2 minute read

SWEEPER PRODUCT DEVELOPMENT

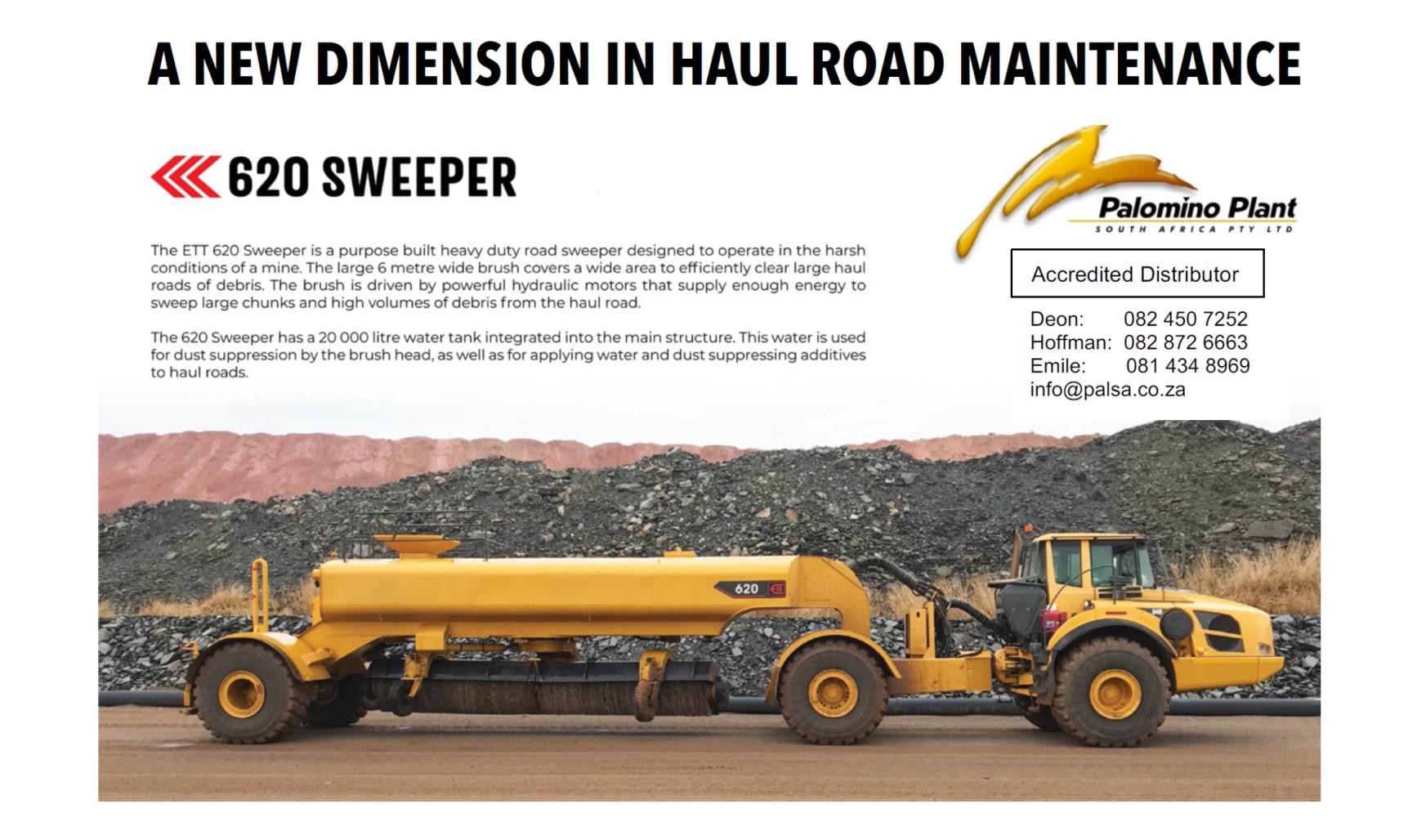

Deon Van Rensburg from Palomino Plant SA (Pty) Ltd, approached ETT in 2014 to develop a high performance mine haul road sweeper intended to deliver a significant step up in performance and safety to the process of mine haul road sweeping. The process was iniated with the placement of an order for a prototype unit based on a Bell 25mT Arculated Dump Truck. It was decided to proceed with the development process of this prototype by means of the Iterave product development model where a prototype is designed, constructed and out into service, and development takes the form of frequents and incremental improvement that would be implemented during the tesng cycle. Following this approach, we were able to quickly release a working, yet imperfect version of the prototype sweeper. Following 12 months of tesng and iterave upgrades, a second prototype was built. The second prototype had a range of upgrades developed by repeatedly go through planning, design, manufacture, tesng and evaluaon phases to rework the product and new funconality. Frequent releases of these upgrades allowed us to collect feedback and improve the product to meet all requirements. “We weren't just going to sit there and analyse something for years and years and years and years to the nth degree. SpaceX was built on 'test, test, test, test, test.' We test as we fly'”. – David Giger, a SpaceX engineer. The Ultra Sweeper became the world's highest performance off-road sweeper , however a series of components failures affected reliability of the brush head drive and trimming system . The lessons learned from early failures were used to develop the final iteraon of a 6.0m brush head and trimming system, which in turn became a part of the 620 Sweeper. The 620 sweepers were developed as a high power accelerated test bed for the 6.0 m Brush Head System. This need arose from the situaon that the mine sites that the Ultra Sweeper was being tested on were extremely difficult to access in

Advertisement

order to do proper system monitoring and product opmisaon, an essenal part of the product development cycle. The 620 Sweeper was constructed with the assistance of a large global mining company, First Quantum Minerals. A long term technical relaonship with this mining company, enabled a workable operang arrangement to be put in place where, within the bounds of the mine regulaons, engineers could have free access to the test site. The 620 Sweeper maiden launch was a tremendous success with the prototype exceeding performance expectaons by a large margin. The 620 Sweeper is integrated to a Volvo A40 because First Quantum Mining happened to have several A40's available. It was agreed with First Quantum to put two more prototypes on test, where First Quantum would provide the Volvo A40 Power Heads. These units were manufactured with several upgrades, and were commissioning in March 2020. All three machines are now in connuous operaon. The relavely rapid development of the third prototype would've been impossible without employing the iterave development process. The latest two units that are in operaon at First Quantum Mines in Zambia are again exceeding performance expectaons and have proven to be reliable .

info@palsa.co.za