Enter the world of sustainability at Croxsons. We are pushing forward with eco-friendly initiatives to make a positive difference. We continuously invest in lowering our environmental impact at every stage of our process, including distribution and delivery. We can all play our part in a better tomorrow, so join us on our journey today.

Watch our sustainability animation here:

For more information visit www.croxsons.com

Editor Paul Attwood editor@fdm-uk.co.uk

Editorial Assistant Anna Startin editorial@fdm-uk.co.uk

Features Editor Henry Peters editorial@fdm-uk.co.uk

Production/Design

Laura Whitehead laura@lapthornmedia.co.uk

Sales Manager Holly Jones sales@fdm-uk.co.uk

Publishing Director

Maria Lapthorn maria@lapthornmedia.co.uk

Lapthorn Media Ltd 5-7 Ozengell Place, Eurokent Business Park, Ramsgate, Kent, CT12 6PB

Show Preview - PPMA Show: ‘Inside the Exhibition’ with Gregg Wallace

Packaging - Understanding Food Packaging Symbols

Packaging - Power to packaging: why less now delivers more Interview - Jemima Boroughs, Managing Director of Shropshire Trading

Sustainability - Heat decarbonisation for manufacturers

Welcome to the latest issue of Food & Drink Manufacturing UK Magazine.

In what will be a busy month for exhibitions, we preview two of the largest. First up is London Packaging Week on 11-12th of September at the Excel in London, closely followed by the PPMA show between 24th and 26th September at the NEC in Birmingham. With the thousands in attendance, both provide excellent opportunities for networking and meeting potential new suppliers and clients.

Also in this issue, we have an interview with Jemima Boroughs, Managing Director of Shropshire Trading. Jemima speaks about the important role that redistributors play in the manufacturing supply chain and the assistance they can give to stock management.

We hope you enjoy this issue and as always, if you have any news that you would like to feature, please email details to editorial@fdm-uk.co.uk

Every effort is made to ensure the accuracy and reliability of material published in Food & Drink Manufacturing UK however, the publishers accept no responsibility for the claims or opinions made by advertisers, manufactures or contributors. No part of this publication may be reproduced or transmitted in any form or by any means, mechanical, electronic (including photocopying) or stored in any information retrieval system without the prior consent of the publisher.

Over half of all lambs across Great Britain are now meeting the target market criteria despite current cost challengesbut there remains considerable room for more production efficiencies that can really boost farm returns, the latest abattoir data indicates.

Information collected at British abattoirs indicates that almost 58 per cent of lambs processed achieved the target grades in 2023.

“Typically, abattoirs will state a base price for the day and bonuses or penalties will be applied depending on the carcase classification”, explained James Ruggeri, Hybu Cig Cymru - Meat Promotion Wales’s (HCC) Industry Development Executive.

“It is therefore very much in the producer’s interest to know the target areas within the classification grid that achieve a base price, and which grades attract a premium.”

He said HCC are offering farmers an opportunity to improve their returns when marketing finished cattle and sheep through the ‘Livestock Selection Programme’, regional training events that are free to all farmers in Wales. They provide practical abattoir-based demonstrations, and assess live animals through to assessment of carcasses.

Details of courses can be found here: https://meatpromotion. wales/en/industry-resources/ scholarship-and-careers/ livestock-selection-training

Circana, the leading advisor on consumer complexity, has today revealed new research highlighting the critical role of data for Small to Medium Enterprise (SME) manufacturers in the UK FMCG sector. While the research indicates that their innovation (NPD) is fuelling growth, retaining distribution remains the linchpin for sustained success in response to large manufacturers who are intensifying sales promotions. It urges SMEs to leverage data strategically to secure their position and compete effectively against industry giants.

Despite easing inflation and lower interest rates, growth in the FMCG market has slowed. Large manufacturers are increasingly relying on volume share as the primary pathway to growth, with sales promotion as the key enabler.

SMEs – defined for the purpose of this research as manufacturers with less than £100M turnover across all categories – have made significant strides. In the past 12 months, they have contributed £20.1Bn to total store sales, experiencing 7.3 per cent

growth. Over the last 13 weeks, SMEs maintained share growth, up 0.2 percentage points from last year. Currently, SME manufacturers hold 15.1 per cent value share, while large manufacturers account for 49 per cent and private label for 36 per cent.

While SME manufacturer growth mirrors the overall market slowdown, there’s a crucial difference; SME unit sales declined over the last 13 weeks. Further analysis of the top 500 brand value share winners across total store confirmed that 94 per cent of brand winners gained volume share, making this growth crucial in the current climate.

It shows that large manufacturers have turned to sales promotion to drive volume share and compete with private label. That coupled with their scale and larger budgets, means they have been able to secure additional store displays, most notably in non-food sectors. This in turn, helps them to sell more goods without risking a reduction in profits from the increased sales promotion investment.

Scotland Food & Drink, the leadership organisation for the nation’s food and drink industry, has announced the launch of a pilot training programme designed to enhance bookable tourism experiences for food and drink businesses nationwide.

Seeking to recruit 50 food and drink businesses, the programme is designed to address the challenges faced by Scottish producers in making their experiences easily discoverable and bookable for international and domestic tourists.

Led by Scotland Food & Drink on behalf of the food tourism leadership group, which includes VisitScotland, the Scottish Government, and the

Scottish Tourism Alliance, this programme builds on insights from the national tourism organisation’s Scotland Visitor Survey 2023, which revealed that nearly half (46%) of visitors engage in food and drink activities during their stay, with nearly a fifth (19%) of long-haul travellers specifically choosing Scotland for its culinary offerings. To capitalise on this growing interest, the programme promises substantial benefits, including training in online reputation management, content creation, and direct marketing.

Businesses will receive dedicated support from advisors to strengthen their online presence and attract the increasing number of tourists visiting Scotland.

This opportunity is ideal for businesses ready to commit approximately 33 hours, plus selfstudy, to fully participate in the programme. In return, they will receive training and mentoring valued at £2,500, all for a nominal fee of £75. Interested businesses should review the eligibility criteria and submit their applications before the deadline.

For more information, please visit https://foodanddrink.scot/ helping-business/services/growth/ scotlands-bookable-food-and-

Sewer blockages due to the impact of fats, oils, and grease (FOG) in wastewater systems is a major environmental challenge, but innovative waste management partnerships are delivering effective solutions, says Chris Clemes, chief executive of engineering technology company, EcoClarity and Rob Menzies, managing director of Serious Waste Management.

Fats oils and grease – otherwise known as FOG - are common byproducts of restaurants and food processing facilities, but FOG disposal has long posed a challenge.

Currently too much FOG enters the sewers and drains, where it often results in blockages, which can significantly impact the public, the environment, and be costly to clear. The alternative is landfill disposal, which fails to capitalise on the value of FOG as a potential renewable fuel source.

Tackling this issue was the inspiration behind EcoClarity’s patented technology, which separates problematic FOG from wastewater and recovers a valuable energy resource for biodiesel production, while returning safe water to the environment. The operational model goes much further though, it involves installing a network of FOG Recovery Hubs at wastewater treatment works and other suitable sites across the UK.

The aim is to provide easily accessible locations for hauliers to offload grease trap waste (GTW) collected from food service establishments (FSEs) and food processing sites, and for utilities to process their own waste streams. The patented EcoClarity system efficiently separates fat, oils and grease from wastewater, resulting in a 98% concentration of oil suitable for biodiesel production, which could ultimately be used to power the trucks transporting the FOG.

The ongoing success of this proven solution relies heavily on close collaboration. EcoClarity’s work with waste services contractor Serious Waste Management exemplifies the power of partnerships in unlocking a FOG-tofuel circular economy, now and into the future.

As EcoClarity sites are registered with Argent Energy’s Carbon Certification Scheme, the company can track the volume of greenhouse gas (GHG) emissions saved by the biodiesel produced from its FOG feedstock. This allows companies to demonstrate their commitment to sustainability and attract environmentally conscious clients and investors.

Historically, most organisations have lacked the specialised data and techniques needed to evaluate how

LEFT: EcoClarity employee onsite at FOG recovery hub in Hull

much FOG is present in their tanker loads, explains Clemes.

Using the EcoClarity data, Serious Waste Management has saved around 47,000 tonnes of GHG emissions since they began working with EcoClarity two years ago.

Sewer blockages are a major concern in the UK, with an estimated 200,000 occurring annually, and FOG cited as the cause in around 75% of cases. A build-up of FOG hinders the smooth operation of sewer systems and wastewater treatment plants (WwTPs), shortens the lifespan of critical assets and increases maintenance costs.

EcoClarity is growing a network of FOG Recovery Hubs across the UK, with plans to scale to 20-30 sites in the next three years. Multiple potential sites have been identified, and the company is currently working on a FOG Recovery Hub in Hull, in collaboration with Yorkshire Water. Sites belonging to United Utilities and Southern Water, as well as two large entertainment venues in London and Cornwall, are also in the pipeline.

Meeting the pace of increasing demand for FOG disposal sites is currently hindered by environmental permit issues, with the process taking up to two years. EcoClarity is engaging with the Environment Agency to tackle the issue and find ways to streamline permit applications.

By fostering partnerships and addressing permitting challenges, the FOG-to-fuel solution can be scaled-up, promoting a more sustainable and efficient wastewater management system for the future.

The PPMA Show organisers, Automate UK, have been busy planning the UK’s largest processing and packaging event to ensure it will be yet another spectacular show between 24-26 September at the NEC Birmingham. Automate UK is excited to reveal that the wellknown broadcaster, entrepreneur and writer, Gregg Wallace, will be spending a day at PPMA Show exploring the fascinating world of processing and packaging machinery, robotics and industrial vision systems as he goes ‘Inside the Exhibition’.

The show is renowned for being ‘the place to be’ for visitors, with plenty of opportunities for them to seek inspirational packaging solutions, discover fascinating new machinery, broaden their knowledge at expert talks, and engage in face-to-face networking. Visitors will walk away from the show armed with a wealth of information and knowledge that can be applied to their own businesses to streamline processes, improve efficiency, and boost productivity.

The annual PPMA Show attracts over 8,000 visitors across the threedays and includes over 350 worldclass exhibitors, comprising over 2,500 brands. These companies will be displaying their state-of-the-art products and services, hosting product launches and live demonstrations to attract the visitors’ attention. Some of this year’s exhibitors include GEA, Bizerba, Videojet, Ulma, Ishida, Beckhoff, Schur Star Systems, Ilpra, Sidel, and JBT Proseal.

One of last year’s visitors from Unilever said: “There is a good, wide range of products on show. We came to the show looking for automation partners, which is where our company is headed. We’ve visited the show a number of times and it always delivers good networking opportunities.”

The comprehensive seminar programme is one of the show’s highlights. It provides visitors with ideal opportunities to top up their industry knowledge and stay informed about the latest trends.

This year’s keynote speakers are:

• Stefan Casey, Nestlé: The digital transformation of FMCG industry: How digital technology is bringing both challenges and opportunities in packaging across the whole value chain

• Jessica Sansom, Huel: The manifestations of climate changerising to the challenge and adapting to a new normal

There will also be a panel discussion by UK Automation Forum on ‘What would make UK food businesses adopt more robots?’. The panel will consist of representatives from the food industry who will be discussing the positive impact that adopting automation can have on the sector, whilst sharing top tips and learnings that help to ensure successful outcomes.

Every year the PPMA Show organisers work tirelessly planning ways to further enhance the visitor experience through introducing new features. One of them will be a dedicated live demonstration theatre where exhibitors will grab everyone’s

We’ve visited the show a number of times and it always delivers good networking opportunities.

BELOW: Gregg Wallace- Image courtesy of Steve Ullathorne

attention when they take to the stage to launch their new products and services.

Another new fantastic feature is a tour each day of the show for those visitors who may be new to the industry or a startup business. This is designed to increase their understanding about the usage of various machinery and what would be suitable for their business.

This year will also see the introduction of icons that will help to identify easily what sectors the exhibitors specialise in.

Automate UK will soon be launching an app for the show which will further enhance the visitors show experience. The app will offer a wide range of functions, such as the content capture which allows visitors to scan QR codes on the exhibitors’ stands to access information about their products and services.

The organisers are excited to announce that the networking reception will take place at the end of day one. This new event provides an excellent opportunity for exhibitors and visitors to connect in a more informal setting, with an array of food & drink available, along with a live performance from the wonderful Soul Brothers. The perfect way to wind down after a busy day at the show.

For more information, please visit: www.ppmashow.co.uk

THE UK’S LARGEST EVENT FOR PROCESSING EQUIPMENT, PACKAGING MACHINERY, INDUSTRIAL ROBOTS AND MACHINE VISION SYSTEMS

Minebea Intec, one of the world’s leading manufacturers of weighing and inspection technology, will be presenting new products at PPMA 2024 in Birmingham from 24-26th September. The focus will be the latest innovation, the “Blue HMI” user interface for checkweighers. The interface enables intuitive operation and thus offers maximum user-friendliness.

Minebea Intec offers a broad portfolio of high-precision checkweighers and, with the new Blue HMI, has further developed the user interface for the entire product range with a view to the future.

Whether you need to introduce a new product, adjust line parameters or define a batch report: The new Blue HMI user interface makes working with checkweighers easier and more efficient. Thorsten Vollborn, Head of Product Management Inspection & Digital Services at Minebea Intec, emphasises the advantages of this technology: “The design concept of Blue HMI is based on what we know from our daily work with high-tech devices. The userfriendly menu navigation and new workflows simplify operation considerably and shorten the familiarisation period.”

In addition to user-friendliness, data security and flexibility also take centre stage. For administrators, Blue HMI offers new and extensive setting options for user and group management. To enable ergonomic working on the system, all checkweighers - including the Synus®, Flexus® and EWK product series - are now also available with a movable display variant.

Blue HMI enables advanced monitoring and analysis functions for checkweighers for better quality control and process optimisation. “The operating unit displays the overall system effectiveness and other statistics based on the current weighing results. It also has various logging functions that make it ideal for audits,” says Dr Thorsten Vollborn. As checkweighers are often located at the

end of a production line, the integrated overall equipment effectiveness provides a clear overview of the efficiency of the production line. All of this is displayed in a new dashboard or “control centre” via new widgets and diagrams.

Versatile interfaces enable optimum integration into the line

With the new user interface, Minebea Intec fulfils the needs and increases the flexibility of its customers by equipping the checkweighers with flexible interfaces such as industrial fieldbuses, Ethernet/IP, Profinet or the company’s own SPC@Enterprise. OPC UA is fully integrated in accordance with specification 40200

ABOVE: The new user interface to easily configure, control, test and audit your checkweighers.

LEFT: The WPL-S provides a static weigh price labelling option as part of end of line solutions.

(Companion Specification Weighing) and is optionally on board. The interface can also be expanded to include the PackML specification 30050 (Companion Specification PackML according to OMAC). “The new ‘Browser Remote View’ function particularly demonstrates the advanced technology of the Blue HMI,” says Thorsten Vollborn. “Similar to an internet router at home, the interface can be loaded like a website in a browser on an authorised client.” The technology used is platformindependent and can therefore be used from any device with a browser, be it a PC, a mobile phone, a tablet or a TV in the meeting room.

Want to find out more about the numerous innovations from Minebea Intec and benefit from meeting specialists? Then we would be delighted to welcome you to Minebea Intec’s exhibition stand B52 in Hall 5.

LEFT: The VisioPointer® ensures product quality, reduces waste and downtime, and optimizes production.

For more information visit: www.minebea-intec.com

The new product VisioPointer® is one of ree new Vision Inspection products from Minebea Intec and fur er enhances e already popular inspection portfolio. It is also one of e key products at helps drive automation wi in food production and manufacturing. Combined wi e Automatic Weigh Price Labeller WPL-A customers can automate eir entire end of production line where labelling plays a significant part of e manufacturing.

The new product VisioPointer® is one of ree new Vision Inspection products from Minebea Intec and fur er enhances e already popular inspection portfolio. It is also one of e key products at helps drive automation wi in food production and manufacturing. Combined wi e Automatic Weigh Price Labeller WPL-A customers can automate eir entire end of production line where labelling plays a significant part of e manufacturing.

Rotech Machines, a pioneer in thermal inkjet technology, is excited to announce that they will be exhibiting at this year’s PPMA Show, taking place from 24-26 September 2024 at the NEC in Birmingham.

Well known for their customer-led solutions, Rotech will be at stand A31, ready to showcase their unparalleled range of printers and demonstrate their expertise and knowledge of the increasingly popular coding technology.

More than two decades ago, Rotech recognised the potential of thermal inkjet (TIJ) in the packaging industry. Since then, they have been advocating its benefits—clean operation, maintenance-free functionality and ability to produce excellent quality prints.

The evolution of TIJ technology took a significant leap forward around 2008 with the development of inks that adhere to standard packaging materials. Rotech was at the forefront, implementing some of the first installations for printing on blister pack foil and flowwrapper films.

This leap forward in capability has led to many other companies adopting the technology as part of their product ranges, with varying levels of knowledge and aftercare.

“Although we all agree that the technology is an excellent choice for various applications, when not installed correctly, or not supported by a knowledgeable team, it could easily be labelled with the same negativity associated with more expensive, service hungry and unreliable technologies.” Says Steve Ryan, Sales Manager at Rotech. “This is where Rotech excel, we have industry leading knowledge, extensive experience with installing and supporting these systems across an array of different industry sectors and can provide a full range of system options.”

With over 1,000 UK installations under their belts, Rotech are well trusted by manufacturers spanning a wide range of industry sectors.

Acquiring a printer is easy; getting it to work to its maximum advantage takes expertise.

They maintain their position as a first-class supplier of the technology by constantly evolving their install techniques based on extensive industry experience.

Rotech invites manufacturers to engage with their coding experts to discuss unique challenges related to late-stage product customisation. “Our expertise lies in the correct application of TIJ technology to meet customer needs, from printer and ink selection to installation and interfacing,” explained Richard Pether, General Manager at Rotech. “Acquiring a printer is easy; getting it to work to its maximum advantage takes expertise.”

Also at the forefront of the Rotech stand, will be a selection of their UK designed and built feeding systems, for applying variable information to packaging off-line.

These feeders are manufactured to handle a variety of flat-form substrates with ease. When paired with a printer and/or labeller, they reliably print and/ or label at high speeds, offering a costeffective solution for coding away from the main production line.

Among the showcased products will be the entry-level RF Lite, a low-cost solution for automating date coding processes, and the newly redesigned RF Auto, a heavy-duty feeder capable of handling products of varying thicknesses. Both systems can be seamlessly integrated with TIJ coders to provide a complete standalone solution.

By Bob Tilling, VP Global Sales, Kallik

The Russian invasion of Ukraine in February 2022 and the sad events that followed had a significant impact on the global supply chain. Food and fuel prices rose sharply across the world and despite falling over the past two years, they still remain high. In fact, according to the Economics Observatory, as of December 2023, food and grain prices were still roughly 12-13% higher than they were in December, 2020.

As anyone working in the food and beverage industry will understand, shortages of certain products due to global conflict or seasonal changes certainly aren’t unheard of. Most companies are familiar with having to modify their recipes, with contingency plans in place to ensure that products still make it onto the shelves and out to consumers.

However, these adaptations don’t just impact the product itself. They will also impact the labelling and artwork, something that cannot be

overlooked. For example, should a business find that its grain delivery is delayed, it might choose to use oats as a substitute. Not only does this change the ingredients listed, it also changes the nutritional value and traffic light system notifying customers of the total energy, fat, saturates, sugar and salt content.

Even making the smallest change to the recipe could mean that a products’ fat content goes from orange to green, or vice versa.

Most food manufacturers would recognise the need to change the ingredient breakdown on the label, but it’s not uncommon for other aspects of the label to be overlooked, resulting in mislabelling, product recalls and even regulatory penalties. This is where automated labelling and artwork management processes come into play, as rules can be set to automatically update the entire label and prevent oversights.

Kallik’s Veraciti has been designed to prevent oversights of this nature. Using AI, the solution can instantly flag every element of the label that needs updating, with the rule-based system allowing manufacturers to make 10,000 changes in as little as 14 days – a task that would take up to six months if they were using traditional, manual methods.

With access to a cloud-based system, all information is contained within a single

As anyone working in the food and beverage industry will understand, shortages of certain products due to global conflict or seasonal changes certainly aren’t unheard of.

- Bob Tilling, VP Global Sales, Kallik

environment. This makes it much easier for staff to update, should ingredient breakdowns or recipes suddenly change - with information only needing to be entered once.

The fact that every department can also access this system prevents the problem of communication oversights and ensures that everyone is working from real-time data and information. This functionality is especially important for food and beverage enterprises selling thousands of products across hundreds of territories, as updates need to be reflected throughout the entire business.

While food manufacturers can’t change geo-political instability, or prevent natural disasters, droughts or the seasons changing, they can put processes in place to safeguard their own production processes and ensure that everything being distributed is labelled correctly.

Pick any can of beans or box of cereal off the supermarket shelf and you’ll find a swathe of food information and symbols on the label. But who decides what’s included on that food label and what are the legal requirements?

Family-owned business Invopak has over 50 years of experience as a leading packaging supplier and is here to decode the wealth of information on food packaging symbols.

The FSA (Food Standards Agency) regulates the food packaging industry to ensure labels are clear and not misleading.

Use By Dates vs. Best Before Dates

• Shorter shelf life (usually 2-5 days)

• Has a Use By Date stamped on it for safety – once this date has passed, there is an increased risk of harmful bacteria that can become dangerous if consumed

• Harmful bacteria can’t be detected through smell, so it’s important to follow the date marked on the label

• Consider the environment (i.e. temperature) that food is meant to be stored, on a warmer day, food can spoil faster as bacteria breeds rapidly on a warm day.

• Examples: fresh meat, fish, chilled goods

• Long shelf life (typically 2-5 years)

• Stamped with an expiry date or ‘Best Before Date’

• Best Before date – indicates when food tastes at its best, potentially food can be eaten after this date has passed, but the texture may be different

• A biscuit can still be eaten once the best before date has passed, it might just be a bit soft, so not ideal for dunking! It won’t make you ill or cause any harm

• High-acidic foods like tomatoes and soft fruits will keep for 12-18 months, but low acid foods (meat and vegetables) will keep for years

• If stored in the right environment (i.e. colder conditions), these items can be kept indefinitely

• Carry out a smell and taste test to see if the item is fit to eat, to prevent edible food from going to landfill

• Examples: dry, frozen and tinned goods

Food packaging is typically single use, and is hard to recycle. Environmental taxes, like the Plastic Packaging Tax and EPR, are designed to encourage manufacturers to change how they package food and promote recycling.

Recycling symbols are now more prominent on packaging and are clearer to understand making it easier to identify if packaging is recyclable.

Labelling a product correctly for allergens is a legal requirement that is also essential for consumer safety. Any food containing any of these 14 allergens, must be listed:

• Celery

• Cereals containing gluten

• Crustaceans

• Eggs

• Fish

• Lupin

• Milk

• Molluscs

• Mustard

• Peanuts

• Sesame

• Soybeans

• Sulphur dioxide

• Sulphites

• Tree nuts

Standardised symbols or icons help consumers easily identify if products contain allergens. For example, the crossed-grain gluten-free symbol helps those who are gluten intolerant or coeliac identify if products contain gluten without having to read the ingredients list.

DEFRA (The Department for Environment, Food and Rural Affairs) has strict guidelines for products labelled as organic: goods have to be grown without man-made fertilisers and pesticides and the product, labels and suppliers have to be certified by an approved UK body so that the origin of the product can be traced.

On the other side of the environmental coin are genetically modified (GM) foods. In the UK foods must be labelled to indicate if they include genetically modified organisms or ingredients. Sometimes food manufacturers will highlight their product has not been genetically modified by using a GM-free symbol.

Recycling symbols are now more prominent on packaging and are clearer to understand making it easier to identify if packaging is recyclable.

Organic and GM-free symbols encourage eco-conscious customers to buy these products, making them an important marketing tool.

The Fair Trade Certification Mark is one of the most recognisable food symbols and raises awareness of the fair trade scheme, makes imports and exports fairer and promotes a positive brand message. Fair Trade certification marks are now displayed on various products including coffee, bananas, sugar and even footballs!

Another logo that is becoming more common is The Rainforest Alliance’s green frog. This symbol can only be used by certified companies that have met the RA’s environmental and social standards for sustainability.

These symbols help people choose products in line with their religious beliefs. It’s not legally required for food and drink products to be labelled

this way, but this is currently under government review. As with all food labelling, any product positively labelled as Halal or Kosher must not be misleading and should adhere to the correct ingredient and preparation guidelines.

The main objective of nutritional symbols is to help people make informed choices about what they are eating by including clear labels on processed and pre-packed foods.

The FSA regulates what and how nutritional information is displayed on food packaging:

• Ingredients (listed in order of weight)

• Energy in kilojoules (kj) and kilocalories (kcal)

• Information on fat, saturates, carbohydrates, sugars, protein and salt content

In 2014, a voluntary traffic light labelling system was introduced to highlight key nutritional information (graded red, amber or green) depending on how healthy the product is and is displayed on the front of packaging.

As the World Health Organisation highlighted numerous health and wellbeing benefits on eating five portions of fruit and vegetables daily, the ‘five a day’ campaign was launched in 2003. As a result, companies use this as selling point and label pre-packaged foods in this way.

Food packaging symbols change often because of new legislation, customer demand or fresh initiatives on health and the environment. Failure to comply can lead to prosecution under Food Law, so it is essential to keep labels up to date.

Food packaging symbols are also about opportunity, enabling food businesses to showcase the benefits of their products, eco-credentials, or a specific dietary requirement.

London Packaging Week will return to London Excel 11-12 September, with 4,500+ visitors and 170+ exhibitors expected at the show.

London Packaging Week will host four co-located events – Packaging Première, PCD, PLD, and Food & Consumer Pack.

Packaging Première connects designers and manufacturers of luxury packaging with major international brands; PCD is the premier event brand for the beauty packaging community; PLD is the drinks packaging event that showcases all types of premium and luxury drinks; and Food & Consumer Pack is designed to drive packaging innovation across the £200bn market for everyday food, drinks and FMCG products.

Last year packaging professionals in attendance were serious about sourcing new products and exploring a vast array of cutting-edge solutions and products. The top three job functions from 2023’s show included designer, managing director and CEO, respectively, with 69% of all visitors selecting ‘finding new products and innovations’ as their primary reason for attending the event.

It was the first time I came to the event and it’s definitely worth it.

James Montero MacColl, Senior Marketing Manager, at London Packaging Week, said the event goes beyond the traditional exhibition format with bespoke workshops, seminars, and awards.

“London Packaging Week connects the world’s top beauty, drinks, luxury and FMCG groups with the packaging suppliers, materials and inspiration that will define

the future of their brands,” added Montero MacColl. “The four events offer brand teams an unrivalled and focused forum to source the latest packaging solutions, meet new suppliers, and solve their biggest innovation challenges.”

Testimonials from leading brands at previous editions are very supportive of the show.

Justin Hutton-Penman, Head of Product Innovation from The Macallan, said: “We visit London Packaging Week for a number of reasons, but primarily it’s about broadening our knowledge of the supply base. We need a wider supply base to deliver what we want to deliver over the next 10 years. And we need to know what’s out there and what’s new, and places like this help us get our heads around that and understand what’s happening in the marketplace.”

Luke Emery, Buying Director at Aldi UK, said “We really enjoyed the fact that we could see new innovative sustainable solutions for our packaging. It was really good that we got to interact with people faceto-face rather than on video calls and build connections. Also, there were some really interesting talks which helped further our knowledge as a team.”

“We got really valuable contacts from the exhibition and had countless good conversations,” added Felicity Murray, Packaging Developer from Unilever.

“It was the first time I came to the event and it’s definitely worth it,” said Simone Borghetto, Procurement Category Manager – Marketing at Ferrero. “We had some very interesting discussions and arranged meetings during and after the event because we’re interested in improving sustainability.”

Join the action and register for your complimentary pass today > click here

CONNECT with 4,500+ visitors

LEARN

market trends at 50+ educational seminars, with sustainability tailored sessions to help you with your business strategy

Join industry leaders and advocates in championing food and drink practices and inclusive solutions at London Packaging Week, where we’re shaping a greener, more equitable future.

DISCOVER the latest eco-friendly packaging solutions

11 & 12 September 2024

Halls S5 & S6 ExCeL London

The UK’s food and drink industry is the country’s largest manufacturing sector by turnover, surpassing the automotive and aerospace industries combined. However, around 40% of the food is imported from other countries (gov.uk). The UK relies on specific countries for key products such as Spain for citrus fruits, the Netherlands for tomatoes, and India and Pakistan for rice (HMRC Trade Data).

There are several reasons why the UK needs to import food from other countries, including climate constraints and seasonal variability. The UK lacks the climate conditions necessary for producing certain fruits, vegetables and crops. There is also a short window of opportunity for crops like tomatoes, lettuce and berries.

Importing food helps meet national demand and ensures the UK’s food security and resilience.

With challenges fuelled by Brexit, international conflicts, and fluctuating currency values, the trading market won’t always be stable and secure. It’s not always beneficial for the UK to import nearly half of its food from other countries. Strong national production can help mitigate international supply risks.

However, much more needs to be done for the food and drink sector to achieve strong profitable and sustainable production and to thereby reduce UK reliance on imported foods.

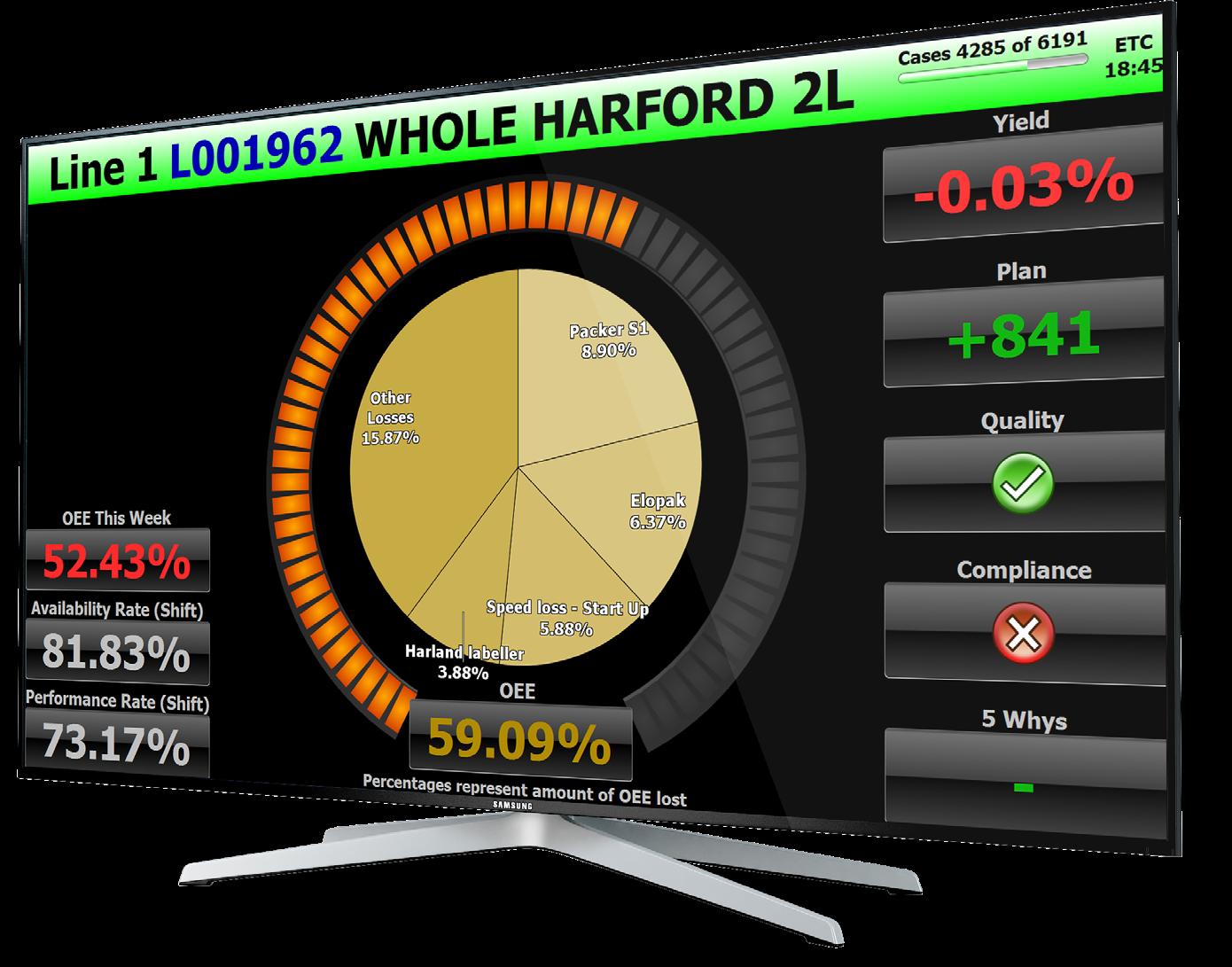

Food manufacturers typically tolerate about 5% of waste within their food processes under normal production conditions. However, with over 55 years experience visiting different food and drink factories, we have observed that the actual wastage in

most factories is significantly higher than 5%.

The main reasons for wastage include wasted raw materials, inefficient production processes, and product recalls. It’s crucial to understand the root causes of the wastage and find better and more long-term solutions rather than quick fixes which are often depressingly only short-term.

For example, during a visit to a vegetable packing plant, we observed an assembly line where various machines were processing spinach. Spinach frequently flew off the line and dropped onto the floor. Rather than stopping the entire system to fix the problem, the operators chose to clean the floor at the end of the day, discarding all the fallen spinach. This approach was considered more ‘efficient’ than stopping production for a few minutes to improve the process. However, this practice results in significant wastage of raw materials for the sake of speed.

Inefficiency in the production line can create a lot of wastage in the bottling industry. We visited a whisky distillery a few years ago. The production line

had a capacity of running 500 bottles per minute. However, it was only producing 250 bottles per minute. Operating below full capacity wasted many resources. One of the root causes was the screw capping machine. Some caps were screwed too tightly, stripping the thread and breaking the seals, while others weren’t screwed down far enough, resulting in leakers. This situation caused a lot of downtime and slowed production efficiency. Considerable time and labour were wasted reworking the bottles.

In addition, there is always wastage associated with product recalls. Recently, food manufacturers recalled at least 60 types of pre-packed

sandwiches, wraps, and salads sold in major supermarkets due to potential E. coli contamination. This could have been avoided with proper quality checks and laboratory tests during the manufacturing process, ensuring 100% food quality and safety. The recalls resulted in significant wastage. What’s worse, approximately 211 people across the UK were affected by E. coli, with at least 67 requiring hospitalisation. Consumer protection from health and safety must be the number one priority at this time, with product quality and appearance being in a vitally important second place.

Other forms of wastage in factories are not always visible to the team. Some factories have become used to the wastage and inefficiency, thus becoming blind to it. While breakdowns and root causes are often easy to identify, short stops and slow running can be much more difficult. This is where our specialist knowledge and experience can be particularly helpful.

Often, all your business needs is a fresh pair of eyes to look into the details of your production processes and uncover performance improvement opportunities. We have enormous experience helping manufacturers discover the root causes of downtime, ensuring product quality consistency, reducing wastage and improving overall performance.

always visible to the team.

If the UK food industry wants to move away from over-reliance on importing food, manufacturers need to focus on improving their internal manufacturing performance to build more robust production systems, where long-term fixes are identified and remedied once and for all, and quick fixes become a thing of the past. This sustainable approach ensures more ‘right first time’, lower overheads, less wastage and greater efficiency. Better still, finished goods go out and stay out as factory returns become distant memories.

If you’re ready to ensure product quality, reduce wastage and enhance efficiency, please reach out to us at info@harfordcontrol.com or call us at +44 (0)1225 764461.

Harford Control announced a solution range update earlier this year and we will showcase our latest end-to-end MIS/MES system on Stand B46 at PPMA.

www.harfordcontrol.com

Luxury packaging plays a critical role in delivering a consumer touch-point experience. However, all mass-produced packaging that serves a functional handling and storage purpose should be given equal attention.

For many consumable products across the value chain, minimalist polymer packaging that delivers a protective shield to safeguard against waste can help to enhance the non-verbal message of sustainability. Symbolically, if packaging items are also processed in the most energy efficient way with less machine downtime, close to zero rejects, and where feasible using recyclable polymers, this unquestionably strengthens the whole lifecycle narrative.

The on-going innovations happening in injection moulding are indicative of just how much sustainable value is aligned to current and future packaging trends and the interlinked dependencies on system efficiencies. With non-recyclable packaging set to be banned by the EU by 2030, UK packaging expert and regional sales manager Ashlee Gough explains why Sumitomo (SHI) Demag is intentionally focusing its efforts on supporting fastcycling packaging manufacturers to more than halve energy consumption.

Manufacturing packaging has always been about balancing processing speed with cost. Now, the sector is also tasked with reducing environmental impact. With many high-end customers pushing to shift to an all-electric production model, Sumitomo (SHI) Demag has invested a lot of time and energy in creating a machinery collection that fuses the company’s all-electric drive technology, processing speed and energy-enhancing features.

“Fluctuating energy costs creates uncertainty. Particularly for packaging manufacturers where energy is the highest and most unpredictable expense. To counteract this, fast processing repeatability and reduced waste, combined with halving energy costs is now deemed imperative,” explains Ashlee.

Switching to all-electric sounds simple enough. Yet, when you have a model that’s been revered for its speed as much as the company’s hybrid

Manufacturing packaging has always been about balancing processing speed with cost.

packaging El-Exis series, accomplishing this takes time. Processing speed has been the biggest hurdle to overcome.

“The challenge for any company is always going to be bringing a packaging machine to market that produces components just as fast, if not faster, without compromising cycle time, service life or energy use,” adds UK Managing Director Dave Raine.

Maintaining repeatability, speed and precision while simultaneously improving energy efficiency by utilising direct drive technology underpins the Group’s packaging strategy. Until recently, matching the force and speed of hybrid packaging machines was inconceivable. But, with 80,000+ all-electric machines now installed globally, Sumitomo (SHI) Demag has fused all their market expertise with application knowledge to edge ahead and give packaging processors the blend of productivity, reliability, and energy savings.

It is all down to Sumitomo’s in-house direct drive technology, emphasises Ashlee. “As each individual axis has a drive that has been developed specifically for each function, it means that packaging processors can achieve faster cycle time plus energy

savings of up to 70 percent when compared to hydraulic machines.”

For the past decade, the El-Exis SP set the benchmark in energy consumption for machines operating a 2 second cycle time. PAC-E matches this speed and achieves the same injection dynamics, yet halves the energy consumption. Also filling a critical gap, the company’s latest IntElect S machine is geared specifically towards plastic processors mass-manufacturing narrow tolerance and thin-walled packaging lids and containers at the fastest speeds.

Both machines have been designed to incorporate future digital product passport technology. “As an active member of the R-Cycle community, being able to offer this interoperable software will go a long way towards supporting plastic traceability and the drive towards larger carbon reductions right across the value chain,” adds Dave Raine.

Around 90 percent of the machines installed annually by Sumitomo (SHI) Demag are now all-electric. The company estimates that a third of these are now used by packaging processors to produce caps, closures, lids and containers used by the consumer, medical and food sectors. “These technological advances opens up the associated benefits of the all-electric moulding machine market to even more packaging applications,” ends Ashlee.

It was the missing piece of the puzzle needed to complete a modernization process lasting many years, with Hell Brauerei KG in Altötting, Bavaria, the first customer in the world to opt for the Innokeg X. With this semiautomatic module that washes and racks kegs in just one operating step, KHS provides a space-saving system for the low-capacity range and thus for quality-conscious family firms such as Hell Brauerei.

Not only are operating processes much simpler and faster since installation of the new technology: the brewery also appreciates the simple operation and flexibility they now have, enabling them to react accordingly to short-term orders and produce seasonal beers efficiently, for instance.

In Altötting, approximately 80 kilometers east of Munich not far from the Austrian border, tradition is writ large. Hell Brauerei, founded in 1890, still racks beer into wooden barrels that are expertly pitched every two years. However, for the brewing process itself state-of-the-art technology is now increasingly being used, with the brewery gradually having renewed its equipment over a prolonged period, starting with the fermentation cellar, then moving on to the bright beer tank cellar and finally the piping and filling. KHS has been largely instrumental in helping to bring these modernization measures to a close.

Georg Hell, who now runs the brewery in its fifth generation, recently invested in a second-hand machine for glass

The KHS

X can process up to 25 returnable kegs or barrels an hour holding up to 58 liters.

filling as his output is still too low for a new one. However, with the Innokeg X the systems provider has now developed a system for barrels and kegs that is perfectly tailored to the requirements of craft beer producers and small and medium-sized companies such as Hell.

The new setup provides clear benefits when it comes to investment and overall costs compared to the use of separate modules for washing and racking. The KHS Innokeg X can process up to 25 returnable kegs or

barrels an hour holding up to 58 liters. The brewery boss is particularly enthusiastic about the multiple processing head that washes and racks his containers in a single step. Moreover, the experienced master brewer appreciates the compactness of the Innokeg X – it fits onto a single euro pallet – and thus the small space needed to accommodate it. This allowed the system to be quickly and easily installed in the production shop without any constructional changes having to be made.

Further pluses of the Innokeg X are its simple operation and universally logical design. KHS has integrated an HMI panel with a touch screen display for operators at eye level and equipped the machine with sensors and actuators for measuring pressure, for example. At the same time, the cost of investment is lower than that for larger or specialized modules and less maintenance and fewer spare parts are required.

As part of any Food processors HACCP program, validation of cook and chill processes is a critical and significant task taking time, effort, and resources.

PhoenixTM have developed a thru-process temperature monitoring technology specifically for this task designed to meet the numerous cook challenges of the food processing market. Ideal for the validation process for any new cook regime, new product, or annual process certification.

An important innovative system in the PhoenixTM range is that designed specifically to handle the challenging monitoring demands of continuous deep fat fryers. The monitoring system has been designed specifically to travel safely through the oil bath, navigating drops and inclines and provide protection from oil impregnation, heat of the oil and allow accurate and repeatable measurement of the food core being cooked.

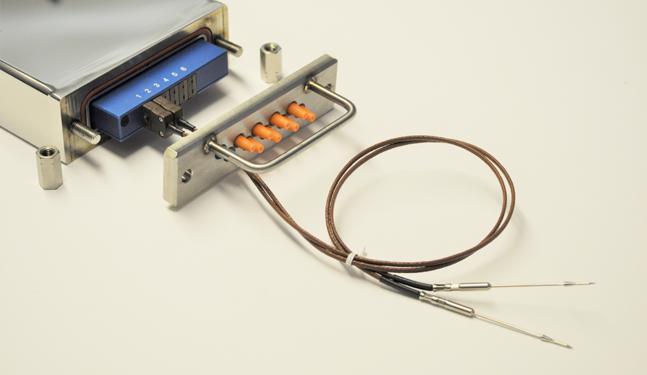

At the heart of the system the data logger provides multiple thermocouples (choice of 6 or 10 channels). The PhoenixTM NT data logger range has been designed specifically for the challenges of monitoring food processing applications with an IP67 case design protecting from moisture/oil. Type K or Type T data logger options allow accurate measurement of both cook and chill processes (Type T measurement range -200 °C to 400 °C). The data logger itself can operate between -40 °C to 80 °C with a data logger accuracy of ±0.3 °C operating below +50 °C. Data logger and thermocouple correction factors can be further applied to the recorded data logger data to maximise measurement accuracy. The data logger is protected from submersion in oil by the TS14-050-2 thermal barrier. The barrier is low height (50 mm) so fits safely through the low height clearance of the fryer line (Top / bottom belts) but provide impressive protection of 25 mins @ 200 °C (Oil) or 50 mins

Probing of the product can be done away from the processing line with care and no need to rush.

(Air). The face plate design of the barrier allows easy access to the data logger and quick efficient exchange of thermocouple cables.

A critical component of the system is the unique food tray which not only contains the thermal barrier but allows fixed positioning of thermocouples within the product samples being measured. Probing of the product can be done away from the processing line with care and no need to rush. Custom designed thermocouples allow accurate / repeatable measurement at the core (cold spot) of the product. The customised thermocouple positions are fixed so that probe or product movement during the run is minimised. Test conditions are maintained also from run to run across the fryer width.

Employing the tray principle, the whole monitoring system can be placed on the fryer line by a single operative safely and efficiently during a production run. Thermocouple cables are retained in the tray so tangling risks are eliminated. The unique saw tooth guide rails fitted to the tray allow efficient true transfer (no rotation) through the whole process. Both entrance decline and demanding exit incline can be negotiated without slipping/stalling which could leave the system stuck/stranded in process. The same system can further pass through any chill process to complete the monitoring task.

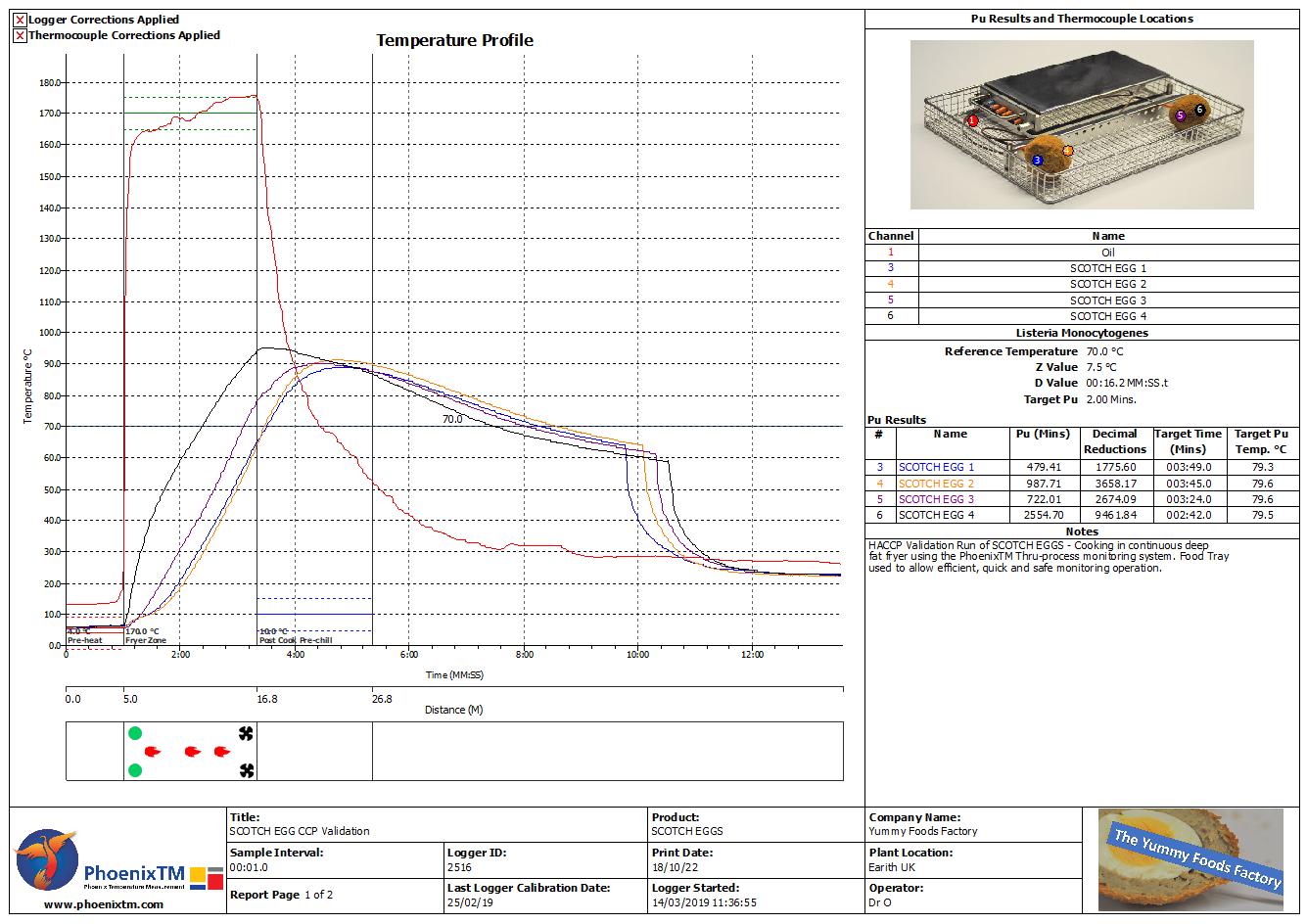

Employing the thru-process temperature monitoring principle provides the food technologist with a complete temperature profile of the cook process from start to finish. This information is like the Cook DNA giving full details of the product and or process temperature which is invaluable to allowing validation of the Cook CCP.

From a temperature profile it is possible to accurately quantify product safety

(pasteurisation) knowing both the temperature, and time at temperature, of the product.

From the profile graph you can see instantaneously the variation in product temperature at any point in the process either at different locations on the product or different product positions within the fryer.

The PhoenixTM Thermal View Food Software provides a comprehensive suite of analysis tools to convert the raw profile temperature data into useful process information. The analysis tools include the ability to calculate Fo/Pu values for the process against target micro-organisms.

For most typical cooks Listeria Monocytogenes is often used as the target micro-organism to quantify lethality. The Fo/Pu parameters (Tref 70 °C, Dt 16.2 s and Z value 7.5 °C) can be input to calculate for each monitoring point the number of

decimal reductions of the pathogen achieved during cook to meet CCP limits.

The information gathered, further to process validation, can be used to allow informed process problem solving and optimisation to maximise product quality, yield, process productivity and efficiency.

Contact PhoenixTM to help Find, Fix and Forget your Food Cook Problems!

Harrowing reports of the recent UK E. coli outbreak have forced UK retailers and caterers to rethink their food safety processes, with the UK Health Security Agency reporting that a member of the public passed away from the outbreak in June. In 2024 there has been 288 confirmed cases of E. coli to date in the UK, with 49% being admitted to hospital.

Sam Roberts, Food Retail lead at mpro5, said: “Businesses across the food sector must learn from past mistakes and seek to protect their customers to avoid damaging their reputations.

“To start, they must prioritise digitising all safety logbooks, which are the bedrock

of any food safety business. Most logs are still physical, paper booklets filled out by hand, creating unwanted extra admin for busy staff and making records easy to falsify.

“Process management apps allow businesses to digitise their logbooks, allowing employees to log their food safety checks with entries timestamped and tied to a user, making them impossible to falsify.

“Data is collected continuously, allowing businesses to spot trends, identify and fix failures quickly, and know their compliance status at all times.”

The introduction of Natasha’s Law in October 2021 means catering businesses now have an even greater

Businesses across the food sector must learn from past mistakes and seek to protect their customers to avoid damaging their reputations. To start, they must prioritise digitising all safety logbooks, which are the bedrock of any food safety business.

responsibility to ensure their food labelling is clear, comprehensive and easy to understand. Failure to comply with the law is a criminal offence, damages businesses and has potentially tragic consequences for customers.

Meatly becomes first ever European company authorised to sell cultivated meat, following UK clearance for its cultivated pet food

Meatly has announced it has received regulatory clearance to sell cultivated meat for pet food in the UK, making it the first in the world to get authorisation for cultivated pet food. A huge leap forward for the cultivated meat industry, gaining regulatory approval also makes Meatly the first-ever cultivated meat company approved for sale in any European country.

The public announcement follows a close collaborative process between Meatly and the UK’s regulatory

bodies, the Food Standards Agency (FSA), the Department for Environment, Food and Rural Affairs (DEFRA), and the Animal and Plant Health Agency (APHA). The relevant UK Government departments have ensured that Meatly complies with all necessary regulations, and Meatly has now passed APHA’s rigorous inspection process. Meatly will continue to adhere to APHA’s ongoing inspections.

As a result of this process, Meatly’s cultivated chicken for pet food can now be sold in the UK.

Beyond the approvals needed, Meatly has proactively prepared a comprehensive safety dossier and conducted extensive testing to demonstrate that its cultivated chicken is safe and healthy for pets.

Testing included demonstrating that their cultivated chicken is free from bacteria and viruses, that the nutrients used to grow the cells are safe, and that the final chicken product is safe, nutritious, and free from GMOs, antibiotics, harmful pathogens, heavy metals, and other impurities.

A Scottish Sea Farms Processing Supervisor has won the inaugural Emerging Talent award at the M&S Select Farm Awards 2024, announced today at the Royal Highland Show in Edinburgh.

Nicole McAleer saw off competition from other leading food producers to scoop the prize, one of five awarded in celebration of the M&S supply chain in Scotland.

The Emerging Talent award, open to anyone aged 35 and under, champions those who are positive role models, making an exceptional contribution to their sector.

McAleer joined the salmon producer over four years ago as a Trainee

Processing Supervisor at South Shian near Oban before progressing to her current position and is believed to be one of only two women in the Scottish sector to perform such a role – the other also working within Scottish Sea Farms.

Originally from Omagh in Northern Ireland, she said she didn’t know what a salmon farm was when she first moved to Oban.

Spending her first six months with Scottish Sea Farms learning the ropes out on the floor, she can now oversee the entire South Shian processing facility, which has the capacity to process up to 140 tonnes of salmon per single shift.

With Scottish Sea Farms’ relationship with M&S now spanning 20 years, the Emerging Talent award brings the total number of accolades received from the retailer to 13-strong.

These include awards for Innovation (2023, 2019, 2017), Low Carbon Farming Pioneer (2022), Outstanding Producer (2018), Young Producer of the Year (2016, 2014), Rural Communities (2016), M&S Champion of Champions (2015), Livestock (2014), Apprenticeship Diploma (2014) and Plan A ‘Future of Farming’ (2010).

LEFT: Scottish Sea Farms Processing Supervisor Nicole McAleer with her M&S Select Farm ‘Emerging Talent’ Award

BELOW: Left to right - Cabinet Secretary Mairi Gougeon MSP and Scottish Sea Farms Processing Supervisor Nicole McAleer with M&S Head of Trade Sue Campbell and M&S Head of Agriculture & Fisheries Steve McLean.

Yuzu Juice, a premium citrus product sourced by the Gerald McDonald Group in Japan, has been awarded the prestigious Best Ingredient of the Year (Gold) at the British Frozen Food Awards. The event took place last month at the Royal Lancaster London.

The entries underwent rigorous evaluation by a distinguished panel from the Craft Guild of Chefs, with the judging process held at Barnsley College. This comprehensive assessment spanned eight weeks and involved 168 consumers, eight professional chefs, and a guest judge. Criteria included taste, texture, cooking process, packaging, presentation, and more.

Maxim McDonald, Managing Director of Gerald McDonald, accepted the award, stating, “I have been advocating for this incredible juice for so long, and I am ecstatic that professional food experts now officially recognize its excellence. Yuzu juice is well and truly breaking into the mainstream.”

Yuzu Juice is supplied by Gerald McDonald globally and is versatile in its applications, including drinks, sauces, desserts, and seafood dishes. It is available in 10-20kg units for food and drink manufacturers and is stocked in the UK, EU, North America, and Japan.

Lineage, the world’s largest global temperature-controlled warehouse REIT, announced the launch of its pioneering initiative, the Food Chain Innovation Challenge. This aspiring global competition invites students and startups to develop and pitch groundbreaking solutions aimed at tackling one of the world’s most pressing issues: food waste, particularly postharvest losses.

The challenge will convene bright minds at three major events across the globe: London, United Kingdom on November 14; Amsterdam, The Netherlands on November 19; and San Francisco, United States also on November 19. Participants are called to present their innovative solutions that can empower different regions of the world – from

Participants are called to present their innovative solutions that can empower different regions of the world.

mature to emerging and developing markets – to mitigate postharvest food spoilage through affordable and scalable methods, thereby enhancing food security, quality, safety, and market access.

Winners from each regional event will win a cash prize. Additionally, an overall winner will be selected from the regional winners and

announced in December. The grand prize winner will receive entry into an incubator program tailored to help them further refine their business development skills and scale their solution effectively.

The Food Chain Innovation Challenge underscores Lineage’s commitment to sustainability, improving the global management of food storage, transport, and distribution. If you’re interested in participating, apply here.

For a glimpse into the 2023 Hackathon, the predecessor to The Food Chain Innovation Challenge, held in Amsterdam watch this video. Also, hear insights from last year’s winner to get inspired and understand the impact of winning this prestigious challenge.

Specialists in supervisory and management level courses

Excellent trainers with hands-on food industry experience

Consistently high examination pass rates

Modern training facility in Skipton, North Yorkshire, close to road and rail networks

In-house or remote training also available for a flexible, cost-effective option

Abbey’s silo evacuation services are available at short notice, with our team of professionals operating nationwide. We respond quickly to ensure your products keep flowing and your sites remain fully operational.

Our focus is on minimising disruption to your business. We remove contaminated products, blockages, or spillages without delay, getting sites up and running in no time. You can call our team to perform silo-to-silo transfers and remove products from tanker trailers or any other vessels that need materials removed.

Abbey Warehouse, which specialises in handling a wide range of products both food and non-food, can help reformat all your products.

Abbey Logistics is the UK’s largest bulk powder road tanker company for food-grade products. We have extensive experience in sugar, flour, salt, starch, and most other powdered and granulated products.

In addition to food products, Abbey works with some of the UK’s largest polymer, cement, lime, and ash

manufacturers, which gives us the knowledge and experience of product characteristics. Our team of planners and drivers are on hand to provide advice and take an operational lead to quickly provide solutions and get our customers up and running again quickly.

Responding quickly is usually vital in silo evacuation. Our customers’ production can be significantly restricted or even stopped due to a blockage or contamination; therefore, it is essential we are able to respond as soon as possible. To enable us to achieve this, our silo evacuation fleet is based in Middlewich, Cheshire, and we can respond to customers anywhere in the UK, being on their site the same day or next day.

Evacuated products can be transferred to our own or third-party tanker trailers, bulk bags, or bag-in-box containers. Once removed from your silo, we can provide onward distribution, storage, or disposal anywhere in the UK.

In addition to silo evacuation, we can also help with major spillages or any powder, granulated, or pellet clean-up operations. Through our bag-to-bulk, rip, and tip services on the Wirral, we can also decant evacuated material into bulk bags and securely store them at our warehouse facility.

Contact Us for a Free Pre-Assessment!

Get in touch with Paul Laverick, Abbey Logistics Head of Powder Operations. Phone: +44 07753 819 678

Email: paul.laverick@abbeylogisticsgroup.com Website: www.abbeylogisticsgroup.com

From 1973 | Trusted by Industry Leaders for Over 30 Years

Industrial Physics, a leading test and measurement instrument provider, announces the acquisition of Torus Group, a UK-based expert in quality control measurement systems and metrology.

The acquisition marks a significant development for Industrial Physics and will increase its ability to serve as a quality partner to customers across several key end markets. The latest move supports the company’s ambitious growth strategy as laid out by Chief Executive Officer, Barry Lyon, upon his appointment in July 2023.

Torus Group, known for its strong portfolio in measurement for metal and rigid packaging in the food and beverage industries, has recently expanded into plastic packaging and medical devices. Following the acquisition, Industrial Physics customers across the globe will have access to an even wider range of solutions, including test and measurement equipment, metrology services and machine enclosure support.

Ehrmann, one of Germany’s leading dairy companies, announced today its UK expansion with the acquisition of Trewithen Dairy. The move – the latest in Ehrmann’s over 100-year history – sees two family-owned businesses come together to bring a new portfolio of tasty dairy products to UK consumers.

Ehrmann will expand Trewithen’s facilities to open a state-of-the-art UK production plant at the site in Glynn Valley, Cornwall. Expected to open in 2026, Ehrmann pudding products distributed in the UK will be produced at the facility; expected to account for 15% of Ehrmann’s global sales each year.

With a guiding principle of ‘from the family, for the family’, the Cornish dairy plant will start producing the full range of Ehrmann dessert products, such as High Protein and Grand Dessert. Ehrmann dairy products are sold in over 75 countries

around the world, from 7 international production sites and 9 international sales offices; generating over 1.1 billion euros each year. In addition to its long term commitment to grow sales of Trewithen’s portfolio of branded and own-label Cornish dairy products, Ehrmann will also make a significant £20 million investment in the dairy’s processing capacity and capabilities.

The acquisition will secure the jobs of over 260 people currently working at Trewithen Dairy, and moving forward, will lead to the creation of many new high skilled roles for the local Cornish economy. In addition, the expansion of the production plant will give dairy farmers in the region a major, stable purchaser for Cornwall’s milk supply, paying a competitive milk price based upon a guaranteed premium.

Since 2022 Ehrmann has been successfully selling a range of products in the UK through major supermarkets Aldi, Morrisons, Iceland and more recently, COOP. As Ehrmann’s UK-produced range expands, the dairy foods producer will increase the distribution of its products in the UK.

Jemima, Shropshire Trading plays a crucial role in the manufacturing supply chain.

Can you explain how your company assists manufacturers with their stock management and the impact this has on their operations?

All manufacturers face issues with stock management, whether that be slow selling lines, discontinued lines, short-dated product, over makes, pack changes, improved recipes or cancelled orders.

Companies generally don’t employ someone to look after these issues and why would they? It’s a known fact that the big 5 supermarkets analyse the

retail arena in depth. Nothing upsets supermarket buyers more than finding a current product in a discounter that has been supplied directly by supplier and you can understand why.

This is the reason many UK manufacturers use problem stock companies, like Shropshire Trading Ltd. We specialise in this marketplace and act as an insurance policy to those manufacturers. It’s such a difficult area, supplying the multiples and then supplying directly the discount retailers, which is bound to upset someone. Shropshire Trading enables manufacturers to manage their problem stock without the need for extra resources or upsetting relationships.

What are some of the biggest challenges you see manufacturers facing today in terms of managing residual stock, and how does Shropshire Trading help address these challenges?

Alongside some of the better-known challenges such as slow selling lines, discontinued lines, short-coded product, over makes, pack size change etc, others include unexpected legislation changes.

It’s a known fact that the big 5 supermarkets analyse the retail arena in depth.

-

Jemima Boroughs

There is a fine line between over and under production. Missing out on sales due to not being able to make enough product versus projecting for growth and generating too much product. We often see a 3-5 year production cycle wherein a manufacturer has little residuals followed by a large increase. Of course, we recognise these patterns in our system, however it can be difficult to address these with manufacturers when their focus is on fresh, A-grade stock.

Time and prioritisation is definitely a big challenge. Residual stock is often low on the priority list due to its perceived lower value. However, the value of residual stock will be higher if it is not left until the very last minute. If the dates are too short, it becomes a waste risk and landfill costs can be high. We spend a lot of time encouraging our suppliers to review their residual stock before it becomes a waste risk, we track contact frequency and regularity of stock from individual manufacturers. This tailored approach enables us to aid stock management at the right time.

Key decision makers – one of the biggest challenges we face is ensuring key decision makers understand first loss is ‘best’ loss and secondly that their brand will be protected

Changes in staff in the company can be a challenge for manufacturer’s residual

stock processes as knowledge is often dependent on individuals rather than company process.

We provide manufacturers personalised reminders to check stock levels with frequency dependant on clients’ internal processes

In addition we deliver educational support by providing all the facts on the discount marketplace and the value of products to help all key decision makers

Sustainability is a key focus for Shropshire Trading. How do you work with manufacturers to ensure that their unsold stock is rehomed responsibly, and what are the environmental benefits of this?

We are an established businesses with direct routes to market. Full supply chain traceability and the ability to recall product if required (in a worstcase scenario) is essential.

At Shropshire Trading, sustainability is a core focus. We work closely with manufacturers to ensure their unsold stock is rehomed responsibly by purchasing excess stock and selling it to UK high street discounters. This process prevents viable products from going to waste or ending up in landfills.

The environmental benefits of this approach are significant. By redirecting surplus stock to consumers, we reduce food waste and its associated environmental impact, such as greenhouse gas emissions from decomposing waste in landfills. This not only supports manufacturers in meeting their sustainability goals but also aligns with broader environmental efforts to minimise waste and promote responsible consumption. Additionally, our approach helps manufacturers maintain their brand integrity and reach new market segments, contributing to a more sustainable and efficient supply chain.

You’ve been instrumental in improving the CRM system to better suit business processes. How has this technological innovation specifically benefited the manufacturers you work with?

Improving our CRM system to better align with our business processes

was a massive project which required perseverance and consistency. We are constantly exploring ways to improve efficiency & our processes.

The benefits of the new CRM system for the manufacturers we work with include:

• Manufacturers receive timely reminders to check stock – helps with inventory management

• Streamlined communicationEnsures we are not over or under contacting a manufacturer – we can find that sweet spot

• We analyse patterns in residual stock occurrences for individual manufacturers, for example, seasonal increases

• The notes and information on our CRM enable us to maintain a personal touch with manufacturers in an increasingly technologydominated world

• Improving the CRM enabled us to change our accounts package so they are now integrated. This has further increased our operational efficiency which ultimately benefits stakeholders. Furthermore, when issues arise we can quickly trace and resolve them.

Overall, the enhanced CRM system fosters a more collaborative and transparent relationship between Shropshire Trading and our manufacturing partners, ultimately leading to better stock management and operational efficiency.

What trends are you seeing in the FMCG manufacturing sector, particularly regarding waste reduction and sustainability, and how are you adapting to these trends?

By leveraging data analytics, we help manufacturers using customised contact methods, which in turn minimises waste.

- Jemima Boroughs

In the FMCG manufacturing sector, there is a clear trend towards waste reduction and sustainability. Manufacturers are increasingly prioritising sustainable practices, such as using eco-friendly packaging, implementing circular economy principles, and enhancing supply chain transparency. Additionally, there is a growing emphasis on reducing food waste through better forecasting, improved inventory management, and partnerships with organisations that can repurpose excess stock.

At Shropshire Trading, we are adapting to these trends by continually refining our processes to align with sustainable practices. We work closely with manufacturers to rehome unsold stock responsibly, ensuring that products are diverted from landfill and instead reach value-conscious consumers through our network of discount retailers.

By leveraging data analytics, we help manufacturers using customised contact methods, which in turn minimises waste. Our commitment to sustainability not only supports the environment but also strengthens our relationships with manufacturers who are working to reducing their footprint.

The pandemic has affected many industries, including manufacturing, how has Shropshire Trading supported manufacturers during this time, particularly with managing excess stock?

During the pandemic, Shropshire Trading played a vital role in supporting manufacturers facing unprecedented challenges with managing excess stock.

Supply chain disruptions, sudden changes in consumer demand, and logistical hurdles led to increased residual stock levels. We provided a reliable outlet for this excess stock, ensuring that manufacturers could quickly and efficiently move surplus products.

Our ability to purchase and redistribute excess stock to high street discount retailers has been crucial. This helps manufacturers free up storage space, reduce holding costs and release capital tied up in stock. We also enable products to reach consumers who need them at a fair price, particularly during economic hardships. Additionally, we have offered flexible solutions, such as adjusting purchase quantities and providing expedited logistics, to accommodate the unique needs of each manufacturer during these uncertain times. Our proactive approach and strong partnership enabled us to effectively support the manufacturing sector throughout the pandemic.

With your goal to become Europe’s leading solution for residual stock challenges, what new initiatives or

partnerships are you exploring with manufacturers to achieve this goal?

We are creating a knowledge base and a more customised learning journey together depending on the size, stage and goals of the manufacturer.

We are attending trade shows in Europe, which are a great opportunity for us to create new partnerships and build our contacts base.

Exploring trends outside the UK, including seasonal sales that may differ from the UK is also key to ensuring we have the knowledge and insights required for the wider European residual stock market.

How do you ensure that the manufacturers you work with comply with regulatory requirements regarding waste and surplus stock management?

Not applicable - we work with product before it becomes termed as “waste”. We do not work with product past it’s use by date. And although we do work with products past their best

Titan is a leading design and manufacturer of innovative end user and OEM high-performance flow meters, used within a wide range of environments and applications.

• Compact, robust, reliable

• Excellent accuracy and repeatability

• Measure low to high flow ranges

• High chemical resistance

• OEM bespoke design capability

before date, we follow all the relevant legislation and guidelines.