Pg Advertiser

1 Annapolis Micro Systems –HD switches support dual 100GbE, 8X Gen4 PCIe, or 128 LVDS

3 Behlman Electronics, Inc. –When it comes to VPX, one company has the most flavors

9 Elma Electronic –Leaders in modular open standards enabling the modern warfighter

13 LCR Embedded Systems, Inc. –All systems GO: VPX and SOSA aligned solutions for any mission

15 Milpower Source –Your design partner for fieldproven mil-grade power & networking solutions

Advertiser Page

AVIONICS

Sponsored by AirBorn AirBorn 16

RADAR/ELECTRONIC WARFARE

Sponsored by Annapolis Micro Systems Interface Concept 16 Annapolis Micro Systems 16-17

TEST & MEASUREMENT

Sponsored by Dawn VME Products

Dawn VME Products 18

UNMANNED SYSTEMS

Sponsored by Dawn VME Products

Dawn VME Products 18

Embedded Tech Trends January 13 & 14, 2025

San Antonio, TX https://embeddedtechtrends.com/

embedded world Exhibition & Conference March 11-13, 2025

Nuremberg, Germany https://www.embedded-world.de/en

VITA EDITORIAL DIRECTOR Jerry Gipper jerry.gipper@opensysmedia.com

GROUP EDITORIAL DIRECTOR John McHale john.mchale@opensysmedia.com

ASSISTANT MANAGING EDITOR Lisa Daigle lisa.daigle@opensysmedia.com

TECHNOLOGY EDITOR – WASHINGTON BUREAU Dan Taylor dan.taylor@opensysmedia.com

CREATIVE DIRECTOR Stephanie Sweet stephanie.sweet@opensysmedia.com

WEB DEVELOPER Paul Nelson paul.nelson@opensysmedia.com

EMAIL MARKETING SPECIALIST Drew Kaufman drew.kaufman@opensysmedia.com

WEBCAST MANAGER Marvin Augustyn marvin.augustyn@opensysmedia.com

DIRECTOR OF SALES Tom Varcie tom.varcie@opensysmedia.com (734) 748-9660

STRATEGIC ACCOUNT MANAGER Rebecca Barker rebecca.barker@opensysmedia.com (281) 724-8021

STRATEGIC ACCOUNT MANAGER Bill Barron bill.barron@opensysmedia.com (516) 376-9838

EAST COAST SALES MANAGER Bill Baumann bill.baumann@opensysmedia.com (609) 610-5400

SOUTHERN CAL REGIONAL SALES MANAGER Len Pettek len.pettek@opensysmedia.com (805) 231-9582

DIRECTOR OF SALES ENABLEMENT Barbara Quinlan barbara.quinlan@opensysmedia.com AND PRODUCT MARKETING (480) 236-8818

INSIDE SALES Amy Russell amy.russell@opensysmedia.com

STRATEGIC ACCOUNT MANAGER Lesley Harmoning lesley.harmoning@opensysmedia.com

EUROPEAN ACCOUNT MANAGER Jill Thibert jill.thibert@opensysmedia.com

TAIWAN SALES ACCOUNT MANAGER Patty Wu patty.wu@opensysmedia.com

CHINA SALES ACCOUNT MANAGER Judy Wang judywang2000@vip.126.com

www.opensysmedia.com

PRESIDENT Patrick Hopper patrick.hopper@opensysmedia.com

EXECUTIVE VICE PRESIDENT John McHale john.mchale@opensysmedia.com

EXECUTIVE VICE PRESIDENT AND ECD BRAND DIRECTOR Rich Nass rich.nass@opensysmedia.com

DIRECTOR OF OPERATIONS AND CUSTOMER SUCCESS Gina Peter gina.peter@opensysmedia.com

GRAPHIC DESIGNER Kaitlyn Bellerson kaitlyn.bellerson@opensysmedia.com

FINANCIAL ASSISTANT Emily Verhoeks emily.verhoeks@opensysmedia.com

SUBSCRIPTION MANAGER subscriptions@opensysmedia.com

• Tel: (480) 967-5581

ONLY VPXtra® OFFERS THE LARGEST SELECTION OF MIL-SPEC POWER SUPPLIES, WITH MINIMAL COSTS FOR ANY ADDITIONAL

Most manufacturers offer just a few VPX power supplies off the shelf, with high costs for full-custom. The Behlman the most COTS AC to DC and DC to DC units configured for a wide range of high-end industrial and military applications. All feature our state-of-the-art new engineering standard, Xtra-reliable design and Xtra-rugged construction.

Insist on the leader. Not just VPX,

By Jerry Gipper

I’ve been cruising on America’s Great Loop with my wife since last December – the Great Loop circumnavigates the waterways of the eastern U.S. It has been a fantastic adventure full of exploration, new experiences, and learning about ourselves. I’ve been involved in boating my entire life, but never have I had the responsibility that comes with being a boat owner on an adventure quite like this. It might sound like a relaxing excursion, but trust me when I say that it is very full of anxiety with every step of the way into the unknown.

After nearly a year and 6,500 miles, we are approaching the end of our journey. Our last legs have had us on the rivers of the central United States for the past several weeks. Recently, heavy rainstorms in the middle part of the country caused heavy flooding in the St. Louis area where we were moored for a few weeks while doing some other trips. We then started back up while the Mississippi River was still at very high river stages. Prior to this high-water situation, the river had been calm, the channels were well marked, and the river relatively free of debris and flotsam. Our days of cruising were relatively calm except when we had to pass through one of the many locks on the upper Mississippi River. The past few days were a different story, however, and have had me reflecting on our adventures. While doing so, I started to think about parallels in the business world.

Our first day back on the river after our break required us to go through the Melvin Price Lock, one of the busiest locks on the Mighty Mississippi. The evening before heading to the lock, we were able to coordinate a time slot to pass through the lock with other boaters departing the next day. Since commercial traffic has priority, it can be a challenge to get a time slot for pleasure vessels. Our coordination of a passage time was a lot like working with a standards organization: We had to collaborate to identify boat types, speeds, desired destinations, and other factors we needed to agree to the best strategy for the next day.

Once through the lock, we encountered the strong and erratic water of the rising Mississippi. The eddies and currents reminded me of the challenges faced by companies in today’s environment with changing regulations, business climates, competition, and evolving technologies. In addition to the currents and eddies, we had much flotsam in the river, debris that was set free by flooding on the tributary rivers. We spent all

day dodging and altering our course, much as companies adapt to changes around them.

The river is managed by the Army Corps of Engineers to keep it flowing and contained within its banks –similar to how government regulations keep industries flowing. We encounter locks, dams, dikes, and sea walls all along the river. We have our navigation charts to aid us on our path. We communicate with others in the ecosystem to ensure safe passage or call for assistance. Sometimes we collaborate with like boaters to make our passage safer.

We are on a small boat on a big river competing with much larger barges and tows. They dominate on the river, but they respect it and work with the smaller craft that cross their paths. This is much like how the VITA ecosystem functions with small and large companies working together in their respective markets to make everyone successful.

Our journey has been full of anxious moments as we anticipate what is ahead. Fortunately, we have countless resources available. We do our research, we study the course ahead, we talk to other boaters, we gather local knowledge, we adapt. As we have traveled, we gain more knowledge and share our knowledge with other Loopers.

There is a lot of time each day while on the water to reflect on life. It amazes me how similar our journey can be to the challenges of business life. Our adventure has been a once-in-a-lifetime experience. I encourage you to consider your own adventure goals.

Occasionally I have had to return to reality. Embedded Tech Trends 2025 is on the calendar for January 13-14, 2025, in San Antonio, Texas. It has been a challenge to plan ETT while on the water each day, but the agenda is quickly coming together. We have a great set of sponsors and editors scheduled to join us. If you are interested, please be sure to visit EmbeddedTechTrends.com for more information on sponsoring or attending.

Fair Winds and Following Seas!

IT AMAZES ME HOW SIMILAR OUR JOURNEY CAN BE TO THE CHALLENGES OF BUSINESS LIFE.

By Jerry Gipper, Editorial Director

Note: This update is based on the results of the September 2024 VITA Standards Organization (VSO) meeting, held in San Antonio, Texas, and hosted by Southwest Research Institute. Contact VITA if you are interested in participating in any of these working groups. The full reports can be accessed at www.vita.com/ StandardsUpdates. Visit the VITA website (http://www.vita.com) for details on upcoming VITA meetings.

Accredited as an American National Standards Institute (ANSI) developer, VITA provides its members with the ability to develop and promote open technology standards.

All published standards are available for download by VITA members and are posted at the online VITA Store for purchase by nonmembers.

Standards within VITA may be initiated through the formation of a study group and developed by a working group. A study group requires the sponsorship of one VITA member, while a working group requires sponsorship of at least three VITA members.

Several working groups have current projects underway. Here’s a roundup of these projects:

Abstract: This document defines a standard for a VPX connector that supports higher data rates, to at least 25 Gbaud, for protocols such as 100GBASE KR4 Ethernet and PCIe Gen 4. The connectors feature a short solder tail intended to be soldered into a blind via. The higher-data-rate connectors compliant to VITA 46.31 are intermateable to legacy VITA 46.0 connectors and follow the same form factor.

Status: VITA 46.31 is approved for VITA Standard Draft Trial Use available to VITA members and is available at the VITA online store. The working group has submitted the document for ANSI process and release.

Draft/VITA 48.9: VPX AFT Cooling –

Retractable Seals

Abstract: This standard defines an air-flow-through module format, 3U and 6U, that uses retractable module rack seals to improve module-chassis seal

durability, simplifies the design by eliminating tapered module and chassis features, and allows easy migration of existing CCA designs to an air-cooled module format.

Status: Working group is developing a draft document.

Abstract: The goal of this working group is to develop a new component derating standard.

Status: This working group has joined forces with the IEEE to jointly develop this standard under IEEE2818. The working group is reviewing comments on draft from public consensus ballot through IEEE.

VITA 65.x: OpenVPX System Standard

Abstract: The OpenVPX standard uses plug-in module mechanical, connectors, thermal, communications protocols, utility, and power definitions provided by specific VITA standards to define a series of slot, backplane, module, and standard development chassis profiles.

Status: The working group is adding additional profiles to this standard.

Draft/VITA 67.3-2023: VPX: Coaxial Interconnect on VPX, Spring-Loaded Contact on Backplane

Abstract: The VITA 67.3 standard defines an open standard for configuration and interconnect (within the structure of VITA 67.0) enabling an interface compatible with VITA 46 containing multiposition blindmate analog connectors with coaxial contacts, having fixed contacts on the plug-in module and spring action on the backplane.

Status: Now open for modifications to SMPS interface.

VITA 68.x: Reference SI Model Standard for Gen 4 and Higher Speeds

Abstract: This family of standards documents a reference model approach for OpenVPX signal-integrity

compliance at baud rates above 10.3125 Gbaud. It defines reference OpenVPX plug-in module and backplane s-parameter models that can be used to create end-end OpenVPX reference channels in conjunction with reference VPX connector and device s-parameter models.

Status: The working group is addressing signal-integrity compliance for Gen4 and higher speeds for VPX and making general updates to remove errata from previous releases.

Draft/VITA 78.0-2022 Revision: SpaceVPX System

Abstract: This document describes an open standard for creating high-performance fault-tolerant interoperable backplanes and modules to assemble electronic systems for spacecraft and other high-availability applications. Such systems support a wide variety of use cases across the aerospace community. This standard leverages the OpenVPX standards family and the commercial infrastructure that supports these standards.

Status: The standard is open for revisions to the 2022 edition.

Draft/VITA 86-2019 Revision: High Voltage Input Sealed Connector Power Supply

Abstract: This standard defines an environmentally sealed connector pair which is compatible with the backplane footprint as defined in VITA 62.0 for 3U power supplies operating in harsh environments operating from a high-voltage input.

Status: The standard is open for revisions.

Draft/VITA 89-202x: MT Circular Connectors – Type 2

Abstract: The VITA 89 MT circular connector standard defines a standard for circular connectors with optical MT. Circular connector shells are compliant to MIL-STD-38999. MT offers options for up to 48 fibers per MT and for physical contact or lensed MT.

Status: VITA working group to develop a new standard for circular connectors with optical MT. Working group is developing draft document.

Draft/VITA 90.x: VNX+

Abstract: The VITA 90.x (VNX+) family of standards builds on the foundation established by VITA 74 VNX. VNX+ significantly increases performance and system versatility beyond VITA 74, while following its mechanical framework.

Status: Working groups are developing drafts for each level of VNX+.

Draft/VITA 91: System Standard for Higher Density VITA 46 Applications

Abstract:: This standard defines a system definition that provides higher pin density to the backplane for VPX applications.

Status: VITA working group to develop a new standard for higher pin density for VPX.

Draft/VITA 92: High Performance Cable –Ruggedized 10 Gbaud Bulkhead High Speed, D- Sub, Rectangular Connector for Copper Cables

Abstract: This standard defines a rugged standardized 10 Gbaud interconnect system with a high pin count and high- density, lightweight, rectangular connector (meets MIL-DTL-24308 physical envelope) for I/O. It can support multiple high-bandwidth protocols and power while optimizing SWaP [size, weight, and power] benefits in smaller systems with limited panel space availability.

Status: The working group is reviewing a draft document.

Draft/VITA 93.x: QMC – Small Form Factor Mezzanine

Abstract: This standard defines a Small Form Factor mezzanine (SFFm) that is significantly smaller than XMC with host and I/O interface connectors. The host interface supports modern high-speed serial fabrics. The I/O interface supports either front-panel or backplane I/O. Multiple SFFm modules can be installed on various carrier-card form factors including 3U/6U Eurocards (VPX, cPCI, VME, etc.), VNX+, PCIe expansion cards, and others. It is suitable for deployment in commercial, industrial, space, or military-grade rugged environments with air-cooled or conduction-cooled formats.

Status: The working group is reviewing draft documents with expectation of releasing in early 2025.

Draft/VITA 94.0-2024xNew: Power Distribution Plug-In Module

Abstract: This standard provides requirements for building a power distribution plug-in module with digital controls that can be used in a VPX chassis. The plug-in module will fit within the standards envelope defined for VPX modules in the VITA 48.x standards.

Status: Working group is developing a draft document.

Draft/VITA 100.0-2024xNew: VITA 100 Base Standard

Abstract: The VITA 100 suite of standards is an evolution to OpenVPX, VPX, and related mechanical standards while embracing a paradigm shift in technology and capability with at least double the pin density, speed, and power for electrical contacts. This document, the VITA 100.0 Baseline Standard, outlines the essential electrical and system architecture for the VITA 100 ecosystem.

Status: Working group is developing draft documents.

For a complete list of VITA standards available for purchase and their status, go to www.vita.com/Standards.

By Jerry Gipper, Editorial Director

The intention of the VITA Technologies Hall of Fame is to honor and preserve the remembrance of those people and technologies that have had the greatest influence on the VITA open standards industry. These are the people who have overcome technical and procedural problems to help bring forth the products that set new expectations. It is our pleasure to honor these contributors to this industry.

Mike Macpherson

Mike spent over 40 years in the defense industry. Mike graduated from the California State University, Northridge (CSUN) in 1982 with a bachelor’s degree in computer science where his specialty study area was numerical analysis. He began his career supporting anti-submarine warfare systems at the Lockheed Corporation in southern California. In 1985 he helped found Vista Controls Corporation, a pioneer in bringing commercial off-the-shelf (COTS) electronic solutions to the military. In 2000, Mike joined the MITRE Corporation, a Federally Funded Research and Development Company (FFRDC), as a Senior Technical Manager. His most notable assignment was that of Program Manager for MITRE’s support to the Army’s Future Combat Systems (FCS) program; in this capacity, Mike led the development of the Network Centric System of Systems Architecture for FCS.

Mike joined Curtiss-Wright in 2005 as a Business Development Director. He moved on to become the Vice President of Strategic Planning for Curtiss-Wright Defense Solutions. While in this role, Mike also served as the Curtiss-Wright representative on the VITA board of directors, where he was active in guidance of VITA. Mike retired from Curtiss-Wright in 2022.

Joe Norris

Having a passion for electronics since childhood, Joe goes back to the end of the vacuumtube era. At 12 years old (1969), he constructed a 12AU6 based flip-flop from what he saw in a book, made from junk from a local TV store, not realizing at the time the implications it had for his future. Joe graduated from Rutgers in 1979 with a Bachelor of Arts CS/EE degree.

Joe did stints with various companies – Formation, Perkin Elmer, Concurrent computer, Honeywell, Telenex, General Signal, Texas Instruments (“firewire”) and many consulting jobs along the way. Always the inventor, Joe founded Technobox, Inc. in 1989.

About 1993, with some practical background in VMEbus design when working for Formation – he used John Rynearson’s (VITA Hall of Fame 2014) 6800 sidecard from Mizar – he had a perception that Futurebus+ (IEEE 896) was the next VMEbus, and became actively

involved with design, production, and marketing of 68000-based FutureBus+ boards under the Technobox brand, making himself somewhat of a “reputation” in the VME community.

Before taking off, FutureBus+ collapsed, with everyone walking away. Joe’s company was stranded and forced to find something else; by a lucky suggestion from Wayne Fischer (VITA Hall of Fame 2014), Joe decided to try IEEE 1386 (PMC) as a Technobox business direction.

Passionately working 24/7 on PMC products, Technobox business took off in 1997. Some of these products are still sold today in various forms. With money rolling in, he was able to hire 10 employees at Technobox’s peak.

Then XMC (VITA 42) was developed, and Joe had the expectation that XMC would naturally follow the business success of PMC. Like FutureBus, he was mistaken with that notion. So, in approximately 2016 Joe sold off some IP/patent which brought in some money for several years. In the meantime, he was trying to find the next thing after XMC.

The industry was primed for a new, smaller mezzanine standard, leading to the formation of the VITA 93, QMC working group. At about 20% of the size of a PMC/XMC module, commensurate with contemporary component sizes, Joe saw this as the next generation of mezzanine standard.

Joe worked feverishly on this standard starting in 2022 as a VITA 93 co-chair and as a primary contributor. His objective was to create a standard with manufacturability, simplicity, cost, and deployment across many industry standards in mind. Joe retired from Technobox in 2024.

Principal Standards Participation:

› IEEE 1386 – PMC

› VITA 42, 61, 88 – XMC

› VITA 93 – QMC

Key Patents:

› 5,313,154 – Frequency deviation between two sources

› 5,784,386 – Fault tolerant synchronous clock

› 5,796,733 – Time division switching system

› 5,805,614 – Fault tolerant switch Fabric via Hamming Codes

› 5,984,688 – IEEE 1386 PCMCIA

› 7,539,026 – Sub-mezzanine Structure for PCB assemblies

Go from development to deployment with the same backplane and integrated plug-in card payload set aligned to SOSATM and CMOSS. Includes chassis management, power and rugged enclosure for EO/IR, EW, SIGINT and C5ISR applications.

By Matthew Tarney

Advanced computing is revolutionizing defense platforms across all domains. Modern C5ISR [command, control, communications, computers, cyber, intelligence, surveillance, and reconnaissance] and the tactical advantages it brings to the battlespace would not exist without the rapid advancement of compute hardware. However, the ability to deploy this hardware in rugged and extreme edge environments depends heavily on the effectiveness and reliability of cooling systems. Preferred methods of cooling like conduction and forced air are often insufficient to meet the thermal needs of these high-performance computers. Systems designers should be aware of both the advantages and challenges associated with next generation cooling such as air flow-through and liquid flow-through. While each adds some additional complexity and risk to the system they are cooling, they bring enormous advantages in terms of cooling performance. Without implementing these higher-capacity cooling mechanisms, systems in the near future will not be able to take advantage of the latest processing hardware for critical edge applications.

It is hard to overstate the rapid pace at which processing technology has changed in the past five years. Breakthroughs in machine learning and artificial intelligence (AI and ML), coupled with the development and scaling of advanced compute hardware like graphics processing units (GPUs), have transformed computing across almost every industry. While the broad adoption of GPUs enables rapid technological advancements, it also creates significant new demands and challenges. One of the largest obstacles to overcome is managing the power consumption of high-performance chipsets and the resulting heat generated by the processors.

Power consumption of GPUs has increased dramatically since the primary use case for GPU processing switched from rendering graphics to handling AI workloads. As recently as 2021 the highest power consumption of any NVIDIA GPU accelerator was 300 watts (W), with most single processors operating in the 100 W to 250 W range. Their latest chipset, the Blackwell B200, has a max power consumption of 1,200 W per chip. This massive increase in power consumption requires new approaches to electronics cooling from the data center to the edge. (Figure 1.)

Until recently high-performance GPUs like those from NVIDIA, AMD, and Intel were found primarily in data centers and research labs. These purpose-built facilities are designed with cooling in mind, and typically use a combination of cold room air conditioners (CRACs), chillers, and targeted liquid cooling to dissipate heat generated by electronics. Air cooling is often preferred, as it is cheaper and less complex, but as power consumption increases air cooling is often insufficient to handle the heat generated by high density electronics racks.

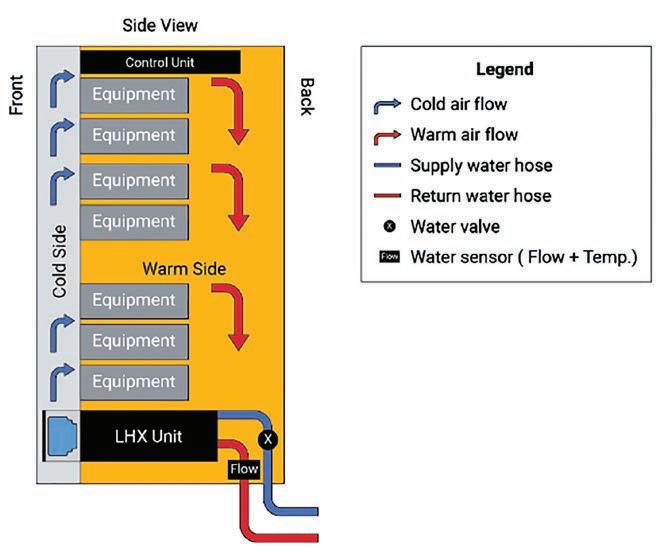

More and more data centers are adopting air-to-liquid heat exchangers (Figure 2.)

A thermal-analysis image demonstrates how heat builds up at the processor location; it also shows the importance of ensuring the PCB has the right thermal-management tools to protect the processor from overheating.

or direct liquid cooling as their primary cooling method. Liquid cooling has many advantages over air cooling; it is more efficient than air, produces less noise, and allows for greater electronics density by eliminating the space required for large heatsinks and sufficient air flow to cool them. However, these systems are often more expensive than air cooling, more complex and harder to maintain, and carry the risk of coolant leaks.

As high-performance computing moves out of the data center and to the edge, especially in aerospace and defense, the challenges associated with cooling become more complex. Many issues exist at the edge that aren’t present in the data center, including environmental extremes, rigorous SWaP requirements, shock, vibration, and motion profiles not encountered in climate controlled, stationary data center applications. In addition, the critical nature of aerospace and defense applications means systems cannot fail, even when subjected to significant stress. Managing thermal load in such extreme applications is a major challenge for system designers. Thankfully, the VITA 48 standard provides multiple options for cooling rugged embedded electronics.

VITA: multiple options for beating the heat

VITA 48 is a standard developed by the VMEbus International Trade Association (VITA) that defines mechanical specifications for ruggedized systems, particularly focusing on cooling methods for embedded systems used in harsh environments. It encompasses a variety of cooling techniques tailored to support high-performance electronics, such as military and aerospace systems, where managing heat dissipation is critical.

Key cooling methods outlined in VITA 48 include conduction, forced air, air flowthrough, and liquid flow through cooling. Each is briefly described below. While cooling capacity is given here as a general reference, please note that actual cooling performance can vary greatly depending on system design and environmental factors.

48.2)

› Method: Transfers heat directly from electronic components to the system’s enclosure, typically through heat frames or wedge-locks.

› Usage: Effective in environments where airflow or liquid cooling is not feasible, such as sealed or rugged systems used in military or space applications.

› Advantages: No reliance on moving parts like fans; highly durable and suited for shock and vibration-heavy environments.

› Cooling capacity: Approximately 80 W to 100 W per slot

› Factors influencing capacity: Thermal interface materials, efficiency of heat conduction paths, and the thermal conductivity of the enclosure play a significant role.

› Method: Air is circulated over modules or a heatsink using fans, without exposing the electronics directly to the external environment.

› Usage: Effective in rugged, sealed systems where it’s important to protect electronics from dust, moisture, or contaminants, while still benefiting from air cooling.

› Advantages: Simple and costeffective; fans can easily be added to increase cooling capacity.

› Cooling capacity: Approximately 120 W to 180 W per slot

› Factors influencing capacity: Airflow velocity, fan efficiency, ambient air temperature, and heatsink design.

Air Flow-Through (AFT) Cooling (VITA 48.5, VITA 48.8)

› Method: Air is directed through a channel or cavity within the modules to cool internal components directly.

Sponsored by Epiq Solutions, New Wave DV, and Wolf Advanced Technology

It’s been two years since the Sensor Open Systems Architecture, or SOSA, Technical Standard revision 1.0 was ratified. Military applications are already requiring SOSA aligned products in systems for radar, electronic warfare, communications, and more. Open architecture approaches like SOSA have changed the way defense electronics designers build tomorrow’s military platforms. In this webcast, members of the SOSA consortium detail how SOSA aligned products can make an impact on designing and specifying critical defense platforms. (This is an archived event.)

Watch the webcast: https://tinyurl.com/4f97vd8z

› Usage: Used in systems where internal airflow is possible, such as those deployed in less extreme environments or where higher levels of heat dissipation are required.

› Advantages: Higher cooling efficiency than conduction and traditional forced air, resistance through card-loks and chassis less important.

› Cooling capacity: Approximately 200 W per slot, depending on airflow rates and the system’s thermal design.

› Factors influencing capacity: Sealed airflow paths, air channel design, and ambient air temperature.

› Method: Liquid coolant is circulated through a cold plate or channels in the module, which draws heat away from the components.

› Usage: Suitable for systems requiring very high levels of heat dissipation, such as high-power computing or signal processing applications.

› Advantages: Provides superior heat dissipation compared to air or conduction cooling; ideal for extremely high-performance systems.

› Cooling capacity: Approximately 300-plus W per slot.

› Factors influencing capacity: Coolant type (e.g., water/glycol, dielectric fluids), flow rate, and cold plate channel design.

Each cooling method in VITA 48 is tailored to specific operating environments and system requirements, balancing factors like environmental sealing, heat dissipation needs, and mechanical hardening.

An additional benefit of designing VITA 48 compliant cooling solutions is that VITA 48 is one of several open standards integrated into the Sensor Open System Architecture, or SOSA, Technical Standard, which is used to establish command, control, communications, computers, cyber, intelligence, surveillance, and reconnaissance (C5ISR) systems guidelines. The alignment between VITA 48 and SOSA supports the creation of rugged,

high-performance systems that are modular, interoperable, and thermally optimized for harsh environments.

VITA 48’s cooling and mechanical standards provide the critical thermal-management infrastructure that SOSA systems rely on to meet performance requirements in military and aerospace applications. By utilizing VITA 48 cooling methods, system designers can create more versatile, efficient, and upgradable systems.

Matthew Tarney is the Global Vertical Growth Leader for Aerospace & Defense at nVent SCHROFF. In this role he is focused heavily on finding solutions to the thermal challenges facing electronics in the aerospace and defense space. Readers may email the author at Matthew.Tarney@nvent.com

nVent SCHROFF https://schroff.nvent.com/en-us/

LCR products enable the fullest capabilities of the best aspects of VPX and SOSA aligned system architectures. Integrated systems, chassis, backplanes and development platforms that help streamline the journey from early development to deployment.

Look to LCR to realize what’s possible in demanding environments across a wide range of defense applications.

Find out how we can help you achieve mission success.

By Jerry Gipper, Editorial Director

Several organizations are actively involved in developing open standards for the defense electronics industry. Here are some key examples, along with their standards:

The mission of the nonprofit VITA organization is to promote the concept of open technology for critical embedded computing via standards. Accredited as an American National Standards Institute (ANSI) developer, VITA enables its members to develop and promote open-technology standards.

VITA’s continuing goal is to unite manufacturers and users through acceptance and implementation of open standards; these standards will encourage use of VITA technologies in complex systems.

Computing system designers worldwide face significant design challenges: reliability of operation, difficult operating environments, long product life cycles to manage, demanding performance, system interoperability, data and system security, and ever-shortening time-to-market windows. VITA technologies are a favorite choice in many embedded systems architectures to address these challenges.

The Open Group promotes the adoption of open standards and collaborates with various industries, including defense, to develop standards for interoperability and data exchange. Under the Open Group, the SOSA [Sensor Open Systems Architecture] Consortium is a collaborative effort between government and industry to develop open standards for C5ISR [command, control, communications, computers, intelligence, surveillance, and reconnaissance] systems.

The SOSA Technical Standard is a modular open systems approach (MOSA) that builds upon the VITA VPX standard that aims to improve interoperability and modularity, reduce costs, and accelerate development cycles for C5ISR systems. By adopting the SOSA approach, the defense industry can reduce costs, accelerate development cycles, and improve system performance.

While not exclusively focused on defense electronics, the IEEE develops numerous standards that are relevant to the industry, including standards for wireless communication, cybersecurity, and signal processing. One is IEEE 1588, a precision clock synchronization protocol used to synchronize clocks across multiple devices in a network. It is widely used in telecommunications and networking, including defense applications.

Another is IEEE 802.11, which is a set of standards for wireless LAN (WLAN) technology, commonly known as Wi-Fi. These standards are used in various military and defense applications, including tactical communications and network connectivity.

JEDEC develops standards for microelectronics, including memory, storage, and semiconductor devices. These standards are essential for ensuring compatibility and reliability in defense electronics systems.

By promoting open standards, these organizations help to foster innovation, reduce costs, and improve the overall performance and reliability of defense electronics systems.

It’s important to note that the defense industry is increasingly embracing open standards to improve system performance, reduce costs, and accelerate development cycles. By adopting open standards, the industry can foster innovation, competition, and collaboration among different vendors and suppliers.

The development of VITA standards is a collaborative effort involving many individuals and organizations from diverse backgrounds. By working together, these individuals and organizations help to ensure that VITA standards meet the evolving needs of the target industries. The following groups and companies are instrumental in shaping VITA standards.

VITA Member companies: Numerous companies, including technology providers and leading defense and aerospace contractors, have contributed to the development of VITA standards. These companies often have representatives who actively participate in VITA working groups and contribute their expertise.

› Defense and aerospace contractors: Engineers from companies like Lockheed Martin, Raytheon, Northrop Grumman, and Boeing play a crucial role in shaping VITA standards. They bring real-world experience and insights into the development process.

› Technology providers: Representatives from companies like Mercury Systems, Curtiss-Wright, Elma Electronics, Samtec, TE Connectivity, Amphenol, and others provide expertise in hardware and software technologies.

Government agencies: Government agencies have played a significant role in shaping the requirements and specifications for VITA standards. Engineers and program managers from government agencies like the U.S. Department of Defense (DoD) and NASA contribute to VITA standards by providing specific requirements and feedback. They often collaborate with industry representatives to ensure that standards meet the needs of military and defense applications.

Academic institutions: Universities and research institutions contribute to the development of VITA standards by providing technical expertise and conducting research in relevant areas. Researchers from universities like MIT, Georgia Tech, and Johns Hopkins often participate in VITA working groups.

Individual engineers and technical experts: Many individual engineers and technical experts have made significant contributions to VITA standards. These individuals often have deep knowledge and experience in specific areas of embedded computing and system design. VITA has the VITA Distinguished Fellows program to encourage individual participation from subject matter experts in the industry.

It’s important to note that the development of VITA standards is an ongoing process, with new standards being developed and existing standards being updated to keep pace with technological advancements. The collaborative nature of VITA ensures that standards are relevant, practical, and meet the evolving needs of the defense and aerospace industries.

Significant challenges

Developing computer standards for the defense industry presents several significant challenges:

Security and cybersecurity:

› Protecting sensitive information: Defense systems handle highly classified and sensitive information. Standards must prioritize robust security measures to protect against cyberattacks and unauthorized access.

› Balancing security and usability: Implementing stringent security protocols can sometimes hinder usability and efficiency. Standards must strike a balance between security and user experience.

Interoperability and compatibility:

› Diverse systems and platforms: Defense systems often involve a wide range of hardware and software components from different vendors. Standards must ensure seamless interoperability between these diverse systems.

› Legacy systems: Many defense systems rely on legacy technologies that may not be easily integrated with newer systems. Standards must consider compatibility with legacy systems while promoting modernization.

Rapid technological advancements:

› Evolving technologies: The rapid pace of technological change can quickly render existing standards obsolete. Standards must be flexible and adaptable to accommodate emerging technologies.

› Balancing innovation and standardization: Encouraging innovation while maintaining standardization can be challenging. Standards must strike a balance between promoting cutting-edge technologies and ensuring consistency.

Cost and time-to-market:

› Rigorous testing and certification: Adherence to strict standards can increase development costs and time-tomarket. Standards must balance the need for rigorous testing with the urgency of deploying systems.

› Balancing cost-effectiveness and performance: Standards must consider the trade-offs between cost and performance, ensuring that systems are both affordable and capable.

International collaboration:

› Harmonizing standards: Collaborating with international organizations to harmonize standards is crucial for global interoperability and supply chain efficiency.

› Addressing cultural and regulatory differences: Different countries may have varying security requirements and regulatory frameworks, which can complicate the development of international standards.

By addressing these challenges, the defense industry can develop effective computer standards that promote interoperability, security, and innovation.

AirBorn’s Power Blade® is a 2300W+, 6U power supply that offers the highest overall VPX power density and power efficiency available today. As a commercial off-the-shelf (COTS) product, it meets the VPX and VITA 62 open architecture and performance requirements. Notably, it delivers nearly twice the output of traditional 6U power supplies with a remarkable efficiency of 95%. This allows customers to support the higher power levels required in modern defense applications without increasing the size of their power supply units.

In addition, the Power Blade® boasts conducted EMI emissions that are well below VPX requirements. This unique feature offers significant cost and space savings compared to alternative solutions on the market.

The Power Blade® VPX power supply is an intelligent power solution that meets and exceeds the evolving needs of modern defense applications. The embedded intelligence allows flexible sharing through dispatchable power which can be configured to control voltage, balance current, or temperature across multiple power supplies. Additionally, Power Blade’s intelligence allows system designers to utilize a dual data bus communication where a system controller or chassis manager can talk to the power supply and inquire about input voltages, output cards, power temperatures, and other information from the power supply, possibly predicting failures.

Radar/Electronic Warfare

Interface Concept

IC-ARM-VPX3c - 3U VPX

LX2080A/LX2160A Arm SBC

The IC-ARM-VPX3c is based on a NXP Layerscape® LX2080A/ LX2160A multicore communication processor featuring 16 Arm® Cortex®-A72 cores. Layerscape LX2 family provides an excellent efficiency / Thermal Design Power (TDP) ratio with dissipated power as low as 30W for LX2080A and up to 45W for LX2160A. With its hardware accelerator and large caches, this SBC provides outstanding computing performance with powerful packet processing offload and Ethernet controllers. The board is aligned with the SOSA Technical Standard. Contact us for more information.

https://www.interfaceconcept.com

Radar/Electronic Warfare

Interface Concept

ComEth4682e - 3U VPX 1/10/25/40/100 GbE Switch

The ComEth4682e is a 3U VPX SOSA aligned Gigabit Ethernet switch, based on a new generation of multi-layer Ethernet matrix for high-speed embedded applications requiring 10/25G and 40/100G connectivity.The ComEth4682e integrates a Layer 2 (Ethernet) and Layer 3 switch, and a control processor to support virtually separated Control and Data Planes for highly secured 3U VPX systems.

The Ethernet packet processor, managed by the dual-core ARM processor, offers remarkable switching capabilities with 1G, 10G, 25, 40 and 100G Ethernet configurations.

https://www.interfaceconcept.com

Radar/Electronic Warfare

Annapolis Micro Systems

64 GS/s Direct RF – 3U & Smaller

With Direct RF, directly digitize and process wideband signals, simplifying system architecture and enabling new EW, SIGINT, and Radar processing capabilities.

• Delivers more than 2300W

• Auxiliary DC Output: +3.3V/60A

• Peak Efficiency of 95%

• Input-Output Isolation 3000VDC

• Main DC Output: +12V/180A

• Overvoltage, Overload, & Overtemperature Protection

www.airborn.com/powerblade

• BSP: VHDL or GUI-based

• Standards: VITA 65 & SOSA

• Optional: GPU processing & Development Kit

www.annapmicro.com/direct-rf-products/

Radar/Electronic Warfare

Annapolis Micro Systems

WILD™ SoM/Chassis Manager/HMC

Highly-Integrated, Secure & Conforms to VITA 46.11

• Applications: System on Module/Chassis Manager/ Hardware Management Card

• Capability: Provides control and access to Plug-In Card JTAG and Maintenance ports, CLK1 usage, network functions & optional advanced security functions

• FPGAs: Xilinx UltraScale+™ Zynq (ZU5EG or ZU11EG) & Microsemi PolarFire

• Mounting: Directly on backplane, via 3U or 6U VPX plug-in carrier card, or cabled

• Power: Only requires 3.3V

• Optional BSP: For customizing Zynq PS & PL for security

• Availability: Commercial off-the-shelf www.annapmicro.com/product-category/chassis-and-backplane-accessories/

Sponsored by LDRA & Wind River

Cloud Native platforms provide a DevSecOps solution enabling organizations to develop mission-critical intelligent systems at agile speed and without the issues of vendor lock-in. Using DevSecOps, military and defense providers can build security best practices into the earliest stages of software development.

This webinar describes how a COTS DevSecOps platform integrated with an analysis and verification tools suite can ensure that intelligent systems such as airborne delivery drones, autonomous vehicles, and factory robots meet the most stringent criteria for safety and security. (This is an archived event.)

Watch the webcast: https://tinyurl.com/55dt86s3

Sponsored By:

3U Switches with VITA 91 HD Connectors Are Designed for High-Performance EW & SIGINT

Annapolis is the first embedded computing manufacturer to integrate new high-density VITA 91 connectors into its COTS products. With HD VITA 91 connectors, SOSA aligned WILDSTAR 3U OpenVPX Switches keep pace with the high speed and bandwidth of the latest high-performance transceivers and FPGAs, including Agilex 9 Direct RF-Series and Versal Premium. These boards and systems are ideal for challenging applications including low latency jamming, EW, or radar.

VITA 91 HD connectors allow for a completely switched backplane, so the expansion plane is no longer defined by a fixed backplane PCB, but is now flexible and fully reconfigurable. Chassis and backplanes with two HD switch slots allows for one switch to handle all Data and Control Plane Ethernet, with the second switch dedicated to the expansion plane. The expansion plane supports Dual 100Gb Ethernet, 8x Gen4 PCIe, or 128 LVDS.

The following SOSA aligned Switches integrate high density VITA 91 connectors and one or two AMD Xilinx Zynq UltraScale+ MPSoC Motherboard Controllers.

HD Chassis also available: The high-density WILD100 3U OpenVPX Chassis come with 6 or 13 conduction slots, and have air or liquid overall cooling.

www.annapmicro.com/vita91/

Sponsored By:

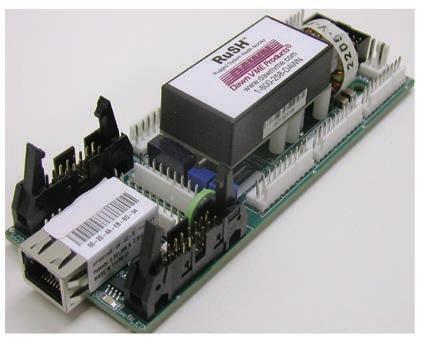

Dawn RuSH Model 426 Wizard System Health Monitor

Control fans, power supplies, LEDs, backplane signals or almost anything else imaginable. Can run off virtually any power source. Ethernet enabled.

Only 2.0” W x 5.9” L x 1.2” H. Its outputs can control fans, power supplies, LEDs, backplane signals or almost anything else imaginable. Its inputs can monitor temperatures, fan speed, voltages, I2C, or the state of any user-defined signal. The user interface is LED, LCD, VF, RS-232 or Ethernet. A wide variety of add-on “Sidekick” modules provide even more functionality.

• Runs on DC or AC (50-440Hz) at 4.5-270V, depending on model.

• Controls fan speed on the basis of temperature (power to drive the fans must be provided by an external source).

• Monitors 9 fan tachometers.

• Variable-threshold fan speed error detection for early prediction of fan failures.

• Accepts 4 analog or 8 digital temperature sensors.

• Totally configurable through an easy, menu-driven interface.

• Handles all outputs (LED, LCD, Ethernet and RS-232) simultaneously.

• Programmable automatic shutdown on a variety of fault conditions.

• “Sidekick” add-on modules monitor current, AC line (voltage and phase), vibration/acceleration, temperature, humidity, air pressure (down to 0.05” H20).

• Rugged – withstands over 15 G’s in all axes. -40C to 85C operation.

www.dawnvme.com/shop/rush-system-health-monitors/rush-426-wizard/

Sponsored By:

PSC-8742 Low Power High Efficiency with Integrated Hold-up Power Supply

3U VITA 62 20W to 190W low power, high efficiency 28V DC/ DC power supply with MIL-STD-704 Hold-up of 50 msec integrated for 135W load.

Dawn PSC-8742 Low Power High Efficiency with Integrated Hold-up Power Supply. 20W to 190W low power, high efficiency 28V DC/DC power supply with MIL-STD-704 Hold-up of 50 msec integrated for 135W load.

Available in Standard VPX and SOSA VPX versions.

Dawn PSC-8742 (Standard VPX version) offers following output currents:

•+5V @ 20A.

•+3.3V @ 4A (& 3.3V_Aux).

(Note: Total wattage from +5V & +3.3V outputs not to exceed 100W).

•+12V @ 6A.

•-12V_Aux @ 3A.

•+12V_Aux @ 3A.

(Note: Total wattage from +12V & +12V_Aux outputs not to exceed 72W.)

Dawn PSC-8742 (SOSA VPX version) offers following output currents:

•+12V @ 10A (VS3).

•+3.3V @ 4A (& 3.3V_Aux).

(Note: Total wattage from +12V (VS3) & +3.3V outputs not to exceed 120W.)

• +12V @ 6A (VS1).

• -12V_Aux @ 3A.

• +12V_Aux @ 3A.

(Note: Total wattage from +12V & +12V_Aux outputs not to exceed 72W.)

(Note: Total wattage from -12V_Aux outputs not to exceed 36W.)

www.dawnvme.com/shop/rush-system-health-monitors/rush-426-wizard/

The Spring VITA Technologies Resource Guide provides the latest technical information and updates on VPX, OpenVPX, SOSA, SpaceVPX, and other standards to engineers, managers, and decision-makers in the United States and internationally.

The Resource Guide will also highlight such key electronics-buying categories as FMC, OpenVPX, Operating Systems & Tools, PMC/XMC, Uncrewed Systems, Radar/EW, and Rugged Computing. Don’t miss this issue!

When the mission calls for a 3-phase 3U power supply that can stand up to the most rugged environments, the military chooses VPXtra 704™ from Behlman – the only VPX solution of its kind built to operate seamlessly from MIL-STD-704F power for mission-critical airborne, shipboard, ground and mobile applications.

> 3-phase AC or 270V DC input; high-power DC output

> Available holdup cards store 700W of DC power for up to 80 msec

> Overvoltage, short circuit, over-current and thermal protection

> Provides full output performance during both normal and abnormal transients