility to extend the Authorisation period beyond the 2027 and

2028 deadlines imposed by these Authorisations as there is the intention of the Commission to replace the Authorisation process for those compounds by a Restriction.

Supply chain partners are urged to implement these solutions before the end of the Authorisation period, facilitating a seamless transition away from chromium VI compounds. APEAL and its members emphasise their commitment to the transition in line with the conditions of the Authorisations.

Developed by APEAL members, the alternative technologies for both ETP and ECCS that ensure continued product and consumer safety, while adhering to global food contact regulations, are now being qualified by stakeholders throughout the supply chain. By proactively embracing alternative solutions, APEAL members aim to uphold the highest standards and regulatory compliance in European manufacturing.

The BCMPA – The Association for Contract Manufacturing, Packing, Fulfilment & Logistics, is helping US food producers from the state of Colorado find their ideal outsourcing partners in the UK for a range of manufactured food and drink goods.

Faced with distribution issues for their products in overseas markets,

the Colorado Department of Agriculture’s (CDA) International Marketing & Business Development Team initially contacted the BCMPA to help build better relationships in the UK.

Following their introduction, conversations were held between the BCMPA and CDA at the IFE Manufacturing exhibition, with the

Association showing how it could help US brands find effective thirdparty outsourcing partners in the UK.

The partnership is already bearing fruit, with a Colorado sauce manufacturer Thunder Snout due to launch a new barbeque sauce into the UK later this year thanks to BCMPA member Sauce Shed.

In addition, the CDA team is spearheading a visit for UK contract manufacturers to Colorado, Wyoming and New Mexico in June.

The objectives of the trip are for US food manufacturers and brands to meet the UK companies and discuss opportunities for establishing manufacturing and distribution in the country. At the same time, the visitors from the UK will be able to meet their US counterparts to identify synergies and develop cross fertilisation of ideas and products, potentially helping them to extend their manufacturing overseas.

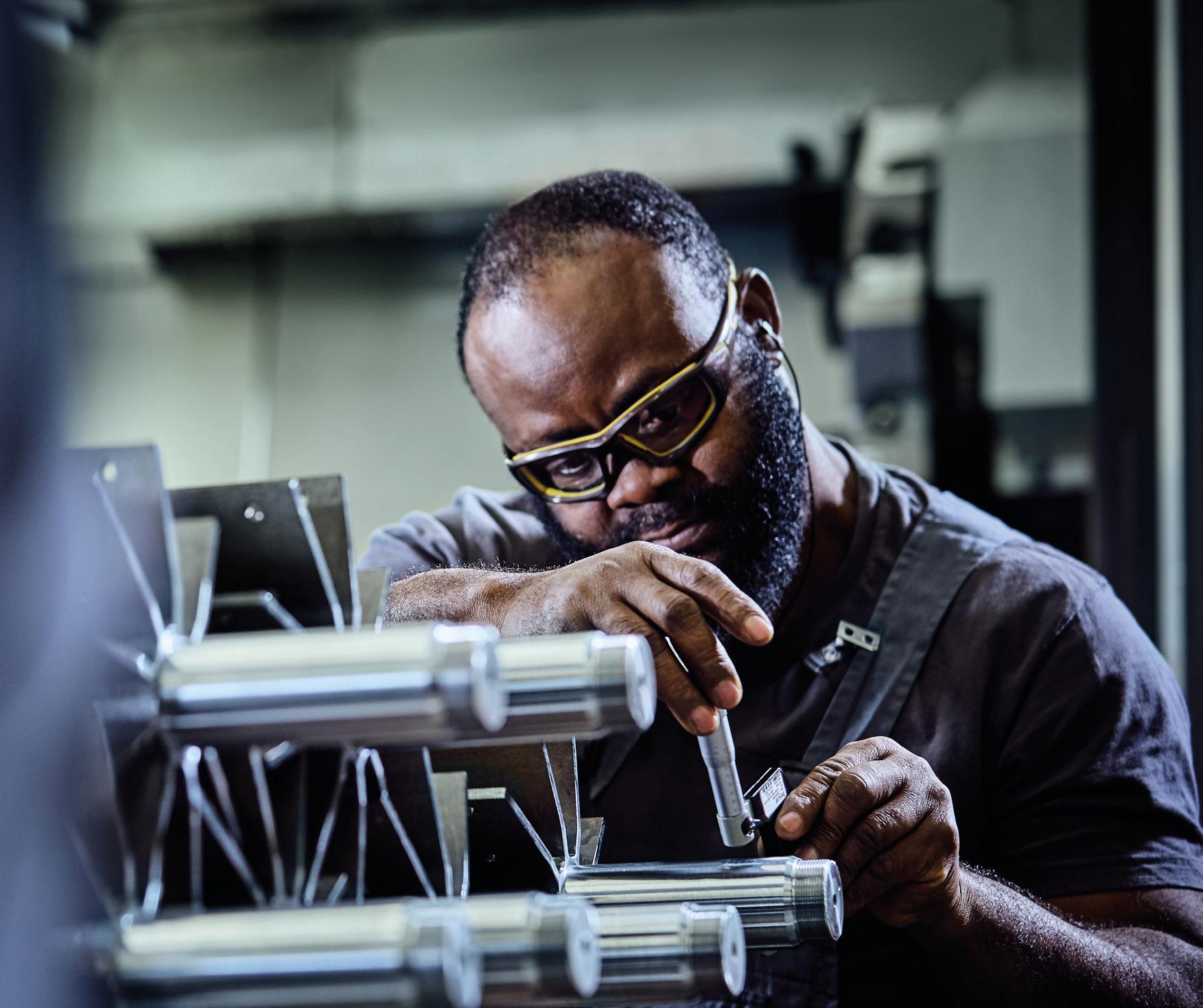

By employing a 6-axis industrial FANUC robot to automate the palletising of its bottled salad dressing line, Swiss condiment producer Brunos has alleviated production inefficiencies, allowing the company to keep pace with its growing order book.

We needed to find a solution with a compact footprint that would tie in with our existing automated processes in terms of quality and productivity.

BELOW: Automating the palletising function with the help of the FANUC M-710iC/50 robot has allowed Brunos to keep pace with the production line, enabling the company to fulfil its ever-growing order book.

Founded in 2001, Brunos produces cooled salad dressings and gourmet butters. Since its inception, sales have risen steadily, prompting this progressive family business to employ increasingly sophisticated production methods to keep up with demand.

Now a 45-employee enterprise, Brunos produces four million products each year at its 3,500m2 production facility in Sarnen, central Switzerland.

Although its production line was already automated, until recently, Brunos’ packaging and palletising function was still a manual process. This resulted in bottlenecks at the final stage of the process, as employees struggled to match the speed of the automated line. Unable to meet increased order levels and at the limit of its capabilities, the firm began to look for an alternative solution – but complex palletising patterns and limited space made their search a potential challenge.

“We had reached our limits,” explains Managing Director Michael Arnold.

“By this point, we had two or three employees packing bottles manually into cardboard boxes, but they could hardly keep up with the speed of our production line. We began thinking about an automated solution for the palletising process, but our space was rather tight. We needed to find a solution with a compact footprint that would tie in with our existing automated processes in terms of quality and productivity.”

Fulfilling complex palletising patterns

Brunos turned to Robotec Solutions AG, a local provider of robot-assisted automation, with more than 800 successful installations to its name across a diverse range of sectors. Jörg Lanz, Head of Sales at Robotec Solutions AG, says: “Working together with our customers, our most important task is to find the best automation solution for the application. In this project to palletise the bottled salad dressings, our main challenges were cycle time, space constraints and palletising patterns.”

With regards to the palletising patterns, Brunos’ production line fills bottles individually before placing them in groups of 6, 10 and 12. These groups then undergo shrink-wrapping in foil.

“We needed to devise an innovative palletising pattern based on the pre-grouping of bottle packs and involving part-rotation,” reveals Jörg. “After completing each layer, we required the robot to place an additional intermediate layer on top. This operation would have to take place without changing the gripper to help minimise cycle time.”

Robotec regularly leverages the quality of FANUC’s range of industrial robots and collaborative robots (cobots) to fulfil its customers’ requirements. In this instance, the ideal robot for the task was the strong, lightweight and

LEFT: The FANUC M-710iC/50 fits Brunos’ requirements perfectly. Capable of carrying heavy loads, its long reach allows optimal processing of the palletising pattern – and always at full speed.

compact FANUC M-710iC/50 6-axis industrial robot with 50kg payload and 2,050mm reach.

“It was clear from the start that we would choose a FANUC robot,” states Jörg. “We’ve been a FANUC partner for over 20 years and often say we have ‘yellow blood’ flowing through our veins. The FANUC M-710iC/50 fits Brunos’ requirements perfectly. Capable of carrying heavy loads, its long reach allows optimal processing of the palletising pattern – and always at full speed. Further plus points include low energy consumption, a small footprint and good availability of spare parts.”

For Brunos, automating its palletising function with the help of the FANUC M-710iC/50 robot has allowed it to keep pace with the production line, enabling the company to fulfil its ever-growing order book. Michael Arnold adds: “We are very happy with the results and success achieved following the introduction of the FANUC robot. It fulfils our expectations in terms of quality and productivity. We are completely satisfied.”

We are very happy with the results and success achieved following the introduction of the FANUC robot.

Check out the video here

The role of ceramic bearings in hygienic and efficient food packaging applications.

In the food and beverage packaging industry, the demand for high-quality products is inseparable from the need for impeccable hygiene and efficient processing. Traditional bearing materials often fall short in meeting these critical requirements. Enter ceramic bearings — a solution that offers not only enhanced performance but also addresses the stringent hygiene standards demanded by food and beverage environments. Here Chris Johnson, managing director at ceramic bearings supplier, SMB Bearings explains the benefits of opting for this material type.

Food packaging settings demand the highest levels of hygiene to ensure products are not just safe for consumption but also maintain their quality. Traditional steel bearings, often prone to corrosion, wear, and particulate generation, present a contamination risk that is unacceptable in these sensitive environments.

Unplanned stops in filling, packaging, or palletising assets in food processing can have cascading negative impacts that severely limit operational efficiencies. These interruptions not only disrupt production schedules but can also lead to compromised product quality and increased costs. In the pursuit of maintaining hygienic conditions, cleaning procedures can inadvertently damage seals and promote bearing corrosion, undermining the bearings’ integrity and longevity.

Furthermore, excessive re-greasing, often a consequence of attempting to mitigate wear and friction, can

inadvertently contaminate products and packaging materials. In this intricate ecosystem, ball bearings play a critical role. Their malfunction due to inadequate maintenance or improper cleaning practices can trigger a domino effect of delays, reduced productivity, and compromised food safety standards.

Ceramic bearings, with their nonreactive and non-porous nature, offer a robust solution. They remain impervious to chemical reactions, thereby eliminating the risk of contaminant introduction and safeguarding the integrity of packaged goods.

Ceramic bearings exhibit exceptional resistance to corrosion, a paramount trait when considering exposure to cleaning agents and washdown procedures. This characteristic ensures that the bearings maintain their structural integrity over extended operational cycles, thus contributing to prolonged equipment lifespan and minimised downtime.

Food packaging processes often involve exposure to elevated temperatures. Ceramic bearings thrive in these conditions due to their high thermal stability. This property prevents dimensional distortions and ensures consistent performance even under temperature fluctuations, crucial for maintaining precision in packaging operations.

What’s more, ceramic bearings’ ability to operate without lubrication at lower speeds, translates into lower friction and reduced heat generation during operation. This contributes to energy savings and improved efficiency in the packaging line, making them an asset in high-throughput environments.

In the realm of food packaging lines, bearings may encounter a multitude of challenges, including extreme temperatures and exposure to excessive moisture and chemicals.

In such settings, the bearings employed need to adhere to a variety of unconventional standards. The presence of contaminants further compounds the situation, manifesting in various ways. In the meticulously regulated domain of food and beverage production, the introduction of contaminants can result in substantial losses in production efficiency. Moreover, the copious moisture stemming from regular washdown cycles can lead to the displacement of lubricants from the component.

Likewise, the bearings must withstand chemical exposure arising from detergents and sanitisers, which can trigger corrosion and expedite the wear of components.

Ceramic bearings are often costlier to manufacture, so design engineers must evaluate the benefits they bring to the specific packaging application and determine if the enhanced performance and longevity justify the investment.

Alternatively, plastic acetal resin bearings present a cost-effective choice and are also resistant to corrosion. Where bearings are suitable for applications involving low loads and speeds.

In the evolving landscape of hygienic and efficient food packaging, ceramic bearings emerge as a transformative force. Their corrosion resistance, temperature stability and frictionreducing properties make them pivotal in safeguarding product quality while optimising packaging line performance. However, the journey towards full integration entails addressing challenges related to precision manufacturing, load-bearing capabilities and cost-effectiveness. By leveraging the distinct characteristics of ceramic bearings and conquering these design engineering hurdles, the food packaging industry can embrace a new era of efficiency, reliability and product integrity.

www.smbbearings.com/ applications/food-industrybearings.html

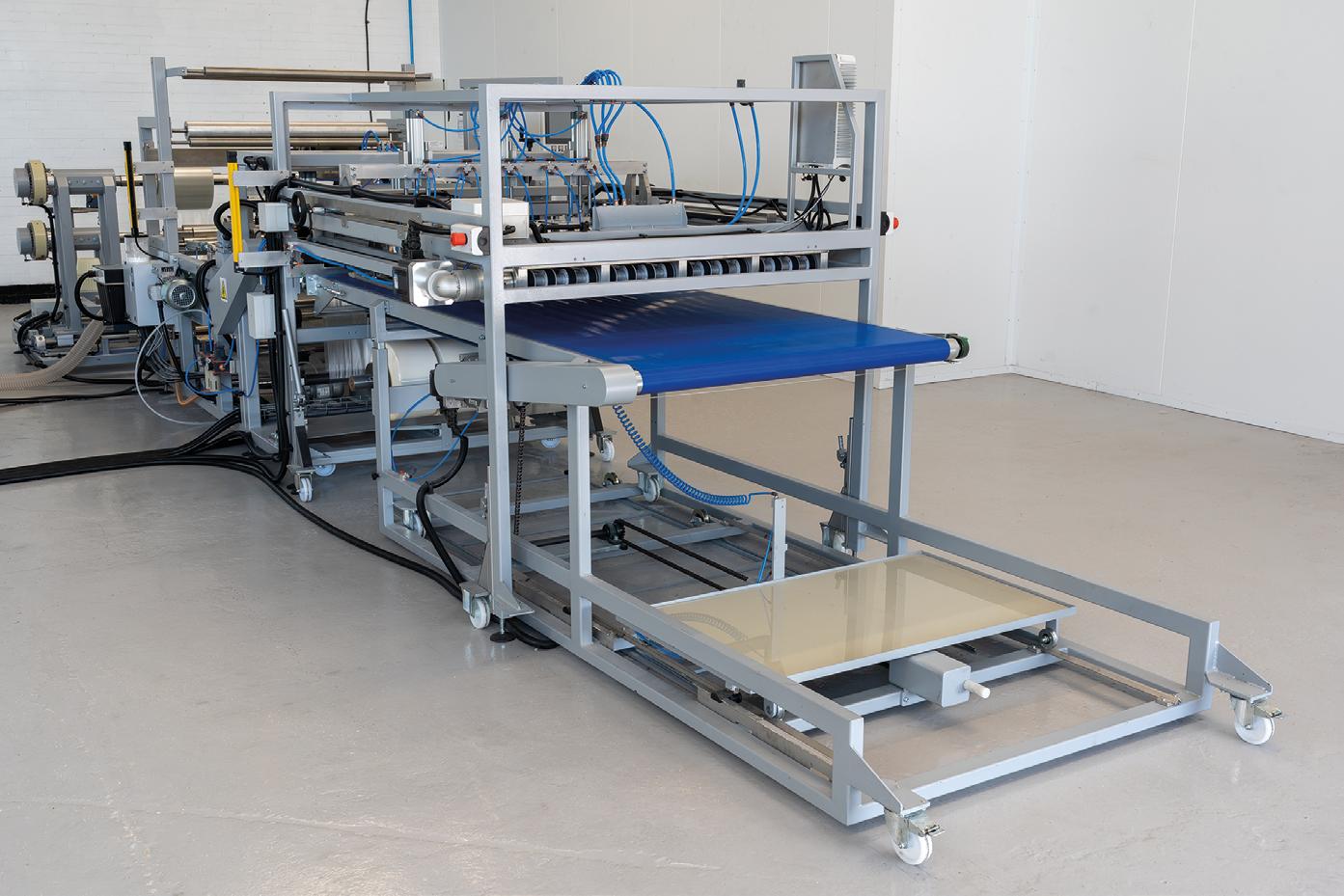

adapa Group, one of Europe’s leading companies in the flexible packaging solutions segment, has just made a major investment in two new lines for high-performance shrink bags at its UK St Helens plant. adapa now offers its UK customers an extensive shrink bag capacity. This strategic move further strengthens adapa’s supply chain agility enabling improved service to existing and new shrink bags customers in the UK.

Two bag-making lines for the UK market

Shrink materials are an important part of adapa’s strategic product portfolio. The specialist for flexible packaging supplies all types, shapes and film thicknesses for perfect shrink solutions and has been doing so for over 40 years. With this recent investment, UK customers will benefit from improved service backed by the group’s comprehensive shrink expertise.

The two new lines in St Helens can process shrink bags in widths of between 200mm and 1050mm and lengths between 100mm and 2000mm. Shrink bags are available in a variety of configurations including straight or round bottom seals, loose or as perforated on reel (POR) formats. Inline printing of single colour stamps and logos are available for the entire range. One line has already been in operation since the beginning of April with the second coming on line at the end of May.

adapa supplies all types, shapes and film thicknesses for perfect shrink solutions and has been doing so for over 40 years.

Overall, the degree of automation and thus the packaging speed depend strongly on the product being filled: while uniform and solid products, e.g. cheese pieces or loaves, can be packaged relatively well automatically, this is not always possible to the same extent for soft products with varying sizes, such as fresh meat.

The shrink bag - a real all-rounder Shrink bags are a packaging solution that has been tried and tested for decades and they are at the same time a real high-tech product: modern shrink materials are extremely thin and consist of several different layers that give the respective packaging its special properties. Shrink packaging is enormously efficient and offers the packaged goods best protection and quality preservation throughout their entire life cycle - from storage to transport and distribution to sales at the POS. Shrink bags are used as ripening packaging for certain products, such as cheese or meat. With their barrier properties optimally adapted to the respective packaged goods, they ensure first-class product quality, e.g. tenderly matured meat or perfectly ripened cheese. In terms of look and feel, shrink packaging is an “honest package”: it presents its contents in a way that is clearly visible and tangible from all sides. In addition, the good printability offers many possibilities for an eye-catching brand presentation, whether in the service counter or on the self-service shelf in the food retailers.

The process sequences in shrink bag packaging are largely automated today. The bags are opened in the machines, filled with the product, vacuumed, sealed and finally shrunk. Robot technology is increasingly used to fill the pouches. This high degree of automation has massively increased the cycle rate (packs/minute) and has led to a doubling of the packing speed in recent years. The high speed, combined with shorter cycle times, leaves less time for sealing, so the sealing media have been adapted to ever smaller processing windows. In addition, shrink bags for these highly automated packaging processes require appropriate mechanical strength as well as particularly reliable sealing seams, as these are exposed to high loads in the filling process.

Overall, the degree of automation and thus the packaging speed depend strongly on the product being filled: while uniform and solid products, e.g. cheese pieces or loaves, can be packaged relatively well automatically, this is not always possible to the same extent for soft products with varying sizes, such as fresh meat.

Surprisingly sustainable thanks to material savings

In the spirit of resource conservation and climate protection, adapa strives with its entire portfolio of flexible packaging solutions to combine the best packaging performance and material usage. In the shrink bag segment, this has been achieved through many years of development work, which has resulted in ever thinner films, and has made this packaging variant an extremely sustainable solution. Shrink bags combine reliable product protectionwhich thus simultaneously counteracts food waste - with minimal material use. For example, a shrink bag with a weight of only about 12 grams is needed for the ripening packaging of a cheese wheel weighing about 3.5 kilograms - on balance, an excellent ratio between the weight of the packaged product and that of the packaging material.

For more information: Visit adapa Group’s website www.adapa-group.com

Responding to the launch of the latest round of funding available from the Freight Innovation Fund, Logistics UK, Deputy Director Policy, Michelle Gardner says:

“Logistics UK welcomes the launch of the Freight Innovation Fund’s latest cohort of accelerator funding.

“It presents an exciting opportunity for SMEs to bid for a share of £1.8 million to develop and trial their creative solutions in realworld environments and help solve pressing challenges within the freight sector.

“The logistics sector is already making great progress on its decarbonisation journey. However, there is still much to be confirmed around the supporting infrastructure to

HCC highlight the importance of balanced diets ahead of exam season

Meat Promotion Wales (HCC) are highlighting the role of red meat in a healthy diet and lifestyle as thousands of school pupils and students across Wales prepare to sit exams this summer.

HCC’s Consumer Executive, Elwen Roberts, explained: “Diet and lifestyle are important factors for parents and students to consider when preparing to undertake exams. Having nutritious and balanced meals including nutrient dense

smooth the journey to net-zero, not least a robust and comprehensive refuelling and recharging network, but initiatives such as the Freight Innovation Fund will help ensure that innovation and technology is part of the solution.”

Logistics UK welcomes the launch of the Freight Innovation Fund’s latest cohort of accelerator funding.

proteins such as Welsh red meat can be a key way for parents to support learners throughout stressful exam and revision periods.”

Welsh red meat can play an important role in a balanced diet and offers many nutrients including natural protein, iron, zinc and vitamin B12. The complete protein found in PGI Welsh Lamb and PGI Welsh Beef can help individuals feel satiated and help avoid the temptation of sugary or salty snacks whilst the iron found in red meat can be easily absorbed and prevents tiredness and fatigue.

Elwen commented: “We know that PGI Welsh Lamb and PGI Welsh Beef offer a wealth of benefits to human health, many of which particularly helpful during exam season. Vitamin B12, for example, can help with energy release whilst zinc aid immune system health, both of which are key for students undertaking exams. We have a wide array of quick, nutritious and family-friendly Welsh Lamb and Welsh Beef recipes which would be perfect for parents, students and families. I would recommend dishes such as Welsh Beef Bolognese or Welsh Lamb tikka wraps which have an ideal balance of protein, carbohydrate and vegetables for the whole family to enjoy.”

56% drop in poultry meat exports

A 56% drop in poultry meat exports since 2020 underscores the erosion of British poultry supply chains due to Brexit, new data from HMRC shows.

Safe, affordable, nutritious poultry is half the meat the nation eats. However, certification alone has cost exporters £55 million a year since 1 January 2021. Meanwhile, importers have enjoyed a competitive advantage, paying £0 since controls have been delayed five times in two years.

Blatant disparity in UK-EU trade has unfairly tipped the scales due to the lack of implementation of border controls, leaving exporters to shoulder the costs and burdens of Brexit alone.

The lack of a level playing field means the UK exported 167,000 tonnes of poultry meat to the EU last year, worth £225 million – down from 380,000 tonnes in 2020. Conversely imports of poultry meat continue to rise, with the UK bringing in nearly 675,000 tonnes from the EU, valued at over £2 billion.

The British Poultry Council believes the cost of not having fair, reciprocated checks is greater than the burdens that come with them – particularly in the absence of a Sanitary and Phytosanitary (SPS) Agreement, in which burdens and checks could be addressed, equalised, and potentially eliminated.

The Sandwich & Food to Go Industry Awards – also known as the Sammies –has announced its 2024 winners.

Organised by the British Sandwich & Food to Go Association (the BSA), the Grammys of the sandwich world celebrates excellence across the industry, from small independents to established sector giants and nationwide chains.

The association, which held its annual awards on Thursday 9th May, presented 20 accolades. The glittering event saw 500 retail, manufacturing and supplier peers come together to celebrate another year’s worth of new products, marketing initiatives, environmental strategies and overall positive performance.

With entries at an all-time high across each of the 19 categories, the panel of industry experts had to work hard to whittle down to a shortlist and decide on the eventual champions.

The awards evening took place at the Royal Lancaster London, hosted by celebrity chef Theo Randall and comedian Charlie Baker.

The awards are a calendar highlight, also acting as a precursor to the annual British Sandwich Week – a seven-day celebration aiming to support the industry, rejoicing in the nation’s love of sandwiches, which returns again this month.

Lynher Dairies, makers of the iconic Cornish Yarg cheese and the World Champion cheese Cornish Kern, has received The Kings Award for Enterprise for outstanding achievement in Sustainable Development.

Recommended by the Prime Minister and approved by His Majesty The King, the dairy in Cornwall has been chosen as a shining example of a proactive and resilient rural business living in the 21st century.

Owner Catherine Mead said the whole dairy team was honoured to be given the most prestigious business award in the UK.

“Artisan cheesemaking is a craft that creates and embraces variation, fostering a culture of care, respect, and attention to detail; but it also requires resilience. We are continuously managing our social and environmental impact as a business, and The Kings Award for Enterprise held us accountable, requiring us to scrutinise and evidence our sustainability efforts to the nth degree,” said Catherine.

“Sustainability is about developing synergy between people, planet, and product. For us, this means improving resource efficiency, preserving the craftmanship of outstanding artisan cheesemaking within our team, championing food provenance, and being advocates for our local, cheesemaking, and farming communities.”

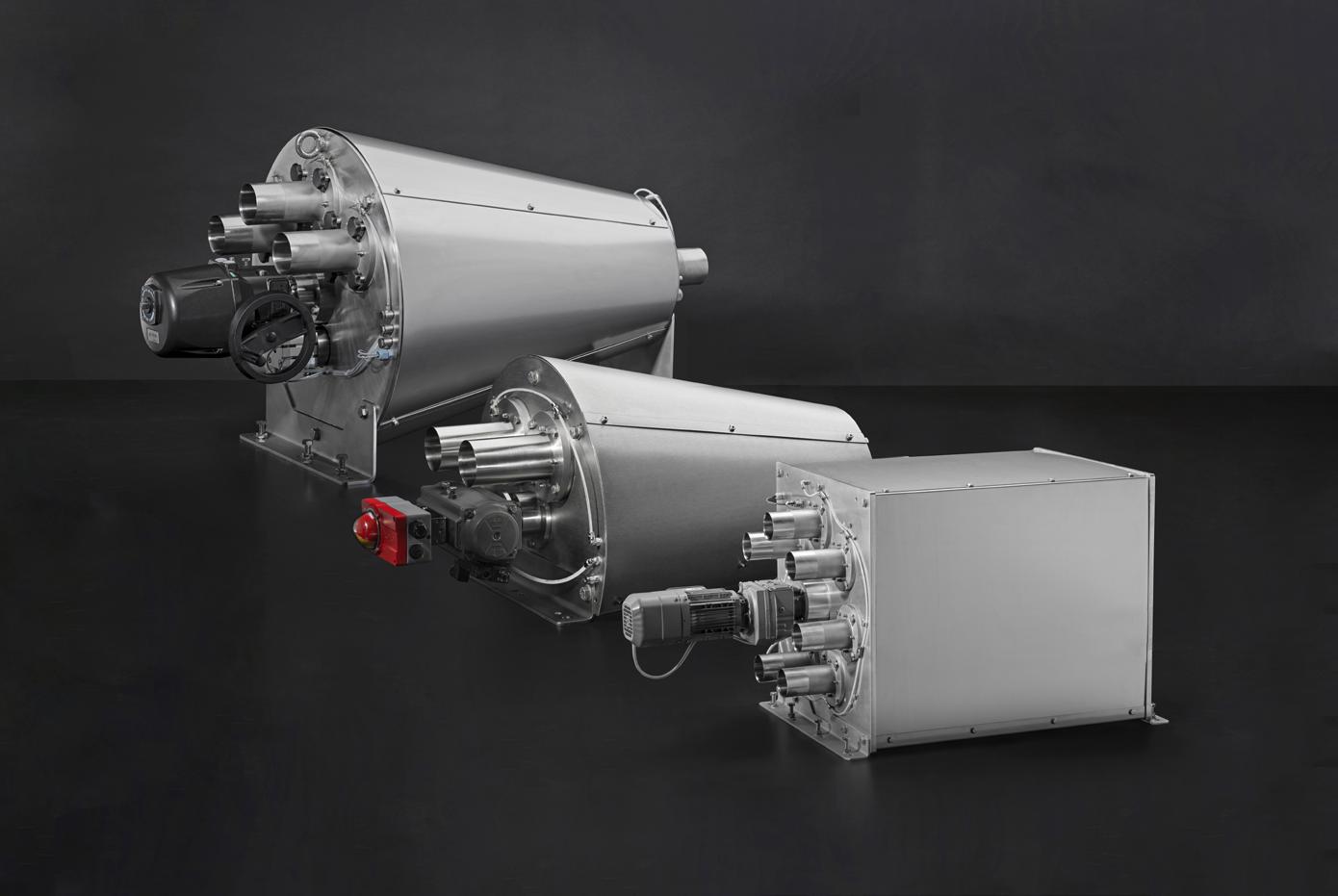

Heat exchangers are commonly used for a wide range of purposes in the food industry, from pasteurisation, sterilisation and evaporation to general heating and cooling. With a wide range of types and designs available from numerous manufacturers, choosing the right solution, from the right supplier, can seem daunting. However, posing the right questions at the beginning of the procurement and design process can prevent future misunderstandings, and ensure that you arrive at the optimal product or system for your specific requirements. Here are nine key questions to ask any potential heat exchanger supplier…

1. Do I actually need a heat exchanger?

Although heat exchangers are the preferred option for many food processing processes that include heat (pasteurisation, sterilisation, evaporation, etc.), it is a good idea to consider alternatives. In some situations, a straightforward heating element or refrigeration system may be more suitable. A creditable heat exchanger supplier will not try to sell you a solution that you don’t need.

BELOW: Does the company use the very latest scientific information on energy and heat transfer?

The last few years have highlighted the importance of energy costs to businesses, both from an economic and environmental perspective.

2. What type of heat exchanger best suits my needs?

The simplest option are plate heat exchangers (PHEs), which consist of combinations of plates and gaskets through which the product and the heating or cooling medium move. They are relatively simple and cost effective and do a good job with simple fluids like milk and thin oils. However, for more viscous substances, non-Newtonian fluids and processes requiring high levels of heat transfer, tubular heat exchangers are more effective.

Tubular heat exchangers consist of different combinations of tubes within tubes, and come in different forms, including those with corrugated tubes. Corrugated tubes increase product turbulence compared to smooth tubes (which are more common), which prevents fouling and improves operating efficiency. Corrugated tube heat exchangers are ideal for products with medium viscosity or containing

small particles in suspension, such as cream, sauces, etc.

3. Will the heat exchanger cope with my product/s?

Product features such as viscosity, solids content and texture will all affect thermal and physical behaviour in a heat exchanger. Suppliers need to understand product properties, as well as factors such as required flow rate and temperature change, in order to supply the correct solution. While there may be plenty of existing data and experience for common materials such as milk, other products such as

BELOW: For high fouling materials and viscous fluids scraped surface heat exchangers (SSHEs) are the best choice

LEFT: The nature of your product will determine the type of heat exchanger you need

complex sauces or meat products will need specific analysis and solutions.

A failure to understand the product can result in ineffective treatment which could affect product safety, product quality, economic returns, or usability of the supplied equipment. If your potential supplier shows little or no interest in your product/s, it’s worth looking elsewhere.

4. How will you design the heat exchangers?

Does the supplier use the very latest scientific information on energy and heat transfer, or is it relying on papers and data which are out of date? While the heat exchanger needs to perform correctly, other considerations, such as ease of installation and maintenance, are also important. A reputable manufacturer will also be able to offer expert insights into the latest technological advancements that could benefit users’ systems process and operational costs.

5. How energy efficient is the system?

The last few years have highlighted the importance of energy costs to businesses, both from an economic and environmental perspective. Some heat exchanger designs are more energy efficient than others (for example, the use of corrugated tubes improves energy efficiency).

Continued >>>

If necessary, you should ask your potential heat exchanger supplier how much influence you, as the client, have on the final design and construction of the system.

In addition, heat exchangers may be able to recover heat from the end of the process and re-use it (known as heat regeneration).

Although potential energy cost savings need to be offset against the capital and running costs of the heat exchanger, your heat exchanger supplier should be able to provide details of the efficiency of all aspects of their equipment and offer heat regeneration where it is desirable.

6. Will you supply a complete system?

Some suppliers will only supply components, leaving the customer or a third-party engineering contractor to combine the heat exchanger and control systems with the necessary ancillaries, such as pipework, pumps, holding tanks, etc. Some systems will use a combination of two or more heat exchangers; for example, a simpler system to pre-cool or pre-heat the bulk of the product and then the more

specialist system to perform the main process.

If your heat exchanger supplier proposes a complete ‘plug and play’ solution, then you can be confident that the various components will work together and the system will perform as expected. You will also have a single point of contact for any maintenance or warranty queries.

7. Do you offer bespoke solutions?

Different materials have different handling requirements and there is no ‘one size fits all’ solution in terms of heat exchanger. That is why manufacturers produce a range of tubular heat exchangers, from simple

LEFT: Tube-in-tube or annular space heat exchangers (such as the HRS AS Series respectively) are designed for more viscous materials

multi-tube designs through to scraped surface designs that are capable of dealing with high-fouling materials while maintaining product integrity.

However, some suppliers like HRS will go further, allowing you to specify particular brands of components or controllers – for example, to comply with existing factory maintenance contracts or traceability systems. If necessary, you should ask your potential heat exchanger supplier how much influence you, as the client, have on the final design and construction of the system.

8. How easily will the system integrate with my current operation?

Following on from the question above, operation and maintenance will vary according to the type of heat exchanger chosen, its design, and the environment in which it is used. Involving your engineering and hygiene teams at an early stage can ensure that your new heat exchanger system is fully integrated with the rest of your facility.

9. What after-sales support do you offer?

Does your potential supplier offer features such as extended maintenance and servicing? Would you be able to take advantage of any future upgrades, such as improvements in tube design? It may not be essential to deal with a company which is based locally, but you should investigate how well they deal with other clients in similar circumstances and what their support offering looks like in your particular country.

Also, what role does the heat exchanger manufacturer play in installation and commissioning? What training is provided for operators and engineering staff? Is equipment fitted with remote access and monitoring systems so that the manufacturer can access key information and metrics and, when necessary, log on and discover any potential issues and quickly identify their resolution?

LEFT: Is equipment fitted with remote access and monitoring systems?

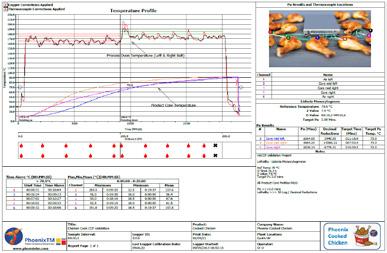

Product Safety

Process Efficiency

Improved Product Yields

Rapid Fault Finding

Full HACCP Certification

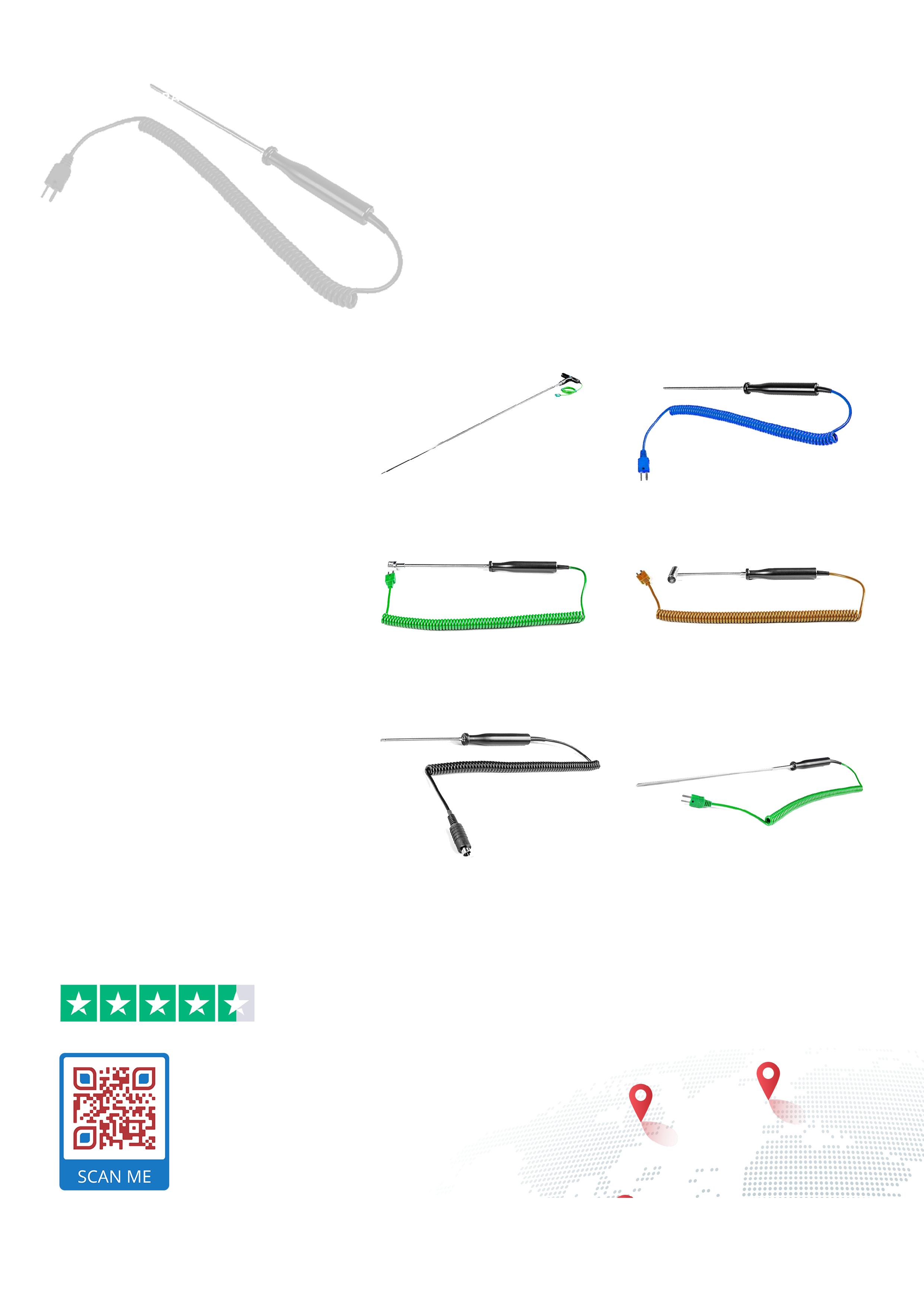

Thru-process temperature monitoring solutions for all your cook applications

PhoenixTM Technology

• Accurate IP67 data logger (Type K or T)

• 10 Measurement Points for full oven mapping

• Thermal barrier options to suit cook regime

• Comprehensive thermocouple range

• Standard miniature thermocouple plugs

• Calibrated thermocouple options

• Food trays and thermocouple jig options

• Full lethality (Fo/Pu) and reporting

• Real Time RF Telemetry options

• Local efficient calibration and service support

Phoenix Temperature Measurement

R H Hall are pleased to announce that Tracy Barry has been appointed as Finance and Operations Director. Tracy joins Managing Director Ray Hall as part of the company’s overall plans and targets, which include adding to the board of directors further in the coming years.

Tracy has been with the business for 13 years, previously working as Finance Manager before progressing to Head of Finance and Operations from 2019. In this new senior position, Tracy will continue to oversee all elements of Finance and Operations within the business, as well as

Scotland Food & Drink, the industry leadership body for the £16bn sector, has appointed John Donnelly as its new Membership and Commercial Director.

Previously John has held senior roles including CEO of Marketing Edinburgh, Commercial Director for the Glasgow 2014 Commonwealth Games, Interim Head of Marketing and Commercial at Scottish Rugby Union, and most recently, as a marketing and strategy consultant.

John brings more than 30 years’ experience in marketing and commercial strategy, strengthening the senior leadership team at Scotland Food & Drink.

Scotland Food & Drink has more than 450 members from across the industry and the country. John, as part of his role, will support the development and delivery of a new

membership strategy that will improve members’ experience and create increased opportunities for sustainable growth across member businesses.

He will be responsible for improving the commercial performance of the organisation to the benefit of members, accessing new sponsorship and commercial partnership opportunities to seek increased collaboration within the industry and further afield.

John’s will lead the business development activity for Scotland Food & Drink and his appointment follows changes and growth within the team. Tracy Cameron has stepped into the role of Scotland Food & Drink’s Interim Head of the Business Development, as she continues to represent members in the Highlands and Islands. The organisation is also recruiting

having more involvement in all commercial aspects with a fresh approach and ideas.

On her new role, Tracy Barry commented “Joining the RH Hall Team in 2010, I soon realised the importance of every member of the team and how each of us had such a big part to play in the future growth and development of the business.

“Growing through the business, to where I can now take on the Directorship is such an honour, and one which I am fully committed to take RH Hall even further and continue to develop our committed employees; thus providing our customers with even more within our Customer Relations.”

for an East of Scotland business development manager, and is once again partnering with Opportunity North East (ONE) to soon recruit a joint-funded North East Business Development Manager.

John Donnelly, Membership and Commercial Director at Scotland Food & Drink, said: “I’m looking forward to working with Iain and the whole team at Scotland Food & Drink to deliver a great service and value for money for our members, and to support the whole sector to achieve its potential.”

Billions of packages are being filled in factories around the world – coffee beans into box bottom pouches, whisky into bottles, tablets into medical packs, and many more. Two common challenges that factories often struggle to overcome are underfilling and overfilling. Both issues can lead to significant consequences for businesses, including product defects, recalls, wasted raw materials and packaging, customer dissatisfaction and brand damage.

When we conducted our research, we found that some factories in other countries deliberately underfill to save on the cost of raw materials. Customers end up paying more than they receive. While most people may overlook this, some choose to take action against such practices.

Two customers in the US filed a lawsuit against a potato chips company for consistently underfilling their chip bags. Although nitrogen gas may contribute to keeping the chips fresh and damage-free during delivery, the net weight of the chips was 58% to 75% lower than the information labelled

on the packages. The lawsuit gained widespread coverage on news and social media platforms, leading to even more customer complaints and causing serious damage to the brand.

Bringing it closer to the UK manufacturing industry, there were still some underfilling incidents happening, even though Average Quantity has been the law for most pre-packaged consumer goods, produced and sold in the UK since

1979. A leading dairy plant pleaded guilty due to T2 failures within the Weights and Measures Act. This was attributed to inadequate testing procedures that had been in place for over 15 years. Though the underfilling was unintentional, it caused huge damage to the brand and the manufacturer was fined.

We can’t just assume that what was ‘good’ yesterday will be good enough tomorrow. Manufacturers need to revisit every aspect of the manufacturing processes and ask: Why? What? Where? When? Who? and How? And most accept answers like ‘We have always done it this way.’

Knowing the consequences of underfilling, many factories decided to take action to be compliant. With the introduction of Average Quantity Law, there was no longer a Minimum Quantity Law for most pre-packaged goods. However, some companies continued to pack to what they called ‘Minimum Quantity.’ This simply meant that they were giving more product away in overfill, whilst gaining no greater legal protection.

Let’s have a look at some numbers.

Imagine you are a medium-sized whisky bottler producing, say, 10 million cases per annum. The industry standard for a case is 9 litres (based on 12 x 750ml bottles).

10 million cases at 9 litres per case equals 90 million litres. With just 1ml of overfill on average, this amounts to giving away 90,000 litres per year. As whisky must be matured in oak casks for at least 3 years before it can truly be called whisky, it has to be worth at least £1 per litre at the time of bottling (3 years later). Thus, this must represent a giveaway cost of around £90,000 per annum on such a volume, per average of 1 ml in overfill.

What’s even worse, HMRC could raise an estimate as they are entitled to the excise duty on overfill, which could be traced back through the previous 6 years. Out of interest, the excise duty charged on 40% strength spirit is £11.50 per litre. The extent of risk is realised by doing the maths - 90,000 x £11.50 x 6 = £? Don’t forget this is only based upon overfill of only 1ml per litre.

Several years ago, when an HMRC Inspector was asked for advice of “How much overfill is acceptable?”, the

Being stuck between rising input prices, and little or no opportunity to pass on these rising costs to retailers, manufacturers need to do everything to protect consumers, their financial health and brand reputation.

response (knowing nothing of process variation and capability) was “Zero –just get it right gentlemen!”

Being stuck between rising input prices, and little or no opportunity to pass on these rising costs to retailers, manufacturers need to do everything to protect consumers, their financial health and brand reputation. Optimising filling process should not be an option – why give it away?

Preventing underfilling, measuring and controlling overfilling, can significantly reduce production costs. Many manufacturers are unaware that technologies are available to help ensure optimal control of the filling

level, with real-time data collection and analysis, feeding back to the management team. Managers can, therefore, take immediate action to ensure legal compliance and reduce the wastage of overfills.

To better control your filling processes, we suggest three key strategies you could implement for your factory:

1. Choose a reliable and trusted technology partner with a proven track record to work with to help you remain compliant and reduce giveaway.

2. In your choice of partner, make sure that they fully understand and can effectively communicate the benefits of process control and legal compliance.

3. Ask your chosen partner to come to your site and prove the claims of 1. and 2.

In 1979, following the introduction of Average Quantity Law, we introduced our ground breaking weight control software which not only met the demanding legal requirements for Average Quantity, but also combined process capability analysis, so that actions prompted to users were based upon true process/machine capability, rather than simply guesswork. This unique solution has never been improved upon and the well-tested algorithm continues to be the mainstay of our Average Quantity/Process Control system.

Let’s make 2024 your best year yet!

Choose Harford Control for your process control improvement journey.

Share your interest by calling +44 (0) 1225 764461 or sending an email to info@harfordcontrol.com.

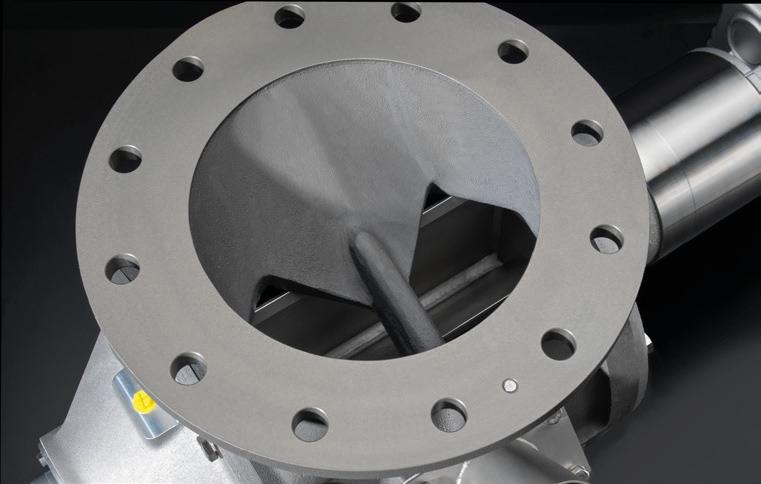

Product quality, product safety. The guiding mantra in dairy production. That’s why the world’s leading dairy producers rely on the products and solutions developed by DMNWESTINGHOUSE. Our rotary valves and diverter valves offer the highest level of precision engineering, preventing bridging and possible contamination during conveying processes. At the same time, they guarantee unparalleled cleanability, drastically increasing product safety while reducing downtime for maintenance and repairs.

Through years of experience and valuable partnerships, DMNWESTINGHOUSE has gained a deep understanding of the global dairy industry and its challenges. We have earned the trust of an industry where hygiene, cleanability, and safety are paramount. In our R&D department, we leverage innovative technology, setting the dairy industry standard. In our factories, we control every step in the manufacturing of heavy-duty rotary valves and diverter valves.

Just like you, we strive for unparalleled quality and consistency. A commitment underscored by our compliance with current certifications, including USDA, EHEDG-ED Class II and ATEX. Whether it’s about infant formula, lactoferrin, (plant-based) milk powders, caseinates or probiotics, at DMN-WESTINGHOUSE, we help you maintain the highest quality standards in dairy.

Many producers of dairy products, ranging from baby formula to lactoferrin, rely on our renowned heavy-duty rotary valves. These valves come in two types and various sizes: the drop-through type (AL/AXL/AML) and the blow-through type (BL/BXL/ BXXL). They comfortably comply with the stringent hygiene standards the dairy industry needs to maintain. All product contact surfaces consist of food-grade material, polished to perfection. They are all radiused and polished to an astonishing 0,8 μm Ra (150 grit), and the rotor vanes have precisely chamfered edges preventing the build-up of conveyed dairy powders.

Many producers of dairy products, ranging from baby formula to lactoferrin, rely on our renowned heavy-duty rotary valves.

MZC-series: standard for safety, hygiene and cleanability

Cleaning intervals will vary depending on which dry dairy substances are processed. To reduce cleaning time and resulting downtime, we developed the MZC rotary valves based on our AL— and BL-series. The MZC-I and MZC-II are equipped with supporting rails so the rotor and end cover can be removed. The MZC-II opens on two sides for unprecedented easy access and superior cleanability.

These valves facilitate premium process handling, raising the bar in cleanability, hygiene, and safety. The rotor body clearances are set automatically when the rotary valve is closed after cleaning.

Adding innovative solutions can take your dairy production to the next level.

We offer:

• Rotor Interference Detection (RID 3.0) is our third generation, detecting unwanted contact between the rotor and body or end covers. This prevents major damage and provides insight into product contamination. RID 3.0 offers 50 times more accurate resistance measurement than its predecessors.

• Shaft seal flow control boosts the reliability of our AL and BL heavyduty rotary valve series even more. Precise flow control prevents the build-up of powder residue on the shaft seals, minimising the risks of seal failure, contamination, leakage, damage and downtime.

• Rotary valves equipped with the Sanitary Air Seal (SAS) outboard bearing shaft seal minimise leak risks due to pressure changes inside the valve, thus maintaining the right airflow.

For maintaining hygiene and preventing contamination, cleaningin-place (CIP) is indispensable. CIP is about cleaning the interior of pipelines, valves, tanks and other equipment without the need for disassembly. In the dairy industries it’s a necessary, often automated method to maintain the highest levels of hygiene and prevent contamination.

Handling dry dairy solids is about maintaining the strictest standards and requirements 24/7. Are you currently

dairy solids is about maintaining the strictest standards and requirements 24/7.

operating Niro rotary valves needing replacement any time soon? Our NR347 rotary valves (NR = Niro replacement) match the outer dimensions of the Niro valves operating within your system, which means they are usually a perfect fit. The NR347 is based on our heavyduty AL250 model and is made of

stainless steel. Meeting all hygiene and safety standards, the NR347 will prove its value day in and day out.

Our diverter valves: boosting efficiency and hygiene

Diverging and converging powders or granulates is a daily routine in dairy production. Safety, efficiency and maximum hygiene are key. That’s why our 2-TDV, 3-TDV, M-TDV, and GPD diverter valves are very much in demand.

• Our 2-TDV and 3-TDV diverter valves are designed for quick disassembly and streamlined distribution. The 2-TDV effortlessly handles two destinations, while the 3-TDV targets three.

• The M-TDV efficiently handles the pneumatic transport of powders or pellets, diverging and converging flows to multiple destinations. Available in different sizes, offering up to 14 ports.

• Our diverter valves are the perfect choice for systems needing regular, quick cleaning with minimal downtime.

Would you like to know more about DMN-WESTINGHOUSE rotary valves or diverter valves and discover why we are the dairy industry’s choice worldwide?

Good food safety starts with temperature data.

Accurate and reliable temperature data is essential for the integrity of the food industry and the safety of consumers.

Tinytag Data Loggers are robust, reliable and highly accurate measuring devices for monitoring temperature and humidity during food processing, storage and cold chain distribution.

Tinytag use simple technology that’s easy-to-use, easy-to-manage and conveniently versatile to help businesses gather vital temperature data at every stage of the food supply chain.

Improve temperature management

Tinytags can aid quality and food safety inspections (including compliance with HACCP regulations) by providing evidence of conditions that’s easyto-read and readily available in userfriendly data logging software, Tinytag Explorer.

Monitoring with data loggers can indicate the need to replace old or faulty equipment, stabilise temperature conditions in refrigerated areas or improve insulation in packaging, helping you to streamline product storage.

Save energy, save money

Temperature data loggers can help to identify the efficiency of heating and cooling equipment, helping businesses to pinpoint where to save energy and save money across their operation.

Data you can trust

Tinytag data loggers bring over three decades of manufacturing experience from an ISO 9001 and ISO 14001 accredited UK manufacturer, Gemini Data Loggers UK Ltd.

Certifiable instrument accuracy through our in-house Calibration Service that’s traceable to National Standards means you can put extra trust in the reliability of your data – and prove it to auditors.

Versatile data logging: portable data loggers

Compact, portable and easy-to-use Tinytag data loggers (temperature, relative humidity and energy consumption) provide a flexible solution for monitoring food processing and cold chain compliance. Tinytags are battery-powered, self-contained devices and have configurable LED alarms for notifying temperature breaches.

The Tinytag Connect system of Radio and LAN (Ethernet) data loggers brings you convenient wireless temperature and relative humidity monitoring at an affordable price and is ideal for use in warehouses and refrigerated storage and distribution, where central data management presents a significant –time-saving – advantage. Mix-and-match Radio and LAN loggers according to infrastructure requirements, get real-time data access and receive email alerts when temperatures are out of range to take fast corrective actions.

Tinytag DI is the secure software for Tinytag data loggers. With Tinytag DI, you can control who has access to your data loggers by managing user access levels. You may also set up groups according to location or department to assign data loggers to the relevant teams. An audit log ensures accurate and consistent data, providing a record of critical events and any changes made to the loggers.

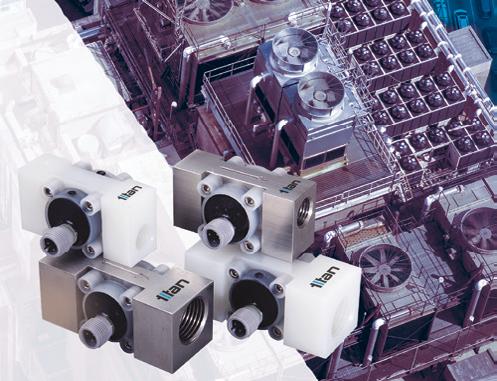

Accurate, efficient and reliable detection of fill levels is a key requirement in many industrial flow and level sensing applications especially when coupled with the growing demands of customer requirements. For example, the trend toward increased automation adds additional complexity in many processing and industrial applications, especially in food, beverage, semi-conductor production, pharmaceutical, printing and repro. Non-contact capacitive sensors are usually the preferred option for these types of applications because they are capable of detecting fill levels, without direct media contact, even with the increasing variety and sensitivity of the liquids often involved in these types of processes.

Capacitive sensing technology offers important advantages especially on applications involving aggressive liquids, food or sensitive pharmaceutical fluids used in closed containers, or where direct contact with foreign particles must be avoided. However, in some applications microfilms or residues will adhere to the inside of the walls of tanks and vessels as the fill level drops. This is where ‘conventional’ capacitive sensors reach their limits of effectiveness

Titan is a leading design and manufacturer of innovative end user and OEM high-performance flow meters, used within a wide range of environments and applications.

• Compact, robust, reliable

• Excellent accuracy and repeatability

• Measure low to high flow ranges

• High chemical resistance

• OEM bespoke design capability REQUEST A QUOTE

+44 (0)1935 812790

because they are unable to reliably recognise or differentiate whether the level measurement is still the medium - or just the microfilms or residues.

Consequently the fluids handling system is in danger of running dry, resulting in unwanted disruption and unplanned downtime. Additionally conventional capacitive sensors being used in ‘sensitive’ applications can be extremely sensitive to even the slightest influence, for example just a touch of the tank or vessel may result in switching errors.

Sensor specialist BAUMER continues to develop and expand its range of innovative (and Award Winning) sensors and the challenges noted above will not have any effect on their latest offering, the new PL240 capacitive sensor. This compact yet robust sensor can be attached outside plastic or glass tanks (even with a wall thickness of up to 6mm). It can reliably detect point levels of water-based media, such as cleaning fluids, milk or laboratory liquids thanks to compensating adherence.

This compact point level sensor measures 40mm x 40mm and can be quickly attached directly onto tanks, vessels or tubes using adhesive tape, cable ties or screws and offers a very high performance allowing for air gaps of up to 1mm between the tank and the sensor. This means the sensor can be installed on a machine part when using swap containers, especially where direct contact is sometimes not possible, or is difficult to establish.

The PL240 sensor adds another user-friendly ‘smart’ fluid monitoring option to the ever-expanding range being developed by Baumer.

In the rapidly evolving landscape of industrial automation, integrating weighing scales into production processes is becoming increasingly crucial. Accurate measurements are essential for quality control, regulatory compliance, and overall operational efficiency. Here, we explore the key factors to consider when incorporating industrial weighing scales into automated production setups.

1. Precision and Accuracy: The Foundation of Reliable Measurements

Industrial weighing scales must provide reliable measurements to ensure consistency in production outputs. Consider the scale’s resolution, accuracy specifications, and calibration processes to guarantee precise readings that meet industry standards.

2. Compatibility with Automation Systems

For a streamlined workflow, it’s essential to choose weighing scales that seamlessly integrate with your existing automation systems. Ensure compatibility with communication protocols such as Modbus, Profibus, or EtherNet/IP to facilitate real-time data exchange between the scales and other production equipment.

3. Withstanding Harsh Industrial Environments

Industrial environments can be demanding, with exposure to dust, moisture, and varying temperatures. Opt for weighing scales built with durable materials and robust construction to withstand these conditions. European stainless steel or IP-rated enclosures can enhance resistance to corrosion and damage, ensuring longevity and reliability in challenging settings.

4. Data Management and Traceability: Enhancing Quality Control

Select weighing scales equipped with advanced data recording and storage capabilities. This allows you to track production metrics, manage inventory,

and meet regulatory requirements, providing a comprehensive view of your manufacturing processes.

Customisation

Every industry has its unique requirements. Look for weighing solutions that offer customisation options to address specific needs in your production process. Whether it’s configuring measurement units, adjusting scale parameters, or integrating additional features, a flexible system can adapt to the evolving demands of your operation.

To maximise the lifespan of your weighing scales, prioritise regular maintenance and prompt support. Choose a supplier that offers comprehensive maintenance plans, calibration services, and technical support. Proactive maintenance not only prevents downtime but also ensures the continued accuracy and reliability of your weighing equipment.

Integrating industrial weighing scales into automated production processes is a strategic move towards enhancing efficiency and product quality.

At Micro Weighing Solutions, we understand the unique challenges of your industry. Our British-made weighing equipment is designed to meet the highest standards of accuracy, reliability, and integration. Contact us today to explore how MWS can elevate your production processes with innovative weighing solutions.

With the VEGAPULS 42 radar sensor, VEGA expands its IO-Link portfolio for factory automation and thus offers an optimal performance spectrum for all level, switching and pressure applications. The all-inclusive range of instrumentation from a single source makes everything easier – including the setup and operation of the most varied and complex processes.

VEGAPULS 42 brings VEGA's decades of radar experience to factory automation. The sensor meets the special requirements of the industry for levels in small tanks or clocked filling processes. It is equipped with everything that hygiene-sensitive processes need: Its switching frequency enables high cycle rates and correspondingly fast level changes. Its flexible connection options range from standard threads to the universal connection for its 1-inch hygienic adapter. When delivered, it is immediately ready for operation and, in the 3-wire version, communication with IO-Link.

All the advantages of radar

As a non-contact measuring principle, radar brings numerous advantages to the clocked processes in the food and pharmaceutical industries, such as filling, that other measuring solutions

cannot offer. The need for this is great, because reliable measured values are becoming increasingly important for efficient plant operation and optimal process control. With IO-Link, VEGAPULS 42 not only communicates universally, but can also be hooked up very quickly and inexpensively via a simple 3-wire connection. Sensor replacement is quick and automatic with the new Smart Sensor Profile 2, and adjustment is very easy using the VEGA Tools app on a smartphone with Bluetooth.

With VEGAPULS 42, you can see at first glance if the process is running as it should or if there’s a problem. An illuminated ring that changes colour allows the sensor to be read from all directions, and even from a distance. “This configuration not only gives you immediate certainty about the current condition of the sensor,” explains product manager Marvin Moser, “but also another way to check the process status.”

360° status display or on-site digital display

Universal connection for hygienic adapter

Stainless steel housing

Protection classes IP66/67/69 Worldwide approvals

Pressure range -1 ... +16 bar

Temperature range -40°C ... +130°C / 15 min @ +150°C steam

Pest infestations pose a significant threat to the integrity and reputation of food and beverage businesses. However, with proper preventative measures, businesses can effectively safeguard their operations against pests.

Here, we outline how taking an integrated approach of traditional and digitalised methods can help protect your food and beverage business from pest infestations.

Housekeeping and sanitation

Maintaining cleanliness is fundamental in preventing pest infestations. Implementing a ‘clean as you go’ policy reduces the availability of food and water which may have been caused by a spillage, thus helping deter pests.

Undertaking regular cleaning of waste bins, kitchen drains and bin rooms is also a key step in stopping pests like ants and fruit flies being attracted.

Educating employees about the pest reporting system enables early detection and timely intervention.

These areas can be a major cause for pests in a food and drink manufacturing environment, so it’s key to take measures to prevent any issues.

Positioning external bins and compactors away from the building and ensuring regular cleaning are crucial to prevent pest attraction.

Checking drainage bungs at the base of bins prevents rodent entry, while ensuring bins are not overflowing

deters pests from gnawing or pecking open bags.

Digital solutions, such as Pelsis Digital, offer the significant benefits of 24/7 monitoring and real-time alerts to effectively control pests when used as part of a holistic prevention strategy.

These systems use sensing technology to track pest activity, allowing businesses to detect and address infestations quickly. By analysing trends, patterns and pest types, you can identify potential vulnerabilities and take proactive measures to guard your business against an infestation.

Some digital pest control platforms also allow you to set thresholds which once met then trigger an alert to the user’s device.

For example, should just one pest be detected you instantly have that information to hand and crucially you know where the activity was allowing you to take swift action. This ultimately decreases the likelihood of an infestation as you are not waiting for traps to be manually checked, or signs of a pest to be witnessed first-hand.

Pest awareness training is essential for onsite maintenance staff and contractors to prevent pests from entering the building.

Educating employees about the pest reporting system enables early detection and timely intervention. This should include regular training with pest management specialists, written materials such as guides and visual aids like posters and videos.

Block entry points

Regular pest control inspections and building fabrication audits are necessary to identify and block potential ingress points. Trend analysis of pest activity data stored on your digital platform can further help target areas susceptible to infestation.

By staying proactive and addressing fabrication issues promptly, businesses can prevent pest entry effectively.

A combination of digital pest control solutions and traditional preventative measures is essential for safeguarding your food and drinks business against pest infestations.

Keep your food and drink facilities pest free

In today’s competitive market, effective pest control is essential for maintaining the integrity of products and ensuring customer satisfaction.

A

combination of digital pest control solutions and traditional preventative measures is essential for safeguarding your food and drinks business against pest infestations.

Creating a ‘best-in-class’ contaminant detection strategy requires understanding the respective strengths and limitations of food inspection technologies. X-ray and metal detection both have the same quality control goal –detecting contaminants. Both have a place on food production lines, and when used together, both can strengthen food safety.

The decision to invest in X-ray or metal detection equipment on food processing lines is dependent upon a manufacturer’s requirements. Neither technology should be a replacement for good manufacturing practices. Rather, food contaminant detection units should always be selected based on operational needs and a risk analysis.

The most common high-risk contamination culprit remains metal. Contaminants can come from a multitude of sources, including:

• Metal fragments breaking off during mechanical cutting and blending operations, or from box blade cutters.