The Insulation tester, Leak Tester Tester, Shaver Leak Tester and Cable Continuity Tester are easy-to-use devices for verifying the functionality of equipment for safety

McGan Insulation Tester

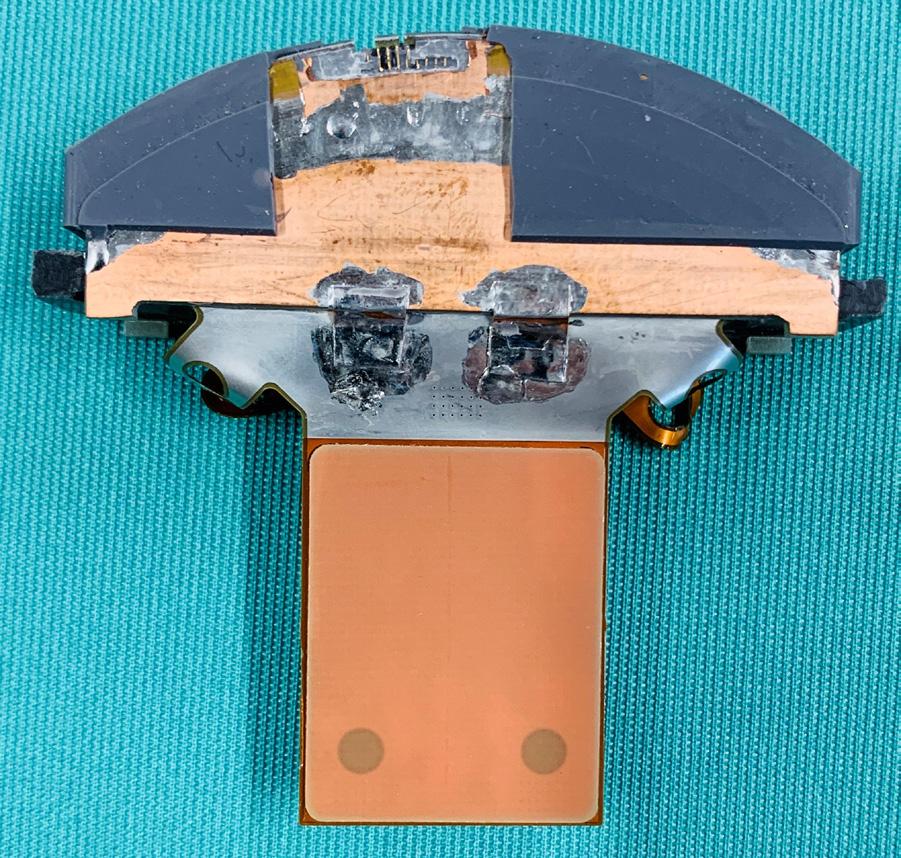

Detect & locate defects such as pinholes, cracks and bare spots in the jacket or coating of laparoscopic and bi-polar electrosurgical instruments

Test the functionality of automated & handheld endoscope leakage testers with healthmark’s new Leak Tester Tester.

Test the quality of monopolar and bipolar cords with this user-friendly, durable device. A green light noti es the user that the cable passed testing.

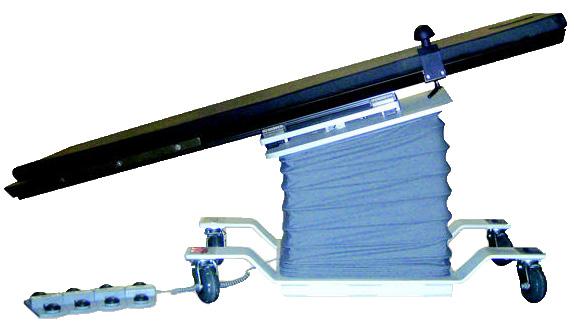

Shaver Leak Tester

Designed for pressure testing arthroscopic shavers to help identify leaks caused by failing seals that degrade over time from repeated use and processing.

For more of Healthmark’s intelligent solutions for instrument care & infection control, visit hmark.com hmark.com | 800.521.6224 | healthmark@hmark.com

P.12 SPOTLIGHT

p.12 Professional of the Month: WO1 Tyler J Scott, M.S.

p.14 Association of the Month: Oklahoma City Biomedical Association (OKCBA)

p.16 Next Gen: Kaleb Kasitz

p.18 Department of the Month: The Christ Hospital Healthcare Technology Management Department

p.20 Company Showcase: Collaborative Medical Solutions

P.22 INDUSTRY UPDATES

p.22 News & Notes

p.30 Ribbon Cutting: Emeritus Clinical Solutions

p.32 AAMI Update

p.34 ECRI Update

p.36 Tech Choice Awards Nominations

P.40 THE BENCH

p.40 Biomed 101

p.43 Tools of the Trade

p.44 Webinar Wednesday

P.46 FEATURE ARTICLES

p.46 Roundtable: CMMS

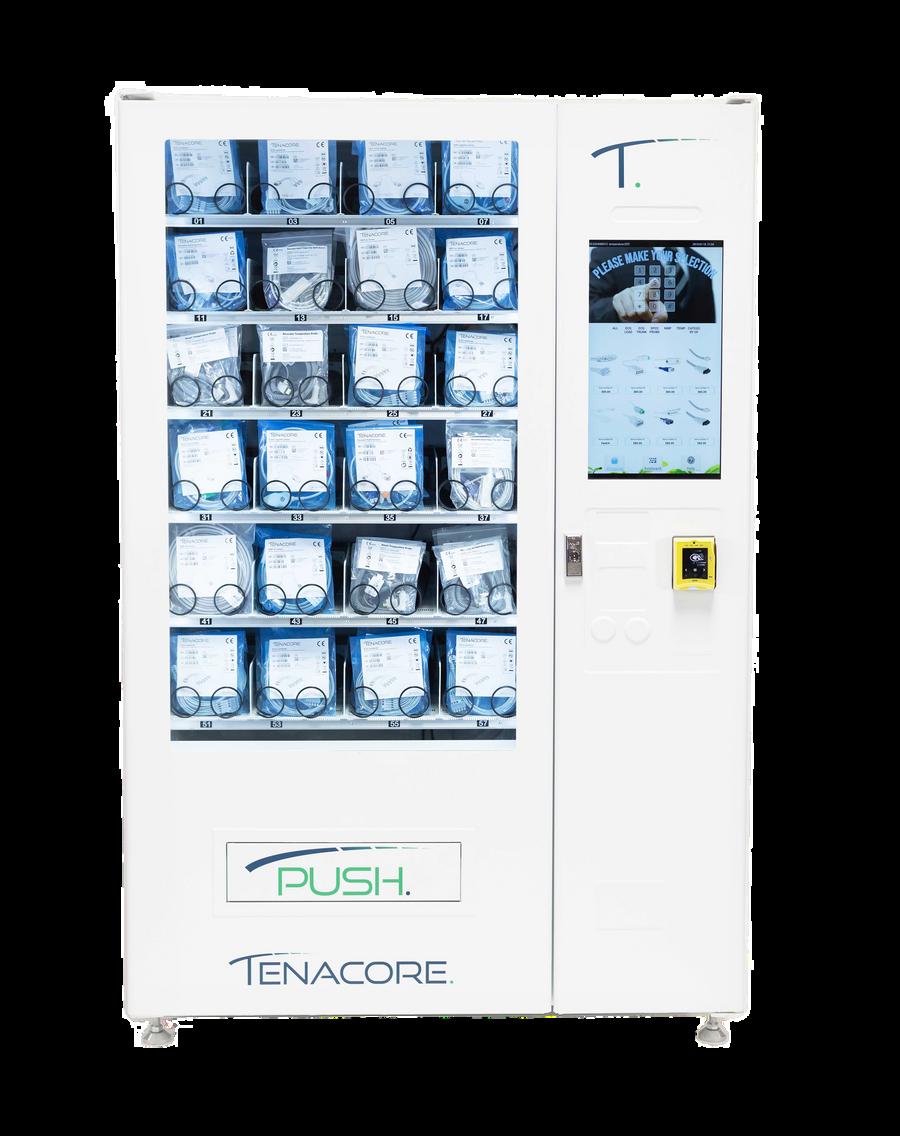

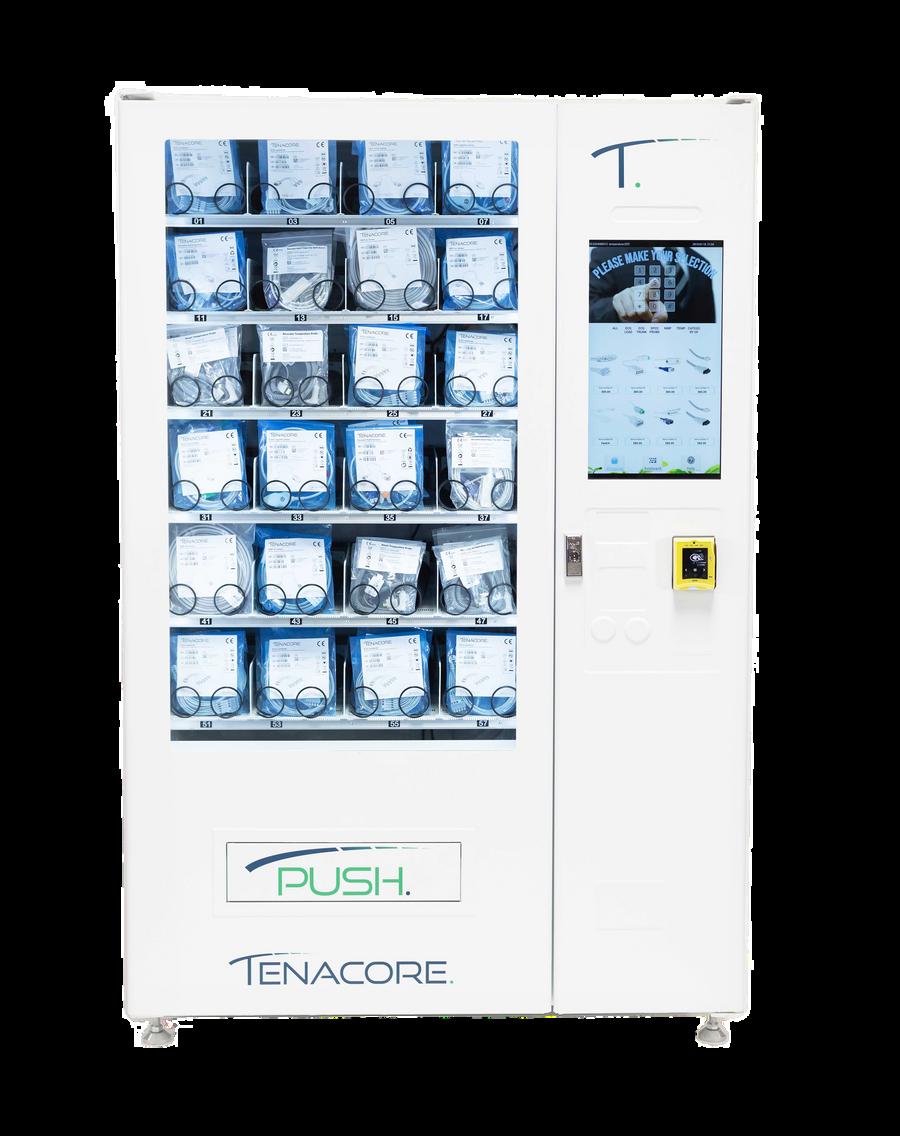

p.52 Corporate Profile: Tenacore

p.56 Cover Story: Non-Conformance Challenge: Repair as Needed Benefits Explained

P.63 EXPERT ADVICE

p.63 Career Center

p.64 SPONSORED: Avante Health Solutions

46

p.66 Networking Notes

p.68 SPONSORED: TKA

p.70 The Future

p.72 SPONSORED: Innovatus Imaging

p.74 Cybersecurity

p.78 Health-ISAC

PUBLISHER John M. Krieg

VICE PRESIDENT Kristin Leavoy

VICE PRESIDENT Jayme McKelvey OF SALES

EDITORIAL John Wallace

CONTRIBUTORS Roger Bowles

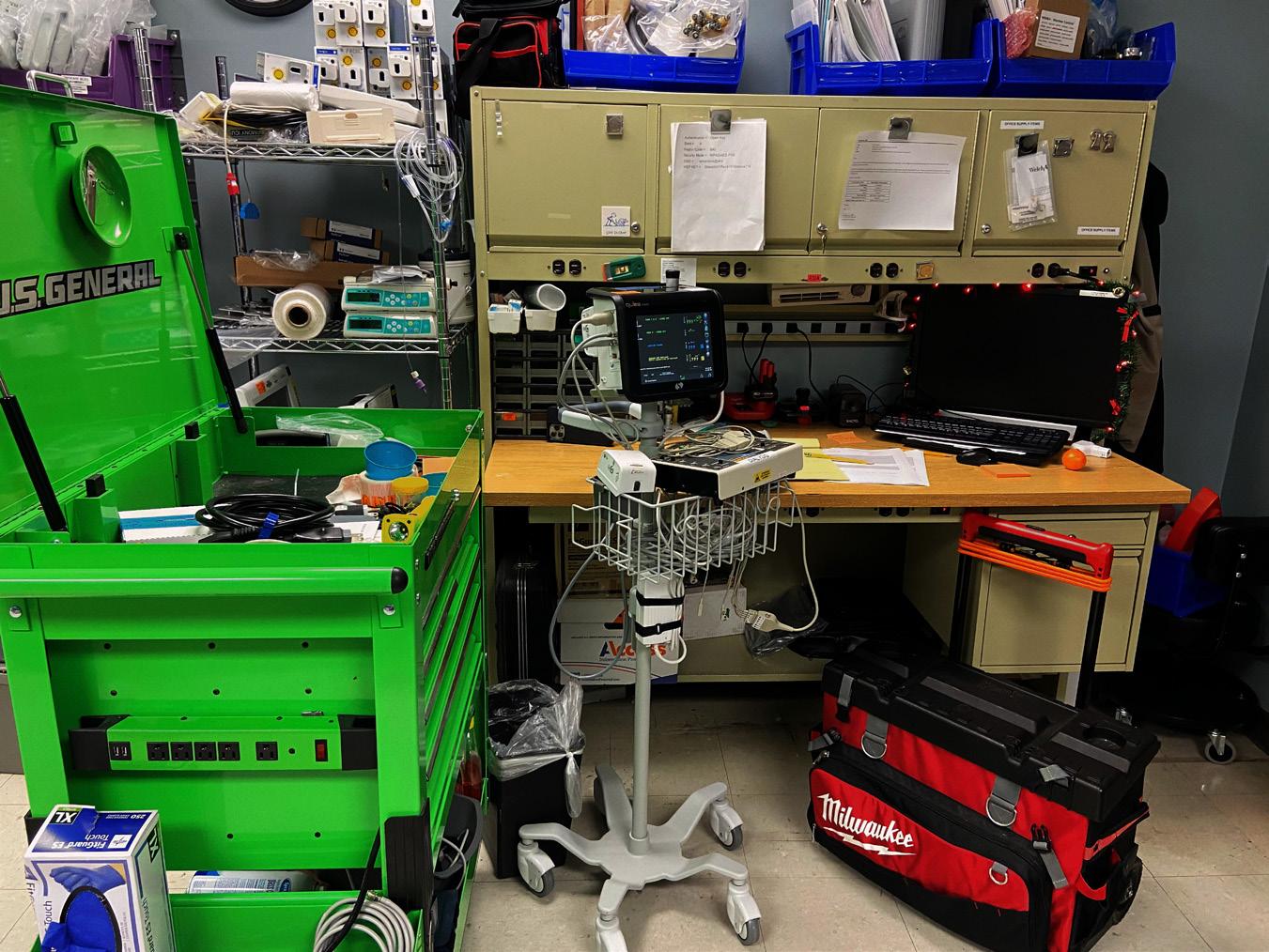

K. Richard Douglas

Jim Fedele

Joie Marhefka

Manny Roman

Steven J. Yelton

ACCOUNT Megan Cabot

EXECUTIVES Emily Hise

ART DEPARTMENT Karlee Gower

Taylor Hayes Kameryn King

DIGITAL SERVICES Cindy Galindo Kennedy Krieg Haley Harris

EVENTS Kristin Leavoy

WEBINARS Linda Hasluem

HTMJOBS.COM Kristen Register Sydney Krieg

ACCOUNTING Diane Costea

CIRCULATION Joanna Manjarrez

Rob Bundick, Director HTM & Biomedical Engineering, ProHealth Care

Carol Davis-Smith, CCE, FACCE, AAMIF, Owner/ President of Carol Davis-Smith & Associates, LLC

Jim Fedele, CBET, Senior Director of Clinical Engineering, UPMC

Bryant Hawkins Sr., Site Manager, Children’s Hospital of New Orleans

Benjamin Scoggin, MBA, MMCi, Director, Clinical Engineering | Biomedical Operations, Equipment Distribution, Clinical IT, DHTS, Duke Health Technology Solutions

Allison Woollford, Biomedical Equipment Specialist at Duke University Health System

Bryant Hawkins Sr., HTM on the Line, Trimedx Site Manager at Children’s of New Orleans

Dr. Brian Bell, HTM Workshop, Faculty Biomedical Engineering at St. Petersburg College in St. Petersburg, Florida

Carlos Villafane, BMET Latino, Certified Biomedical Engineering Technician III, Baycare Health Systems

Chace Torres, Bearded Biomed, Lead Technician SPBS, Dallas-Fort Worth Metroplex

p.83 Bulletin Board Sponsored by MedWrench

p.84 [Contest] What’s on Your Bench?

p.85 Biomed Brainbuster

p.86 HBA Scrapbook

p.87 CABMET Scrapbook

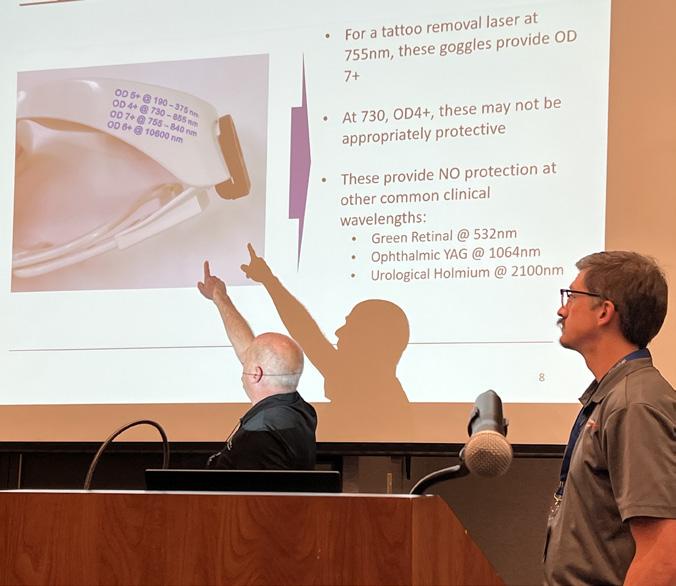

p.88 NCBA Scrapbook

p.98 #HTMLife

p.92 Preferred Vendors

p.94 Service Index

p.97 Alphabetical Index

At the forefront of Healthcare Technology Management education, the College of Biomedical Equipment Technology (CBET) is redefining what it means to be a leader in this critical field. Our cutting-edge programs in Biomedical Equipment Technology (BMET) and Healthcare Information Systems Management (HISM) are designed to equip you with the advanced skills needed to excel in today’s healthcare landscape.

At the forefront of Healthcare Technology Management education, the College of Biomedical Equipment Technology (CBET) is redefining what it means to be a leader in this critical field. Our cutting-edge programs in Biomedical Equipment Technology (BMET) and Healthcare Information Systems Management (HISM) are designed to equip you with the advanced skills needed to excel in today’s healthcare landscape.

BY K. RICHARD DOUGLAS

Colonel William Lordan Keller was an Army doctor and surgeon who served during World War I and later as the chief of the surgical service at Walter Reed General Hospital. After retiring in 1935, he went on to be appointed by President Franklin D. Roosevelt as a lifetime consultant in surgery at Walter Reed. His contributions to Army medicine left a legacy.

Naming a hospital in his honor was part of that legacy.

Keller Army Community Hospital can be found in West Point, New York. West Point is also home to the nation’s first military academy. West Point prepares young men and women to become officers in the U.S. Army. Cadets attend the academy for four years, graduating with a Bachelor of Science degree and a commission as a second lieutenant.

Keller Army Community Hospital Warrant Officer Tyler J. Scott, M.S., is chief of the equipment management branch at the hospitals.

“I come from a long lineage of military members, but was unsure if the military was for me, so I decided that I would instead go to college. I was unsure what I wanted to do for a career upon my completion of college. My father, Mark Scott, had worked on communication equipment while he served in the U.S. Army, and he suggested that I might like a career in repairing equipment,” Scott says.

He says that his dad was absolutely right.

“He encouraged me to become a 68a biomedical equipment technician and I grew a passion for repairing/

maintaining equipment. I have since spent 10 years in the field and progressed to becoming a 670a health services maintenance technician operating at Keller Army Community Hospital in West Point, New York,” Scott adds.

He says that he attended an 11-month biomedical equipment technician program at the medical education and training campus at Fort Sam Houston, Texas as part of his advanced individual training to become a 68a biomedical equipment specialist.

Scott explains that the biomedical equipment specialist (68a) is someone responsible for servicing and maintaining all medical equipment, calibrations and preventative maintenance, installations and keeping records of services performed.

“I also attended the warrant officer basic course at Fort Sam Houston as part of my 670a health services maintenance technician program. I have also completed the 70K medical logistics officer’s course to gain a wider scope of logistics as a whole,” Scott says.

He started his biomed career at the 14th Combat Support Hospital in Fort Benning, Georgia. He deployed with that unit three times to Kosovo, Iraq and to Puerto Rico during Hurricane Maria.

“I then became the chief of operations of the United States Army Medical Materiel Agency Medical Maintenance Operations Division Utah at Hill Air Force Base, Utah. From there, I became the Chief of the Equipment Management Branch at Keller Army Community Hospital, West Point, New York,” Scott says.

Currently, Scott’s area of specialty is project and life cycle management.

“I ensure that my staff acquire, maintain, sustain and repair our medical equipment within Keller,” he says.

Scott is a demonstrated logistician through the International Society of Logistics.

One of the challenges in the biomed field is staying up to date with the ever-changing medical field.

“The medical device industry is advancing so quickly, by the time you think you have the newest and greatest equipment; something new is on the market. This is great for us biomeds, though as we get to work on the latest and greatest equipment and integrate more with the information technology personnel. This allows us to have a greater presence among the hospital and build strong cohesive teams,” Scott says.

When not working, Scott remains the technician and keeps tools close at hand.

“I enjoy working on and repairing anything I can get my hands on from vehicles to Roomba robot vacuums. I also enjoy the outdoors and going fishing. I am a huge large-mouth bass fisherman,” he says.

Scott was recently married to his fiancée, Andrea Mills, in Central Park.

“We have a 10-year-old son, Braxton, and a 10-year-old daughter, Makenzie,” he says.

Scott still has several goals as he continues through his career.

“I want to continue to make a positive impact on the HTM field. I want to build strong independent teams that have the same passion as I do. I desire to eventually work at a strategic level of planning and development. My overall goal is to integrate emerging technologies to provide quick, accurate and precise diagnosis of patients,” he says.

The U.S. Army is lucky to have an HTM expert of Scott’s caliber.

FAVORITE BOOK:

“The Reaper” by Nicholas Irving

FAVORITE MOVIE:

“Black Hawk Down”

HIDDEN TALENT:

The ability to remember almost everything I have ever heard. I am great with random knowledge.

FAVORITE FOOD:

Texas Roadhouse ribeye rare with mushrooms

FAVORITE PART OF BEING A BIOMED?

Working with a close-knit team that ensures patient safety by placing life-saving equipment into the hands of providers.

WHY DO YOU READ TECHNATION?

To stay up to date with anything and everything HTM-related.

BY K. RICHARD DOUGLAS

Ok lahoma City is the capital and most populace city in the state of Oklahoma. It sits in the central portion of the state. The city offers visitors a cowboy and western museum, a banjo museum, a zoo, a botanical garden, walking trails to a water taxi cruise down the Bricktown Canal and more. The city juxtaposes its western heritage with its modern accouterments.

The biomed community is represented by an association focused on bringing biomeds together. The Oklahoma City Biomedical Association (OKCBA) evolved after a delayed beginning.

“There were several attempts by the original members going back to 1989, but the first official meeting was in 1994 at Southwest Medical Center with Juan Lara, Steve McCartney, Bob Thompson, Ken Reimer, Gene Butler and Larry Henderson. There may have been others, but these were the names that could be remembered,” says OKCBA President Shannon Landsberger.

He says that Juan Lara, Steve McCartney, Bob Thompson and Ken Reimer are credited as the founding members.

“Juan Lara had the initial idea of creating a biomed association and was the one who attempted to get meetings together from 1989 to 1994. He worked at

Midwest Regional Hospital at the time. Steve McCartney was voted in as president of the association early on and kept it going until October 2017 when I was voted in as president. Steve still continues supporting the association as vice president today,” Landsberger says.

He says the original group maintained annual meetings (often at restaurants) from 1994 through 2017, typically around October.

“Steve McCartney was president during most of that timeframe, with me joining the group in 2016, and becoming president in 2017. At that time, Steve stepped down into the vice president position. In 2018, we changed to a bi-annual meeting schedule with April and October being the months we typically planned for. I have worked towards bringing more content to our meetings, with a focus on continued education,” Landsberger says.

OKCBA typically has vendor education as well as discussion topics related to the biomed field at each meeting.

“I also added in a spotlight on retirees, whom we do a more in-depth review of their career with them during the meeting after they retire, often turning into some educational discussions on career plans. Moving forward, I am working with others in the group to move to a quarterly biomed association meeting, which will hopefully entail vendor education at every single meeting, and rotate hospitals in the area so that we are not favoring one facility over another,” Landsberger says.

The OKCBA does not have a formal conference or symposium, although it makes the most of its scheduled meetings. Landsberger tries to get the most productive use out of the regular meetings.

“Our last meeting consisted of a discussion about Ken Reimer, a long-time member and local biomed company owner who recently retired. Ken sponsored nearly all of our meetings until our last meeting before his retirement in October of 2023. I gave a 30-plus minute discussion/code review on AAMI ST108 and its impact on facility design, biomed interaction, and the positive impact of high-water quality in our SPD areas,” Landsberger says.

He says that the group also had plenty of discussion around the general status of the biomed space in Oklahoma including a talk about outsourcing, open positions and future meetings changing to four times per year.

As the HTM profession still seeks methods to recruit new talent to replace the baby-boomer retirees, it has been the biomed associations, in their respective cities and states on the front lines.

“Our biomed association meetings are 100 percent free. We make it a point to let all of our traveling vendors and sister hospitals know about the meetings as well as when to attend meetings, and our influx of new people is fairly steady. I have about 70 members on my email list at this time, and our attendance has grown from an average of five to seven people per meeting in 2016, to around 20 per meeting now in 2024,” Landsberger says.

He says that in Oklahoma, there is no requirement for certification or an education minimum to be a biomed.

“Due to this, biomed is not always recognized as an occupation with a high-level skillset and pay remains relatively low for many. I want to work towards getting our membership AAMI-certified, with continuing education credit mostly provided during our meetings as educational content from vendors. Once this is established, I

will work towards discussions with hospital leaders about the benefits that come with a certified and better educated biomed shop,” Landsberger says.

He says that the intent is for hospital organizations to see the value and offer incentives for those who become certified.

“Once the pay level starts to increase, I think that will help draw in more applicants to the region,” Landsberger adds.

Some biomed associations have a local technical school or dedicated biomed training program that the association can build a relationship with.

“We do not have any biomed schools in Oklahoma, and many of the technical schools have moved away from an in-depth electronics program in favor of short, focused courses that can be completed in a few weeks each. This has limited our ability to recruit biomedical staff locally, and we must often look to biomed programs in other states for added personnel,” Landsberger says.

How did the pandemic impact the way the association operates or affect its members?

“Operationally, it slowed progress down quite a bit, forcing places and personnel to perform better planning around shipment and install timeframes. There was also a need to increase contingency funds on projects a bit more to accommodate the rapid increase in the price of goods and services. Vendor labor prices have risen significantly in the last several years, and I believe it will have a long-term effect on the cost-of-service ratio (COSR) for facilities. Until things stabilize, there is likely to be some added financial tension between biomed groups and administration regarding the added costs for maintenance,” Landsberger says.

Biomeds in the Sooner State have a place to rub elbows, catch up on the community and receive education in centrally located Oklahoma City.

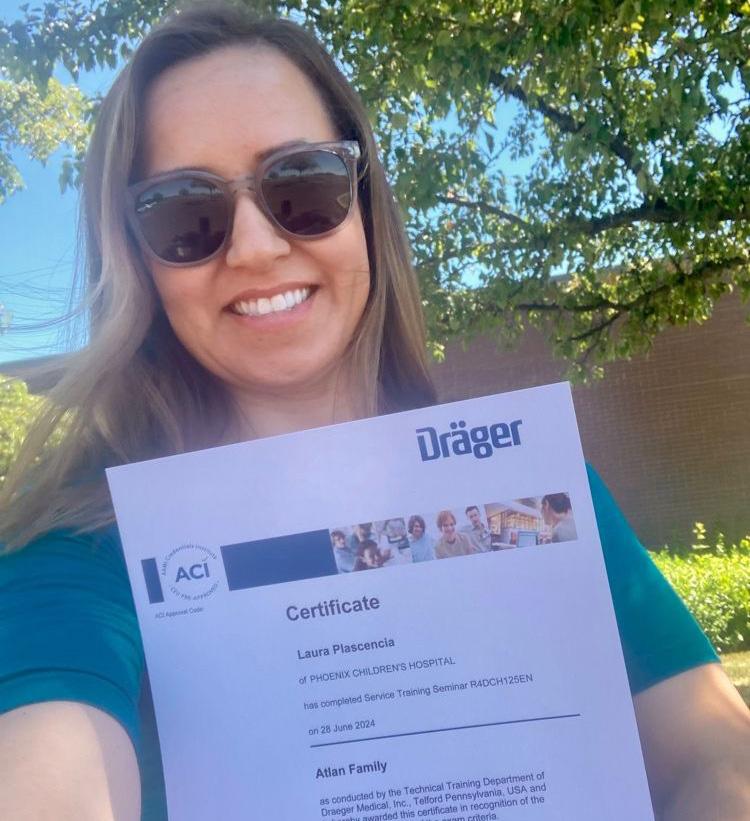

Kaleb Kasitz

Kaleb Kasitz earned a Bachelor of Science in Biological Engineering at the University of Missouri. He currently serves as a Biomedical Engineering Technician II with the Choctaw Nation of Oklahoma Durant Regional Medical Clinic. Kasitz enjoys the problem-solving aspect of his biomed career. TechNation found out more about the Kansas native during a Q&A.

Q: WHERE DID YOU GROW UP?

A: Louisburg, Kansas.

Q: WHERE DID YOU RECEIVE YOUR HTM TRAINING/ EDUCATION?

A: Received a B.S. in Biological Engineering from the University of Missouri and have gained multiple training certificates from different manufacturers on their equipment throughout the years.

Q: HOW DID YOU FIRST DISCOVER HTM?

A: Leaned about the field in college, but more so after when I was applying for jobs and was having a hard time breaking into the industry on the R&D side of biomed.

Q: HOW DID YOU CHOOSE TO GET INTO THIS FIELD?

A: After college I was really trying to get a job in the R&D side of biomed devices but was having a hard time breaking into the industry with no experience aside from my education. So, I took a different approach to the industry and found a clinical biomed job, started there and have progressed in that over the years.

Q: WHAT DO YOU LIKE MOST ABOUT YOUR POSITION?

A: The thing I like most about my position is that it is a good mix of engineering problem solving and that mindset mixed with the

direct impact of helping people in their daily lives by facilitating their medical care.

Q: WHAT INTERESTS YOU THE MOST ABOUT HTM?

A: The most interesting part of HTM is that the field is always changing. Medical equipment and technology are always advancing making it so that there is always something new and challenging to learn and grow with.

Q: WHAT HAS BEEN YOUR GREATEST ACCOMPLISHMENT IN YOUR FIELD THUS FAR?

A: My greatest accomplishment so far has been receiving an IHS award for excellence in customer service. Due to the nature of this award, it was nominated by a peer for my dedication and accomplishments for the company and health care in the region as a whole. The fact that I was nominated and recognized by my peers and chosen from a large field of nominees for this award makes it special and a great accomplishment.

Q: WHAT GOALS DO YOU HAVE FOR YOURSELF IN THE NEXT 5 YEARS?

A: To continue to grow in the field and hone my skills and move up in the HTM industry.

FAVORITE HOBBY: Traveling

FAVORITE SHOW OR MOVIE: “Letterkenny”

FAVORITE MEAL: Love to cook at home and try new things.

WHAT WOULD YOUR SUPERPOWER BE? Green Lantern Ring of Power

1 THING ON YOUR BUCKET LIST: Hot air balloon ride over Cappadocia, Turkey.

SOMETHING YOUR CO-WORKERS DON’T KNOW ABOUT YOU:

I was a competitive water skier in college. I lived in Australia for a year. I love to cook and try new foods.

BOOTH 501 B BOOTH 501

Flat & Fixed Rate Repairs

New AIV-Manufactured Parts & Pump Accessories

New AIV-Manufactured Fetal Monitor Transducers

AIV-Certified Refurbished Pumps Replacement Case Kits for GE Telemetry

BY K. RICHARD DOUGLAS

Th e Christ Hospital in Cincinnati, Ohio, has been caring for patients for more than 130 years. The hospital has developed into a health network that includes several facilities and more than 100 physician locations.

The extensive network requires management of 30,000 devices with an approximate $210 million replacement value.

“HTM is responsible for hospital, AOC, physician offices, nursing school equipment, research center, across Ohio, Kentucky and Indiana,” says Greg Herr, director of healthcare technology management (HTM) department at The Christ Hospital.

The network’s HTM department has 32 full-time employees, which includes two managers, a supervisor of business operations and a biomed equipment lead. The team also has three specialist BMET 2s, a respiratory specialist BMET 2, two specialists for anesthesia, an imaging team with three specialist 3s, two specialist 2s and a specialist 1. The department also has an IT medical security specialist. There are also other biomeds and specialists that round out the diverse team.

“HTM handles systems in cath/hemo, EP, oncology, surgery, infusion pumps (two-way integration), data integration engine (data capsule), several different PACS (cardiology, orthopedics, OB/neonatal, vascular, and just

in process of implementing a new all-in-one 3D portal for cardiology, and next radiology.) Starting work on enterprise imaging architecture,” Herr says.

“The department has one team dedicated to CE/IT integration and works with the biomedical and imaging team to ensure equipment is integrated safely with proper documentation,” Herr says.

Herr says that service contracts are centralized in HTM except for lab, a few in the operating room and central. He says they are managed by the business operations supervisor and director, and coordinated with purchasing and legal.

In terms of data collection, when onboarding new equipment, the process to capture required information and a master class table is used to reduce errors and duplicate descriptions.

“Data is collected from the purchasing process, much of the medical capital – but not all – goes through HTM. The CMMS vendor reviews new system entries, cleans up master equipment index names, and other data quality. Data collection for contracts are collected as contracts are signed and POs created. Date, amount, vendor, term of contract and coverage are identified,” Herr says.

He says that a new process is being developed to streamline workflow and get more accurate data.

The department is involved in several projects with IT, nursing and other clinical services.

Some of those projects include new equipment in the

NICU, cath lab replacements and an imaging wing at Liberty Medical Center.

“During COVID, HTM moved systems from hospital to hospital, setup a temporary ICUs, and converted anesthesia machines to ventilators during the worst of the crisis. Today, mostly recovered, the department is still getting back on track with projects delayed at the time,” Herr says.

He says that the team also worked on an EP project to develop a new five-room suite, with ancillary support areas. It has been a project for 30 months and was recently completed.

“HTM planned and moved much of the existing systems. Included new imaging systems, but also HTM worked out new team sharing in the room, lighting and sound needs. Now, the department is swinging back to the old area and developing it for IR/ vascular,” Herr says.

“During COVID, HTM moved systems from hospital to hospital, setup a temporary ICUs, and converted anesthesia machines to ventilators during the worst of the crisis.”

Herr says that a few years ago, the hospital lost considerable dollars with fridge/freezer failures, either because to the devices failed or loss of power. The health care system was searched and the system began targeting high-risk fridges/freezers with drugs (pharmacy or lab), food and nutrition, off-site physician offices for vaccines/drugs, and med fridges in nursing units, Herr adds.

- Greg Herr

He adds that a current big project is a centralized monitor unit, to collapse all the unit stations into one centrally located system.

The HTM team has also applied its collective expertise to problem-solving.

He says that HTM worked with users on alarm escalation, managed continuity and helped clinical users develop standardized practices using the temp tracking software. This is an ongoing project that is already several years in duration. The health care system lost only small amounts of items in a physician office fridge with loss of power when the owner did not respond in time. Otherwise, it has cut losses substantially.

At The Christ Hospital, the healthcare technology management department keeps the large inventory operating and refrigerators cold.

Collaborative Medical Solutions Inc. is built on a proven foundation with more than 15 years of helping domestic and international clients manage previously owned medical imaging equipment. Collaborative Medical Solutions is successful helping clients capture the best value for their used equipment and creating an easy path to upgrade technology as well as capture cash from their assets.

“We pride ourselves on making the process easy, providing great value and being well funded to create fast and easy transactions,” the company’s website states.

Collaborative Medical Solutions Inc. Principal Trey McIntyre recently shared more information about the company with TechNation

Q: CAN YOU TALK ABOUT THE COMPANY’S HISTORY AND HOW IT ACHIEVES SUCCESS?

MCINTYRE: We formed Collaborative Medical after nearly 20 years in the pre-owned medical imaging equipment space. Then, five years ago, it was an international client from those early days in that business who came to us with an endoscopy opportunity. We had become friends over the years, and it was great to connect again and work together. While endoscopy equipment was somewhat of a new category, the root of what we do remains the same. Relationships matter to us, so we take a collaborative approach with our customers, and work hard to offer flexible solutions for their biggest problems.

We’ve had a lot of success by helping providers rethink scope repair strategies, create simple paths to upgraded technology, and better manage their assets.

Q: WHAT ARE YOUR UNIQUE SELLING POINTS?

MCINTYRE: We think of ourselves as well-rounded, meaning that we have built an in-house repair lab with expert technicians and rigorous quality measures. We’ve maintained the right inventory of patient-ready, cost-effective equipment – and it all comes together to create strong maintenance, loaner and equipment upgrade programs which have proven to be powerful and dynamic for our customers.

Q: WHAT ARE SOME CHALLENGES THAT YOUR COMPANY FACED LAST YEAR?

MCINTYRE: Last year, we focused on investing in a great new facility in the Charlotte, North Carolina area. Space had quickly become a challenge for us as we were growing the business but not our building. It was a massive project, and of course, there were delays along the way, but as of January 1, we’re operating from a purposely designed space where our team can thrive and grow into our next phase.

Q: WHAT PRODUCT OR SERVICE THAT YOUR COMPANY OFFERS ARE YOU MOST EXCITED ABOUT RIGHT NOW?

MCINTYRE: We’ve done away with the traditional maintenance contract style, and instead we put together a program that really aligns everything we do to solve the biggest challenges our customers

face. Our Collaborative Approach is a scope maintenance program that helps plan for the future and reduce downtime while avoiding the unnecessary costs of managing endoscopy assets.

Q: CAN YOU DESCRIBE YOUR COMPANY’S FACILITY FOR TECHNATION READERS?

MCINTYRE: As I mentioned, we’re headquartered just outside of Charlotte, a great location minutes from the airport and the uptown area. While we’re still enjoying the fresh new space, we moved into earlier this year, we’re already committed to our expansion: another new building which will double our current square-footage. From here, our team will grow, our repair capabilities will continue to increase and we’ll launch advanced training programs. We’ve built our current facility with an open concept, and there’s a lot of interaction between our lab and the office teams. And even though we are team-minded, we love visitors and always welcome customers to come see us! We’re proud of the team and the space we’ve put together and certainly want to share it.

year, he brought with him decades of experience and a clear vision of the endoscopy repair lab he wanted to build. From working directly with OEMs, hospital administration, doctors, and technical staff, he knows the pain points that providers face every day. He’s designed our quality and maintenance programs with this in mind.

Our Collaborative Approach is a scope maintenance program that helps plan for the future and reduce downtime while avoiding the unnecessary costs of managing endoscopy assets.

Q: PLEASE TELL ME ABOUT YOUR EMPLOYEES AND HOW THEY CONTRIBUTE?

MCINTYRE: When Alan Koreneff joined the team last

The senior technicians he has hired are among the most talented in the repair industry, and we’re thrilled to have them on board. The techs at our benches have an average of 15 years spent with their hands on flexible scopes from all major brands.

Q: IS THERE ANYTHING ELSE YOU WANT READERS TO KNOW ABOUT YOUR COMPANY?

MCINTYRE: If you want a new approach to scope maintenance, I’d encourage you to talk with us. Discover what our Step-Up program would mean to your facility, or how our transparent scope evaluations ultimately reduce your risk, and much more. We’ll get creative with you, and we’ll keep it simple. Our solution can be comprehensive, it can be flexible – but it will always be collaborative.

For more information, contact CMS at Support@CMSscopes.com.

Bryant Hawkins Sr., a leading voice in the healthcare technology management (HTM) industry and host of the acclaimed podcast “HTM On The Line,” proudly announces the release of his first book, “Dare To Be Great.” Scheduled for publication on October 1, 2024, this inspirational work offers a blueprint for those seeking to unlock their full potential and rise to greatness in their personal and professional lives.

Hawkins is a recognized HTM leader. He won the inaugural Tech Choice Award for Influencer of the Year and serves on the TechNation Digital Advisory Board.

“Dare To Be Great” distills Bryant Hawkins’ years of experience as a motivational speaker, industry leader and mentor into a powerful narrative that challenges readers to embrace the discipline, commitment, and mindset necessary to achieve their dreams. Drawing on real-life examples, including stories of triumph over adversity and insights from some of the HTM industry’s successful figures, Hawkins provides actionable strategies to help readers navigate their paths to success.

“I wrote ‘Dare To Be Great’ to inspire individuals to pursue their highest ambitions, to step out of their comfort zones, and to transform their lives through a firm commitment and relentless work ethic,” said Hawkins. “This book is for anyone who dares to dream big and is ready to take the necessary steps to turn those dreams into reality.”

Key themes in the book include:

• Power of Consistency

• Personal Accountability

• Overcoming Obstacles

• Inspiring Quotes and Insights

“Dare To Be Great” is not just a book; it’s a movement. It’s

an invitation to anyone ready to elevate their life, to break free from mediocrity, and to pursue excellence with passion and purpose, a press release states.

Hawkins is the founder of “Elevating HTM”; a non-profit organization dedicated to inspiring the next generation of HTM professionals. He is also the host of the popular podcast “HTM On The Line,” now in its second year, where he has interviewed over 50 distinguished guests. Known for his motivational speaking, motivational Monday videos and HTM newsletters, Hawkins has a passion for helping others achieve success by sharing the principles that have guided him throughout his journey.

UptimeHealth, in collaboration with the College of Biomedical Equipment Technology (CBET), is excited to announce the Dental Fix Summit 2024, taking place October 3-6, 2024, at the Embassy Suites by Hilton Nashville Airport. This four-day event is designed to equip independent dental equipment repair technicians and biomedical technicians with the latest technical training, business strategies and networking opportunities in the dental industry.

The Dental Fix Summit 2024 is a unique opportunity for technicians to advance their skills and knowledge through hands-on workshops, insightful sessions and interaction with industry leaders. Attendees will have access to OEM technical training and business solutions tailored to the needs of independent service organizations. This event also offers a chance to earn continuing education units (CEUs), enhancing the professional growth of participants.

Key Highlights of Dental Fix Summit 2024:

• OEM Technical Training: Attendees will receive comprehensive training on the latest dental equipment and technology from original equipment manufacturers (OEMs), ensuring they stay ahead in the fast-evolving dental market.

• Business Growth Opportunities: Independent technicians will learn how to expand their businesses, leverage shared resources, and utilize group buying power to access discounts on merchant processing, accounting services, freight rates and other essential business solutions.

• Networking and Community Building: The summit will foster a sense of community among like-minded professionals, offering invaluable networking opportunities to build connections that can support long-term business success.

• Expanded Skill Sets for Biomedical Technicians: Biomedical technicians will have the chance to level up their expertise by adding dental services to their skill sets, opening up new avenues for career growth.

“This collaboration between UptimeHealth and CBET represents a significant step forward in providing top-notch education and resources to the biomedical and dental equipment repair community. We are committed to supporting these technicians as they continue to drive innovation and excellence in their field,” said CBET President Richard “Monty” Gonzales.

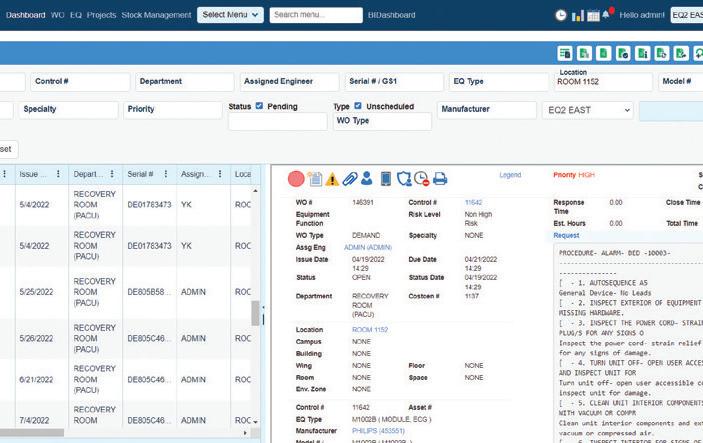

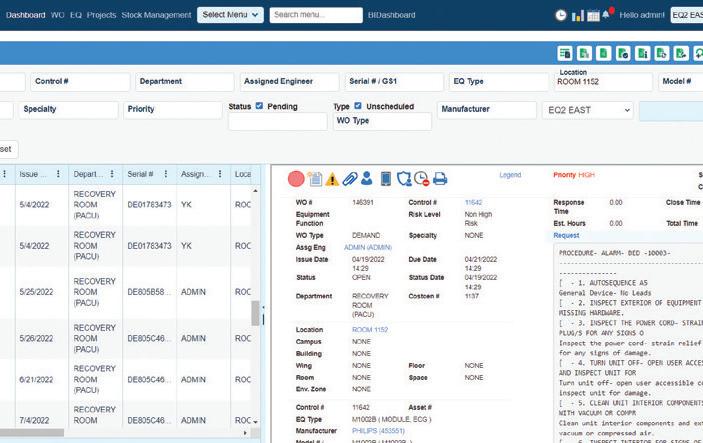

EQ2 HEMS: A "Smart CMMS" that Makes Everything from Managing Work Orders to Maintaining Compliance, Reporting, and Capital Planning Easier

Numerous integrations, to streamline workflows

Superior regulatory compliance reporting included

Mobile app designed for offline and online work means you can always access what you need when you need it

Data and information in the format that fits the needs of all levels of management and the hospital as a whole

St. Philip’s College (SPC) hosted Legacy Day: The Legacy Continues on Friday, Aug. 16, to celebrate the feast day of the college’s founding president, Saint Artemisia Bowden, and unveil three newly renovated campus buildings.

Saint Artemisia Bowden was canonized by the Episcopal Church in 2015. Her feast day is recognized worldwide on Aug. 18 in the Episcopal calendar. The same year she was elevated to sainthood, she was named President Emeritus by the Alamo Colleges District in recognition of her leadership and service to SPC.

The three-hour event showcased the revitalization of the Cybersecurity Innovations Center, the Bowden Legacy Building, and the Applied Science Building, while highlighting the college’s rich history with a ribbon cutting and tour of each building.

The Cybersecurity Innovations Center, previously named the Campus Center, has been transformed into a central hub for government, university, and industry partners in the cybersecurity field. Over the last 70 years, this building underwent four renovations, enlarging its capacity in 1970, 1978, 1987, and 2022.

The Bowden Legacy Building, constructed in 1954 on the original land purchased by Artemisia Bowden in 1922, is now home to the St. Philip’s College Early College High School with

San Antonio ISD. This building honors the college’s founder, continuing her legacy of inspiring future generations.

The Applied Science Building has been a hub of innovation and hands-on learning since its construction in 1992. Renovations have expanded the college’s program offerings in Automotive Technology, Histology, Biomedical Engineering, Vision Care, and Nurse Aide.

Legacy Day activities included check presentations, refreshments, a cornerstone ceremony by area Masonic lodges, gifts to mark the occasion, and remarks by special guests, including Saint Artemisia Bowden’s great-great-niece, Jennifer Walker. To connect the three locations there was a New Orleans-style Second Line Parade, led by the SPC cheer team, Student Government Association student leaders, employees with decorated umbrellas, and a drumline.

“As we celebrate the transformation and expansion of St. Philip’s College, we remember our 126-year heritage and history,” said St. Philip’s College President Dr. Adena Williams Loston. “On this Legacy Day, we honor the unwavering determination of one woman—our founding president, Saint Artemisia Bowden. Her 52 years of devotion to the college leaves us with a sense of pride that challenges us to strive for greatness.”

Biomedical device test and measurement specialist Rigel Medical has agreed to a new partnership with a U.S. government and military contractor as it continues to expand its North America operations.

The collaboration will see Tampa-based Rigel Medical link-up with small business certified service-disabled and veteran-owned (SDVOSB) MEAK Solutions in a move that marks a “significant step forward” in developing and improving the supply and support of biomedical test equipment provided to U.S. government and military sectors.

Working together, both companies will bring their respective technologies and specialist expertise to a broader market, while driving the development of solutions for customers, including additional reach into military veterans’ hospitals and healthcare facilities across the country.

Rigel Medical testers comply with U.S. regulations, so leveraging MEAK’s SDVOSB status will effectively enable the company to meet the requirements of VA hospitals with sector leading biomed equipment solutions, said Lewis Lennard, product manager-North America.

“MEAK Solutions’ SDVOSB status positions us perfectly to serve government agencies, particularly the Department of Veterans Affairs (VA),” he added. “Our new partnership allows us to provide VA hospitals with the high-quality biomedical test equipment, ensuring the best care for the country’s veterans. Indeed, supporting VA hospitals with advanced biomedical solutions directly contributes to the health and well-being of veterans, aligning with our commitment to improve patient care.”

Located in Mentor, Ohio, MEAK Solutions specializes in providing solutions for government, military, and commercial clients. The company has more than 50 years of combined industry experience and a best-inclass quality assurance team to meet government and industry requirements.

Eric Kettani, director at MEAK, said: “We are excited to partner with Rigel Medical, which has a strong track record of delivering innovative biomed testers into the U.S. market. We will be working together to strengthen our offering and in partnership, we will be committed to advancing the development of innovative applications and solutions for the benefit of VA hospitals and their patients.”

Seaward Group USA supplies a wide range of electrical safety instruments to ensure the safety of any product or appliance from the design, compliance and manufacturing stages through to servicing repair and calibration. This includes advanced technology laboratory and production line testers capable of carrying out hi-pot, ground bond and a variety of other tests, as well as EMC test equipment.

The company has an extensive national U.S. sales, service and calibration capability.

The Oregon Biomed Association recently announced the dates for its 2024 Expo & Education Vendor Fair. The event will be held November 7-8 at Holiday Inn Portland-Airport (8439 NE Columbia Ct, Portland, OR 97220).

This is the first OBA Expo since before the COVID pandemic. It will feature educational seminars each day. Breakfast, lunch and

snacks will be provided with registration.

The exhibit hall will host the vendor fair with a happy hour, prizes and awards!

The event is FREE for OBA members! Visit www.orbmet.org/ expo2024 for details.

Spearhead-class expeditionary fast transport ship USNS Burlington (T-EPF 10) arrived in Colón, Panama on Aug. 18, 2024 as part of U.S. Naval Forces Southern Command/U.S. 4th Fleet’s Continuing Promise 2024.

Panama is the final stop on this iteration of the Continuing Promise mission, which has seen previous stops in Jamaica, Costa Rica, Honduras, and Colombia. This visit to Panama is the seventh such visit for Continuing Promise since the exercise first began in 2007, and first visit to Colón since 2019. Burlington served as the primary ship for Continuing Promise 2023, which stopped in Almirante, Panama.

“We are excited for Continuing Promise’s return to Panama,” said Lt. Cmdr. Zachary Smith, Continuing Promise 2024 mission commander. “We have seen so much success on this mission with our various partners and we aim to finish strong with our

partners here.”

Thirty U.S. Navy medical professionals specializing in dentistry, family and geriatric medicine, optometry, nursing, pharmacy, biomedical equipment repair, land radiology will partner with Panamanian Ministry of Health personnel and civilian medical professionals to provide care at Clinica Dr. Hugo Spadafora and Parque de Juventud during the mission’s visit to Colón.

Along with medical personnel, the CP24 team also includes a detachment from the U.S. Fleet Forces Band called “Uncharted Waters.” The band will perform and conduct music clinics at seven separate events throughout the visit.

Panama is the last mission stop of Continuing Promise 2024. After departing Panama, USNS Burlington will sail back to the United States to complete the mission.

— Story from Story by Lt.j.g. Daniel Ehrlich

TRIMEDX – an industry-leading, independent clinical asset management company delivering clinical engineering services, clinical asset informatics, and medical device cybersecurity – has been recertified with the highly regarded International Organization for Standardization’s Medical Device Quality Management System (MD QMS) certification ISO 13485, a widely recognized international standard outlining best practices in developing an effective MD QMS that covers the safety and quality of medical devices throughout their lifecycle.

This recertification, now valid through Aug. 2027, reverifies that TRIMEDX continues its dedication to maintaining a comprehensive quality management system (business policies and procedures), ultimately impacting its service excellence to clients.

“This reaffirms our commitment to excellence for our clients, associates and stakeholders,” says TRIMEDX CEO Henry Hummel. “Our quality of service standardizes work and contributes to continuous improvement as we progress. By verifying these processes, we aim to achieve best-in-class customer satisfaction, quality service and, ultimately, impact clients’ ability to ensure patient safety.”

This standard analyzes and evaluates everything TRIMEDX does from a risk perspective, so risk control is included in all parts of the business. ISO 13485 outlines best practices in

developing an effective MD QMS that covers the safety and quality of medical devices throughout their lifecycle. TRIMEDX was recertified by third-party registrar DEKRA.

The ISO 13485 certification couples with TRIMEDX’s Service Organization Control (SOC) 2 Type 2 and ISO 27001 certification (valid through Dec. 2026) to make up TRIMEDX’s Quality Management System covering MD QMS and Information Security Management System (ISMS) standards.

“Achieving this level of compliance requires a continued commitment and demonstrated ability to monitor system activity and quickly take corrective action with the people, process, and technology in place,” says Denisa Lambert, vice president of quality and regulatory compliance. “Our comprehensive approach to data protection and responsive action sets us apart in delivering service excellence to clients.”

MD Expo is headed to New England with support from two of the top HTM organizations, AAMI and the New England Society of Clinical Engineering (NESCE). HTM professionals from the United States and beyond will gather this October at the Mohegan Sun in Uncasville, Connecticut. The conference is free for all hospital employees, active military and students.

The MD Expo to be held October 8-10, 2024 has been pre-approved for up to 8 CEUs.

One highlight (of which there are many) is the AAMI CBET Study Course led by Dave Scott. This training will cover each area of the CBET exam outline including:

• Anatomy and physiology

• Public safety in the health care facility

• Fundamentals of electricity and electronics

• Healthcare technology and function

• Healthcare technology problem-solving

• Healthcare information technology

Learners who attend this course will have access to course materials which include module slides, practice exams and key test-taking notes. All attendees in this live session can direct questions to the instructor in real-time that will either be answered at the end of the session or addressed via the AAMI discussion group. The AAMI discussion board feature is accessible in the AAMI LMS where they are encouraged to

share information and ask questions throughout the duration of the course and the days that follow. Attendees will also have access to the recording of the October CBET Study Course online which they’ll be able to view for up to 1 year.

There is a $125 fee for the two-day CBET Review Course. However, several free educational sessions are included in the free MD Expo registration including:

• AI Demystified: How to Effectively Use AI to Develop or Improve Your Quality Management System presented by Mark Cooksey

• An Aging Model for Medical Equipment presented by Binseng Wang and Torgeir Rui

• Bridging the Gap Between Nursing and Biomed presented by Leah Goldberg and Cassandra Eilers

For a complete list of educational sessions, visit mdexposhow.com/education/

Another highlight of MD Expo New England is the Reverse Expo – Real Decision Makers. Real Opportunities on October 9.

The Reverse Expo will allow medical equipment sales and service vendors who are registered exhibitors of MD Expo a unique opportunity to meet with more than 20 supply chain, procurement and healthcare technology directors from America’s most prestigious hospitals, imaging centers and health systems.

Find out more about MD Expo at MDExpoShow.com

MD Publishing is planning ahead with events scheduled for 2025. Sign up for the newsletter at MDExpoShow.com to stay abreast of the latest details.

For a sneak peek, pencil in these dates on your calendar:

MD Expo Spring 2025

April 15-17, 2025

Proudly supported by CMIA

The spring 2025 MD Expo will be held at the Pechanga Resort Casino in Temecula, California.

HTM Mixer Denver

May 15-16, 2025

Proudly supported by CABMET

Join us at the Omni Interlocken Hotel in Broomfield, Colorado.

HTM Mixer Milwaukee

July 31- Aug. 1, 2025

Proudly supported by WBA (Wisconsin Biomedical Association)

Join us at the Hyatt Regency Milwaukee in Milwaukee, Wisconsin.

Online registration is open for the HTM Mixer. Find out more via the short video: tinyurl.com/37rymw27

The HTM Mixer Lexington, proudly supported by KAMI, will start on Friday, November 15 and conclude on Saturday, November 16 at the Marriott Resort Griffin Gate (1800 Newtown Pike, Lexington, KY 40511). A kickoff party will be held at 6 p.m. on Saturday night with live music, a bourbon tasting, food and entertainment.

An HTM Mixer has everything an MD Expo offers. Think of it as a hybrid event that combines the best of a state association annual meeting and an MD Expo. The two-day conference includes an exhibit hall, educational opportunities and networking events.

The education line-up features a wide range of topics including:

• Digital Portable and Mobile X-ray Devices

• How to Maximize HTM’s Role in the Capital Process

• Immersive Training for Technicians: Using Extended Realities and AI to Create Better HTMs

• Resilience: A tool for today’s HTM challenges

• Project Management Involving Medical Equipment Installations

• Data-Driven Decision-Making to Increase Asset Availability and Reduce Costs

• HTM Equipment Integration Challenges Working with

• Top-Notch Customer Service within the Clinical Environment, for Non-Clinical Associates

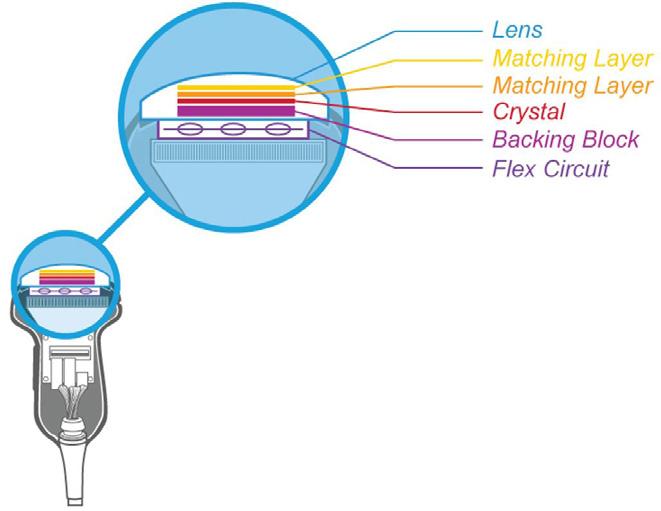

• Care and Handling of Endoscopes and Ultrasound TEE Transducers

Register today at HTMMixer.com

At Emeritus Clinical Solutions, they believe that hospital beds are the most critical medical devices in a health care setting. While others may overlook them, Emeritus loves and cares for hospital beds, recognizing their paramount importance. They have proven there is a better way to provide hospital bed and stretcher maintenance services, one that prioritizes the needs of hospitals and their patients. The company’s innovative approach revolutionizes these services, making them more patient-centric and efficient.

Emeritus Clinical Solutions Senior Sales Manager Webb Clark recently shared more information about the company.

A: Our staple program is called Bed Maintenance 2.0. This is an outsourced solution with a truly in-house feel. Emeritus will place technicians on-site at your facility full time Monday to Friday to run the patient bed and stretcher program. The Always-On-Site methodology returns hundreds of labor hours back to the HTM department so your biomeds can focus on modalities that they’re a) vested in and b) have actual expertise in. Emeritus will stock OEM parts on-site and your brand neutral, bed expert is working out of your hospital full time. This approach completely erases wait times for parts and service. Travel fees are also non-existent. This is a full-service program, so all costs associated with PMs and repairs are paid for via a firm-fixed monthly rate.

Q: HOW DOES YOUR COMPANY STAND OUT IN THE MEDICAL EQUIPMENT FIELD?

A: 1) We are an HTM company solely focused on patient beds and stretcher maintenance. Furthermore, we are reinventing the way bed maintenance is thought of and performed. 2) Case in point: Always-On-Site. Nobody shows up in a van a week after a service request is placed – Emeritus is already there. Thus, even the back-and-forth correspondence associated with scheduling service is eliminated. Likewise, the need to approve hundreds of POs for parts and services throughout the calendar year is gone. 3) Operations. This is something I can’t overstate enough – from an operations standpoint, Emeritus is exceptional. One of the biggest frustrations HTM managers experience with their vendors is found in communication, or lack thereof. Services can be finicky because of the inherent human element. Managers rely on clear expectations, communication and robust reporting. I would put Emeritus’ operations against any OEM or ISO in the HTM field.

Q: WHAT IS ON THE HORIZON FOR YOUR COMPANY?

A: We are constantly looking to improve our processes. We do this by examining what our competitors offer, then go where they’re not willing to go. Beds exist in a no-man’s land. In roughly half the hospitals in the United States, bed maintenance is assumed by HTM. The other half of the time, beds will fall under the Facilities Department. With that in mind, we have developed a Targeted Transporter Training Program to help hospitals who have transport teams with high turnover. This education program requires quarterly, or even monthly, training. When we talk about cost savings, Emeritus will go well beyond just doing the repairs required. We are looking to cut the head off the snake and reduce the actual number of repairs required. Your Emeritus bed-technician is not only an extension of your HTM team; but will also maintain

rapport with Facilities, Nursing, EVS, and transporters so that the bed and stretcher program is run efficiently. Recently, the Joint Commission has introduced new regulations pertaining to mattress management. Emeritus is already performing mattress audits on behalf of EVS teams, and we are fine-tuning a comprehensive mattress management program to boot.

A: I would challenge your readers to consider how effectively they’re currently tackling bed maintenance. Patient beds do not get the respect they deserve. Forty years ago, a bed was little more than a glorified shopping cart with a mattress on top. Today, beds are outfitted with bed exit alarms, inflatable mattresses, nurse call systems, etc. They’re not the beds of yesteryear and they shouldn’t be treated as such. There is no device at your facility that affects the inpatient experience more. Biomeds are the silent heroes of health care. Your patients don’t understand if the sterilizers in the basement aren’t humming. But they do know if they slept comfortably. They will remember if nursing staff had to move them into another room in the middle of the night because of a broken bed. Furthermore, their families will know and the reputation of your hospital largely hinges on this experience.

We find that too many in-house programs are run inefficiently. Your technicians did not enter this field to work on beds and stretchers. Frankly, most of them loathe working on beds. If you’re not invested in advancing your

technicians’ careers, rest assured – someone else will. Hiring good biomeds is tougher than ever. While beds may feel rudimentary enough to make first call on, you must ask yourself – where does this lead? Often, it leads to a wormhole of trial and error parts ordering. This is how beds rack up in our hallways which invites scrutiny from leadership and regulatory agencies. We find in-house programs lean on OEM support 40-70% of the time and there is a great cost associated with module level repairs.

Traditionally, HTM managers reserve full-service solutions for OR, SPD or imaging equipment. Equipment that, when it breaks, the hospital starts cancelling cases immediately resulting in loss of revenue. By contrast, there are a lot of redundancies when it comes to your bed and stretcher inventory. So why full service? Because an ineffective bed program is a waste of time and money. And the redundancies only compound this error. HTM’s bandwidth is precious. If your technicians are not proficient in this modality, they’re wasting hundreds (in some cases over a thousand) labor hours annually. Couple this with how money is being spent. How often are your technicians leaning on OEM support for troubleshooting or even on-site services? Ask yourself, is this truly an in-house program?

Emeritus is on a mission to reinvent bed maintenance. Bed Maintenance 2.0 is a program that’s meant to optimize your workflow in an often overlooked and misunderstood modality.

For more information, visit emerituscs.com.

On June 28, the Supreme Court issued a decision in Loper Bright Enterprises v. Raimondo, which overturned the legal doctrine known as Chevron Deference. Since 1984, it required Courts to give broad deference to a government agency’s interpretation of ambiguous Federal law. Under Loper Bright, courts must now instead “exercise independent judgment … [and] not defer to an agency interpretation of the law simply because the statue is ambiguous.”

It’s shaken up the industry. In a July 9 AdvaMed webinar, Selina P. Coleman, partner at the Life Sciences Health Industry Group, called it “a landmark supreme court decision, which is ushering in a seismic shift in the balance of power between agencies and courts.”

This decision could have a wide-ranging impact on many aspects of business in America, including medical devices and healthcare technology management. It might also elevate the importance of standards, making them more vital in the lawmaking process, and affecting the role of the work standards developers like AAMI regularly accomplish.

authority granted to them by congress. Once established and made known, agency rules still have the force of law.

Now, though, courts can exercise more discretion in reviewing any challenges to agency interpretations of law, reducing the likelihood that an agency issuing a new rule will go unchallenged.

The role of voluntary consensus standards in supporting medical device regulation may not lessen in this new environment. “When FDA recognizes a standard, they’re saying they will accept conformance with that standard as evidence to support a manufacturer’s claim of compliance with related regulations. But meeting the standard is not required. You don’t have to use the standard,” explained Joe Lewelling, vice president of industry at AAMI. “Right now, it is not clear that Loper Bright would hinder FDA’s current practice.”

In fact, standards might become more important, he said.

She noted that amicus briefs may carry more weight in the future, because these filings may provide more context for judges interpreting statutes.

To start, overturning Chevron deference does not change the function of regulatory agencies, nor does it limit Congress’s power. Agencies like EPA and FDA retain the rulemaking

“They will allow the FDA, in partnership with the medical device stakeholders, to declare what is necessary for safety and effectiveness without putting those specific details in the statutory requirement as well,” he explains.

Diane Wurzburger, vice-chair of industry for AAMI’s Board of Directors, is the executive of regulatory affairs, developed markets, and global strategic policy for GE HealthCare. She agrees that standards will continue to be very important as they bring “an aspect of objectivity.”

“Many standards set criteria that are black and white,” she told AAMI News. “Very simplified, it’s ‘yes’ or ‘no’ – it’s either going to meet the spec or it doesn’t meet the spec” – which is a level of clarity desired by regulators and companies alike.

Ending Chevron deference allows different interpretations of a regulation and “that’s where there may be an opportunity

for a work product of AAMI [or another standard developer] to help clarify what an interpretation means or is intended to be,” she added.

What will actually happen is up in the air, in part because the ruling is so recent, and it did not wipe any current regulations off the books. The decision in Loper Bright Enterprises v. Raimondo only applies to new or pending litigation, and did not retroactively affect rulings on past challenges to regulation. However, a ruling issued by the Court three days after Loper Bright in Corner Post Inc. v. Board of Governors, found that the six-year statute of limitations to challenge agency rules under the APA was triggered not by the issuance of the regulation but from the date a party suffered injury as a result of the rule. This finding greatly expands the universe of regulations that may be challenged. As such, a new business may challenge an old regulation that was formerly upheld under pro-Chevron framework.

“It could work in several directions, so it’s very complicated and may not have the impact everybody predicts the same way,” said Jeff Gibbs, director at Washington, D.C.-based law firm Hyman, Phelps & McNamara. “We live in a very big country with a lot of legal issues and a lot of legal systems. It’s not a simple decision that’s just going to have a clearly visible outcome.”

Patricia Griffin is general counsel for the American National Standards Institute (ANSI), which coordinates the U.S. voluntary consensus standardization system. She told AAMI News that “there are many unknowns regarding Loper, including whether the decision will have any impact on the federal government’s reliance on voluntary consensus standards, what kind of deference will remain now that Chevron is gone, how many new challenges will be permitted under Corner Post (issued after Loper), how congress and the judiciary will respond to the challenges brought about by these landmark decisions, whether voluntary consensus standards will become more important in the regulatory/congressional context, or how these cases impact current debates about standards Incorporated By Reference.”

She noted that amicus briefs may carry more weight in the future, because these filings may provide more context for judges interpreting statutes.

At the July 9 AdvaMed seminar, David A. Bender, senior associate at the Life Sciences Health Industry Group, presented an analysis of past challenges to FDA, CMS and EPA. He found that when circuit courts applied Chevron deference in their ruling, agencies won over 93% of cases. Agencies only won 38.5% of cases when courts reviewed agency action de novo. Since 2000, FDA won in every appellate opinion that applied Chevron deference.

With Chevron deference ended, Coleman posits that there will be “more emphasis on technical legislation drafting to the extent that clarity can be achieved through Congress and stakeholder support.” Industry stakeholders, including standards developers, may also be called on to collaborate with lawmakers to help work clarified, specific language into legislative drafting.

“Industry input will become more valuable on the front end before statutes are enacted to try to get things right the first time, which we know can be a tall order,” she said.

Wurzburger expects it to take six months to year to see some clarity.

“Maybe there’s going to be some cases to help us understand of how those decisions are going to be made,” she said. We can’t say “whether some courts will continue to provide deference to the agencies while others will not.”

But the impacts may not be as widespread as if Chevron hadn’t already been weakened by decades of other court rulings, added Lewelling.

“Chevron had been dying the death of 1,000 cuts for some time now … Loper Bright wasn’t the first case restricting it’s impact, but it does appear to put the nail in the coffin of the Chevron deference.”

BY TOM TOCZYLOWSKI, ECRI’S ASSOCIATE DIRECTOR OF HEALTHCARE PRODUCT ALERTS

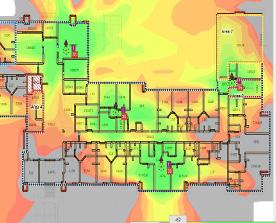

Challenges associated with legacy equipment asset information can lead to safety issues. Standardization and normalization of CMMS data can lead to better outcomes and can be a part of a robust Total Systems Safety Approach.

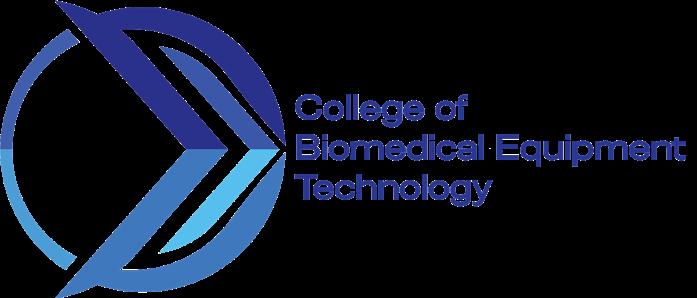

Healthcare technology management (HTM) teams leverage computerized maintenance management systems (CMMS) to enable more efficient work order management. A well-organized CMMS can also help reduce asset downtime and improve maintenance workflows. Often, inconsistent equipment naming conventions and descriptions, and variable device classifications, can negatively impact predictive replacement planning and management of preventive maintenance. This could include variable manufacturer and vendor names (which may change over time), model names and device types.

This inconsistency in CMMS data can also lead to missed cybersecurity threats, recalls and field corrections that could impact the safety of patients and staff. Standardized CMMS data can lead to better operations while mitigating risk and enhancing regulatory compliance. This is evident in the matching of recalls to CMMS inventory for departments utilizing robust recall management solutions (like ECRI’s Alerts Workflow). As work orders are assigned, whether it be for preventive maintenance or corrective maintenance resulting from recalls or incident reports, the process will run smoother with normalized data in the

system. In addition, if there are assets under alternative equipment maintenance (AEM) or advanced analytics and reports being run, the documentation in the CMMS can more easily be organized and tracked with a clean data set.

Each year ECRI produces a “Top 10 Patient Safety Concerns” list. For 2024, “Unintended Consequences of Technology Adoption” was Number 4. As healthcare technologies have been adopted, their widespread implementation without full appreciation of their potential impact is associated with serious risks, including injury or death. Part of that proper adoption of medical equipment includes maintaining performance and maintenance data, and having a system to quickly respond when there are safety issues or recalls. Organizations must have good processes for evaluating, implementing, and maintaining technologies to prevent unintended consequences and to address emerging issues.

At ECRI, we consider recall management and consistent data to be part of Total Systems Safety for a health care organization. We have seen the danger of improperly maintained equipment, missed recalls or corrections, or even improper use of technology. Misapplication or misuse of health technology could lead to negative consequences, including patient harm. ECRI’s Total Systems Approach to Safety is a comprehensive programmatic approach to improving patient safety in health care organizations. It is a transparent learning system that builds reliability and resiliency that supports optimal behaviors for safety.

By redesigning the elements of the safety system,

health care providers are supported to deliver care in a more reliable and resilient way. Our proactive systems approach is anchored in safety science, clinically informed human factors engineering, and health equity to prevent errors, reduce harm, and enhance the overall quality of care by integrating various safety-related processes. This can include preventive maintenance schedules, plans for keeping up-to-date instructions and labeling documentation, and, crucially, maintaining a clean equipment inventory. This approach requires a culture of safety and a commitment to continuous improvement, enterprise-wide communication, and engagement of staff and patients to reduce adverse events, improve patient outcomes, and increase patient and staff satisfaction.

ECRI is an independent, nonprofit organization improving

the safety, quality, and cost-effectiveness of care across all healthcare settings. ECRI is the only organization worldwide to conduct independent medical device evaluations, with labs located in North America and Asia Pacific. ECRI is designated an Evidence-based Practice Center by the U.S. Agency for Healthcare Research and Quality. ECRI and the Institute for Safe Medication Practices PSO is a federally certified Patient Safety Organization as designated by the U.S. Department of Health and Human Services.

For more information, visit www.ecri.org.

Tom Toczylowski, ECRI’s Associate Director of Healthcare Product Alerts

HTM professionals generated over 1,200 nominations for the 2025 Tech Choice Awards with the top 5 nominees for each of the 13 categories named as finalists. Voting begins October 1 and is open until January 15, 2025.

The Tech Choice Awards (also known as the Wrenchies) are the people’s choice award for the HTM community. The winners are based 100 percent on the number of votes each finalist

received during the voting period. A special thank you goes out to the sponsors who help make the Tech Choice Awards possible. The sponsors do not have any input when it comes to selecting winners.

Wrenchie winners will be announced in the March issue of TechNation with an award ceremony planned for the MD Expo set for Southern California in April 2025.

OF THE YEAR, sponsored by USOC

OF THE YEAR, sponsored by MedWrench

• Rana Helou, biomedical engineer II, Crothall

• The ProHealth Care Biomedical Engineering Department

• Memorial Hermann Health System Biomedical Engineering Department

• University Hospitals Health System Healthcare Technology Management Division

• Washington Regional Medical Center Biomedical Department

• UT Southwestern Medical Center’s Healthcare Technology Management Department

OF THE YEAR, sponsored by 626 Holdings

• Earl Morris, BMET, Harrison County Hospital

• David Scott, senior biomedical technician, UC Health

• Charles Woolfolk, HTM manager, Baylor Scott & White Health

• Greg Czajka, support services operations director, Advocate Aurora Health

• Stephen Ellithorpe, executive director, Providence

• Nicole Ruffin, BMET II, Renovo Solutions

• Codi Nelson, program director, Crothall

• Brandi Caton, supervisor of clinical engineering, Trimedx

• Manuel Vanderpool, senior site manager, Trimedx

OF THE YEAR, sponsored by Prescott's

• Webb Clark, senior sales manager, Emeritus

• Samantha Moriarty, manager of clinical engineering operations and inpatient compliance, Brigham and Women's Hospital

• Lewis Lennard, product manager (North America), Rigel Medical

• Michael Toomalatai, chief biomedical engineer, Department of Veteran Affairs

• Millicent Alooh, regional director, BMET implementation at Rice360 Institute for Global Health

MILITARY BMET OF THE YEAR, sponsored by College of Biomedical Equipment Technology

• Tyler Scott, chief, healthcare technology management, Keller Army Community Hospital, U.S. Army

• Bailey Messina, FSE Boston Imaging, U.S. Air Force

• Eric Dalsin, information systems biomedical equipment support specialist, Southeast Louisiana Veterans Health Care System, U.S. Navy

• David Lindsay, CBET, Renew Biomedical, U.S. Army

• Phillip Villegas, hospital corpsman and biomedical equipment technician, U.S. Navy

EDUCATOR OF THE YEAR, sponsored by Maull Biomedical

• Jim Durocher, biomedical professor, St. Clair College

• Dr. Jeffrey Smoot, professor of HTM, MiraCosta Community College

• Phil Pash, director of HETM, IU Indianapolis

• Donald Armstrong, technical training program manager, Renovo Solutions

• Larry Fennigkoh, Ph.D., educator, Milwaukee School of Engineering

DIRECTOR/MANAGER OF THE YEAR, sponsored by MW Imaging

• Mike Busdicker, system director, clinical engineering, Intermountain Healthcare

• Ashley O’Mara, VISN 1 chief clinical engineer, VA New England Healthcare System

• Douglas Redwine, operations manager, healthcare technology management, Texas Health Resources

• Sandy Mason, senior manager, Trimedx

• Rudy Flores, market director, Central United States, UHS

sponsored by Avante Health Solutions

• April Lebo, vice president of demand generation, Probo Medical

• Wanda Legate, senior vice president business development, Tri-Imaging Solutions

• Jenn Nichols, general manager clinical engineering-west operations, Trimedx

• Carol Davis Smith, director, clinical engineering internship program, University of Connecticut

• Izabella Gieras, director clinical engineering, Cedars-Sinai

OF THE YEAR, sponsored by Pronk Technologies

• David Ebo Anderson, biomed & lecturer, Koforidua Technical University

• Edward Reyes, clinical engineering professional, U.S. Department of Veterans Affairs

• Ratish Kumar Mohan, biomedical engineer, Hospital Sisters Mission Outreach

• Clement Appiah Anokye, senior clinical engineering manager, Ghana Health Service & Operation Smiles

• Jeff Ruiz, senior site manager, Trimedx, Miles for Myles

OF THE YEAR, sponsored by Soma Tech, Intl

OF THE YEAR, sponsored by MultiMedical Systems

• North Carolina Biomedical Association (NCBA)

• Clinical Engineering Association of Illinois (CEAI)

• HTMA-NTX

• HTMA-OH

• New England Society of Clinical Engineers (NESCE)

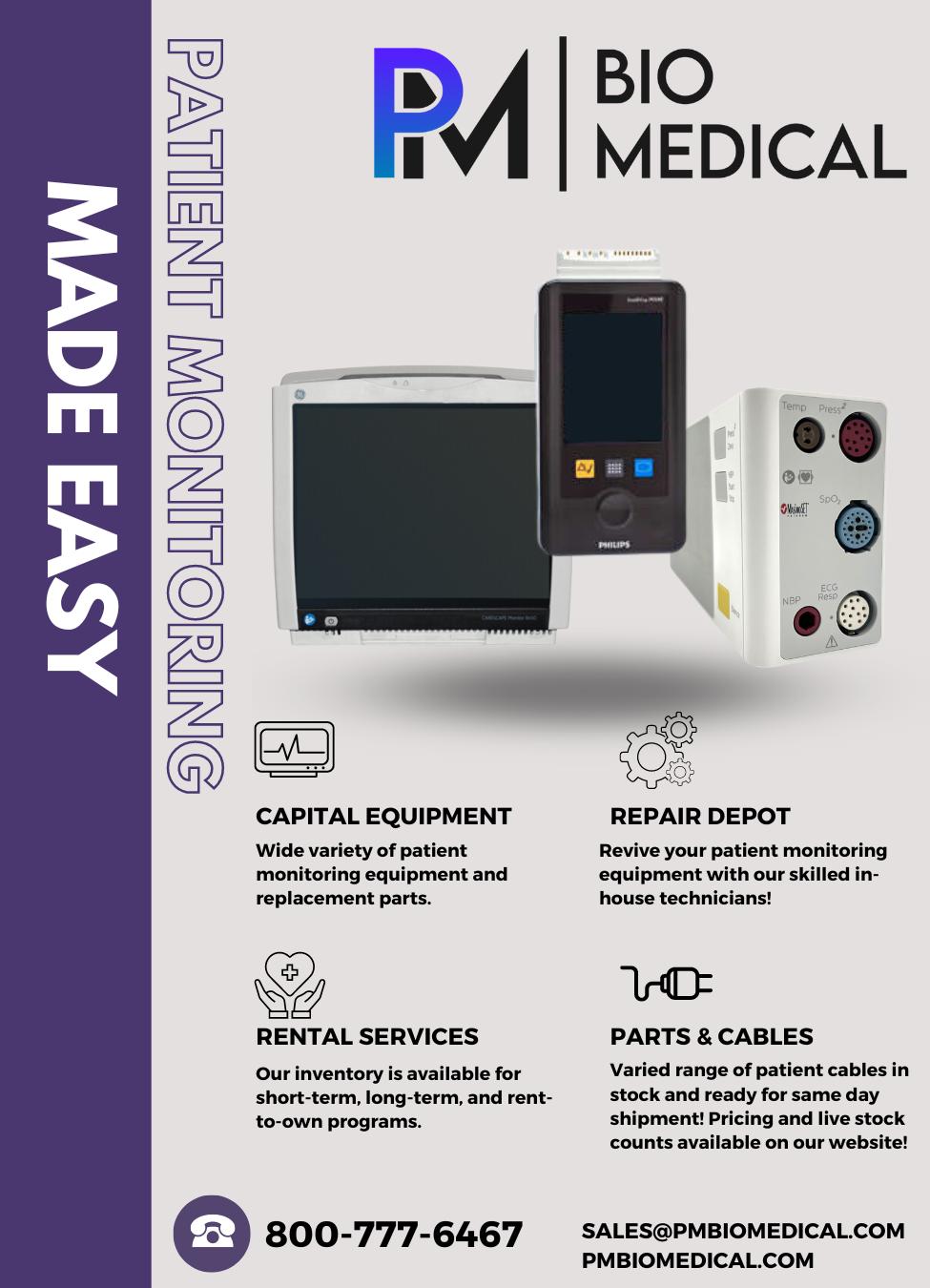

• PM Biomedical, pmbiomedical.com

• Prescott’s, prescottsmed.com

• RSTI, rsti-training.com

• Tri-Imaging Solutions, triimaging.com

• USOC Medical, usocmedical.com

Visit 1technation.com/tech-choice-awards to vote for your favorites. Voting ends January 15, 2025.

• Jennifer Chester, creator of “Bella the BMET”

• Kim Rowland, vice president Women In Leadership

• Jewel Newell, co-founder of I-HTM

• Chyrill Sandrini, host of HTM Insider

• Carlos Villafane, founder of Biomedtechnicians.com

BY CARLOS VILLAFANE

Recently, I read an article from Gallup titled “The New Challenge of Engaging Younger Workers” from February 2024. This article explained that since March 2020, there has been a dramatic decline in engagement at work among younger generations. Per their study, “the younger group of millennial and Gen Z employees (born 1989 or later) have experienced a five-point decline in engagement.”

This trend has been happening for years, as another Gallup survey from 2019 mentioned that “only 29% of millennials are engaged at work, meaning only about three in 10 are emotionally and behaviorally connected to their job and company.”

Why is this happening? The article mentioned something that grabbed my attention: “This generation of workers, especially, is looking for an employer with a purpose they can identify with.”

What can be done to connect and engage the next generation in the HTM/biomed field?

This is something that should concern each one of us. We already know there is a need for new HTM professionals, as so many BMETS and field engineers who started working in our field in the 1970s, ’80s and ’90s are retiring. Also, there are not many schools that offer biomedical engineering courses today when compared to previous decades.

We need to recognize that each one of us can do something to help, as we have a very important purpose in health care and in our communities that we can share with the newer generation. We contribute to the maintenance and improvement of devices that can diagnose, treat, and manage health conditions, directly enhancing patient care and saving lives.

What can you do to share your passion for your career as a BMET?

LOOK FOR OPPORTUNITIES TO SHARE YOUR EXPERIENCE.

• You don’t need to be a teacher to talk to students. Many local middle & high schools enjoy having professionals talk about their careers during career

fairs and similar activities. Can you volunteer to visit a local school, vocational or trade school? AAMI has plenty of printed material and resources that you can use to interest the students.

• Is there a local biomed engineering college near your area? Be a mentor! You can provide guidance, support and inspiration to the students already interested in our field.

• Are you a member of your local biomed/HTM association? If not, get involved! Your support helps the local association to spread the word in the community about our jobs.

• Familiarize with and use social media and online tools to reach the younger generations, as they are more receptive to the use of technology to learn. There are plenty of places online you can use to share success stories, breakthroughs, opportunities, thoughts, and suggestions: Lists, question-and-answer platforms (like Quora), Facebook groups, YouTube (if you want to share videos), etc. Recently there has been an increase of BMET/ HTM-related channels online, podcasts, motivational videos, etc. Follow them, subscribe and volunteer to be interviewed on any of these channels if you can!

• Write articles for your favorite HTM magazine.

• Think about the aspects that make HTM a great career path and share them. For example:

• Everyone involved in the HTM field has the privilege to work in health care, so job security is almost guaranteed. (Even during COVID, we were always busy taking care of the medical devices without interruption).

• The HTM field has tremendous growth potential: Reportlinker.com predicts a “compound annual growth rate of 15.5% through 2026.”

• We work with cutting-edge technology that evolves rapidly. There are constant opportunities to familiarize and learn about new medical devices and new technology.

• We are helping the community by keeping life-saving medical devices in optimal performance to take care of their health needs.

• We never get bored at work!

• Emphasize the real-world Impact that we have.

• Showcase how careers in the HTM field contribute to solving global health challenges, improving patient outcomes and advancing medical research.

By looking for opportunities to talk about our experiences, we can effectively engage and inspire the newer generation to pursue careers in our exciting HTM field!

Carlos Villafañe, CBET, CET, can be found online at biomedtechnicians.com and youtube.com/ @tecnicosbiomedicos

Register at WebinarWednesday.live Eligible for 1 CE credit from the ACI.

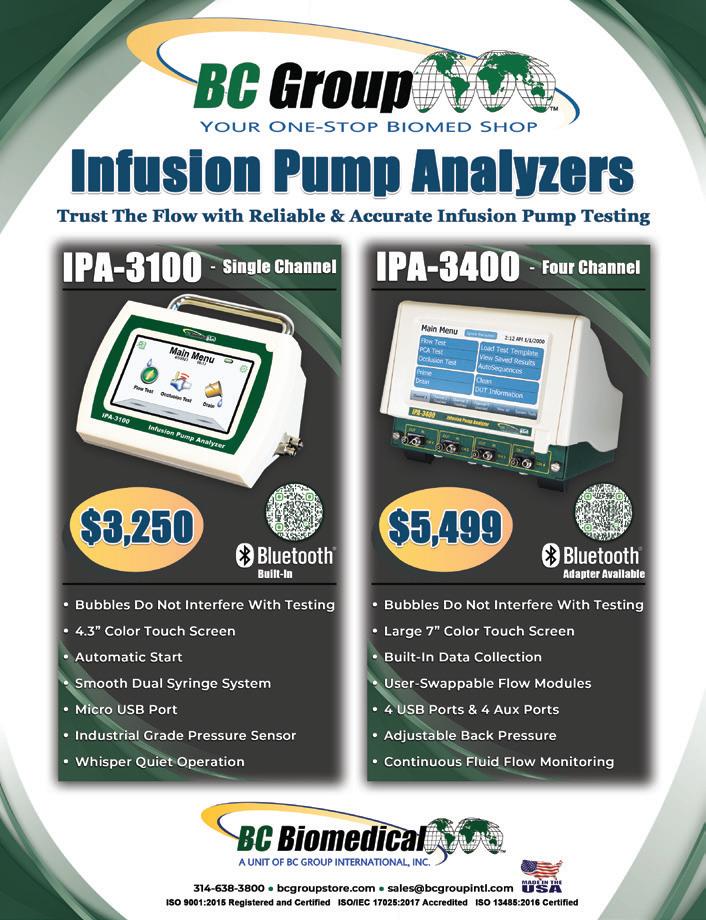

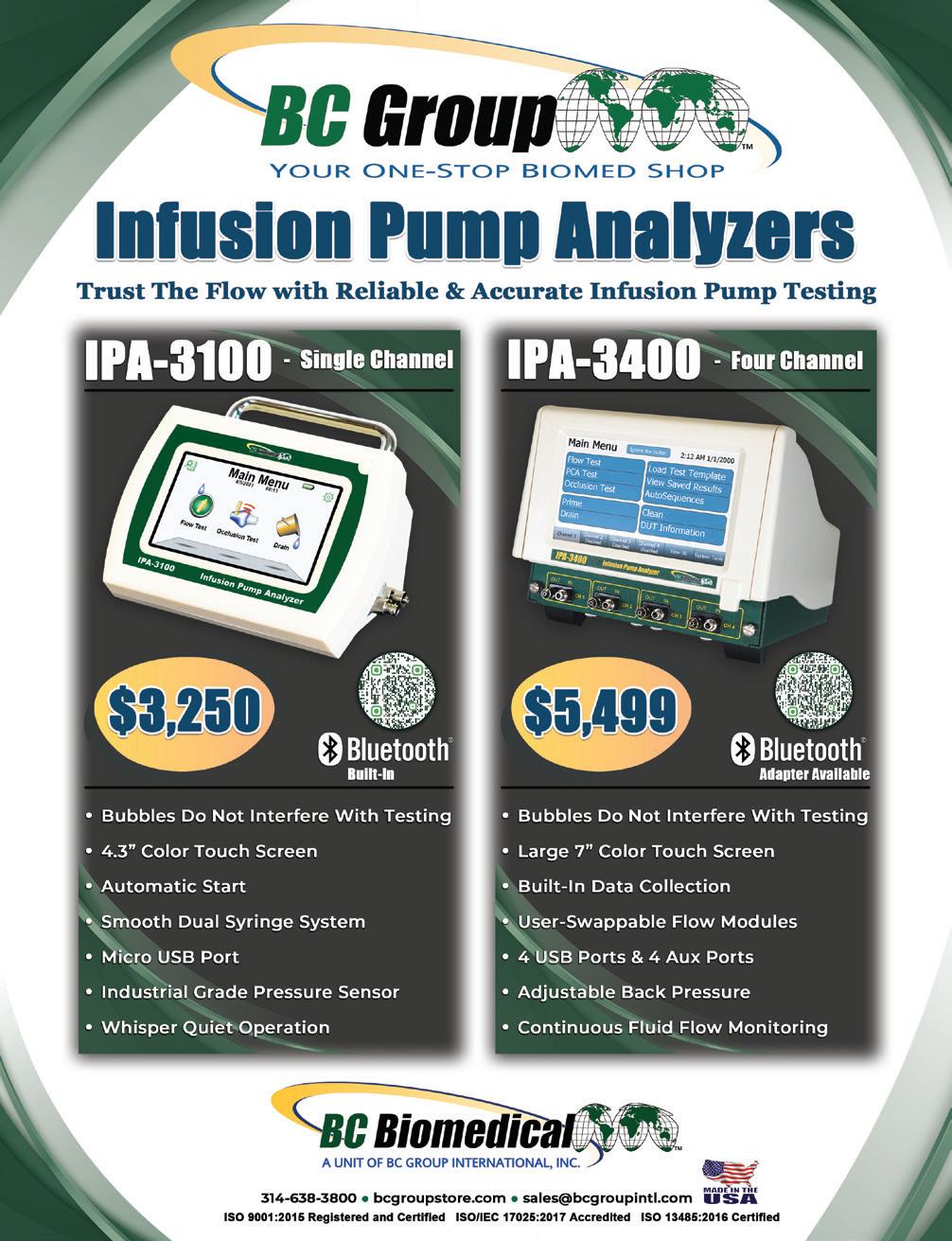

The next generation of infusion device analyzers

The revolutionary IDA-6 Infusion Device Analyzer puts simplified infusion device testing right at your fingertips. With just one touch, effortlessly navigate through the intuitive interface, boost the accuracy of your tests, and easily generate reports —all on a user-friendly 10-inch touchscreen.

Modular design – Simplified calibration with field exchangeable channels to eliminate downtime

4-Channel testing – Test up to four infusion pumps at once

No priming after initial setup – Accelerate test time

IntelliPump Technology – No mess testing with a water recirculation system

OneQA-enabled – Workflow automation simplifies testing, enhancing accuracy and efficiency

Transform your infusion pump testing with the IDA-6 Infusion Device Analyzer today.

For more information, visit flukebiomedical.com

The Webinar Wednesday presentation “Research to Implementation – Understanding Key Components of a Successful RTLS Platform” sponsored by Cognosos is eligible for 1 CE credit from the ACI. Access the on-demand version of the webinar at WebinarWednesday.live.

Cognosos Director of Product Marketing-Healthcare Jeff Stiffler informed participants regarding key components of RTLS platforms, in addition to expected benefits and future trends.

Takeaways from the session included:

• RTLS platform definition

• Key components

• Hardware technology – IR, ultrasound, BLE, UWB

• Software technology – AI/ML, on-premise

• Expected Benefits and ROI

• Current trends and future outlook

Stiffler also answered attendees’ questions during a Q&A session. The Q&A session is included in the on-demand version at WebinarWednesday.live

Todd Peterson, a biomedical technician at Mary Greeley Medical Center in Iowa won an Amazon gift card as part of Webinar Wednesday’s 10th anniversary celebration.

Attendees were asked “Excluding CE credits, why do you attend Webinar Wednesday?”

“To keep up with the fast-moving changes in the health care industry.”