MARITIME

MARINE BUSINESS

COMMERCIAL MARINE BUSINESS

Tugs, Towing & Salvage | Industry News | Power & Propulsion

Tugs, Towing & Salvage | Industry News | Power & Propulsion

Tugs, Towing & Salvage | Industry News | Power & Propulsion

Tugs, Towing & Salvage | Industry News | Power & Propulsion

Norwegian fish farm uses shore power instead of diesel

A new report says the global pipeline has doubled in a years

A UK port warns that redundancies are imminent

Could this be the way to decarbonise CTVs?

The UK Crown Estate opens up the seabed

Neander Motors’ Joel Reid on what’s best for working vessels

Heerema breaks the world record

Leo Hambro Commercial Director Tidal Transit

Small enough to fit in a backpack, we take a sneak peek

The world’s first offshore production plant is launched

Latest news in what’s been recovered at sea

The little-known city at the heart of France’s maritime industry

PATROL 24 WP is designed for most challenging weather conditions – its designated operation areas are Baltic and Mediterranean Sea as the vessel is foreseen also for FRONTEX missions.

Baltic Workboats have delivered three vessels from same series to German Customs in 2018 and now another one is set to be delivered to EU country coast guard within next month.

The vessel is designed with Baltic Workboats patented wave-piercing hull to reduce accelerations on the crew in heavy seas up to 40% and improve fuel economy of the vessel up to 20%. The vessel features spacious wheelhouse with separate command room in order to allow vessel to operate as scene coordinator.

The accommodation and mess area is foreseen for the crew of eight. The vessel is designed taking account sub-zero temperatures and possible sea freeze in Baltics while also considering high temperatures and humidity of Mediterranean Sea.

The vessel is fitted with Baltic Workboats

IAMCS (Integrated Alarm Monitoring and Control System) to allow control of vessel’s systems from a single screen and make vessel operable by single person if necessary.

The PATROL 24 WP also features daughter boat in aft deck RIB-well to allow operating in extra shallow areas where the access with mother vessel would be difficult.

8 For further enquiries https://bwb.ee/

A Norwegian cod farm has become the first such facility to switch to shore power rather than use diesel generators.

Norcod, based in Trendheim, has implemented shore power as the energy source at its Frosvika production facility in Meløy municipality, Nordland county.

An agreement to survey 7,000km2 of water and 161km of coastline has been signed by MENAS, the Middle East Navigation Aids Service.

The eight-month project was agreed with Bahrain Ports and Maritime Affairs, and will cover all main channels and approaches to Bahrain, such as its islands, reefs, inner channels, private jetties and fisheries harbours.

Provision of an AtoN service in Bahraini waters is essential in meeting the needs of the mariner, says MENAS CEO Peter Stanley, as well as specifying exactly what kind of aid and how many are needed in each area.

MENAS has divided the waters into nine zones and each will look at factors such as vessels involved, facilities ashore and the marine environment.

A final report will plot traffic density for each area according to vessel type and size and measure the probability of risk.

The energy powering the feed barge comes from clean hydropower, the firm says, and as well as unplugging the generators it is also using energy-efficient waterborne feeding technology.

This has significantly reduced noise, and the subsequent near-silent operations are beneficial to immediate surroundings and employees, the company says.

“Our ambition has always been to set the standard in responsible, industrial-scale farming of

top-quality cod, through constant operational improvements that ensure sustainability and fish welfare,” said Chief Sustainability Officer Hilde R Storhaug. “By installing wired onshore power, we are making a valuable contribution to reducing climate

impact both locally and globally.

“We estimate we’ll save around 160,000 litres of diesel on an annual basis, which translates to a 420-tonne reduction in CO2 emissions related to the feed barge and the equipment it supplies with energy.”

International subsea geotechnical services provider Bluefield Geoservices says it has performed what is believed to be the deepest ever cone penetration test (CPT).

The CPT was done in water depths of more than 4,000 metres in the Pacific Ocean with the firm’s ROVcone, a proprietary CPT system that can be paired with other ROVs or other equipment such as a trenching machine.

“Bluefield operators successfully completed 23 seafloor CPTs to a push depth of two metres as part of an ongoing geotechnical site investigation campaign to assess the ocean floor conditions that characterize this vast abyssal plain,” the company says.

“This is an exciting milestone for the entire Bluefield team, both the skilled operators in the field and the subsea engineers that

have worked so diligently in recent years to develop our exclusive toolkit of deep-sea geotechnologies, including the ROVcone CPT system,” said Bluefield managing director Jim Edmunds.

Most CPT systems, he says, are depth rated to 3,000m. Bluefield services site investigations for offshore construction in the renewable energy, oil and gas and subsea mining sectors.

Lloyd’s Register and Triumph Energy have announced a joint project to ensure vessels are built and operated sustainably.

A new ShipRight procedure for vessels within the offshore energy, decommissioning and renewable energy sectors is the ultimate aim, guaranteeing that they comply with relevant requirements, such as being built with the most sustainable materials available and able to meet IMO 2030 and 2050 requirements.

Triumph, a marine technology company specialising in green technology and automation, will

be instrumental in developing designs for integrating remote facilities and artificial intelligence to reduce crewing levels for offshore and back deck operations.

“As part of the project, Triumph has developed designs which incorporate technology that demonstrates reduced greenhouse gas emissions, advanced energy recovery systems and the use of certified sustainable materials

for vessels used within offshore, renewables and decommissioning sectors,” the company says.

“Verification of a vessel’s green credentials along with the initial higher CAPEX has always been a major barrier to entry for obtaining financing for new build vessels,” said Gray Johnstone, Triumph chief operating officer. “The development of a notation that verifies 100% a vessel’s sustainability, compliance to IMO 2050 and Carbon Positive verification will remove these barriers and pave the way for a decarbonised maritime sector.”

For the latest news and analysis go to www.maritimejournal.com

As energy prices rocket, a licensing round for oil and gas exploration around the UK has been launched.

The North Sea Transition Authority (NSTA) has launched its 33rd licensing round for the Southern North sea, the UK’s main gas basin, it says.

Welcoming the round, the East of England Energy Group (EEEGR) said it hoped to address security of supply for the medium to long term.

“With a focus on energy security, our region is quite literally keeping the nation’s lights on, and heating our homes and businesses.” said executive chair Martin Dronfield. ”We really need to see a more integrated strategy for offshore energy developments across oil and gas, wind, hydrogen and carbon capture, and associated infrastructure, to really maximise the potential of our region’s skills and supply chain businesses.”

A report by Renewables UK reckons the global pipeline of floating offshore wind has project has more than doubled in 12 months.

A year ago, worldwide projects of wind generated 91GW among 130 projects, the agency says.

Now, there are 230 projects generating a total of 185GW of electricity, the EnergyPulse Insights report says.

“The pipeline includes projects at any stage: operational, under construction, approved, in the planning system or at an early stage of development,” Renewables UK says.

Spearheading the projects is the UK, with the largest floating wind portfolio in the world, at 33GW, the report claims.

”The UK’s pipeline has increased from 23GW a year ago to over 33GW, and from 29 projects to 51, which are being developed in the North Sea

(Scottish and English waters), Celtic Sea and the North Atlantic Ocean,” says Rnewables UK.

”Within the global 185GW pipeline, 121MW is fully commissioned over nine projects in seven countries, 96MW is under construction, 288MW is consented or in the pre-

construction phase, 31GW is in planning or has a lease agreement and 153GW is in early development or is in the leasing process.”

A joint project has been launched to investigate the onboard capture, storage and off-loading of carbon dioxide in what is thought to be a world first.

The project, initiated by the Global Centre for Maritime Decarbonisation (GMCD), has rounded up the Oil and Gas Climate Initiative (OGCI), Stena

Bulk and Alfa Laval, among others, as technology partners.

It aims to demonstrate end-to-end shipboard carbon capture at scale by testing a carbon capture unit onboard a Stena Bulk MR tanker to assess operation challenges while the ship is at sea.

“Since the production of

zero-carbon fuels to scale will take some time, we see carbon capture coupled with low carbon fuels as one of the potential pathways to help the shipping industry navigate to a net zero future,” said Sameer Kalra, president of the Marine Division with Alfa Laval.

“We want to evaluate the commercial and environmental implications as well as identify the challenges and opportunities in the implementation of a carbon capture system on board a vessel. The findings will help in the development of the technology at scale.”

North and Standard Club are a step further towards merging to form NorthStandard in February 2023.

Approvals from the UK’s Competition and Regulatory Authorities mark a major step forwards in the plan to merge, says Rob McInally, director of marketing and communications

with North P&I. Once formally merged in February, the new NorthStandard will be one of the largest providers of insurance in the maritime industry, with consolidated premiums of around $750 million (€773 million) a year.

“The approval from several regulatory and competition

authorities in key regions around the world is a major step towards enabling our plans as NorthStandard to offer a competitive range of high-quality services to our members and brokers”, said Jeremy Grose,

Standard Club CEO.

“The merger will allow us to work together with our colleagues from North to shape an organization to meet the challenges of a changing shipping world.”

the latest news and analysis go to www.maritimejournal.com

The UK’s Port of Liverpool is to restructure its containers division and has confirmed it will shortly start a redundancy consultation process.

The news follows a marked deterioration in the volume of containers handled by the port plus strike action in recent weeks by Unite the Union, which has rejected a 10.2% increase in basic pay.

“We have seen an increasing decline in the movement of containerised cargo for Liverpool over the last few months, in line with industry figures which show a 4.6% drop in volume across Europe.

”This, together with a recent sharp fall in container vessel charter rates of around 50%, indicates a rapid decline in throughput is expected over the next few months,” said a

spokesperson for Peel Ports Group, which operates the Port of Liverpool.

Fabian Bez stepped into the CEO post on October 1, and on November 1, Heiko Vietmeier will join as CFO of Torqeedo, the marine electric drive maker.

The two will replace Dr Markus Müller, CTO and CSO of Torqeedo’s parent company DEUTZ AG, and Dr Alf Harkort, who served as interim managing directors while the search was on for new leaders.

Fabian Bez has experience in strategic corporate development, including electrification and batteries, working at Webasto Thermo as divisional CEO. He has also worked as a consultant in alternative drives and renewable energy.

Heiko Vietmeier will begin his new role on November 1, coming from Defontaine Group, a manufacturer of slewing bearings for a range of applications including wind turbines and transport.

He has first and master’s

degrees in business and accounting and is a chartered accountant.

Torqeedo was founded in 2004 in Bavaria, near Munich, when Christoph Ballin and Friedrich Böbel began to look into electric boat propulsion.

Norway has committed to making its entire fleet of vessels – from small boats to commercial ships – carbon neutral by 2050.

Speaking at the recent SeaTech 2022 exhibition and conference in France, Johann Johan Hammerstrøm, first secretary at the Norwegian Embassy in Paris, told delegates that already in place was a law allowing only zero-emissions vessels on its fjords as early as 2026.

“Norway has the world’s fifth largest commercial fleet, the second largest offshore fleet, the second biggest oil and gas fleet and seven per cent of the world fleet,” he said. “But we consider ourselves as a front runner, a pioneering country in terms of implementing projects such as the world’s first fully electric ferry in 2015.

“We have 103 private companies involved in the initiative, as well as green ports and 70 electric or hybrid ferries in circulation today.”

Hydrogen was one of the key fuels that Norway was focusing on, he said, which would be used for short or medium-distance ships.

“We will be launching a hydrogen ferry later this year,” he said.

The London Protocol has been amended so that sewage sludge can no longer be dumped in the ocean.

Sewage sludge was formerly on the list of permissible wastes that can obtain dumping permits, but after a proposal was submitted by South Korea and Mexico it was removed and dumping is now prohibited worldwide.

considerably anyway over recent decades, with many regional conventions already banning it through domestic legislation.

However according to Annex 1 of a ‘reverse list’, the list of materials that can still be considered for dumping at sea includes inorganic geological material, vessels and platforms or other manmade structures and ‘specific bulky items’.

When Seacat Sceptre hit the water in March 2022, Crew Transfer Vessel operators the world over took notice, reports Jake Frith

Click here to read article on Maritime Journal online

Waves at sea are inherently unpredictable, and while we can predict trends, we can never accurately predict what the next wave will be. With that in mind, FOSS derives much of its benefit from the IMUs (inertial measurement units) communicating with the active aft foil rams, which react fast enough to make a big difference in the vessel’s efficiency

8 The rear U-Shaped foils are hydraulically actuated at up to 1Hz

Click here to read article on Maritime Journal online

8 The main horizontal foil is bolted between the two hulls just forward of amidships

Consisting of a TTS-4/140 series tensioner, an adjustable radius controller, a reel drive system and an overboarding chute, the spread was mobilised onboard a locallyavailable construction support vessel (CSV).

“Another fantastic project for MDL where our fresh approach to overcoming project challenges delivered a successful campaign,” said Chris Reid, vice president-sales at MDL.

“The application of MDL’s lay spread, with our marketleading tensioner as the master item, delivered a safe and lean mooring solution, allowing for the wire rope to be installed in a single offshore trip, using a vessel of opportunity – that is, one that was readily available in the region.”

During the project, more than 6.4km of the 149mm OD sheathed Spiral Strand Wire Rope (SSWR) was transpooled at the mobilisation port in Singapore from storage reels onto five transportation reels. The SSWR was then deployed to moor in an FPSO in 310-500m water depths.

This was the first time an MDL tensioner was used for the installation of a wire rope off a CSV, allowing the project team to maintain consistent line tension and squeeze on the product while benefitting from MDL’s failsafe grip technology preventing unexpected loss of product.

Eliminating the risk associated with hose or other griprelated failure, this unique system removes the single point failure risk associated with other standard tensioners on the market. It provides a directly mounted manifold and accumulator on each individual active grip cylinder, ensuring that the required grip force is maintained in the event of any unforeseen system failure or black out.

Also used on the project was MDL’s adjustable radius controller, which optimised the handling of the wire rope as it

was deployed from the double-drum transportation reels, by hydraulically moving in and out to maintain the product in the firing line.

The project followed other mooring projects in the Gulf of Mexico and offshore Brazil, where a similarly innovative approach was taken using an RDS-based spread mobilised onboard a heavy load carrier.

Climate change models are predicting that France will have to spend €8 billion to protect the country’s buildings - and that doesn’t include roads and railways - as sea levels rise.

Presenting at the recent SeaTech 2022 event in Brest, France, Marissa Yates, a researcher with the government environment institution CEREMA - Centre d’études et d’expertise sur les risques, l’environnement, la mobilité et l’aménagement - (Centre for Studies on Risks, the Environment, Mobility and Urban Planning) said their models offered predictions, but that more data were needed.

Yates’s modelling predicts that 1.5 million

people are exposed to the risk of marine flooding; 30km2 of land could be lost to coastal erosion within 50 years; and up to 30,000 buildings could be flooded in the 2100s at the cost of €8 billion.

“We have taken estimates of global climate change and applied it to local scenarios,” she said, adding that France had borders in five oceans and demographics were changing which necessitated action.

However there was still a desperate need for data in order to more accurately make predictions. Despite some records showing that there had been a 16cm sea level rise between 1902 and 2010, just two

8 This was the first time an MDL tensioner was used for the installation of a wire rope off a CSV

photographs showing the changing coastline meant seasonal variability and other factors could have played a part, she said.

”Data is sometimes inadequate or contradictory,” she said. ”So we need to take action now without having all the answers. We need to take no-regrets decisions, and assess nature-based solutions for coastal protection.”

Specific measures were not named, but there was a need for observation that hadn’t been accomplished yet, Yates said.

Quoting IPCC (Intergovernment Panel on Climate Change) models, sea levels were predicted to rise by 70cm within a century, Yates told attendees.

and

to

Work has begun to build a fourth berth at DP World’s London Gateway hub, which will increase cargo capacity by a third

It’s hoped that the resilience of the UK supply chain will be strengthened by the £350 million (€398 million) project, which builds on DP World’s £2 billion (€2.3 billion) investment in Britain over the last decade.

“I am delighted that we have taken the next step in delivery of the new fourth berth and made clear our commitment to investing in and regenerating the areas where we operate,” said Ernst Schulze, UK chief executive of DP World.

“Over the next 10 years we have earmarked a further £1 billion of investment in this country.”

The construction work will create 1,000 new jobs with the growing logistics park eventually home to 12,000 employees once it completes in five years’ time.

Civil engineering company McLaughlin & Harvey, is working with the port operator to build the new terminal.

“We are delighted to have been awarded the contract with DP World and to begin delivering this vital piece of national infrastructure. We bring with us extensive experience in the marine sector and look forward to engaging with our local supply chain and creating jobs locally,” said Seamus Devlin, covil engineering director, McLaughlin & Harvey Civil.

DP World operates two deep water ports at London Gateway and Southampton in the UK with access to freight rail terminals and a rapidly expanding logistics park on the doorstep of the capital.

By offering a choice of deep-water entry and exit points to and from the country, the port operator said it is giving greater flexibility to shipping lines, cargo owners and exporters.

Back in July, DP World announced that London Gateway handled more than one million TEU in six months between January and June - a record for the port.

Together with throughput at the Port of Southampton, the performance contributed to a record volume of cargo in the first half of the year for DP World’s UK port operation of 1,937,000 TEU.

to www.maritimejournal.com

We are delighted to have been awarded the contract with DP World and to begin delivering this vital piece of national infrastructure. We bring with us extensive experience in the marine sector and look forward to engaging with our local supply chain and creating jobs locally

‘‘

The €335 million renewal work, which will be carried out in three stages over a total of nine years, has been handed to four contractors after a tender process that concluded on October 6.

It will include electrification and wind turbine installation to reduce CO2 emissions, and the quayside will be given a new orientation to ensure there is enough distance between passing ships and the terminal.

An underwater dam will also be built in the final phase to provide additional protection for a nearby nature reserve, the contract provides.

The four winning tender companies were Artes-Roegiers, Artes-Depret, Herbosch Kiere and Boskalis - which ’all have extensive engineering experience in large-scale hydraulic engineering’, according to spokeswoman Daniela Baicoianu, and will form a temporary company under which to operate.

The depth of vessels that will be able to moor at the 1,200m quayside will increase from 13.5 metres to 16, and because it is vital that ships can still moor during the works, it will be done in three stages

The depth of vessels that will be able to moor at the 1,200m quayside will increase from 13.5 metres to 16, and because it is vital that ships can still moor during the works, it will be done in three stages.

“With the modernisation of the Europa Terminal we are underlining our ambitions as a container port,” said Jacques Vandermeiren, Antwerp-Bruges Port CEO. ”As a world-class

port, it is essential that we continue to play at the highest level and are able to accommodate the biggest ships.

“We are, however, aware of the impact of our activities on the surrounding area and local residents. That is why we are committed to reducing mooring emissions, among other things. With a new efficient and sustainable terminal, we are building the port infrastructure of the future.”

Capacity, said PSA Belgium CEO Cameron Thorpe, would increase by more than 70,000 TEU a year.

”We are very happy to undertake this project,” said the four contractors in a joint comment. ”It is a strategic project for the future of the port. It is technically complex and will be carried out in phases without too much disruption to container traffic. It will be a technical and operational feat, but one that we can handle thanks to our extensive expertise.”

Jan de Nul’s offshore jack-up vessel has made neat work of an 80-turbine installation at France’s first commercial wind farm, the Saint Nazaire wind farm.

The Vole au vent was used to complete the installation of the turbines, each 6MW, bringing the total generating capacity 7of the wind farm to 480MW.

The electricity generated, says Jan de Nul, will make up 20% of the Loire-Atlantique’s annual consumption.

The turbines were loaded onto the Vole au vent in sets of four at the port of Saint-Nazaire, then transported the 12 miles

to the northern part of the Bay of Biscay for installation.

It wasn’t just a case of sticking the monopiles in the seabed, however; because the seabed in the area is rocky and uneven,

rock fragmenting operations had to be carried out first to give the jack-up barge a stable base from which to operate.

This was carried out by the company’s Cutter Section Dredger, Fernão de Magalhães, which fragmented the seabed with her rotating cutter head to smooth the ground.

The dredger is 138.5 metres long, with an installed power of 23,520kW.

France is on an energy drive, with plans to build 50 other wind farms of comparable size by 2050.

He also announced plans earlier this year to build another six nuclear reactors.

The Port of Antwerp-Bruges and operator PSA Antwerp have agreed to renew the Europa Terminal so that today’s bigger container ships can continue to call at Antwerp

CorPower Ocean and Maersk Supply have installed a subsea export cable off Portugal so that a wave energy converter can be connected to the grid

The 100-tonne cable was installed using Maersk’s Maersk Achiever vessel, and it will provide power and data connection from an on-land substation to the demo site 5.5km offshore.

CorPower’s Wave Energy Converter (WEC) will later form part of a larger four-system array, which will make it one of the world’s first grid-connected wave farms.

To install the cable, the Maersk Achiever was first positioned in a safe water depth within the cable corridor roughtly 1km offshore.

“A messenger line was passed from an onshore winch to the Maersk Achiever, and then connected to a pull-in head,” said Marine Operations manager Robert Argo. “As the cable was being deployed, buoyancy was attached to assist with the cable float into shore. Once onshore, the cable was pulled through a pre-installed cable conduit running under the beach and into the on-land substation, while the remaining cable was deployed using an onboard cable tensioner.

“During the lay operation, cable protection was added to provide additional mass where required for on-bottom stability. Various parameters were also monitored throughout including cable tension, cable departure angle and touch down monitoring. On completion a visual and positioning survey was carried out by a remotely operated vehicle.

“The cable lay process is a notoriously challenging aspect for marine energy projects, with much planning required and adaption to weather windows and ocean conditions. We are thankful to our highly diligent and professional partners, including Maersk Supply Service for their close support throughout the operation entire.”

CorPower is now gearing up for the arrival of the C4 PTO (Power Take Off) system, which has completed a rigorous one-year dry test programme in Sweden. Once transported the PTO will be integrated with a composite hull, which was

custom built at CorPower Ocean’s Portuguese base, in Viana do Castelo.

The WEC will later be fused to the cable through a quickconnect interface located at the anchor-head. While providing power connection to feed electricity to shore through the 7.2kV cable it will also deliver high speed communication to the wave farm through fibre optic cores.

Britain’s River Thames is to be naturally restored in ongoing works that will include major engineering.

Wet civil engineering firm Land & Water has secured a contract for works along the entire length of the River Thames, which is the second longest river in the country at 215 miles.

The Thames Water River Restoration Project aims to improve fish passage, habitats and resilience in the river from its source in the Cotswolds, western England, to where it empties into the North Sea at the Thames Estuary.

Work will include weir removal or modification, channel bed re-profiling,

riverbank re-profiling and replacement with softer, natural options.

“Barriers to fish passage will also be overcome, with pass channels and other

solutions such as rock ramps and in-channel gravel to allow fish to lay their eggs,” says divisional business manager Fiona Moore. ”As custodians of the environment, it also ensures that we are safeguarding habitat for the flora and fauna for years to come.”

The project is being run by Thames Water, the UK’s largest water and waste water service provider, with a 15 million customer base.

Clodagh Pickavance, media relations manager for Thames Water, said a project to restore seven river stretches and four fish passages would run until March 2025, when further similar projects would be drawn up.

Land & Water is one of the first companies to be awarded a contract.

For the latest news and analysis go to www.maritimejournal.com

Once onshore, the cable was pulled through a preinstalled cable conduit running under the beach and into the on-land substation, while the remaining cable was deployed using an onboard cable tensioner

‘‘

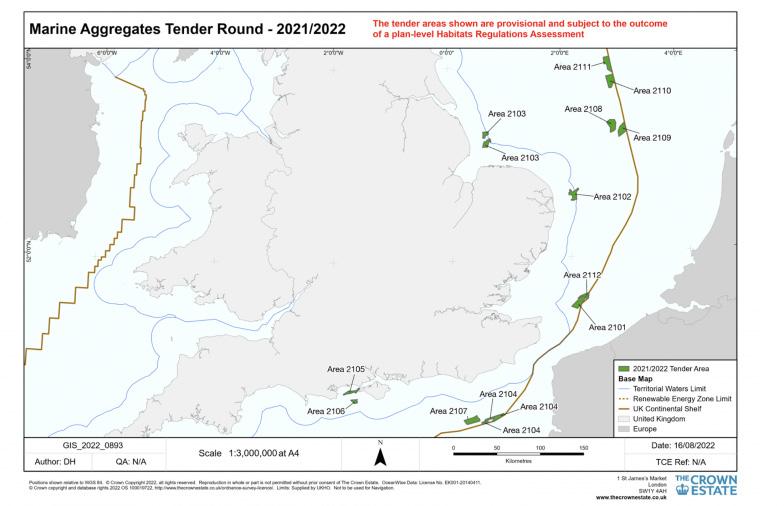

Bidding for dredging is likely to be offered in 12 areas around the UK next year as the building industry demands more marine aggregates

Click here to read article on Maritime Journal online

8 Marine aggregate tenders round for Crown Estate, 2021-22

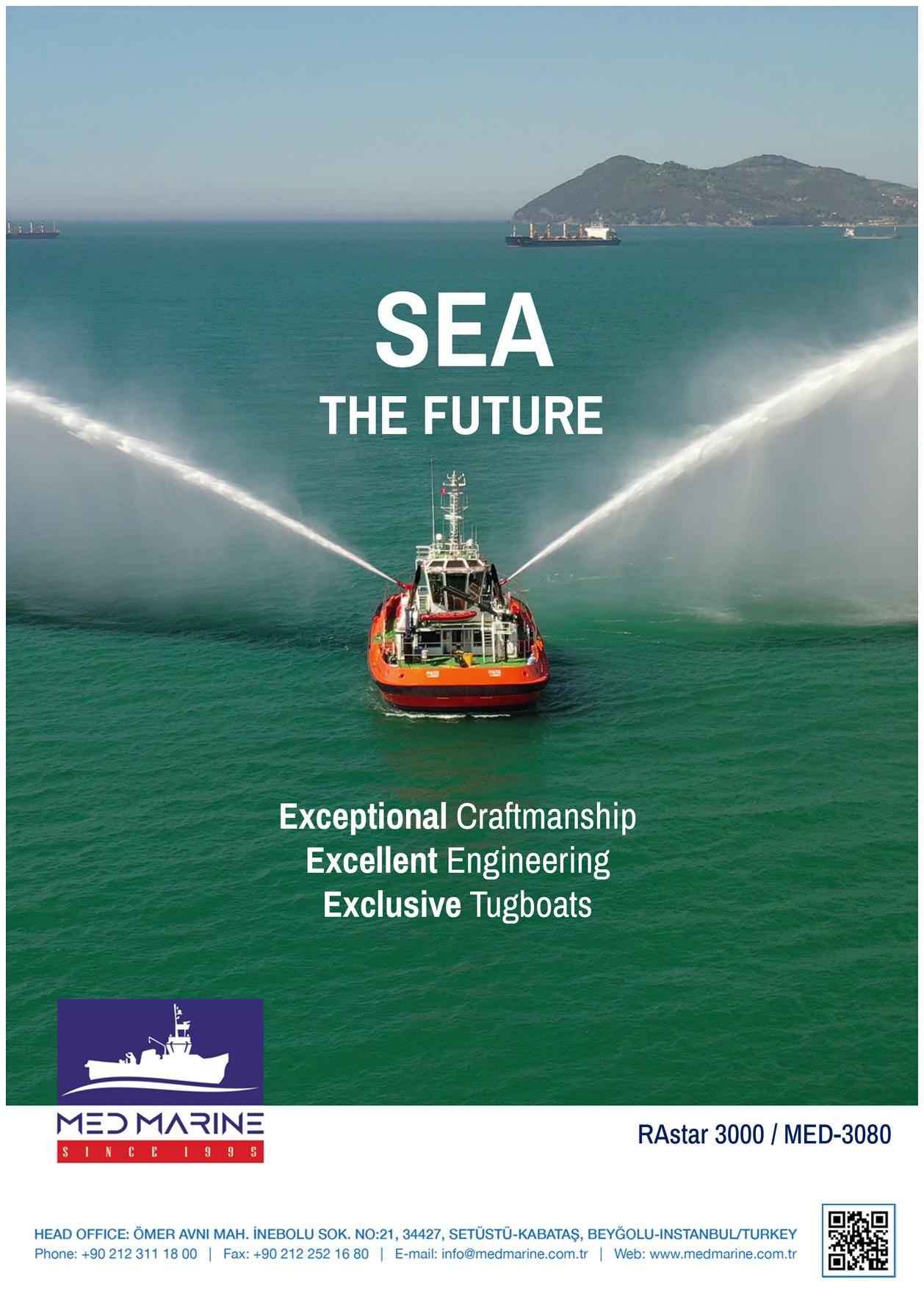

Kongsberg Maritime has agreed a sizable contract with Med Marine to deliver 32 US-series azimuth thrusters for newbuild ASD tugs

The order, which will provide propulsion for 16 tugs, comes at a time when Kongsberg senses positive future potential for the tug construction sector. The Norway-based maritime technology company says the tug market is very important and that since last year market trends have turned positive after the worldwide pause in shipbuilding due to the Covid pandemic.

It adds that the shipping industry and the terminals and harbours that service it are now in renewed need of tugs to assist and that in general the market is looking very positive.

Turkey’s Med Marine is typical of the modern tug builder that has geared up over several years to produce series-built vessels either for operation in its own fleet or to the order of third party tug owners.

Kongsberg itself has been active producing thrusters following its acquisition of Rolls-Royce Commercial Marine in 2019, the largest such in its history. More than 6,000 USseries thrusters have been delivered globally in the past 50+ years, the product evolving in answer to the drive to cut both time and costs from the tug building process accompanied by the shipping industry’s own quest for higher standards of performance.

US-series thrusters are project specific, featuring Computational Fluid Dynamics modelling and offering a range of propeller and nozzle combinations in the constant drive to ensure high standards of operational efficiency. A particular feature is the HD slipping clutch, allowing “cost efficient fire-fighting operations”.

Three of the 16 Med Marine tugs will also feature Kongsberg’s Pro-Duct nozzle, a high-efficiency nozzle and propeller

combination that has shown to provide higher bollard pull for the same power input as an equivalent TK nozzle.

Yıldız Bozkurt Özcan, General Manager at Med Marine, said: “In the maritime industry you can’t get much more demanding than the duty cycle of a tug’s azimuth drive unit. Following three decades of fitting Kongsberg thrusters into our tugs we know that with the US-series thrusters we are making a solid investment for our customers in a wellproven, reliable product that has evolved to keep up with the demands placed by our modern, high bollard pull tugs.”

Wider in Italy has chosen a pair of MAN 12V175D-MEV marine variable-speed genset engines for its new Moonflower 72 superyacht project.

The Wider serial hybrid propulsion system comprises two 1,860 kW-rated variable speed engines and 1 MWh battery bank in combination with the permanent magnet alternators providing the power for a DC grid.

Marcello Maggi who heads W-Fin Sarl, the holding company that owns 100% of Wider’s equity, explained the company’s decision. “The choice to equip the project with only two diesel generators gave us the possibility to optimise the space and the layout of the engine room without compromising performance and safety,” he said.

“In fact, the focus was to increase the global efficiency of the complete propulsion system

and we believe that – with the combination of the Wider Management System, batteries and especially the MAN 175D engine – we have found the right balance.

The company estimates the set-up will optimise the performance by an additional 7%. “To comment further on the generators’ amazing features, we would note the double

shock-absorbing installation that cuts structural vibrations completely, a very compact SCR system integrated into a very innovative exhaust system, and a TBO [time between overhauls] of an amazing 30,000 hours,” said Luciano Cardini, head of Wider Engineering.

The MAN 175D engine range comes in three variants of 12, 16 and 20 cylinders with an output ranging from 1,500 to 4,400 Kilowatts. Optimised for propelling ferries, offshore support ships, tugs and other working vessels, the system can be tailored for other market areas such as superyachts like the Moonflower 72, planing yachts and naval marine applications.

MAN Energy Solutions’ production facility in Denmark will deliver the engines to Wider in April 2023.

8 Kongsberg will supply 32 azimuth thrusters to Med MarineGermany-based Ben Buchele Elektromotorenwerke has unveiled a new range of stainless steel, water-cooled, induction motors for use in confined spaces.

The three-phase asynchronous motors are suited to applications where high performance is a requirement, but noise and heat must be kept to a minimum, such as in small spaces, including cleanrooms.

“With our WD model, you can achieve significant reduction of the footprint on people and the environment through noise emissions and heat dissipation,” said Detlef Koslowsky, head of sales at Ben Buchele.

“As opposed to air-cooled motors, watercooled motors do not cause swirling of dust or dirt, making them the ideal solution for hygienically critical areas. The S1 duty cycle means that the motor runs continuously, which is important for these types of application.”

The new range of motors is available globally in 0.75 to 300 kW capacity.

Starting with the WD71 model and going up to the WD315; WD is a reference to ‘watercooled’ in German, while the numbers represent the motors’ frame size. The dimensions of the products vary as the motors

maritime hybrid engines and anchor/mooring winches, among target applications.

Depending on the end use and customer preference they can be supplied coated, or painted in white, which will likely be the chosen option for those utilising them in food production environments.

Credit: Ben Buchele8 The motors are suited to applications where high performance is a requirement, but noise and heat must be kept to a minimum

increase in frame size in 13 total increments, including 80, 90, 100, 112, 132, 160, 180, 200, 225, 250, and 280.

Koslowsky said the range will be sold to both original equipment manufacturers (OEMs) and end users, with test facilities, printing devices, textile machines, injection machines,

The new water-cooled (or WD) range can be used in the most challenging conditions, such as those where seawater, salty air, and ambient temperatures of up to +60°C are present. Manufactured with high-quality, application-sensitive seals and sealants, they can achieve protection levels according to IP56, 66, or 67, depending on the motor.

While the range is standard based on frame size and capacity, each unit is prepared accordingly to individual specifications. With the variable multi-foot attachment and adjustable casing, the shape of the motor can even be modified multiple times, including onsite. The coolant supply openings are located on the non-driving side to allow for further ease of modification.

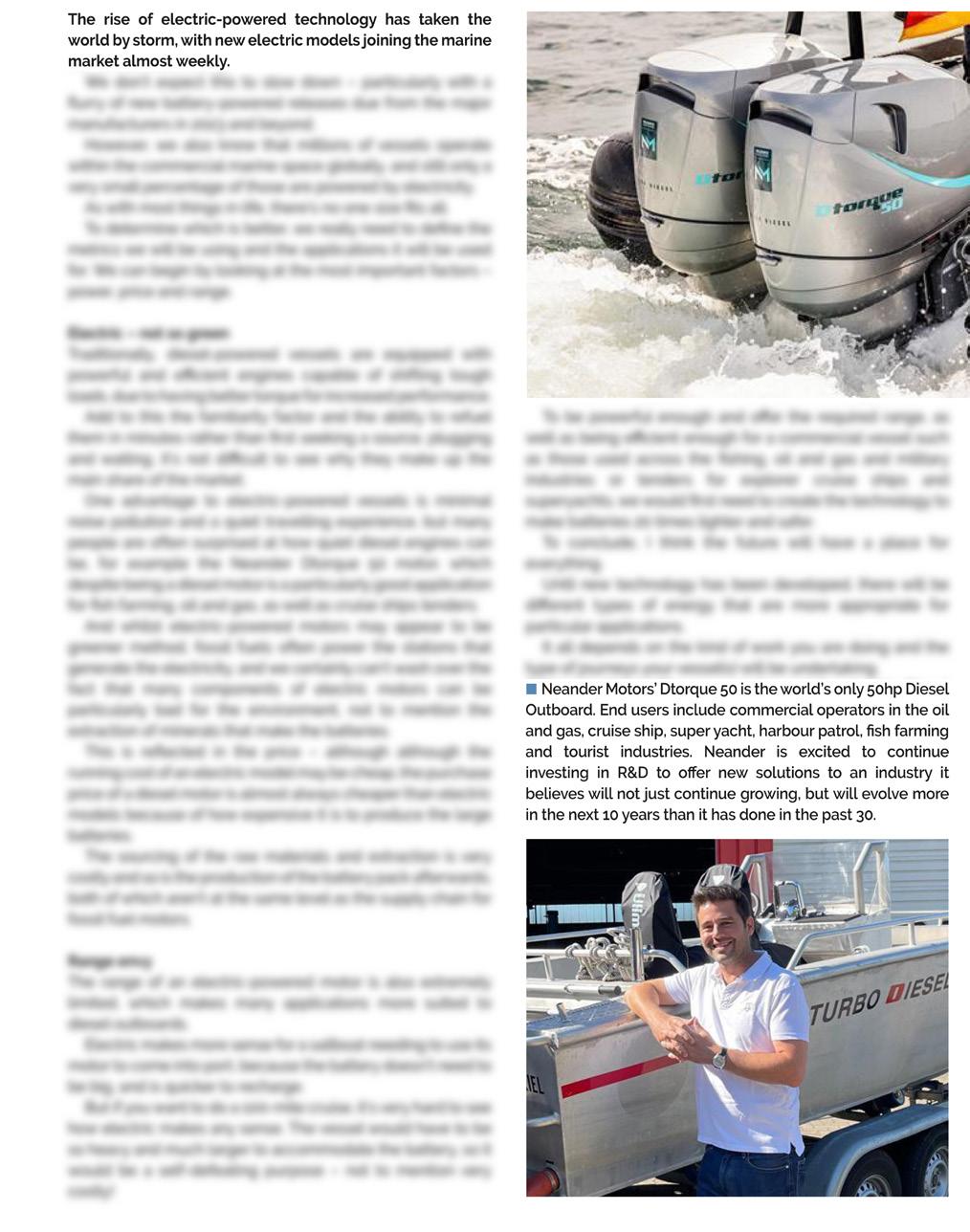

8 Dtorque 50 diesel outboards

8 Dtorque 50 diesel outboards

Holland Shipyards Group has struck a deal with Trafikverket Sweden for the delivery of four autonomous all-electric ferries.

The ferries will sail in accordance with autonomy level 2, meaning they are remotely monitored but with crew on board to take control if necessary. Autonomous control will be from Trafikverket’s remote control centre based in Stockholm.

“We are extremely proud to be a part of this pioneering step in shipbuilding,” said Cor Hoogendoorn, director Holland Shipyards Group.

The deal includes the initial delivery of two ferries with four automooring facilities and two charging stations, a simulator facility and a remote control centre.

The tender covers the whole procurement of four ferries, eight automooring facilities, four charging stations and more.

The ferries measure 86 metres by 14.24 metres and have a 60 car capacity. While mooring, the vessels are charged by an onshore charging facility which takes approximately four minutes.

Autonomous sailing technology is intended to increase passenger safety in the long run.

With a fully operational system in place, responses are more consistent, removing the potential for human error and reducing the risk of unexpected events.

8 The fully-electric autonomous ferry

8 The fully-electric autonomous ferry

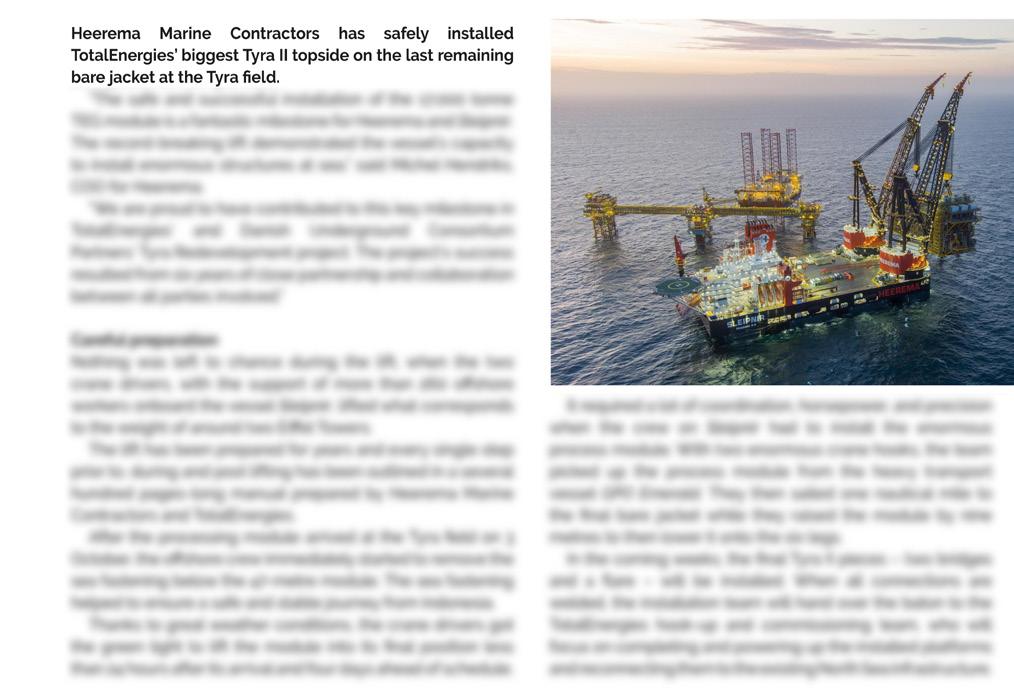

A heavy lift contractor has broken a record with the lift of a 17,000 metric tonne heavy process module, which it says is the heaviest crane lift ever undertaken at sea

Pontoon hiring firm ScaffFloat has added a 2.8t crane to its product - leading to some comparing it to a workboat.

Made entirely from scaffold components, the ScaffFloat system has now been fitted with a crane and used in a project on the River Thames for ladders, chains and wooden fendering installation.

The crane, which can lift 600kg and was fitted to a steel crane base, was designed according to the Lloyd’s Register Code for Lifting Appliances in a Marine Environment and assessed in line with IMO standards, founder and managing director Toby Budd says. The pontoon was licensed by the Port of London Authority as a commercial vessel before the work was carried out.

For the project on the Thames ScaffFloat mobilised an 8m x 6.4m ScaffFloat, fitted

with two 60hp, high-thrust outboards giving 0.8t of bollard pull and a 5-knot service speed, said Budd. Thirty of the company’s small 0.5m3 patented plastic floats provided

15m3 of buoyancy, giving it a comfortable 5t payload on the large open 50m2 wood deck.

”We started off with simple pontoons that could be used for access. Then we added outboard pods to the pontoons turning them into workboats, suddenly they became much more useful to our customers and now 90% of our hires go out as a ‘vessel’.

”We then added spud legs, deck winches, and other bolt-ons to add further value. But there is no doubt that it is the addition of a knuckle boom crane that marks the biggest advance in the system from an engineering perspective. Lifting is a key component for most marine works and I am delighted we can now offer this to our customers.”

ScaffFloat won the Spirit of Innovation Award at Seawork in 2019. It is now developing a crane base for larger projects.

8 Heerema has nstalled TotalEnergies’ biggest Tyra II topside on the last remaining bare jacket at the Tyra fieldCrane manufacturer Liebherr has confirmed the successful completion of two major installation projects using its largest offshore crane in Germany and France.

The HLC 295000 has a lifting capacity of 5,000 tonnes and a maximum lifting height of 175 metres above deck, and was used on Orion, which Liebherr says is ‘currently considered the world’s most innovative vessel in the offshore wind industry’.

In the first project, French offshore wind farm Fécamp, Orion and the crane set down a 1,300-tonne jacket foundation on prepared seabed in preparation for a 2,200-tonne transformer platform to be placed on top.

“It was particularly important not to lose sight of the tight schedule and the weather conditions in Normandy. which was achieved not least thanks to the good dynamic positional system of the Orion and the high precision in the control of the HLC 295000,” says LiebherrMCCtec Rostock.

For the German Arcadis Ost 1 wind farm in the Baltic Sea. the crane was used to install 28 monopile foundations with lengths of up to 110 metres and weighing up to 2,100 tonnes each.

Lieberr says the crane is often in use for 24 hours non stop.

”Our initial experience indicates that the installation times of previous vessels of about 3 to 3.5 days per monopile can be significantly reduced to about 0.9 to one day per monopile with the use of the Orion and our HLC,” said Robert Pitschmann, global application manager, Liebherr-MCCtec Rostock.

8 Liebherr’s installation vessel Orion transporting the HLC 295000 heavy-lift crane

“The innovation of the Orion is the ability to install the monopiles floating,” says Liebherr. “This means that no time-consuming jack-up process of the ship out of the water is necessary, as it has been the case up to now with jack-up units.”

“The HLC series and the expansion of the heavy-duty crane range are firmly anchored in Liebherr’s strategy, not least because of the energy transition,” the company says. “In order to ensure a sustainable energy supply for present and future generations, significantly more and larger offshore wind turbines are being built.

“For the construction of these modern wind turbines, the lifting height of the HLC 295000 is a decisive factor. In addition, there is a trend towards decommissioning disused oil and gas platforms. This involves dismantling large and heavy parts on the open sea.”

dlm-uk com

Specialist expertise in bespoke logistics was called upon in a recent single-ship transport of three 36m catamaran fast ferries

Peters & May received an enquiry from Golden Cargo in January 2022 concerning the transport of three aluminium, light construction carbon fibre ferries from their builder, Brodrene AA in Hyen, Norway to their new operator, Hellenic Seaways in Piraeus, Greece.

The vessels are broad of course (36m x 9.7m), but relatively light at just 82 tonnes each.

As Paul Elsom, Peters & May’s Global technical director, explained, there was an additional challenge of getting all three ferries onto one vessel.

“At Peters & May we take both decarbonisation of all our operations and providing the best value to our clients very seriously,” he said. “With this in mind, instead of fulfilling this transport with more than one trip, we decided to look at using the state-of-the art Rolldock Sky heavy cargo vessel with one of the ferries stowed below deck level and the other two above.

It would take a bit of maths to get all three aboard securely, particularly as they all had to be tandem lifted, but this is what we do and successfully moving the three ferries in just one trip would save both carbon from the atmosphere and costs for our client

“It would take a bit of maths to get all three aboard securely, particularly as they all had to be tandem lifted, but this is what we do and successfully moving the three ferries in just one trip would save both carbon from the atmosphere and costs for our client.”

Rolldock Sky, launched in 2016, is a highly configurable 142m vessel with three different loading modes – Float-In / Float-Out, Roll-On / Roll-Off and Lift-On / Lift-Off.

During Flo-Flo operations, the vessel can submerge to 12.5 metres, creating a draught in hold of 6.6 metres. With a draught of 5.67 metres, the vessel is suitable for shallow draught waters, and each deck crane can lift up to 350mt, or 700mt in tandem lifting.

Peters & May was unable to use Rolldock Sky’s submersible functionalities on this occasion, as the fjord depth at the loading location meant local regulations deemed this too risky in the unlikely event of a vessel systems fault and subsequent salvage operation.

The vessel’s tandem lift capability would be key to this operation though, not due to the overall weight of the ferries, but to follow the lifting conditions stipulated by the shipbuilder.

“Loading operations started on July 11 and took two days because one ferry was stowed underdeck while the other two were on deck,” said Elsom. “Using two cranes in a tandem lift configuration meant that the ferries had to be loaded in a fore and aft configuration.”

The loading operation was conducted in a fjord in northern Norway, which brought its own positives and negatives.

“The steep valley sides made it glass calm - so perfect lifting conditions,” said Elsom. “The marine traffic there was very light, so we had plenty of time to get things set up well, but there was no berth available, leaving us to conduct the lifts at anchor.

“Finding a suitable anchorage in the very deep water there was a bit of a challenge in itself. We used tugs to deliver the ferries alongside the ship and all loading, cradling and lashing equipment had to be supplied to the vessel at its last port of call - in Finland!”

Thanks to meticulous planning by Elsom and the Technical Team and loadmaster attendance at both POL and POD (Port of loading and Port of discharge), the operation went without a hitch at either end.

Peters & May would like to thank maritime logistics company Golden Cargo SA, based in Piraeus, Greece, who kept in close contact with the ferries’ owner (Hellenic Seaways/ Attica Group) in Greece, ensuring they could remain confident in this special project shipment through every step from booking to delivery.

Peters & May has worked with major commercial vessel owners and operators for more than a decade, shipping vessels and their equipment across the globe.

For the latest news and analysis go to

8 Rolldock Sky‘‘

A third motion compensation pile gripper will be built by civil engineering equipment maker Huisman following an order from offshore energy firm Heerema.

The new gripper will allow installation of wind turbines 12.5 metres in diameter, 115 m in height and 3,200 tonnes in weight.

It has been designed specifically for Heerema’s semi-submersible crane vessel (SSCV) Thialf, on the side of which it will be positioned once completed.

Dubbed ’’Heerema’s workhorse’ by Heerema, Thialf has undertaken some impressive projects in her almost 30 years of life.

In 2020, eight months of work were completed when seven platform topsides, seven jackets and 22 conductors were removed by reverse installation for ExxonMobil Canada’s Sable offshore natural gas facility

In 2020, eight months of work were completed when seven platform topsides, seven jackets and 22 conductors were removed by reverse installation for

ExxonMobil Canada’s Sable offshore natural gas facility. The work involved the removal of 48,000 tonnes of infrastructure, and the company says 99% of that was recycled at the ABLE UK decommissioning yard.

This year, Thialf has been involved in projects in projects in the Baltic Sea, including the Arcadis Ost 1 offshore wind farm.

“Huisman is very honoured to receive this order, for Heerema’s first pile gripper,” said David Roodenburg, CEO of Huisman. ”This is a complex project, the execution of which will draw upon the knowledge and experience of both parties. We are looking forward to collaborating with Heerema to deliver this innovative gripper.”

Zero-emissions CTV concepts are getting close to delivery, with offshore charging technology a crucial factor.

Tidal Transit’s zero-emissions crew transfer vessel should be a reality within two years, in tandem with a project it’s already working on with Artemis Technologies.

Tidal Transit already has a fleet of six CTVs, which have been on regular long-term charter with developers and operators including Orsted, Equinor, RWE and SSE for more than 10 years.

And that’s what’s been the driving force behind the company’s new concept, says commercial director Leo Hambro – first-hand experience of working at such different projects, whether they’re near shore or at more distant wind farms.

The company is in the process of raising the funds to build out an entire fleet of ‘green’ vessels to meet predicted demand as renewable energy projects gain ground; and this is in parallel with a slightly different boat that it’s developing with Artemis Technologies and other companies in the latest round of the Clean Maritime Demonstration Competition, which awarded the consortium £3.4 million (€3.8 million).

“They fill slightly different roles,” says Hambro. “With Artemis, we are using the efoiling technology on vessels that we anticipate will be travelling much further distances on pure electricity.

“Because it can get out of the water it can go further and faster, but it’s more about taking people.

“The Tidal Transit vessel is more of a multi-functional CTV, which will take cargo and can operate for days at a time. A genset will give it redundancy if it needs it, or if electric charging isn’t available.”

The concept is based on a Capilano hull with quad propulsion for redundancy, and expertise from Seaspeed on how to optimise the hull, says Hambro. Power will mainly come from modular battery packs, the quantity of which will depend on the wind farm site.

Crucial to a wider roll-out is MJR’s charging technology – whereby vessels can be plugged in at the turbines and charge while they’re at sea. The technology is now ready to go and while designed initially as a retrofit product for wind farms, the scalable technology should eventually be built into wind farms as opposed to being added to them afterwards.

“Now the MJR charging concept is waiting to be delivered, it’s sitting there waiting to be installed, so this makes it possible,” says Hambro.

“We are talking about vast quantities of batteries – our vessels will have 3.5MWh or

more – and in fact we also intend to retrofit some of our vessels to battery for the very near shore work. We have had to wait for the battery density to go up and the infrastructure to be there.”

But won’t all these batteries be extremely heavy?

Hambro says that compared with the weight of heavy fuel tanks and systems there isn’t a huge difference.

“It’s also a constant weight, whereas fuel will fluctuate,” he says. “You do need to have a charging point for the workhorse before you can do it. But already, there are multiple onshore charging solutions where you can plug in overnight for 12 hours.

“Offshore charging has multiple benefits – you can have a higher charge rate, it’s effectively free electricity, and we’d be able to recharge our boats in about two hours.

“It’s actually going to be easier to install them offshore rather than onshore and there’s much more kilowatt capacity from the turbine than you could ever dream of getting from the grid.”

The Tidal Transit concept makes it more than a CTV, says Hambro.

“It’s much more of a workhorse, carrying cargo, potentially bringing hydrogen back from the wind farms – you need different types of vessels for different wind farms with different distances and so on,” he says.

“Our CTV will be able to carry 12-24 passengers, up to 4x10’ containers (or 2x20’), as well as providing above-deck, 24hr marine crew accommodation. We intend to build out multiple vessels along this line.”

The offshore wind industry is crying out for decarbonisation due to the vast quantity of power produced there, says Hambro.

“Although there are opportunities for fuels like hydrogen to be produced, the most efficient use of the power is as electricity, without CO2 or NOx.”

For operations far from shore, when a CTV might stay in the field for up to a fortnight, fuel savings will become even more significant, and Hambro estimates that several sites off the east coast of Britain could save around 30,000 litres of diesel within two weeks.

Delivery of both vessels is expected in the next 14-16 months, he says – the main delay to earlier delivery time being currentsupply chain issues.

We are talking about vast quantities of batteries – our vessels will have 3.5MWh or more – and in fact we also intend to retrofit some of our vessels to battery for the very near shore work. We have had to wait for the battery density to go up and the infrastructure to be there

‘‘

US Ambassador Dr Amy Gutmann attended the launch of Chicago, a hybrid backhoe dredger with full electric capability, in the Port of Hamburg

“This is not only the present, but it’s also the future,” said US Ambassador Dr Amy Gutmann as she was interviewed at the launch of the Port of Hamburg’s new backhoe dredger Chicago on October 4.

First Mayor of Hamburg Dr Peter Tschentscher hosted the ceremony.

Built at the Hitzler Werft Shipyard in Lauenburg, the 25m x 8.5m vessel is unusual as only the second of its kind for the port, which already operates the levelling vessel Otto Stockhausen.

Chicago, said spokeswoman Julia Kück, will undertake most of the levelling work at the port. She is also designed

for multi-purpose coastal, estuary and inland waterway operation, and will also be used for maintenance work, water depth assessment and towage and materials transport on the Elbe North Sea estuary and river.

She has two Caterpillar 500kW C4.4 ACERT engines and a Caterpillar 99kWe C4.4 auxiliary diesel as well as its two kW Buchele electric motors - which allow it to run on purely electric for two hours at six knots.

For her main job she has a 9.7m wide silt plough weighing 3.7 tonnes. With a listed 15kN bollard pull and a swing frame, she will also boast a 1.2m diameter moonpool and space on board for a single 10ft or 20ft container.

The world’s largest ice-rated ConRo vessel has been named in a ceremony at the Swedish Port of Skellefteå, where it will also be the biggest ship to ever call.

A bottle of Champagne was broken against Bosnia Enabler’s 242m hull in the traditional way amidst pomp and ceremony put on for politicians and representatives of trade and industry among other guests.

The container ship is a multi-fuel (LNG, LBG, diesel and synthetic diesel) vessel, which

owners Wallenius Sol claims per transport unit has a reduced fuel consumption of 57%, 63% reduced greenhouse gas emissions, and 99% reduction in sulphur, nitrogen oxide and particulates.

“I am honoured to be given an assignment like this. I myself have a background in this industry and with climate change in mind it is important that we use the shipping industry,” said ship godmother Ulla Löfven, the wife of Swedish prime minister Stefan Löfven.

and

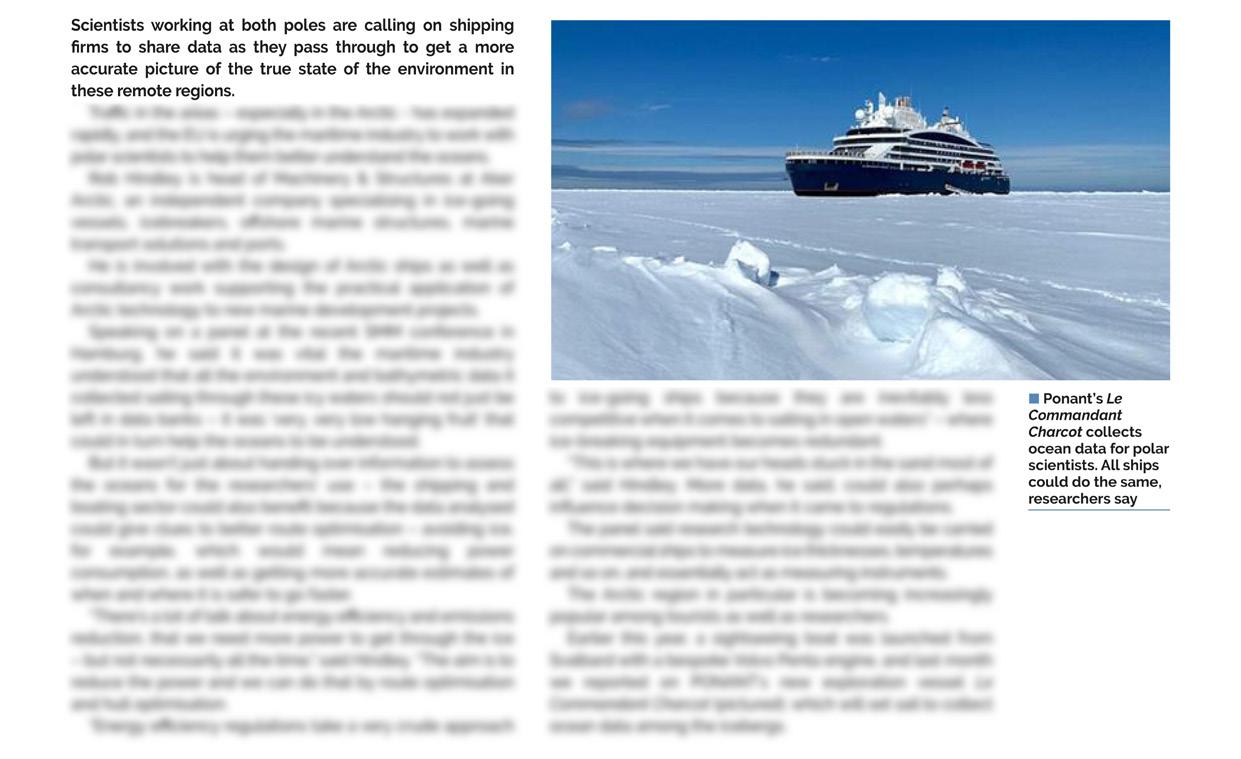

Experts and researchers say increasing traffic at both poles, especially the north, is an increasing cause for concern.

As polar expeditions rise in popularity among tourists, more boats are being built for the purpose - and they are gaining in size as well as quantity.

Maritime Journal in May was given access to a 12-seater tourist boat, the Kvitbjørn (Polar Bear), which was launched in a collaborative effort among Volvo Penta (the engine designer), Marell boats (the boat builder) and Hurtigruten (the travel agency based on the Arctic island of Svalbard).

But this 14m boat pales in comparison to the Viking Polaris that has just been delivered by Vard Søviknes in Ålesund, Norway, a 205m long vessel with a beam of 23.5 metres, a capacity for 378 guests and 189 state rooms.

And this is the second of her class to be launched by Vard in the area - coming after sistership Viking Octantis, also an ice strengthened, Polar Class 6 vessel with a longer hull, straight bow and fin stabilisers for as calm as possible journeys in the polar regions.

Tourism is not the only reason why traffic is increasing in the regions, there is a greater emphasis on scientific exploration. Gone are the days when explorers in thermal underwear

“Indigenous people are the first ones impacted by increased traffic because they are the first to the site, said Emmanuelle Quillérou, environmental & natural resource economist at the University of Bretagne Occidentale.

“There is more risk to themselves - they typically don’t go out to sea when it’s not safe but this is exactly when people need help.”

and crampons strapped tents on their backs and picked their way across frozen wastes - they prefer to sail in luxury now, with vessels like Ponant’s Le Commandant Charcot a case in point.

At the recent SeaTech expo in Brest, France, increased traffic at the polar regions came under the spotlight, with several sessions discussing the potential harm to the polar environments as traffic increases.

One aspect was safety, and not just of the ship crew and passengers, but of the local populations.

The lack of ice forecasting was also a problem, she said - where ice charts are available there is no forecasting as such.

Oil, chemicals and plastic pollution are an increasing problem that the non-profit research organisation SEDNA is addressing, with testing equipment that can replicate different sea scapes and temperatures and what effects the different pollutants can have.

“We are working with the IMO on this,” said Nicolas Dubreuill, director of operations with SEDNA. ”Commercial traffic is developing but cruisers bring tourists to look at the melting ice. This is fantastic for tourism but not for the environment.”

8 Viking Octantis, VARD’s first polar expedition cruiser

8 Viking Octantis, VARD’s first polar expedition cruiser

Offshore emergency support vessel operator North Star has launched its first daughter craft for the offshore wind market.

Christened Grace Darling after a lighthouse keeper’s daughter who risked her life to save sailors from a shipwreck in 1838, the vessel is the first of four hybrid craft developed by Chartwell Marine and being built by Alicat Workboats for North Star.

All four vessels will be named after ’iconic women’ from the northeast of England.

The hybrid boats will transfer in-field crew and technicians between their work on wind turbines and the service operation vessel (SOV) on which they live during the work.

“We are very pleased to have officially launched the Grace Darling and bring the world’s first offshore wind hybrid propulsion daughter craft to market. There is a long history of iconic women hailing from the region, and we wanted to enhance their legacy by naming our new green fleet in their memory as well as commemorate our local roots,” said North Star CEO Matthew Gordon.

Once all four craft are delivered, North Star will have the largest daughter craft fleet in Europe, with 67 assets, it says. Grace Darling was officially launched at the Royal Norfolk and Suffolk Yacht Club in Lowestoft.

The VIP event was attended by a number of the UK’s leading offshore wind developers, after the daughter craft was delivered ahead of schedule to further performance and field

operations readiness, prior to the firm receiving the planned early delivery of its service operations vessel mothership to the Port of Tyne early next year.

Hosted by:

A new autonomous underwater vehicle fits in a standard airline carry-on bag, but packs in industry-leading technology – and will be unveiled at next year’s Oceanology International Americas (OiA)

Click here to read article on Maritime Journal online

For the

news and analysis go to www.maritimejournal.com

The huge potential for offshore wind projects is likely to excite the commercial marine sector as the US commits to offshore wind

Offshore wind development in the US has been given a major boost after the Joe Biden administration launched ‘coordinated actions’ that will result in new floating platforms being developed.

The initiatives develop the government’s existing plans to deploy 30GW of fixed-bottom offshore wind by 2030 with advance lease areas in deep waters to deploy 15GW of floating wind by 2035. Two thirds of America’s offshore wind energy potential lies in floating intallations, the US administration believes, yet just 0.1GW is globally generated in this way.

As well as advancing the lease areas for floating offshore wind, the government is creating a ‘Floating Offshore Wind Shot’ to accelerate work in engineering, manufacturing and other areas of innovation. The aim is to reduce the costs of the technology by more than 70% to $45 per megawatt hour.

The initiatives develop the government’s existing plans to deploy 30GW of fixed-bottom offshore wind by 2030 with advance lease areas in deep waters to deploy 15GW of floating wind by 2035

“Achieving this cost target will require focused research, development and demonstration to catalyze continued cost reductions, with a focus on manufacturing, engineering and continued increases of offshore wind turbine capacity,” says the announcement. “Agencies will also continue collaborating to develop the robust domestic supply chain and transmission infrastructure needed to acccelerate floating as well as fixed-bottom offshore wind.”

The government has also launched a prize competition for wind platform technologies under initiatives funded by a Bipartisan Infrastructure Lawto develop tools for project design and allocate funding for research, development and demonstration.

The US has been late to the offshore wind party, with major projects only just being announced this year.

According to market intelligence firm 4C Offshore, the country has 182 projects listed, of which two are operating. The recent announcement is bound to spark interest for the engineering and manufacturing potential that such a rapidly growing sector will mean.

Two firms have strengthened ties in science and technology with a focus on floating wind turbines.

Navtek Naval technologies and Seawind Ocean Technology have agreed to work more closely together to develop Seawind’s integrated floating wind turbine concept.

The two have also agreed to strengthen ties in science and technology within the marine sector. The firms will plan and work on the construction, transport and installation of Seawind’s 6.2MW floating prototype, based on a Gamma 60 onshore two-bladed wind turbine that was certified

by DNV in December 2019. The turbine has twin blades, which the firm says increases generation efficiency and improves rotor stability. It can be installed and assembled with a simple tug tow and straight-forward anchoring, which is cheaper and less risky than conventional turbines, Seawind says.

The agreement with Navtek is the second Seawind has signed in recent months, following an agreement with Blue Ocean Sustainable Solutions in April to act as the project engineering and permit-technical office for Seawind’s floating offshore wind projects in Portugal.

the

and

to

8 Joe Biden

Maridea is a Dutch subsidiary of the MULTI Engineering Group and it has designed a Moray Base concept, which is based on what it calls a ‘monopile type’ floating foundation.

“The concept features a thick-walled steel tubular structure without nodes, reducing fatique hotspots which could eliminate the need for costly offshore repairs,” Maridea says. ”The base is constructed using a monopile fabrication process, avoiding traditional fabrication practices with complex nodes that increase production time, whilst the four sections of the foundation allow for easier global transport and assembly.”

AiP has been given to a sample location in the Central North Sea and is based on a 25-year lifetime design without the need for intermediate dockings, potentially.

The Moray Base concept has been designed to support wind turbines that can generate up to 15MW of electricity and can operate in harsh offshore environments. The turbine is fitted in the corner of the base to allow easier access for crane and other maintenance vessels.

“Moray Base was designed with mass production and simplicity as main drivers,” said Christiaan Schuiling, product development manager, Maridea. ”This resulted in the revolutionary shape. The commercial feedback from industry has been very positive, but achieving AiP from LR underlines that the unusual design is also feasible and efficient from a stability and structural perspective.”

”The difference with other designs is the easy of production of the circular members, which can be produced similar to the way monopiles are produced today,” managing director Jeroen Lusthof told Maritime Journal

”The transport of the individual sections doesn’t require specialized ships. The assembly can be done at a quay side with approx. 8m of water depth. There is no need for a drydock. The whole process aims at efficiency and avoidance of bottle necks.

”The anchoring is via a 3 or 4-legged mooring system consisting of chain with rope stretcher sections.

”Model testing was performed at Marin for the Moray 1 design, which confirmed our numerical models and indeed AiP was granted by Lloyd’s Register for the design.”

”The Moray Base design offers a real and tangible vision for how floating wind farms can operate in inhospitable conditions, a crucial step as the industry drives towards a sustainable future,” said Markus Büsig, North Europe Area Manager, Lloyd’s Register.

”Our next goal is to develop a prototype or demonstrator,” said Lusthof. ”We have quotations for the manufacturing, transport, assembly and installation of reputable companies confirming the costs saving potential.”

8 Maridea’s ‘ground-breaking’ floating wind conceptLloyd’s Register has awarded approval in principle to a floating wind concept that can support turbines in water of up to 100m deep, its designers claim

The Moray Base design offers a real and tangible vision for how floating wind farms can operate in inhospitable conditions, a crucial step as the industry drives towards a sustainable future

A bio-methanol plant at the Port of Amsterdam will be operated by the UK engineering company PX Group, owner GIDARA announced today.

Netherlands joint venture GIDARA Energy uses its own patented High-Temperature Winkler (HTW) technology, a gasification process, to convert non-recyclable waste into advanced biofuels for use in many sectors, including marine fuels.

In April 2022 it announced plans to set up the plant, known as AMA (Advanced Methanol Amsterdam) to produce bio-methanol in a way that ’creates significant carbon savings compared to fossil-based fuels’. It said it would produce 90,000 tonnes of renewable methanol a year through the conversion of 180,000 tonnes of local non-recyclable waste, which at the moment is being incinerated.

PX Group was involved in the Front End Engineering Design (FEED) phase of the project, and will now take on its operation and maintenance, initially helping with building and commissioning.

In 2021, PX Group was bought by Ara Partners, a private equity firm that set up the GIDARA JV with GI Dynamics.

Neil Grimley, px Group’s Managing Director of GIDARA Projects, comments: “I’m looking

Righton Blackburns is the leading supplier of metals and plastics to today’s marine and shipbuilding industry, offering the most comprehensive and market specific range of products available, including: Copper Alloys, Aluminium, Stainless Steel, Plastics, Composites and Special Products.

forward to continuing what is now an extremely close relationship with GIDARA. We’ve already been working with them on the ground in the Netherlands through the FEED stage, and we’ll now be taking on even

more responsibility in the coming months.”

Lebus YP 2019.qxp_Lebus YP 17/12/2019 15:07 Page 1

The plant is due to become operational in 2024.

8 Wim Van Der Zande CEO of GIDARA Energy (left) and Geoff Holmes, PX Group CEOThe world’s first offshore hydrogen production unit has been launched, aiming to demonstrate the reliability of an electrolyser at sea

After completing dockside tests, the Sealhyfe hydrogen production facility will be connected to BW Ideol’s floating wind unit, which has been in operation at the Ecole Centrale de Nantes’ SEM-REV site off France’s west coast for the past four years.

“Lhyfe’s project is an important and much needed step towards the development of integrated and autonomous renewable power production systems, using floating wind and green hydrogen in this specific instance,” said Paul de la Guérivière, chief executive of BW Ideol.

“Being the floating wind asset owner and being responsible for the day-to-day operations and maintenance of the asset, we look forward to studying all aspects of the interaction between the wind turbine and the hydrogen production system. This added return on experience will further contribute to BW Ideol’s unique preparedness for the development and execution of future commercial-scale deployments.”

Engineering school Ecole Centrale de Nantes has an ambition to make offshore renewable hydrogen a reality, said director Jean-Baptiste Avrillier.

“This world premiere is a source of great pride for the school,” he said. “This ambitious project confirms the role of our SEM-REV site in accelerating the development of renewable marine energies and the active contribution of the school to meet the challenges of energy transition.”

Five wave energy projects have been chosen to develop their concepts in the next phase of the EuropeWave programme.

Trimaran (Arrecife Energy Systems), Sea-Saw WEC (AMOG Consulting), ACHIEVE (CETO Wave Energy Ireland), MARMOK Atlantic (Architecture SAU) and Blue Horizon 250 (Mocean Energy) will all progress to the second round in the ‘Phase Gate’ process, sharing a €3.6 million pot over the next nine months to create a prototype ready for trials during Phase 3.

Based on a similar programme devised by Wave Energy Scotland (WES), EuropeWave is an R&D programme combining almost €20 million of national, regional and EU funding to create a pre-commercial procurement programme (PCP) for wave energy technology.

“EuropeWave is about propelling the wave energy sector further towards commercialisation,” explained Tim Hurst, managing director of WES.

“Scotland’s collaboration with our European partners and the five successful technology developers means we have an ideal platform for supporting Scotland’s and Europe’s ambitious net zero targets, all while

fostering greater openness, standardisation and risk-sharing.”

In the third and final phase of the EuropeWave PCP, three prototype designs will be deployed at the open-water facilities of Biscay Marine Energy Platform in the Basque Country and European Marine Energy Centre in Scotland for a 12-month demo and testing programme.

and analysis go to

8 Ecole Centrale di Nantes’ SEM-REV siteBeing the floating wind asset owner and being responsible for the day-to-day operations and maintenance of the asset, we look forward to studying all aspects of the interaction between the wind turbine and the hydrogen production system

‘‘

The history of Dutch towage service provider Muller stretches over a hundred years, its tugs’ black funnels with the large white letter M a regular sight in Dutch waters and beyond. Muller operates a diverse fleet of both seagoing, harbour and pusher tugs along with seagoing and inland barges providing a range of services beyond just towage.

The Dordrecht-based company has now ordered a Damen ASD Tug 3212, a sign of confidence demonstrating healthy demand for capable towage services to support North Sea oil and gas decommissioning and renewable energy activity. Commenting on the order, Damen says day rates look to remain firm for premium workboats into the foreseeable future, not least because high-efficiency new vessels are in short supply and very much in demand.

While this purchase represents its first newbuild contract in many years, Muller has operated Damen Pushy Cats and Multi Cats in the past and both companies are family owned and located close to each other. Damen’s short delivery time and its build for stock policy were factors in securing the order.

Providing a bollard pull of 83t, the ASD Tug 3212 is a capable vessel in its basic form, even more so with the range of options available for specific roles, and Muller has opted for almost all of them, indicating the intention to maximise its capabilities. The specification includes IMO Tier III aftertreatment system, large afterdeck winch together with open stern, hydraulic towline guide pins, deck crane and support boat. A winterisation package for operations in high latitudes is specified, including additional insulation, heated windows and a GMDSS A3 rated communications system.

The tug is currently in build at Damen Song Cam Shipyard in Vietnam.

Bram Muller, CEO of Muller Dordrecht, said at the signing ceremony: “After many years we are happy to be working together once again with Damen Shipyards. This ASD Tug 3212 will strengthen our tailor-made solutions for our customers, not only offshore but also in-port.”

Fairplay Towage Germany’s Fairplay Towage Group is another European tug owner with a long history and diverse fleet of more than 100 vessels operating in 29 ports, including recently increasing its presence in Rotterdam. Its fleet was enhanced in 2017 when fellow German tug owner Bugsier Reederei merged with Fairplay. It also owns the Hamburg dockyard Theodor Buschmann and has a 50% participation in Multraship Towage & Salvage in The Netherlands.

Fairplay’s fleet is soon to be enhanced with two Damen RSD Tug 2513s, to be delivered in January 2023 as with Muller’s order, from the builder’s Vietnam facility. Damen first showcased its ‘always stern first’ RSD Tug 2513 to maritime media in 2018 (MJ June 2018) your correspondent commenting: “Experience will judge the eventual success of this intriguing new design and it will be interesting to see how Innovation [the first vessel’s name], the new impressive addition to Damen’s portfolio fairs in a market that thrives on the challenge of innovation.”

Four years on with around 20 delivered and a worthy number of yard allocations noted for the series, it is clearly making an impression on the market.

Fairplay’s examples will feature powerful render-recovery winches with auto-tensioning systems along with fifi1-rated firefighting systems. Fairplay has also opted for immediate IMO Tier III compliance, specifying Damen’s NOx reduction system featuring selective catalytic reduction. Another factor in Fairplay’s decision to choose Damen was for its Triton digital platform for optimisation of operational efficiency.

Joschka Böddeling, Damen Sales Manager, said: “We are very pleased to be supplying Fairplay with these state-ofthe-art tugs. Fairplay has operated Damen-built vessels for many years and we were delighted when last year they purchased a Shoalbuster 2711 for general operations in the North and Baltic Seas. This latest contract further reinforces the cooperation between our two companies.”

Arkadiusz Ryz, Fairplay Towage Polska, said: “We are delighted with this order, which is connected to our last year purchase from Damen. Thanks to strong connection with our clients we actively respond to the growing market needs with highest quality and efficiency available. Those two highly maneuverable and high performance new modern tugs will strengthen our fleet and cooperation with Damen.”

8 Fairplay has chosen the increasingly popular Damen RSD Tug 2513 for its latest order

8 Muller’s order demonstartes a healthy European demand for capable towage services

8 Muller’s order demonstartes a healthy European demand for capable towage services

Damen Shipyards has boosted its order book with notable contracts for three of its next generation tugs for Dutch and German ownersCredit: Damen Credit: Damen

Classification society ClassNK has issued its Approval in Principle (AiP) for an ammonia-fuelled tug.

Tugboat owners and builders globally are likely to sit up and take notice of the recent AiP by ClassNK for ammonia-fuelled tug A-Tug, which has been developed by NYK Line and IHI Power Systems Co Ltd (IPS).

In an industry that is globally increasingly committed to meeting the demands for decarbonisation, any alternative fuel innovation in the towing industry can only happen with the blessing of classification societies, so this could be seen as an important milestone.

Adequate safety measures for such a project are important as ammonia is toxic to humans and corrosive to materials, and progress builds on ClassNK’s Guidelines for Ships Using Alternative Fuels, which sets out necessary standards to minimise risks for ship crews and the environment by stipulating requirements for installation, controls and safety devices.

No CO2 is emitted when ammonia is combusted, and NYK Line suggests that zero emissions can be realised considering even the fuel life cycle of such a vessel by using CO2-free hydrogen (using renewable energy

of CO2, controlling the combustion to prevent its generation and any discharge overboard.

The desire to prevent leakage of toxic ammonia and adequate safety measures in the event of leakage are also issues that have to be considered. Work to address the challenges involved NYK Line and IPS producing a design to install ammonia fuel-related equipment safely and practically in a limited space by developing an ammonia fuel engine, selecting equipment and devising the equipment layout in the tug’s design. The companies involved say they have achieved the design of A-Tug that overcomes these challenges without changing the size of a conventional tug.

8 ClassNK’s approval for an ammonia-fuelled tug will be of interest globally

or gas or coal using carbon capture and storage) as a raw material for ammonia.