ENERGY GL BAL

Summer 2024

Turboexpanders in Organic

Rankine Cycles: Transforming

Renewable Energy Storage

Photo courtesy: Raygen

with green hydrogen from PEM electrolyzers

We’re scaling up production

Producing enough green hydrogen is the key to decarbonizing businesses that can’t be directly electrified. Our power-to-X processes convert renewable electricity and water into green hydrogen and its derivate net-zero fuels. Together with our subsidiary H-TEC SYSTEMS we are mass-producing PEM electrolyzers and scaling up production of green hydrogen –moving big things to zero in the energy, heavy industry, and transport sectors.

ENERGY GLOBAL

CONTENTS

03. Guest comment

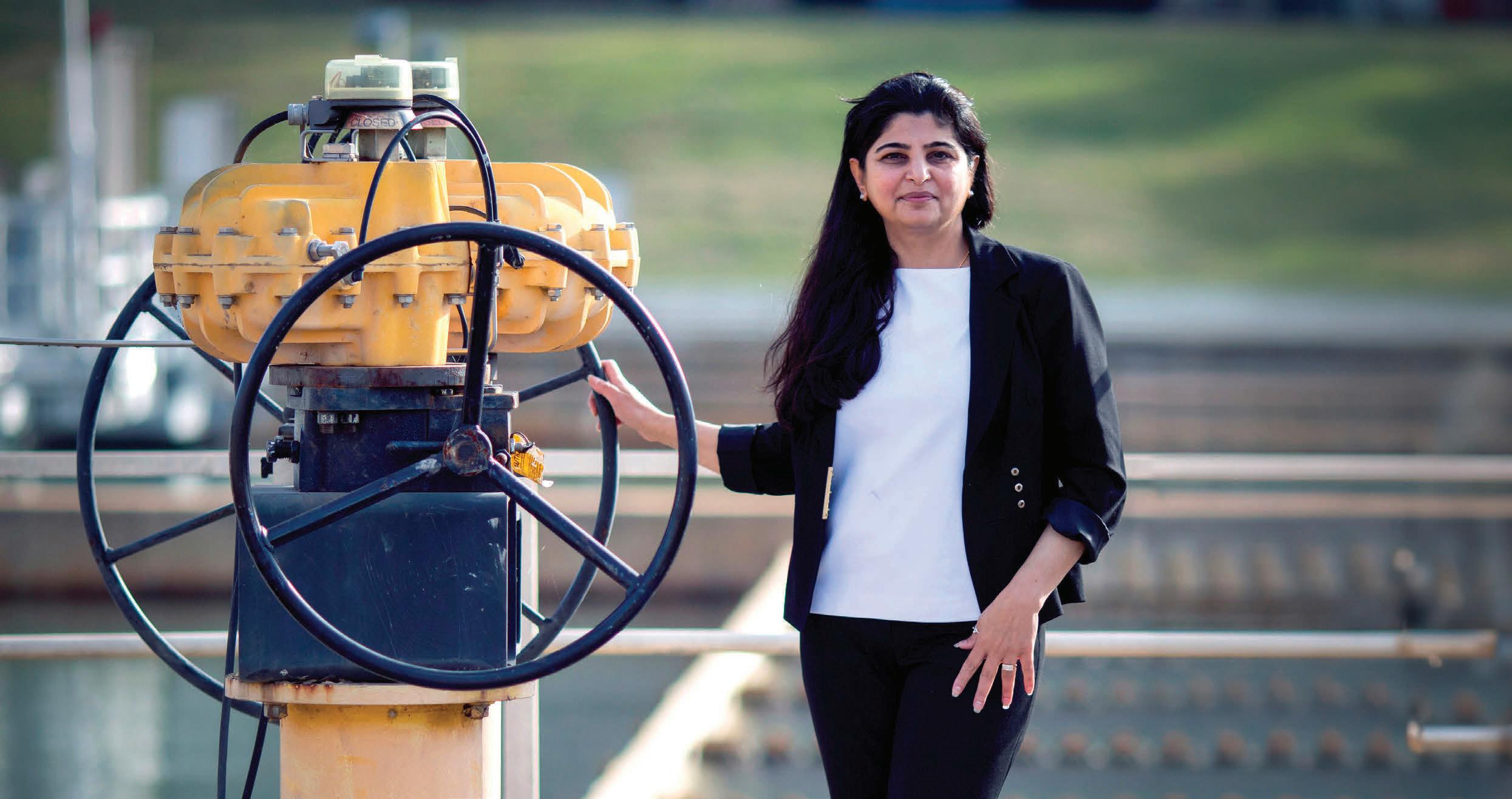

04. Significant growth in Asia Pacific

Neha Tatikota, Senior Analyst, Frost & Sullivan, provides an overview of the power industry in the Asia Pacific region, looking at six key markets.

30. Finding the flow

Iulian Maciuca, Industry Sector Manager – Renewables, Celeros Flow Technology, details how to meet the challenges of offshore wind turbine installation with reliable equipment.

36. LiDAR: Empowering wind energy's ascent

Matthieu Boquet, Head of Market and Offering of Wind Energy, Vaisala, France, examines the uses of LiDAR technology in wind farms.

40. Tracking clouds to forecast the solar future

08. The future is offshore

Phil Combes, Head of Offshore Wind Engineering UK & Ireland, Ramboll, assesses the critical importance of offshore wind for a net-zero future.

12. The intermittency challenge

Louis Mann, Atlas Copco Gas and Process, USA, considers how the use of turboexpanders in organic Rankine cycles can aid solar-energy-storage on the path towards a sustainable energy future.

18. The power of sea state monitoring

Lars Ivar Leivestad, Miros, Norway, poses the question: how can offshore wind operations unleash maritime safety and efficiencies?

24. The next phase for offshore wind

Jan Behrendt Ibsø and Antonela Mitrana, COWI, Denmark, outlines the next phase for offshore wind: digital tools, data-driven design, and hydrogen.

James Luffman, Meteorologist and Founder of Solcast, a DNV Company, explains how satellites and algorithms are being used to finance, build, optimise, and predict global solar generation.

46. Navigating the winds of change

Dr Evgenia Golysheva, Vice President of Strategy and Marketing, ONYX Insight, UK, looks at ways to close the green skills gap within the wind industry.

50. Renewable energy generation: driving the green future

Sergio López, General Manager of Soltec, Spain, explores how new technology and innovation in renewable energy will help create a greener future.

54. Global news

Discover the transformative role of turboexpanders in organic Rankine cycles (ORC) for sustainable energy storage. Explore meticulous design considerations and the impact of turboexpander technology on groundbreaking applications. With over 40 years of experience in ORC for geothermal energy, trust Atlas Copco Gas and Process for reliable and efficient medium-duration energy storage solutions.

Our priority is the safe on-time delivery of your global energy projects. CRC Evans utilises market-leading welding and coating services, technologies and advanced data solutions, combined with a right first time approach.

MANAGING EDITOR

James Little james.little@palladianpublications.com

EDITOR

Jessica Casey jessica.casey@palladianpublications.com

EDITORIAL ASSISTANT

Théodore Reed-Martin theodore.reedmartin@palladianpublications.com

SALES DIRECTOR

Rod Hardy rod.hardy@palladianpublications.com

SALES MANAGER

Will Powell will.powell@palladianpublications.com

PRODUCTION DESIGNER

Kate Wilkerson kate.wilkerson@palladianpublications.com

EVENTS MANAGER

Louise Cameron louise.cameron@palladianpublications.com

DIGITAL EVENTS COORDINATOR

Merili Jurivete merili.jurivete@palladianpublications.com

DIGITAL ADMINISTRATOR

Nicole Harman-Smith nicole.harman-smith@palladianpublications.com

DIGITAL CONTENT ASSISTANT

Kristian Ilasko kristian.ilasko@palladianpublications.com

ADMINISTRATION MANAGER

Laura White laura.white@palladianpublications.com

Editorial/Ad vertisement Offices: Palladian Publications Ltd

15 South Street, Farnham, Surrey, GU9 7QU, UK +44 (0) 1252 718 999 www.energyglobal.com

COMMENT

Patrick Donati

Founder, Terrawatt

In 1H22, the conflict escalation in Ukraine prompted Russia to significantly reduce its gas supplies to its EU customers. This abrupt reduction triggered a surge in gas prices, thrusting the EU into an energy crisis. Throughout the decade spanning from 2010 – 2020, average gas prices fluctuated within a range of €5/MWh to €35/MWh. However, in August 2022, gas prices skyrocketed to an unprecedented high of €300/MWh, dealing a severe blow to consumers and businesses across the continent. This sharp escalation had far-reaching ramifications, causing inflationary pressures throughout the entire spectrum of the European economy. Russian gas, vital for not only heating but also electricity generation, played a central role in this crisis, leading to a staggering 114% increase in household electricity prices on average across Europe.

In response to this crisis, the momentum towards net zero in Europe gained significant traction. Governments across the Eurozone were spurred into action, racing to reduce their reliance on Russian gas. Italy, in particular, felt the impact of soaring gas prices acutely, as a substantial portion of its electricity was generated from natural gas.

This heavy dependence on natural gas stemmed from Italy’s comparatively sluggish progress in transitioning to renewable energy sources, largely driven primarily by regulatory uncertainties. Italy saw minimal renewable energy development since 2012, largely due to a regulatory shift that abruptly ended subsidies for renewables, causing the market to stagnate overnight.

Since 2022, the Italian government, driven by European legislation mandating the implementation of a certain level of renewable capacity and exacerbated by a severe energy crisis, has enacted a series of regulatory reforms aimed at streamlining the notoriously opaque

and complex permitting process. The primary permitting method for solar projects in Italy, known as The Autorizzazione Unica, has historically been burdened by bureaucracy, often taking up to two years to complete and requiring the submission of over 100 distinct documents. To address this issue, the government introduced the Procedura Autorizzativa Semplificata (PAS) tailored to utility scale solar farms situated on industrial land, within 500 m of industrial zones, on reclaimed mines and dumps, and in other heavily anthropized areas. The PAS can, theoretically, be approved in 30 days using the principle of ‘silenzio assenso’ – silence implies assent. Governing bodies have 30 days to object to a project before it is automatically considered permitted.

In practice, despite best efforts to liberalise the solar development industry in Italy, projects are still constrained by a dizzying mix of local, regional, and national regulations that severely limit the areas suitable for large scale solar farms, the backbone of the energy transition. The availability of suitable land, particularly reclaimed mines and dumps is scarce and often requires substantial investment to make them viable for solar projects. Many of these sites remain improperly reclaimed or abandoned, necessitating significant large capital expenditure before they can be utilised for solar farms.

In essence, developers experience marginal practical effects in their day-to-day operations, with only a slight acceleration observed in the initial stages of permitting plots for land already suitable for solar. What the industry truly needs is a comprehensive simplification of the administrative burden placed on developers to navigate the permitting process, particularly for unused farmland. This would enhance efficiency and encourage broader adoption of solar energy in Italy.

The Asia Pacific region offers significant growth opportunities. Strong economic growth has returned to many parts of the region, driving electricity demand growth higher. Most households in the region have access to electricity, but average household consumption rates are much lower than those of highly developed economies. The next 15 years will see this picture change as increased wealth drives up demand. At the same time, the region has largely been a laggard when it comes to renewable energy investment (with the notable

exception of China). Policy makers across the region are aiming to try and address this situation, but the reality is that fossil fuels will remain key to the regions power supply.

So how will investment in key country markets unfold over the course of the next decade?

Australia

Due to the retirement of coal-fired power facilities – approximately US$12 – US$20 billion will go to phasing out coal-fired generation

over the next 10 years – and increased electricity demand, renewable energy will become pivotal to electricity supply in several states from 2024. Australia plans to add 7.3 GW of onshore wind and over 50 GW of solar energy to the grid by 2030. Improving the regulatory situation related to planning approvals will be pivotal as to whether this can be achieved. Residential solar photovoltaics (PV), already installed on more than 3 million Australian homes, will continue to see significant growth. A total of US$132 billion will be invested in wind and solar PV between 2023 and 2035, 98% of total

power generation investment. By 2035, renewables will account for 74.7% of electricity generated, up from 49% in 2023.

Japan

Japan is currently heavily dependent on fossil fuels for power generation. The country has previously had attractive incentives schemes for decentralised solar PV, but has invested limited amounts in utility scale projects. Wind power accounted for just 0.9% of electricity generated in 2023, exceptionally low by

Neha Tatikota, Senior Analyst, Frost & Sullivan, provides an overview of the power industry in the Asia Pacific region, looking at six key markets.

global standards. Availability of land is an issue in Japan, the population density is high and there has been opposition to renewables in rural parts of the country. Utilities have been hostile to renewables and the required grid investment has not been made.

Russia’s invasion of Ukraine has heightened Japan’s focus on energy security. Solar PV is forecast to double as a share of total electricity generated to 16% by 2035 with US$163.7 billion invested by 2035. Given Japan’s limited land availability, offshore wind will be a key technology. Project costs for the technology are currently high, but these will slowly decline over the course of the decade. Policy improvements and technological advancements will both support growth, with US$72.9 billion invested by 2035.

To address energy security, Japan’s GX Implementation Council unveiled a new policy to resume the operation of 17 nuclear power reactors in 2023 (of which 11 actually came online) and raise the operational life of current nuclear facilities from 40 to 60 years for long-term energy security. 22 reactors slated for decommissioning will either be replaced by next-generation reactors or restarted.

Despite all of these efforts, coal, natural gas and other fossil sources will still account for 54.3% of electricity generated by 2035.

South Korea

Energy security is also a top priority in South Korea, which (like Japan) is almost totally dependent on imported energy. The 2023 10th Basic Plan for Long-term Electricity Demand and Supply emphasises nuclear power and renewables as sources of potential high growth. However, the government has slashed the 9th Basic Plan’s electricity generated from renewable target from 30.2% to 21.6% in 2030, indicating weaker support for renewables. Given the lack of clear support, Frost & Sullivan forecasts the target will be missed, with only 17.3% achieved by 2030 and 23.1% by 2035. Offshore wind is the bright spot, with US$117 billion invested, meaning electricity from wind power will increase from 0.7% in 2023 to 8.6% by 2035. Nuclear capacity will increase, and plants are likely to get life extensions. Nuclear will remain a key source of baseload power, consistently supplying 30%/y across the next decade. There will also be an expansion of natural gas. South Korea has a number of long-term supply contracts with Australia and Qatar for LNG. Natural gas will also account for approximately 30% of electricity generated across the decade.

Vietnam

Vietnam’s Power Development Plan 8 plan approved in 2023, sets a target for renewables to constitute 80% of energy usage by 2050. Coal-heavy Vietnam is drafting tax breaks and other perks to drive owners to install solar panels in buildings, to become independent of the outdated grid and the frequency of outages. Despite these efforts, natural gas and particularly coal, will the mainstay of Vietnam’s electricity supply well into the 2040’s. Frost & Sullivan forecasts coal capacity will increase further through the current decade, but as capacity starts to decline in the early 2030s, natural gas and renewables will take over. The country faces a demand-supply mismatch; the state utility EVN’s pressure to keep costs low and projects running behind schedule are the main challenges to investment. Wind targets of 6 GW of offshore and 21.8 GW of onshore wind by 2030 in the new draft plan are highly ambitious. The targets also include 12.8 GW of solar PV by 2030. Frost & Sullivan estimates that these will be unmet and extended

over a much longer period. Vietnam will invest an average of US$12 billion/y in its electricity grid to 2030 as it tries to increase the capacity for renewable energy, but this will not be enough to enable it to meet the targets.

Indonesia

The state utility PLN has revised its power supply master plan and has increased its renewable target to 32 GW, from the previous 20.9 GW. It expects renewables to account for 75% of new capacity, with the remaining 25% natural gas. The Just Energy Transition Partnership (JETP) scheme has led to US$21.5 billion of funding for Indonesia’s energy transition. As part of this scheme, two coal power plants with a combined capacity of 1.7 GW are to be closed, although the final date is currently scheduled as 2040. Much of the focus has been on renewable development over early coal plant retirements. The hope is that by boosting renewables that it will eventually lead to the closure of coal plants. The reality is that coal will dominate the energy mix for the next 15 years. 3.4 GW of renewable energy capacity was expected in 2023, of which only 2.8% reached commercial operation. Indonesia aims to increase the share of renewables in its electricity mix to reach 44% by 2030 – Frost & Sullivan forecasts this will be 24%, 22% of which will be hydropower and geothermal.

China

China has dramatically increased its investment in wind and solar PV in the past five years, with a new record in 2023. Utility solar PV and onshore wind have historically dominated investment, but China is now the leading market for offshore wind and changes to regulations have incentivised investment in decentralised solar PV. China has 27 GW of nuclear plants under construction, with a further 48 GW planned and 93 GW officially proposed. Unlike many countries, China has a track-record of proceeding with proposed projects and the Chinese leadership is committed to nuclear as part of its decarbonisation strategy, so Frost & Sullivan expects the majority of these plants will be constructed. Plants will also be used for dedicated hydrogen production. Despite all this, coal will continue to dominate China’s energy mix, remaining the number one electricity source until the late 2030s. In November 2023, the government introduced capacity payments for coal plants, providing 7% in additional revenues for existing plants and ensuring proposed plants are constructed. Part of the motivation for doing this is the expectation that the utilisation of existing and new plants will gradually decline as renewables increases, but China wants coal to ensure energy security. Gas will play a relatively small role in China, with priority given to industrial users.

Conclusion

That Asia Pacific needs substantially more electricity as part of wider economic growth is a given. Investor appetite for what is seen as a high growth region is strong. The majority of the countries have strong solar PV potential and coastlines enabling them to exploit the high efficiency levels that come from offshore wind power. But ultimately how much of total power investment is low carbon and how fast countries can reduce their dependence on coal will be down to the degree of regulatory certainty achieved and the effective implementation of supportive policies by national governments over the coming years.

Unlocking Renewable Energy Storage: Turboexpanders Lead the Way

The transition towards a sustainable society is essential in combating climate change. The integration of turboexpanders in Organic Rankine Cycle (ORC) has ushered in a new era of energy storage innovation. Meticulous design considerations have been crucial in adapting turboexpander technology to the dynamic requirements of energy storage systems. The successful commissioning and rigorous validation of RPPCs show us the impact of turboexpanders in groundbreaking applications.

Our expanders have been integral to Organic Rankine Cycles (ORC) in geothermal energy for more than 40 years. With this proven track record, we bring unparalleled experience to the table, ensuring reliable and efficient ORC power generation for medium-duration energy storage.

Join us on this journey as we redefine what’s possible in renewable energy storage.

Photo courtesy: RaygenOffshore wind is one of the fastest-growing renewable energy sources in the world, with the potential to provide clean, reliable, and affordable electricity to millions of homes and businesses. According to the International Energy Agency (IEA), offshore wind could generate more than 18 times the current global electricity demand, provided governments and industry work together to accelerate its deployment.

Offshore wind is especially important for the UK, which has the largest installed capacity after China and the most ambitious targets in the world. The UK aims to quadruple its offshore wind capacity to 50 GW by 2030 and to reach net-zero greenhouse gas emissions by 2050.

However, achieving these goals will not be easy, as the offshore wind industry faces several challenges, not least political and regulatory uncertainty, grid integration, supply chain bottlenecks, environmental impacts, and social resistance. But what are the most significant

challenges facing offshore wind in the UK, and what are the possible solutions for the industry to overcome them?

The importance of offshore wind for the global and UK energy transition

Offshore wind is a key technology for the global and UK energy transition, offering several advantages over other energy sources.

First, offshore wind has a higher technical potential than onshore wind, as the wind speeds and capacity factors are higher and more consistent at sea than on land. This means that offshore wind farms can produce more electricity per unit of installed capacity and can operate at higher load factors throughout the year. As a result, a comparatively small number of offshore wind farm projects can deliver massive quantities of renewable energy capacity in relatively short timescales when compared to other energy sources. For example, the single

Seagreen project developed by SSE has a capacity of 1.1 GW and can deliver enough green energy to power approximately 1.6 million UK homes.

Second, offshore wind has a low carbon footprint, as it does not emit any greenhouse gases or air pollutants during operation and has relatively low lifecycle emissions compared to fossil fuels and nuclear power. Indeed, according to the IEA, offshore wind has a life cycle carbon footprint (including construction, operation, and decommissioning) more than 99% lower than the equivalent coal-fired power station. It is also lower than other clean energy sources, like nuclear, due to the simpler construction and operation processes.

Third, offshore wind has a positive socio-economic impact, creating jobs, stimulating economic growth, and supporting local communities. According to a report by RenewableUK, the offshore wind industry

Phil Combes, Head of Offshore Wind Engineering

UK & Ireland, Ramboll, assesses the critical importance of offshore wind for a net-zero future.

in the UK supported 26 000 direct and indirect jobs in 2019 and contributed £5.4 billion to the UK GDP. The same report projected that the offshore wind industry could support as many as 69 800 jobs and contribute £18.6 billion to the UK GDP by 2026 if targets are met. Moreover, the offshore wind industry provides opportunities for local employment, skills development, innovation, and benefits for coastal communities, such as improved infrastructure, tourism, and fisheries.

Finally, offshore wind does not typically face the same level of community resistance as solar farms or nuclear power stations, for example, as it places most of the infrastructure out at sea. As with any infrastructure development, offshore wind does inevitably face some challenges, but these are outweighed by significant benefit compared with land-based energy sources. Modern developments, such as HV DC cables that reduce transmission losses, allow the farms to be placed further offshore minimising potential issues with coastal communities.

The challenges and possible solutions

Despite the importance of offshore wind for the global and UK energy transition, the industry faces several challenges that could hinder its growth and development. The offshore wind industry depends on stable and supportive policies and regulations to attract investment and reduce costs. However, the policy landscape for offshore wind is often complex and uncertain, involving multiple levels of governance at the national, regional, and local level, as well as different sectors, such as energy, environment, planning, and maritime.

For example, in the UK, the offshore wind industry is subject to the Contracts for Difference (CfD) scheme, which is a competitive auction mechanism that guarantees a fixed price for the electricity generated by offshore wind farms for 15 years. However, the CfD scheme is subject to periodic reviews and changes, which can affect the level and frequency of support for offshore wind projects, as was the case with the Auction Round 5. The government implemented a maximum price cap that failed to reflect the changing reality resulting from the Ukraine war and inflation.

The result was a sum total of zero bids from offshore wind developers. This was a significant missed opportunity, though hopefully also a major lesson learned for governments. Whilst offshore wind is a very mature technology, the industry will still require external support if the necessary progress towards net-zero targets is to be maintained.

The offshore wind industry also has to comply with various environmental and social regulations, such as the Habitats Directive, the Marine Strategy Framework Directive, the Marine and Coastal Access Act, and the Planning Act, which can impose constraints and delays on the development and operation of offshore wind farms. Greater clarity and certainty on the policy and regulatory framework is needed, as well as more coordination and harmonisation among the different stakeholders and jurisdictions involved. Collaboration between the relevant stakeholders involved should lead to the maximum benefits of offshore wind development being realised. This also applies to community engagement where developers will benefit from building trust and relationships with communities local to offshore wind developments.

The offshore wind industry requires adequate and efficient grid infrastructure to connect the offshore wind farms to the onshore grid and to transmit the electricity to the demand centres. However, the grid infrastructure for offshore wind is often insufficient and outdated, as it was designed for the conventional power system, which is based on centralised generation sources. This has created several challenges, including grid congestion, curtailment issues, losses, instability, and security issues.

A good example is that in the UK, the offshore wind industry relies on point-to-point connections which are individual cables that link each offshore wind farm to the nearest onshore substation. However, this approach is costly, inefficient, and unsustainable, as it requires multiple seabed crossings, landfall sites, and onshore reinforcements, and does not allow for optimal use of the offshore wind potential. The offshore wind industry needs more investment and innovation in grid infrastructure, such as offshore grid networks, which are integrated systems that connect multiple offshore wind farms to each other and to the onshore grid and enable cross-border electricity trade and system balancing.

Moreover, the offshore wind industry would benefit from more flexibility and smartness in the grid operation, such as demand response, energy storage, and digitalisation. These measures would maximise the utility of offshore wind and additionally benefit other decentralised and intermittent renewable energy sources such as solar and onshore wind.

The offshore wind industry requires a robust and competitive supply chain to deliver the components and services needed for the development, construction, and operation of offshore wind farms. However, the supply chain for offshore wind is often limited and constrained, as it faces high demand, low supply, high costs/risks, and low margins. In the UK, the offshore wind industry suffers from a shortage of key components, such as turbines, foundations and vessels, which could all affect the successful development of new offshore wind projects.

The offshore wind industry is further constrained by a lack of skilled and experienced workers to run offshore wind farms, particularly engineers and technicians. To address this, more investment in the UK supply chain will be needed, along with greater standardisation and modularisation of components, more innovation and automation of processes, and more training and education of the workforce. All of this should be captured in a dedicated industrial strategy for the UK offshore wind industry with input from all relevant stakeholders.

Offshore wind’s offer of a high potential, low carbon energy source, along with the major additional benefits, makes it a critical technology for the global and UK energy transition. But if this potential is to be realised, the challenges facing the industry – including regulatory uncertainty, grid integration, and supply chain bottlenecks – which could hamper its growth and development will need to be overcome. Fortunately, these challenges, whether that is clarity and certainty on policy and regulatory frameworks, stepping up investment and innovation in the grid infrastructure, or increasing capacity in the supply chain, can be addressed and overcome. Doing so will secure the offshore wind industry’s vital role in the global and UK efforts to reach net-zero emissions by 2050 and provide sustainable, secure, and affordable energy future for all.

The intermittency

Louis Mann, Atlas Copco Gas and Process, USA, considers how the use of turboexpanders in organic Rankine cycles can aid solar-energy-storage on the path towards a sustainable energy future.

intermittency challenge

The climate emergency has made the transition towards a low-carbon world not only essential but also urgent. While a lot of progress has been made in the technology underpinning renewable energy supplies (such as solar and wind) in recent decades, its characteristic intermittency continues to present a challenge. Weather conditions and daily solar cycles create variability in energy production, and this results in a discrepancy between supply and demand. As a result, developing high-tech solutions

for short, medium, and long-term energy storage is crucial. While batteries are proving to be an effective solution for short-term energy storage (less than four hours), their high initial costs limit their economic viability for medium to long-term storage. In contrast, mechanical and

thermo-mechanical energy storage systems use less expensive storage mediums, making them a more cost-effective solution for longer durations. Historically, pumped hydro has been the predominant medium to long-duration energy-storage solution, but its dependence on specific geographic locations limits broader adoption. With less geographic constraints, thermo-mechanical systems become an important alternative. At the heart of most thermo-mechanical energy-storage technologies is power-generating turbomachinery, which is crucial in the system’s efficiency, reliability, and adaptability.

This article provides an overview of the success of turboexpanders in organic Rankine cycles (ORCs). It then goes on to show that the expert technological knowledge and experience from this field can be directly transferred to solar and thermal-hydro energy-storage facilities. And as shown in a pilot study, this provides a method to better deal with the variability inherent in renewable-energy sources.

Turboexpanders and ORCs

Turbomachines are not a new technology, and turboexpanders have been an important element in the energy industry for many decades. The term ‘turboexpander’, or simply expander, originates from turbines specifically used in industrial refrigeration. Cryogenic radial inflow turboexpanders were developed in the late 1930s for use in air separation, and by the 1960s, their effective refrigeration and power recovery capabilities led to their widespread use in natural gas processing, petrochemical production, and refineries. The tried and tested features that enabled turboexpanders to excel in these applications were later recognised as beneficial in other hydrocarbon-utilising applications, such as ORCs.

Turboexpanders have long played a central role within ORCs, a process used in the transformation of low to medium-grade heat into electricity. ORCs function in a similar way to traditional steam cycles but use an organic working fluid, such as butane or pentane, which have significantly lower boiling points than water. Historically, ORCs have proved valuable in geothermal power production and waste heat recovery, where the working fluid can be effectively matched to the heat source, enabling efficient energy conversion. It has been shown that machinery selection within these cycles can further benefit the process. For instance, turboexpanders equipped with variable inlet guide vanes (IGVs) provide flexibility for use where ambient temperature fluctuations may alter operating pressures in an ORC. The ability to run efficiently at a wide range of operation allows for additional energy recovery when ORC condensing temperatures vary, such as with daily or seasonal weather patterns.

Thermal-hydro energy storage

More recently, ORCs equipped with flexible turboexpanders have begun to be utilised in energy storage systems. In contrast to the steady operation of baseload geothermal plants, energy-storage systems require rapid start-ups, frequent start-stop cycles, and fast shutdowns because of the dynamic characteristic of the energy networks. These elements need careful consideration at the turboexpander design stage to maintain performance and longevity.

A case study highlighting the success of such a system can be seen in a pilot plant that opened in August 2023, in Carwarp, Victoria, in the southeast of Australia. Named RayGen Power Plant Carwarp (RPPC), it combines solar and thermal-hydro energy-storage facilities while utilising ORC technology with Atlas Copco Gas and Process turboexpanders.

RPPC integrates a combination of proven technologies in a novel way. Figure 1 shows how the solar collector and thermal-hydro energy-storage function together as a unified solar power plant. A field of smart mirrors concentrates sunlight onto photovoltaic solar modules in a tower-mounted receiver. This produces 1 MW of electricity for every 2 MW of heat, with a combined energy conversion efficiency of around 90%. The heat is removed by cooling water, which is then stored in an insulated

Figure 1 . Diagram of RayGen’s solar power plant. Source: RayGen.

pit at near boiling temperature. At the same time, electricity sourced from the photovoltaic system (or the grid) powers a chiller to produce cold energy stored in a separate water pit. The stored energy can be then converted back to electricity using an ORC at a chosen time, producing stable electricity even when the sun is not shining.

In the ORC process (Figure 2), heat from the hot water pit is transferred to a pressurised working fluid, in this case, anhydrous ammonia. This fluid evaporates and then expands through a turboexpander, generating power via a generator. Before the cycle can repeat, the working fluid must condense back into a liquid. This is achieved by rejecting heat to the cold-water pit, which is at a near freezing temperature, and then the fluid is repressurised by a pump before starting the cycle again.

To fully take advantage of variable energy prices, medium-duration thermal-hydro energy-storage systems must be designed for rapid start-ups (RPPC can begin operation in under five minutes). While a single start-stop cycle daily is usual for such an operational set up, the system can also manage multiple daily start-stop cycles to match fluctuations in energy prices. Hourly changes in energy pricing are central to the benefits of employing medium-duration energy storage systems: if renewable-energy production is high, the energy supply will likely exceed demand, which would see energy prices drop. Such lower energy prices mean cold-energy storage via the chillers makes economic sense. At times of low renewable energy supply, however, prices increase, and the energy that has been stored can be sold to the grid.

Tried and tested turboexpander technology

Integrally geared radial inflow turboexpanders are a well-suited match for ORC plants, and they are underpinned by tried and tested technology. The variable IGV system is at the heart of the turboexpander flexibility, allowing it to perform at high efficiency across a wide operating range. As well as the IGVs, the turbine stage also comprises a radial inflow expander wheel and discharge diffuser, a robust design that allows for large pressure drops and condensation at the discharge of the machinery which can improve overall cycle performance. The expander wheel is directly mounted to a high-speed pinion of a gearbox, with a shaft seal isolating the working fluid from the nitrogen-purged gearbox. The bull gear is connected to a synchronous generator by a low-speed coupling. Under load, the turboexpander operates at a constant speed which is governed by the grid. Turboexpanders come in a wide range of sizes to suit different applications. In small hydrocarbon gas processing settings, for example, turboexpanders may use impellers as small as 1.75 in., operating at speeds of 125 000 rpm. In contrast, turboexpanders used in energy production, particularly in geothermal applications, are typically much larger. These larger units often feature impeller diameters of 36 in., operate at 7000 rpm, and they can produce up to 25 000 hp. Using multiple expander pinions on a single gearbox and generator can further this power production on a single train. In both geothermal and waste-heat recovery applications, integrally geared configurations usually start at 5000 hp to be economically viable, though turboexpanders directly coupled to high-speed generators may be suitable for much lower power outputs.

Reliable and efficient energy storage

The construction of RPPC finished in 2023 and over an initial test period the pilot plant validated RayGen’s solar power plant technology. It also provided further confirmation that the ORC and the turboexpander would perform as expected and within specification. This successful demonstration opens the door to developing larger commercial scale plants in Australia and internationally.

Considering the battle against rapid climate change, the expansion in the applications of turboexpanders within ORCs from traditional geothermal power plants to emerging solar-energy-storage systems is an exciting development. Though innovative in this new application, the turboexpander relies on tried and tested technology.

RPPC’s success not only underscores the capabilities of turboexpanders and ORC technology in capturing and storing solar energy, but it also marks a significant step forward in sustainable power solutions. By incorporating proven technologies into medium-duration energy-storage systems, the industry can better handle the variability inherent in renewable energy sources. Leveraging established technologies, such as ORCs, traditionally used in geothermal and waste-heat recovery, to tackle new challenges in the energy transition represents a lower-risk approach to innovation. As this journey toward a resilient and sustainable energy infrastructure progresses, turboexpanders continue to play an essential role in the transition.

Figure 3 . Integrally geared turboexpander rendering.

Lars Ivar Leivestad, Miros, Norway, poses the question: how can offshore wind operations unleash maritime safety and efficiencies?

As the global energy industry continues to gather momentum, and offshore wind projects multiply, the maritime industry is also gearing up to meet the demands of this rapidly evolving sector. Indeed, recent research found that the market for offshore wind turbine installation vessels is currently valued at US$746.48 million and is expected to grow to around US$3.64 billion by 2031.1

As the need for installation and maintenance vessels swells, so does the need for technologies that enable efficient operations by providing insights into the sea state, helping operators to meet industry standards and objectives.

Accurate sea state information has always been fundamental for ensuring the safety and effectiveness of offshore operations, no matter the sector. While that is a fact, and one that is unlikely to ever change, how industry monitors the marine environment is constantly evolving and improving.

As the industry grows, offshore wind developers are constantly looking to refine and optimise their offshore installation and operations and maintenance (O&M) operations – for that, new cutting-edge technology, providing reliable data, is needed.

Miros has been constantly evolving its radar-based systems to remain at the forefront of the offshore sector. The company’s technology gauges live ocean data – waves, currents, sea levels, and weather conditions – providing comprehensive real-time insights, as well as offering short-term prediction of waves and vessel motion, which is key to unlocking effective offshore vessel activities in support of offshore wind.

The motion of the ocean

One aspect of vessel operations within the wind industry that can be particularly

impacted by the weather, and subsequent wave and current conditions, are ‘Walk-to-Work’ (W2W) initiatives. While this process gives wind technicians easier access to fixed or floating wind turbines, enabling O&M activities to run more smoothly, the connection of the gangway system to the turbine throws up obvious risks, and the impact of waves and currents is amplified.

To carry this work out safely, developers and operators require a precise understanding of the current sea state and, therefore, rely on forecast data to enable planning for operations. However, traditional weather forecasts do not always close this knowledge gap, as forecasts are typically less accurate and infrequent, given they are designed to predict longer, slow changing trends.

The ocean surface is not static and can change in a matter of minutes, or even seconds, resulting in operators typically relying on inaccurate or out-of-date seas state information. This has a knock-on effect on offshore operations, especially W2W deployments.

In order to further support planning and operations –that rely more heavily on forecast data – Miros recently launched ‘Forecast’, an application which integrates real-time measured data with forecasted sea conditions. By combining these two elements, clients, like vessel operators, receive the necessary insights to navigate the next steps in their activities, elevating safety with a data-led approach.

The risks of ignoring waves

It is also worth developers considering the potential implications of not having access to high-quality, real-time sea condition data, particularly for offshore wind support vessels.

Not having the right wave and weather information can have severe consequences, especially around safety for offshore workers and assets. Making decisions based on incomplete information increases the chances of accidents, vessel collisions, equipment damage, and in a worst-case scenario, loss of life.

Many offshore operations are also subject to regulatory requirements and safety benchmarks that become more

difficult to adhere to without proper information, potentially leading to fines, legal issues, and reputational damage.

Put simply, if an operator has access to local real-time data and knows what the offshore conditions are like, it significantly reduces the likelihood of being caught off guard.

Sea-state-as-a-service

Miros’ Internet of Things (IoT)-enabled wave sensors are developed and tested for use in the harshest ocean conditions. As a result, they offer an immediate improvement in sea-state monitoring, providing up-to-the-minute data, crucial for optimising offshore wind farm installation and operation.

Moreover, the comprehensive and centralised approach enabled by the ‘Sea-State-as-a-Service’ subscription model further enhances the usability and accessibility of this technology. By subscribing, rather than buying hardware outright, clients receive included premium support and guaranteed uptime, increasing the operational output of wind turbines.

Under as-a-Service, warranty of the state-of-the-art technology and latest Microsoft Azure cybersecurity is included as a standard. If any matters or questions arise, Miros experts are ready to address them.

It also comes with advanced cloud-sharing capabilities and the intuitive, easy to use Data Explorer cloud dashboard; given the number of potential stakeholders in an offshore wind project – owners, installers, O&M crews, asset integrity analysts – the value here is obvious.

On the dashboard, located on the miros.app, users can arrange the real-time measurements in a manner that suits them best, to see the data that matters the most in a preferred view – it is not pre-configured. There is also the option to access historic data, which is beneficial for asset integrity and understanding what impacts the waves have had to a structure over time. This not only allows for safer offshore maintenance activities, but also lowers various cost points for wind farm developers and vessel operators.

Much needed cost relief

That cost point is crucial considering the huge financial pressures wind farm developers and their supply chain partners are currently under. Because Miros owns, insures, and maintains its sensors under the as-a-Service model, the upfront investment for asset owners is low and the risk element is removed.

The subscription solution also means that maintenance can be planned strategically around real-time sea state insights, improving efficiency and sustainability by streamlining the number of trips that engineers need to make.

Offshore wind activities are ramping up, while at the same time the costs faced by the industry are also increasing. Wave measurement can help to reduce these costs by helping companies to better schedule their maintenance based on reliable data, thereby extending the lifespan of assets and ensuring the safety of workers.

For example, if a turbine requires maintenance but it cannot be approached by vessels because of wave heights,

RENEWING WHAT’S POSSIBLE

SEPTEMBER 9-12, 2024 | ANAHEIM, CA

RE+ 24 marks its 20th year as the largest and most comprehensive event in North America for the clean energy industry, and this year is going to be bigger than ever. Register today for discounted early bird rates through June 21.

REGISTER NOW | RE-PLUS.EVENTS

then the data will flag this. The maintenance team can then reschedule to do other work at another location at the wind farm in the meantime, rather than having to turn back to port and wait for a break in the conditions. Better data means better scheduling, up-to-date details, and clearer information. There is also an insurance element to consider, particularly for supply chain support. Certain contracts for offshore supply vessels will allow for paid weather downtime. With live data, developers can accurately assess whether it is safe for crews to work or not. Although a wave height and a safe operation limit is typically agreed before operations are conducted, access to live sea state data means companies can accurately say when that limit is reached, rather than leaving it up to looking out the window.

Tried and tested

In order to showcase the benefits of the technology, Miros carried out research alongside Trios Renewables and the University of Strathclyde into how scheduling maintenance can improve the overall performance of a wind farm. This project found that by having real-time sea-state understanding across the site, there is a

clear uplift in operators’ ability to achieve an optimised maintenance routine.

Weather windows can be accurately identified precisely across all corners of the site. Altogether, the study found that operators can save up to £1 million/y from minimising failed attempts to board turbines for maintenance work when having accurate real-time sea-state monitoring. This number does not include the additional energy generated, and therefore profit, stemming from the extra uptime gained. This study was based on an existing offshore wind farm, which is comparably smaller than newer offshore wind farms going live. Therefore, larger cost saving should be achievable at larger sites and turbines.

The Miros Wavex system has also been deployed aboard Rem Power’s state-of-the-art commissioning service operation vessel (CSOV) to support its operations globally. Incorporating Wavex, the vessel operator can securely deploy wind farm technicians on turbines at the site through its W2W gangway.

As a result, weather-critical vessel manoeuvres can be conducted safely, mitigating the risks of accidents and improving situational awareness, with vital real-time information displayed on live dashboards and sharable with all project stakeholders.

.

up-to-the-minute views of local sea conditions combined with the forecasted condition data, marine operations teams, site managers, control room operators, and other stakeholders involved in offshore wind operations can confidently elevate maritime safety and operational efficiency.

With Miros’ sensor supporting O&M activities, the vessel operator reported successful results. Captain Kristian Stavset, who utilised Miros’ technology onboard his ship, explained they use the Miros data for mainly two reasons: 1) To evaluate whether the weather forecast is in line with the actual weather conditions. 2) To use the Miros measurements with regards to wave direction vs swell direction vs surface current direction and speed to evaluate and establish the optimal vessel heading to be used when working up against wind turbine generator/transition piece.

Conclusion

By adopting such integrated and future-oriented systems, operators can engage in a two-pronged approach, bringing a spotlight on the safety of offshore crews and enhanced efficiencies for improved costs together under one umbrella. As the offshore wind industry continues to develop, and offshore vessel support becomes even more important for driving the energy market towards net zero, reliable sensors and systems that enable these operations present a turn-key solution to the sector, unlocking wider capabilities in line with expanding industry need.

References

1. ‘Offshore Wind Turbine Installation Vessel Market: Exploring Trends and Global Forecast 2031 | Industry Research Biz’, Industry Outlook 2023 Reports, (25 January 2024), www.linkedin. com/pulse/offshore-wind-turbine-installation-vessel-jihqc/

Figure 3 Knowledge of real-time accurate local wave and weather conditions facilitates optimised operations, reduced risk, and enhances overall efficiency and safety for maritime operations.

On the surface, the 10 massive wind turbines that make up the Jeonnam 1 offshore wind farm (OWF) look like any other of its kind. But down below, at the ocean floor, there is a story about an engineering problem and its solution that has a lot to say about where the offshore wind industry is heading.

Jeonnam 1 OWF is the first commercial offshore wind farm in South Korea and is nearing completion with an expected delivery of first power set for later this year.

The project is a 51-49 joint venture between SK E&S and Copenhagen Infrastructure Partners (CIP).

Situated off the coast of Shinan County in Jeonnam Province, the finished wind farm will add 99 MW of clean energy generation to the Korean grid, effectively doubling the country’s current installed capacity of 100 MW.1 The wind farm is expected to produce green electricity equivalent to the consumption of approximately 60 000 households in South Korea.

Jan Behrendt Ibsø and Antonela Mitrana, COWI, Denmark, outlines the next phase for offshore wind: digital tools, data-driven design, and hydrogen.

The project encountered various technical challenges throughout the design phase. Most notably the engineers had to deal with significant seabed mobility – a challenging phenomenon where the entire seabed in the area is being exposed to either erosion or sedimentation over time. A considerable amount of engineering effort was dedicated to accurately incorporate this phenomenon into the design process. The approach resulted in a foundation design that balances the necessary conservatism with optimal efficiency. The site’s water depth ranges from 5 – 20 m with the selected solution of steel monopile foundations featuring an 8 m diameter. Scour protection measures around monopiles are essential at the site, yet they cannot counteract the potential global seabed lowering occurring beyond the protected area. Due to the combination of seabed mobility and environmental conditions, including shallow water depths at some of the locations, identifying a uniform design for scour protection proved challenging.

This situation required conducting physical model tests to develop tailored scour protection strategies that could effectively address these unique conditions. A joint effort between the project owners, the transport and installation contractor, COWI, and Deltares, a world-leading institute in the Netherlands, made it possible to find the optimal scour protection solution at Jeonnam 1 OWF, accounting for the challenging conditions at the positions investigated.

The process shows how digital tools can help when an offshore wind project is challenged by a complex environment. This is key for further scaling up the industry, since the power of digital models and big data sets this way can help realise offshore wind farms on sites that previously would have been deemed too expensive or risky to utilise.

COWI has come to rely on a number of digital platforms whenever it helps design the world’s large offshore wind farms. The company develops some of the software itself, and one of the more recent tools to be added to its kit is called COWIND Digital Toolchain. It is specifically designed for optimising the design of monopile foundations for offshore wind turbines. This platform takes into account thousands of parameters to determine optimised and consistent designs for each foundation. It operates in the cloud, allowing for scalability and adaptability to changing design requirements. COWIND Digital Toolchain is flexible and can be customised to meet project-specific needs while ensuring adherence with ISO 9001 requirements for traceability and standardisation.

Another example of a useful digital tool is COPILOD, which allows for the direct generation of design drawings and reports. It significantly speeds up the production of foundation designs, reducing costs and resources by up to 80%. Further, COWI deploys COSPIN and COWAL as support systems. COSPIN is used for geotechnical design checks, while COWAL generates wave loads. These systems automate processes and improve efficiency in the design phase.

Software platforms and tools like these have become indispensable in order to streamline the design process, reduce costs, and improve efficiency in offshore wind farm projects and the industry will undoubtedly move towards a more digitalised and data powered approach to design in the years to come.

For both the Jeonnam 1 project and other recent offshore wind farm projects, the software has been essential to standardising the foundation design across the several foundation units found within any offshore wind farm. This standardisation process is saving costs, and it also simplifies the manufacturing process, and the installation phase for the offshore wind farm project.

Jeonnam 1 OWF’s foundation solution also comprises innovative installation solutions. The embedded part of the foundation being either composed of a monopile (MP) driven to target depth with an impact hammer or composed of several structural components: MP, insert pile (IP) and grout annulus, to form a rock socket. COWI’s extensive experience with drilled monopile foundations played a crucial role in this strategic decision, ensuring the foundation’s adaptability and resilience to the site’s conditions.

Seven tips for offshore wind developers: Focus on reliability, flexibility, and innovation

Some of the possible solutions that focus on reliability, flexibility, and innovation for an OWF project are the following:

1. Feasibility studies: Conduct thorough feasibility studies to identify technically and financially feasible locations for OWFs that have the least possible impact on the environment and society.

2. Conceptual design: Select optimal foundations and turbine locations through a comprehensive conceptual design process. This establishes a basis for the financial assessment of the OWF.

3. Wind resources analysis: Utilise high-quality analysis, measurements, wind resource studies, and site-specific wind data input to ensure accurate assessment of wind resources and maximise energy production.

4. Metocean studies: Perform site-specific meteorological and oceanographic studies, considering anticipated climate change effects, wave and hydrodynamic modelling, and statistical analysis to ensure design accuracy.

5. Aeroelastic loads analysis: Determine wind loads and conduct structural response analysis to assess the aeroelastic behaviour of the turbines, ensuring their structural integrity and reliability.

6. Geoscience surveys: Conduct comprehensive geological studies, geophysical surveys, and geotechnical investigations to facilitate the design and selection of appropriate foundation types such as jacket piled foundations, monopiles, anchored foundations, gravity-based foundations, and suction caissons.

7. Scour assessment and protection: Assess and design scour protection measures to mitigate the potential impact of seabed erosion on the OWF structures.

With achieved project certification, Jeonnam 1 OWF is not only a significant benchmark for South Korea but also serves as a reference for future offshore wind projects by SK E&S and CIP/COP, both in South Korea and internationally.

Jeonnam II and III offshore wind farm projects are already in the pipeline and early concept design works has been initialised. Together with Jeonnam 1, these projects will bring the total added offshore wind power capacity to approximately 1 GW – a significant contribution to South Korea’s politically set goal of reaching 14.3 GW of installed capacity.

Many offshore wind farm projects are currently in the planning and development phase in South Korea. However, like in many other countries, the electrical grid constraints are very significant in South Korea. Hence some of the green power from the planned offshore wind farms will have to be converted into hydrogen, for example, for the use for the heavy steel manufacturing industries in the country.

Offshore wind and hydrogen

Combining offshore wind with hydrogen production is receiving increased attention and interest across the world due to some key factors influencing the build out of offshore wind and green fuels.

In Europe, the politically set target of establishing more than 300 GW of offshore wind capacity towards 2050, just in the North Sea, causes an immediate problem: The grid onshore will not be able to handle this load coming in from the sea. At the same time most countries will face constraints related to electrical transmission which will make it difficult for such an amount of green energy to reach its end user.

Offshore wind farms when located more than approximately 70 – 80 km from shore will also need expensive high voltage direct current (HVDC) equipment offshore, including very expensive converters and transformers and costly electrical transmission offshore cables.

To minimise the energy losses, it is key to place the consumption or the conversion of energy in the proximity of the offshore wind farm.

To transport the energy in the form of hydrogen, which is needed as the energy carrier for the green transition in the chemical and steel manufacturing industries, is approximately one-fifth of the cost of transporting the energy as electrical power.

If offshore wind and electrolysis is combined offshore, it is possible to have a higher utilisation of the electrolysis plant and hence have more operational full load hours of hydrogen production.

Using a combination of electrical transmission and hydrogen as energy carriers also provides a flexibility as to use hydrogen when the electricity prices are low or negative and electrical transmission when the demand for electricity is higher and the electricity prices are higher (Figure 3).

Case scenario analysis for offshore wind and hydrogen production

Together with renewables consultancy Brinckmann, COWI has analysed different cases and scenarios of offshore wind combined with hydrogen production. The first case on the

left in Figure 3 shows a fully system integrated hydrogen energy hub offshore with a hydrogen pipeline (48 in.) to shore.

Another case shown to the right is where we have a traditional pure electricity hub offshore with an electrical transmission to shore and hydrogen production onshore behind the meter (direct transmission line to the electrolysis plant).

The cases are all for 10 GW offshore wind farms located 90 km from shore in the North Sea and at approximately 30 m water depth. The energy hub can be a jacket platform or an artificial island.

The difference in levelized cost of hydrogen (LCOH) is a 16% lower LCOH for a system integrated hydrogen energy hub offshore.

The middle case in Figure 3 is for a limited (1 GW) electrical transmission connection to shore and it shows a similar result as fully system integrated H2 energy hub offshore.

Conclusion

Making these considerations are key for the budding Korean offshore wind industry and really for all markets with huge plans

up of offshore wind, it is important to harness the energy of the wind in ways that both makes financial sense and not least brings the most value to consumers.

References

1. ‘Jeonnam 1 Offshore Wind Project in Korea Reaches Financial Close and Begins Onshore and Offshore Construction’, Copenhagen Offshore Partners (11 October 2023), https://cop.dk/jeonnam-1-offshore-wind-project-in-korea-reachesfinancial-close-and-begins-onshore-and-offshore-construction/

FINDING THE

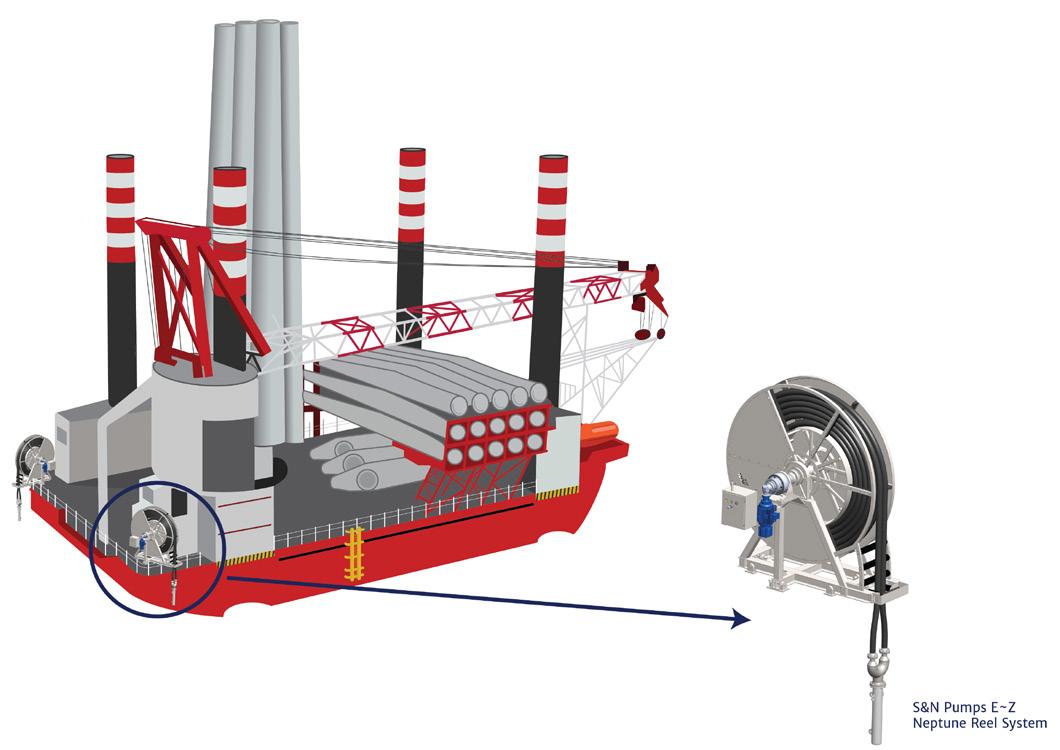

Iulian Maciuca, Industry Sector Manager – Renewables, Celeros Flow Technology, details how to meet the challenges of offshore wind turbine installation with reliable equipment.

As society becomes increasingly environmentally conscious and governments worldwide pledge to reduce their environmental impact, renewable energy is heralded as the answer to a carbon-free future. Wind energy has seen significant growth in recent years and the total installed wind capacity globally is 906 GW.1 Yet, building and operating offshore wind farms relies on specialist wind turbine installation vessels (WTIVs) and associated critical flow control equipment, such as electrical submersible pumps (ESPs). This article explores some key challenges facing the development of WTIVs and the considerations operators need to take when specifying reliable flow control equipment.

The race for renewable energy

Many governments have set bold targets in a bid to reduce their carbon emissions. According to McKinsey’s Global Energy Perspective report, 64 countries have pledged their commitment to achieving net zero in the coming years. 2 One way to achieve this target is by diversifying away from

the reliance on traditional fossil fuels and embracing the energy transition, with a move towards renewable energy sources. Indeed, countries and companies alike are investing heavily in this area. The International Energy Agency estimates that renewable energy capacity will have to triple if more than 60% of total electricity generation is to come from renewables by 2030.3

The wind energy market is growing and showing no signs of slowing down as governments worldwide seek to increase their capacity for renewable energy. The Global Wind Energy Council’s 2023 Global Wind report indicates that, globally, 77.6 GW of new wind power capacity was connected to power grids in 2022 (a y/y growth of 9%).

Of this, 8.8 GW was from offshore wind, bringing the total global offshore wind capacity to 64.3 GW.1

Offshore wind farms have a much larger generation potential than onshore wind turbines. There is a more consistent supply of higher wind speeds across the water compared to across land, and so offshore turbines can

better harness the wind levels to produce more energy than onshore turbines. Also, their size is not restricted in the same way as land-based turbines are as there is less opposition to development from local residents.

However, there are several challenges to overcome in the development of offshore wind farms. These include limited accessibility, prevailing weather conditions, water depths, and the difficulty of bringing the electricity onshore to connect to the grid. In addition, there is a limited availability of specialist WTIV vessels and skilled operators. These factors are exacerbated by the trend towards even bigger and more efficient wind turbines.

Super-sized turbines

The world’s first offshore windfarm was built in 1991, in shallow waters off the coast of Denmark. The Vindeby site consisted of 11 wind turbines with blade lengths of 17 m and heights of 54 m, capable of generating 450 kW each.4 The annual power was equivalent to 2000 – 3000 Danish households.

Technology has come a long way since then. In 2023, the world’s first 16 MW offshore wind turbine was installed in southeast China’s Fujian Province. The wind turbine, which is positioned approximately 35 km from the shore, boasts the world’s largest per-unit capacity. The turbine is 152 m high and includes the world’s longest turbine blades at 123 m, with each blade weighing 54 t. The total swept area of the three blades is approximately 50 000 m2, which is equivalent to the area of seven standard-sized football fields. At full wind speed, the wind turbine can generate 34.2 kWh of power after one full rotation. Its annual power output is estimated to average over 66 million kWh and is expected to meet the annual demand of 36 000 three-person families – replacing 22 000 t of standard coal and saving 54 000 t of carbon dioxide.

It is clear to see that wind turbine technology has made significant advances in recent years. As operators have sought to improve efficiencies and capacities, more reliable and larger turbines – coupled with larger rotor diameters and higher hub heights – have been designed and built. It is predicted that,

by 2030, the industry will be deploying 20 MW turbines with rotors of up to 300 m in diameter.

The challenge with installation

WTIVs are vessels that have been specially designed to transport, install, and carry out maintenance and repairs on offshore wind turbines. In 2020, there were 16 WTIVs worldwide. However, current WTIVs will not be able to accommodate the next generation of larger-sized wind turbines, and so they need to be upgraded or new ones built. The next-generation turbines will need a crane capacity of 2500 – 3500 t to get them upright (compare this to 500 t in 2005 when the first jack-up was deployed for offshore wind).

WTIV operators are already building cranes that will be ready to handle 20 MW turbines but, according to a report by Wind Europe, the demand for offshore wind turbines will outpace the supply of WTIVs capable of handling these new, larger turbines and there will be a shortage in 2024. 5

The State of the European Wind Energy Supply Chain research, published by Rystad Energy, states that global demand for WTIVs is expected to grow more than five-fold towards 2030.6 Excluding Chinese WTIVs, the global number of operating vessels is expected to increase to 25 by 2026 (based on confirmed newbuild orders), and by 2030, 60 – 65 vessels will be needed.

Ensuring these vessels are built to install the super-sized turbines efficiently is important. Since offshore wind farms are situated in difficult to access locations, the failure of any equipment can be extremely expensive and can cause major project delays. Operators often rely on specific time slots that are dictated by the limited availability of vessels and crews, as well as by weather patterns, and it could take days for replacement parts to be delivered should one fail.

Achieving accurate flow control

These new WTIVs will need to be fitted with reliable equipment, including flow control technology, which is essential because it transfers seawater that is critical for various installation activities including drilling, firewater duties, and providing ballast on semi-submersible structures.

One piece of flow control equipment that is key to wind turbine installation is the ESP. There are many considerations to take when specifying pumps, such as technical specifications, including sizing and flow rate required. Reliability is also paramount, so maximising operational life and minimising total cost of ownership are essential. It is futile to have a pump that can deliver the right flow rates if it cannot withstand the harsh marine environments and fails after its first use.

Corrosion resistance is key

Pumps need to be corrosion-resistant and specially designed so that they provide reliable operation in seawater. Additionally, as seawater acts like a conductor and is corrosive, proper isolation between the electrical equipment and seawater must be provided.

One example is Celeros Flow Technology’s S&N Pumps ESP range, which is built to withstand marine conditions.

SUPPORTING THE ENERGY TRANSITION

At Celeros Flow Technology, we recognize the challenges that the global energy transition raises for our customers.

We apply our engineering pedigree, application knowledge and technical expertise to deliver sustainable flow control solutions that help to decarbonize existing operations and develop more renewable resources.

Together, we can create a safer, more resilient and cleaner energy future.

• Biofuels

• Carbon Capture & Storage

• Energy from Waste

• Hydrogen

• Low Carbon Ammonia Storage & Distribution

• Offshore Wind

These versatile pumps have been specially constructed using high-grade, robust corrosion-resistant materials such as stainless steel. A Duplex material grade design is also available to provide enhanced corrosion protection. Equipped with powerful motors up to 750 hp, these pumps can achieve flow rates of up to 4500 gpm and are available in diameters between 4 – 24 in. Depending on the requirements of the application, these pumps can be orientated either vertically or horizontally.

Preventing blockages

Corrosion is not the only challenge in a marine environment. The presence of marine wildlife can also affect equipment uptime and reliability. For example, seaweed and crustaceans, such as barnacles, can attach themselves to equipment which can have a negative effect on equipment performance. If they grow on pumps, they can create a thermal barrier around the motor, which can reduce the amount of heat that can be dissipated. Other adverse consequences of the growth of marine life include the risk of reduced fluid flow through the piping of the vessel or rig, and the potential for turbulence at pump intakes. Marine organisms could also cause severe blockages which are expensive and time-consuming to remove: in worst-case scenarios, entire sections of pipework may need to be replaced.

One way to prevent blockages caused by the growth of marine wildlife on pumping equipment is to use bio-foul

prevention systems. For example, the SNSAFE system from Celeros Flow Technology provides a robust solution to significantly improve pump service life. SNSAFE includes an anode cage assembly which attaches to the motor housing of an ESP or the suction of a vertical turbine pump. Strategically placed copper anodes have a DC current passed through them, which releases copper ions into the seawater at a predetermined rate. This averts the growth of unwanted organisms.

Reel advantages

Pre-loading reel systems, which provide a reliable supply of raw seawater, are another vital piece of equipment on WTIVs. They store, lower, and retrieve a hose with an ESP attached below the ocean surface to deliver seawater to an elevated offshore structure when it is required. A complete seawater lift system consists of a reel with the hose, power cable, safety cable, and a submersible pump/motor with all necessary controls.

Traditionally, reel systems were mounted on the leg of a crane or platform. To make deployment of water quicker and easier, systems are now designed to mount directly to the main deck either with removal anchor pins or by welding. However, there is one weakness with these systems: hoses can stretch and are at risk of puncture or fracture. This failure can further result in the reel system snagging and causing expensive project delays.

To minimise the risk of failure, hose technology is being continually developed. For example, the E-Z Fit Reel System from S&N Pumps includes a hose with reinforcing wire along its entire length. This system acts to support the combined weight of the pumps, shroud and the full water columns, which in turn eliminates hose stretch and extends hose life. To further maximise the life of the hose, the E-Z Fit Reel System includes a custom-engineered roller solution that intuitively maintains the radius bend of the hose throughout deployment and retrieval.

Conclusion

The race to decarbonise the world’s energy supply is placing new challenges on energy generation technology and, by association, on the safety-critical flow control systems on which energy infrastructure relies. As a full lifecycle partner, Celeros Flow Technology works closely with its customers to anticipate the operational and sustainability challenges of the renewables sector, ensuring that flow control equipment and services continue to deliver the performance and reliability required to deliver the energy transition efficiently.

References

1. ‘Global Wind Report 2023’, Global Wind Energy Council, https://gwec.net/ globalwindreport2023/

2. ‘Global Energy Perspective 2022’, McKinsey & Company, (26 April 2022), www.mckinsey.com/industries/oil-and-gas/our-insights/global-energyperspective-2022

3. ‘World Energy Outlook 2022’, International Energy Agency, (October 2022), www.iea.org/reports/world-energy-outlook-2022

4. ‘Vindeby Offshore Wind Farm’, Wikipedia, https://en.wikipedia.org/wiki/Vindeby_ Offshore_Wind_Farm

5. ‘Offshore wind vessels availability until 2030’, WindEurope, (14 June 2022), https://windeurope.org/intelligence-platform/product/offshore-wind-vesselsavailability-until-2030/

6. ‘The State of the European Wind Energy Supply Chain’, Rystad Energy, (19 April 2023), www.rystadenergy.com/insights/the-state-of-the-european-wind-energy-supply-chain

LiDAR: Empowering

Matthieu Boquet, Head of Market and Offering of Wind Energy, Vaisala, France, examines the uses of LiDAR technology in wind farms.

The wind power industry leverages LiDAR to understand and accurately harness the planet’s natural air movement and help power a cleaner future. Given wind energy’s ongoing evolution, remote sensing LiDAR technology is no longer just nice to have – it is necessary across different stages of a successful wind farm project. Globally, wind generation capacity is ballooning, increasing by 75 GW or 9% in 2022. With new on and offshore projects currently in planning and construction to meet increasingly urgent renewable energy goals, the planet’s installed wind energy capacity will only continue escalating. But with growth comes challenges – and an increasing need for accurate and reliable wind data measurements.

Meteorological masts cannot accurately measure the wind’s behaviour at the unprecedented hub height of today’s towering turbines. They are also extremely costly and hold significant safety risks for wind farms constructed in increasingly complex terrains or harsh offshore environments farther from shorelines.

Given these growing concerns, LiDAR – or light detection and ranging – is rapidly emerging as the industry’s new standard for wind measurement, empowering users with accurate, widely accepted – and often bankable – data. LiDAR provides safe, accurate, and cost-effective solutions throughout the lifecycle of wind

wind energy’s ascent

energy projects, helping stakeholders and decision-makers overcome challenges and open new avenues to success.

LiDAR: Technology for today’s wind projects

Modern LiDAR systems have achieved parity with met mast data and outpace met masts in most situations.

Met masts typically can only measure up to the full height of modern turbines with mathematical extrapolation, introducing the possibility of error. Worse yet, these tall structures equipped with anemometers and other meteorological instruments require long permitting processes and can come with high equipment and maintenance costs and significant safety hazards.

LiDAR, on the other hand, sends light beams into the atmosphere, which are reflected and returned by particulates moving with the wind. Using the Doppler effect, the LiDAR unit analyses the frequency of those reflections and computes a highly reliable wind speed. Pulsed LiDAR technology measures multiple heights simultaneously, providing a complete wind profile with no temporal resolution or accuracy compromises. And multiple measurement heights mean more data, more quickly, providing constant spatial resolution throughout the entire wind profile.

LiDAR units deliver data as accurate as met mast data and fully comply with International Electrotechnical Commission and other regulatory standards. LiDAR’s range of available data is extensive, as is the processing power of modern LiDAR units and their related software. The technology also often comes with modern, cloud-based management and analytics tools, making its insights more accessible and easier to manage. These factors improve situational awareness and allow for previously unattainable benefits, like out-of-the-box power performance testing (PTT) according to industry best practices and the IEC standard.

In some situations, LiDAR complements met masts – filling in gaps in the data, validating and expanding measurements and drastically reducing uncertainty. The technology’s ease of use and deployment — and its ability to accurately measure the full wind profile of even the largest turbines and assess wind characteristics across larger areas – make LiDAR instruments

ideal for reducing costs, speeding up wind energy projects, and maximising wind turbine performance and profitability.

A LiDAR solution for each stage of wind energy projects

Onshore and offshore, LiDAR technology supports every stage of a wind farm project.

Precise wind resource assessment

In the critical phase of Wind Resource Assessment (WRA), LiDAR instruments provide a distinct advantage over traditional methods, enabling developers to efficiently and accurately assess the wind characteristics of potential sites, both onshore and offshore.

Some ground-based or buoy-mounted vertical wind-profiling LiDARs provide accurate wind measurements up to 300 m over 20 simultaneous heights. LiDAR’s mobility, cost-effectiveness and ability to deploy in remote, complex terrain or difficult-to-reach offshore environments underscore the technology’s value in conducting wind measurement campaigns quickly and safely without the need for expensive met mast installations.

For onshore WRA campaigns, developers like RES are embracing standalone vertical profiling LiDAR campaigns using systems like Vaisala’s WindCube® vertical profiling LiDAR. RES completed a 12-month measurement campaign at Northern Ireland’s Corlacky Hill wind farm using a single verified LiDAR, representing a 40% cost savings over a conventional met mast setup. The LiDAR data helped optimise turbine layout and maximise energy yield with zero safety incidents.