4 minute read

LUBRICATION SOLUTIONS TO WEAR RATE REDUCTION

By Chuck Strait

Advertisement

Petron Corporaon, located in New Berlin, Wisconsin, USA, has over 50 Years of experience manufacturing high performance lubricants focusing on surface mining, underground mining, and ore processing. Petron Corporaon's specialty lubricants excel in lubricang equipment such as Draglines, Electric/Hydraulic Shovels, Loaders, Haul Trucks, and any other mobile pit equipment, as well as Crushers and all types of Mills.

Let's face it

Mining Equipment is designed to have parts wear out while sll maintaining the machine integrity. While it is beneficial that high wear items can simply be replaced, it is also detrimental if these parts wear out too oen. Early wear causes loss of upme and throughput, which negavely impacts the company's boom line. A classic example of this would be the pins and bushings used in almost all mining equipment. Petron Corporaon has recognized that the tradional lubricaon techniques and products no longer provide the protecon needed in modern mining equipment owing to their ever-increasing demands. Some historians call pin and bushing joints the first type of bearings. They have been around for thousands of years and were originally used in applicaons such as rotang wheels on wooden axles. However, in today's mining world there are hundreds of machines that use various materials and configuraons for their pins and bushings. Though material construcon has changed from the original plain wood pins and bushings, providing a lubricang film and eliminang contaminaon between the pin and bushing has not. How is Petron Corporaon different? Petron has pioneered the development of specific high viscosity lubricants that greatly reduce wear on slow moving gears, pins, and bushings. Tradionally, these applicaons were lubricated with a Mul-Purpose Grease with a soap addive. This soap, much like a sponge, holds the base oil and addives in suspension unl sufficient force is applied to squeeze out the oil into the load zone. By their nature Mul-Purpose Greases do not flow due to their high soap content. Formulang our products with primarily heavy viscous oils, in many cases above 50,000 cSt, along with a light carrier oil, allows Petron lubricants to have the characteriscs of a much lower “apparent” viscosity lubricant. This lower “apparent” viscosity lubricant will flow readily into a load zone, deposing select addives and high viscous oil molecules right where they are needed the most, while remaining viscous enough to eliminate the need for large amounts of soap to hold the oil in suspension. This lubricant film then separates even the highest loaded surfaces, greatly reducing the possibility of contact wear, while the light carrier oil washes the would-be contaminaon out of the load zone and safely away.

Wear reducon is the key

Today's mining equipment uses the most sophiscated form of bronze pin bushings, and their ability to reduce wear is impressive. Even though bronze is extremely reliable and durable, it is sll designed to be a “wear” material. The purpose of wearing is to

reduce the damage to structural steel components. The bronze bushing is much less expensive to replace than something like the loader boom arm, and, therefore, it is used as a wear material to reduce damage to the other rotang components. Typically, in these applicaons there are two types of wear on pins and bushings: A. Galling - is when excessive contaminaon builds up between the pin and the bushing surface and the load pressure forces the contaminaon into the bronze bushing. B. Impact loading – is when a sudden impact is applied to the bushing surface greater than the lubricant film can withstand causing a rupture. If proper lubricaon maintenance is pracced, the replacement and/or repair of pins and bushings can be greatly reduced. Most pins and bushings today have “lubricant grooves” on the inner diameter that aid in purging contaminaon from the bushing by forcing out unwanted materials while providing a film thickness for the pin to rotate on. These lubricant grooves can also capture contaminaon if the proper lubricaon intervals are not maintained. Therefore, wear can occur if the bushings are not purged adequately. The use of Petron Open Gear Lubricants on your pins and bushings will form the thickest lubricant film possible allowing most contaminants to remain suspended in the film unl they are purged out. This very thick film will also cushion the blow of a sudden impact keeping the surfaces apart greatly reducing the wear rate on those parts designed to “wear out.” Petron Corporaon is acvely seeking new distributors for Africa region. If you are interested in becoming a Petron Distributor, please contact Chandrasekar at rchandrasekar@petroncorp.com For more informaon about Petron Corporaon's products or services, feel free to visit our website at www.petroncorp.com or email – info@petroncorp.com

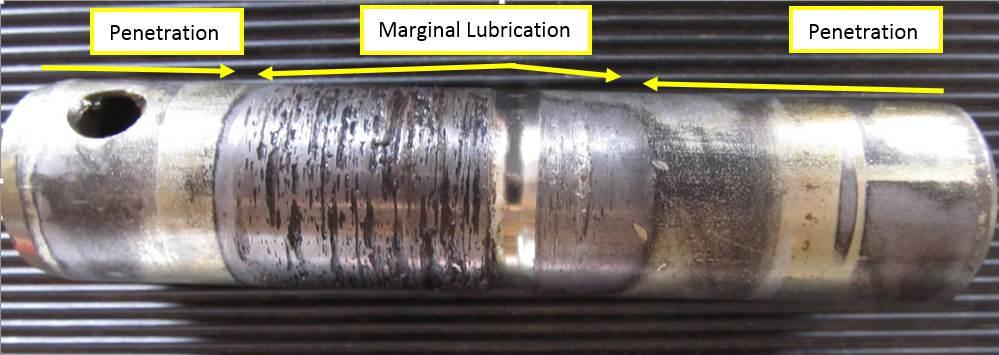

As seen in the photo above, tradional lubricants only penetrate a paral distance from the end of the pin toward the load zone, leaving the heaviest loaded secon of the pin with marginal protecon.

www.petroncorp.com lnfo@petroncorp.com