MANUFACTURING Engineering

Success Through Innovation

Issue 61 2023 £4.95 www.pecm.co.uk

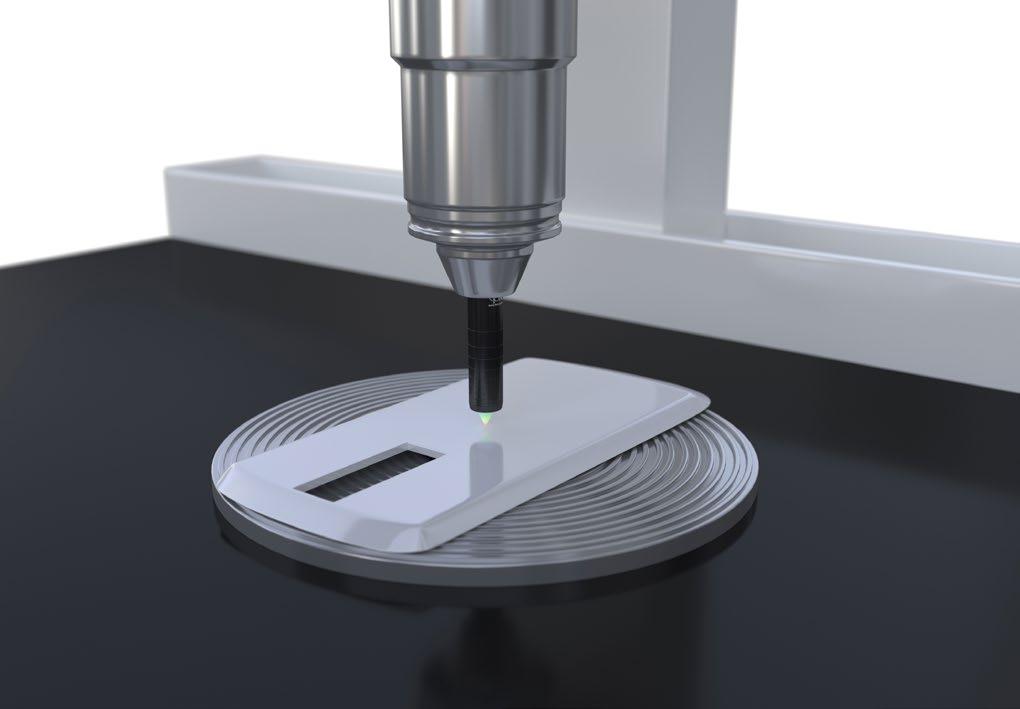

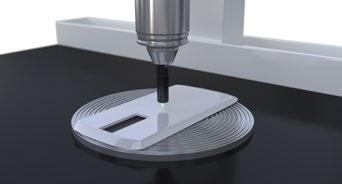

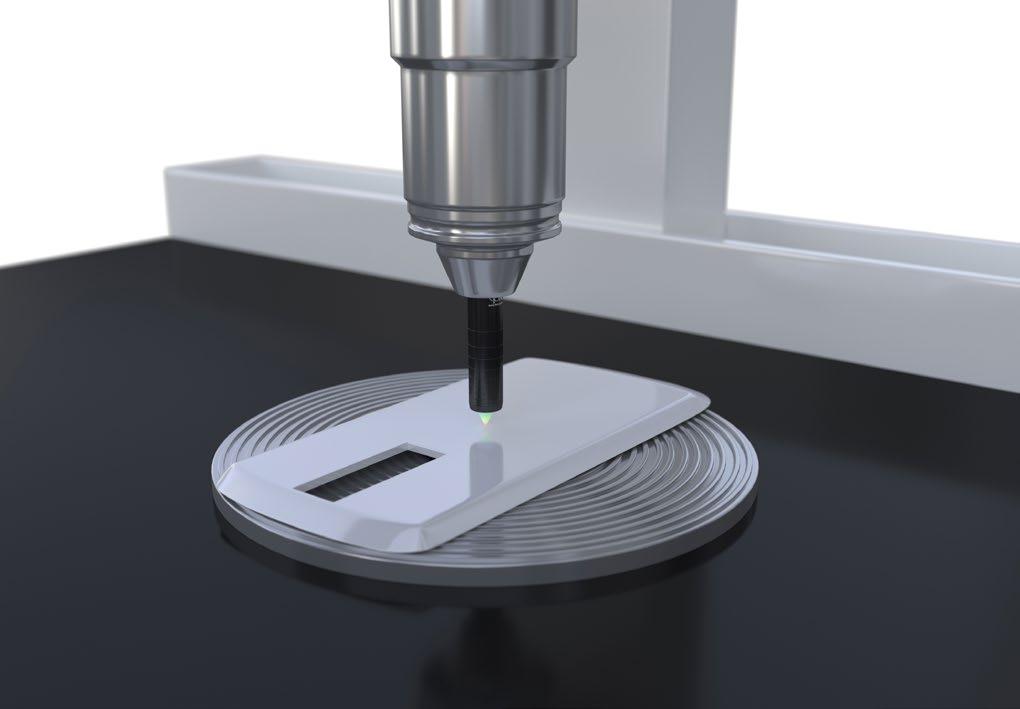

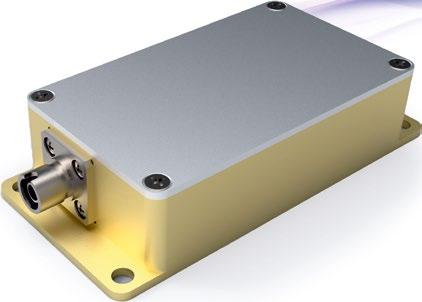

MICRO-EPSILON - 112

Advantages of optical sensors in coordinate measuring machines

MIDTHERM LASER - 18

Midtherm lasers in on growth after £1.2m machine investment

Process

Control & PECM Global

ABB - 6

Opportunities for Data Convergence and Analysis in Industrial Plants

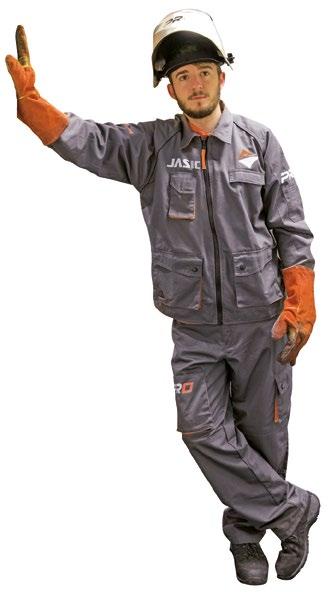

Such is our confidence in this technology we offer an unparalleled 5 year full warranty on all models Find out more www.jasic.co.uk Exclusive UK Importer 0161 793 8127 /jasicuk @jasicuk Out of the Box

MANUFACTURING Engineering Process Control &

Inside Issue 61

Brillopak’s five-year phased automation roadmap accelerates packing efficiency at Morrisons fresh-produce operations in Thrapston

SUMITOMO

Guidance to support regulatory compliance, efficiency and best practice success

PTC

Codebeamer becomes part of PTC’s Digital Thread

IFE MANUFACTURING

Uncover food processing and packaging innovation at IFE Manufacturing 2023

FANUC

Fanuc hosts robotics competition to inspire Gen Z engineers

CKF SYSTEMS LTD

CKF supply their latest robotic case packing system to a leading 3PL

ROBOTICS & AUTOMATION

SHOW

The latest technologies transforming logistics and manufacturing

EMS

End to end automation will be essential to meet changing demands

NOVOTEK

Combating flooding with automation

FOODEX

Foodex Manufacturing Solutions returns to the UK Food & Drink Shows in 2023

OMNIFLEX

How distributed alarm annunciator systems can help nuclear, petrochemical and oil and gas facilities comply with strict safety standards

Issue 61 PECM 3

Sections Editor’s Choice CHEM UK Show Preview 3D Printing Automotive Engineering Boilers & Maintenance IFE Show Preview Coatings Control & Automation Electrical & Electronics Facilities Management Fluid Handling Food Processing Gears, Drives & Motors Health & Safety Machining & Machinery Measurement & Monitoring Packaging Process Technologies Pumps Software & Systems Tools Training & Recruitement Valves & Flow Control 6 42 44 46 48 49 53 54 74 82 86 87 88 89 93 112 124 126 132 136 140 144

Inside...

BRILLOPAK

Cover photo: Brillopak

® UK's largest distributor AUTHORISED HUCK TOOLING SALES, HIRE & REPAIR RIVETS,THREADED INSERTS MAGNA-LOK® BOBTAIL® PENTALOK HUCKTAINER® C5OL® MAGNA-GRIP® BOM® ·�·Traditionally Innovative

Subscribe

The leading source for innovators in Technology, Manufacturing and Maintenance within the Engineering & Processing industry worldwide.

Published bimonthly, a subscription to PECM magazine is essential for Process Engineers, Chemical Engineers, Instrumentation Engineers, Mechanical Engineers, Plant Engineers, Precision Engineers, Environmental Engineers & General Engineers, Companies and Organizations in the Food, Dairy, Beverage, Brewing, Semiconductor, Pharmaceutical, Biotechnology, Chemical, Oil & Gas, as well as all UK's major manufacturing units.

Every issue of the magazine contains the latest news, in-depth features, together with product innovations and case studies showing how process engineers are implementing new technologies to reduce costs and impact on the environment.

With over 140,000 readers worldwide the publication is widely read, recognized, and well respected within the Process, Engineering & maintenance industries.

A subscription to PECM magazine is the industry's 'must have' publication.

Hardcopy Edition

SUBSCRIBE TO 6 BIMONTHLY ISSUES OF PECM FOR JUST £27

• The magazine gets delivered directly to your door once every issue is published

• The quality of the hard copy enhances the reading experience

To Subscribe please call 01304 806039

Digital Edition

SUBSCRIBE TO OUR DIGITAL EDITION COMPLETELY FREE OF CHARGE

Designed for the digital age, the magazine has been created for easy viewing on all electronic devices. All our issues stored in one place: get unlimited access to our previous and future issues.

To Subscribe please visit www.pecm.co.uk/subscribe

MANUFACTURING Engineering Process

The Team

EDITOR IN CHIEF

Antony Holter editor@mhmagazine.co.uk

BUSINESS MANAGER

Josh Holmes josh@mhmagazine.co.uk

SALES DIRECTOR

Harrison James harrison@pecm.co.uk

Tel: 0203 907 9166

SALES MANAGER

Martin Richardson martin@pecm.co.uk

Tel: 01304 086039

DIGITAL MANAGER

Jamie Bullock jamie@mhmagazine.co.uk

Tel: 01227 936971

EDITOR

Elizabeth Hutton elizabeth@pecm.co.uk

STUDIO DESIGNER

Richard Bland richard@mhmagazine.co.uk

ACCOUNTS DEPT

Alison Holmes accounts@pecm.co.uk

Tel: 01227 936976

PUBLISHING DIRECTOR

Martin Holmes martin@mhmagazine.co.uk

Tel: 01304 806039

DIGITAL ASSISTANT Stacey Goodwood

Tel: 01227 936971

Please mention Process Engineering Control & Manufacturing when responding to items in this issue.

Issue 61 PECM 5

Media Global Ltd. 18/20 Newington Road, Ramsgate, Kent, CT12 6EE Tel 01304 806039 l Fax: 08721 152240 l www.pecm.co.uk Every effort is made to ensure the accuracy and reliability of material published in Process Engineering, Control & Manufacturing however, the publishers accept no responsibility for the claims or opinions made by the contributors, manufacturers or advertisers. No part of the publication may be reproduced or transmitted in any form or by any means, mechanical, electronic (including printing), recording or stored in any information retrieval system without the prior written consent of the publisher.

Control &

MH

A GOLDEN OPPORTUNITY

Opportunities for Data Convergence and Analysis in Industrial Plants

By Vinod Ninan

Today, the average industrial plant uses less than 27% of the data it generates, according to industry experts at the ARC Advisory Group, Boston (arcweb.com). Typically, the remaining 73% of data—much of it produced by plant process-control system as highfrequency operational control (OT) data—is put in a historian and seldom used.

In addition, there are large volumes of other valuable functional data residing in the company’s general business or IT systems, and still more in the engineering systems (ET), covering specific design information for various assets. In addition to being rarely used, all of this data is normally scattered about in separate silos and networks that support little or no cross-referencing.

That’s where the golden opportunity lies, which we can now unlock with new software platforms that simplify better convergence and analysis of OT/IT/ET data. The benefits can be impressive, such as higher production rates from existing assets, less downtime as a result of predictivemaintenance practices, safer operation,

reduced energy and other raw material inputs, and lower environmental impact.

By better convergence of OT/IT/ET data, we mean bringing together previously separate elements, which have now been streamlined and integrated so that they proceed seamlessly. To achieve this, we accumulate all OT, IT, and ET data in a data lake. Next, we contextualize and store related data in an industry-specific data model, such as paper making or plastic extruding, for example. Then we apply advanced analytics and industrial AI algorithms to identify correlations that were not previously visible.

Industrial artificial intelligence (AI) can play a major role in identifying these patterns and making process predictions. The terms AI (artificial intelligence) and ML (machine learning) are often used interchangeably, which can be confusing at times. AI is the overarching science of making machines and physical systems smarter by embedding “artificial intelligence” in them. ML is a subset of AI that involves systems gaining knowledge over time through “self-learning” to become smarter and more predictable, without human intervention.

As an example, consider a motor, which is an essential and omnipresent manufacturing asset in your plant. The motor generates a lot of operational data, such as temperature, pressure, and flow rate measurements from various stages of the production process.

In terms of the different types of data we have:

OT data: Motor speed, vibration level, and bearing temperature are typical parameters monitored in real time by OT systems to tell us how the motor is performing. This normally comes from automation system or a process controller components such as PLCs or a DCS.

IT data: If we want to see things such as the motor’s maintenance history, when it was last serviced, how much has been spent on repairs, or if the right bearings are in stock, we must find it in various IT systems, usually somewhere in the ERP solution.

ET data: Information about factors such as whether the motor is within its design speed limits, how much vibration it can take, the safe operating temperature for its bearings

6 PECM Issue 61

EDITOR’S CHOICE

ABB PROCESS AUTOMATION

or what the useful bearing life should be, is all residing within the ET (or engineering design) systems.

Traditionally, each of these systems operates independently and generates a lot of data that is seldom used or cross-referenced. To acquire a holistic overview of the motor, we integrate information from all of these systems and store the relevant pieces in a contextualized data model. This allows us to visualize and activate optimum equipment operation for the best overall process results.

A motor is just one example. In a large manufacturing plant, there can be hundreds of such assets performing several functions and running under different operating conditions with varied design parameters; all with data stored in various systems.

Widespread OT/IT/ET integration and contextualization is, therefore, critical to obtain a complete view of the plant and carry out valuable analytical tasks that improve operations, asset integrity and performance management, safety, sustainability, and supply chain functions. What emerges are patterns that accurately predict future behavior, allowing improved process performance.

We have been using AI/ML to deliver a higher degree of prediction accuracy and optimization to operations, processes, and assets. Combining AI with deep industrial domain expertise empowers operators to run their industrial processes safer, more effectively, and more sustainably.

There are several barriers—perceived and otherwise—that hinder the implementation

of advanced analytics. The most common reason for hesitation is the perceived complexity. People mistakenly think it is much more difficult to achieve than it is. Another explanation we get is the incorrect belief that, to use big data, you must make massive capital expenditures, because it is an “all or nothing” undertaking. It is not as you can start with small steps. Other reasons might be lack of cooperation between OT, IT, and ET people, and just generally slow adoption of new digital tools in many industrial sectors.

The fact is that it is easy to join this digitalmaturity journey, no matter where you are, using data and signals that are already available in your process control, business, and engineering systems.

For further information, please visit www. new.abb.com

Issue 61 PECM 7

Combining AI with deep industrial domain expertise empowers operators to run their industrial processes safer, more effectively, and more sustainably.

LensConnect … Zoom, Focus & Iris remote-controllable from PC Introducing the award-winning computar LensConnect Series

Precise adjustment of Focus & Iris USB connector standard Inspection while moving focus

• Easy Installation

• High Resolution at any position

• Superb stopping accuracy

Connection Diagram

• Outstanding repeatability

• Low voltage and current

• Superior and versatile interface

computar-global.com info@cbcuk.com

020 8457 2618 catalyst of optics

EDITOR’S CHOICE

GEMÜ Introduces the New Innovative Solution to Water Hammer or Vapour

Pressure Surge

Pressure surges are recurrent problems that occur as a result of turning on pumps, changes in temperatures of enclosed liquids or switching the valves too rapidly. This could damage the plant components and cause the shut-off valves to accidentally open for a brief moment. The medium may then get contaminated which leads to product loss or downtime due to necessary repairs. GEMÜ has developed the 652 Pulsation Damper to compensate pressure and volume fluctuations. Based on tried and tested diaphragm valve technology and reliable actuator design, this new innovative solution is CIP/SIP capable and totally drainable. To absorb and compensate the pressure surge, the GEMÜ 652 Pulsation Damper’s main function is to dampen as much volume as possible within a specific operating range. The body is designed without a sealing weir and therefore the actual expansion volume is compensated by the moving diaphragm. This ingenious solution by GEMÜ will solve multiple problems in many varied applications. Please contact us to speak to one of our local product specialists for further information about this product.

For more details click here

GEMÜ 652 Pulsation Damper product flyer

Protecting Your Plant

Rotech Motion Sensor’s can be used whenever information or monitoring of shaft rotation, position, direction, speed, slip etc is required!

Rotech Motion Sensor’s can be used for indication, control, interlocking, protection, sequencing, alarm initiations and many more functions!

Rotech Motion Sensor’s can be used wherever materials are transported or processed By conveyors, elevators, screws, mixers, etc!

Web: rotechsystems.co.uk

Email: sales@rotechsystems.co.uk

Tel: +44 (0)151 356 2322

Issue 61 PECM 9 EDITOR’S CHOICE

Monitoring the world

AUTOMATION AMBITION

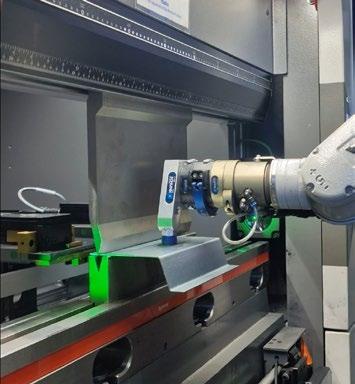

Brillopak’s five-year phased automation roadmap accelerates packing efficiency at Morrisons fresh-produce operations in Thrapston

Packing automation success is all in the planning. Embarking on a mission to reconfigure its fresh-produce packing hall at Thrapston, the Morrisons Centre of Excellence - which prepares and delivers 130 million packs of fruit every year to 82 stores - has succeeded in its automation vision and ambition.

British automation specialist Brillopak supported Thrapston at every phase of the five-year programme. In total, Brillopak installed 11 fully integrated fresh-produce packing lines comprising around 40 machines, with equipment and capital investments split across three defined phases.

Rather than piecemeal different technologies together, Thrapston’s site manager at the time, Matthew Peczek, sought a cohesive automation investment approach to increase efficiency, achieve packing consistency and optimise produce quality.

Taking the decision to completely redevelop the factory layout in 2017, Matthew was resolute that all machinery would be designed and placed linearly, with everything coming from the chillers and out to the back end for distribution, in one continuous flow. His linear vision has since been realised. Now, every part of the line faces in the same

direction throughout the packing hall.

Having seen the possibilities accomplished when managing the Morrisons Rushden depot, Matthew, now Head of Operations for produce at the company, was confident that Brillopak director David Jahn and his engineering team would see the bigger picture and deliver these transformational benefits. Most importantly, Brillopak was completely aligned to the investment roadmap that assisted Thrapston in reaching its end point.

Phasing in the flow

In 2016, Brillopak delivered stage one -

optimising the manual packing of apples into crates. Thrapston commissioned five of Brillopak’s award-winning and ergonomic PAKStations to replace less efficient manual packing and turntable operations. This was the first step to automation and enabled the site to get familiar with the automation.

To support these apple-packing lines and eliminate any potential bottlenecks, two Crate DESTAKers, five bale arm closers and five double stackers for palletising were also introduced. The result was five integrated packing lines that maintained a consistent packing pace, each feeding out onto the main track to an existing palletising system.

This first phase was intentionally designed as a holding pattern in Thrapston’s automation plan, allowing for the subsequent robotic machines that were to follow. “As a result of the fast payback due to labour efficiency, enhanced produce quality and reduced complaints, the plan was always to replace the PAKStations within two years. Swapping out with three fully automated UniPAKer robotic crate packing systems in phase two,” reflects Matt. It was, he affirms, always central to their produce strategy of improving quality and process efficiency and reducing costs and waste.

Having got the measure of the design requirements and long-term goals at the outset, Brillopak’s Automation Architecture meant that the innovative firm had already factored in the available real estate. The team built the framework of the PAKStations to match the dimensions of the UniPAKer machines, as well as the conveyor infeed and outfeed heights; enabling a seamless and simple swap over, to mitigate any packaging disruption.

“We literally pulled out the UniPAKer machines and inserted the robotic machines into the apple lines,” affirms David. Local power requirements and access points, as well as feeds to the main conveyor track for each line had already been considered at the initial due diligence planning phase. Craig Savage who project managed the entire programme, affirms that the devil really was in the detail. “It involved multiple simulations to define the best

10 PECM Issue 61

CONTROL & AUTOMATION

BRILLOPAK

With 40 individual Brillopak machines now on site and running continuously, Matt upholds the value of working with a single and reliable integrator.

With Brillopak’s vision, Thrapston’s machinery has been designed and placed linearly and in one continuous flow from the packing hall to the chillers.

approach.”

New access doors and platforms were inserted and refrigeration doors were moved. Approximately one fifth of the main track was removed along with the overhead crate feed track. To optimise efficiency a two-tiered conveyor track was proposed. Now, the lower level feeds all the clean empty crates to the 11 packing lines, while the top tier transports filled fresh produce crates to the palletiser.

Another key advantage of this modular line design and phased introduction of machinery was that Brillopak was able to retain and redeploy the existing conveyors, which previously transferred crates to the PAKStations. “From a sustainability perspective, where components can be repurposed, we do, as it boosts the ROI even further,” adds David.

Upscaling on 11 lines

Applying the best practice gained from phases one and two, in 2021 Thrapston completed its full-scale automation transformation with the roll out of six new linear packing lines. Handling a range of flow-wrapped and tray-sealed fresh produce, including pears, tomatoes, apricots, blueberries and grapes, Brillopak delivered a further five UniPAKers, one PAKstation, six bale arm closers, two Crate DESTAKers and six double stackers.

With 40 individual Brillopak machines now on site and running continuously, Matt upholds the value of working with a single and reliable integrator. One that can factor in all the unknowns and deliver innovative yet easy to operate ‘plug and play’ machines that talk seamlessly to each other. In particular, Matt appraises

Brillopak’s foresight and deep integration knowledge. “We had a clear vision of how the linear Thrapston packing lines would ultimately look and partnered with the Brillopak engineering team throughout every phase of the process.”

This collaborative teamwork approach is a result of the personal relationship the Morrisons’ fresh produce team, site managers and engineering experts share with Brillopak. Matt expands: “The robotic packing solutions that Brillopak builds are extremely intuitive to operate and very reliable. As testament, our robot potato lines in Gadbrook continue to run as efficiently as the day they went in seven years ago. We know they are always going to work and maintain their efficiency and presentation consistency.”

The smoother and gentler handling of fresh produce has been proven to reduce complaints by over 30 percent and almost instantly, reports the Head of Operations.

However, for Matt, the real Brillopak value comes from dealing with one machinery supplier. “There’s definitely something to be said for Brillopak’s amenable and accommodating approach. Integrating with other suppliers’ equipment is probably the hardest aspect. Yet, this is something I entrust to David and the engineers.

“Brillopak will often go above and beyond during the handover to ensure all their machinery is seamlessly integrated with conveyors, downstream camera graders and other equipment. Even when it’s not technically their responsibility. I don’t know of many other integrators that would undertake this level of meticulous service and support before, during or post install,” notes Matt.

Since embarking on the first automation project with Morrisons fresh produce almost 6 years ago, Matt is adamant that this trusting collaboration with Brillopak has helped to accelerate and optimise its packing efficiency.

With all five fresh produce sites now kitted out with end-to-end Brillopak machinery, a side-line benefit is how much the manufacturer has been able to streamline its stockholding of spares and components. “Dealing with one automation provider formed part of our produce directive. From a maintenance and ongoing service perspective, dealing with one or two machinery suppliers, versus liaising with multiple contacts is evidentially more straightforward. Being able to pre-plan projects and roll automation platforms out in phases as part of a wider, aligned plan certainly helps to mitigate investment risks,” ends

Issue 61 PECM 11

further information, please visit www.brillopak.co.uk

Brillopak’s phased approach to automation at Morrisons fresh produce operations in Thrapston

For

GROUP DYNAMIC

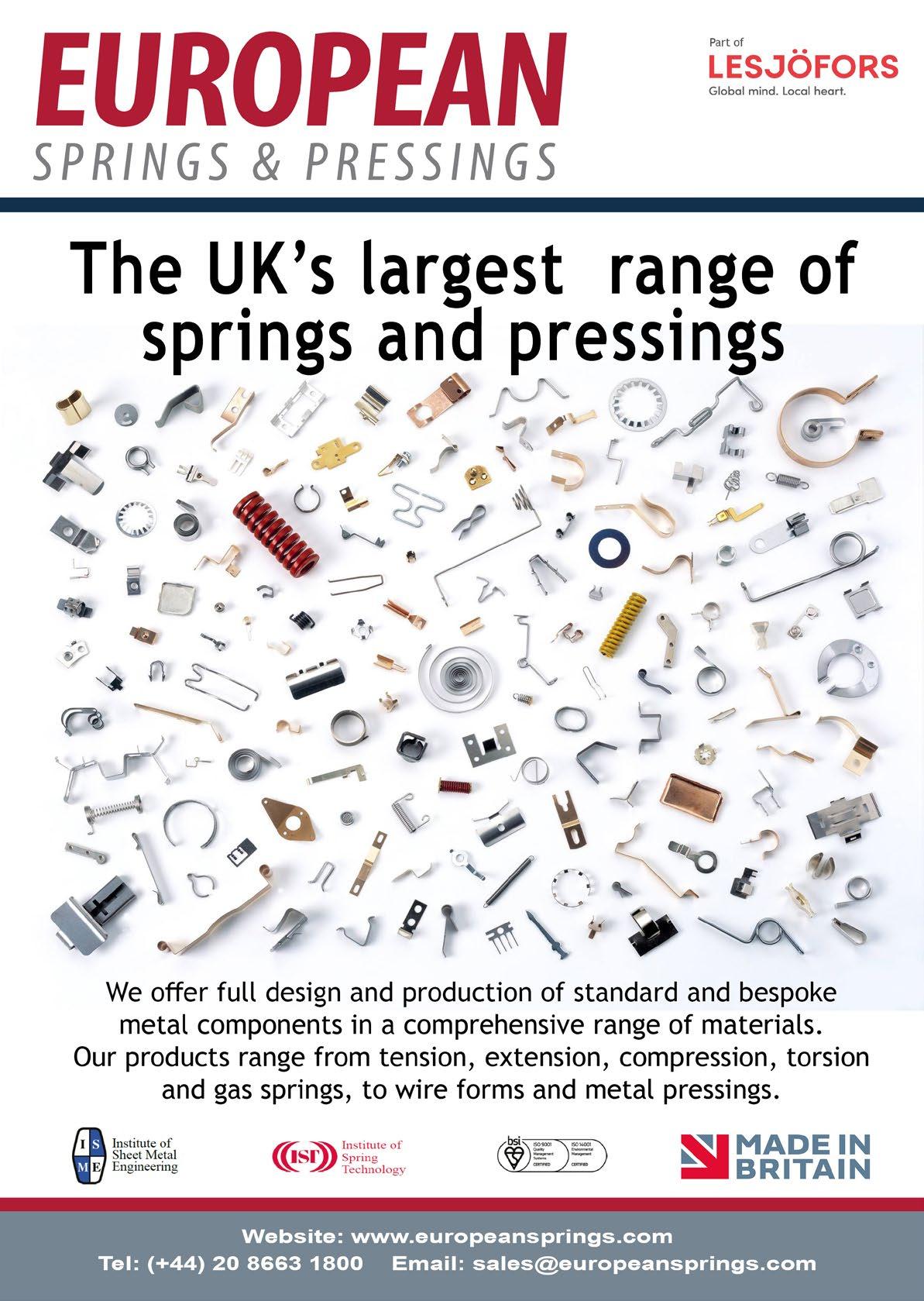

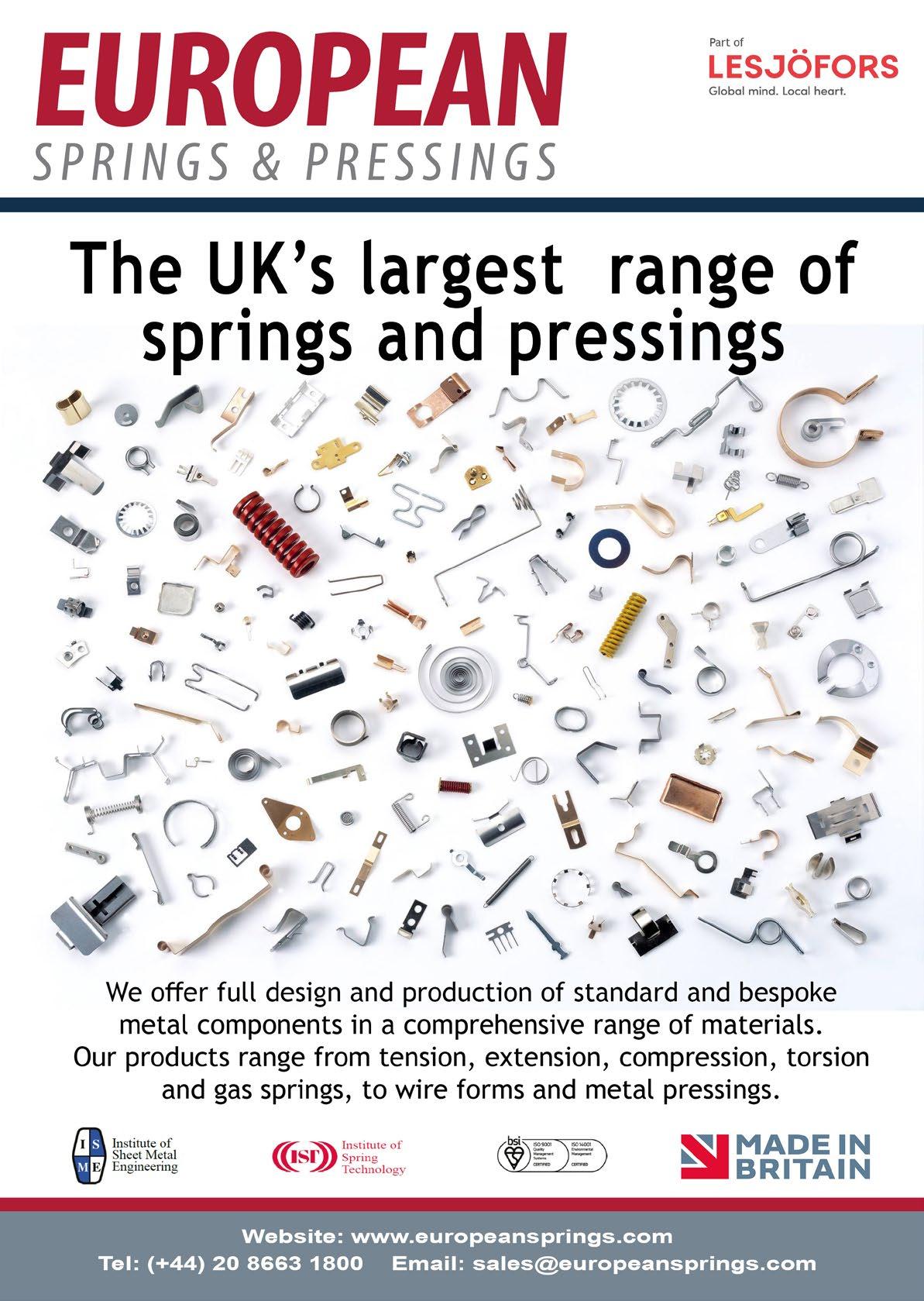

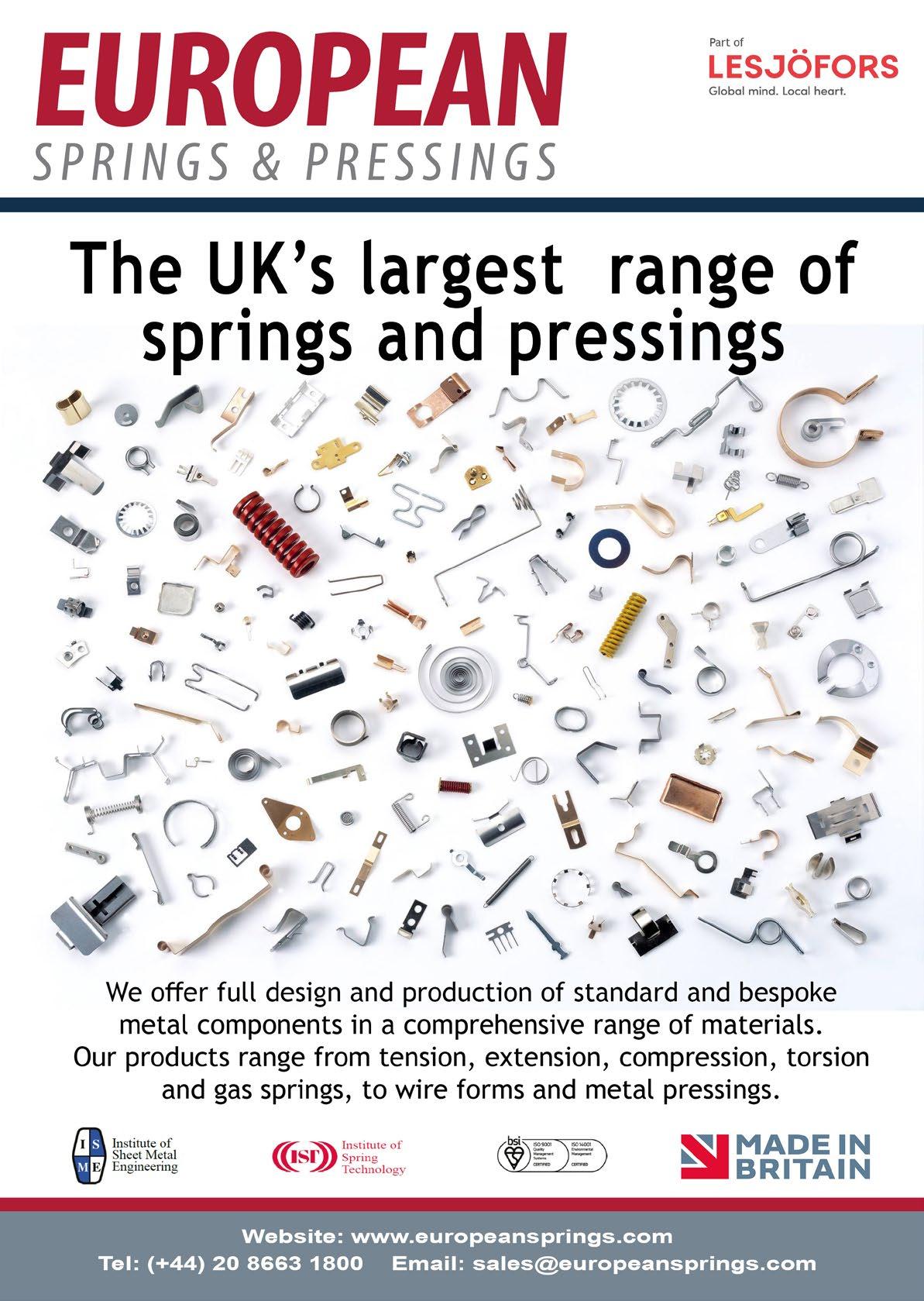

EUROPEAN SPRINGS & PRESSINGS

Reaping the rewards of increased collaboration

After a few years of rethinking the way they work together, European Springs & Pressings have been reaping the rewards of increased collaboration with its sister companies. Making their mutual platform of products and services more accessible has enabled the spring and stamping firm to deliver a wider range of manufacturing capability and products to their customers than ever before.

Working more closely with UK manufacturing partners Metrol Springs and Lesjöfors Heavy Springs UK has brought significant benefits for the respective companies, as well as allowing the group to offer an unrivalled portfolio of springs, pressings, wireforms, gas struts and industrial hardware.

Shared attendance at exhibitions, pooling experience at cross-company strategy meetings and developing a mutual knowledge of each other’s products and specialisms has broadened the shared capability the companies can offer and increased their sales reach considerably.

This support brings tangible benefits to their clients as well. European Springs’ commitment to providing the coiling and pressing expertise that customer’s need - in order to find custom-made solutions for their manufacturing processes - remains unchanged, with the added assurance that when they claim to have the required capability in the UK to design and produce the optimal component at the most competitive price, they make good on that promise.

This culture of collaboration has been fostered by their parent company, Lesjöfors Springs & Pressings. Although not a household name in the UK, since its conception 150 years ago Lesjöfors has patiently and practically built from its manufacturing base by acquiring a broad network of companies with specialist capabilities and strengths.

Lesjöfors is now the biggest spring manufacturer in the Nordic region, the third largest in Europe, and has a strong

and growing presence in the US and Asia. Their culture of supporting innovation, and developing capability is why European Springs & Pressings Ltd. joined the group in 2007.

Lesjöfors’ dedication to investment, both in people and technology, mirrors ESP’s, and has allowed them to develop as a business, as well as recruit and retain the talent, and acquire the machinery required, to continually provide the high quality manufacturing that client’s demand.

The culture of collaboration developed within European Springs’ UK manufacturing family, alongside the market-leading portfolio of products and services across the Lesjöfors group, means that customers can continue to rely on the ESP promise - to provide innovative design solutions, reliable service and custom-made, quality components.

For further information, please visit www.europeansprings.com

12 PECM Issue 61

EDITOR’S CHOICE

Working more closely with UK manufacturing partners Metrol Springs and Lesjöfors Heavy Springs UK has brought significant benefits for the respective companies.

BEHIND CLOSED DOORS

THORITE

Exposing the truth about wasted energy in compressed air systems

Looking back to 2021, it was easy to consider compressed air as something of a ‘free’ resource. Energy prices were low and manufacturers generating compressed air for one area of their factory could utilise it in another area for next to zero marginal cost. However, since energy prices began their upwards journey, compressed air is no longer the cheap commodity it once used to be.

In 2022, the British Compressed Air Society (BCAS) conducted research into the extent of compressed air use in UK industry. They found that 70% of UK industry uses compressed air in some form or another and that on average, 30% of a business’s entire energy costs could be attributed to compressed air generation.

Using figures from the (then recent) UK Energy-related products policy study, conducted by ICF in May 2021, they calculated the combined energy usage for the mid-point of all industrial compressor technologies over their lifetime at 11.71 TWh. Based on the current UK average nondomestic electrical unit cost of 12.49p/kWh at the time, the figures were substantialequating to £1.475 billion being spent by UK companies to generate the compressed air their businesses rely on.

Add to this the fact that on average 32.9 per cent of this energy was being wasted through leaks and inefficient practices - equivalent to £485.43 million in wasted electricity spend - and we began to understand the extent of which this presents a problem for UK manufacturing.

Skip forwards to today and the Department of Business, Energy and Industrial Strategy (BEIS) has recently published its figures for UK average non-domestic electricity costs for the final quarter of 2022. This figure now stands at 24.56p/kWh according to statistics, but it is estimated that many industrial tariffs are now reaching as high as 50.73p/kWh as of January 2023.

If we use the Government’s current published figures as a starting point and adjust the BCAS research for today’s prices,

commodity it once used to be.

we find that £2.943 billion is being used to generate compressed air in the UK. At a loss rate of 32.9%, that’s almost £1 billon of wasted energy every year in the UK, equivalent to £2.62 million every single day.

This staggering figure may come as a surprise to many of the UK’s manufacturers who have until recently worked on an ‘out

and the results are astonishing.

While energy savings in the past might have been outweighed by the cost of fixing leaks, thanks to the latest energy prices, the return on investment to combat inefficiencies is now months, not years. Not to mention the opportunity to reduce carbon emissions by up to 3.2 tons per year - a consideration that companies can’t help but be aware of.

With all things considered, isn’t it time your company found out what is happening behind closed doors?

For further information, please visit www.thorite.co.uk/energy

14 PECM Issue 61

COMBINED SAVINGS

As energy prices continue to rise, can your business afford not to know how much compressed air your system is wasting? Isn't it time you found out what happens behind closed doors?

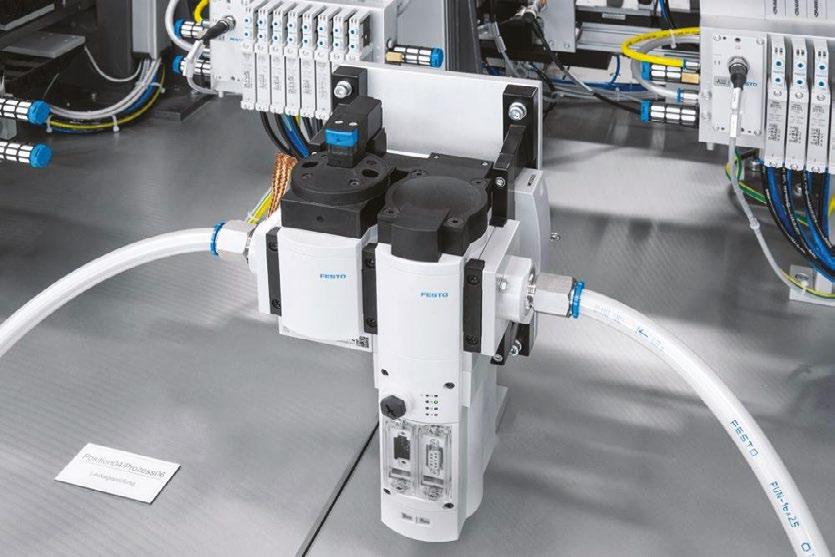

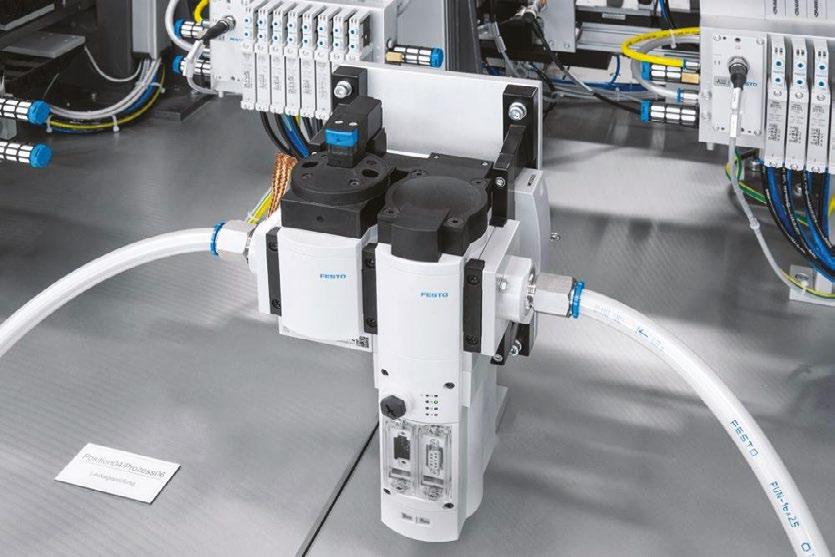

Automating Energy Saving

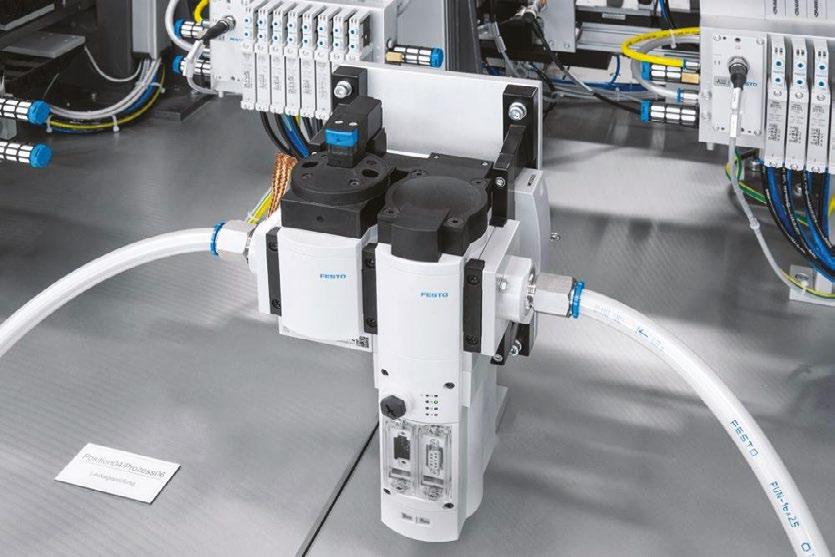

MSE6 - E2M Energy Efficiency Module

MANUFACTURING SOLUTIONS We’re Exhibiting! visit us at Stand G70 EFFICIENCY &

Festo’s combination of a field bus node, flow and pressure sensor, proportional pressure regulator and stop valve in one intelligent service unit component.

start-up of idle machines

Integrated Leak detection, measurement and reporting

Integrated Leak detection, measurement and reporting

Up to the minute comparative data reporting

www.thorite.co.uk Visit our website More information 0800 034 5850

Up to the minute comparative data reporting www.thorite.co.uk Visit our website More information 0800 034 5850

Automated shut-off & start-up of idle machines

THE REX-SYSTEM

Your all-in-one solution

Pentagon, pro-actively supporting you from the early stages of design assistance right through to mould tool manufacture and repeat production of your injection moulding project. Your new or existing plastic injection moulding project will benefit from years of technical moulding experience!

DESIGN DEVELOPMENT MOULDING TOOLING

BEYOND THE MOULD

www.pentagonplastics.co.uk

Benefit from the comprehensive DC 24 V circuit protection solution for mechanical and plant engineering. The REX system combines power supply, communication, circuit protection and power distribution in one system.

YOUR BENEFITS:

• Increased machines availability: Clear error detection, high transparency and remote diagnosis

• Flexibility: Easy assembly, modularity and convenient adjustment

• Time saving: Innovative and flexible connection technology

• Cost efficiency: No further accessories necessary

www.e-t-a.co.uk

Dirty Parts Cleaning at the Lowest Cost

Rozone’s bioremediating ROwasher range outperforms every parts washer on the market and beats our previous machine’s running costs by 54.5% and uses 30%-37% less consumables. * The ROwasher is the first innovation in parts washing for decades. It is UKdesigned and manufactured, together with the bioremediating filter mat and the ROwash degreaser. Find out how the ROwasher works at www.rozone.co.uk/rowasher/ how-it-works

Contaminants such as oils and grease are always present in engineering and workshop environments. Current legislation makes us improve our sustainability, environmentally friendly and health and safety credentials.

The ROwasher reduces toxic solvent use, cuts any toxic waste and improves the technicians’ working environment, whilst reducing operating costs. All ROwasher features and benefits can be found at

www.rozone.co.uk/rowasher/ features

Discover more about bioremediation at www.rozone. co.uk/bioremediation

Look at the science. The Science Behind the ROwasher by Dr Ibrahim Khalilhttps://youtu.be/tmDkeLOvuJs

Call Rozone’s ROwasher experts on 0121 514 0607. Or contact us at www.rozone.co.uk/contact/ or email info@rozone.co.uk.

*Based on data from controlled laboratory trials in 2022

16 PECM Issue 61

UK Manufacturing services delivering ease of communication and a smooth supply chain

E NG I NE E R N G T E CHNOLOG Y

| websales@pentagonplastics.co.uk Tel: +44 (0) 1403 264 397 |

E-T-A Circuit Breakers Ltd. +44 (0) 1296 420336 info@e-t-a.co.uk

EDITOR’S CHOICE

Work smarter, not harder

Workspace that adapts to your needs, not the other way around

The widest range of accessories on the market

Future-proof

Multiple sizes and combinations available Productivity and well-being

DESIGN YOUR PERFECT WORKSTATION

Suitable virtually to any environment, application and industry Concept workbench

The Treston 3D Configurator can be used to design an industrial or technical workstation that best meets your needs. To get started, all you need is a mobile phone or a computer with internet browser; no downloading is required and using the software is free of charge.

3D.Treston.com ERGONOMICS | ESD | LEAN

treston.com

REAPING THE BENEFITS

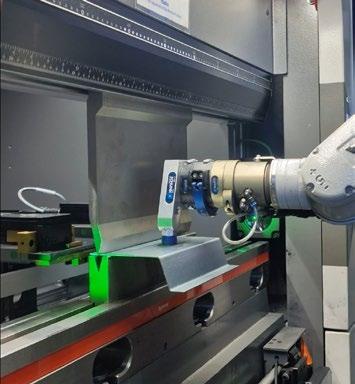

MIDTHERM LASER

Midtherm lasers in on growth after £1.2m machine investment

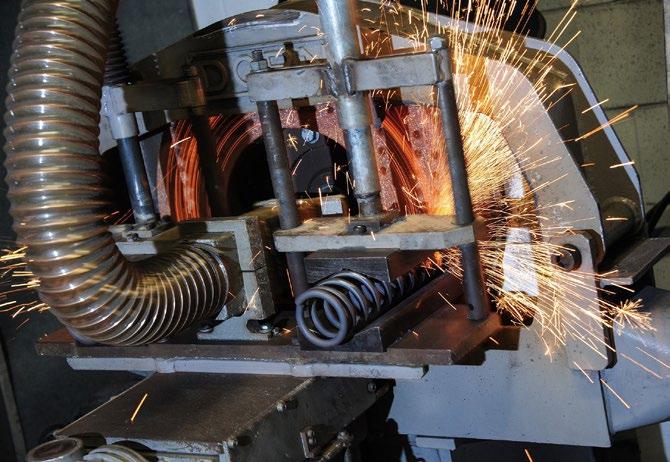

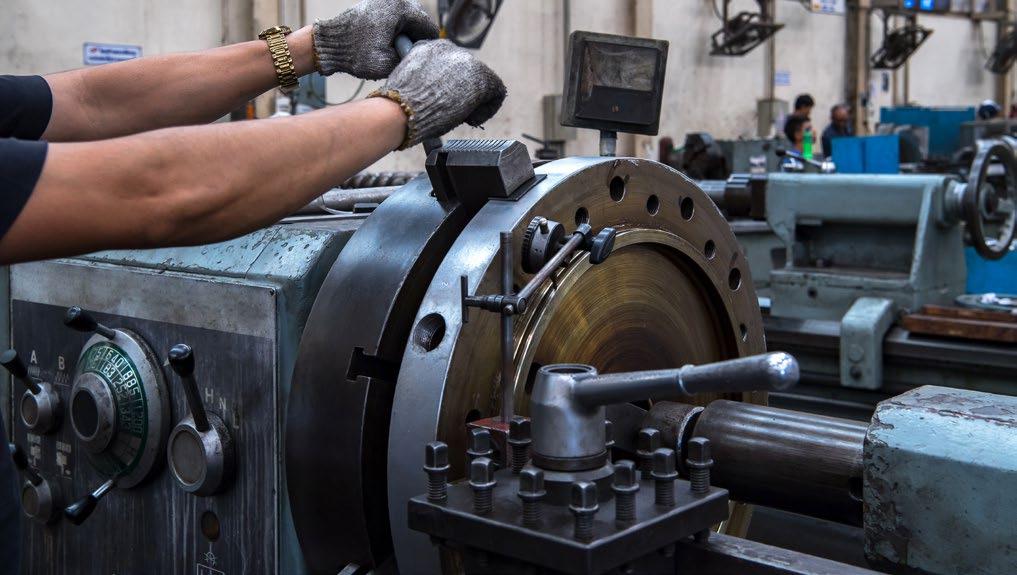

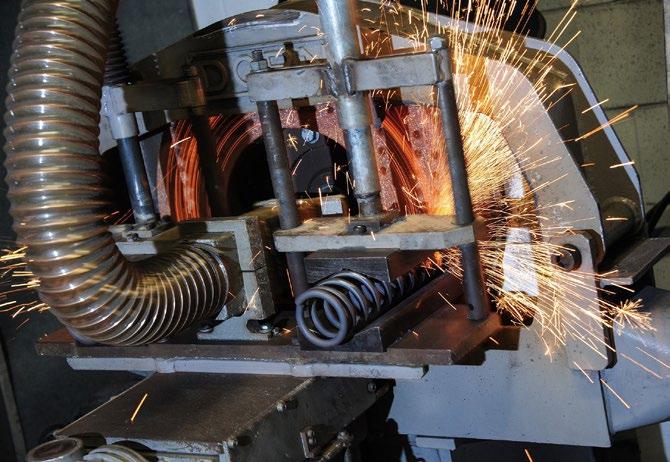

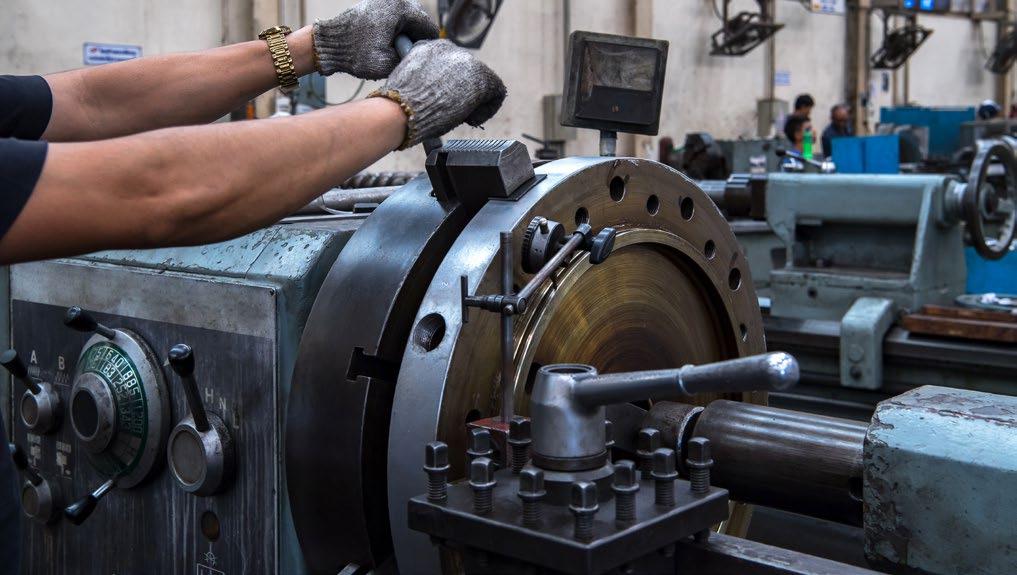

A specialist sub-contract laser cutting and forming specialist is reaping the operational and environmental benefits of a £1.2m machine investment.

Midtherm Laser, which employs 45 people at its factory on Peartree Lane in Dudley, has increased its capacity and speed of processing thanks to the installation of a new Bystronic Bystar Fiber 12kW laser with part automation.

One of the largest purchases in its 23year history introduces the next level of power in fiber laser cutting and will help the company deliver high cutting dynamics and thin to thick cutting capabilities to a customer base that spans aerospace, automotive and decorative work to food processing, agricultural and conveyors.

It has also made a massive difference to the firm’s environmental performance, with

the Bystronic model replacing two older CO2 machines and is already delivering a 50% energy saving – the equivalent of powering 2100 average homes every month.

“Our expertise in laser cutting and metal forming is respected throughout our sector and has led to us increasing sales by a further 6% last year, a great achievement considering the volatility of the market,” explained Mark Hannon, Director of Midtherm Laser.

“The knowledge of our experienced people is one of our greatest strengths and we like to complement this with a sustained investment programme that incorporates the latest technology into our production processes.”

He went on to add: “The 12kW Bystar Fiber is a class leading machine that can cut from 0.5mm to 30mm in mild steel,

aluminium, and a host of other materials. It gives us more capacity to target new opportunities and, importantly, means three quarters of our machines are now fiber technology instead of gas.

“With this in mind, and when you consider we have also invested in LED lighting, sensor switches and electric vehicles and charging for our staff on the road, it’s not difficult to see how we have managed to cut our energy usage in half since 2018.”

Midtherm was originally established in 1968 by Ray Andrews and operated through sister companies offering powder coating, enamelling and UV flues.

There was a laser cutting machine that was occasionally being used at one of the factories and the decision was taken in 2000 to put it to better use by creating a ‘laser’ business that initially employed just three people.

18 PECM Issue 61

EDITOR’S CHOICE

With orders starting to take off, Ray’s son Richard Andrews moved the business to its current 20,000 sq ft factory on Peartree Lane in Dudley in 2004, with the next big milestone taking place in 2018 when Mark Hannon replaced Dean Cockayne as Director and took over the operation alongside Richard and Kate Birt.

Today, Midtherm Laser works with more than 500 companies across 20 different sectors, cutting or forming various sheet metal from 0.5mm to 30mm to a +/- 0.25mm tolerance.

It is also the only sub-contract laser provider that can offer the cutting of nonferrous materials without the risk of cross contamination for industries, including food processing and chemical manufacture.

Richard Andrews, Director at Midtherm Laser, concluded: “There has been a lot of investment recently, with the new laser following the installation of automated warehousing and the rebrand to form the Midtherm Group.

“Embracing new technology is a must for our business, but the company still thrives on the same values my father started it on in 1968, which are quality, service and technical knowledge.”

Today, Midtherm Laser works with more than 500 companies across 20 different sectors, cutting or forming various sheet metal from 0.5mm to 30mm to a +/- 0.25mm tolerance.

For further information, please visit www.midthermlaser.co.uk

Issue 61 PECM 19

From left, Gavin Brettell, Linda Whitehouse and Mark Hannon (all Midtherm Laser)

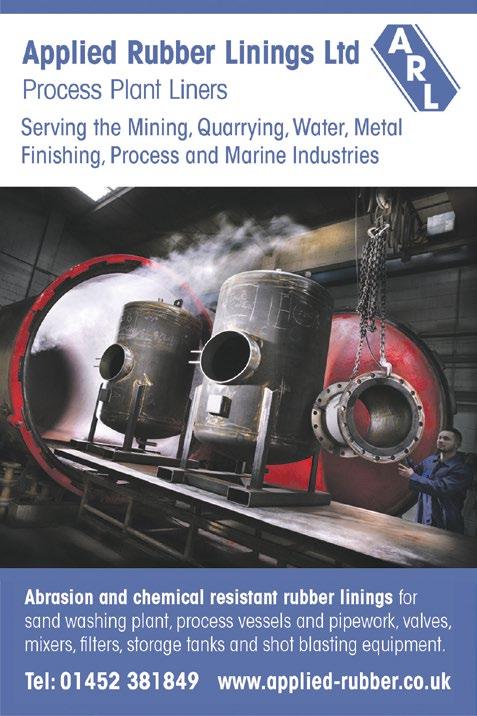

Protection of Submerged Gas Pipeline Calls for the SeaShield 70/80™ System

Winn & Coales (Denso) Ltd.’s SeaShield 70/80™ System was recently utilised during maintenance works on a National Grid pipeline in Cumbria.

Crossing the Duddon Estuary near Barrow-in-Furness, the existing anti-corrosion coating on the National Transmission System (NTA) pipeline had suffered mechanical damage due to shifting sand banks in the area. The remote location prohibited excavation machinery from accessing the site, requiring sections of the 10-inch diameter pipeline to be excavated by hand, thereby restricting the amount of pipe that could be accessed.

Once excavated, surface preparation was conducted to remove light marine growth and loose rust before the SeaShield 70/80 System was applied. Designed for the protection of submerged and shoreline pipelines, the system features water-displacing petrolatum tape and primer, a tough PVC-backed bitumen tape, and a glass-fibre reinforced outerwrap; all of which combine to form a robust protective coating with exceptional impact and mechanical strength.

Work was undertaken by the Pipeline Maintenance Centre on behalf of Cadent Gas, with products supplied by Lynvale Ltd.

Winn & Coales (Denso) Ltd are leading manufacturers and suppliers of corrosion prevention and sealing systems. Their SeaShield systems have offered comprehensive corrosion control on jetty piles and marine structures for the last 50 years.

20 PECM Issue 61 • Clean hygienic design • Stainless Steel • Easy to clean • Minimum maintenance • High performance • Low energy

www.denso.net

EDITOR’S CHOICE

A completed SeaShield 70/80™ System application at Duddon Estuary, with the inner petrolatum tape application shown inset.

ViSWIR … Bringing Visible & SWIR into Focus

ViSWIR Hyper APO Features:

• Capable of fully corrected focus shift in visible and SWIR range (400nm - 1700nm)

• Achieves spectral imaging with a single sensor camera by simply syncing the lighting

Floating design adjusts focus for different wavelengths

8mm, 12mm, 16mm, 25mm, 35mm* and 50mm* (*2023)

ViSWIR Lite Features:

High transmittance at whole wavelength of 400nm - 1700nm by adopting hyper wideband AR coat

Outstanding cost-performance for single-wavelength lighting & narrow-band imaging

Compact design

5mm, 8mm, 12mm, 16mm, 25mm, 35mm, 50mm

Issue 61 PECM 21 HRS Heat Exchangers | info@uk.hrs-he.com | +44 (0)1923 336 313 | www.hrs-heatexchangers.com

Introducing the award-winning Computar ViSWIR-Series

computar-global.com

8457 2618 catalyst of optics

A

info@cbcuk.com 020

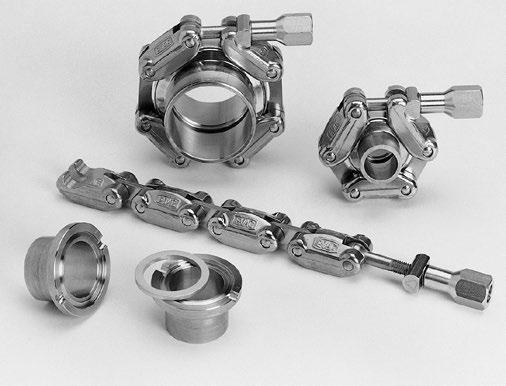

HUCK® FASTENERS

STAR FASTENERS

Mastering Time

We lose time, we kill time, we save time, and we have all the time in the world, but one thing is certain we cannot slow it down or stop the march of time, but we can control how we use it.

“All we have to decide is what to do with the time that is given us” J.R.R. Tolkien.

The effective use of time is a critical factor in a number of manufacturing and construction applications, and more often than not a key factor in profitability. From a manufacturing perspective, the amount of time required to complete a product or assembly directly impacts the number of these items that can be produced during a given time period. Similarly, the time required to assemble, install, or fabricate a product or system on-site can be critical to revenue generation and income.

In many cases, it is actually the joining of elements, either through welding, adhesives, or the installation of fasteners, that can significantly contribute to the time required to assemble a product

or system. Correspondingly, the choice of joining methods can have a critical impact on efficiency and productivity. In addition, a quality manufactured or installed product or system can cut expensive downtime, and reduce timeconsuming maintenance requirements.

Good time management, or being the master of your time, enables you to be more productive with the time you have. Increased productivity ensures you stay on top of your to-do list, whatever that may be… being more productive, meeting deadlines, gaining time for product / business development, ultimately leading

to doing more things that you enjoy or even leaving work on time! Whilst we cannot reclaim wasted time, we can control how we use it.

Here we look at Huck® Structural Blind and Huck® LockBolt® fasteners from a time, efficiency and productivity perspective. This will help to highlight how correct fastener selection, joining decisions and succeeding actions can define whether time is your enemy or ally

HUCK LOCKBOLTS AND HUCK STRUCTURAL BLIND FASTENERS

Over the past 30 years, HuckBolt® engineered two-piece LockBolts and Huck structural blind fasteners have become the fastening option of choice for a number of demanding applications where welding, nuts and bolts, and other joining methods were once regularly employed.

When Huck structural blind and HuckBolt fasteners are used there is no need for lengthy training meetings or to

22 PECM Issue 61

EDITOR’S CHOICE

Good time management, or being the master of your time, enables you to be more productive with the time you have.

Time saving ideas - Star Fasteners can powder coat any stock item or encapsulate Hucktainers®

employ a team of specialist technicians, all that is required for someone to become proficient at installing them is an understanding of what the installed fastener should look like - a quick visual inspection.

Two-Piece HuckBolts - Available in a wide range of materials and in sizes up to 1-1/8” (28.5mm), they have the ability of delivering up to five times the overall fatigue strength of conventional nuts and bolts. In addition to providing a high level of reliable clamp performance, HuckBolts also provide a highly vibration-resistant joining option.

While the strength of HuckBolts is a key characteristic, HuckBolts also offer several important time-saving features. Installation of these fasteners usually requires less than two seconds. As they are swaged fasteners (cold forged onto the pin during the installation process by the tooling), they never need retightening or re-torquing, even in the most vibrationintensive application.

Huck® Structural Blind Fasteners - are available in a variety of materials and sizes (up to 3/4”). Similar to HuckBolts, these advanced fasteners are also installed using a direct tension swaging technique. And like the installation of HuckBolts, this process provides for both a fast and secure installation. Similarly, a quick visual inspection is all that is required to confirm their proper installation, adding to the speed of assembly associated with these advanced fasteners.

TIME-EFFICIENT, COST-EFFECTIVE JOINING

Both two-piece HuckBolts and structural blind fasteners combine unmatched speed of assembly with the ability to use lower-priced / less specialist labour. “Remember that time is money”(Benjamin Franklin); this combination ensures that these LockBolts and blind fasteners are highly cost effective, adding a strong measure of cost control to a wide range of manufacturing or assembly applications.

THE TIME BENEFIT FOR END USERS

Installation and assembly time can be reduced when using Huck fasteners. These precision manufactured fasteners have several key features, for example, locking mandrels and swaged collars, eliminating the need for additional processes such as re-tighten nuts and bolts, waiting for adhesive to set or for welds to cool. This quicker realization of income can be significant, adding to the overall value of any product, installation, or system assembled with Huck fasteners.

STAR FASTENERS – HUCK® FASTENER DISTRIBUTOR, HOW CAN WE HELP

Efficient inventory management is necessary to maintain time critical production schedules and meet consumer demand. There is nothing more frustrating than when stockouts prevent product assembly or the fulfilment of customers’ orders on time.

Star Fasteners have several solutions to limit stock shortages and get stock to customers on time; these include great supplier connections and excellent inventory control. It is important to us that we hold good stocks and match our product supply to customers’ demands to limit stock shortages and lead times. We

know how frustrating it can be to be left without a reliable supply, not only does this impact the financial and operational aspects of a company, but it influences the emotional and hard-earned relationship with customers. It is essential to us that our customers have trust in our supply and feel confident in the fastening and installation tooling solutions provided. Together with a full hire fleet of air, battery and hydraulic tools, and an in-house tool repair workshop, customers are never left without a backup installation tooling solution and we can always keep production line rolling. Star Fasteners understand the importance of a quick and efficient service, but by using Huck fasteners you can get more done, and have less to do!

For further information, please visit www.starfasteners.co.uk

Issue 61 PECM 23

Huck® Blind structural Fasteners Huck® LockBolts®

Huck® 254 installation tool

Huck® Range Force Battery Tool

FineCal are a supplier of Industrial Consumables and work extensively within the Engineering and Composite industries.

includes:

Adhesives Abrasives Technical Tapes PPE Labels

FREE product samples available and FREE on site surveys to discuss your application requirements.

Please call on 0117 971 1111 or email us at sales@finecal.co.uk Our

Custom Inline Disc Filters

You design, we create

Helapet knows that no single filter can be suitable for the varied filtration applications that are used across industries.

Our new online design tool provides customers with a simple-to-use design wizard, combined with enhanced information to guide customers through the 100’s of available filter combinations.

24 PECM Issue 61

leading supply partners include:

Visit www.finecal.co.uk to try our brand new abrasive belt builder!

Our product portfolio

@FineCal Group www.finecal.co.uk

Try out our filter design tool for yourself today! Visit filterdevices.com EDITOR’S CHOICE

INNOVATION | PERFORMANCE | AVAILABILITY FFKM sealing solutions for your most demanding applications Precision Polymer Engineering | Greenbank Rd, Blackburn, BB1 3EA, England | 3201 S. Blue Bell Road, Brenham, TX 77833, USA. Discover the benefits of Perlast® Perlast® is a registered trademark of Precision Polymer Engineering Perlast® perfluoroelastomers are exclusively manufactured by Precision Polymer Engineering. Tel: +44 (0)1254 295 400

THE CLEANROOM CONUNDRUM

Guidance to support regulatory compliance, efficiency and best practice success

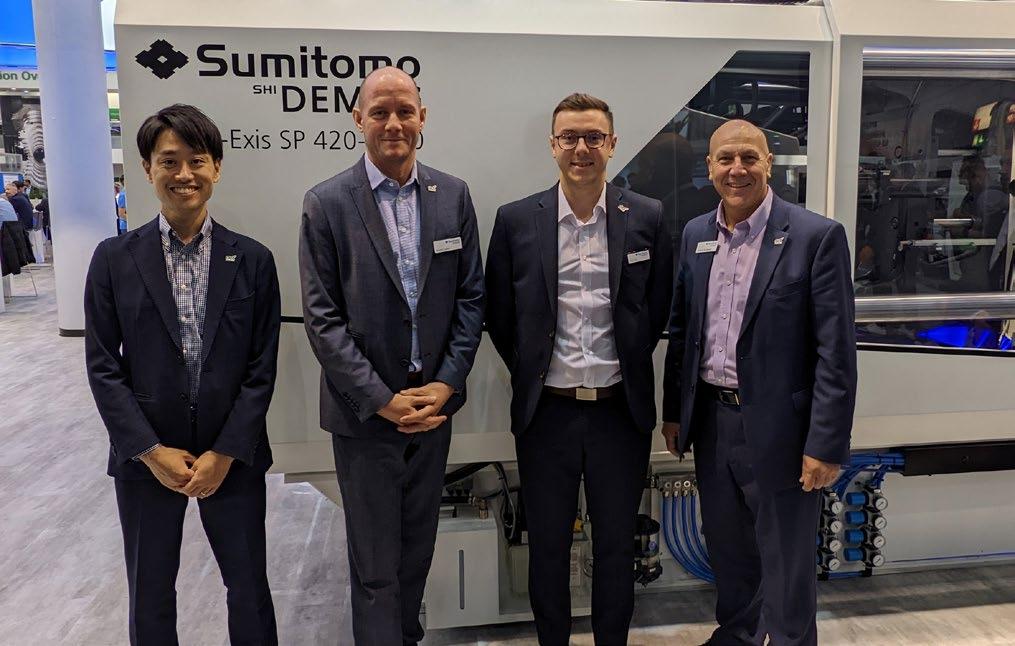

Creating a cleanroom environment that meets GMP regulations can often be a cumbersome task for organisations within the medical moulding space. As well as being costly and timely to implement, regulatory compliance often results in the process becoming more convoluted than strictly necessary. The guidance from the global medical team at Sumitomo (SHI)

Demag is to keep the process simple, and to utilise technical expertise and knowledge.

With production space at a premium, medical injection moulding experts at the firm - Andrew Sargisson, Regional Sales Director, and Sam Carr, UK Medical Business Development - share their cleanroom production industry insights, tips and the top trends shaping the MedTech cleanroom space.

In the latest 2022 report curated by Data Bridge Market Research, the global cleanroom technology market is anticipated to grow to USD4.25bn by 2029. Driven by a surge in demand for high quality medical applications compliant with regulatory standards, control variables, including air flow, humidity and equipment temperatures, are all essential considerations.

MORE THAN A WHITE SPACE

There are three critical features that medical manufacturing cleanrooms must effectively observe and implement.

The first of these requirements is that internal surfaces and equipment needs to be designed in a way that mitigates contamination and can be sanitised with ease. Furthermore, a source of filtered air flow is needed to effectively regulate

temperature, humidity and air quality, while simultaneously extracting particulate contaminations. Introducing robust operational and maintenance procedures and ensuring staff are fully trained is equally critical.

Rising energy costs combined with the upfront costs of building a cleanroom means that investment decisions are rarely taken on a whim. Most medical moulders will only embark on cleanroom projects to fulfil regulatory FDA, GMP Annex 1 and CFR Part 211 requirements.

In order to comply with these requirements, the equipment used in the manufacture, processing, packing or holding of a drug product needs to be of an appropriate design, adequate size and suitably located.

26 PECM Issue 61

EDITOR’S CHOICE

SUMITOMO

The Sumitomo (SHI) Demag global medical team (L to R - Shota Takemura, Medical Team Japan - Anatol Sattel, Head of Business Unit Medical, Germany - Sam Carr, Medical Team UK - Andrew Sargisson, Regional Sales Director Business Unit Medical, based in Germany)

The choice of moulding machinery selected for cleanrooms is generally customerspecific. Where medical components need to be manufactured and packed in a selfcontained cleanroom environment to meet ISO Class 7 or 8 standards and comply with any GMP Annex 1 and FDA regulations, a fully configured all-electric injection moulding machine can be a straightforward way to eliminate the biggest contamination risks … people.

That’s because the exposed points where a plastic component may come into contact with the environment are all enclosed. For that very reason, virtually every global cleanroom project undertaken by the medical team at Sumitomo (SHI) Demag now features an IntElect machine.

KEEPING IT SIMPLE

Andrew Sargisson stresses the need for organisations to keep things simple when it comes to commissioning moulding machinery for a cleanroom environment and cautions against over specifying superfluous equipment. This, he claims, is likely to create needless issues down the line.

For example, focussing solely upon the cleanroom classification itself could leave medical manufacturers exposed to unwarranted compliance requirements that, once approved, they must continue to adhere to. Sometimes effective ventilation is all that’s required. Yet, for sterile medicinal products, the requirementsdefined by Annex 1 of the EU and PIC/S GMPs – are now even more stringent.

This is where global expertise is a true benefit. Out of regulatory fear, people may submit a user requirement specification (URS) request for a cleanroom solution that is excessive for the medical component being made.

As a global medical team that works collaboratively across borders and are all GMP-trained, the group is able to pull in technical experts and provide high quality consultancy at the start of any medical

cleanroom project. This makes it much easier to manage defined steps for design, installation, operational and production Qualifications and Validations of cleanroom machinery.

Turning Cleanrooms into ‘Greenrooms’ As filtered air controlled production environments, moulding cleanrooms are extremely energy intensive. Experts estimate that in some cleanroom facilities, the air units that circulate fresh air and extract particulates can consume around 60 percent of all production power.

Given today’s energy crisis, there’s a real push to conserve natural resources and reduce the ecological impact. Yet, stringent workflows to prevent pollutants spreading and contaminating products make this inherently challenging in cleanrooms.

To counter any adverse impacts of the ensuing energy crisis, medical moulders may want to consider fully utilising any ‘white space’ inside their cleanrooms, occupying any extra space with additional machinery or equipment. The benefits of this are multiple, in that organisations can increase their operational capacity without the need to power or fuel additional space.

Lower ceiling heights is another tactic to reduce the overall atmosphere that requires HEPA filter control. Even if the physical space remains unchanged, the reduced footprint of today’s compact allelectric machines now enables MedTech manufacturers to optimise their cleanroom envelope, boosting cost and productivity metrics considerably.

Clamping

down on heat generation

Over-cluttering is not in-line with the GMP standards. Removing free-standing periphery equipment from the floor and integrating into the moulding machine cell, including hot runner controllers, cables, and even automation, eliminates another surface area and consequently additional sources of heat generation.

Integrated electric direct drives is another consideration. Providing the force

transmission, one of the key processing advantages of electric drives is the ability to control the linear axis with velocities in excess of 500mm/s. With no belts spinning, the drives don’t have to work as hard.

This increased efficiency gained from direct drives means that they use considerably less energy – in the case of the IntElect between 40% and 85% less than conventional solutions.

Having this level of drive control also makes a subtle difference to clamp force. Use too much force and the machine’s energy consumption rises. Rather than diverting straight to the maximum clamp force, a medical IntElect machine, with its smaller than average injection unit, can override and select the appropriate clamp force for a particular combination of component geometry and polymer material. For high cavitation medical components, where precision is fundamental, this is a gamechanger, as the machine isn’t overworking itself. When this happens not only is excess heat being generated, it can also cause premature tooling wear and tear.

Heat transference is another consideration. A portion of electrical power is used to directly heat the barrel to melt resin. Another to run the machine drive, inverters and motors, which in turn also generates heat. All of the heat generated must be dispersed either via thermal convection or – in most cases – an active cooling system.

Thermal imaging of the direct drive provides a good indicator of any inefficiencies and heat emissions. On the IntElect machines, the active air cooling (fan) is not activated until the motor reaches 55°C. If no heat emission on the drive, no additional energy is consumed.

Big moulds … small contained space

In order to achieve the highest production output in the smallest space, the medical IntElect’s larger than average platen area offers greater production flexibility and accommodates various high cavity tool configurations.

Issue 61 PECM 27

In the latest 2022 report curated by Data Bridge Market Research, the global cleanroom technology market is anticipated to grow to USD4.25bn by 2029.

A fully configured all-electric injection moulding machine can be a straightforward way to eliminate the biggest contamination risks … people

Comprising tie bar distances between 360mm and 1100mm, this enables cleanroom medical manufacturers to get the most output in the minimum footprint.

Among the latest developments by Sumitomo (SHI) Demag is the feasibility to combine LSR and thermoplastic moulding in one cleanroom moulding cell, allowing moulders to switch between the two. Other innovations from the company include integrating laminar air flow systems to flood the mould surface and part handling areas with HEPA filtered air.

GMP compliant technical features, such as raising the machine 100mm off the floor, helps to maintain cleaning standards. Additionally, total stainless steel fixed platen coverage on the top, sides and underside without any cut outs ensures air flow is not disturbed. Inside the cell, yet outside the mould space, cooling, temperature and pneumatics can be attached. Eliminating cables and hoses in the mould space.

Once parts are moulded, integrated robotics can quickly and accurately transfer components to the conveyor system, chute or packaging system as required.

CLEANER COMMUNICATIONS

A huge leap forward in cleanroom production is the introduction of smarter communication platforms. Specifically OPC-UA architecture. Designed to enhance traceability and optimise processing stability, medical manufacturers can now extract all performance data from the machine and all the contained periphery equipment, without stepping foot into the cleanroom environment.

Supporting interoperability and securely recording time series data and analysing process parameters, the OPC-UA interface records, channels and collates every processing aspect from all the peripheral devices attached to the cell. This contextualised data is then submitted from the core of the production cell, straight to production and QC managers.

Information such as CO2 consumption and recycling rates can be captured during the production of medical components. Circling back to help manufacturers collate more robust documentation of its ecological production footprint.

Rather than trying to second guess cleanroom compliance implications, the Sumitomo (SHI) Demag medical team works collaboratively with customers to examine the cleanroom processing pains

Inside the cell, yet outside the mould space, cooling, temperature and pneumatics can be attached. Eliminating cables and hoses in the mould space.

and provide suggestions and solutions.

By considering all these factors, achieving regulatory compliance in MedTech cleanrooms may not be as complex as perhaps first presumed. To summarise:

• Utilise excess cleanroom space in the most effective and advantageous manner possible.

• Don’t over-think or over-specify equipment: Draw upon the expertise of a global team to assist with scoping out the design, installation, operational and production requirements.

• Support and enhance interoperability by deploying smarter communication tools

GMP compliant technical features on the medical IntElect includes total stainless steel fixed platen coverage on the top, sides and underside, without any cut outs to ensure air flow is not disturbed

For further information, please visit http://uk.sumitomo-shi-demag.eu/

28 PECM Issue 61

Specialist Training for the Storage Tank Industry

Live online, classroom, in-house or e-learning

•Gain or renew your 5-year Certificates of Competence*

•Courses based on EEMUA 159

• English, Dutch, German and French language options

•Select from courses throughout 2023, including:

TankAssessor courses*

27-30 March 2023 – in French –classroom – Près de Paris, FR

24-27 April 2023 – in German –classroom – Hanover, DE

5-8 June 2023 – in Dutch – classroom – Rotterdam, NL

4-7 September 2023 – in English – live online

TankInspector courses*

20-22 March 2023 – in English – live online

22-24 May 2023 – in Dutch – classroom – Rotterdam, NL

Storage Tanks e-learning

On-demand – in English or in Dutch

In-house courses

By arrangement for your choice of: time, language, location, or live online

More choices, information and registration at www.eemua.org and events@eemua.org

Issue 61 PECM 29 EDITOR’S CHOICE

Above ground flat bottomed storage tanks A guide to inspection, maintenance and repair Publication 159 Edition 5

Available in the UK from Labtex, Vacuubrand manufactures a comprehensive range of laboratory and instrumentation vacuum pumps, gauges and controllers for both coarse and fine vacuums. Vacuubrand’s first priority is to offer sophisticated equipment which meets the highest quality, professional standards expected of a modern laboratory. For example, ‘intelligent pumps’ make lab work more efficient, allowing chemists and technicians to focus their attention on other tasks.

The versatile Vaccubrand chemistry pumping unit, PC 3001 VARIO select

• Unsurpassed performance

• Uncompromising chemical resistance

• Fully automatic evaporations

• Minimal operating and maintenance costs

• Whisper quiet

• Environmentally friendly, without oil and water consumption

• The Vacuubrand Chemical Resistance Chart

• Chemical resistance is essential when working with aggressive gases and vapors.

www.labtex.co.uk

Labinox

Manufactured in 316-grade stainless steel as standard, and built according to customers’ designs and dimensions, our expertise ranges from simple fabrications and machining to high specification projects for the pharmaceutical, food processing, water, paper and chemical industries.

Pressure Vessels

Labinox stainless steel pressure vessels are durable, high-quality and can be built to your exact specifications.

Stainless Steel Filters

Fabricated to customer requirements and specifications, Labinox stainless steel filters are designed to ensure easy access, maintenance and cleaning.

Tanks

Our steel tanks offer the perfect solution for storing a variety of liquids in a range of capacities. Steel has a resistance to many damaging factors, making it naturally durable and longlasting, while the practical tank designs make them easy to clean and maintain.

Stand Up Writing Desks

Made from 316-grade stainless steel as standard, our stand-up writing desks are sturdy and high-quality. The sleek design ensures quick and easy cleaning, while minimising places for dirt and bacteria to get trapped. Labinox’s bespoke service means that all stand up writing desks are made according to your requirements and are suitable for a variety of uses.

Trollies

Labinox 316-grade stainless steel trolleys provide a secure and effective way of storing and transporting items. The practical and hard-wearing designs can be built to exact customer specifications and ensure quick and easy cleaning for optimum hygiene levels. Available with a customisable number of tiers, our trolleys are practical, reliable and lightweight.

www.labtex.co.uk

30 PECM Issue 61

01484 600 200 info@labtex.co.uk www.labtex.co.uk For innovative process and control equipment, contact Labtex today! HUBER-Inspired by temperature

The UK’s Laboratory Equipment Experts

Vacuubrand’s high-quality and reliable range of chemistry diaphragm pumps, are designed for working with aggressive gases and vapors!

EDITOR’S CHOICE

MEET THE NEW GENERATION ECO-FRIENDLY PARTS WASHER LOW ENERGY CONSUMPTION Eco-mode and double skinned tank reduces energy usage by up to 54%* HEALTH & SAFETY Non-hazardous, non-flammable, no vapours POWERFUL CLEANING Solvent-free, aerospace approved * Based on internally conducted controlled laboratory tests in 2022. We are looking for ROwasher distribution partners across the globe. Call us or email export@rozone.co.uk for more information. NO EXPENSIVE SERVICE CONTRACT Self-recycling, easy to maintain LOW ENVIRONMENTAL IMPACT Assists compliance with ISO14001 REDUCES WASTE Bioremediation technology, oil-eating microbes keep fluid clean +44 (0)121 514 0607 www.rozone.co.uk

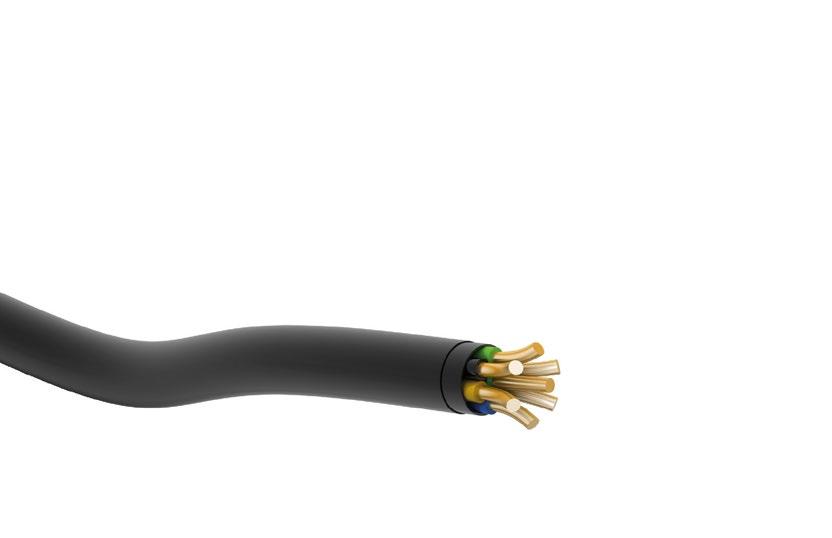

PEI-Genesis celebrates opening of its new sales office in Singapore

PEI-Genesis, a global leader in the design and assembly of custom engineered interconnect solutions, has announced it expansion into Southern Asia-Pacific region, allowing it to support local customers across the region. This follows the opening of the company’s new sales office in Singapore in December 2022. The company placed its first APAC footprint in Zhuhai, China in 2015. Since then, it has opened sales offices in 10 major APAC markets.

A ribbon-cutting ceremony followed by a lion dance was held to mark this auspicious milestone. Members of PEI-Genesis leadership, including Steven Fisher, CEO, Alex Tsui, Vice President & Managing Director APAC, and Bernard Koh, Regional Sales Director of South Asia, attended the opening ceremony. At the same time, Trusted Advisors from PEI’s sales departments in Singapore, Vietnam, Indonesia, and Thailand, representatives of the core account customers, and suppliers joined them to celebrate in Singapore.

“We are continuously investing in more talent to engage closely with our local customers while also searching for new assembly sites to support Mil-Aero customers in the region. The establishment of the APAC South office has once again fulfilled PEI’s promise to improve delivery speed, achieve good inventory management, and strengthen the professional service capabilities of the local team,” says Alex Tsui, Vice President & Managing Director APAC.

In 2015, PEI-Genesis placed its first footprint in APAC, opening its

Zhuhai, China production facility. Today, there are sales Trusted Advisors in 10 major APAC markets, including Japan, South Korea, mainland China, Hong Kong, Taiwan, India, Vietnam, Thailand, Indonesia, and now Singapore. Due to the COVID-19 pandemic, PEIGenesis was unable to officiate a proper opening in October 2021, delaying it almost a year and a half later, now taking place in December 2022.

In addition to PEI’s Trusted Advisors, the new office has a call center with technical engineering support to serve local customers more effectively.

we make ideas come to life

RMIG is the world’s largest manufacturer and supplier of perforated metal and its related products.

We know our customers’ requirements for price and quality and meet their demands with uncompromising service.

Not only do we offer standard and bespoke perforated metal sheets, we are able to offer you a range of secondary operations as detailed below.

Complete solutions

With a continued investment in the latest equipment and a network of professional partners we are able to produce prime quality products and solutions – from a simple perforated sheet to the fully formed and coated custom made part.

Cutting

We can cut and shape perforated sheet to meet the needs of your nal application.

Levelling

For some applications a high degree of atness is required, we have processes in place to ensure our perforated coils and sheets meet with your most demanding requirements.

Rolling and forming

We can roll, bend and form perforated sheets to match your design.

Aesthetic nishes and protective coating

We can offer powder coating and hot dip galvanizing solutions to meet your speci cations.

For more information please contact us tel: 01925 839610 | email: info.uk@rmig.com | www.rmig.com

32 PECM Issue 61 C M Y CM MY CY CMY K

EDITOR’S CHOICE C M Y CM MY CY CMY K

For more information, visit www.peigenesis.com

Vibration monitoring 24/7

Monitoring and Condition Based Maintenance of rotating machinery. This complete solution makes your machines fit for Industry 4.0

• Continuous diagnostic: Full coverage of your critical assets at all times.

• Early diagnostics: Monitoring of imbalance, wear and overall vibration.

• Maximum efficiency: Permanent diagnostics helps keep your assets running efficiently.

• Easy integration: ifm provides individual solutions suited to different types of machines. Reducing costs, avoiding unplanned downtime and optimising processes: The ifm application solutions.

ifm – close to you!

your critical assets from spinning out of control!

/ uk ifm.com / uk Go ifmonline Go ifmonline years

on ifm products

Protect

ifm.com

WARRANTY

LATEST NEWS FROM PTC

Codebeamer becomes part of PTC’s Digital Thread

PTC, one of the world’s leading digital transformation specialists, has announced a major milestone for engineers, with the seamless integration of its Codebeamer® (Application Lifecycle Management) product version with Windchill® (Product Lifecycle Management).

Completed via the OSLC standard, this latest innovation improves visibility across the entire digital development process and should help manufacturers of complex products innovate quicker and better.

PLM solutions like Windchill manage parts, models and documents, while ALM solutions like Codebeamer automate software development and delivery processes to increase productivity and ensure compliance. Software development teams typically work according to agile methodologies.

By integrating the ALM and PLM solutions, all software and hardware product development teams can now benefit from the advantages of lifecycle management systems and the ability to quickly respond to changing requirements, as well as capture, link, track and manage all

For further information, please visit www.ptc.com

requirements. At the same time, it provides full traceability from start to finish.

You get an end-to-end user experience with a single sign-on, links visible in both directions and automatic detection of links after changes.

“With this integration, we have reached another milestone for engineers in the industry,” said Elliot Clarke, UKI regional director at PTC.

“Now that these two leading solutions work seamlessly together, we are providing end-to-end support for the entire digital development process for both hardware and software. This takes collaboration between different development teams to a new level and especially helps manufacturers of complex products innovate faster and better.”

34 PECM Issue 61

PTC

With this integration, we have reached another milestone for engineers in the industry.

EDITOR’S CHOICE

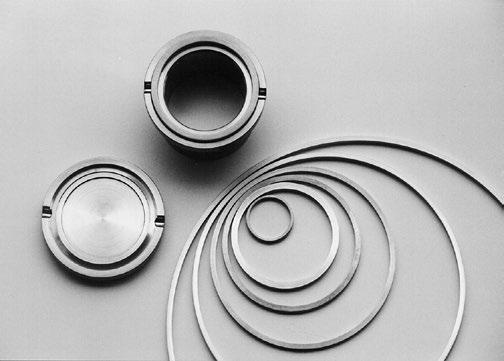

High-performance seals for rotary, reciprocating & static applications

All specification, design and manufacture carried out in-house in our 24/7 manufacturing facility

OEM engineered seal design –typically 3-5 days versus 8-10 weeks industry standard

Over £2.5m of semi-finished material and finished sealing products kept in stock

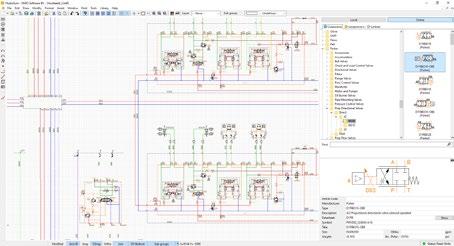

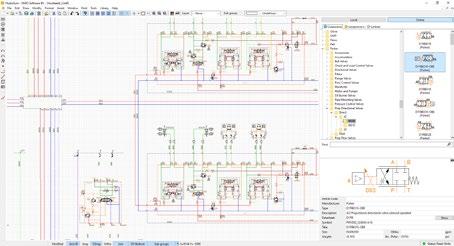

Flawless design of your hydraulic system schematics

HydroSym is intended for the design of your hydraulic systems. It is a dedicated, standalone software solution with all the tools to help you to draw flawless hydraulic schematics.

Create schematics for your hydraulic system in no time. You do not need training nor extensive knowledge of CAD-type software to use HydroSym. Smart Tools in our

For primary containment of hazardous substances

…

MIPC® helps practitioner-level engineers stay on-site and on top of the latest industry developments and good practice in primary containment of hazardous substances, including in pressure systems.

Ussing a blend of live, online classes, one-to-one sessions with expert tutors, and e-learning, enhaanced by a mentor’s support and guidance

EEMUA’s Mechanical Integrity Practitioner Certificate course d delivers in-depth training to engineers where they work – giving the flexibility to learn on-site or on-call

Registration open now for the next MIPC course. Learning starts 20 March 2023.

Induction of 2 hours from February 2023 adapts coursework to each learner and their site/s' needs.

For more information please contact EEMUA online-learning@eemua.org +44 (0)20 7488 0801 www.eemua.org

MIPC® shortlisted for the Best E-learning/ Online Education Initiative memcom membership excellence awards 2020 and 2022

software will help guide you to a flawless design, such as smart connecting lines with information flows, automatic jumpers, easy positioning of items between connecting lines, and straightforward changing of solenoid properties. You’ll draw your first hydraulic diagram within minutes!

https://paro.nl/hydrosymhydraulic-schematic-design

Issue 61 PECM 35 TECHNICAL DISTRIBUTION CENTRE Leicester +44 (0) 116 275 4720

TECHNICAL INSPECTION CENTRE Newcastle +44 (0) 191 422 4200 ENGINEERED SEALS DIVISION Sheffield +44 (0) 114 243 2777 www.m-seals.com

SPECIALISTS IN DESIGN, MANUFACTURING AND DISTRIBUTION OF SEALS FOR THE GLOBAL MARKETPLACE

EDITOR’S CHOICE

HV MAINTENANCE

POWER CONTINUITY

Offering High Voltage Maintenance remedial works during planned inspection works out of hours as well as running repairs and replacements

New HV installation works, can save your site thousands each year due to the higher efficiency of the latest transformer technologies. Upgrade to protect the environment. Our directly employed staff and both experienced and technically trained with decades of experience in the field. Whether 11kV to 66kV our authorised engineers have the professionally certified capabilities to ensure that every site is successfully serviced and maintained to current legislative standards.

Power Continuity contractors have all the credentials, expertise and certification to provide the most comprehensive ‘ in house’ services, covering design, installation and maintenance of all HV and LV supply equipment and networks, regardless of size and make at any location in the UK.

High Voltage Tailored solutions , bespoke to ensure your sites total safety, efficiency, compliance and reliability 24/7.

FACT- we understand your expectations and can tailor our services to suit your site.

Rest assured, with Power Continuity, you’re working with the most professional and highly competent Electrical HV Engineers, at your service.

HV SERVICES

All our comprehensive maintenance service contracts covers both older installed HV & Transformers as well as newly installed equipment, regardless of manufacturer.

Whether bulk oil switchgear , modern insulated devices, Induction Disc Relays, or even microprocessor based protection units. All our servicing of switchgear, transformers, electrical protection systems, complies with BS 6626 and BS 6423

EMERGENCY CALL OUT 24-7

If a breakdown occurs on an HV or LV system it’s an inconvenience, but if the primary HV system fails then you rapidly need an

engineer on site , immediately.

We provide same day response for all our contract clients.

Remember - Maintenance is designed to keep equipment in good condition.

Current Regulations state that you must maintain your system regularly.

But delays in maintenance are costly both economically as well as legally.

This applies to all HV systems across your estate. Service-Repair-Certify

SERVICES

Power Continuity offers a full range of options which are bespoke, tailored to your specific HV system as well as offering ‘one off’ remedial maintenance and internal inspections during OOH shutdowns, all carried out to BS6626:1985 and BS6867:1987 standards.

Earthing solutions, including field-based soil resistivity surveys, design options, installation and commissioning.

Our onsite services include:-

• HV & LV SF6, vacuum and oil filled switchgear maintenance

• Switchgear modifications

• Lifting of operational restrictions

• Discharge testing

• Visual inspections

• Earth testing

• Oil sampling

• HV Generators

• Emergency Standby generators

FAULT FINDING SOLUTIONS

Wondering if there may be a fault somewhere in your High Voltage electrical system?

• Concerned about joints?

• Joint replacement?

• Phase shift?

We can provide a thorough fault-finding service with a written diagnostic report and remedial works.

Our engineers perform electrical testing and inspection for all your High Voltage systems to ensure that they are safe, legal and operating within the very best performance parameters.

HIGH VOLTAGE ELECTRICAL INSTALLATIONS

Power Continuity provides a full design and build capability for all your HV electrical system requirements, including HV Switchgear, transformers, HV cabling installations, jointing, terminating, and testing. Your project will be expertly managed and co-ordinated by our specialist team, ensuring project completion is carried out to highest, industry leading standards.

For all your HV needs

Contact Power Continuity

0845 055 8455

We’re here to help 24/7

For further information, please visit www.powercontinuity.co.uk

36 PECM Issue 61

EDITOR’S CHOICE

PRECISION INJECTION PLASTICS

LINTON PLASTIC MOULDERS

Reliability, quality and value for money

For over 43 years Linton Plastic Moulders have been delivering precision injection plastics to our customers all around the world. Founded in Linton Cambridgeshire 1980, Linton soon became a well-known trade moulder in the area supporting many companies in different sectors such as, printing, fasteners, lighting systems, medical, communications, pet industry and many more.

For many years the Linton ethos has been about knowledge. The experience and knowledge gained over the earlier years has been the driving force of growth and then the acquisition by The MEL Group.

The MEL Group has made significant investments in capital equipment including factory relocation into a new facility within walking distance from the group headquarters in Sudbury, Suffolk.

Linton Plastic Moulders have won contracts in the communications, aerospace, electrical sectors and are proud to involved in the design and manufacture of headsets for both military and civil aviation authorities.

Injection Moulding

Reliability, quality and value for money are the hallmarks of the in house and subcontracting plastic injection moulding service. Customer satisfaction is integral to the company’s growth.