6 minute read

The Wikihouse project — Alastair Parvin

2.9. Technical integration and accessibility

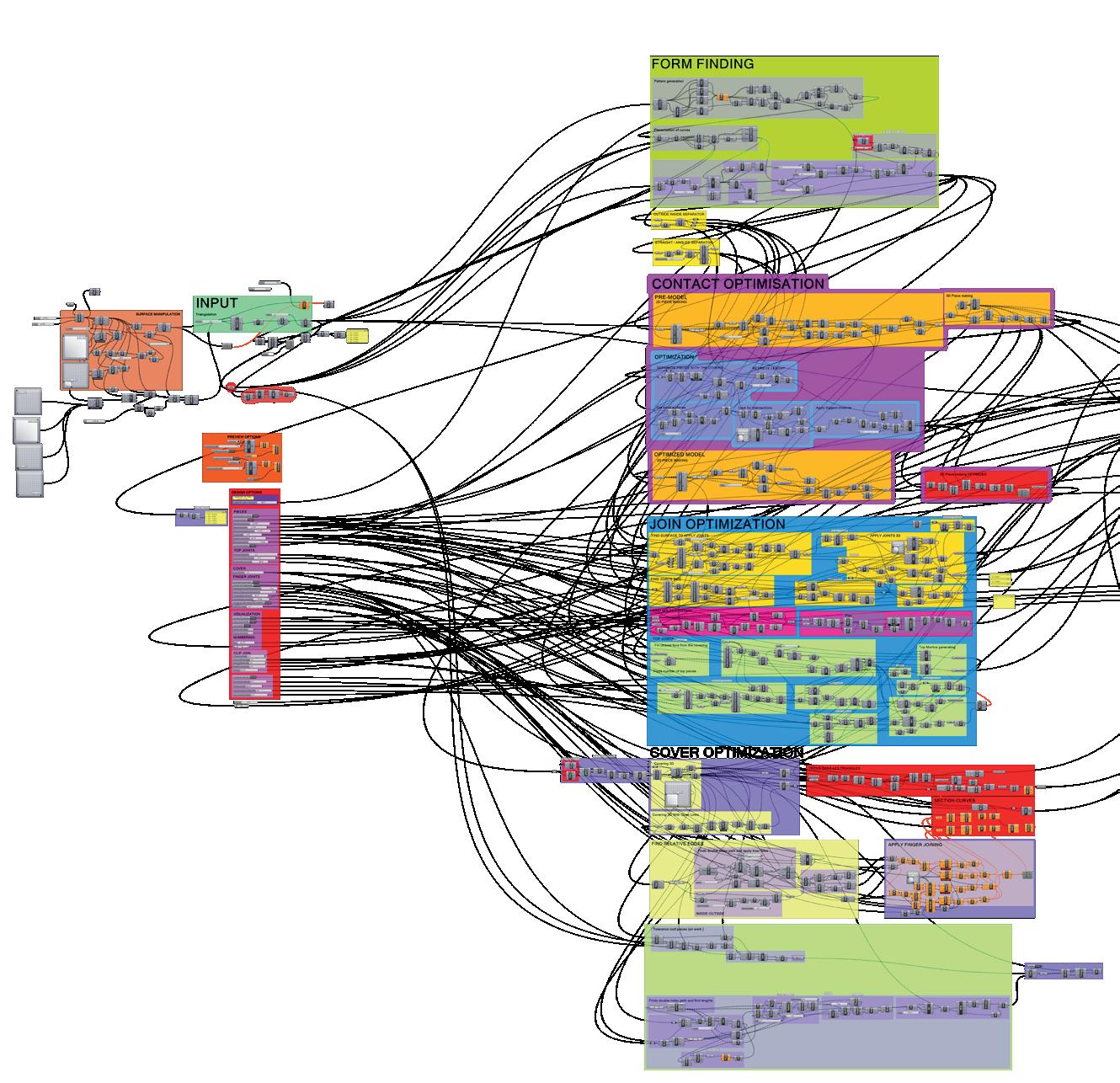

It is possible to work the wood in such a way as to obtain a finished product in a single process. The pavilion ICD/ITKE is built without nails or screws using a single connection system. By following this principle, it is also possible to develop an integrated computational design containing several different elements. This is the case for the project Wikihouse, which offers a house in kit form, to be cut to size at the CNC and assembled yourself. From the structure to the hammer, a pack of multiplex boards and a milling machine are supposed to be the only tools necessary for its realization. By returning the construction to the hands of those who inhabit it, the Wikihouse offers an awareness of the material reality of housing through personal attachment to the work done. Nevertheless, the robotic construction of housing is confronted with a whole series of constraints that make its real application limited.

Advertisement

a. The Wikihouse project — Alastair Parvin According to Parvin, architects work for the richest. He argues that a preconceived idea visualizes architects as the heads who will solve the problems of tomorrow’s world. In reality, there is a crisis and few jobs for architects. As a result, they can only work for those who can pay, the 1 % the wealthiest people in the world. Parvin believes that this model, in addition to not being democratic, is not a very coherent business strategy. He seeks a way to relate architecture to the 99 %, potential other customers. The problem is that the building is often the most expensive answer to any problem. Faced with this, he is ready to question the very foundation of the architect’s profession, building. His training has actually prepared him well to solve various issues and find innovative solutions.

Variation examples of Wikihouses25

The Wikihouse is cutted oud with a CNC. All parts are designed to be automatically associated with the standard elements they must contain 26

First functionnal prototype of Wikihouse - Wiki Farmhouse28

Integrated connection system29

Spare parts 30

Packaged parts - Wiki Farmhouse 31

On-site assembly 32 He suggests an example: a school offers 20 million books to rebuild its infrastructure, because it is contained in an old building and the corridors are too small to accommodate all the students, resulting in an absolute mess. In the end, the office did not come back with an architectural solution. Instead, they proposed to replace the single ring tone for delayed ring tones, which can make it easier for students to transit without building anything, saving millions of pounds. If this example is very specific, quite far from the subject, he points out to us that a lot of money is wasted in architectural resolutions that are not particularly adequate.

Today, architecture is perceived as something great, something massive. Cities are built by those who have the power to invest. To fight this monopoly, Parvin argues that we must build small. To bring architecture back to those who do not have it, to produce an architecture appropriate to people’s wallets, he proposes a house whose manufacturing plans are self-service. Following the path outlined by the encyclopedia Wikipedia, The Wikihouse project is an open source construction system, meaning that everyone can access 3D models online, which can be modified and improved. These plans are adaptable by users thanks to the free software Sketchup. Once the model has been adjusted to their needs, they click on a button and receive all the cutting plans necessary for its manufacture. To obtain the parts, they must inject these planes into a digital milling machine to cut them into standard plywood boards. The result is a kind of IKEA© kit, which is larger and helps us to build a house. No nails, no screws, no bolts, all the design is integrated. The interest of this concept is not only material, it is also temporal. Indeed, you only need to plan a big day and two or three motivated people, without any particular

skills, to set up the whole thing. The objective is to produce a skeleton that can then be isolated, covered and furnished according to means and desires. Moreover, since the manufacturing is based on a CNC, the house is potentially never finished, it is always possible to develop additional elements or parts. These parts that may be available in the Wikihouse, adapted to each project through parametric models. It is also possible to expand or even produce the neighbour’s residence.

« We’re moving through a world where the factory is everywhere and the design team is everyone ».29

Détail d’assemblage33

Un simple marteau suffis à assembler l’ensemble du projet34

Système de fabrication d’une Wikihouse27

Frame of a of a Wikihouse prototype 35 The few cases that have been built have shown that the process is particularly social, bringing people together around a personal project. These prototypes also allowed Parvin’s team to draw some lessons: all the parts must be humanly transportable, they must be symmetrical or clearly defined, to avoid that one makes mistakes in the puzzle or that if one misunderstands, the mistake has no impact on the result. Such an open source project reminds us that, even if we work with new technologies, we must not start from scratch, we must copy and appropriate pre-existing models. This approach to construction is not innovative, that’s how houses were built before the industrialization of the building, in the community. It is necessary to stop treating citizens as consumers, but rather as stakeholders. The project Wikihouse is also intended to become an open encyclopedia of the manufacture of everyday objects.30

« If design’s great project in the 20th century was democratization of production, I think design’s great project in the 21st is the democratization of production. And when it comes to architecture cities, that really matters1 . »31

The number of users of Wikihouse is growing and has brought together a community that experiences and shares its feelings, problems and solutions. Wikihouse would like to integrate all these paths into a parametric software capable of producing an increasingly adaptable habitat, the product of a collective intelligence. The software should provide, depending on the location, the type of material used and even

1 « si le grAnd projet du design du XXe sièCle étAit lA démoCrAtisAtion de lA produCtion, je pense que le grAnd projet du design du XXie sièCle est lA démoCrAtisAtion de lA produCtion. et quAnd il s’ Agit d ’ ArChiteCturer les villes, C’est vrAiment importAnt. »

laws relating to the location where the general shape and elements are correctly dimensioned. The project seeks to become the foundation of a new building technology. One might wonder whether it would still be necessary to hire architects. But Parvin admits that they are essential, because they are able to cope with the mass of information related to laws and implementation in general, which are the biggest obstacles to the development of the project. Wikihouse.

32

Personally, I do not believe that the legal framework is the only essential contribution of the architect. Even if it becomes possible to build one’s own house, I think it is more fruitful to see in it a renewal of the inhabitants with the environment in which they live, to make them responsible for their home. It would be interesting to observe architects collaborating or using this project. Indeed, they can provide it with original architectural solutions, not necessarily within everyone’s reach, which could also bring out the Wikihouse of his generic condition. In my opinion, there is especially potential in a Wikihouse designed by an architect and erected by its resident. It is possible to explore this potential related to the project Wikihouse through the book written by Matthew B. Crawford. He relates the issues related to the pathologies caused by the segmentation of the work process and their impacts on our current society.

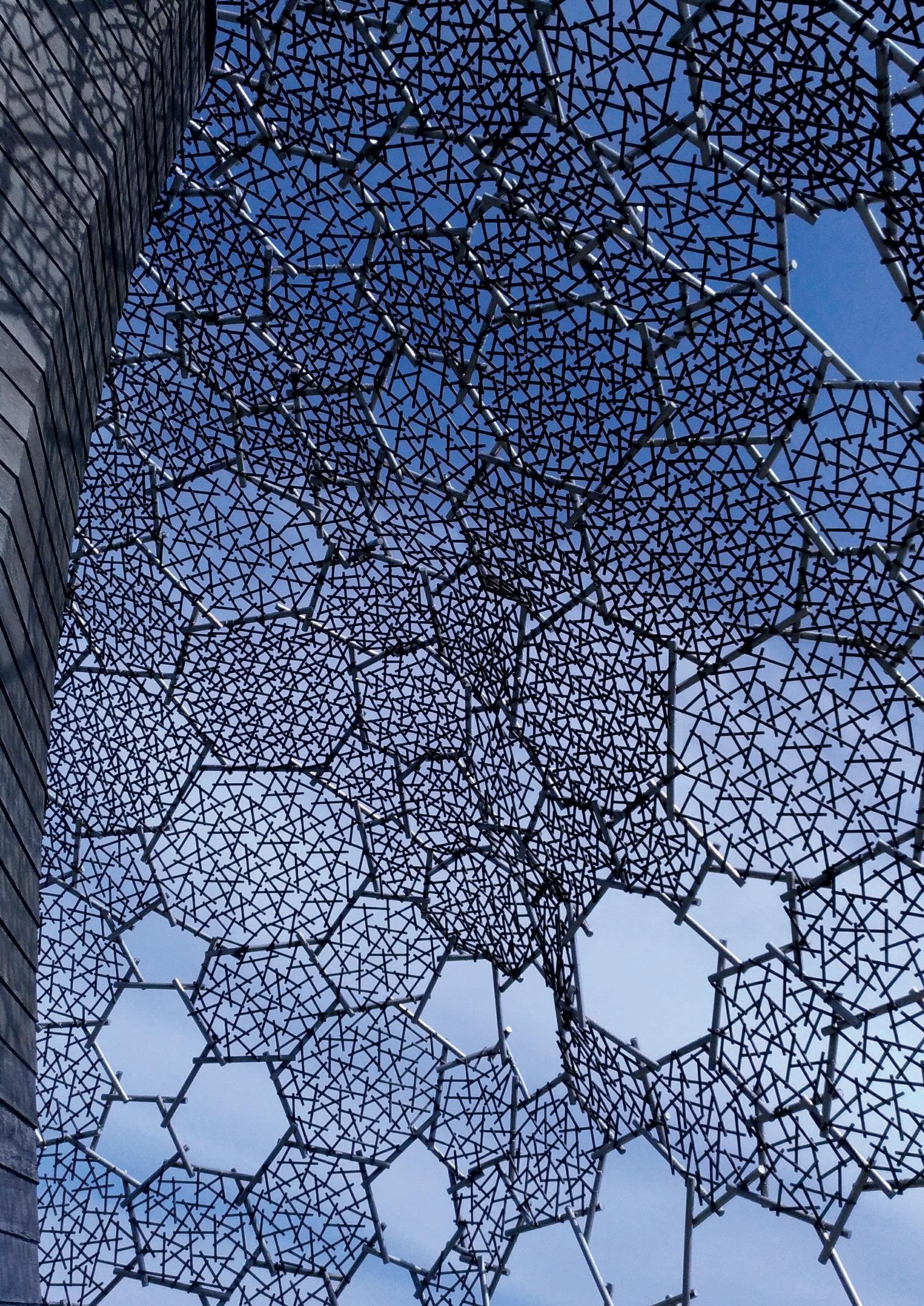

Huaxia Star Libary China 2018 Dot Architects, built with the Wikihouse system36