7 minute read

SOLVING THE CHALLENGES OF MINING COMMUNICATIONS

Modern mine operators are increasingly recognizing the need for technologically advanced communicaon systems for both worker safety and operaonal efficiency. Keeping workers connected and informed is key to a safe and efficient workplace and communicaons play a vital role in ensuring operaonal coordinaon. We have asked Regional Director Carsten Laursen and Regional Sales Director Stuart Will from DAMM Cellular Systems how their communicaon soluons conform to these requirements.

Fail-safe voice and data communicaons

Advertisement

Why should mining companies consider a DAMM radio communicaon soluon? “DAMM fully understands the crical importance of fail-safe voice and data communicaons. We specialise in providing equipment perfectly suited to the remote, harsh environments and severe working condions of mining operaons. Our soluons provide crucial communicaons integraon between the mining site, rail and port operaons and centralised administraon, enhancing both efficiency and the safety of personnel,” says Carsten. When communicaon systems fail, mining companies have to stop operaons, which costs millions a day. The decentralized architecture of the DAMM system combined with a fully redundant setup prevent downme, even if the network is hit by lightning. Along with high availability, DAMM's system includes a wide range of other safetyenhancing features, including clear voice quality even in noisy environments, emergency calls, man-down funconality, geo-locaon services, mulple pre-empve calls, broadcast messaging alerts and direct alarm dispatch to emergency units. Carsten Laursen Regional Director

Easy to deploy, move and maintain

How are DAMM's products specifically useful for the mining sector? “Our IP65-protected outdoor base staons are built for remote areas, harsh environments from high heat and dust to rain and low temperatures. Their compact design and low weight make them easy to mount directly in masts, providing coverage for the enre mining site. In addion, their design

makes them suitable for portable deployment, e.g. on trailers that can be moved to adapt to changing mining locaons or along haul roads. Thanks to the simple and self-configuring setup, you can quickly and seamlessly expand your system when needed,” Stuart explains.

Breakthrough TCO and proven success

What makes DAMM's products especially suitable for the African region? “Not only are our products built for harsh environments and for improving operaonal efficiency and safety. We are commied to offering soluons that ensure low CAPEX and OPEX. One of the key features of our outdoor base staons is their cost efficiency. The low power consumpon saves on electricity costs and even allows a completely solar-powered soluon providing portability saving costs every day. In addion, the base staons are designed with passive cooling, which means there is no addional cooling systems requiring a power source, maintenance, or repair – indeed low maintenance is a key trait of our products. Our system is not only cost-efficient when it comes to purchasing and operang it. Due to the high reliability, you are also guaranteed a minimum of costly downme with operaons coming to a standsll,” says Carsten. Stuart adds, “We have many years of experience in providing costeffecve soluons to major players within the mining industry around the world and have delivered systems for huge operaons run by Rio Tinto, BHP, Glencore and Fortescue Metals Group (Australia), New Gold (Canada) and BUMA (Indonesia) to name but a few. We therefore have the know-how and the experse needed to support similar large-scale operaons in Africa.”

About DAMM

With its nearly 40 years in the industry, DAMM is a well-established name within TETRA radio communicaon and has built up extensive experience in delivering products that can endure the harsh environments that characterise the mining industry. DAMM's TetraFlex® soluon is 100% IP-based and comes with complete outdoor and/or indoor base staons and comprehensive features as well as integrated soware such as network management, voice and data recording and full dispatch applicaons.

To learn more about our products and soluons and how we can help you, please contact Carsten Laursen Regional Director cl@damm.dk

Stuart Will Regional Sales Director sw@damm.dk

Stuart Will Regional Sales Director

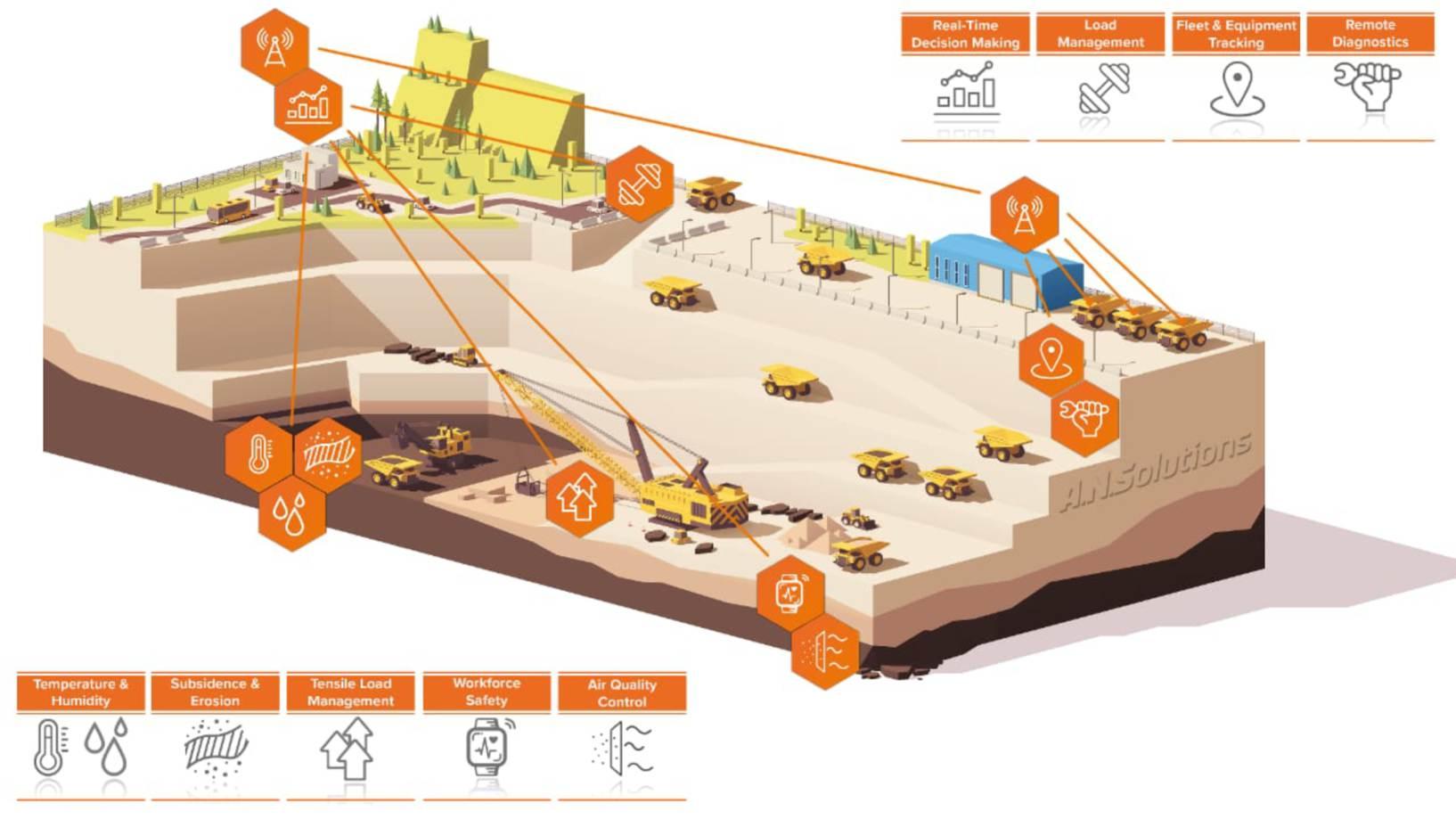

A.N. Solutions Enables Smart Mining Applications with Reliable Wireless Connectivity

Smart Sensors Improve Efficiency and Cut Costs

The mining industry has come a long way from pickaxes and shovels to sophiscated machines and tools. Yet another revoluon is sweeping the industry. Powered by wireless sensor technology, the Internet of Things (IoT) brings connecvity to every piece of equipment in the field while offering significant benefits, from enhanced safety to cost reducon and increased efficiency. Whether it's an underground or a surface mine, the miners' safety is of paramount importance. Methane gas buildup may cause an explosion. Contaminated dust and volale organic compounds (VOCs) are toxic and pose a significant health hazard. Machine operator's fague can cause an accident. By keeping a watchful eye on air quality and worker's vital signs, wireless sensor devices spring into acon when crical condions are detected. They help prevent accidents and save lives 24/7. Mining operaons require a lot of sophiscated tools and equipment. Open-pit mining requires a fleet of dump trucks and earth-moving equipment. Every mechanical failure results in costly downme and may affect many other links in the producon chain, snowballing the losses. Smart connecvity allows a company to diagnose each vehicle's health remotely, and schedule maintenance proacvely. Vehicle usage can be opmized by tracking and analyzing its performance. Ground subsidence and erosion are extremely dangerous while being everpresent in open-cast mining. By detecng minute shis, lt sensors monitor ground subsidence and provide advance warning. It is also important that the dump trucks do not get overloaded. Wheel load scales help ensure that the truck load is within the acceptable range. Fied with radio transmiers, they relay real-me data to the operaons control center.

How Sensor Network Operates

Mines use a wide variety of sensors that measure all kinds of parameters, from temperature and humidity to lt and acceleraon. However, all this valuable sensor data needs to be harvested and transmied, oen in real-me, so that it can be analyzed and visualized, and acons can be taken in a mely manner. Wireless technologies hold the key to solving this challenge. Each sensor node is equipped with a ny radio transceiver and antenna. An embedded microcontroller is its “brains.” Soware determines the mode of operaon of a sensor node and the frequency of data transmission. A sensor node can serve as a pure monitoring device or when equipped by an actuator, will perform a control funcon.

Baery-powered sensor nodes can operate autonomously for years and are easily fied even into the most hard-to-reach locaons. They offer the ulmate flexibility in the network configuraon.

Wireless Soluons that Work Reliably

A.N. Soluons specializes in developing reliable and rugged wireless sensing soluons that work in the environments that are most “unfriendly” to a radio signal, from trains to industrial equipment to mines. A.N. Soluons has been building ATEX compliant soluons and designs capable of operang in the -85°C to 145°C temperature range, which far exceeds IP67 requirements. With a large porolio of reference designs from different industries, A.N. Soluons can create a futureproof system quickly and cost-effecvely. The recent proliferaon of wireless standards makes it difficult to select the one that best fits the applicaon. A.N. Soluons will help you select the wireless protocols and components spanning 169MHz up to 5.2GHz radio spectrum to achieve an opmum range vs. signal strength, baery life, and important characteriscs, according to your requirements. Soware fine-tuning is important for a secure and efficient sensor data acquision and storage process, as well as baery life. Antenna design is a crical factor for reliable data transmission. Long baery life is the key to smooth operaons, and A.N. Soluons has mastered different baery technologies, including industrialgrade rechargeable cells, and more. Many mines have wired or wireless legacy systems in place. Replacing them completely is prohibively expensive. A.N. Soluons' experts will be able to seamlessly integrate a new wireless network with the legacy system, and combine the data collected. A.N. Soluons offers comprehensive expert services for every stage of wireless product development - from a thorough review of the current architecture and the need assessment to mapping out a migraon plan and creang a proof of concept. Combining in-depth knowledge of wireless protocols, such as IEEE 802.15.4/Zigbee, 6LowPAN, and LoRa, and their compability, with all aspects of connecvity and device management, network security, and sensor data acquision, A.N. Soluons experts will provide step-by-step guidance.

The advantages of working with A.N. Soluons are many: ● In-depth experse in all facets of IoT design; ● Its own product line of rugged IoT components; ● Rapid prototyping using 3D modeling; ● Safety and compliance cerficaon assistance; ● Extensive partner ecosystem of industry leading vendors and service providers, incl. Bosch Sensortec, Microchip, Nordic, Qorvo, Sensirion, and more; ● Flexible engagement opons and support packages; ● Uncompromising “Made in Germany” quality.

Explore our IoT soluons and contact our engineers at www.an-soluons.de.

Thomas Lerm, Founder & CEO thomas.lerm@an-solutions.de Tel: +49 351 30900 195

www.an-solutions.de

The safe and clean Direct In-line Pumping System for economic & environmental wastewater lift stations