With over 40 years of expertise, BME aligns Blasting Solutions and Metallurgy to deliver a complete mining solution. From precision explosives and initiation systems to advanced chemical and metallurgical processing, we optimise the entire mining value chain – enhancing performance, profitability, and efficiency.

As a global industry player, we’re committed to sustainability and safety, providing innovative solutions that minimise environmental impact while maximising operational safety. Our technical expertise spans key regions, including the Americas, Africa, Indonesia, and Australia.

Setting the pace

PACE Valves is Proeger’s sole and preferred distributor for all HighPressure Severe Service applications throughout Africa. It is well-resourced to service the backfill industry better.

Editor

Nick Barnes

editor@miningbusinessafrica.co.za

+27 10 055 3356

Web/Sub-Editors

Jimmy Swira

Jimmy@miningbusinessafrica.co.za

+ 27 10 055 3356

Anita Anyango anyangoanita18@gmail.com

Contributing Writers

Chantelle C.

chantellec@miningbusinessafrica.co.za

+ 27 10 055 3356

Susan M.

susanm@miningbusinessafrica.co.za

Sales and Marketing

Winnie Sentabire

winnie@miningbusinessafrica.co.za

+27 83 530 6832 | +27 10 055 3356

Angeline Ntobeng

angien@miningbusinessafrica.co.za

+ 27 078 322 5938

+ 27 010 055 3356

Accounts

Precious Chirunga

accounts@miningbusinessafrica.co.za

+ 27 10 055 3356

“The increased government presence at the 2025 Investing in African Mining Indaba is doubtless a welcome development.”

Ask any investor in African mining about one of the biggest challenges they face. Among the issues topping the list is government bureaucracy or indifference to the urgency of granting approvals needed for project implementation.

While due process is key, the lengthy time it takes to finalise a supposedly routine process is worrying. By the time the necessary paperwork is issued, a mining company may have incurred cost overruns, or market conditions may no longer be ideal for investment.

In light of this, the increased government presence at the 2025 Investing in African Mining Indaba is doubtless a welcome development. Hopefully, it will foster collaboration between the private sector, non-governmental organisations, and governments to unlock the immense economic potential of the mining sector.

Ongoing developments bode well for the growth of African mining. Currently, there is significant demand for critical minerals to drive the clean energy transition.

Nick Barnes editor@miningbusinessafrica.com

Art Director/Layout

Augustine Ombwa

Arobia Creative Consultancy

austin@arobia.co.ke

+254 772 187 334

Circulation/Sales info@miningbusinessafrica.co.za

+ 27 10 055 3356

Published By Media Icon (Pty) Ltd

The 2025 Investing in African Mining Indaba will see a bigger and better government offering, strongly positioned, and elevated at MI25, designed with attendees in mind.

Investing in African Mining Indaba is a perfect networking platform for stakeholders from different sectors

As the African mining industry continues to grow, the role government must fulfil in ensuring sustainable investment and development is becoming increasingly important. In acknowledgement of this, Mining Indaba is investing significantly in ensuring the presence of a larger mining government contingency in 2025.

Enhanced government proposition

In support of this objective, ensuring the voice of government mining and supporting ministries will be heard across the event – not only in the governmentdedicated Intergovernmental Summit, but across all key programmes including Disruptive Discussions, Sustainability Series and Technology and Innovation.

“Our government activity will also take place in a new home for 2025 – the CTICC 2 building –which will provide a larger space

for ministers to engage collaboratively, greater attendance opportunities at the Ministerial Symposium and more effective engagement and time in our Intergovernmental Summit, new country investment forums, and traditional country showcases. As the government hub –we will offer ministers a single point of contact from which they can navigate the full Mining

Indaba event comfortably and frequently,” says Zeinab El-Sayed, Head of Government Partnerships.

Future-proofing government focus

The 2025 theme, “Future-proofing African Mining, Today!” is anchored on six key content pillars, emphasising equality for all, to guide Mining Indaba’s future objectives. Futureproofing from a government perspective involves implementing policies and regulations that ensure sustainable development, environmental protection, and social responsibility in the mining industry. It also involves fostering innovation and technology adoption to enhance efficiency and competitiveness in the sector.

“Cross-border cooperation is essential for governments to address the challenges facing their countries in an increasingly interconnected world. In order to future-proof their economies, governments ought to collaborate with

each other and engage with the private sector to implement effective and sustainable policies. The success of these partnerships will be crucial in ensuring that the continent remains competitive and resilient in the face of evolving global challenges,” continues El-Sayed.

“A future-proof mining ministry is one that looks at how to encourage investment with the ultimate objective of creating sustainable and economic wealth for every African country. This requires collaboration – between governments, as well as industry, to ensure an aligned approach that responds to challenges around regulatory environments, infrastructure needs and community support. Mining Indaba will remain the platform to provide solutions and facilitate conversations that lead to positive outcomes in this regard,” highlights Laura Cornish, Head of Content & Strategic Partnerships.

What can attendees expect in 2025?

New for 2025

1. Country Investment Forums

Closed door discussion that will bring together ministries, community representatives, mining companies, investors, and chambers of mines to discuss ideas and address concerns, aiming to

enhance each country’s investment profile with actionable outcomes.

2. Investment guides

These guides will provide detailed information on investment opportunities, regulatory frameworks, and potential risks for interested parties. Additionally, attendees can look forward to interactive workshops and networking opportunities to foster collaboration and knowledge-sharing among stakeholders.

Ministerial Symposium

Attendees can expect engaging discussions on innovative solutions for sustainable development, networking opportunities with industry leaders, and the chance to contribute to shaping the future of African value chains. The symposium will provide a platform for sharing best practices, fostering partnerships, and driving actionable outcomes to advance socioeconomic growth in the region.

BME’s approach to sustainability addresses some of mining’s most pressing challenges, particularly the need to reduce carbon emissions.

Omnia Holdings company BME, a silver sponsor at the 2025 Investing in African Mining Indaba, will be sharing its commitment to decarbonisation and advanced technologies – supporting the mining sector’s drive to reduce its environmental footprint while enhancing operational efficiency.

According to Ralf Hennecke, Managing Director of BME, the company is known for its emulsions, equipment and electronic initiation technology that enhance mines’ environmental sustainability efforts.

As an integral part of the Omnia Group, whose core purpose is ‘innovating to enhance life, together creating a greener future’ BME is pleased that Omnia CEO Seelan Gobalsamy will be participating in the 2025 Mining Indaba in Cape

Town, in the panel discussion on ‘Sustainable Investment: Catalyst or Constraint for Mining Development?’

Further, Nishen Hariparsad, BME’s General Manager for Technology and Marketing, will participate as a panelist in the session on ‘The role of technology in building and undermining sustainability in African mining’.

“We feel that these are vital conversations for the sector, on topics that we are confident to share our own insights and learnings,” said Hennecke. “Our own sustainability journey has allowed us to impact positively on our customers’ mining efficiencies and sustainability goals.”

Driving decarbonisation

BME’s approach to sustainability addresses some

of mining’s most pressing challenges, particularly the need to reduce carbon emissions, with Hennecke emphasising the critical link between energy efficiency and carbon reduction.

“Reducing energy consumption is a direct path to lowering carbon footprints, particularly in countries like South Africa where coal-fired electricity dominates,” he said. “Our innovations, from emulsions to electronic initiation systems, empower mines to achieve significant energy savings while meeting stringent environmental standards.”

Technology for sustainability

BME’s technological advancements have been critical in delivering these efficiencies, according to Hariparsad. The company’s AXXIS® technology,

for instance, has allowed mines to take significant strides in enhancing blasting precision and efficiency.

“Our AXXIS Titanium® system supports larger, more controlled blasts, reducing the frequency of interruptions and streamlining operations,” he explained. “This streamlines energy consumption, and also contributes to better rock fragmentation, which reduces energy demands in subsequent loading and crushing phases.”

Integrating BME’s Blastmap™III blast planning software further enhance mines’ ability to optimise blasting outcomes. This has a ripple effect on energy efficiency, reducing fuel consumption and greenhouse gas emissions across the mining process.

“Our ESG-focused initiatives extend across the value chain,” Hariparsad added, “ensuring that we safeguard the environment and communities while enabling our mining customers to achieve their green goals.”

BME’s dual salt emulsions also contribute to this focus, offering a greener alternative to traditional explosives. By reducing nitrate leaching and greenhouse gas emissions, these emulsions reduce risk of environmental damage, and help mines to comply with local regulations and international standards.

“The manufacturing process for dual salt emulsions is also more energy-efficient, as it operates at lower temperatures – further reducing energy consumption and carbon emissions,” he explained.

Another aspect of BME’s sustainability portfolio is its pioneering use of recycled oil in its emulsions, effectively removing millions of litres of potentially hazardous waste from the market annually. This innovation prevents water and soil contamination while promoting a circular economy. The company also supports local economies through this initiative, partnering with small businesses to collect and deliver recycled oil.

Following an exciting rebranding exercise under the Omnia Group, BME now operates through two core divisions: BME Blasting Solutions and BME Metallurgy. This has given

the company a broader impact to strengthen customer’s sustainability efforts across the mining cycle.

“Our ability to contribute at both the blasting and mineral processing stages gives us a definite edge in the market,” said Hariparsad. “From breaking rock to optimising mineral recovery, our solutions align with the mining sector’s ESG priorities and help mines meet Scope 1, 2 and 3 emission targets.”

BME continues to take this strategy forward through its global growth trajectory. The company’s successful integration with its Indonesian joint venture, along with expanding operations in Canada, Australia and West Africa, highlight its ability to deliver value in diverse markets.

“We’re leveraging our expertise to support the growing demand for green metals and other critical resources,” says Hennecke. “BME’s investment in local operations and infrastructure, including the progress in detonator plants in Canada and Australia, underscores our commitment to sustainable growth.”

“In Indonesia, the integration with our joint venture partner, MNK, is progressing well,” he said. “Three new contracts were secured in Indonesia, signalling further growth in the region.”

The company boosted its in-country presence in Canada by commissioning a non-electric detonator plant, and its organic growth strategy and infrastructure development in Australia is progressing well – with the commissioning of a detonator plant underway.

He highlighted that safety underpinned the company’s positive performance, reflected in the way it maintained its Recordable Case Rate (RCR) of zero for the period. This world-class safety record was supported by the ‘Safety for Life’ programme and the collective efforts of the team.

“This focus is integral to our sustainability and ESG commitments, which align with Omnia’s efforts in creating a positive and sustainable impact for the planet and communities,” said Hennecke.

Corflex Pinch Valves for high and low pressures in abrasive slurry applications.

Hard-wearing, non-porous, slip-resistant, Heron Vynagrip PVC matting enables mines and associated industries to mitigate the risk of slip accidents on wet surfaces to improve compliance with Mine Health and Safety Regulations.

HERONRIB Matting is available for customers on the African continent from Gold Pack (Pty) Ltd in Durban, South Africa.

From a business perspective, accidents result in costly downtime to production and translate into loss of revenue. Furthermore, it is not only the productivity of the worker that is impacted but all of the other departments that now have to deal with the outcomes of an accident.

Gold Pack (Pty) Ltd supplies HERONRIB to mines and other operations to reduce slip accidents and provide comfort and protection from bacterial infection in barefoot areas. This non-slip matting is highly recommended due to its unique features, convenience, and diverse applications.

HERONRIB wet area matting is suitable for showers and wash areas, canteens and kitchens, bars and pubs, in fact for any work area that may encounter liquid spills or splashes.

The HERONRIB non-slip matting is ideal, due to the following features:

• It is slip-resistant and drains superbly.

• It has anti-bacterial treatments, antimicrobial and anti-fungal properties

• It is easy to cut and lay and will contour to uneven surfaces

• Exceptionally hard-wearing and can be fitted without tools.

• Can be rolled up easily for cleaning underneath.

• Embossed surface

• Two-layer construction and channelled underbars

• Made from flexible PVC

• UV resistant

The non-slip matting offers

• Four-way drainage

• Excellent hygiene, easy to clean

• Easy to cut to fit, contours to uneven surfaces

• Can be used indoors or outdoor

Fostering a positive culture

Besides improving productivity, the use of HERONRIB matting can indicate that a company cares for and highly values employees. This can foster a positive corporate culture in an organisation the following ways:

• Reduced sick leave and absenteeism

• Lower the rate of employee turnover

• Reduced hiring costs

• Higher levels of skilled employee retention

• Improved company culture and inclusion

• Increased age diversity and intergenerational collaboration

• Attracting top talent.

Last but not least, Gold Pack (Pty) Ltd guarantees prospective customers on the continent that the HERONRIB brand is of premium quality. It is made of are made of highest quality anti-slip materials with proven certified slip resistance (DIN 51097: C; ASTM 1677: 0.9/0.7).

• Easy to install - cut to shape/size

• Hygienic and easy to clean

• Warm & comfortable for barefoot traffic

• ‘Sanitized’ anti-bacterial & anti-fungal properties

• Four-way drainage

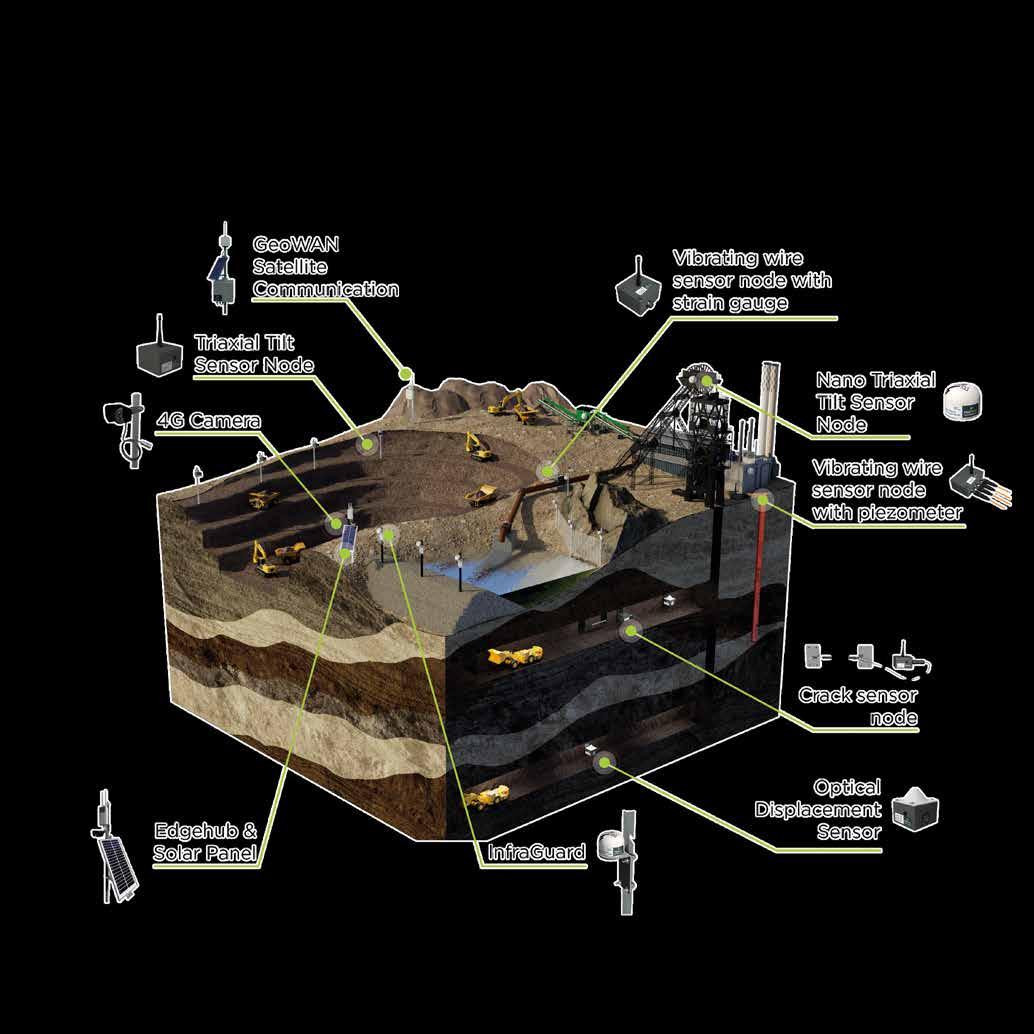

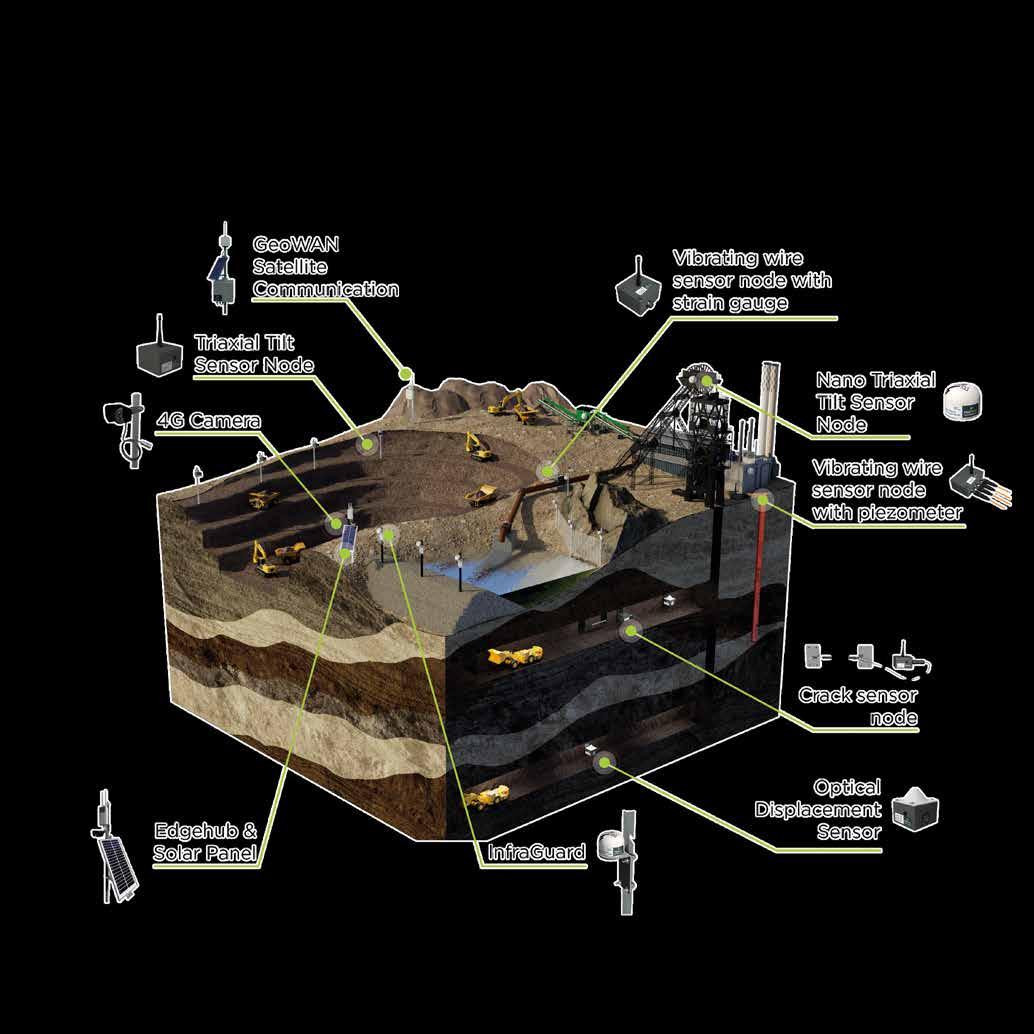

Wireless remote condition monitoring:

Near real-time updates

Automated alerts

Enable proactive risk management Up to 12 Years Node

Battery Life

Install a variety of sensors with ease and adapt as your needs change.

As mining companies embark on new projects, inevitably, ESG risks and compliance requirements will escalate, necessitating the use of reliable reporting methods. Addressing this critical need, through a partnership with seasoned environmental and social advisory firm Kongiwe, ONYEN is set to revolutionise ESG reporting in 2025 with its cutting-edge AI-powered solution.

The Minerals Council of South Africa (MCSA) notes that the country’s mining companies invested hundreds of millions of dollars in ESG (Environmental, Social, and Governance) initiatives in 2023, particularly in water conservation and biodiversity preservation.

Now, buoyed by favourable commodity prices and improved confidence in the new Government of National Unity, investors are expected to loosen their tight purses, accelerating the development of greenfield and brownfield projects. Consequently, ESG spending is expected to increase. Elsewhere on the continent, a similar trend is unfolding; for example, ESG reporting is now mandatory for public companies in Zimbabwe.

Against this backdrop, ESG reporting has topped the agenda of recent high-profile discussions on mining in Africa, especially in support of reporting requirements for listed companies and attracting investment amongst juniors. Observing this development, Laurie Clark, CEO and founder of Onyen Corporation - a Toronto-headquartered, globally focused provider of ONYEN Risk, Compliance, and Sustainability reporting solutions - remarks: “It’s not just about gathering data but ensuring its relevance and quality. Poor data leads to flawed decision-making. Hence, sound reporting is essential. ONYEN’s solution identifies gaps, measures progress, and

provides actionable insights - a unique and vital capability for the industry.”

Encouraged by the response at the 2024 Investing in Mining Indaba, ONYEN is increasing awareness of its revolutionary ESG reporting software in the mining sector for 2025. The company is well-placed to meet the needs of its customers - junior, small, and mid-tier operations - after establishing a strategic partnership with Kongiwe Environmental, a globally renowned professional environmental and social science advisory based in Johannesburg, South Africa, and Vancouver, Canada.

The partnership gives ONYEN a “boots-onthe-ground” presence in Africa. The company will be facilitating ONYEN’s ESG reporting solution for customers.

Keen to serve new customers, Clark describes Kongiwe as tailored to handle the unique challenges of the African mining environment. She is excited about the opportunities the partnership with the company will unlock: “Establishing a presence through a strategic partnership with Kongiwe’s local expertise in Africa gives us the ability to offer hands-on support beyond the resources industry.”

The AI-powered software overcomes the limitations of traditional ESG reporting solutions, offering convenience and cost-effectiveness, which enables compliance. This is evident in its unique features.

With traditional reporting systems, accessing relevant data becomes a challenge for interested parties such as CEOs, investors, boards of directors, and rating agencies. On the other hand, as a SaaS/cloud solution, ONYEN provides a single panel of view on the website, which can be accessed as and when needed at any time. This simplifies reporting needs.

What’s more, one of the key things customers - of which there are now over one hundred in the mining industry - really like about the ONYEN product is how data is input once and then filters through to other applicable areas. The intelligent links are critical to ease of use. Users can also extract reports tailored to different reporting standards without having to re-input data. This is one of the strengths that give ONYEN a competitive advantage.

The product is designed with the same principles used in building trading and securities exchange systems - an area of expertise for ONYEN’s team, who have built many such systems globally. This offers unparalleled flexibility and precision in data management. Unlike traditional systems bound by standard reporting periods (e.g., monthly, quarterly, annually), the ONYEN system is ‘period reporting agnostic.’ This means users can extract and analyse data for any custom period or date range, empowering them to create tailored insights for internal reviews or

formal reports for regulatory and investor needs. Moreover, Scorecard Templates are fully customisable to an organisation’s specific requirements, incorporating dynamic elements such as panels, graphs, and trend analyses. This ensures that all data entered is consistent, measurable, and ready to be presented in a format that suits both management and external stakeholders. Even more, real-time dashboard alerts/updates eliminate errors related to inconsistent data, which result in dropped scores on the ONYEN scorecard report. The system is updated in real-time with ESG data from operational and onsite management systems. It summarises data and highlights variances above set thresholds, enhancing data accuracy.

ONYEN Corporation has made its solution costeffective through ease of setup and flexible pricing plans suitable for organisations, regardless of size or compliance reporting needs. Available plans include standard, advanced, and custom.

In a nutshell, through convenience and costeffectiveness, ONYEN offers the end user the following compliance-enhancing benefits:

• Collecting and controlling sustainability data for review by rating agencies.

• Engaging communities with updates, bulletins, and notices.

• Reducing errors with automatic data validation and proofing.

• Year-over-year analysis benchmarking performance comparisons with peers in size, industry, type, and more.

High sustainability scores have become one of the key factors in raising capital and a true barometer for a successful compliance system. Many customers have closed capital-raising rounds because of being on ONYEN. Investors are impressed with the measures, transparency of the data provided, and risk analysis shown. ONYEN drives capital to customers.

By and large, ongoing developments in the resources sector indicate that ESG is not just a tick-box obligation but a central business priority.

This shift is driving demand for convenient, costeffective solutions like ONYEN that will help the industry achieve compliance.

The following points underline this trend:

• In its Mine 2024 report, consultancy PwC says that sustainability factors have become key in mergers and acquisitions decisions.

• SRK Consulting partner Wouter Jordaan notes that mining companies are increasingly considering ESG at the outset of mining operations, including planning for closure.

• A 2023 KPMG study found that failure to meet ESG reporting requirements was a major obstacle to the conclusion of half of all deals.

• During a panel discussion at the 2024 Sanlam ESG Conference, Southern African Institute of Mining and Metallurgy Environmental, Social, Governance, and Sustainability Committee Chairperson Professor Michael Solomon observed:

“With a global focus on a just energy transition, the mining sector faces various internal and external pressures to deliver on ESG, carbon neutrality, and abatement targets.”

• Sound ESG reporting is now part of financial reporting, as governed by the Task Force on Climate-Related Financial

Disclosure (TCFD) or the International Financial Reporting Standards (IFRS) S2 Sustainability Disclosure Standard (June 2023). Once voluntary, these - and many others -have become obligatory.

ONYEN Corporation, headquartered in Toronto, Canada, has satellite offices in Vancouver, Canada; Lagos, Nigeria; and Mexico City, Mexico. With Kongiwe Environmental, it also serves SubSaharan Africa.

Looking ahead, Clark vows that ONYEN Corporation is ready to meet the growing demand for reliable compliance and risk reporting solutions in the African mining sector in partnership with Kongiwe Environmental: “We are committed to helping mining companies eliminate guesswork and enhance accuracy in ESG reporting.”

For more details, contact: Laurie M Clark ONYEN Corporation +1 647-503-3433

Email: laurie.clark@onyen.com Website: www.onyen.com

With a vastly experienced workforce, adequate machinery, and a commitment to continuous improvement, Benoni-based G4 Mining and Civils (Pty) Ltd is well-equipped to manage projects of any scale in the South African mining sector.

Recent announcements of investments in various projects have revived optimism within the South African mining sector. G4 Mining and Civils (Pty) Ltd is eager to play a part with distinction, as it has done in the past decade.

G4 Mining and Civils provides mining infrastructure and civil engineering solutions. The company specialises in reinforced concrete, bulk earthworks, geotechnical engineering, water reticulation, and bulk water infrastructure services.

Relevant Know-How

Relevant know-how gives G4 Mining and Civils the competitive edge to manage projects of any scale. Thus far, the company has completed projects in mining infrastructure such as cooling tower construction, foundations for steel structures (e.g., MCC, mine stores, and others), winder houses and winder foundations, shaft collars, and chrome mine reflux classifiers. Its material handling experience includes thickener foundations, surge bins, DMS plants, filter presses, and overland conveyor support foundations.

“We are well equipped to complete mining infrastructure projects, materials handling, and storage solutions,” the G4 Mining and Civils MD pronounces the company’s preparedness, highlighting the pivotal role of the workforce, keeping abreast of evolving needs, and plant and equipment.

He lauds the pivotal role the workforce has played: “A company’s success does not rely on the efforts of one individual. The commitment and resilience of the G4 Mining and Civils workforce have played

an integral role in our growth over the last 10 years. The adaptability and willingness to tackle new challenges beyond one’s role are greatly appreciated. This ensures that we can learn and push our company to new heights.”

In particular, the organisation’s approach to retaining critical skills has paid massive dividends. A typical case is that of engineering students who joined the company fifteen years ago and are now an integral part of the G4 Mining and Civils management team.

Without a doubt, the most critical of G4 Mining and Civils’ human resource assets is the wellrounded group of individuals who form part of the shareholders’ group. The company complies with BBBEE codes of practice by empowering from within, rather than externally. This ensures that the team is invested in its success.

G4 Mining and Civils strives to keep abreast of evolving project requirements. This is mainly achieved in the following ways:

• Adherence to ISO 9001 certification and an internal Quality Management System to uphold quality in all activities.

• Continually improving by receiving client feedback and tailoring services to meet unique project requirements.

• Defining risks and managing them as a vital part of the tendering process.

• Understanding the role of the company’s operations in the mining industry and their effect on the planet, thereby striving to increase efficiency and sustainability.

The company’s reasonably flat structure facilitates quick decision-making, which is key to project delivery. The highly dedicated site teams operate close to the coalface to ensure a good understanding of the client’s needs. Any problem areas are addressed quickly.

Ultimately, due to these factors, G4 Mining and Civils can deliver projects within budget, on time, and, most importantly, to the client’s expectations.

G4 Mining and Civils owns plants and equipment, including TLBs, excavators, tippers, 14,000L water carts, and ride-on rollers, among others. In addition, the company has an extensive inventory of small tools and equipment at its disposal.

Should there be a need for any additional plant, the MD explains that G4 Mining and Civils utilises a thorough vendor application process to ensure that the companies they work with meet their values and requirements. “We are aligned with several key service providers that we can lean on to assist us with any shortfalls.”

G4 Mining and Civils recognises that equipment downtime is a common challenge in construction projects. To manage this risk, G4 Mining and Civils runs an on-premises workshop to maintain and service its plant and equipment, keeping up with workload demands.

G4 Mining and Civils, always forward-thinking, has been observing unfolding trends. Currently, South African suppliers of various mining-specific products and services are looking for more opportunities in other African countries.

However, for G4 Mining and Civils, the primary focus is on growing its presence in the South

African mining sector, improving quality, and building capacity. “We are comfortable operating in the South African mining sector,” the MD explains, underlining the mindset of turning challenges into opportunities that have helped the company thrive. “As a company, we are constantly learning and growing. Staying true to our strengths and producing a high-quality service is a top priority.”

In terms of enhancing high-quality service, G4 Mining and Civils is looking to align its in-house system more closely with ISO 45001 (Occupational Health and Safety) and ultimately receive certification for this standard. In addition, leaving no stone unturned, the company is focusing on building capacity through workforce development, skills training, and internal knowledge.

With all ducks in a row, G4 Mining and Civils is hoping to see gains. “Having recently updated our website and increased our social media presence, we are excited to see what increased exposure may bring in 2025 and beyond,” enthuses the MD, declaring the company’s concrete commitment to excellence in upcoming projects.

G4 Mining and Civils has grown in leaps and bounds in the mining space over a decade, achieving notable delivery milestones in projects of different scales.

The most recent project is the successful completion of the Two Rivers Project in May 2024. It involved civil and earthworks for the crusher facility in Steelport.

The MD reminisces about the feat: “We cast 3,605 m³ of concrete, used 222 tonnes of reinforcement, and moved 153,000 m³ of earthworks, requiring a total of 457,455 manhours. This project was a strong showcase of our ability to manage complex projects and deliver top-quality outcomes for our clients.”

Currently, the company is constructing a triple-cell cooling tower and two double-cell precoolers in Zondereinde. This project will require about 1,300 m³of concrete to be cast, 41 tonnes of rebar, and 1,100 m2of formwork.

Remarkably, these structures are more than 20 metres high and pose challenges in construction when working at heights. Attention to detail and thorough safety procedures are integral to the project’s success. The G4 Mining and Civils team expects this project to be completed in the first quarter of 2025.

After that, it will be more of the same, continuing the quest for handling more project milestones.

G4 Mining and Civils (Pty) Ltd +27 (0)11 100 7126 info@g4miningandcivils.co.za 3 Kirschner Road Benoni North AH Benoni 1501

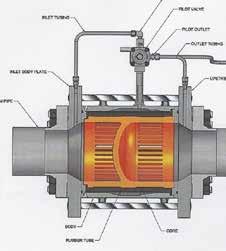

PACE Valves is Proeger’s sole and preferred distributor for all High-Pressure Severe Service applications throughout Africa. It is well-resourced to service the backfill industry better.

Process and Allied Contracting Equipment, trading as PACE Valves (Pty) Ltd, is a project-based company that provides a wide range of turnkey valve solutions to different industrial sectors (namely mining, water reticulation, refrigeration plants, chemical processing, oil and gas, smelters, SX plants, etc.). It prides itself on continuing to meet clients’ ever-changing needs.

PACE Valves is regarded as one of the world’s top ‘go-to’ companies for supplying an extensive range of premium products. The company has established strategic partnerships worldwide, which allow it to expand the global reach of highquality commodity valves.

“We believe our expertise and market presence makes us the ideal partner to provide innovative, reliable solutions that meet the growing demands of diverse industries,” says Charlotte Vaughan, MD of PACE Valves.

One such winning partnership is with Australianbased OEM specialist Proeger Flow Control Solutions. This deliberate partnership has allowed PACE Valves to better service the Backfill industry in Africa. PACE Valves is Proeger’s sole and preferred distributor throughout Africa for all High-Pressure Severe Service applications.

What sets the PACE Valves team apart is its vast experience and technical knowledge. The company strives to provide efficient service, fit-for-purpose products, and quality technical

know-how to assist clients in improving their overall return on investment.

“We pride ourselves on our after-sales service and technical advice, including on-site installation and commissioning assistance,“ Vaughan explains.

Unsurprisingly, PACE Valves has completed various projects and is currently involved in others. One project in which PACE Valves played an instrumental role is the Kamoa Copper S.A. Backfill Plant where it assisted with specialised paste and severe service valves.

PACE Valves is also proud to be part of the Rosh Pinah Backfill Plant in Namibia.

“Thus far, we have successfully manufactured and supplied Class 1500 actuated knife gate valves, emergency borehole dump valves, flush water injection valves, and diverter valves,” says Vaughan, upbeat about further growth.

“We will continue to join forces with Proeger Australia, enabling us to offer unique, high-end solutions to our clients within the mining space.”

With over 43 years of success, Charlotte Vaughan, MD of PACE Valves, has a positive outlook for the future and the ever-increasing market demands. She is excited to lead the business to further growth and expansion.

279 Evergreen Road, Tunney Ex 7, 1401, South Africa, Tel: +27 114526826, Email: sales@ pacevalves.co.za, website: www. pacevalves.co.za

After improving mobile equipment fleet performance at a Zambian mine, the Rithmik team are eager to deploy their integrated AI-driven solutions, Asset Health Analyser (AHA) and Asset Performance Analyser (APA), in other regions of Africa. These innovative solutions enhance equipment efficiency, reduce costs, and drive productivity.

At present, mine operators in Africa are zealously focused on increasing production to meet the demand for critical minerals and, of course—most importantly— boost the bottom line. However, in this quest, they may inadvertently overlook downtime for vital equipment. Unfortunately, in most cases, this occurs when least expected.

In light of this, Rithmik Solutions is raising awareness about the costly effects of downtime on mobile equipment fleet, emphasising the importance of investing in sound maintenance solutions that can optimise performance. Drawing from its extensive know-how, the globally focused, Montréal-based analytics firm is committed to offering assistance to help mining companies make informed decisions.

AI-Driven Predictive Maintenance Solutions

Rithmik provides two AI-driven predictive maintenance solutions to industries: Asset Health Analyser (AHA) and Asset Performance Analyser (APA). Ross Barichievy, the company’s Chief Operating Officer, informs African mining operators - through an interview with Mining Business Africa - about the value of these innovations in fleet management.

AHA offers convenience to fleet managers in managing maintenance matters, particularly in the following areas:

AHA is scalable and can be trained on data specific to a customer’s mine or equipment type, such as fleet management position/status, payload, and maintenance work orders. “We can refine the insights to the site operating context

and ensure greater accuracy and actionability,” Barichievy affirms.

ii. Earlier Identification of Health Issues (Predictive Maintenance)

Most importantly, AHA facilitates informed maintenance decisions. It assists fleet managers in the earlier identification of equipment health issues, allowing a shift from reactive maintenance to a predictive maintenance approach.

While the strategy is nothing new, Barichievy points out that, distinctively, Rithmik’s analytics enable fleet managers to unlock predictive maintenance capability faster and with less overhead. “With AHA, the right maintenance happens at the right time, which increases equipment availability, lowers maintenance costs, ensures equipment operates within the set parameters, and minimises fuel consumption for every tonne of material hauled.”

A common challenge that fleet managers face is equipment and software non-interoperability. However, Barichievy says they can rest assured that both AHA and APA are designed to be equipment and software agnostic. “Rithmik’s products leverage existing equipment data sources and data collection systems already in place at customers’ mining operations. This interoperability makes Rithmik a great solution for mixed fleets and also provides the ability to scale across customers’ operations as an enterprise solution covering multiple fleets.”

Designed to complement AHA, APA generates anomalies focused on the operational

performance of mining assets. These performance insights span Asset Health, Equipment Operator, or Environmental Operating Condition and assist fleet managers in understanding where action needs to be taken to maximise fleet productivity.

APA enhances operator performance and equipment health to increase efficiency and productivity. Barichievy demonstrates how this is achieved: “APA models ideal equipment operating performance based on the unique context of the mine site. The output is used as a comparison mechanism across the entire fleet, enabling fleet managers to quickly identify areas within the mine or pieces of equipment performing below target. Further specificity allows the isolation of operators from equipment health causes of low productivity.”

As mining companies ramp up production, they need reliable means to increase equipment availability. Cognisant of this urgency, the team at Rithmik are on hand to address enquiries and customise AI-driven predictive maintenance solutions relevant to the unique needs of customers.

The team at Rithmik have a success story to share with African mining operators: a customer deployment of AHA and APA in Zambia resulted in a phenomenal turnaround in fleet performance.

Previously, there was a challenge at a mine. The use of APA identified increased haulage time of 15% and increased fuel use of 21% on a subset of the production truck fleet.

AHA made a massive difference. Its analytic output enabled a further diagnosis showing systemic premature turbocharger failure. The root cause was the operator practice of overriding the engine shutdown sequence, preventing sufficient turbo spooldown time. Ultimately, by leveraging the power of Rithmik’s insights, the fleet manager was able to increase availability (reduce unscheduled truck maintenance and increase productivity) and fuel efficiency.

Looking ahead to 2025, the Rithmik team are eager to replicate this success across other regions in Africa.

Unlock the full potential of your mobile mining fleet with Rithmik’s advanced analytics. Unlike any other solution, we bridge the gap between Operations and Maintenance, empowering data-driven decisions that boost productivity, cut fuel costs, and enhance reliability.

By blending cutting-edge artificial intelligence and cloud computing innovations with deep expertise in mining operations, Rithmik optimizes your existing data and tools— no additional sensors or hardware required.

The YES solution helps mining companies achieve ESG goals and empower communities beyond mining. This approach enhances the attractiveness of mines to investors and promotes a legacy of empowered youth.

The Youth Employment Service (YES) is the largest 12-month, full-time youth employment programme in the country. YES empowers business to create critical youth jobs that integrate into their social and labour plans (SLPs), environmental, social and governance (ESG) strategies, and the Mining Charter.

Additionally, businesses can earn up to two levels up on their B-BBEE scorecard in return for creating the required number of youth jobs. By partnering with YES, also contribute to long-term sustainable development and community upliftment, helping to create futurefacing youth jobs that align not only with critical industry needs, but with the development of self-sustaining communities beyond the lifespan of the mine.

With over 1,829 corporate partners, YES has created more than 168,000 jobs for young South Africans, injecting R9.1 billion into communities through YES Youth salaries. Beyond its B-BBEE incentives, YES provides mining-specific

solutions that offer shared value to companies, communities, and the country.

How can mining companies get involved with YES?

Business can choose to place youth within their own structures or within a YES host partner through the turnkey solution.

By placing youth inside your business, you create a talent pipeline of employees that best match your organisation’s culture and values. Through the turnkey solution, YES works with host partners to give businesses a reliable way to make an impact. YES is also able to offer a solution where your company supports minefunded SMEs as part of your local economic development (LED).

Driving LED and empowering communities with the YES turnkey solution

The YES turnkey solution seamlessly integrates job creation for youth into the Mining Charter

and SLPs. It is a vehicle for mining companies to generate jobs outside of the industry to cocreate communities that thrive with self-reliant economies.

The YES turnkey solution works with 22 YES-vetted host partners across the country to allow companies, that cannot place youth internally, an affordable way to create broadbased impact through uplifting communities.

By placing youth with host partners, resource and mining companies can create youth work experiences with community-based NPOs and SMMEs working in some of the most critical sectors in South Africa, including education, healthcare, digital, conservation, early childhood development, the green economy, and SMME development, enabling young people to contribute to building self-reliant and thriving communities where they live.

The YES model can also see young people deployed in community-based SMMEs and/or mining and resource company supply chains, effectively boosting the capacity of local businesses to deliver goods and services to their neighbouring mines and beyond.

Join the future of change

By creating youth jobs in sectors that build economic, social, and environmental stability, the YES solution helps mining companies achieve ESG goals and empower communities beyond mining. This approach enhances the attractiveness of mines to investors and promotes a legacy of empowered youth.

Want to know more? Contact our Business Development team with any queries: corporatesupport@yes4youth. co.za.

TalbotAnalytics addresses water risks through a comprehensive water management approach. The platform integrates data from smart meters that monitor water volume, quality, and system performance. It provides a holistic view by identifying patterns, detecting anomalies, and generating predictive insights for water systems in mining and industrial companies.

Data from smart meters informs actionable insights that enhance water management.

However, relying solely on smart meter data without integrating key metrics can lead to various water risks, even with advanced smart meters that monitor water quality and assist with asset management. While smart meters provide valuable insights, they often function in isolation and may not incorporate other crucial external factors needed to understand water systems thoroughly. For instance, smart meters might overlook climatic variations, specific conditions of the catchment area, or competing demands from other users, which can significantly affect water availability and quality.

This limited perspective can lead to critical gaps in identifying risks, such as sudden contamination events, infrastructure failures, or inefficiencies in water allocation. Furthermore, the ability to generate predictive insights is diminished without consolidating data from multiple sources. This makes it challenging to anticipate shortages, operational disruptions, or potential cost implications. These cost implications should not be underestimated, as they can affect the financial health of water management operations.

Overall, relying on isolated metrics often

results in reactive management practices, missed opportunities for optimisation, and increased operational expenses.

TalbotAnalytics’

TalbotAnalytics Software as a Service (SaaS) uses sensors, IoT, and AI to address water risks in mining and industrial companies through a comprehensive water management approach. It utilises proprietary intellectual property (IP) in water risk studies alongside the expertise

of specialists in the field. This foundation ensures the platform is based on a thorough understanding of the essential information for effective water resource management.

Specifically, TalbotAnalytics offers convenience in the following areas:

1. Holistic

By integrating data from smart meters that monitor water volume, quality, and system performance, TalbotAnalytics provides a holistic view of water systems. The platform employs machine learning to process this data, identifying patterns, detecting anomalies, and generating predictive insights. This proactive method enables organisations to tackle potential risks before they escalate, optimising resource use and enhancing operational efficiency.

2.

TalbotAnalytics provides interactive, cloudbased dashboards that empower users –including process engineers, consultants, and planners – to visualise and interpret data easily. With an emphasis on accessibility and ease of use, the platform is designed to be accessible even to users without technical expertise.

The platform features intuitive dashboards that present data clearly and can be customised, making it easy to interpret and act on almost

The platform’s versatility allows it to tackle unique water challenges, whether improving water management in complex operational systems, enhancing resource allocation in large-scale infrastructure, or promoting more sustainable practices. With its ability to adapt to various requirements and deliver actionable insights, TalbotAnalytics is an invaluable tool for organisations aiming to strengthen water security, optimise performance, and ensure long-term sustainability.

Well-Equipped and Committed Sound water management will be key as mining and industrial companies look forward to continuing to ramp up production in 2025. The TalbotAnalytics team is well-equipped and committed to helping them use smart water meters effectively to increase efficiency, achieve cost savings, and facilitate compliance in water management processes.

Nerospec OSCON works closely with mining companies, machine Original Equipment Manufacturers (OEM), and third-party Proximity Detection Systems. This ensures that each Vehicle Intervention Controller (VIC) solution, is tailored to the specific needs of the operation.

Mining operations worldwide are embracing cutting-edge technologies to enhance safety and operational efficiency. Among these advancements is Nerospec OSCON’s Vehicle Intervention Controller (VIC) installed directly on a mining machine to control its critical functions and automate safety interventions.

As an integral component of EMESRT Level 9 Collision Avoidance Systems, the VIC is designed to prevent accidents by overriding operator inputs when necessary. Nerospec OSCON, with its unparalleled expertise and innovative solutions, is leading the charge in transforming safety standards across the mining industry.

Seamless integration

As the first 100% agnostic fleet-wide machine interface controllers, they seamlessly integrate with any Trackless Mobile Machine (TMM) and third-party Proximity Detection Systems. This universal compatibility ensures that, regardless of a machine’s make, model, type or age, Nerospec OSCON’s solutions provide consistent and reliable intervention controls. By bridging

the gap between machine control and safety systems, these controllers are setting a new standard for operational safety in the mining industry.

1.

Within a functional Level 9 Collision Avoidance System, Nerospec OSCON’s HUB controllers play a crucial role by executing “CRAWL” or “STOP” commands issued by third-party Proximity Detection Systems. When the third-party proximity detection system detects a potential risk and issues a command, our controllers intervene to ensure the machine responds as instructed, either by reducing speed to a crawl or stopping entirely, safeguarding both personnel and equipment.

2.

Nerospec OSCON’s HUB controllers are engineered to prioritise safety by automatically stopping the machine in a controlled and safe manner if any fault is detected in the system. This feature operates independently of the

operator or the functionality of a Level 9 system, ensuring that even in the event of a malfunction, the machine is brought to a safe state to prevent potential incidents.

Nerospec OSCON’s HUB controllers serve as a black box recorder for a fully functional Level 9 system, capturing all “CRAWL” and “STOP” events initiated by the third-party Proximity Detection System and executed through the machine intervention control. This ensures comprehensive validation, verification, and oversight reporting, enabling mines to monitor and assess the effectiveness of their Level 9 Collision Avoidance Systems. Beyond this critical functionality, the controllers also provide advanced data logging features, offering insights into machine health, maintenance schedules, and productivity analytics. These capabilities empower mining operations to make data-driven decisions for improved safety and operational efficiency.

Nerospec OSCON’s HUB controllers are designed to integrate seamlessly with any

machine, regardless of the OEM make, model, type, or age, for both surface and underground mining operations. This unmatched flexibility ensures that mining operations with diverse fleets ranging from legacy equipment to modern machines can achieve consistent and reliable intervention controls. By supporting intelligent and non-intelligent machines alike, Nerospec OSCON’s solutions deliver safety and operational benefits across the entire fleet.

Collaboration with OEMs and thirdparty

Collaboration lies at the heart of Nerospec OSCON’s success. By working closely with mining companies, machine Original Equipment Manufacturers (OEM), and third-party Proximity Detection Systems, Nerospec OSCON ensures that each solution is tailored to the specific needs of the operation.

The following steps provide a high-level overview of our approach, focusing on key stages rather than detailing every step involved in the implementation process:

• Conducting detailed site assessments to understand fleet composition and operational challenges.

• Developing integration plans

with machine OEMs, including comprehensive drawings for mechanical, pneumatic, hydraulic, and electrical systems.

• Establishing control philosophies for actuator management, covering one or a combination of throttle, transmission, service brake, park brake, retardation, and lockout functions (articulation, boom, bucket, basket), etc.

• Creating a site implementation plan that encompasses installation, cold commissioning, and hot commissioning, ensuring validation, verification, and oversight for a fully functional Level 9 machine and system.

• Providing robust training and ongoing support to mine personnel for the seamless adoption of the technology.

Since 2015, Nerospec OSCON has demonstrated its unwavering commitment to mining safety by successfully installing over 7,500 HUB range of loggers and controllers across more than 480 machine types, collaborating with over 70 different machine OEMs.

The impact of Nerospec OSCON’s solutions is evident in the significant reduction of accidents across its installations. On average, our web-based dashboard platform Short Interval Monitoring and Control (SIMAC®) records approximately 5,200 “STOP” events per week across the mining fleets actively being monitored. These events represent critical safety interventions where the third-party Proximity Detection System has identified a breach of the machine’s critical zone, prompting our controllers to bring the machine to a safe stop. This proactive system plays a vital role in preventing collisions and safeguarding lives in mining operations.

These figures highlight not only the effectiveness of the technology but also the behavioural changes it fosters within mining environments. Operators are becoming increasingly safety-conscious, driven by the consistent feedback and intervention provided by the systems.

In an industry where safety is paramount, Nerospec OSCON’s VIC solutions provide an essential layer of protection. By delivering failsafe intervention controls and fostering a culture of safety, leading the charge toward achieving zero fatalities in mining operations worldwide. For mines looking to comply with EMESRT Level 9 standards and elevate their safety practices, Nerospec OSCON offers a proven, globally recognised solution. Together, we can build safer mining environments and protect the workforce, the industry’s most valuable asset.

Don’t miss the world’s premier mineral exploration and mining convention

2-5 5

PROSPECTORS & DEVELOPERS ASSOCIATION OF CANADA

Up to 30,0 00 attendees 700+ hours of programming

1,100+ exhibitors Delegates from 130+ countries

Meet investors & senior executives Unrivaled networking pdac.ca/convention | Toronto, Canada

“Stormwater analysis is also vital in establishing the water balance for any mining operation as it helps in understanding and managing the runoff from rainfall – which consolidates the volumes of water available and the respective uses.”

Climate change has already started to lead to more variable rainfall patterns – making it more difficult to make accurate predictions

With South Africa experiencing numerous devastating flood events in recent years, this has placed a spotlight on the challenges inherent in minimising flooding – by undertaking accurate stormwater analysis and using this analysis to place infrastructure away from vulnerable flooding areas.

One of the key aspects of placing infrastructure is guided by estimating the flood levels and modelling where flood levels through hydrological and hydraulic modelling of stormwater volumes and flows, according to hydrologist Charmaine Thulo, a member of SRK Consulting’s water team. A fundamental objective is to manage the risk to life and property, but there are also stringent water regulations which must be observed.

“Regulation GN704 of the Water Act requires that clean water runoff that is not contaminated by mine infrastructure be separated from runoff water that comes into contact with mine infrastructure.” said Thulo.

The analysis of stormwater patterns is therefore the subject of specialised computer modelling, to simulate storage in pollution control dams as well as assisting the sizing of drainage channels and pipes. This modelling helps minimise discharge from the pollution control dams. Such models utilise detailed rainfall data from one or more sources, to establish baselines and predictions for 1-in-50-year or 1-in-100-year floodlines.

“At the same time, many clients such as mines are looking for ways to reduce their reliance on external water resources like

municipalities,” she explained. “This can include finding ways to store more water for their own use, while still managing the risk of excessive stormwater inflows which could exceed the capacity of their pollution control dams.”

Rainfall more variable

She highlights that historic rainfall data has been the traditional benchmark for stormwater analysis, as it has in the past provided a reliable basis for what to expect in the future. However, climate change has already started to lead to more variable rainfall patterns – making it more difficult to make accurate predictions.

“Our modelling of stormwater now has to take this into account, as there could be significant variations going forward which demand adjustments to the designs and specifications of water infrastructure,” she said.

For mining companies with tailings storage facilities (TSFs), for example, there are also recent standards which require stricter compliance. The Global Industry Standard on Tailings Management (GISTM) focuses on climate change adaptation and explicitly demands that signatories recognise climate change factors and build these into their designs – to ensure that TSFs remain stable and safe for their long life spans and to reduce the risk of environmental impacts.

Reviewing drainage

“These concerns have led to some clients asking us to review the capacity of their TSF penstocks, decant pipes and water channels,” said Thulo. “This is an important consideration as rainfall is

a key factor in the stability of structures such as tailings dams, and drainage capacity must keep up with the volumes of rainwater being retained on the surface.”

Stormwater analysis is also vital in establishing the water balance for any mining operation as it helps in understanding and managing the runoff from rainfall – which consolidates the volumes of water available and the respective uses. Such an exercise helps identify water sources and allows for efficient allocation to its facilities including plants, tailings and return water storage dams. These calculations, which must ensure operational efficiency and environmental compliance, must now also deal with the uncertainties associated with climate change, she concluded.

With three years of experience in the field on several South African projects, Charmaine Thulo is a hydrologist with SRK Consulting. Her work has covered various aspects of hydrology including floodlines, mine water management and stormwater management planning.

Her areas of expertise include mine water balance, and the hydraulic and hydrological modelling of watercourses using HECRAS and GIS (ArcMap). She holds a BSc degree in Hydrology & Water Resources, and a BSc (Hons) in Geography.

free of cavities & maintenance

AZ Sealing System Solutions for a cleaner and safer environment

According to ISO 15848, TA-Luft and API 641 (German standard) Local for local - Local manufacturer since 1985

Plug Valves with PTFE-sleeve two-way and multi-way valves

HIGH PERFORMANCE valves for processes with demanding requirements

Valves with PFA/ FEP lining full safety for operator and environment

Sampling systems safe, representative, reliable

Control plug valves precise equal percentage or linear control

Piping accessories metallic or with PFA / FEP lining, Lined strainers, Lined ball check valves, Lined sightglasses

Actuation aligned, verified and tested components

Special solutions customized plug valves made of cast and forged special materials

Email: info@az-armaturen.co.za Contact No: +27 (0) 11 397 3665 engineered. fast. dynamic.

AZ-Armaturen South Africa (Pty) Ltd 28 Derick Coetzee Street, Jet Park Ext 20, Boksburg 1459

www.az-armaturen.co.za

Mining companies cannot avoid the risk of flooding during the current rainy season in sub-Saharan Africa. However, what they can control is the risk it poses to their operations.

By Nick Barnes

Strict regulations obligate industries and local authorities to practice sound water management without compromise. In South Africa, the relevant regulation is the 1998 Water Act. Similar regulations apply in other countries across the continent.

In mining operations, among others aspects, the Water Act calls for the effective control of stormwater, which is one of the causes of contaminated discharge from activities. Consequently, mines must be well-equipped with suitable pumps and ancillary equipment to manage this risk.

Given the risk stormwater poses to mining operations, suitable pumps and related ancillary equipment are a non-negotiable necessity. Stormwater has significant effects on both open pit and underground mining environments. This is mainly in the following areas:

• Flooding of critical work areas disrupts production and delays schedules.

• Water ingress from flooding damages critical machinery and equipment, resulting in unplanned replacement and repair expenses.

• Increasing operational costs of pumping large volumes of water, with energy accounting for over 30 percent of costs.

• Erosion of haul roads, embankments and pitwalls, causing instability.

• Deposition of soil, rock, and contaminants from tailings or waste piles in nearby water bodies negatively impacting ecosystems.

• Contaminated water may necessitate advanced treatment before disposal, a costly exercise.

• The need for more dams, ponds and stormwater for storage – another expense.

• May affect regulatory approvals (for instance, delays in obtaining water use licence).

To mitigate these challenges, informed selection of appropriate pumps is paramount. This ensures that systems rise to the occasion when needed.

Recently, dewatering specialist, Integrated Pump Technology shared insights with Mining Business Africa. The company observed that 90% of pump failures are due to putting wrong pump into an application being used. This is a striking statistic underlining the importance of proper selection. Even more intriguingsometimes, even when pump selection is correct, poor monitoring can still cause pump failure. Justin Bawden, Key Account Manager at Integrated Pump Technology, explained phenomenon: “Mines will generally have multiple pumps located around their operations, and these are frequently moved from one location to another as needs change. Due to this, personnel can lose track of which models and capacities are needed where. Besides, the size and condition of the pipelines in place may not always suit the application.”

Correct approach, smooth operations

Thus, to ensure smooth pump operations, three steps should are vital:

1. The application

Awareness of the factors and influences of each application is vital to providing a suitable and lasting solution to mitigating the risk of flooding

and consequent loss of life, equipment and production.

2. Monitoring and forecasting of water inflows

In operations where dewatering activity is conducted - whether on open cast or underground mines - it is imperative that monitoring and forecasting of water inflows are done, Bowden advised. “Monitoring and forecasting will allow for the necessary planning and specification of the correct capacity of pumping equipment, as well as hose sizes and materials.”

Furthermore, it is important to ensure that the existing pipeline on site is suited to the scale of the pumping solution. Hence, it is paramount to gather accurate information about the pipeline’s diameter, length, material of construction, age and condition, as well as valves or bends that may affect flow.

3. Regular performance testing

It is essential that dewatering pumps perform on their rated curve. And so, performance testing should be carried out regularly.

Performance testing confirms that the units deliver expected results in critical dewatering

functions while maintaining energy efficiency, a central to controlling operating costs. “The long-term benefits of such tests are significant,” Bawden explained. “Timely maintenance interventions ensure a longer product lifecycle.” Informed decisions, desired output

In the long run, informed decisions in pump selection ensure the desired performance in applications. Ultimately, suitable stormwater management pumps contributes to safety, environmental compliance, and uninterrupted production in mining operations.

Different types of pumps are deployed for stormwater management in mining operations. The following are the most common mining-specific pump types OEMs have in stock: centrifugal pumps, submersible pumps, slurry pumps, dewatering pumps, diaphragm pumps, and vertical turbine pumps.

Specifically, the following are the main considerations for stormwater pumps in mining:

• Capacity: The ability to handle sudden inflows from heavy rainfall.

• Durability: Resistance to corrosion, wear, and abrasiion.

• Mobility: Portable pumps for easy deployment during emergency response.

• Power Source: Diesel-driven pumps for off-grid, remote sites.

• Environmental Compliance: Prevention of water contamination or discharge of pollutants into natural water bodies.

Often specified in the transfer of abrasive and corrosive materials in projects, HDPE pipes have a firmly entrenched niche in African mining. NICK BARNES examines why this trend will continue in the foreseeable future.

The South African Plastic Pipe Manufacturers Association (SAPPMA) foresees increased demand for all ranges of pipes continuing in 2025 and beyond across various sectors. HDPE pipes enjoy a wide spectrum of applications, including—but not limited to—irrigation, water distribution, sewage disposal, and slurry conveyance.

For the transfer of slurry, acids, and other materials in mining projects, high-density polyethene (HDPE) pipes are one of the preferred products, particularly where flexibility, chemical resistance, and durability are key requirements. HDPE is generally a highly flexible and durable thermoplastic.

We asked SAPPMA members, considered leading suppliers of HDPE pipes to the industry, to establish why mining engineers specify their products. The members highlighted several common features that make HDPE pipes ideal:

• Time in mining is of the essence: The lightweight nature of HDPE pipes allows for ease of transportation and installation, which cuts labour costs. Furthermore, regarding installation,

fusion welding methods—for instance, butt or electrofusion welding—allow for a seamless connection.

• Chemical resistance: HDPE pipes can transport corrosive materials.

• Abrasion resistance: They can handle tailings and other sharp particles in fluids.

• Recyclability: The recyclability of HDPE pipes, indirectly, helps mines contribute to reducing the carbon footprint.

• Leakage resistance: HDPE pipes are resistant to leakage. This reduces environmental contamination risks.

• Reduced operating costs: Miniminal replacement needs to reduce operating costs.

• Affordability: Capital equipment costs are skyrocketing, so the comparative affordability of HDPE pipes makes them a cost-effective option.

• Long service life: HDPE pipes are highly appreciated for their long service life. In some cases, depending on the application, they can last for over fifty years.

• Lower operational costs: Additionally, the minimal need for frequent replacements lowers operational costs over

time.

• Thermal resistance: Due to variance in thermal conditions, slurries have extreme temperatures. HDPE pipes can resist this.

• Pressure resistance: Typically, slurries have high pressures. HDPE pipes are engineered and manufactured to handle this.

As mining companies are launching projects in the region, prudent product selection in slurry conveyance is paramount. The most critical aspect is quality, and HDPE pipes are no exception.

SAPPMA CEO Jan Venter said the end-users in industries should ensure that their pipes are compliant with industry-specific standards such as ISO, ASTM, or other relevant certifications for mining applications.

In South Africa, all pipes carry the mark of SAPPMA and the South African Bureau of Standards, SANS 4427 approval. Besides, all fittings meet international standards. SAPPMA accredits verified plastic pipe producers and affiliated suppliers in South Africa and the region.

Interact with our AR 3D pump models and seal assemblies

YEARS OF POWERING PROGRESS, PUMPING EXCELLENCE

What can be done when pressure-reducing valves underperform or fail due to component breakdown? Peter Telle of Ultra Valves demonstrates how to address this challenge.

By Jimmy Swira

In pressure-reducing valve (PRV) stations, one of the common problems encountered is when recommended flow rates are far higher than normal control valve standards (which are based on a 6 m/s velocity). When this occurs, the inevitable result is significant damage and frequent replacement of components.

Valve Selection

With mine operators inundated with numerous valves, informed selection is key to effective pressure reduction at valve stations. Drawing from his extensive experience, Peter Telle, director of Ultra Valves, suggests consideration of the following factors:

i. Pressure Rating Required

The pressure rating is determined by the maximum incoming pressures at various levels. Depending on these pressures, it is often advisable to standardise on the highest pressure rating required. This makes all the equipment standard, easier to carry spare stocks, and prevents maintenance staff from installing the wrong pressure valve in an unsuitable application.

ii. Valve Size Smaller than Pipe

In valve selection, knowledge of maximum and minimum demand flow rates is paramount. However, these are not always available, and PRV stations are often sized according to the installed pipe size. With conventional pilot-operated valves, this can lead to instability at low flows and pipe bursts. Through proper selection, the PRVs will

normally be smaller than the pipe size, resulting in substantial cost reductions and better operation. These cost savings also impact isolation valves and strainers installed in most stations.

In dual-stage reduction at any PRV station, unscrupulous suppliers often install lowerpressure valves on the outlet side of the PRV station. This is extremely dangerous, as it can result in pipe breaks during maintenance and cause serious injuries to maintenance staff.

iii. Cavitation

One of the major considerations in PRV selection is their resistance to cavitation. In most highpressure (50 bar and upwards) PRV stations, it is often necessary to have two valves acting in series to overcome cavitation.

These are considered essential on the downstream side of any PRV station. They are required to prevent overpressure in case of rapid

reduction in demand, where pressure-reducing valves are often too slow to react. Additionally, if there is any malfunction of the PRV, the relief valve ensures that the pressure does not increase beyond safety levels.

Strainers are considered essential at the inlet of PRV stations to ensure no malfunction occurs due to particles in the water. These are a maintenance issue and should be regularly checked and cleaned.

Traditional pilot-operated valves have been the standard method for reducing high incoming pressure to a level suitable for driving mining equipment and potable water. These valves have been used in the mining industry for many years and are still in use. However, they have the following limitations:

• Pilots are vulnerable to dirty water as they have very small orifices and require strainers that need regular maintenance.

• Pilots are easily tampered with by unskilled staff, preventing proper valve operation.

• Pilots, made of stainless steel or brass, often get stolen for scrap value.

• The reaction time of the valves is slow, and when downstream demand is stopped too quickly, overpressure often results, leading to broken pipes and production stoppages.

• Staff often mishandle these valves due to a lack of understanding, resulting in faulty operation.

• Pilot-operated pressure-reducing valves should never be installed in series, as they become vulnerable to unstable operation, which can lead to pipe breakages.

When deployed in challenging conditions, ratioreducing valves have proved to be an effective alternative to traditional pilot-operated valves, mainly due to the following reasons:

• They have no external pilots or control tubing, which are often damaged or

tampered with.

• They have an instant reaction time and can be used in series with other ratio or pilot-operated pressure-reducing valves.

• They cannot fail completely and will keep working with a slight leak when required to close.

• They can accept up to a 5:1 pressure drop without cavitation, a significant improvement over pilot-operated PRVs. Through informed selection, mine operators can choose appropriate ratio-reducing valves.

The reticulation layout identifies the levels where PRV stations are required, the incoming pressure at each level, and the pressure required on that level. Maximum flow rates should also be indicated on these layouts.

The question arises of whether the mine requires adjustability of the outlet pressure. If not, the automatic choice should be ratio-reducing valves, which have become the ideal choice for most miners. These valves are not adjustable and are ordered according to the ratio between inlet and outlet pressures required.

In high-pressure stations, an upstream ratioreducing valve with an adjustable PRV on the downstream side is recommended (if adjustability is required). This ensures stable operation, as the ratio-reducing valve keeps the combination stable.

Sharing his experience, Telle observes that selecting suitable pressure-reducing valves is not a cure-all for intermittent high-pressure challenges at valve stations. There is always a problem lurking out there.

Cognisant of this, Telle advises mining companies to raise awareness among their staff about the dangers associated with high-

pressure water. “PRV suppliers should hold training sessions with mines to ensure better knowledge among operating staff. Mines should also consider maintenance contracts with control valve suppliers, as this will result in more reliable operations.”

Afew months ago, leading a team at Ultra Valves, Peter Telle was consulted to design and install pressure-reducing valve stations at an Anglo American deep-level mine.

Anglo American Mines required a PRV station to reduce pressure from 95 bar to 19 bar – a pioneering venture in the country’s gold mining sector at the time. The station was equipped with electronic safety measures, such as a line break (runaway) shutdown and extended blow-off of the relief valve. However, serious problems were experienced, as the valves became extremely unstable at certain pressure drops.

Another problem experienced was that the recommended flow rates were far higher than normal control valve standards (based on 6 m/s velocity). This resulted in significant damage and frequent component replacement.

To address the problem, the PRV stations were completely imported from Grove in the USA. Engineers in the USA built a test valve at a hydro power station in San Francisco and discovered (after one year) that the wrong rubber formula had been used for the control tubes. This issue was resolved, and additional modifications were made to the strainers, which required smaller apertures.

Last but not least, here is sage advice from Telle regarding strainers: “Although ratio-reducing valves are far less susceptible to dirt particles, it is always recommended to install decent strainers in PRV stations.” This stems from his experience in a recent project where 100-bar stations were supplied to a South African mine. These stations, equipped with two ratio-reducing valves in series on each leg, initially suffered from high dirt content in the water. The issue was eventually resolved when the mine used better water settlers.

By offering rapid, non-destructive elemental analysis, hand-held X-ray fluorescence (XRF) analysers are becoming critical tools in exploration and mining projects.

By Jimmy Swira

Continuing with the trend witnessed in 2024, more exploration and mining projects are set to be launched in 2025. Certainly, hand-held X-ray fluorescence (XRF) analysers will be one of the instruments of choice in applications where rapid, non-destructive elemental analysis across various materials is required.

Compact and battery-powered, hand-held XRF analysers have an X-ray tube and detector. Here’s how they work: Emitting X-rays onto

a material causes the atoms in the sample to emit fluorescent X-rays in return. Every element produces unique emitted X-rays. This allows the analyser to identify and quantify the elements present, providing the geologist with suitable data.

The incorporation of modern technology has elevated the output of handheld XRF analysers to the next level. This is evident in the product features and the capabilities they enable.

Features

Recently, reputable OEMs were kind enough to share information about their handheld XRF

analysers with Mining Business Africa Interestingly, in their range of product brands, key features stand out, particularly:

• Respected for their portability, hand-held analysers are lightweight, compact, and easily carried in the field. Furthermore, the handheld design makes them suitable for use in confined spaces.