Paul Wellener, Vice Chairman of the US Industrial Products and Construction practice at Deloitte, discusses how manufacturing supply chains are changing

Paul Wellener, Vice Chairman of the US Industrial Products and Construction practice at Deloitte, discusses how manufacturing supply chains are changing

Ericsson, Deloitte, Peak Design and IONETIC feature in this issue to discuss sustainable manufacturing, enduring supply chains, the need for niche battery packs and IoT sensors used in energy management

Hello Manufacturing Digital readers, It’s the last magazine of 2022 - what a year! I’ve interviewed some incredible business leaders from the manufacturing sector, more to come in the next 12 months…

In this issue, we catch up with Deloitte’s Paul Wellener, Vice Chairman of the US Industrial Products and Construction practice, who shared with us how manufacturing supply chains are evolving. Jens Erler, IoT Client Principal at Ericsson, joined us to talk about IoT sensors, AI-enabled energy management platforms and energy use optimisation. Peak Design discusses how it has cleaned up its supply chain and learned to manufacture more sustainable items, while IONETIC explains the need for niche vehicle manufacturers to have access to battery packs and how it’s meeting the need.

I’ll be back next year - see you in 2023!

HELEN ADAMSHelen.Adams@bizclikmedia.com

“ It’s the last magazine of 2022 - what a year! I’ve interviewed some incredible business leaders from the manufacturing sector ”

Pharmaceutical manufacturing company Merck has opened a new vaccine packaging facility in Singapore, which has become a biopharma hotspot.

Sanofi began construction of a US$434mn vaccine plant in April and, in 2021, BioNTech announced plans for regional headquarters in Singapore, which will include an mRNA manufacturing facility.

We need the suppliers to want to participate, cooperate, and know they have taken part in a fair process

READ MORE

When it comes to long-held supplier relationships, personal knowledge of the company is important when making supplier decisions

Latinas

EDITOR'S

READ MORE

Cellular IoT connectivity is a key enabler, allowing the optimisation of energy use, and can detect problems before they emerge

Jens Erler

IoT Client Principal, Ericsson

READ MORE

CHOICE

James

Paul Wellener, Vice Chairman of the US Industrial Products and Construction practice in Deloitte… He started working on the shop floor 30 years ago.

“An engineer by training, I then got a business degree and started in manufacturing,” says Wellener. “At that point in time, I was manufacturing parts in the automotive industry, but I moved into consulting a few years later.”

Wellener has been in consulting ever since, though he has remained consulting for manufacturing organisations, whether automotive or aerospace-based.

“I'm just naturally a person who likes operations and working to see tangible products. In manufacturing, it's so easy to see results day in and day out,” he says. “When you see a product on the assembly line, you can see your impact on it just a few hours – or a few minutes – later.”

Food and drink manufacturer Nestlé, IT giant Ericsson & Embratel are strengthening 5G technology in Brazil with new smart factories & a private 5G network.

As manufacturers dig in for the busy winter period, Rob Bright, Cloud Assess CEO, says it's crucial that workforce training is not overlooked; businesses should ensure upskilling and reskilling remains a priority.

Amid the cost-of-living crisis, business margins are under strain, with the most recent CIPS UK Manufacturing PMI pointing to the lowest growth in factory activity since June 2020.

The days of cheap overseas production may be over. Manufacturers are now returning home, hoping to reduce their reliance on international suppliers to protect their consumer base against global supply chain disruptions.

The 2D printing press was discovered in more than one culture throughout different points in history – Chinese craftsmen in the 9th century, however, carved words onto inked wooden blocks as the first iteration. In 1440, Johannes Gutenberg created the first typeface printing press, taking over from monks who used to hand-transcribe manuscripts. The recent advent of 3D printing has revolutionised the manufacturing industry, so here’s a short history.

1981 1981 1981

3D printing first documented in Japan

1980s Japan saw a transformation in the economy, with computers becoming mainstream and a place for Hideo Kodama’s rapid prototyping system, which used UV light to polymerise a photosensitive resin. Though Kodama was unable to create a patent for 3D printing, he is generally regarded as the de facto inventor.

1986 1986 1986

For American builder Charles Hull, necessity really was the mother of invention. He needed tiny custom parts made quickly for the furniture he manufactured, so he built a 3D printer that printed photosensitive resin layer by layer.

Hull filed the first patent for Stereolithography, also known as the ‘SLA’, in 1986.

The first ‘self-replicating manufacturing machine’ was created by Dr Adrian Bowyer, in what was known as the worldwide RepRap Project. Bowyer was later awarded an MBE in the New Years Honours for his dedication to 3D printing.

First prosthetic limb printed

It’s rare in history for a single limb to make history. But, in 2008, the world heard about the first prosthetic leg to be 3D printed, offering amputees a new opportunity in life. The following year, the patents moved into the public domain and manufacturers got to work.

Ukrainian school to be 3D printed

As shown by the 2008 prosthetic limb, 3D printing can have an altruistic angle. Now, this technology is moving into battle – almost literally. More than 2,000 schools have been damaged by the Russian invasion of Ukraine. Now, non-profit technology start-up TEAM4UA is working with authorities in Lviv to 3D-print a school in the city.

Atrailblazer is an innovator, someone who wants to be the first to do something – not for the glory, but because it must be done.

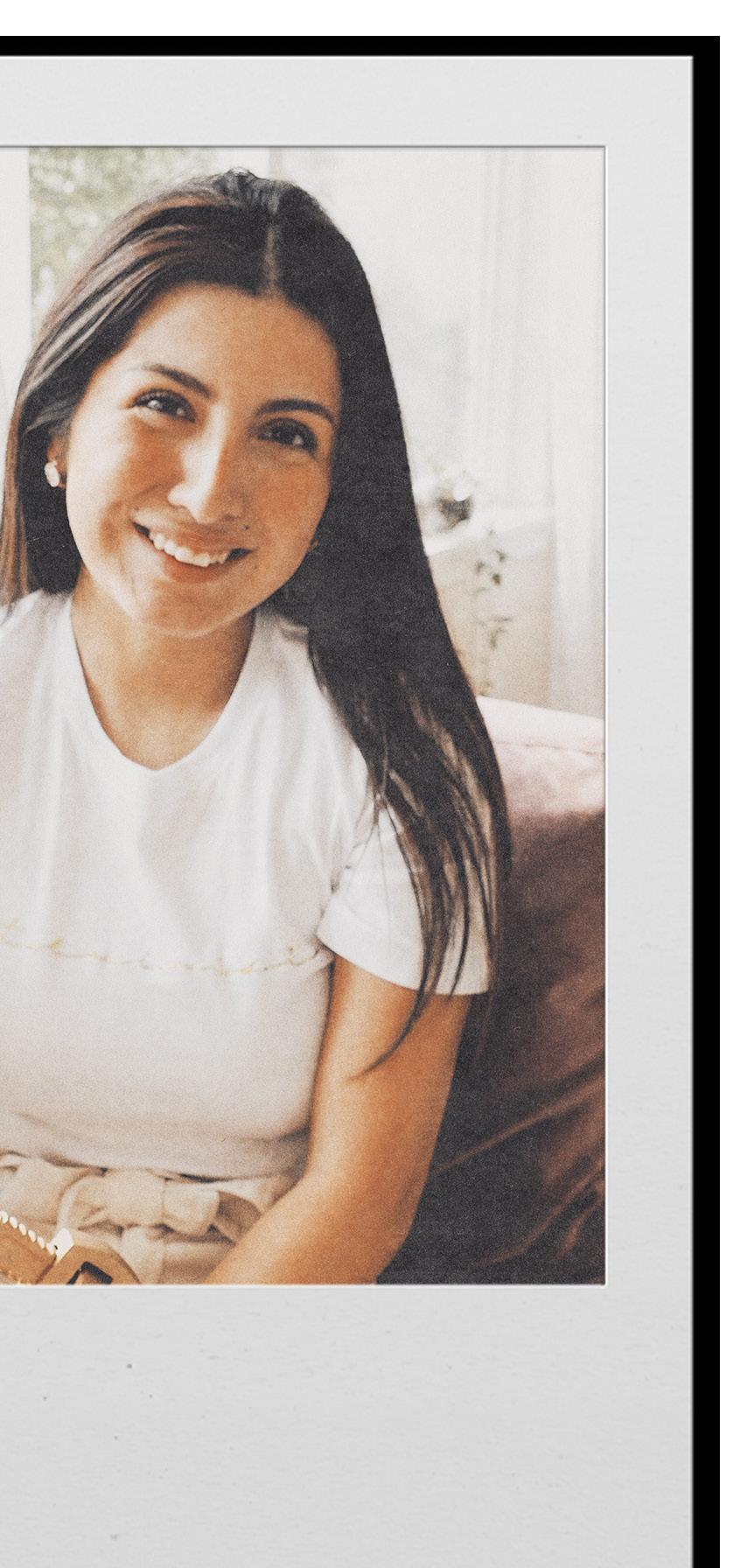

In 2019, Diana Iracheta founded Latina Engineer, an accessible resource with a focus on STEM education for Latinas, specifically those in Engineering. It is Iracheta’s hope that this will build a network of Ingenieras across the world and inspire Latina students to forge an engineering role for themselves.

“Anytime I am given a problem, my brain lights up with questions, ideas, and plans,” she says. “I even begin to envision 3D models of more efficient designs. My love for problem-solving is what got me into engineering.”

Mechanical engineering and Latina leadership

Iracheta was born in 1996, in Monterrey, Mexico. At the age of 12, she and her family moved to the USA, where Iracheta learned English within six months of their arrival. Seven years later, she became STEM Club President at Waubonsee Community College. Later, Iracheta went on to earn

an Associate’s Degree in Physics from the same College and then a Bachelor’s Degree in Mechanical Engineering from Northern Illinois University. Throughout this time, she gained experience in product design, monitoring of equipment and machinery used in the manufacturing industry.

Now based in Oswego, Illinois, Iracheta is a Manufacturing Engineer at Amsted Automotive. In her role, Iracheta is responsible for a three-person Automation Technician Team and her more recent experiences include automation design for production, implementing automation plans and fixturing for manufacturing.

Iracheta is constantly looking for ways to make the manufacturing process more efficient, especially in regards to reducing manual labour.

Showing the world that Latinas can engineer Besides having interests in problem solving and mechanics, Iracheta is also a pro at wow-ing audiences during public speaking engagements and encouraging other Latinas through her volunteer work with Latina Engineer.

“My volunteer work stemmed from my passion for engineering and dedication to expanding minority participation in STEM fields,” she said. “I am incredibly passionate about motivating women in STEM to continue their engineering education and become leaders.”

To encourage and celebrate Latinas in engineering, as well as across STEM, Iracheta founded Latina Engineer and the Diana Iracheta Foundation NFP as a place to show off Latina talent.

The non-profit organisation is a network of Ingenieras, which seeks to empower minority groups studying or working across STEM and offer them developmental resources. Latinas account for just 2% of STEM professionals and Latina Engineer aims to increase this figure. Over the past two years, Iracheta has hosted various

events where Ingenieras have shared their stories, fears and aspirations. She offers one-on-one calls with STEM students, creates educational content full of engineering school advice and job search resources – all with the vision to advance the representation of Latinas in engineering.

The foundation launched an annual conference in October, International Latina Engineer Week. The aim behind this is to shine a spotlight on all of the incredible Latinas who work in engineering and create a platform for them to network together and inspire others.

Iracheta was the Keynote speaker for SHPEtinas Region 5 Conference, part of SHPE in 2022. She received the ICCTA Pacesetter award in 2020 and is a co-author in Hispanic Stars Rising: A New Face of Power.

» “I’m the co-founder and CEO of AlisQI, where I’m focused on AlisQI’s international expansion. “I hold an MSc in Business Information Technology from Twente University in the Netherlands and have previously led multiple QMS implementation projects across the globe.”

» “AlisQI combines Quality Control with integrated SPC, Document Management and QESH Management in one user-friendly platform for manufacturing. The software is designed to automate routine tasks, eliminate variation, reduce waste, and make quality accessible throughout the organisation. The no-code approach enables key users to deploy their own processes and workflows, allowing them to embed quality management in their day-to-day operations.

»

“In all honesty, I am surprised by how many low-tech manufacturers still operate. Manufacturing is probably the only industry where you still see paper processes.

“Traditionally, a manufacturer’s focus lies on hardware automation, and administrative processes are often neglected. Of course, I am exaggerating, but the trend is very valid. There is a world to win in deploying smart technology in manufacturing and you don’t

need to be a visionary to tell what the future will look like. We often challenge manufacturers to look at other domains and be inspired by how processes are being automated. Don’t be shy in your technological ambitions. There are a tonne of AI, OCR and integration (micro)services out there these days. Deploying this technology is fairly easy. Of course, you might need to adapt some of your operation to reap benefits from these technologies, but they are democratised and available for each and every company.”

» “We see manufacturers struggling with the scarcity of personnel. This is an issue across the board. Quality managers are very difficult to find these days – just ask shop floor operators and experienced IT staff. This poses a serious risk to both the growth as well as the continuity of a manufacturer, and this issue won’t be solved any time soon. People seem to be less motivated to work in a manufacturing environment. With the big upswing in digitisation, young folks prefer office jobs over craftsmanship. That’s a shame. Manufacturers need to find a way to make their industry more attractive again. At the same time, they need to adapt their operation to become less dependent on the human factor.

“Standardisation and automation are key in that respect. For skilled IT personnel, a small or medium-sized manufacturing plant might not be the most appealing environment to work in. Deploying tools that can be implemented by the line organisation is AlisQI’s answer to this. Our no-code platform enables quality teams to implement smart quality automation by themselves. This makes them less dependent on both the shop floor workers and the IT teams.”

»

“At AlisQI, next year will all be about the empowerment of the quality worker. Our platform will be extended with smart integration features. There’s a plethora of AI, OCR and integration services available that will make life much easier as well as more efficient.

“We often look at other domains to inspire ourselves about the future of manufacturing IT. We typically look at marketing technology, as they are a frontrunner in smart and easy-to-deploy automation. Things we are currently working on are plug-and-play PowerBI integration,

where our users can use any BI tool they want to create custom reports. Other features we will release within the next months include automated PDF Certificate of Analysis (COA) data extraction and an embedded integration platform.

“With the PDF COA data extraction feature, manufacturers no longer need to review their incoming COAs manually. Instead, they simply forward the emails they receive from suppliers to AlisQI and

they’ll be provided with the charts and non-conformity detection we’re famous for.

“The embedded integration platform allows AlisQI users to create custom system or instrument integrations with easy-to-use plugand-play components. That enables the quality team to not only deploy our software in their processes, but also to create custom integrations. With these updates, we reduce the IT dependencies even more.”

“DON’T

With 2.5 quintillion bytes of data produced every day, how is it that supply chain disruptions—particularly at Tier 2+ suppliers—are still going unreported? This is the question that Dr. Lisa Smith asked herself when embarking on her PhD research at the Technical University of Vienna. Fast-forward through years of research and development, and Prewave was born. A platform that uses AI to find, understand and categorise supply chain risks; we predict supply chain disruptions well in advance.

y Predictive, real-time and historic monitoring

y Access to millions of regional, local and international news and social media sources, as well as publiclyavailable databases, in 50+ languages

y 140+ risk categories

y A 360° supplier score

y Real-time, highly relevant reporting

y End-to-end supply chain risk platform

Our process follows a logical succession of steps to achieve an unprecedented level of transparency across all supply chain tiers.

We begin with a list of your direct suppliers. With it, we map out your entire supply chain, down to the raw material. Yanfeng is one of the clients that has achieved complete supply chain visibility through this process.

Once every supplier has been identified, an in-depth screening process uncovers past incidents, establishing a risk score for each supplier. We then set up real-time monitoring for more than 140 risk categories. This allows clients like VW and BMW to stay in the know at all times—from rumours of pollution at a Tier 3 supplier to a labour strike at a shipping harbour.

Prewave takes it one step further. Our data enables the monitoring of entire commodity markets. This allows clients, like the beverage giant AbinBev, to get an exact and to-the-minute overview of the entire production side of a commodity, and anticipate shortages and disruptions well ahead of time.

Beyond improving supply chains from an operational and sustainability standpoint, Prewave leverages its technology to offer a one-of-a-kind compliance solution for international supply chain legislation. Audi, BMW and Porsche employ this approach to achieve compliance with the German Supply Chain Act, as well as other international supply chain legislations.

A company that continues to evolve to meet the demands of the market, Prewave is committed to take the platform to the next level, creating a multi-tier supply chain risk solution that covers the full risk lifecycle.

“Prewave enables us to find out about sustainability risks much earlier on, so we can respond more quickly.”

Marco Pilippi Head of Procurement Strategy, AudiBOOK A DEMO TRUSTED BY

PRODUCED BY: MIKE SADR

PRODUCED BY: MIKE SADR

There’s an old saying which, in a world awash with ‘Big Data’, has taken on greater meaning: ‘All models are wrong; some models are useful.’

But forward-thinking companies are working on how to tame overwhelming amounts of data, with machine learning (ML) and artificial intelligence (AI) to speed up processes, save on spending and find new opportunities for business growth.

These industry leaders include Las Vegas, NV-headquartered Westfall Technik. The growth trajectory of Westfall Technik has proven to be compelling for customers and the markets alike. Accelerated by the significant platform built through the acquisition of 15-20 companies over a 4-year timespan, the company has seen continued solid organic growth from their customers in their target markets of healthcare and consumer packaged goods and continues on their new customer acquisition journey.

Westfall’s corporate methodologies, backed by their “Stacked Integration Model”, certainly deliver as these relate to their value proposition supported by correlative moulding processes and effective Industry 4.0 concepts.

Westfall’s portfolio of healthcarerelated products features medical devices, pharmaceutical delivery systems, diagnostic tools, consumer health products, and

Westfall Technik’sDavid

Schultz andArkestro’s Edmund

Zagorin explain how machine learning and game theory can benefit supply chains across industries

a range of services that also includes the moulding of plastic parts used in COVID-19 diagnostic rapid testing for both home and clinical use.

VP and Chief Supply Chain Executive David Schultz joined Westfall in February this year. He is responsible for the global supply chain across the entire enterprise, covering a broad range of critical responsibilities, including all areas of procurement and supply chain functions.

“Westfall is a company that's made over 15 acquisitions in the last four-and-a-half

years. This activity, along with significant organic growth, has resulted in explosive expansion, with hundreds of millions of dollars in revenue,” explains Schultz. “And, as all those companies were brought together, I was approached by Mark Gomulka, the CEO of the organisation, who said, ‘We need somebody to come in and put this all together, make this all work as a cohesive unit’. And that’s now my major goal: to bring all those operating units together and build teams of people who can leverage the proper intelligence.”

Among Schultz’s early business decisions was the introduction of a Predictive Procurement Orchestration solution provided by San Franciscobased Arkestro for use across the entire Westfall enterprise.

“I first met David at a Chief Procurement Officer event, where he was chairing the conference and giving a talk about the state of the market and some of the changes that he was seeing,” says Arkestro Founder and CEO Edmund Zagorin. “I saw that we had alignment in terms of how we perceived the market landscape. One of those key points of alignment was that there's so much volatility and complexity that it can be really challenging to deliver business impact fast using any digital solution that requires widespread user adoption to be successful. That's something that we take really seriously, so David and I got to talking, ultimately finding that we had vision lock.”

Zagorin has a background in quantitative network analysis and strategic sourcing consulting. He and his team launched Arkestro to help large enterprise procurement teams solve tough supply chain problems, drive continuous process improvement, and – in his own words –be their supplier's best customer.

Westfall is also an Arkestro Corporate Alliance Partner and will advise on the functionality of new Arkestro products and capabilities. Westfall recently joined the Association of Plastic Recyclers’ Demand Champions Program and the Ellen MacArthur Foundation's Global Commitment for a New Plastics Economy.

The Arkestro platform embeds preferred outcomes into any organisation's system or process, which practically means

TITLE: CHIEF SUPPLY CHAIN EXECUTIVE COMPANY: WESTFALL TECHNIK INDUSTRY: SUPPLY CHAIN LOCATION: SOUTH CAROLINA, US

David is a senior management executive whose broad business experience and data-driven approach enables organisations to dramatically reduce costs in extremely competitive markets.

He is an imaginative dealmaker passionate about building trusting relationships and highly skilled at managing several billion dollars of spend resulting in significant dividends and speed-to-margin.

Prior to joining Westfall, David served as VP CSCO/Chief Procurement Officer for several public and privately held companies.

He thrives in organisations that promote and support the acquisition of new skills, technologies, and transformative thinking.

TITLE: FOUNDER AND CEO

COMPANY: ARKESTRO

INDUSTRY: PROCUREMENT

LOCATION: SAN FRANCISCO, US

Edmund Zagorin is a procurement thought leader obsessed with the power of recommendations to fix broken processes and supply chains. Prior to founding Arkestro, Edmund worked as a consultant focused on datadriven supplier negotiations for large healthcare providers, contract manufacturers and multi-campus retail brands.

Edmund is widely recognised as an expert on the emerging role of machine learning and artificial intelligence in procurement and has presented executive briefings on this topic to leadership teams.

pre-populating validated data about the supplier, the pricing and commercial terms of a transaction. It accomplishes this using an AI model that simulates a procurement cycle before it happens and then sends recommendations on quotes to the suppliers. Arkestro also routes more purchases to preferred suppliers (including suppliers that align more with ESG and risk objectives) and the price recommendation functionality saves significant time and resources.

Environmental, social and governance (ESG) criteria are vitally important, so Westfall Technik also leverages the Arkestro platform

to ensure they are working with suppliers that meet their environmental goals, while improving the effectiveness and productivity of the internal supply chain team.

"Westfall Technik's decision to work with Arkestro validates the value that we bring to managing supplier relationships, while also highlighting an important and innovative use case for us," says Zagorin.

Investing in technology means investing in people Schultz says he had a very specific challenge he wanted to address at Westfall and was initially drawn to the

EDMUND ZAGORIN FOUNDER & CEO, ARKESTRO

“Westfall Technik's decision to work with Arkestro validates the value that we bring to managing supplier relationship”

SCHULTZ CHIEF SUPPLY CHAIN EXECUTIVE, WESTFALL TECHNIK

SCHULTZ CHIEF SUPPLY CHAIN EXECUTIVE, WESTFALL TECHNIK

platform’s predictive pricing feature, which he felt was unique and well-suited to offer transparency and credibility with the supplier base. Once he took a closer look at the platform, he realised it was the most practical solution to provide the best value possible in the least amount of time.

“David came to me shortly after joining the organisation and suggested multiple options to accelerate the transformation to one operating system and mindset,” says Westfall Technik CEO Mark Gomulka. “It was vitally important that our supplier and customer partners fully understood the power of One Westfall and the competitive advantages for their respective businesses. The Arkestro platform has been a key part of our strategy to attain this vision on the supply side of the equation.”

“It's not just technology, it's people, and the pedigree of Edmund’s background and experience, as well as his vision for the company, was very reassuring to us”

DAVID

Schultz found that the team of people behind the platform were also eager to support his own business operations, as well as the vast ecosystem of suppliers he deals with on a daily basis.

“We invest in people,” explains Schultz. “It's not just technology, it's people, and the pedigree of Edmund’s background and experience as well as his vision for the company – this was all very reassuring to us. In particular, we need the suppliers to want to participate, cooperate, and know they have taken part in a fair process.

“Data-driven solutions are the ultimate goal – we should all do our best to ignore any opinions masquerading as fact,” says Schultz. “There’s certainly a tremendous amount of information out there about AI and ML, which is very important, but I often remind myself that it’s the intersection of artificial intelligence with human intelligence that really makes it all work.”

pricing for everything from materials to spare parts. This might include suppliers working with manual spreadsheets, having to copy and paste prices and pitches, dealing with procurement teams on a case-by-case basis, and a wealth of additional measures, each created from scratch by individual companies and teams.

56% percentage of companies that experienced more disruptions to their supply chain in 2021 than in previous years, according to the Hubs Supply Chain Resilience Report 2021

“And, in many cases when it comes to long-held supplier relationships, personal knowledge of the companies is important when making supplier decisions,” says Zagorin. “Traditionally, the entire process can take, conservatively speaking, weeks, but frequently, months and sometimes years depending on the complexity. When we looked at this, we knew that if we simulated the process at the start where requests are pre-filled with validated data-driven recommendations, Arkestro could make it so much easier and faster for suppliers to conduct business.”

Arkestro is at the forefront of costmodelling by ML and behavioural science, says Zagorin, following the groundwork on dynamic pricing laid by Expedia and Uber.

“Predictive pricing is a concept that fundamentally simplifies a transaction,” says Zagorin. “It’s not necessarily better for one side or the other; the advantage is it's so much faster to settle the terms of the transaction, enabling both parties to move on to building great supplier relationships.

The Arkestro platform is designed to cut through the disparate collection of workflows and workarounds that a typical company has to deal with today in order to source

“Data-driven solutions are the ultimate goal – we should all do our best to ignore any opinions masquerading as fact”

Arkestro’s data and behavioural economics research backs this up, demonstrating how the platform is better in financial terms for the procuring organisation, particularly for those companies looking to scale operations across more spend without necessarily having additional procurement headcount available.

“That's really Arkestro’s mission: to amplify the impact of procurement’s influence,” says Zagorin. “And that's where we see the power of embedding ML recommendations on price and supplier terms into processes wherever they are – be that email, spreadsheets or other systems the company might already be using.”

Westfall’s work with Arkestro has allowed Zagorin’s team to learn from a large company working with thousands of suppliers. Zagorin himself has said that David’s input has been something of an inspiration, particularly his drive to get teams working with data to see what benefits can be generated.

“David got his team to ‘kick the tyres’ and challenge us really early on when we came together,” says Zagorin. “I’m always a student of our clients, and David has a great ability to get people in a room to say, ‘We’re going to see how this works, so let’s analyse the

data and use it carefully and strategically to make the proper decisions’. David has referenced on several occasions that, in the business world, we all need to be cautious of ‘opinion masquerading as fact’. It's been really powerful and a big part of what's made the partnership so great.”

Schultz says that he and his team have been impressed with the Arkestro platform’s ability to bring order to traditional networks of suppliers, contacts and contracts, which inevitably produce a cascading flow of actionable data at every turn.

“It's been awesome to see what our extended team at Westfall has done with the platform,” says Schultz. “Most procurement and supply chain leaders

DAVID SCHULTZ CHIEF SUPPLY CHAIN EXECUTIVE, WESTFALL TECHNIK“It's the intersection of artificial intelligence with human intelligence that really makes it all work”

will tell you every industry's a little bit different, every category of spend is a little bit different, that there are unique dynamics with a supplier relationship based on how much money you spend with them. Or perhaps it’s a case of ‘Do we have a contract with them? How often is that potentially going to change? Is the contract being used as a kind of ad hoc purchase?’ All of these questions create a tremendous amount of complexity –and complexity can often mean more work. That’s why having model-driven recommendations can help cut through the noise.

“It’s that old expression,” he says. “‘All models are wrong; some models are useful’

– we would say that all models are wrong, some models are useful, but the Arkestro model – used in partnership with our customers/suppliers – is the best way to get a tangible business impact.”

WESTFALL TECHNIK »

ARKESTRO »

Tfor up to 10% of global emissions, making it the second-biggest industrial polluter. Perhaps even more shockingly, though, is McKinsey’s 2020 report on the climate impact of fashion, which revealed that the trajectory of the industry as a whole had strayed up to 50% away from the agreed 1.5-degree pathway.

While much of this pollution comes from emissions created as products are moved across the supply chain and wasted garments rot in landfills, the way clothes are manufactured plays a big part, too. For example, water used in dyeing processes

pollution, while denim retailer Levi Strauss projects that creating and wearing just one pair of 501 Levi’s uses 3,781 litres of water over the product’s lifetime.

In addition to the environmental impact, people who make clothes can suffer from the impact of hazardous chemicals and unsafe working environments, particularly in countries such as Bangladesh.

But, in recent years, consumers have shifted from wanting cheap items fast, to well-made clothing from a clean, ethical supply chain. Fashion houses and textile manufacturers have, surprisingly, listened.

The e2open connected supply chain platform provides the end-to-end visibility and collaboration you need to tackle unpredictability. Build trust and confidence with your channel, supply, logistics, and global trade partners. Take control of supply constraints through direct procurement and meet customer commitments in the face of disruptions and scarcity.

The connected supply chain. Moving as one™. www.e2open.com

E2open and the e2open logo are registered trademarks of e2open, LLC, or its affiliates.

Annie Nyborg is the Sustainability Director at Peak Design. In her role, she oversees all of Peak Design's social and environmental efforts.

“I took a somewhat circuitous route to Peak Design and the sustainability field,” says Nyborg. “I did an Undergrad at Stanford for International Relations and then received my Master’s in Latin American Studies at UCSD. After that, I worked primarily in policy research and programme evaluation.”

But Nyborg didn't want to be in the evaluation field forever. She’s been passionate about photography since high school and planned to transition to a fulltime freelance career in photography.

Through a few chance encounters, however, she ended up meeting with Design Peak's CEO, Peter Dering.

“We hit it off,” she says. “He offered me a position initially in business development, but I was hesitant to join a product

“MY TRAINING HELPED ME ASK THE RIGHT QUESTIONS AND FIGURE OUT HOW PEAK DESIGN COULD HAVE THE BIGGEST IMPACT”

ANNIE NYBORG

SUSTAINABILITY DIRECTOR, PEAK DESIGN

company because of its environmental impact. I realised that it actually posed a wonderful opportunity to create change within the corporate sector, which I think is imperative to successfully tackle some of our biggest environmental and social challenges.”

Nyborg accepted the position and, within a year of being there, was asked if she could focus entirely on Peak Design’s corporate social responsibility work.

“I liked Peak Design's products, but the company had done nothing to address its environmental or social impact, so I felt there was a great opportunity there,” explains Nyborg. “There weren’t a lot of academic tracks or degree programmes in sustainability back when I was in school, but my training as an evaluator helped me ask the right questions and figure out where and how Peak Design could have the biggest impact. Fortunately, the whole team has always been super supportive of the proposed environmental work that makes my job easy.”

Now, Peak Design is manufacturing more sustainable products because the company wants to keep designing and selling great gear in perpetuity.

“If we destroy our planet, it'll be pretty tough to do business,” says Nyborg wryly.

Peak Design’s primary design work is completed in San Francisco, but the company works closely with its partners in both Vietnam and China on sample iteration.

“Prior to COVID-19, our team would be out working with our international manufacturing partners multiple times a year, and we're slowly getting back into that routine,” says Nyborg. “Our primary soft goods factory is located in Vietnam, and

our primary hard goods factory is in China. Really cleaning up a supply chain is one of the greatest challenges a product brand has because of the complexity of the chain.”

Peak Design has invested significant resources into its ‘Tier One’ facilities to ensure compliance of its high social and environmental standards.

“Our goal is to continue working through our supply chain tiers to implement these standards throughout, but it is going to take time and significant resources.”

As a certified B Corp, Peak Design’s Fair Trade process was relatively low lift, due to having a strong and engaged partner in Vietnam.

“Our partner had been subcontracting out factory space to manufacture our products and because they didn't have full control over those factories, the audit findings consistently came back very bad,” explains Nyborg. “We attempted to support those factories and invested in capacity building to bring them up to our standards, but were unsuccessful.”

Operating consistently out of factories that failed to meet Peak Design’s environmental and social standards wasn't going to work for Nyborg, so the company’s Vietnam partner proposed building a brand new factory that Peak Design would manage directly and see to it that its standards were met.

“That factory construction was completed about three years ago,” says Nyborg. “When we engaged with Fair Trade to certify the factory, our partners were able to relatively quickly implement the necessary changes to meet Fair Trade standards.”

During her time at the company, Nyborg has navigated several big challenges at Peak Design. “I'm not sure if there is

any single greatest challenge,” she says. “In terms of nuts and bolts challenges, ensuring our supply chain meets our environmental and social standards is probably the most challenging. But otherwise, our challenges often lie in a more conceptual realm of how a small product design company can have the greatest possible environmental and social impact.”

Peak Design tries to look at root causes and question how it might tackle those, as opposed to putting a plaster on symptoms. Setting a good example for responsible business is important, and can be achieved via the use of Fair Trade Certified factories.

“Being a small business, we aren't vastly moving the dial by that alone,” she says. “I personally keep pondering business' role in policy development and government affairs. Many say that business should stay out of politics – and I certainly would love to stay out of politics; that said, there is big business money being used to push legislation that is antithetical to the work that we do. Unfortunately, I think the only way to address some of these critical root causes in the timeframe that will make a difference is through policy.”

Throughout her role at Peak Design, Nyborg has learned some big lessons.

“Don't worry about messing up,” she says. “Take everything as a learning opportunity and be transparent. Above all, don't let perfection be the enemy of progress”.

Her last piece of advice is one that many worldwide brands in fashion and beyond could do with taking notice of, as it’s particularly damaging to ongoing environmental efforts.

“Don't greenwash. Just don't. It significantly hinders the good work we're all trying to do.”

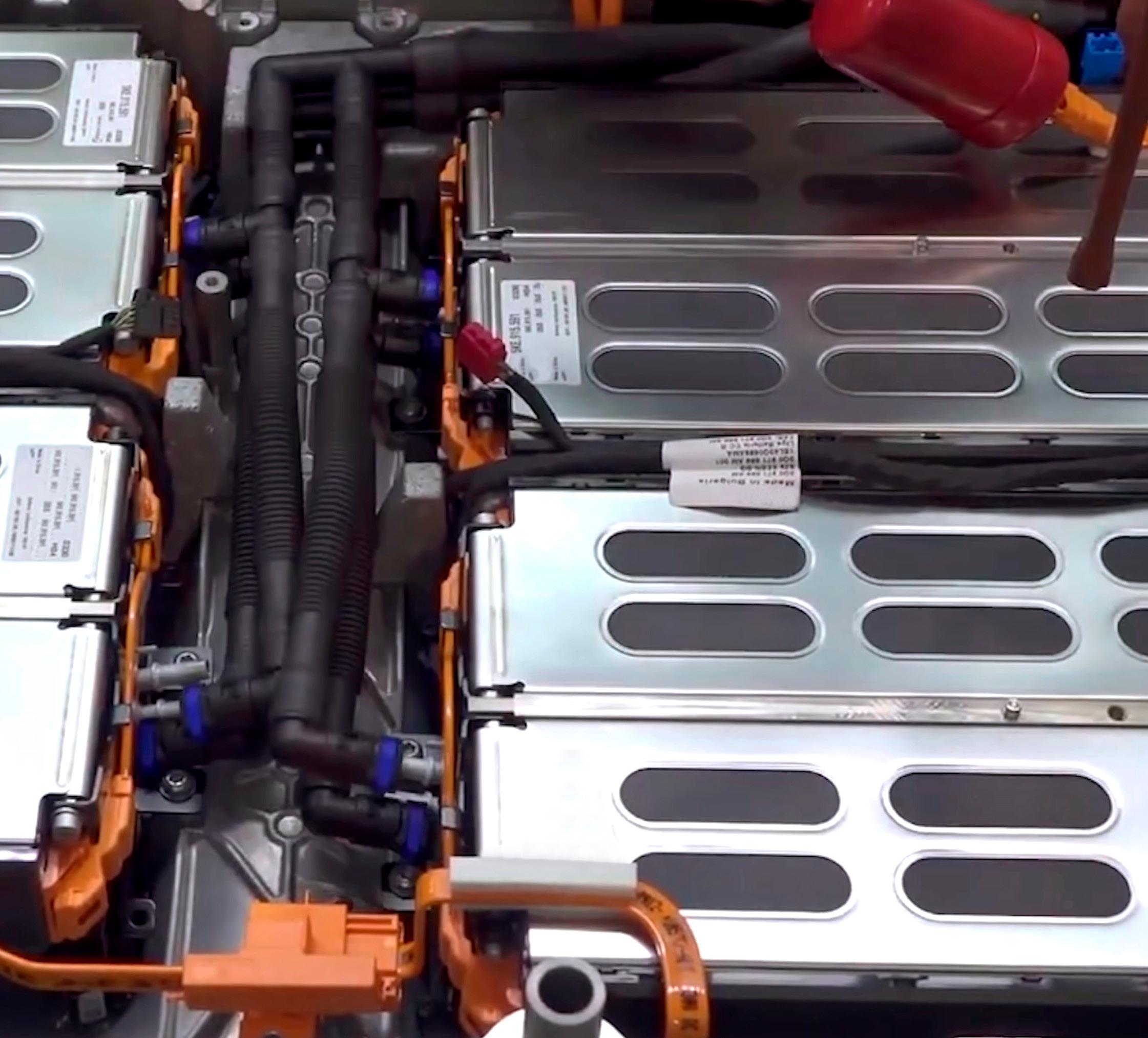

Niche automotive companies are currently not well served by the current market options for battery packs. What’s more, the options that do exist right now are either very expensive, the minimum order quantities are set too high or the engineering optimisation isn't good enough. This leaves specialised automotive companies with a bad product or a product that has no business case.

This year, James Eaton, became the CEO and Co-Founder of IONETIC, a battery pack technology company focusing on both design and manufacturing of battery packs, specifically for niche automotive companies.

JAMES EATON CEO AND CO-FOUNDER, IONETIC

JAMES EATON CEO AND CO-FOUNDER, IONETIC

The business has developed a bespoke battery pack design platform, which can automatically generate designs according to multiple fully adjustable parameters in a matter of days – helping automotive manufacturers strike an efficient balance between cost and customisation. “We looked holistically at the whole problem to work out: how do we actually provide good engineering solutions that are cost effective?”

Eaton studied Mechanical Engineering at Imperial College London, a subject with a high dropout rate.

“I did four years there and I got my Master’s,” he explains. “My third and fourth year projects were both on battery packs. One was on the design and manufacture of racing specification battery packs and then my dissertation was modelling and simulation of racing specification battery packs.”

He was immediately hired by Imperial as a researcher and spent more than a year working with industry partners on automotive battery pack analysis, data and design. Then, after four years of studying battery packs, Eaton set out to build his

“We always want to serve niche vehicle players, we never want to leave those people behind”

own company, with a manufacturing strategy to build battery packs in the UK for any car company or any other niche vehicle battery pack application.

“If you have a £20mn vehicle development budget and it currently costs £50mn to develop a battery pack, that means you can't electrify,” explains Eaton. “There's just no route in. You also can't go to the big cell OEMs because their minimum order quantity is US$1bn. That's really where we're targeting, because there aren't really any great solutions if you're a niche vehicle manufacturer trying to electrify. There are only compromises.”

The companies that support certain pockets of society are the niche vehicle manufacturers – they're the people who make trucks, buses, delivery vans and those are the vehicles that are made in low quantities, yet they need to be electrified, too. All these things need to be served, whether it's the biggest car company on the market or the 100th niche vehicle manufacturer in the UK, so IONETIC will have its first production line for prototypes in 2023.

“We'll go into full scale production, scaling up over the next three-four years. By 2027, we should have the capability

A modern network must be able to respond easily, quickly and flexibly to the growing needs of today’s digital business. Must provide visibility & control of applications, users and devices on and off the network and Intelligently direct traffic across the WAN. Be scalable and automate the process to provide new innovative services. Support IoT devices and utilize state-of-the-art technologies such as real-time analytics, ML and AI. And all these must be provided with maximum security and minimum cost.

This is the power that brings the integration of two cloud managed platforms, Cisco Meraki and Cisco Umbrella. This integration is binding together the best of breed in cloud-managed networking and Security. cisco.com cisco CiscoSecure CiscoSecure

to manufacture five gigawatt hours of battery packs. In the process of setting up IONETIC, Eaton realised that while there was a lot he knew about battery packs and electric vehicles, he would still have to learn how to run a business.

“There’s been a lot of the business side to learn, a lot of economics especially relevant at the moment,” Eaton says. “I’ve learned that you've just got to be adaptable and stay open to learning all the time. One of the things I like to have a philosophy on is that I'm always trying to learn what I don't know.”

New businesses come up against many challenges - from establishing a headquarters to Work From Home policies. But with LinkedIn having 57 million organisations on its platform, how does a new business choose its own name? This was something Eaton struggled with, but using his engineering mind, he found a solution. “I wanted to make up a word, so in true engineer fashion I sat down with Excel and wrote

JAMESdown every battery word, then every prefix and suffix I could think of. I just came up with IONETIC!”

IONETIC are set to sell across the UK and Europe, but are they concerned about going further afield?

“We always want to serve niche vehicle players,” says Eaton. “We never want to be in a position where we're denying service to people because they only want a hundred battery packs because that's sort of part of the founding mission of the company. We never want to leave those people behind.”

“We never want to deny service to people because they only want a hundred battery packs”

EATON CEO AND CO-FOUNDER, IONETIC

“We've got to identify all the suppliers, we've got to have backups and strong relationships with these companies”

JAMES EATON CEO AND CO-FOUNDER, IONETIC

As a part of the business learning process, Eaton has received hands-on experience in the varied challenges of the supply chain.

“The supply chain is going to be the biggest challenge,” says Eaton. “Outside of that I think, it really is just about getting from zero to one. Getting through all of the design stages obviously takes some time. We’re oneyear-old, so we haven’t gone through all that yet, but that's the biggest ongoing challenge and it will be for the foreseeable future. But one day we will be in a place where we are the go-to for battery pack design and manufacturing, at least in the UK and hopefully in the long term in Europe, as well.”

Eaton has a lot of things on his 2023 to-do list. As the company grows, it must continue hiring. “We’re growing the team significantly, supporting design testing and manufacturing quality. You've got to get all your steps in place for ISO 9001.”

ISO 9001 is a part of the International Organisation for Standardisation quality management systems set of standards. This helps businesses make sure that they meet consumer and stakeholder needs across all statutory and regulatory requirements, dependent on their product.

In addition, Eaton will continue to strengthen IONETIC’s supply chain goals.

“We've got to identify all the suppliers, we've got to have backups and strong relationships with these companies.”

Clearly, while setting itself apart in its sector, IONETIC isn’t too different from other manufacturers when it comes to the nitty-gritty.

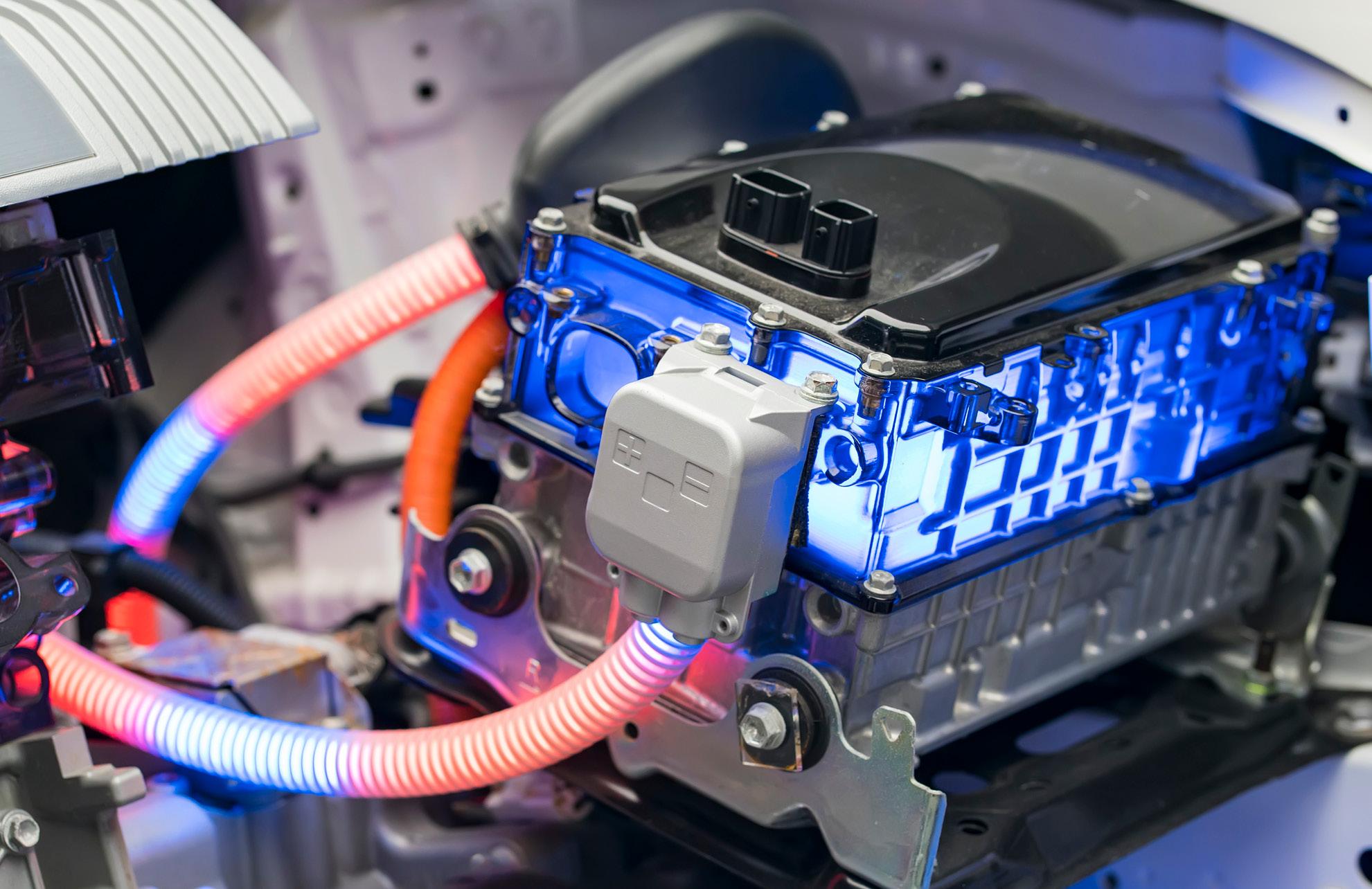

Jens Erler, IoT Client Principal at Ericsson, explains how IoT sensors and AI-enabled energy management platforms can enable energy use optimisation

WRITTEN BY: HELEN ADAMSricsson is one of the world’s leading providers of Information and Communication Technology (ICT) to Communication Service Providers. The company works hard to ensure that consumers and enterprises experience the full potential and value of connectivity through the creation of technology and services that are both adoptable and scalable.

Jens Erler is a IoT Client Principal at Ericsson and is more than qualified for the role. “My expertise lies in cellular

connectivity, digital industry transformation and business model innovation,” Erler explains. “I have more than 25 years of experience across different industries leveraging IoT connectivity to accelerate digital transformation and sustainability.”

Before joining Ericsson's IoT organisation, Erler was the head of Ericsson's energy practice in Western and Central Europe. Over the years, Erler has had a comprehensive experience working across industries and developed a deep-rooted passion for responsible digital transformation.

Suppeco delivers a paradigm shift in B2B attitude - leveraging customer-supplier relationships to drive collaborative performance excellence, relationship driven resilience, and sustainability deep into the ecosystem & supply chain. Ask us about collaborative relationship driven co-resilience. Ask us about operational compliance for sustainable supply chain.

“I see it as critical to making the world an improved, sustainable society for future generations,” Erler says. “I am committed to driving meaningful change through the work I do each day, and Ericsson, the company I have the honour of working for, plays a critical role in enabling digital transformation.”

According to Erler, connectivity is not only about putting a SIM card into a device.

“Such devices (sensors measuring environmental conditions, for example)

may need to connect to many different cellular networks in different countries and may require certain connectivity service levels – and will definitely need to be protected against cyber-attacks,” says Erler. “All of that needs to be managed at a large scale to allow our enterprise customers to build a successful business with solutions contributing to global sustainability targets.”

By providing customers with the tools and services to do all this, Ericsson helps them remain successful in what will eventually be a fully-connected world, while also reducing their carbon footprint.

,

AND ”

“If we want to work toward a more connected and sustainable future, we know that we must work hard to deliver positive change. At Ericsson, we realise and appreciate the role we are able to play in shaping that change in order to create a brighter tomorrow.”

In Ericsson’s efforts to facilitate digital transformation, the company is specifically focusing on industries where such transformation can achieve a positive sustainability impact on business operations of its enterprise customers. One such industry is the construction sector.

“In the building sector, we are working with enterprises providing energy management solutions to property owners and operators

“I’M COMMITTED TO MEANINGFUL CHANGE THROUGH THE WORK I DO, AND PLAYS A CRITICAL ROLE IN ENABLING DIGITAL ”

by allowing them to monitor, control, and optimise energy usage, but also to detect faults in heating systems that may cause unnecessary energy consumption early enough,” says Erler.

This is critically important in today’s energy environment, providing property owners with the ability to decrease their energy costs and CO2 emissions, while still increasing property value.

Through robust cellular IoT connectivity management solutions, Ericsson has been able to help its customers create a measurable saving of 10% energy cost through adjusting heating system parameters according to the local climate conditions of each building, its energy performance, and projected heating demands as we approach the winter months.

“Alongside IoT sensors and actuators and AI-enabled energy management platforms, cellular IoT connectivity is a key enabler, allowing the optimisation of energy use, and can even detect problems before they emerge, saving time and money,” says Erler.

“Another example is logistics. Telematics solutions for truck transport companies can allow such companies to reduce fuel consumption significantly through route optimisation, tire pressure optimisation and coaching truck drivers to apply an ecofriendly driving style. Accumulated, such solutions also have the potential to reduce fuel consumption by 10% or more.”

A third example is the electrification of transport.

“Electric vehicle charging stations depend on scalable cellular connectivity

management to enable predictive maintenance, consumer payment and –increasingly important – the growing electric vehicle charging, which will generate a lot of load in electricity networks which creates the need balance electricity supply and consumption along the feeder lines of electricity distribution networks.”

For Erler, these are just a few examples. Each industry has an environmental footprint, but digital transformation can lead to a significant reduction of this.

As the US and Europe edge towards the winter months, property managers with portfolios that lack energy efficiency are growing increasingly concerned about what the coming months will bring.

“With 75% of buildings across Europe not being energy efficient, consumers are already scaling back when it comes to setting their thermostat temperatures and monitoring their electricity usage in preparation for colder temperatures,” says Erler. “The proper next steps for these regions would be to adopt connectivity, deploy building energy management solutions, and invest in renewable energy, such as solar panels, wind farms and green hydrogen solutions to mitigate what could potentially be devastating winters in the coming years.”

Ericsson sees great importance in raising renewable and energy efficient targets, as well as putting significant resources behind achieving them.

“Through predominately automated processes, we give enterprise customers across all industries the capability to optimise processes for both efficiency and sustainability. Deploying technology that

is scalable and predictive is paramount,” says Erler. “From an Ericsson internal perspective, we pride ourselves on our commitment to achieve Net Zero carbon emissions by 2030. The more that renewable energy is deployed and the more we deploy connectivity-driven solutions that improve energy efficiency, the closer we will come to achieving that goal. Limiting the risk of triggering climatic tipping points within the ecosystem

is a primary goal to achieve a sustainable future and a liveable planet for all.”

One example is the Lewisville, Texas 5G Smart Factory which runs 100% on renewable electricity. “This factory is a full-scale operation, demonstrating the potential of connectivity while fully embracing Industry 4.0,” explains Erler.

“With the goal of achieving Net Zero in Ericsson’s own activities by 2030, integrated environmental systems have been designed

to reduce energy consumption by 24% and indoor water usage by 75% when compared to a similar building. With factories in general being major electricity users, it is paramount to enable energy monitoring tools that gather data from building management systems for tracking realtime energy consumption. Our hope is that others will adopt efficient and sustainable practices to enhance productivity and energy efficiency.”

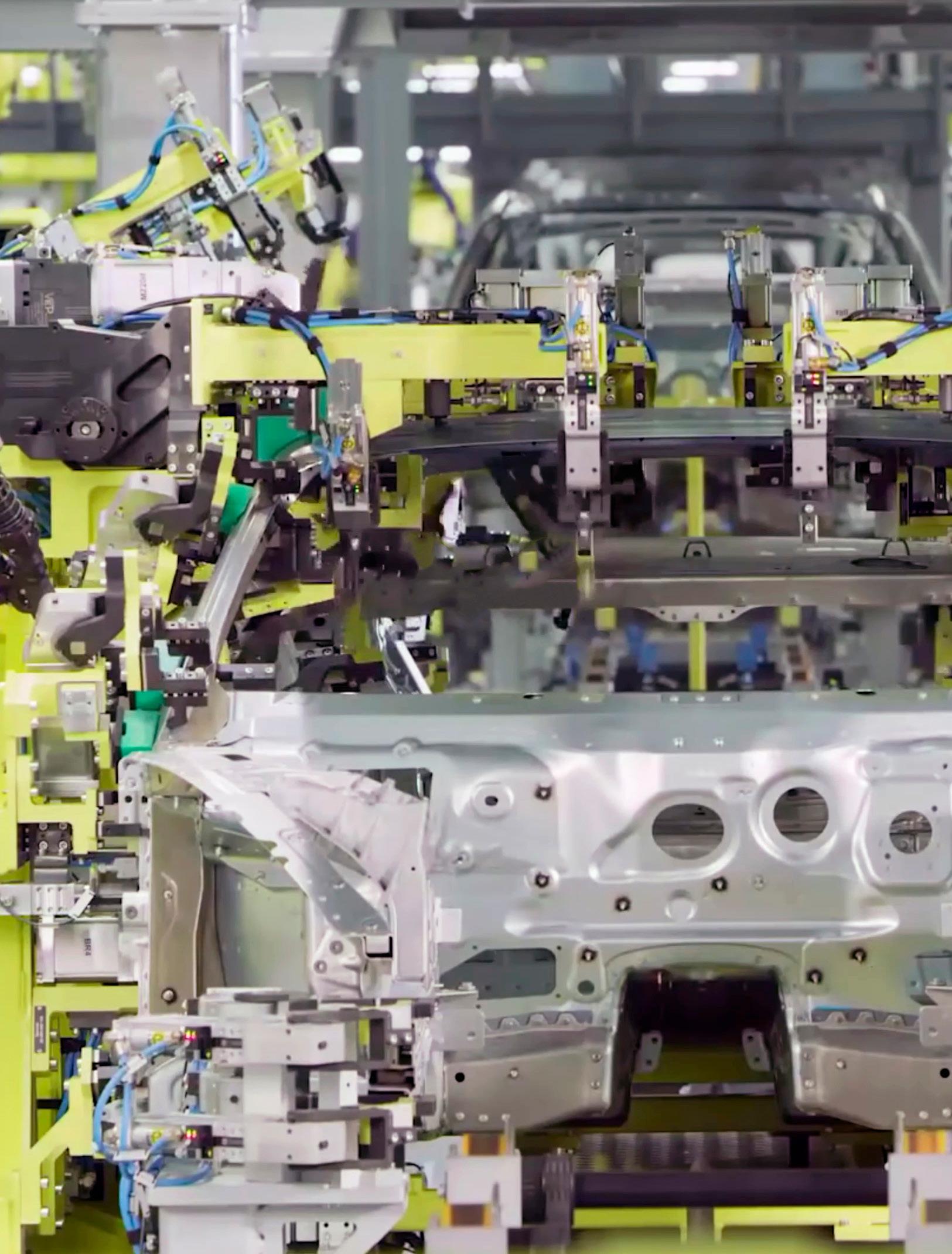

Paul Wellener, Vice Chairman of the US Industrial Products and Construction practice at Deloitte, discusses how manufacturing supply chains are changing

WRITTEN BY: HELEN ADAMSeloitte recently did a study that was focused on perceptions of talent. The company interviewed parents, asking for their perceptions on manufacturing and whether they would encourage their child to go into the profession. Results showed that, over the past four years, there has been an almost 50% increase in the positive responses given by parents about the manufacturing profession. Someone helping construct this more positive perception behind the scenes is Paul Wellener, Vice Chairman of the US Industrial Products and Construction practice in Deloitte. He also leads client organisation teams and sits on the board of the National Association of Manufacturers, representing Deloitte.

Manufacturing is a lucrative target for cybercrime. As a large industry with valuable data and a growing IoT attack surface, your data is of direct value to hackers.

“An engineer by training, I then got a business degree and started in manufacturing, working in shop floor supervision 30 years ago,” says Wellener. “At that point in time, I was manufacturing parts in the automotive industry, but I moved into consulting a few years later.”

Wellener has been in consulting ever since, though he has remained consulting for manufacturing organisations, whether automotive or aerospace-based. Sitting on the National Association of Manufacturers, Wellener utilises his considerable knowledge – particularly in manufacturing consulting – to represent Deloitte.

“I'm just naturally a person who likes operations and working to see tangible products. In manufacturing, it's so easy to see results day in and day out,” he says. “When you see a product on the assembly line, you can see your impact on it just a few hours – or a few minutes – later.”

Deloitte's smart factory consulting Deloitte has made its name in industrial products and construction across the manufacturing business.

“We serve large global aerospace companies, heavy equipment companies, the global HVAC and electrical companies in the industrial space,” explains Wellener.

Deloitte manufactures a wide range of products and services, as well as offering operations-oriented consulting. Wellener is an expert in technology consulting for different software packages.

“We do a number of things around smart factories. For example, how to digitise your operations. We also do a number of things in mergers and acquisitions; we do our financial audit work for many of those clients who are our test clients. We do tax and trade-type of work for them, on a global basis.”

PAUL WELLENER VC OF THE US INDUSTRIAL PRODUCTS AND CONSTRUCTION PRACTICE, DELOITTE

PAUL WELLENER VC OF THE US INDUSTRIAL PRODUCTS AND CONSTRUCTION PRACTICE, DELOITTE

“We're still working to bring things closer together”

PAUL WELLENER VC OF THE US INDUSTRIAL PRODUCTS AND CONSTRUCTION PRACTICE, DELOITTE

PAUL WELLENER VC OF THE US INDUSTRIAL PRODUCTS AND CONSTRUCTION PRACTICE, DELOITTE

This year, Wellener led Deloitte into a study of the manufacturing supply chain, Meeting the Challenge of Supply Chain Disruption, in conjunction with the Manufacturers’ Alliance.

“We surveyed around 200 executives in July who are all supply chain, transportation, logistics, and manufacturing executives, generally oriented around North America,” said Wellener. “We got the results from them as it relates to some of the supply chain challenges that everybody is facing, whether they're in the US or other parts of the world.”

Results showed the very heavy impact from supply chain disruption on all sorts of aspects of business and the frequency of those disruptions increasing.

“Recently, we're seeing some waning in those disruptions, but they're still at higher levels than ever before,” says Wellener. “Over half of the executives stated that their companies have definitely had impacts from a profitability standpoint because of these supply-chain-oriented disruptions. I'd say that's probably some of the key things coming out of the study.”

Results showed shipping delays, part shortages, transportation delays, the talent shortage and people-challenges as the biggest issues.

“Supplier networks are not as broad and robust as they are probably going to become in the future,” says Wellener. “We're seeing a lot of companies now thinking about dual supplies and not just having one supplier, but bringing suppliers closer to the point of production.”

This trend is known as ‘nearshoring’ or ‘onshoring’, but this will mean nothing if the part shortages, transportation challenges and other problems are not solved.

The results generally hit Wellener’s expectations, but he was surprised at how high of an impact labour was.

“In

“We've seen labour shortages, but we were thinking that they were spread like peanut butter across the board and impacting businesses in lots of different areas. Yet, I think we saw an outsized impact on the labour shortages in manufacturing and the supply chain.”

Traditional manufacturing supply chains are changing

During Wellener’s time at Deloitte, the skills he learned over the past three decades have remained massively relevant.

“If I reflect, I would say my biggest lesson is that the more things change, the more things stay the same,” says Wellener. “30 years ago, what we were doing in the shop floor around lean manufacturing and eliminating waste is what we're doing today through the nearshoring work that's going to take place. We're still working to bring things closer together.”

While some things never change, Deloitte is implementing technology in a very different way than it did back when Wellener started in the 1980s.

“We all have mobile devices that have the ability to connect anywhere and have any application on them. So there's a lot of things that are in place today that enable us to do many of those things we would have loved to do 35 years ago. But I'd still say that's the lesson, that the more things change, the more they stay the same.”

Over the next 12 months, what else does Wellener anticipate will stay the same – or change? “We're very bullish on the opportunities for us to continue to support manufacturers,” he says.

“Deloitte is generally very bullish on the manufacturing part of the economy. There's so much pent-up demand in corporations for capital goods that they haven't been able to get their hands on in the last couple of years.

“There's still pretty significant consumer demand for many types of products out there,” Wellener says. “Manufacturing is going to continue to be strong for the next six to twelve months.”

Deloitte interviewed parents and asked for their perceptions on manufacturing and whether they would encourage their child to go into the profession. Results showed that, over the past four years, there has been an almost 50% increase in the positive responses given by parents about the manufacturing profession.

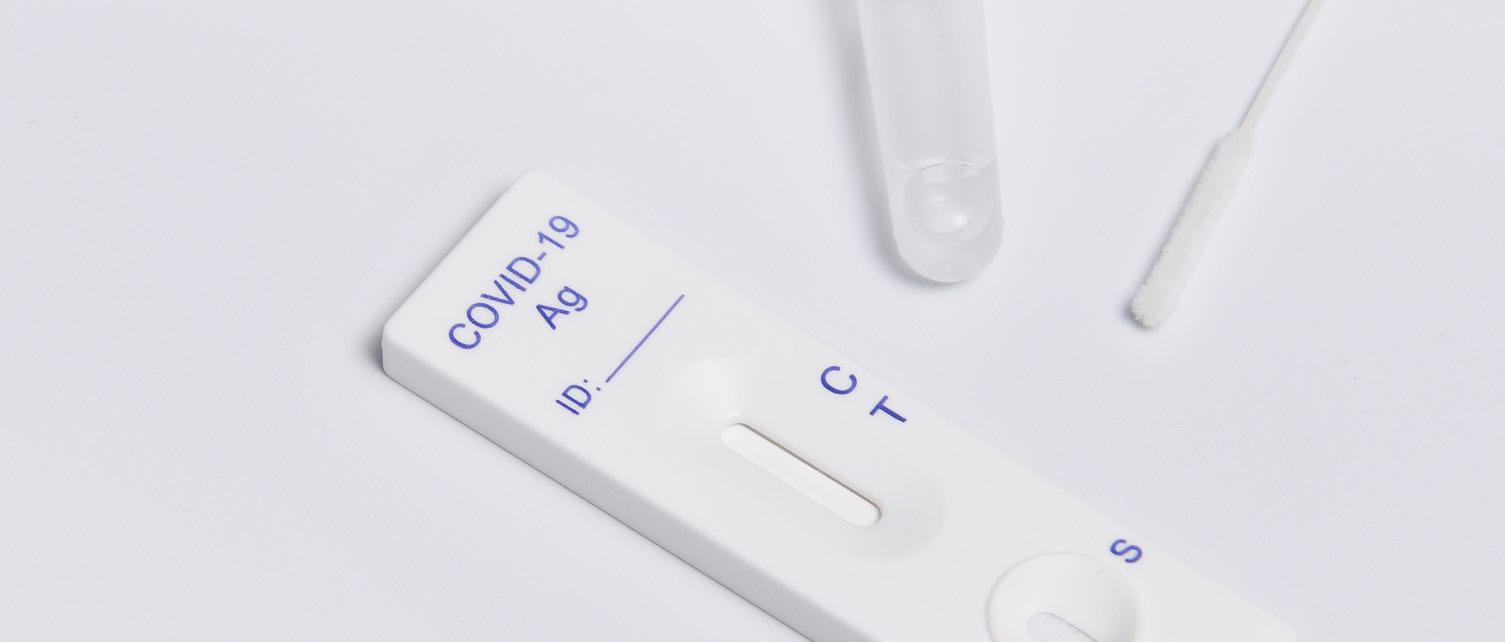

Medical equipment manufacturers have been busy over the past two years, increasing efficiency and widening the distribution of care. At this time, more than any other, manufacturers are aware that the eyes of the world are upon them, expecting low costs, sustainable sourcing and a smooth supply chain.

Here are our Top 10 medical equipment manufacturers of the moment – some of which were founded in the 1800s, others far more recent, yet all of them working with dedication to make the world a healthier place with widespread access to healthcare.

Medical equipment manufacturers have been busy over the past two years, increasing efficiency & widening the distribution of care. Here’s our Top 10

Siemens Healthineers AG –a subsidiary of Siemens AG, the German multinational conglomerate corporation and biggest industrial manufacturer in Europe – is determined to fight the world’s most threatening diseases and widen global access to healthcare.

Siemens Healthineers is a global manufacturer of superconducting magnetic resonance imaging (MRI) magnets, which are used for medical applications such as MRI body scanners. Siemens Healthineers Llanberis is also the manufacturer of IMMULITE reagents, used in blood analysers to assist in diagnoses and treatment.

Cardinal Health manufactures and distributes items used in medical laboratories.

In a recent partnership with TerraPower, Cardinal Health announced a manufacturing and distribution agreement for Actinium-225, which is used in drug trials for diseases such as breast, prostate and colon cancers.

The company is present in more than 30 countries and, with 44,000 employees worldwide, Cardinal Health is a bastion of modern healthcare.

A Fortune 500 Company, Stryker has 46,000 employees and has spent five consecutive years as one of Fortune's ‘World's Best Workplaces’. In 2021, Stryker had global sales of US$17.1bn, had spent US$1.2bn on research and development, and owned 11,657 patents.

With 44 manufacturing locations across the world, Stryker is a leading medical technology company determined to improve global healthcare. The company builds items across orthopaedics, medical and surgical, neurotechnology and spinal care.

BD is a global medical equipment manufacturing company with an ambition to advance the health of the world. BD offers support to the healthcare heroes at the forefront of the sector, through the development of new technologies, services and solutions.

BD’s laboratory scientists work hard to advance researchers’ capabilities to build the next generation of diagnostics. The company is dedicated to keeping costs low, manufacturing increasingly efficient medical equipment and improving safety for healthcare professionals.

As a frontrunner in medical technology, GE Healthcare helps healthcare professionals to make more informed decisions through the use of data analytics and applications. Its 50,000 employees lead a business that prioritises precision health and improved outcomes.

GE Healthcare recently invested US$30mn into a new manufacturing line at its facility in Cork, Ireland, creating 140 jobs. The line will manufacture injectable diagnostic imaging agents used in healthcare procedures such as Computed Tomography.

Philips is a leader in health technology, with a zeal for meaningful manufacturing. This year it expanded a factory in Maharashtra, India, for manufacturing mobile surgery systems.

All big businesses are moving in a sustainable direction and Philips is no different. Nevertheless, it’s unwavering in its commitment to healthcare, covering everything from patient monitoring systems to dental care.

"Philips is committed to keeping healthcare accessible and affordable,” said Hans de Jong, President of Philips, Netherlands. “By 2020, we will be CO2 neutral worldwide.”

Global healthcare leader Abbott has 113,000 staff members working in 160 countries, with the aim of helping people live life more fully, across all life stages. Headquartered in Chicago, Abbott Laboratories was founded in 1888 and is known for manufacturing a range of healthcare products.

In 2020, Abbott manufactured one of the first rapid COVID tests, which could indicate a positive result within 15 minutes. The company sent 3 million tests to California’s most disadvantaged school districts for free.

Johnson and Johnson lives by the idea: ‘Profound change requires boldness’. As one of the most recognised healthcare brands in the world, the company has boldly been producing world-changing breakthroughs for over 130 years.

The company is currently researching how to optimise plastics manufacturing, with the ambition of reducing the harm caused to the environment as well as human health. In addition, Johnson and Johnson is also developing medical devices that can create 3D-printed artificial joints.

For more than 60 years, medical equipment manufacturing company Medtronic has been on a mission to do the extraordinary – to “contribute to human welfare by application of biomedical engineering in the research, design, manufacture, and sale of instruments or appliances that alleviate pain and restore health” – to, ultimately, extend life.

The company works across neuroscience, in fields such as gastric therapies through to spinal technologies, as well as in surgical robotics and patient monitoring solutions.

Medtronic recently announced that it will separate the company's combined Patient Monitoring and Respiratory Interventions businesses (‘NewCo’) under the company's Medical Surgical Portfolio.

"This separation will allow Medtronic to focus our company and our capital on opportunities better aligned with our long-term strategies to accelerate innovation-driven growth, positioning NewCo to unlock value,” said Geoff Martha, chairman and CEO of Medtronic.

Merck (known as ‘MSD’ outside of the USA and Canada) has one purpose: to use the power of cutting-edge science to save and improve lives all across the world.

Since its inception in 1891, the company has dedicated itself to bringing hope to patients and their families by developing medicine and vaccines, with aims to be the top research-intensive biopharmaceutical company in the world.

CEO Rob Davis recently discussed Merck’s business development plans

and sustainability ambitions with its investors and analysts. “Frankly, we continue to see a portfolio of opportunities that we are interested in,” said Davies. “That is our priority, because we continue to believe the best thing we can do for long-term value creation is to invest in the sustainability of our business, which is investing in the pipeline of the future.”

“We will act only when science and value align,” agreed CFO Caroline Litchfield.

Your global partner for the manufacturing of high-quality lipids

“We continue to believe the best thing we can do for long-term value creation is to invest in the sustainability of our business”