www.opengroup.org/sosa 2023 | Volume 3 | Number 1 2023 Interview with Mike Orlovsky, chair of the Business Working Group, SOSA Consortium P 16 To subscribe to the SOSA Update, Radar/EW, and McHale Report e-newsletters, and receive future copies of the SOSA Special Edition, CLICK HERE. To subscribe to The Open Group’s SOSA E-newsletter, CLICK HERE.

By

By

EDITOR’S PERSPECTIVE

9 SOSA a key part of MOSA mindset

By John McHale, Editorial Director

SOSA FEATURES

10 SOSA Membership List

14 SOSA Consortium Information

16 Interview with Mike Orlovsky, chair of the Business Working Group for the SOSA Consortium

20 Is high-performance electronic warfare compatible with open standards?

By Robert Normoyle, Herrick Technology Laboratories

24 Bringing the benefits of GCIA to next-generation ground vehicles

By Jacob Sealander, Curtiss-Wright Defense Systems

By Jacob Sealander, Curtiss-Wright Defense Systems

28 Exploiting direct RF FPGAs for electronic warfare

By Rodger Hosking, Mercury

34 MOSA, SOSA, VPX, and power considerations

By Matt Renola

40 Multi-INT and SOSA: A consideration of next steps

By Patrick Collier, Aspen Consulting Group and Denis Smetana, Curtiss-Wright Defense Solutions

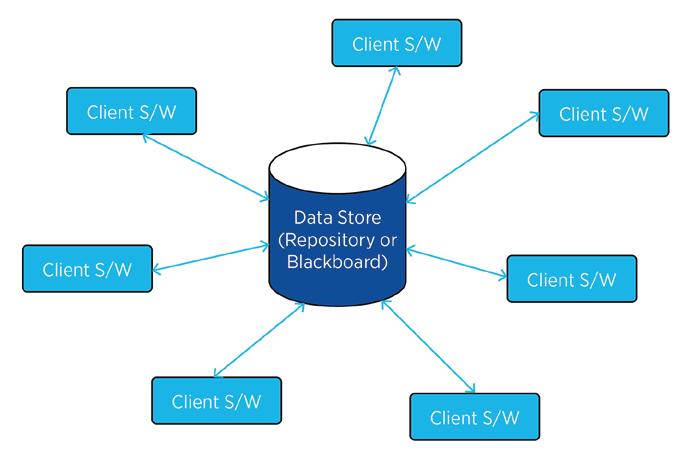

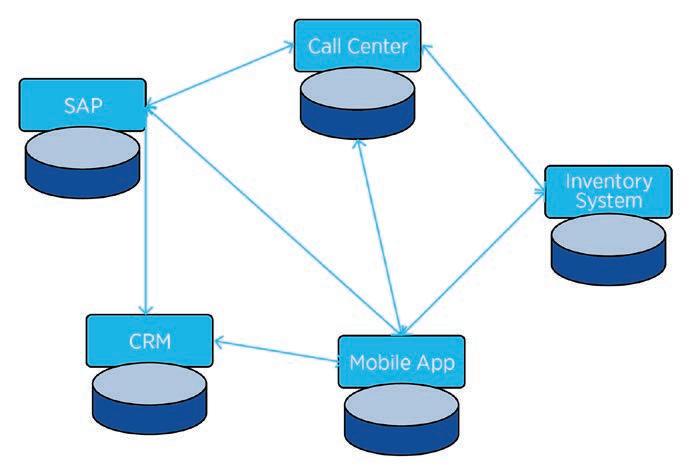

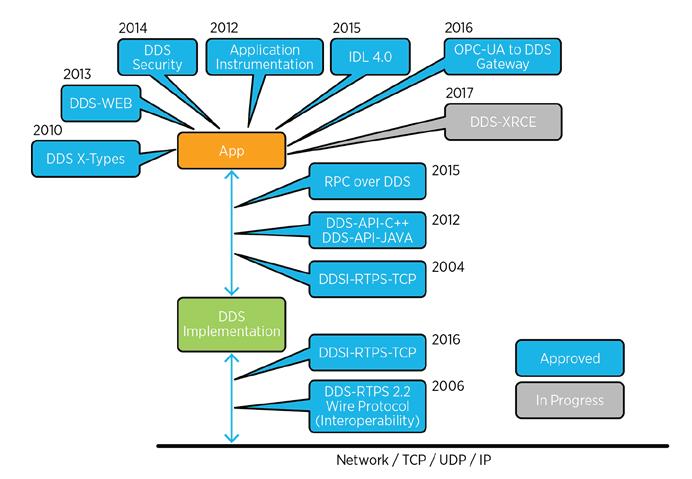

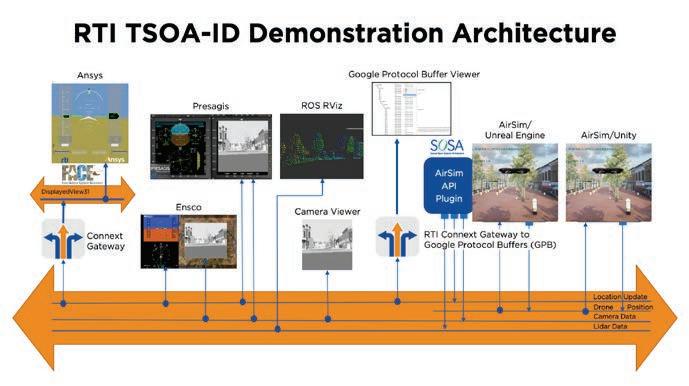

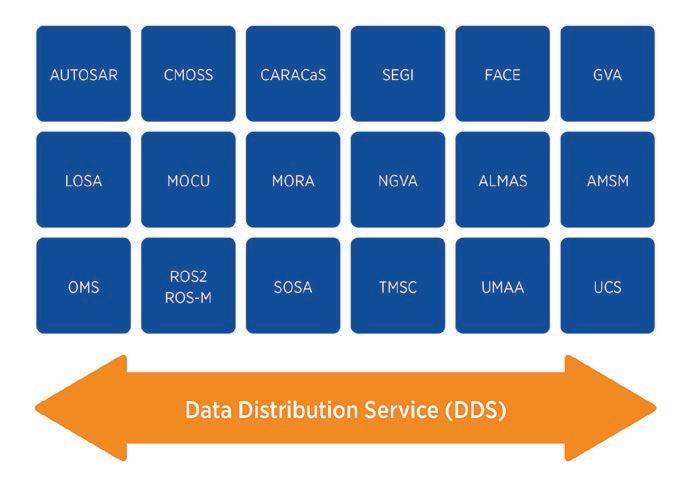

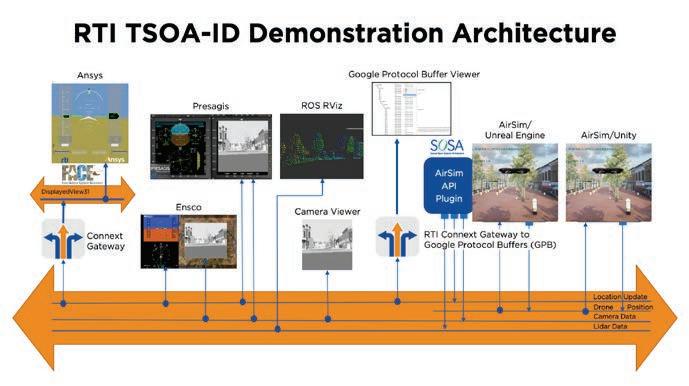

44 MOSA systems: The benefits of deploying a datacentric architecture

By Andre Odermatt, RTI

By Andre Odermatt, RTI

ON THE COVER

The U.S. Department of Defense’s most recently introduced bomber aircraft, the B-21 Raider, is expected to serve within a larger family of systems for conventional long-range strike, including intelligence, surveillance and reconnaissance; electronic attack; communications; and other capabilities. It is nuclear-capable and designed to accommodate manned or unmanned operations. The Raider was designed with a modular open systems architecture (MOSA) approach. U.S. Department of Defense photo.

50 SOSA’s rubber is meeting the road in rapid system development

By Travis Doll, Sciens Innovations and John Orlando, Epiq Solutions

54 AI, open standards to play key role in future SWaP designs for UAS payloads

By Dan Taylor

By Dan Taylor

SOSA SPEAKOUTS AND PROFILES

58 SOSA Speakouts

64 SOSA Profiles

© 2023 SOSA Special Edition

@theopengroup 2023 VOLUME 3 NUMBER 1 SOSA™ and logo design and

States

other countries.

The Open Group Certification Mark™ are trademarks of The Open Group in the United

and

© 2023 OpenSystems Media

SOSA’s rubber is meeting the road in rapid system development

By Travis Doll, Sciens Innovations and John Orlando, Epiq Solutions p.50

Bringing the benefits of GCIA to next-generation ground vehicles

4 | SOSA Special Edition 2023 www.opengroup.org/sosa

Jacob Sealander, Curtiss-Wright Defense Systems p.24

Gold Sponsors

PG SPONSOR

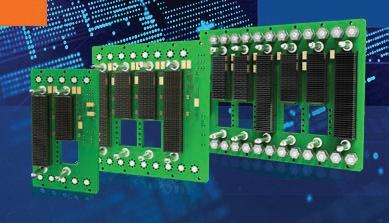

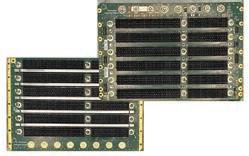

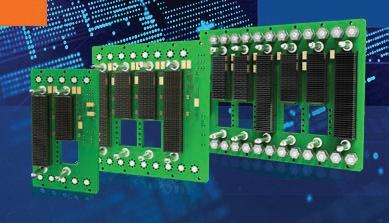

3 Annapolis Micro Systems –

The only full ecosystem of 3U & 6U 100GbE products aligned with SOSA

58 Annapolis Micro Systems –Executive Speakout

8 Atrenne – When failure is not an option

58 Atrenne – Executive Speakout

7 Elma Electronic – Leaders in modular open standards that enable the modern warfighter VPX

59 Elma Electronic – Executive Speakout

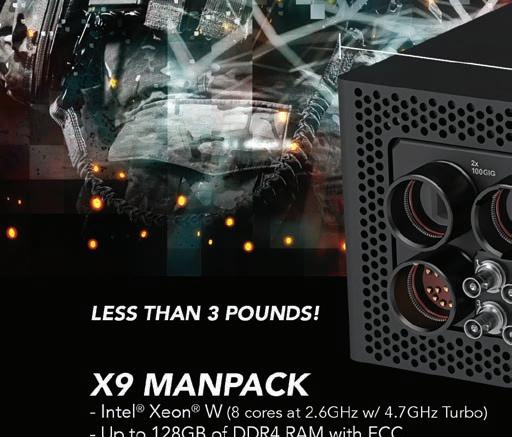

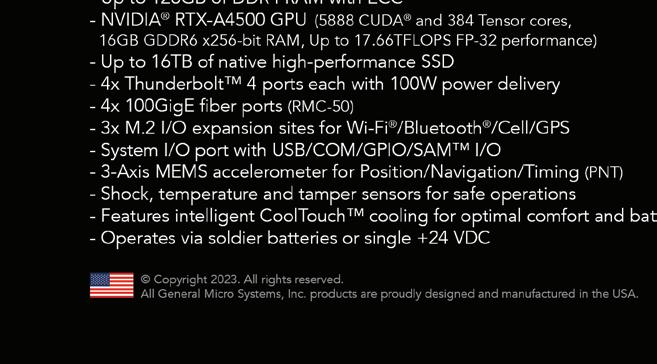

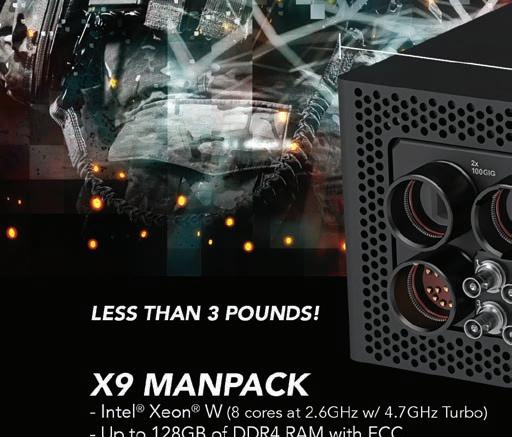

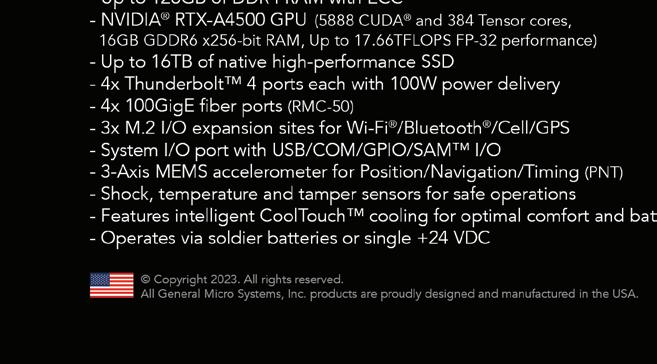

13 GMS – X9 Spider. The world’s most powerful full-feaetured wearable AI computer

60 GMS – Executive Speakout

2 Kontron – Introducing the VX307H

60 Kontron – Executive Speakout

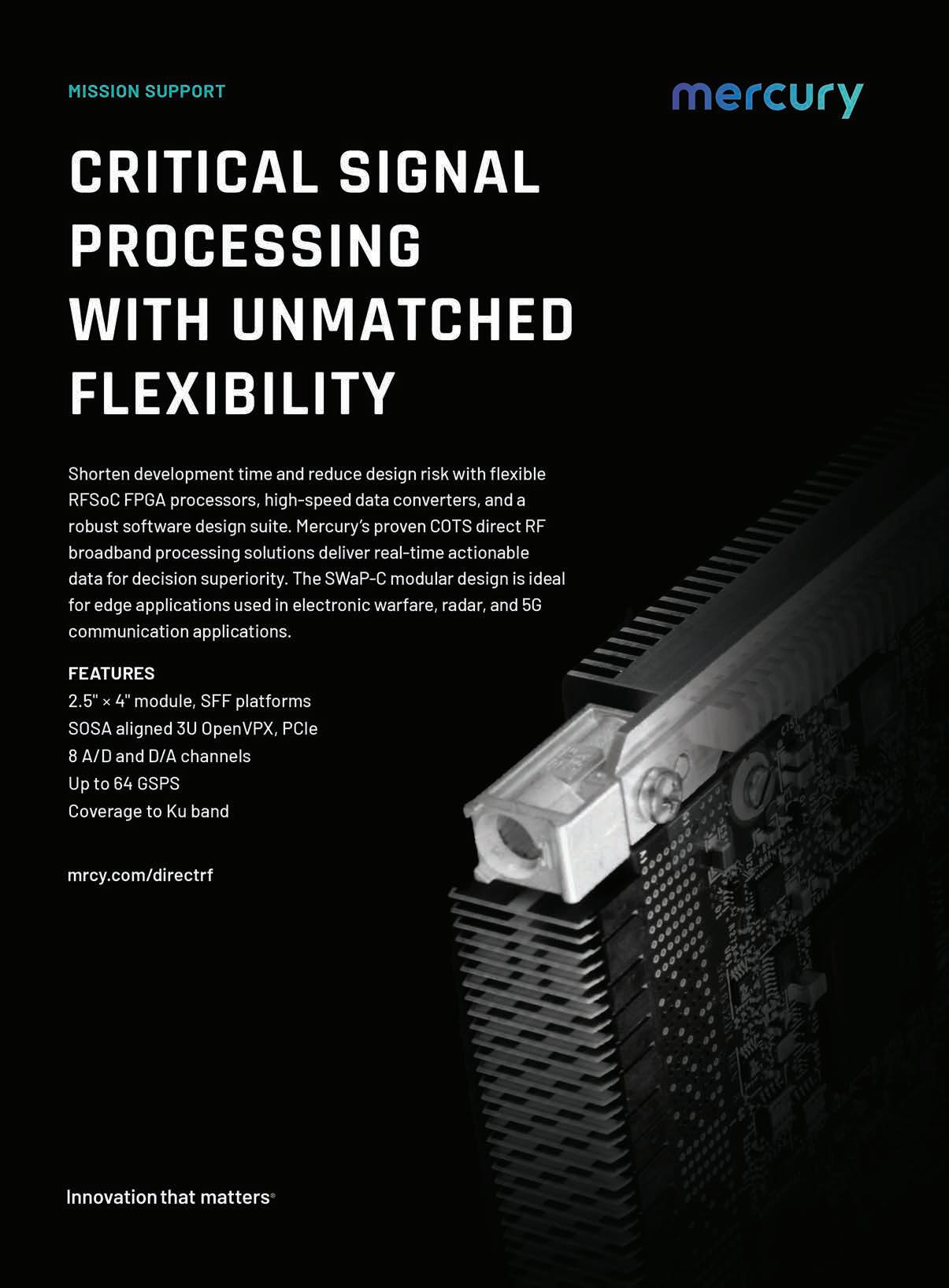

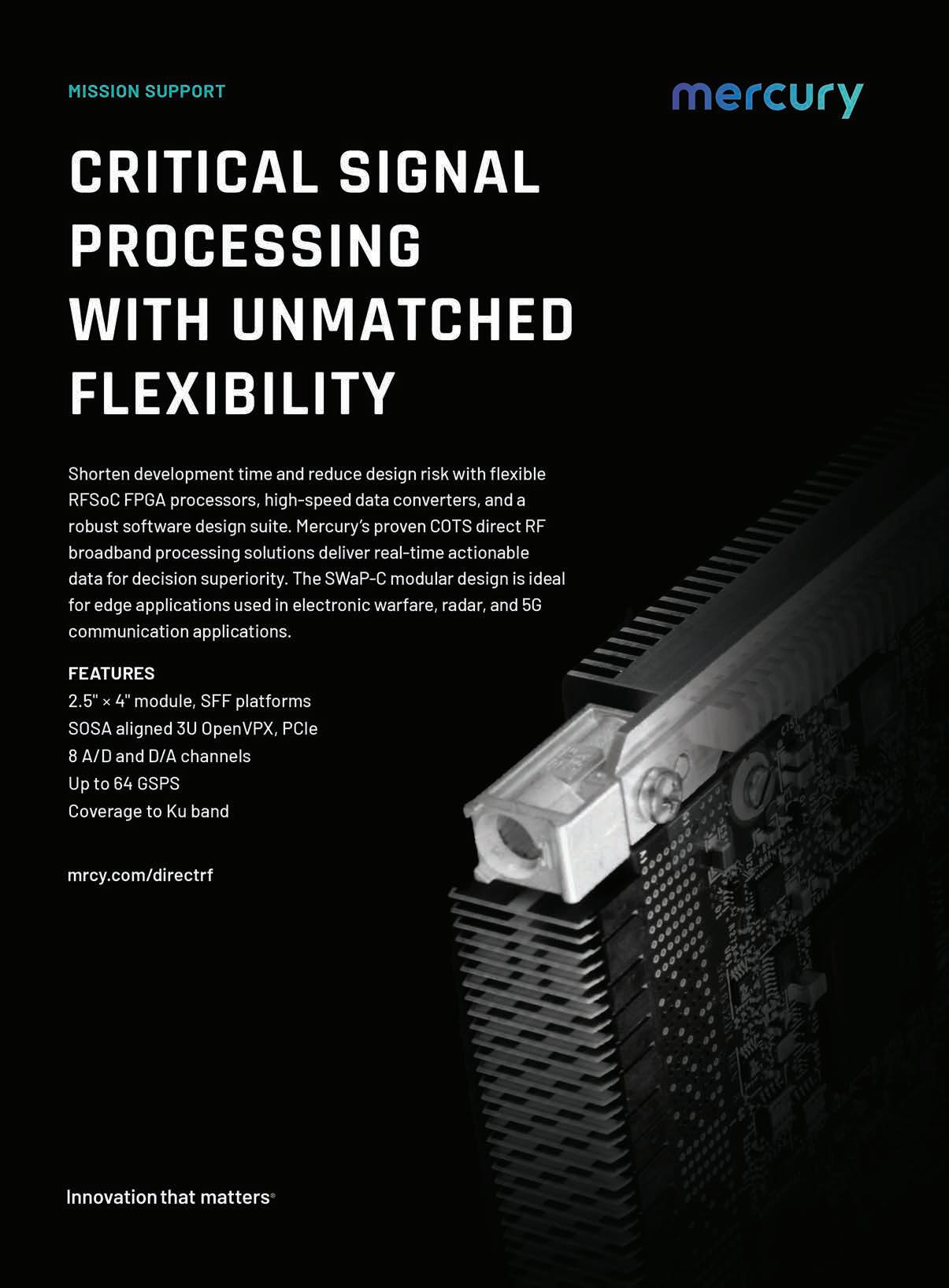

61 Mercury Systems, Inc. –Executive Speakout

84 Mercury Systems, Inc. –Critical signal processing with unmatched flexibility

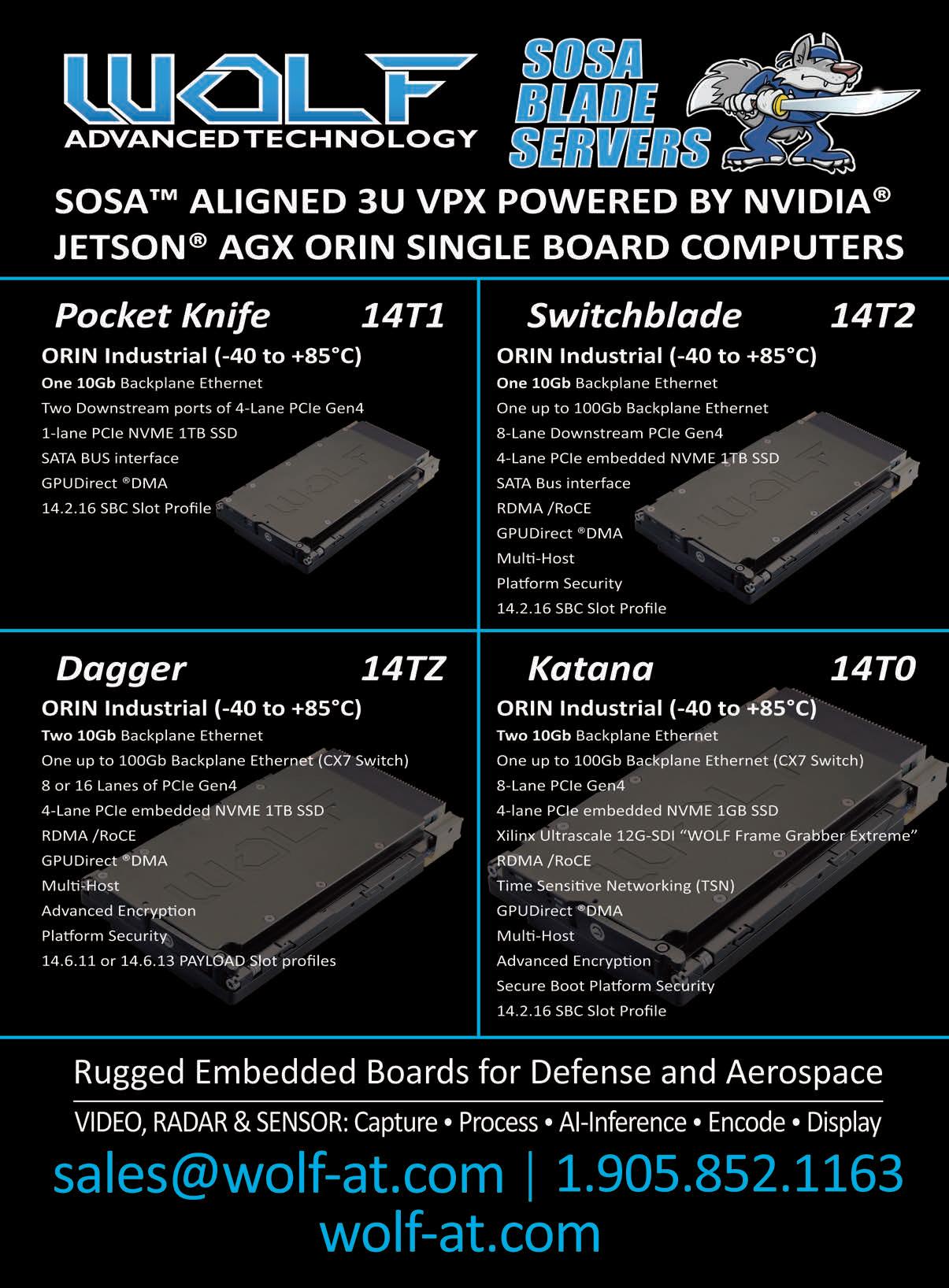

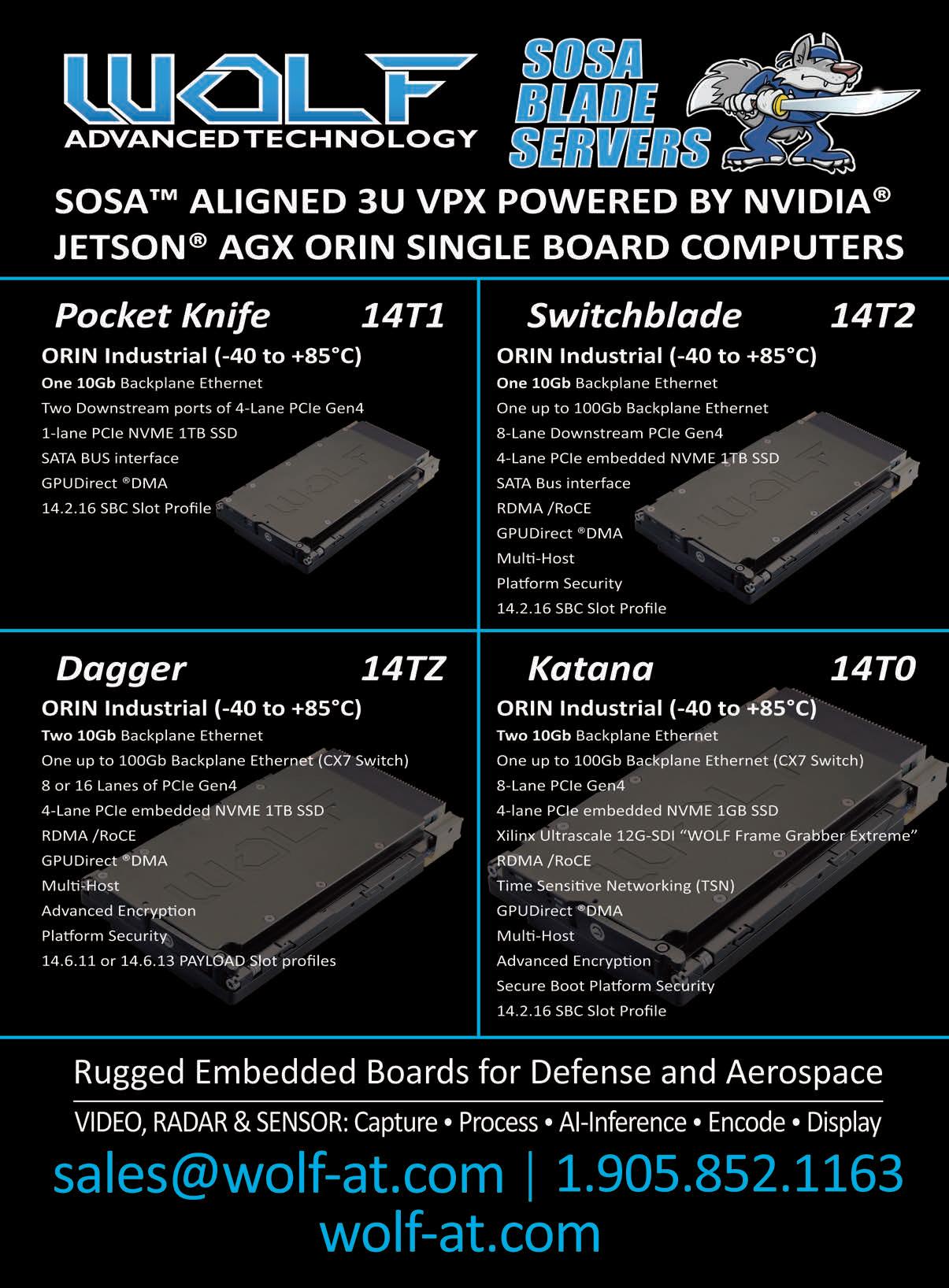

5 Wolf Advanced Technology –

SOSA aligned 3U VPX powered by NVIDIA Jetson AGX Orin single board computers

63 Wolf Advanced Technology –Executive Speakout

Advertiser Index

aligned OpenVPX chassis with advanced cooling

39 PWR Advanced Cooling Technology –Engineering the unfair advantage

26 Rantec – Engineered power conversion for tactical applications

49 Samtec – Interconnect solutions

43 Sealevel – Get it right

63 SR Technologies (SRT Group) –Executive Speakout

19 The Open Group –The Open Group SOSA Consortium

GROUP EDITORIAL DIRECTOR John McHale john.mchale@opensysmedia.com

ASSISTANT MANAGING EDITOR Lisa Daigle lisa.daigle@opensysmedia.com

TECHNOLOGY EDITOR Dan Taylor dan.taylor@opensysmedia.com

CREATIVE DIRECTOR Stephanie Sweet stephanie.sweet@opensysmedia.com

WEB DEVELOPER Paul Nelson paul.nelson@opensysmedia.com

EMAIL MARKETING SPECIALIST Drew Kaufman drew.kaufman@opensysmedia.com

WEBCAST MANAGER Marvin Augustyn marvin.augustyn@opensysmedia.com

VITA EDITORIAL DIRECTOR Jerry Gipper jerry.gipper@opensysmedia.com

SALES/MARKETING

DIRECTOR OF SALES Tom Varcie tom.varcie@opensysmedia.com (734) 748-9660

DIRECTOR OF MARKETING Eric Henry eric.henry@opensysmedia.com

OPERATIONS & AUDIENCE DEVELOPMENT (541) 760-5361

STRATEGIC ACCOUNT MANAGER Rebecca Barker rebecca.barker@opensysmedia.com (281) 724-8021

STRATEGIC ACCOUNT MANAGER Bill Barron bill.barron@opensysmedia.com (516) 376-9838

STRATEGIC ACCOUNT MANAGER Kathleen Wackowski kathleen.wackowski@opensysmedia.com (978) 888-7367

SOUTHERN CAL REGIONAL SALES MANAGER Len Pettek len.pettek@opensysmedia.com (805) 231-9582

DIRECTOR OF SALES ENABLEMENT Barbara Quinlan barbara.quinlan@opensysmedia.com AND PRODUCT MARKETING (480) 236-8818

INSIDE SALES Amy Russell amy.russell@opensysmedia.com

STRATEGIC ACCOUNT MANAGER Lesley Harmoning lesley.harmoning@opensysmedia.com

EUROPEAN ACCOUNT MANAGER Jill Thibert jill.thibert@opensysmedia.com

TAIWAN SALES ACCOUNT MANAGER Patty Wu patty.wu@opensysmedia.com

CHINA SALES ACCOUNT MANAGER Judy Wang judywang2000@vip.126.com

PRESIDENT Patrick Hopper patrick.hopper@opensysmedia.com

EXECUTIVE VICE PRESIDENT John McHale john.mchale@opensysmedia.com

EXECUTIVE VICE PRESIDENT AND ECD BRAND DIRECTOR Rich Nass rich.nass@opensysmedia.com

TECHNOLOGY EDITOR Curt Schwaderer curt.schwaderer@opensysmedia.com

ASSOCIATE EDITOR Tiera Oliver tiera.oliver@opensysmedia.com

ASSOCIATE EDITOR Taryn Engmark taryn.engmark@opensysmedia.com

PRODUCTION EDITOR Chad Cox chad.cox@opensysmedia.com

MARKETING COORDINATOR Katelyn Albani katelyn.albani@opensysmedia.com

FINANCIAL ASSISTANT Emily Verhoeks emily.verhoeks@opensysmedia.com

SUBSCRIPTION MANAGER subscriptions@opensysmedia.com

CORPORATE

REPRINTS

OFFICE 1505 N. Hayden Rd. #105 • Scottsdale, AZ 85257 • Tel: (480) 967-5581

WRIGHT’S MEDIA REPRINT COORDINATOR Kathy Richey clientsuccess@wrightsmedia.com (281) 419-5725

6 | SOSA Special Edition 2023 www.opengroup.org/sosa PG ADVERTISER 53 Amphenol Aerospace –Data is dominance 33 Behlman Electronics, Inc. –3 Phase. 3U. 1 Choice. 46 Cyber Radio Solutions –3U VPX MORA/SOSA compliant SDR platforms 59 Cyber Radio Solutions –Executive Speakout 37 Eizo Rugged Solutions –The future of high-performance embedded computing has arrived 38 Epiq Solutions –3U VPX spectrum dominance 27 LCR Embedded Systems, Inc. –Develop. Demonstrate. Deploy. 61 LCR Embedded Systems, Inc. –Executive Speakout 62 Milpower Source –Executive Speakout 62 New Wave DV –Executive Speakout 32 North Atlantic Industries –Unmatched modularity, unbeatable performance 23 Pixus Technologies –SOSA

www.opensysmedia.com

Leaders in Modular Open Standards that Enable the Modern Warfighter VPX

Get all the latest slot profiles aligned to SOSATM 1.0 and CMOSS in a single backplane, plus VITA 46.11 chassis management, air and conduction cooled guides, and much more.

With you at every stage!

elma.com Elma Electronic Inc.

A Attrreennnne e C Coommppuuttiinng g S Soolluuttiioonns s atrenne.com W h e n f a i l u r e i s n o t a n o p t i o n Enclo sures ackpl a ne ystem Inte gration Custom S olutions CompactPCI VM E 1972-2022 Years

Editor’s Perspective

By John McHale, Editorial Director

SOSA a key part of MOSA mindset

Welcome to the SOSA Special Edition 2023, our third offering of what is an annual issue highlighting editorial content on The Open Group’s Sensor Open Systems Architecture (SOSA) Technical Standard from the pages and website of Military Embedded Systems magazine, as well as the products aligned and conformant to the Technical Standard – all put together exclusively by our staff.

Even before the release of the SOSA Technical Standard revision 1.0, the consortium was a key component of the U.S. Department of Defense’s (DoD’s) push toward having new systems and upgrades leverage open architectures, as mandated four years ago in the socalled Tri-Service Memo from the U.S. Air Force, Army, and Navy leadership, which asserted that a modular open systems approach (MOSA) for weapon systems “is a warfighting imperative.”

The bottom line: MOSA approaches will enable long-term schedule and cost savings for the DoD.

Based on feedback from the SOSA community, savings are already happening, said David Tremper, Director, Acquisition Integration and Interoperability, Office of the Undersecretary of Defense, in his keynote at the MOSA Virtual Summit held February 22 and hosted by Military Embedded Systems

He listed specifics he heard directly from the SOSA Technical Standard community illustrating these savings.

› “The cost to generate a proposal has gone down 75%.”

› “The reusable NRE compounds, creating billions in savings when tens of companies apply SOSA across multiple programs.”

› “High TRL [technology readiness level] system that used to take us

24 months to build is now available in under six months.”

› “The new funding we get is going toward new capability development, not platform integration.”

Tremper called on the community to continue providing “quantifiable metrics of value-added” and sharing them with DoD leadership.

MOSA is also being embraced by the Special Operations Forces (SOF). At SOF Week 2023, Jim Smith, U.S. Special Operations Command (USSOCOM) Acquisition Executive at SOF Acquisition, Technology & Logistics, told me that the SOF community is “absolutely invested in [MOSA]. We want to have a best-ofbreed capability, we want many industry partners to solve some tough problems. To do that and work within the JADC2 [Joint All-Domain Command and Control] construct, we have to pursue open architectures. We found it’s very conducive to not only competition but [also for] having a ‘big tent’ philosophy for our partners.”

Smith cited the Mission Command System as just one example of MOSA’s impact: This system involves more than 17 different vendors contributing to the capability, he said. Smith attributed the success of this approach to USSOCOM’s adherence to open architecture, which prevents designers and vendors from being locked into proprietary systems.

USSOCOM also created a new Program Executive Office for SOF Digital Applications in an effort to accelerate the software-acquisition process, Smith noted. “We now have six-plus programs that are in continuous development/continuous deployment pipeline for software acquisition. We’ve completely changed the culture on how we’re doing that, and what’s made that hum is our absolute adherence to MOSA.”

Accelerating the DoD acquisition process continues to be a challenge, as I noted late last year in my November/December 2022 Editorial Perspective column. My point was that changing this type of bureaucracy is not easy, as there’s no replacement for government-acquisition processes, so new processes are needed to test, develop, and procure technology and get it more quickly into the hands of warfighters.

Consortia like SOSA and the Future Airborne Capability Environment (FACE) provide a gateway for nontraditional defense suppliers and small businesses to gain entry into the defense market.

“Small businesses with niche capability have had a hard time getting into bigger acquisition programs because they were not part of the prime community,” Tremper said in his keynote address. “[Now putting the] government in a position where it can bring in a third-party integration of hardware and software is profoundly important for small-business insertion into big acquisition.”

The SOSA Consortium provides tools and guides for helping businesses get involved in SOSA. In the Q&A on page 16, Mike Orlovsky, senior scientist at L3Harris and chair of the SOSA Consortium’s Business Working Group, discusses those guides and more.

Neither this edition, nor the prior two, could have happened without the help and cooperation of Reggie Hammond and her colleagues at The Open Group, as well as the SOSA Outreach Committee cochairs – Valerie Andrew of Elma Electronic and Gina Peter of Mercury Systems. Many thanks for everyone’s help on this third iteration of the SOSA Special Edition.

www.opengroup.org/sosa SOSA Special Edition 2023 | 9

About the SOSA TM Consortium

www.opengroup.org/sosa

The Open Group Sensor Open Systems Architecture (SOSA™) Consortium enables government and industry to collaboratively develop open standards and best practices to enable, enhance, and accelerate the deployment of affordable, capable, interoperable sensor systems. The SOSA™ Consortium is creating open system reference architectures applicable to military and commercial sensor systems and a business model that balances stakeholder interests. The architectures employ modular design and use widely supported, consensus-based, nonproprietary standards for key interfaces.

For additional information please visit https://www.opengroup.org/sosa.

SOSA SPONSOR

Air Force Life Cycle Management Center

https://www.aflcmc.af.mil/

Collins Aerospace

https://www.collinsaerospace.com/

Joint Tactical Networking Center

https://www.jtnc.mil/

Lockheed Martin

https://www.lockheedmartin.com/

Marine Corps Systems Command, Product Manager EWS

https://www.marcorsyscom.marines.mil/ Portfolios/CES/

NAVAIR

https://www.navair.navy.mil/

NIWC Atlantic

https://www.niwcatlantic.navy.mil/

U.S. Army CCDC C5ISR

https://c5isr.ccdc.army.mil/

U.S. Army PEO Aviation

https://asc.army.mil/web/tag/ peo-aviation/

U.S. PEO C3T

https://asc.army.mil/web/peos/

U.S. Army PM PNT

https://pm-pnt.army.mil/home

US Army Project Manager

Electronic Warfare and Cyber

https://peoiews.army.mil/

U.S. Space Force Space and Missile Systems Center

https://www.spaceforce.mil/

SOSA PRINCIPAL

BAE Systems Inc

https://www.baesystems.com/en/home

Booz Allen Hamilton

https://www.boozallen.com/

Cubic Corporation

https://www.cubic.com/

Curtiss-Wright Defense Solutions

https://www.curtisswrightds.com/

Elbit Systems of America

https://www.elbitsystems-us.com/

FLIR Systems

https://www.flir.com/

GE Aviation Systems

https://www.geaviation.com/

General Dynamics

https://www.gd.com/

Huber+Suhner Astrolab

https://www.hubersuhner.com/en

Intel Corporation

https://www.intel.com/content/www/us/ en/homepage.html

L3Harris

https://www.l3harris.com/

Leonardo DRS

https://www.leonardodrs.com/

Mercury Systems

https://www.mrcy.com/

NASA

https://www.nasa.gov/

Northrop Grumman Corporation

https://www.northropgrumman.com/

Raytheon Technologies

https://www.rtx.com/

Sierra Nevada Corporation

https://www.sncorp.com/

SR Technologies

https://www.srtgrp.com/

SRC, Inc.

https://www.srcinc.com/

VadaTech

https://www.vadatech.com/

SOSA ASSOCIATE

II-VI Aerospace and Defense

https://www.iiviad.com/

Abaco Systems

https://www.abaco.com/

Acromag, Inc.

https://www.acromag.com/

Aegis Power Systems

https://aegispower.com/

AirBorn, Inc.

https://www.airborn.com/

10 | SOSA Special Edition 2023 www.opengroup.org/sosa

SOSA ASSOCIATE (continued)

Aitech

https://aitechsystems.com/

Amphenol

https://amphenol.com/

Ampro ADLINK Technology, Inc

https://www.adlinktech.com/en/Index

Analog Devices

https://www.analog.com/en/index.html

Anduril Industries

https://www.anduril.com/

ANELLO Photonics

https://www.anellophotonics.com/

Annapolis Micro Systems Inc.

https://www.annapmicro.com/

Apogee Semiconductor

https://apogeesemi.com/

Atrenne

https://www.atrenne.com/

Ball Aerospace

https://www.ball.com/aerospace

Behlman Electronics

https://www.behlman.com/

CACI International

https://www.caci.com/

Chameleon Consulting Group

https://chameleoncg.com/

Cobham Advanced Electronic Solutions

https://caes.com/

CodeMettle

https://www.codemettle.com/

Comtel Electronics

https://comtel-online.com/

Concurrent Technologies

https://www.gocct.com/

Cornet Technology

https://cornet.com/

COTSWORKS, LLC

https://cotsworks.com/

CRFS

https://www.crfs.com/

Critical Frequency Design

https://www.criticalfrequency.com/

Crossfield Technology

https://www.crossfieldtech.com/

Crystal Group

https://www.crystalrugged.com/

Dawn VME Products

https://www.dawnvme.com/

Delta Information Systems

https://www.delta-info.com/ DornerWorks

https://dornerworks.com/

DRS Signal Solutions

https://www.leonardodrs.com/

DRTI

https://drti.com/

EIZO Rugged Solutions

https://www.eizorugged.com/

Elma Electronic

https://www.elma.com/en

EPI

https://www.engineeredprod.com/

Epiq Solutions

https://epiqsolutions.com/

Epirus

https://www.epirusinc.com/

Expeditionary Engineering, Inc.

https://www.xp-eng.com/

FiberQA

https://www.fiberqa.com/

Freedom Power Systems

https://www.vicorpower.com/all-products/ vicor-power-systems

Frontgrade Technologies

https://frontgrade.com/

GALT Aerospace

https://www.galt.aero/

General Micro Systems, Inc.

https://www.gms4sbc.com

Georgia Tech Research Institute

https://gtri.gatech.edu/

Glenair

https://www.glenair.com/

GORE

https://www.gore.com/

Herley Industries, Inc.

https://www.ultra.group/us/

Herrick Technology Laboratories, Inc.

https://www.herricktechlabs.com/

HII Mission Technologies

https://hii.com/what-we-do/divisions/ mission-technologies/

Hughes Network Systems

https://www.hughes.com/

IDEAS Engineering & Technology

https://www.ideas-tek.com/

Inertial Wave, Inc.

https://www.inertialwave.com/

Innoflight, LLC

https://www.innoflight.com/

Interface Concept

https://www.interfaceconcept.com/

iRF Solutions

http://irf-solutions.com/

ITT Cannon LLC

https://ittcannon.com/

ITZ, LLC

https://itz.org/

Jacobs

https://www.jacobs.com/

Jovian Software Consulting

https://www.joviansc.com/

Kontron America

https://www.kontron.com/en

LCR Embedded Systems, Inc.

https://www.lcrembeddedsystems.com/

Lead Dog Technologies

https://leaddog.tech/

Leidos

https://www.leidos.com/

www.opengroup.org/sosa SOSA Special Edition 2023 | 11

SOSA ASSOCIATE (continued)

LGS Innovations

https://www.caci.com/

Mathtec, Inc.

https://mathtechinc.com/ Meritec

https://meritec.com/

Micro Focus (USA) Inc.

https://www.microfocus.com/en-us/home

Microchip Technology Inc.

https://www.microchip.com/

Micropac

https://www.micropac.com/

Midwest Microwave Solutions

https://www.mms-rf.com/

Milpower Source

https://milpower.com/

Moog Inc.

https://www.moog.com/

Motorola Solutions Inc.

https://www.motorolasolutions.com/ en_us.html

New Wave Design and Verification

https://newwavedv.com/

North Atlantic Industries, Inc

https://www.naii.com/

NVIDIA

https://www.nvidia.com/en-us/

One Stop Systems

https://onestopsystems.com/

OnTime Networks

https://ontimenet.com/

Orion Technologies, LLC

http://www.oriontechnologies.com/

Orolia Defense & Security

https://www.oroliads.com/

Pacific Defense

https://www.pacific-defense.com/

PacStar

https://pacstar.com/

Parry Labs, LLC

https://parrylabs.com/

Phoenix International

https://www.phenxint.com/

Pixus Technologies USA

https://pixustechnologies.com/ Quantic Electronics

https://quanticnow.com/

QRC Technologies

https://www.qrctech.com/

RADA Technologies LLC (RADA USA)

https://radausa.com/

Rantec Power Systems

https://rantec.com

Real-Time Innovations, Inc.

https://www.rti.com/en/

REDCOM Laboratories

https://www.redcom.com/ Red Hat

https://www.redhat.com/en

Red Rock Technologies

https://www.redrocktech.com/

Riverside Research

https://www.riversideresearch.org/

RTD Embedded Technologies, Inc. https://www.rtd.com/

Saab, Inc.

https://www.saab.com/

Samtec, Inc.

https://www.samtec.com/

Sciens Innovations

https://www.sciensinnovations.com/

ScioTeq

https://www.scioteq.com/en

Sealevel Systems

https://www.sealevel.com/

Selex Galileo

https://www.leonardo.us/

SI2 Technologies

https://www.si2technologies.com/

Skayl LLC

https://www.skayl.com/

Smiths Interconnect Americas

https://www.smithsinterconnect.com/

Southwest Research Institute

https://www.swri.org/

StreamDSP, LLC

https://streamdsp.com/

Systel, Inc.

https://www.systelusa.com/

TE Connectivity

https://www.te.com/usa-en/home.html

Technology Service Corporation

https://www.tsc.com/

Tektronix

https://www.tek.com/

Telephonics

https://www.telephonics.com/

The MITRE Corporation

https://www.mitre.org/

Tomahawk Robotics

https://www.tomahawkrobotics.com/

Tucson Embedded Systems, Inc.

https://www.tucsonembedded.com/

University of Dayton Research Institute

https://udayton.edu/udri/

Variable Software

https://www.variablesw.com/

ViaSat, Inc.

https://www.viasat.com/

VITA

https://www.vita.com/

W-IE-NE-R Power Electronics Corp.

http://wiener-us.com/

Wolf Advanced Technology

https://wolfadvancedtechnology.com/

Note: List current as of 7/25/2023

12 | SOSA Special Edition 2023 www.opengroup.org/sosa

SOSA TM Consortium Information

As sensor systems increase in number, applications, cost and complexity, users need to address issues such as affordability, versatility and capabilities. Sensor systems should be rapidly reconfigurable and reusable by a greater number of stakeholders. The Open Group’s SOSA Consortium enables government and industry to collaboratively develop open standards and best practices to enable, enhance, and accelerate the deployment of affordable, capable, interoperable sensor systems.

The SOSA Consortium is creating open system reference architectures applicable to military and commercial sensor systems and a business model that balances stakeholder interests. The architectures employ modular design and use widely supported, consensus-based, nonproprietary standards for key interfaces that are expected to:

Email The Open Group ogsosa-admin@opengroup.us.

For more information, visit www.opengroup.org/sosa

LinkedIn: www.linkedin.com/company/the-open-group/

Twitter: https://twitter.com/theopengroup

You Tube Channel: https://www.youtube.com/user/theopengroup/video

• Reduce development cycle time and cost

• Reduce systems integration cost and risk

• Increase commonality and reuse

• Reduce sustainment and modernization cost

• Support capability evolution and mitigate obsolescence

• Enable technology transition

• Facilitate interoperability

• Isolate the effects of change

14 | SOSA Special Edition 2023 www.opengroup.org/sosa

Consortium Information

JOIN THE SOSA CONSORTIUM

Get involved and gain influence in defining open standards and certifications

Being a member of The Open Group gives organizations early access to the latest information and developments regarding open standards and best practices, and enables them to participate in The Open Group’s highly influential Forums and Work Groups. We provide a collaborative, vendor-neutral environment where member representatives can:

• Network with a world-class community of peers, experts, and industry leaders

• Have early access to information on industry developments

• Gain insight for future decisions from both major customers and suppliers of IT

• Influence outcomes that benefit their organizations

• Grow professionally, and enhance their credibility in the industry

• Learn best practices

The SOSA Consortium provides a vendor-neutral forum for industry and government to work together to develop capabilities and support for modular, open sensor systems.

The SOSA approach provides an agile and platform-agnostic open systems architecture for multi-intelligence C4ISR systems. The architecture incorporates both hardware and software components to handle demanding processing and data requirements, ease system upgrades, reduce total cost of ownership, and promote competitive acquisition with minimal system reworks.

Contact The Open Group if your organization is interested in joining. One of our membership representatives will get in touch to provide you with the rules of engagement and membership information.

Email The Open Group ogsosa-admin@opengroup.us.

THE OPEN GROUP: MAKING STANDARDS WORK

The Open Group works with customers and suppliers of technology products and services, and with consortia and other standards organizations, to capture, clarify, and integrate current and emerging requirements, establish standards and policies, and share best practices. Our standards ensure openness, interoperability, and consensus.

The Open Group is a global consortium that enables the achievement of business objectives through technology standards. With more than 900 member organizations, we have a diverse membership that spans all sectors of the technology community –customers, systems, and solutions suppliers, tool vendors, integrators, and consultants, as well as academics and researchers.

TM

SOSA

www.opengroup.org/sosa SOSA Special Edition 2023 | 15

SOSA interview with Mike Orlovsky

Below is the excerpted transcript of an interview previously conducted by the SOSA consortium with Mike Orlovsky, the Business Working Group chair for the consortium.

What is your title at L3Harris and level of participation in the Sensor Open Systems Architecture (SOSA) consortium?

ORLOVSKY: I’m a senior scientist with L3Harris. My role is to focus on open system architectures, the modular open system approach (MOSA), and model-based system engineering. I’m focused on the high-performance needs of sensor and signal processing. In the SOSA Consortium, I serve as the Business Working Group (BWG) chair. My involvement with the SOSA Consortium started around the 2015 timeframe, and I’ve been working with open system architectures since the early 1990s. In that time, we’ve seen tremendous growth, with the emergence of reference architectures and the defining of the hardware and software implementation of those reference architectures.

Before my participation in the SOSA Consortium, I was with a small team focused on application of the Future Airborne Capability Environment (FACE) Consortium products. We joined a large team demonstrating a software-defined system applying the FACE Technical Standard. Our group demos were centered around the sensor portions of the mission system.

These demos clearly showed the significant value of application reuse, but my biggest takeaway was the benefits realized at the integration phase. With open systems, and the conformance-checking tools on those interfaces – even though we were working with sophisticated sensor systems – integration went a lot quicker.

Did the FACE Consortium provide an example or model for the SOSA Consortium from a software perspective?

ORLOVSKY: The answer is yes, but it’s threefold. Yes, the FACE Consortium provided a model framework for standards development that SOSA was able to leverage. Yes, the FACE consortium hosted SOSA working groups for about 18 months until the SOSA Consortium officially stood up. And, yes, the SOSA Technical Standard leverages the FACE software and data standards, and the FACE Consortium. Given my experience with open systems, with consortium-based standards development, the FACE Technical Standard, and my keen interest in making sensors more agile, I took a role in the SOSA Consortium. I was the inaugural software working group chair. As the consortium grew, the Software Working Group evolved into the Software Environment Subcommittee, which was led by Michael Majors, as I transitioned to the chair of the Business Working Group.

SOSA SPECIAL EDITION 16 | SOSA Special Edition 2023 www.opengroup.org/sosa

Mike Orlovsky

Under your leadership, the BWG has developed the SOSA Business Guide and will soon release the SOSA Acquisition and Contracting Guide. Were those assets modeled on preexisting and similar FACE documents or were you starting from scratch?

ORLOVSKY: There were, I believe, two prior BWG chairs and an initial release of the Business Guide. When I became chair, George Dalton was the vice chair. George and I worked out our vision for what the BWG products would be. Our fundamental charter was to focus on the business aspects of the SOSA Technical Standard deliverables to complement an exceptional team working on the technical standard. We had two existing subcommittees, one focused on Business Architecture and the other on Outreach, working on the external facing side of the SOSA Consortium market.

The Outreach Committee, co-chaired by Valerie Andrew and Gina Peter, is very closely engaged in communicating to the outside world. For example, they work closely with groups like the Association of Old Crows (AOC), and Association of the United States Army (AUSA), and they reach out to different communities to share the SOSA Consortium message. In the Business Architecture subcommittee, co-led by Mondo Mikhail, Pete Jha, and Jeff Evans, we define the set of products needed to support the SOSA Consortium business ecosystem. So, when a company or program is looking to use and apply the SOSA Technical Standard, we’ve developed and provided them with the information they would need. We’ve laid out, and are delivering on a plan, for the different guides to help interested people understand the SOSA Consortium Business Ecosystem.

The Business Guide makes the case for the SOSA Consortium, explaining to the reader what the benefits of the SOSA Technical Standard are, while the Acquisition and Contracting Guide, shows the reader, once convinced, how they would go about using and implementing the SOSA Technical Standard? Is that correct?

ORLOVSKY: The Business Guide provides the overall picture. When released, the Acquisition and Contracting Guide will provide specific guidance and examples of language that various acquisition authorities can tailor to meet their program needs. This will help to ensure customers receive SOSA aligned products that will deliver the MOSA benefits they are trying to achieve. [The Acquisition and Contracting Guide is currently in formal review; the document is expected to be released by the end of 2023.]

To help ensure customers get what they want, we’ve also started working on a Supplier Guide, to help suppliers prepare for this new marketplace. Specifically, the purpose of the Supplier Guide is to help suppliers progress through the SOSA ecosystem starting from a design, through conformance, to producing a product that is conformant to the SOSA technical standard. We’ll be developing the Supplier Guide throughout 2023, and we encourage customers and suppliers to engage in the consortium to help design a more productive SOSA marketplace.

Will the Supplier Guide take suppliers through the process from inception to deployment?

ORLOVSKY: Exactly. With complex systems, you can have many interpretations, so the guide helps you get started very quickly. The Business Guide, Acquisition and Contracting Guide, and Supplier Guide are all developed to be in harmony with the conformance program, the technical standard, and the reference implementation guide. Together, they are all part of the SOSA Technical Standard body of knowledge that will create a more efficient and innovative sensor marketplace.

When you were putting the Acquisition and Contracting Guide together, what were some of the most common questions that you wanted to address?

ORLOVSKY: Many of us have developed proposals in the past and, given our experience and perspective, we wanted to explain what that actually meant from a business perspective, rather than to simply issue a one-line edict saying, “You shall be SOSA conformant.” Providing consistent reference language that a supplier will recognize will also help them as they are developing their response to an RFP.

The Acquisition and Contracting Guide is intended to provide the business framework to help ensure a more efficient marketplace for sensor solutions that deliver the benefits of MOSA. The Acquisition and Contracting Guide is, therefore, more focused on the management and contracting personnel. It is intended to complement the technical standard and it assumes that there will be engineering counterparts defining the needed SOSA Technical Standard profiles and requirements.

Is the Acquisition and Contracting Guide audience intended to convince the acquisition community to establish SOSA Technical Standard requirements or to help define those requirements as accurately as possible?

ORLOVSKY: The Business Guide makes the case to establish the SOSA Technical Standard requirements and the Acquisition and Contracting Guide helps to define effective MOSA strategies and contracts by leveraging the SOSA Technical Standard. Since the Tri-Service joint memorandum [in 2019], the government is looking for solutions that are based on open standards. The SOSA Technical Standard allows the development of sensors that are more agile and more adaptable using open interfaces. The SOSA Technical Standard helps to break apart stovepiped solutions and

SOSA SPECIAL EDITION www.opengroup.org/sosa SOSA Special Edition 2023 | 17

provides customers the ability to involve a wider portion of the industry and encourages more creative and competitive solutions to the problem.

Is the Acquisition and Contracting guide crafted to help the widest number of potential respondents clearly understand what’s being asked for and what’s being called out? Essentially, to toss out the widest net possible to encourage and stimulate the greatest amount of creativity and innovation?

ORLOVSKY: Yes, it really is to help open that space to different suppliers so that, through open architectures, they can offer components that will plug in and address the acquirer’s need. This reduces barriers to entry to companies that may not be able to compete at the system level. It truly widens the aperture. Innovation is therefore encouraged at the module level, and a company’s intellectual property – their “secret sauce” – is bounded by open interfaces, but also protected, so they can achieve higher returns on their investment through reuse, upgrades, and sustainment of their products. That’s a double-edged sword, however, because if they rest on their laurels, the open interfaces also allow them to be replaced. That market pressure ensures investment dollars stay focused on innovation which is where our customers and technical teams both want to be.

In the process, was there anything that surprised you the most?

ORLOVSKY: I’d have to say that I was most surprised by how hard it was to get input from subject-matter experts from the acquisition community. With everything going on in the world, these folks are highly tasked, so at times we had to get creative to tap into the expertise and experience of acquisition authorities. We reached out to the various service branches to get their input, we provided sample language for them to review, and we invited their advice. It took a bit longer, but in the end, the guide reflects the work and experience of many people and organizations.

Is that again proof of the value of the consortium model – that instead of working in a vacuum, you had feedback services?

ORLOVSKY: Right. The consortium model for the SOSA Technical Standard has worked extremely well. The service branches and the government side have been very active participants. Similarly, we also have a wide breadth of industry participating, ranging from smaller Tier 3 suppliers to Tier 2 and Tier 1 suppliers. It’s impressive how that cross-section works together. At our face-to-face meetings, we’re drawing upwards of up to 150 and 160 participants. And the consortium can leverage all that experience, which then is reflected in our various products, which in this case, is the Acquisition and Contracting Guide.

Will this be a living document?

ORLOVSKY: Yes. Each of our three guides will go through a revision and modification process very similar to the technical standard, as we learn things and as the ecosystem adapts and evolves. Updates are planned nominally on a three-year drumbeat, at which time the guides will be revisited and either confirmed as still good, or revised to reflect lessons learned. Since, of course, we will all be three years smarter.

Is there anything we didn’t touch on or ask that you were looking forward to discussing?

ORLOVSKY: The one thing that I’m probably most proud of is that we have this exceptional team of talented individuals in the BWG all working on defining these documents. There’s usually a point person to take ownership and get the document through the challenging periods, but it really is the whole team that’s working on and supporting the overall effort. I’m also proud how L3Harris, a principal member in the SOSA consortium, has supported my participation and that of my other colleagues. This work has been very professionally rewarding. Even on those challenging afternoons during face-to-face meetings when working on consensus results in spirited discussions! ■

Michael “Mike” C. Orlovsky is the Business Working Group chair for the Sensor Open Systems Architecture (SOSA) Consortium. Mike has been with SOSA since the incubation (2015) and transition to a full consortium, serving as the Software Working Group Chair from 2016 through the end of 2019. He is a senior scientist in Space & Airborne Systems with L3Harris Technologies.

SOSA SPECIAL EDITION 18 | SOSA Special Edition 2023 www.opengroup.org/sosa

The Open Group SOSA™ Consortium empowers government and industry to collaboratively develop open standards and best practices.

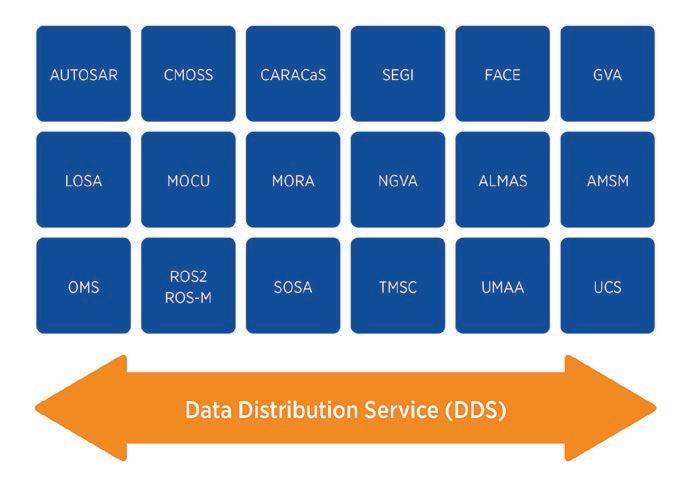

The SOSA Technical Standard leverages and complements open standards in government

open interfaces, enabling the development of capabilities made up of common components. The

components and hardware elements, as well as electrical and mechanical interfaces composing the SOSA sensor element.

For more information and to obtain the SOSA Technical Standard email: ogsosa-admin@opengroup.us

Join the SOSA Consortium Today

We support the warfighters and soldiers in the field and strive to arm them with the electronic tools they need for mission success. Industry, government, and suppliers are successfully joining their unique perspectives to leverage technology and standards in support of the warfighters and soldiers in the field.

https://www.opengroup.org/sosa/join The Open Group: Leading the development of open,

The Open Group is a global consortium that enables the achievement of business objectives through technology standards. Our diverse membership of more than 900 organizations includes customers, systems and solutions suppliers, tool vendors, integrators, academics, and consultants across multiple industries.

® ™

An integrative and inclusive standard to accelerate the development of affordable, agile, and composable sensor systems

Is highperformance electronic

warfare compatible with open

standards?

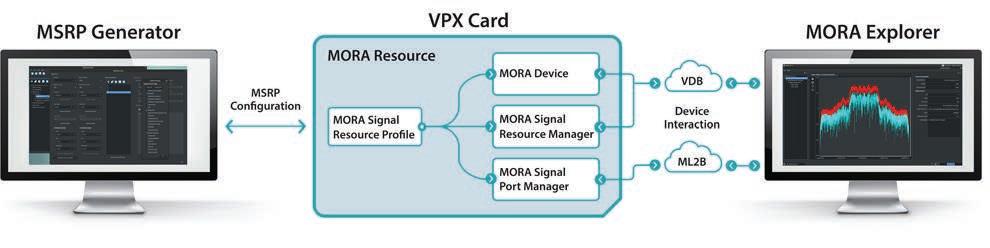

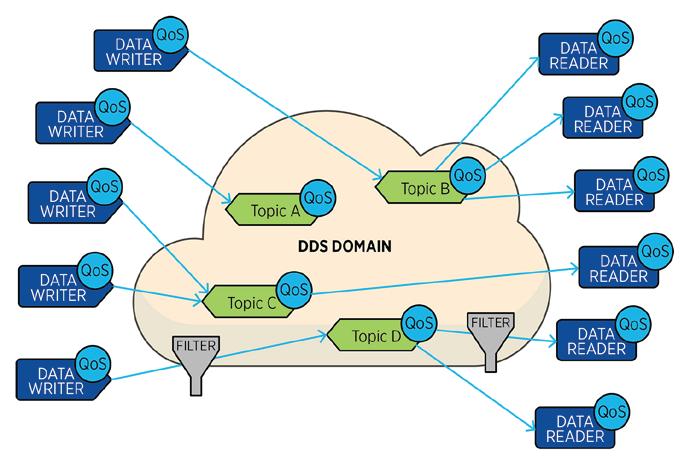

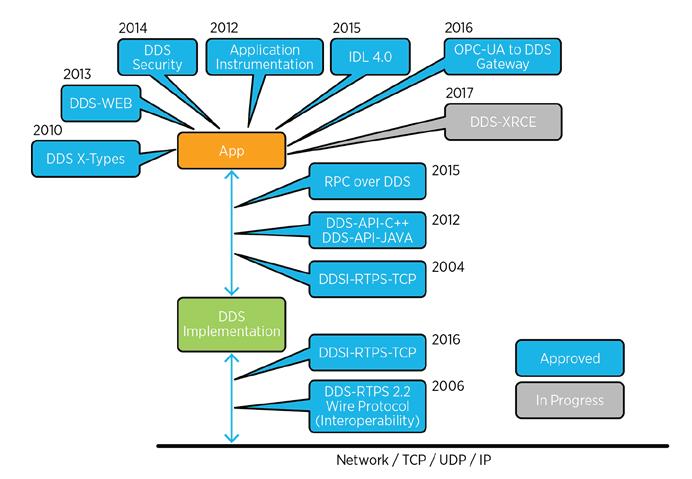

By Robert Normoyle

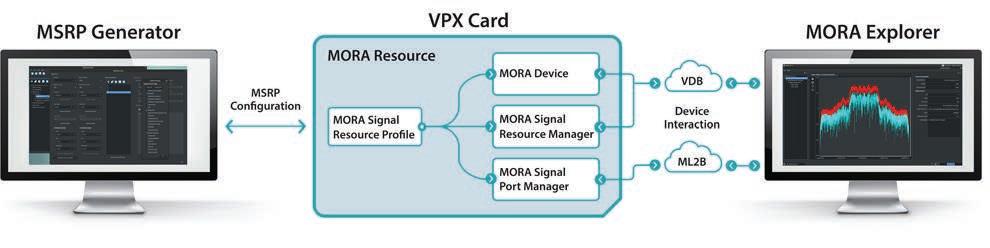

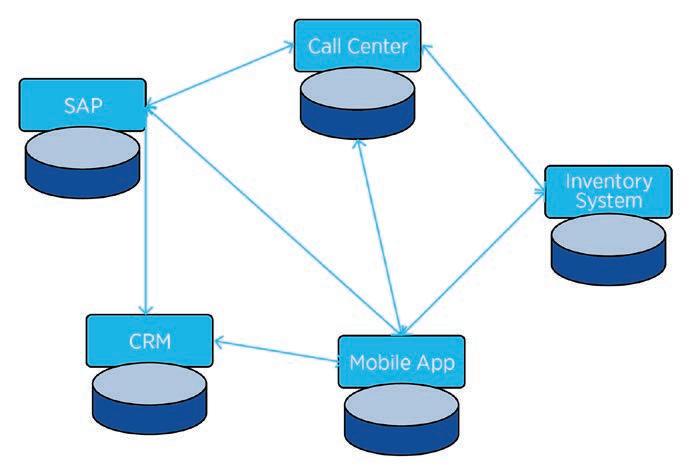

Today, multiple agencies are involved in open architecture standards to ensure that weapons and defense system features match up with their perception of future systems specified and beginning to be used by the U.S. Department of Defense (DoD). Examples of key attributes provided by these standards relevant to electronic warfare (EW) are the VPX backplane profiles and MORA/V49.2 protocols. The DoD has had a hand in developing both of these in order to specify and develop reference architectures to verify performance.

Prior to the promulgation of the SOSA [Sensor Open Systems Architecture] framework, systems integrators based their designs on a standard such as VPX, VXS, or VME, and declared their open architecture, though at that time there wasn’t a robust systemlevel specification to enable interoperability of 3rd-party components. The standards provided mechanical and high-level signal type definitions, leaving designers with a lot of leeway on signal protocols. Often the backplane, the board interfaces, and the data protocol interfaces were proprietary. Even though the designer could state the design as open architecture, the modular open systems approach (MOSA) goals were not effectively achieved – namely, the goals of interoperability, scalability, competition, faster refresh, and lower cost.

This disconnect was even more prevalent with high-performance electronic warfare (EW) systems, since the coordination between components and systems is expected at a nanosecond scale and extreme frequency coverage. A stretch goal for instantaneous frequency coverage has been 2 to 18 GHz, 16 GHz of instantaneous bandwidth, for electronic surveillance (ES), electronic attack, and digital RF memory (DRFM) capabilities. In addition to this range, banded capability at millimeter frequency was also desirable. Even though government agencies specified MOSA-based approaches, there was no technical detailed description of what this meant and how to verify it. The

architectures were so intricately interdependent upon custom designs that changes could only be done by original equipment providers. The government agencies were still tied to a single source for simple upgrades to an architecture, resulting in simple changes to designs costing millions.

Do standards really support interoperability?

The pioneer computer programmer Grace Hopper coined the phrase: “The nice thing about standards is that there are so many of them to choose from”, implying that the use of standards is not effective, and every organization may “choose” to use something different, thus negating interoperability.

SOSA SPECIAL EDITION

20 | SOSA Special Edition 2023 www.opengroup.org/sosa

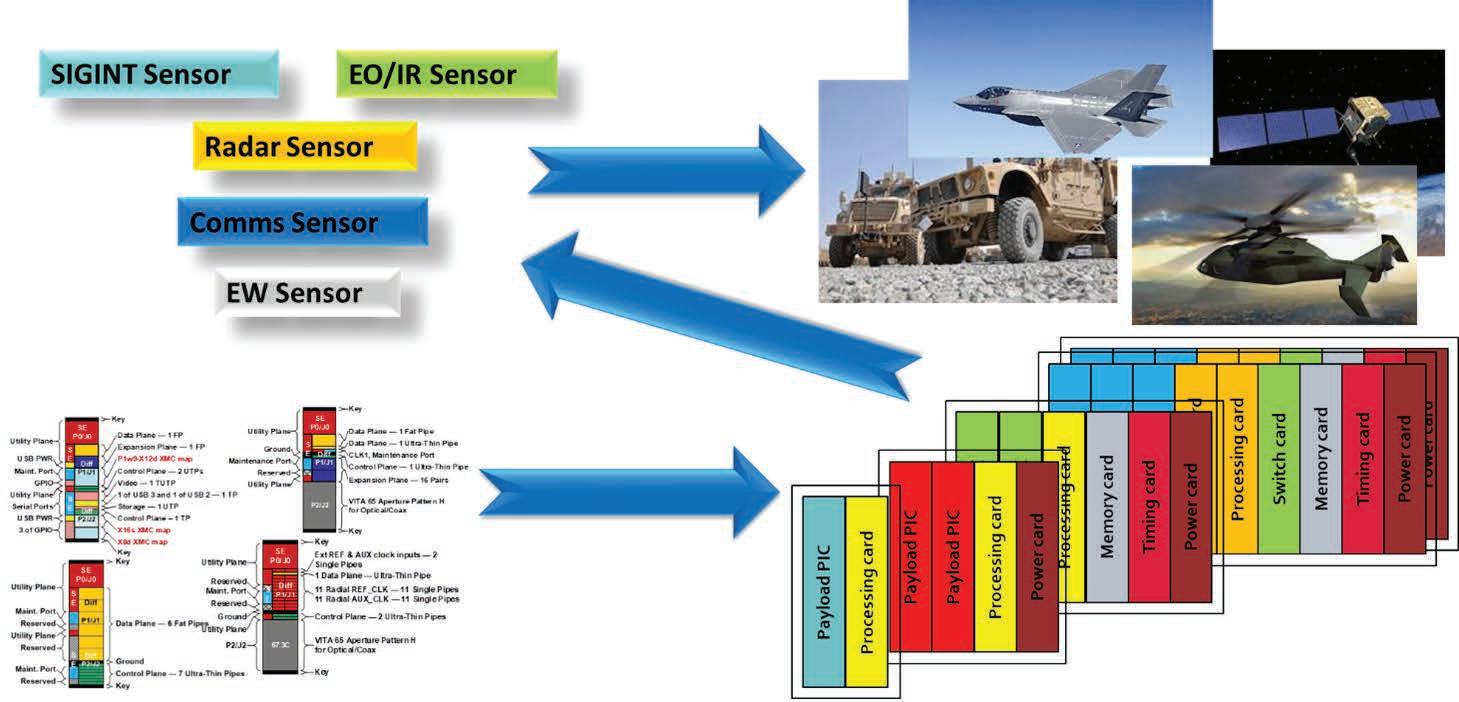

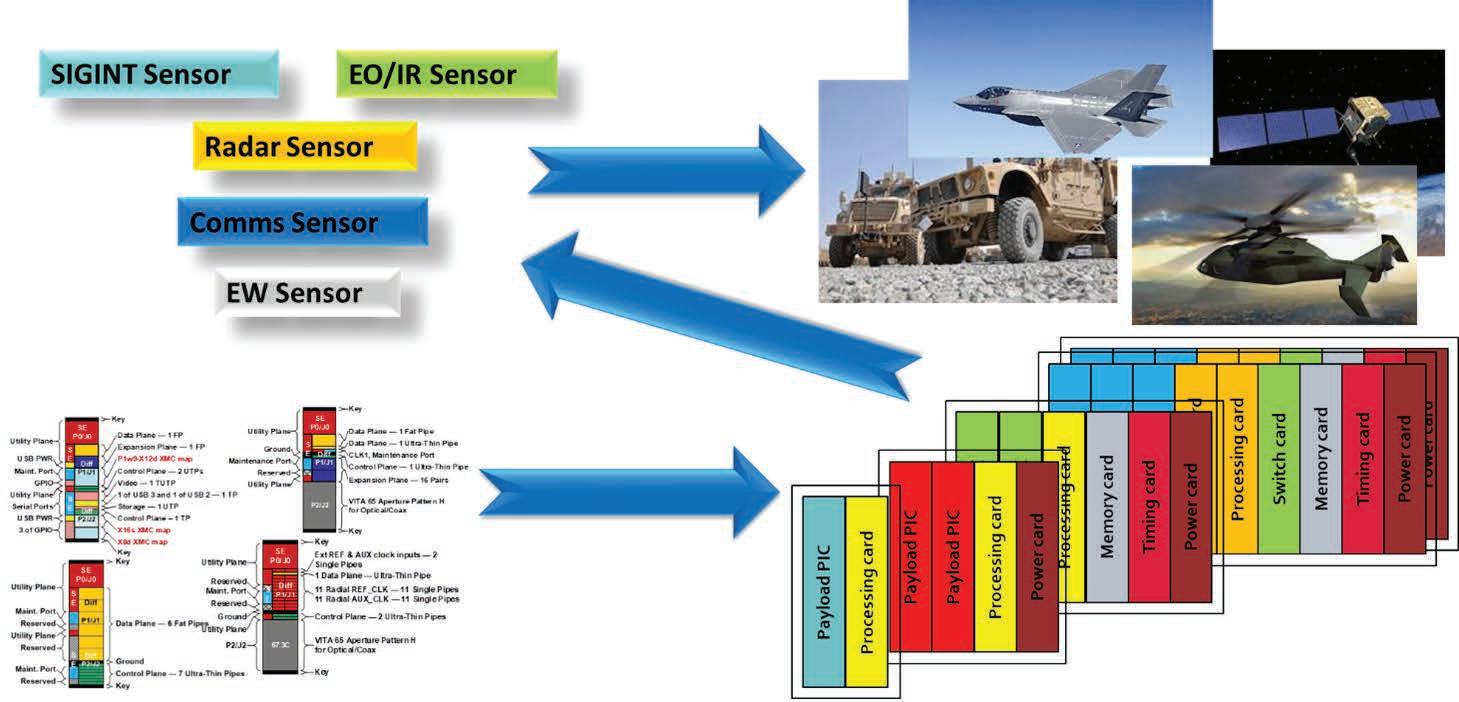

This statement has been a typical pushback about hewing to standards, though over the last five or 10 years there has been a convergence between DoD organizations and industry. Examples of this convergence are the CMOSS [C4ISR/Electronic Warfare Modular Open Suite of Standards], SOSA, and CMFF [CMOSS Mounted Form Factor] efforts, which have been using the best attributes of multiple standards such as VPX, VITA 49, MORA [Modular Open RF Architecture], VICTORY [Vehicular Integration for C4ISR/EW Interoperability], FACE [Future Airborne Capability Environment], and HOST [Hardware Open Systems Technologies] to develop a framework that is being adopted by a majority of the suppliers and becoming required by more and more DoD programs. These interfaces have been designed by a consortium of industry, government, and academia engineers who are vetting the proposed architecture components with their real-life experiences of EW, signals intelligence (SIGINT), radar, and communications systems requirements. This situation is a key difference from how standards were developed a decade earlier, at which time the primary drivers were just industry with very little government involvement.

Can standards really support high-performance EW requirements?

In the early days of digitized audio – namely the 1980s – a similar problem existed, as custom cards were needed to compress/expand audio signals. As personal computer (PC) technology evolved, it became viable to use software-based encoder/decoders on the processors as opposed to using custom hardware solutions. This maturation was an enabler for the development of audio and video compression software that provides interoperability across platforms, whether Mac or PC, at a low cost and with very little effort by the user. When programmable technology approaches the performance to directly process the signal phenomena of interest, then open architecture approaches and standards are viable.

Today we have arrived at a point where the latest processors used for EW analytics and jamming can directly ingest, manipulate, and create jamming waveforms over ultrawide bandwidths. These processors include FPGAs [field-programmable gate arrays] for front-end processing and detection. An EW system can provide frequency coverage of 16 GHz of instantaneous frequency coverage and also provide nanosecond precision control, status, and IQ data interfaces via SOSA standards.

A similar matured situation exists today: Capabilities of software-defined radio (SDR) have reached the information processing rate needed to handle multiple gigahertz of bandwidth. A two-slot 3U VPX card can provide simultaneous transmit and receive capability of 4+ GHz. Multiple copies can be integrated into a SOSA chassis to provide 16 GHz of coverage, such as in a range of 2-18 GHz.

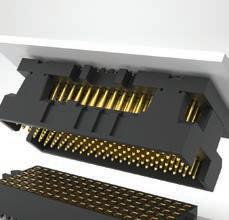

Today, backplane architectures are available that can convey over 200 Gbps of data as GbE and PCI per slot, which is sufficient to convey 4 GHz of data each direction. MORA/V49.2 interfaces provide timestamped high-precision information including IQ data packets, control packets, and status packets between modules and systems. This protocol, combined with the 1 PPS and 100 MHz reference clocks in a system architecture, makes it possible to achieve nanosecond precision. The standards bodies continue to progress efforts to make the standards synergistic and move forward with new enhancements to support emerging technology. New VPX connectors are being defined that support bandwidth of 800 Gbps per module, which is sufficient to convey 16 GHz of instantaneous bandwidth at 16 bits resolution.

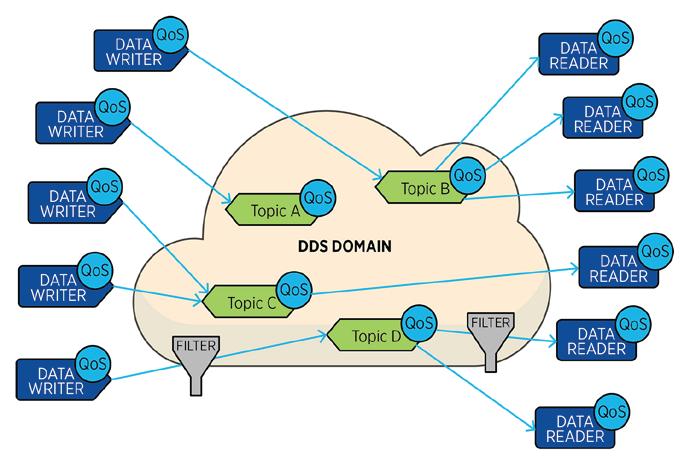

Interoperability advantages of SOSA standard for EW solutions

The SOSA standards group consists of more than 100 organizations and more than 1,000 members, all working to proactively develop an interoperable framework for multiple-intelligence (multi-INT) applications. EW engineers are part of this group and voice their expertise to mold the standard to meet demands of high-performance EW.

The consortium also takes into account the other modalities of operation including communications, radar, and SIGINT. The resulting standards have enabled companies to build products based on the standards, anticipating that multiple DoD programs can leverage them.

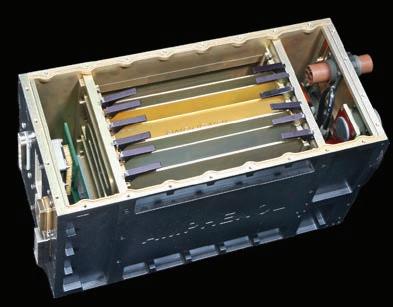

This alignment reduces the time and schedule of acquisition programs because the chassis and the modules are being developed in advance of the acquisition cycle, rather than during the program’s NRE phase. This reality is quite different from legacy acquisitions where chassis were typically custom-designed for an acquisition effort, with commercial off-the-shelf (COTS) modules typically needing modification to support the customization required by the prime. Today, a chassis built for one program is being rapidly deployed for another.

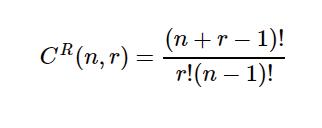

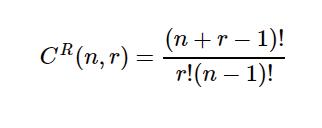

This same phenomenon is also true for VPX modules, where modules from a variety of vendors can be used in multiple chassis. Figure 1 shows the number of combinations viable in four and eight SOSA payload slots, based on 1 to 20 unique payload cards, such as EW SDR. The combination with repetition formula

SOSA SPECIAL EDITION

HTLv-C11 HTLv-C19 Number of Slots 4 8 Card Types Combinations 1 1 1 2 5 9 3 15 45 4 35 165 5 70 495 6 126 1287 7 210 3003 8 330 6435 9 495 12870 10 715 24310 20 8855 2220075

www.opengroup.org/sosa SOSA Special Edition 2023 | 21

Figure 1 | Shown: the configurations in a chassis as a function of card types and number of slots in a chassis.

was used as shown. The repetitions do not include the same cards configured differently in a chassis. The maximum number of SDR modules is based on a quick survey of vendors at the 2022 Association of Old Crows Annual International Symposium and is a conservative number.

The number of configurations is staggering, perhaps not all of them uniquely beneficial, though if only 10% are deployable architectures, it is still an impressive number of configurations compared to the single-purpose chassis of the past since it could provide dozens of architectures ready for redeployment for different missions and platforms. It was unprecedented in legacy EW architectures to reuse modules and chassis for multiple configurations for multiple programs and platforms that are not just EW focused, but multi-INT. Companies are seeing the phenomenon in the integrations of SOSA aligned chassis and SIGINT/EW VPX modules. This situation enables SDR modules from multiple vendors to be used in multiple chassis for a diversity of programs and products providing fully integrated solutions can employ modules from multiple performers.

FPGA partial reconfiguration enables multi-INT capability

The framework and interfaces for a generic mission manager which can support SDR reconfiguration is a being defined by SOSA. Just as there were many ways a chassis can be configured with different SDR modules, there are also many ways that the SDR cards can be dynamically configured to support different mission requirements at the depot or to dynamically change the SDR capability of the chassis in situ of a mission. There are three high-level use cases:

1. A SOSA chassis built for a specific EW program is redeployed to support a different EW program and/or another operational mode such as SIGINT or radar

2. SOSA chassis reconfigured at the depot with an alternate mission-specific card set

3. SOSA chassis dynamically reconfigured in situ to support different modalities of operation

An example of repurposing a notional SOSA chassis payload cards is shown in Figure 2 and 3. In Figure 2, the chassis provides a total of 16 GHz of ES and EA capability by configuring each of the eight payload slots with 2 GHz IBW [instantaneous bandwidth] UWB [ultra wideband] SDRs providing a 20 MHz to 20 GHz frequency coverage. In Figure 3, the same chassis is reconfigured at the depot to provide eight channels for instantaneous precision DF [direction finding] and eight channels for ES [electronic support]. The same chassis provides a high precision interferometer DF while simultaneously providing 8 GHz IBW of frequency coverage.

An example of dynamically reconfiguring a chassis in situ is presented in Table 1. For this notional example, the chassis is configured as shown in Figure 2. It has eight SDR cards each with 2 GHz IBW which can be dynamically configured for different operations during the mission. During the start of the mission, it is in Mode 1, utilizing all the channels for ES providing 16 GHz of IBW surveillance. As it detects targeting threat

radar, it moves to Mode 2, reallocating ES channels for a look-thru jamming technique while still maintaining 14 GHz IBW for ES. When a missile-targeting radar is detected, it moves to Mode 3, by dynamically reloading firmware and bonding channels coherently together to form a digital RF memory (DRFM) jamming channel. While in this mode, there is still 10 GHz of instantaneous BW ES capability. To determine the effectiveness of the EW technique, it switches to Mode 4, reconfiguring UWB SDR 4 and 5 to create a UWB radar. As mentioned

SOSA SPECIAL EDITION

1 2 3 4 5 6 7 8 2 GHz IBW ES/EA 2 GHz IBW ES/EA 2 GHz IBW ES/EA 2 GHz IBW ES/EA 2 GHz IBW ES/EA 2 GHz IBW ES/EA 2 GHz IBW ES/EA 2 GHz IBW ES/EA

Figure 2 | Notional chassis configuration consisting of eight payload slots providing 16 GHz IBW, each with a 20 MHz to 20 GHz frequency range.

1 2 3 4 5 6 7 8 Dual 80 MHz IBW ES/EA Dual 80 MHz IBW ES/EA Dual 80 MHz IBW ES/EA Dual 80 MHz IBW ES/EA 2 GHz IBW ES/EA 2 GHz IBW ES/EA 2 GHz IBW ES/EA 2 GHz IBW ES/EA Mode ID Chassis Mode of Operation UWB Ch 1 UWB Ch 2 UWB Ch 3 UWB Ch 4 UWB Ch 5 UWB Ch 6 UWB Ch 7 UWB Ch 8 1 ES Only ES ES ES ES ES ES ES ES 2 ES + Jam ES ES ES ES ES ES ES EA + ES 3 ES + JAM + DRFM ES ES ES ES ES DRFM1 Rx DRFM1 Tx EA + ES 4 ES + JAM + DRFM + Radar ES ES ES Radar Rx Radar Tx DRFM1 Rx DRFM1 Tx EA + ES

Figure 3 | Notional chassis depot configuration consisting of four payload slots providing Instantaneous DF capability and four payload slots providing 8 GHz IBW, each with a 20 MHz to 20 GHz frequency range.

22 | SOSA Special Edition 2023 www.opengroup.org/sosa

Table 1 | Shown is a notional example of dynamic reallocation of SOSA SDR payloads throughout an EW mission.

earlier, this is a notional representation of one scenario to represent the potential value of dynamic in situ mission management. Many other dynamic configuration usages exist.

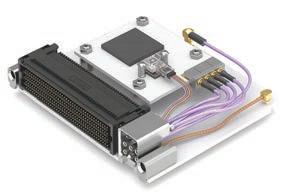

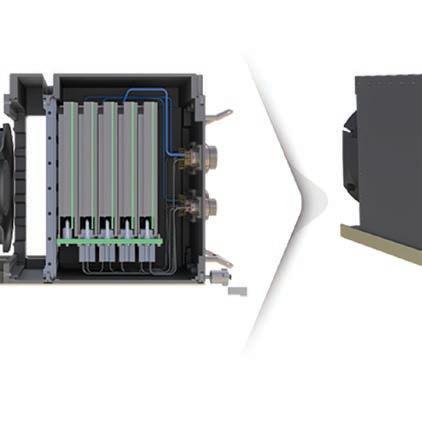

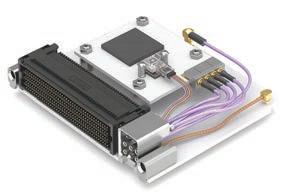

RF and FPGA technology –SOSA aligned for EW

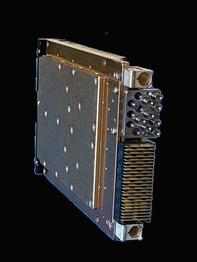

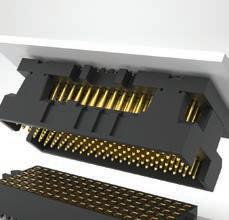

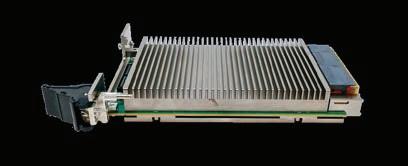

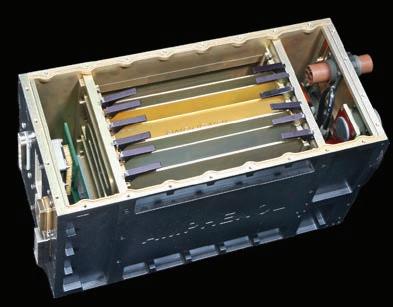

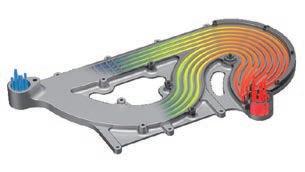

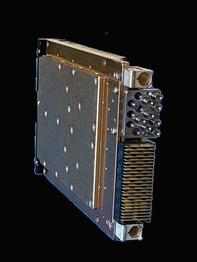

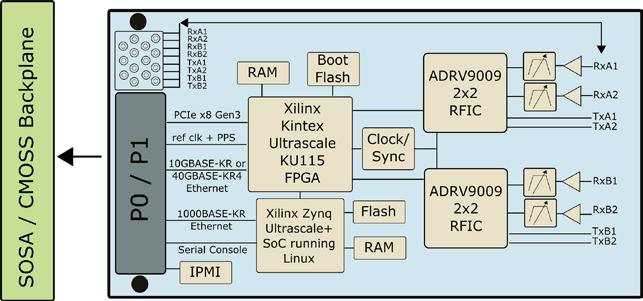

HTL’s UWB SDR module and 19-slot chassis capability is based on the HTLv-43 (RF converter) and HTLv-53 (digitizer + FPGA) which provides a total of 4 GHz of full-duplex simultaneous capability with a frequency range of 20 MHz to 20 GHz. The modules provide four 2 GHz RF tuners: two receivers and two exciters. Each of the channels are independently tunable, though can be made phasecoherent to one another and across multiple cards. The superheterodyne architecture enables the necessary selectivity when operating in congested and/ or contested dynamic RF environments. (Figure 4.)

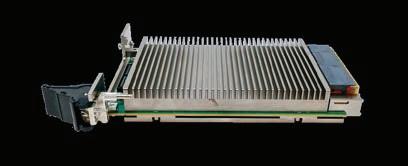

HTL provides both an 11-slot and 19-slot chassis aligned with SOSA release 1.0. These chassis can support dozens of configuration options. With the HTLv-43/53 cards they can support the UWB configuration capabilities presented. With the HTLv-43/53 cards, the 11-slot provides 8 GHz of IBW for both ES and EA or DRFM capability, whereas the 19-slot provides 16 GHz of the same type of capability. The frequency range for each chassis can be extended to 44 GHz with the use of HTL44E frequency extender. ■

Robert Normoyle is the Director of Open Systems at Herrick Technology Laboratories (HTL), where he leads the development of SOSA/CMOSS-based modules and chassis. Mr. Normoyle has more than 40 years of experience developing high-performance EW, radar, and SIGINT systems. He began his career at NRL and has worked at several SDR companies including L3 and DRS. He also worked at Johns Hopkins University Applied Physics Laboratory providing technical guidance to multiple programs for the Navy, ONR, Army C5ISR, and DARPA. He led the APL’s contributions to the V49.2 standard and VPX profiles, which are foundational for the CMOSS and SOSA standards. Readers may reach the author at RNormoyle@HerrickTechLabs.com

Herrick Technology Laboratories

https://www.herricktechlabs.com

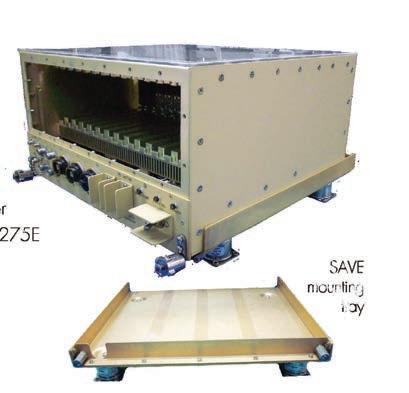

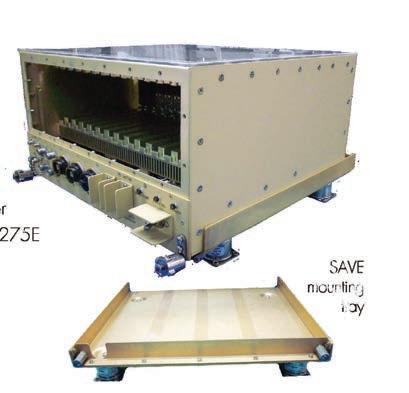

SOSA Aligned OpenVPX

Chassis With Advanced Cooling

• Designed specifically for high-wattage applications

• Various SOSA aligned profile options

• Speeds to PCIe Gen4 and 100GbE

• Modular MIL Rugged design for versatility

• SlotSaver SOSA aligned chassis manager mezzanine

www.pixustechnologies.com

Figure 4 | Shown is the HTLv-53 digitizer plus FPGA.

Figure 4 | Shown is the HTLv-53 digitizer plus FPGA.

www.opengroup.org/sosa SOSA Special Edition 2023 | 23

Bringing the benefits of GCIA to nextgeneration ground vehicles

By Jacob Sealander

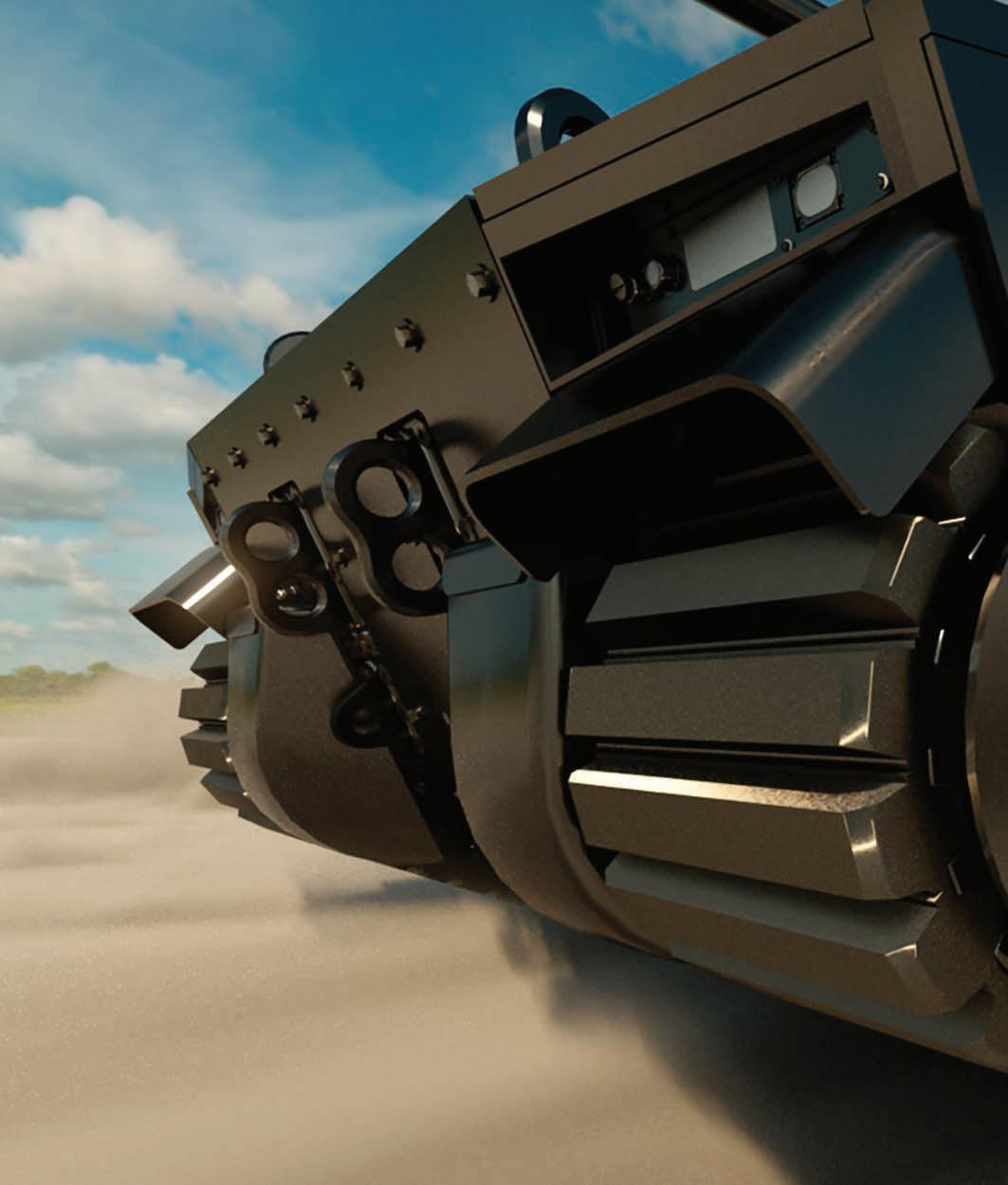

The partnership between Curtiss-Wright and BAE Systems to develop a standardized modular open systems approach (MOSA) open architecture for next-generation ground vehicles is an example of how the benefits of MOSA-aligned open standards can be leveraged to deliver new capabilities to next-generation ground vehicles, such as the U.S. Army’s Optionally Manned Fighting Vehicle (OMFV).

Technological change is driving a new generation of ground combat vehicles, as seen by the U.S. Army’s Optionally Manned Fighting Vehicle (OMFV) competition. Through the OMFV competition, the Army is seeking a new infantry fighting vehicle that is agile, lethal, and survivable while also ready to deploy today’s and tomorrow’s most advanced technology and support tomorrow’s emerging capabilities.

Modular open systems approach (MOSA)aligned solutions are critical for enabling technology on ground vehicles to be rapidly refreshed and new capabilities quickly fielded to meet emerging threats

on the battlefield. A vehicle designed with this level of flexibility can consistently meet and exceed the Army’s specific agility, lethality, and survivability goals. MOSA builds in the room to grow to match the Army’s needs and can be easily upgraded and adapted to remain dominant in the fight.

Key Army initiatives – such as Project Convergence, which led to the creation of standards like Ground Combat Systems (GCS) Common Infrastructure Architecture (GCIA) and CMOSS Mounted Form Factor (CMFF) – have been part of the Curtiss-Wright mission. It has also been directly involved in the development

of many of the foundational standards referenced in GCIA, such as OpenVPX, SOSA, VICTORY [Vehicular Integration for C4ISR/EW Interoperability], MORA [Modular Open RF Architecture], and CMOSS [C5ISR Modular Open Suite of Standards]. GCIA is helping to move the next-generation combat vehicle away from traditional stovepiped and purposebuilt electronics and toward a standardized core infrastructure that can host all of the capabilities needed for OMFV.

The GCIA standard

The GCIA standard defines the requirements for a network computing infrastructure that can host all of the vehicle’s

SOSA SPECIAL EDITION

The brief for the U.S. Army’s Optionally Manned Fighting Vehicle (OMFV) calls for a modular, open systems approach that combines state-of-the-art technologies to equip troops for the ever-changing, interconnected, multidomain, joint battlefield. The OMFV will replace M2 Bradley Fighting Vehicle, versions of which date back to the early 1980s. Curtiss-Wright is partnering with BAE Systems on its OMFV solution, which is aimed at bringing agility, lethality, and mobility solutions to the U.S. Army. Image courtesy BAE Systems/Curtiss-Wright.

24 | SOSA Special Edition 2023 www.opengroup.org/sosa

required functions and enables different sensors and effectors to be easily integrated and plugged into that core infrastructure over time. The use of a GCIA infrastructure eases integration on a specific platform and facilitates integration and data movement between platforms. GCIA delivers numerous benefits, including portability of technology and rapid incorporation of new technology.

It builds on existing standards such as the Sensor Open Systems Architecture (SOSA) Technical Standard and the OpenVPX hardware standard that defines the rugged modules called out in SOSA. By specifying rugged processing, networking, I/O, and graphics modules aligned to the SOSA profiles and built using the OpenVPX modules called out in SOSA, ground vehicles are increasingly moving to a MOSA-based GCIA compliant architecture.

The MOSA system elements included in the GCIA architecture include line-replaceable modules (LRM), line-replaceable units (LRU), chassis, fully integrated systems, and the scheme of connectivity. In addition, the U.S. Army’s Standardized A-Kit/Vehicle Envelope (SAVE) – a new physical size, weight, and power (SWaP) and connector standard for fielding new C5ISR [Command, Control, Computers, Communications, Cyber, Intelligence, Surveillance and Reconnaissance] capabilities – can be leveraged to speed and simplify the installation of CMFF systems in Army vehicles by regularizing the size, shape, and physical interfaces (RF, data, power, etc.) for mounting those types of systems. SAVE joins the CMOSS standards – such as VICTORY, MORA, and OpenVPX – already called out by the GCIA framework, but it covers only the purely physical elements, instead of defining how data flows between the systems integrated on a vehicle.

Delivering key MOSA assets

A GCIA implementation delivers on key MOSA benefits, including the ability to quickly react to evolving threats, easily upgrade systems, and reduce vendor lock to lower costs and drive interoperability. In addition, the standard addresses failure resiliency, because the GCIA system infrastructure uses a distributed network with no single point of failure.

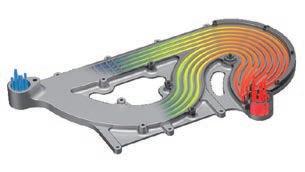

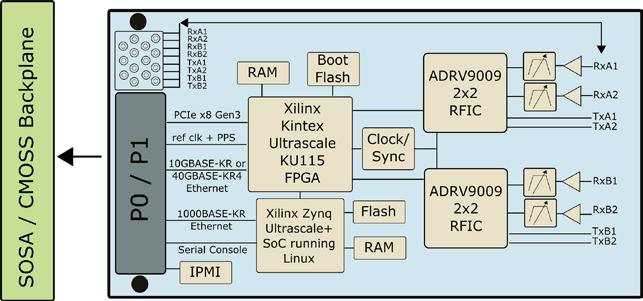

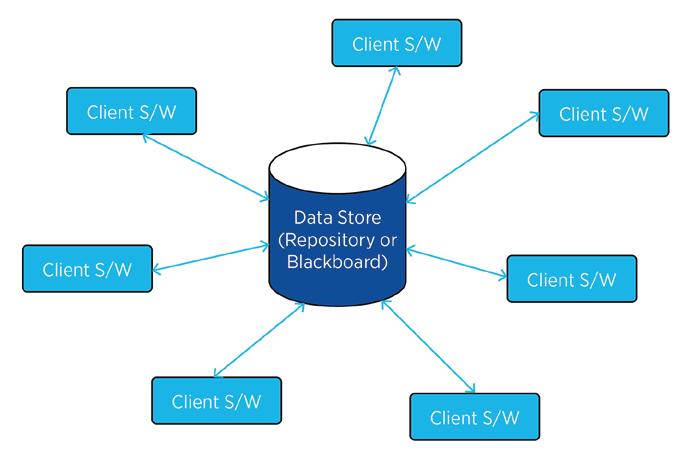

The ability to move applications and functions using distributed network resources to any spot in the vehicle will provide an unprecedented new level of fault resiliency compared to today’s vehicle architectures, in which there is very little built-in redundancy. A distributed network architecture enables multiple different functions to be hosted in the same chassis or located in different places on a vehicle, since they are all connected over the GCIA internal vehicle network (IVN) with data transported using well-defined standards such as VICTORY. (Figure 1.)

GCIA defines how the network moves and shares data to support all the resources needed to host the different functions on a ground combat vehicle. For example, GCIA defines a version of Ethernet that supports TSN [timesensitive network] standards for safetycritical data movement on the standard core network. The GCIA network can accommodate very low latency paths while providing determinism. Diverse capabilities – such as fire control, targeting, 360° situational awareness, and vehicle-protection systems – can all be hosted by the GCIA-defined infrastructure, which minimizes or eliminates the need for specialized hardware.

SOSA SPECIAL EDITION

www.opengroup.org/sosa SOSA Special Edition 2023 | 25

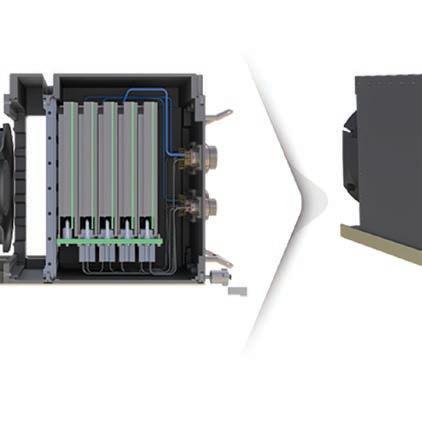

Figure 1 | An eight-slot, user integrationready powered enclosure uses natural convection cooling and can reduce the work of CMOSS/SOSA Technical Standard 1.0 system development.

Today, new ground-vehicle capabilities are typically hosted in their own discrete boxes, all of which host their own internal computers and require a space claim on an already-crowded vehicle. Each box will usually have its own software, which also needs to be able to communicate with the next layer of software on the vehicle network. All of this has to be qualified, which takes a long time to do and adds program risk. GCIA helps to mitigate risk. While it looks to the SOSA Technical Standard for system profile definitions and VITA hardware standards, GCIA limits their approved use to only a handful of SOSA profiles and a narrow subset of hardware standards.

These constraints force designers to build from a much-smaller set of building blocks right from the get-go, which will greatly reduce the time required to field new technology and tech refreshes in ground-combat vehicles. GCIA focuses on the requirements for enabling a core

compute networked infrastructure that will enable a system designer to simply “plug in” all desired capabilities. For example, it directs the use of specific processing and software, and defines the types of displays (dumb versus smart) and security (multilevel security boxes versus single-level boxes).

System designers can use the specified building blocks to develop their software on the very same hardware platform that all other GCIA compliant suppliers are using. That means solutions developed for GCIA-based applications will be transportable between different hardware elements, not just within the vehicle itself, but also from platform to platform and from compute instance to compute instance.

GCIA represents a paradigm shift on how to establish a next-generation vehicle architecture by defining an overall integrated solution. The standard will play a major role in bringing the many advantages of MOSA to next-generation ground vehicles such as OMFV. Such open architecture/distributed network-based combat vehicles are expected to meet and exceed the Army’s requirements now and for years to come. ■

Jacob Sealander is Chief Architect, C5ISR Systems, for CurtissWright Defense Solutions. He has worked at Curtiss-Wright since 1996 in various design, engineering, and management positions including engineering manager of embedded systems, mechanical engineering manager, and manager of product line engineering. Sealander can be reached at jsealander@curtisswright.com

Curtiss-Wright Defense Systems • https://www.curtisswrightds.com/

SOSA SPECIAL EDITION

www.rantec.com inquiries@rantec.com (805) 596 6000 Owned, operated & manufactured in the USA

Engineered Power Conversion for Tactical Applications 26 | SOSA Special Edition 2023 www.opengroup.org/sosa

3U VPX Power Supplies Designed in Alignment with the SOSATM Technical Standard

SERVING CRITICAL DEFENSE PROGRAMS FOR OVER 30 YEARS lcrembeddedsystems.com | (800) 747-5972 Develop. Demonstrate. Deploy. STREAMLINING THE JOURNEY VPX system realization is the totality of 3 top level activities: • Lab development and integration • Field test and demonstration • Final system deployment LCR has the products and experience to ensure success every step of the way. Design Solutions from Start to Finish for SOSA™ Aligned Payloads

Exploiting direct RF FPGAs for electronic warfare

By Rodger Hosking

As technologies evolve, government defense organizations steadily evolve electronic warfare (EW) solutions to counteract and then surpass capabilities of their adversaries by leapfrogging each other in an ongoing mission imperative to maintain dominance. Essential functions of EW systems are acquiring RF [radio frequency] signals of interest and then performing the required signal-processing tasks to deliver an effective response. This fosters new technologies and architectures that boost performance levels in both operations.

Several emerging FPGA [field-programmable gate array] architectures combine advanced RF [radio frequency] data converters and the latest processing engines within a single package. Using advanced silicon processes and packaging technologies, offerings include both monolithic designs and multi-chip modules. These new, highly integrated devices represent transformative technology for electronic warfare (EW) applications, yielding significant performance advantages over the traditional collection of discrete components that are typical of previous architectures.

Direct RF technology

One of the most challenging requirements of modern EW systems is to capture and generate high-frequency, wideband RF signals using high-speed data converters. These are typically connected to the antenna with analog frequency translation stages to convert between RF antenna signal frequencies and the lower IF [intermediate frequency] frequencies that data converters can digitize. These RF tuner stages require mixers, amplifiers, filters, oscillators, and numerous discrete analog components, all carefully packaged and shielded to maintain signal integrity, increasing cost, size, power, and complexity in any EW system.

The most straightforward approach to eliminate these cumbersome frequency translation stages is to boost the sampling rate and the maximum input signal frequency of monolithic data converters so they can handle RF signals directly with no translation. Performance levels of these so-called direct RF devices have advanced steadily, driven by the obvious benefits for commercial, industrial, and defense markets.

SOSA SPECIAL EDITION

28 | SOSA Special Edition 2023 www.opengroup.org/sosa

The vast size of 5G commercial wireless markets provides special incentives, because the large number of local, massive-MIMO [multiple input/ multiple output] phased-array antennas each typically needs 64 transmit/receive elements to steer receive and transmit signal beam patterns. Antenna directionality is achieved by precisely shifting the relative phase of signals to each element, so each element requires its own signal-processing channel.

In such systems, eliminating the frequency translation stage from each channel not only saves SWaP [size, weight, and power] and cost, but also simplifies channel synchronization by removing analog RF components subject to component tolerances, aging, temperature drift, reliability, and maintenance issues. To address these problems, discrete monolithic direct RF ADCs and

DACs [analog-to-digital converters/digital-to-analog converters] capable of directly digitizing RF signals at 1 GHz and above have appeared during the last decade.

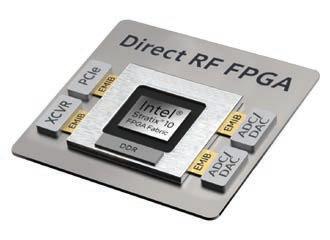

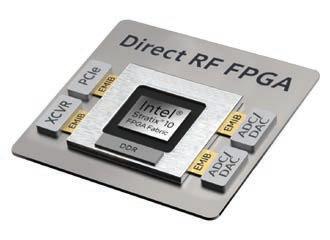

In 2017, Xilinx introduced the acclaimed RFSoC [radio frequency aystem-on-chip) with eight 5 Gs/sec ADCs, eight 9.8 Gs/sec DACs, Zynq UltraScale+ FPGA fabric, multicore Arm processors, and dual 100 GbE interfaces, all within a single monolithic device, fully qualifying as a direct RF FPGA. The RFSoC data converters support RF signal frequencies up to 6 GHz and offer channel synchronous operation for phased arrays. Initially targeting the 5G wireless infrastructure market, the RFSoC was immediately embraced for defense applications including radar, countermeasures, EW, and communications.

Now, direct RF data converters offering sampling rates as high as 64 Gs/sec can directly digitize RF signal frequencies up to 38 GHz. Available as packaged BGA [ballgrid-array] devices or in chiplet form, these monolithic devices are extremely compatible with the new generation of FPGA processing architectures discussed next.

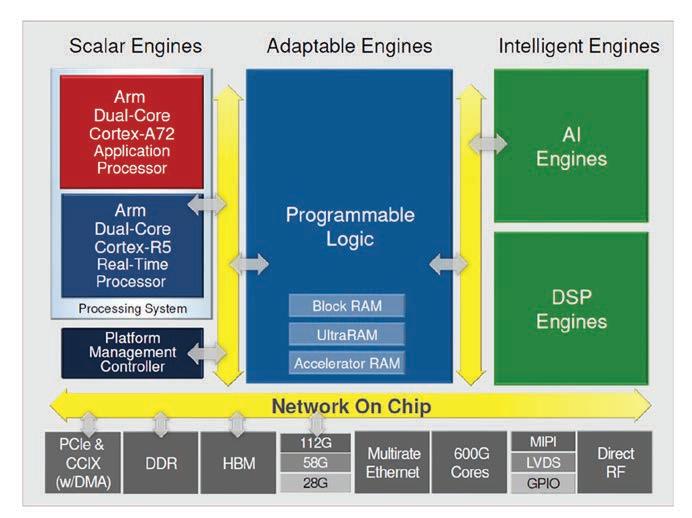

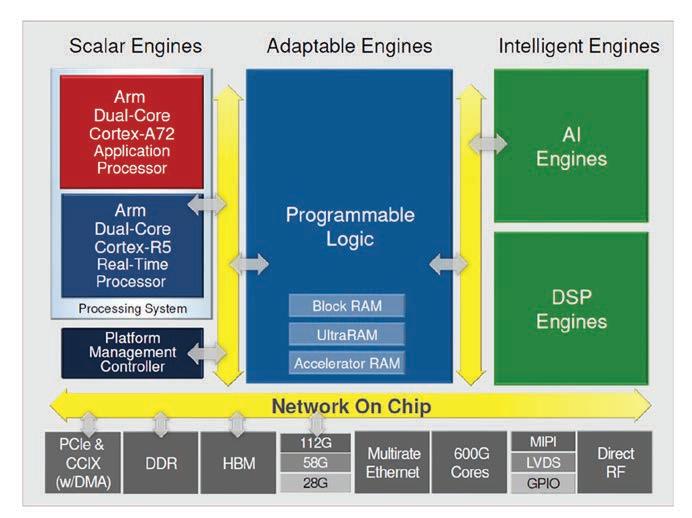

AMD Xilinx Versal ACAP FPGAs

AMD’s Versal ACAP [adaptive compute acceleration platform] devices based on its 7 nm silicon process consists of a series of six SoC architectures, each with specific blends of different processing engines and powerful peripherals, shown in Figure 1.

The scalar engines include the dual core Arm Cortex-A72 application processor and the dual-core Arm Cortex-R5 real-time processor. Unlike most scalar processors that implement single instruction, single data structures, these Arm processors provide single instruction, multiple data (SIMD) operations. This boosts performance for many algorithms by processing more data for each sequentially executed instruction. Scalar processors target general applications, and the software is extremely portable across a wide range of platforms.

The adaptable engines utilize programmable logic FPGA fabric plus various types of memory, including block RAM, UltraRAM, and accelerator RAM. Configurable logic in

SOSA SPECIAL EDITION

www.opengroup.org/sosa SOSA Special Edition 2023 | 29

Figure 1 | AMD Xilinx Versal ACAP FPGA includes a blend of adaptable FPGA, DSP, and AI [artificial intelligence] engines; direct RF converters; multicore Arm processors; network-on-chip; multirate Ethernet I/O; and system interfaces. Diagram courtesy Xilinx.

FPGAs provides an ideal platform for real-time state machines, control logic, complex timing, Ethernet packet processing, and synchronization, all essential functions for many EW systems. These kinds of operations are often impossible for scalar processors, even those running a real-time operating system. High level design entry tools help development tasks for signal processing tasks, but less so for real-time logic and control functions.

Versal offers two types of intelligent engines: The DSP engines are specialized, highly efficient real-time signal-processing blocks that include fixed- and floating-point multipliers, accumulators, arithmetic units, data multiplexers, and barrel shifters for both scalar and vector data types. With over 14,000 DSP engines in the largest Versal devices, highly parallelized processing architectures can process real-time data streams from high-rate direct RF data converters. As a result, DSPs deliver the lowest latency of all processing classes. Because each new generation of FPGAs adds new types of fabric resources and enhanced DSP engines, configuration code for FPGAs tends to be quite family-specific, even for devices from the same vendor.

The other intelligent engines are AI [artificial intelligence] engines, each consisting of a 2D array of AI tiles, which come in two versions. The general AI engines are balanced to support both machine learning (ML) applications and advanced signal processing for beamforming, radar, FFTs, filters, video enhancement and image processing. The AI/ML engines are optimized for ML tasks including image and speech recognition, medical diagnosis, statistical arbitrage, and predictive analytics, and they also offer extended support for ML data types. For machine learning applications, they are eight times more efficient in the silicon area than DSP engines, reducing power by about 40%.

Onboard, flexible high-bandwidth memory (HBM) enables data transfer bandwidths up to 820 GB/sec, representing an 8-time increase in bandwidth compared to traditional DDR5. The Versal ACAP AI RF series, available soon, offers on-board direct RF ADCs and DACs, following the highly successful theme introduced by RFSoC.

To interconnect all of these numerous resources, ACAP includes an extremely wideband, configurable network-on-chip that offers a uniform interface and protocol to simplify system integration.

This heterogeneous mix of ACAP resources gives designers the freedom to assign compute power to the processing engine most suitable to the task at hand, and the ability to adaptively reassign resources as required. This flexibility of ACAP delivers as much as ten times the performance compared to dedicated processor types alone. Versal development tools target high-level design entry from frameworks, models, C-language, and RTL coding. Users can create a custom development environment to suit their project needs and programming preferences. Other Versal hardware/software platforms will evolve to help speed EW development tasks and support high complexity applications with extreme performance requirements.

AMD Xilinx ACAP direct RF FPGA products

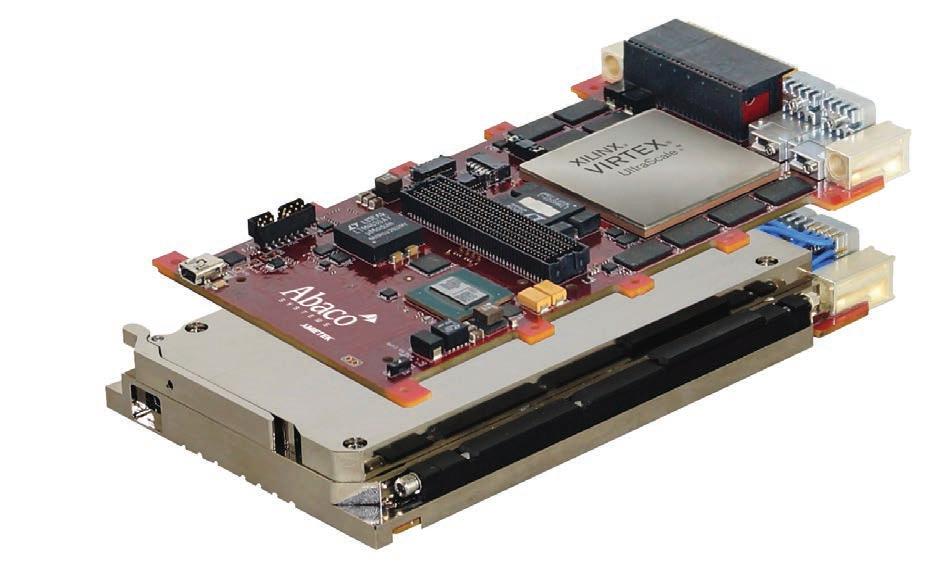

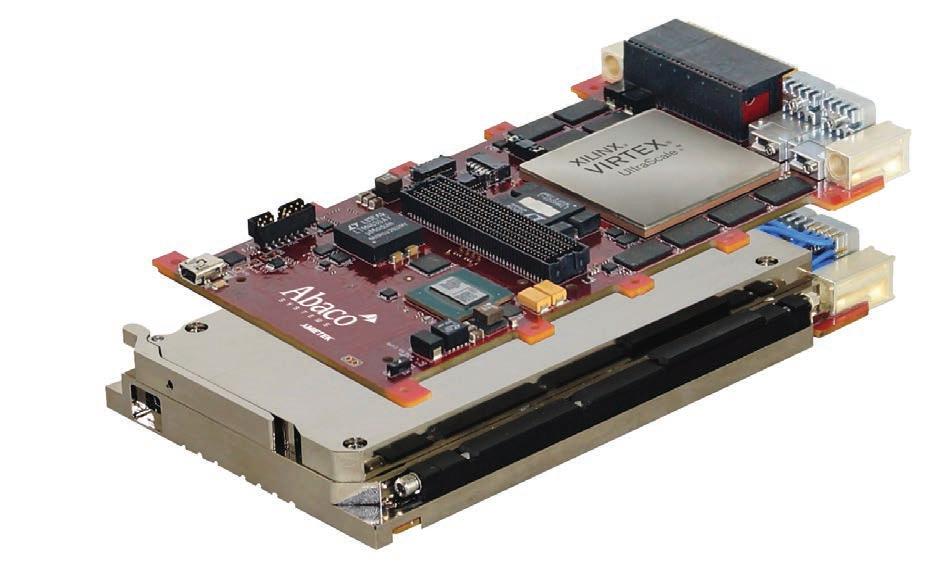

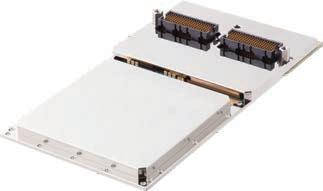

Although the Versal ACAP AI IF series with the integrated direct RF data converters is not yet available, several product offerings combining the Versal ACAP with direct RF data converters have already been released. (Figure 2.)

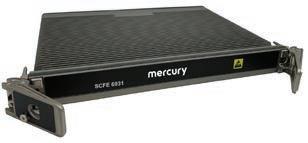

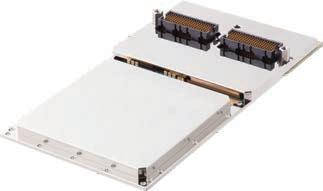

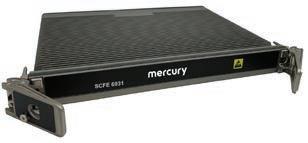

Figure 2a/b/c | Three AMD Versal ACAP direct RF solutions: 2a is the RFS1140RF system-in-package with single AI core and four-channel/64 Gs/sec ADC/DAC; 2b is the SCFE6931 SOSA aligned 6U OpenVPX card with two AI cores and optical I/O; 2c is the 5560 SOSA aligned 3U VPX card with Versal HBM FPGA and direct RF mezzanine.

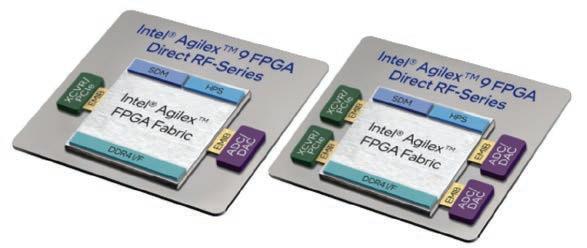

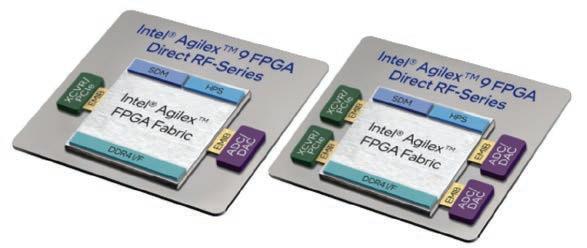

Intel Stratix 10 AX and Agilex 9

Direct RF FPGAs

Intel offers two families of Direct RF FPGAs, the Stratix 10 AX and the new Agilex 9 shown in Figure 3. These multichip modules take advantage of Intel’s chiplet fabrication capabilities to attach various combinations of chiplets to the main FPGA chip using EMIB and 2.5D packaging processes. The Intel Direct RF devices use the Jariet Electra-MA 64 Gsps 10-bit chiplet data converters for all three of the devices shown below. A fourth device listed in Figure 4 uses chiplets with 4 Gsps 14-bit ADCs and 12 Gsps 14-bit DACs.

Figure 4 shows resources in four different Intel direct RF devices. Note that the AGRW027 and AGRM027 devices

SOSA SPECIAL EDITION

Figure 2a

Figure 2b

Figure 2c

30 | SOSA Special Edition 2023 www.opengroup.org/sosa

BECAUSE EACH NEW GENERATION OF FPGAS ADDS NEW TYPES OF FABRIC RESOURCES AND ENHANCED DSP ENGINES, CONFIGURATION CODE FOR FPGAS TENDS TO BE QUITE FAMILYSPECIFIC, EVEN FOR DEVICES FROM THE SAME VENDOR.

use the same FPGA chip, illustrating the advantage of using different types and combinations of chiplets for data converters and other peripherals to efficiently create new components.

Intel direct RF products

The industry’s first open architecture board using an Intel direct RF FPGA is the Mercury DRF3182 released in January 2023. (Figure 5.) The 3U OpenVPX card features the Stratix10 AX device. It enables direct RF digitization of four transceiver channels across a 2 GHz to 18 GHz frequency band to support numerous EW applications. Eight PCIe Gen3 x4 data plane ports deliver 64 GB/sec of data across the backplane to other cards.

As soon as the new Intel Agilex 9 devices become available, board vendors will be eager to incorporate them in open architecture embedded computing boards to speed adoption in deployed systems.

Direct RF FPGAs: the bottom line for EW

By eliminating the analog RF frequency translation stage of EW designs, direct RF not only reduces SWaP and cost, but it also boosts performance by reducing latency, minimizing analog phase and amplitude uncertainties, and simplifying channel synchronization. Direct RF data converters contain dedicated digital frequency translators (DDCs and DUCs) that can instantaneously tune across a very wide span of frequency to implement complex sweeping and hopping patterns, a critical advantage for many advanced countermeasure algorithms.

Traditional scanning receivers that sequentially tune across a span can easily miss such transients outside of the current scan window. Direct RF enables EW systems to “stare” across a wide frequency span to detect any transient spectral activity that might be of interest. Once a signal is detected, the direct RF wideband data converter stream can also be delivered to a DDC to zoom in on a narrow band of interest for signal exploitation.

Figure 3a Figure 3b