s our brewing landscape continues to transform and evolve, we need to be both proactive and reactive when it comes to business. Working with distributors to ensure your beer reaches markets that are out of bounds from your in-house sales force is a clear and obvious way to sell more of your product further afield.

But in speaking with a wealth of breweries in putting together this edition such as Dildo Brewing Co in Newfoundland, it is abundantly evident that focusing on your local market remains more than important than ever.

And a central facet of that is your taproom or tasting room. These places represent what is commonly known as a third space.

A third space is somewhere that is not your place of work, and not your home but instead an alternative environment where you can enjoy a sense of community.

As Bart Watson, the chief economist for the Brewers Association, wrote way back in 2018, taprooms, brewpubs and tasting rooms “arguably fall among the third space alternatives”, and he added that think you can also make a strong case that taprooms have certainly played a role in rejuvenating beer’s on-premise culture and also draught beer volumes.

While the idea is nothing new, the premise of hyper-localisation in the

word of craft beer can only become more prominent and relevant in 2024, and beyond.

Seemingly gone are the days where many breweries were awaiting that acquisitive call from a macro to add their business to the big beer family.

Instead we are seeing more and more breweries concentrating on producing and selling their beers in a geographical area around the facility.

As many argue, this is one route for smaller breweries to compete with the more established breweries, and larger brewing businesses that have broader distribution networks at their disposal.

But while the benefits of hyper-localisation for breweries are evident, it’s crucial for owners to navigate potential challenges such as striking the right balance between local focus and maintaining a broader appeal where desired, and also staying adaptable to evolving community preferences are key factors to consider.

As recent years have showed hyper-localisation is not just a trend. Instead it’s a strategic approach that can significantly impact a brewery’s success.

For brewery owners, investing your time and resources into understanding, embracing, and contributing to the local community is hopefully a recipe for not just brewing beer but also success.

Tim Sheahan Editor

Hop-Creep Challenges: Navigating the diacetyl dilemma in craft brewing’s dry-hopping technique, Expert Insights from Chris White, President of White Labs.

Comment | Finance

Notch Financial tackles accounts receivable challenges with insights on DSO and CCC optimization.

Focus | Rtd Cocktails

FlavorSum highlights the expanding opportunities for breweries in the RTD alcoholic beverages market, emphasizing the importance of flavour in crafting successful premium cocktails.

Meet The Brewer | Blindman Brewing

Nick Hendrickson tells the story of how Lacombe, Alberta’s Blindman Brewing and owner Kirk Zembal exemplify innovation in the craft beer industry. Comment

the innovative use of terpenes in brewing, emphasizing their potential to revolutionize flavour profiles and sensory experiences in beer.

Focus | Taste Panel Etiquette

Scott Ungermann, Senior Advisor at First Key Consulting, underscores the critical role of proper training and etiquette in ensuring the effectiveness of taste panels within breweries.

Focus | Brewing Technology

A compact brewhouse concept by banke GmbH: a comprehensive solution for breweries seeking enhanced productivity and reduced energy consumption.

Comment |

Ryan Mallough, VP of Legislative

with the CFIB, highlights both positive strides and challenges faced by small businesses in the Canadian alcohol industry.

Davies,

18

Expert Commentary | Keg Loss

Courtney Fromm, National Manager at Kegshare, outlines the challenges of losing kegs and, more importantly, why there is a solution at hand.

email courtney.fromm@kegshare.ca phone 705-737-7687

30

Meet The Brewer | Les Brasseurs du Petit-Saul

Author Jason Murray provides an insider’s perspective on Les Brasseurs du Petit-Sault, a thriving microbrewery and hidden gem near the border of Quebec in Edmundston, New Brunswick.

Tim Sheahan Editor tim@brewersjournal.ca

+44 (0)1442 780 592

Jakub Mulik Staff photographer

Johnny Leung Canada Partnerships johnny@brewersjournal.ca

Richard Piotrowski Publisher Richard@brewersjournal.ca

Magdalena Lesiuk Graphic Design GraphMad@gmail.com

Nicholas Hendrickson Contributor

Jason Murray Contributor

CFJ Media

2275 Upper Middle Rd E #101, Oakville, ON L6H 0C3

The Brewers Journal Canada is a quarterly magazine. Subscriptions can be purchased for four or eight issues. Prices for single issue subscriptions or back issues can be obtained by emailing: johnny@brewersjournal.ca

CANADA One year: $39

INTERNATIONAL One year: $49

39

Meet The Brewer | Dildo Brewing Co.

Inaugurated in June 2018, Dildo Brewing Company, led by head brewer Al Goodyear, embarks on an exciting expansion, signaling the beginning of a new era in Newfoundland.

The content of The Brewers Journal Canada is subject to copyright. However, if you would like to obtain copies of an article for marketing purposes high-quality reprints can be supplied to your specification. Please contact the advertising team for full details of this service.

The Brewers Journal Canada is printed at Manson Group, St. Albany’s, UK.

All rights reserved. No part of this publication may be: reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording or any information storage or retrieval system, without the express prior written consent of the publisher. The Brewers Journal Canada ISSN 2398-6948 is part of Reby Media, 42 Crouchfield, Hemel Hempstead, Herts HP1 1PA. It is published quarterly in Canada by CFJ Media, 2275 Upper Middle Rd E #101, Oakville, ON L6H 0C3, Canada. Subscription records are maintained at CFJ Media, 2275 Upper Middle Rd E #101, Oakville, ON L6H 0C3, Canada. The Brewers Journal accepts no responsibility for the accuracy of statements or opinion given within the Journal that is not the expressly designated opinion of the Journal or its publishers. Those opinions expressed in areas other than editorial comment may not be taken as being the opinion of the Journal or its staff, and the aforementioned accept no responsibility or liability for actions that arise therefrom.

IN THE REALM OF CRAFT BREWING, HOPPY BEERS REMAIN A BELOVED STAPLE, WITH DRY-HOPPING BEING A VITAL TECHNIQUE FOR CRAFTING COMPLEX AND AROMATIC BREWS.

CHRIS WHITE, PRESIDENT OF WHITE LABS AND AN EXPERT CONTRIBUTOR TO BREWERS JOURNAL CANADA, ADDRESSES A COMMON CHALLENGE IN THIS PROCESS – HOP-CREEP, PARTICULARLY THE DIACETYL ISSUE.

Hoppy beers are still as popular as ever, and dry-hopping is a common and necessary practice to make the best hop-forward beers. This technique produces ultra-aromatic beers that lend to the complexity and craveability of this style, but come with its own challenges. One of the most notable challenges is hop-creep - the increase in diacetyl formation after dry-hopping, which results in beer with undesirable buttery/buttered popcorn characteristics.

Diacetyl, a vicinal diketone widely regarded as an unpleasant off-flavor in most beer styles, is a natural byproduct of yeast fermentation. When yeast consumes sugars, it creates amino acids, mainly valine; meanwhile, α-acetolactate is created as a byproduct of amino acid metabolism. Excess α-acetolactate leaks out of the yeast cell and is naturally oxidized into diacetyl before being reabsorbed by the yeast cell. brewersjournal.ca

Present at a very low flavor threshold (50150 ppb), diacetyl contributes a buttery flavor and slick, coating mouthfeel to the beer. Once formed, it can only be removed from the beer through reabsorption and conversion by the yeast cells. As fermentation approaches the end, the yeast will uptake the diacetyl and convert it to acetoin, a flavorless compound.

At times, this reabsorption can be stalled in fermentation for various reasons, leaving residual diacetyl in beer. Unhealthy yeast, highly flocculant strains, and practices such as dry-hopping, can all cause problems with diacetyl cleanup. Extending tank residency times and raising the temperature to perform a diacetyl rest are common strategies used to ensure the reabsorption of diacetyl, particularly in lagers, where the cold fermentation temperatures slow down this activity.

Longer yeast contact time and warmer temperatures aid in the conversion of diacetyl to acetoin, thus reducing the concentration to a level below the flavor threshold. However, the time to perform diacetyl rests, and any unplanned tank residency time can contribute to added costs, production plan disruptions, and less beer produced overall.

In ales, and specifically for dry-hopped beers, there are multiple methods to keep diacetyl low. One way is to ensure optimal yeast health and, therefore, yeasts’ ability to reabsorb diacetyl. Another method is by using α-acetolactate decarboxylase (ALDC) enzymes. ALDC works by breaking down

the diacetyl precursor during fermentation and preventing diacetyl from forming. This is a method that has been favored in lager brewing, but can be seamlessly applied in hoppy beers.

With all enzyme usage, it is critical to understand when, where, and how to add them to get the most effectiveness. Enzymes like ALDC will denature or fall apart, at high temperatures, so using enzymes that target fermentation byproducts need to be added on the “cold-side” (post-heat exchanger) to maintain the integrity of the enzyme itself. Because it is added directly to fermentation, ALDC also needs to be sterile and well-homogenized in the fermentor.

Ideally, these enzymes are added in-line during wort transfer or directly into the cone before knockout, so that it mixes thoroughly with the wort coming in. Enzyme effectiveness relies on chemistry, and its ability to find its substrate in that complex wort in order to do its magic. And to do its magic, it has to be wellmixed with wort.

As with any beer sensory component or quality control check, test and measure as much as you can. For diacetyl, these compounds are analyzed using a gas chromatograph, but without having access to this, a forced diacetyl test can also be performed to get qualitative results. The bottom line - ALDC enzymes can be a huge game-changer in crafting the highest quality hoppy beers, without the worry of diacetyl and hop-creep.

IN BREWING, THERE ARE A NUMBERS OF WAYS YOU CAN GET AWAY FROM THE DESK AND FOCUS ON HIGHVALUE ACTIVITIES THAT WILL HELP YOU INNOVATE AND GROW YOUR BUSINESS.

HERE IS NOTCH FINANCIAL TO EXPLAIN MORE.

Accounts receivable (AR) is an incredibly important part of any business. After all, it’s how you get paid for the beer you brew. However, accounts receivable can also be one of the most unpredictable and time-consuming activities for operations and accounting staff. Many breweries are plagued by late and non-payments and waste precious labour hours on inefficient processes to follow up on and collect payments from customers and licensees.

Two critical operational metrics that demonstrate the health of a business’s accounts receivable are days sales outstanding and cash conversion cycle. Days sales outstanding (DSO) is the number of

days it takes to collect on a credit sale. Cash conversion cycle (CCC) is the number of days it takes a company to convert inventory into cash flow from a sale.

The lower your DSO and CCC are, the faster and more predictably you’re getting paid for your products. Not only does this make your own cash flow easier, but it also primes your business for growth at scale.

OUT WITH THE OLD

While digitization and automation are the norm in many industries these days, food and beverage still lags. If it’s not broken, don’t fix it–right? This line of thinking has caused the brewing industry to fall behind

in implementing modern approaches that can help their business grow.

Many breweries are still:

Accepting cash and cheque as their preferred payment methods

Storing credit card information incorrectly or having to call to input payment details for every individual invoice

Using ‘cash on delivery’ payment terms

Sending paper invoices

Offline and manual payment processes like the above make it more likely that customers will pay you late or lose your invoice, or the payment methods may bounce–increasing both your DSO and CCC. Looking for opportunities to bring payments online and automate can make all the difference in improving these metrics and streamlining operations.

There are several key benefits breweries can experience when bringing their payments online.

Increase on-time payments and reliability

The most important and most obvious benefit of digitized payments is streamlined accounts receivable. You can significantly reduce the amount of outstanding accounts receivables when switching from manual to digital collections. This is because you can ‘pull’ payments rather than wait for customers to ‘push’ payments,

providing you more control over when you get paid. You also benefit from minimizing accounting and operations labour hours spent on collecting outstanding payments.

Provide a better customer and licensee experience

If you’re trying to grow your business and distributor/licensee network, making yourself easy to work with can go a long way. For example, a bar manager who finds paying you cumbersome may not be as likely to want to order from you again or recommend your beers to their patrons. Providing auto-payment, payment schedules and on-demand digital invoices makes your customers’ operations easier, giving you an edge over your competitors when earning new business

More time to focus on what matters

In smaller brewery operations, people tend to wear many hats. It’s not unlikely that head brewers and tap room managers might be fulfilling accounting duties by sending invoices and following up on payments. However, this is not the best use of their time. It’s also probably not why they got into the brewing industry to begin with. Allowing software to do what doesn’t need to be done by a human frees staff up to focus on what matters–crafting great beer and engaging with their community.

Setting up to scale

Despite how it sounds, digitizing and automating payments doesn’t have to be complicated. In this day and age, there are several software programs that help you with this to varying de-

grees. When browsing, look for a platform with features that:

Safely and securely store your customers’ digital payment information, like credit cards and EFT

• Automatically send upcoming payment reminders and follow-ups for unpaid invoices

• Pull payments on a scheduled date or cadence

• Provide a customer view of all paid bills and outstanding invoices

• Syncs with your accounting system

All of the above will help you get away from the desk and focus on high-value activities that will help you innovate and grow your business.

RTD ALCOHOLIC BEVERAGES REPRESENT AN OPPORTUNITY FOR BREWERIES TO EXPAND THEIR ASSORTMENT AND APPEAL.

SOME BRANDS ARE SUCCESSFULLY PIVOTING TO BEVERAGES THAT ADDRESS EVOLVING NEEDS FOR HIGHQUALITY, COMPLEX, AND CONVENIENT DRINKING EXPERIENCES.

PREMIUM COCKTAILS ARE THE NEWEST RTD FRONTIER, WITH SEVERAL DEVELOPMENT PATHWAYS AVAILABLE TO BREWERS AND DISTILLERS. WHICHEVER PATH YOU CHOOSE FOR YOUR BRAND, REMEMBER THAT FLAVOUR PLAYS AN ESSENTIAL ROLE IN THE SUCCESS OF YOUR COCKTAIL, EXPLAINS FLAVORSUM.

Canadian breweries that battled tough headwinds in the past few years may have calmer sailing in 2024. Industry research company IBISWorld anticipates Canadian brewery sales will increase +1.8% in 2024 to reach nearly $7bn USD after losing -2.3% in revenues annually since 2019. The growth is muted compared to the U.S., however, where beer sales may grow by +3.8% each of the next few years.

For breweries, well-known paths to growth include limited editions, maltbased seltzers, or non-alcoholic beers. But canned RTD cocktails could offer a new opportunity to diversify with an expanded menu and build sales as beer drinkers explore other alcoholic beverage options.

RTD cocktails are gaining attention worldwide. International Wine & Spirit Research (IWSR) anticipates global RTD volume will increase +3% annually through 2027, outpacing the alcohol category’s forecasted growth of 1%. North American drinkers purchased almost $2 billion in RTD cocktails in 2023, up from $1.45 billion in 2022. The 35% gain in annual dollar sales helped RTD cocktails pick up four share points of the readyto-drink alcoholic beverage market.

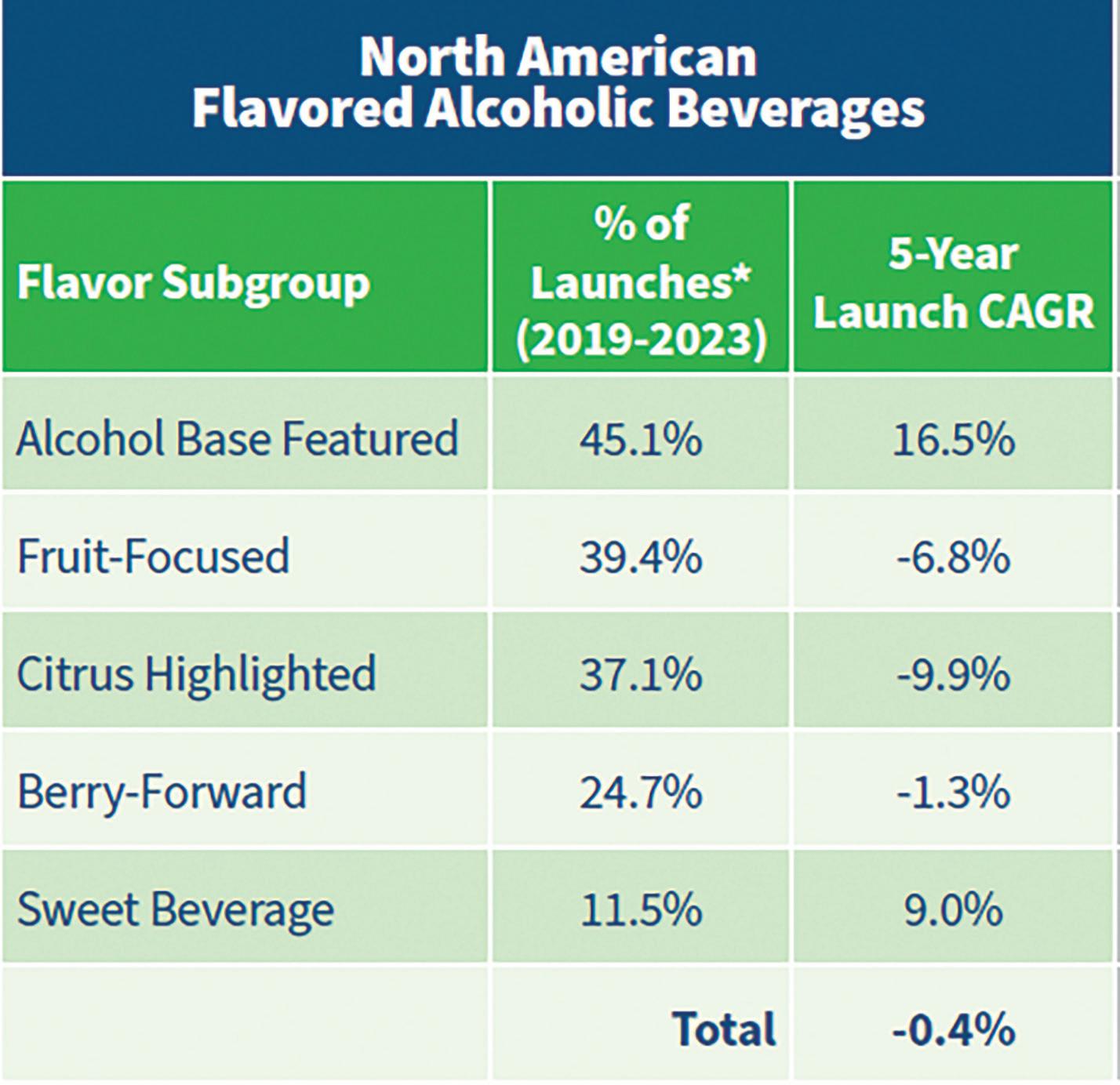

Image 1

The ready-to-drink cocktail is evolving to premium formulas using spirit bases, hard teas, or hard lemonades as producers strive to keep pace with growth goals and changing buyer expectations. The shift is generating results. RTD cocktails sold in the U.S. experienced volume growth of +14% between 2021 and 2022, almost offsetting the -10% downturn in hard seltzers. The LCBO reported a +40% growth in canned cocktails in 2023.

Brewers interested in crafting RTD cocktails can enter the segment through a few paths. Some breweries in the U.S. are adding distillery capabilities to their operation. Although exact numbers are unknown, the U.S. Brewers Association estimates that about five percent of breweries (450) have spirits permits.

U.S.-based Dogfish Head Craft Brewery started distilling more than 20 years ago. According to Impact Databank, Dogfish’s canned cocktails are segment leaders, with volume gains of +52% in the last year (296,000, 9-liter cases). The company offers a line-up of nine canned cocktails (including two variety packs). The brand’s newest cocktails, Grapefruit & Pomegranate Vodka Crush and Pineapple & Orange Rum Crush, feature natural flavours and 7% ABV. (Image 1)

Ontario’s Collective Arts added a Tequila Paloma to its canned cocktail line in mid-2023. The 5% ABV carbonated drink includes grapefruit juice, lime juice, citric acid, hibiscus extract, and natural flavours. The cocktail is the fifth entry for Collective Arts, joining Citrus Gin Collins, Vodka Lemon Squeezy, Paradise Found Rum Daiquiri, and Cherry Whiskey Sour. (Image 2)

Some brewers are sourcing spirits to include in their RTD cocktails. Daybreaker vodka cocktails from Two Roads Brewing in the U.S. hit shelves two years ago with sourced vodka. The brand recently launched a premium 12% ABV Espresso Martini cocktail under a new brand, Nightshaker, that blends vodka, cold brew coffee, and natural flavours. (Image 3)

Building distilling capabilities or bringing spirits into brewing operations can result in a tempest or two.

The flammability of spirits requires additional safety and security in the production areas.

Brewers face more complexity (and cost) when running a brewery and distillery.

Finding team members with distilling expertise may be challenging in some regions.

State and provincial laws will vary for spirit distribution.

For distribution support, the brewer may need to explore a wine or spirits house in addition to their beer wholesaler.

The shift to delivering a more premium (and often spirit-based) RTD drinking experience requires brewers to adjust their product development considerations.

Fortunately, several pathways are available to breweries interested in developing a premium RTD cocktail, including:

Branding the spirit base in the RTD cocktail for breweries that distill their own spirits. Craft brands will connect their known brewery beverages with spirits, which helps build credentials. Flagging characteristics like “smallbatch” or “house-made” can differentiate start - ups from more sizable brands. (Image 4)

Raising the ABV beyond the traditional 4.55% found in hard seltzers. FlavorSum Senior Application Scientist Blake Lyon notes, “An ABV of 12.5% can eliminate the need for preservatives, allowing you to make a “no preservatives” label claim. Try to align the ABV with the expectations of the cocktail as your budget allows.”

For brands distributing in Canada, regulations prohibit high ABVs for readyto-drink cocktails. A 473 mL RTD cocktail can have up to 5.4% ABV, while the limit for a 568 mL can (roughly 1 pint) is now 4.5% ABV, down from 11.9%.

The revised regulations align with Canada’s Guidance on Alcohol and Health, which advocates citizens limit alcohol intake to 1 or 2 standard drinks per week. If daily drinking occurs, the guidelines recommend not exceeding two drinks on any day.

A standard drink “unit” reflects 10 mL or 8g of pure alcohol. You can calculate the units in your beverage using the following formula: ABV x mL ÷ 1000.

For a 12 oz or 341 mL canned cocktail, the recommended standard drink is 1.7 “units”: 5% ABV x 341mL ÷ 1000 = 1.7

Some spirit-based RTDs with higher ABV accommodate Canadian restrictions by reclassifying their beverages as spirits and packaging their drinks in bottles. Liquor stores will shelve the beverage next to liqueurs or aperitivos. The adjustments enable brands to stay within the recommended drinking guidelines.

For example, a spirit-based cocktail with 18.4% ABV in a 125 mL bottle has the following drink “units”: 18.4% x 125 ÷ 1000 = 2.3

Offering no-alcoholic cocktails to support the shift toward moderation in alcohol consumption and offer drinkers a complex experience without side effects. Statistique Canada reports about one in

four Canadian adults abstain from alcohol, and a no-alc RTD option provides desirable social and health benefits. Canadian brands are responding. Quebec-based Brasseurs Du Nord recently launched Bluff, a carbonated, 0.5% ABV line-up that includes a margarita and a gin & tonic cocktail made with natural flavours. (Image 5)

Exploring technology to elevate the drinking experience. Some breweries are creating premium RTD cocktails by infusing the drinks with nitrogen. The nitrogen creates delicate micro bubbles that help foster a thicker and creamier texture. Using nitrogen can also instill a sweeter taste without adding sugar or sweeteners. And unlike carbon dioxide, nitrogen doesn’t create acidity. Muskoka Brewery recently launched a nitrogen-infused Espresso Martini and Raspberry Gin Fizz. The 8.0% ABV cocktails made with gin, vodka, and natural flavours gained kudos on social media from buyers and in online reviews.

Getting creative with flavours by offering a twist on traditional cocktails. Global research firm Mintel reports that one-third of U.S. spirit drinkers like to try new cocktails, with more than four-in-10 GenXrs willing to take a flavour adventure. (Image 6)

North American RTD cocktail launches over the past five years are shifting toward calling out the alcohol base – gin, vodka, whisky, rum, or tequila. (Image 7) Cocktails featuring single flavours often highlight familiar favourites, but brands are changing the landscape with hundreds of novel pairings. Almost 600 unique flavour profiles launched in the North American RTD segment in the last five years. Of the more than 130 flavours introduced in North America in the most recent year ending November 2023, about 50% are new combinations to the market (Mintel GNPD). New blends feature tropical flavours like yuzu or lychee with fast-growing flavours including peach, coffee, and black cherry. (Image 8)

Critical decisions for brewers beginning the RTD cocktail development process include the following.

Choose the beverage base. While specific spirits account for most North American RTD cocktail launches, about one-third of beverage innovations feature grain-neutral spirits. FlavorSum’s Blake Lyon points out that GNS options are “very clean tasting, straightforward to layer flavour upon, and widely available.” (Image 9)

Identify your cocktail inspiration. Your ready-to-drink cocktail formula can reflect a unique recipe, and you can discover thousands of ideas through market sweeps or online searches. Having a familiar cocktail name can help with acceptance, however, and only about 100 cocktails are ‘officially’ designated recipes in bar-tending competitions. NielsenIQ data for the U.S. market lists about 30 named cocktails in the ready-to-drink format. Many are growing in the most recent year as more brands enter the RTD space and purchase rates increase. (Image 10)

Set your ABV target. Replicating a high-ABV drink like a Mai Tai (26% ABV) or a Long Island Iced Tea with 22% ABV may be cost-prohibitive or a regulatory challenge. Flavour solutions can help you pursue a Long Island Iced Tea “like” beverage by featuring alcohol flavours to infuse the rum, tequila, gin, triple sec, and cola notes. Remember that each provincial liquor board may have unique guidelines for RTD cocktails. Check with your flavour supplier for resources to help navigate the commercialization process across Canada.

Establish your ingredient guardrails. Here, you’ll consider your brand reputation, marketing goals, and budget to help you determine:

The sweetener system as sugar or juice. If you want to formulate a reduced-sugar beverage, you’ll need to consider gums like acacia to help round out the mouthfeel.

The desired label claims, such as natural or no-added preservatives, will guide ingredient selection and may influence your ABV target.

• The level of ‘true-to-concept’ in your RTD cocktail. Some beverages, like a gin fizz, align readily in the ready-to-drink format. Others, like

Image 7a Mai Tai, have complex formulas that offer development challenges like ingredient costs. You can mirror the Mai Tai experience by putting a twist on the flavour with something like pineapple to avoid direct comparisons.

Find your flavour partner. If you plan to distribute your RTD cocktail in the U.S., choosing a flavour supplier with a portfolio of TTB-approved solutions can help you navigate the American approval process. Wherever you plan to market your beverage innovation, having flavours designed specifically for alcoholic beverages will help you meet taste expectations. Incorporating flavours into your premium RTD cocktail provides several benefits:

• You’re not limited by ingredient availability since natural flavours can replicate almost any taste.

• You can collaborate with your flavour house to develop combination flavours that ‘fit’ with your base and help your brand stand out from competitors. You have control over the flavour profile, meaning you can enhance specific notes while downplaying others to create a unique drinking experience.

• You also have control over the flavour intensity.

• You can add solutions, like citric acid, to brighten and add depth to the flavour.

• To replicate opaque RTD cock-

tails, like Palomas, you can incorporate natural Cloud® flavours into your beverage.

RTD alcoholic beverages represent an opportunity for breweries to expand their assortment and appeal. Some brands are successfully pivoting to beverages that address evolving needs for high-quality, complex, and convenient drinking experiences. Premium cocktails are the newest RTD frontier, with several development pathways available to brewers and distillers. Whichever path you choose for your brand, remember that flavour plays an essential role in the success of your cocktail.

Image 9

Image 12

Image 9

Image 12

AS BREWERS AND BREWERY OWNERS, WE ALL KNOW

HOW COSTLY AND INCONVENIENT THE ISSUE OF LOSING KEGS IS. HERE COURTNEY FROMM, NATIONAL MANAGER AT KEGSHARE, OUTLINES THE CHALLENGES FACED BY THE INDUSTRY BUT, MORE IMPORTANTLY, WHY THERE IS A SOLUTION AT HAND.

Keg loss is an unfortunate part of doing business, this will probably come as no surprise to any of you reading this.

Kegs get stolen, or they’re left in someone’s garage for years. Or perhaps they were picked up or returned to the wrong owner by accident. And don’t get us started on the kegs that have been turned into tables or umbrella stands…

As a result, even a company with no keg growth must replenish their fleet every year to cover the lost kegs. This is significant cost to business, especially when typical keg loss in the industry is 8 to 10%.

Thankfully, however, help is at hand. Ensuring you keep VERY good records using Excel or similar is time-consuming and subject to human error. This method probably means you can cut losses to 6%.

You could also use a keg management app like Kegshoe to track via a dashboard 3 to 5% loss, or perhaps you could add GPS tracking to kegs, which is a very costly exercise.

Alternatively, you can follow the many brilliant busy brewers across Canada that continue to discover the ease and convenience of Kegshare. This a groundbreaking keg rental service combining powerful tracking technology with hands-on human support.

Kegshare has identified this serious problem and has reduced losses down to 2%, and we are continuing to look for ways to reduce loss even further. We are engaging in pilot keg tracking programs to increase our efficiencies, so don’t be alone in the search and rescue process let Kegshare assist you.

The concept is ingenious in its simplicity. Rather than buying and storing dozens of kegs, brewers can now rent as many—or as few—as needed. By offering low-monthly rates with zero maintenance costs, Kegshare allows brewers to concentrate on what they do best—making epic beer, cider and wine!

Depending on their needs, brewers can choose between three, five and 10-year rental programs, with extra kegs available for short-term leasing to accommodate those specialty summer-inspired IPAs and lagers, or winter-wonderland stouts and ales, which means brewers can save money by not paying storage fees for empty kegs. Brewers also have the option of changing keg sizes at no cost.

When it comes to new breweries, the ability to rent a fleet of kegs instead of buying them outright—before their beer, cider or wine is even out the door—means that’s one huge initial expense brewers can put towards other needs, like specialty hops or those hand-picked spruce buds and needles so popular in winter ales.

To break it down, Kegshare is a software-powered company, which uses an online order and invoicing system for placing and managing orders, tracking delivery and return reports, and can even supply the brewer with a keg’s prior use and history.

AND, YES, THERE’S AN APP FOR THAT.

Brewers use the app’s dashboard to keep track of how many kegs they’re actively

using and how many are still available to them. Brewers are guaranteed access to well-maintained kegs, so as soon as one empty is dropped off, they immediately have access to another keg from one of the many distribution centres conveniently located across Canada.

Brewing is a time-honoured craft steeped in tradition, but that doesn’t mean your keg rental and distribution systems have to remain in the dark ages. Let Kegshare make the logistics of keg rental and distribution easy, convenient and affordable, giving you more time to make great products.

We manage and maintain a strong relationship with the top keg distributors across Canada. We work with each of them to secure empty keg storage, delivery, empty keg pickup from licensee, provide easy access pnts for drop off and pick up of Kegshare kegs.,. Our partner distributors are in British Columbia, Alberta, Saskatchewan, Manitoba, Ontario, Nova Scotia, and New Brunswick. They include Containerworld, Good Hustle, Direct Distribution, Connect Logistics, District Brewing Co, WETT Distribution, Lake of Bays Brewing CO, Broadhead Brewery, Elk Packaging & Logistics, Timax and TNG (Prologix). Quebec and Newfoundland coming soon!

email courtney.fromm@kegshare.ca phone 705-737-7687

IF YOU’RE A BREWER THINKING OF SUSTAINABILITY OR AREAS TO GROW, OR IF YOU ARE IN NEED OF INSPIRATION OR GUIDANCE, THEN LOOK TO KIRK ZEMBAL AND BLINDMAN BREWING, EXPLAINS NICHOLAS HENDRICKSON – AUTHOR.

Innovation is a common word in the craft beer industry. People use it, more often than not, to describe the products that the brewery they are speaking about are producing. When you hear the word, you might think of a barrel aging program, being the first to do something in their respective region, winning awards for their beer program, or even sometimes in regards to something like sustainable business practices. When it comes to Blindman Brewing and owner Kirk Zembal, all of these things apply.

When speaking about the topics listed above, to truly show how innovative Blindman is, it would be most prudent to touch on all of them. Firstly, the barrel aging program – this is something that Blindman has taken seriously since their inception.

A program they have named Bieres de Coupage. When you think of barrel aging in the beer industry, the first things that come to mind are probably Imperial Stout, or maybe even Barleywine. Blindman does those, but also does some extremely interesting products that few others dare to venture into in these respects.

They have a coolship (or Koelship, depending on where you’re reading this from) program, something that is exceedingly rare in the craft beer scene, especially here in Canada. This form of cooling the wort and sending it into barrels is a way to get some truly unique and beautiful beers through mixed fermentation. Just one of the many ways that Blindman is continuously innovating day-to-day and year-to-year.

To the second point of innovation from above, being the first to do something in your respective region, this could characterize many areas of the Lacombe-based

business. Firstly, they were the first brewery to open their doors in Lacombe. When being the first, this comes with both pros and challenges to tackle.

You are the first to the market, but that oftentimes comes with the challenge of educating your respective market on what you are trying to do and why they would like the beer you are producing, something that Kirk has mentioned is a continuous point of attention when creating something wild and different, especially beers coming from the Bieres de Coupage program.

The best way Kirk and his team have found to tackle the challenge of being innovative, but still finding success within the general populous is, in his own words, to at times be “everything to everybody”.

While in concept this is a no-brainer, this is an interesting challenge to tackle from a production perspective, but one

that many breweries try to do. Blindman has seemingly found a healthy balance between producing their best-selling beer in the Blindman River Session Ale, fruited sours, a full lager program, hop-forward expressing beers, and a barrel program.

But beer isn’t the only way that Blindman is innovating in regard to beverages. Something that Kirk was very excited to talk about (his face lit up with excitement when talking about it), was that of hop water. For those of you who have not ventured into this area of the beverage sector, hop water is a sparkling water beverage that is being infused with hop products, typically flowable ones instead of the standard pellets, to give all the hoppy deliciousness that people want from a Pale Ale or an IPA without the calories or the alcohol to boot.

This is going to be an interesting area of the beverage sector for years to come, and it is through their innovative thinking

that Blindman was one of the first breweries in Canada to really take a proper swing at it.

But aside from how they innovate in the production of liquid refreshments, there is another very important area that Blindman is innovating in, and one that many people should be looking to into the future of the industry, and that is for sustainable business practices. This can come in the form of recycling malt bags, sending spent grain off to local farmers, recycling PakTech’s off the top of four and six packs, and even something as huge as having a CO2 recapture system. Hint: Blindman has all of these in place.

You could tell when Kirk was discussing this topic that he was very adamant about being sustainable as a business and staying committed to finding ways to not be wasteful. As stated above, virtually every aspect of their production has a sustainability initiative. From sending their spent

grain away for feed, which livestock love to eat, to recycling malt bags.

But the one worth exploring the most, mainly because they were the first brewery in Canada to implement this, is that of a CO2 recapture system. These systems have been creeping their way into the minds of brewery owners and brewers for the better part of the last decade. But whether it be the prohibitionary status of the cost of purchasing and installing one, or the fact that the technology is still rather new, those who have fully adopted it are few and far between.

With that being said, a CO2 recapture system is a huge way for a brewery to fully commit to sustainable practices as well as a sound financial investment. For those of you in the know, we all know how ridiculously expensive food-grade CO2 has come to be over the last half decade, and this is in area where Blindman is now saving a fair bit of expenses in purely by bringing it in-house.

These systems, in a nutshell, allow a brewery to recapture the CO2 produced during the production of beer, clean it back to a level where it is safe to use in stable products, and repurpose it rather than sending it off into the atmosphere. Another note worth mentioning is that by not allowing CO2 to go into the atmospheric air within your brewery and cellar, it creates a safer work environment for those working there – something that Blindman has taken seriously and has led the charge on.

With all this being said, you would think those are plenty enough places for a brew-

ery to be innovative in, but Kirk and his team don’t think so and continue to find other ways to get their beer out to the masses. Blindman recently announced a partnership with with Dandy Brewing out of Calgary.

And when asked about it, Kirk wanted to make it clear that this was not a merger or an all-out-purchase, but rather an amalgamation of resources. A true “rising tides raise all ships” type of mentality, something that this industry has prided itself on since its inception.

But Calgary isn’t the only market that Blindman has expanded into outside of their Lacombe headquarters. One that few have ventured into, aside from the big conglomerates, is that of the Asian beer market. Blindman has found a niche following in Hong Kong and Japan for their beer. And while this is undoubtedly not how one could keep a business afloat, it just goes to show how fully committed Blindman Brewing is on finding new areas to innovate and grow.

So, when thinking of sustainability or areas to grow, if you are in need of inspiration or guidance, look to Kirk Zembal and Blindman Brewing. A true living, breathing story of what it looks like to want to grow, be sustainable, be creative, and to fully commit to it.

IN THE EVER-EVOLVING LANDSCAPE OF CRAFT BREWING, SHANLEIGH THOMSON, FOUNDER OF SHAN.FERMENTS, BRINGS FORTH AN EXPLORATION INTO THE REALM OF TERPENES AND THEIR ROLE AS THE FLAVOR ARCHITECTS OF BEER. TERPENES, COMPOUNDS FOUND IN PLANTS LIKE HOPS, OFFER BREWERS AN EXCITING AVENUE TO PUSH THE BOUNDARIES OF CREATIVITY AND ENHANCE THE SENSORY EXPERIENCE OF THEIR BREWS. THOMSON DELVES INTO RECENT ADVANCEMENTS IN EXTRACTION TECHNIQUES, SHEDDING LIGHT ON HOW BREWERS CAN LEVERAGE SPECIFIC TERPENE FRACTIONS TO PRECISELY MANIPULATE FLAVOR AND AROMA PROFILES.

Terpenes are volatile organic compounds found in a wide range of plants, contributing to their aromatic and flavor profiles. In the context of beer, hops are the primary source of terpenes, imparting the well-known bitter, floral, and citrus notes characteristic of many beer styles.

However, the brewing process can affect the integrity of these compounds, leading to a loss of their potent sensory contributions (Dietz, Cook, Wilson, Oliveira, & Ford, 2023).

Recent advancements in extraction and isolation techniques have enabled brewers to incorporate specific terpene fractions into their beers, allowing for a more precise manipulation of flavor and aroma profiles. For instance, supercritical CO₂ extraction has been employed to isolate terpene alcohols and sesquiterpenes from hop oils, offering a nuanced palette of sensory attributes (Dietz et al., 2023).

The integration of terpene extracts into beer can significantly influence the multi-

sensory perception of the final product. Dietz et al. (2023) found that monoterpenes, such as geraniol, can impart fruity and floral aromas to beer, enhancing sweetness and contributing to a smoother bitterness.

Conversely, sesquiterpene fractions were associated with a harsher bitterness, indicating the complex interplay between different terpene types and sensory experiences.

For professional brewers, this opens up exciting avenues for beer innovation. By selectively incorporating terpene fractions into their brews, brewers can craft beers with tailored sensory profiles, moving beyond traditional flavor boundaries.

In a conversation with Tristan Fetherston of Beacon Brewing in Sidney, British Columbia, we explored the practical benefits of using terpenes in brewing. His insights offer a clear perspective on how terpenes enhance craft beer, making flavors like those in their West Coast IPA both distinct and consistent.

Fetherston’s firsthand experience highlights the simplicity and economic efficiency of terpene use in brewing. “Using terpenes is super easy, dosing is super simple. It’s a straight add at high krausen for additional bio-transformation, or cold side,” he explains, showcasing the straightforward incorporation process. The cost-effectiveness of terpenes is also emphasized: “For your dollar, it’s your best bang for your buck as far as advanced products go.”.

Terpenes offer brewers a palette of flavors and aromas that can significantly elevate the complexity of beer. By carefully selecting and incorporating specific terpene fractions, brewers can craft beers with tailored sensory profiles, moving beyond traditional flavor boundaries.

Fetherston’s testimony supports this, noting the consistent and true-to-style profiles that terpenes provide: “If I want a Mosaic type hop, I don’t have to worry about purchasing Mosaic pellets that may not be [the flavour profile] that I want. This is always consistent and true to what I think of when I think Mosaic.”

The absence of vegetal matter in terpene additions not only reduces bitterness but also enhances yield retention, a significant advantage in brewing efficiency. “Since there isn’t any vegetal matter, I get great yield retention,” Fetherston points out.

This benefit, along with the precision in flavor and aroma profiling that terpenes allow, underscores their value in creating consistent and high-quality beers. “There’s no guesswork in the profile, I don’t have to worry about crop variation,” he adds, highlighting the reliability of terpenes in achieving desired sensory outcomes.

Integrating terpenes into beer production aligns with sustainable brewing practices by minimizing waste and environmental impact. Terpenes can be created with a much smaller acreage impact; an essential when identifying steps forward in an already over-supplied hop market. Terpene products are significantly more concentrated, meaning that instead of shipping a large pallet or a 20kg box from places like New Zealand or Washington, a much smaller shipment is required, resulting in a reduced carbon footprint in the supply chain.

During our discussion, Tristan was hardpressed to find any major disadvantages to using terpene technology. While it seems there are few downsides to terpene implementation, there are a few things to take into consideration when choosing whether to integrate terpene technology into your brews.

The potency of terpenes demands meticulous balance to prevent overpowering essential beer flavors. An understanding of each terpene’s sensory impact and its synergies with additional brewing ingredients (such as hop pellets and advanced lupulin) is limited in research, but wholly fundamental to the success of a “terpenated” beer.

Careful selection of terpene fractions based on the target sensory profile is key, with monoterpenes for floral/fruity nuances and sesquiterpenes for bitterness. Terpene addition timing is critical for maximizing flavor impact. Experimentation across different brewing stages, from the boil to post-fermentation, is necessary to

fine-tune their effect. While much of this seems daunting, any of the current purveyors of terpenes for brewing such as AbstraxTech do the integration legwork for you which is a plus.

The addition of terpenes to beer specifically is fairly new, and as we all know, compliance and regulatory bodies can be slow to catch up with technology. Knowing your local government agency’s rules and regulations when it comes to terpene use is essential before you start experimentation.

Not all terpene suppliers are the same! Employing sophisticated extraction methods, such as supercritical CO₂, affects the final sensory profile. Collaboration with reputable suppliers of food-grade products is super important when attempting to use any advanced product.

The use of terpenes in brewing is an area ripe for exploration, with potential for creating unprecedented beer styles and flavor profiles. Continued research, such as that conducted by Dietz et al. (2023), is crucial for understanding the complex interactions between terpenes and other components of beer. As the industry navigates increasing complexity in supply and sustainability, innovations like terpenes emerge as a crucial advancement in technology.

Dietz, C., Cook, D., Wilson, C., Oliveira, P., & Ford, R. (2023). Exploring the multisensory perception of terpene alcohol and sesquiterpene-rich hop extracts in lager-style beer. Sensory Science Centre, Division of Food, Nutrition and Dietetics, School of Biosciences, The University of Nottingham, Sutton Bonington Campus, Leicestershire, UK.

• Abstrax Tech. (2024). The Ultimate Guide to Beer Terpenes. Retrieved from https:// abstraxtech.com/blogs/learn/the-ultimate-guide-to-beer-terpenes

AT THE NORTHERN TIP OF NEW BRUNSWICK, NEAR THE BORDER OF QUEBEC, SITS LES BRASSEURS DU PETIT-SAULT.

CELEBRATING THEIR TENTH YEAR IN BUSINESS, GENERAL MANAGER ANDRE LEGER RUNS A HIDDEN GEM LOCATED AT 45 RUE DE L’EGLISE IN DOWNTOWN EDMUNDSTON.

HERE JASON MURRAY TELLS ALL…

One of the few microbreweries in the province in 2014, they’ve seen nothing but positive changes in their drive to create a solid, sustainable beer business. They follow markets in Europe as well as Canada and the US and have tried to adapt as the market dictates. They continue to grow based on quality products, trying new things and knowing when to hold on to classics.

“We want to be at the heart of our community,” Leger says. “Where people can meet and share.”

The idea was much bigger than beer for the founders of Les Brasseurs. They

wanted the taproom to be a nice addition to their downtown but also a place where people could gather and have a conversation.

With over a dozen locally themed beers, there’s something for everyone looking to get to the roots of their region through the eyes of local heroes and folklore. La Kedgwick Pilsner, Soeur Catherine Old School IPA and the Louis XVII Amber Ale are on offer to locals and visitors alike.

Les Brasseurs du Petit-Sault has always taken a collaborative approach to the growing number of microbreweries in the province. They like to see more people providing more beer experiences and

have even done local collaborations including working with the restaurant right next door.

“They carry all of our beers and we sell their food,” he explains.

Like most businesses they had to adapt quickly during Covid. They made changes, kept things efficient and added pick up at the door and home deliveries to their list of services. Came back strong with some renovations and a new patio and Andre thinks they’re better off for the experience.

“It pushed us and brought us somewhere we would never have gone,” Leger says.

Everyone is happy to be back face-to-face, seeing crowds again and hearing great conversations around big long tables. The evolution of providing awesome service also shows in their line-up of beers. Les Brasseurs has added a cream ale, a hazy IPA and Mexican inspired Cerveza Republique light beer to their quiver.

“Beer helps form connection,” Leger said. “It brings people together.”

There will be new changes and challenges for all breweries in the future. Working together and building a strong foundation will be the key to everyone’s success. Smaller, newer beer companies, taprooms and restaurants will have to work on regulations and how to make products more available in the province.

With more and more beer being sold by region, the government of New Brunswick will have to find ways to increase shelf space for the growing number of locally crafted beers. There might also be a need for a conversation about easier access but also where and how small market beers are consumed.

“Beer laws definitely need to be updated,” Leger muses.

Les Brasseurs du Petit-Sault is re-launching their first beer from July 2014. A Belgian Wheat Beer named Tante Blanche. They’re starting to sell eight packs and experiment with new ideas for seasonal offers. Hoping they eventually make it to their classic lineup. The crew even host a Funk & Beer Festival in the fall, bringing together great music, local food trucks and any costume you can dream up.

And they keep winning awards, picking up three more recently from the Down East Brewing Awards. Their lineup of brewmasters, dedicated staff and passionate beer people like Andre Leger will ensure a strong future. Get out and support your local breweries and taprooms and bring everyone back to the heart of your communities.

Consider making a trip to northern New Brunswick, summer, fall, winter or spring and check out Les Brasseurs du Petit-Sault located at 45 Rue de l’Église, Edmundston, NB. Be sure to tour around Madawaska County to find hidden treasures lurking around every corner.

You can also get to know the history of the region, where to stay, ski, swim, fish or mountain bike from: https://edmundston.ca/en.

Check out https://en.petitsault.com for their full list of beers, hours of operation and upcoming events and features.

A WELL-TRAINED AND COHESIVE INTERNAL TASTE PANEL IS A CRITICAL COMPONENT OF A SENSORY PROGRAM IN ANY BREWERY OR BEVERAGE COMPANY. HERE IS SCOTT UNGERMANN, SENIOR ADVISOR OF TECHNICAL SERVICES AT FIRST KEY CONSULTING, TO EXPLAIN WHY.

Furthermore, these are not all learned skills – some members will be anosmic to certain elements such as Diacetyl and other defects.

That is why a panel must be constructed to cover all aspects of flavor and aroma dimensions. All taste panels need rules and guidelines to function properly and maintain quality in the brewery while providing proper evaluations of products.

“Taste Panel etiquette centers on building an environment where independent evaluations can occur without influence from outside factors. In this way panel etiquette isn’t just about being courteous, it’s about accurately and confidently measuring how a product is perceived.” -

Lindsay Barr, Founding Partner & CSO, DraughtLabThe taste panel has three main goals and mandates:

1. Ensure existing product quality and consistency

2. Develop and evaluate new products

3. Empower employees with training that fosters inclusivity

To meet all three goals consistently, proper training and etiquette are vital keys to success. Taste Panels are a necessary element of a quality system.

The reason a panel is necessary is that no single taster has all the tools at their disposal to make appropriate quality decisions. All tasters are humans and as such have inherent differences in their perceptive abilities.

These guidelines should be particular to the brewery, clearly documented and should include the obvious such as scheduled time and place, no smoking, gum-chewing, or eating prior to tasting, complete bans on perfume or cologne or scented lotions, and how and when to clean the glassware, and so on.

A first-time taste panel participant at a brewery often faces a somewhat harrowing experience. In addition to written rules, most taste panels have their own set of unwritten rules, the navigation of which can be made more difficult if the taste panel does not incorporate proper etiquette into its routines. Taste panels can miss defects and push forward incompletely developed new products if there is any inherent bias or favoritism developed by entrenched attitudes and/or lack of proper decorum.

These five simple guidelines for etiquette should be incorporated into the written procedures for every taste panel in some way to foster inclusivity and eliminate sources of potential bias:

“There is no talking while tasting” is an easy rule to follow and is usually followed quite well. The key is to stay seated and stay quiet until all taste panel members have finished – that’s the hard part. It is important to minimize possible distractions, including conversation among other participants, as distracted tasters are more likely

to lose focus and become less effective at catching defects or recommending potential product improvements. Distracted tasters are more likely to lose focus and therefore less effective at catching defects or improving a product.

Simply being quiet is not enough on its own. Taste panel members should maintain a neutral expression throughout the tasting session, since nothing produces instant partiality as much as one taster dramatically reacting to whatever is in their glass.

Words are not necessary when the brewmaster makes a frowny face while sniffing beer #3 – inherent bias creeps in for the other tasters. Inside jokes about the products that are being tasted or the taste panel in general are also not helpful and can actually work in direct opposition to efforts directed at encouraging inclusivity, since people who don’t feel in on the joke may fear it applies to them. If people don’t feel in on the joke, they may fear it applies to them.

Fearful tasters are also more likely to lose focus and therefore become less effective at catching defects.

Once everyone has finished tasting it is a very important function of the panel to talk about the beers (or the hop-waters or whatever else they are tasting.)

The sharing of comments aloud while the product is still in front of the tasters is critical to the development of the panel, as the connections made between the words and the flavors and aromas discovered during tasting will help develop a lexicon for the panel to employ going forward.

When one panel member says “esters” and another panel member smells the esters in the glass, this further solidifies the training of all members of the panel.

This sort of commonality is only possible in an environment where everyone is allowed a voice while others listen. If some tasters are denied the opportunity to express their opinions, diverse views

will not be heard and opportunities will be missed.

Since taste panel members will not always agree on matters of quality, level of defect, or even preference in style or approach, there needs to be a systematic method in place for deciding upon the follow up actions.

As personal disagreements can lead to internal conflict, one should always challenge the idea rather than the person, and when looking for a path toward resolution, the emphasis should always be upon the process rather than the personality.

Disparaging the competition is also highly counter-productive insofar as it engenders an atmosphere of superiority which in turn may lead directly to bias. As biased tasters are generally less effective at identifying defects and inherently disinclined towards analysis, such prejudicial comparisons should be avoided.

Different members of taste panels

bers feel rushed, they may struggle to complete the task thoroughly and properly, while if the panel speeds through the process without allowing all members ample time, then the panel will have missed the opportunity to reach its full potential.

It only takes a quick “Is everybody done?” when everyone is clearly not done to create that air of rushing for those one or two tasters who are not done which will then cause them to rush through those last couple samples and have an incomplete evaluation. Rushed

are therefore less effective at recognizing defects.

These five guidelines for etiquette are not just appropriate for taste panel success, they also apply to cross-functional meetings or any other group discussions geared toward fostering improvements in communication.

When people respect and listen to their peers they are much more likely to learn from one another and feel included and valued for their contributions, which will in turn make them more valuable and effec-

A STORY THAT STARTED BACK IN 2016, DILDO BREWING COMPANY WOULD GO ON TO OPEN ITS DOORS IN JUNE OF 2018. AND NOW, NEARLY SIX YEARS ON, UNDER THE STEWARDSHIP OF HEAD BREWER AL GOODYEAR, THE BUSINESS IS ON THE VERGE OF COMPLETING AN EXCITING EXPANSION THAT MARKS THE START OF THE NEXT CHAPTER HERE IN NEWFOUNDLAND.

“I still can’t really put my finger on it. I think we all know it when we experience it. But it’s hard to put into words.”

Al Goodyear is toasting his first anniversary as head brewer at Dildo Brewing Co. A beautiful waterfront brewery, museum and taproom in the province of Newfoundland and Labrador.

“I like to have a view when I brew,” he smiles. “Last St Patrick’s Day I was getting ready to start and haven’t looked back since. I’ve landed in a great spot here.”

And he’s got great reason to beam, too. It’s been some ten years since he helped a friend move west to Vancouver. A trip that would open his eyes to some of the fantastic breweries and taprooms that exist across Canada and the contributions they made to the culture and community around them.

“We managed to move from Newfoundland to Vancouver in about seven days. So it was pretty much driving constantly!” he recalls. “But stopping in at various breweries, you could see they all had their own little twist but with a similar vibe. They shared a cultural thread where everyone was welcoming and happy to be there.”

He adds: “People were enjoying the company of other people, the teams were happy to be there and you can chat with them about the beers. There was a core element of ‘we are here for the beer’ and that really resonated with me.”

A decade or so on, Goodyear and the team at Dildo Brewing Co continue to welcome patrons of their own to enjoy brilliant beers, all coupled with an enviable environment to imbibe in, too.

And in 2024, the brewery is undertaking an exciting expansion that will significant-

ly boost its output capabilities and enable Goodyear to create even more smallbatch beauties to run alongside the brewery’s ever-popular core range.

The story of Dildo Brewing Company & Museum started back in 2016 with local brother and sister Angie Reid and Roger George. Together with their spouses Rob Reid and Debbie George, they set out to bring craft beer and a much needed hub of the community to Dildo, Newfoundland.

Back in 2016, there was a shortlist of craft breweries operating within Newfoundland, none of which were anywhere near Dildo. The community of Dildo has always been a popular attraction to locals and visitors alike. However, it was lacking a community hub once people came to visit. Owners recognized this demand growing

in their hometown and were quick to land on a solution to this problem... Craft beer! Within the community of Dildo was a cultural heritage museum that has showcased the rich history of Dildo’s fishermen. This museum had been operating for over 20 years but was slowly falling to the wayside due to needed renovations and repairs.

This problem within the community again presented a great solution to the owners. It was determined in 2017, that this museum would be renovated and reworked to house the Dildo Brewing Company & Museum. Therefore offering a community hub, craft brewery, restaurant and museum all in one.

Owners Angie, Debbie, Rob and Roger have not looked back since opening their doors in spring 2018. After a major revamp

There was a core element of ‘we are here for the beer’ and that really resonated with me.”

to the build they were happy to see waves of visitors coming to their outport community, popularity that will ramp up even further in 2024 and beyond.

But before his new calling, Goodyear got his professional break in brewing back in 2017 thanks to Liam McKenna at YellowBelly Brewery and Public House in St John’s. Born in Scotland and trained as a microbiologist at the University of Guelph in Ontario, McKenna has worked more than 20 years as a professional brewmaster and beverage consultant in North America and Europe.

Dubbed “the great polemicist of the craft brewing movement” by The Irish Times, McKenna has a brewing philosophy embodying a passion for quality, purity, balance, and taste – four key elements that

are reflected in the complex and delicious beers he has created for YellowBelly.

“Like most brewers I had a homebrewing background, I knew Liam and I knew I wanted a career change,” he recalls. “It was the right place at the right time.”

Goodyear joined YellowBelly working in the cellar and fulfilling a range of other roles such as scrubbing floors, too. But the position of brewer came available and he took it with both hands.

“You could say I was something of a known quantity to Liam so that’s probably why I got the job!” he laughs…

After a year in St John’, Goodyear made the short journey north-west to join the team at Quidi Vidi Brewing Company, a brewery founded in 1996 by David Fong. Here he would work as a senior production brewer and training a raft of other brewers, too. “I like the mix of art and science brewing gives you,” he explains. “And training others for me was important. Knowledge-sharing is one the biggest and best qualities there is in the world of craft beer. I’m a firm believer that a rising ride raises all boats.”

Around the start of last year it was time for a change and Goodyear got word that the opportunity to take on the head brewer role at the renowned, aforementioned, Dildo Brewing Co and Museum was on the horizon.

“They needed someone to take on that position. Every time I came to visit it felt right, it just felt right,” says Goodyear. “I respected the ownership here and I fell in love with the place. It’s a pleasure to work here and with these people.”

“I try and take inspiration and influence from as many sources as possible.”

And since joining early in 2023, Goodyear has taken on the stewardship of popular staples such as The Dildo Lager and Uncle John’s Lager as well as creating a wealth of one-off, seasonal brews of his own.

“We’ve got four brands here that I keep on flowing but the owners also allow me to do what I like and keep my finger on the pulse of what might be popular with our fans. I try and take inspiration and influence from as many sources as possible,” he says.

The brewery’s excellent lagers account for the bulk of production but they are by no means a solely lager brewery, either. “We have a very strong craft beer following here that seeks out beers of all styles, be that lager, gose, IPA or other expressions,” he says. “What I do notice though is that our trends in Newfoundland are probably a few years behind other parts of Canada. Emerging trends, or those dying out, take longer to be felt here.”

Goodyear and his relish and enjoy opening people’s eyes to beer styles they may not be aware of, or ones they don’t think they’d appreciate. “We are giving people choice but it’s all about baby steps. If they like a light lager that’s great - try ours!” he smiles. “Then I’d suggest a Vienna Lager and before you know it, maybe a Double IPA might make an appearance…”

In addition to a recent Barrel-aged Tripel release, the brewery is also undertaking an exciting project ageing Imperial Stout underwater. “The temperature is absolutely perfect for this. I just hope we don’t get high losses!”

Most of the brewery’s beers are sold and enjoyed at their popular taproom with a small part of their output packaged in can. But capacity across the board is on the verge of being ramped up due to a major expansion at Dildo Brewing Co.

A new facility, that will run in addition to the brewery’s existing waterfront location, will house a new four-vessel 20bbl brewhouse and a number of 60bbl fermenters, with Goodyear already eyeing extra lagering tanks also. While this new capacity will enable greater production of the brewery’s core offering, the head brewer is as enthused by the way this will open up the older brewpub set-up.

“It’s going to be one big pilot system,” he grins. “It will allow me and the team to experiment more, which we’re obviously very excited about.”

And that team will soon grow with an addition to the brewery team expected to join this spring. A season that will surely mark the start of another vibrant chapter in the life and times of Dildo Brewing Co, and those associated with it.

“It has been a great first year being part of this story. We have healthy culture with everyone pulling in the same direction,” says Goodyear. “I’m excited about what the future holds.”

THE NOVEL COMPACT BREWHOUSE FROM BANKE GMBH COMBINES MANY ADVANTAGES IN TERMS OF TECHNOLOGY, ENGINEERING AND ECONOMY. WITH ONLY TWO BREW VESSELS AND THUS THE SMALLEST FEASIBLE FOOTPRINT, A REVOLUTIONARY 6 BREWS PER DAY ARE ACHIEVED IN 60 MINUTES OF LAUTERING TIME. COMBINED WITH A STATE OF THE ART ENERGY MANAGEMENT SYSTEM, THE LOWEST POSSIBLE ENERGY CONSUMPTION CAN BE ACHIEVED.

Anew type of mash-lauter tun and a whirlpool-kettle with energy-saving boiling system form the core of the 2 vessel system. Compact brewhouses with knock-out volumes from 5 to 100 hl with very high batch size flexibility are currently feasible. The plants are optionally combined with a new energy management system, thus achieving very low specific thermal energy consumption of less than 4 kWh/hl of cast-out wort.

The conical lauter and boiling systems are based on the brewhouse technology developed by Gilbert Moser as recently presented [1,2]. The concept has already been implemented in nine breweries with brew sizes of 2.5–40 hl. Reliable results on technology, wort quality, and economy are thus available. Based on an exclusive license, banke has further developed the concept with its own engineering and also optimized it in terms of energy (Fig. 1).

The heart of the new concept is a combined mash and lauter tun in which the lautering surface is located in a cone (Fig. 2).

Mashing-in is carried out by the banke pre-masher, which ensures ideal process conditions for high yields by homogeneous mashing right from the start [3].

Mash heating is carried out by means of an external special heat exchanger and enables infusion and decoction mashing processes in only one brew vessel (Fig. 3). In the case of decoction mashing, the partial mashes are overlaid on the residual mash at boiling temperature (95–99 °C) and homogeneously mixed with the residual mash after starch disintegration. In this way, even problematic malts with

high gelatinization temperatures, which are increasingly expected due to dry and hot summers, can be processed well.

The decoction process is also used to produce lager beers full of character and to improve the haze stability of wheat beers. The single-vessel technology offers a high degree of flexibility in mash preparation and can be retrofitted to existing (conventional) plants without an additional mash vessel.

The separation of husks and wort takes place according to a principle similar to that of a coffee filter. A hollow coneshaped, loose and highly permeable filter cake is formed on the walls of the cone, which allows a very high permeability of wort with good retention of fine particles. The geometry makes use of the effect from cake filtration, a cake with equal resistance always builds up over a filter area.

This behavior enables the spent grains cake to be washed out evenly, which explains the good brewhouse yields. Unlike in classic lauter tuns, the spent grains cake remains largely in suspension throughout the process, so that the resistance that builds up is relatively small. In the lautering process, the first wort is displaced by sparging water and only at the end is the spent grains cake drawn dry for dehydration.

The high quality of the mashing and lautering work was confirmed in spent grain analyses (Table 1). The degradable and washable extract as well as the brewhouse yield were within the specifications of MEBAK (Central European Commission for Brewing Analysis) and the German brewhouse norm DIN 8777.

In addition to short lautering times, the patented mashing and lautering technology (EP 3 052 606) enables very high flexibility in lautering, as the conical lautering surface is already fully occupied with small mash volumes. Variations in wort OG from 6 to 24°P are feasible with different brew sizes of 40-100% of the maximum wort volume.

These are ideal conditions for brewing marginal brands or experimental beers with smaller batch sizes, without having to compromise on wort quality. The mash and wort are heated via external heat exchangers, so that the vessels do not require heating surfaces and a defined and gentle heat transfer is ensured for highly variable brew volumes.

Spent grains removal takes place via a slide valve on the cone. The conical shape favors the draining (Fig. 2). In small plants, the spent grains can be collected in a mobile buffer tank. Alternatively, discharge is fully automatic via an eccentric screw pump. Low speeds and generous

dimensioning of the pumps ensure a long service life and low maintenance costs.

The following goals were achieved in the development of the new boiling system:

2 % total evaporation for lowest possible energy consumption.

2 %/h evaporation rate – very low heating power required for boiling

109 °C heating temperature – the low heating medium temperatures allow cost-effective energy supply with wood pellet or wood chip heating systems frequently avoiding the need for costly and time-consuming certification processes

Best wort quality due to efficient evaporation and gentle heat transfer

The wort boiling system operates according to the external boiler principle (Fig. 3). The heat transfer for heating and boiling the wort takes place via a special heat exchanger heated by heating water, which enables very low flow temperatures and also works very gently. The countercurrent flow of heating water and wort achieves a low thermal load and good heat transfer. The gentle heating with simultaneously high heating rates of 1 °C/min is reflected in the wort analysis data (Table 1). A low increase in the heat stress index (TBI) and stands for good flavor stability of the beers.

The low decrease in coag. nitrogen promises beer with very good foam stability.

Alternatively, heating can also be carried out with low-pressure steam.

The novel guidance of the heated wort below the wort surface in the kettle leads to an improved expulsion effect and thus achieves maximum evaporation efficiency with only 2 % total evaporation. The relaxation vaporization indicated by steam bubbles in Figure 3 “wort boiling” leads to

effective outgassing of undesirable flavorings such as DMS. Excellent low values of this off-flavor were determined in worts at end of boil (11 µg/l, Tab. 1).

Hot trub separation is achieved by means of the classic whirlpool function. The vessel geometry is optimized for high hop loads to enable good trub separation with minimal wort losses.

Due to the vessel combination of mash-lauter tun with a whirlpool-kettle, a very fast brewing rhythm is achieved. The total occupancy of the mash-lauter tun is approx. 4 hours due to the extremely fast lautering time of only 60 minutes. The occupancy time of the whirlpool-kettle is well below 4 hours. Another advantage for the brewing rhythm is that the product is only ever

transferred from the mash-lauter tun to the whirlpool-kettle, so that the two vessels do not block each other during loading, as is the case with the classic combination of mash and wort kettle with lauter tun. In contrast to a conventional 2-vessel brewhouse with a mash/ wort kettle, the next brew can already be mashed in the new compact brewhouse during wort boiling.

For a beer with an OG of 12 °P, a brew rhythm of 4 hours can be assumed. For a comparable brew rhythm of a conventional brewhouse, two additional vessels, a separate mash kettle and a separate whirlpool are required. The total duration of a brew in the new concept is even shorter than in the classic 3-vessel brewhouse plus whirlpool, since heating is already started during lautering via the external boiler.

In addition to the new external boiling system, the basis for the minimal energy consumption is the integrated energy management system.

The combination of a low evaporation rate ≤ 2 % and energy recovery allows the thermal energy requirement in the brewhouse to be reduced to below 4 kWh/hl.

The core of the energy management system is the recovery of wort cooling energy at the highest possible temperature using fresh brewing water. This energy is stored in a high-temperature stratified brewing water tank at two temperature levels. Likewise, the thermal energy from wort boiling is recovered. The higher temperature water of approx. 96 °C is available for direct infusion to the mash.

The water stored at 80 °C is used for mashing in and sparging. As mentioned above in the text, the infusion process can be flexibly supplemented with decoction. In this process, the partial mash is heated by means of an external heat exchanger and largely with recovered energy.

With a heating water flow temperature of only 109 °C at the external boiler, renewable energies can be flexibly used for wort boiling, for example standardized and therefore cost-effective pellet or wood chip heating systems from regular building services and equipment suppliers. The use of solar thermal and power-to-heat is also possible.

The new compact brewhouse achieves up to 6 brews per day with 60 minutes of lautering time by combining a novel mash-lauter tun with a whirlpool-kettle. The conical lautering surface not only allows very fast lautering with good yield, but also impressive flexibility in the grist load. Together with the small footprint, the brewhouse offers ideal conditions for micro and small breweries with an output of up to 150,000 hl per year.

The simple concept with only two vessels and the prefabricated frame units offers a clear advantage in investment costs compared to classic brewhouse systems, while at the same time requiring low maintenance. The low thermal power requirement and low energy consumption also make the system extremely attractive in terms of operation and investment in an energy supply system. Last but not least, the award-winning beers from the first plants show that first-class beers can be brewed with it.

Mitterhofer, G.; Moser, G.: Klein, aber oho! – Neuartiges Brausystem, 6 (2017), BRAUWELT

Banke, F.; Reuber, V.; von Terzi, K.: Compact brewhouse with high energy efficiency, VI (2023), BRAUWELT INTERNATIONAL

Banke, F.; Nuber, C.: AlloySius – Vom Vormaischer zum Maischefertiger, 28 (2007), BRAUWELT

Authors

Friedrich Banke, Dipl.-Ing. (Process Technology) CEO

Steve Grundy

Korbinian von Terzi, Dr. rer. nat. (Brewing and Beverage Technology) Head of R&D / Technology banke GmbH, Gewerbering 2, 84416 Taufkirchen (Vils); office@banke.de Top5-solutions

EVERY FIRST WEEKEND OF SEPTEMBER, THE BELGIAN BEER WEEKEND BEER FESTIVAL IS HELD WITHIN THE GRAND PLACE OF BRUSSELS.

SO WHO BETTER THAN OUR RESIDENT BELGIAN BEER EXPERT PAUL DAVIES TO TELL US MORE?

On the Friday, Saturday and Sunday large and small brewers present their beers for tasting in one of the most beautiful settings imaginable. Expect new release beers, street food, music and much more. The festival opens its doors to the public at 6pm on Friday but a more significant celebration takes place earlier in the day.

The Feast of St Arnoldus is celebrated each year on 14th August. A special celebration is organised by the Belgian Brewers at the beginning of September at the Cathedral of Saint Michael and Saint Gudula when the Ridderschap van de Roerstok (Knights of the Brewers’ Paddle) proceed through Brussels from the Brouwershuis to the Cathedral behind a cask of beer.

The beer is then blessed with Abbot Erik de Sutter from Abdij Grimbergen and Pere Bernard Lorent from Abbaye de Maredsous conducting the ceremony. Hymns accompany the ceremony by the Sine Nomine choir with the Limburgs Trompetkwartet providing musical accompaniment. Homage is given to those members of Belgian Brewers who have passed away over the twelve months.

At the end of the ceremony the beer is processed out of the Cathedral and to the Town Hall on the Grand Place. Speeches are presented during an academic session, drawing attention to the current situation with the Belgian brewing industry and we enjoyed some interesting debate on how politicians would be able to assist in developing the industry and some discussion around current trends with the

emergence of no and lo alcohol beers debated at length. During the session there was also an enthronement ceremony of the Knighthood of the Brewers’ Paddle when two new honorary members were inducted.