1 minute read

Rinus Roelof

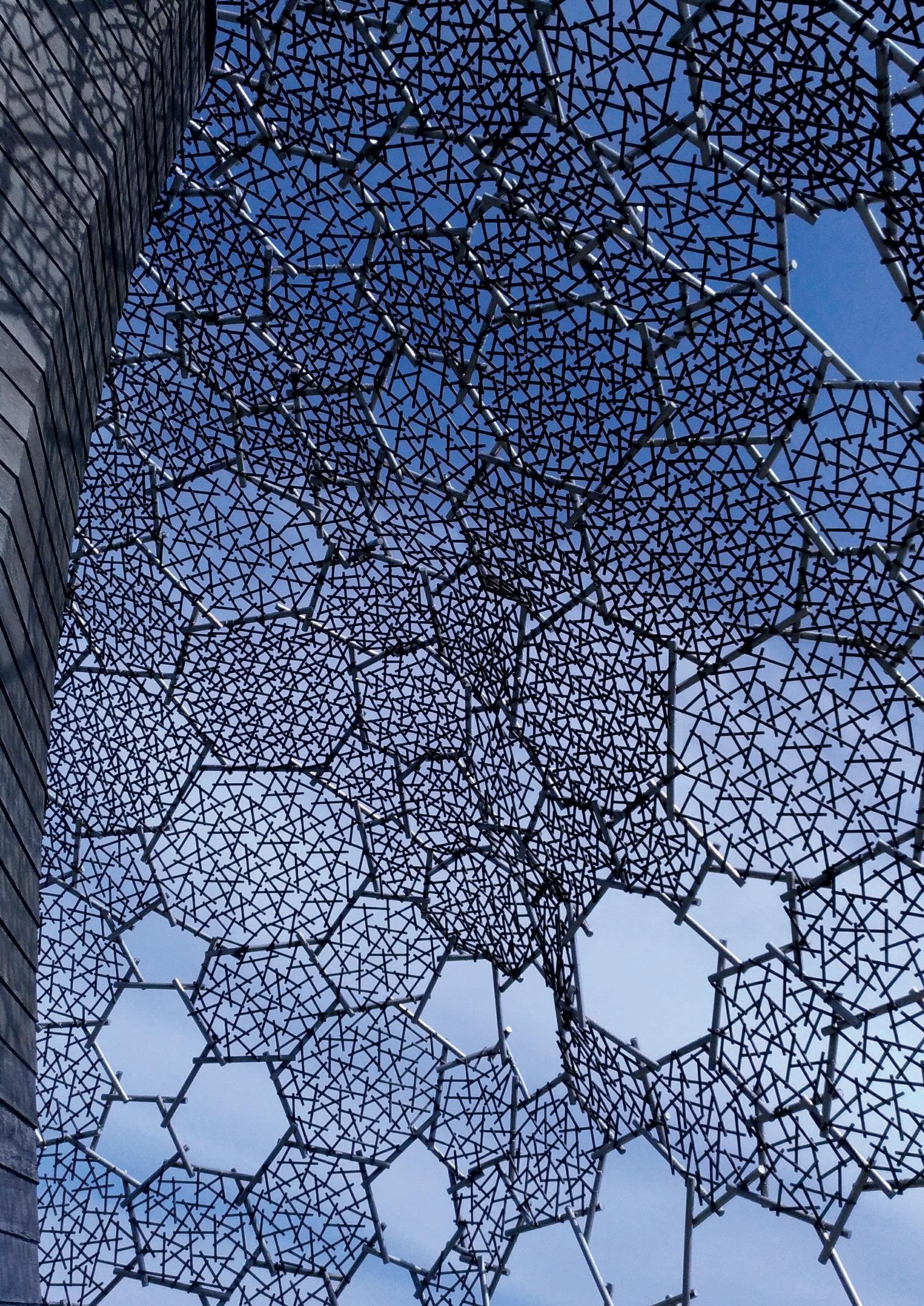

Prototype realised by Rinus Roelof71

2.14.3. Pavillons

Advertisement

Apart from the purely architectural production related to selfsupporting structures, a multitude of pavilions built by researchers, professors and students have been created following the renewal of this technique in the light of the evolution of technologies relating to architecture. It is interesting to highlight the diversity of results, made possible by the production of small and medium-scale prototypes. The pavilions are exploring the possibilities of these structures more and more deeply by dazzling each other. The outcome of my research is to propose a new one, by transforming a reference into an idea, as the following few examples have done.

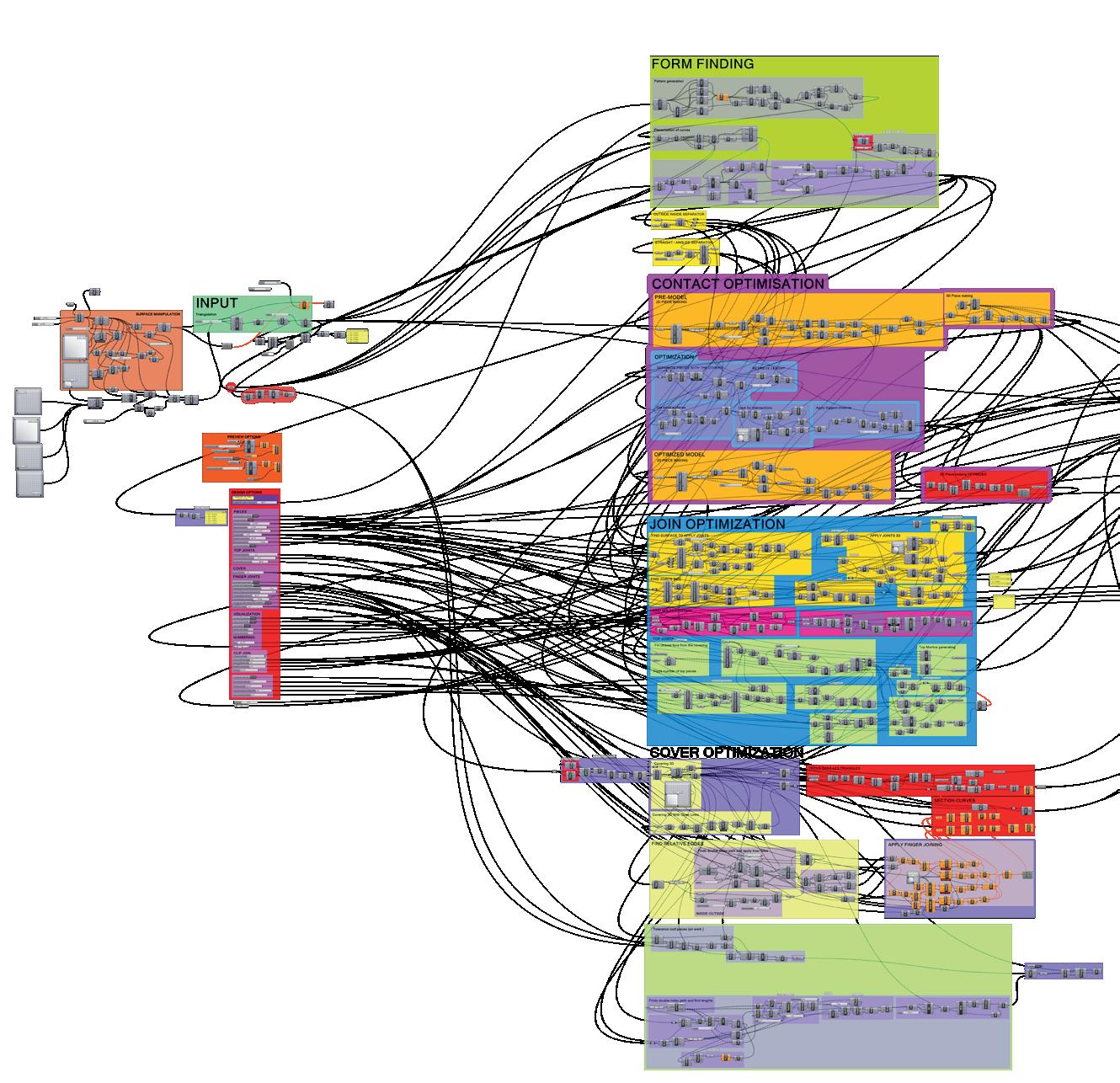

a. Rinus Roelof Rinus Roelof is a Dutch professor who studies reciprocal structures, among other things. A trained sculptor, he used his knowledge through digital processes to experiment and produce new forms. His approach has the particularity of being playful to introduce the subject. It works its structures in a generative way, i.e. it is the multiplication of an element that defines the result. He started by building domes by referring to Da Vinci’s drawings seen above. These structures hold thanks to the pressure exerted between the elements between them, in order to be able to go further it was necessary to get rid of the need for the gravitational force. He thus attempted to transform the appearance of the element itself in order to create an internal constraint to the structure. To draw them, he simply folded a model drawn on paper in order to obtain polyhedra. The shape of a part then blocks its neighbours and conversely, it results in a reciprocal system and thus self-stressed.57

Unlike the Mount Rokko Observatory, where the work is mainly focused on the motif and only includes linear elements. Many of the pavilions that will be described below follow an approach where their expression is the result of a constant dialogue between a framework and the physiognomy of its elements. This makes the production of the parts more technical, but the assembly even easier.

Prototype realised by Rinus Roelof72