4 minute read

ABB robot helps test extreme high-temperature systems

Electric aircraft close to take-off

Technology is being developed that could see electric aircraft in our skies within just 10 years. David Latimer, Chief Executive Officer of Magnomatics, explores how pressure to reduce noise and carbon dioxide emissions is driving the innovations that will make this possible.

Advertisement

It is fast becoming a matter of when, rather than if, a short-haul electric aircraft will take to our skies. The pace of innovation is accelerating as more organisations bring their research and development resources to the goal of creating the all-electric aircraft. As in the automotive sector, the aviation industry is turning to electric and hybrid technology to reduce environmental impact, as a future without jet fuel becomes a real possibility.

For example, Rolls-Royce, Airbus and Siemens are working on the E-Fan X programme, which will have a two-megawatt (2MW) electric motor mounted on a BAE 146 jet. It is set to fly in 2021.

United Technologies, which includes engine-maker Pratt & Whitney in its portfolio, is working on its Project 804, a hybrid electric demonstrator designed to test a 1MW motor as well as the sub-systems and components required. The firm says it should provide fuel savings of at least 30 percent. It should fly in 2022 and is forecast to be ready for regional airliners by the mid2020s.

Moving to electric aircraft would help the aviation sector meet EU targets of a 60 percent reduction in CO2 emissions, 90 percent less NOx and 75 percent less noise by 2050. The technology would see batteries put inside a plane’s wings instead of being slung underneath them, making the aircraft more aerodynamic.

Electric aircraft close to take-off

All of these initiatives are supported by the relevant governments. In the UK, the Aerospace Technology Institute (ATI) has been established to stimulate and steer the technical innovation required to maintain the UK as the number one in the European aerospace sector. It is set to allocate £150m per annum of funds to innovative projects and has secured a total of £3.9 billion research and technology funding.

Highly reliable flight actuator

Whether pure electric or hybrid, industry experts agree that there will also be the need for reliable all-electric actuators for control surfaces and other systems. Most large aircraft currently use hydraulics, but these systems are inefficient and carry the risk of leaking potentially harmful fluids.

Magnomatics has been working with collaborators Triumph Aerospace, Romax and the University of Sheffield to develop a highly reliable and compact flight aircraft control surface actuator.

For the more-electric aircraft, existing electromechanical actuator systems –both rotary and linear – are prone to mechanical jamming events caused by failures in the mechanical drivetrain. For example, the mechanical gearbox in the rotary topology and the screw/gearbox in the linear topologies.

These failures can be caused by a combination of shock loads, such as wind gusts or object strikes, and the kinetic energy in the rotor of the high-speed motor driving the actuator. The large mechanical gear ratio employed between the motor and the control surface has the benefit of reducing the volume/mass of the actuator motor but increases the kinetic energy stored in the output rotor of the electrical machine.

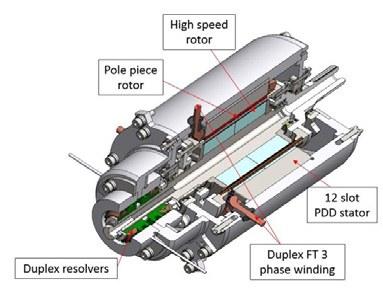

Magnomatics has designed, built and tested a number of prototype electric motors as part of the Electro-Mechanical Magnetic Actuator Systems (EMMAS) project. The electric motors use Magnomatics’ proprietary Pseudo Direct Drive (PDD) technology.

The PDD integrates a permanent magnetic motor and a magnetic gear, resulting in a very compact electric motor. When compared with current benchmark technology, the results look very promising.

Two variants of the PDD have been designed, a basic machine and a second one using a fault-tolerant (FT) stator winding and a fault-tolerant control system developed by the University of Sheffield. Even with the fault-tolerant winding, the PDD is around half the mass of current technology with a conventional winding.

The PDD has a further benefit – low inertia. This results in a very good response rate, making it suitable for military applications on unstable aircraft where a high bandwidth is required.

The low inertia and inherent torque fuse also protect the actuator system from jams or impacts. Rather than failing, the magnetic gear in the PDD simply slips until the problem is removed. This takes place without damaging the system components, which means other actuator components, such as end stops, can be light-weighted, bringing further benefits for this type of actuation system.

This slipping function has already shown to be of great benefit in difficult applications in other sectors. In the oil and gas sector, a pump driven by a Magnomatics magnetic gear has been installed in a particularly difficult oil well in California, by artificial lift specialist ZiLift, which is based in Aberdeen. This pump ran continuously for over two years whilst previous installations were failing after just 30 days.

All these features suggest that a PDD based actuator for flight control surfaces will be as reliable as the traditional hydraulic systems used today. This is a key step on the way to the all-electric aircraft. A number of aircraft manufacturers and leading suppliers are showing interest in this exciting new technology.

www.magnomatics.com

About the author:

David joined Magnomatics in February 2013 in a business development role and became CEO in December 2015. Before Magnomatics, David was Chief Executive Officer of EVO Electric, a spin-out company from Imperial College. Under David’s leadership, EVO gained a strong position in the electric and hybrid vehicle sector and it formed a joint venture with GKN Driveline in June 2011.