索具行业的权威刊物

VOL.49

(总 第49期)

共享资料 免费交流

ISSN 国际刊号:2219-5904

索具学院/ SCHOOL:

国家标准《起重机 安全 起重吊具》7月1日起正式实施了

《索具世界》所关注的产品包括:

钢丝绳,钢丝绳索具,索具配件,卸扣,吊带索具,纤维缆,捆绑带,链条,压套机, 拉力机,手拉/手扳葫芦,电动葫芦,起重机配件,防坠落安全保护产品

LRW covers:

Wire Ropes, Wire Rope Slings, Wire Rope Attachments, Shackles, Synthetic Slings, Cordage, Lashings, Chains, Swaging Machines, Test Beds, Manual Chain Hoists, Lever Hoists, Electric Hoists, Crane Attachments, Fall Protection Products

SOME FISH GO MUCH DEEPER.

有些鱼游得更深。

Some sea creatures are more specialized than others. More fit to the extreme conditions under water. Like our subsea shackles and hooks for ROV-operations. Green Pin® offers an ocean of possibilities with our range of specialized and certified components. Designed and produced with the right subsea mindset. For more control. For more precision. And for more possibilities. So make sure you choose Green Pin®. The great white with the green pin.

有些海洋生物比其他生物更专业,更适合水下的极端条件,就像我们用于海底ROV作 业的卸扣和吊钩。Green Pin®用我们专业的、有保证的,全系列的配件为客户提供 了一个海洋应用的可能性。为了更好的控制,更加精确,更多的可能性,我们用正确 的海底思维进行设计和生产。因此请确保你选择Green Pin®,带绿销子的大白。

GREENPIN.COM/ROV

编者语 EDITOR'S NOTE

如期到来的秋天,湛蓝的天空万里无云,徜徉在红叶飞舞遍树金黄的林荫小道上,微风中带有一丝淡 淡的桂花香,夕阳无限好。

年已过四分之三,蓦然回首,我们过得不太容易。在越来越严格的防疫措施下不断缩小活动范围,生 活和工作都有一定程度的影响。取消的计划,延后的安排,失去的机会,等等,都是始料不及的不能预见、 不能避免而且不能克服的客观情况。用乐观的心态去想,我们也许有了更多跟重视的人相处的时间,也许 有了更多思考人生的时间,也许有了更多独处的空间,也许有了更多尝试的机会。一切皆有可能。

本着随遇而安的人生态度,编者认为在做好充足的物资准备和自我强健体魄以后,剩下的就是接受跟 看开吧。人生百年,淡然一笑间。

当然,我们在过好自己的小日子的同时,也可能会留意外面的世界,看看有哪些方面可以“师夷长技”。 学无止境,世上繁华千千万万,或多或少会在我们的人生历程里留下痕迹,可以试着“取其精华,去其糟粕”。 生命的意义在于勇于尝试,未来仍然是未知的,可是不往前走又怎能知道前方是万丈深渊还是康庄大 道呢?不忘初心,砥砺前行,共勉之。

Herecomesthecooling-offseason.Temperatureisgettingcozyafteralongsummer.Mysense leadsmetoembracetheoutdoors,toenjoythesoundofcrunchingleavesunderfootandthesmell ofosmanthusfragrans.ThecitywhereourteamstaylocatesinSouthChina,nowturnstobeawarm, visuallypleasingpalate,filledwithgreen,red,orangeandbrown.

AftercelebratingtheMoon-cakeFestivalinmid-September,peopleinChinaarefacingstringent pandemicmeasuresimposedbygovernments,becauseofaCOVID-19wavecrossthenation.

Localgovernmentsimplementanelectronicmonitorsystemtotracecitizens’movements, infectionstatusandvaccinationinformation,furthermoregeneratingaQRcode.Residentsneedtouse thesystembymobilephoneondailylife.Beforeenteringpublicareas,includingschools,hospitals, libraries,subwaystations,buses,shoppingmalls,restaurants,airports,workplacesandresidences, everyonehavetoflashingtheirphoneandshowtheQRcode.OnlywhentheQRcode’sbackground isingreenandthePCRtestshowsCovid-19negative,peoplecangetthepermissionforentering.

Followingtherecentescalationofthepandemicinthecityourteamstay,aPCRtestwithtime gapisgoingfrom7daysearlierthisyear,to72hours,48hours,andnowevery24hours.

Additionally,moreandmorepeopleareaskedtostayathomeor14-daysquarantineathotel,as themonitorsystemshowsthattheyhaveclosecontactwithCOVID-19patients.

Anxiety,fear,depressionandfrustrationfueledthecityagain.

Hopewewillgetthroughitsoon.

6

杂志动态 UPCOMING EVENTS

2022年11月 25-28 日,亚洲国际物流技术与运输系统展览会,上海新国际博览中心

25-28 November2022,CeMATASIA2022,ShanghaiNewInternationalExpoCentre,China

2022年11 月 8-11 日,国际内部物流解决方案及流程管理展览会,深圳国际会展中心(宝安新馆)

8-11 November 2022, LogiMAT China 2022, Shenzhen World Exhibition & Convention Center, China

2022年11月15-17日,东南亚海洋工程装备展暨研讨会,新加坡滨海湾金沙会展中心

15-17 November 2022, OSEA 2022, Marina Bay Sands, Singapore

2022年11月22-25日,上海宝马工程机械展,上海新国际博览中心 (取消)

22-25November2022,baumaCHINA2022,ShanghaiNewInternationalExpoCenter,China (canceled)

2022年12月7-10日,中国国际海事会展,上海新国际博览中心

7–10December2022,21stMarintecChina,ShanghaiNewInternationalExpoCentre,China

2022年12月14-16日,2022集装箱多式联运亚洲展,国

家会展中心(上海)

14-16December2022,IntermodalAsia2022, The National Exhibition and Convention Centre (NECC), Shanghai, China

欢迎浏览《索具世界》中英文网站

《索具世界》网站资讯丰富,简、繁、英三个不同的版本任君选择。如果您想了解某类产品、某个品牌或某家企业的最新 资讯,只需输入关键词搜索,或在首页标签栏点击标签即可分类筛选;如果您想采购产品或寻找供应商,可以在线浏览我们 的采购指南和供应商栏目,也可以直接下载PDF,质量上乘、信誉良好的索具供应商和索具产品尽在这里;如果您想翻阅《索 具世界》杂志,只需点击杂志栏目即可在线浏览本年杂志。赶快前往 www.lrwmagazine.com,或扫描本页二维码,浏览

更多索具行业资讯!

Visit LRW Magazine's official website

Scan the QR code and check out what's happening in the Chinese and worldwide lifting and rigging industry.

7

CONTENTS

2022 VOL.49 总 第49期

《索具世界》杂志是由香港索具世界杂志社有限公司出版的 一本致力于为索具行业搭建信息交流平台的中英期刊。目前免费 向国内外索具行业各大企业及用户赠阅。欢迎业界来电索阅或洽 谈合作。

Lifting & Rigging World Magazine (LRW) is bilingual magazine published in China. It is widely distributed in China and the Asia Pacific. LRW covers the wire rope, lifting and rigging industries wordwide, with a primary focus on China. The magazine is established to deliver essential information, analysis and insight into the fastdeveloping global lifting and rigging sector.

ISSN国际刊号: 2219-5904

Published by出版单位:

LRW Media Limited

《索具世界》杂志社有限公司

香港湾仔骆克道315-321号骆基中心25楼F室

Room F, 25/F., Lucky Plaza, 315-321 Lockhart Road, Wanchai, Hong Kong

Director总监:

彭仕杰 Pang See Kit seekit.pang@gmail.com

Honored Editor荣誉主编:

Editorial Reviewer责任编辑:

Editor编辑:

Designer美术编辑:

Reporter编辑/记者:

Production制作:

Account Manager客户经理:

Editorial Office编辑部

余美慧 Michele Yu

石昀 Sharon Shi

黄丽雅 Mandy Wong

凌永铖 Anson Ling

朱月容 Judy Zhu

冯劲烽 Feng Jing Feng

黄丽雅 Mandy Wong

地址:广州市越秀区小北路65号华宇大厦15楼H室

Room H, 15/F, Hua Yu Office Building, 65 Xiao Bei Road, Guangzhou, China

Postcode : 510045

电话: +86-20-83545140

Email : Irwmagazine@gmail.com

中国大陆独家代理:广州市博兮风广告有限公司

Mainland China Advertising: Guangzhou Boxifeng Advertising Co., Ltd.

新闻特搜 BRIEFING

生产120级吊装索具的山东神力索具又获奖了!

Shandong Shenli Rigging's Grade 120 Chain Components enables the company achieve higher improvement and reputation among the industry

荷兰皇家Van Beest集团收购西班牙Sling Supply International

Royal Van Beest Group acquires Sling Supply International S.A.

人事变动:Talurit集团新任命首席执行官9月1日走马上任 Talurit Group announce new CEO

bauma CHINA 2022取消,2024年11月上海再聚

bauma CHINA rescheduled to 26-29 November 2024

CODIPRO's website shines in new splendor

The Crosby Group to Commence Cash Tender Offer for All Outstanding Shares of KITO CORPORATION

DLM Pioneers Industry Sustainability Drive

LEEA Awards 2022 finalists announced

P26

产品新闻 WHAT'S NEW Green Pin®全系列水产养殖业用配件

Full Green Pin® Aquaculture Product Range now available OZ Expands Stainless Steel Hoist, Trolley Range

展后报道 REPORT

P30

OGA x MOGSEC & PSC 2022凝聚石油天然气能源及石化产业翘楚

OGA x MOGSEC & PSC 2022 ended on a high note with attendees

P10

CONTENTS

展前报道 REPORT

P36

年度工业盛会——CeMAT ASIA亚洲物流展,邀您11月25-28日重聚上海新国 际博览中心

Let's meet at the annual gathering "CeMAT ASIA" on 25-28 November 2022 in Shanghai

2022集装箱多式联运亚洲展将移至(上海)国家会展中心举办 Intermodal Asia – Your Platform in Asia to Meet the Intermodal Market

索具学院 SCHOOL

P40

国家标准《起重机 安全 起重吊具》7月1日起正式实施了

会展资讯 EXHIBITIONS

P44

供应商详情 SUPPLIER'S INFO

P48

产品索引 BUYER'S GUIDE

P50

广告索引 ADVERTISER'S INDEX

P70

P11 P13 P32

9

近日,2022年山东省企业技术创新促进会企业技术创新奖评 选结果揭晓。神力索具荣获“创新驱动发展突出贡献单位”;神 力索具报送的“120级吊装索具技术研发与应用”项目荣获“企 业技术创新优秀成果三等奖”;神力索具技术中心主任张体学荣 获“创新驱动发展带头人”称号!

神力索具是我国生产制造80级、100级、120级索具产品的 大型民营高新技术企业。创新引领发展,科技成就未来。公司始 终秉承做科技创新强者的发展理念,以优质产品和强劲的科技创 新能力奠定品牌战略发展的基石,使公司的科技创新能力和产品 始终处于国内外同行业前沿。

目前,神力索具共有各专利120余项。2020年,神力索具与 中国科学院金属研究所合作研发120级索具高强韧新材料,对材 料的关键性能技术指标进行了深度研发设计。另外,神力索具还 参加了《索具用80级、100级链环》等4项国家标准制定的起草 工作和6项国家标准的函审工作。

在神力索具董事长杜亚中、总经理杜大平的带领下,神力索 具全员创新,全面贯彻落实“抓创新就是抓发展,谋创新就是谋

未来”理念,开展科技攻关,推动技术创新,促进技术创效,在 新产品、新技术、新材料方面取得显著成效,为公司高质量发展 作出积极贡献。

Shandong Shenli Rigging's Grade 120 Chain Components enables the company achieve higher improvement and reputation among the industry

After this year's Moon Cake Festival, a good news has come to Shandong Shenli Rigging Co., Ltd.. As the local association "Enterprise Technology and Innovation Association of Shandong Province" unfolded the winners of the year's outstanding entities, persons, technologies and innovation.

Shandong Shenli Rigging has won awards from three categories. Thanks to the contribution on technology and innovations, the company won "Enterprise with Great Improvement". Their "Grade 120 Lifting and Rigging Products" awarded 3rd prize of "Outstanding Enterprise Technology and Innovation". Moreover, their head of R&D center, Mr. ZHANG TiXue, was recognized as "One who plays a leading role in the industry".

This is the result of years of hard works the company focusing on high quality lifting and rigging products, Shandong Shenli

Rigging keep investing themselves in the innovation and advanced technology for higher grade products. In 2020, they announced the collaboration with Chinese Academy of Sciences, Institute of Metal Research, to contribute themselves to develop new material and work out Grade 120 lifting and rigging products. Now, the company is able to provide their valued customer with Grade 80, Grade 100 and Grade 120 Lifting and Rigging products. With years of experience of knowhow among the industry, Shandong Shenli Rigging also participate in the drafting (4) and review (6) of China's national standards such as "Grade 80 and Grade 100 Master links for Lifting and Rigging Industry". What they did may help to enhance this home-grown company's brand prestige and comprehensive competitiveness inside and outside China.

新闻特搜 BRIEFING 10

生产120级吊装索具的山东神力索具又获奖了!

荷兰皇家Van Beest集团收购西班牙Sling Supply International

荷兰皇家Van Beest集团在今秋宣布收购西班牙Sling

Supply International S.A.(下面内容有部分简称之为 “Slingsintt”)。这是一家致力于为各行业提供吊装解决方案的 企业,集设计、生产、检验和认证于一体。主要服务于全球风能行业, 给机舱、轮縠、塔架、叶片等风力发电机组件提供完善的吊装设备。 透过与原始设备制造商(OEM厂商)的紧密合作,这家企业在定 制起重设备工程方面处于业界领先地位。

此次收购极大地巩固了Van Beest集团在陆上及离岸海洋工

程、采购、施工以及OEM方面作为系泊设备、绑扎设备和起重 设备服务商在全球的领导地位。被收购后,Slingsintt公司将作为 Van Beest集团内的一个独立子公司继续发展,由Mikel López、 Igor Rodríguez和 Eneritz Miranda Muxika分别担任研发/业务 总监、营运总监和财务总监。

Van Beest集团首席执行官Hendrik Kok对此次收购作出了 评价,他说:“Sling Supply International公司以提供模范的起 重产品和吊装服务闻名于业界。此次收购为集团增添了一家‘宝藏’ 企业,(未来我们)在譬如风能行业等高速发展的市场可以打开 更广阔的营销渠道。”

Sling Supply International联合创办人兼首席执行官Pedro Garitaonandia也表达了自己的看法,他说:“Van Beest集团和 Slingsintt公司以供应商和客户的身份合作了四十年,早已成为关 系紧密的合作伙伴。我很开心Slingsintt公司将作为集团一部分继

续成长,可以预见未来前景无可限量。”

此次交易尚在进行中,由DVAN Advocaten、BAUM Legal Tax M&A、JLCasajuana Abogados Legal advisors和V4 Financial Partners提供法律和财务方面的咨询。

Sling Supply International S.A.(简称“Slingsintt公司”) 总部位于西班牙,现有35名员工。这家企业致力于为各行业提 供吊装解决方案,例如风电场、铸造工场、铁路、港口、造船厂 等场所以及机械加工、自动化、渔业和建筑等行业,为客户提供 设计、制造、测试和认证服务,并且主要开发和生产风力发电机 各组件所用的起重设备。拥有40多年的行业经验,Sling Supply International公司凭借成熟的工艺、还有和风能行业的OEM世界 巨头一起开发产品,在业内拥有良好的声誉。更多信息,请参阅 https://www.slingsintt.com/。

荷兰皇家Van Beest集团专注于生产适用于吊装、捆绑及系 泊应用的优质起重机配件和吊钩用配件,是领先于业界的制造商。 1922年,Van Beest由Dirk van Beest创立,自一家小小的铁匠 铺发展起来,今年,集团成立100周年了。旗下拥有多个品牌: Green Pin®、Irizar Forge和Heuer Hebetechnik,为客户提供无 比优越的服务,产品行销全球90多个国家。集团总部位于荷兰, 而且在德国、法国、西班牙、巴西和美国设立了子公司,现有200 位员工。详情可浏览官网 https://www.vanbeest.com/。

11 索具世界 Lifting & Rigging World 11

Royal Van Beest Group acquires Sling Supply International S.A.

The Royal Van Beest Group has acquired Sling Supply International S.A. ('Slingsintt'), based in Spain. Sling Supply International is dedicated to the design, manufacturing, testing and certification of lifting solutions in a wide range of industries. Its main business is focused on the global wind industry and consists of the development of tools for the lifting of nacelles, hubs, towers and blades. Slingsintt has gained a leadership position in this market through its excellence in the engineering of custom-made lifting equipment, in close cooperation with leading Original Equipment Manufacturers (OEM's).

This acquisition significantly contributes to Van Beest's mission of worldwide leadership in mooring, lashing and lifting equipment for the onshore and offshore Engineering, Procurement and Construction (EPC) industry and OEM's. Sling Supply International will be managed as a separate entity within the group and will be led by Mikel López (R&D/ Commercial Director), Igor Rodríguez (Operations Director) and Eneritz Miranda Muxika (Finance Director).

Hendrik Kok, CEO of the Royal Van Beest Group, comments: "Sling Supply International is well-known in the industry for offering exemplary lifting services and products. With the acquisition, we add a jewel of a company to our group and one with fantastic exposure to a high-growth market like the wind industry". Pedro Garitaonandia, co-founder and CEO of Sling Supply International, adds: "Van Beest and Slingsintt have been great partners for four decades as supplier and customer. I could not be happier that Slingsintt will continue its growth as part of the group and foresee a bright future ahead for the combined companies."

During the acquisition process Van Beest and Sling Supply International were advised by DVAN Advocaten, BAUM Legal Tax M&A, JLCasajuana Abogados Legal advisors and V4 Financial Partners.

Sling Supply International S.A. ('Slingsintt') is dedicated to the design, manufacturing, testing and certification of lifting solutions in a wide range of industries including windfarms, foundries, machine tooling, automotive,railways, ports, shipyards, fishing and construction. Its main business is focused on the development and manufacturing of lifting equipment for all types of components for wind turbines. With over 40 years of experience, Sling Supply International has built a strong reputation for the sophistication of its engineering and its co-development of tools with the world's leading wind industry OEM's. Sling Supply International is based in Spain and has 35 employees. For more information, please see https://www.slingsintt.com/.

Founded in 1922, the Royal Van Beest Group is the leading manufacturer of premium quality crane- and below-the-hook components that are used in lifting, lashing and mooring applications. It is Royal Van Beest Group's 100th anniversary this year. What began as a small smithy founded by Dirk van Beest. The company offers customers unparalleled service by having the Green Pin®, Irizar Forge and Heuer Hebetechnik brands under one roof. The Royal Van Beest Group has 200 employees and branches in The Netherlands (head office), Germany, France, Spain, Brazil and the USA. Its products are available in more than 90 countries worldwide. Please go to https://www.vanbeest.com/ for more.

新闻特搜 BRIEFING

12

人事变动:

Talurit集团新任命首席执行官9月1日走马上任

瑞典Talurit集团旗下的Talurit AB公司早前宣布任命Victor Lindh为新的首席执行官,任期自本年9月1日起正式生效。而 前首席执行官Thommy Andersson被聘为业务拓展总监,兼任公 司董事会监事。

Victor Lindh已在Talurit集团工作了八年,此前担任副总裁 一职,负责销售和市场工作。他于瑞典查尔姆斯理工大学机械与 工业经济专业毕业,获硕士学位,曾作为交换生到瑞士苏黎世联 邦理工学院(学习)。他的管理才能和工业技能是无容置疑的, 过去他为集团带来了很大的发展,未来也进入一个新的阶段助力 Talurit集团更上一层楼。

而Talurit AB公司的前任首席执行官Thommy Andersson 自1998年起就一直担任该职位,为集团服务30多年。在他的领 导之下,集团随着行业的发展而不断前进(,并取得不错的成绩)。

Talurit公司有着丰富的发展史,持续供应以客户为中心的优质产 品,而且产品的使用寿命远远超过同类型厂家,Thommy始终忠 于此,而且一直在守护成果。卸任之后,Thommy Andersson作 为业务拓展总监,将继续为Talurit集团效力,专注发展各子公司, 同时巩固集团在全球的市场占有率和无可取代的地位。

全球正在经历大变局,置身于这个时代,Talurit集团的目标 仍旧保持不变,就是通过他们在业内有名的创新的顶级产品和解

Talurit

Lindh(右)为新的首席执行官,左边这位是前 首席执行官Thommy Andersson,现任业务拓展总监,兼任公司董事会 监事

Talurit AB announces the appointment of Victor Lindh (the right one) as Chief Executive Office, while Thommy Andersson (the left one) will leave his role as CEO and continue as Business Development Director and become a member of the company's Board of Directors

决方案来带领这个行业继续向前走。作为Talurit集团的首席执行 官,Victor Lindh将在集团在过去几十年里延续的势头和取得的成 功的基础上,带领业界领军人物进入又一个发展新篇章。

Victor Lindh对此表达了自己的看法,他说:“这对我来说 是比较重要的一个工作机会。首席执行官这个职位责任重大,我 很期待和我们这一群优秀的同事们一起继续巩固集团获得的成果, 继续引领行业前行,继续成为钢丝绳专业人士首选的供应商。众 人齐心,创造更多价值,相信未来会创造更多,去促使大家在高效、 安全的工作环境下给到客户出色的产品和解决方案。”

Thommy Andersson也表达了自己的看法:“很开心我们集 团由这年轻一代去接棒管理,为这个行业注入新的教育和经验。 能够更多地投入到世界各地的业务发展项目,也让我非常兴奋。 我们的新产品和技术可以介绍给更多有趣的领域和客户。”

Victor Lindh补充说:“本人作为首席执行官还相当年轻, 我必须冷静下来,前任首席执行官Thommy Andersson过去为公 司传授的知识(和做事方法等经验)未来仍然会保持在公司内部, 而他享有长期股份,也在董事会占有席位。除此之外,我也感受 到了集团管理层的大力支持,我很高兴能够加入一个在行业内具 有这种高水平能力和令人敬佩的管理团队。”

13 索具世界 Lifting & Rigging World

13

AB公司任命Victor

Talurit Group announce new CEO

Talurit AB, the parent company in Talurit Group, announces the appointment of Victor Lindh as Chief Executive Officer (CEO), effective from September 1, 2022. Thommy Andersson will leave his role as CEO and continue as Business Development Director and become a member of the company's Board of Directors.

On September the 1'st, Talurit AB in Sweden appointed Victor Lindh as the new CEO. Victor Lindh has worked within the group for 8 years in total and was previously positioned as Vice President focusing on Sales and Marketing. Victor holds a master of science degree in mechanics and industrial economics from Chalmers university of technology with an exchange period at ETH in Switzerland. With an undoubted aptitude for management and engineering he has already brought great improvements to the business and initiated the next stage for the group.

Victor Lindh will take over operations from Thommy Andersson, who has been in the company for over 30 years and has served as CEO since 1998. Under his leadership, the group has excelled and stayed adaptive to the changes of the industry. He has ensured that the brand has stayed true to its rich history of delivering customer-centric premium products with a service life far exceeding the competitors. Thommy Andersson will stay within the group as Business Development Director, focusing on growing the group's subsidiaries and sustaining the global success.

At a time surrounded by major global changes, the objective stays the same - to lead the way forward in their field by delivering the innovative top-tier products and solutions they are known for. As CEO of Talurit Group, Victor Lindh will build

upon the momentum and success achieved during the past decades and bring the market-leader through a new chapter of development and expansion.

Victor Lindh, CEO, Talurit Group, comments:

"Of course, I am very humbled by this opportunity and the responsibilities that comes with it. Together with all my great colleagues, I look forward to continuing building upon what we have to ensure we continue leading the industry being the wire rope specialists'first choice. It is together with them we will build value, and I believe we will do so even more in the future helping them deliver great applications from their efficient and safe workplaces."

Thommy Andersson, Business Development Director at Talurit Group, comments:

"It is with great pleasure we can announce a younger generation management including fresh education and experience in our field. It is also very exciting for me to be able to focus more on business development projects around the world. There are so many interesting areas and customer segments to develop with our new products and technology in the process of being introduced."

Victor Lindh, CEO, Talurit Group, adds:

"As a rather young CEO it is of course calming to know that the knowledge Thommy has will remain within the company for the future given his long-term interest and seat at the board. Apart from that I also feel strong support from the MDs within the group and I am very happy to join a management team with this high level of competence and respect within the industry."

新闻特搜 BRIEFING 14

Talurit AB公司任命Victor Lindh(右)为新的首席执行官,左边这位是前 首席执行官Thommy Andersson,现任业务拓展总监,兼任公司董事会 监事

Talurit AB announces the appointment of Victor Lindh (the right one) as Chief Executive Office, while Thommy Andersson (the left one) will leave his role as CEO and continue as Business Development Director and become a member of the company's Board of Directors

bauma CHINA 2022取消,2024年11月上海再聚

原定于2022年11月22日–11月25日举办的bauma CHINA 2022(上海国际工程机械、建材机械、矿山机械、工程车辆及 设备博览会)将延期至2024年11月26日–11月29日,依旧在上 海新国际博览中心举办。

主办方–慕尼黑展览(上海)有限公司的公告原文如下: 尊敬的参展商、观众及合作伙伴:

鉴于当前新冠疫情形势仍严峻复杂,为了确保展商和客户利益 最大化,获得更加优质的参展效果与参观体验,原定于2022年11 月22日–11月25日在上海举办的bauma CHINA 2022(上海国 际工程机械、建材机械、矿山机械、工程车辆及设备博览会)将延期 至2024年11月26日–11月29日举办,地点不变。

主办方慕尼黑展览(上海)有限公司总经理徐佳女士表示:“举 办bauma CHINA这样的大型国际性博览会,首要前提是确定性,要 确保展会能达到预期的质量和效果。在当前形势下,如期举行并达 到预期效果存在着很大的不确定性。为了避免临时延期导致展商和 客户产生经济损失,展会主办方本着负责任的态度,在现阶段即做 出及时告知展商的决定。虽然这是一个令人遗憾的决定,但我们对 中国市场的未来始终充满信心,因此希望所有关心和爱护bauma CHINA的朋友们和伙伴们,从现在开始为2024年bauma CHINA 成功举办做出努力。相信届时我们将再汇聚上海,共同展示广大展 商的创新成果,深入交流,扩大合作。”

中方主办单位一致认为:慕尼黑博览集团的决定充分考虑了全 体展商的利益,及时做出上述决定对于各方来说都是既艰难又明智 的举措,中方主办单位将协助慕尼黑博览集团共同做好延期的后续 工作。

bauma CHINA展会于2002年在上海新国际博览中心由慕尼 黑博览集团与中国工程机械工业协会、中国国际贸易促进委员会机 械行业分会、中工工程机械成套有限公司共同首次主办。展会历经 20年,成长为拥有33万平米展示面积、3000余家展商、超20万观 众的专业展览,是中国及亚太地区颇具规模和影响力的工程机械行 业盛会和交流平台。无论是20年的“时间”,还是33万平米的“空间”, 都见证了中国工程机械行业快速发展的历程。

展望下一个20年,我们坚信,中国工程机械行业定会焕发新的 生机,创造出新的辉煌!让我们共同期待2024年在上海重逢。

因为热爱,所以期待!

bauma CHINA展现给世人的,不仅仅是一个具有强大影响力 的展览会,更是一个具有凝聚力的共同体。连接彼此的,正是长久以 来人类在面向星辰大海的探索中,在规天矩地的实践中,尊重科学、 尊重自然、尊重规律的文化共识。

2024年11月26-29日,上海见!期待和合共融,与时携行! 更多信息,请登录官网 www.b-china.cn。

新闻特搜 BRIEFING

bauma CHINA rescheduled to 26-29 November 2024

bauma CHINA, Asia's largest and most important event for the Construction Machinery, Building Material Machines, Mining Machines and Construction Vehicles., which was scheduled to be held on 22-25 November 2022, announced rescheduled to the Shanghai New International Exhibition Centre from November 26 to November 29 in year 2024.

The organizers of bauma CHINA, have had to follow China's national epidemic prevention measures to reduce the risk

of transmission and protect public health, rescheduling of the event will ensure a safe environment for the maritime community to meet and do business. They will stay determined to deliver a high-quality event and look forward to greeting everyone to Shanghai again.

For more information please contact baumachina@mm-sh. com.

Lifting & Rigging World 索具世界

CODIPRO's website shines in new splendor

CODIPRO, the Luxembourgish specialist for swivel lifting rings, is proud to announce the launch of its new website www. codipro.net!

Based on the feedback of its customers and distributors, CODIPRO has completely redesigned its website, which is currently one of the essential supports for the marketing of its swivel lifting rings.

The products are now categorized in a more targeted way so that visitors can access the information they are looking for in just a few clicks. "Our goal with this new site is to provide visitors with an easier way to learn about CODIPRO's products and to browse the information according to their own choice", explains Pauline Piron, Marketing Coordinator of CODIPRO.

This website has been designed and built for CODIPRO's distributors, called "Experts", but also for users of lifting rings. The latter will find an exclusive tab with solutions adapted to their sector of activity, information on CODIPRO's technical support, etc. Experts have access to a dedicated web portal

where they can find all the graphic elements necessary to promote CODIPRO's lifting rings. The management and traceability tool CODITRACER as well as the training courses provided by the technical team are also made more accessible. This new version is modern, complete and user friendly. It is available in 6 languages (French, English, German, Spanish, Italian and Portuguese), intuitive and adapted to each visitor profile. Enjoy your visit! www.codipro.net.

CODIPRO designs and manufactures high quality articulated swivel lifting rings. Since its takeover in 2004 by the shareholders of NO-NAIL BOXES and its move to Wiltz (Luxembourg), CODIPRO has been growing steadily. Certified ISO 9001, ISO 14001, ISO 27001 and SRC, patented and in compliance with the most stringent safety standards, CODIPRO is part of the lifting division of the ALIPA Group, the Luxembourgish packaging and industrial lifting specialist with approximately 150 employees.

新闻特搜 BRIEFING 18

The Crosby Group to Commence Cash Tender Offer for All Outstanding Shares of KITO CORPORATION

Completion of regulatory clearances marks key step in agreed combination process announced by both companies on May 16. Business combination of The Crosby Group and KITO CORPORATION to create a global provider of comprehensive lifting solutions.

The Crosby Group, a leading provider of lifting and rigging solutions, and KITO CORPORATION, a leading manufacturer of material handling equipment with 90 years of experience in the development and production of hoists and cranes, today announced that they have secured all regulatory clearances for their business combination and that The Crosby Group will

commence a cash tender offer to acquire all outstanding shares of KITO CORPORATION for JPY 2,725 per share on September 26. The cash tender offer price represents a premium of 64.3% compared to KITO CORPORATION's undisturbed closing share price on May 13, the last trading day before the transaction was originally announced.

The cash tender offer will commence on September 26 and the transaction is expected to close in Q1 2023, following the settlement of the cash tender offer and the completion of the squeeze- out period.

The proposed combination will bring together the

新闻特搜 BRIEFING

complementary capabilities, geographic footprints, and product portfolios of two industry-leading companies to better serve customers, team members, and communities. Wellpositioned to accelerate growth through investments in its products, people, and facilities, the combined company will bring customers a broader portfolio of products, globally, and provide increased levels of service, support, and training.

Robert Desel, CEO of The Crosby Group, said: "The receipt of regulatory clearances and commencement of the cash tender offer are key milestones as we work toward the completion of our business combination with KITO CORPORATION and thus the creation of a global provider of comprehensive lifting solutions.

"Pairing our highly complementary product portfolios gives our global customer base access to a broad range of lifting and material handling solutions from one trusted source. Together we will create compelling value for our stakeholders globally. KITO CORPORATION shares our core values of safety, reliability, and innovation, and we look forward to completing this process."

Yoshio Kito, CEO of KITO CORPORATION said: "We are pleased to have received the necessary regulatory clearances. We believe this combination creates excellent value for all stakeholders, and we are excited to build upon a combined business to better serve our customers, team members, and communities. This combination will allow us to grow as a global business and provide our customers with expanded, best-in-class product offerings, with the same dedication and support to which they are accustomed."

SMBC Nikko serves as the tender offer agent as well as lead financial advisor, Mizuho Securities USA LLC acted as financial advisor, and Kirkland & Ellis LLP and Mori Hamada & Matsumoto acted as legal advisors for The Crosby Group. Debt financing is being provided by UBS Investment Bank, KKR Capital Markets, Sumitomo Mitsui Banking Corporation, Mizuho Bank, and ING Capital. Nomura acted as financial

advisor and Nishimura & Asahi acted as legal advisor for KITO CORPORATION.

The Crosby Group, a KKR portfolio company, is a global leader in the innovation, manufacturing and distribution of products and services used to make lifting and rigging safer and more efficient, with premier brands such as Crosby, Gunnebo Industries, Crosby Straightpoint, Crosby BlokCam, Crosby Airpes, Acco, McKissick, Crosby Feubo, Trawlex, Lebus, Speedbinders, and CrosbyIP. With global engineering, manufacturing, distribution and operations, The Crosby Group provides a broad range of products and solutions for the most demanding applications with uncompromising quality that exceed industry standards.

Since its founding in 1932, KITO CORPORATION has been a leading manufacturer of material handling equipment, specializing in meeting our customers' need for lifting, transporting, and securing operations. KITO CORPORATION supplies products that enhance customer safety and productivity in a wide range of worksites where heavy objects are handled, with premier brands such as KITO, Harrington, Peerless, Jiangyin, Erikkila, Van Leusden, KITO Weissenfels, SCC, and Fall Safe. From the factory floors of key industries, such as construction, civil engineering, and manufacturing, to high-tech factories of semiconductors and liquid crystal panels and the entertainment field, KITO CORPORATION products have been widely used and have earned KITO CORPORATION a high degree of trust from customers all over the world as a leading company for material handling equipment.

21 索具世界 Lifting & Rigging World 21

DLM Pioneers Industry Sustainability Drive

Dynamic Load Monitoring (UK) Ltd. (DLM), of Southampton, UK is pioneering a series of measures to inspire the engineering sector to be greener and more sustainable. The strategy will align the business further with the industries it services day-to-day, especially renewable energy.

DLM has been ISO 14001 certified for many years, which means it meets the criteria for an environmental management system and can be certified accordingly. ISO 14001 maps out a framework that a company or organisation can follow to set up an effective environmental management system. This has supported much wider sustainability strategy that serves as a blueprint for other businesses to follow.

Martin Halford, managing director at DLM, said: "Although we are a small company in the engineering sector we have big plans around sustainability, backed by a passion to change the culture and behaviour of our organisation and lead by example. We have several passionate staff members, who are keen to drive a few key initiatives that we have already been implementing for a period."

The company identified third parties to assist, including the Clever Software Group, a bespoke software development firm that crafts custom software and data solutions for people in business. The first task was to digitalise the sales and calibration department, empowering employees to adopt completely paperless working processes. DLM embraced a Solent Local Enterprise Partnership (LEP) scheme and worked

with True Horizon, a unique consultancy supporting brands to balance purpose and profit, introducing carbon footprint tracking along the way.

A purpose and profit balance

Halford acknowledged that a switch to recycled and recyclable packing, for example, did see the business incur initial cost but reiterated that this was about a long-term, moral obligation to balance purpose and profit. As well as top-level strategy, DLM has also implemented smaller, equally important, behavioural measures, such as introducing plants to the office and encouraging lunchtime walks.

He said: "Some ideas were suggested by a group of Southampton University students, who worked with us on an innovation project. They investigated our current habits across the company and tabled some improvements. They have all so far been well received, but we need to keep momentum up by continuing to encourage fresh input. It's a team effort— much like watering the plants. Taking lunch and other breaks is a constant challenge because we're trying to dovetail this campaign at a time when we've never been busier, but it's about bigger-picture thinking."

While the short-term impact of these improvements has already been felt, DLM is committed to long-term, cultural change both within the business and elsewhere as the benefits are noted in and out of the engineering and manufacturing markets. It is also important to demonstrate to offshore wind and other renewable energy stakeholders that the company is

新闻特搜 BRIEFING 22

committed to the same end goals.

There are business incentives too. Sustainability is likely to see companies looked upon favourably in future tender situations, and DLM would rather be proactive than playing catchup. Where ISO 14001 was once the standard, it will likely go beyond that in time. Recruitment too will be easier for greener companies, especially as the next generation enters the workforce. Halford hopes that future employees will accelerate this rate of positive change.

He said: "We believe that a younger audience will be more naturally ambassadorial. To that end, we will continue to work with the [Southampton] university and one day hope to have a dedicated sustainability role within the company—perhaps filled by a former student that already knows the business. We'll also more forthrightly challenge suppliers and partners to come with us on the journey. We can yet make sure we have a bright—green—future."

www.talurit.com

23 Lifting & Rigging World 索具世界 收绳机 各式模具 剪绳机 压接接头 压套机 计米器 拓锐机械(宁波)有限公司 电话: +86 8630 8590 l +86 153 8189 2699 电子信箱:info@talurit.cn l vanilla.chen@talurit.cn 瑞典制造

手动工具拉力试验机 THE

1948 熔头机

ORIGINAL SPLICING SYSTEMS SINCE

LEEA Awards 2022 finalists announced

The Lifting Equipment Engineers Association has announced the LEEA Awards 2022 finalists, chosen from the inspiring collection of high quality entries from the Association's members.

The winners will be announced during the 'party of the year' at the LEEA Awards Ceremony, which will be held at the P&J Live events venue in Aberdeen on the evening of Wednesday 5th October 2022 – the first evening of LiftEx 2022. The ceremony hosted by LEEA CEO Ross Moloney will feature special guest speaker Sir Ian McGeechan, Scottish former rugby union player and coach. The announced finalists are as follows:

BEST ATS (Accredited Training Scheme) Training Member

Technical Royal Excellence Oil and Gas Services

GGR Group

JCD Training

EDF Generation

Best Digital Innovation

Core Inspection Software Ltd

Onix AS

RI Connect Inc

Certs Assured

Select Plant Hire (Laing O'Rourke)

新闻特搜 BRIEFING 24

Green Pin®全系列水产养殖业用配件

1-Green

一般来说,渔业和水产养殖业对水下产品最明显的要求是: 耐用。因为那些设备经常暴露在水和盐里,环境温度也在不时地 变化。这时候,在水下作业的渔网和系泊系统就需要“适用于水 下作业,同时高于行业标准”的卸扣、螺栓和其他系泊配件。

Green Pin®水产养殖用的卸扣和螺栓无疑就是不错的选择。作为 渔业养殖户的首选,它们有什么过人之处呢?

此前Green Pin®已推出Green Pin®水产养殖用D型卸扣和

Green Pin®系泊用T型螺栓,最近又推出了三款新的产品,包括:

Green Pin® 系泊用卸扣、HDG弓形卸扣和HDG锻造强力环,让 这一系列产品更完整。

Green Pin®系泊用弓形卸扣NS9415 BN,专门为系泊应用 而设计,带有安全插销和方形沉孔螺纹销(平销),其中的方形 沉孔螺纹销与黄色安全插销相结合,提供双重安全保障,可以防 止横销意外松脱。另外,沉孔螺纹销可以防止螺栓旋转,卸扣组 装起来更顺心,而且还有助于减少渔网和系泊缆绳的损耗。这款 弓形卸扣的开口很大,可以连接宽度更大的系泊钢板或连接件, 适用于单肢或多肢索具组合。

Green Pin® D型卸扣NS9415 FP,仅适用于单肢系泊系统。

其中的方形沉孔螺纹销与安全活塞相结合,也是保持了Green Pin®产品一流的品质,可确保系泊系统的绝对安全。在Green Pin®产品在系泊方面的无数经验累积下,该卸扣进行了超过 40000次循环的疲劳测试,次数是NS 9415标准要求的两倍,行 内暂时没有超过这个数据的。还有,安全系数领先于业界,最小 破断负荷达到7倍的极限工作负荷。

Green Pin® 弓形卸扣NS9415 BN 经热浸镀锌处理,带有安 全插销和螺纹横销,同样提供双重安全保障,可防止横销意外松脱。 这款卸扣也是适用于单肢或多肢索具组合。

Green Pin®热浸镀锌处理的80级锻造强力环,专门设计用 于单肢或双肢索具组合。这款强力环开口很大,可搭配大尺寸的

GreenPin®hotdippedgalvanizedbow

吊点或连接件。

Green Pin®系泊用NS 9415标准T型螺栓。这是一款带有 T形末端接头的Green Pin®系泊用螺栓,保持Green Pin®产品的 一流品质,给养殖户系泊系统的绝对安全提供保障。这款螺栓安 装起来很容易,看着螺栓表面的绿色部分就可以知道下水深度, 而且它的特殊类型螺纹可以更好地固定螺栓。

Green Pin®养殖业用弓形卸扣FP,带有方形沉孔螺纹销(平 销),跟预留给横销的两孔齐平,表面平滑没有突出来的部分, 可以避免螺母被网状或绳状物体勾住,还有助于减少横销对连接 绳索的磨损。这款卸扣同样适用于单肢或多肢索具组合。

Green Pin®全系列水产养殖业用配件在设计和疲劳测试都是 依据NYTEK规定的NS 9415标准进行的,并且均获得DNV型式 认证。全系列产品经过了镀锌处理,即使是在恶劣的环境或者是 在含盐的场地使用,也能确保长期耐用。还想了解更多详情,请 浏览greenpin.com。

WHAT'S NEW

26

产品新闻

Pin®系泊用弓形卸扣NS9415 BN Green Pin® Mooring Bow Shackle NS9415 BN

2-Green Pin® D型卸扣NS9415 FP Green Pin® Dee Shackle NS9415 FP

3-Green Pin® 弓形卸扣NS9415 BN经热浸镀锌处理

shackleNS9415BN

Full Green Pin® Aquaculture Product Range now available

5-Green Pin®系泊用NS 9415标准T型螺栓 Green Pin® Mooring T Bolt NS9415 T

6-Green

4-Green Pin®热浸镀锌处理的80级锻造强力环

Green Pin® hot dipped galvanised grade 8 master link

If ever durable products were required, it is probably most visible in the fishing and aquaculture industries. Equipment is constantly exposed to water, salt and different temperatures. For aquaculture cages need to be secured under water reliably for longer periods of time to safeguard large investments. Your underwater cages and mooring systems therefore need shackles, bolts and other mooring accessories that are below surface, but above standard. That is why the Green Pin® aquaculture shackles and bolts are the top choice for fish farmers.

As Green Pin® has launched the Green Pin® Dee Shackle NS9415 FP and Green Pin® Mooring Bolt NS9415 T recently, the aquaculture range is now extended with three new products that make the range complete: the Green Pin® Mooring Shackle, HDG Bow Shackle and HDG Master Links. The products within the new Green Pin® aquaculture range have been designed, extensively fatigue-tested and DNV type approved by the NS 9415 standard as required by NYTEK regulation. Galvanization of Green Pin® lifting accessories assures long-term durability, even under harsh, salty conditions.

The Green Pin® Mooring Bow Shackle NS9415 BN with safety bolt and a sunken bolt that has been designed for mooring applications. The shackle offers a double safety (safety bolt and synthetic cotter pin) which prevents accidental unscrewing of the pin. The sunken bolt prevents rotation of the bolt, making it much easier to assemble. It also minimizes the risk of damage to the cage net or mooring line. The wider shackle mouth enables to connect the shackle to a mooring or connecting plate which is wider than usual. The shackle is suitable for both one-leg and multi-leg systems.

The Green Pin® Dee Shackle NS9415 FP is a dee shackle with a square sunken hole screw pin (flush pin) which provides best-in-class quality, guaranteeing absolute security for your mooring system. Testifying to its superior record when it comes to mooring safety, the 40.000 cycle fatigue rating is twice that required by NS 9415 and unparalleled in the market. What is more, the safety factor leads the industry with an MBL of seven times the WLL. It is suitable for one-leg mooring systems only.

The Green Pin® Bow Shackle NS9415 BN is hot dipped galvanized bow shackle with double safety (split pin and safety bolt) which prevents accidental unscrewing of the pin. The shackle is suitable for both one-leg and multi-leg systems.

The Green Pin® hot dipped galvanised grade 8 master link, with large opening to accommodate larger connecting links. The Master Link is designed for a one- or two-leg sling.

The Green Pin® Mooring Bolt NS9415 T is a grade 8 mooring bolt with a T-shaped end fitting that provides best-in-class quality, guaranteeing absolute security for mooring system. The mounting depth is indicated by the green colour, which makes the installation of the product much easier and the special type of thread will result in a better fixation of the bolt.

The Green Pin® Fishing Bow Shackle FP is a bow shackle with a square sunken hole screw pin (flush pin). The Green Pin® Fishing Bow Shackle FP contains no protruding parts so it does not damage or get caught in fishing nets. Another important feature is that the chamber in the shackle eye hides the screw thread and reduces wear of rope. The Green Pin® Fishing Bow Shackle FP is suitable for both one-leg and multi-leg systems. For more, please go to greenpin.com.

27

索具世界 Lifting & Rigging World 27

Pin®养殖业用弓形卸扣FP Green Pin® Fishing Bow Shackle FP

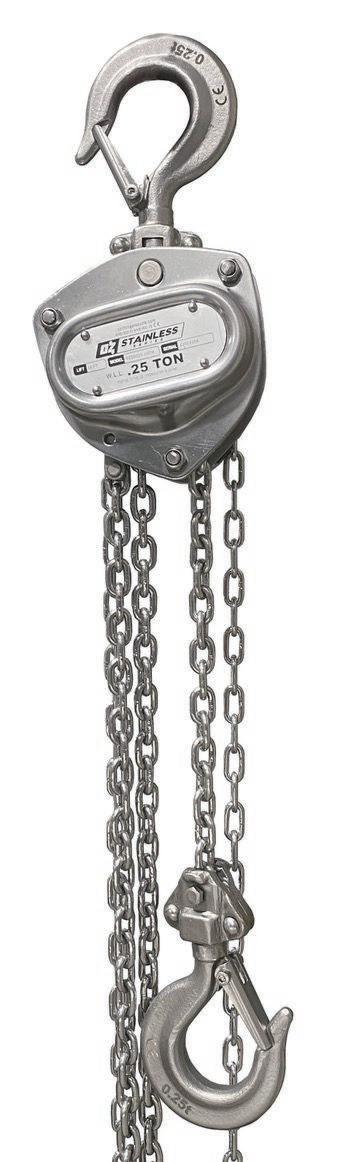

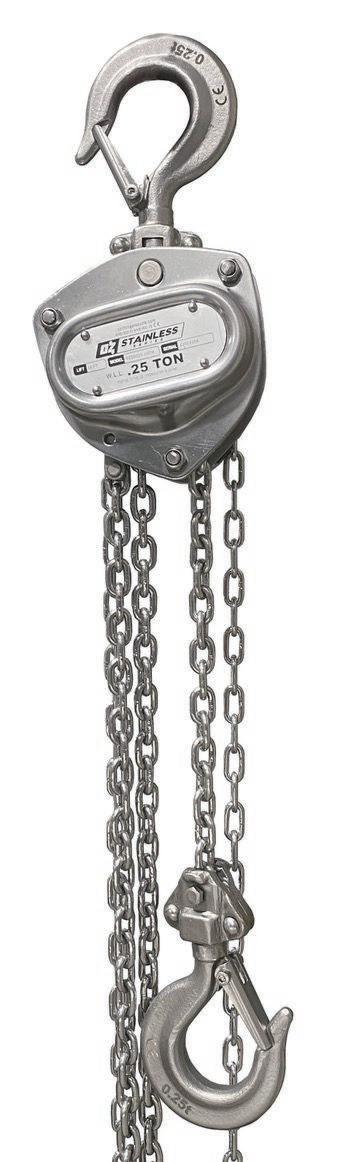

OZ Expands Stainless Steel Hoist, Trolley Range

OZ Lifting Products LLC has added a 0.25-ton capacity manual chain hoist and trolley to its ever-growing stainless steel range.

The Winona, Minnesota-based manufacturer has added to the line in a piecemeal fashion, with 0.5-ton capacity versions joining those in 1-ton and 2-ton only last year, while 3-ton and 5-ton hoists and trolleys are expected in the coming months. Discussions about stainless steel lever hoists are ongoing—and the company already stocks a range of stainless steel beam clamps.

The manual hoist remains the centerpiece of the stainless-steel range. Like other products in the line, the new, 0.25-ton version is designed for lifting and pulling. The hoist is lightweight and minimal effort is required to lift loads, but it is durable enough for some of the most demanding marketplaces. The trolleys, meanwhile, fit most common I-, S- and W-beams; end users have different types of beams depending on the construction requirements of the building or structure where the lifting equipment will be installed and employed.

Steve Napieralski, president at OZ Lifting, said: “We have had a lot of inquiries for the .25 so we decided to add that to the line and, given that most of our sales are for both the manual chain hoist and trolley, it makes sense to continue to expand them together—at both ends of the capacity scale. In most instances, the products are used in lifting versus pulling applications, but the ability to do both remains a selling point.”

There is no specific application for this kind of manual hoist and trolley, beyond the fact that stainless steel is used in corrosive environments, including wastewater treatment plants, saltwater, or wash-down applications.

Napieralski added: “We have a successful carbon steel hoist and trolley range [from 0.25 to 5 tons]—cost and application drive the decision whether that would be sufficient or if the stainless steel alternative is more suitable. Stainless is typically

two or even three times the cost of carbon steel, which is significant for certain end users, and carbon is perfectly adequate in numerous scenarios. We have several [new] products on the horizon in both steel types.”

The stainless products require a similar maintenance program as their carbon counterparts, Napieralski explained. He

WHAT'S NEW 产品新闻 28

OZ Lifting's new 0.25-ton capacity stainless steel manual chain hoist.

also stressed the importance of adhering to maintenance and inspection programs, especially if the equipment is being operated in a highly corrosive environment. OZ Lifting outlines these requirements in an owner’s manual, included with every shipment, along with test certification. As the documentation states, the product meets a range of standards, including the American Society of Mechanical Engineers (ASME).

Both the 0.25-ton capacity manual chain hoist and trolley are in stock and ready to ship.

索具世界 Lifting & Rigging World

OZ Lifting's new 0.25-ton capacity stainless steel trolley.