Hello, and welcome to the latest edition of The Brewers Journal! So that was summer then, I suppose? The weather was…indifferent but the same can’t be said for the frankly brilliant beers poured at the wealth of excellent beer festivals we were blessed with over those socalled summer months. I hope they were a productive and fruitful experience for all of you.

Here at The Brewers Journal we’ve been incredibly busy, too. In addition to our magazine and podcast we have launched our new video interview series. We’ve also hosted our Brewers Lectures in Leeds, Nottingham, Bristol and, most recently, Newcastle.

And as I always explain during those events, in what’s obviously a challenging time for beer, brewing and, of course wider hospitality, I feel that being able to meet up, enjoy each other’s company and celebrate all of the fantastic work taking place in this sector is truly important.

And when we talk about the fantastic work happening in beer, we look forward to doing that once more at our upcoming Brewers Congress in London! It’s taking place on the 18th and the 19th October at The Business Design Centre in Islington. As you’ll see in this edition of the magazine, we have two days of talks, trade exhibits and excellent beer. So I want to say a huge thank you to our speakers, panellists, everyone planning to attend this year, as well as the wealth of best-inclass exhibitors and also our sponsors.

A central part of this event is, of course, our Brewers Choice Awards. It’s our annual celebration of the brilliant talent this industry boasts. At the end of the summer, judges from across the brewing spectrum once again converged on The Red Lion in Barnes, London, to debate and discuss the excellent entries submitted for the 2023 iteration of the awards. The winners of which, will be crowned in London this October with tickets available online. The categories up for discussion were Young Brewer of The Year, Brewer of The Year, New Brewery of The Year, Brewery of The Year, New Beer of The Year, Beer of The Year, Branding of The Year, Lifetime Achievement and Global Ambassador.

You can read more about those excellent brewers and breweries in our shortlist spreads in this edition, with the winners announced on the evening of the 18th October. Best of luck to all involved!

You can rely on us to continue to champion the fantastic brewing industry and all related to it. Our eyes and ears are always open for how we can better serve this unsurpassable sector.

I hope you all have a fantastic autumn and a successful second half of 2023. Thanks again and best of luck in all that you do.

Tim Sheahan Editor

Comment | Alcohol duties and tax

Dan Finn — corporate solicitor and lead of Brabners’ specialist breweries and beverages team — sets out the new rates and what sole traders and limited companies need to know.

Comment | Greener brewing

For breweries looking to the future, there are wealth of issues to consider when it comes to energy usage, explains George Webb, Liquid Gas UK’s CEO.

Comment | Labelling

Great beer, great branding and great packaging make for a great trio. here vale labels offer some advice on how to ensure your beer looks the part on the shelf.

Dear John

Fuller’s Vintage Ale is a special beer for many, and John Keeling is no exception. recently he had the opportunity to take this revered beverage on the road for a number of tastings across the UK. This is how he got on.

Brewers Intelligence | Autumn

The latest insights from the world of hops, malt, sales and yeast.

Brewers Congress 2023

All you need to know about this year’s event from the leading speakers and panelists, to the bestin-class exhibitors and the brilliant talent on the shortlist of our 2023 Brewers Choice Awards.

Homebrewing

Alex Redpath, the head brewer at Full Circle shares his homebrewing story and also a treasured recipe, too.

78

Technology | Canning

The products and services available that can help you kick-start your canning journey.

83

62

The Future of Craft Beer As craft transitions from high growth to saturation, the key to success is to double down on what makes your brand, and craft, special, argues Luca Lorenzoni.

Tim Sheahan Editor tim@reby.media

+44 (0)1442 780 592

Melissa Cole Contributing Editor

Tim O’Rourke Technical Editor

John Keeling Contributor

Josh Henderson Head of sales josh@reby.media

+44 (0)1442 780 594

Jon Young Publisher jon@reby.media

Reby Media 6 Grove Road, Hemel Hempstead, Herts, HP1 1NG

The Brewers Journal is a published four times a year and mailed every March, June, September & December. Subscriptions can be purchased for four issues. Prices for single issue subscriptions or back issues can be obtained by emailing: subscribe@ reby.media

UK & IRELAND £29 INTERNATIONAL £49

The content of The Brewers Journal is subject to copyright. However, if you would like to obtain copies of an article for marketing purposes high-quality reprints can be supplied to your specification. Please contact the advertising team for full details of this service. The Brewers Journal is printed at Manson Group, St Albans, UK.

67

Meet The Brewer | UnBarred UnBarred Brewery of Brighton, on living to inspire discovery through boundless creativity.

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording or any information storage or retrieval system, without the express prior written consent of the publisher. The Brewers Journal ISSN 2059-6650 is published bimonthly by Reby Media, 6 Grove Road, Hemel Hempstead, Hertfordshire, HP1 1NG. Subscription records are maintained at Reby Media, 6 Grove Road, Hemel Hempstead, Hertfordshire, HP1 1NG.

The Brewers Journal accepts no responsibility for the accuracy of statements or opinion given within the Journal that is not the expressly designated opinion of the Journal or its publishers. Those opinions expressed in areas other than editorial comment may not be taken as being the opinion of the Journal or its staff, and the aforementioned accept no responsibility or liability for actions that arise therefrom.

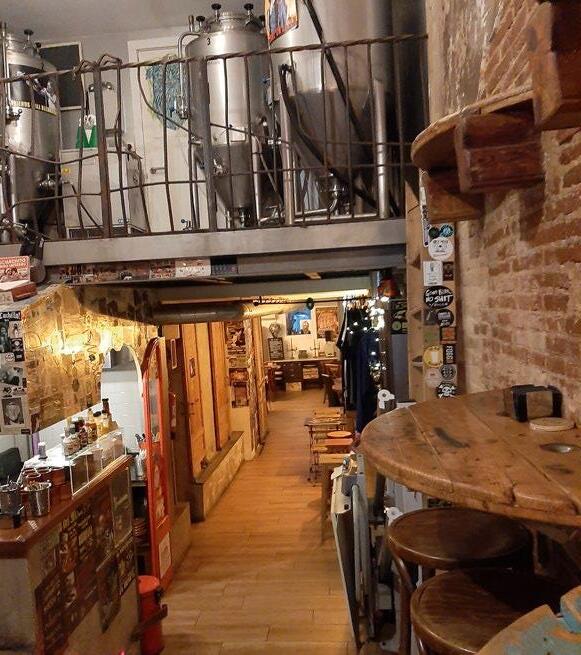

The Beer of Barcelona Paul Davies us on a comprehensive tour of the Catalan capital.

What do we do about the fact that so many of our historic brands are in foreign hands?

Don’t get me wrong, I don’t mean this in a jingoistic way, it’s simply that cask and real ale brands are mostly anathema to the majority of the rest of the world, and that means we’re losing important parts of our brewing heritage, as a result of them falling into foreign hands, says Melissa Cole.

For over four years now, I’ve been asking questions about Worthington White Shield and have been met with a wall of silence, so the latest ‘pause’ surprises me not at all, but it does upset me; brands like White Shield are a living part of our history, even if it’s attached to the fairly ugly colonial bit, and are something to be treasured and celebrated, not sold off wholesale to the highest bidder. As someone who is firmly caught in the capitalist cycle, I am not stupid enough to think that these things don’t happen, but if we are to learn anything from the current state of our waterways, power suppliers and railways, if the things that are important stay in our hands, we can control them, if it stays down to shareholders with no emotional or historical stake in them, we are in trouble.

The big takeovers of Bass and Whitbread happened almost right at the beginning of my career, and my then mentor, Mike Bennett (who broke the Bass story before even the nationals got hold of it), was sounding the alarm about the inevitable running down of traditional brands that may have been sitting slightly on the margins at the time, but perhaps what even he couldn’t have foreseen was the wholesale destruction of popular and profitable brands within such a short timeframe.

To be clear, this isn’t taking aim at just Molson Coors, ABI managed to destroy Boddington’s in next to no time (please don’t talk to about what it is they serve in America, it remains one of the most depressing beers I’ve ever drunk), and holds in its hands other historic brand IP like Mackeson Stout, Flowers Best Bitter and Flowers IPA, along with goodness knows what else, it’s pretty hard to find out - and that in itself is simply ridiculous.

Not to mention the fact that the stranglehold they have in tied houses and with contracts elsewhere, has undoubtedly contributed to the demise of cask ale in the UK, why waste time training people on a ‘living organism in the cellar’ when you can just sell them something that’s significantly more ‘plug and play’.

All of this said, I do have some hope about the White Shield situation, as Molson Coors does have a history of outsourcing production of brands like Stones Bitter but if there wasn’t such an outcry, would they even bother? I’m sure their shareholders wish they wouldn’t.

And whilst I wouldn’t be stupid enough to say that I have all the answers, what I do know is we can’t just sit back and wring our hands about this niche form of cultural vandalism, we have to make loud and prolonged noise about it, or we’ll be kissing, or perhaps sipping, them goodbye.

Anglia Maltings Holdings (AMH), of which Crisp Malt is part, has announced its commitment to Net Zero by 2045 and has launched our inaugural Sustainability Report.

The report outlines their Sustainability Strategy, which is guided by the UN Sustainability Development Goals and by the company purpose and values. It lays out the goals for AMH’s three businesses – maltsters, Crisp Malt; food ingredient producers, EDME; and cereal processors, Micronized Food Products – and the plans for achieving them.

Significant inroads have already been made. Electricity across the company’s UK sites is from 100% renewable sources. The adoption of best techniques, including heat exchangers and CHP (combined heat and power) systems, ensures that CO2 emissions are minimised. There is very little waste. Co-products from processing, for example, go to animal feed. Plus, the location of Crisp’s UK sites in the heart of the country’s best cereal growing regions, ensures the minimalisation of HGV food miles.

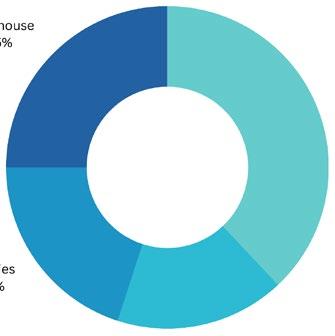

On premise drinks sales bounced back into year-on-year growth last week— ending a run of five weeks of negative numbers.

CGA by NIQ’s Daily Drinks Tracker shows average sales in managed venues in the week to Saturday (19 August) were 5% ahead of the same period last year. The return to growth follows a challenging late July and early August, when cool weather kept many consumers away from pubs’ beer gardens and terraces. However, trading improved in line with the temperatures last week. There was a particular surge in sales in midweek, with Tuesday (up 10%), Wednesday, which was boosted by England’s semi-final victory over Australia (up 17%), and Thursday (up 15%) all in double-digit growth—but trading was more modest on Friday (down 3%) and Saturday (up 4%) as rain moved back in.

Warmer weather lifted the beer category, where sales rose 10% year-on-year. Wine (up 9%) and cider (up 1%) were also posi-

tive, but soft drinks (down 2%) and spirits (down 4%) were both negative.

Award-winning North London based Hammerton Brewery is launching its popular core range Nitro Stout favourite TINT in cans using Widget technology. Last year Hammerton released their Nitro Dry Stout on draught and it quickly became their biggest selling stout and moved into their core range. Since that time they have heavily invested in research and development to expand their knowledge and capabilities with Nitrogen technology by investing in a liquid nitrogen tank and nitrogen doser for their canning line and have been carrying out R&D using widget cans for the last 12 months. They are now believed to be the first English brewery to can a Stout using widget cans.

Co founder Lee Hammerton said: “Myself and our brewers, have always enjoyed being innovative and trying new and challenging projects when it comes to brewing beer.

“Due to the popularity of TINT, our Nitro stout and a long term ambition to be able to produce a Nitro Beer in can using Widget technology we decided that we would try and achieve the ambitious task of being able to put our much loved dry stout in widget cans.”

Timothy Taylor’s chose to work with Thornbridge for the first collaboration beer in their 165-year history to create Artesian, a refreshing Elderflower and Gooseberry Pale Ale, ideal for summer refreshment.

The two breweries have long admired each other’s approach to cask and craft beer respectively, with Landlord and Jaipur both being widely regarded as the pioneers within their respective categories, and both having won more awards than any other beers.

The brewers’ mutual knowledge and passion led them to brew a style of beer that could be showcased in the more traditional cask format for pubs, but also enjoyed in keg format in bars and

restaurants and from cans at home. The Artesian collaboration with Thornbridge comes just five months after Timothy Taylor’s Hopical Storm became its first beer to be launched in can.

The total number of breweries in the UK has risen in the second quarter of 2023 according to new figures released. The latest data from the SIBA UK Brewery Tracker covering the period from the start of April 2023 to the end of June 2023, shows the net brewery number across the UK grew slightly (by two) over that three-month period.

“Seeing the net brewery number rise across the UK is not only a sign that confidence in the sector remains, but that the demand for quality locally made beer continues to rise.

“However there has been a significant number of brewery closures and change of ownership, with some consolidation and buyouts alongside new businesses opening. So whilst modest growth is ahead of expectations and common perception, it’s not quite the overly positive picture that the headline figures paint,” said Andy Slee, SIBA Chief Executive. The new opening figures highlight the consumer demand for craft beer and the growth in popularity of brewery taprooms, with recent consumer polling showing eight out of ten people believe a well-run independent brewery has a positive effect on its local community* –and that community-spirit is a sentiment shared by brewers, with 98% of SIBA brewers saying they consider their local community to be important to them.

Yorkshire’s multi award-winning Acorn Brewery is set for growth with a change of ownership at the 20-year-old Barnsley brewery.

Launched in 2003 on an ex-Firkin 10-brewers-barrel plant, Acorn’s caskales quickly gained renown to see expansion to a 25-barrel brewery in Wombwell.

Now there is the capacity to produce 170

brewers-barrels (278 hectolitres) a week with annual turnover of some £1m. The directors Dave and Christy Hughes have decided that new ownership is needed to take the business forward. The brewery has been sold to Sonas Capital; a Greater Manchester based company specialising in developing successful small businesses (SMEs).

With the sale, the employment of the seven strong brewery team has been secured and a general manager will be recruited. Founder Dave Hughes will continue in a consultancy role for the forseeable future while Christy will take retirement, due to recent ill-health.

The Portman Group has farewell to Nicola Bates, who after five years as director of strategy and external affairs has been appointed as the new chief executive of WineGB – the trade association for English and Welsh Wine and will leave the Portman Group in October.

Commenting, Portman Group chief executive Matt Lambert said: “Nicola has been a pivotal part of the team over the last five years, shaping the Portman Group’s voice as the UK alcohol marketing regulator and torchbearer of the industry’s ongoing commitment to social responsibility.”

The Portman Group said it is also pleased to announce that David Saer, the current head of policy and public affairs, will become the group’s new director of external affairs in October 2023.

Joining in 2019, David has led the Portman Group’s thought leadership on alcohol policy and engagement with policymakers across the UK. Tfrom a diverse range of sectors including food and consumer goods, aerospace ana biopharmaceuticals. Commenting, Lambert said: “I look forward to seeing David bring this extensive experience to leading the external affairs team, as the Portman Group continues to champion and challenge the alcohol industry to uphold the highest standards of responsibility.”

The longstanding ‘freeze’ on alcohol duty came to an end in August. Alcohol duty is now expected to rise with inflation (running at about 10% per annum at the time of writing). To soften the effects of these increases — and as part of a new ‘Brexit pubs guarantee’ — the Draught Relief scheme will theoretically increase the profitability of alcoholic drinks sold in pubs. However, whether this will cancel out the duty increases is a different story. Beer is liable for duty as soon as it is ‘produced’ or fit for consumption — yet the amount of duty paid depends on the alcohol’s strength and the quantity of beer being produced.

The new rate of duty applicable to beer produced with an ABV of 1.3% to 3.4% is £9.27 per litre of pure alcohol. For beers at 3.5% to 8.4%, this rises to £21.01. Beers with an ABV of 1.2% and below attract no duty, which may encourage some brewers to turn their hands to micro IPAs and non-alcoholic options. Furthermore, small brewers (those independently producing no more than 4,500 hectolitres of pure alcohol) will qualify for ‘small producer’ relief, which will reduce the rate of duty. Excise duty is also payable on alcoholic beverages being exported to EU countries. Since Brexit, breweries may also need to register for VAT in the EU member state they supply beverages to (being mindful that VAT rates differ across member states). Extra care should be taken to ensure that the taxation rules of each member state exported to are followed and that the tax for each member state is paid correctly. As a brewery, the tax you pay on profits made from beverage sales depends on the structure of your business (for example, whether you operate as a sole tradership or limited company). Sole traders are personally required to pay tax on profits earned, while companies are taxed as separate legal entities. In practice, many breweries start life in sole tradership form and later incorporate when the business has started to generate revenue and

perhaps needs to take on new liabilities such as employees, property leases and third-party loans. Since there is no separation between owner and business, sole traders pay income tax and National Insurance Contributions (NICs) on profits. In contrast, a company structure means that the business pays corporation tax (currently at 19%) on profits. However, income tax is then payable on the salaries received by founders and employees.

Shareholders of the business are also eligible to receive dividends (which could be paid as a top-up or in lieu of salary) in respect of their shareholding — which attract slightly lower tax rates than income tax and are also NIC-free for both the employer and employees. Being able to incentivise employees by granting shares and/or share options can be a significant benefit of running the business through a limited company structure, rather than operating as a sole tradership — but it’s worth noting that tax charges can arise on the issuance of shares to employees. To the extent that any shares (but not options) are gifted or issued for less than the market value, that discount will be taxed as a benefit in kind and the employee would pay an income tax charge on the difference between the market value and the price (if any) that they have paid for their shares. However, there are likely to be options available that can minimise the tax charges for both the brewery and relevant staff receiving the shares. In some cases, this might also provide an associated corporation tax relief on profits. Tax charges will arise on the sale of your brewery business or its assets, assuming that the brewery or assets are being sold for a profit. Sole traders will pay capital gains tax (CGT) on the profits made from selling the brewery or assets. Similarly, shareholders will pay CGT on the sale of their shares in the brewery. However, Business Asset Disposal Relief can be claimed in either of those scenarios - subject to certain conditions - to reduce the rate of CGT payable from 20% to 10%, subject to life time limits.

UK PRIME MINISTER RISHI SUNAK CALLS IT

“THE MOST RADICAL SIMPLIFICATION OF ALCOHOL DUTIES FOR OVER 140 YEARS”

— BUT HOW WILL THE NEW RATES OF ALCOHOL DUTY AFFECT THE TAXES PAYABLE BY OUR BREWERIES AND THEIR SHAREHOLDERS?

HERE, DAN FINN — CORPORATE SOLICITOR AND LEAD OF BRABNERS’ SPECIALIST BREWERIES AND BEVERAGES TEAM — SETS OUT THE NEW RATES AND WHAT SOLE TRADERS AND LIMITED COMPANIES NEED TO KNOW.

Brewing is an undeniably energy-intensive industry, and with UK Government pushing forward with plans to decarbonise the economy across all sectors, all brewers are considering how they use energy, and where their energy comes from. For breweries located off the mains gasgrid, options for a greener future may seem limited, but renewable liquid gases (RLGs), such as bioLPG and rDME, have secured approval from the Government to be developed at scale and will be coming onto the market in the coming years.

With the cost and efficiency of electricity being a prohibitive factor for some brewers, bioLPG and rDME will offer a ‘drop in’ solution. This means no changes or recommissioning of the brewhouse will be required given these new green fuels are chemically identical to conventional liquified petroleum gas (LPG).

The key difference however is that the new RLGs are produced from sustainable feedstocks rather than traditional fossil fuels, offering up to 90% carbon emissions reductions or even carbon negative when carbon capture and storage is used in their production. Energy in brewing is broken down into two primary units – thermal to generate heat or steam, and electrical for power. While energy use in breweries varies depending on size, location and types of beers produced, well over a third of the total energy used in most breweries is spent on boiling the wort.

As the brewing process is complex, with brewers requiring flexibility from day to day in brew schedules, and with heat used in several stages, a versatile and reliable fuel source is needed. Although boilers run on a range of fuels, options can be limited for the significant proportion of the UK’s regional breweries operating off the mains gas grid.

[CROSSHEAD] Liquefied petroleum gas (LPG) [CROSSHEAD]

Currently, the most efficient fuel for

off-grid heat is LPG.Not only does LPG provide an instant, efficient heat source, it also offers reduced emissions compared to solid fuels.

As the brewing sector strives to use more renewable energy, the liquid gas industry has a solution. CEO of trade association Liquid Gas UK, George Webb, explains: “While LPG is already considered a cleaner fuel choice, we recognise it doesn’t go far enough in tackling climate change, which is why the liquid gas industry launched its ambition to transition to 100% renewables by 2040, in order to meet net zero.”

He adds that a cleaner fuel source in the form of RLGs will soon be available for off-grid industries and properties.

“Made from a diverse mix of sustainable biological feedstocks and processes, RLGs are chemically identically to LPG and considered a ‘drop-in’ solution,” says Webb.

RLGs offer up to a 90% reduction in carbon emissions and carry the same low nitrogen oxides (NOx), sulfur oxides (SOx) and particulate matter as conventional LPG, contributing to cleaner air quality.

“Because they’re chemically identical, RLGs can be used with existing tanks and appliances,” he adds.

FOR BREWERIES LOOKING TO THE FUTURE, THERE ARE WEALTH OF ISSUES TO CONSIDER WHEN IT COMES TO ENERGY USAGE, EXPLAINS

GEORGE WEBB, LIQUID GAS UK’S CEO.

”They also improve energy security by reducing our reliance on imported fossil fuels, which was a big concern for the brewing industry last year.”

In August this year, the Government published the long-awaited Biomass Strategy. Biomass is part of the Government’s renewable energy strategy and its ambitious plan to accelerate the decarbonisation of the economy across all sectors.

Central to achieving net zero by 2050 is the transition to wide-scale adoption of low-carbon technologies.

Importantly, the Biomass Strategy recognises the role of RLGs to decarbonise heating and meet net zero targets.

“The inclusion of RLGs in the strategy not only gives the green light for LPG producers to ramp up domestic production, but it also averts the potential scenario of increased operational costs that brewers would’ve faced if the transition to electrified heating was enforced,” explains Webb.

“We’re pleased the Government signalled

their support for RLGs and the important role they play in the future off-grid energy mix in the Biomass Strategy.

“It’s great to know customers can now opt for this low-carbon ‘drop-in’ solution – avoiding unnecessary costly retrofits and appliance changes at a time when finances are tight for so many.”

He explains that, for brewers, the prospect of replacing direct or steam boilers to suit electrified heating elements would have required significant capital investment and greater ongoing costs.

“It would also mean a shift to a heating source that doesn’t offer the same reliable level of control or heat consistency as LPG. This could have affected the quality and consistency of the beer being brewed.

“If multiple industries had to switch to electrification, we’d also see issues with the electricity grid being unable to meet demand, particularly in more rural areas, so it’s a comfort for brewers to know that LPG and RLGs are a futureproof fuel they can continue to order and use with

confidence,” he goes on.

He adds, to date, the industry has invested more than £260 million in developing and deploying RLG solutions, with a further £600 million investment forecast over the next two years.

As the demand for biomass sources increases, Webb points out that brewers may be able to monetise their spent malt and hops with a biomass processing company, which could provide a new revenue stream and a circular solution which could see these feedstocks return to the brewery in bioLPG or rDME tanks as new fuel.

Liquid Gas UK is the trade association for the LPG and renewable liquid gas (RLG) industry in the UK, representing a membership of companies who are LPG and RLG producers, distributors, equipment manufacturers and service providers.

It goes without saying that a label is the most important part of any bottle or can, as it sets out your identity as a brewery and gives customers key information about the amazing beer they are drinking. Whilst it may seem a simple process at first, printing that label, with the best finish and value for your beer brand, can be a challenging process.

So, whether you’ve got a new design or want to improve your current label, we have created a quick guide to help you pick the right material, reduce your costs and meet sustainability targets. If you want to find out more about our label printing service, you can talk to our team on stand 301 at this year’s Brewers Congress.

Picking the right material and finish depends on whether you are using a bottle or a can. Protective shoulders on bottles help to protect your labels from scratching and scuffs during filling and transport.

This gives you access to a wider range of materials beyond traditional polypropylene including semi-gloss and textured paper stocks.

These shoulders also allow you to use a variety of enhancements to help your brand stand out, including foiling which adds metallic elements to your labels and embossing which creates raised areas of text or imagery across your prints.

Cans on the other hand, limit your choice of materials as there is no shoulder to protect your label stock.

With this in mind, it’s mostly recommended you use a plastic based facestock such as PP or PE, as this is more resistant to rips and scratching on canning lines and in transport. Historically, this would need to be coupled with a laminate to ensure that print is protected, doubling the material cost of your label.

However, we has recently invested in print technology that doesn’t need the lamination layer due to the durability of the inks. This helps to keep your cost as low as possible.

There are also options to enhance the look of a can label. For example, silver PP will allow you to add metallic elements to your labels and textured varnish will give your product a unique tactile feel.

There are a variety of printing methods used in the production of labels, with some requiring set up plates that increase your initial cost. These plates can reduce your flexibility in the long run as you may need to purchase a new one each time you make an amendment to your label.

As a digital printer we don’t use set up plates for standard print. This means you pay lower set up fees than those associated with traditional printing methods and have full flexibility to amend your labels at any time without incurring extra costs.

We also have no minimum order quantities – giving you flexibility on how many labels you order. However, as with

There are options available to enhance the look of a can label

any printer, the cost of the label reduces as the quantity increases.

So, the best way to reduce your cost is to try and bundle as many label types together into a single order.

Over the last few years there has been lots of innovation across the print industry to help brands meet their sustainability targets.We have a wide variety of these materials and innovations to choose from. This includes the use of recycled stock across a range of materials including papers and plastics.

The switch from standard to recycled materials can significantly decrease the amount of greenhouse gasses, water and virgin materials that go into the production of your labels.

Detachable labels can also support the reuse of bottles. We now offer a textured paper that detaches when washed at high temperatures, ensuring your label and branding remains intact at point of sale, but still supports reuse. All the paper labels offered by Vale Labels are also FSC approved. This means that these paper products come from suppliers that meet strict environmental, social and economic standards.

Last year we decided to expand our business to provide a unique opportunity to become a service provider within the beverage industry. For many years we have been providing solutions to major blue chip companies around the world for cleaning systems and solution solvers. In 2022 Easi-Keg Solutions was launched.

We reached out to the major players within the keg and cask cleaning Industry and asked them what was missing and what is required. With their input we have now designed and provide mobile and onsite key solutions for Keg and cask cleaning.

To make this work we required some key players to come on board with our vision and help to operate and bring new ideas within the keg cleaning world. We are delighted to announce Andy Pollard joined us in 2023 who has a wealth of knowledge within this industry and is now the Operations Director for Easi-Keg Solutions.

In 2021 we had a unique opportunity to bring on board one of the most respected mechanical and design sales engineers within specialist cleaning systems. Simon Barnes, now Sales Director for Easi Keg Solutions, has worked closely with our design engineers in making this happen. Simon is always pushing to look into the future and listening to what the customer wants, and how things can be made more efficient or cost effective using new technology.

Currently we are working on new technology which will completely change Keg and cask cleaning, a process which has not been seen before.

We have recently acquired a new location for our own Keg and Cask cleaning services with the most up to date cleaning technology. We can also provide storage, repair, modification and rebranding.

This is our first year at The Brewers Congress 2023 - October 18th and 19th. We are looking forward to everyone coming to see us on Stand 605, if you are able to attend.

easi-keg.com

Ihave talked about Vintage Ale in the past. In those pieces I explained the reason why and how Fuller’s came to brew these beers. I talked about how we choose the ingredients each year and how we brew and process this beer for aging. Indeed, one of my points was the importance of time on the development of flavour in these beers.

Unfortunately, because of the rarity and price of these beers not everybody gets the chance to try different ages released over the years.

I have done a number of vertical tastings of the Vintage Ale, but these have been mainly for beer writers and influencers. I have always wanted to take Vintage Ale out to tastings for people who are interested in them or just interested in Fuller’s as a brewery.

I was discussing this in Edinburgh with my friend Chris Mair and whether it could be done. I had in fact done one of these at The Hanging Bat some years ago when Chris ran the pub. This came about because Chris was up for it and Fuller’s were willing to support this despite the beers being rare and valuable.

I remember the evening going very well and Chris had got a good crowd of people in. Mind you, drinking 8.5% beer all evening is usually conducive to a good time.

I wondered if other places would like to do these tasting. Chris immediately said yes and straight away got the ball rolling.

Chris contacted a couple of breweries - North Brewing in Leeds as well as Wiper and True in Bristol. Both were very enthusiastic, and this now meant I had to do something about this.

I had to persuade Asahi to supply the beer free to the tastings and to do that I

had to get them to understand the value of doing this, too. Well, that turned out to be no problem at all, Asahi thought it was a great idea and Ben Aisbitt who is my contact immediately started looking at the Vintage stock levels to see which were the best ones for the tasting.

I thought that we should do a warmup tasting in Edinburgh which is where Chris is based, Chris suggested Cloisters should host and we booked a date with them.

Ben was going to supply Vintages 2022, 2019, 2016, 2015, 2000 and 1999. I suggested sending some cask beer, to see if Fuller’s was still popular in Edinburgh. So, Ben put a firkin of ESB, London Pride and IPA on the order.

Cloisters managed to get 22 people to buy a ticket so there were no more excuses, and I booked my tickets and hotel. Ben and his wife came along, too. It was a great event; and these events really are made by the people that turn up. One person, Craig Garvey, was at the original tasing at the Hanging Bat. I noticed that the Fuller’s cask beer was going down well too, and some people were taking pictures of the pump clips!

The next event was to be at the North Bar. I wanted Guy Stewart, the current Fuller’s head brewer to join us. Once I told North this, they wanted to do a collaboration beer too. Chris had gone straight to the top and had contacted Christian Townsley, one of the founders of North, who was an enthusiastic supporter of this event.

Seb Brink their head brewer started the ball rolling regarding the collab. We originally wanted to do a mild but we then changed our plans and opted for a sparkling ale.

FULLER’S VINTAGE ALE IS A SPECIAL BEER FOR MANY, AND JOHN KEELING IS NO EXCEPTION. RECENTLY HE HAD THE OPPORTUNITY TO TAKE THIS REVERED BEVERAGE ON THE ROAD FOR A NUMBER OF TASTINGS ACROSS

THE UK. THIS IS HOW HE GOT ON.

The North Bar managed to get twenty odd tickets sold. The North Bar is a great place to do these events, as it’s right in the heart of Leeds.

Again, this was a fun evening and with Guy on hand to take the pressure off me I was able to sit back and enjoy it too. The next day we went to the brewery to make the collab. So, I was able to have a cup of tea, a couple of pints and a pizza whilst the brewers did the work. I am sure my words of encouragement were a great inspiration to them. The beer turned out to be really good too which shows that me looking over everybody’s shoulder really works.

Unfortunately for the next event in Bristol at Wiper and True Guy could not join me. So, I had to fly solo for this one. Again, Chris had gone straight to the top and had asked Michael Wiper who had readily agreed to host an event. We were booked in at the Wiper and True Barrel store at St Werburgh and it had

sold out. No pressure then but remember 8.5% beer is very conducive to a good time. Great crowd and a great event.

The next day I had a great tour of the brewery. I can say that both breweries North and Wiper and True were spotless and great examples for good design. No wonder they make great beer. Next, Beverly who is The Fuller’s Brewery Shop Manager contacted me and asked if I would do a tasting with Guy at the shop.

Naturally I said yes. The event was really well organised with each table having cheese and ham to try with the beer too. I must admit the Chiswick audience was the politest but maybe that was because the beer demanded their full attention - it certainly wasn’t the ability of the presenters.

I will have to find some more breweries who can host these events. Have beer will travel is my new motto.

Mind you, drinking an 8.5% beer all evening is usually conducive to a good time.”

Tropical flavours. Fruit bomb beers. Unlocking bound thiols. These are buzz phrases often tossed around whenever the topic turns to biotransformation.

In reality, biotransformation of hop compounds by yeast strains in beer is a fascinating and multifaceted process – one being embraced with great excitement and enthusiasm.

Brewers are right to be intrigued, given the clear potential to optimize the use of hops and create evermore diverse and desirable beers.

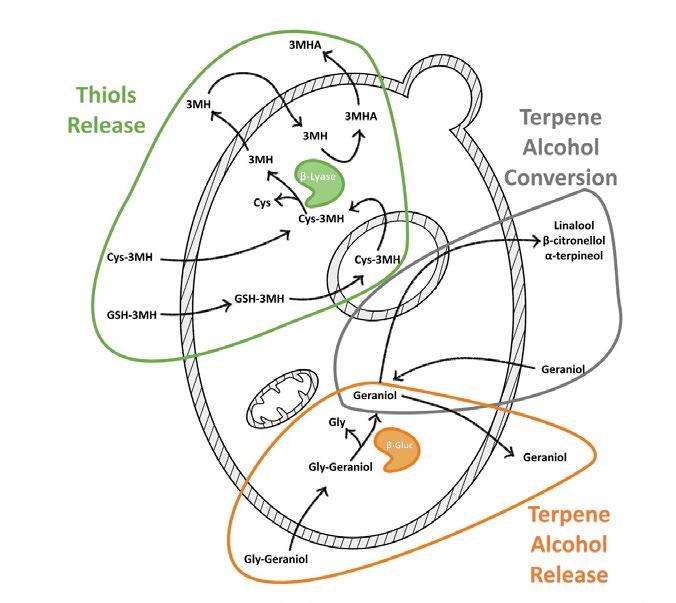

During fermentation, biotransformation occurs when some yeast-derived enzymes convert odorless and flavourless hop precursors into desirable flavours and aromas (Fig.1), making it particularly relevant for popular styles like the juicy and fruity IPAs. Research on this subject is constantly emerging, with much of the knowledge being borrowed from the wine industry. This complex process involves three main reactions: i) Terpene alcohol release and ii) conversion, and iii) Thiol release.

The main contribution of biotransformation to the final beer is the release of flavour active molecules, like monoterpene alcohols and thiols, from their non-aromatic precursors performed by two yeast-encoded enzymes, β-glucosidase and β-lyase.

The conversion between different hopderived terpene alcohol, like geraniol and linalool, can also moderately contribute to the final product flavour profile. This process, though not fully understood, is also thought to be enzyme mediated.

The enzyme β-glucosidase releases the aromatic terpene alcohols from a nonaromatic glycoside precursor, such as

geraniol from geranyl glycoside. This enzyme is not produced by most brewing strains, being more commonly present in yeast of the Brettanomyces and Pichia genus, thus the impact of this enzyme is reduced in most beers. Furthermore, the terpene alcohols flavour threshold is reasonably high (ppm to ppb), so a considerable amount of molecules need to be released into the beer before its impact is perceived. For that reason, the main focus of brewers and winemakers all around the world is in the reaction performed by the enzyme β-lyase, also known as cysteine S-conjugate beta-lyase. During fermentation, this enzyme

releases volatile thiols that contribute notes of passion fruit and grapefruit from precursors present in malt and certain hop varieties.

Unlike terpene alcohols, these volatile free-thiols can be detected at extremely low levels, in the parts per trillion range, so any small increase is likely to be detected by the consumer. Some of these compounds, namely 3-mercaptohexan-1-ol (3MH), 3-mercaptohexyl acetate (3MHA), and 4-methyl-4-mercaptopentan-2-one (4MMP), are known to contribute tropical qualities to the beer aroma. Not all yeasts are created alike, and only

yeast strains that present a functional version of the IRC7 gene are capable of performing this reaction.

At White Labs we screened our entire yeast collection for the presence of this enzyme activity, and developed a blended culture of several high activity strains (WLP077 Tropicale Yeast Blend) to produce a beer with tropical characteristics.

Nevertheless, this gene is tightly regulated by wort composition, particularly Free Amino Nitrogen (FAN) content, and only when FAN levels drop below a certain threshold will the yeast present this activity.

To try to circumvent this limitation, brewers can manipulate the FAN content in the beer, change the hop additions to maximize precursors or try to apply one of the commercially available genetically modified (GMO) strains with continuous activity of the enzyme.

Hops, as the main source of boundthiol precursors, also need some consideration as each hop variety contains different types and amounts

of compounds that will impact the final flavour profile of the beer.

Some of the most popular hop varieties, like Citra, contribute high amounts of volatile thiols to the beer and do not benefit significantly from biotransformation.

On the other hand, more traditional varieties like Cascade, Saaz or Simcoe contain higher amounts of thiols in the bound and non-aromatic form. Such hop varieties particularly benefit from interaction with high β-lyase activity yeast strains to achieve tropical aroma profiles. The challenge for the brewers is then to provide the selected yeast strain with plenty of precursors, so that the final product presents an improved aroma and flavour.

Introducing hops during the mash and focusing on whirlpool and fermentation hop additions are some of the most popular approaches.

Some recent research indicates that whirlpool additions significantly contribute to increased precursor

concentration in wort, and that cold storage might be necessary for the release of a significant portion of the volatile thiols back into the beer. Thiol precursors can also be introduced in the brewing process from other sources, namely grape derivative products like Phantasm or even malt, increasing the overall impact in flavour and aroma.

The impact of all these new ingredients and techniques is still being assessed, with new information becoming available all the time.

Gravity Systems was formed to meet the growing demand in the craft beer market for a single source for all brewhouse, fermentation, services generation and distribution. It is our aim to be the most complete partner in the brewery industry by building long term partnerships with our customers.

New Zealand is so special to James Heffron

he’s basically built his Cornwall brewery around Kiwi hops.

He first travelled to New Zealand nearly 25 years ago, 15 years before he would start Verdant brewery and deliver some of Britain’s most punchy and popular hop-forward beers.

“I was travelling there from 1999 to 2001 and there was a better beer scene at that point in New Zealand than at home.

“I met my wife Hagit there — she’s from Israel and was back-packing — and we went back in 2010 to celebrate 10 years together. It was that trip that I have these memories of great locally-made beers, and there were so many good breweries.

“There was one day when we visited a brewery and bought some beers to takeaway. We drove through to the Nelson Lakes region and there were hop fields on either side of the road and it blew my mind that here were these amazing ingredients that were going into the beer I was drinking at the end of the day.

“It was after that trip that I went home and started home brewing.”

Heffron and his wife had a food business, specialising in Middle Eastern food, Fal Falafel, but when he got the beer bug a brewery was soon on the horizon.

“I approached beer recipes in the same way as our catering business – loads of flavour and making people love what they are consuming.

“We registered Verdant in September 2014, and we were brewing on a 200-litre system and holding down other jobs but straight away I was hassling [distributor] Charles Faram in the UK to get a contract for New Zealand hops.

“I knew we needed these New Zealand hops to make a success of Verdant. And Nelson Sauvin was right up there in the hops I wanted to contract, and it plays an important role in our brewery.

“New Zealand Hops, and especially Nelson Sauvin, are just striking. There’s a really interesting balance between fruit and savoury, there’s a hedgerow kind of thing, and a wildness about them. I genuinely struggle to describe them.

“Nelson for instance is gooseberry, white grape and white wine but there’s a sweatiness, a dankness, a diesel note, some nettle, celery tops — it’s just so multi-layered.

“When it comes to Nelson beers, I take a sniff and a whole world of different flavours emerge. You don’t only get one and stop, it just keeps on going.”

Heffron understands there are critics who don’t like Nelson Sauvin, but he has a clear message for them.

“I do see some people say ‘I don’t get on with Nelson Sauvin’. When I see that, I genuinely think: ‘you’re insane’. It’s one of the most amazing hops in the world. There’s nothing you can replace it with.”

Also in the south, Kent brewery Curious have an obsession with Nelson Sauvin, but for much different reasons.

Brewer Wes Lynch says the brewery’s flagship lager is dry-hopped with Nelson Sauvin specifically to create a beer that will appeal to wine lovers.

That dates back to the creation of Curious in 2011 when it was started by the Chapel Down winery in Tenterden, on the premise of winemakers who were curious about brewing.

“And what’s the easiest hop to tie back to wine-making?” Lynch asks rhetorically. “Nelson Sauvin.”Curious beers were initially contract brewed but in 2019 Chapel Down decided to build a brewery and taproom.

“Of course 2019 wasn’t the best year to start a brewery …”

The impact of Covid on a brewery that had just been commissioned resulted in Chapel Down selling the brewing operation.

NELSON SAUVIN IS A WONDERFUL HOP. IT IS ALSO INCREDIBLY VERSATILE, TOO, REGARDLESS OF BEER STYLE OR DISPENSE EXPLAINS MICHAEL DONALDSON FOR NZ HOPS

“However we still retain a lot of that original brand identity,” Lynch says, “and we still try to celebrate the terroir and provenance of this area, not just the wine, but the locally-grown hops. “Our flagship beer, Curious Brew Lager, was always based around a heavy dose of Nelson Sauvin in the dry-hop.

And while we’re now focused on local hops from a sustainability perspective, English hops are not known as massively citrussy, flavourful, hops so we’re very selective about what hops we import and we want to be punchy and impactful with those hops that we do import. Which again fits Nelson Sauvin perfectly.”

The other link back to wine-making for their lager is a secondary fermentation with champagne yeast which adds effervescence and dries out the beer, giving a nice canvas on which Nelson Sauvin can shine. Carbonated at 5gm/ litre, the result is a “dry, punchy lager but not in an overwhelming way”.

The big dose of Nelson Sauvin in the dryhop compensates for the dryness and the high bitterness (35 IBU) in the 4.7%

ABV lager.

“That citrussy sweetness rounds it out and makes it more palatable to the regular lager drinker while craft drinkers enjoy that extra bitterness and dryness,” Lynch says.

At Redemption Brewery in London, Andy Moffatt is a huge fan of the way Nelson Sauvin’s heavy-hitting aroma can lift cask ale.

Exposure to oxygen more in cask beer slightly reduces the punchiness of the hops, and in an era when even cask beer drinkers are looking for a hoppy hit, hyper-flavoured New Zealand hops work perfectly.

“You don’t get the full punchiness of the aroma hops in cask beer compared with keg beer, but the New Zealand hops work very well because they are punchy in their own right but they don’t overwhelm the beer in terms of sessionability,” Moffat says.

He has been using Nelson Sauvin for

more than 10 years in his flagship Big Chief IPA and he likes the way that hop adds value, aroma- and flavour-wise, without taking away from a drinker’s ability to have a few pints.

“Sometimes with keg beer, those bigger hops — like Citra or Nelson Sauvin — can result in an oily, slick feeling going down your throat and it can feel too much sometimes. That intensity, after you have a pint or two, can feel like too much.

“But in cask ale with Nelson Sauvin, you still get that hop character standing out, with the gooseberry and tropical notes, but it’s a bit more subtle and balanced so you don’t get that strong flavour coming through. Nelson Sauvin, in cask, works very, very well.”

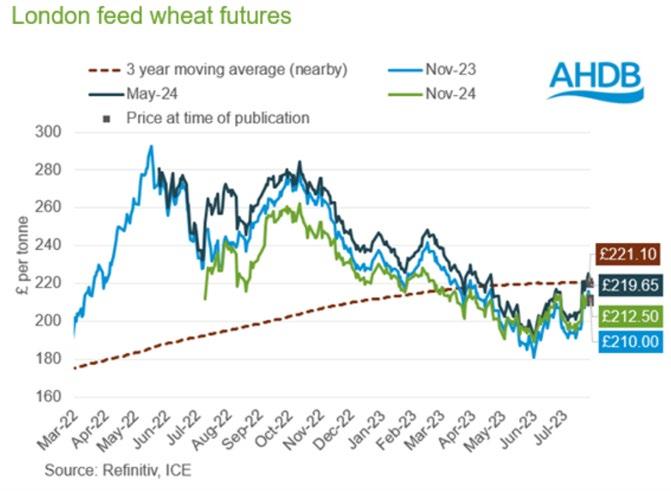

The malting barley market in England has yet to trade in any significant quantity as intakes open and existing contracts are delivered, and the market assesses yield and quality of the upcoming crop.

The wider market has seen significant volatility in feed grain prices, primarily due to the Russia/Ukraine conflict and the bombing of export silos in Odessa and drone attacks on some of the Ukrainian loading points for cargoes on the Danube river.

These events are bullish, but the market also realises the reality of adequate supply. Export competitiveness from the UK for feed grains is hampered by domestic prices and a stronger Sterling.

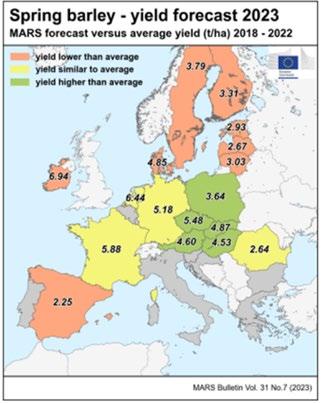

Winter barley in ‘good’ condition. Yields are slightly down due to a dry April & May. Winter barley harvest in England and Scotland is progressing with East Anglia and the South of England ahead as expected.

However, progress has been interrupted by a southerly jet stream bringing more rain than we would normally expect at this time of year.

Yields on the farm have been average or slightly below average which is disappointing. However, reflects the dry weather spell throughout April and May. Predictions for yields of spring barley in the EU- 27 are down 13.6% from the five year average.

Early spring barley crops are showing promising signs on quality.

Initial results are positive with reasonable yields of full specification barley without the screening issues seen in the winter crop – we remain hopeful that this trend will continue as the crop comes

to harvest over the next six weeks or so (weather permitting). Due to the extended drilling window, we expect a prolonged harvest period for the crop this year.

Yield predictions for the EU remain mixed, French crops are mostly harvested with reasonable results. Results in Spain have become reality, with yields down c.20% from the 5 year average. Yields in Northern Europe are predicted well down from the 5 year average due to the extended dry spell during the growing season.

A wet harvest is forecast, but it shouldn’t affect quality Trade attention is very

model below suggests that as we move into August that rainfall is likely in all harvesting areas leading to a snatched harvest with higher moistures than 2022 crop. When coupled with relatively low temperatures then there is no imminent danger to quality and with the combining power that is available on farms then there is the expectation that harvest opportunities can be taken between the rain events.

When it comes to India Pale Ale (IPA) and New England India Pale Ale (NEIPA), 2023 has been a remarkable year. Craft brewers around the world have been pushing boundaries, creating stunning examples of these hop-heavy styles.

Using the ratings from the popular beer app, Pint Please, we’ve compiled a list of this year’s standout IPA and NEIPA offerings. From well-known breweries to hidden gems, let’s dive into the 2023’s top-rated IPAs and NEIPAs.

India Pale Ales and New England India

Pale Ales are the two most popular beer styles of the new beers that breweries are currently brewing. As our previous study showed, IPA and NEIPA are the hottest styles and get most love from the breweries.

The IPA, known for its strong hop flavour and higher alcohol content, has long been a favourite of craft beer enthusiasts. Its broad style allows for endless variations, from the resinous and bitter West Coast IPAs to the balanced and

citrusy East Coast versions.

The NEIPA, on the other hand, is a relatively new entrant to the beer scene. Characterized by its hazy appearance, juicy flavour profile, and softer bitterness compared to traditional IPAs, NEIPAs have been rapidly gaining popularity over the past few years.

Their fruit-forward flavour and creamy mouthfeel have made them a hit among those who might not typically enjoy the assertive bitterness of a traditional IPA. Data from Pint Please confirms the power of the “hop revolution” in modern brewing. As craft brewers continue to experiment and push the boundaries of these styles, it’s clear that the world’s thirst for IPAs and NEIPAs is not waning. For beer lovers, this means we can look forward to more creative, flavourful, and exciting brews in these styles in the years to come. In the first five months of 2023, we dug into the ratings submitted to the Pint Please app, seeking to understand the trends in IPA and NEIPA preferences. We discovered that all the beers in our top 20 list sport an alcohol content between 5.0% and 7.0% ABV, illustrating a

preference for moderately strong brews. The first beer to break this pattern is La Cristal IPA, with an ABV of 4.7%, placing a respectable 46th on our list.

This roundup of top-rated IPAs and NEIPAs focuses predominantly on Europe, aligning with Pint Please’s primary market.

The European craft beer scene is vibrant and diverse, and this is reflected in the variety and quality of the beers rated. A standout in our analysis is the Finnish brewery Salama Brewing Company. After being crowned the best Finnish brewery based on Pint Please ratings in 2022, Salama continues to impress in 2023. Its recent release, Ultraviolet 5, leads the pack, affirming the brewery’s commitment to quality and innovation. We will delve deeper into the specific ingredients that set these IPAs and NEIPAs apart in an upcoming article. There, we’ll explore the selection of hops and malts that contribute to the exceptional flavour profiles and high ratings of top rated brews. So, stay tuned for a more detailed analysis of what’s inside these top-rated beers.

AS

CLEAR THAT THE WORLD’S THIRST FOR IPAS AND NEIPAS IS NOT WANING, EXPLAINS JUHA KARPPINEN, THE CO-FOUNDER AND CEO OF PINT PLEASE.

For the Brewers Choice Awards 2023, the categories up for discussion were Young Brewer of The Year, Brewer of The Year, New Brewery of The Year, Brewery of The Year, New Beer of The Year, Beer of The Year, Branding of The Year, Lifetime Achievement and Global Ambassador.

This year’s submissions were judged by an array of talent that included decorated author and Brewers Journal contributing editor Melissa Cole, Stephanie Brindley, John Keeling, former brewing director at London-based Fuller’s, Lotte Peplow, the craft beer ambassador in Europe for the Brewers Association, Paul Davies, founder of the award-winning AleHunters Brewery Tours, freelance beverage and hospitality consultant Sean Robertson. Tim Sheahan, global editor of The Brewers Journal chaired the proceedings. He said: “It was once again a genuine privilege to share a room with so many regarded figures from across the world of beer.

“As with every year, the quality of entries in each-and-every category was skyhigh, predictably making the judging process an incredibly tricky task.

“I’d like to thank everyone that entered and a huge well done to everyone that has made the shortlist this year. We look forward to announcing the winners, alongside the recipients of the Roger Ryman Lifetime Achievement (supported by Konvoy) and Global Ambassador (supported by Kegstar) awards, at our 2023 Brewers Choice Awards dinner in London this October. Hopefully you’ll join us there.

“Special thanks to our sponsors and also to Angus, Clare and the team at The Red Lion in Barnes for expertly hosting our judging session.”

The winners of the 2023 Brewers Choice Awards will be announced at the Brewers Choice Awards taking place on the evening of the 18th October in London.

Supported by Lallemand

To contend this award, we wanted to see a detailed overview of the business success you’ve had in the last 18 months. Breweries were to showcase key moments for the business such as new investments they’ve made, new distribution deals they’ve struck or successes they’ve had in exporting their beer to other countries. And also, we asked them to tell us about their brewery’s approach to all facets of business such as its work in the community, and its commitment to training and developing its staff.

In the last 12 months, Anspach & Hobday has grown from three wholesalers to eight. They also saw a revival of export post-Covid. Previously Italy had been their biggest market. This has returned alongside France with new markets in Belgium, Luxembourg and Finland. They now have more than 10 regular lines of London Black on the continent alone, a 4.4% porter that continues to elevate the brewery thanks to its ongoing success.

During what has been an incredibly difficult year for hospitality, North Brewing has put their core values at the heart of everything they do to ensure that every business decision they make is for their customers, employees, community and partners no matter where they touch the business. Thanks to this their focus remains on further embedding their deep-rooted connection within the local community, along with their friends across the world. They’re celebrating another successful year, which has so far been full of exciting new projects, collaborations events, and product launches. Not only this, but they continue to brew the best quality beers while growing a team, the culture and the business.

FROM ACROSS THE BREWING SPECTRUM CONVERGED ON THE RED LION IN BARNES, LONDON, TO DEBATE AND DISCUSS THE WEALTH OF EXCELLENT ENTRIES SUBMITTED FOR THE 2023 ITERATION OF THE BREWERS CHOICE AWARDS. HERE’S HOW THEY GOT ON.

As they emerged from the pandemic, the industry faced different and more challenging times with extreme pressures on running costs, materials and a changing consumer landscape. Despite this, Northern Monk continue to grow with increased presence in supermarkets, while maintaining quality and producing and launching innovative, exciting new products. They have also continued to champion and support local and national charitable causes and campaigns.

Signature Brew believe that no great music experience is complete without great beer. From their state-of-the-art brewery in East London Signature Brew proudly produce fresh, award-winning beer that brings people together. Their unique approach to reaching drinkers has helped them grow rapidly even throughout difficult recent years. Their beer is sold at more than 400 permanent stockists and is tracking more than £10 million revenue by 2024. Their mission is uniting people through the power of incredible beer, great music and unforgettable experiences.

There are some incredibly talented young brewers working in the UK brewing industry. Some young brewers are running their own operations, others are cutting their teeth working at established outfits. Regardless, these brewers are making their mark on the industry and are certain to have a long, successful career in the field.

Lost and Grounded Brewers

Virginia is an Italian brewer living in Bristol. She has been living and working in the UK for the past five years. She says she feels very lucky to have found a new brewing family to continue her path and develop her skills while she helps Lost and Grounded expand and thrive. She says she is committed to maintaining and continually improving the beers they produce as a team. And of course, she is forever spreading the craft beer love.

She adds that brewing is a true labour of love. It requires a team effort to make consistently high-quality beer. She says she still has a lot to learn but she’s also a hard worker, constantly challenging herself to get better results. At the end of the day, it’s all about making better beers and surpassing customer expectations!

Samuel

Samuel Fraise has been working at Attic since the early days (early 2019) after they had been open for only a few months. He came in during his studies for his masters in brewing and distilling at Heriot-Watt. He was promoted to head brewer role in early 2021 as one of the directors stepped back from the brewery to help manage the wider business. Since then Sam manages a team of 5, soon to be 6 and oversees production of 120HL/ week, a significant jump from the 32HL/ week production he was managing only 2 years ago. During 2022 Sam also undertook a large project of putting in place documentation and process to obtain SALSA approval. This and much more besides, too.

Following his previous commendation as young brewer of the year which showcased how he designed and installed their 4-vessel 25HL brewhouse with 100HL fermentation capacity and 50HL packaging capacity, he has overseen the installation of a further 75HL fermentation capacity and 25HL packaging capacity. This has been testament to the success of the brewery over the last 18 months in what is a very difficult time for the industry. The installation of the new vessels was able to be completed with minimal disruption to production as their chiller was originally scoped for expansion on installation and our pipework was able to be built-off with no need for down-time. He kept a focus on chilling efficiency during the new installation which has helped our packaging operations and particularly their canning line run so well up to this point.

According to his colleagues Pietro has really helped continue to grow Northern Monk and make sure they’re producing extraordinary beer, at higher quantities, more efficiently while being more sustainable and not lowering their standards of quality. He has worked hard to continue to shape their brewing output as they have expanded rapidly both in terms of volume and the team itself. He has taken on fresh responsibilities with enthusiasm and determination.

Campervan Brewery

Over the past four years, his skills and experience as a brewer have grown alongside Campervan Brewery. After graduating from Heriot-Watt with a Masters in Brewing and Distilling and starting his career at a lager brewery in Glasgow, he has progressed from the position of brewer to head brewer to now a combined role of head brewer/ production manager. He has overseen two expansions in fermenting capacity, the installation of a canning line, created a barrel-ageing/mixed fermentation project and implemented several quality projects, including working towards their SALSA audit later in 2023. He believes the past year has seen him contribute significantly to the business helping it achieve its current success.

Brew York

Nadia Spencer joined Brew York in May 2021 via a Hit Training Brewing Apprenticeship. She achieved a Pass with Distinction in February 2023 and has become a notable young ambassador and one-to-watch in brewing. Nadia has an incredible career and future ahead of her and is a shining asset to the beer industry. In addition to being a skilled brewer she is eloquent and speaks about her work with intelligence and passion. As someone who is committed to inclusivity and working to make the industry a fair and safe place for all, she is an impressive role model for others who may need to ‘break the mould’ and pursue a brewing career.

FERMENTATION RANGE

AROMA & FLAVOR

ALCOHOL TOLERANCE

ATTENUATION RANGE

™ is a true bottom fermenting Saccharomyces pastorianus hybrid from the novel Group III lineage that has been selected to produce a robust lager strain with ideal characteristics for clean lager beer with distinct avor characteristics and superior fermentation performance.

™ was selected using classical and non-GMO breeding methods and inhibits the production of hydrogen sul de (H2S) o - avors.

Wyllie Recycling Perth wyllierecycling.co.uk

Winelab Kildare winelab.ie

WDS Group Bury wdsgroup.co.uk

First Mile Birmingham thefirstmile.co.uk

Jolly Good Beer Wisbech jollygoodbeer.co.uk

First Mile London thefirstmile.co.uk Niche Solutions Northampton nichesolutionsgb.co.uk

Binit Clyst Honiton binituk.com

Staggeringly Good Portsmouth staggeringlygood.com

Recorra Lancing recorra.co.uk

Supported by Rankin

We can think of countless fantastic beers that have been produced in recent months. In the entries, we wanted to hear how this beer is shaping a trend or exploring new techniques and flavours.

Exale

Jazz Dragon

This is the first double IPA they have brewed at Exale. They always start developing recipes thinking about the the kind of beer that they would like to drink themselves and this beer is no exception. They wanted to make a full bodied beer that could be paired with a wide range of food, especially dishes with a bit of heat, and use the opportunity to experiment with as many techniques of getting hop flavour and aroma into a beer as possible.

Saltaire

El Dorado

Created as part of an ongoing collaboration series, El Dorado is a robust double IPA, bursting with flavour. El Dorado was created to showcase a move towards the latest trends in beer and exploring new techniques. Available in can, keg and cask, it’s a punchy, unique and flavourful tropical beer.

Stroud Brewery

Easy Peasy

A balanced lower alcohol ale - it packs all the punch of a hoppy american ale, but light on the alcohol And it’s organic.

Supported by Barth Haas X

We want to celebrate the very best beer the UK has to offer. We’re not looking at dozens of categories, instead recognising one beer - The Brewers Choice ‘Beer of the year’.

Burning Sky

Petite Saison

This mixed fermentation saison is a light and easy drinking small beer. Barrel aged for a few months, this delicate beer was then dry-hopped for a refreshing finish.

Double-Barrelled Parka

Centennial hops on the hot side meet bright, juicy citrus fruit notes from Citra on the dry-hop. All wrapped up with a soft mouthfeel and lashings of peach from their house yeast. Perfectly drinkable, balanced and moreish. Parka was the first beer they brewed when they built Double-Barrelled, and it has been a central part of who they are ever since they began brewing.

Northern Monk Faith

Faith is the largest hazy beer by volume

(excl. Brewdog) in the UK. One can of Faith is sold every three seconds in the UK. It has seen 60% volume growth in the five years 17-18 to 21-22 while keg sales were up 145% in 2022 year-onyear. Faith is their biggest selling beer across both the Refectory bar sites, and is sold in hundreds of pubs, bars and supermarkets across the UK

Supported by SSV Limited

One of the finest qualities many brewers boast is humility. So this category it was always likely to need some convincing/ persuading/forcing when it comes to ensuring these excellent brewers are considered. We wanted to acknowledge a brewer that is truly an industry tour de force. What sets them apart from the rest? Is it the beers they create, expansion they’ve overseen or a team they’ve built. Maybe it’s all of those….

Seb Brink

North Brewing

His colleagues call him a genius. The team first met the would-be head brewer of North when he was brewing in his garage and cuckoo brewing at Brass Castle for his brand Golden Owl whilst supplying one of the North bars round the corner from his house. He’s gone from that to leading a team of 25, brewing over 20,000HL PA. He’s done it seamlessly, like it’s the most natural thing in the world, negotiating a worldwide pandemic, and a move from a 3,000sq ft brewery to one of 23,000sq ft. He always pushes and challenges, every brew is an opportunity to tweak something, try something new and aim towards

perfecting a beer (Although they know that he would never be 100% happy…).

Jordan Childs

Mash Gang

Jordan Childs has gone from being a bored homebrewer to head brewer overseeing four global sites in the UK, EU, USA and Australia releasing over 100 different beers in under three years. One peer said working with Jordan reminds them of why they do what they do, challenging what a beer is and using science to create something new and exciting. “Not only has he rewritten the rulebook for no-and-low, he has made it f*@king cool,” they added.

Mark Tranter

Burning Sky

Burning Sky, a brewers dream. It was the dream of long-term brewer Mark Tranter who has a love of both punchy hopforward pales and of beautiful Belgian beer tradition. A brewer’s brewery, they are fortunate to be blessed with a talented team. Burning Sky say that whilst industrial units are convenient, they seldom inspire, so they chose to locate themselves within the beautiful and inspirational South Downs, occupying refurbished farm buildings in a slightly quirky village. A true farmhouse brewery. Whilst ambitious, they have never wished to grow out of, or beyond the buildings they occupy. Instead they invest heavily in the areas that they wish to grow in.

A raft of excellent new breweries have opened in the last few years. Some of these outfits have focused on the art of Lager, some IPA, some mixedfermentation sours and some a mix of each. Regardless, each tread their own different path in the industry of brewing. We wanted to hear about those early landmark points for the business. Maybe they’ve offered employment to local people, it could be the investments they’ve made, securing deals for their first beers with pubs, bars or restaurants. It could be all of the above We asked to be told about the brewery’s approach to facets of business such as its work in the community, commitment to training and

developing its staff, relationships with the broader industry and their approach to issues such as sustainability.

Azvex

Adam Henderson, founder of Liverpoolbased Azvex Brewing Company, is absolutely driven and fully committed to delivering the best beer he is capable of making and to offer the best possible experience for his customers. For many years he has spent countless hours researching, brewing and experimenting to improve his understanding of beer and his ability to make better and better beer. He has also spent even more hours learning about running a business and how he can improve it to better benefit his customers. He therefore created Azvex to achieve these goals. A brewery that has made fantastic strides since being founded in 2020.

Balance Brewing & Blending was started in 2021 by Will Harris and James Horrocks. The first time they mashed in a Balance beer was June 2021 and their first release was in May 2022. The long period of time is due to the fact that all of their beers are barrel aged and fermented with their house culture of saccharomyces, brettanomyces and lactobacillus, taking anywhere from six months to two years to come to fruition. They are the only brewery solely producing mixed ferm beer in Manchester and one of only a small number in the UK as a whole. This is a style of beer they love and feel has been underrepresented in the UK. The complexity and character of these beers is unsurpassable, at least in their opinion!

At Floc, their aim is to make world-class beer using quality ingredients with a passion for flavour and drinkability. They brew modern, flavourful beer to be enjoyed with friends in pubs, on the beach or wherever you enjoy spending time. They like their beer to be hoppy and hazy, with the odd lager in the mix, sometimes strong, sometimes session strength but always with a dedication to quality and drinkability. They make the beer they love to drink and hope their customers like it too. Their dream isn’t to

grow exponentially, it’s to build a brewery and business which is sustainable, enjoyable to work for and to create beer which brings joy and excitement.

Great Beyond Brewing Company is an independent craft brewery based in Hoxton, East London, founded by three beer-loving friends and experienced brewers, Ollie, Nick and John. They take pride in their work, their community, and their values. Their approach to brewing emphasises quality, sustainability, and creativity. They are passionate about combining the best ingredients and techniques to produce beers that inspire and delight their customers.

Founded in 2020 Sureshot began as a chance meeting between director/ founders James Campbell & Michael Forde at IMBC. From there an ambition grew to create a brewery that celebrated beer through enjoying it. Key landmarks include the opening of an adjacent taproom in November 2022. Export, beginning in 2023, involved The Netherlands, Norway, Sweden, and Japan to be followed by Finland, Denmark, Switzerland and France. Securing permanent lines at craft beer bars across the UK they are also undertaking the expansion of brewing capacity with enhanced kit - to be complete in October. Taking beer seriously but not themselves, Sureshot focus on what people love: hoppy IPAs, clean lagers, and flavourful pale ales.

As a modern-focused, independent brewery nestled in a railway arch under Windsor Central station – a town rich in brewing history - they hope to add variety to Windsor’s beer scene. Their mission is to use the latest innovations in beer combined with influences, styles and ingredients from all around the world. They revel in the open-minded nature of seasonal brewing and the sensory experiences that come with it. Hence, their range consists of two core beers and a rotating offering aiming to mix cutting edge flavours with classic styles.

COME AND VISIT US AT STAND 417

Wilderness is a family run brewery based in mid Wales, founded n 2017. They don’t rush into things, instead preferring to let nature do the talking. They make wild little beers and co-ferments, experimenting with new ingredients, seasonality, barrel ageing, and mixed fermentation. They brew and package all of their beer in house, and condition in bottles or cans. They brew & package everything by hand, in house all can, keg or bottle conditioned and they use their own fruit, grown in their orchard or harvested by the team.

Supported by Potter

ClarksonGreat branding helps sell beer. Now we have that revelation out of the way, we want this category to showcase the stunning array of design that breweries leverage to brand their beers. From the striking to the subtle, modern beer is blessed with some truly impressive branding; from the work that graces bottles and cans to keg founts, cask badges and beyond.

In 2020 the team developed their nitro-porter London Black. A modern interpretation of London Porters, poured on nitro to give a smooth head. It’s full of flavour and marketed as their local alternative to macro stouts. In the beginning there was no specific glassware - but it was still a good looking pint, even in their standard Anspach & Hobday glass. To take this beer to

the next level of brand presence they needed to develop a truly great glass, one which could capture the brand and proposition of the beer. They very consciously decided that Guinness “used to have it right”. They said the tulip works perfectly evoking London’s Porter past. The 20oz tulip strikes the balance between craft beer and heritage: Just like London Black.

Corinium Ales branding is a celebration of Cirencester, and its Roman and brewing heritage. Cirencester (Corinium) was not only the second largest Roman town to London (Londinium), but in the late 1700s, Cirencester Brewery was one of the most complete breweries of its size outside of London. Their family of award-winning ales with a Roman themed names and numbers and links to local history make a worthy contribution to Cirencester’s strong sense of place tying up the brand with location that has huge appeal to the customers who say it is “eye-catching, attractive and has an identity that is among the best”.

After rightly focusing on elevating the quality of their beers over the past 24 months – and they do feel they have created a great foundation to build on – a consistent and quality look was the next logical step, to now represent the quality of the beer they produce. In January 2022 they employed the services of Ryan Plews and the team at

WeAreBrandd, to help them visualise all of these emotional and often practical wants. So now, they say, you hopefully see a lot less clutter and noise, which makes their beers not just simpler to recognise but, more importantly, accessible to everyone.

They said they know this can possibly come across as fairly bland or mainstream, but a massive pet peeve of theirs is the alienating nature of certain brands, excluding not just potential customers but so many communities and walks of life.

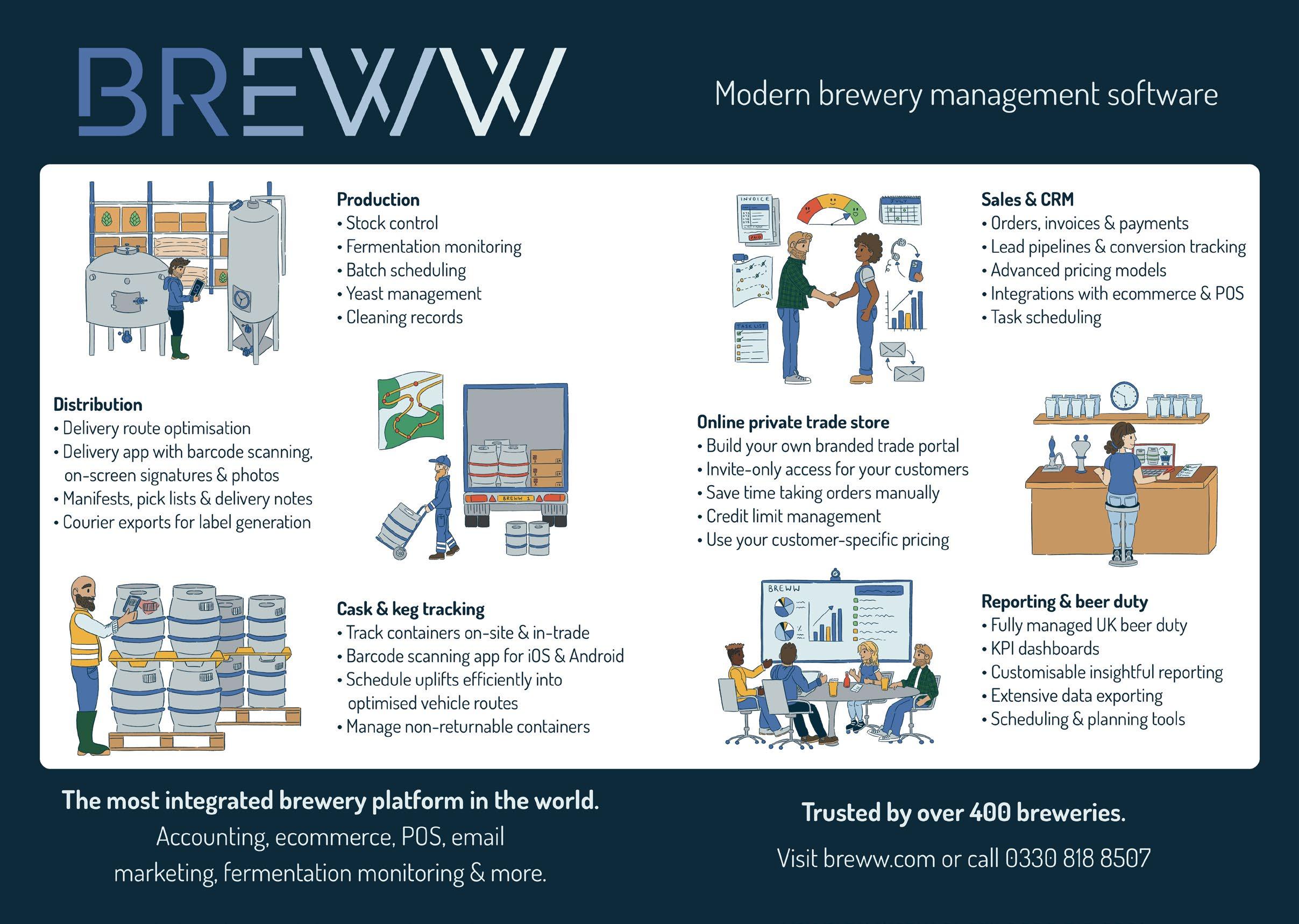

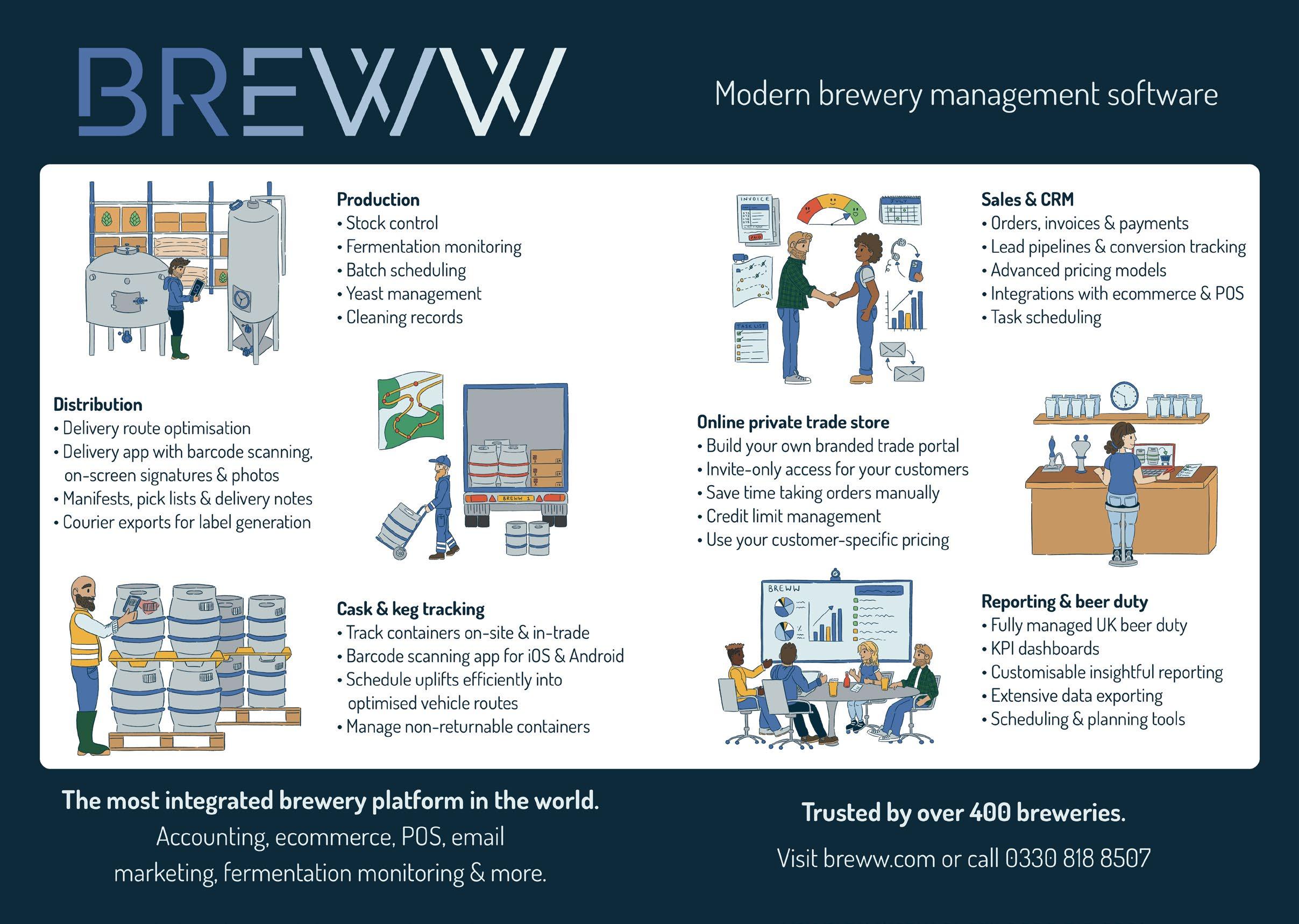

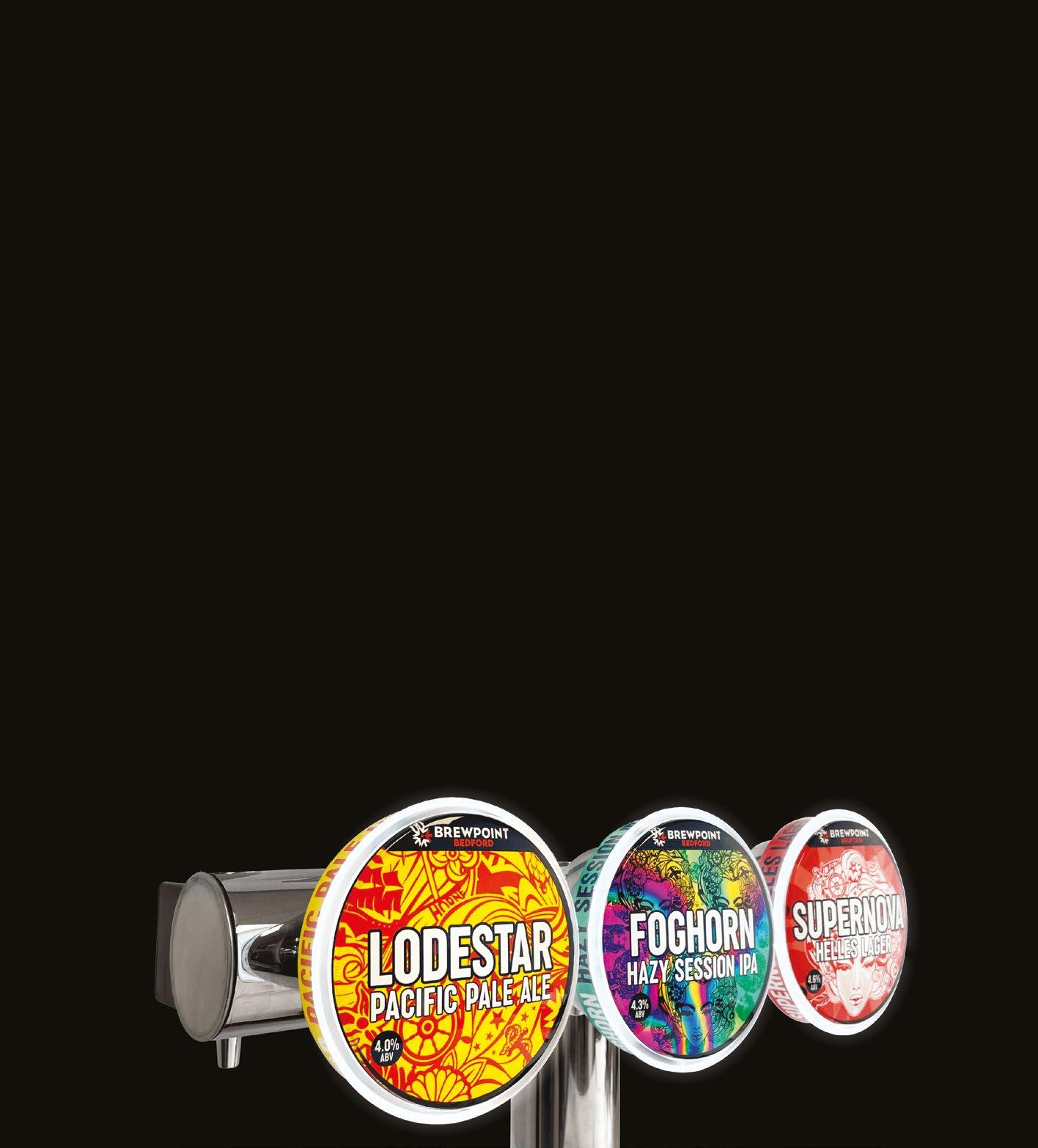

WELCOME TO THE 2023 BREWERS CONGRESS

HERE YOU’LL GET THE FULL LOWDOWN ON THE WEALTH OF TALENT AND BEST-IN-CLASS BUSINESSES TAKING PART IN THIS YEAR’S EVENT

Manufacturers and suppliers from the world of ingredients, packaging, capital equipment. software, measurement, analysis, branding and more are all taking part in the biggest Brewers Congress to date. So here is a glimpse of variety of innovation you can expect at the October event.