17 minute read

Breaking News

More than $1.3 Million Awarded to Support Research Linking Monash and Industry Federal Minister for Education, the Hon Dan Tehan MP, recently announced that three Monash University research projects will receive more than $1.3 million in Australian Research Council (ARC) Linkage grants, to be matched by industry partners.

The Linkage program promotes research partnerships between researchers and business, industry, community organisations and other publicly funded research agencies. By supporting the development of partnerships, the ARC encourages the transfer of skills, knowledge and ideas as a basis for securing commercial and other benefits of research. One of the funded projects includes investigating new materials for zero carbon energy storage.

Professor Douglas MacFarlane will lead this project, which will develop new materials to advance the technology of thermal energy storage. New and inexpensive ways of storing renewable energy are urgently required. The project will focus on new materials that store thermal energy in the temperature range between 10 0 to 22 0 C that is optimal for distributed storage of solar and wind energy.

The other projects include: clarifying the legal basis for protecting geographical indications for wines; and investigating nutrient runoff to support clean water and land management.

Monash University Provost and Senior Vice-President, Professor Marc Parlange, said the results were evidence of the strength of the University’s record for enterprise and innovation. “With its unrivalled record of collaboration with industry partners to pioneer discoveries and advance new technology, Monash is consistently recognised as Australia’s most innovative university,” he said.

“The latest ARC Linkage outcomes demonstrate Monash researchers are building on that record even further. My warmest congratulations to everyone who has been successful this funding round.”

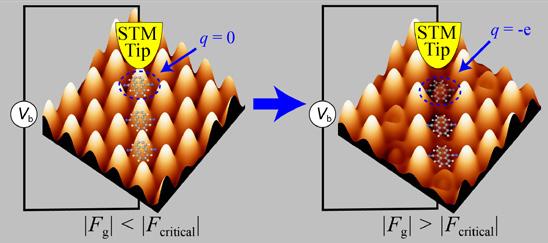

Controlling the Charge State of Organic Molecule Quantum Dots in a 2D Nanoarray A Monash University study has fabricated a self-assembled, carbonbased nanofilm in which the charge state (electronically neutral or positive) can be controlled at the level of individual molecules, on a length scale of around one nanometre. The atomically-thin nanofilm consists of an ordered two-dimensional (2D) array of molecules which behave as ‘zero dimensional’ entities called quantum dots (QDs). This system has exciting implications for fields such as computer memory, light-emitting devices and quantum computing. The School of Physics and Astronomy study shows that a singlecomponent, self-assembled 2D array of the organic (carbon-based) molecule dicyanoanthracene can be synthesised on a metal, such that the charge state of each molecule can be controlled individually via an applied electric field. “This discovery would enable the fabrication of 2D arrays of individually addressable (switchable) quantum dots from the bottom-up, via self-assembly,” said lead author Dhaneesh Kumar, a PhD student in the FLEET Centre of Excellence. “We would be able to achieve densities tens of times larger than state-of-the-art, topdown synthesised inorganic systems.” Quantum dots are extremely small – about one nanometre across, which is equivalent to a millionth of a millimetre. Because their size is similar to the wavelength of electrons, their electronic properties are radically different to conventional materials. Ordered arrays of charge-controllable quantum dots can find applications in computing memory, as well as light-emitting devices (such as low-energy TV or smartphone screens).

New Centre to Address AI and Digital Ethics

A new centre for artificial intelligence (AI) and digital ethics has been launched by the University of Melbourne, to address ethical, policy and legal challenges posed by new technologies. Combining expertise from Melbourne Law School, Melbourne School of Engineering, the Faculty of Arts and the Faculty of Science, the Centre for Artificial Intelligence and Digital Ethics (CAIDE) will bring insights to AI and digital ethics with a uniquely Australian focus.

The Centre seeks to facilitate cross-disciplinary research and teaching to promote the fair, safe and accountable use and regulation of AI and digital technologies, drawing on a range of different perspectives including from the humanities, social sciences, science, law and engineering.

Scanning tunnelling microscope images of DCA on Ag(111).

BREAKING NEWS

University of Queensland Charging Up for a Sustainable Future

(L to R): University of Queensland Professor Aidan Byrne and University of Queensland Chief Operating Officer Greg Pringle.

The switch has been flicked on one of Queensland’s largest behind-the-meter battery storage systems, capable of powering 175 average homes for 24 hours. The Tesla Powerpack battery system delivers two megawatt-hours of energy storage and will help the University of Queensland meet its renewable energy goals.

University of Queensland Chief Operating Officer, Greg Pringle, said the large-scale battery and inverter system could store enough energy to power up to 10% of the St Lucia campus for two hours.

“To put it into perspective, the university uses a large amount of electricity to power lecture theatres, laboratories, libraries and other facilities for more than 50,000 students and staff,” Pringle said.

“We are on track to become the first university in the world to offset 100% of our electricity use using our own renewable energy generation. This battery storage system will help us to support that ambitious goal - it will complement the Warwick Solar Farm which is nearing completion, and recently won a coveted Australasian Green Gown Award.”

The $2 million investment, funded through the earnings generated from University of Queensland’s rooftop solar arrays, has the energy storage equivalent of around 500,000 standard AA batteries.

University of Queensland’s Energy and Sustainability Manager, Andrew Wilson, said the battery storage system was a key component of the University’s plan to become an active participant in the energy market from the start of 2020. “We can now trade in the wholesale energy market – the goal is to charge when prices are low and renewable energy is abundant, and then discharge when demand and prices are high,” Wilson said. “To facilitate this we are using a custom control system which was developed by one of our engineering graduates, to monitor wholesale energy prices around the clock and automatically control our trading of energy.”

University of South Australia Researchers Support NASA to Keep Astronauts Safe

Associate Professor Craig Priest (South Australian Node Director of the Australian National Fabrication Facility (ANFF) and Foundation Fellow at the University of South Australia’s Future Industries Institute) is set to play an important role in keeping astronauts safe, as part of a new partnership with the National Aeronautics and Space Administration (NASA).

Associate Professor Priest is leading research into the development of microfluidic sensor platforms (laboratories miniaturised on to a microchip) designed to monitor human health factors. These platforms will be an initial focus of the international partnership between NASA and the ANFF.

Associate Professor Priest says the partnership will harness some of the exciting research in nanotechnology and microfluidics, being undertaken at UniSA’s Mawson Lakes campus in a world class research environment, supported by the ANFF.

“When you are working and travelling in space there is no doctor on board or regular health testing facilities, and we know astronauts are operating in a challenging environment,” said Associate Professor Priest.

“We are aiming to work with NASA to develop non-invasive health self-assessment, and possibly wearable tools that will be able to analyse things like sweat and saliva and track health effects in real time. The research supports ambitions for further and longer journeys into space and will help astronauts to monitor and mitigate the physiological effects of longer exposure to space environments.”

Director of the University of South Australia’s Future Industries Institute, Professor Emily Hilder, said the partnership with NASA is a strong indicator of the quality and relevance of the research being undertaken here in South Australia.

“This is a hugely exciting project and testament to the world class talent we have at UniSA. It also shows that UniSA researchers are playing an important role in some of the many applications supporting the international space industry.”

BREAKING NEWS

Successful trials of titanium-copper alloys for 3D printing could kickstart a new range of high-performance alloys for medical device and aerospace applications.

Adding Copper Strengthens 3D Printed Titanium

A recent study has found that current titanium alloys, used in additive manufacturing, often cool and bond together in column-shaped crystals during the 3D printing process, making them prone to cracking or distortion.

And unlike aluminium or other commonly used metals, there is no commercial grain refiner for titanium that manufacturers can use to effectively refine the microstructure to avoid these issues.

But now, a new titanium alloy with copper appears to have solved this problem.

Professor Mark Easton from RMIT University’s School of Engineering said their titanium–copper alloy printed with “exceptional properties” without any special process control or additional treatment.

“Of particular note was its fully equiaxed grain structure: this means the crystal grains had grown equally in all directions to form a strong bond, instead of in columns, which can lead to weak points liable to cracking. Alloys with this microstructure can withstand much higher forces and will be much less likely to have defects, such as cracking or distortion, during manufacture,” Easton said. The collaborative project involved leading researchers in the area of alloy composition and grain microstructure from RMIT University, CSIRO, the University of Queensland and the Ohio State University.

CSIRO Senior Principal Research Scientist, Dr Mark Gibson, said their findings also suggest similar metal systems could be treated in the same way to improve their properties.

“Titanium-copper alloys are one option, particularly if the use of other additional alloying elements or heat treatments can be employed to improve the properties further,” said Gibson. “But there are also a number of other alloying elements that are likely to have similar effects. These could all have applications in the aerospace and biomedical industries.”

University of Sydney Prepares for the Hydrogen Economy

University of Sydney researchers have found evidence of how hydrogen causes embrittlement of steels.

When hydrogen moves into steel, it makes the metal become brittle, leading to catastrophic failures. This has been one of the major challenges in moving towards a greener, hydrogen-fuelled future, where steel tanks and pipelines are essential components that must be able to survive in pure hydrogen environments.

The researchers found hydrogen accumulates at microstructures, called dislocations, and at the boundaries between the individual crystals that make up the steel. This accumulation weakens the steel along these features, leading to embrittlement.

The researchers also found the first direct evidence that clusters of niobium carbide, within the steel, trap hydrogen in such a way that it cannot readily move to the dislocations and crystal boundaries to cause embrittlement. This effect has the potential to be used to design steels that can resist embrittlement.

Lead researcher Dr Yi-Sheng Chen, from the Australian Centre for Microscopy and Microanalysis and Faculty of Engineering at the University of Sydney, said these findings were an important step to finding a safe solution to produce, store and transport hydrogen.

“These findings are vital for designing embrittlement-resistant steel; the carbides offer a solution to ensuring high-strength steels are not prone to early fracture and reduced toughness in the presence of hydrogen,” Dr Chen said.

Senior author Professor Julie Cairney, from the Australian Centre for Microscopy and Microanalysis and Faculty of Engineering at the University of Sydney, said these findings were a positive step towards implementing clean fuels. “Hydrogen is a low carbon fuel source that could potentially replace fossil fuels. But there are challenges with the use of steel, the world’s most important engineering material, to safely store and transport it. This research gives us key insights into how we might be able to improve this situation,” Professor Cairney said.

Top: Dr Yi-Sheng Chen with the Atom Probe Tomography, key equipment that will enable his research.

Bottom left: Illustration highlighting the association of hydrogen (red) with the dislocations in the crystal structure of steel.

Bottom right: Illustration highlighting the concentration of hydrogen atoms (red balls) at the crystal boundaries and dislocations in steel.

BREAKING NEWS

(L to R): Governor of New South Wales, the Honourable Margaret Beazley AO QC is greeted by Professor Hala Zreiqat AM.

The University of Sydney has provided $10.5 million to create a bioengineering facility “that brings together excellence in research and teaching in service of better health outcomes for us all.”

The Governor of New South Wales, the Honourable Margaret Beazley AO QC, recently joined University of Sydney ViceChancellor and Principal, Dr Michael Spence AC, and Professor Hala Zreiqat AM to launch the new, state-of-the-art $10.5 million Australian Research Council Centre for Innovative BioEngineering facility at the University of Sydney.

Speaking at the launch, Dr Spence said, “This laboratory sums up much of what we want to do at the University and what we think is the future of New South Wales and Australia. The new facility is a place that brings together excellence in research and teaching in service of better health outcomes for us all.”

Leading the centre is biomedical engineering academic and 2018 NSW Premier’s Woman of the Year, Jordanian-born, Professor Zreiqat. She has pioneered advances in tissue bioengineering and the creation of 3D-printed materials such as tendons, ligaments and bone.

“The centre aims to provide researchers with the interdisciplinary skills and mentorship to be leaders in the rapidly evolving, highly innovative field of bioengineering,” Professor Zreiqat said.

“Our brand-new $10.5 million laboratories will allow our researchers to make fundamental discoveries that will shape the future of healthcare,” she said.

Scientists Discover Ripple in Development of Complex Oxides

Research from a team led by scientists at the United States Department of Energy (DOE)’s Argonne National Laboratory, offers a new, nanoscopic view of complex oxides, which are promising materials for advanced microelectronics.

The new research reveals insights about freestanding complex oxides that could eventually create an entirely new research field: complex oxide microelectronics.

Using scanning probe microscopy, the team studied lead zirconium titanate (PZT), a type of single-crystal complex oxide ferroelectric thin film. Such single-crystal films possess ideal properties for microelectronics – they are highly polarized, endurable and fast-switchable, making them suitable for future ferroelectric random-access memory chips, for example.

Growing these thin films requires temperatures of about 700°C, which can deteriorate the interfacial layer’s properties if the PZT is grown directly on silicon. So the researchers grew the PZT on a more amenable substrate – a base of strontium titanate (STO) with a ‘sacrificial layer’ of lanthanum strontium manganite (LSMO) sandwiched in between. To transfer the PZT thin film to another substrate, the researchers broke the bonds that united it with the LSMO.

After transforming the PZT into a freestanding film, the research team flipped the film over and gently redeposited it onto an identical STO-LSMO substrate. This gave a first-ever view of PZT’s detached underside.

The team used electrostatic force microscopy with 20nm radius probes to measure the material’s local ferroelectric properties. Their analysis showed that the local static properties of the bottom surface of freestanding PZT were quite similar to those of the top surface.

This finding is very encouraging for future complex oxide microelectronics, because it confirms that the interfacial surface of the transferred PZT film is a high-quality ferroelectric layer. That means the transfer technique should be able to combine the best materials from different worlds, such as PZT (ferroelectric) and silicon (semiconductors). So far, no direct growth technique has achieved this without damaging the interfacial surface.

Scanning tunneling microscopy topography of a rippled MoS2 single layer as a result of strain relaxation (bottom). The corresponding dI/dV map at the valence band edge (middle), and the strain map (top) are overlaid. (Image by Argonne National Laboratory.)

BREAKING NEWS

Five Key Opportunities Identified for Hydrogen Industry Growth A report from the national science agency, CSIRO, has mapped the critical research steps Australia must take to realise a potential 7,600 jobs and $11 billion a year, by 2050 from the burgeoning hydrogen industry. The report found investing in research could solve industry challenges to create five key national opportunities: hydrogen exports; integration of hydrogen into gas networks; transport; electricity systems; and industrial processes.

Steps to translate Australia’s strong hydrogen research capability into a key pillar of the nation’s energy and export profile are laid out in Hydrogen Research Development and Demonstration (RD&D): Priorities and Opportunities for Australia.

Australia’s current hydrogen research footprint includes 23 institutions actively exploring hydrogen in various technology and research areas, as well as another 23 hydrogen-specific demonstration projects and research facilities around Australia. CSIRO Research Director, Dr Patrick Hartley, said CSIRO was on a mission to bring together industry, government and other research organisations to fast-track emerging hydrogen technologies.

“This isn’t limited to the domestic industry development – we’ll link Australian expertise with international projects,” Dr Hartley said. “The overall focus will be on enabling Australia’s domestic and export hydrogen industries.

“Importantly, solving the challenges identified can have a multiplier effect that boosts demand for hydrogen – particularly in large scale industrial settings – and encourages further hydrogen supply cost reductions through improvements in efficiency and economies of scale.”

In developing the report, researchers undertook extensive consultation including interviews with representatives from 35 industry and government organisations, over 80 interviews with researchers from 23 institutions, and an extensive literature review.

GLOBAL TECHNOLOGY LOCAL SUPPORT Email: enquiry@bestech.com.au

Dynamic & Fatigue testing system

Ergonomic, Versatile, High Performance Testing System

Testing wide range of materials:

Advanced/ Biomedical Manufacturing Assemblies Dental Implants

TMF, LCF, Fracture Mechanics, HCF, High-strain rate & Component testing

www.bestech.com.au

Call: (03) 9540 5100

BREAKING NEWS

Olympus Introduces new Ultrasonic Capability Source: Olympus Australia

Olympus has introduced the Omniscan X3 phased array flaw detector into the non-destructive testing market. A new key feature is the Total Focus Method (TFM) which brings new imaging, similar to techniques used in medical ultrasound. For materials experts this gives a new way of finding and studying material flaws, such as hydrogen attack, cracks, corrosion, bonding and more.

The new feature uses a phased array ultrasonic probe where each element is fired and every other element receives, so there is a time-based waveform for every point. The TFM is a method of analysing this data and creating an image. Because the beams travel at many angles, the image shows a better definition of the shape of the reflector and is easier to understand.

Olympus is a world-leading manufacturer and distributor of high quality analytical, optical and precision engineering products, for geochemical, scientific and industrial applications. The Olympus industrial leadingedge testing technologies include X-ray fluorescence, X-ray diffraction, remote visual inspection, ultrasonic testing and microscopy.

New Study Brings Astronomical Approach Down to the Nanoscale

Researchers at Columbia University and the University of California, San Diego, have introduced a novel ‘multi-messenger’ approach to quantum physics that represents a technological leap in how scientists can explore quantum materials.

“We have brought a technique from the inter-galactic scale down to the realm of the ultra-small,” said Dmitri Basov, Professor of Physics and Director of the Energy Frontier Research Center at Columbia University. “Equipped with multi-modal nanoscience tools, we can now routinely go places no one thought would be possible as recently as five years ago.”

The work was inspired by ‘multi-messenger’ astrophysics, which emerged during the last decade, as a revolutionary technique for studying distant phenomena, like black hole mergers. Simultaneous measurements from instruments such as infrared, optical, X-ray and gravitational-wave telescopes, can, taken together, deliver a physical picture greater than the sum of their individual parts. conventional electronic semiconductors. One example is materials with properties that can be controlled by light, which can offer improved functionality, speed, flexibility and energy efficiency for next-generation computing platforms.

Experimental papers on quantum materials have typically reported results obtained using only one type of spectroscopy. The researchers have now shown the power of using a combination of measurement techniques to simultaneously examine a material’s electrical and optical properties.

The researchers performed their experiments by focusing laser light onto the sharp tip of a needle probe coated with magnetic material. When thin films of metal oxide are subject to a unique strain, ultra-fast light pulses can trigger the material to switch into an unexplored phase of nanometer-scale domains, and this change is reversible.

By scanning the probe over the surface of their thin film sample, the researchers were able to trigger the change locally. They also simultaneously manipulated and recorded the electrical, magnetic and optical properties of these light-triggered domains with nanometer-scale precision.