Starting your own business is a huge achievement. There are countless risks, challenges and hurdles to overcome be fore you even make it to ‘Day One’. So to go on to hit the year mark, then the anniversaries to follow is a genuine feat and one that should be commended and applauded.

And the two breweries we place in the spotlight in this issue’s profiles know that feeling all too well, even if they’re too mod est to admit it.

When Matt Phillips went it alone in beer, he was a 27 year old brewer, living in a windowless apartment and a mountain of credit card debt. But fast-forward to 2022 he, and his near 100-strong team kicked off the year by toasting 20 years of beers.

In celebrating that fantastic anniversary the business has gone on to produce some 90,000HL of beer per annum and is proud to be one of the only craft brewers in Can ada to malt its own barley. Not only that it has its own distilling arm too, in the form of Phillips Fermentorium.

Phillips Brewing and Malting Co of British Columbia has much to be proud of during those first two decades. “Could I envisage doing what we’re doing back when I started out? God no. I was focused on flavour and making the best beer I could. If that meant I’d be around two or three years down the road then that was a success,” he recalls. “So it’s great to still be doing what I love but it is certainly not by design.”

If you leave Phillips Brewing, take a left head down into the USA then east some 6000km you’ll eventually reach Nova Sco tia, home to Boxing Rock Brewing Compa

ny. The Shelburne-based business is the answer to the question of what happens when two chemical engineers with a pas sion for craft beer join forces.

The brewery was the 2022 recipient of the prestigious Taste of Nova Scotia ac colade for best producer. Since 2013, the brewery founded by Henry Pedro and Emily Cowin, been making a name by keeping the great and the good satiated with excellent beer, all while challenging perceptions along the way.

And starting out in 2013 means next year marks their important tenth year in the business of brewing. “I’m sure the team are planning lots of ways to celebrate our anniversary next year, and I’m glad be cause I don’t really deal with that stuff,” says co-founder Henry Pedro. “For me, I’m more proud that we have a team of 24 working at Boxing Rock. I spend my time waking up thinking about the 23 other people I need to pay. It’s a responsibility but it’s also a blessing. I know that.”

One of the great privileges of working on this publication is being able to speak to, and tell the story of, breweries such as these. Hearing about their countless achievements is always a thrill and we look forward more such stories in the is sues to come.

We hope you enjoy the issue, and best of luck to all of those attending and compet ing in this year’s Brewers Choice Awards, the winners of which will be crowned at The 2022 Canadian Brewers Choice Awards & The Presentation Dinner. This takes place on Thursday, December 8, 2022, at Old Flame Brewing Co. in the Dis tillery Historic District of Toronto. We hope to see you there.

Tim Sheahan Editor

Alexandra Skinner from WorkSafeBC explains how a commitment to health & safety is one of the best ways for employers to protect their greatest resource – their people.

PART 1. In addition to now-familiar concerns like Covid, Health & Climate Change, Geopolitical Conflicts, and rising inflation have added to the heightened sense of unpredictability. FlavorSum looks at what predictions are in store for 2023.

Escarpment Laboratories shares some research the team did on yeast storage time between batches of beer.

Founder Matt Phillips reflects on how Phillips Brewing & Malting Co. has grown and evolved in the last 20 years, and why there is so much more to come too.

Following the launch of LalBrew NovaLager, it’s modern hybrid lager yeast, Lallemand brewing explain how modern yeast breeding methods will surely continue to provide novel, non-GMO yeast strains with commercially important characteristics.

Robert Percival, the regional sales manager for Europe at Lallemand Brewing, explains how knowing what lager strain is most suited to the beer you are brewing is all-important.

In challenging and volatile times, companies that truly understand their processes, workflows, and data tends to be most resilient. First Key Consulting guide you through plotting your brewery’s success with Process Mapping.

PART 2. FlavorSum continues to look at what predictions are in store for 2023, with a deep dive in flavours.

Is this the beginning of the end for PVC and Brass? Dan Broaddus, a Technical Advisor at Canadian Beverage Supply, explains all.

Craft beer is thriving in Mexico. Here Marcos Gottfried of Cerveza México, explains how small brewers are driving industry growth.

Sabrina Pirillo takes us on a journey to Edmundston, New Brunswick, where Les Brasseurs du PetitSault blends together regional brews with the Art of Storytelling.

Part 2. Paul Davies, a Beer Sommelier and international beer judge, continues his journey of stunning Belgium breweries and blenderies, this time through his experience of the Bruges Beer Festival, which returned earlier this year.

What happens when two chemical engineers with a passion for craft beer join forces? You get Boxing Rock Brewing Company of Nova Scotia,

Tim Sheahan Editor

tim@brewersjournal.ca +44 (0)1442 780 592

Jakub Mulik Staff photographer

Johnny Leung Canada Partnerships johnny@brewersjournal.ca

Sheena Strauss Homebrew Journal knwl.on.tap@gmail.com

Richard Piotrowski Publisher Richard@brewersjournal.ca

Magdalena Lesiuk Graphic Design GraphMad@gmail.com

CFJ Media

2275 Upper Middle Rd E #101, Oakville, ON L6H 0C3

The Brewers Journal Canada is a quarterly magazine mailed every Spring, Summer, Autumn and Winter. Subscriptions can be purchased for four or eight issues. Prices for single issue subscriptions or back issues can be obtained by emailing: johnny@brewersjournal.ca

CANADA One year: $39

INTERNATIONAL One year: $49

The content of The Brewers Journal Canada is subject to copyright. However, if you would like to obtain copies of an article for marketing purposes high-quality reprints can be supplied to your specification. Please contact the advertising team for full details of this service. The Brewers Journal Canada is printed at Print Buy, 15 - 1253 Silvan Forest Drive, Burlington ON, L7M 0B7

All rights reserved. No part of this publication may be: reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording or any information storage or retrieval system, without the express prior written consent of the pub lisher. The Brewers Journal Canada ISSN 2398-6948 is part of Reby Media, 42 Crouchfield, Hemel Hempstead, Herts HP1 1PA. It is published quarterly in Canada by CFJ Media, 2275 Upper Middle Rd E #101, Oakville, ON L6H 0C3, Canada. Subscription records are maintained at CFJ Media, 2275 Upper Middle Rd E #101, Oakville, ON L6H 0C3, Canada. The Brewers Journal accepts no responsibility for the accuracy of statements or opinion given within the Journal that is not the expressly designated opinion of the Journal or its publishers. Those opinions expressed in areas other than editorial comment may not be taken as being the opinion of the Journal or its staff, and the aforementioned accept no responsibility or liability for actions that arise therefrom.

To ensure there is a beverage for everyone that comes to the table thirsty, Musko ka Brewery has continued to stay on top of trends in the industry by releasing new products such as their lineup of beyond beer beverages including Wandr Alco hol-Free Sparkling Tea Infusions, Muskoka Spirits Hard Sparkling Waters, and Squeeze the Day Juicy Hard Seltzers. The new part nership with Rally Beer continues to help diversify their consumer base and capture more occasions.

“There has been a gap in the marketplace for a beer that appeals to an active life style and an authentic brand that supports the active communities. That’s what we’ve sought to create with Rally,” says Wood. “By joining forces with Muskoka Brewery, Rally is looking forward to deepening our connec tion with consumers who want better-foryou options to kudos the occasion!”

“

Rally has pioneered the concept of functional beer in Canada, and we are so excited to be a part of what they have built,” says Todd Lewin, President of Muskoka Brewery. “We are looking forward to bringing togeth er two brands that have championed out doors inspired beverages and make beer more approachable for all.”

Functional beer is born from the shift of con sumer trends towards balance and making healthier choices while still consuming the products they love. Rally Beer offers a lineup of functional beers brewed to be rich in electrolytes for an adventure-based life style, offering a perfect parallel to Muskoka Brewery’s mantra of venturing off the beaten path and drinking in the moment.

“This is certainly an exciting time for myself and Rally Beer. My mission was always to inspire as many people as possible to get outside, be active and grow the community through our brand,” says Alan Wood, Found er of Rally Beer Company. “Joining Muskoka Brewery will be a catalyst to grow that com munity even further and encourage more

people to connect in the great outdoors and toast all of life’s epic adventures.”

As a trailblazer of the Ontario craft beer industry, Muskoka Brewery has been an innovator with a wide portfolio of unique and premium craft beers, while continu ing to evolve with shifting markets, and staying relevant with the changing tastes of consumers.

“It’s a challenging time for all industries with inflation and changing consum er demand, but Muskoka Brewery is built to invest in growth and be proactive to the changes of the industry. We are staying ahead by going now where the con sumers are going to be in the future,” says Lewin.

Alan Wood, Todd Lewin and Bob Macdonald cheers to a new partnership. (CNW Group/Muskoka Brewery)

At the core of both company’s values are being welcoming and encouraging every one to reach for a beverage that fits their lifestyle. Muskoka Brewery has strived to craft iconic experiences for Canadians, one glass at a time, and Rally Beer holds the same values. From the ultra-athlete to the weekend warrior to the first-timer, Rally is designed to be enjoyed by all. Both com panies are committed to playing an ac tive role in fostering inclusive, accessible, and diverse communities that are centred around a balanced approach to toasting the occasion.

“After

Lewin.

Two of the most critical risks that employers must manage are those associated with con fined spaces and carbon diox ide (CO2)—often in tandem, as confined spaces may contain CO2.

Employers must also ensure workers are aware of these risks—and include workers in creating and implementing risk manage ment programs.

There have been reported incidents of worker injuries entering confined spaces at craft breweries in B.C., and fatalities in other countries.

Confined spaces in breweries include grain bins and silos, process tanks, and brewing equipment like mash and lauter tuns, and grain-dust collectors.

“During inspections, cleaning, or trouble shooting inside a tank, the space a worker is entering becomes their breathing zone, making it dangerous when there is not enough oxygen or there is a toxic chem ical inside.” says Jose Barranco, Manager Risk Analysis Unit, WorkSafeBC.

Barranco notes that entering a con fined space can also lead to other inju ries from falls, temperature extremes, and engulfment.

“We want workers to avoid breaking the “plane of entry”,” says Barranco, “Which basically means, avoid any part of the body entering confined spaces.”

Barranco says using mirrors or cameras on extension poles to inspect the inside of these spaces is one way to avoid en try, as is using cleaning-in-place sys tems to minimize entry for cleaning.

However, he notes that it’s not always possible to avoid entering a confined space.

“Eliminating the risk is best,” he says, “But if that’s not possible, employers are respon sible for ensuring safe work procedures around confined spaces are documented, communicated to workers, and followed to the letter.”

The Occupational Health and Safe ty Regulation (OHSR) requires that be fore a worker enters a confined space the employer must implement a written confined space entry program. In addi tion, workers entering a confined space must be trained to do so, including being trained in rescue procedures.

Workers involved in the beer production processes may be at risk of exposure to hazardous levels of CO2. In addition, the beer fermentation process produces carbon dioxide gas, which may leak out of hoppers or tanks and into the work ing environment.

“Most CO2 leaks and exposure occur in the fermentation and in the bottling area, which is likely where the majority of employees work,” Barranco says.

Workers can be exposed to CO2 when purging, cleaning, or inspecting fer mentation and bright tanks; when working around leaking valves, fit tings, or cylinders; and while working around packing lines, dispensing are as, walk-in coolers, and keg filling and cleaning areas.

“Carbon Dioxide is colorless and odourless, so you won’t be able to detect a leak,” Bar ranco says. “It’s also heavier than air, so if you have a filtration system on an upper floor and there’s a CO2 leak, it will drift down to a lower floor.”

At higher levels of exposure, CO2 can become toxic or suffocate employees by displacing the oxygen they are breathing.

An assessment must be done to identify ar eas where there is a risk of hazardous CO2 exposure. This assessment will help iden tify appropriate controls to reduce these risks, which could include the following:

Increased ventilation to keep CO2 at a safe level

• Monitoring by CO2 sensors, that will alert if levels become dangerous

• Focused inspections of equipment or systems where a failure could result in a harmful environment

WorkSafeBC has several resources to help employers keep their breweries safe, including:

• Health and Safety for Craft Breweries and Distilleries guide Checklists to creating and implement ing health and safety programs Poster for the workplace about the risks of confined spaces and CO2.

For more information, visit: worksafebc.com/craftbrewing

Managing risk in the workplace in volves thinking about what might harm workers and then determin ing whether reasonable steps are being taken to prevent that harm from occurring.

• Understand the risks: To protect workers, begin by identifying work place hazards. A hazard is anything that may cause harm, such as chem icals, electricity, or equipment.

• Assess the risks: What risks do the identified hazards pose to workers? The risk is the chance that somebody could be harmed by these hazards, as well as the potential severity of harm. Make sure the appropriate at tention and level of control are dedi cated to each one.

• Implement measures: The great est risk should be addressed first. If it cannot be eliminated, control measures must be implemented to minimize it.

• Communicate: Make sure every one is aware of the risk manage ment program. Provide managers, supervisors, and workers with ori entation and training on how to identify hazards and what to do to control the risks. Document and share safe work procedures and pol icies with workers.

• Monitor and update: Monitor the effectiveness of the control meas ures in place and make improve ments and adjustments as needed. This includes conducting regular safety inspections to identify new or changing hazards.

With 36% of consumers believing func tional food and beverages can improve or enhance mood (Innova), interest in mood-boosting botanicals like mush rooms and hemp is rising. Ashwagandha is currently the most frequent botanical in mood-boosting positionings, lion’s mane is the top functional mushroom, and saf fron remains the fastest growing herb or spice (Innova).

Other botanicals to watch:

• Bacopa for memory and anxiety sup port (+95.6% CAGR over the last five years)

• Maca for anxiety, stress, and depres sion support (+74.6%)

• Lemon balm for sleep, anxiety, and appetite support (+73.4%)

More of us are experienc ing anxiety (the body’s response to stress) in our daily lives. This “anxiety culture” is more than fear associated with developing issues ac cording to Michael Schapira, Ph.D., ad junct professor of philosophy at Saint Jo seph’s University, Philadelphia. Schapira notes that anxiety culture “has become characteristic of our dealing with the in creasing problems and undefined solu tions of a rapidly changing world.”

How can food play a role in alleviating anxiety? Global consumers are turn ing to food and beverage choices to improve their mental and emotion al well-being. We can expect to see a continued focus on stress relief and

mood-boosting ingredients across nearly all food and beverage catego ries. Other health-related benefits like brain health, gut health, and immune support will also be important.

Stand Out Statistics:

• In the US, almost half of consumers (49%) experienced stress in the 12 months, while nearly two-fifths (38%) dealt with anxiety (Mintel).

• Nutritional benefits are a top five driv er for consumers when it comes to food (Innova).

• Brain health is outpacing overall ac tive claims in food and beverage, growing at 12% CAGR ending in Q1 2022 vs 4% for other active health claims (Innova).

According to Precedence Research, the $129.3 billion global functional beverages market could grow at an 8.94% CAGR from 2022 to 2030. And interest is rising. Ac cording to a FlavorSum proprietary study, 56% of US adults are looking for purpose ful beverages.

We expect to see more fermented drink options like kombucha and kefir on store shelves. Brand Essence research predicts kombucha sales will deliver a 15% CAGR, surpassing $2 billion in North America by 2027. Technavio es timates North American kefir sales will reach almost $900 million by 2026 on a growth rate of almost 8% compound ed annually.

People are learning more about the gutbrain axis, and we anticipate brands will provide education supporting health claims like gut health, immune support, and im proved vitamin and mineral absorption.

THEIR FOOTING, SUPPORT MENTAL HEALTH, AND REACH LIFESTYLE AND SUSTAINABILITY GOALS.

Technology is becoming a more influ ential part of cooking and shopping. We search for new recipes on Tik Tok and Pinterest. Then, we talk to smart devices in our kitchens that can start the grocery list and have appliances that connect with recipe apps to automatically adjust cooking temperatures.

Stand Out Statistics:

• Americans are cooking 51% more often compared to pre-pandem ic levels. They’re also baking 34% more (Hunter).

• Individuals are 5 times more likely to use a recipe they found on social media versus recipes they saw on TV (Social Chain).

• The worldwide smart kitchen appli ances industry is worth an estimated $13.18 billion (Grand View Research).

Platforms like Tik Tok and Pinterest have helped many people feel more confident trying new recipes at home. Popular dish es or globally-inspired flavors with millions of views have a real-world impact. In early 2021, a popular Tik Tok pasta recipe caused feta cheese shortages in U.S. grocery stores. The relationship between the digital and “real” food worlds will continue to deepen, and brands that are part of the conversation will create stronger connections.

While online grocery shopping picked up during the pandemic, the relationship be tween in-store and online is complex. Over the last twelve months, the proportion of Americans who say they have purchased groceries online declined. But slightly more people say they now do “most” or “almost all” of their grocery shopping online (Food Navigator). With inflation rising and grocery budgets not stretching as far, we may see increases in pre-shop planning and online shopping to cut down on unplanned or impulsive purchases. For brands, the shift away from impulse means getting inno vation news out digitally (and on the right channels) vs in-store.

Awareness of global issues is expanding, and more people are making conscious

food and beverage choices. Whether se lecting a plant-based option or looking for upcycled ingredients, shoppers will con tinue looking for foods and beverages that align with their sustainability and environ mental goals.

Stand Out Statistics:

• 70% of U.S. teens say that their sus tainable actions can make a differ ence, while 56% worry about climate change (Mintel).

• 56% of adults in Canada consider food waste when purchasing food and drink in stores (Mintel).

• About 90% of plant-based food con sumers aren’t vegetarian or vegan (NPD Group).

Unfortunately, inflation is expected to stay above the Federal Reserve’s goal of 2% in 2023. As rising prices take their toll on household finances, shoppers will look for ways to economize their grocery budgets. According to Mintel, saving strategies will include finding value through bundling and deals (52%), reduced dining-out (39%), choosing store brands (36%), store switch ing (31%), and brand changes (17%).

Even though some people will be willing to forgo purchases, others are still willing to pay a premium for sustainable options. Most shoppers buying plant-based op tions make the choice for health and en vironmental reasons. Some health benefits associated with plant-based foods include reducing inflammation and reducing the risk of cancer and diabetes. Parents who wish to pass their sustainability convic tions to the next generation will look for kid-friendly plant-based options like nondairy pudding pouches and cheese sticks.

Forbes recently reported that 79% of Americans prefer personalized service that helps them feel seen, heard, and val ued. Brands are responding with tactics like social media feeds based on hob bies and interests, meal delivery kits with weekly options, and personal styling ser vices. People are also tailoring food and drink choices to fit their habits and goals, seeking a custom eating experience in and out of home. New formats like low or

no alcohol beverages and inclusions like CBD can fill this desire for customization.

Stand Out Statistics:

• 58% of global consumers are drink ing more non-alcoholic and low-ABV cocktails than a year ago (2022 Bacar di Cocktail Trends Report).

• No- and low-alcohol volume will grow by 8% CAGR between 2021 and 2025, compared to regular alcohol volume growth of 0.7% CAGR during that same period (IWSR Drinks Mar ket Analysis).

• The CBD category is forecasted to reach $23.6 billion by 2025 (Grand View Research).

The idea of “mindful consumption” takes inspiration from popular mental health and wellness practices. Innova reports that one-third of consumers aged 18-25 are now saying that they never consume alcohol. We expect the moderation trend will continue as people prioritize mental health and clarity and as the quality of low or no-alcohol choices improves.

Some people are exploring how CBD can help in their daily lives by reducing stress and pain or promoting sleep. Beverages fit well with the CBD category because of their versatility and portability. The U.S. CBD drinks market is expected to grow by 65% in 2023 and reach a value of around $657 million as more brands enter the market and states approve the ingredi ent (BevNet). Canada’s current regulatory environment limits purchase of canna bis-infused beverages to five cans per purchase, but brands are anticipating an easing of the limit in 2023. As more prod ucts become available, continued educa tion and transparency will be important for building trust and brand loyalty.

What’s your next opportunity for innova tion? Whether you’re looking for marketing insights or help with formulation, Flavor Sum is here with the expertise to help you create great-tasting products that align with consumer needs and inspire brand loyalty. Contact us to talk about getting the support you need!

be OK to use for several generations. If you have any concerns about the health of a re pitch however, we always suggest going back to a fresh yeast pouch.

This does depend on your yeast strain. There is not much good information or data out there on how long brewery yeast will last between batches, especially at craft beer scale and with craft beer strains such as ale yeasts.

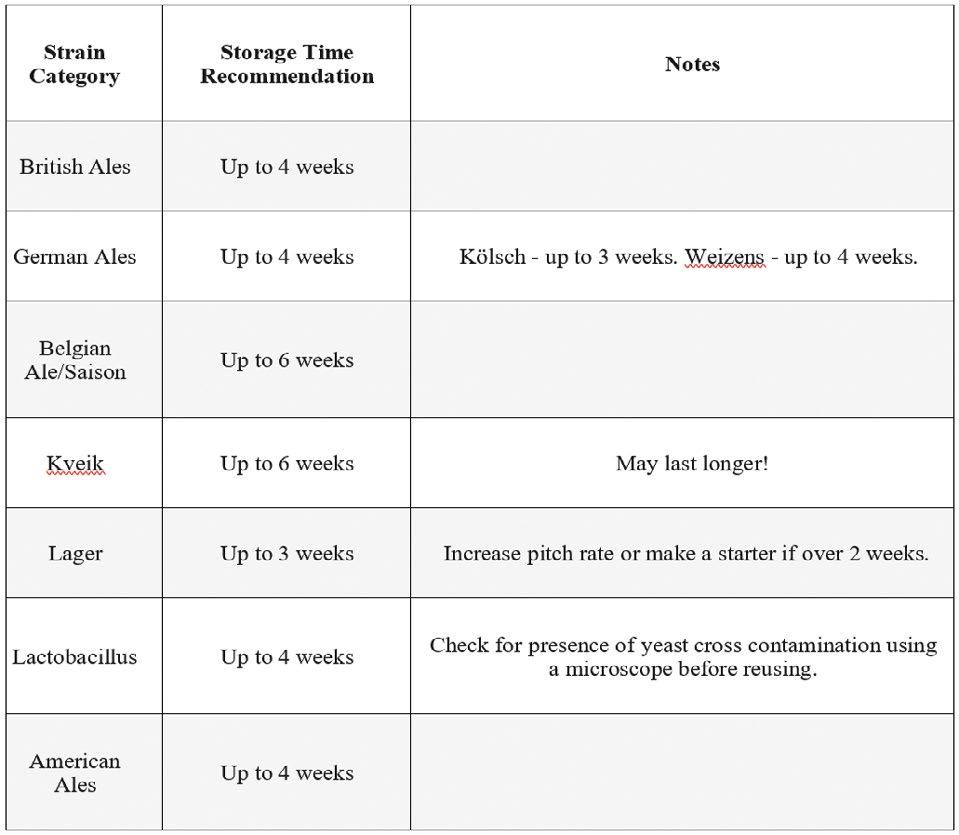

In general, we recommend maximum storage times of yeasts based on the fol lowing table:

A great study titled “Long Term Yeast Stor age: Novel Approaches” was shared at the MBAA conference in 2019 by Matt Couch at Lazarus Brewing. This study showed that a pH buffer (potassium phosphate) and sunflower oil can help improve yeast viabil ity during storage between batches. These results are promising and stay tuned for some results from Escarpment Labs test ing the impact of pH buffers and nutrients on yeast storage between batches.

We decided to put yeast storage, without any additives, to the test! We selected two

ur simple answer is: for most yeast strains, plan to reuse it within 3 weeks, although some strains can last longer between repitches.

Note for homebrewers: you have a lot more flexibility here, if your stored yeast is more than 1 month old we recommend building up a stir plate starter and your yeast should

Note 1: If you are able to perform a propagation/“vitality starter” step prior to pitching, you can often extend the viable shelf life of your stored yeast up to several months.

Note 2: Storage time is HIGHLY dependent on the viability of the yeast coming out of your fermen tation. If the viability is below 80%, we suggest using the yeast within 1 week of cropping.

strains that are not known to be super har dy, but which also aren’t super picky about storage: Kölsch, and Isar Lager.

Fresh slurry from Escarpment Labs has a long shelf life due to how we grow and feed the yeast. Since the yeast produced at Escarpment Labs is packed with pH buffers, micronutrients, minerals, and other factors that radically enhance shelf life, we needed yeast cropped from a beer fermentation in order to obtain accurate real-world results.

Luckily, our friends at Royal City Brewery down the road helped us out with some “gen 1” yeast slurries, freshly cropped and stored at refrigerator temperatures (2-4ºC). The yeast was tested at over 95% viability when it was cropped at the brewery, indi cating this yeast was of excellent health coming out of the beer fermentation.

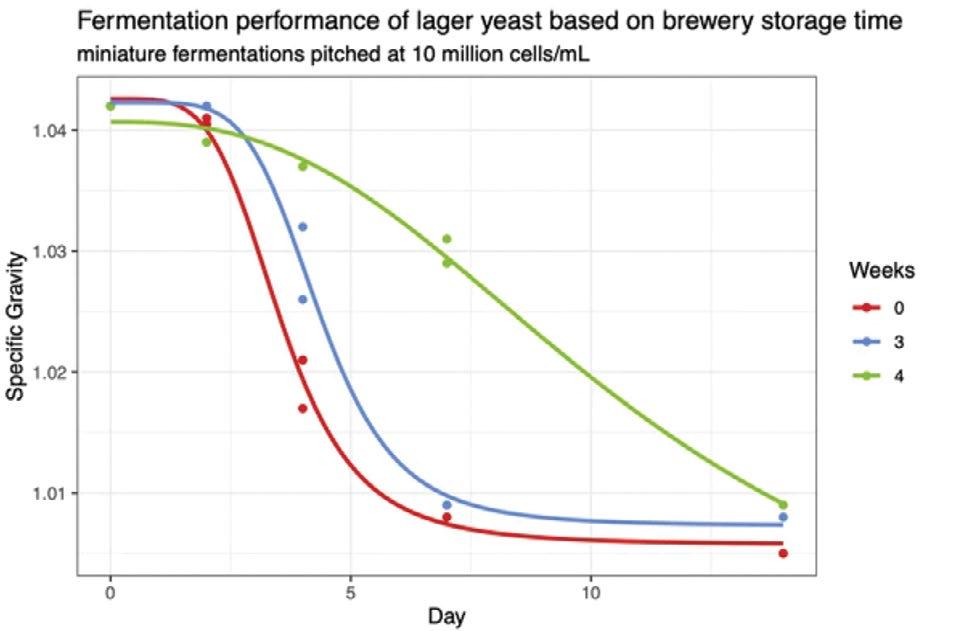

For this experiment, we stored the yeast in the fridge and pulled samples at 0 weeks (fresh), 3 weeks, and 4 weeks in order to as sess the impact that yeast storage time has on fermentation performance.

We chose 3 and 4 weeks as this is around the maximum amount of time most brew ers and yeast suppliers will recommend storing yeast between batches of beer.

We then took the stored yeast slurry and pitched it into miniature wort test fermen tations at a rate of 10 million cells/mL. This rate is a bit low for Isar Lager but we wanted to keep pitching rate consistent between the strains. The fermentations were run in duplicate to ensure consistency. The wort had a starting gravity of 1.042, and we mon itored the specific gravity using a handheld densitometer (Anton Pair DMA35). The Kölsch was fermented at 21ºC while the Isar Lager was fermented at 15ºC.

We found that the fresh yeasts fermented very well, with each strain within its expected fermentation timeline. The Kölsch strain was close to finished at day 3, and down to ex pected FG at day 7 (1.008). The Lager strain was at expected FG (~1.009) at day 7 as well.

Storage impacted the lag time as well as the total fermentation time of both yeasts. Interestingly we found that 3 weeks of stor age resulted in much better fermentation performance than 4 weeks of storage, sug gesting that these yeasts were starting to lose vitality at this point.

This lines up with conventional wisdom, that “regular” yeast strains such as Kölsch and Isar Lager will rep itch well for about 3

weeks, but start deteriorating in vitality af ter that point.

We have not yet assessed the sensory im pact of prolonged yeast storage. It is possi ble that yeast stored for 3+ weeks may also present a higher risk for fermentation off-fla vours. This would be a great follow up study!

We also had some slightly confusing viability results, as the slurries all recorded above 90% viability for the duration of the experiment using viability staining and a microscope. It would be a good idea for us to repeat this experiment and build in a secondary viability test such as viable plate counting. Nonethe less, the impact of storage on yeast vitality and performance was clear!

We’re inspired to try to find ways that brewers can extend the viable shelf life of their yeast between batches, so that brewers can get more generations out of their liquid yeast pitches. We’re also looking at quicker ways to assess yeast vitality. However we’ve been a bit dissat isfied with the traditional methods such as the acidification power test (we get variable results based on strain). Stay tuned for more practical yeast science from our team.

The data presented in this post were col lected by two University co-op students: Karina Regimbal and Ana Ivosevic. Con gratulations on your successful co-op terms Karina and Ana!

Today, beer is the most popular alcoholic beverage in Mexico, followed by tequila, and the Mexican beer market as a whole has re mained strong, even during the height of the Covid-19 pandemic. According to Mexican national statistics agency INEGI, Mexico sold close to 5.5 million litres of beer between January-May 2021, an increase of almost 41%.

Beer production in Mexico has a long and surprising history. The first beer to be brewed on Mexican soil can be traced back to the time of conquis tador Hernán Cortés, when Alfonso Her rera – an emissary of Cortés – asked the Spanish crown for permission to establish the nascent New Spain’s first brewery at the foot of the Popocatépetl and Iztac cíhuatl volcanoes.

Although breweries and consumption became more popular during the 18th century, the establishment of the the modern industry, and the most emblem atic breweries, took place during the lengthly, polemical rule of Porfirio Díaz –known as the Porfiriato – during the late 1880s and early 1900s.

But while the large, foreign-owned brew eries remain dominant in terms of sales, one area that has been experiencing sig nificant growth over recent years is the ar tisan beer industry. Thanks to ever greater quality and innovation, consumption of Mexican craft beer is on the rise across Mexico and beyond. In fact, independent ly-produced brews accounted for an es timated one in every 100 beers sold in Mexico during 2021, according to Mexican beer association Acermex. This is in part, the association says, a result of beer con sumption levels which are now at a level above those seen before the pandemic.

However, although it only accounts for a small percentage of Mexico’s total beer industry, the artisanal beer segment has experienced phenomenal growth over the past decade. According to ACERMEX, to tal artisanal beer production increased by 2405% between 2011 and 2018, from 10,594 hectolitres to 265,405 hectolitres. In the 12

months from 2017 to 2018 alone, produc tion in Mexico grew by 65% year-over-year.

The states of Jalisco (29%), Baja California (17%) and Nuevo Leon (14%) account for the lion’s share of artisanal breweries within Mexico, with the US, Canada and Europe the primary export destinations.

As an illustration of the strength of the in dustry, our event – Cerveza México, which supports and promotes Mexico’s craft beer brewers and associated suppliers – is an ticipating a 50% rise in exhibitors for the 2022 compared with 12 months before.

The event, which is also the stage for the yearly Cerveza Cup competition for best professional and amateur brews, is also ex pected to attract high numbers of national and international visitors.

Working closely with brewers and associ ations within Mexico, we have seen growth year after year in the artisan beer industry and that is down to a dramatic improve ment in product quality which is driving consumption and sales.

There is also an increasing confidence with in the artisan industry, which is attracting ever greater numbers of aficionados thanks to its quality and originality of the products.

Consumption is now well established in both metropolitan areas and tourist hubs, and I predict that the sector will go from strength to strength over the coming years, with interest in Mexican craft beer likely to increase both inside and outside Mexico. I invite suppliers, retailers, importers and exporters to find out why Mexican artisan beer is a product worth a taste.

Cerveza México take places from October 21-23, 2022 in Mexico City’s World Trade Center with the parallel Cerveza México Suppliers and Inputs exhibition running from October 21-22, 2022.

A second event, Cerveza México Guadala jara, will take place from May 12-14, 2023 in Expo Guadalajara, Guadalajara, Mexico.

HERE MARCOS GOTTFRIED, THE ORGANISER OF CERVEZA MÉXICO, EXPLAINS HOW SMALL BREWERS ARE DRIVING INDUSTRY GROWTH.

IN A YEAR IT STARTED BY TOASTING 20 YEARS OF BEERS, PHILLIPS BREWING AND MALTING CO HAS MUCH TO BE PROUD OF DURING THOSE FIRST TWO DECADES. HERE, FOUNDER MATT PHILLIPS REFLECTS ON HOW THE

HAS GROWN AND EVOLVED IN THAT TIME, AND WHY THERE IS MUCH MORE TO COME TOO.

“Brave and foolish are close cous ins, right?” smiles Matt Phillips. “I just think in your 20s you don’t realise just how close they are!”

While Phillips Brewing and Malting Co has long since become one of British Columbia’s most treasured breweries, it all began with a 27 year old brewer, a windowless apart ment and a mountain of credit card debt.

But in celebrating its 20th anniversary last year, the business has gone on to produce some 90,000HL of beer per annum, employ 95, and is proud to be one of the only craft brewers in Canada to malt its own barley. Not only that it has its own distilling arm too, in the form of Phillips Fermentorium.

“Could I envisage doing what we’re doing back when I started out? God no. I was fo cused on flavour and making the best beer I could. If that meant I’d be around two or three years down the road then that was a success,” recalls Phillips. “So it’s great to still be doing what I love but it is certainly not by design.”

Before Phillips Brewing and Malting Co came to be, Phillips cut his teeth at estab lishments such as the Grizzly Paw Brewing Company, Spinnakers, Wild Horse in Pen ticton and The Whistler Brewing Company.

“I grew up in the East Coast of Canada and each of those roles gave me new experi ences, they helped me learn more and also stretch my career a little,” he says.

And working at breweries such as Spin nakers in Victoria, Phillips thrived with the creative license afforded to him. “They had a real interest in pairing food and beer so it was a great opportunity to really delve into the flavours.”

But it was his time at The Whistler Brewing Company that really help sow the seeds of Phillips going out on his own.

“There was a time where I had to water down a really nice lager to make a light la ger. There was technical skill involved but in any case, I really didn’t like the idea of doing it. In my opinion, the resulting beer was was nowhere near as good,” he says. “It was at that point that I realised that to have kind of creative licence and control of my beers, the only real way to do so was to have my own brewery. And that really helped set the tone.”

Phillips points back to a period towards the mid-nineties when Canada had a boom of breweries opening but by the late nineties, businesses in Canada and North Ameri ca were closing which meant there was a wealth of equipment on the market at in expensive prices.

He recalls: “It was then I realised that if I was going to do this, and not be beholden to the shareholders, then this was the time and I needed to make that jump.

“So I put together a business plan and got rejected everywhere I went. But every time I’d ensure I picked up some credit card ap plications on my way out of the door. And made sure to use those cards to buy all of the used kit I started out with!”

As Phillips said, brave and foolish are close cousins, but he also thinks luck played a lit tle part too.

“When it came to sorting things like the li cense, I realise how fortunate I was that things went as quickly as they did. I found a place in April and signed the lease. By June I had a licence and was up and running by the third week of July. I had beer out a month later,” he smiles. “It all moved very quickly.”

Those first beers were launched on the 26th August 2001. They were produced in a 1,300 square foot facility that was also home to his office/apartment. But as de mand for the brewery’s beers grew, so

did the need for space. They’d move into a new site in 2004, somewhere that was a “game changer”.

“At our first spot we were based on the sec ond floor of an industrial building and that really doesn’t work too well for breweries,” he says. “And one time we had a rupture on one of the tanks overnight, which proceed ed to flood our downstairs neighbours. We weren’t too popular at that point.”

But upon outgrowing their second site, the team would eventually go on to move to the current facility some 13 years ago.

“It got to the point where we were using the parking lot as warehouse space so every day you’d lose a couple of cases of beer to kids in the neighbourhood and

stuff like that,” he recalls. “It was time to find somewhere else.”

Following a period searching, Phillips had even investigated the idea of opening a farm-based brewery. But after moving on from that idea, in 2008 Phillips would eventually find the ideal place. Located on Government St in Victoria, it’s a facil ity that has grown and evolved alongside the brewery’s output. “There’s not an aw ful lot of industrial space available down town so we count ourselves fortunate.”

At the start of this year Phillips Brewing and Malting Co kicked things off by celebrating 20 years of Phillips beers. To mark its 20th year brewing, they’ve taken a trip down memory lane to bring back some of the many different beers it has released in that time.

They started with Kaleidoscope Mosaic IPA – a fan favourite from 2013. This brew is a psycho-tropic trip with boat loads of mosaic hops, famous for their tropical fruit punch to the palate. You’ll find flavours of guava and sweet citrus with subtle IPA bit terness. As they say, it’s a taste symmetri cally balanced no matter how you spin it.

And in April came Thorny Horn Sour Rasp berry Brown Ale, a re-release they said they had no choice but to bring back, fol lowing hundreds of requests for it. First brewed in 2015, and again in 2017, Thorny Horn is a Raspberry Sour Brown Ale with a tangy berry nose that leads to a rich, slightly sharp raspberry tartness through the body, and finishes puckeringly dry thanks to the addition of our house strain of Lactobacillus.

Reflecting on the countless beers they’ve brewed, with 70% of these sold in BC, Phil lips says he’s still incredibly excited by the industry he loves.

“I’m still very much excited by new flavours, new styles and the increasing variety of in gredients we can work with,” he says. “New hops and different yeasts, there is always more to learn and explore.”

And then there’s the small matter of malt. An area Phillips is so passionate about that the business would launch its malting plant in 2015 and they are one of the only craft brewers in Canada to malt their own barley. This facility allows them to work with local farmers, cut down on environmental emis sions, better control quality, and increase the creativity of their recipes.

He explains: “Vancouver Island produces amazing barley. By malting in-house we are able to support local farmers, and by using barley grown 15 minutes away we are also able to cut down on the emissions of transporting malt across the country. Final ly, malting in-house gives us greater con trol over the quality of the final product.”

Like starting the brewery itself, Phillips says opening the maltings was something of a leap of faith early on but one he’s forever glad he did. “To have creative control over something as important as malt is really a dream come true, and working with other breweries and distillers who use it is incredibly rewarding.”

And it’s not just other distillers using these grains, Phillips Brewing and Malting Co

also has a distilling arm to call its own. The Fermentorium is a distilling house where unrestrained creativity and a hand-crafted approach shape unique recipes of all kinds.

It’s a place where Old World craftsmanship meets modern techniques, as spirits are artisanally distilled in tandem on a clas sic 1920s British copper still affectionate ly christened ‘Old George’, and a modern German-built still.

Although their output has produced in ternational award-winning whisky, Phillips says The Fermentorium has at times been a steep learning curve but one they’ve en joyed the challenge of.

“You can sell Whisky at three years but that sure ain’t the one I want to drink!,” he laughs. “We did our first at five years using barrels that were in pretty good shape.

“But when it comes to Whisky, you’ve real ly got to have some faith in the liquid and processes that are taking place. At about the two-year mark, we were about to pour out what would become some of our best barrels because they just had such sulphur nose to them.

“The barrels previously had beer in them and it created this crazy sulphury nose. We thought these are just taking up space and will never come good so let’s get rid. But of course we were too chicken to actually do it and thankfully they came good. You are learning each and every day.”

And for Phillips, learning, collaborating and working remains at the heart of everything

he does. Back in the summer of 2021, On tario-based Steam Whistle Brewing and Phillips Brewing & Malting Co. announced a partnering that sees these two Canadian craft brewing leaders team up to help grow one another’s portfolio of products in their respective markets.

The arrangement embodies the collabora tive spirit that has long-defined craft beer, as each partner has used their local exper tise and decades-old relationships to help the other build their business. There was no change in ownership to either partner, and they have each remained completely independent. This collaboration is a natural fit, as both brewers share the same values and have a history of quality, innovation, sustainability, and community.

“Most breweries have done collaboration beers but sometimes they really stretch the meaning of he word collaboration. It’s of ten just a photo opportunity,” he says. “With Steam Whistle, for me, that’s what real col laboration looks like. We’re working together and both parties benefit as a result.”

And it is initiatives such as this that contin ue to drive Phillips and the business he has built up over the last 20 years. Just don’t call him a veteran.

“In BC there were a fair few breweries that opened in the 1980s, long before us. But then lots have opened since us, too. I like to think of us somewhere in the middle,” he smiles. “But then again, I do end up on the old man panel at events from time to time so maybe I am a veteran these days!”

(or BAB) wisely pushed the date back to have more chance of reduced restrictions allowing the festival to take place. So the festival was held on the second weekend of April, just before Easter. Another change was a new venue!

After years of moving around the city with the Markt, ‘t Zand and Belfry being used re cently, the festival found a new home. The old Beursehalle just off the Zand square has been replaced with a state-of-the-art facility. The brand new Bruges Business and Convention Centre opened its doors in the New Year and is a perfect location for the festival.

Lots of space, plenty of ventilation, truly outstanding food, many bathrooms (essen tial for a beer festival) and outside space for those who need a break. Upon entry you purchase a bier kaart with credit for beers. This can be easily topped up via a QR code which links you to a payment site. This sys tem proved to be seamless and other festi vals could learn from this.

as always by Maitre D Rudy Vossen the evening was awash with brewers, retail ers, beer tourists and enthusiasts from all over the world. And they bring their beers with them.

Expect heavyweight Belgian classics, homebrews and one-offs from regional producers. I always champion UK brew eries and pitched up with some faves from Boxcar, Boutilliers, Brew By Num bers and Skin Contact from London Beer Factory’s Barrel Project – so good that I was asked where in Belgium it had come from!

The great thing about this fest is that many of the smaller breweries get an opportuni ty to showcase their beers to a large au dience. 80 brewers presented 500 beers, with many specially brewed for the occa sion and 68 new beers being available for the first time. And we only had two days to work through that lot! I felt that hitting some Oude Bruin from Brouwerij ‘t Verzet at 11am was a tad on the early side but as always I’m up for a challenge.

Author Paul DaviesWhat wasn’t different was the triumphant return of the international bottle swap at De Bierboom. Everyone’s favourite pre-fest party was once again awash with outstanding beers, great food and the best company you could wish for (including Kristof from Fort Lapin who stopped by with e delivery). Marshalled

An Oude Bruin Harvest 2021 at 6% abv was a perfect start to a long day. Man, these guys know their craft. Two more treats on show was the new nitro porter Ants Pants 4.9% abv and Naked Kameradski at 15% abv. I have always loved the company of the guys from the industrial park in Anzegem.

Back on the first weekend of February 2020, a high old time was being had at the 13th beer festival in the beautiful city of Bruges. The usual pre-fest bottle swap at De Bierboom, followed by a sore head on the morning of the fest. Hanging out with old friends, meeting new ones and enjoying delicious beers from around Belgium. Little did anyone know that it would be more than two years be fore the next edition.

Well, the 14th edition of the Brugs Bier Festival was going to be different. Firstly, it wasn’t held on the first weekend of Feb ruary. De Brugse Autonome Bierproevers

THE BRUGS BIER FESTIVAL RETURNED EARLIER THIS YEAR, FOLLOWING A COVIDENFORCED ABSENCE, AND PAUL DAVIES WAS STRAIGHT OUT OF THE BLOCKS TO TAKE IN THE GREAT AND THE GOOD IT HAD TO OFFER. AND THAT MEANT SAMPLING SOME OF THE WONDERFUL 500 BEERS ON OFFER.

Always on form, up for a laugh but forever taking their business extremely seriously. If like me you are a fan of roodbruin then join me at their Oude Bruin Fest in Kortrijk on the 7th and 8th October.

I always feel that the morning of a beer fest is the best time of day. Plenty of room, less queuing and the opportunity to speak and listen to friends in (relative) peace. I was de lighted to bump into Lars Pillen, who along with Emmanuel Maertens runs the Bruges Beer Experience.

Lars is a fellow beer nut and along with be ing a generous host is excellent company. Our quiet conversation was disturbed by the crew from Focus-WTV from West Flan ders. It didn’t take long before I was being interviewed and asked for my British take on the festival and Belgian beer.

Fellow guides were in attendance and it’s always great to catch up with Liselot who runs Beer Secret and hosts tastings and tours in Bruges, Brussels and Ghent. An other guide who was there was Katie Van de Weghe aka Queens of Hop.

Katie not only hosts events, tastings and tours but she also works at Bourgogne des Flandres and has been honing her brewing skills. She recently launched her first beer. Drama Queen was brewed at Brouwerij Stokhove and is an English Porter weighing in at 6.7% abv.

Well what can I say? Hanging out with Jef Pirens of D’Oude Maalderij can be an ex perience. To put it mildly. Seriously it was great to catch up on all things D.O.M and his restaurant Mash. Never standing still he has a number of plans up his sleeve with further collabs with other like-mind ed brewers, events and a new initiative ‘Orde Der Domestieken’ – a selected group of beer enthusiasts will act as am bassadors for the brewery and be availa ble to assist at various festivals. In return ‘Domestieken’ receive special beers, in sight into the beers and brewery and can enjoy free beer at festivals when seen wearing the exclusive members t shirt. I jumped at the chance and can’t wait to get stuck in, and maybe get involved in a little brewing….

One beer unique to the festival is the BAB Mystere, commis sioned from Brouwerij Strubbe, Ichtegem which is brewed in the former kettle of brewery Aigle Belgica, the renowned but defunct brewery of the seventies in Bruges. The beer is pro duced in honour of former Bruges resident and World War One flying ace André de Meulemeester who was born into a brew ing family and whose brewery merged with Belgica in Ghent to form Aigle Belgica. He also formed the Club Mystere where former pilots of the Great War were invited to his house for club dinners. He was also a painter and his works have been exhibit ed posthumously. The Mystere beer bottle is wrapped in paper depicting some of his art.

Around the time of the festival numerous restaurants and bars also participate, featuring beers that are poured during the festival and a special beer of the month. The fest also en courages donations to a. umber of charities, Pelicano which finances the basic needs of children in poverty; De Varens a special school for mentally and physically disabled children; BC Spermalie a special education primary school for children suffering from multiple disabilities; and Klub Tarnowski who support Ukrainian refugees arriving at the Polish city of Tar now. Donations are made in a number of ways, either direct ly at the information booth or by donating your festival glass and/or remaining beer credits.

So another BAB Brugs Bier Festival drew to a close. And next year it will be the 15th edition. And guess what? It’s being held in the sum mer on the 10th – 11th June! See you there, Cheers! Special thanks to Filip Geerts, Belgium Beer Board and Caitlin Mackesy Davies for their photos.

Of the four primary brewing in gredients (water, malt, hops, and yeast) it is the yeast that has the most complex and dynamic effect on beer fla vour. Not only does yeast produce a range of unique flavour compounds such as es ters and phenolics, but it also transforms compounds from the malt and hops.

Yeast transforms malt sugars into alco hol and CO2 and produces enzymes that interact with hop-derived flavour com pounds in a process called biotransfor mation. Some notable beer styles are defined by a particular yeast strain, in cluding Weizens, Abbaye ales, Saisons and Lagers. The lager yeast strains are used to brew the majority of beer con sumed worldwide and as such they have been studied extensively.

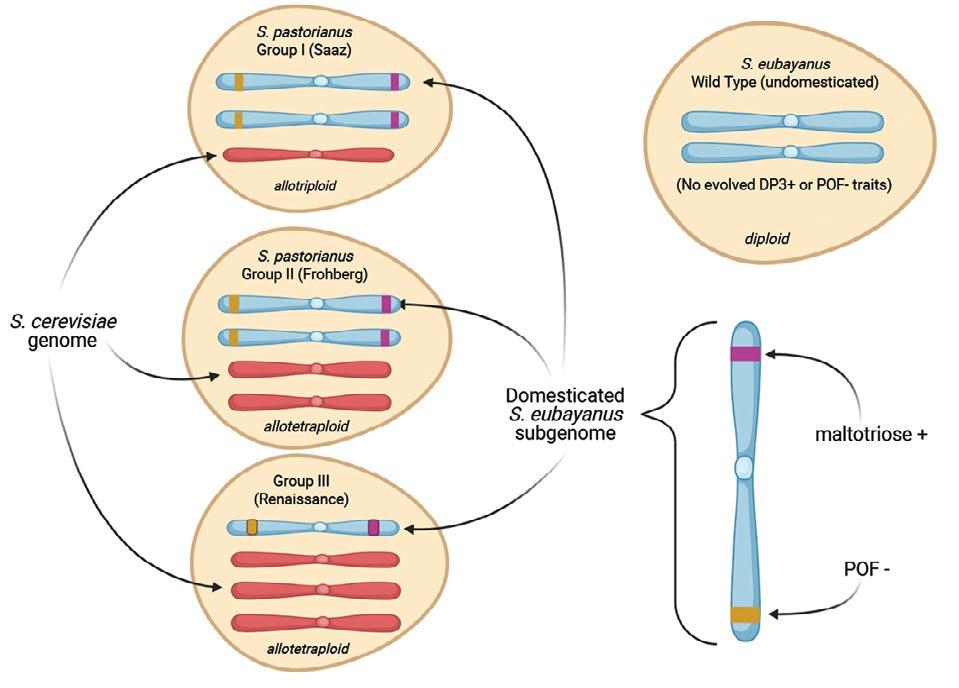

The history of lager yeast has its roots in 15th century Bavaria when two closely related yeast species, Saccharomyces cerevisiae (ale yeast) and Saccharomyces eubayanus (cold-tolerant yeast), hybridized to form a new natural hybrid species known as S. pastorianus, or better known as lager yeast.

There has been significant innovation in ale strain development over the years resulting in a wide variety of yeast strains that contribute to the diverse range of ale beer styles. On the other hand, innova tion of lager strains has been much more limited. Since S. pastorianus strains were domesticated in commercial breweries and do not exist naturally in the environ ment, selection of novel lager strains is more challenging.

A major breakthrough in lager yeast inno vation occurred in 2021 when Renaissance BioScience (Vancouver, Canada) devel oped a novel breeding methodology to create unique and diverse lager strains.1

Using these methods, Renaissance BioSci ence selected novel lager strains that con tain a greater proportion of the S. cerevisiae subgenome compared to the S. eubayanus subgenome, leading to the formation of a third category of lager strains designated Group III (Renaissance).

Authors:Over the following centuries, this hybrid strain was domesticated through selective repitching of fermentations with the best fermentation performance. As brewing technology advanced over the centuries, the selective pressure led to a major ge netic bottleneck that restricted the genetic diversity of lager yeast.

Ultimately this led to the formation of two categories of modern lager yeast, Group I (Saaz) and Group II (Frohberg). Both groups have similar fermentation per formance and flavor characteristics and are largely differentiated based on their genomic composition. The Group I strains have a larger proportion of genes from S. eubayanus compared to S. cerevisiae and are therefore slightly more cold-tolerant compared to Group II strains.

The Group II strains have roughly equal genomic contributions from each paren tal species and have become the domi nant workhorse lager strain globally due to their more robust fermentation kinet ics, more neutral aroma profile and lower off-aroma production (especially acetal dehyde and diacetyl).

In collaboration with Lallemand Brewing, the first commercial strain from this new Group III category is now available to brew ers with the launch of the LalBrew NovaL ager™, a modern hybrid lager yeast.

The development of LalBrew NovaLager™ started with the identification of Ale and Lager parental strains with ideal brewing characteristics. The Ale parent is a unique strain selected from nature in Vancouver, BC, that was refined using adaptation and selective breeding to be an ideal “American Ale Yeast Breeder” with high attenuation, unique and subtly fruity aroma, low diacetyl production, and no H2S production.

To select the ideal “Lager Breeder”, a wellknown workhorse Group II lager strain was sporulated to form a diploid strain which retained bottom fermentation characteristics and cryotolerance. These Ale and Lager breeders where then hy bridized to create LalBrew NovaLager™, which combines the innovative traits from the S. cerevisiae parent with the cold-tol erance and robustness of a traditional Group II lager strain (Figure 1 overleaf). Importantly, since LalBrew NovaLager™ was developed using only non-geneti cally modified techniques such as breed ing and adaptive evolution methodolo gies, it is considered non-GMO.

FOLLOWING THE LAUNCH OF LALBREW NOVALAGER, ITS MODERN HYBRID LAGER YEAST, LALLEMAND BREWING EXPLAIN HOW MODERN YEAST BREEDING METHODS WILL SURELY CONTINUE TO PROVIDE NOVEL, NONGMO YEAST STRAINS WITH COMMERCIALLY IMPORTANT CHARACTERISTICS.

Zachari Turgeon, MSc. Renaissance Bioscience Corp. Principal Scientist - Microbial Research and Innovation

Eric Abbott, MSc. Lallemand Brewing Technical Support Manager

Alexei Titov, Lallemand Brewing Technical Sales Manager

In essence, this breeding strategy in volves isolating the S. eubayanus part of a traditional domesticated lager strain in order to rehybridize this La ger parent with a new Ale parent to produce a novel, modern hybrid lager strain that opens the door to more lager beer style diversity.

With roots in traditional lager histo ry combined with modern laboratory methods, the release of LalBrew NovaL ager™ represents the next innovation in lager yeast. Going forward, these mod ern yeast breeding methods will surely continue to provide novel, non-GMO yeast strains with commercially impor tant characteristics. The future of brew ing yeast is exciting!

References: 1 Turgeon, Z., Sierocinski, T., Brimacombe, C. A., Jin, Y., Goldhawke, B., Swanson, J. M., Husnik, J. I., & Dahabieh, M. S. (2021). Indus trially Applicable De Novo Lager Yeast Hy brids with a Unique Genomic Architecture: Creation and Characterization. Applied and environmental microbiology, 87(3)

• Efficient fermentation and high attenuation to produce crisp, highly at tenuated lagers

• Short maturation times due to the inhibition of H2S and low production of diacetyl

• Unique flavor profile consisting of fruity, vibrant and clean aroma profile

• Cryotolerance conferred by the presence of the S. eubayanus subgenome

• Broad temperature tolerance due to an increased S. cerevisiae genomic content

• Lower pitch rates due to a higher viability relative to traditional lager strains.

• Bottom fermentation typical of traditional lager strains.

• Biotransformation of the hop derived compounds in modern beer styles such as Cold IPA or IPL with the expression of beta-glucosi dase enzyme.

Lager yeast strains are classified into dif ferent lineages based on their genomic structure. Each S. pastorianus strain has a subgenome derived from both the S. cerevisiae and S. eubayanus parental strains (Figure 2). The two traditional la ger groups arose by natural hybridation events. Group I (Saaz) lager strains are allotriploid with three sets of chromo somes, one from S. cerevisiae and two from S. eubayanus.

Due to the greater contribution from the S. eubayanus subgenome these strains are more cryotolerant. Group II (Frohberg) lager strains are allotetraploid with four sets of chromosomes, two from S. cerevisiae and two from S. eubayanus. Due to the greater contribution from S. cerevisiae these strains exhibit more robust fermentation charac teristics including broader temperature and alcohol tolerance.

Lager is the most popular beer in the world. Clean and refresh ing, this style has won over 90% of the international beer market. The production of lagers is a re cent innovation in the history of brewing, which is measured by thousands of years. The appearance of lagers is attributed to the XV-XVI centuries, and Bavaria is con sidered the birthplace of the style.

The key feature of the lager style is using the authentic type of yeast called Saccha romyces pastorianus. In the 1980s, while studying the DNA of the lager yeast, re searchers discovered that it was a hybrid of the ale yeast Saccharomyces cerevisiae and a hitherto unknown microorganism.

But in 2007 microbiologists found that the genes of that microorganism are 99.5% identical to a yeast found in Patagonia, which the local population used to pro duce alcohol at low temperatures. Yeast was contained in “galls“, spherical growths on southern beech trees, inside of which juice is fermented (Figure 1). This strain was named Saccharomyces eubayanus.

The most well-known lager yeast strain Weihenstephan 34/70 as well as LalBrew

DiamondTM belong to the Group II lin eage. Both Group I and Group II strains are genetically very similar and have changed very little over the centuries since their domestication in 15th centu ry Bavaria.

Figure 2. Comparative genomic structure of Group I (Saaz), Group II (Frohberg) and Group III (Re naissance) lager strain lineages.

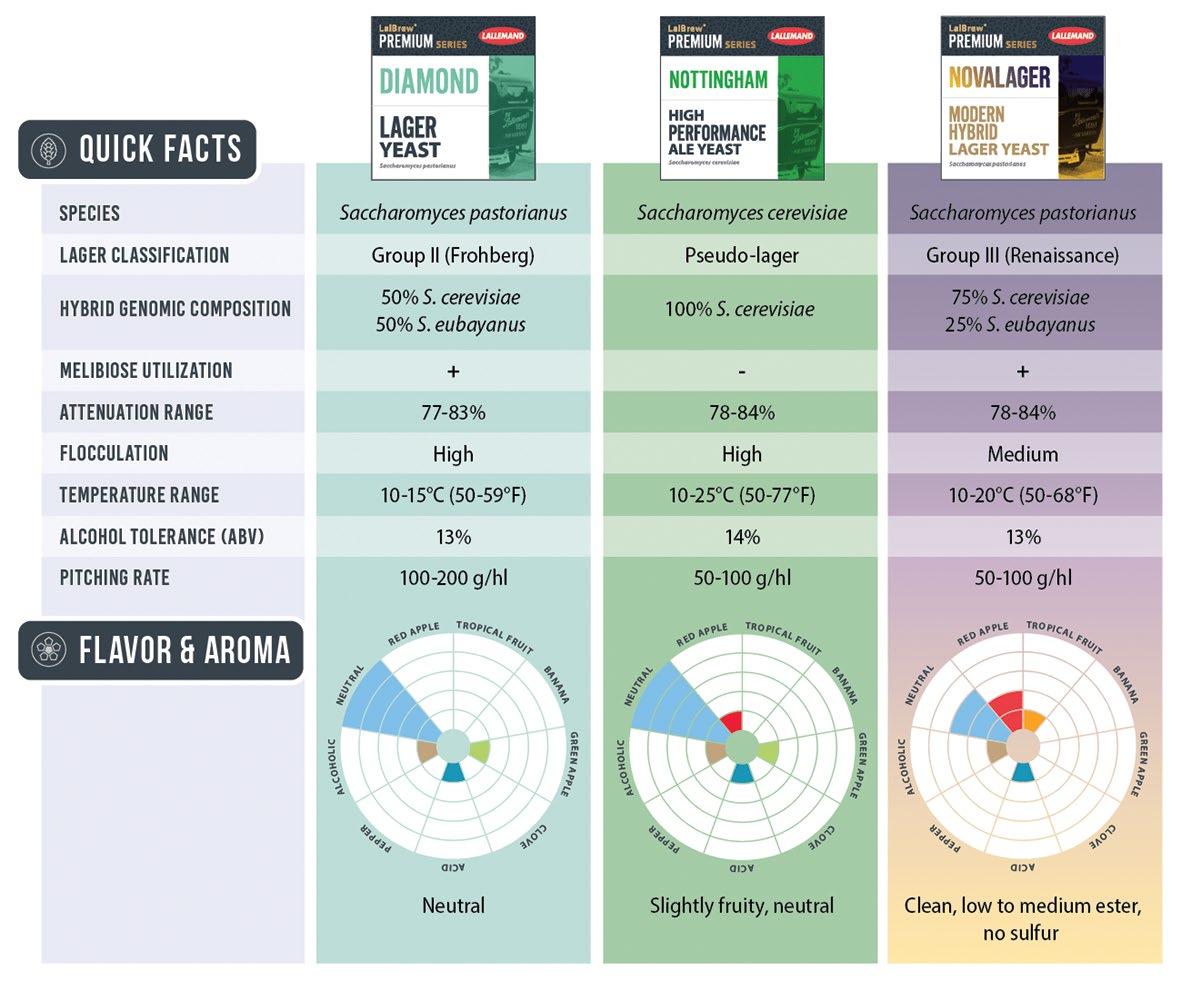

Some brewers have used neutral ale strains to ferment at colder tempera tures in order to produce neutral beers that are “lager-like”, but not considered true lagers since they are not ferment ed with S. pastorianus. LalBrew Notting hamTM is an excellent option for brew ing pseudo-lagers due to its neutral profile and broad fermentation temper atures range.

Recently, classical and non-GMO meth ods have been used to breed novel lager hybrid strains that are distinct from the Group I and II traditional lineages1. These novel Group III (Renaissance) strains are allotetraploid with four sets of chromo somes, three from S. cerevisiae and one from S. eubayanus.

The first commercial example of the Group III lager strains is LalBrew NovaL agerTM, which represents the first major

innovation in lager yeast strains in cen turies. Due to a greater contribution from the S. cerevisiae subgenome the LalBrew NovaLagerTM strain demonstrates toler ance to warmer temperatures, more ro

bust and rapid fermentation, a unique fla vor profile and low levels of diacetyl and H2S while maintaining cryotolerance im parted by the S. eubayanus subgenome (Figure 3)

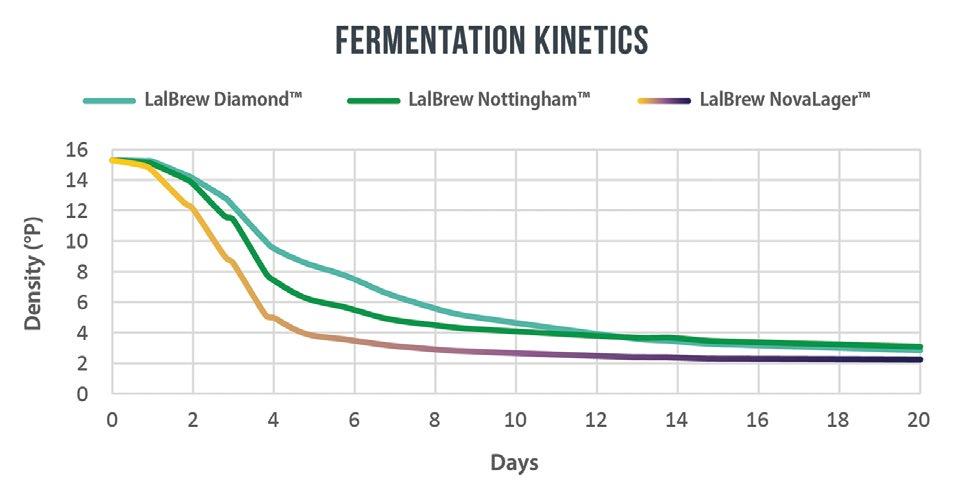

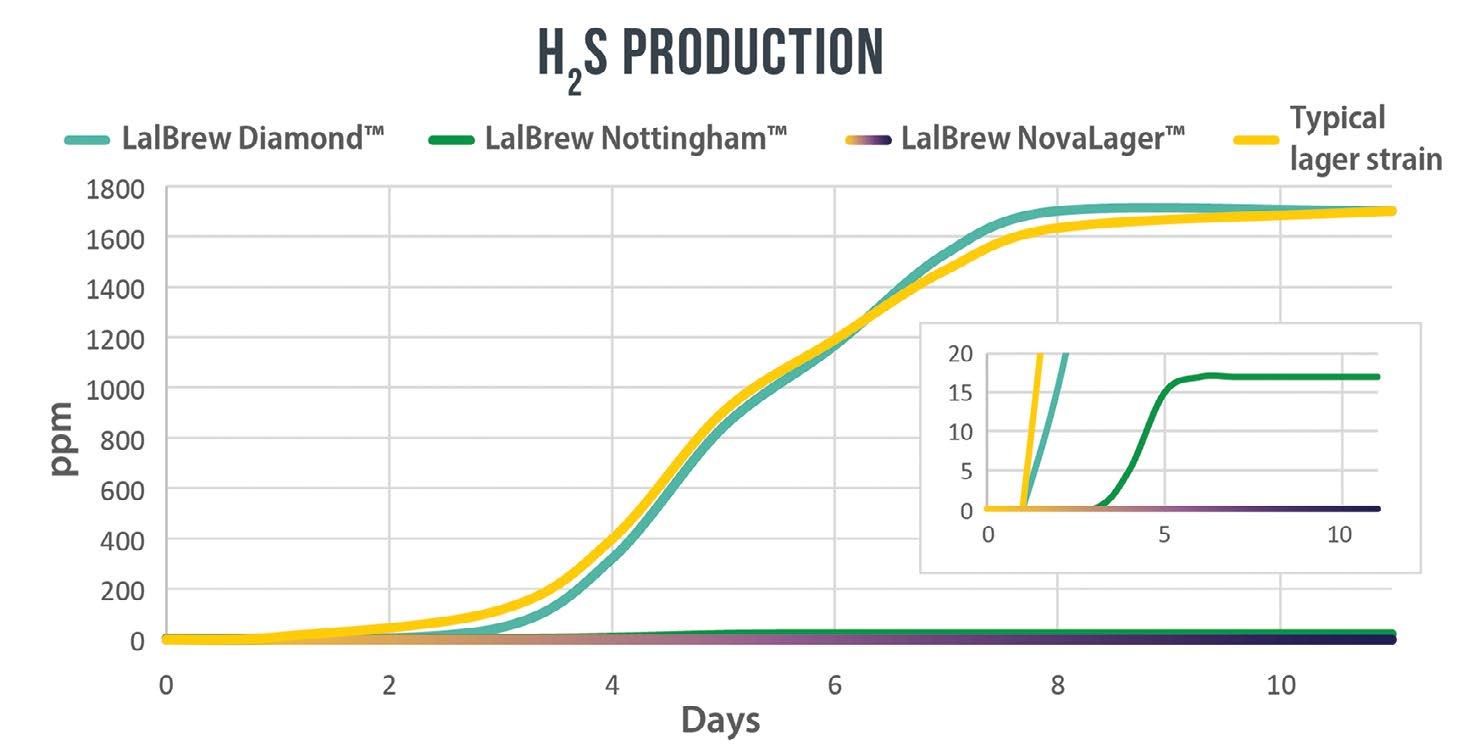

Figure 3. Fermentation kinetics of different LalBrew® Premium Series yeast strains for lager styles. Standard all-malt 15°P pale wort pitched with 1.5 million cells/ml/°P and fermented at 12°C.Figure 4. H2S production during fermentation with LalBrew® Premium yeast strains for lager beer styles. A typical lager strain is shown for comparison purposes. Traditional lager strains (LalBrew DiamondTM, typical lager strain) produce more H2S than ale strains (LalBrew NottinghamTM). H2S levels are undetectable for fermentations with LalBrew NovaLagerTM. Standard all-malt 15°P pale wort pitched with 1.5 million cells/ml/°P and fermented at 12°C.

All brewing yeasts produce some amount of H2S during fermentation as a part of nor mal amino acid metabolism (See our Tech nical paper, Impact of Hydrogen Sulfide in Brewing2). With ale fermentations, H2S is depleted efficiently by CO2 scrubbing dur ing active fermentation and reabsorption by the yeast after full attenuation.

With lager fermentations, the cooler, slow er fermentations result in less CO2 scrub bing and the bottom fermenting, medium flocculant lager yeast does not reabsorb H2S as efficiently. Small amounts of H2S at threshold detection levels produced by traditional lager strains such as Lal Brew DiamondTM are considered an important part of the normal sensory profile for many lager beers.

However, poor wort nutrition or brew ing techniques can result in elevated levels of H2S and an undesirable aro ma of rotten eggs. This can be avoided by adding nutrients to the wort (espe cially when using adjuncts) and leaving the beer in contact with the yeast be fore transfer or filtration to allow time for H2S reabsorption.

The LalBrew NovaLagerTM strain was selected for reduced H2S production by disrupting specific sulfur metabolic

genes (Figure 4). As a result, LalBrew NovaL agerTM does not require the long maturation times typical of traditional lager strains.

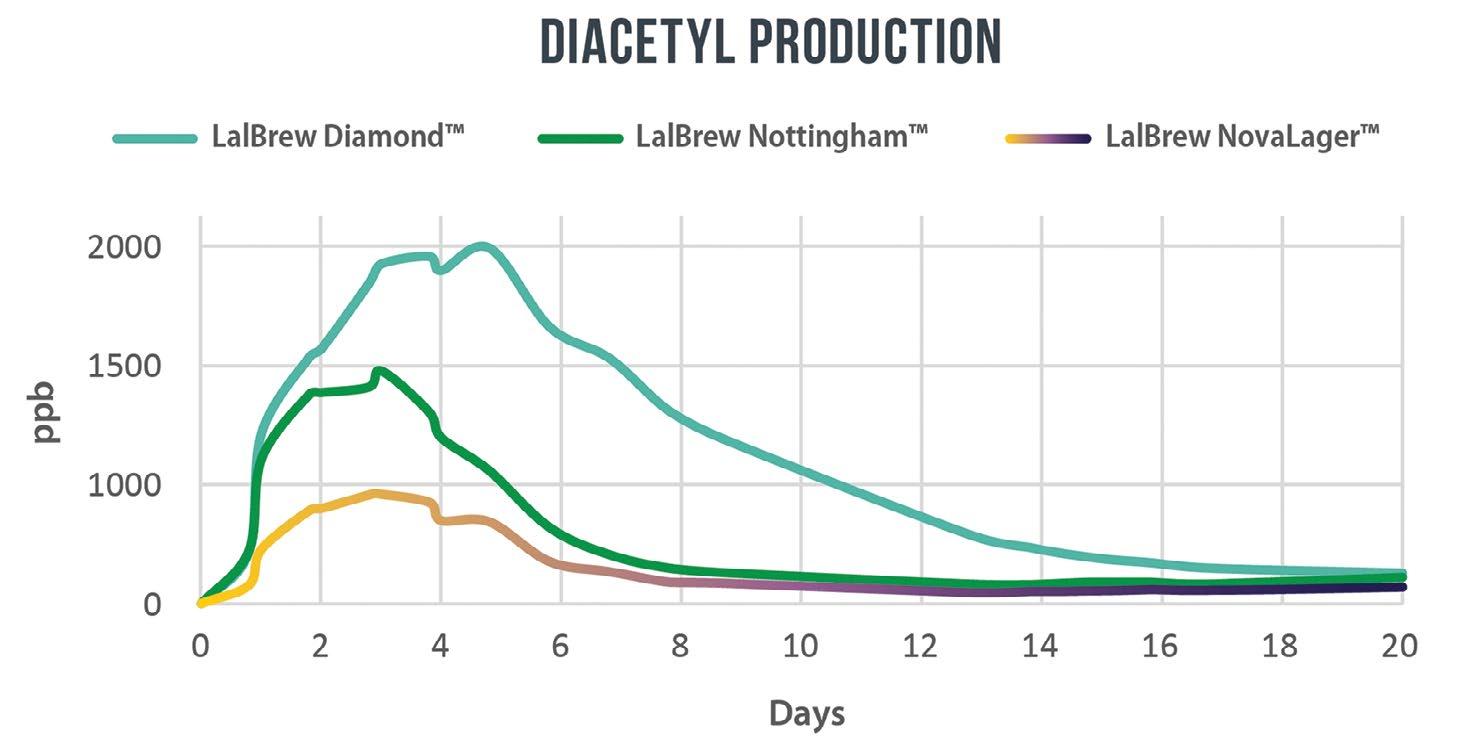

Diacetyl is a common fermentation byprod uct that is perceived by most people as an off-flavour. It is produced from a side reac tion by yeast metabolizing amino acids into valine. The yeast produces α-acetolactate, which is then excreted out of the cell. The α-acetolactate is then decarboxylated into diacetyl and reabsorbed back into the yeast at the end of fermentation where it is metab olized into acetoin, a flavourless compound.

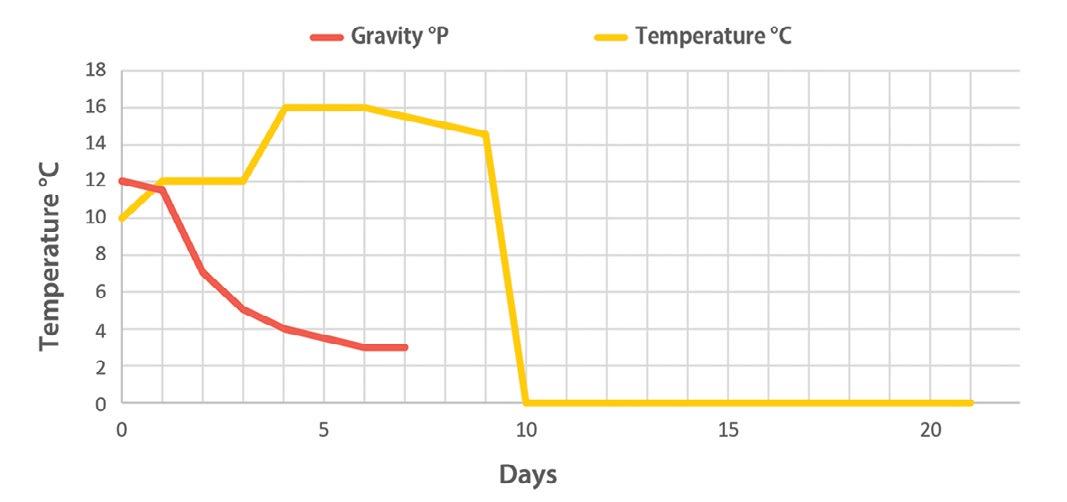

Diacetyl reabsorption by the yeast takes time and is faster at warmer ale tempera tures compared to cooler lager tempera tures. Diacetyl may be present in packaged beer when fermentations are incomplete, and the yeast is unable to completely re absorb the diacetyl. For this reason, lager fermentations usually employ a diacetyl rest by raising the temperature at the end of fermentation to give the yeast time to re absorb the diacetyl before transfer off the yeast (Figure 5)

Diacetyl production can also be inhibited by using an α-acetolactate decarboxylase (ALDC) enzyme, which allows the direct breakdown of α-acetolac- tate into flavour

Figure 5. A typical diacetyl rest is performed by increasing the temperature for several days at the end of active fermentation

Figure 6. LalBrew NovaLagerTM exhibits higher “ale-like” uptake of valine similar to LalBrew Nottingham compared to traditional lager strains.

less acetoin and prevents the formation and normal metabolism of diacetyl by the yeast cell.

Strain selection will also impact diacetyl production. Ale strains such as LalBrew NottinghamTM will tend to produce less diacetyl as a result of more efficient valine uptake. LalBrew NovaLagerTM demon strates valine uptake and diacetyl levels

that are similar to ale strains (Figures 6-7), which contributes to shorter maturation times required for this strain compared to traditional lager strains.

Traditional lager strains such as LalBrew DiamondTM produce few esters and are very neutral leading to clean, dry and re

freshing beers. Modern interpretations of lager styles tend to be more flavorful, of ten with higher hop rates than traditional lager beers.

The LalBrew NovaLagerTM strain produces low to medium esters for a more aromatic lager beer, and expression of a -glucosi dase enzymes promotes biotransformation and complexity of hop aromas.

Figure 7. The level of diacetyl produced by different yeast strains for lager styles.

On the border between New Brunswick, Quebec and Maine, the Republic of Madawaska is nestled in the Appalachians that border the picturesque Saint-John River Valley. Edmundston, New Brun swick, is Madawaska’s most populous city and serves as the core business and service centre.

Edmundston is predominantly French and used to be called “Petit-Sault” (small falls), pertaining to the confluence of the St. John and Madawaska rivers. Before the arrival of the first settlers, the Maliseet First Nations

lived on both sides of the Saint John Riv er Valley which they called “Madoueskak,” meaning land of the porcupines. This histo ry plays a strong role in one microbrewery’s epic tale.

Here, at Les Brasseurs du Petit-Sault, a warm welcome and a cold pint await, along with local history told through a oneof-a-kind experience.

Opening its doors in downtown Ed mundston in 2014, Les Brasseurs du Petit-Sault houses a craft microbrewery, tasting room and patio all in what used to be an old police station. Inside the brewery, where the raw materials and malt is kept, President and CEO, André Léger points out the new section of the building along with the original brick wall of the police station. There is a micro brewery (Les Brasseurs du Petit-Sault) and a moonshiner’s restaurant (Moon shin’hers Café Bistro Inc.) in the old po lice station—how ironic.

What gives Léger’s beer its unique taste and bold flavours is he brews it with the purest water taken from the winding Ir oquois River basin, uses the finest malts and hops and finishes the suds with their Belgian yeast. Belgian-inspired, the beers unite Belgium and Madawas ka County.

There is always a lot of buzz surrounding the name of the next brewed batch, mainly because every beer is named after leg endary characters or quaint stories tied to the colourful history of the region.

The tasting room features eight permanent beers on tap—Snap Dickie Cream Ale, John Glazier American Pale Ale, Saison Du Djâbe Belgian Style, Spoutnique IPA, Kedgwick German Pilsner, Double Vision Double IPA, Louis XVII Amber Ale and the Soeur Cath erine Old School IPA—with the rest on sea sonal rotation.

“From the start, the way we wanted to do our branding was to talk about the people and the characters that had an impact, re gionally. And then with a link to our name and our branding, it is a bit of a play on nos talgia,” says Léger.

The story behind the Soeur Catherine IPA is based on Edith Marquis, born in St. Agatha, Maine in 1898, who later became known as Sister Catherine, a grade one teacher in Ed mundston. Her class was not the most pop ular and the IPA is inspired by her legendary stubbornness, methodically brewed with five varieties of hops, reflecting bitterness in both the beer and…well…Soeur Catherine. Style: West Coast IPA, Appearance: Pale Amber, Ingredients: Water, malted barley, hops, yeast, Mouthfeel: High bitterness, malty, citrus & piney aromas and Pairing: Cured meats, barbeque et spicy dishes.

The Kedgwick Pilsner, on the other hand, is inspired by André Arpin. An dré has been navigating the Kedgwick for many moons in his ancestral canoe, a legacy of the first Kedgwick River set tler. Founder of Canoë Restigouche, he was decorated runner-up at the annual canoe race in 1975.

He surely would have been declared the winner if the judges had not been drinking so much beer during the race. This lager, inspired by the German-style pilsner, is as cool as the Kedgwick Riv er’s rapids and as clear as the moon over the Forks.

Like the river, it goes down smooth! Style: German Pilsner, Appearance: Pale Gold, Ingredients: Water, malted barley, hops, yeast, Mouthfeel: Crisp lager, complex, floral hops and Pairing: Very versatile! Piz za, grilled meat, fish, seafood.

The brewery has done quite well for it self since its inception, receiving several awards and accolades:

Silver medal at the 2020 Down East Brewing Awards - Porter/Stout catego ry (Canon Franchetti Cappuccino Stout)

Silver medal at the 2019 Atlantic Ca nadian Beer Awards - Belgian Style Specialty Ale category (John Baker Dubbel)

Gold Medal at the 2018 Canadian Brew ing Awards- Belgian Style Specialty Ale category (John Baker Dubbel)

“Our beers are designed with malt, so we have different variants of malt. We do use a German malt for authenticity in certain specific beers we do, but we have been try ing to use more and more local products,” says Léger. “And it has been possible be cause before there were no maltery’s and now in New Brunswick, there’s a couple.”

“Every maltery has their different taste sig nature. So, we have been trying to develop some new beers using those new malts, and that does give a different taste to our beers. So, let’s say we do a Pale Ale or Pils ner, or something like that, we use a local malt with a specific taste and that is what’s interesting to the flavour.”

Currently, the local malt is coming from a place near Caraquet, a town that is sit uated on the shore of Chaleur Bay in the

Acadian Peninsula, about 2.5 hours from Edmundston. Additionally, there was an other maltery about 50 kilometers from the brewery, (located in Quebec situated just on the border) who have been around for about a decade, according to Léger.

“They make specialty malt, which typically means malts that are roasted. So, they will roast to a different level, which brings char acter and colour to the beer, with a more caramel taste, which is very interesting,” ex plains Léger.

“A lot of the breweries back then used to have those specialty malts from the national brands, so us using a very local, a very boutique type of maltery always provided us with a very dif ferent and specific taste for a beer that’s an Amber Ale, which is quite popular and wide spread but using a very specific knowledge, which gets us a very signature taste.”

When the brewery launched in New Brunswick in 2014, Les Brasseurs du Pet

From the start, the way we wanted to do our branding was to talk about the people and the characters that had an impact, regionally,” André Léger

it-Sault was the first brewery to launch as part of a new wave of openings. There were a couple of breweries that started out in the 90s—Picaroons Brewing Com pany in Fredericton and Pump House Brewpub in Moncton—who were the ear ly pioneers who paved the way for the brewing scene.

The brewery consists of five 30 hl (3,000l) fermentation tanks and two that are 60 hl (6,000l). “We started working on this project

in 2013, made our first beer and sold our first batch which happened to be a Blanche.”

When Léger was asked what his best sell er is, he had several different answers, all which were dependent on several factors and the time of year. “That’s always a diffi cult question to answer because obviously if you look at all of our beers, cream ale is our biggest seller, but it’s in a grocery chan nel, at the hockey rink and a beer that sells a lot on tap. It’s an easy drinking beer. But if

you look at it from the brewery on tap here, it’s absolutely IPAs.”

Often, when Léger comes up with his sea sonal batches, they usually become best sellers immediately. During the summer months, he typically makes a fruit beer. Last year, Léger made a sour beer made out of raspberries but this year, he creat ed a batch he has wanted to do for a long time – strawberry and rhubarb, which was a huge hit.

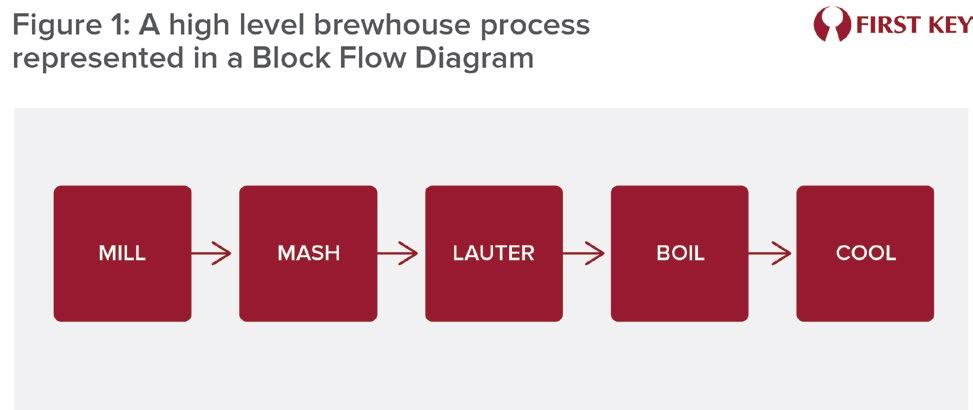

Process mapping is a fundamen tal tool which can be applied across all aspects of the busi ness – from raw material order ing and management to com plex processing or blending to distribution logistics. Process mapping will provide val uable insights into your business.

There are numerous adaptations of pro cess maps and selecting the right one for the application is important. The most ba sic is the Block Flow Diagram (BFD), where a process is sketched as blocks connect ed by arrows to illustrate its steps and flows (Figure 1).

Process Flow Diagrams (PFD) or Flow Charts allow for visualization of processes and decision-making steps (Figure 2), us ing a series of standard symbols already included in most productivity suites like Word, Visio, Google Drawings, etc. These can be made for high-level business pro cesses or can delve into the intricacies of turbid mashing.

Swimlane Diagrams add the extra layer of responsible parties to flowcharts which is a useful tool when various departments are involved in the success of a process. They can be used to identify bottlenecks and staffing needs.

Once operations and processes have been mapped, the “as-is” state of operations is revealed. Potential gaps materialize and opportunities for improvement become visible. Business processes like billing can now be communicated across the organ ization and supply processes can be finetuned to minimize wait times, maximize space usage, or increase efficiencies.

Management can also leverage process maps to determine measurement points, define key performance indicators (KPI) and focus operational improvements on critical steps of processes.

The manufacturing world has seen sev eral methodologies that leverage process mapping tools to assess and improve pro cesses. Total Quality Management (TQM), Dr. W Edwards Deming’s legacy[2], is a pro cess-centric approach to quality manage ment that promotes iterative analysis of processes, prioritizes improvements, and leads their implementation. Dr. Deming’s approach uses process mappings in the shape of value and information maps.

These tools aid in the visualization of cur rent (as-is) and future (to-be) states of the process being analyzed. Furthermore, the mapping activity itself is an egalitarian ex ercise that relies on information across the

organization. Successful companies that use process mapping involve and leverage the plant floor operators and technicians to truly define the real processes. The net re sult of process mapping is an aligned and knowledgeable organization and an en gaged team that is focused on identifying opportunities for improvement and a spirit of inclusion and teamwork.

Other methodologies seek to generate operational improvement through an inte grated approach. Lean Six Sigma (LSS) is comprised of waste reduction (lean man ufacturing) and statistical tools to identify and control process deviations (six sigma).

But a common denominator among meth odologies is the use of process mapping. Scott Durnin, a senior technical advisor at First Key, says the act of engaging in pro cess mapping activities can help an organi zation understand the cost of its operations.

By process mapping the material flows and steps within a brewery, the inherent process losses of each step (e.g., dry hop ping, pump and piping losses, centrifuge discharge, etc.) can be identified and quan tified. It is this level of detail that makes pro cess mapping such an essential tool. Loss es may not be identified at the managerial level alone, Durnin highlights that involving brewers and technicians is the secret to ensuring the process maps accurately rep resent the real-world process.

Dr. Jack Buffington, Director of Supply Chain and Sustainability at First Key, says, “Process mapping leads to standard op erating procedures, which lead to metrics, which lead to accountability.”

Whether operating a nano or a major brew ery, repeatable recipes are a determining factor of quality. To achieve more control of operations, breweries opt for specialized software that connects critical business ar eas to inform business decisions (e.g. Ekos, Orchestrated Beer, etc.).

These tools offer the ability to monitor and control operations from a single platform. Inventory, production, cellaring, sales, pack aging, accounting, and even compliance data is aggregated in a series of interfaces designed to accomplish tasks optimally.

Warehouse operators can update inven tory from a tablet when a shipment is received. Brewers can update lot infor mation to reflect recipe deviations and maintain cost transparency. Omnichannel sales can be aggregated to ensure high customer satisfaction. Brewery software has improved business operations deci sion-making and reduced overhead costs by automating processes.

In recent years, numerous brewery soft ware offerings entered the market. While in principle all brewing operations have sim ilar manufacturing processes, volume and number of SKUs are the main input varia bles to determine the right fit.

A medium-sized craft brewery may need to prioritize connectivity to existing financial and point of sale (POS) solutions, while a na tionally distributed brewery that focuses on a limited number of SKUs may need to ac count for highly granular process variations.

Thus, large operations have distinct func tionality software requirements. Further more, large enterprises require increased application availability and data protection. These prerequisites may tip the scale to wards a long-standing software solution.

Configuration is a crucial step in imple menting brewery software solutions. Many brewery ERP software solutions are based on their manufacturing counterparts (e.g., SAP, Oracle NetSuite, etc.) but are tailored to fit the business of brewing.

To make a tailored product into a bespoke one, precise data must be fed into it. Pro cess mapping exercises provide the data required for the successful configuration of