More competitors. More demands. More rapidly emerging threats.

Analog Devices has a depth of industry and technical expertise that is unmatched. Together with an unrivaled portfolio of RF and microwave solutions, you can now reduce the prototype phase of design by months and get to market faster than you ever thought possible.

Editor’s Perspective

7 Standards don’t die ... By John McHale

University Update

8 Recent RPI acquisition ushers in quantum era on U.S. campus By Lisa

DaigleDefense Tech Wire

10 By Dan Taylor

Editor’s Choice Products

42 By Military Embedded Systems Staff Guest Blogs

44 Consolidated avionics improves helicopter capability By Jason Wilden, Cubic Defense

Connecting with Military Embedded

46 By Military Embedded Systems Staff

Subscribe to the magazine or E-letter

Live industry news | Submit new products http://submit.opensystemsmedia.com

WHITE PAPERS – Read: https://militaryembedded.com/whitepapers

WHITE PAPERS – Submit: http://submit.opensystemsmedia.com To unsubscribe, email your

Published by:

SPECIAL REPORT: Helicopter avionics

14 Open standards a top concern for U.S. military helicopter avionics By Dan Taylor, Technology Editor

MIL TECH TRENDS: FACE conformance and avionics safety certification

18 Verifying FACE conformance for Ada software By Benjamin M. Brosgol, AdaCore

24 The Future Airborne Capability Environment (FACE): A strategic imperative for U.S. military competitiveness By Tim Reed, Lynx

26 EMI gaskets for avionics help keep military aircraft flying high By Dominic Testo, Specialty Silicone Products

30 Enhancing military and aerospace software testing with data-driven development strategies By Ricardo Camacho, Parasoft

INDUSTRY SPOTLIGHT: Managing reduced SWaP in military avionics systems

34 Avionics databus users demand more reliability and flexibility By John McHale, Group Editorial Director

40 AI technology and USSOCOM An Interview with Shield AI's Brandon Tseng By John McHale, Group Editorial Director

FIRST UNIVERSAL POWER SUPPLY FOR ALL ARMY CMFF APPLICATIONS

Introducing the VPXtra® 400DW-IQI, Behlman’s first power supply with a wide range DC input that is fully compliant for all platforms in the Army CMFF program. This rugged, highly reliable switch mode 3U VPX unit meets a new standard of adaptability, and is backed by unmatched integration support from the Behlman team.

> Developed in alignment with the SOSA™ Technical Standard and VITA 62.0

> Delivers over 400 watts of DC power via two outputs

> 90% typical efficiency

> Features cutting-edge Tier 3 software

> System management integration via VITA 46.11 compatible IPMC

PAGE ADVERTISER/AD TITLE

29 AirBorn – Introducing Power Blade 2000W+ power module

2 Analog Devices, Inc. –Accelerating time from concept to product

5 Behlman Electronics, Inc. –No one powers the Army like Behlman

3 Cobham Advanced Electronic Solutions (CAES) – CAES. Pioneering advanced electronics

22 Dawn VME Products –Dawn single slot OpenVPX development backplanes

23 Elma Electronic –Leaders in open standards; Enabling the warfighter with OpenVPX

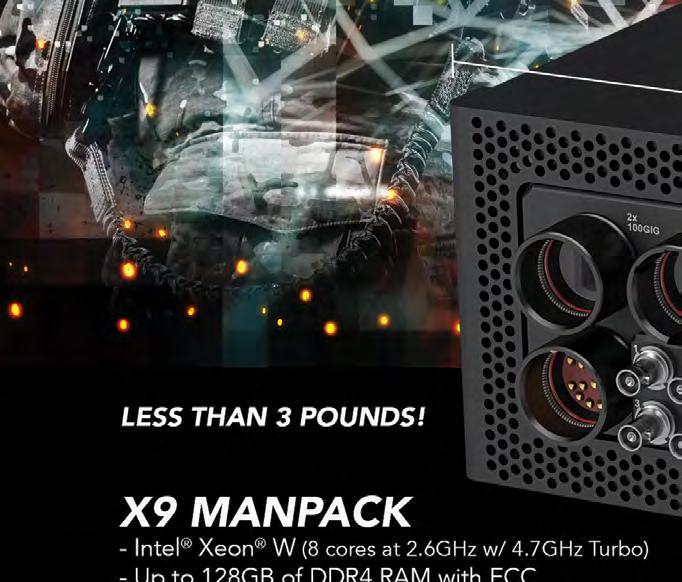

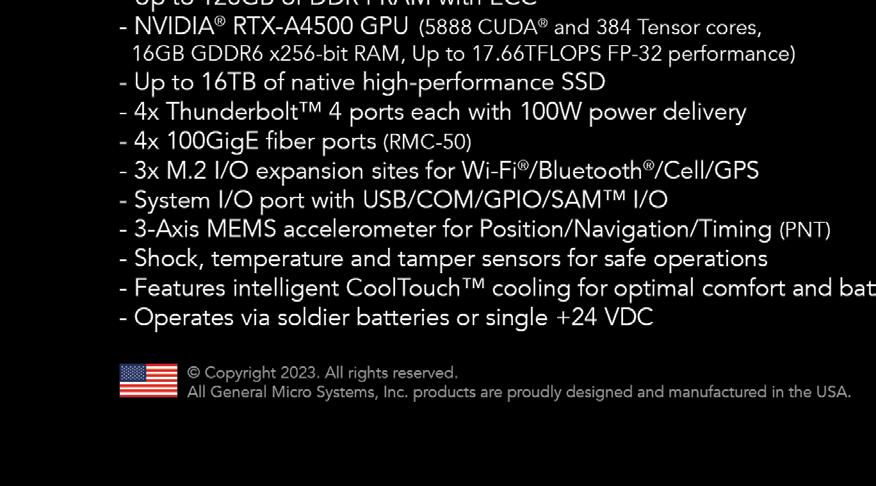

48 GMS – X9 Spider. The world's most powerful full-featured wearable AI computer

17 New Wave Design – We create precise, SOSA aligned VPX and XMC solutions for mission critical applications.

17 Phoenix International –Phalanx II: The ultimate NAS

33 PICO Electronics Inc –DC-DC converters, transformers & inductors

37 Pixus Technologies –SOSA aligned products in the slot profile configuration you need

38 Sealevel Systems, Inc. –Rugged Performance. Refined Processing.

32 State of the Art, Inc. –Reliability … the only option

9 Times Microwave Systems –MilTech Light-Weight; Mini Multiport

IEEE MTT-S International Microwave Symposium June 16-21, 2024 Washington, DC https://ims-ieee.org/

2024 IEEE Nuclear and Space Radiation Effects Conference July 22-26, 2024 Ottawa, Canada

https://www.nsrec.com/information-2024/

Uncrewed Systems Virtual Conference Powered by Military Embedded Systems Sponsored by LDRA, Mercury, RTI, & Wind River

https://tinyurl.com/mr3393rz (This is an on-demand event.)

GROUP EDITORIAL DIRECTOR John McHale john.mchale@opensysmedia.com

ASSISTANT MANAGING EDITOR Lisa Daigle lisa.daigle@opensysmedia.com

TECHNOLOGY EDITOR – WASHINGTON BUREAU Dan Taylor dan.taylor@opensysmedia.com

CREATIVE DIRECTOR Stephanie Sweet stephanie.sweet@opensysmedia.com

WEB DEVELOPER Paul Nelson paul.nelson@opensysmedia.com

EMAIL MARKETING SPECIALIST Drew Kaufman drew.kaufman@opensysmedia.com

WEBCAST MANAGER Marvin Augustyn marvin.augustyn@opensysmedia.com

VITA EDITORIAL DIRECTOR Jerry Gipper jerry.gipper@opensysmedia.com

DIRECTOR OF SALES Tom Varcie tom.varcie@opensysmedia.com (734) 748-9660

STRATEGIC ACCOUNT MANAGER Rebecca Barker rebecca.barker@opensysmedia.com (281) 724-8021

STRATEGIC ACCOUNT MANAGER Bill Barron bill.barron@opensysmedia.com (516) 376-9838

STRATEGIC ACCOUNT MANAGER Kathleen Wackowski kathleen.wackowski@opensysmedia.com (978) 888-7367

SOUTHERN CAL REGIONAL SALES MANAGER Len Pettek len.pettek@opensysmedia.com (805) 231-9582

DIRECTOR OF SALES ENABLEMENT Barbara Quinlan barbara.quinlan@opensysmedia.com AND PRODUCT MARKETING (480) 236-8818

INSIDE SALES Amy Russell amy.russell@opensysmedia.com

STRATEGIC ACCOUNT MANAGER Lesley Harmoning lesley.harmoning@opensysmedia.com

EUROPEAN ACCOUNT MANAGER Jill Thibert jill.thibert@opensysmedia.com

TAIWAN SALES ACCOUNT MANAGER Patty Wu patty.wu@opensysmedia.com

CHINA SALES ACCOUNT MANAGER Judy Wang judywang2000@vip.126.com

PRESIDENT Patrick Hopper patrick.hopper@opensysmedia.com

EXECUTIVE VICE PRESIDENT John McHale john.mchale@opensysmedia.com

EXECUTIVE VICE PRESIDENT AND ECD BRAND DIRECTOR Rich Nass rich.nass@opensysmedia.com

DIRECTOR OF OPERATIONS AND CUSTOMER SUCCESS Gina Peter gina.peter@opensysmedia.com

GRAPHIC DESIGNER Kaitlyn Bellerson kaitlyn.bellerson@opensysmedia.com

FINANCIAL ASSISTANT Emily Verhoeks emily.verhoeks@opensysmedia.com

SUBSCRIPTION MANAGER subscriptions@opensysmedia.com

Gen. Douglas MacArthur’s quote, “Old soldiers never die, they just fade away,” doesn’t exactly describe standards, but it’s close. Some standards never die or fade away. Take MIL-STD-1553 and VMEbus – both still thrive today. Who knows: Maybe Ethernet will outlast them all, as it seems to be everywhere.

MIL-STD-1553, which dates back about 50 years, is a 1-megabitper-second databus standard; it’s seen many other standards blow past it in the fast lane – like Fibre Channel and Ethernet –but still it keeps going and notching new design wins for companies that produce MIL-STD-1553-based products.

Many years ago, when I worked for a different publication and had a lot less gray hair, I penned a story called “Death, taxes and MIL-STD-1553.” All these years later, in this issue, I revisited the topic in a story on avionics databuses, found on page 34. I asked Mike Hegarty, Marketing Manager for Data Device Corp. (DDC – Bohemia, New York), whom I’ve known for decades, about why MIL-STD-1553 is still so popular.

“Death, taxes, and MIL-STD-1553, didn’t you write that?” We laughed, then he spun some gold with his next quote on why MIL-STD-1553 won’t die, but continues to thrive.

“It’s the classic definition of a dominant market standard. People use it because they’ve used it before,” he explains. “They use it because it’s in the aircraft, it’s part of the infrastructure. The idea is that as you start putting new electronics and updated systems onto aircraft, you’re not going to want to rewire the aircraft or if you do, you want to minimize it. Because the aircraft systems were all architected around MIL-STD-1553, it becomes the nervous system for the aircraft.

“And the reality is, it still works,” Hegarty continues. “It’s a highly engineered solution. It’s reliable. It’s robust and from an electrical-environmental point of view, it does very well. So, in a lot of cases, there’s no reason to change it.”

The same could be said of the venerable standard my company was founded on 40 years ago, VMEbus, which also happened to be the title of our first publication. Today the magazine is dubbed “VITA Technologies,” covering many other technologies out of the VITA Standards Organization like VPX, but it’s still printing words and paragraphs on VME.

We’ve had many titles based on standards over the decades, and while those titles may have faded away as the standard became less ubiquitous, the standards themselves still exist form a sustainment level as well as in new designs. PC/104 comes to mind.

John.McHale@opensysmedia.com

The venerable VITA Technologies has the seniority in our library, but our publications based on 21st-century standards may be our most popular. Take the Sensor Open Systems Architecture (SOSA) Special Edition, for example.

This is our 4th annual SOSA Special Edition, covering the SOSA Technical Standard, with content straight from the pages and website of Military Embedded Systems magazine, as well as information regarding the products aligned to the technical standard, all put together exclusively by our staff. The SOSA Technical Standard (rev. 1.0) was developed within the SOSA Consortium.

Part of SOSA’s popularity is the enthusiasm of the volunteers developing it, which in SOSA’s case includes not only industry but also Army, Air Force, and Navy entities; other standards groups like VITA; and major commercial semiconductor companies like Intel and NVIDIA. Every level of the supply chain has participation.

With the fervor around SOSA and DoD interest, it may be the hottest standard around today. That is, if you feel comfortable calling a standard “hot.”

Or you could say “hot off the press,” when talking about the SOSA Special Edition, which, if you received Military Embedded Systems via postal mail, you’ll notice the 2024 SOSA Special Edition polybagged with it. If you don’t have a copy, visit us online at https://militaryembedded.com to peruse the latest SOSA Special Edition.

We also produce a third publication on standards, the FACE Special Edition – which covers the Future Airborne Capability Environment (FACE) Technical Standard – which we will publish in August. To view last year’s FACE Special Edition, visit https://issuu.com/opensystemsmedia/docs/face_special edition_2023_e-mag_final

The 2024 SOSA Special Edition will also be distributed at the MOSA Industry and Government Summit at the Gaylord Convention Center in National Harbor Maryland (June 17-18).

And just a reminder: MOSA (modular open systems approach) is not a standard. It’s an approach mandated by the government to leverage open architectures and open standards like SOSA, FACE, VPX, and the like.

Standards might not be considered “hot” by some, and for other folks they may fade away. For my company, they are kind of important … so I hope those we’ve talked about don’t fade away any time soon.

In early April 2024, Rensselaer Polytechnic Institute (RPI –Troy, New York) and IBM officially unveiled the world’s first IBM quantum computer on a university campus. The IBM Quantum System One was lauded by university and company officials as key to helping the nation solve some of the world’s most complex problems, including those leveraging artificial intelligence and machine learning (AI/ML) in the military and defense realm.

The following week saw the introduction of the Defense Quantum Acceleration Act (S.4105/HR.7935), legislation aimed at stimulating the U.S Department of Defense (DoD) approach to quantum technology and advancing U.S. national security. At present, there are a handful of individual efforts in the quantum arena across the DoD, but the bill’s sponsors (Sen. Marsha Blackburn and Rep. Elise Stefanik) believe that the legislation will drive the DoD to maximize its resources and better unify the work on quantum computing at U.S. national research laboratories.

“Quantum’s impact on our national security will be considerable and we must take immediate steps to ensure the United States is the first nation to reach quantum advantage,” said Rep. Stefanik.

This bill – currently referred to the Senate Armed Services Committee – seeks to establish a framework for the DoD to optimize its approach to the development and transitioning of quantum technology by naming a quantum advisor to the Secretary of Defense to develop a strategic quantum roadmap and provide an independent budget assessment of current DoD quantum budgets to Congress, according to a DoD press release. The bill would also authorize a quantum technology testbed to enable the Defense Innovation Unit (DIU) to successfully investigate and promote near-term quantum capabilities, using the $55 million of funding it received in the National Defense Authorization Act of 2024.

Central to the U.S. government’s approach to and emphasis on quantum computing is an educated, informed, and well-trained work force.

During the RPI Quantum System One ribbon-cutting ceremony, RPI president Marty A. Schmidt stated: “RPI is building upon our longstanding collaboration with IBM to harness state-ofthe-art computing to find solutions to global challenges, while training the next-gen workforce in quantum.”

Schmidt called out Curtis R. Priem – RPI Class of 1982 and vice chair of the Institute’s Board of Trustees – as the catalyst for RPI’s

push into the research of and practical applications for quantum computing. Priem, the co-founder of computing giant NVIDIA Corp., pledged more than $150 million to establish RPI’s new Curtis Priem Quantum Constellation, a center for collaborative research that will prioritize the hiring of additional faculty leaders who will leverage the quantum computing system.

“I am extremely excited to support RPI as it moves into this important realm,” Priem said. “This investment will keep RPI at the forefront of technology and innovation, as well as lead the country in leveraging this powerful technology for the good of our nation.”

At the heart of the IBM Quantum System One at RPI is the 127qubit IBM Quantum Eagle processor, with which the company has recently demonstrated the capability to perform utilityscale calculations. IBM defines utility-scale as the point at which quantum computers could serve as scientific tools to explore a new scale of problems that remain intractable for classical methods. (Figure 1.)

A qubit, or quantum bit, is the basic unit of information used to encode data in quantum computing; enabled by the novel properties of quantum mechanics, qubits can store vastly more data than traditional bits, crack and/or harden cryptographic systems, and perform incredibly advanced computations that would take thousands of years for even classical supercomputers to complete.

As such, the hope is that they will be able to make massive, generational strides in such areas as AI, advanced materials, and space exploration.

AI-piloted F-16 “dogfights” human pilot in DARPA test

The Defense Advanced Research Projects Agency (DARPA) conducted the first-ever in-air tests of artificial intelligence (AI) algorithms piloting an F-16 fighter jet autonomously in direct combat scenarios against a human-piloted counterpart, according to an agency statement. The tests were carried out using the X-62A or Variable In-flight Simulator Test Aircraft (VISTA), a specially modified F-16, at Edwards Air Force Base.

These demonstrations showcased the potential of AI to execute complex aerial combat maneuvers independently; the milestone in the Air Combat Evolution (ACE) program marks a significant step in the development of autonomous flight capabilities within visual combat ranges. DARPA’s ACE program focuses on integrating AI into tactical aviation, with the aim of establishing a framework for ethical and trusted human-machine teaming across both military and civilian aerospace applications.

Shield AI acquires Sentient Vision Systems, forms Shield AI Australia

Shield AI, a company that develops advanced AI [artificial intelligence]-aided pilot technologies, is acquiring Sentient Vision Systems, an Australian company specializing in AI-enabled real-time situational awareness technologies. According to the Shield AI announcement, the merger is intended to enhance the company’s intelligence, surveillance, and reconnaissance (ISR) operations and provide advanced ISR capabilities necessary for addressing the complexities of modern defense and security environments.

Shield AI’s acquisition follows its previous cooperation on the Sentient Observer project, a wide-area motion-imagery solution that is part of a broader initiative to deliver cost-effective surveillance capabilities akin to those provided by more expensive drones and crewed aircraft. The integration of Sentient’s ViDAR technology with Shield AI’s Hivemind AI pilot is intended to help smaller aircraft undertake missions typically reserved for larger aircraft.

The Israeli navy conducted a test of Rafael’s C-DOME system – a naval version of the Iron Dome system – to intercept a target at sea, Rafael announced. The company stated that the test accomplished the first combat interception by C-DOME, which is currently integrated on Sa’ar 6 corvettes. C-DOME is designed to counter a variety of threats including rockets, cruise missiles, sea-skimming missiles, and drones.

Introduced in 2023, the C-DOME’s modular configuration is designed to provide advanced defensive capabilities to vessels previously unprotected or inadequately equipped for air defense, the company says, noting that it uses an open architecture design to ensure compatibility with existing ship sensors and combat management systems (CMS). It has capabilities similar to the Iron Dome, which is a series of batteries across Israel that fires interceptor missiles at incoming targets.

Figure 1 | Image via U.S. Air Force.

Figure 1 | Image via U.S. Air Force.

Next Generation Interceptor to be developed for U.S. Missile Defense Agency by

The U.S. Missile Defense Agency (MDA) chose Lockheed Martin to develop the Next Generation Interceptor (NGI), a new addition to the nation’s missile defense arsenal. According to the Lockheed Martin statement, the company will enhance the Ground-based Midcourse Defense (GMD) system with the NGI, which is designed to defend against long-range ballistic missiles from adversarial states with an interceptor that features a multiple-kill vehicle capability. Lockheed describes the NGI as a first line of defense, tip-to-tail interceptor.

The NGI program will proceed with its Critical Design Review and integrate into the broader weapon system, followed by flight testing. The first interceptor is expected to be operational in 2028.

Autonomous security drone to be jointly developed by Draganfly, Knightscope

Knightscope and Draganfly will collaborate to integrate Knightscope’s autonomous security robots (ASRs) and emergency communications products with Draganfly’s drones, Draganfly announced. The partnership is intended to enhance the functionality of Knightscope’s emergency communications platforms and its Security Operations Center user interface, with the aim of providing a comprehensive surveillance and security system capable of rapid deployment and multimodal operation, the company says.

Draganfly drones will be equipped to perform aerial surveillance and monitoring, capable of being dispatched in real-time to assess situations from above, complementing Knightscope’s ground-based technologies: “Integration of the drone solution with ASRs, emergency communication systems and the KSOC represent a major advancement in readiness and efficiency,” Draganfly officials stated. “A rapidly deployable, multimodal operation for surveillance, monitoring, intervention, and post-event evidentiary support will benefit Knightscope’s clientele and greatly elevate community safety.”

prototype completes in-water testing for DARPA

The U.S. Defense Advanced Research Projects Agency (DARPA) reports that it accomplished full-scale, inwater testing of the Manta Ray prototype uncrewed underwater vehicle (UUV) – built by Northrop Grumman – earlier this year. According to a DARPA news release, the testing, done off the coast of southern California, demonstrated at-sea hydrodynamic performance, including submerged operations using all of the large UUV’s modes of propulsion and steering: buoyancy, propellers, and control surfaces.

The Manta Ray project is intended to develop and demonstrate a new class of long-duration, long-range, payload-capable UUVs ready for long-duration operations in dynamic maritime environments; DARPA is collaborating with the U.S. Navy on the next steps for testing and transition of this technology. PacMar Technologies is now testing its full-scale energy harvesting system for the Manta Ray.

Lockheed Martin will build SOSA aligned airborne electronic defense system for MH-60R helicopter

Lockheed Martin, Intel Corp., and Altera (an Intel company) are joining forces to support the Stimulating Transition for Advanced Microelectronics Packaging (STAMP) program for the Office of the Under Secretary of Defense for Research and Engineering (OUSD R&E). Lockheed Martin will develop a low size, weight, and power (SWaP), Sensor Open Systems Architecture (SOSA) aligned airborne electronic defense system, leveraging the Altera multi-chip package (MCP2) for expected use on the U.S. Navy’s MH-60R multimission helicopter.

The Naval Surface Warfare Center (NSWC) Crane Division Strategic & Spectrum Missions Advanced Resilient Trusted Systems (S2MARTS) Other Transaction Agreement (OTA) vehicle awarded the project, which will be managed by the National Security Technology Accelerator (NSTXL). “We are excited to work with Intel, Altera, and OUSD to provide a revolutionary leap in defense systems capabilities, utilizing high-performance U.S.-built semiconductors,” says Deon Viergutz, vice president of spectrum convergence at Lockheed Martin.

Figure 3 | Image via Lockheed Martin.

Figure 3 | Image via Lockheed Martin.

Training software gets classified designation for DoD use Second Front Systems (2F), a public-benefit software company that facilitates delivery of mission-critical software solutions, announced that Learn to Win training software is now available for use by U.S. Department of Defense (DoD) Impact Level 6 (IL6, classified level) through 2F’s Game Warden DevSecOps platform and secure cloud hosting environment. According to the 2F announcement, Learn to Win training software training modernizes on-the-job training, enhances proficiency, and accelerates mission-critical learning for DoD-connected users by enabling personnel to access training on mobile, tablet, and desktop devices.

Learn to Win is the first application to reach IL6 – specifically designated for classified information, up to and including information classified as SECRET – through the Game Warden platform. “Being able to deploy mission-critical training in a rapid and secure way is a strategic imperative for our military. Leveraging Game Warden has helped us achieve that goal for our 20+ DoD customer organizations,” said Andrew Powell, Learn to Win’s Co-Founder and CEO.

Harris Technologies to build EO/IR payloads

L3Harris Technologies won a contract worth $414 million from Boeing subsidiary Millennium Space Systems to build and equip electro-optical/infrared (EO/IR) payloads for the Space Development Agency’s (SDA’s) Fire-control On Orbit-supportto-the-war Fighter (Foo Fighter) program. The critical sensor technology will outfit the SDA’s constellation of eight satellites. The Foo Fighter satellite system will use fire-control quality sensors to track specific threats that are not currently tracked by the existing constellation. The Foo Fighter satellites will prove out advanced sensor technology to detect and track hypersonic missile threats as part of the DoD’s larger missiledefense architecture. “As global threats continue to rise, these experimental Foo Fighter satellites will test new technologies to fill potential missile-defense capability gaps within the Department of Defense portfolio,” said Ed Zoiss, president of L3Harris Space & Airborne Systems. The infrared payload work will be performed at the company’s Wilmington, Massachusetts facility.

Army cancels EW tool contract, will focus on software modernization

The U.S. Army recently announced the cancellation of the Electronic Warfare Planning and Management Tool (EWPMT) task order competition under the RS3 Enterprise contract, a decision officials say was prompted by evolving requirements and a strategic realignment within the program.

According to the Army’s press release, moving forward, the Army will continue to prioritize its service-specific EWPMT fielding of current capability and will also focus on EWPMT software architecture modernization. Program Executive Office - Intelligence, Electronic Warfare, and Sensors (PEO IEW&S) is working on a pilot program as part of the architecture modernization in collaboration with the United States Marine Corps (USMC), shifting EWPMT’s electromagnetic warfare and spectrum management capabilities to the Tactical Assault Kit (TAK) framework. This effort is being led by the Electronic Warfare Integration (EWI) product management office.

Boeing won a $178 million contract from the U.S. Air Force for the production of seven additional MH-139A helicopters, along with sustainment and training support, which increases the total number of MH-139A aircraft ordered by the Air Force to 26. In its announcement, Boeing said that additional aircraft are at various stages of production, with deliveries of the first Low Rate Initial Production (LRIP) aircraft anticipated this summer.

The MH-139A, known as the Grey Wolf, took its initial flight in December 2023 and is currently undergoing further testing. The MH-139A is a versatile helicopter adapted from Leonardo Helicopters’ AW139 that can be configured with an array of custom military equipment, supporting a range of missions including patrol, search and rescue, and the transport of troops and cargo.

Figure 5 | Learn to Win has earned a classified designation for DoD users leveraging its training software. Image via Second Front Systems.

Figure 6 | Shown: the MH-139 A helicopter. Photo via U.S. Air Force.

Figure 5 | Learn to Win has earned a classified designation for DoD users leveraging its training software. Image via Second Front Systems.

Figure 6 | Shown: the MH-139 A helicopter. Photo via U.S. Air Force.

U.K.’s first jet-to-jet teaming trial demos crewed-uncrewed cooperation Qinetiq conducted what it called the first crewed-uncrewed teaming trial in the U.K., demonstrating direct cooperation between a manned jet and an autonomous drone. In its announcement, Qinetiq noted that the trial –which took place at Boscombe Down in Salisbury and the MOD Hebrides range – involved a QinetiQ jet and a modified Banshee Jet 80 uncrewed aerial system (UAS). The drone, operating autonomously, received and executed commands from the crewed aircraft at speeds of up to 350 knots (402.7 mph). The company said that its technology includes QinetiQ’s Airborne Command and Control for Swarm Interoperable Missions (ACCSIOM), which facilitates communication between manned aircraft and drones using NATO’s standard Link 16 datalink. The trial, said company officials, marks a step forward in integrating crewed and uncrewed systems within the U.K.’s existing combat air fleet, which aligns with broader defense strategies aiming to incorporate advanced autonomy in military operations.

AI-assisted optronics consortium formed for EU

The European Commission signed a Grant Agreement for the launch of the STORE [Shared daTabase for Optronics image Recognition and Evaluation] collaborative research project, to be coordinated by Thales and funded by the EDF (European Defense Fund). The project brings together a group of 20 partners (made up of manufacturers, SMEs, and academics) from eight European Union member states and Norway with the aim of building a shared image database secured by the latest advanced technology and developing and evaluating artificial intelligence (AI) algorithms used in data analysis of ground platform imaging systems. According to the Thales announcement, STORE will be the foundation for Europe’s first shared, scalable database of defense imagery and explore different algorithm solutions for threat detection. It will specifically address issues of data governance and the cost-effective development of sovereign technologies. By combining optronic sensors with AI-based analysis techniques, STORE is intended to set up future ways of augmenting warfighters’ perception of the battlefield.

DSP hardware to be provided by Mercury to BlueHalo for U.S. Space Force program

National-security engineering firm BlueHalo selected digital signal processing (DSP) hardware from Mercury Systems to support the U.S. Space Force (USSF) Satellite Communication Augmentation Resource (SCAR) program. Under the agreement, Mercury engineers will provide a field-programmable gate array (FPGA)-based common signal acquisition and digital beamforming solution for BlueHalo’s BADGER system, a multi-band deployable ground communications system that simplifies mission operations through agile and re-configurable beamforming tiles.

BlueHalo won the $1.4 billion SCAR contract in 2022 by the Space Rapid Capabilities Office (SpRCO), a direct reporting unit of the USSF. Last year, BlueHalo demonstrated target tracking and processing of signals using Multi-band Software Defined Antenna (MSDA) tiles deployed on its BADGER product. Mercury is currently delivering hardware, based on its Quartz RFSoC and Navigator Design Suite commercial product offerings, against an initial contract award received from BlueHalo in 2023. Under the new production agreement, Mercury engineers will deliver subsystems for additional BADGERs systems throughout 2024.

Domestic battery tech supply chain to get boost from DIU contract

Energy-storage provider Stryten Energy reports that it received a contract award from the Defense Innovation Unit (DIU) Family of Advanced Standard Batteries (FAStBat) project to develop and evaluate a prototype 6T lithium-ion battery and potentially extend the technology to other cross-service platforms. The DIU’s FAStBat program – intended to address the supply-chain, cost, and life cycle challenges that pose barriers to the widespread adoption of lithium-ion technology in the wider U.S. Department of Defense (DoD) – seeks to support the domestic growth of manufacturing capacity to underpin the U.S. defense industrial base.

Scott Childers, Vice President of Essential Power at Stryten Energy, said of the award: “Stryten Energy is developing domestically owned, cuttingedge technology to improve ground vehicle reliability and efficiency. Through this contract award, we will strengthen U.S. supply chains and provide reliable energy storage technology for the warfighter.”

Figure 7 | QinetiQ tested the U.K.’s first crewed-uncrewedteaming demonstration with an autonomous jet drone. Image via Qinetiq.

Figure 7 | QinetiQ tested the U.K.’s first crewed-uncrewedteaming demonstration with an autonomous jet drone. Image via Qinetiq.

If a U.S. military helicopter pilot could time-travel from the year 1990 to today, that displaced pilot probably wouldn't recognize modern cockpits. Instead of switches and buttons, today's platforms increasingly use sleek displays and customizable dashboards, depending on the mission. Open systems and modular architecture are behind much of this shift.

Modernizing helicopter avionics systems is a different engineering challenge than in a fixed-wing aircraft, especially from a size, weight, and power (SWaP) perspective as space is more limited in rotary craft cockpits. However, similarities also exist when it comes to leveraging open architectures and a modular open systems approach (MOSA) strategy with software and hardware.

Open systems at the forefront

When it comes to designing future avionics for helicopter platforms, the message from the military has been clear: no more black boxes.

Mississippi Army National Guard personnel perform aerial maneuvers in an AH-64 Apache. Photo: Army National Guard Sgt. Jovi Prevot.

“I would say the number one thing we’re looking at from a rotary-wing avionics perspective is open systems,” says Luke Schmidt, senior director of business development at RTX subsidiary Collins Aerospace (Charlotte, North Carolina). “This really started with Congress saying, ‘Hey, all platforms are going to be open.’ And so we’ve taken that seriously.”

Schmidt says a big catalyst for open systems is the U.S. Army’s Future Vertical Lift (FVL) plan to develop five different sizes of aircraft to eventually replace the service’s UH-60 Blackhawk, AH-64 Apache, CH-47 Chinook, and OH-58 Kiowa helicopters.

RTX has been focused on “really understanding the requirements of that and what does open mean, from a requirements perspective,” he explains. “We spent a lot of time on working through that with the Army.”

The basic message from not just the Army but from the U.S. Department of Defense (DoD) is to leverage MOSA in all new platforms and technology upgrades.

“We’re seeing opportunities to open up – partially – on some of the current fleets such as the Blackhawk and the Chinook, and potentially pieces of the Apache,” he says. “The DoD is trying to get away from this black box mentality. There’s always going to be a chassis, but it’s what inside the chassis and the standardization of the chassis. So you can quickly pull a card out and put a new card in, and go iterate quickly on the software. That is really where our focus is.” (Figure 1.)

Lockheed Martin, manufacturer of the H-60 and H-53 helicopter platforms via its subsidiary Sikorsky (Stratford, Connecticut), says in a statement that open standards are key to their designs.

“Lockheed Martin continues to align with our customers in the application of MOSA standards to existing and future 21st-century security solutions,” a spokesperson says. “This mission-first approach enables rapid, affordable aircraft avionic insertion as technology or mission requirements dictate.”

The spokesperson adds that achieving the benefits of open systems goes beyond data communication to power, thermal, and environmental requirements, which must be “comprehensively and unequivocally met across all missions.”

Flying today’s helicopters certainly look a lot different than they did a quarter century ago. Today’s platforms feature digital displays similar to what might be seen in modern consumer vehicles. RTX showcased a simulator at the Sea-Air-Space exposition in April 2024 that enabled the pilot to toggle between different displays showing different information, such as fuel or armaments or situational awareness information depending on what the pilot needs at any given time.

“Situational awareness is an area we focus on a lot, whether it’s larger displays or helmet technology,” Schmidt says. “How can we bring the right situational awareness to the pilot so they can effectively fly the aircraft and manage the battle and the mission that they’re on? It’s about sensors and how we provide that information to the pilots so they can make the right decision at the right time.”

New technologies on the horizon could change the game even more for pilots five to 10 years from now. Schmidt says RTX is looking at helmet technology and helping pilots operate in a degraded visual environment, which has been an ongoing problem for the services.

“I’m a former Army pilot myself, so if we’re able to crack that code – that degraded visual environment and digital night vision – I think that’s what can be a gamechanger,” he says. “It’s important especially knowing the type of environments we ask our helicopter pilots to fly in. It’s not always just about landing in a dusty environment. Sometimes it’s flying through fog.”

Tiltrotors the future?

Tiltrotor platforms can offer military users so much in the way of versatility and agility: The interest in these platforms started at the turn of the century with the V-22 Osprey for the Marines, Navy, and Air Force Special Operations, but the Army has also bet big on this type of platform with its recent selection of Bell’s V-280 Valor for its FVL program. The platform beat out a more conventional helicopter design from Boeing and Sikorsky.

Bell Textron received a $1.3 billion contract in December 2022, which includes $232 million to be spent on continuing preliminary design and development of virtual

prototypes of the aircraft, according to an Army statement.

“The new aircraft will extend the reach of U.S. forces’ air assault missions while enabling ground forces to conduct decentralized operations at farther distances,” according to a Bell statement. “The aircraft will provide greater speed, range and survivability.”

The Army’s requirements call for a platform that can fly at 6,000 feet in high temperatures with up to 12 passengers and travel more than 1,700 nautical miles without refueling. (Figure 2.)

The need for pilots to alternate between tiltrotor and conventional helicopter platforms makes commonality and open systems all the more important, Schmidt says.

“There could be a lot of commonality there, and I think that’s important, especially if pilots are going from

Sponsored by Aitech, Curtiss-Wright, and Intellisense Systems

In this webcast, experts discuss how modular open systems approach (MOSA) strategies like OpenVPX and the SOSA and FACE Technical Standards take advantage of commercial off-the-shelf (COTS) parts, address the hardware and software solutions gap within electrical power systems, and enable reduced size, weight, and power (SWaP). (This is an archived event.)

Watch this webcast: https://tinyurl.com/2wfzzwxk

one platform to another,” he says. “It’s really less about that type of helicopter and more about what the flight deck looks like, which can be pretty common despite being different types [of helicopter].”

Sustainability and affordability still a focus

The end user also wants improved sustainability and affordability of platforms. MOSA eases that path by enabling rapid, lower-cost upgrades to the platform versus having to take an aircraft offline for several months to do a major modification or upgrade.

“Open systems is a way the military and the DoD are looking at how they can decrease their sustainment costs on these platforms,” Schmidt says. Another request is that the services want to “fly before they buy,” which plays into the affordability concern and puts pressure on the defense industry to be able to quickly demonstrate capabilities under

development without having to rely on a PowerPoint slide, he adds.

“Whether it’s a display, or software, or a card – we want to show them our stuff,”

Schmidt says. “I think that goes a long way with the DoD when we’re willing to bring money to the table. We’re not expecting the military to pay for everything.” MES

FACE conformance and avionics safety certification

The Future Airborne Capability Environment (FACE) approach is a government/industry initiative, managed by the FACE Consortium under the auspices of The Open Group. Its goal is to reduce software development/deployment costs through source code portability and reuse and thereby avoid vendor lock-in. A key element of the FACE approach is an official process and test suite for verifying that software conforms to the requirements specified in the FACE Technical Standard. However, this process currently does not easily accommodate Ada, a language with a long history of successful usage in safety-critical airborne systems, both military and commercial. There is a solution to this hurdle, however: a practical approach to FACE conformance verification for Ada code (both Ada 95 and Ada 2012), in particular for software that is not part of the underlying operating system.

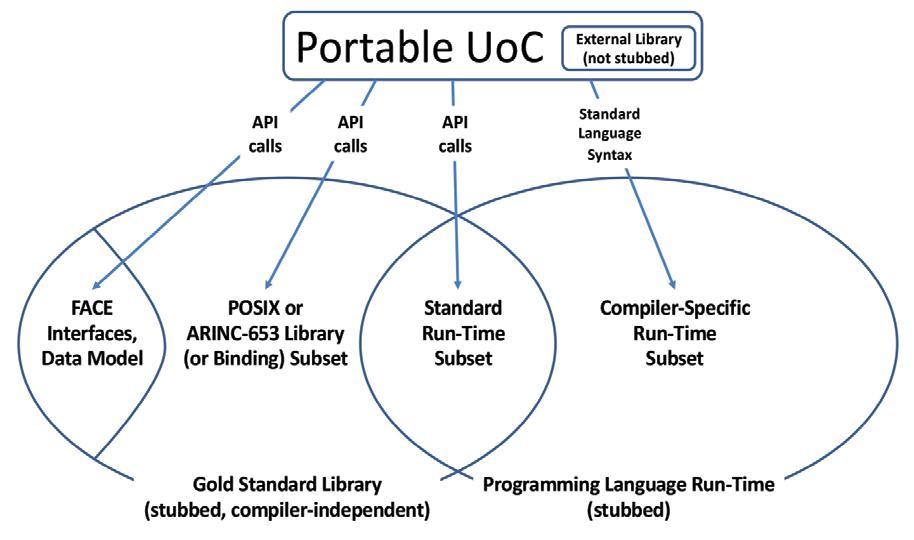

First, a bit of background, or “FACE Conformance Verification 101.” The Future Airborne Capability Environment (FACE) Technical Approach is based on several elements:

› a segmented software architecture that separates portable from platform-specific components

› an expressive and language-agnostic data modeling technology that ensures a consistent interpretation for data communicated across components › tiered “profiles” and “capability sets” that impose safety-oriented restrictions on standard software interfaces and language features

Although it is focused on portability and does not address functionality or assurance requirements, the FACE approach accounts for the fact that in practice, an airborne system comprises components at varying levels of safety sensitivity. The FACE Technical Standard thus defines subsets of standard application program interfaces

Photo courtesy U.S. Department of Defense/U.S. Air Force.

(APIs) – in particular POSIX and ARINC653 – at several levels (called profiles). In increasing order of criticality, from most permissive to most restrictive, these are General Purpose, Safety Extended, Safety Base, and Security. Analogously, the FACE Technical Standard defines subsets of standard language features for C, C++, Ada 95, Ada 2012, and Java (“capability sets”): General Purpose, Safety Extended, and Safety Base/ Security. As an example, the predefined generic package for unbounded strings can be used in the General Purpose capability set for both Ada 95 and Ada 2012, but because of its dependence on dynamic memory management it is excluded from the Safety Extended and Safety Base/Security sets.

To verify that a candidate software component – or in FACE terminology a Unit of Conformance (UoC) – meets the requirements defined in the FACE Technical Standard, the FACE Consortium has established a rigorous process that relies heavily on a Conformance Test Suite

(CTS). The specifics depend on whether the UoC is part of the underlying operating system (OS), as the OS implementation is necessarily platform-dependent and does not have the portability requirements of application code. Going forward, we focus on portable components, with the term “UoC” referring to software that is not part of the OS.

Because the UoC might have proprietary or classified content, an underlying principle for FACE conformance is that the UoC supplier should not be required to expose the source code. This principle constrains the conformance procedures and makes it unlike other software assurance standards, such as DO-178C. Indeed, the key property checked by the CTS is that there are no uses of language features or external interfaces outside of the ones permitted by the capability set and profile targeted by the UoC. This property can largely be verified by link-time tests. In brief:

› The UoC supplier compiles the source code with a toolchain (either a native or cross development environment). The header files (C and C++) or compilation unit specifications (Ada) should be the same as those used for the Gold Standard Library (see Figure 1).

› The CTS generates the permitted run-time libraries for the toolchain’s target platform, based on the selected profile and capability set. These are stubbed libraries (interfaces only, null code bodies) comprising the following (Figure 1):

• FACE interfaces and data model

■ APIs for FACE services such as IO and inter-UoC data communication that are permitted by the targeted profile, together with APIs generated for the UoC’s data model

• POSIX or ARINC-653 library

■ The APIs from these standards that are permitted for the targeted profile

• Standard run-time subset

■ The APIs defined by the language standard that are permitted by the targeted capability set

• Compiler-specific run-time (CSRT) support

■ APIs that are invoked from the compiled code and which implement run-time functionality that is expressed in standard language syntax (e.g., threading, memory management, and exception handling)

› The CTS attempts to link the UoC object code against these stubbed libraries.

The CTS generates a report with one of three possible outcomes:

› Success. The submitted UoC object code links successfully against the above libraries and does not use features that are permitted but have usage restrictions. The UoC is considered to have met all FACE requirements that can be tested by the CTS. However, some FACE requirements are feature restrictions based on language syntax rather than run-time library support. If the UoC uses such a feature, it may still link successfully against the CTS libraries but is not necessarily FACE conformant. For such requirements the UoC supplier needs to demonstrate, by providing the results of source-code inspection, that the UoC meets the restriction(s) that are not detected by the CTS.

› Inspection required. The submitted UoC object code links successfully against the above libraries and uses a feature that is permitted but has usage restrictions. In this case the UoC supplier needs to substantiate the usage through inspection (of design or code).

› Failure. A failure is reported if the UoC object code fails to link. If there are link errors with unresolved symbols, then the UoC supplier will need to either make appropriate corrections for a subsequent conformance verification attempt, or else provide the relevant additional libraries to resolve the symbols and explain why these libraries should be permitted. (As an example of the latter, if the UoC contains code in both C and Ada that meet the FACE requirements, then the object code in either of these languages will fail to link against the libraries supplied for the other language. The UoC supplier can provide the needed libraries and must substantiate their inclusion.)

For a formal conformance verification, the UoC supplier needs to demonstrate a successful CTS execution and provide the necessary source inspection evidence to an agent from an organization approved by the FACE Consortium as an official Verification Authority.

The challenge for Ada

For C, and to a large extent for C++ (Java introduces some unique issues and is outside the scope of this discussion), the CTS process works effectively: the compiler-specific run-time subset is fairly minimal, for example including numeric routines implemented in software rather than hardware. But for Ada, this library is much more extensive. An Ada program expresses run-time functionality such as threading not by invoking a standard API (e.g., pthread_create) but rather by using standard programming language syntax that is compiled into calls on subprograms in the CSRT.

Furthermore, it is unrealistic to expect that the features supported by a CSRT will exactly match the features allowed in the targeted capability set. FACE conformance requires the library to supply at least the permitted functionality but permits it to provide more. The challenge for the CTS is to account for several factors:

› The CSRT for a given Ada toolchain will support some features that are prohibited by the targeted capability set (this is also true for C and C++, since some capability set restrictions are unrelated to run-time APIs)

› To show the absence of these features from the UoC, source inspection evidence is required

› The specific features subject to inspection will vary across Ada toolchains

The CTS is flexible enough to be used for verifying FACE conformance for Ada UoCs; however, the process is not clearly defined. Ad hoc procedures need to be used to generate the relevant stubbed libraries, to demonstrate that these libraries are acceptable, and to determine what must be verified by inspection. The overall process has proved to be rather clumsy in practice.

Working within the Operating System Subcommittee of the FACE Technical Working Group, an Ada Conformance Tiger Team led by AdaCore has prepared a practical solution. The proposed approach uses the current CTS as supplemented by two main elements:

› Toolchain assessment package. A test suite comprising Ada code that violates the FACE capability set requirements and a script that attempts to invoke an Ada toolchain to compile and link each test against applicable run-time libraries.

› Toolchain support package. Documentation and other artifacts needed for adapting the CTS so that it generates the needed run-time libraries and performs the link-time testing of the submitted UoC object code

Toolchain assessment package

Toolchain Capability Assessment Test Suite (TCATS): This is a test suite derived from the FACE capability set requirements. In general, a given requirement specifies restrictions on one or more language features and thus yields multiple tests. Each test is a legitimate program in the full Ada language but exercises a feature that violates the requirement.

Comprising well over 100 tests, the TCATS covers all the capability sets and both Ada 95 and Ada 2012. An example illustrating a FACE requirement and one of the resulting TCATS tests is shown in Figure 2. The tests themselves are vendor-neutral, but the results of compiling and linking the tests will vary based on the toolchain and its CSRT.

TCATS results worksheet (template):

This Excel file is a spreadsheet that, when completed, will show how a given toolchain processes the TCATS. Each TCATS test is represented by a row in the spreadsheet. For each row, prefilled columns specify a unique ID for the test, the wording of the requirement from which the test was derived, and the capability set(s) and Ada language version(s) for which the test is to be used. An additional column – the result of submitting the test to the toolchain – is blank.

Toolchain invocation script: This script is a standard Ada program (both Ada 95and Ada 2012-compatible) that takes as input a listing of all the TCATS test files and produces as output a text file documenting the toolchain’s ability to detect the restriction violations embodied in the tests. The script invokes an Ada toolchain on each test and checks whether the test was successfully compiled and linked. If a test fails to compile, or if it compiles but fails to link, then the script identifies the associated restriction as being verified by the CTS; otherwise, the restriction is noted as requiring verification by inspection. These results are captured in the output file.

The script invokes a nonproprietary Ada toolchain on one of the authorized host conformance verification platforms, namely the GNAT GPL 2017 edition on Windows 10. This version of the GNAT technology has appropriate licensing for use with the CTS, and it supports both Ada 95 and Ada 2012. The script is readily tailorable to other Ada toolchains and other native or cross platforms as needed.

The UoC supplier and the Verification Authority agent can use the script output to complete the toolchain capability worksheet. During official conformance verification, if the UoC successfully links against the CTS libraries, the Verification Authority can use this worksheet to determine which requirements still need to be verified by inspection.

Detecting source code invocations of compiler-specific run-time API

A UoC whose source code invokes functions from the CSRT is not FACE conformant, since the code would clearly be nonportable. However, there is no way for the CTS to detect violations, since CSRT functions can be invoked from a conformant UoC’s object code. Though nonconformant, a UoC whose source code invokes a CSRT function will thus link successfully. This issue is not unique to Ada; it applies to all the FACE supported languages. Detection necessarily requires source code inspection. For Ada, the UoC supplier must demonstrate two properties:

› The only units referenced in the UoC’s “with” clauses are either other compilation units in the UoC, units from the standard run-time library permitted by the targeted capability set, or else units from the POSIX or ARINC-653 library permitted by the targeted profile.

› The only units allowed as parents of child UoC units are other units in the UoC. The UoC is thus not allowed to define child units of CSRT packages, nor is it allowed to define child units of predefined Ada packages. (In the latter case, such child units could reference private declarations and therefore be non-portable).

The McHale Report, by mil-embedded.com Editorial Director John McHale, covers technology and procurement trends in the defense electronics community.

Figure 2 | FACE Technical Standard requirement and TCATS test is shown.The UoC software supplier thus needs to provide the following evidence:

1. The list of all top-level compilation units defined by the UoC

2. The list of all child units defined by the UoC

3. The list of all compilation units “with”ed by units in the UoC

4. Documentation showing that all the units in (3) are in (1), (2), or the Gold Standard Library for the targeted profile and capability set

5. Documentation showing that the root unit of each unit in (2) is a (package or generic package) unit in (1)

support package

Given the constraint of no changes to the CTS software, the provider of the toolchain to be used for Ada conformance verification needs to supply the relevant

The Dawn family of one-slot OpenVPX test station and development backplanes gives engineers the ability to perform compatibility tests and easily reconfigure payload module profiles and slot interoperability to meet custom requirements.

Highly useful as stand alone or in combination with other backplanes, with or without RTM connectors. Multiple units can be topology wired using MERITEC VPX Plus cables.

supplementary artifacts (documentation, scripts, installation instructions, configuration files) to enable the UoC provider and the Verification Authority to conduct a conformance verification with the existing CTS. More specifically, the package provided for an Ada toolchain needs to include a CTS users guide supplement with detailed instructions on setting up the toolchain and running it from the CTS:

› Installing and configuring the Ada toolchain

› Generating the Ada Gold Standard Library and the toolchain’s Programming Language Run-Time, based on the targeted capability set and profile

Using this information, the UoC supplier and the Verification Authority can then run the CTS on an Ada UoC: this will entail linking the UoC object code against the Programming Language Run-Time and Gold Standard Library for the targeted capability set/profile and producing a conformance report, just as is done for other languages. The main difference with Ada is the use of the TCATS results worksheet to establish the requirements that need to be verified by inspection.

The larger picture

It is important for a developer to be able to check incrementally (as part of continuous integration/DevOps) that the UoC meets the restrictions imposed by the targeted profile and capability set. Ada offers two solutions:

Available 3U and 6U in VITA 65, VITA 67.1, VITA 67.2, VITA 67.3, Nano-RF, SOSA-aligned and Power Supply slot profiles. Custom configurations available.

Rugged, Reliable and Ready. You need it right. You want Dawn.

› Pragma Restrictions, a standard pragma in Ada 95 and Ada 2012, can be supplied with relevant arguments at each compilation to ensure that prohibited features are not used (i.e., the compilation unit will be rejected if it uses such a feature). For example, pragma Restrictions(No_Dependence => Ada.Strings.Unbounded) will detect uses of unbounded strings. As an aid to developers, if a FACE capability set restriction violation can be detected by a standard pragma Restrictions argument, the

TCATS Results Worksheet template has an entry associating that argument with the relevant test(s).

› A static analysis tool can be used to detect violations of FACE requirements, including those that are syntactic in nature and are not expressible via arguments to pragma Restrictions. An example of such a tool is GNATcheck, which is part of AdaCore’s GNAT Static Analysis Suite.

The approach to FACE conformance for Ada has exposed several issues that are relevant to the conformance procedures for other languages. One is the use of a test suite (TCATS) to determine whether a violation is detected by the toolchain and its CSRT. It is important for the UoC supplier and the Verification Authority to know with confidence which require ments will entail source code inspection, and a test suite such as the TCATS can serve this function. A second issue is the need to detect source code references to the CSRT. This is not testable by the CTS, and rules are required for C, C++, and Java with respect to the inspection evidence that the UoC supplier needs to provide.

A well-defined and practical conformanceverification process for Ada is important for the successful adoption of the FACE approach within the defense commu nity, and the solution described here will fill a current gap. It is incremental in nature, working with the existing CTS and using link-time tests as its basis. Although evolutionary, the Ada con formance approach is also innovative and has introduced several elements (a toolchain assessment package and a toolchain support package) that for malize aspects absent from or implicit in the procedures for other languages. Artifacts such as the TCATS and the rules for detecting source code references to compiler-specific APIs are relevant for other languages and may help guide future enhancements to the FACE con formance verification process.

As of early 2024, the Ada approach described here is under consideration within the FACE Consortium, and artifacts com prising sample toolchain assessment and toolchain support packages have been

prepared and submitted. Although the final details may vary, a FACE conformance verification solution for Ada based on these packages is expected to be approved in the near future. Further enhancements include procedures for verifying mixedlanguage UoCs (in particular, when both Ada and C are used) and incorporating the TCATS as part of CTS execution. MES

Dr. Benjamin Brosgol is a senior member of the technical staff at AdaCore. He has been involved with programming language design and implementation throughout his career, concentrating on languages and technologies for high-integrity systems with a focus on Ada and safety certification (DO-178B/C). Dr. Brosgol is an active member of The Open Group FACE Consortium’s Technical Working Group, and in particular he has been involved with the development of the IDL-to-Ada mapping.

AdaCore • https://www.adacore.com/

In the past, any reflection on America’s military competitiveness looked at how it stacked up against traditional adversaries such as China and Russia. But the world is changing quickly, and the U.S. needs to ensure that its military stays strong and can compete against new threats – Iran, Lebanon, and North Korea, for example – and not just face off with old enemies.

The development of the Joint Concept for Competing (JCC) during the 2023 U.S. Joint Chief of Staff meeting underscores a new set of threats and a new dynamic. The nature of modern strategic competition includes enhancing military capabilities to address these emerging threats alongside those of our historical opponents and non-state actors. The diffused nature of 21st-century conflict encompasses threats from newly empowered state competitors, including Iran and North Korea, alongside more traditional opponents like Russia and China. Meanwhile, non-state actors and international terrorist networks exploit new technologies and expand their capabilities.

Enhancing interoperability and open architecture standards with FACE

In this complex environment, initiatives like the Future Airborne Capability Environment (FACE) are critical to sustaining U.S. military competitiveness now and into the future. By promoting open architecture standards, interoperability, and the rapid integration of avionics capabilities, FACE fosters the agility, innovation, and cost efficiency needed to counter modern challenges. As America’s military transitions to meet the demands

of competition in the 21st century, embracing initiatives such as FACE will be a strategic imperative.

Furthermore, FACE mitigates many risks associated with cooperating with our allies, including complex compliance requirements, integration challenges, and allocating shared resources, for example. Its emphasis on interoperability and innovation can address adversarial challenges and technological advancements from competitors, making it crucial for U.S. military competitiveness. Let’s dive deeper into each of these areas:

› Compliance requirements. FACE’s open standards and modular architecture enable the rapid integration of capabilities aligned to common standards, reducing the need for custom compliance efforts when working on collaborative projects such as the Joint Strike Fighter. The emphasis on interoperability also creates alignment on integration requirements early in the design process.

› Integration challenges. FACE’s open systems architecture facilitates plug-and-play interoperability, minimizing the effort required to leverage disparate allied systems. The

U.S. Navy photo of F-35C jet by Mass Communication Specialist 3rd Class August Clawson.ability to swap out modular components also decreases integration timelines and costs. FACE’s promotion of common interfaces and data sharing further eases international system integration.

› Resource allocation. FACE’s incremental and spiraling development process – a risk-driven software development model – enables allies to share costs in smaller increments that are better aligned to shared priorities; that is, the open architecture lets allied nations develop and integrate capabilities that align with shared standards independently. This approach reduces friction over proprietary limitations and control.

› Fostering innovation. FACE focuses on the interface level and offers ample opportunities for innovation on the prime, OEM, and tier levels. With a standard operating environment established by FACE, vendors can concentrate on implementing new features effectively rather than spending time managing compliance with FACE standards.

Countering the unexpected with real-time operating systems and enhanced capabilities

FACE’s modular open systems architecture enables speedy integration and fielding of new capabilities to better counter unexpected threats. This method makes it easier for the military to pivot in response to adversaries exploiting new vulnerabilities. The ability to spiral-develop and swap capabilities provides operational flexibility to adjust tactics as adversaries evolve.

This is where a FACE conformant, DAL A-certified real-time operating system (RTOS), such as LynxOS-178, can provide additional value. LynxOS-178 is certified conformant to the FACE Technical Standard v3.1 across Arm, x86, and PowerPC. LynxOS-178 is one of several RTOS deployment options included as part of the LYNX MOSA.ic operating environment. By leveraging complementary capabilities like partitioning, virtualization, and trimmed-down unikernel architectures, system architects can achieve improved composability and build robust, resilient platforms that meet real-time requirements while still conforming to open standards. LYNX MOSA.ic multitiered partitioning approach enables strict isolation of components into separate virtual machines with allocated resources while the unikernel deployment option provides further optimized RTOS component runtimes that maximize resource utilization and timing, while minimizing excessive, unused RTOS features. (Figure 1.)

Together, these capabilities empower architects to truly realize the benefits that standards initiatives such as FACE offer, like rapid integration, interoperability, and innovation, while still addressing the performance, safety, and security demands of mission-critical defense and aerospace systems. As experts have stated, conformance testing is only the beginning. To sustain long-term military competitiveness, the U.S. must embrace open standards and innovative technologies that transform those standards into secure, reliable, and adaptable missioncritical computing platforms. The combination of open architectures and hardened real-time capabilities will strengthen the U.S. strategic position in the face of unexpected threats and long-term global competition.

Figure 1 | By leveraging complementary capabilities like partitioning, virtualization, and trimmed-down unikernel architectures, avionics architects can achieve improved composability and build robust, resilient platforms that meet real-time requirements while still conforming to open standards.

In essence, FACE provides a foundation to rapidly adapt to changing strategic contexts while fostering a vibrant vendor ecosystem. Its focus on modular designs, open standards, and continuous integration enables the U.S. to counter unforeseen challenges. At the same time, the emphasis on open architecture and common standards incentivizes vendors to compete and innovate within a broad, cross-platform market. This vibrant technology ecosystem, enabled by FACE principles, introduces more players and solutions to expand the military’s capabilities.

The critical role of FACE in sustaining U.S. military competitiveness amid global tensions and great power competition cannot be overstated. Embracing open architecture standards comparable to FACE ensures that the U.S. remains at the forefront of military innovation and preparedness, enhancing its strategic position in an increasingly competitive global landscape. MES

References:

https://www.csis.org/analysis/us-joint-chiefs-new-strategy-paper-jointconcept-competing

https://sgp.fas.org/crs/natsec/R43838.pdf

https://apps.dtic.mil/sti/trecms/pdf/AD1156584.pdf

https://www.defense.gov/News/News-Stories/Article/Article/3390241/ innovation-critical-to-success-as-dod-faces-competition-with-china/ https://www.defense.gov/News/News-Stories/Article/Article/2989958/ potential-for-great-power-conflict-increasing-milley-says

Tim Reed is the CEO of Lynx Software Technologies, a mission-critical edge software company that serves the aerospace, military, and federal markets. Tim joined Lynx in June 2022, after a long tenure with Green Hills Software. During his time at Green Hills, Reed held a variety of roles including senior vice president of the Advanced Products division and a member of the executive leadership team. Tim’s experience spans automotive, industrial, aerospace, and defense end markets. He holds a bachelor’s degree in engineering and applied science from the California Institute of Technology.

Lynx Software Technologies https://www.lynx.com/

In the world of military avionics, rubber gaskets can seem trivial compared to the role played by sensors, optics, and displays –only until electromagnetic interference (EMI) disrupts performance. Fortunately, shielding silicones can provide mission-ready solutions and save military avionics from degradation or outright malfunction.

Electromagnetic interference (EMI) can cause military avionics to degrade or even malfunction. The sources of EMI are numerous and include electronic jamming, corona discharge from power lines, crosstalk from nearby avionics circuits, and weather phenomena like lighting, snowstorms, and dust storms.

Whether EMI is human-caused or naturally occurring, electronics designers need to address potentially dangerous interference beyond just the printed circuit board (PCB) level.

In military aviation, EMI can affect everything from cockpit radios and radar systems to flight navigation and global positioning system (GPS) communications. Because military aircraft are laden with sensors, EMI can also affect engine performance, fuel consumption, and weapons systems. When the U.S. Army experienced 29 crashes of

Today’s avionics designers face challenges that include a proliferation of frequencies, the increased sensitivity of digital circuits, and requirements to pack more numerous and more powerful electronics into smaller enclosures. Effective PCB layout and design is important, but designers also need to select the proper enclosure material and seal. Effective gasketing between mating surfaces is essential, not only for EMI shielding but also for environmental sealing and thermal insulation. (Figure 1.)

In military aviation, EMI can affect everything from cockpit radios and radar systems to flight navigation and global positioning system (GPS) communications. Because military aircraft are laden with sensors, EMI can also affect engine performance, fuel consumption, and weapons systems.

EMI silicones and MIL-DTL-83528

EMI gaskets that are made from electrically conductive silicones can meet all these requirements. Like other types of enclosure gaskets, they can seal out the environment and protect avionics against water, dust, and debris. Silicones also provide high- and low-temperature resistance, resist thermal aging, and do not readily transfer heat between objects. Although silicone is normally an electrical insulator, the addition of metal or metal-coated particles imparts electrical conductivity.

The shielding that these specialized silicones provide is measured by defined levels of EMI protection in decibels (dB). For military avionics and other defenserelated applications, MIL-DTL-83528 establishes the general requirements for electrically conductive elastomeric shielding gaskets that contain silver

its Black Hawk helicopters during the mid-1980s, at least five were blamed on radio frequency interference (RFI), a form of EMI.particles. This U.S. military specification is divided into lettered sections, each of which defines the shielding requirements for specific types of filled materials.

For example, MIL-DTL-83528 Type A defines the requirements for silver-plated, copper-filled silicones capable of 110 dB of plane wave shielding effectiveness at 10 GHz with a continuous use temperature range of -55 °C to +160 °C. To determine whether a supplier’s material meets these requirements, a designer can review the results of independent testing or determine if the product is part of the U.S. Department of Defense (DoD) M83528 qualified product list (QPL). (Figure 1.)

Pure silver versus silver-plated fillers

Historically, pure silver-filled elastomers were specified on part drawings for military gaskets. Silver is subject to extreme price fluctuations, however, and today’s avionics projects sometimes use silver-plated materials instead. Silver is also used to coat nonmetallic materials, but the lower cost of these compounds comes with tradeoffs in terms of electrical conductivity and volume resistivity (VR), an indirect measure of EMI shielding effectiveness.

Table 1 compares different types of silver-filled silicones. Nickel-graphite silicones are also used for EMI shielding, but the MIL-DTL-83528 specification is only for silver-filled compounds.

For avionics designers who are unfamiliar with filled elastomers, adding metal or metal-coated particles does not make the base material excessively hard and difficult to compress. Today’s shielding silicones are available in a variety of durometers (a measure of hardness) and include softer materials that provide good tensile strength, elongation ability, and tear resistance. For applications where there is contact with fuels or chemicals, fluorosilicones can be used as the base elastomer.

EMI gasket fabrication

EMI gaskets for avionics enclosures can have flat, two-dimensional (2D) shapes or three-dimensional (3D) structures. Typically, designers send their computer-aided design (CAD) files to a fabricator for gasket cutting or molding. EMI shielding elastomers are available as compression-molded sheets, continuous rolls, ready-to-mold compounds, and extrusions. Some gasket fabricators have in-house toolrooms and testing laboratories, but others outsource these functions.

There are many ways to cut gaskets, but flash cutting is cost-effective because it does not require custom tooling and works directly from a designer’s CAD file, making this technique a good choice for rapid prototyping and short production runs. Importantly, flash cutting produces EMI gaskets with a minimal loss of material and very smooth edges, which are important for reliable sealing in military avionics.

Die-cut EMI gaskets use metal tools called dies to cut specific shapes and sizes from sheets or rolls, an approach that helps achieve precise dimensions, parts nesting, part-to-part uniformity, and punched holes with specific radii. Because it requires custom tooling, die cutting is recommended for EMI gaskets

Figure 2 | This EMI silicone is part of the qualified product list (QPL) for MIL-DTL-83528 Type A.in higher volumes. Die cutting – while limited to flat gaskets – in the same way as flash cutting, supports the use of conductive pressure-sensitive adhesives (PSAs) for attachment to enclosure surfaces.

Molded EMI gaskets are produced using compression molding, a process that places EMI silicone into the cavity of a heated mold. For larger avionics gaskets (such as for miliary radars) that resemble a picture frame, molding can reduce material waste and increase material yields. That occurs because unlike die cutting, molding uses only the smallest amount of material required. Molded EMI gaskets are available in 2D shapes, but compression molding can also achieve 3D designs. (Figure 3.)

Molded frame gaskets don’t require splicing or bonding, both of which raise the risk of EMI leakage when done incorrectly. Cut frame gaskets waste the material in the middle of sheet or roll, but they still offer some advantages for larger gaskets. Machining a large metal mold increases project costs, and design changes may require changes to tooling. Still, stock EMI sheets with dimensions of just 15 inches by 20 inches may require side-splicing so that the sides of the frame are wide enough.

Rolls in custom sizes can eliminate the need for side-splicing and don’t require corner bonding. With a large enough roll, a fabricator can simply cut out a large gasket. While that does not eliminate the problem of material waste, nesting a smaller avionics gasket within a larger gasket can increase material yields. By partnering with a fabricator who offers a choice of material form factors and fabrication methods, avionics designers have options to ensure quality and control costs.

Gasket fabricators also differ in their ability to test and certify EMI silicones. Some vendors only provide certificates of conformance (COCs) while others also offer certificates of analysis (COAs). With military projects, COAs are important because they indicate the results of batch level testing. Because some

suppliers may substitute a compound’s ingredients for less expensive alternatives, COAs demonstrate a batch’s compliance with the MIL-DTL-83528 specification.

EMI can cause military avionics to degrade or malfunction, but designers sometimes overlook the importance of enclosure-level sealing. After all, parts like rubber gaskets can seem trivial compared to sensors, optics, and displays. EMI gaskets are critical, however, and proper material selection can reduce the risk of inadequate shielding and cost overruns. MES

Dominic Testo is the Business Development Manager for Specialty Silicone Products (SSP) in Ballston Spa, New York. He has been with the company for nearly 15 years in several capacities. Testo holds a bachelor of science degree in marketing from Siena College (Loudonville, New York).

Specialty Silicone Products · https://www.sspinc.com

AirBorn’s new VPX Power Supply is a VITA 62, Open VPX compliant, 6U system with models for a 270 VDC input IAW MIL-STD-704. Power Blade is a SOSA aligned, conduction cooled, switch mode unit built for highend defense applications.

• Auxiliary DC Output: +3.3V/60A

• Efficiency of >94% Typical above 50% Load

• Input-Output Isolation 2100VD

• Main DC Output: +12V/180A

• Overvoltage, Overload, & Overtemperature Protection

• Programmable Regulated Current Limit

• VITA 46.11 System Management

Continuous testing is indispensable in a well-functioning CI/CD pipeline, as testing consumes the most time and re-sources. In a data-driven development (DDD) process, organizations must use tools supporting automation and optimization – critical for continuous testing – driving larger code coverage, intelligent test execution, and bidirectional traceability, and thereby further enhancing software quality and reliability.

When organizations in the military and aerospace sectors adopt a data-driven development (DDD) process, it becomes crucial that they select key performance indicators (KPIs) that are relevant to the industry’s unique challenges and requirements. For software developers and lead engineers in this domain, essential raw KPIs may include tracking

the number of requirements implemented per development cycle and the number of lines of code written per day per engineer. These metrics, often recategorized as velocity and sprint burndown, enable valuable insights into labor costs and time-tomarket considerations.

Additionally, other software development KPIs pertinent to the military and aerospace industry may encompass code complexity, code execution time, memory usage, number of threads, and others aimed at helping development teams adapt to evolving requirements, prioritize issues, and address high-risk areas efficiently.

For the quality assurance (QA) teams operating within the military and aerospace sector, collecting KPIs such as the average number of defects per line of code becomes paramount. Typically, embedded software in this industry maintains an average of 15 to 50 issues per 1,000 lines, serving as a critical metric for evaluating software robustness and determining whether the application is fit for deployment or delivery.