17 minute read

COGNEX

Cognex Introduces High Speed Steerable Mirror for Large Area Scanning with a Single Barcode Reader

Cognex Corporation (NASDAQ: CGNX), the leader in industrial machine vision, has released the High Speed Steerable Mirror, a patented technology designed for use with the DataMan® 470 barcode reader that supports large field of view applications with a single compact system.

The new steerable mirror attachment expands DataMan’s field of view both vertically and horizontally, giving 3MP and 5MP barcode readers an effective resolution greater than a 50MP sensor. Coupled with the latest in liquid lens technology, this system can both change field-of-view and depth of focus dynamically. A single DataMan system can now be used for pallet scanning, aggregation, and other large area applications that previously required high-resolution PC-vision or multiple fixed-mount sensors.

The steerable mirror arrives preassembled to the front of a DataMan 470. The unit is configured using a built-in web-based setup wizard, allowing operators to deploy an application in five minutes or less. The user simply enters their application specifications, and the wizard automatically calculates the optimal scanning pattern, ensuring the highest read rates in the shortest cycle times.

“The High Speed Steerable Mirror changes the game for large area applications that typically require a multi-reader solution,” said Matt Moschner, Cognex’s Sr. Director of ID Products. “Now, e-commerce and logistics companies can get up and running more quickly, and achieve the same high accuracy scanning results with lower maintenance costs.”

For more information about the High Speed Steerable Mirror, visit:

www.cognex.com/en-gb/high-speed-

steerable-mirror or call +44 121 296 5163.

Powering actuators directly with Linear electric motors rather than air cylinders can result in huge cost and emission savings across the board. So much of our industry uses compressed air that is often regarded as the fourth utility, after electricity, natural gas and water. However, compressed air is more expensive than the other three utilities when evaluated on a per unit energy delivered basis. Quin Systems, exclusive UK suppliers of LinMot Linear Motors for over 25 years, can help you calculate the predicted carbon and energy

savings achieved by switching from a pneumatic solution to a linear motion Linear Motors Slash Energy solution. Costs to 5% of Pneumatic Solutions LinMot, one of the world’s leading manufacturers of industrial linear motors has released a new component of its LinMot Designer software that can quantify just how energy efficient its solution is, and the sizeable return on investment their motors can provide over pneumatics.

Powering actuators directly with Linear electric motors rather than air cylinders can result in huge cost and emission savings across the board. So much of our industry uses compressed air that is often regarded as the fourth utility, after electricity, natural gas and water. However, compressed air is more expensive than the other three utilities when evaluated on a per unit energy delivered basis. Quin Systems, exclusive UK suppliers of LinMot Linear Motors for over 25 years, can help you calculate the predicted carbon and energy savings achieved by switching from a pneumatic solution to a linear motion solution. For more information, please contact Quin Systems on 0118 LinMot, one of the world’s leading manufacturers of industrial linear motors 977 1077 or sales@quin.co.uk. Website: www.quin.co.uk/linmot has released a new component of its LinMot Designer software that can quantify just how energy efficient its solution is, and the sizeable return on investment their motors can provide over pneumatics.

Efficiency and CO2 results from Linmot Designer® for the worked example: Efficiency and CO2 Emission

Total moving Distance per Cycle 4 m Moving mass: 5kg Motion Continuous: 8000h/year

Total cycle Time: 6 secs Friction Force: 100N

Linear motor (Linmot)

Electric Motor Power(1) [W] 95

Electric Electricity Consumption CO2 Emission Electricity Costs Power(2) per Year(3) per Year(4) per Year(5) [W] [kWh] [kg] [EUR]

143

1'145 573 137

Pneumatic Cylinder

Air Piston Air Consumption Electric Electricity Consumption CO2 Emission Electricity Costs Diameter per Year(1) Power per Year(2) per Year(3) per Year(4) [mm] [Nm3] [W] [kWh] [kg] [EUR]

63 461'293 6'815

54'516 27'258 10'484

Example

Take an example within the handling and assembling sector. Linear actuation is required on the horizontal plane to move items through to the next stage of the production process. A single LinMot Linear motor with guide can replace a traditional 63mm diameter rodless air cylinder for this task, ultimately reducing annual energy cost by over 10,000 EUR and CO emissions by over 26,000 kg. The return on investment is significant. Energy saved by using a single electrically driven actuator over a basic traditional pneumatic cylinder the potential to cover its higher initial outlay within a very short timeframe typically less than a year. Combined with the extraordinarily long operation life of LinMot Linear Motors and the next to zero servicing requirements mean LinMot’s solution will continue working for years. This improves the cost benefits and environmental efficiency of your production line by a significant margin.

EXAMPLE Take an example within the handling and assembling sector. Linear actuation is required on the horizontal plane to move items through to the next stage of the production process. A single LinMot Linear motor with guide can replace a traditional 63mm diameter rodless air cylinder for this task, ultimately reducing annual energy cost by over 10,000 EUR and CO2 emissions by over 26,000 kg.

Linear

The return on investment is significant. Energy saved motor by using a single electrically driven actuator over a basic < 5% Air traditional pneumatic cylinder has the potential to cover its Energy cost higher initial outlay within a very short timeframe, typically less than a year. Combined with the extraordinarily long operation life of LinMot Linear Motors and the next to zero servicing requirements mean LinMot’s solution will continue working for years.

For more information, please contact Quin Systems, the LinMot distributor for UK & Ireland on 0118 977 1077 or sales@quin.co.ukThis improves the cost benefits and environmental Website: www.quin.co.uk/linmot efficiency of your production line by a significant margin.

The innovative Linmot Linear motor combined with a high stiffness linear guide provide high-speed and energy-efficient performance in a clean design. Direct mounting of the load with absorption of

2

sales@quin.co.uk

Keep your daily operati on running Keep your daily operati on running smoothly by securing and monitoring smoothly by securing and monitoring your valuable keys and equipment your valuable keys and equipment whilst keeping them easily accessible. whilst keeping them easily accessible.

Ensuring keys and tools are kept secure & readily available Ensuring keys and tools are kept secure & readily available can be a tricky balance to maintain, however this is can be a tricky balance to maintain, however this is achievable with our key & asset management systems. achievable with our key & asset management systems.

Shadow Boards can be upgraded by adding our Single Unit’s Shadow Boards can be upgraded by adding our Single Unit’s (T1) to them subsequently increasing the organisati on and (T1) to them subsequently increasing the organisati on and security of your valuable machine tools. security of your valuable machine tools.

Contractor and employee safety when maintaining factory Contractor and employee safety when maintaining factory machinery is vital to all food processing companies, with our machinery is vital to all food processing companies, with our Lock Out, Tag Out (LOTO) system we can ensure that you will Lock Out, Tag Out (LOTO) system we can ensure that you will know who is working on which machine at a glance. know who is working on which machine at a glance.

For the food processing industry, we off er Metal Detectable For the food processing industry, we off er Metal Detectable Access & Retenti on Pegs which identi fy any mislaid pegs Access & Retenti on Pegs which identi fy any mislaid pegs when processing the food and are easy to detect and when processing the food and are easy to detect and withdraw. withdraw.

Whilst keeping keys & assets secure our products also Whilst keeping keys & assets secure our products also increase accountability by making sure that you can see who increase accountability by making sure that you can see who has which key or asset at any ti me simply by just glancing at has which key or asset at any ti me simply by just glancing at the system. the system.

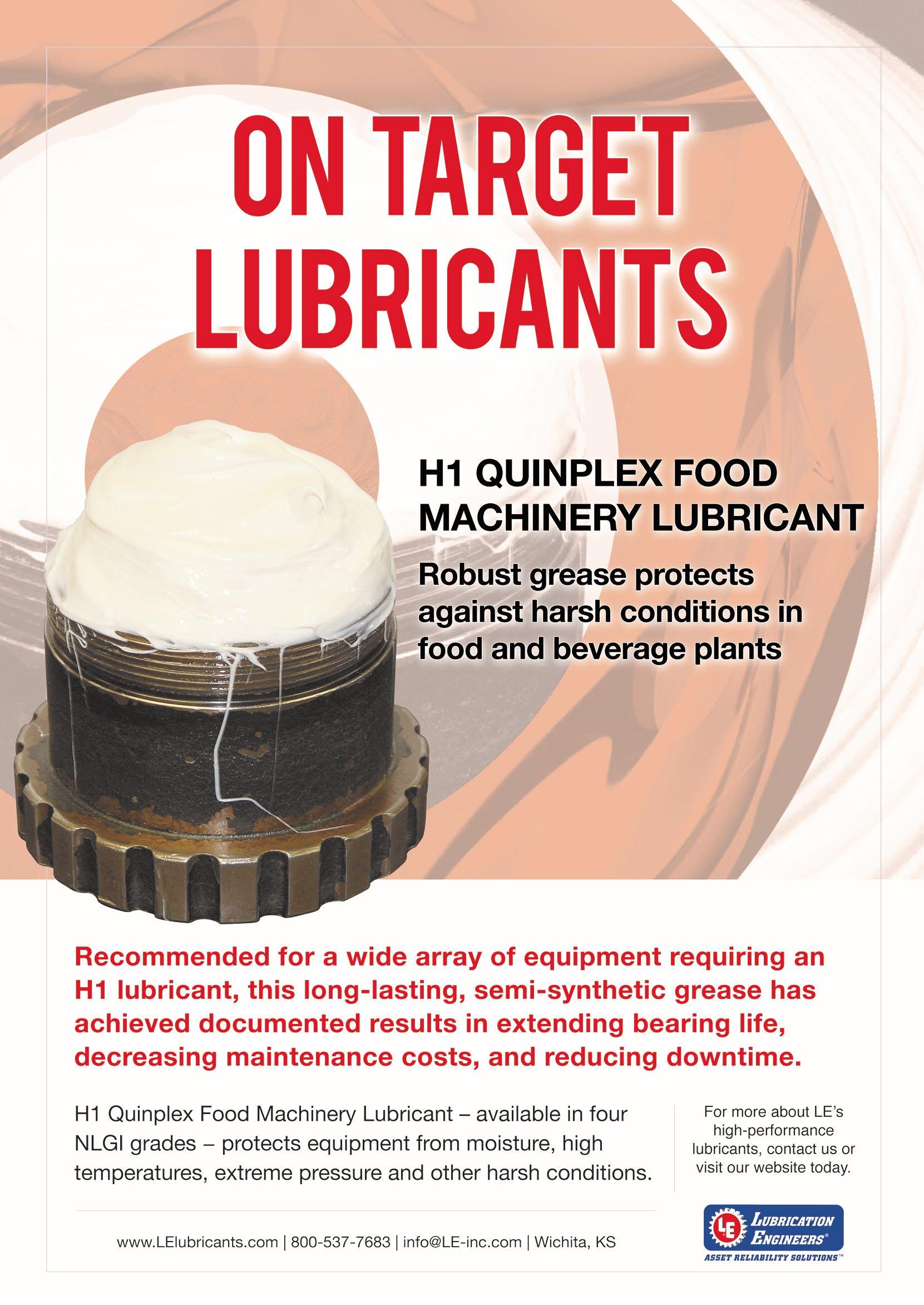

Tacky, Water-Resistant Grease Keeps Critical Equipment Running

To prevent costly damage often associated with the severe operating conditions found at many food, beverage and pharmaceutical facilities, Lubrication Engineers offers several food grade oil and grease solutions. These lubricants have been used for years to provide dependable reliable operation in critical equipment.

LE has received hundreds of testimonials over the years showcasing how these products have helped customers prevent downtime and ensure lubrication and equipment reliability. Typical applications include blenders, bottle washers, cams, conveyors, gearboxes, slides, conveyer chains, cookers, bottling machines, packaging equipment, valves, hydraulics, canning machines, bushings and more.

Regardless of load, temperature, environment, and speed, LE has a suitable food machinery lubricant solution for these critical applications. One of these solutions is H1 Quinplex Food Machinery Lubricant (4022-4025), which provides dependable operation of a variety of critical equipment in severe conditions such as moisture and high temperatures. This high-performance food grade grease plays a significant role in preventing costly damage that can result from these types of operating conditions.

H1 Quinplex Food Machinery Lubricant is a semi-synthetic grease suitable for a broad operating temperature range in a variety of applications. It is robust enough to withstand moisture, high temperatures, extreme pressure, and other hard conditions. It features an aluminum complex thickener base, providing extreme water resistance, excellent mechanical stability, reversibility, and tackiness. The backbone to H1 Quinplex Food Machinery Lubricant is its additive Quinplex, LE’s proprietary impactresistant additive that contributes to the grease’s outstanding water resistance, tackiness and enhanced mechanical stability. It also increases H1 Quinplex Food Machinery Lubricant’s wearreducing capability and helps form a barrier against corrosion.

Switching to H1 Quinplex Food Machinery Lubricant often leads to longer bearing life, fewer equipment repairs, less downtime and lower lubricant consumption. This highperformance white grease is available in four different NLGI grades – 00 (4022), 0 (4023), 1 (4024), and 2 (4025). It is registered NSF H1 for incidental food contact, and it is Kosher Pareve and Halal certified – meeting the stringent requirements of food, beverage and pharmaceutical manufacturing facilities.

Lubrication Engineers is a trusted lubrication reliability partner to companies all over the world, with nearly 90 lubrication reliability consultants across the United States, and a network of distributors across the globe. Learn more about protecting your equipment with LE’s H1 Quinplex Food Machinery Lubricant at www.LElubricants.com.

Safety and shaft couplings in hygienic design

The coupling manufacturer ENEMAC from Kleinwallstadt, a supplier of stainless steel safety and shaft couplings for more than 40 years, has always been oriented towards the strict hygiene regulations of food production as well as medical and pharmaceutical technology. This has resulted in a wide range of stainless steel coupling variants. The range includes safety couplings for reliable torque limitation in packaging machines or filling plants and shaft couplings for backlash-free torque transmission made of stainless steel.

The ECR torque limiting clutch, for example, is designed for indirect drives such as sprocket or toothed belt drives and offers infinitely adjustable disengagement torques between 15 Nm and 350 Nm.

The EWC metal bellows coupling, for nominal torques between 5Nm and 1,000Nm, consists of a stainless steel bellows, stainless steel hubs, and stainless steel screws. In order to comply with the regulations, the parts are joined using the micro-plasma welding process. the EWR type metal bellows coupling in half-shell hub design. This is particularly suitable for use in systems that are difficult to access, where space is limited and where the input and output units are rigid or cannot be moved. The type EWR covers a torque range from 10 Nm to 1,200 Nm.

A shaft distance of up to 3 m can be bridged with the stainless steel spacer coupling EWLC. This shaft distance coupling consists of two metal bellows couplings which are connected by a variable-length intermediate pipe. This shaft coupling, which is also made entirely of stainless steel, can thus compensate for misalignments of a considerable magnitude and can also be used as a backlash-free connecting, cardan or synchronous shaft. The EWLC type is available in 7 sizes for nominal torques of up to 1,200 Nm. For less demanding environments, ENEMAC also offers many safety couplings as corrosion-protected variants. Special hardening processes are used to nitrocarburise or gas-nitride and then oxidise the main components of the torque limiters. The installed cup springs are coated and balls and ball bearings are made of stainless steel. This makes these types of couplings suitable for many outdoor applications and wherever moisture could become a problem.

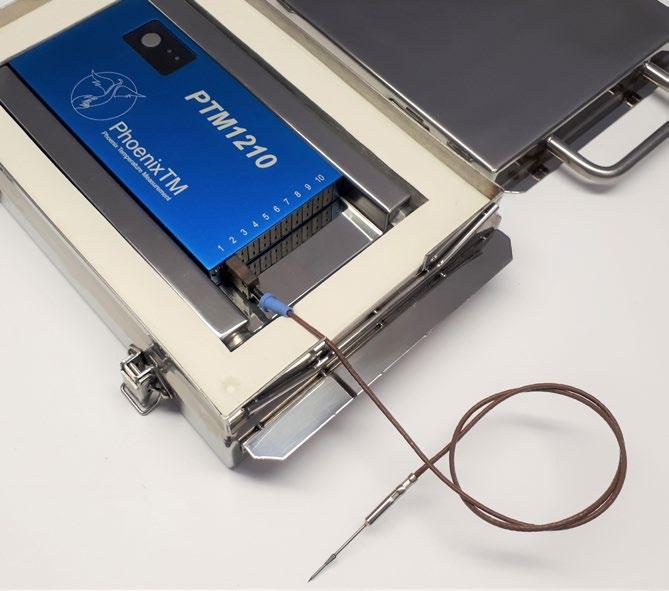

PhoenixTM solution to HACCP Cook & Chill CCP Validation

As part of any Food processors HACCP program, validation of cook and chill processes is a critical and significant task, taking time, effort, and resources.

PhoenixTM have developed a thruprocess temperature monitoring technology specifically for this task, designed to meet the challenges of the food processing market. Ideal for the validation process for any new cook regime, new product, or annual process certification. Whether performing an oven survey “oven mapping to identify cold spots” or validating the cook under production conditions, the thru-process profiling solution gives you the accuracy, efficiency, and reliability you need to satisfy your HACCP demands.

As its name suggests, thru-process profiling is the method by which product and or process temperature is monitored throughout the complete cook / chill process. The data logger making the physical temperature measurement, with multiple thermocouples, travels safely with the product through the process. Protection from process conditions such as heat, steam, water, and oil is provided by a suitably designed thermal barrier. The thermal barrier provides robust protection to the data logger to prevent damage but also ensure that it maintains a safe operating temperature to give accurate temperature readings. Monitoring of continuous conveyorised linear and spiral ovens and semi-continuous or rotational batch cooks is feasible where the use of external recorders with trailing thermocouples is tedious, completely impractical, and possibly unsafe . Employing the thru-process principal, process monitoring can be performed under true production conditions without compromising line productivity . At the heart of the thru-process monitoring system is the PhoenixTM data logger. The PhoenixTM NT data logger range has been designed specifically for the challenges of monitoring food processing applications with an IP67 case design protecting from moisture. Type K or Type T data logger options allow accurate measurement of both cook and chill processes (Type T measurement range -200 °C to 400 °C). Data logger and thermocouple correction factors can be applied to the recorded data logger data to maximise measurement accuracy. PhoenixTM offer a range of thermal barriers to suit the process type, duration, and temperatures. Even if a standard thermal barrier cannot meet the process requirements, PhoenixTM can often custom design a unique solution to suit.

Monitoring core temperatures of food products can be a challenge and getting it right or wrong can have a significant influence on the data collected and therefore any decisions or conclusions made. PhoenixTM offer a range of different designs of thermocouple to suit different product types and sizes. The needle thermocouples ensure you can measure the true core/cold spot of the product accurately and repeatably. Fitted with standard miniature thermocouple sockets, the data logger is also compatible with other generic commercially available thermocouple designs.

Employing the thru-process temperature monitoring principle provides the food technologist with a complete temperature profile of the cook process from start to finish. This information is like the Cook DNA giving full details of the product and or process temperature which is invaluable to allowing validation of the Cook CCP. From a temperature profile it is possible to accurately quantify product safety (pasteurisation) knowing both the temperature, and time at temperature, of the product. Employing the thruprocess temperature monitoring principle provides the food technologist with a complete temperature profile of the cook process from start to finish.

From the profile graph you can see instantaneously the variation in product temperature at any point in the process either at different locations on the product (whole chicken) or different product positions within the cooker, cooking rack or across a mesh belt. The PhoenixTM Thermal View Food Software provides a comprehensive suite of analysis tools to convert the raw profile temperature data into useful process information. The analysis tools include the ability to calculate Fo/Pu values for the process against target micro-organisms. For a typical chicken cook process the lethality parameters for Listeria Monocytogenes (Tref 70 °C, Dt 16.2 s and Z value 7.5 °C) can be input to automatically and accurately calculate for each monitoring point the number of decimal reductions of the pathogen achieved during cook to meet CCP limits.

The information gathered, further to process validation, can be used to allow informed process problem solving and optimisation to maximise product quality, yield, process productivity and efficiency.

Contact PhoenixTM to help Find, Fix and Forget your Food Cook Problems!

The value of water as a production factor

The availability of water for industrial production has been taken for granted for many years and in most countries. Climate change is putting an end to this. Even though water is still cheap compared to its value, it becomes precious as soon as production output is affected due to shortages.

The current situation: in many cases industrial effluents have to be treated before being discharged into the sewage system. Reusing water is often not economical for factories because the specific costs per cubic metre of treated wastewater is higher than for fresh water.

However, this calculation is not entirely correct for several reasons:

1. Industrial effluents must be treated in any case, so these costs already exist. For a cost comparison with fresh water, only the additional costs to achieve the required water quality should be considered, not the full treatment costs. To complete the picture, the risk of pro-duction losses due to water scarcity must also be taken into account.

2. The quality of fresh water is often higher than what is really needed in production. Many production processes do not require potable water. It is also a waste to use potable water for sanitary purposes. Therefore, it may not even be necessary for a water recycling process to achieve potable water quality.

more economical to treat only single side streams. The treated effluent from one production line may be sufficient for another process or at least for cleaning trucks or for sanitation. This reduces the invest-ment costs for effluent treatment as well as the operation costs because the hydraulic load is reduced.

4. Another side effect may be material recovery from treatment residues or concentrates. This may reduce material purchasing costs or become another source of income.

5. Industrial effluent treatment and utilisation can be done with compact, customised side stream plants that offer all flexibility production lines and effluent characteristics demand for. Ideally, these plants are modular and can easily be extended as the production grows.

IndustrialEffluentTreatment&Utilisation

Helpingourclients,saveontheirwastewaterdisposalcostsusing WEHRLE’sadvancedbiologicaltreatmentandfiltrationtechnologies.

WEHRLEdesignsandbuildsturnkeywastewater treatmentplantsacrossmultiplemanufacturing sectors.Ourclientsachieveefficacyintheir wastewatertreatmentbyuseoflowenergy technologiesandbymaximizingrecyclingand reuseofthetreatedeffluent.WEHRLE’smodular design aids in reducing the installations footprintonthesite,aswellasfutureproofing forchangesinproductionandprovidinga sustainableapproachtoloweringthesites carbonfootprint.

WEHRLE’swastewatertreatmentplantsapply automationwherepossibleandallowremote access,makingthemoperatorfriendly.Theyare renowned for their reliability and this is demonstratedbymorethan350installations globally. Our comprehensive portfolio of services include: ► Conceptdesignandpilottrials ► Detaileddesignengineering ► Manufacturingandassembly ► Constructionandcommissioning ► Serviceoperationandmaintenance ► Remotetechnicalsupport

WEHRLEarea160-year-oldfamilyrunbusiness, locatedinSouthwestGermany.ItsUKdivisionis basedinBloxham,Oxfordshireandhasbeen operatingforover20years. Shouldyourequirefurtherinformationplease contact: info@wehrle.co.uk or visit our website.