1.1. Environment Brief 01 - UEA Enterprise Centre drawing process

(Hand Drawings) A1, 1:100, Pencil Drawings

1. ‘A Leader in the Circular Built Environment: Arup Group Limited’, Ellenmacarthurfoundation.org <https://ellenmacarthurfoundation.org/circular-examples/a-leader-in-the-transition-to-a-circular-built-environment-arup-group> [accessed 10 April 2023] 2. ‘Architype / the Enterprise Centre / the UK’s Leading Passivhaus, Sustainable Architects’, Architype.co.uk <https://www.architype.co.uk/project/the-enterprise-centre-uea/> [accessed 04 April 2023]

Demand-led Ventilation Vein System with using Plant Rooms

Using LED lighting and an intelligent control system is a great way to reduce lighting loads and overall energy demand. By only using lighting when it is needed, and adjusting lighting levels based on occupancy and daylight levels, you can significantly reduce energy consumption. What is more, the building consists of 3 Plant Rooms which keep the temperature cold enough. As the engineering director of the UEA Enterprise Centre explained that the system was designed especially for efficiency in summer.

The structure keeps the temperature in the south wing because of the classroom and learning needs. It keeps the cooling system accurate to the student’s current clothing. Furthermore, the Enterprise Centre includes a small amount of Air Cooling Systems involved in a 300seat auditorium. To determine the amount of air cooling system required for a 300-seat auditorium, we need to consider several factors, such as the size of the auditorium, the number of people in the room, the heat generated by lighting and equipment, and the local climate.

Similarly, using a demand-led ventilation system controlled by occupancy and CO2 sensors is a smart way to ensure that fresh air is delivered when and where it is needed while minimizing energy consumption. By only ventilating areas that are occupied, and adjusting ventilation rates based on actual occupancy levels, you can reduce the amount of energy needed to heat or cool the air.

It’s also interesting to note that the building has three ventilation plant rooms, which suggests that the ventilation system is designed to be flexible and adaptable to different areas of the building. This can help ensure that each space receives the appropriate amount of ventilation while minimizing energy waste.

Heating and ventilation system

The Enterprise Building Heating and Ventilation system includes several components, which are:

Radiators: Radiators are a common way to provide heat to a building, and they work by circulating hot water through pipes that run along the walls or floors. The heat from the water radiates out into the room, warming the air.

DX coil to auditorium: A DX coil, or direct expansion coil, is a type of heat exchanger that uses refrigerant to cool or heat air. In the case of an auditorium, a DX coil might be used to cool the air in the room during hot weather.

District heating: District heating is a system where a central plant generates heat, usually from burning fossil fuels or biomass, and then distributes that heat through a network of pipes to buildings in a specific area. This can be an efficient way to heat buildings, especially in densely populated areas.

AHU heat recovery: An AHU, or air handling unit, is a component of a heating and ventilation system that circulates and filters air. Heat recovery in an AHU refers to the process of capturing heat from the air that is being exhausted from the building and using it to preheat the incoming fresh air.

Insulation system: Insulation is a key component of any heating and ventilation system, as it helps to reduce heat loss and improve energy efficiency. An insulation system might include materials such as fibreglass, cellulose, or foam, which are used to insulate walls, floors, and ceilings.

All of these components work together to create a comfortable and energy-efficient heating and ventilation system for a building.

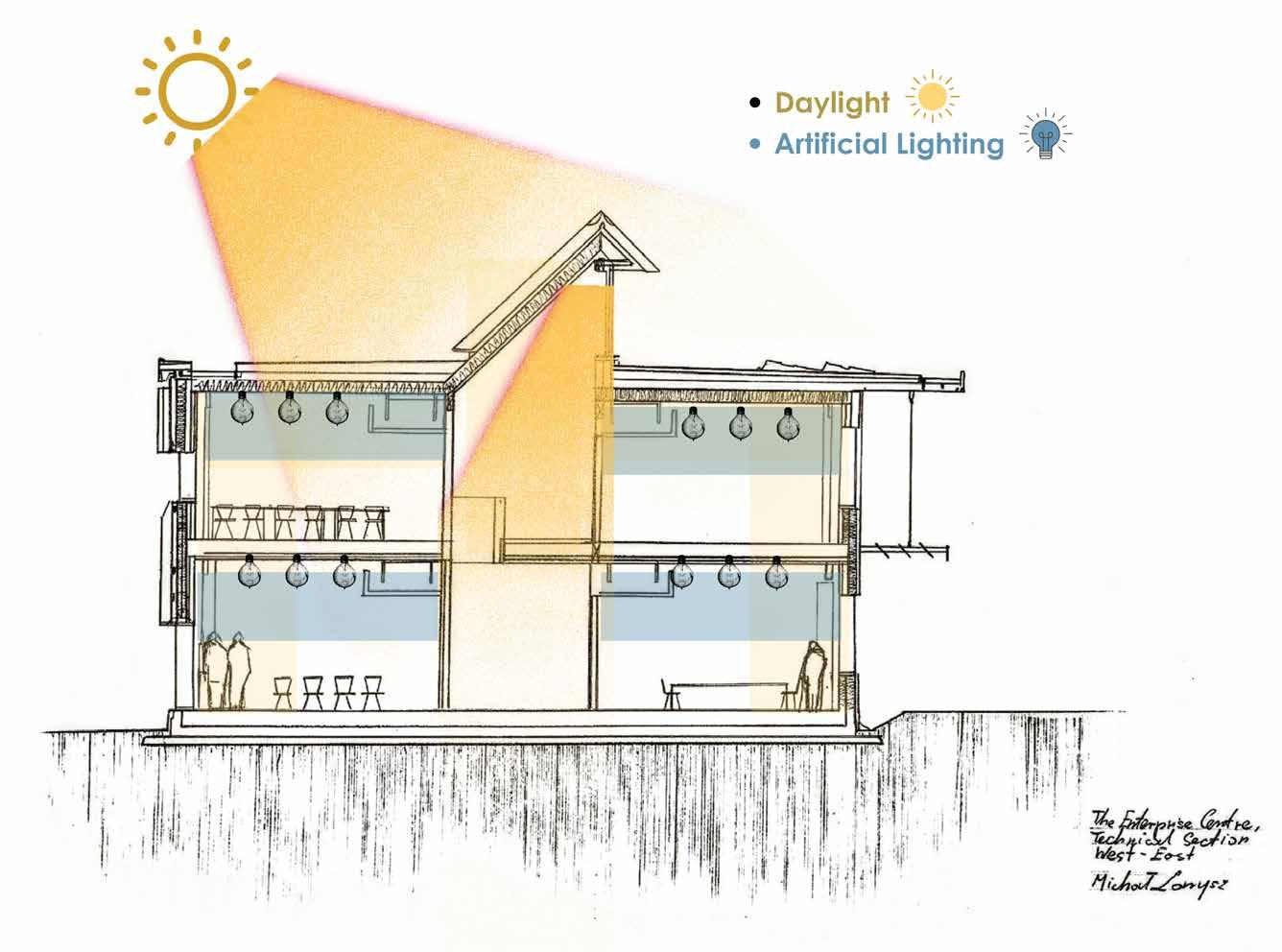

Lighting and power system

The Enterprise Centre building lighting design incorporates several energy-efficient strategies.

Using daylight as the primary source of light is a great way to reduce energy consumption, as it allows the building to rely on natural light rather than artificial lighting. This can also have benefits for the occupants, as natural light has been shown to have a positive effect on mood and productivity.

Additionally, the absence of down lights in the ceilings suggests that the lighting design has been carefully considered to minimize energy waste. Down lights can be a major source of heat loss and energy waste, as they often require large amounts of energy to run and can generate a lot of excess heat.

Using task-focused lighting is another smart strategy for reducing energy consumption, as it allows the building to provide targeted lighting in areas where it is needed, while avoiding excess lighting in areas that do not require it.

Balanced colour temperature is another important consideration in lighting design, as it can help create a comfortable and naturallooking environment. Choosing a color temperature that is similar to natural daylight can help reduce eye strain and create a more pleasant atmosphere for building occupants.

Finally, the use of intelligent lighting controls and pendant lighting can help create a comfortable and adaptable lighting environment, while minimizing energy consumption. By using controls to adjust lighting levels based on occupancy, daylight levels, and other factors, the building can reduce energy waste and ensure that lighting is provided only where and when it is needed.

Water and waste system

The UEA Enterprise Centre is a great example of a passive house that incorporates eco-friendly solutions for water supplies. Here are some more details about the specific watersaving features of the building:

Rainwater harvesting system: The roof of the building is designed to collect rainwater, which is then stored in a tank and used for non-potable purposes such as flushing toilets and watering plants. This helps to reduce demand for clean water and also helps to prevent storm water runoff.

Water-saving solutions:

The building is equipped with watersaving fixtures such as low-flow toilets and faucets, as well as waterefficient appliances like dishwashers and washing machines. These help to reduce water consumption and save energy.

Rainwater & greywater recycling: In addition to the rainwater harvesting system, the building also has a greywater recycling system that treats wastewater from sinks and showers and recycles it for use in toilet flushing. This reduces the amount of clean water that is used for nonpotable purposes.

Refuse & recycling provision:

The building has a comprehensive waste management system that includes recycling bins and waste reduction measures. This helps to reduce the amount of waste that is sent to landfills and promotes sustainable practices.

Flood protection:

The building is designed to be resilient to flooding and incorporates measures such as raised floors, flood gates, and drainage systems to protect against flood damage.

This helps to reduce the risk of property damage and ensures that the building can continue to operate during extreme weather events.

Horizontal & Vertical services distribution in the Enterprise Centre.

In the Enterprise Centre building services such as water, electricity, and data cabling across the floors of a building. This has been achieved through the use of floor and ceiling voids, as well as panels that can be easily removed for maintenance purposes. By adopting this approach, the services can be accessed and modified with ease, allowing for greater flexibility in the use of the building.

In terms of vertical services distribution, a key consideration is how to integrate water and waste systems within the architecture of the building. This can be achieved through the use of risers and walls, which can be designed to accommodate pipes and ducts for water and waste distribution. Voids and panels can also be used in this context, to conceal the pipes and provide easy access for maintenance.

In addition, it is important to consider strategies for integrating rainwater into the building’s services infrastructure. This may involve the installation of special pipes and tanks for the collection and storage of rainwater, which can then be used for nonpotable purposes such as flushing toilets or irrigating gardens. By incorporating rainwater into the building’s services infrastructure, it is possible to reduce the demand for mains water and improve the sustainability of the building.

Day 1 - Learning the technique - Lamella Roof Structure

On the first day, we met in groups and were given a location, ours being in the courtyard. We were shown the materials we would be using, which were pre-cut timber with ready-made mortise and tenon joints.

We were separated into 2 groups and each group was responsible to create the peace of Lamella Roof Structure by using different types of joints. One of the groups had to create joints using the wire. The other one had to use the more stable drill, which we found was easier to make.

The whole day we used to experiment with the woods and after that, we share the pros and cons. After constructing a simple frame, we measured how many square metres it covered by measuring the length and width and timed it. We were focused to try as many versions as possible to save time in the next few days. We computed this by counting the number of timber batons utilised. We could figure out how big the frame could be by counting how many batons we had in total.

Nevertheless, we managed to get enough experience with materials to end the end of the day make a key decision on which technique is the best to be used. We also used that time to prepare the master pieces of wood to cut the materials faster and involved a whole group of people.

Day 2 - Testing first prototype structure - Tension & Compression

We carried the framework again to test the strength of the two-layered structure we worked on the day before.

We realized that the structure is crushing in the weak spots because of the tension and compression. Then we started tasting various solutions for this problem. Starting with another way to combine the peace of wood. Using an additional layer of screws into the woodwork, but when the structures become bigger and the wood breaks. Then we combine the work of 2 groups and put the frame on each other.

With a double layer, the structure was stronger, but it lacked flexibility and added a lot of weight.

We were able to find the weak places in the joints by resting the structure on top of the chairs. Nevertheless, we have noticed it is crucial to use the wire to make the weak points stronger.

After that, we came up with another idea to use the wire on the opposite points of the Lamella structure. It was a key observation that has a massive influence on tension and compression.

Construction Brief (Mudchute Diary)

Day 3 - Preparation & Testing Lamella Structure on site.

We started testing the structure on the site with an outstanding with on the Canary Wharf buildings. To begin with, we started testing the joint in our workshops. Not all of them were working. Nevertheless, after a few failures, we moved the structure to the site which has the level changes. That makes this task more demanding. We used professional safety equipment to make sure that the work on site is under safety requirements.

On-site, we realized that because there is a level change the structure gets more tension than before. Thankfully, different types of joints and additional wires on opposite sites make the construction safe. Felt proud and happy about our work we move on further.

We gather natural materials including timber and use them in our structure. We dig holes in the site and put them inside the wood to make extra support for the group. That day was a wind that bring additional challenge and experience to our diaries.

Construction Brief (Mudchute Diary)

Day 4 - Final Critique with another student groups, Final Feedback

We returned to our original location to destroy the construction. Each screw and nut was replaced, and the wire and timber used for braces were deposited in a separate garbage box.

We got a privilege to compare the final design with other group. After that we share the thought with our friend and make a final conclusion. We realised that the same ideas has been tasted on the various structures and gave a different outcome.

Since the mortise joints were loose, generating gaps in our joints produced structural issues. The timber batons we used were bent and cupped, making it difficult to make a consistent frame. As a result, some joints were tight while others were lax. This taught us that every piece of wood functions differently; the straighter the wood, the closer it was cut to the centre.

The 4 Days Mudchute Workshop was a great experience that gave me a lot of practical knowledge. I am glad that I could spend these 4 days on honest, productive work because now I can use the experience in creating new architectural drawings.

6.2. Circle Building by ARUP Elements & Materials

Primary structure: The primary structure of the building is made up of a series of reinforced concrete columns and beams that support the weight of the building. These elements are designed to provide the necessary strength and stability to ensure the building can withstand loads and forces over time.

Engineered wall: The building also features an engineered wall system that helps to distribute loads and forces throughout the structure. This wall is typically made up of precast concrete panels that are connected to the primary structure using steel connections.

Roof cassettes: The roof of the Circle Building is made up of a series of prefabricated cassettes that are designed to be quickly and easily assembled on site. These cassettes provide a durable and weatherresistant layer over the building and are supported by the primary structure.

Weatherproofing layer: Underneath the roof cassettes, there is a weatherproofing layer that is designed to protect the building from water damage and other weatherrelated issues. This layer typically consists of a waterproof membrane that is installed over the engineered wall system.

Rain screen façade: Finally, the exterior of the Circle Building features a rain screen façade that helps to protect the building from wind and rain. This façade typically consists of a series of metal panels that are installed over the weatherproofing layer and attached to the engineered wall system.

7. Structure Brief 01 - Tension + Compression

Case Study - Denver Airport, Northeast Denver, Colorado, U.S.

Including different building components which allow making a building more sustainable including: Slab: This is a new Peikko product that allows for the mechanical connection of slabs. This product makes it possible to connect two adjacent slabs, creating a stronger and more stable structure.

Wall and foundation (Horizontal): Peikko have adapted their existing “SUMO® Wall Shoe” product for horizontal connections between walls and foundations. This allows for a mechanical connection between the wall and the foundation, creating a more stable structure.

Beam, Column, and Wall: Peikko has also adapted their existing “PCs® Corbel” product to make a mechanical connection between a beam and a wall or column. This connection is almost hidden, creating a clean and seamless appearance.

Slab/Wall: Peikko has developed a new product that allows for mechanical connections between slabs and walls. This connection creates a stronger and more stable structure, especially in areas where high loads are expected.

Wall (vertical): Peikko has adapted its existing “SUMO® Wall Shoe” product to allow for vertical connections between two wall elements. This mechanical connection creates a more stable structure, particularly in areas where lateral forces are expected.

Column/Foundation: Finally, Peikko offers their existing Column Shoe product cast with lime mortar. This allows for a strong mechanical connection between a column and its foundation, ensuring the stability and durability of the structure.

The milestones for the design were experimenting with the steel joints cast with lime mortar. This approach has been explored by GXN, and they have worked with the theory that Peikko brackets can be cast out with lime mortar, which can then be removed again by hydro-blasting. The idea is that the mortar only needs to protect the connection from fire and corrosion and needs to transfer any loads. The advantage of using lime mortar is that it is a more sustainable and environmentally friendly material than other types of mortar. Lime mortar is made from natural materials and has a lower carbon footprint than traditional cement-based mortar. Additionally, the use of lime mortar can lead to a waste reduction and more efficient use of materials.

However, there are also potential drawbacks to using lime mortar in steel joints. For example, the strength and durability of the joint may be compromised using lime mortar. Additionally, there may be challenges in terms of ensuring the accuracy and consistency of the joint, which could impact the overall structural integrity of the building. Some potential strategies for customizing the Circle House construction system for a hilly site could include: Using a modular design approach that can be easily adapted to the contours of the site. Incorporating site-specific materials into the construction, such as stone or timber. Implementing innovative foundation solutions to accommodate the slope of the site Using advanced digital design and fabrication techniques to create a more precise and efficient construction process By exploring these and other options, Tim Bruun and Rasmus Feddersen hope to develop a construction system that is adaptable, sustainable, and responsive to the unique challenges of building on a hilly site.

‘A Leader in the Circular Built Environment: Arup Group Limited’, Ellenmacarthurfoundation.org <https://ellenmacarthurfoundation.org/circular-examples/a-leader-in-the-transition-to-a-circular-built-environment-arup-group> [accessed 10 April 2023]

‘Architype / the Enterprise Centre / the UK’s Leading Passivhaus, Sustainable Architects’, Architype.co.uk <https://www.architype.co.uk/project/the-enterprise-centre-uea/> [accessed 04 April 2023]

9. Structure Brief 02 - GIF Process Making, Hand Drawing 1:20 (Structure Brief 02)

Wall Build-up (All layers including facade system)

The Material layering:

1. Faber Cement frame 8 mm

2. Wood Frame - (Moulded pressure-impregnated wood)

3. Insulation (Pressure-resistant insulation VELFAC 200)

4. Steel brackets for fixing and supporting facade elements (15 mm wind plate)

5. Second form work 24x45mm

6. Weather Board (Blackboard) - 12 mm wind prof board

7. Form-work for facade cladding 24x45mm

8. Facade cladding 25mm cork, retained with wing fittings

Facade System (Mosa), Ceramic Tiles - Cradle to Cradle Silver

The Mosa Facade System, made of ceramic tiles, has received the Cradle to Cradle Silver certification. This certification evaluates products based on their performance in five categories: Material Health, Material Reutilisation, Renewable Energy and Carbon Management, Water Stewardship, and Social Fairness.

This solution is designed for easy disassembly and reusability, making it a sustainable choice for building exteriors. The system uses mechanical fasteners to mount ceramic tiles onto a lightweight ventilated facade. The mechanical fasteners allow for easy removal and replacement of individual tiles, without damaging the surrounding tiles or the building substrate. This means that the facade system can be easily updated or repaired without generating waste.

The Mosa Facade System is available in two different types of fixations: visible and concealed. The visible fixation system features a stainless steel bracket that is visible on the surface of the facade, giving it a distinctive look. The concealed fixation system, on the other hand, features a hidden bracket that is not visible on the surface of the facade, giving it a more seamless appearance.

Material Health, the certification ensures that the product has been designed with materials that are safe for human and environmental health. This includes the absence of harmful chemicals and the use of materials that can be reused or recycled.

Material Reutilisation evaluates the product’s potential for reuse and recycling at the end of its useful life. The Mosa Facade System has been designed to be easily disassembled and its ceramic tiles can be reused in other applications.

Renewable Energy and Carbon Management evaluates the product’s carbon footprint and its use of renewable energy sources. The Mosa Facade System is manufactured using renewable energy sources, and its carbon footprint is minimized through efficient production processes and the use of local materials.

Water Stewardship evaluates the product’s impact on water resources. The Mosa Facade System uses a closed-loop water system that minimizes water consumption and pollution.

Social Fairness evaluates the product’s social impact, including labour practices and community involvement. The Mosa Facade System has been designed with fair labour practices and engages with the local community to promote sustainability and social responsibility.

The Cradle to Cradle Silver certification of the Mosa Facade System demonstrates its commitment to sustainable design and production, and its positive impact on human health, the environment, and society.

Brief 02 - Gridshell Case Study

Weald & Downland Living Museum

The Weald & Downland Living Museum in West Sussex, UK features a unique building known as the Gridshell, which is a timber-framed structure that has been designed with several considerations in mind.

Design for Manufacture & Assembly (DfMA): The Gridshell has been designed with a focus on Design for Manufacture & Assembly (DfMA) principles, which means that the building components have been prefabricated off-site and assembled on-site, reducing construction time and costs.

Building type: The Gridshell is a unique public building type that serves as an exhibition space for the museum, showcasing traditional building methods and materials.

Site context: The museum is situated on a 50-acre site in the South Downs National Park, surrounded by woodland, fields, and traditional rural landscapes. The site context is important to the museum’s mission, as it focuses on the preservation and interpretation of rural life and architecture in the South of England.

The museum’s site context has been carefully considered in the design of its buildings and exhibits. Many of the museum’s buildings have been relocated to the site from other locations in the region, and they have been carefully restored and interpreted to showcase traditional building methods and materials.

Structural span / structural optimization: The Gridshell’s structural system is optimized for its span, which is achieved through the use of a latticed timber frame that provides strength and stability while minimizing the amount of material used.

Cost / Construction time: The building was financially supported by the Heritage Lottery Fund, what is more, the accurate amount of money spent on the construction is not public. Creating the building in the construction took 2 years from 2000 - 2002.

Environmental considerations: The Gridshell has a low embodied carbon footprint, as the timber frame is a renewable and low-carbon material. Additionally, the building’s design allows for natural ventilation and daylighting, reducing the need for artificial lighting and HVAC systems.

Site logistics: The Gridshell was prefabricated offsite and transported to the museum, where it was assembled on-site. The rural site context posed some logistical challenges, but careful planning and coordination helped to overcome these constraints.

20. Case Study : Triaxial Gridshell of Eucalyptus –’, IAAC Blog <https://www.iaacblog.com/programs/case-study-triaxial-gridshell-of-eucalyptus/> [accessed 10 April 2023]21. ‘Architype / the Enterprise Centre / the UK’s Leading Passivhaus, Sustainable Architects’, Architype. co.uk <https://www.architype.co.uk/project/the-enterprise-centre-uea/> [accessed 04 April 2023]

21. ‘Case Study -Fresh Sawn Oak Structure’, Englishwoodlandstimber.co.uk <https://www.englishwoodlandstimber.co.uk/wp-content/uploads/Case-Study-Singleton-Museum-gridshell-STRUCTURAL-Oak.pdf> [accessed 10 April 2023]

1. ‘A Leader in the Circular Built Environment: Arup Group Limited’, Ellenmacarthurfoundation.org <https://ellenmacarthurfoundation.org/circular-examples/ a-leader-in-the-transition-to-a-circular-built-environment-arup-group> [accessed 10 April 2023]

2. ‘Architype / the Enterprise Centre / the UK’s Leading Passivhaus, Sustainable Architects’, Architype.co.uk <https://www.architype.co.uk/project/theenterprise-centre-uea/> [accessed 04 April 2023]

3. Bates, Elizabeth, ‘Types of Wood Joints’, MT Copeland, 2021 <https://mtcopeland.com/blog/types-of-wood-joints/> [accessed 10 April 2023]

4. ‘Case Study -Fresh Sawn Oak Structure’, Englishwoodlandstimber.co.uk <https://www.englishwoodlandstimber.co.uk/wp-content/uploads/Case-StudySingleton-Museum-gridshell-STRUCTURAL-Oak.pdf> [accessed 10 April 2023]

5. ‘Case Study : Triaxial Gridshell of Eucalyptus –’, IAAC Blog <https://www.iaacblog.com/programs/case-study-triaxial-gridshell-of-eucalyptus/> [accessed 10 April 2023]

6. ‘Creating the Circular Building’, Resource.Co <https://resource.co/article/creating-circular-building-11508> [accessed 04 April 2023]

7. ‘Downland Gridshell’, Weald & Downland Living Museum (The Weald & Downland Living Museum, 2020) <https://www.wealddown.co.uk/buildings/ downland-gridshell/> [accessed 15 April 2023]

8. ‘Facade Tiles > Products > View Tile Series’, Mosa Tiles <https://www.mosa.com/en/products/facade-tiles> [accessed 15 April 2023]

9. Ijeh, Ike, ‘Enterprise Centre: A Plan Is Thatched’, Building, 2015 <https://www.building.co.uk/focus/enterprise-centre-a-plan-is-thatched/5075508.article> [accessed 20 March 2023]

10. ‘MOSA Ceramic Façade System - MOSA Facades BV’, Ongreening.com <https://ongreening.com/en/products/mosa-ceramic-fa-ade-system-mosafacades-bv-24605> [accessed 20 March2023]

11. ‘No Compromise – Passivhaus Enterprise Centre in Norwich’, CIBSE Journal <https://www.cibsejournal.com/case-studies/no-compromise/> [accessed 20 March 2023]

12. ‘Project Gallery’, in Energy Atlas (De Gruyter, 2021), pp. 196–217

13. Santos, Sabrina, ‘Arup Designs Prototype Building Based on Circular Economy Principles’, ArchDaily, 2017 <https://www.archdaily.com/868121/arupdesigns-prototype-building-based-on-circular-economy-principles> [accessed 20 March 2023]

14. ‘The Circular Building’, Arup.com <https://www.arup.com/perspectives/the-circular-building> [accessed 21 April 2023]

15. ‘The Circular Economy Building’, Archello <https://archello.com/project/the-circular-economy-building> [accessed 21 April 2023]

16. ‘The Enterprise Centre’, Ongreening.com <https://ongreening.com/en/Projects/the-enterprise-centre-architype-1177> [accessed 21 April 2023]

17. Hanson UK <https://www.hanson.co.uk/en/case-study/the-enterprise-centre> [accessed 21 April 2023]

18. ‘Timber Frame Joints’, Timber Frame HQ <https://timberframehq.com/construction-details/joints/> [accessed 15 April 2023]

19. ‘UEA Enterprise Centre Wins Sustainability Award’, BA Systems, 2015 <https://www.basystems.co.uk/blog/uea-enterprise-centre-wins-sustainability-award/> [accessed 15 April 2023]

20. ‘University of East Anglia – the Enterprise Centre’, 3PM, 2017 <https://www.3pm.uk.com/project/the-enterprise-centre/> [accessed 15 April 2023]

21. ‘University of East Anglia Enterprise Centre’, Designingbuildings.co.uk <https://www.designingbuildings.co.uk/wiki/University_of_East_Anglia_Enterprise_ Centre> [accessed 15 April 2023]

22. E-architect.com <https://www.e-architect.com/cambridge/nrp-enterprise-centre> [accessed 20 March 2023]