MANUFACTURING PRODUCTION

COMPRESSED AIR FLUKE PRECISION ACOUSTIC IMAGER ENABLES AIR LIQUIDE TO CUT COSTS

INTERVIEW WHY WOMEN’S GROUPS ARE IMPORTANT

JULY 2023

ENGINEERING

MANUFACTURING PRODUCTION

03 Manufacturing & Production Engineering Magazine CONTENTS Editor Paul Attwood editor@mpemagazine.co.uk Senior Editorial Assistant Francesca Amato editorial@mpemagazine.co.uk Features Editor Harry Peters editorial@mpemagazine.co.uk Production/Design Laura Whitehead laura@lapthornmedia.co.uk Sales Manager Charlotte Chapman charlotte@mpemagazine.co.uk Sales Executive Alex Costa alex@lapthornmedia.co.uk Accounts Richard Lapthorn accounts@mpemagazine.co.uk Circulation Manager Leo Phillips subs@mpemagazine.co.uk Publishing Director Maria Lapthorn maria@lapthornmedia.co.uk Lapthorn Media Ltd 5-7 Ozengell Place, Eurokent Business Park, Ramsgate, Kent, CT12 6PB Tel: 01843 808 117 08 14 32 46 48 Company News: Aquaterra Energy seals multi-million riser deal with BP Asset Finance: Attitudes to funding... Packaging: Allpack Launches grip® Taper Company News: Get It Made launches new fund to champion women in innovation Training & Education: Has the Upswing in Female Lift Truck Instructors Begun? 08 48 32 14 46 Welcome to the latest edition of Manufacturing & Production Engineering Magazine. In this edition we hear about the Manufacturing Growth Programme. One of the UK’s most successful industrial business support programmes comes to an end in June after helping the manufacturing sector to create or safeguard an impressive 12,435 jobs since 2016. We also hear about the exciting news of Turnbull & Scott winning the 2023 Sustainable Development Award, a wonderful achievement, congratulations. We hope you enjoy this issue and as always, if you have any news that you would like to feature, please email details to editor@mpemagazine.co.uk

Paul Attwood Editor @mpemaguk mpemagazine.co.uk Every effort is made to ensure the accuracy and reliability of material published in Manufacturing & Production Engineering Magazine however, the publishers accept no responsibility for the claims or opinions made by advertisers, manufactures or contributors. No part of this publication may be reproduced or transmitted in any form or by any means, mechanical, electronic (including photocopying) or stored in any information retrieval system without the prior consent of the publisher.

Editors Note

Deadline Nearing to Enter 2023 Create the Future Design Contest

Time is running out to enter the Create the Future Design Contest, an exciting challenge — sponsored by Mouser Electronics — to engineers and students worldwide to create the next great thing. Mouser, which has sponsored the contest for ten years, is joined again by valued manufacturers Intel® and Analog Devices, Inc. as co-sponsors. The competition is produced by SAE Media Group, an SAE International Company. COMSOL is also a principal sponsor of the contest. The deadline to enter is July 1.

The grand prize winner receives worldwide recognition and a cash prize of $25,000 for an innovative product that benefits society and the economy. Previous contests have produced more than 15,000 design ideas from engineers, entrepreneurs and students in more than 100 countries.

The Create the Future Design Contest brings attention to product designs that enhance humanity, improve healthcare quality or help provide sustainable solutions. Previous grand prize-winning entries include self-destroying plastics, a selfcontained organ and limb transport device, and an economical rapid screening device to prevent foodborne illness.

The contest was created in 2002 by the publishers of Tech Briefs magazine to help stimulate and reward engineering innovation.

The grand prize winner will be chosen from the winners in seven entry categories: Aerospace and Defence, Automotive/Transportation, Electronics, Manufacturing and Materials, Medical, Robotics and Automation, and Sustainable Technology.

For more information, visit https://eu.mouser.com/ createthefuture/.

Manufacturing Growth Programme delivers 12,435 SME jobs as it targets new-look funding landscape

One of the UK’s most successful industrial business support programmes comes to an end in June after helping the manufacturing sector to create or safeguard 12,435 jobs since 2016.

The Manufacturing Growth Programme (MGP), which is designed and delivered by Oxford Innovation Advice, will see funding from the European Regional Development Fund end and is now urging the Government and local authorities to ensure that tailored advice for manufacturing SMEs is quickly put in place.

A recent independent evaluation of the programme found that MGP has delivered excellent value for money and achieved real results.

The report revealed that over 95% of companies surveyed expected their business to grow in the next five years because of receiving support from the programme, with 63% identifying the development of new products as one of the key areas.

In addition, 63% said they had already seen an increase in turnover, while 52% cited improved productivity as the main outcome of the support received.

MGP was established in October 2016 to address some of the main barriers to growth experienced by SME manufacturers.

Since then, it has been providing grant funding for business improvement/capital projects and specialist mentoring from industry experts, with 4564 companies assisted across the East and West Midlands, Yorkshire & Humber and the South East.

Its dedicated team of

Manufacturing Growth Managers has delivered more than £13.9m of grants that, in turn, have unlocked over £25.7m of private sector investment. Importantly, it also generated £42,073 Gross Value Added (GVA) per employee in the companies it supported.

The Manufacturing Growth Programme is the UK’s largest and leading business support programme for SME manufacturers, delivering consistent, tailored support across 183 local authority areas. The findings of this latest evaluation report have proved that the MGP model has worked effectively to address market failures.

The report additionally highlighted how Oxford Innovation Advice adapted the programme during Covid-19 and Brexit to continue delivering high quality business support and effectively assist manufacturing SMEs through these difficult circumstances.

Oxford Innovation Advice has over 30 years of experience in designing and delivering effective business support programmes that generate growth for businesses, local communities, and the economy.

The team has supported over 33,000 SMEs across the country and developed a suite of innovative resources and tools for businesses, policymakers, and funders.

For more information on Oxford Innovation Advice, visit www.oxfordinnovationadvice.co.uk

For more information on the Manufacturing Growth Programme, visit www. manufacturinggrowthprogramme. co.uk

Latest News 04 Manufacturing & Production Engineering Magazine

44 per cent of manufacturing workers find their work exhausting

44 per cent of manufacturing workers are finding their work exhausting with more than a quarter (26 per cent) feeling emotionally frustrated. These are the findings from O.C. Tanner’s 2023 Global Culture Report which collected and analysed the perspectives of over 36,000 employees, leaders, HR practitioners, and business executives from 20 countries around the world, including 2,792 from the manufacturing industry.

The report suggests a number of reasons why manufacturing employees are suffering both physically and emotionally, with a poor balance between their working lives and personal lives more likely to result in exhaustion and potential burnout. In fact, when an employee doesn’t have the balance right, they

are 89 per cent more likely to suffer burnout. An organisational culture that doesn’t prioritise staff recognition will also increase the odds of poor mental health, with employees who feel appreciated for their efforts and results, 80 per cent less likely to suffer burnout.

If employees are to obtain a healthy balance between their work and personal lives, the report recommends that leaders give their people a say in how they work, as well as what work they do. Organisations must also establish pragmatic practices and expectations that support balance, while ensuring employees have opportunities to take time away from work without feeling any pressure, guilt, or obligation to work during their time off. Ensuring senior leaders communicate and demonstrate the importance of

balance is also key, thereby making it a normal, natural part of everyday culture.

The culture must also be one of support and appreciation, in which frequently and authentically recognising employees’ efforts, achievements and career milestones becomes commonplace.

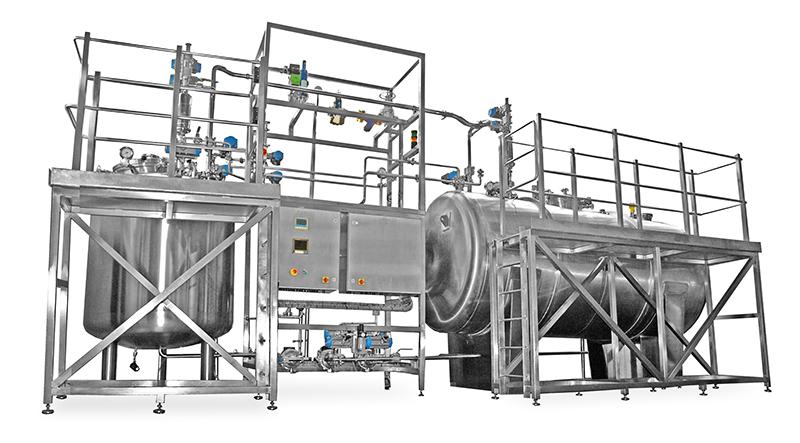

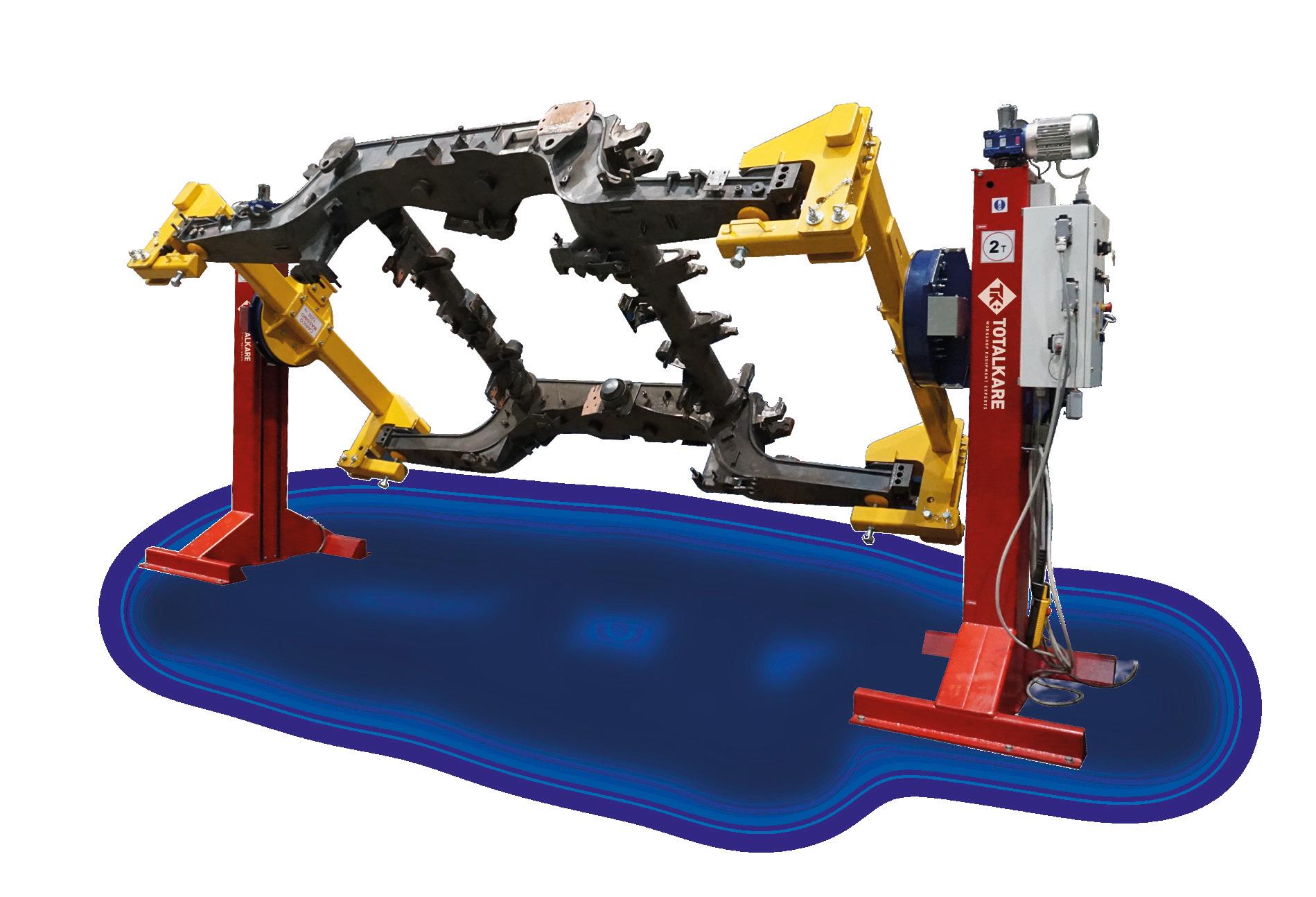

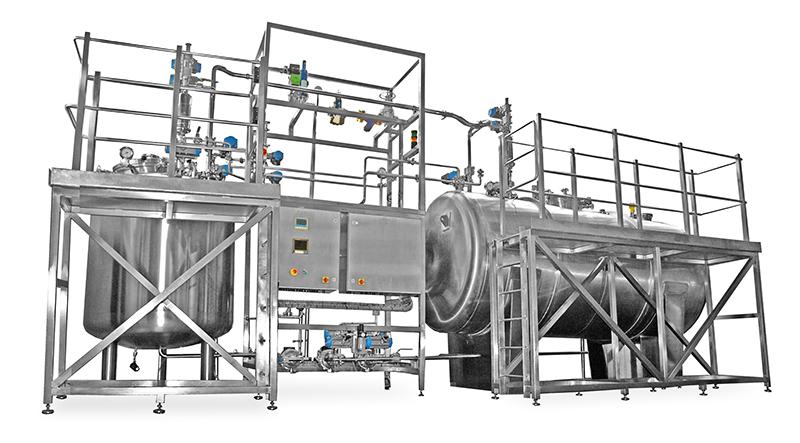

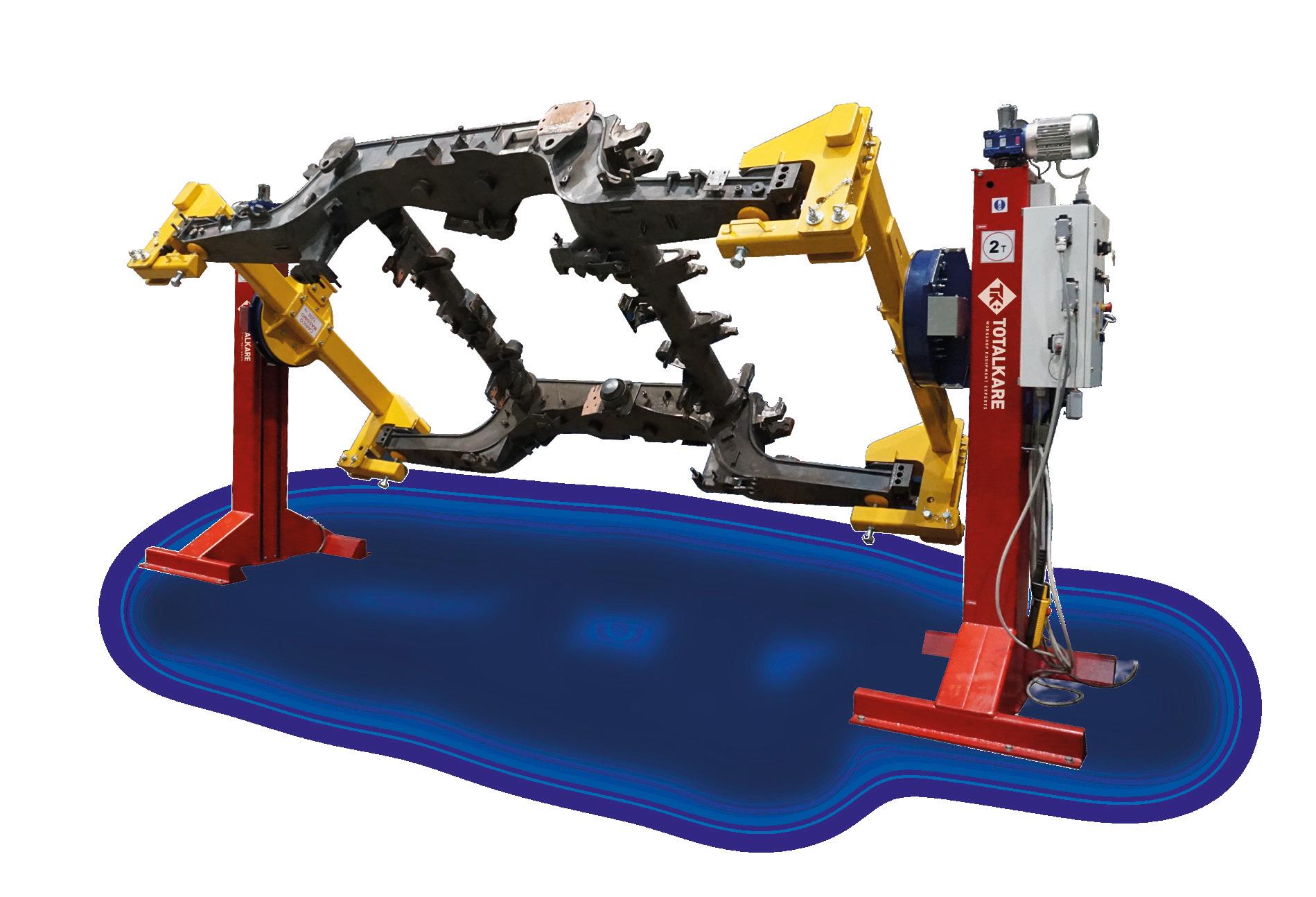

Totalkare’s ergonomic positioners are single or double column devices that enable the lifting and rotation of a product during welding and assembly operations.

With overall capacity from 2,000 - 90,000kg to suit, they are both compact and flexible.

05 Manufacturing & Production Engineering Magazine Latest News GET A QUOTE: T:0121 585 2724 / WWW.TOTALKARE.CO.UK

Caribbean Blinds expands installer partnerships after successful debut at FIT Show 2023

Outdoor shading manufacturer, Caribbean Blinds, has partnered with a number of new installers following their successful debut at this year’s FIT Show – the UK’s only dedicated event for the window, door, hardware and flat glass industry.

As the country’s number one fabricator and installer trade exhibition, the FIT Show celebrated its ten year anniversary at the NEC Birmingham from the 23rd to 25th May. Acting as the perfect platform to showcase their entire award-winning range of luxury external shading systems including patio awnings, louvered roofs and external blinds, Caribbean Blinds’ stand allowed installers to see and feel the superior quality and finishing touches of their products firsthand.

Magnetic Analysis Corp. Celebrates 95 Years of Leadership in Developing NDT Instruments and Solutions: The MAC® Edge Now Includes a New Milestone

Magnetic Analysis Corp.

(MAC®) is celebrating its 95th Anniversary in business this month, a milestone that commemorates nearly a century of service to the metals industry.

The company, which was founded in a small facility in Long Island City, New York, in 1928, is a recognized global leader in nondestructive testing. Today, operating on an international scale, MAC helps metal manufacturers around the world meet demanding specifications for Eddy Current, Ultrasonic, Phased Array Ultrasonic, and Flux Leakage test systems, along with application specific material handling,

The 95-year milestone is a testament to MAC’s longstanding dedication to customer service and technological advancement. “As we celebrate this anniversary,” says Dudley Boden, MAC’s President and CEO, “we focus on tomorrow’s opportunities.” Boden affirms that “testing demands placed on the metals industry will undoubtedly become more exacting and complex throughout the next five years, but the MAC team is dedicated—as we always have been—to meeting the highquality standards of our customers

and staying one step ahead of the curve.”

Joseph Baldauff, MAC’s Vice President of Technology, adds that “our continual upgrading of existing products and solutions reflects MAC’s ongoing commitment to delivering innovative, powerful, and robust solutions for NDT applications. Our success and longevity are due in part to the advanced capabilities we have brought to the market for nearly a century.”

MAC’s nondestructive test systems can be found testing wire, tube, and parts in mills throughout the world.

Three facilities form the backbone of the company: MAC’s ISO 9001-2015 certified manufacturing and engineering headquarters in Elmsford, NY; a manufacturing and ISO/IEC 17025:2017 laboratory- certified plant in Boardman, Ohio; and Magnetic Analysis Nordic’s manufacturing plant in Östersund, Sweden.

With the support of its subsidiaries and field engineering network, MAC serves customers throughout North America, Europe, Scandinavia, South America, India, Korea, China, and Australia.

The Sudbury based firm also introduced their latest awning and pergola sales aids, including sample kits that enable installers to effortlessly sell their products. Caribbean Blinds’ louvered roof pergolas attracted the most interest from installers over the course of the three-day event, with a total of 239 installers registering as partners at the show, and 10% investing in sampling there and then.

Caribbean Blinds is committed to helping installers maximise sales of external shading in conjunction with glazing and providing a profitable additional revenue stream as a result. The team strongly believes that the reason for the high registration rate was due to the ease of adding their products to any range, including their dedicated installer academy, the use of their own delivery vehicles and their two-week UK manufacture guarantee.

Since completing on its 10,000sq/ ft factory extension at the end of 2022, Caribbean Blinds has not only onboarded six new members of staff – with plans to recruit six more – but the company’s ability to hold much higher levels of stock has reduced both price volatility and lead times.

For more information, visit www.cbsolarshading.co.uk

Company News 06 Manufacturing & Production Engineering Magazine

Manufacturing and supply chain solutions group in £5.5m refinancing deal

A specialist manufacturing and supply chain advisory group has secured a £5.5m finance package from Frontier Development Capital (FDC) to support its growth nationwide.

The funding will enable Rugby-based Sirius A Corporation to consolidate its position as one of the UK’s largest outsourced suppliers of laser cutting, fabrication, precision machining and supply chain solutions services. It will also allow directors Bill Boswell and Ben Cufley to complete the management buy-

in they began in 2018.

Sirius, which now employs 160 staff at six locations, was founded in the 1970s when it made one of the first laser cutting machines in the UK. The business has grown steadily over the years as a result of increasing demand for low volume, high precision components used in industries such as cleantech, aerospace and non-automotive vehicle electrification.

As a result of a successful buy and build strategy, it operates under a number

£2m press investment for SDE Technology

A Shropshire-based pressings and assemblies specialist has invested more than £2m in acquiring its largest ever progression press.

SDE Technology has installed the impressive 1000-tonne Chin Fong press and coil handling line at its Brixton Way factory in Shrewsbury, an installation that will allow larger die usage and help create larger products for use in the automotive sector.

The press, which has a bed size of 4.5metres x 1.8metres, has capacity for over £2m of new revenue, with the management team already in discussions with larger OEMs and tier 1s looking for security of supply and

opportunities to de-risk the supply chain.

Eight new jobs have been created and tens safeguarded because of the investment.

“This is our largest ever progression press and one of the largest in the UK automotive supply chain,” explained Richard Homden, Managing Director of SDE Technology.

“It is a fantastic time to invest in this new capability. Yes, there are current headwinds, but for the bold there are also opportunities, with lots of reshoring, electrification and carbon reduction projects currently being discussed.

of different brands. They include Sirius Supply Chain Solutions and Precision Laser Processing in Rugby, Intec Project Engineering in Redditch, Laser Process in Cannock, Quality Components in Pontefract, LaserIT in Bristol and Essex Laser Job Shop.

Advisors on this deal include Debrett’s (Will Mason), Clarke Willmott (Kim Klahn), Browne Jacobson (Paul Ray) and Dains (Rob Wilson).

“The £2m investment will be a game-changer for our business and the West Midlands as a whole.”

SDE Technology is one of the largest manufacturers of pressings and assemblies in the UK, employing more than 130 people across its core production business and at Salop Haulage Ltd.

The company has overcome tough trading conditions, the pandemic, chip shortages and energy costs to secure several new opportunities in the automotive sector and is now planning on maximising its latest Hot Form Quench (HFQ®) process.

This is a revolutionary hot forming process for producing high strength aluminium parts for use in the automotive, aerospace, and renewable sectors and gives designers the freedom to create parts that offer significant weight savings, yet still deliver higher structural strength.

It also delivers improved formability in six and seven thousand series alloys that cannot be formed cold. In some instances, it can also reduce the part counts from multiple components to just one.

Chris Greenough, Commercial Director at SDE Technology, concluded: “The Chin Fong investment comes off the back of two earlier press installations, offering 100 and 200-tonne capabilities.

“These have been put in initially to deliver pressings for the white goods industry, but they could also be used to support other tooling projects going forward.”

For further information, please visit www.sde.technology

07 Manufacturing & Production Engineering Magazine Company News

Aquaterra Energy seals multi-million riser deal with BP

Aquaterra Energy, a leader in global offshore engineering solutions, has secured a multi-million subsea riser contract through a competitive tender with BP for a subsea well development project located in Trinidad and Tobago. Aquaterra Energy will provide a complete end-to-end managed service as a fully independent riser system and connector OEM.

The contract will see Aquaterra Energy deliver a subsea riser system to BP’s Cypre Project, off the southeast coast of Trinidad and Tobago. The system will be operated from a jack-up rig, supporting gas exploration from seven development wells in a water depth of around 80m. As part of the project, Aquaterra Energy will be providing local in country content, working alongside

local fabricators, and transferring knowledge to teams. Drilling activities are expected to commence in 2023 with gas production to begin in 2025.

James Larnder, Managing Director of Aquaterra Energy, said: “This contract cements our position as one of the leading riser system specialists globally. We’re proud to say we won our first riser contract with BP back in 2010, and 13 years on we continue to work together. BP chose us because we could deliver a fully integrated approach with access to solution driven engineers. This is one of the reasons why our riser project experience continues to grow, and I am looking forward to the next part of that journey.”

Andrew McDowell, Operations Director at Aquaterra Energy comments: “The win further demonstrates our

team’s global riser system expertise and collaborative approach to project delivery. We’re looking forward to sharing this experience and working closely alongside engineers in Trinidad and Tobago, sharing our knowledge and building on existing local capabilities.”

Aquaterra Energy will provide an integrated package of equipment, including rig modifications and personnel for full end-to-end delivery, focusing on enhanced offshore efficiency and improved safety.

Autonomous vehicle specialist lays foundations for growth with encouraging post IPO results

The company behind the driverless Auto-Pod and a new autonomous luggage/cargo dolly for aviation has posted a promising first set of results since it listed on AIM.

Aurrigo International plc saw revenues reach £5.3m for the year ending December 31st and has immediately set-out ambitious expansion plans to maximise new contracts in its automotive division and an exciting multi-year partnering agreement with Changi Airport Group

(CAG) in Singapore.

The company, which was founded by brothers David and Graham Keene thirty years ago, successfully raised £8m in the IPO last September and will be using the financial backing to roll-out its industry-leading transport technology in the UK, Europe, North America and Asia.

More than 30 jobs have already been created since the listing, with a fresh recruitment drive just beginning to take the workforce at its Coventry

Advanced Engineering Centre and international offices past 100 for the first time in its history.

There has been significant progress in all areas of the business since the IPO, with continued investment in R&D helping to bring to market the eagerly anticipated Auto-Dolly Mk3 and AutoDolly Tug Mk3 - the latter focusing on delivering an electric-powered tug that can be converted to autonomous in the future.

Both are currently being tested airside at Changi Airport as the aviation sector explores new ways in which it can become more efficient and, importantly, meet global commitments to improve environmental performance by reducing emissions.

Aurrigo’s autonomous technology offers solutions in both areas with the two vehicles designed to reduce baggage and cargo loading and unloading times, improve movement efficiencies around the airport and boost health and safety by eliminating a lot of the manual operations.

The fact that both are electric powered is a big ‘green’ positive, especially when you consider that they will increasingly replace old fleets of tugs that are diesel fuelled.

For further information, please visit www.aurrigo.com

Company News 08 Manufacturing & Production Engineering Magazine

DALBY EVOLUTION+ SPRAY BOOTHS

Proactive Energy Saving Technology

Gas Fired or Full Electric Option

Automatically modulating airflow with 100% in Performance mode & 50% in Economy mode.

“HighLight” high performance LED lighting system

Hi-visibility Mode indicator countdown timer

‘ProActive’ Touchscreen control

Stop/Start energy saving technology

Energy consumption as low as 1KW*

Energy Savings Of Up To 65%*

AquaDry blowers

Invertor control

Rear Extract, Pit extraction or Raised Floor airflow options

Conveyorised line options

Space Saving Design

Energy cost per job recording

Robotised paint application options

Turnkey installation available

enquiries@dalby.co.uk | 0116 291 6000

dalby.co.uk

Harry Dalby Engineering Ltd. Gloucester Crescent, Wigston Leicester, LE18 4YQ *Terms & Conditions apply Engineering the Highest finish

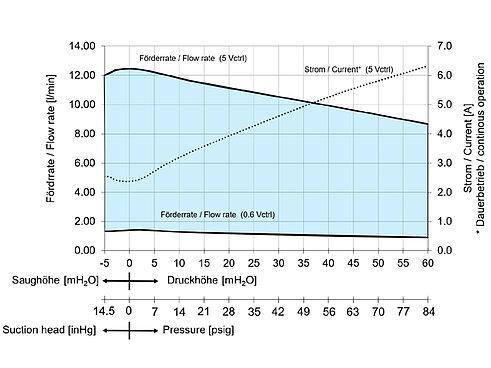

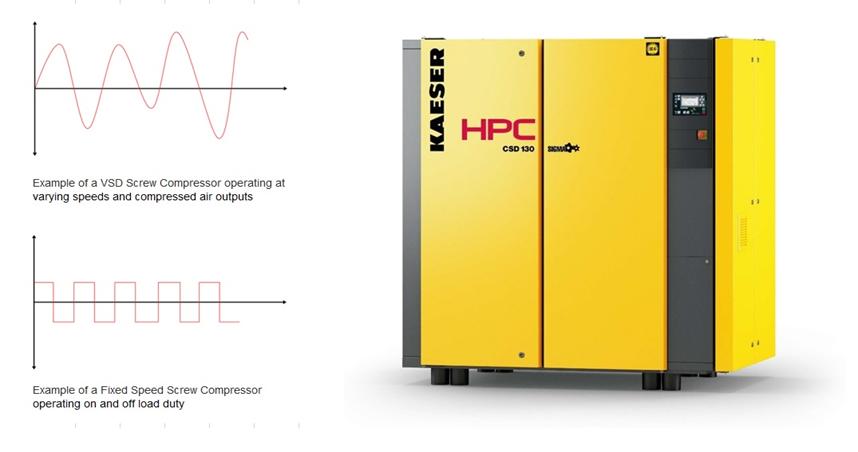

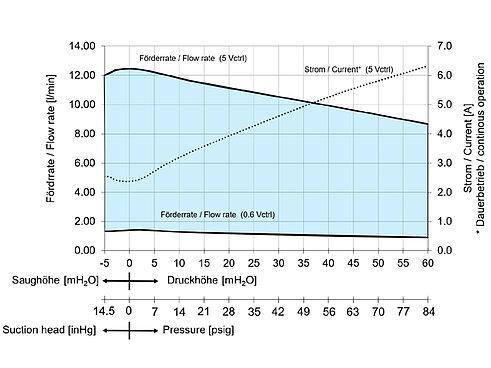

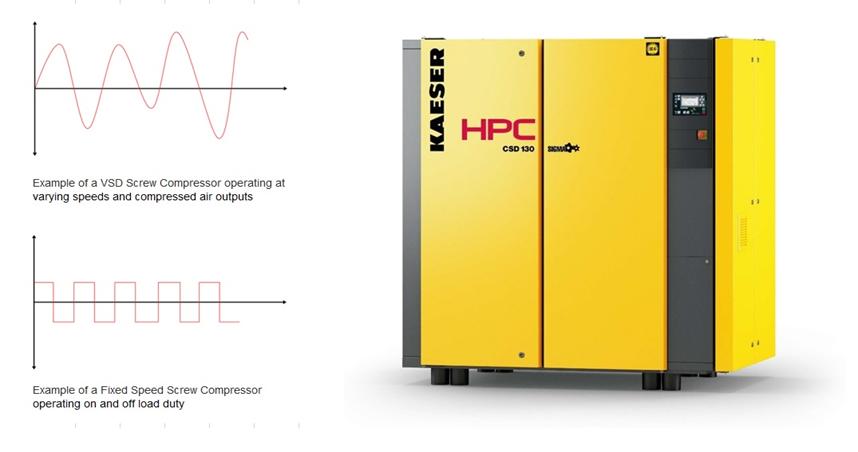

Why There’s No Such Thing As A OneSize-Fits-All Compressed Air Solution

A new White Paper by HPC Compressed Air Systems is challenging the notion that Variable Speed Drive (VSD) screw compressors are suitable for all applications.

Selecting the right compressor for a facility’s compressed air demands is vital.

Many compressed air providers will have customers believe that VSD screw compressors are the best option, no matter the application. But is this always the case?

In its White Paper, titled ‘Fixed Speed Drive vs Variable Speed Drive Screw Compressors’, HPC argues that VSD screw compressors are not the onesize-fits-all compressed air solution that VSD proponents would have customers believe.

Customers need to analyse their unique compressed air demands first, it says, to determine whether a Fixed Speed Screw Compressor, VSD Screw Compressor, or a combination of the two is right for their application.

In many cases, VSD Compressors will not be the most efficient or cost-effective choice.

Ultimately, what matters most, the White Paper says, is the compressed air system’s efficiency - and the key to a compressor’s efficiency is its Specific Power.

To ensure the best Specific Power, the White Paper recommends an Air Demand Analysis (ADA) is completed to

determine the customers individual air requirements.

Based on the ADA profile, it will be possible to identify the most economical and efficient configuration, whether that is a single or multiple Fixed Speed solution, a VSD solution, or a combination of the two.

What’s Inside HPC’s White Paper

HPC’s White Paper covers some of the most important considerations when choosing the right compressed air solution, including:

• The differences between Fixed Speed and VSD Rotary Screw Compressors

• How Fixed Speed & VSD Screw Compressors work

• Which type of Screw Compressor is the most efficient (and under what conditions)

• VSD Harmonics

• Motor energy losses

• Specific Power variances

• Energy savings

• The value in Compressed Air Energy Audits.

HPC KAESER: “More Air, Less Energy”

HPC KAESER’s strategy to specifying a compressed air solution boils down to “More Air, Less Energy”. HPC KAESER compressor stations are designed to ensure they have the best Specific Power to save customers on energy costs.

And HPC and its nationwide network of Authorised Distributors are experienced and qualified to design, install, and tailor the compressed air system to meet customer’s individual requirements while maximising efficiency.

To download the ‘‘Fixed Speed Drive vs. Variable Speed Drive Screw Compressors’ White Paper, visit: www.hpccompressors.co.uk/ white-papers

Find out more about HPC’s compressed air solutions and other services by visiting www.hpccompressors.co.uk

10 Manufacturing & Production Engineering Magazine

Compressed Air

Fluke Precision Acoustic Imager enables Air Liquide to cut costs, reduce waste and improve pipeline efficiency

Sustainability targets are encouraging industries globally to further improve the efficiency of operations. Advanced ultrasonic measurement devices are providing the required insights to reduce waste in gas distribution.

Air Liquide, the multi-national company supplying industrial gases and services to the health and industrial sectors has cut costs, reduced waste and boosted the efficiency of pipelines in Italy through the use of advanced ultrasonic measurement devices from Fluke

Air Liquide has benefited from the ii910 Precision Acoustic Imager, designed by Fluke to make it easier, faster and safer to carry out highsensitivity detection of gas, corona and partial discharge (PD). Suitable for use by operators with minimal training, the point-and-shoot device can also detect compressed air, gas and vacuum leaks, making it ideal for detecting leaks in gas distribution systems.

Strong sustainability agenda to drive energy efficiency

Driven by a strong sustainability agenda, Air Liquide wanted to increase energy efficiency and reduce its carbon footprint by tackling costly

leaks of air and nitrogen at its dual mixed refrigerant (DMR) refinery in Syracuse, Sicily. The company chose to carry out measurements every two years on all pipelines around the refinery – 7,000m for compressed air and 9,435m for nitrogen – as well as 5km of interconnecting pipelines. Leak detection and repair (LDAR) checks are also required every 12 months by Italy’s environmental regulator ISPRA. With a frequency range of 2kHz to 100kHz and 64 digital MEMS microphones, the ii910 makes it possible to locate leaks rapidly, detecting a 0.005 cubic feet per minute (CFM) leak at 100PSI from up to 32.8 feet (a 2.5cm3/sec leak at 7 bar from up to 10m). The acoustic imager also incorporates a 1280 x 800 resolution (1,024,000 pixels) LCD display and offers a battery life of more than six hours in the field. Finally, by eliminating the need for secondary cables or other devices, the ii910 gives operators the ability to swap easily between detecting the leak or PD and fixing them.

Several leaks rapidly identified Air Liquide called on the services of Belgium-based Intero – The Sniffers who carried out all the required measurements using the ii910 acoustic

imager. Thanks to highly sensitive sensors on the device that work with Fluke’s SoundSight technology, the imager’s ultrasonic signals quickly revealed several leaks on the refinery’s air pipeline and multiple leaks on the nitrogen system. This enabled Air Liquide’s engineers to take immediate action to minimise the leaks and achieve instant efficiency gains.

Says Sebastiano Carpinteri, Process Engineer at Air Liquide Priolo, says: “Because our Syracuse refinery operates on a 24-hour basis, avoiding downtime is essential. That means tests for leaks must be carried out as easily as possible and results analysed in the shortest time. Using Fluke’s ii910 Precision Acoustic Imager, measurements over the entire pipeline can now be assessed from a static position by just one person. The intuitive device clearly identifies leakages, enables measurements to be carried out without any kind of infrastructure required and makes it easy to produce up-to-date and accurate reports on the locations of leaks.”

More information on Fluke’s ii910 Precision Acoustic imaging equipment is available on the website.

11 Manufacturing & Production Engineering Magazine

Compressed Air

Ward CNC Continues Commitment to After Sales & Support with Key Appointment

T W Ward CNC Machinery Ltd (Ward CNC) are delighted to announce the appointment of David Cockbill who has joined the company in the position of Head of After Sales and Service.

David joins Ward CNC with a wide range of technical engineering knowledge and skills as well as a wealth of experience in after sales. David started his career as an Electrical Engineer with progression to more recent roles of heading up After Sales and Service departments with responsibility for driving the customer experience.

Operating from both Ward CNC’s Sheffield & Redditch showrooms, David’s responsibilities in managing the After Sales and Service team includes the overall responsibility for the company’s growing team of Field Service, Internal & Application Engineers, Projects & Installations, Quality/Health & Safety in addition to Customer Service & Spare Parts.

Commenting on his appointment, David states “I am privileged to have recently been appointed as Head of After Sales & Service with this well established and market leading Sheffield and Redditch based machine tool company. I am pleased to see even from my first few days with the company such a high performing team with a first-class reputation for After Sales Support.

“I would encourage both existing

and potential future customers to contact myself or one of our team to discuss all your After Sales and Service requirements.”

Speaking of David’s appointment, Executive Director Stephen Bodsworth states “We are delighted with the appointment of David which is fantastic news for our customers and colleagues alike.

“Working alongside Head of Technical Engineering Mario De Vito, we believe we have the structure and performance driven culture in place to ensure our customers receive the very highest level of After Sales & Service Support.”

Managing Director Simon Whitworth adds “David joins us at a very exciting time as we continue the investment into our stock portfolio, infrastructure, showroom facilities and people. In addition to the recent enhancements of our After Sales team, we have recently had further expansion of our UK-wide network of Regional Sales Managers.”

Epicor Appoints Chief Product & Technology Officer

Epicor, a global leader of industryspecific enterprise software to promote business growth, today announced Vaibhav Vohra has been appointed Chief Product and Technology Officer. With this move, the Product Development and Product Management teams will be unified under Vohra’s leadership, further enabling Epicor to deliver customer-centric SaaS solutions and continued innovation through AI, automation, and design.

“In his time at Epicor as Chief Product Officer, Vaibhav has been instrumental in driving our product strategy and spearheading the Epicor vision for the connected Data Supply Chain,” said Epicor CEO Steve Murphy. “We are confident that with Vaibhav’s leadership, we will continue to deliver the innovations and intelligence our customers across the Make, Move, and Sell industries require to compete in today’s marketplace.”

This transition comes after a collaborative succession planning effort alongside Bill Wilson, who over the past year has served as Chief Technology Officer leading the Product Development organization, delivering best-in-class, industry-focused technologies for Epicor customers. Wilson will continue serving as a technical advisor for all products and overseeing key customer initiatives, including leading the Retail product teams.

People On The Move 12 Manufacturing & Production Engineering Magazine

We are delighted with the appointment of David which is fantastic news for our customers and colleagues alike.

DF Capital appoints new managing director for commercial assets

DF Capital, the specialist commercial lending bank supporting dealers and manufacturers with working capital solutions, has appointed David Witherspoon as managing director - commercial sectors. David is responsible for all lending activity across agriculture, industrial and transport asset types and leads the bank’s sector manufacturer programme and client management teams.

David has over 30 years’

experience within the equipment finance lending space. For the past three years he has run his own consultancy delivering value added services to manufacturers, vendors and distributors as well as their financial services providers. Before that, he worked at DLL for almost 18 years in a variety of senior global roles. Earlier in his career, he also

worked for GE Capital, Woodchester Credit Lyonnais, Sabre Leasing and Mercantile Credit.

David Witherspoon, managing director - commercial sectors at DF Capital, commented: “It’s a pleasure to be joining an ambitious business which places great importance on its partnership approach to working with customers. My experience stretches across all the sectors DF Capital operates in today, so I look forward to getting to know my colleagues, our partners and hitting the ground running.”

Carl D’Ammassa, CEO at DF Capital, commented: “I am delighted to welcome David to the DF Capital team. David has depth of product and commercial sector experience having successfully led similar lending business at a local, regional and global level. As well as David’s proven leadership experience, his strategic mindset will be put to work to help us further grow the reach of our lending products across more sectors and asset classes so that we can support more manufacturers and dealers working capital needs.”

24/7 boiler room performance monitoring with Babcock Wanson’s Navinergy

Now available from industrial process heating specialist Babcock Wanson is the Navinergy digital platform for 24/7 boiler room performance monitoring. This innovative system allows customers to monitor their boiler room from any device, anywhere in the world, to optimise energy and water efficiency, and ensure regulatory compliance.

The Navinergy platform integrates all the components needed to supervise and operate the boiler room, including control, regulation, recording, visualisation and communication.

Navinergy is available with all Babcock Wanson firetube boilers and is fitted as standard with Babcock Wanson’s BW7DAYS seven day unattended boiler operating system.

For more information, including a short video on the benefits of Navinergy, go to www.babcock-wanson.com/2023/02/09/ navinergy-the-connected-boiler-room/, or contact Babcock Wanson on 020 8953 7111 / info@babcock-wanson.com

13 Manufacturing & Production Engineering Magazine People On The Move

Attitudes to funding…

At Close Brothers Asset Finance we regularly survey business owners in the sectors we fund, including Manufacturing. Taken from our latest survey, in this piece we focus on attitudes to ‘funding’, finding out, for example, if firms are planning on seeking funding, and if they’re confident about getting access to the loans they need to grow their business.

A key finding is that only half of Manufacturing firms are aware of Asset Finance, meaning a large number still haven’t taken advantage of the many benefits to be gained from leveraging value from their existing assets.

Access to funding

A third of Manufacturing business owners say getting access to funding is a ‘major challenge’ and more difficult now than it was a year ago. A further 56% tell us it’s a ‘moderate challenge’ and as difficult now to access finance as it was a year ago. Only 5% say it’s become easier.

Exactly 40% admit to having been declined access to finance by a bank in the last six months, but despite the additional challenges, 77% of Manufacturing firms are planning on seeking funding for investment in 2023, although 63% have delayed their investment decisions because of market uncertainty.

Funding options ranked in order of popularity: 1.

Unfortunately, 47% of Manufacturing respondents to our survey stated they had missed a business opportunity in the last 12 months because of a lack of available finance.

Impact of energy price rises

The increases in the cost of doing business, compounded by significant energy price rises, has had a major impact on businesses in all sectors, including Manufacturing, leading to 47% of firms in the industry needing to take out finance just to cover higher energy costs.

Nearly seven in 10 (67%) business owners disclosed that their energy bills had risen, with a further 59% stating it had impacted their profitability. As a consequence, 91% have implemented various energy-saving measures, including (in order):

1. Switching off lights

2. Lowering the thermostat

3. Turning off air conditioning

4. Insulation

5. Switching providers

Interestingly, well over half of firms polled said they’d consider moving to a four-day week to save on energy costs, which is well below the UK average of 57%.

For more information, please visit: closeasset.co.uk/manufacturing

14 Manufacturing & Production Engineering Magazine

Bank loan

Credit cards

Overdraft

Invoice finance

Finance lease

Personal / family funding

Hire purchase 8. Asset based lending 9. Operating lease 10. Refinance 11. Crowd / peer to peer

2.

3.

4.

5.

6.

7.

Asset Finance

A third of Manufacturing business owners say getting access to funding is a ‘major challenge’ and more difficult now than it was a year ago.

Nearly seven in 10 (67%) business owners disclosed that their energy bills had risen, with a further 59% stating it had impacted their profitability.

SUPPORTING THE UK MANUFACTURING

• Unlock the value of existing assets

• Invest in new equipment

• Create positive cash flow

All lending is subject to eligibility, status, and our lending criteria. The right to decline any application is reserved.

Brothers Asset Finance is a trading style of Close Brothers Limited. Close Brothers Limited is registered in England and Wales (Company Number 00195626) and its registered office is 10 Crown Place, London, EC2A 4FT.

Close

closeasset.co.uk/mpe

With specialist industry knowledge and tailor-made support, we offer a range of finance options which can allow you to:

Contact us today, we’re here to help

Tech Tips – Why the VOLLMER VGrind 340S is the machine of choice for medical industry tool manufacturers

As one of the world’s most heavily regulated industries, the medical sector and the manufacture of everything from pharmaceuticals and healthcare aids to surgical instruments, implants and prosthetics to dentistry – everything has to adhere to the most stringent of standards. So, when it comes to surgical cutting tools for the industry, the leading OEMs and their supply chain rely upon production machines from VOLLMER.

With a pedigree unsurpassed in cutting tool production, the latest VOLLMER VGrind 340S is the machine of choice for the medical industry. Here, Rotary Tooling Application Engineer and VOLLMER of Americas resident medical expert, Carlos Becerra explains why.

Whilst many industry segments utilise tools manufactured from materials like HSS, carbide and PCD; tools for surgical applications and orthopaedics are often manufactured from stainless steel. The main reason is that when surgeons are undertaking procedures like bone and cartilage drilling, grinding or shaving; carbide tools have the propensity to break or create excessive heat during operations. The ultra-hard characteristics that make carbide perfect for many manufacturing processes – are also the same attributes that make them unsuitable for invasive procedures. Surgical tools are generally manufactured from 174PH, 420, 440A, 455 or M2 tool steel with lengths from 50 to 250mm and diameters from 0.3 to 12mm. And here lies the challenge…

With small diameters and a stainless grade with a likelihood to deflect during machining, precision production can be a challenge.

- Carlos Becerra

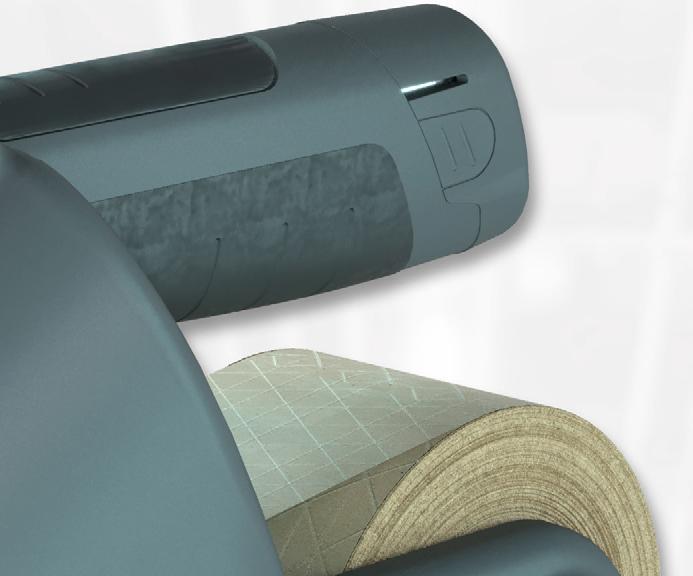

The Steady Rest & ‘Run-Out’

The steady rest is the single most critical factor in producing cutting tools to a standard beyond that made on rival machines. The innovative steady rest on the VGrind 340S supports the tool and prevents tool deflection during grinding. Any tool deflection will have an adverse impact on not just the precision of the tool, but also the ‘runout’. Surgeons’ hand tools typically operate at high speeds, exacerbating the ‘run-out’ impact of cutting tools. Run-out can result in reduced accuracy and even excess heat generation if a tool is rubbing against a bone instead of cutting. This can adversely affect the well-being of the patient. Run-out of up to 5mm is common in tools that are not precisely manufactured with a supporting steady rest to prevent deflection. Not only can excessive run-out generate excessive heat, but it

can also diminish precision where and when we need it most. Furthermore, excessive vibration in the surgeon’s hand tool can lead to….well let’s not think about those consequences.

To categorically eliminate this obstacle, the steady rest on the VGrind 340S provides support under the tool to prevent deflection – but it also provides a supporting finger over the tool body support to eliminate movement. However, VOLLMER has taken this innovation a step further, providing two steady rest points, and not just one. The steady rest system supports the cutting flutes of the tool as well as the cutting tip of the tool. With typical tool shank diameters for hand tools being 4.5mm and the cutting flutes often much smaller, the potential for deflection grows with decreasing tool diameters.

As you would expect from VOLLMER, we have doubled down on eliminating deflection, such is its importance and potential for disrupting the quality of cutting tools manufactured on the VGrind 340S. To eliminate deflection, VOLLMER has also introduced automated tool run-out compensation. Integrated into the NUMROTO control software, the run-out compensation cycle will utilise a measuring probe during operation to probe tools in multiple positions around the diameter of the tool. Taking live ‘in-cycle’ measurements, the VGrind 340S will automatically measure the tool and re-calibrate the programme to accommodate and eliminate any tool deviations caused by deflection. This in-process cycle can be programmed to run at intermittent periods throughout a production cycle. So, for tools with critical dimensions, probing can be integrated into the production of every tool, or if the operator prefers – every 10, 20 or 50 tools.

16 Manufacturing & Production Engineering Magazine

The innovative steady rest on the VGrind 340S supports the tool and prevents tool deflection during grinding.

Machining & Machinery

Automation

The OEM recipients that specify medical and surgical procedure tools often require high production volumes that can be in the region of 5,000-off. To support precision volume production, the VGrind 340S is supported by the HP160 automated tool loading system that can accommodate up to 900 tools. The HP160 loading system on the VGrind 340S facilitates 900 tools with the medical standard 4.5mm diameter shanks. The number of tool positions decreases depending upon the shank diameter.

Not only does the VGrind 340S accommodate up to 900 tools, but manufacturers can also set the machine to run multiple programmes sequentially without manual intervention. So, if a company needs to run a batch of 50 3-flute tools and then 500 2-flute tools of different diameters and geometry that are then followed by other tool variants - the VGrind 340S can easily accommodate this. The result is unmanned operation, reduced costs and around-the-clock production – all

- Carlos Becerra

- Carlos Becerra

technology and process stability –running through the very DNA of the machine is a high level of flexibility. The VGrind is the only machine to incorporate multi-level machining with two spindles located on its A-axis. Feeding this paradigm leap in innovation is a grinding wheel package that accommodates up to 8 wheel sets. With 8 different wheelsets, the VGrind 340S can automatically change from a flute grinding wheel to a gashing wheel, cup wheel, a 1A1 wheel for relief and OD grinding or any other type of wheel.

with complete process stability. Having supported medical companies for several years, I can comfortably say that the technology in the VGrind 340S has been able to manufacture 100% of the tools that I have encountered to date.

Flexibility

To produce 100% of the tools that I encounter daily, the VGrind 340S not only delivers astounding productivity,

This flexibility enables the VGrind 340S to produce an unparalleled variety of cutting tools with zero manual intervention. With in-process grinding wheel probing and automated wheel dressing; long periods of precision lights-out production can be achieved – regardless of the multiple tool types required. The flexibility of the VGrind 340S is complemented by the next-generation V@DISON IoT digital solutions and the NUMROTO tool grinding software to enable customers to stretch their imagination with cutting tool design.

17 Manufacturing & Production Engineering Magazine

Machining & Machinery

The OEM recipients that specify medical and surgical procedure tools often require high production volumes that can be in the region of 5,000-off.

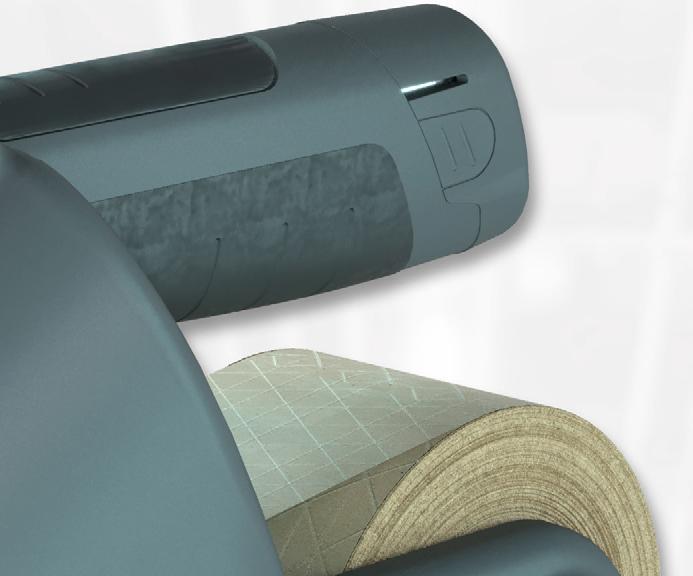

Revolutionary Electroform technology from Holdson set to disrupt manufacturing industry

Holdson, a UK-based electrochemical polishing machine tool supplier, has announced the launch of its flagship product, the Electroform machine.

Powered by a one-of-a-kind dynamic contour electrode and utilising machine learning algorithms, Holdson’s Electroform technology ensures optimal polishing for additively manufactured components.

These cutting-edge, patent-protected machines are designed to address the challenges of traditional mechanical polishing, offering significant cost savings and increased throughput while being more environmentally friendly.

Holdson’s Electroform machines operate up to six times faster than competitor machines, and their unique technology allows for superior control over material removal rates helping to achieve extremely precise surface finishes. Furthermore, the technology is protected by patents, ensuring Electroform’s competitive advantage in the marketplace.

The company’s commitment to sustainability has meant that the electroform machines have been developed to use recyclable consumables and electrolytes. This closed-loop system eliminates hazardous waste and reduces the risk of exposure to hazardous materials.

Developed with the medical, automotive, and aerospace industries in mind, Holdon’s Electroform series of machines act as a cost-effective and high-quality solution for post-processing metal

components that have been additively manufactured.

Holdson has been developed over the past several years by a team of experts with decades of combined experience in materials technology, metallurgy, and precision engineering. The company’s team is dedicated to creating a sustainable and efficient manufacturing process that provides high-quality results for its clients.

Neil Dickinson, Chief Technology Officer at Holdson said: “We’re thrilled to finally launch Holdson and introduce our patented Electroform series machine to the market.

“Our machine is a game-changer for the manufacturing industry, providing a faster and more efficient solution for post-processing metal components. And with our focus on sustainability, we’re confident that we’re providing a responsible and effective solution for our clients.”

Holdson has already secured significant traction in the marketplace, with firm orders and commitments for multiple machines. Furthermore, the company has formed part of a major InnovateUK collaboration, showcasing the innovative and disruptive nature of its technology.

Chantelle Brandon Reeves, Senior Innovation & Growth Specialist at Innovate UK EDG said:“Innovate UK EDGE are proud to be supporting Holdson on its growth journey. The innovative business is poised for rapid growth in the coming years. We look forward to seeing what the future holds

for this company, and are positive that Holdson’s revolutionary product offer can make a significant impact on the medical, aerospace, automotive, and energy sectors.”

Holdson is now accepting orders for the Electroform series machine, with delivery expected to begin later this year. With a commitment to sustainability and a focus on innovation, the company is poised to become a leader in the electrochemical polishing industry.

Robert Woollin, Industrial Engagement Manager at AMPI said: “I am thrilled to see Holdson launch their innovative Electroform machines, which have the potential to revolutionise the electrochemical polishing industry. AMPI looks forward to supporting Holdson’s growth through its UKRI Strength in Places Fund innovation programme and building a strong relationship over the coming months.”

For more information visit: www.holdson.co.uk

18 Manufacturing & Production Engineering Magazine

Machining & Machinery

Neil Dickinson, CTO Holdson

Pentagon, pro-actively supporting you from the early stages of design assistance right through to mould tool manufacture and repeat production of your injection moulding project. Your new or existing plastic injection moulding project will benefit from years of technical moulding experience!

DESIGN DEVELOPMENT MOULDING TOOLING BEYOND THE MOULD

UK Manufacturing services delivering ease of communication and a smooth supply chain www.pentagonplastics.co.uk | websales@pentagonplastics.co.uk Tel: +44 (0) 1403 264 397 |

Canadian-based ice resurfacing specialist Resurfice Corp (“Resurfice”) has returned to Thordon Bearings (“Thordon”) with a repeat order for its grease-free SXL and ThorPlas-Blue polymer bearings for Resurfice’s Olympia range of ice arena resurfacing machines.

In a relationship dating back almost thirty-years, Thordon has supplied more than 700m (2296.6ft) of the robust material to Resurfice – enough to span the length of eleven ice hockey arenas – with Resurfice usually placing two orders each year.

The most recent order is for 22m (71.2ft) of SXL and 4m (13.1ft) of ThorPlas-Blue, held in stock for quick and easy machining to Thordon’s specifications for installation to existing and newbuild machines, including the self-propelled, all-electric Olympia Millennium E.

Each ice resurfacer takes six to ten SXL bearings in the augers that gather the ice chips off the rink and then lift them into the hot water tank. Resurfice has also started using the heavy-duty ThorPlas-Blue material in the Olympia steering linkage assemblies.

Greg Auger, Commercial Director at Millstream Engineering, Thordon’s authorized industrial distributor in Ontario, Canada, said: “These machines return from arenas all over the world for a major overhaul every ten years or so, but will also use the

bearings for servicing and refits as well as for new machines. The use of polymer grease-free bearings has certainly been an important factor in the evolution of ice resurfacing technology.”

“Thordon’s proprietary bearing polymers have been hugely successful in our ice resurfacers,” said Lisa Schlupp, Purchasing Manager at Resurfice Corp. “They are very durable, resulting in minimal maintenance for our ice stadium customers. If you’ve got oily, greasy bearings and the grease drips onto the ice rink, then you end up with a mass of black spots trapped in the ice. Hockey players, skaters, and other winter sports enthusiasts expect a clean, smooth, and debris-free arena and that’s why these machines have to use grease-free bearings in their rotating components.”

Scott Groves, Thordon’s Vice President, Sales, said: “Ice resurfacing is very much a niche market; a niche within a niche. As with other types of industrial machinery, our greasefree polymers check all the boxes. They are durable, robust, and selflubricating, and easy to machine which saves manufacturers and operators considerable time and money. We have had a long relationship with Resurfice, which, like Thordon, is a family-owned business with a solid reputation for quality, reliability, and environmental sustainability.”

Ice resurfacers are large electric or mechanical machines used in winter sport arenas to scrape, clean, smooth and polish the ice surface. The main components include a “snow box,” hot water tank, wash water tank, a conditioner, and a broad bush.

As the resurfacer moves around the rink it cuts away a razor thin layer of ice, lifting the flakes into the snow box. At the same time, any dirt and debris are lifted into a waste tank, as clean water sprays the surface to “condition” the ice layer and even out any skate marks and grooves, leaving a smooth, glossy finish.

Resurfice Corp has been at the forefront of ice resurfacing technology for more than 50 years. In 2016, the company unveiled the OLYMPIA Millennium H, representing a quantum leap forward in performance, precision control, and fuel efficiency. The company’s first fully electric OLYMPIA Millennium E was launched in 2008.

20 Manufacturing & Production Engineering Magazine

Resurfice machines keep the ice clean and smooth with Thordon grease-free bearings

Machining & Machinery

Tiger·tec® Gold

Fascinating milling work. Exciting solutions.

Go for better, go for Gold

Efficiency-oriented businesses cannot make any compromises when it comes to milling. Customers seeking to optimise their production must not only improve their productivity, but also guarantee process reliability. Rely on power and expertise for your milling work. High-performance milling: Tiger·tec® Gold.

tigertec-gold.walter

Application - Aircraft Screwdriver Fastener Torque Control

Interface Force was recently approached by an Aircraft manufacturer who wanted to ensure the correct torque and clamping force were being applied to fasteners during assembly.

The Customer’s Challenge

An aeroplane manufacturer needs a solution where they can control the torque when fastening screws on their aeroplane models. They do not want to create any damage to materials or apply too much torque when plane components are being fastened together.

Interface’s Solution

Interface’s Model T15 Hex Drive Rotary Torque Transducer can be attached to the fastening workbench, measuring and recording torque, rotational speed and angle of the screwdriver. The LWCF Clamping Force Load Cell is installed, measuring the forces applied on the screw being fastened.

Interface’s Model T15 Hex Drive Rotary Torque Transducer can be attached to the fastening workbench, measuring and recording torque, rotational speed and angle of the screwdriver.

Results are sent to the SI-USB4 4-channel USB Interface Module, which is connected to the customer’s PC or laptop where data is logged, graphed and displayed.

The Results

The aeroplane manufacturer was able to calibrate their screwdriver by measuring its torque, rotational speed, and angle when attaching components to their aeroplane. They were also able to measure the forces being applied to the screw, to ensure it was not applying too much torque to the components.

Items Used to Complete the Test

• T15 Hex Drive Rotary Torque Transducer

• LWCF Clamping Force Load Cell

• SI-USB4 4-channel USB Interface Module

• Customer PC or Laptop

How It Works

1. The T15 Hex Drive Rotary Torque Transducer is attached to the screwdriver fastening bench.

2. The LWCF Clamping Force Load Cell is placed beneath the bolt head.

3. The T15 Hex Drive Rotary Torque Transducer measures the screwdriver’s torque, rotational speed and angle, for the customer to determine the right amount of torque needed to be applied to the screw to prevent any damage to the materials being fastened together.

4. The LWCF Clamping Force Load Cell measures the forces applied to the screw, so the customer can determine the maximum torque it can take.

5. The measurements and results are sent to the SI-USB4 4-Channel USB Interface Module, where the customer can record the results when connected to their PC or laptop.

For more information about the force and torque sensors mentioned in this application note or how Interface Force Measurements could help with your force, torque or pressure measurement challenges please email us at info@interface.uk.com or visit our website www.interfaceforce.co.uk

22 Manufacturing & Production Engineering Magazine

Measurement, Sensors & Monitoring

TVR Instruments Limited 143 Butt Road, Colchester CO3 3DP Essex UK, Tel: +44 (0) 1206 575755 Email: sales@tvri.co.uk www.tvri.co.uk Your partner in UK and Ireland Instruments Ltd Temperature-Relays and Sensors Monitoring of Current, Voltage and Phase Controls for Suction Plants Relays for Frequency and Speed Measuring-Transducers ZIEHL industrie-elektronik GmbH + Co KG Daimlerstr. 13, 74523 Schwäb. Hall, Germany, +49 791 504-0, www.ziehl.de Measuring, Controlling, Monitoring - on highest level

How Sensors Are Used to Enable Smart Factories and More Efficient Manufacturing, Reports IDTechEx

By Yulin Wang, Technology

With the high inflation, increasing labor costs, labor shortage, energy crisis, and hybrid working, the manufacturing industry experienced significant turmoil in 2022. Although some of these have started to get eased, 2023 is still expected to be a challenging year for the manufacturing industry.

Forbes recently published an article, “The 5 Biggest Business Trends In 2023 Everyone Must Get Ready For Now”, listing a few key transitions in the manufacturing industry. One of the most interesting transitions in the manufacturing business is the trend toward digital transformation. Digital transformation, along with Industry 4.0, has been a buzzword for many years. However, despite the fancy name, digital transformation is often a vague concept for manufacturers. IDTechEx believes that digital manufacturing can be deconstructed into two main themes: safe human-robot interaction (HRI) to achieve higher productivity and an increased level of autonomous mobility for material and goods transportation. These themes are ultimately enabled by cutting-edge sensor technologies.

Yulin

Safe HRI to Achieve Higher Productivity

Safety has always come as the overarching priority when it comes to using robots/machines in the manufacturing industry. Robots can pose a variety of hazards to workers. For example, while industrial robots are designed to operate at a safe distance from people, these devices traditionally lack the sensory skills required to identify

adjacent humans. Recently, with the fast adoption of collaborative robots (cobots), human operators are directly exposed to the workspace of robots, which can lead to further collisions, risks, and dangers. In order to mitigate safety concerns, IDTechEx has seen multiple sensors, such as force and torque sensors, LiDAR, and tactile sensors being installed on robots to equip them with better environmental perception and collision avoidance capabilities. One of the critical applications of sensors in robots is proximity detection and collision detection. Proximity detection can be achieved using photoelectric sensors (photoelectric fences), LiDAR, and capacitive proximity sensors. Photoelectric sensors/light curtains can be an ideal solution for industry robots. A safety light curtain is made up of a transmitter and a receiver. The transmitter transmits modulated infrared light, which is received by the receiver to create an array of light beams (also known as a light curtain). When a human operator enters or is blocked by the protection net, the light receiver circuit replies through the internal control circuit, which outputs a signal to the machine, causing the machine to slow down or stop its operation, thereby preventing the occurrence of a potential collision.

By contrast, force and torque sensors are commonly used for cobots when it comes to collision detection. Unlike industrial robots, cobots work in the same workspace as humans, meaning that a physical light curtain/fence would not suffice. IDTechEx noticed that the majority of commercialized cobots are equipped with at least one force/torque (F/T) sensor at their joints. F/T sensors have two main functions, including force measurement and collision detection. F/T sensors are typically installed around the robot’s end-effectors to measure the force. Depending on the tasks, the range of forces needs to be preset, and when the collision happens, the force or torque

24 Manufacturing & Production Engineering Magazine

Measurement, Sensors & Monitoring

Analyst at IDTechEx Safety has always come as the overarching priority when it comes to using robots/machines in the manufacturing industry. Robots can pose a variety of hazards to workers.

-

Wang

Tinytag Data Loggers: Robust Environmental Monitoring Solutions

Data loggers for indoor, outdoor and industrial/process application

• Rugged and compact

• Easy to use

• Dust, splash or waterproof

• Data downloaded to PC

• Cost-effective

Manufactured in the UK

Accompanying probes are available for monitoring extremes of temperature, and for awkward to reach areas such as pipework.

For sites requiring remote data access, Tinytag Radio and LAN loggers gather data automatically for viewing on a PC, across a LAN, or remotely across the inter net.

Plus 2

Rugged outdoor/industrial temperature/RH logger

From £110 +VAT

Energy Logger

Non-invasive single & three phase power monitoring

Full kit £995 +VAT

Tinytag Ultra 2

detected by the sensor will exceed the pre-determined range, thereby informing the robot to stop its operation. With the increasing safety requirement of HRI, more F/T sensors are expected to be installed. Most cobots have one F/T sensor installed at this stage, typically around the end-effector. However, IDTechEx has noticed that a few cobot OEMs (e.g., Franka Emika) are starting to incorporate more torque sensors on all the joints to enable better force control and collision detection.

Increased Level of Autonomous Mobility

Autonomous mobility is one of the most important parts of a robot’s autonomy. Autonomous mobility requires the robot to have the capabilities of navigating, localizing, and avoiding obstacles. In the context of the manufacturing industry, mobile robots, especially automated guided vehicles (AGVs) and autonomous mobile robots (AMRs), will be used for material transportation. The autonomous mobility function of mobile robots is enabled by sensors such as LiDAR, cameras, and ultrasonic sensors. Different sensors have benefits and drawbacks, and in reality, multiple sensors are usually used in combination with each other to achieve the best overall performance. For instance, LiDAR is relatively easy to use, and they are immune to poor weather. However, LiDAR usually comes with a high cost.

By contrast, cameras or imaging sensors are the only ones that can be used for object classification/recognition, but they have poor performance when it comes to adverse weather or limited

visibility. In terms of the manufacturing industry, IDTechEx believes that cameras will be increasingly adopted because those robots tend to work in a well-controlled indoor environment with stable illumination. At this stage, IDTechEx believes that many indoor AGVs in the manufacturing industry can perform on level 3 autonomy, meaning that the robotic onboard systems can achieve most of the autonomous driving tasks and multiple AGVs can be monitored simultaneously by one operator. With the trend toward level 4 and a higher level of autonomy, IDTechEx believes that more robust sensors will be incorporated. A detailed analysis of the market forecast can be found in IDTechEx’s latest research, “Sensors for Robotics 2023-2043: Technologies, Markets, and Forecasts”.

To find out more about this IDTechEx report, including downloadable sample pages, please visit www.IDTechEx.com/ rosensors

25 Manufacturing & Production Engineering Magazine temperature » humidity » power usage » co2 » count » voltage » current

Gemini Data Loggers (UK) Ltd Scientific House, Terminus Road, Chichester, West Sussex, PO19 8UJ, England

Telephone: +44 (0)1243 813000 email: info@tinytag.info www geminidataloggers.com www.tinytag info

Automatic data collection Bundles – 3 loggers/receiver/ software from £1,100 +VAT Radio and LAN Indoor temperature & RH From £80 +VAT

Tinytag

Measurement, Sensors & Monitoring

Autonomous mobility is one of the most important parts of a robot’s autonomy. Autonomous mobility requires the robot to have the capabilities of navigating, localizing, and avoiding obstacles.

- Yulin Wang

Farnell raises

Turnbull & Scott win the 2023 Sustainable Development Award!

£4000

for Leeds hospice in memory of much-loved colleague

Farnell colleagues have raised more than £4000 for a Leeds hospice after completing a charity walk in memory of a colleague who sadly passed away last year.

Jason Stokes joined Farnell in 2012 in the role of Technical Content Editor before going on to deliver the role of Product Manager. On 20th November 2022, Jason died after bravely battling a rare form of cancer and, in his memory, colleagues from Farnell have undertaken a charity walk to raise funds on behalf of St Gemma’s Hospice, where Jason spent his final days.

Starting at Farnell’s head office, 21 colleagues completed the 21 mile route around Leeds in 6.5 hours, taking in some landmarks across the city that were significant to Jason including his first house, Headingly cricket stadium, St Gemma’s Hospice and Elland Road, the home of his beloved Leeds United. At the time of writing, a total of £4,157 + £596 in GiftAid has been raised.

Joshua Ahern, Farnell Product Manager for Interconnect, said: “Jason was a muchloved colleague and friend to many at Farnell and we are proud to have raised so much money for a fantastic cause in his memory.

“The money donated will help fund the amazing team at St Gemma’s Hospice and, although the care they gave Jason in his final days can never be repaid, we hope that the funds donated will help.”

Everyone at Turnbull & Scott is extremely honoured to be recognized by Scottish Engineering as the Sustainable Development Award winners. We are continually committed to investing in innovative products and in our dedicated workforce so that we can help our customers solve and deliver the solution to their comfort or process heating, drying, cooling, chilling, and energy saving challenges. In doing so, we are increasingly passionate about helping companies work toward a NetZero future.

This award comes as a great birthday present for the company as we celebrate our 90th Anniversary this year and reaffirms our belief that we are on the right track to have another successful 90 years ahead!

Our Managing Director Peter Murphy commented on the award win, “We are delighted to be receiving this award in 2023, the year we celebrate our 90th birthday.

“We have been quietly helping our customers to reduce their heat energy consumption for much of that time and to receive the

Sustainable Development award is a huge honour, particularly in 2023 with so many companies doing so much wonderfully innovative engineering to solve the climate change challenge.”

Winning the award rounded off a great week for Turnbull & Scott after exhibiting at the 2023 All-Energy event in Glasgow. It was great to connect with so many amazing people across the two days and discuss the creative ways in which we can help customers with their energy saving challenges.

Events & Awards News 26 Manufacturing & Production Engineering Magazine

We have been quietly helping our customers to reduce their heat energy consumption for much of that time and to receive the Sustainable Development award is a huge honour.

Events & Awards News

Manufacturers scoop eco innovation awards following groundbreaking R&D programme

Three manufacturers have scooped awards for eco innovations developed as part of a groundbreaking R&D programme.

Relic Plastic CIC, based in Heysham, ELE Advanced Technologies, based in Colne, and City Centre Commercials, based in Liverpool, were recognised for their climate change action at the Eco Innovation awards, organised by Eco-I North West (Eco-I NW), a research and development programme to create new sustainable technologies, products and services.

The programme is delivered by a consortium of universities - Lancaster, Central Lancashire, Cumbria, Liverpool, Liverpool John Moores and Manchester Metropolitan - and will have given more than 330 SMEs access to the extensive knowledge base, cutting-edge research facilities, built new networks to drive innovation, and supported the development of innovative solutions which will save 3,850 tonnes of CO2.

Relic Plastic CIC, based in Heysham, who manufacture high-quality, handmade products such as shower combs, knife handles and furniture using postconsumer plastics such as DVD cases, bottle tops, sweet tubs, and industrial plastic waste.

Working with University of Central Lancashire and Lancaster University it has been able to increase its partnership with the community including 50 businesses, schools and community groups to reduce plastic waste in landfills

and increase awareness and sustainable action.

The ‘Most impactful undergraduate’ award went to Lee Ollerenshaw from the University of Central Lancashire, who worked with ELE Advanced Technologies, a high precision parts manufacturer based in Colne. The project focussed on improving resource optimisation and waste management and supported the company’s net zero roadmap.

The ‘Best concept in development’ award went to City Centre Commercials, based in Liverpool, who worked with Liverpool John Moores University to manufacture and test its novel GeoBrick, a clay-free unfired brick which is made from recycled aggregate from construction, demolition, and excavation waste.

Eco-I NW, which is part funded by the European Regional Development Fund (ERDF), was led by the Centre for Global Eco-Innovation (CGE) team at Lancaster University.

Gühring Celebrates 50th Anniversary

On the 19th of May, Guhring UK celebrated its 50th anniversary in style with a celebratory event at its Birmingham headquarters. Hosted at the state-ofthe-art manufacturing site in Estone Drive, Guhring welcomed technical partners, customers, suppliers as well as esteemed guests such as Chairman of the Board Oliver Guehring.

Guhring UK was founded 50 years ago in a rented facility a few miles from its existing site as an operation that was only selling drills to local manufacturers with a trade counter for ‘walk-in’ ordering. Wind forward to today and the company operates from a 60,000sq/ft manufacturing facility that produces solid carbide and HSS round tooling as well as PCD tools with a complete service for bespoke specialised tooling production, regrinding and service, coating, tool design and much more. Opening proceedings, Guhring UK Managing Director

Chris Weston presented the company’s first product catalogue from 50 years ago and discussed the journey from a small local supplier to one of the UK’s most successful cutting tool manufacturers. Chris said: “Today, the range has grown exponentially. We can now offer almost every rotary cutting tool from drills, reamers, taps and milling cutters in HSS, carbide, PCD and Cermet along with grooving tools, tool holders and vending and tool management systems. Most of these tools are manufactured here in the UK and we also hold up to £5m of inventory of standard product lines for next-day delivery.”

Looking to the future, Chris continued: “Moving to this fantastic facility in 2017 was a huge leap forward and it will be the springboard to help us grow over the next 50 years.

“We have 35,000sq/ft of land to expand our manufacturing capabilities – futureproofing our business for the long term future.”

27 Manufacturing & Production Engineering Magazine

Altus Introduces

a New High-Resolution Quins Inspection

Solution to Meet Growing Demands in the Electronics Industry

Altus Group, a leading supplier and service provider of capital equipment for the electronics industry, is pleased to introduce the innovative new Quins HR inspection solutions to its customers in the UK and Ireland. Developed by Quins with customer feedback in mind, these new high-resolution units are designed to effectively address the increasing challenges faced by manufacturers due to the shrinking size of components and the growing demands of inspection requirements. With the widespread adoption of 01005 components, the need for the highest level of accuracy in inspection

has become crucial to ensure fault detection and traceability for production support. The Quins LC20HR and LC20HR/UV units offer unparalleled image quality and resolution and is equipped with the LS30 Quins box boasting an impressive 4800 dpi capability. The system is accompanied by an upgraded SL300 computer, delivering enhanced data processing capabilities to handle the increased demands of modern inspection applications.

The enhanced resolution of the Quins LC20HR and LC20HR/UV units ensures that even the smallest components can be accurately inspected, meeting the stringent quality standards of the

New Cesium Atomic Clock Provides Autonomous Precise Time of 100 ns Holdover for Months

From everyday applications such as mobile phones and banking to complex underwater defense missions, the need for synchronized precise timing and frequency solutions is critical to safeguard and process data as intended. Many of these applications rely on Global Navigation Satellite Systems (GNSS) to provide that precise time and frequency, but GNSS is susceptible

to jamming and spoofing attacks. To provide multiple industries— including telecommunications, data centers, metrology, aviation and defense—with a long-term and precise timing and frequency solution, Microchip Technology announces the 5071B cesium atomic clock that can perform autonomous time keeping for months in the event of GNSS denials.

Microchip’s 5071B is the nextgeneration commercial cesium clock to the existing 5071A, which has been the primary contributor to international time for more than three decades. The 5071B is available in a three-unit height (3U) 19-inch rackmount enclosure, providing a compact product to work in environments where it can be easily transported and secured versus a larger

industry. The higher computing power also supports the enhanced processing required to maintain efficient production operations. Additionally, the modular software employed in all Quins variants makes inspection easy and stress-free for new product introduction (NPI) and smallscale production runs.

Anthony Oh, Operations ManagerInspection Products at Altus Group, said: “We have had a great run since we partnered exclusively with Quins to support the UK and Irish market with their processes. Their products are really enjoyable to support, our customers find their products very interesting and valuable to use throughout the production process. What is ideal about Quins is that a single unit can be used for so many inspection processes to generate returns. This latest variant catering for 01005 components will only ensure that the offering of Quins remains complete and future proofed for many sites.”

“We are always listening to customers and trying to stay ahead of their needs,” said Quins CEO Klaus Kornhaas. “We are seeing more and more applications with 01005 components stretching inspection apparatus at production facilities.With Altus, we have significantly grown our market presence over the last years due

alternative designed specifically for laboratory environments.

The 5071B has upgraded electronic components to address possible obsolescence or non-RoHS circuitry. The product provides 100 ns holdover for more than two months, maintaining system synchronization when GNSS signals like GPS are denied. For example, this capability would enable a 5G network to remain fully operational for months without GNSS.

As a cesium beam tube product with no deterministic long-term frequency drift, the 5071B provides absolute frequency accuracy of 5E-13 or 500 quadrillionths over all specified environmental conditions for the life of the product.

For military applications requiring rapid deployments for system radars, 5E-13 stability eliminates the need for the acquisition of external synchronization sources prior to radiating. In satellite communications, this enables the user to broadcast and transmit over very small frequency bands without drifting out of band for

28 Manufacturing & Production Engineering Magazine

Latest Product Launches

Klaus Kornhaas