Cover Image: Courtesy

COVER STORY: PG 12

Axial fans for Underground Mining Environment

Modern axial fans incorporate new features. This underlines that OEMs are upping their game in the development of products to meet evolving ventilation and cooling needs for workers in underground mining.

TEAM

Editor

Nick Barnes

editor@miningbusinessafrica.co.za

+27 10 055 3356

Web/Sub-Editors

Jimmy Swira

Jimmy@miningbusinessafrica.co.za

+ 27 10 055 3356

Anita Anyango anyangoanita18@gmail.com

Contributing Writers

Chantelle C.

chantellec@miningbusinessafrica.co.za

+ 27 10 055 3356

Susan M. susanm@miningbusinessafrica.co.za

Sales and Marketing

Winnie Sentabire

winnie@miningbusinessafrica.co.za +27 83 530 6832 | +27 10 055 3356

Angeline Ntobeng

angien@miningbusinessafrica.co.za

+ 27 078 322 5938

+ 27 010 055 3356

Accounts Precious Chirunga

accounts@miningbusinessafrica.co.za

+ 27 10 055 3356

Editor’s Note

Action Speaks Louder than Manifesto Pledges

South Africa’s 2024 national elections have come and gone. Life goes on. The earth is still round, and the sky is still blue. The elections were conducted without incident, despite warnings from the doomsday merchants. It’s a sign of a mature 30-year-old democracy, done with baby steps.

But, what’s in it for mining companies?

Mining companies are banking on South Africa’s newly formed Government of National Unity (GNU) to ‘make things happen’ for them. Cobbled together from parties with different political ideologies, it will be interesting to see how this arrangement is sustained over the next five years. Just a caution in hushed tones: politicians are known for flip-flopping positions for their convenience.

Long may the GNU succeed in creating a conducive environment for mining business activities to flourish. The South African economy needs the mining sector to ignite growth, and a predictable regulatory environment is the starting point. There is a clean slate for the incoming administration (as this goes to press).

For one thing: the GNU has its work cut out in turning the much-talked-about potential into reality. Here’s to getting hands dirty. At the end of the hurly-burly, action speaks louder than fiery podium manifesto pledges

Nick Barnes editor@miningbusinessafrica.com

Art Director/Layout

Augustine Ombwa

Arobia Creative Consultancy austin@arobia.co.ke +254 772 187 334

Circulation/Sales

info@miningbusinessafrica.co.za

+ 27 10 055 3356

Published By Media Icon (Pty) Ltd

30 44 02 CONTENTS May - June 2024 Media Icon (Pty) Ltd makes every effort to ensure the accuracy of the contents of its publications, but no warranty is made as to such accuracy and no responsibility will be borne by the publisher for the consequences of actions based on information so published. Further, opinions expressed are not necessarily shared by Media Icon (Pty) Ltd. Location: Max Offices Sandton, 145 Second St., Parkmore Gauteng 2196, South Africa www.miningbusinessafrica.co.za

20

Cross-belt

The Cross-Belt PGNAA Conveyor Convenience

The cross-belt Prompt Gamma Neutron Activation Analysis (PGNAA) system has become one technique used in the pre-concentration of conveyed bulk ore flows. When applied correctly, the method could help African mining operators improve ore grading, thereby boosting recovery, reducing operating costs, and achieving a low environmental footprint.

By Jimmy Swira

By Jimmy Swira

Mining companies have their work cut out to sustain their operations in the present environment. They are contending with a myriad of challenges, including treating lower-grade ore deposits, high operating costs, and compliance with ESG reporting (particularly the environment and social license to operate components).

The challenge with low-grade deposits

Lower-grade deposits generally contain a large proportion of material of no value. Hence, they are difficult to extract. What is more, their

transportation, communication, and processing are expensive and energy-intensive. Authors and researchers, Gary Noble and Scott Ferguson from Thermoscienfic Instruments Australia, highlighted this during their presentation at the Preconcentration Digital Conference in November 2020.

Thus, the logical step is to eliminate barren material from ore before it escalates into both a burden and cost. However, the biggest problem faced is the technique to be applied.

Unfortunately, more often than not, current or conventional individual particle sorting technologies fall short in handling large volumes. Typically, they have a low capacity (up to 300 tph for larger particles and much less for smaller

particles). They have a large footprint, making them more expensive to manage. This rules them out for high tonnage pre-concentration (Metso et al.).

Preconcentration using PGNNA technologies

One technique for dealing with low-grade ore earlier worth exploring is preconcentration through bulk ore sorting using Cross-belt Prompt Gamma Neutron Activation Analysis (PGNAA) technologies. In preconcentration, bulk ore sorting, they separate large volumes of barren gangue from a fully loaded conveyor belt based on the grade as measured or inferred from a sensor measurement (Metso, March 19, 2016).

2 Mining Business Africa |May - June 2024

elemental analysis of minerals

A Cross-Belt PGNAA analyser positioned above a conveyor belt (Image credits: ScanTech)

Furthermore, Metso’s industry brief, Bulk Ore Sorting Improves Profitability and Sustainability, posits that, in today’s low-grade mining operations, preconcentration through bulk ore sorting using PGNNA technologies can bring massive changes. Through the process, waste can be diverted to processing. In this way, high-feed-grade material can facilitate improved recovery. Moreover, it can lower the cost of energy needed for transportation, communication, and waste at the tailing dam.

From an environmental perspective, the gains are significant: reduced greenhouse gas emissions and water loss per tonne of produce. In the bigger scheme of things, from an economic perspective, it can reduce the capital cost of life and increase profitability.

Why PGNAA cross-belt analyzers

Small wonder, Prompt Gamma Neutron Activation Analysis (PGNAA) technologies through cross-belt analyzers have opened up a wide range of opportunities in diverse industries, including mining. Cross-belt analyzers target particular depths and surface areas that represent the entire amount of material on the belt.

Located strategically above the conveyor belt (either in-pit or plant feed), cross-belt analyzers penetrate the entire cross-section of raw material. In real-time, they provide uniform measurements of the material continuously, which enhances accuracy. Effectively, this removes the necessity of constantly sampling coarse (primarily crushed) conveyed ore flows. Typically, each element in a sample produces a unique set of characteristics. Once identified, analysing the gamma-ray spectrum determines the concentration of elements. Thermofisher’s ebook, PGNAA and PFTNA Technology for Nonscientists state this.

Ultimately, PGNAA minimises sample errors. Besides, the high frequency of analysis helps reduce variation in material quality.

Through continuous online elemental analysis and monitoring of raw materials, cross-belt analyzers provide plant managers with a clear picture of grade and gangue composition. Then, equipped with information available in real time, they make sound decisions to use resources better and improve metal recovery.

One may ask: Can award-winning instruments from some of the most respected OEMs guarantee expected results?

Getting the most out of cross-belt PGNAA

The answer lies in the saying: A bad carpenter blames their tools. This would apply to the deployment of PGNAA cross-belt instruments on conveyor belts.

Handily, there are several measures to get the most out of PGNAA. Compiled from the “how-to“ of several manufacturers, the following are some of them:

1. Heterogeneity, instrument accuracy, and precision

Two factors are central to effective bulk ore sorting: the natural heterogeneity of the material at the measurement location and, of course, the accuracy and precision of the measurement. As regards assessing ore heterogeneity, Noble and Ferguson point out that drill core data can be utilised through metre-by-metre elemental assays.

Metso elaborates on heterogeneity: “Most mining deposits are naturally heterogeneous and lend themselves well to bulk ore sorting, but this must be implemented as early as possible before excessive mixing occurs. Material presented to the sorter needs to have sufficient grade variability occurring in large enough batches of material for effective separation”.

2. Crossbelt conveyor set up In Crossbelt Conveyor Considerations: What You Need to Know, Thermofisher Scientific’s Kevin Gordon lists several factors that can impact results:

• Conveyor material for construction

The material from which conveyors are made and how they are set up could affect the accuracy of the analysis and the ease of use of the equipment.

• Material profile

The right material profile should be placed on the conveyor belt. And so, controlling the material profile is important through loading. There are downsides to both extremes, so a perfect balance should be sought.

Overloading can cause physical damage, resulting in unpredictable results. On the other

hand, low belt loading can reduce the number of measurable gamma-ray events attributed to the limited mass available to emit gamma rays.

The aforementioned approach may be elementary, but more details on boosting the performance of cross-belt PGNAA instruments are provided in white papers and technical reports from manufacturers.

Massive benefits

In the main, for plant operators, there are massive benefits for mining operators of using cross-belt PGNAA in both existing and greenfield operations:

1. Existing operations

If conducted close to the mining face, bulk ore sorting can potentially reduce ore transport requirements. After rejecting barren gangue, less ore can be transported to the processing plant for downstream processing. Besides, after effective sorting, an increase in feed grade can lead to improved recovery.

2. ii. Greenfield operations

In greenfield operations, sorting at the face can enable the reduction of the size of downstream processing equipment. Eventually, this can cut capital and operating costs, besides improving production.

Viable avenue

Without a doubt, cross-belt PGNAA instruments present one of the viable avenues for mining companies with operations in Africa to cope with challenges in the contemporary environment. They offer the convenience of managing the challenges of declining ore grades, increasing operating costs, and ESG reporting compliance.

Mining Business Africa | May - June 2024 3

Gold - real time ore grade measurement

SCANTECH GEOSCAN GOLD innovative sensing solution provides accurate data on gold ore feed quality at the beginning of mineral processing in real-time.

Gold mining companies now have a new capability available to help with representative grade measurement in conveyed plant feed. Elemental measurement combined with moisture and fragmentation data can provide new levels of plant control through improved ore management, early waste rejection, process improvements through reduced consumption of resources such as energy, water and reagents, and reduced fine tailings generation. Higher and more consistent feed grades result in higher metal recoveries and increased product for the same throughput capacity generating major increases in revenue and reductions in costs. GHG emissions can be significantly reduced by processing less waste unnecessarily.

Primary crushed material on a conveyor can be representatively and continuously measured

over small tonnage increments in real time using high specification prompt gamma neutron activation analysis (PGNAA). Recent advances as well as ongoing incremental improvements have resulted in Scantech GEOSCAN GOLD being used successfully on gold ores. Successful performance is already proven in many challenging bulk ore sorting applications in base metals and PGMs. Analysers are installed in gold mines in North America, Latin America, Australia, Asia and Africa. The average concentration of the Gold in the ores is 1 gram per tonne or 1 part per million.

The analyser measures a suite of elements over each 30 second increment of conveyed flow, including proxies for gold where available, as well as direct measurement of gold over 5-10 minute increments at precisions suitable for decision making (as low as 0.2 – 0.3ppm

Au achieved). Decisions can be made for ore blending changes, bulk increment diversion, and feed forward control. The measurement data is also used for metal accounting and ore reconciliation.

The analyser measures elements in primary crushed rock in conveyed flows at <100 t/h to >10,000 t/h irrespective of belt speed, particle size, mineralogy, dust, moisture, or segregation/ layering.

Benefits of GEOSCAN GOLD

Higher quality measurements (e.g. precisions) enable tighter process control and improved outcomes. Customised analyser configurations and calibrations for specific applications produce the most useful, timely data possible to meet each client’s measurement requirements for effective process control.

4 Mining Business Africa |May - June 2024 Hand-held X-ray Fluorescence (XRF) Spectrometers in Ore Grading

A Crossbelt analyser from Scantech

Metal recoveries can reduce by 10% or more due to feed quality variability alone. Major gold companies are now measuring feed quality variability to develop a better understanding of its controls and consequences, and introducing systems to manage and improve it.

Other benefits include:

1. Unmatched proven performance;

2. Customised calibrations;

3. Operational at completion of commissioning;

4. Patented non-contact design means minimal maintenance and no wear parts ;

5. No sampling necessary during normal operation;

6. Data directly transmitted to plant control system and owned by site;

7. Proven short paybacks in a few months and sometimes weeks

8. Measurement data can be used simultaneously for various applications: bulk sorting, ore blending, ore reconciliation, ore tracking, feed forward control, metal accounting, etc.

9. Immediate feedback to mining operations helps confirm grade delivered against expected quality so schedules can be adjusted in real time,

10. Feed forward control can be used to identify quality parameters that affect

processing in real time:

• ore hardness for mill feed control,

• mineralogy and deleterious content for reagent dosing control to optimise recoveries, e.g. clays, talc, sulphides, carbonates, carbonaceous, etc.,

• sulphur content for diverting sulphide ore to flotation and oxide ore to leaching, segregating acid generating waste from clean waste, smelter feed chemistry control, etc.

Scantech is calling on all gold mining companies in Africa – and indeed, worldwide - to contact them should they require more information regarding the high performance GEOSCAN GOLD for the minerals industry.

Contact: George Tabi, Sales and Marketing Manager – Africa Email: g.ndohtabi@santach.com.au, sales@scantech.com.au

Mining Business Africa | May - June 2024 5 Website: www.scantech.com.au Email: sales@scantech.com.au PREMIUM QUALITY ON-BELT ELEMENTAL ANALYSER FOR MINERALS GOLD

technology,

ore flows

Rocks2data

module. Scantech International_March.indd 1 26/02/2024 5:34:33 PM

World first GOLD analyser for conveyed ore, unique capability, proven

digitising

through

customisation

Lithium battery storage for mining operations

Uninterrupted Power Storage

It is hard not to notice that mines are using lithium-ion battery energy storage systems with renewables. In this way, they are achieving two objectives: ensuring that downtime in the power supply does not interfere with production, and cutting emissions from the use of diesel generators.

By Nick Barnes

By Nick Barnes

There is a strong business case for effective grid-scale Battery Electric Storage Systems (BESS) in the current mining environment. Concurrently, to meet demand, there is an increase in lithium-ion battery brands released to the market. This has widened the range of BESS options to select from.

Previously, lead-acid batteries were the primary battery product. However, comparatively, grid-scale lithiumion batteries have emerged as an affordable option, with a growing market share.

Pressing needs

Advances in technology incorporated have placed lithium BESS as a strong option to meet the pressing needs in mines, which are a stable and predictable power supply, and reducing greenhouse gas emissions.

1. Predictable energy sources

Mining is inherently power-intensive. Essentially, they require a consistent

and optimal supply to ensure continuous operations.

Hence, as they are increasing production, mining companies need predictable sources of power as backups to utilise during peak demand or in the event of downtime of primary sources. Usually, downtime can translate into millions in a loss of revenue.

Besides, what a perfect time to have alternative sources to explore!

Mines are bearing increasing operating costs and falling profit margins. Against this backdrop, according to the Institute of Materials, Minerals and Mining (IMMM), power consumption accounts for up to 40 per cent of a mine’s operating costs.

2. Reducing emissions

Mining companies are acknowledging their culpability as ‘biggest’ polluters and are seeking avenues in their operations from pit to port through which to clean up their act. Increasingly, they are embracing lithium-ion BESS as one sure way they can achieve this.

Renewables the catalyst

The falling cost of switching to renewables, mainly wind and solar, has underscored the need for reliable BESS. While wind and solar are affordable, the downside is that they cannot provide consistent and reliable power, as they are at the mercy of inclement weather. So, using reliable lithium-ion BESS offsets the intermittency.

BESS enables the microgrid to increase the amount of renewable energy it uses. It compensates for sudden variations in the power output of solar panels and wind turbines, according to Saft, a BESS solutions provider.

Sebastien Hita Perona, Saft’s energy storage solutions general manager, explains: “Energy storage solves renewables’ intermittency and allows them to be integrated into base load resource planning.”

In an insight Enabling renewable energy with battery energy storage (2023), McKinsey & Company) sheds more light: “The flexibility BESS provides will make it integral to applications such as peak shaving, selfconsumption optimization, and backup power in the event of outages.”

McKinsey & Company mentions cycle life and affordability as the determining factors for battery selection, and lithium-ion batteries fit the bill as they tick these critical boxes.

What gives lithium-ion batteries the edge

Based on information suppliers of BESS shared with MBA, the following factors are driving mining companies to Lithium-ion batteries:

1. Longer life cycle - Longer Depth of Discharge (DOD)

The rule of the thump is the Longer Depth of Discharge (DOD) and longer life cycle. From this perspective, Lithium-ion batteries have the edge over conventional lead-acid batteries.

The recommended maximum depth of discharge (DoD) of the batteries is 80%, which translates into a life of 5000 cycles. In contrast, lead-acid batteries

6 Mining Business Africa |May - June 2024

Eskom’s Hex Battery Storage system in South Africa

are limited to a discharge range of 40-50% DoD. This yields a cycle life of 1800-2500 cycles. Even though this statistic is for premium lead batteries, average ones could be lower.

2. Lighter

Transportation is a big cost as mines are in remote areas far from suppliers. Compared to lead-acid batteries, lithium batteries are the better option. In addition, they are lighter - a quarter of a lead acid battery’s weight with the equivalent capacity. In addition, the volume is equivalent to a third lead acid battery.

3. Reduced expenditure (cost savings)

Thus, due to the long-life cycle, lithium batteries are less often replaced, which translates into reduced expenditure on battery storage. Further, less weight reduces the transport costs and lessens the burden of installation.

4. High charge efficiency

If recharged over two hours, the charge efficiency of lithium batteries is 96% (4% lost). This efficiency improves to 98% (2% lost) if recharged over ten hours.

In comparison, the average charge efficiency of lead-acid batteries is 67% (33% lost). Also, lead-acid batteries are not rechargeable in two hours. The closer a lead acid battery gets to a 100% state of charge (SoC), the slower it charges.

5. Improved safety

Over-charging a lead acid battery reduces its lifespan dramatically and may cause the release of toxic gases. As standard, LiFePO4‘s safety LiFePO4 batteries include battery management system (BMS) electronics, which protect the batteries against overcharge, over-discharge and short-circuit complications. This boosts safety.

Uptake

in mining

Amid all the hype, it is tempting to ask: are mines adopting LFP BESS in droves?

The fact is that mining companies are conservative in exploring new technologies. Their thinking goes: if it’s not broken, why fix it? The mindset is: “It’s fine, but isn’t there something that works better?”

Nonetheless, some are breaking new ground in demonstrating that battery

storage is a sustainable option they can turn to. One of them is South Africa’s Harmony Gold in the Free State.

Following commissioning a few months ago, Harmony Gold 30 megawatt (MW) solar photovoltaic is delivering green electrons to our shafts and is expected to deliver approximately 70-gigawatt hours of renewable energy to Harmony’s Free State operations per annum. The miner expects to reduce carbon dioxide emissions by approximately 65,000 tonnes in the first 12 months of operation.

The plant is Phase 1 of an ongoing project; Phase 2 is in the pipeline.

Harmony Gold expects an estimated annual saving of R425 million in electricity costs once Phase 1 and 2 are complete.

The mine in Free State uses a lithium-ion battery energy storage system.

Hopefully, other mining houses will follow suit.

Grid-scale Lithium-ion Battery Market Size, Outlook: Shaping Future Trends and Growth from 2024 to 2031

Mining Business Africa | May - June 2024 7

Uninterrupted Backup Power, Efficient Mining

BlueNova, a South African lithium battery manufacturer, is committed to providing mining companies in the region with reliable and cost-effective standalone lithium battery solutions.

Blue Nova offers a diverse range of standalone batteries tailored for residential, commercial, and industrial use, each with unique features. The batteries range from 13V-8Ah-104Wh batteries to 780V-280Ah218kWh high-voltage batteries, ensuring reliability during outages.

Industrial-grade batteries guarantee uninterrupted operations in demanding environments. The larger containerised iESS systems are custom-built and start at 250kVA–500kWh, while the larger iESS systems, like the one at Midstream Estate in Cape Town, are 6MW–17MWh systems. BlueNova could go bigger should the application require it.

Besides standalone batteries, BlueNova’s solution includes battery monitoring and control units, remote battery monitoring, and control units. Shedding light on what each of these products entails, the company’s Product Manager demonstrates: “A battery monitoring device simply observes and reports on a battery’s status, like its voltage, temperature, and state of charge. On the other hand, a battery monitoring and control system not only monitors but also actively manages the battery. This includes features like adjusting charging rates, balancing cells, and even remotely controlling the battery’s operation, optimising its performance and lifespan.”

BlueNova has been observing recent developments in the battery storage niche market as new suppliers enter the market. The product manager guarantees that the company is a cut above its competitors.

He explains that Blue Nova, part of the Reunert Group, one of the largest engineering companies in Southern Africa, brings a wealth of experience and expertise to the field of battery storage solutions. “With almost a decade of operations in South Africa, specialising in exceptional, high-quality, high-performance lithium-ion batteries, Blue Nova is wellpositioned to provide robust guarantees about the quality of the In a nutshell( Of its products?

8 Mining Business Africa |May - June 2024

for mining operations

Lithium battery storage

Lithium battery storage for mining operations

) , BlueNova prides itself on the following strengths:

1.

Proven Track Record

With nearly 10 years of successful operations in South Africa, Blue Nova has a proven track record of delivering reliable and highperformance lithium-ion batteries to a wide range of industries, including mining.

1. Reunert Group’s Legacy

Being part of the Reunert Group adds an extra layer of assurance. The Reunert name carries a legacy of excellence and reliability in engineering solutions, spanning decades ( Centuries, since 1888). This legacy assures customers that Blue Nova, under the Reunert umbrella, is committed to delivering long-lasting, top-quality products.

1. Long-Term Commitment

The assurance that Reunert gives about being present for the next 20 to 50 years further solidifies the commitment to quality and sustainability. This commitment extends not only to the initial supply of batteries but also to ongoing support, maintenance, and innovation to meet evolving industry needs.

1. Quality Standards

Blue Nova adheres to stringent quality standards and certifications, ensuring that every battery supplied meets or exceeds industry benchmarks for safety, reliability, and performance.

1. Customer Satisfaction

Blue Nova’s focus on customer satisfaction is reflected in its track record of providing tailored solutions, responsive customer support, and continuous improvement based on feedback and

technological advancements.

In a nutshell, Blue Nova, backed by the Reunert Group’s legacy and long-term commitment, offers a solid guarantee of supplying top-quality batteries that meet and exceed industry standards. This ensures reliable and sustainable energy storage solutions for mining and other industries.

Advice on product selection

Based on over eight years of experience, efficiency and reliability are vital in mining operations, and an informed choice of lithium batteries is important. Thus, as a leader in energy solutions, Blue Nova is cognizant of the critical factors that mining companies must consider when selecting lithium batteries for their diverse applications. The following are critical:

1. Durability and reliability

Mining environments require batteries that can withstand extreme temperatures, vibrations, and shocks. Blue Nova’s lithium batteries are engineered with robust materials and advanced technology to ensure durability and reliable performance, even in harsh conditions.

1. Energy Density and Capacity

Mining operations often require high energy density and large-capacity batteries to support heavy equipment and extended operations. Blue Nova offers lithium batteries with high energy density, providing ample power while minimising space and weight requirements.

1. Safety and Compliance

As safety is key in mining operations, choosing batteries that meet industry standards and

regulatory requirements is important. Blue Nova’s lithium batteries adhere to stringent safety protocols, including built-in protection mechanisms against overcharging, overdischarging, and short circuits. ( You could metion that LiFeP0 is the safest lithium)

1. Lifecycle and Maintenance

Longevity and low maintenance are key considerations for mining companies looking to optimise their investments. Blue Nova’s lithium batteries are designed for an extended lifecycle with minimal (Zero) maintenance requirements, reducing downtime and operational costs.

1. Integration and compatibility

Seamless integration with existing mining equipment and systems is crucial for efficiency and ease of implementation. Blue Nova provides customisable battery solutions that can be tailored to fit specific mining applications and integrate with various equipment and control systems.

“By prioritising these factors and leveraging Blue Nova’s expertise in lithium battery technology, mining companies can enhance their operations with reliable, high-performance energy solutions tailored to their unique needs,” states the product manager.

By and large, being a South African company, Blue Nova offers several benefits to mining companies. Firstly, sourcing locally helps streamline supply chains, reducing reliance on international suppliers and lessening risks from global disruptions. This results in predictability. Furthermore, it fosters closer collaboration, leading to customised solutions tailored to mining needs.

New Engineered Vacuum Pump Sets

Repair & Service

Technical Sales & Support

Service Exchange Vacuum Pumps

On Site Performance Testing

10 Mining Business Africa |May - June 2024 N A S H L I Q U I D R I N G V A C U U M P U M P S V a c - C e n t S e r v i c e s h a s b e e n m a n u f a c t u r i n g N A S H L i q u i d R i n g V a c u u m P u m p s a n d C o m p r e s s o r s 1 0 0 % L o c a l l y s i n c e 1 9 8 7 V a c - C e n t S e r v i c e s o f f e r t h e e n t i r e N A S H V a c u u m P u m p a n d C o m p r e s s o r r a n g e W e m a k e i t t o s u i t y o u r p r o c e s s ! V A C - C E N T S E R V I C E S ( P T Y ) L T D O F F E R S T H E F O L L O W I N G :

H E A D O F F I C E 1 2 4 S N A P P E R R O A D W A D E V I L L E T : + 2 7 1 1 8 2 7 1 5 3 6 I N F O @ V A C C E N T . C O . Z A W W W . V A C C E N T . C O . Z A

Intelligent conveyor belt lining

Smarter, Safer, and More Efficient Conveyor Maintenance

Conveyor belt maintenance has a huge impact on safety and productivity in mining. Handily, sensor-embedded intelligent conveyor belt plastic lining presents an opportunity for applying predictive maintenance, which forestalls downtime and mitigates risks.

By Jimmy Swira

Picture this: a conveyor belt is in perfect working condition after post-installation commissioning, given a thumbs up. Good to go.

Ideally, in above-ground and underground operations, conveyor systems should work flawlessly when duty calls. But in the unforgiving world of bulk material handling, naturally, they are exposed to abrasion, wear and tear, and the risk of fire. It is par for the course.

Ghastly

The cost of this can be too ghastly to contemplate, not least when management has eyes on achieving big figures. At best, the consequence is the loss of productivity because of unplanned downtime; at worst, fatalities and serious injuries.

Measures in place

Preemptively, mining companies should have measures firmly in place to handle this. But human laxity always creeps in—management thinks they are on top of things. Besides, there is a tendency to subject every expenditure, even as critical as safety, to obsessing over cost containment. They seek answers to the question: How much will it cost us? Is it worth it?

Unfortunately, this comes at the expense

The colossal costs of conveyor failure

There is a high price to pay for a poorly monitored conveyor belt. There are several documented cases globally. Sadly, many more could unfold currently as mining activity ramps up. Incidents in these countries stand out:

Australia

In Australia, an Australian gold miner, Victoria Gold, could not meet its full-year

production projection after its overland conveyor suffered extensive damage. Replacing the conveyor belt resulted in downtime to crushing, conveying, and stacking.

South Africa

In South Africa, in 2018, a burning underground conveyor belt at Parabora Copper Mine in Limpopo Province resulted in a tragic incident. There were six fatalities and 48 injuries.

of workers’s health and safety, which the Mine Health and Safety Act (MHSA) obligates mines to prioritise devotedly. And so, miners must identify hazards and minimise all known risks the workforce could face from exposure.

Surely, there is a clarion call for mining companies to invest in technologies to enable effective and efficient management of conveyor belts through monitoring.

Intelligent conveyor belt lining

Fire risk mitigation is a critical requirement that involves preventing and safely dealing with belt fires. Fortunately, with rational investment in suitable technologies, this is achievable.

One technology for mining companies is intelligent plastic lining. Embedded with temperature and wear sensors, the lining’s sliding properties facilitate the smooth flow of bulk materials. In conveyor systems, the technology has proved reliable in preventing major damage attributed to fires and allowing predictive maintenance.

The route to go

For smarter, safer, and more efficient conveyor belt maintenance, intelligent conveyor belt lining could be the route.

For more on this technology, see the following article.

In 2020, at power utility Eskom’s Medupi station, a faulty conveyor belt feeding coal into generation units caused power blackouts in some parts of the country. The functioning conveyors could not take the required amount of coal. Following this, the power utility implemented “load-shedding” to ration power supply. Sadly, similar cases have been a dime and a dozen since.

Mining Business Africa | May - June 2024 11

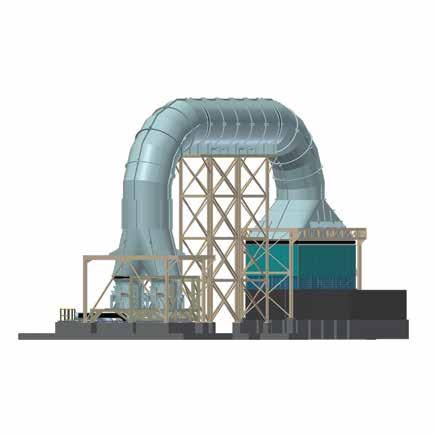

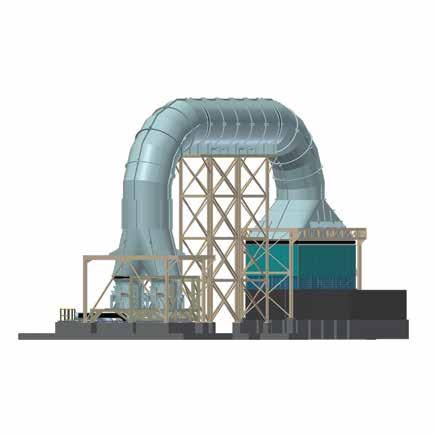

Innovations Go Deeper for Adequate Ventilation

Modern axial fans incorporate new features. This underlines that OEMs are upping their game in the development of products to meet evolving ventilation and cooling needs for workers in underground mining.

By Nick Barnes

Mining companies are going into deeplevel environments in search of highgrade ore. The challenge before them is that the deeper they go, the tougher conditions workers are exposed to at the coalface of activity.

Underground, usually, workers face extreme temperatures (peaking at 50 degrees Celsius), humidity, dust, and fumes.

Thus, to ensure ideal working conditions, reliable, robust, and innovative ventilation systems are necessary. Once well implemented, the payback is immense: a reduction in worker fatigue, which increases safety and production.

OEMs answer the call

Interestingly, OEMs that provide various ventilation systems are answering the call to meet complex challenges that arise as mining goes to greater depths. Mining Business Africa sifted through some innovations or upgrades of existing technologies from Research and Development (R&D) endeavours. In the main, there is an effort to enable convenience, costeffectiveness, elevated safety, and sustainability.

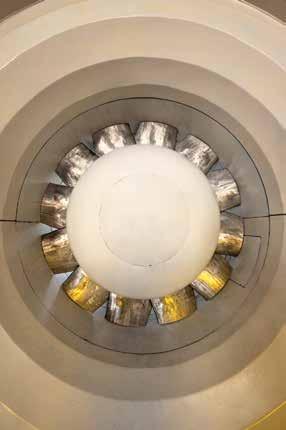

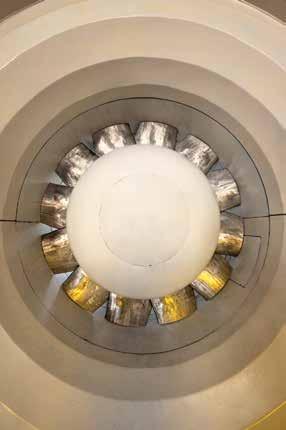

Axial fans

One area where this is noticeable is the niche of axial fans. Relevant OEMs involved in the area have gone all-out to create modifications and incorporate accessories addressing current industry needs.

This is significant, as axial fans are instrumental.

Used in various ventilation and cooling applications, axial fans remove dust and gases and provide fresh air for worker safety.

Mounted on the shaft collar, axial fans, draw ambient air through the air cooler and deliver chilled air to the mine’s ventilation shaft.

What stands out in the innovations witnessed among axial pump brands introduced to the market are increased health and safety compliance, energy efficiency, modular convenience, and robustness.

1. Noise reduction

On the one hand, axial fans serve a vital purpose, providing fresh air for workers. On

the other, their operation can have unintended consequences.

Detrimentally, the high decibels of noise that axial fans produce can pose a risk to workers’ hearing, resulting in a violation of local and environmental regulations.

On the risk of high noise levels, the Mine Health and Safety Council (MHSC) expounds: “Exposure to excessive noise results in permanent impairment of hearing/permanent hearing loss (noise-induced hearing loss). The Council singles out high noise levels as one of the most common injuries in the South African mining sector.

There are thresholds on noise levels from equipment, including axial fans. The total operational or process noise emitted by any equipment must not exceed a milestone sound pressure level of 107 dB(A) and no employee’s Standard Threshold Shift (STS) must exceed 25 dB from the baseline when averaged at 2000, 3000, and 4000 Hz in one or both ears.

As mine health and safety regulations obligate noise abatement measures, handily, new fans accommodate custom silencers. Retrofits of old fan models are also carried out on projects.

2. Energy efficiency

Managing the strained power sources has become a business imperative. To achieve this, mining companies are leaving no stone unturned, exploring every available opportunity. And if one of them involves cutting the power consumption of fans, why not?

Studies show that ventilation can consume between 40 per cent and 50 per cent of a mine’s energy costs. And so, there are tangible energy savings to be had.

Typically, as traditional fans direct air to areas that are not populated, traditional axial

fans waste a lot of power. Hence, to handle this, modern axial fans have sensor tracking, which automatically responds to real-time demand. Eventually, this ensures that the amount of air released is only according to need.

An electronic controller fitted with radio frequency identification trackers can regulate a fan in line with low- or high-flow volumetric requirements to disperse gases and ventilate an area.

Trackers monitor underground equipment heading into an area where ventilation is required. A case in point is the number of people and trucks moving into an area, even a truck’s engine details.

3. Modular convenience

In current mining equipment models, modular solutions are the in-thing. With modular equipment, a mine can add or remove accessories such as silencers or adapters.

4. Robustness

Impeller failure is one of the common problems that surfaces in axial fans. And if it does, its impact on production and worker safety is significant.

Usually, fans face high temperatures and vibration effects. However, hubs on steelfabricated impellers allow operations in harsh conditions.

Also, in what has become standard, fibrereinforced plastic (FRP) material is used to solve the problem of the limitations of plastic hubs. Fitted on axles, plastic hubs endure extreme stresses such as high speeds, natural oscillations, and vibrations, which lead to damage and excessive deformation.

However, reinforced plastic offers extra protection, making the hubs more robust. With heat resistance, impact, and shock-energy absorption, the material offers protection against damage and excessive deformation.

Keeping abreast

From the look of things, it seems axial fan OEMs are not resting on their laurels and are keeping abreast of the evolving ventilation needs of underground mining operations. This bodes well for mining companies aiming to realise sustainable and profitable operations.

12 Mining Business Africa |May - June 2024

fans for Underground Mining Environment

Axial

Axial fans at a mine site

free of cavities & maintenance

Product range

Plug Valves with PTFE-sleeve two-way and multi-way valves

HIGH PERFORMANCE valves for processes with demanding requirements

Valves with PFA / FEP lining full safety for operator and environment

Sampling systems safe, representative, reliable

Control plug valves precise equal percentage or linear control

Piping accessories

AZ Sealing System Solutions for a cleaner and safer environment

metallic or with PFA / FEP lining, lined strainers, lined ball check valves, lined sightglasses

Actuation aligned, verified and tested components

Special solutions customized plug valves made of cast and forged special materials

According to ISO 15848, TA-Luft and API 641 (German standard) Local for local - Local manufacturer since 1985 www.az-armaturen.co.za

ARMATUREN

AZ-Armaturen South Africa (Pty) Ltd 28 Derick Coetzee Street, Jet Park Ext. 20, Boksburg, 1459 Email: info@az-armaturen.co.za Contact Number: +27 (0) 11 397 3665 engineered. fast. dynamic. Low-Emission Plug Valves

Fugitive Emissions

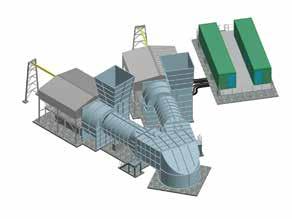

Axial fans for Underground Mining Environment Overcoming Obstacles in Mining Ventilation:

Air Blow Fans Innovative Solutions for African Mines

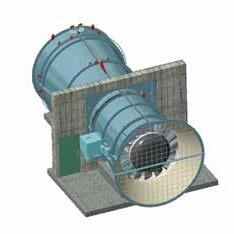

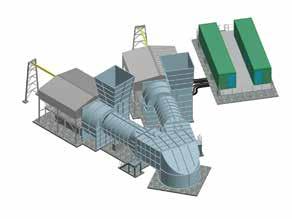

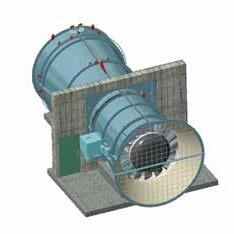

As a proudly African company, Air Blow Fans (ABF) has been designing, manufacturing, and engineering both turnkey and custom mining ventilation solutions across the continent for the past 25 years. Established in 1998, the South African-based business specialises in both centrifugal and axial flow fan systems, offering a comprehensive range of services, including engineering, refurbishments, automated balancing and remote monitoring.

While many of Air Blow Fans’ competitors may focus solely on either axial flow or centrifugal fan technologies, the company’s in-house engineering capabilities allow it to tackle the most complex ventilation challenges using either. These range from small auxiliary and jet fans for underground applications to fans larger than 4 metres in diameter, from shaft sinking applications to main ventilation systems and underground boosters.

One project illustrates ABF’s problem-solving prowess. A mining client in Rwanda required a fan resistant to foreign debris being ingested into the system. ABF’s in-house designed centrifugal backwards-curved radial-tip fan not only solved

the debris issue but significantly increased the system’s campaign life – a critical factor, as the client had previously been forced to shut down the fan almost daily for cleaning. Impressed, the client noted they hadn’t needed to stop the system since the new ABF fan was installed, also negating the need for remote monitoring and automatic balancing add-ons.

Similarly, when a South African coal mine sought a redundant bifurcated centrifugal fan system (with each fan capable of providing the total required airflow) ABF delivered an aerofoil-bladed centrifugal system with a motor and gearbox combination which provides the low-speed requirements of the fan to achieve high efficiency and flow rates. Recognising the application’s unique requirements, the company also incorporated blast panels on the shaft top elbow – a feature not typical in hard rock mining. The successful supply, installation, and commissioning of the two 4.8-metre diameter, 1,100 kW centrifugal fans and accompanying equipment, earned the project the prestigious “Best Project Team of the Year” award from the client.

As mining across Africa becomes more

14 Mining Business Africa |May - June 2024

A large centrifugal fan system built and installed at a mine in Zimbabwe.

Jet Fans at ABF’s workshop in Springs, South Africa.

Fan blades designed using biomimicry offer enhanced aerodynamics

Axial fans for Underground Mining Environment

mechanised, the need for advanced auxiliary fan designs has grown. ABF’s focus on improving aerodynamics and reducing power consumption has been invaluable, helping clients optimise energy usage, especially important as many mines now generate their own power. As part of this innovation, ABF explored biomimicry in developing new fan solutions. One client in Ghana initially questioned the “strange-looking bumps” on the fan blades, only to learn they were inspired by whale fins – a design that enhances aerodynamic efficiency. This nature-inspired approach, combined with advanced engineering, has resulted in a fan Gavin Ratner, ABF’s CEO, describes as more efficient and cost-effective than competitors’ offerings.

Complementing its well-established fan solutions, ABF has more recently branched out into the design and supply of dust control scrubbers for underground mining applications. Drawing on its years of experience in the sector, the company has developed a deep understanding of the challenges mines face in managing airborne dust, and its scrubber systems incorporate sophisticated engineering codes to maximise their effectiveness.

Beyond manufacturing, ABF handles all civil work, electrical reticulation, and installation to ensure the highest standards until project completion. And once the project has been signed off on time and within budget, the company’s team of qualified, experienced technicians is available 24/7 to address any issues that may arise, whether it’s troubleshooting an out-of-balance problem, replacing mechanical components (like bearings and motors) or performing precision trim balancing. Importantly, ABF can mobilise its field service crews within 24 hours to ensure that clients’ operations remain uninterrupted.

To further enhance reliability, ABF has developed an AI-powered remote monitoring system that detects potential equipment failures before they occur. While mechanical components remain the company’s core focus, this innovative technology augments the offering, helping ensure clients’ mining operations run smoothly and efficiently.

At the heart of Air Blow Fans’ success lies an unparalleled problem-solving ability, honed over 25 years of tackling the mining industry’s most complex ventilation challenges. Whether designing a fan resistant to foreign debris, creating a redundant system to ensure uninterrupted airflow, or drawing inspiration from nature to enhance efficiency, the company consistently pushes the boundaries of what’s possible. As the industry continues to evolve, this proudly African business will remain at the forefront, leveraging its pioneering spirit and engineering passion to keep the continent’s mines running safely and efficiently, one tailored project at a time.

16 Mining Business Africa |May - June 2024

An auxiliary fan being assembled by ABF staff in Springs, South Africa.

A bifurcated centrifugal fan system during installation at a coal mine in Mpumalanga, South Africa.

A large axial flow fan built and installed at a mine in the Free State, South Africa.

Surface miners

To use or not to use surface miners

Noddy McGeorge, principal mining engineer at SRK Consulting (South Africa), examines the ideal conditions in which surface miners can be employed and where traditional methods may be more suitable.

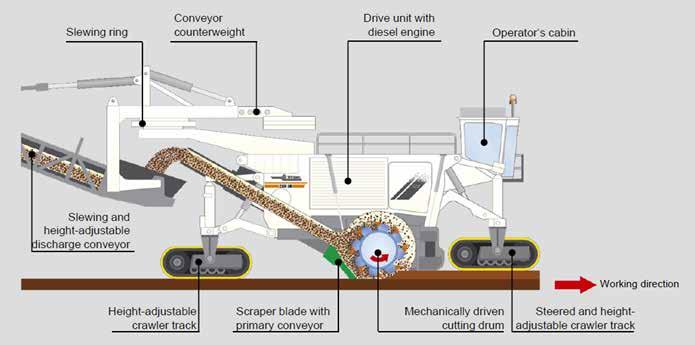

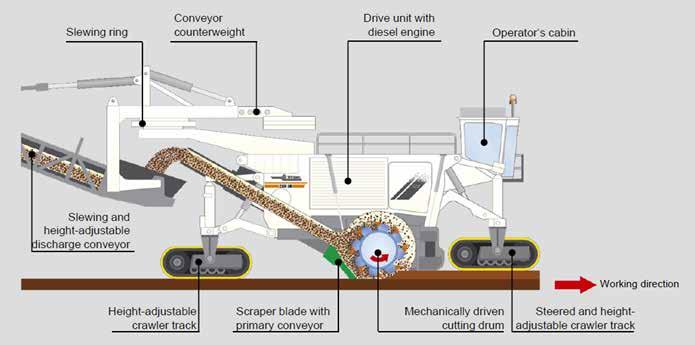

A close up of the cutting drum below the machine with the picks inserted

Surface miners are an adaption of the method of rock cutting that utilises a drum with picks attached to break the rock, similar to the underground continuous miners. There is also a variant that uses a rotating drum that applies the same principles.

Limitations

Given that the machine cuts the rock or ore without blasting one of its limitations is the inherent strength of the material (compressive strength) that it cuts and the mass of the machine and the power that can be applied to the material to be excavated.

Upscaled in size

One of the equipment manufacturers used to apply the equipment in road rehabilitation where the miner cuts the original bitumen surface away. In the last few years, the machines have been upscaled in size to make them suitable for excavating surface mines in both the ore and the overburden material.

Types of surface miners

A picture of a Wirtgen miner loading the cut coal into an adjacent truck on an opencast coal mine in Australia. The picture is a cutaway drawing showing the cutting action and the discharging of the material.

The key in using this type of surface miner is that the material cut below the drum can either be lifted up and loaded into a truck or simply side casted or left in a windrow behind the machine. The machine is capable of cutting to a depth of between 0.1m to 0.6m in each pass and where necessary can adjust while in motion.

The second type of surface miner is the Vermeer miner where the drum is in the front of the machine and the material is collected behind the drum with a spade with gathering arms. The machine can also operate where it cuts the material and leaves it in place and a secondary operation using a front-end loader and truck removes the material.

The cutting method is limited by the picks and is approximately 10 - 50cm per pass which means that the operation can be accurate in cutting only the ore and not the waste hence limiting the dilution. This makes it suitable in thin tabular deposits where drilling and blasting cannot be applied and that the ore has to be selectively extracted.

The drum type surface miner which was developed by Krupp was applied more like a shovel or bucket wheel excavator in thicker seams but could also be used in thinner seams where necessary. Its limitation was the cutting pattern on the drum. Based on the limited cutting profile it only found use in soft applications such as coal and lignite. A picture is shown below.

Currently the large hydraulic shovels can apply a larger breakout force similar to this surface miner and hence free dig the thicker seams but are not as accurate in separating the ore / waste interface.

Conditions suitable for surface miners

The surface miner is best utilised for selective mining in thin slices to minimise dilution by accurately separating the ore / waste interface. It can be done on inclined seams up to around 20 degrees but becomes traction limited at steeper

dip.

The main advantage is that the machine breaks the material without blasting and hence limits dust and other environmental concerns. Also, it allows a better control of any highwall faces and hence allows a steeper wall or better recovery of ore within the mining licence at the boundaries. In thin seams the machine is able to recover material that would be lost using bulk mining methods where the cost and practicality of recovering the ore becomes prohibitive.

Typically, in most current opencast operations the cut off on seam thickness with large bulk mining is at 0.75m based on the physical digging parameters and often more when the cost of extraction is considered. Based on the productivity of the machine, which is governed by the depth of the cut and the

This can be a constraint when the full mining process includes other mining equipment that may constrain the available area and where the surface miner activities are not matched to the speed of exposure of the ore. The cutting process also generates a small well graded sized product and hence eliminates secondary sizing at the plant. In cases where the ore is cleated or closely jointed the system can handle the excavation with limited complications.

When the seam is thin the alternatives to drill and blast include ripping with a dozer or trying to free dig with an oversized shovel but these methods lose the degree of selectivity that the surface miner can apply. The increased dilution then makes the methods cost prohibitive. In some applications the surface miner may also compete in a capital shoot out with the bulk mining method by eliminating the drills and

Mining Business Africa | May - June 2024 17

Noddy McGeorge

Surface miners

loader providing the overall ore targets are within the capability of the machine.

Rock

conditions determining the type of equipment

Like any rock cutting application the force that can be applied at the point of the pick and the speed of advance all are interrelated as well as the control of the depth of the cut which result in the productivity of the system. The typical range of compressive strength of material that the miner can cut is between 10 and 70 Mpa with the consequent alteration of the productivity. In the softer materials the material dispatch method can also affect productivity where material does not flow adequately or time is lost changing between trucks.

Types of material mined based on their compressive strength

The production rates of the larger machines can range from an instantaneous rate of 1500 Bank cubic meters per hour (BCM’s/Hr) in the soft material to around 500 BCM’s/Hr in 50Mpa material. This can be contrasted to a typical underground continuous miner that cuts at a rate of approximately 500 BCM’s/Hr in coal at an instantaneous rate. The advantage in the surface miner is there is less time lost in the dispatch of the material to the clearance mechanism. This means on coal a typical large miner should be capable of cutting between three to four million tons per annum in a coal application. The surface miners have been applied in Iron ore, limestone, coal, lignite, kimberlite, salt and phosphate application and Wirtgen report having sold over 450 machines into mining applications.

Steps to optimise the performance of surface miners

The main application of the miner is to produce ore where the conditions do not allow bulk scale methods with drilling and blasting, where it reduces cost per unit. Hence the main optimisation is to keep maximum productivity of the machine and its cutting time maximised to keep the costs down to compete with the bulk mining methods.

Surface loading equipment typically achieves around an 80% availability and around 80% utilisation in a well designed operation. It is expected that the availability targets can be matched by a surface miner but the utilisation would be lower because of the more frequent changing of the picks on the drum and the repositioning of the equipment.

As noted the area needed for the surface miner operation is larger than the bulk mining so the inventory of available cutting area needs to be large to get the best utilisation. In some operations the multiplicity of seams and their

constrained shape in casting methods make this difficult. Where the machine is being used for a specific application in optimising resource recovery etc the optimisation is mostly around maximising cutting time on the machine.

Benefits that surface miners bring to open-cast mining projects

As noted, the surface miners can have some specific advantages in the extraction of the ore and can produce at a reasonable rate if the overall mine production rate is small. This then gives a capital advantage over the bulk mining method for the smaller capacity. A single surface miner will replace the drills as well as the loader in a bulk operation. The maintenance of a single unit as opposed to multiple units may also be an advantage.

Depending upon the project location, the servicing of the machine by the equipment manufacturer may be a constraint. When mining close to the reserve boundaries, the use of the surface miner allows a steeper slope to be cut thereby maximising resource extraction in the property.

The other benefit is because of the accuracy of the cutting of the waste / ore interface and minimising dilution it allows recovery of thinner seams that are normally discarded. The operating cost of the equipment is unlikely to compete with the bulk mining method in seams that are 1.5m or thicker so its key benefit is in recovering the thin seams. The grading of the material may have a benefit in the elimination of secondary breaking which also attracts losses and plant beneficiation inefficiencies.

18 Mining Business Africa |May - June 2024

A Wirtgen miner loading the cut coal into an adjacent truck on an opencast coal mine in Australia (Image credits: Wirtgen)

A cutaway drawing showing the cutting action and the discharging of the material.

WIRTGEN GmbH · Reinhard-Wirtgen-Str. 2 D-53578 Windhagen T: +49 26 45 / 131 0 A WIRTGEN GROUP COMPANY 280 SM(i): Surface Mining combines safe mining operations with modern cost-effectiveness: the 280 SM(i) replaces the entire equipment otherwise needed for blasting, drilling and pre-crushing. It cuts costs, delivers mined raw materials of higher quality, and ensures more efficient exploitation of the deposits. Take advantage of innovative solutions from the technology leader. www.wirtgen.com www.wirtgen.com/mining Blasting? No! Safety? Yes!

EMESRT Level 9 Controls for Trackless Mobile Machinery

The Last Line of Defence

Mining companies should not view EMESRT Level 9 Control as a grudge investment, but as a potential gain. Currently, there are some pending grey areas. However, mining companies have to be proactive by collaborating with OEMs to find suitable intervention control solutions commensurate with the risks in their respective trackless mobile machinery (TMMs).

By Jimmy Swira

By Jimmy Swira

In the South African mining environment, the sub-regulation of Regulation 8.10 of the Mine Health and Safety Act (MHSA) on dieselpowered trackless mobile machinery (TMMs) is transforming the management of collision avoidance systems (CAS). The regulation obligates mining companies to implement the industry standard Moving Equipment Safety Round Table (EMESRT) - Level 9 (Intervention Controls). Through EMESRT, the International Council on Mining and Minerals aims to eliminate all fatalities from vehicle interactions in mining by 2025.

Typically, EMESRT) Level 9 stipulates that TMM must incorporate automated machine controls that prevent unsafe vehicle-to-vehicle and vehicle-to-person interactions. This is in the event the operator has failed to implement the prior Level 7 (operator awareness) alarm and Level 8 (advisory control) alerts in a timely manner. In the end, this reduces the risk of fatalities.

Grey areas

S outh Africa is one of the latest countries to ratify EMESRT officially, relatively speaking. So, as you would have thought, there are several grey areas to address. The main ones are the timelines applicable to every mine to adopt and implement, and the huge financial outlay entailed to replace the old fleet with EMESRT-compliant.

So what’s next?

The buck stops with mining companies

Surely, mining companies do not have the luxury of waiting for matters to be clarified before they act on Level 9 Control regulations. The buck stops with them as their operations are inherently risk-prone.

Where there is mining activity, there is always the risk of TMM accidents lurking, ready to pounce. While there may be concerns with the sub-regulation of Regulation 8.10, it is noteworthy that the Mine Health and Safety Act (MHSA) compels mining companies to protect their employees from hazards through the adoption of reliable mitigation measures. This implies exploring every available avenue.

Highlighting the prevalence of risk is not fearmongering. Statistics back this up.

In 2022, Global Data, a data and analytics company, conducted a survey whose findings reflected the overlooked extent of the risk that abounds. The results showed that the failure of vehicle interaction controls contributes to 30% to 40% of mining industry deaths globally. Worryingly, half of these involve pedestrians in underground mines.

New chapter

In an interview with Mining Business Africa published in the March/April 2024 edition, two experts in mining law offered their views on the implication of EMESRT on compliance. Pieter Colyn, a Mine and Occupational Health and Safety Executive and Head of Department, and Warren Hendricks, a Mine and Occupational Health and Safety Executive at ENS Africa, a firm involved in African mining projects. They argued that mining companies should regard the regulations as a new chapter in their drive to mitigate the risk of vehicle collisions, rather than a constraint.

“Employers in South Africa, working with OEMs, are the forerunners in the investigation, design, installation, testing, certification, and utilisation of such “means” (intervention controls) in various mining environments. This brings about opportunities for OEMs to develop new and innovative systems for application at a mine,

locally and internationally,” they stated.

The two highlighted opportunities for OEMs and mining companies (employers) to enter partnerships in testing systems in “real world” mining environments, which vary from operation to operation. In due course, the collaborative arrangements between OEMs and employers would help implement safe and healthy parameters for such systems to operate in such environments.

In this publication’s 2024 Mining Indaba Edition, Probe Integrated Mining Technologies (IMT) CEO, Gert Roselt, concurred with the two legal dons. Going further, he suggested implementing systems that allow for the interoperability of capabilities. “Implementing reliable integrated systems that can comply with Level 9 requires long-term commitment and solid investment in sophisticated CAS systems that provide high integrity object detection, operator warning, and automatic intervention, when necessary, to prevent an accident,” he spelled out.

There are enormous gains from implementing technologies that enable EMESRT compliance; a case in point is in the statistics from South Africa’s mining sector. The Minerals Council attributed the reduction of fatalities to only one TTM collision-related death recorded in 2022 to the increase in the adoption of advanced proximity detection and CAS.

Turning aims to reality

Through EMESRT, the International Council on Mining and Minerals aims to eliminate all fatalities from vehicle interactions in mining by 2025. The onus is on mining companies at the core face of operations to turn this into reality by embracing the last line of defence in vehicle-tovehicle and vehicle-to-pedestrian interactions.

20 Mining Business Africa |March - April 2024

Chaired by Bernard Swanepoel, this event will bring together leaders from government, industry, coal producers, alternative energy providers, investors, funders and independent experts, who will discuss key issues such as:

• How is the conversation around the energy transition developing internationally and what are the implications for South Africa?

• What is the global outlook for coal and its role in the future energy landscape?

• What will a diversified and sustainable energy portfolio look like?

• What is the future of coal in Southern Africa?

• How are major coal producers diversifying their portfolios and managing demands to lower carbon emissions?

• What are the latest developments in renewable energy and its contribution to South Africa’s energy mix?

• What are investors’ perspectives on how to fund the energy transition?

• What is Eskom’s perspective on coal and alternative energy sources and the roles they will each play in the future energy mix of South Africa?

• How are the issues around coal transport and logistics being overcome to increase export capacity?

• What are the challenges and opportunities for junior coal miners in 2024 and beyond?

• And much more...

MEETING ENERGY NEEDS FOR THE FUTURE Contact us about sponsorship opportunities:

The

sponsorship@resources4africa.com

2024 Coal & Energy Transition Day, for producers, traders, investors and users is brought to you by Resources 4 Africa, the organisers of the Joburg Indaba.

23 JULY 2024 | www.coalindaba.com COUNTRY CLUB JOHANNESBURG, AUCKLAND PARK 6TH EDITION Mining Industry Partners: Premium Sponsor: Coal & Energy IN-PERSON & ONLINE! +27 (0) 11 463 7799 // +27 (0) 61 421 9492 registrations@resources4africa.com For more information, visit our website, www.coalindaba.com

EMESRT Level 9 Controls for Trackless Mobile Machinery

Collision Prevention Systems (CPS)

CRAWL

& STOP Machine Intervention Control (CxDI) Technology for Trackless Mining Machines (TMM)

Our HUB controllers lead the industry in machine interface (CxDI) for CPS compliance, delivering superior safety, real-time monitoring, and increased productivity for both surface and underground mining operations.

Nerospec OSCON’s range of specialist controllers provides a universal interface for Trackless Mining Machines (TMM) when integrated with a third-party Collision Warning/Detection/Management device (CxD). These controllers adhere to industrystandard Minerals Council South Africa (MOSH) intervention controls, supporting any machine OEM, make, model, type, or age. They are also the first 100% agnostic fleetwide machine interface controllers (CxDI), integrating seamlessly with the CxD and the Machine OEM Controller.

Our intelligent CxDI machine controllers offer advanced data logging capabilities, providing valuable insights into machine health, maintenance schedules, productivity analytics, and real-time monitoring. With over 5,000 successful installations on various mobile equipment from over 45 different OEMs and spanning more than 200 machine types since 2015, Nerospec OSCON has established itself as a leader in the field.

Enhancing Safety Across the Mining Sector

Mining companies continuously strive to maximise revenue while maintaining safety standards. However, increased productivity can inadvertently elevate safety risks due to the proximity of machinery and personnel.

The mining industry faces significant safety challenges, particularly concerning trackless

mobile machines (TMMs) and associated fatalities. Yet, advancements in technology, such as CPS regulatory compliance (Level 9 outside South Africa), offer promising solutions. Nerospec OSCON has been at the forefront of spreading this technology globally, ensuring safer working environments in mines across four continents.

Recognising the urgent need for safer mining environments, Nerospec OSCON advocates for the implementation of reliable, MOSH-compliant CPS (Level 9) intervention control technologies. Drawing on over two decades of engineering experience, we assist organisations in achieving zero machine fatalities by deploying fail-to-safe machine intervention control (CxDI) solutions.

Our CPS (Level 9) control standards intervene through automated and fail-to-safe machine control, preventing unsafe interactions between vehicles and personnel. The system solution incorporates the CxD, which detects potential threats and alerts operators to react. If the operator does not respond, the CxD instructs our CxDI to either initiate a crawl or bring the

machine to a stop, effectively reducing fatalities.

Through our intelligent reporting platform, SIMAC (Short Interval Monitoring And Control), Nerospec OSCON reports an average of over 600 CPS (Level 9) Stop events per week across our customers’ fleets in 2024, marking a significant decrease from the previous year. This highlights the successful adoption of technology and the resulting behavioural changes within the industry.

Expanding Reach and Impact

As the demand for safer mining practices grows, Nerospec OSCON remains committed to extending the reach of our fit-for-purpose HUB controllers beyond South Africa. Our controllers provide a universal interface for TMMs, integrating seamlessly with both intelligent and non-intelligent machines.

Approximately two-thirds of machines operating in South African mines are nonintelligent, emphasising the need for robust thirdparty vehicle interface controllers like our HUB controllers to achieve CPS (Level 9) compliance. These controllers ensure safety benefits extend throughout the entire mine, regardless of machine intelligence or production area.

Join Us in Building Safer Mining Environments

With over 5,000 successful installations and counting, Nerospec OSCON is poised to replicate our success with new clients in the African mining sector. Join us in building safer mining environments and achieving CPS (Level 9) compliance across your fleet.

Let Nerospec OSCON be your partner in implementing reliable, industry-leading CPS (Level 9) technology to safeguard your mining operations and protect your most valuable asset—your workforce.

22 Mining Business Africa |May - June 2024

Backfill valves for underground copper mines Seamless Backfill Conveyance in Extreme Conditions

Three years ago, a project at the Kamoa copper mine in the Democratic Republic of Congo showed the application of high-pressure valves in backfill conveyance. The main takeaway from the installation was that the valves have to meet the following features to excel: severe service zero cavity, zero dead space isolation, dump and diversion valves rated to 250 Bar.

By Jimmy Swira

By Jimmy Swira

Tailings disposal management has become an important operational objective, as mining companies strive to meet stringent environmental compliance requirements.

Interestingly, converting the tailings into backfill has emerged as a cost-effective way of putting the waste to good use - turning trash into a treasure of sorts if you will. The paste fills out mined-out areas underground like stopes that pose a hazard to employees and can interrupt work. Paste backfill is made by mixing a binding agent, water, and tailings, or just water and tailings. The option to use depends on a mine’s particular requirements.

An elaborate task

However, a mine faces an elaborate task in conveying the paste backfill using suitable tools like valves and pumps. This is because of the material’s abrasive and corrosive nature and high-pressure properties, which can test a product’s tolerance to the extreme.

But what works perfectly, or near perfectly (truth be told, there is no perfect product)?

Learning from a project in the DRC

It is plausible to learn from applications in practical project situations. There are scores of projects where valves have been applied for backfill conveyance. And it has worked like a charm. These could provide ample information to base on. But we reference a project where

the team involved was keen to share their details on valve requirements they were privy to. And that is the Kamoa Copper Mine project in the Democratic Republic of Congo (DRC).

Mammoth valve test

Ordinarily, performing this duty in an underground copper mine can be a mammoth test for valves, which can succumb to harsh conditions and fail, stalling progress. This is not a situation mine management would stomach with production at its peak.

The requirements

So, pump selection had to be meticulous, with no margin for error. The selected valves were to allow a mine to go deeper underground and sustain higher pump pressures. They had to fulfill requirements relating to high-pressure range, sizes, connection types, functionality, and resistance to wear.

The specifications

After careful consideration, the team recommended high-pressure valves, with the following specs - severe service zero cavity, zero dead space isolation, dump and diversion valves rated to 250 Bar. This is more or less the standard requirement of valves for the conveyance of abrasive, corrosive, and highpressure backfill in underground copper mining environments in African mining.

So far, three years after installation, the valves are still in perfect working condition. This proves that correct product specs guarantee a seamless backfill conveyance in extreme conditions.

24 Mining Business Africa |May - June 2024

Backfill valves for underground copper mines

Process & Allied Contracting Equipment (Pty) Ltd Valves

Whilst Covid-19 and lockdown may be a thing of the past, and the war between Russia and the Ukraine not making prominent headlines in the news although it is still very much going on, these factors have created a knock-on effect in terms of the increase in raw material costs, particularly for specialised valves.

Despite the challenges of trying to remain economically priced in an ever-increasing competitive market, industrial valves supplier, Process and Allied Contracting Equipment (PACE Valves) MD Charlotte Vaughan states there is a surge in tenders and procurement in the valves industry, with “Substantial growth in new builds and expansion projects across the mining sector”.

“The outlook for the valves industry in South Africa is promising. We have the right skills set, knowledge and ability to continue to grow the industry, as well as continue to meet our clients ever changing needs”, says Vaughan.

Mining Business Africa | May - June 2024 25

Backfill valves for underground copper mines

Partnership Benefits

“We have the right skills set, knowledge and ability to continue to grow the industry, as well as continue to meet our clients ever changing needs.”

While South Africa may have to deal with Country specific challenges and global interferences, both our ability to persevere through those challenges and our outlook are among the most “commendable” in the workplace globally, Vaughan adds.

“Value for money, cost-effective solutions, technical assistance and value-added service are all contributing factors to remaining successful in this business. We need to react quickly to clients’ needs and find suitable and timeous solutions to their on-site demands”.

The partnership between PACE and Australian based OEM specialist flow control solutions, Proeger, has allowed PACE to better service the Backfill Industry in Arica. PACE has become Proeger’s sole and preferred distributor for African projects and the companies collaborate on severe service paste projects. The latest of which being the backfill area for Kamoa Copper S.A. in the DRC.

Whilst this project is ongoing, all the highly specialised valves have been successfully delivered, installed and commissioned with great success.

“We have been privileged to work with like the likes of DRA and Paterson & Cooke on these projects and we look forward to continuing this working relationship for years to come”.

“We will continue to join forces with Proeger Australia, as the partnership enables us to offer a unique solution to the mines’ severe service and backfill sections as well as assisting to advance our install bases, product recognition and growth”, she says.

PACE Valves aims to continue to expand its

Corflex Engineering (Pty) Ltd

footprint both locally and internationally.

“We would like to be the forerunners in high pressure severe service and paste areas of industry, and the go-to Company for all lowpressure valve requirements. It is my goal to provide quality service, products, and technical knowledge to be able to assist our clients in improving their return on investment”.

“We will continue to put our best foot forward to grow the business further and ensure another 40 years of success”, concludes Vaughan.

“Value for money, costeffective solutions, technical assistance and value-added service are all contributing factors to remaining successful in this business.”

Corflex Pinch Valves for high and low pressures in abrasive slurry applications.

26 Mining Business Africa |May - June 2024

Secure Storage, Continuous Operations

As water is the life of mining operations, African mining companies should exercise prudence in the procurement of steel storage tanks.

Mining is a water-intensive industry, and because of some odd pattern of nature, mining operations are in water-scarce areas. Surely, this calls for the adoption and implementation of sound water management practices, more so in the current operating environment.

Unfolding developments

Predominantly, developments are unfolding, causing a mindset change in water management. First, there is an increase in mining activity to meet the demand for critical minerals such as lithium, cobalt, and graphite. Also, there is more focus on the underground environment in search of valuable ore due to declining grades in shallow areas.

Pertaining to minerals, of great interest is global data from the U.S. Geological Survey (USGS) and WRI’s Aqueduct tool. It shows that at least 16% of the world’s land-based critical mineral mines, deposits, and districts are in areas already facing high or extremely high levels of water stress.

Based on this, WRI predicts that mining operations will strain water resources, shrinking water resources for agriculture and industry. Operational challenges and risks abound for mining companies.

Sound management - a necessity

Evidently, the success of scheduled critical mining projects hinges on a reliable water supply. Consequently, sustainable water storage on site is fundamental.

On the importance of water storage tanks for business, SBS Tanks, a storage tank manufacturer, shares its views. The company explains that backup and processing water storage tanks are necessities for the manufacturing and mining industries that are heavily reliant on water. In these sectors, water is needed not only for operational activities but also for safety measures, including fire protection systems, cooling systems, and cleaning processes. The need to reduce environmental impact by reducing fresh water usage results in the further need for processed and recycled water storage.

Hence, in industries, water storage tanks are fundamental for operations. Otherwise,

an interruption to the water supply can cause downtime with a impacting heavily on productivity, reducing revenue.

Prudent decisions

Unquestionably, as water storage tanks are pivotal to mining operations in the current atmosphere, prudent decisions in the selection of suitable products are critical.

There are several tank material options available to select from, including concrete. But the most common ones are steel and polyplastic tanks. There are pros and cons to each of these, depending on the application.

Steel tanksRelating to steel tanks, the following are factors that drive choice: