WINTER 2022

Advancing a sustainable energy future for all

We are advancing the world’s energy system to be more sustainable, flexible and secure.

ENERGY GLOBAL

WINTER 2022

36. Staying safe whilst subsea Austin Harbison, Smart Technology Manager, CRP Subsea, UK. 42. Taking the power back Paul Cairns, Managing Director at MJR Power and Automation, UK. 48. Overcoming supply challenges with collaboration

Cerianne Cummings, Offshore Wind Market Director, Kent. 52. Reshaping Kazakhstan's energy sector

Taylor Mattie, Director of Geothermal Technologies and Innovations, Baker Hughes, USA.

Serik Shakhazhanov, Chairman of the Management Board of Eurasian Group LLP, Kazakhstan. 56. Enhancing resilience and stability Dr Carlos de Palacio, Renewable Segment Manager Grid Integration, Hitachi Energy, Spain. 60. A strong energy storage foundation Martin Vogt, CEO of MPC Energy Solutions 64. Here comes the sun? Mark Rowcroft, Development Director, Exagen, UK. 68. Striving for sustainable solar Dongyoung Kim, Technical Assistant, Reddie & Grose. 72. Fuelling North America's Renaissance in anaerobic digestion Shawn Kreloff, Bioenergy Devco Founder and CEO, USA. 76. Global news

Rasmus Rubycz, Market Manager New Energy, Atlas Copco Gas and Process Division, Germany.

Copyright © Palladian Publications Ltd 2022. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner. All views expressed in this journal are those of the respective contributors and are not necessarily the opinions of the publisher, neither do the publishers endorse any of the claims made in the articles or the advertisements.

One coating company protecting the future

With a growing portfolio of high performance products, Seal For Life offers innovative corrosion prevention and thermal insulation technologies for infrastructure protection.

A track record of more than 60 years, always pushing the boundaries to develop new solutions for the challenges of tomorrow.

sealforlife.com

COMMENT

Simone AccorneroCo-Founder & CEO, FlexiDAO

The energy sector is responsible for over three-quarters of human-caused emissions,1 making decarbonisation of our energy supplies the single biggest carbon dioxide challenge our generation faces today.

Many of the perceivable solutions involve transitioning to an electricity-based economy; for instance, updating to electric heat and transport, or replacing natural gas with hydrogen produced in electrolysers. Yet, pursuing these solutions will increase demand for electricity and put more pressure on our power grids, which are currently running on a mix of carbon-free and carbon-intensive sources. For the electrification of our society to truly reduce emissions, we need carbon-free electricity grids.

As some of the largest energy buyers, companies have a crucial role to play in generating enough demand for carbon-free electricity. Voluntary corporate procurement has been critical in expanding the deployment and installation of new renewable electricity so far. According to the current, most adopted global carbon accounting standard (The GHG Protocol), organisations can buy renewable electricity to meet their annual electricity demand and claim they are running on ‘100% renewable energy’ in their Scope 2 market-based emissions accounting.

Whereas market-based emissions accounting has provided incentives for companies to act, the challenge is that it does not consider the real locational and market constraints of our electricity grids, nor the hourly or sub-hourly fluctuations in where electricity comes from. ‘100% renewable energy’ claims do not mean that a business is running on carbon-free electricity every hour of the day.2 To give an example, a Dutch data centre consuming electricity throughout the day and during the night could claim to be ‘100% renewable’ by covering its annual consumption with electricity generated from a solar plant in Portugal. There is no chance at all that the actual electrons related to the volume of electricity (and the underlying certificates as assurance) procured from the solar plant (which will only be producing electricity when it is sunny during the day) ever actually reach the data centre (which is on an entirely different power grid to these electrons).

To remain credible and effective,3 Scope 2 market-based emissions accounting needs to be modernised and adapted to represent the current and future market reality. Market-based accounting needs to reflect the physical constraints of the power grid by imposing stricter requirements4 for quality criteria with regards to location (production should take place in the same or neighbouring power grid as consumption) and time (production should take place in the same hour as consumption).

As the rules of the energy game change to favour a more granular, accurate, and data-led accounting system, the right price incentives will be implemented to drive deeper decarbonisation of our power grids. Many of the technologies needed to fully decarbonise our energy grids – such as long-duration storage – currently suffer from a lack of demand driving down their costs and stimulating further adoption. If businesses begin accounting for their actual electricity usage on an hourly rather than annual basis, and focusing on the local grids that businesses actually operate on, corporate energy buyers will start to seek out these solutions for the times of the day when they are currently reliant on fossil fuels, using their purchasing power to much greater effect.5

References

1. ‘4 Charts Explain Greenhouse Gas Emissions by Countries and Sectors’, World Resources Institute, (2020), www.wri.org/insights/4charts-explain-greenhouse-gas-emissions-countries-and-sectors

2. BJØRN, A., LLOYD, S. M., BRANDER, M., and MATTHEWS, H. D., ‘Renewable energy certificates threaten the integrity of corporate science-based targets’, Nature Climate Change, No.12, pp.539 – 546, (2022), https://doi.org/10.1038/s41558-022-01379-5

3. ELGIN, B. and RANGARAJAN, S., ‘What Really Happens When Emissions Vanish’, Bloomberg UK, (2022), www.bloomberg.com/ news/features/2022-11-01/intel-p-g-cisco-among-major-companiesexaggerating-climate-progress

4. ‘GHG Protocol to assess the need for additional guidance building on existing corporate standards’, Greenhouse Gas Protocol, (2022), https://ghgprotocol.org/blog/ghg-protocol-assess-need-additionalguidance-building-existing-corporate-standards

5. ‘Advancing Decarbonisation through Clean Electricity Procurement’, International Energy Agency, (2022), www.iea.org/reports/advancingdecarbonisation-through-clean-electricity-procurement

location,

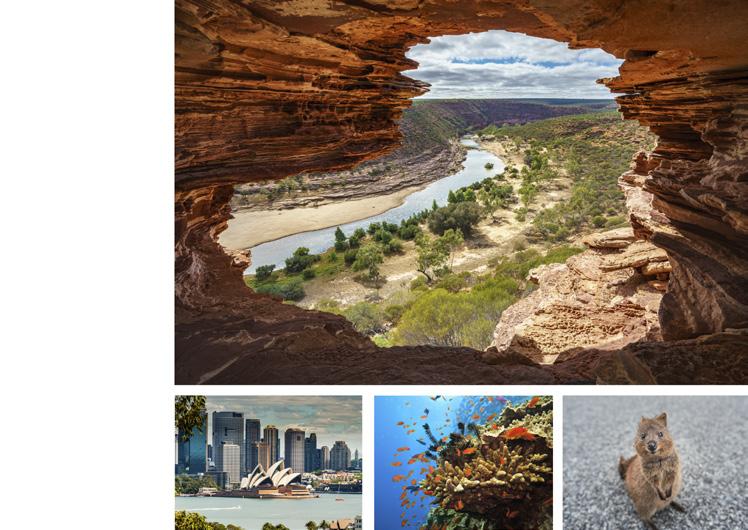

Jessica Casey, Deputy Editor, and Abi Larkin, Editorial Assistant, Energy Global, UK, look at the Australian renewables sector.In September 2022, the Australian government passed legislation with the aim of reducing carbon emissions by 43% by 2030 and achieving net zero by 2050.1 The country also has a Renewable Energy Target scheme, which aims to reduce greenhouse gas emissions from the electricity sector, by encouraging investment in renewable energy power sources, including wind and solar farms, and hydroelectric power stations. 2 Australia is an island nation and generally considered to have a hot climate – factors which also contribute positively to the likelihood of green energy generation being achieved.

With concerns over climate change and global warming ever present, it is becoming increasingly important to reduce global emissions and improve the sustainability of power supplies. In addition, Russia’s recent conflict with Ukraine, and the subsequent restrictions on gas supply to Europe, has meant many countries have needed to find alternative sources of energy.

Australia did not escape the wider effects of this, with the cost of oil, gas, and electricity increasing significantly. But with Australia well positioned to take advantage of natural resources, such as wind and solar, renewables could help Australia to meet the demand of domestic energy demand.

In 2021, 29% of Australia’s total electricity generation was from renewable energy sources, including solar (12%), wind (10%), and hydro (6%) – this share of renewables was the highest on record, with the previous peak being 26% in the mid-1960s.3

Wind

Wind generation in Australia grew 19% in 2021, and by an average of 15% y/y over the last decade.3 The wind industry has also experienced significant technological advancements over the past few decades, especially in regards to the size and generation capacity of wind turbines. In the 1980s, wind turbines were approximately 17 m tall with a capacity of approximately 0.75 MW; the latest generation of offshore wind turbines in 2021 were up to 250 m tall, with a generation capacity of up to 15 MW.4

According to NOPSEMA, Australia’s offshore energy regulator, a site is considered to be suitable for an offshore wind project if:

location,

location: Australia

F It has high and relatively consistent wind speeds.

F It has an appropriate water depth.

F The site is either able to be connected to an electricity grid, or is in a suitable location for the generation of energy export products such as hydrogen and ammonia.5

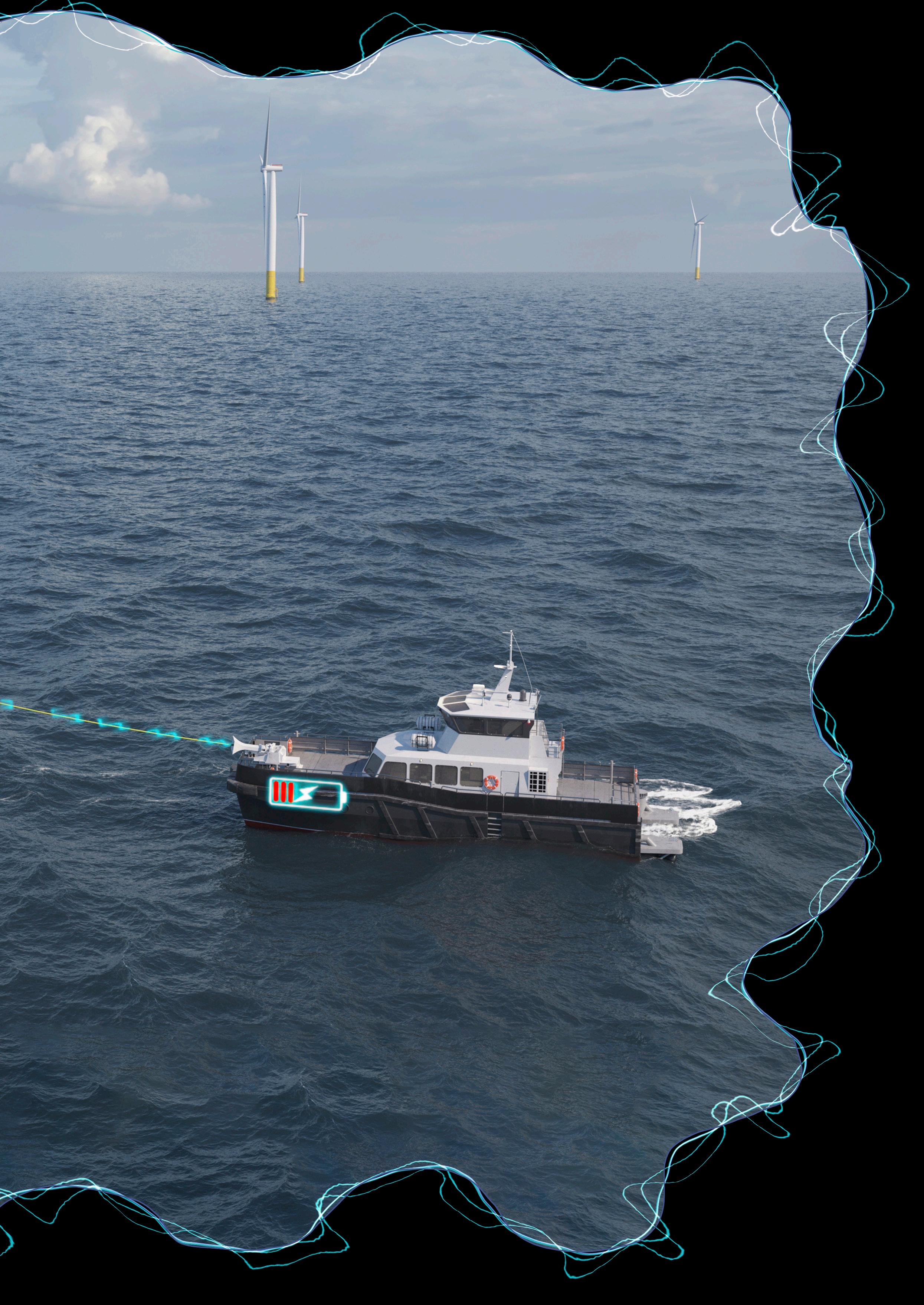

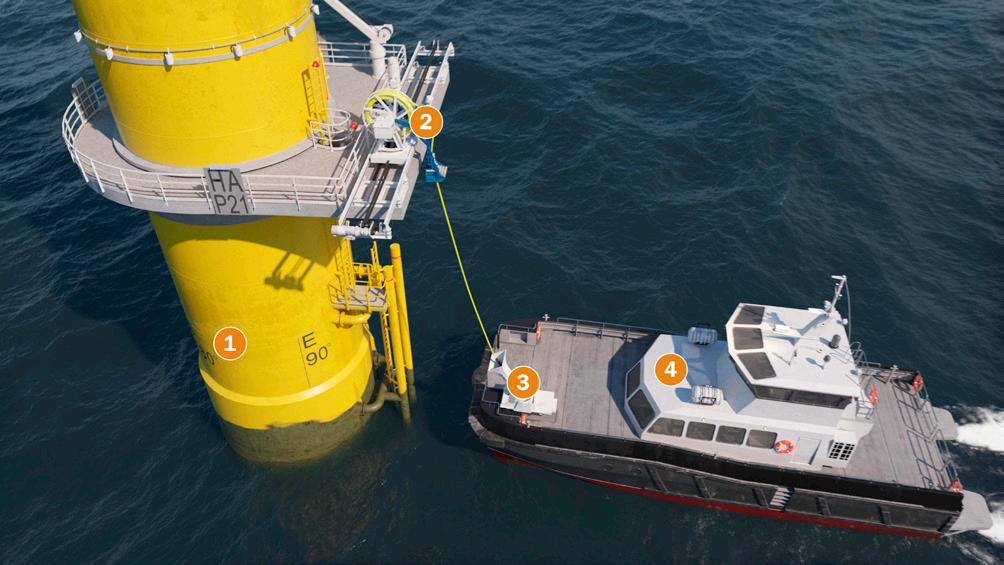

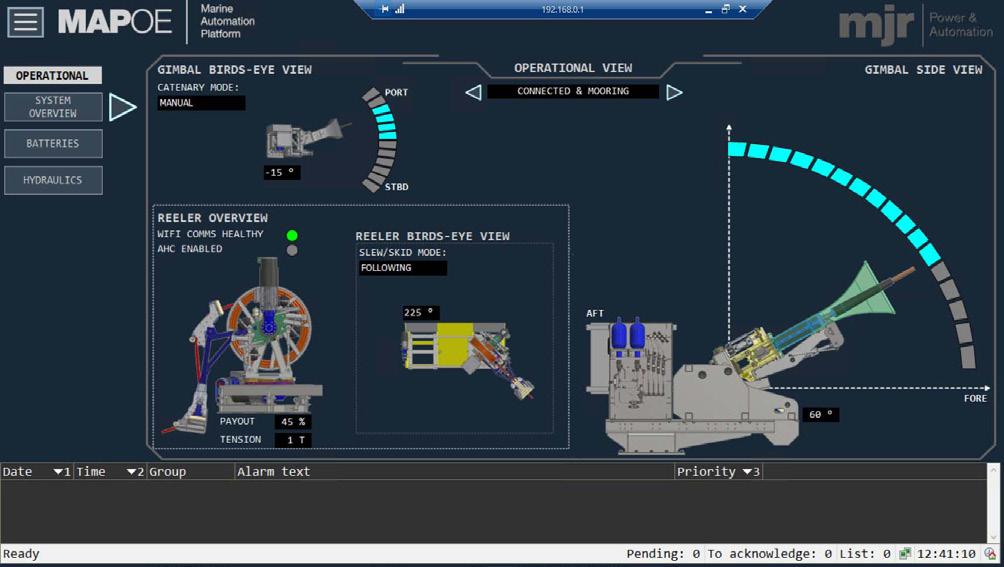

As an island, Australia has some of the best wind resources in the world. These are mainly located in southern parts of the country, which is situated in the ‘roaring forties’ – areas between latitudes of 40 – 50˚ south in the Southern Hemisphere with persistent winds from the west. The southwest of Western Australia, southern South Australia, western Victoria, northern Tasmania, and elevated areas of New South Wales (NSW) and Queensland have good wind resources.5

Many projects are being developed in these areas. One such example is BlueFloat Energy and Energy Estate’s proposed capacity expansion from 1.275 GW to 2.085 GW of the Greater Gippsland offshore wind project. The project is located in the Bass Strait off the coast of Gippsland in Victoria, which was declared as the first area to be assessed for suitability for offshore wind developments by the Australian government in August 2022.6

In addition, BHP has signed a renewable power purchase agreement (PPA) with Neoen that is expected to supply 70 MW of electricity to Olympic Dam and will support Neoen in constructing the 203 MW Goyder South Stage 1b wind farm. This wind farm will form part of the larger Goyder Renewables Zone in South Australia – a hybrid wind, solar, and storage project – and will introduce new renewable generation into the South Australian electricity grid. Neoen will also construct a large scale battery energy storage system in Blyth to support the PPA and assist in improving the stability of the South Australian electricity grid.7

These projects are just two examples of how Australia is utilising its abundant natural resources; along with the Australian government’s commitment to the Global Offshore Wind Alliance (signed on Energy Day at COP27 in Sharm-El-Sheikh, Egypt,)8 this implies that Australia intends to harness its offshore wind potential as a key part of its future energy mix.

Solar

When people think of Australia, the sun generally comes to mind, and is one of the main attractions for tourists visiting the country. In fact, the Australian continent has the highest solar radiation per square metre of any continent, and consequently some of the best solar energy resources in the world, receiving an average of 58 million PJ of solar radiation per year – this is approximately 10 000 times larger than its total energy consumption.9 However, Australia appears to be endeavouring to make the most of what is available: large scale solar farms are on the rise, with almost 7 GW of generation connected to the electricity grid,10 and an increase in Australia’s large scale solar energy capacity to a total of 5.8 GW across 80 projects, as of February 2022.11

Solar and battery storage

Several of the solar projects have been combined with a battery energy storage system (BESS). BESS’s can help renewable energy supplies effectively respond to energy demands, even when the sun is not shining. For example, Energy Vault Holdings, Inc. has recently announced a notice of award from Meadow Creek Solar for the deployment of a 250 MW/500 MWh BESS at the Meadow Creek solar farm in Victoria. The BESS, being co-located with solar photovoltaics (PV), will provide the resiliency and flexibility of charge and discharge, essential to stabilising renewable energy supply across the network as Australia adopts the Australian Energy Market Operator’s Integrated System Plan.12

Also on the horizon is the Sun Cable project in the Northern Territory, which, at 10 GW, will be the world’s largest solar farm and will feature a battery 150 times larger than the 150 MW Hornsdale Power Reserve in South Australia.13,14 The project is not expected to generate any electricity until 2026; nevertheless, its continued development is a positive sign of the important role large scale solar will play in Australia’s transition to a renewable-fuelled future.

Solar and wind

Many companies are also utilising Australia’s solar and wind in combination with each other. For example, Iberdrola has chosen Australia for the company’s first wind-solar hybrid plant in the world, Port Augusta. The renewable facility, located in South Australia, combines 210 MW of wind power with 107 MW of PV power. Comprising 50 wind turbines and 250 000 solar panels, the complex is the largest wind-solar hybrid farm in the Southern Hemisphere and will prevent 400 000 tpy of carbon dioxide emissions.15 The fact that a Spanish company has chosen Australia for its first solar-wind hybrid plant is testimony to the resources available. Another example of a solar-wind hybrid project is bp’s Asian Renewable Energy Hub (AREH) in the Pilbara region of Western Australia. The company will develop the project in multiple phases, creating up to 26 GW of combined solar and wind power generating capacity. At full scale, the AREH will produce approximately 1.6 million t of green hydrogen. From 1 July 2022, bp took a 40.5% stake and operatorship of the AREH project and will develop the project in collaboration with its project partners: InterContinental Energy, CWP Global, and Macquarie Capital, and Macquarie’s Green Investment Group.16

In addition, Fortescue Future Industries and Windlab are to partner on a Super Hub which could generate more than 10 GW of wind and solar power and underpin the industrial scale production of green hydrogen from purpose-built facilities within Queensland.17 Green hydrogen is considered by many as a possible solution for the decarbonisation of many industries, including transport and energy storage. This ‘Super Hub’ could be incremental in improving the attainability of industrial scale green hydrogen, which has been constrained by the lack of renewables available to power the electrification process. The first stage includes the 800 MW Prairie wind farm and 1000 MW Wongalee project with construction, subject to approvals, expected to

commence in 2025, with power anticipated to begin to be produced by 2027.18

Hydropower

Australia has more than 100 operating hydroelectric power stations, with a total installed capacity of approximately 7800 MW. They are located mostly in NSW and Tasmania, where there is the highest rainfall and elevation,19 with most of the hydroelectricity generated by Hydro Tasmania’s network of power plants and the Snowy Mountains Hydro Scheme in NSW.20

Particularly in Tasmania, hydropower provides much of the state’s electricity. In fact, the abundance of hydropower assets in Tasmania means that it is one of the few jurisdictions in the world that gets all its power from renewable energy – in 2021, approximately 99.9% of Tasmania’s electricity generation came from renewables, according to the Clean Energy Council’s Clean Energy Australia Report 2022.21

The importance of hydroelectricity to Australia’s net zero goals is being demonstrated through the schemes and investments that are being put in place. The Tasmanian integrated hydropower scheme utilises hydro energy from six major water catchments and involves 50 major dams, numerous lakes, and 29 power stations with a total capacity of 2600 MW.19 The Australian government is also making targeted investments to help realise the significant potential that pumped hydro can deliver to the market. The government is supporting pumped hydro through:22

F Partnering with the Tasmanian government to expedite the 1500 MW second Tasmanian interconnect, known as Marinus Link, through to a final investment decision by 2024.

F Making up to AUS$1 billion of low-cost loans available from ‘Rewiring the Nation’ to eligible ‘Battery of the Nation’ projects.

F Providing additional equity to Snowy Hydro Ltd to construct Snowy 2.0.

The biggest new hydro project is Snowy 2.0, a 2000 MW/350 000 MWh project currently under construction in NSW. In 2020, the project received state and federal environmental approval, both of which were fast-tracked as part of the government’s COVID-19 recovery efforts, a AUS$125 million transmission investment by Clean Energy Finance Corp. and approval of a segment factory, which will manufacture 130 000 concrete tunnel segments for use during construction.19 Once complete, Snowy Hydro 2.0 will provide more energy storage capacity than all of the utility scale batteries in the world combined.23

Queensland Premier, Annastacia Palaszczuk, has also recently announced a plan to build the world’s largest capacity pumped storage hydropower project in the north of Queensland. The Pioneer-Burdekin project would provide 5 GW of installed capacity and 24-hour storage, enabling flexibility and security of the state grid. The project is part of the state government’s wider energy plan to reach 70% renewable energy by 2032 and 80% by 2035.17

Conclusion

Australia is not alone in adopting multiple sources of renewable energy in order to cut greenhouse gases. It may not be a solution that will happen in the immediate future due to the time it will take for projects to be approved and constructed; however, the projects that have been highlighted are just some examples that indicate Australia is actively working towards the Paris Agreement’s goals of limiting global warming to 1.5˚C. With the increasing number of proposed renewables project, it is no surprise renewables are expected to supply 69% of Australia’s main electricity grid by 2030,20 and with investment from both international and Australia-based companies, it puts the country in good stead to achieve their net zero goals.

References

1. ‘Australia passes a law for net zero emissions by 2050’, Reuters, (2022), www.reuters.com/ world/asia-pacific/australia-passes-law-net-zero-emissions-by-2050-2022-09-08/

2. ‘Renewable Energy Target Scheme’, Australian Government: Department of Climate Change, Energy, the Environment and Water, www.dcceew.gov.au/energy/renewable/target-scheme

3. ‘Renewables’, Australian Government: Department of Climate Change, Energy, the Environment and Water, www.energy.gov.au/data/renewables

4. ‘Offshore wind energy’, NOPSEMA, (2021), www.nopsema.gov.au/sites/default/files/2021-11/ Offshore%20wind%20energy%20brochure_0.pdf

5. ‘Australia’, Asia Wind Energy Association, www.asiawind.org/research-data/market-overview/ australia/

6. ‘BlueFloat Energy and Energy Estate announce expansion of Greater Gippsland Offshore Wind Project to 2.085 GW’, BlueFloat Energy, (2022), www.bluefloat.com/bluefloat-energyand-energy-estate-announce-expansion-of-greater-gippsland-offshore-wind-project-to-2085-gw/

7. ‘New wind and battery project in South Australia’, BHP, (2022), www.bhp.com/news/mediacentre/releases/2022/11/new-wind-and-battery-project-in-south-australia

8. ‘Australia signs with the Global Offshore Wind Alliance’, Clean Energy Council, (2022), www.cleanenergycouncil.org.au/news/cop27-energy-day

9. ‘Solar energy’, Geoscience Australia, www.ga.gov.au/scientific-topics/energy/resources/otherrenewable-energy-resources/solar-energy

10. ‘Solar energy’, Australian Renewable Energy Agency, https://arena.gov.au/renewableenergy/solar/

11. ‘Solar Report Quarter 1, 2022’, Australian Energy Council, (2022), www.energycouncil.com.au/ media/nb0fjq2z/australian-energy-council-solar-report_q1-2022.pdf

12. ‘Energy Vault Issued Notice of Award From Meadow Creek Solar Farm for a 250MW/500MWh Grid-connected Battery in Victoria, Australia’, BusinessWire, (2022), www.businesswire.com/ news/home/20221026005391/en/Energy-Vault-Issued-Notice-of-Award-From-Meadow-CreekSolar-Farm-for-a-250MW500MWh-Grid-connected-Battery-in-Victoria-Australia

13. ‘Large-scale solar’, Clean Energy Council, www.cleanenergycouncil.org.au/resources/ technologies/large-scale-solar

14. Hornsdale Power Reserve, https://hornsdalepowerreserve.com.au/

15. ‘Iberdrola starts up the world’s first wind-solar hybrid plant in Australia’, Iberdrola, (2022), www.iberdrola.com/press-room/news/detail/iberdrola-starts-up-the-worlds-first-wind-solarhybrid-plant-in-australia

16. ‘Renewable energy hub in Australia’, bp, www.bp.com/en_au/australia/home/who-we-are/ reimagining-energy/decarbonizing-australias-energy-system/renewable-energy-hub-inaustralia.html

17. ‘World’s largest capacity pumped storage hydropower project to be built in Queensland, Australia’, International Hydropower Association, (2022), www.hydropower.org/news/largestcapacity-pumped-storage-project-queensland

18. ‘Game changing North Queensland Super Hub to power green hydrogen with wind, solar’, Fortescue Metals Group, (2022), www.fmgl.com.au/in-the-news/media-releases/2022/11/14/ game-changing-north-queenland-super-hub-to-power-green-hydrogen-with-wind-solar

19. ‘Hydro Energy’, Australian Government: Geoscience Australia, www.ga.gov.au/scientifictopics/energy/resources/other-renewable-energy-resources/hydro-energy

20. ‘Hydro’, Clean Energy Council, www.cleanenergycouncil.org.au/resources/technologies/ hydroelectricity

21. ‘Clean Energy Australia Report 2022’, Clean Energy Council, https://assets.cleanenergycouncil. org.au/documents/resources/reports/clean-energy-australia/clean-energy-australiareport-2022.pdf

22. ‘Pumped hydro’, Australian Government: Department of Climate Change, Energy, the Environment and Water, www.energy.gov.au/government-priorities/energy-supply/pumpedhydro-and-snowy-20

23. ‘Here and now: The state of low emissions technology in Australia’, Australian Academy of Technological Sciences & Engineering, (2022), www.atse.org.au/wp-content/uploads/2022/07/220711-ATSE-Explainer-energy-tech.pdf

t is generally accepted that a wide range of sustainable and integrated energy sources are going to be needed to reach the greenhouse gas (GHG) targets set by the world community at COP meetings, in order to prevent global temperatures from rising to 2˚C above pre-industrial levels. To this end, the use of solar and wind power has increased dramatically over the last few years, but what happens at night time, when it is cloudy or the wind drops?

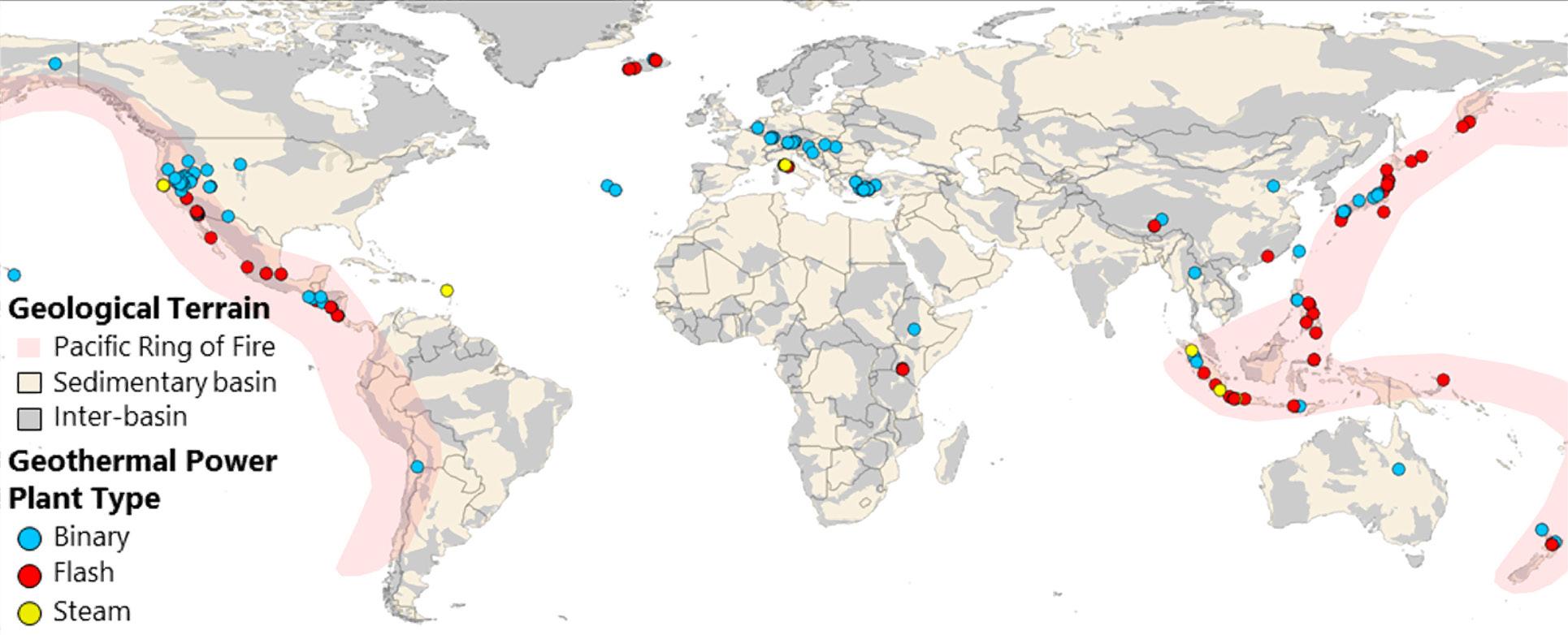

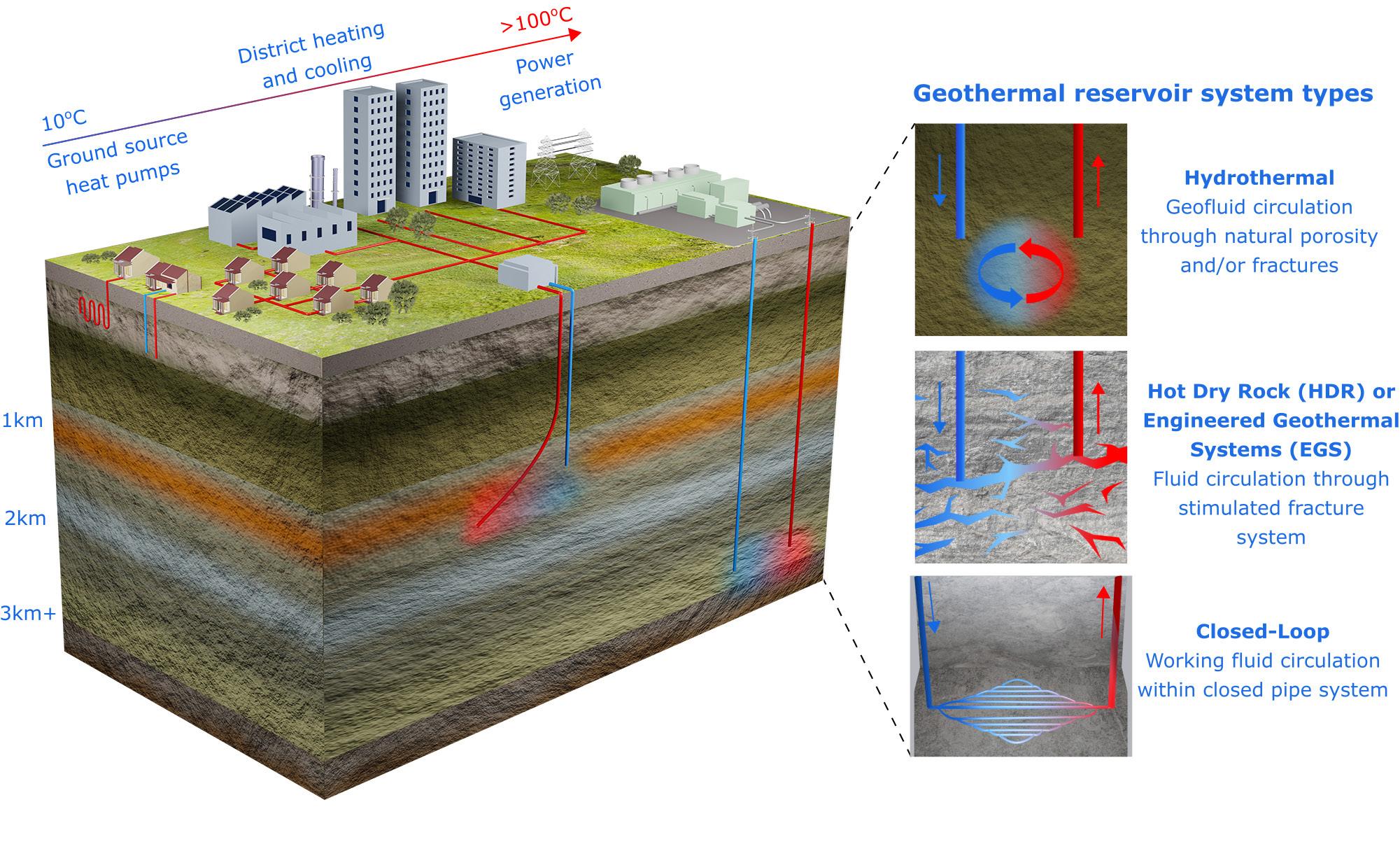

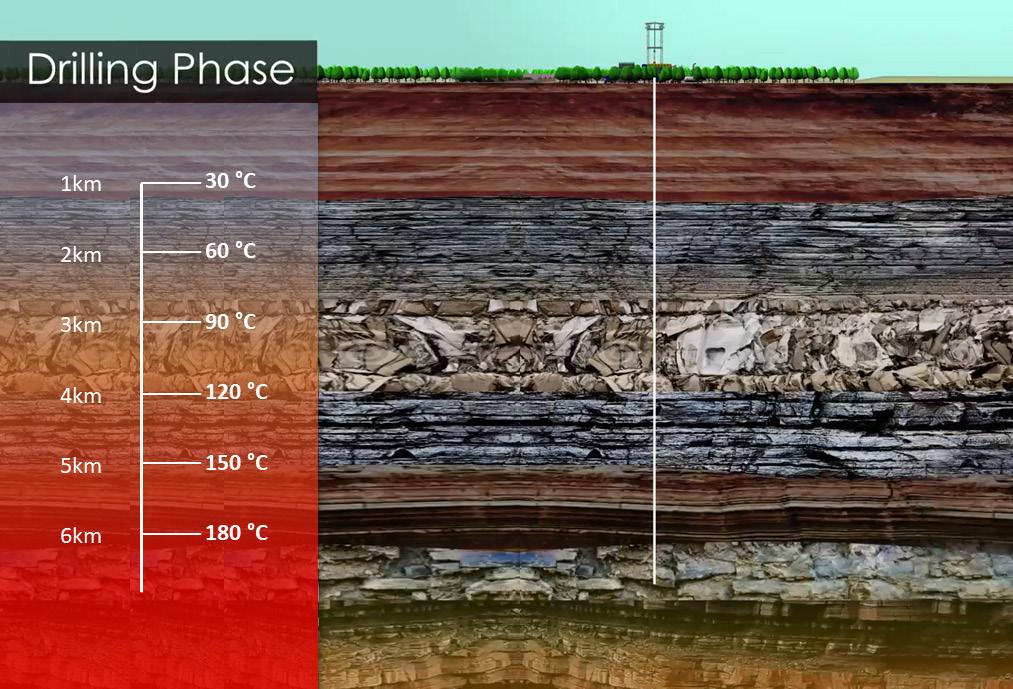

Step forward energy from within the Earth itself. Originating in the heat generated when the planet was first formed and constantly regenerating through radioactive decay, geothermal energy is always there and fully sustainable. It has been used as a local heat source for millennia, as well as more recently to generate electricity in places where there is a high heat flow close to the surface of the Earth (Figure 1).

But accessing geothermal energy need not be confined to these regions – in fact, there is potential for utilising it throughout the globe.

Heat from within the Earth

The temperature of the Earth’s subsurface rises with distance from the surface. This gradual change, known as the temperature gradient, is usually approximately 25˚C for each kilometre of depth, increasing up to temperatures in excess of 900˚C where rock may be in a molten state – magma. Near plate boundaries and volcanic centres, such as the Pacific ‘Ring of Fire’, magma rises towards the surface where it heats underground aquifers to temperatures of 350˚C or more and pressurised water escapes in the form of geysers, hot springs, and steam vents. These surface emanations have been utilised for decades in places such as Iceland, Italy, New Zealand, and California, the US (Figure 2). Naturally occurring hydrothermal fluids such as these can be used directly to heat buildings, greenhouses, and swimming pools, or, where hot enough, they can be used to produce steam for electrical power generation.

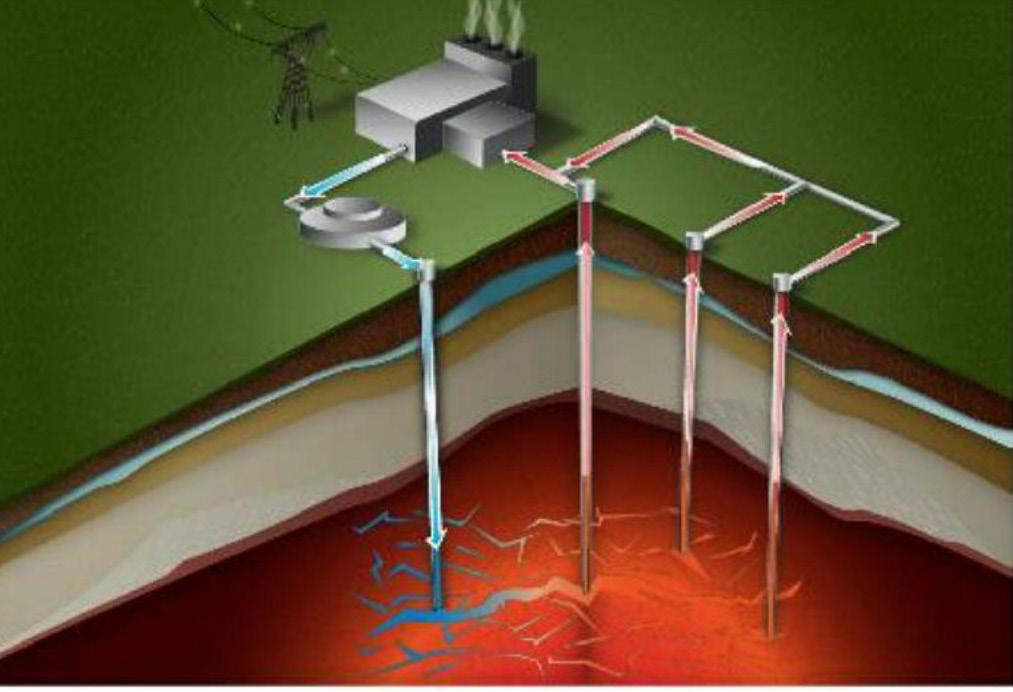

However, rather than rising to the surface, most of the heat remains locked in the Earth, and this is where its potential as a global sustainable energy source lies. Geothermal energy is now being developed in a variety of different geological settings throughout the world; all it requires is a system by which fluids heated within the subsurface can be accessed by drilling. These hot fluids may be naturally occurring water or brine, in pores and fractures in permeable rocks. If the hot rock does not contain enough natural cracks for the fluid to flow easily, it can be artificially fractured and a fluid circulation system developed. Sometimes the rock does not contain sufficient water to give commercially useful flow rates, in which case additional water can be pumped from the surface into the hot dry, fractured rocks, where it is heated by conduction. Once the hot fluid comes to the surface, whether by pumping or under natural convection, it can be used to produce steam for power generation, and in many cases the water cooled after use is pumped back into the aquifer to create a circular system (Figure 3).

Historically, geothermal developments were located close to surface expressions of natural hydrothermal geofluid circulation systems, often in igneous or metamorphic rock areas. However, recent advances in technology give increasing

Dr

CGG, UK

looks at how geothermal energy, with the help of geoscience, can be accessed throughout the world – and how the add-on value chain is crucial to economically exploiting the resource.

Ellie MacInnes, Head of Geothermal,

,

Ellie MacInnes, Head of Geothermal,

,

capability for finding hidden geothermal systems and for accessing geothermal energy from sedimentary basins.

Geoscience has the answers

Since this energy is based within the Earth, geoscience is the route to finding the optimum ways to access it. In order to do this, it is important to understand not just areas of high heat flow in the subsurface, but also how permeable and porous the rocks are and whether fluids will flow through them easily or if fracturing will be needed. Being able to recognise how rocks respond chemically and physically to heat and pressure, and how they change when fluids pass through them, makes it possible to assess how easy it will be to drill through them to access geothermal fluids.

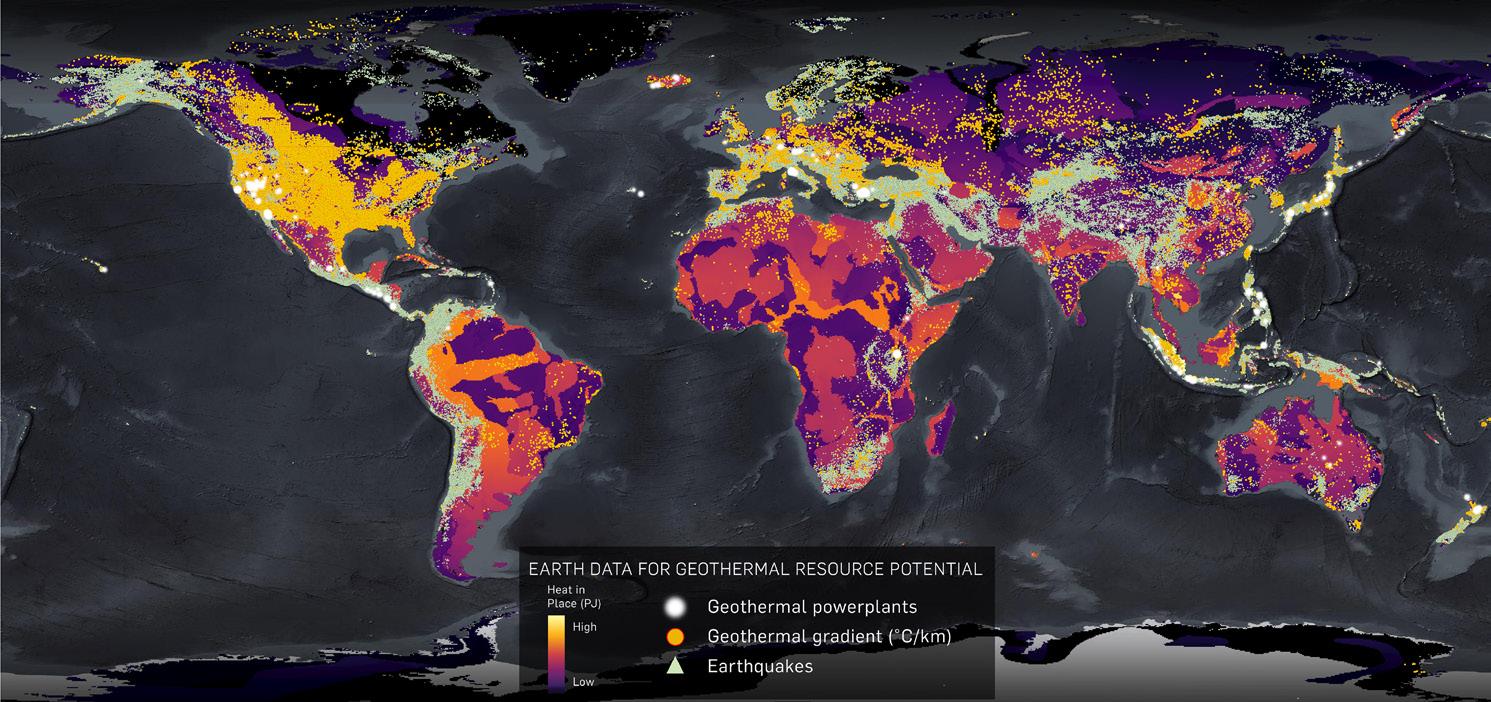

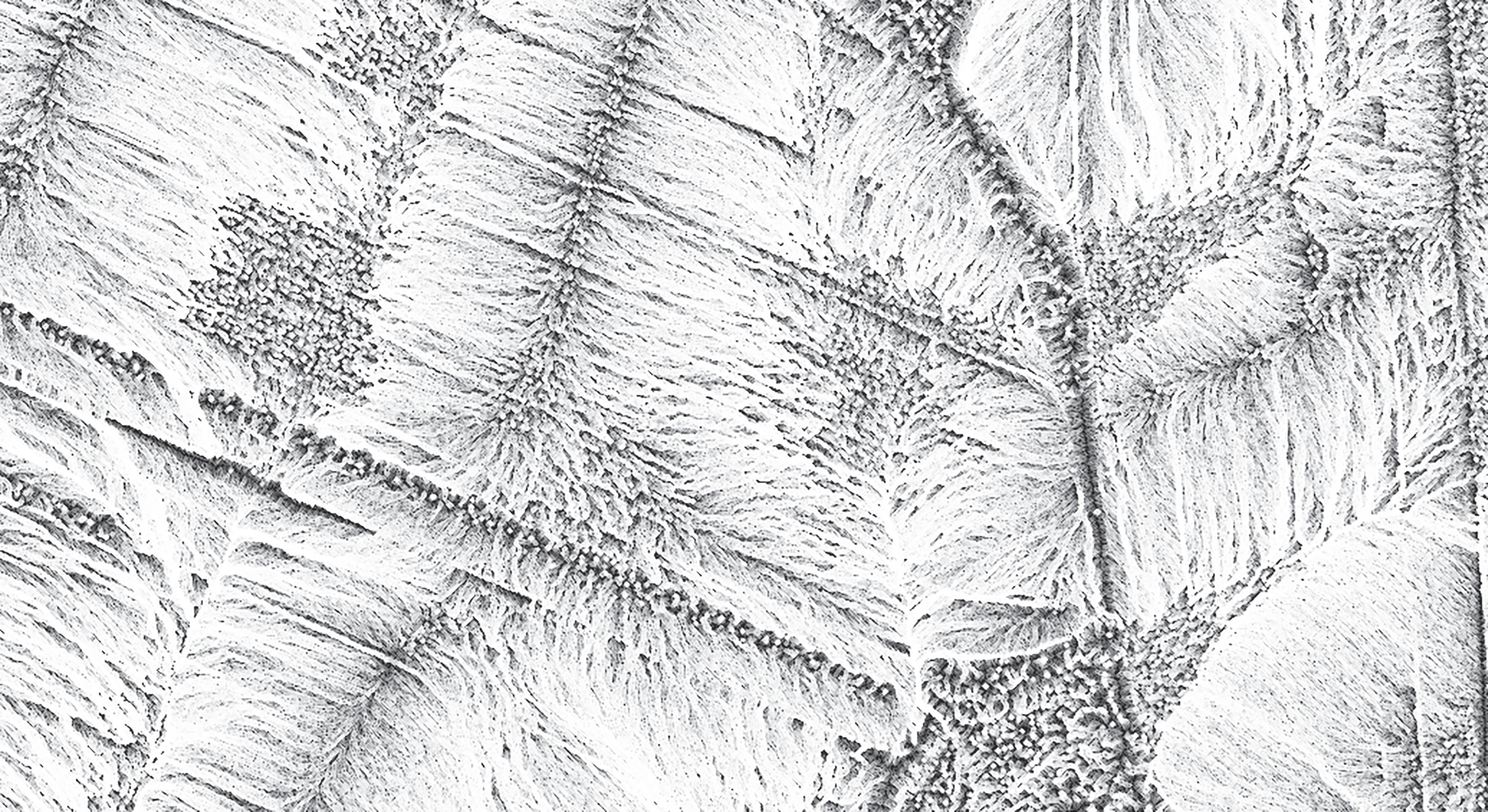

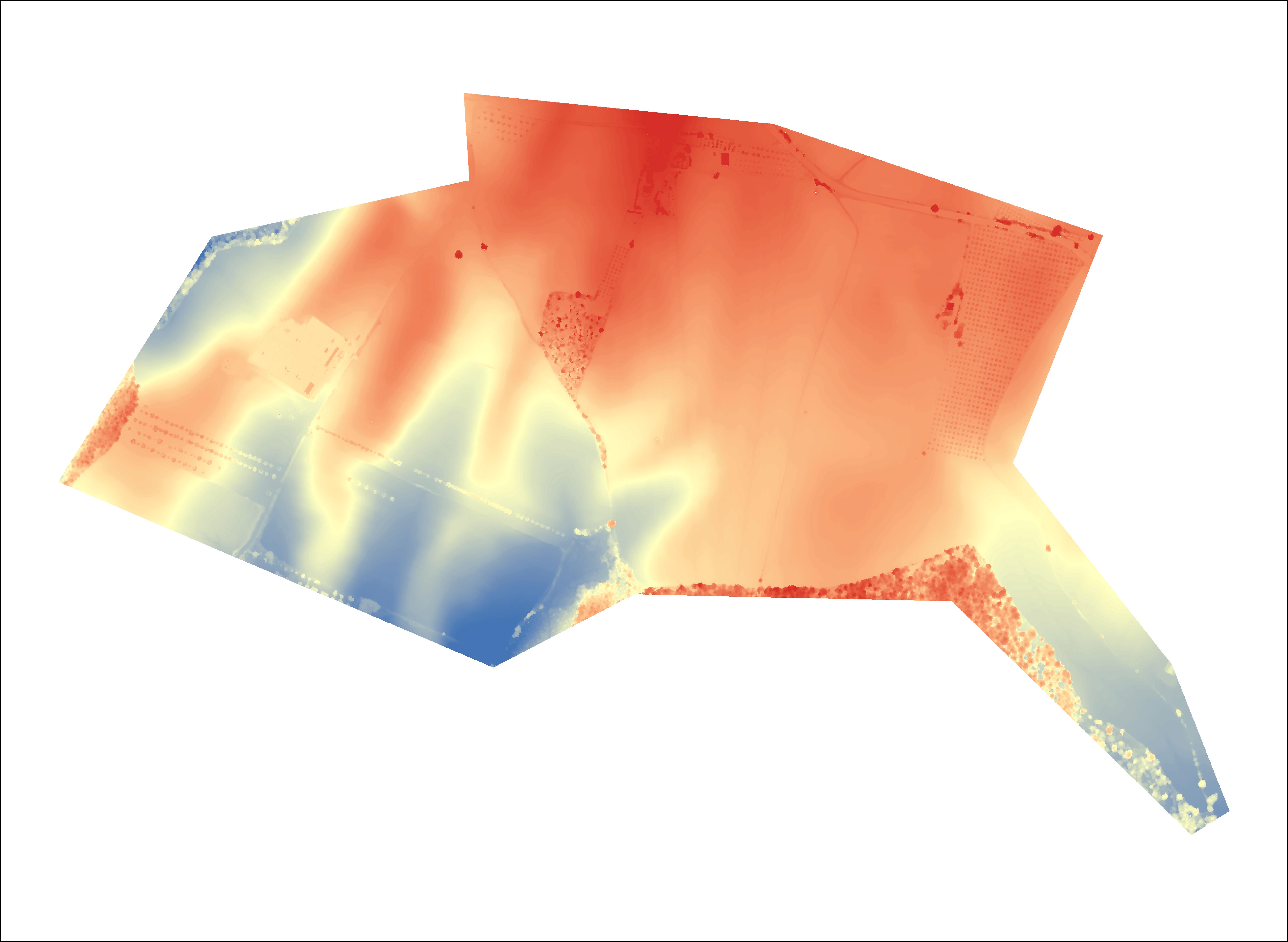

Companies that have worked in the oil and gas industry for many decades have built up a valuable and detailed understanding of the Earth and its subsurface. One such company is CGG, a global geoscience technology and HPC leader that has been collecting and interpreting geoscientific data for over 90 years. Its geoscientists can draw on their knowledge, skills, and technologies to bring valuable intelligence and capabilities to help better understand and de-risk the development of geothermal energy throughout the world. Over the last 20 years, for example, CGG has undertaken more than 150 geothermal projects, mostly applying geophysical technologies such as analysis of magnetotellurics, gravity, and microseismicity in traditional areas such as the ‘Ring of Fire’, but latterly also helping companies explore and develop ‘hidden’ geothermal resources using these techniques (Figure 4).

Over the years, CGG geoscientists have collected extensive databases of the important parameters that need to be understood in oil and gas exploration, and many of these, such as temperature gradients, porosity, permeability, fluid chemistry, and flow rate, are also essential for geothermal projects. All this data has been merged with the company’s extensive seismic

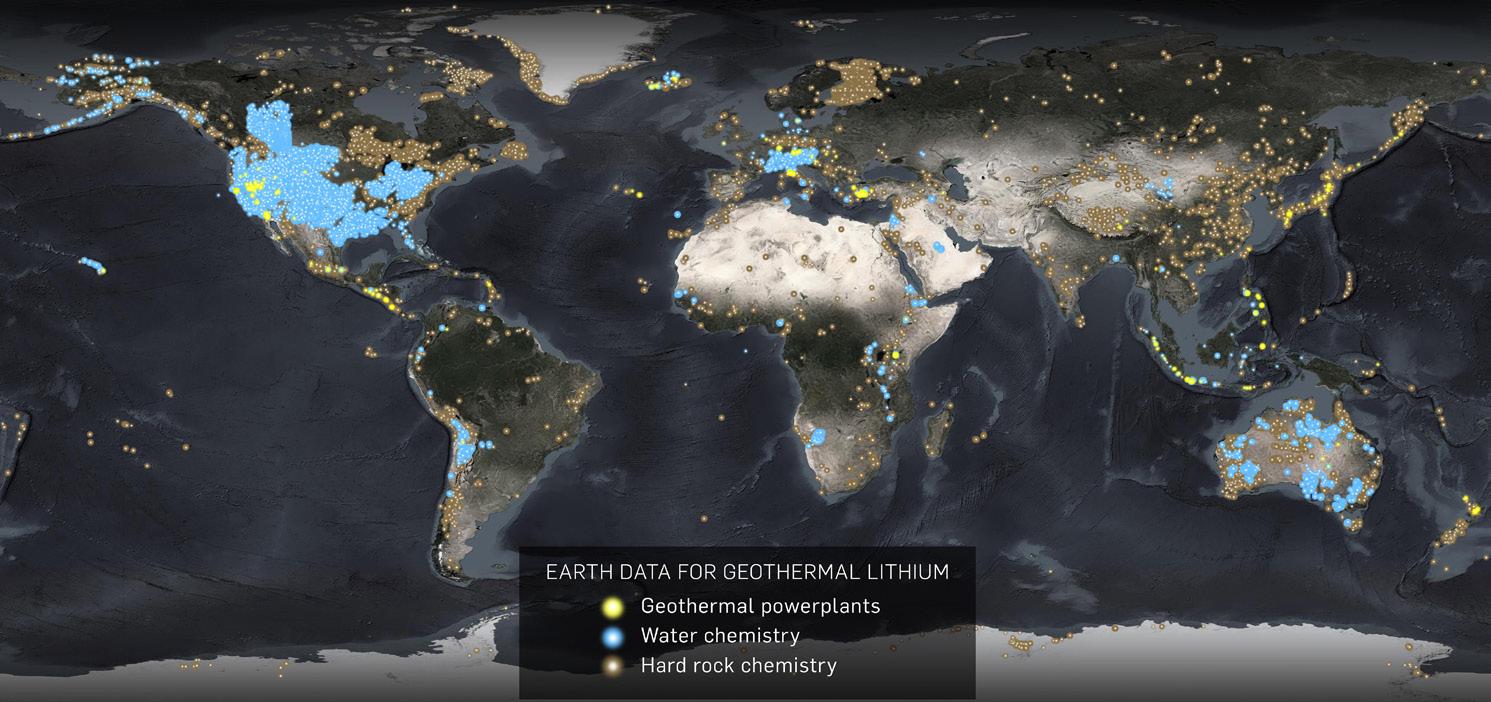

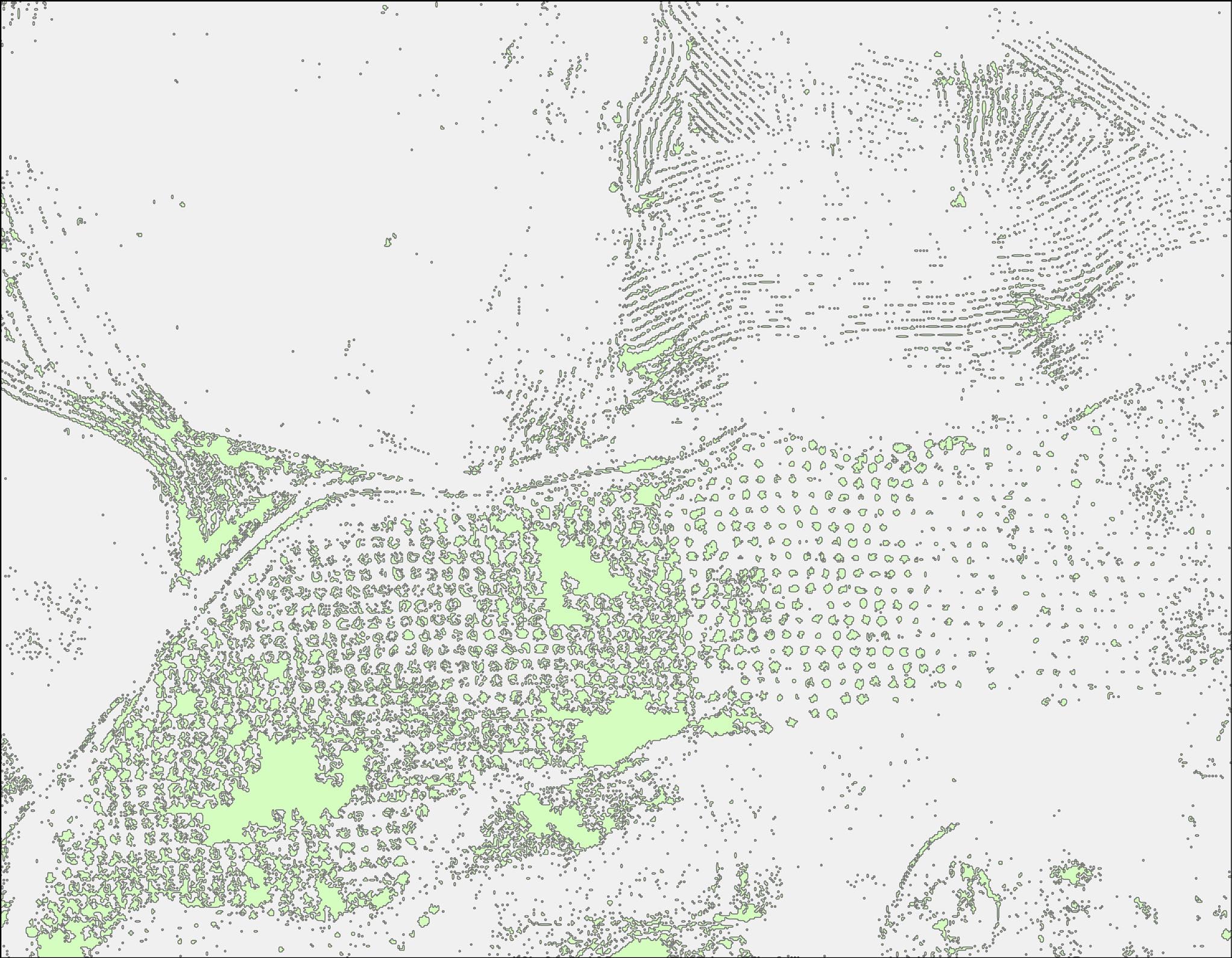

library to develop a geoscientific understanding of the Earth which can help identify new potential areas for the development of geothermal energy projects. Using this information, CGG recently completed a global Geothermal Resource Assessment study that can be used not only to identify and assess potential promising geothermal energy sites, but also to analyse the nature of the geothermal reservoir rock and provide information on production and monitoring solutions (Figure 5).

Sedimentary basins have been a major focus for the oil and gas industry, but they are of interest to the geothermal industry, not only because over the years a great deal of geological knowledge has been gathered about them, but because, unlike volcanic areas, they are often close to population centres and therefore any geothermal resource developed in them will have a ready market. The aquifers of the Paris Basin, for example, have been providing district heating for over 700 000 people for more than 30 years. However, key properties of the producing layers, such as distribution of porosity and permeability, which will identify the rocks with high rates of fluid flow that will make future development of this resource more effective, remain poorly understood. To reduce this uncertainty, a recent study by CGG, using established oil and gas techniques such as seismic inversion and recently developed rock physics-guided deep neural networks, was able to characterise the reservoirs and guide the location and design of future geothermal wells.

In oil and gas field areas, the percentage of water co-produced from the subsurface reservoir increases as the hydrocarbons are extracted. This water, which is usually discarded or pumped back into the reservoir, can be at temperatures high enough to be used directly for heating or in some cases to generate electricity. There are some technical challenges – the higher flow rates needed for useful geothermal energy production may need a wider

diameter borehole, for example – but it is a promising and potentially cost-effective development.

The geothermal value chain

However, accessing the natural heat of the Earth is not just about producing heat to generate electricity; there is abundant thermal energy in the fluid remaining after driving the turbines. The value of this remaining thermal energy varies with climate: 40˚C water would, for example,

provide much more additional heating in the Arctic than in the Tropics.

If the geothermal resource is hotter than approximately 120˚C, it can be converted directly to electricity using flash, steam, or binary turbine systems and supplied to the grid. As the water cools, it can be recycled, with cascading uses as the temperature drops. Geothermal fluids of less than 120˚C can be used directly to heat or cool residential and industrial premises, for some manufacturing processes, and in agriculture and fish farming, all without access to a power grid or without imposing extra demand on an existing power grid. Other uses for thermal energy include drying industrial cement and aggregate and for pulp, paper, and food processing.

Since approximately 40% of carbon released into the atmosphere currently comes from domestic and industrial heating and cooling, switching as much as possible to geothermally sourced heat makes sense, through individual ground source heat pumps and on an industrial scale. China is a leader in the field of geothermal direct heat; Sinopec Green Energy has built 719 heat centres in China and drilled over 700 wells. It annually produces 15 MWe, and estimates it has saved 16 million t of CO 2 emissions since it started in 2006.1

After passing through flash or steam turbines, the steam is normally condensed to water for re-injection into the reservoir to maintain geothermal fluid pressures and flow rates. However, if alternative sources of injection water are available, the condensate can be used directly with minimal further treatment as potable water. In coastal arid environments, geothermal energy can be used in desalination plants, to preheat the saline water prior to final desalination using gas, for example.

As with wind, solar, and nuclear, geothermal electrical energy can be used to generate green hydrogen through hydrolysis of fresh water. The freshwater condensate from flash or steam geothermal turbines provides a self-contained hydrogen-generation system, whereas the other energy sources would need an external source of fresh water – a potential problem in water-stressed areas.

A potentially very important economic benefit from geothermal projects is in critical mineral production. When brines are trapped at high pressure deep in the Earth, they often have high concentrations of minerals, including critical elements such as lithium and manganese, as well as rare earths, platinum group metals, and arsenic, all of which are in high demand for the production of batteries

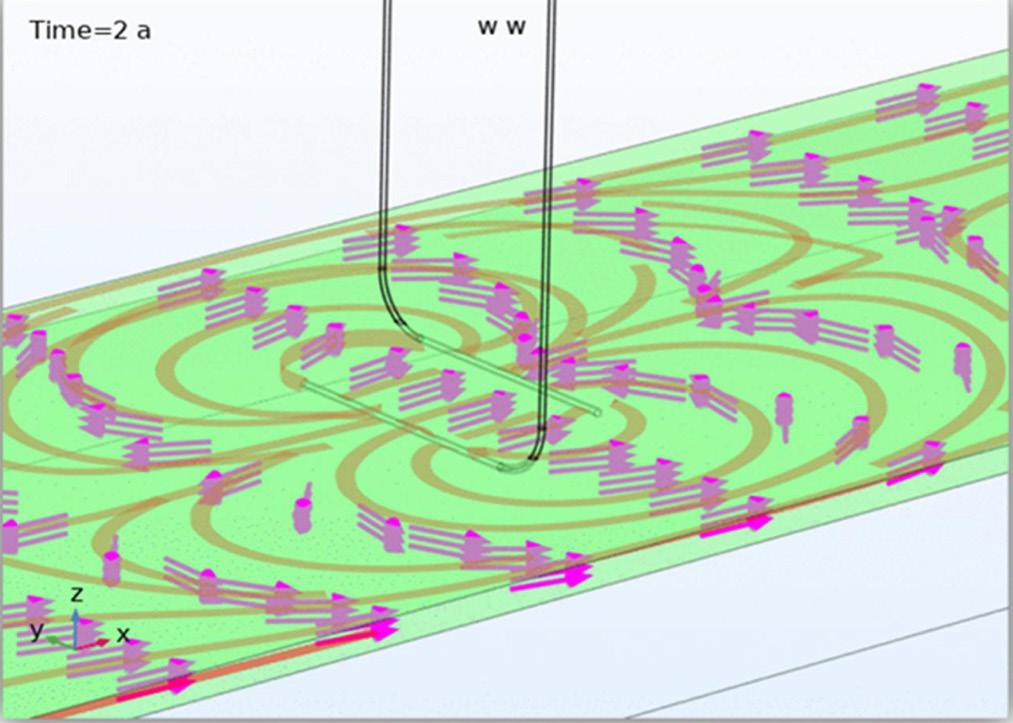

Figure 4 Geophysical 3D modelling delineates most prospective geothermal reservoir zone.

Figure 4 Geophysical 3D modelling delineates most prospective geothermal reservoir zone.

and electronics and the construction of wind and solar farms. If these critical minerals can be economically extracted and purified from the brines, geothermal projects would become more cost-effective at a wider range of locations.

Considerable research is being undertaken on this idea in, among other places, the Salton Sea, a shallow, saline lake in southern California, the US, that lies on the San Andreas fault and is an area of high geothermal activity, where there are already a number of producing geothermal power stations. Several of these are working on direct lithium extraction from the hot brine residuals from the power plants, and it has been estimated that the 11 existing geothermal plants along the Salton Sea alone could have the potential to produce enough lithium metal to provide approximately 10 times the current US demand. 2

Since at the moment the value of lithium is 6 – 8 times greater than that of geothermal power, mineral extraction from brines could be the key to making geothermal projects more economic. A knowledge of the subsurface and constituents of geothermal waters may be key to unlocking this promise, and this can be provided through CGG’s Lithium Brine Screening study, which evaluated more than 250 000 data points and 27 000 lithium measurements to create a comprehensive and consistent water chemistry database, supplemented by key engineering and geochemical characteristics (Figure 6).

This cascading chain of additional uses and products is an important aspect of geothermal projects, as they can deliver more than electrical energy alone.

Decades of cumulative expertise

The capabilities, technologies, skills, and understanding acquired by CGG over many years is relevant to geothermal projects because the exploitation of a geothermal project follows a similar trajectory to that of an oil or gas discovery and uses similar technologies. Initially, research may be on a global scale, aided by products such as the global Geothermal Resource Assessment study and then, akin to the exploration phase of an oil and gas project, it will move to a more regional scale, where subsurface knowledge from CGG’s seismic databases

will be crucial. Having identified a promising area, the project would progress to the appraisal stage, where, to understand the reservoir and predict what the resource will be, a detailed knowledge of the rock properties is key. This is followed by the development stage, in which detailed 3D structural models based on seismic, other geophysical technologies, and well data are used to ensure optimum well placement into the aquifer. Once a geothermal project is underway, reservoir modelling tools and seismic are used to monitor what is happening underground and to help to understand the flow of the fluids in the subsurface.

Therefore, to ensure geothermal projects can take full advantage of the value chain and minimise subsurface risks, it is vital that there is a good understanding of the subsurface using geoscience knowledge, including the databases, technologies, skills, and experience developed over many decades by companies, such as CGG.

References

Taylor Mattie, Director of Geothermal Technologies and Innovations, Baker Hughes, USA, explores geothermal power in the context of offtakers.

One would be hard pressed to find an industry today that is not actively working to decarbonise and participate in the global energy transition. While many may focus on wind, solar, and battery storage as

possible replacements for fossil fuels, other solutions are often overlooked.

One such example is geothermal energy, which uses the vast energy of the Earth in the form of heat for power generation or heating and cooling. It has been used to generate power for nearly 100 years and counting, and Baker Hughes has been supporting this energy source in various capacities for nearly half that period.

Using the heat generated within the Earth means geothermal is always on, making it a baseload energy source. Unlike wind and solar, it is producing energy more than 95% of the time and is indifferent to the sun shining or the wind blowing. Its continuity and reliability of supply and availability are significant advantages. Consider too,

most geothermal systems today generate zero carbon emissions and take up a fraction of the surface footprint compared to wind and solar generation sites.

There are barriers to developing geothermal, however; projects require high levels of up-front capital investment – typically between US$2 – US$7 million per well. Even though those costs can be recouped over the long term, operators and investors want a quick payout or to reduce costs and eliminate as many risks as possible. Developers and investors want assurance that the energy produced will be purchased if a geothermal plant is constructed. This is known as the offtaker.

Geothermal and the digital world

In the past few years, however, a new type of geothermal power offtaker is dawning on the horizon: datacentres and crypto farms. These differ from traditional power and heat purchasers due to both the massive volumes of energy required to run them and the nature of the facilities themselves. Here, geothermal is used as a zero-carbon fuel and enabler for the digital world. And the digital world is energy-hungry.

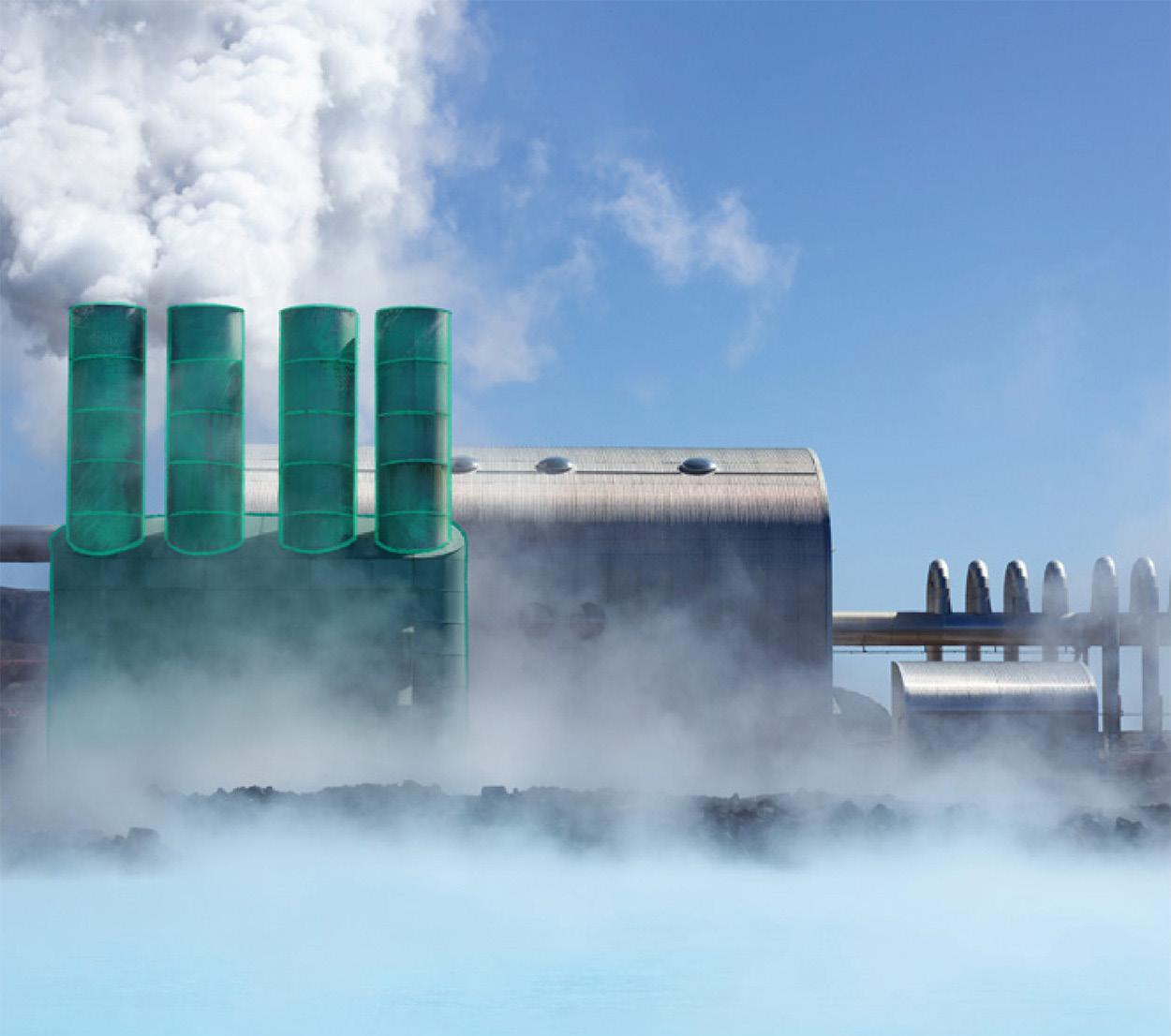

Figure 1 While many focus on wind, solar or batter storage, geothermal is often overlooked as an alternative energy source.

Large datacentres being planned today have power demands that can range up to 300 MW, or roughly the equivalent demand of 225 000 – 300 000 average households. Looking forward, the trend is to further leverage economies of scale and deploy even larger installations.

There are a number of operational datacenters and crypto mining facilities already using geothermal for their energy needs – some of which were developed with the support of Baker Hughes and its bespoke technology portfolio.

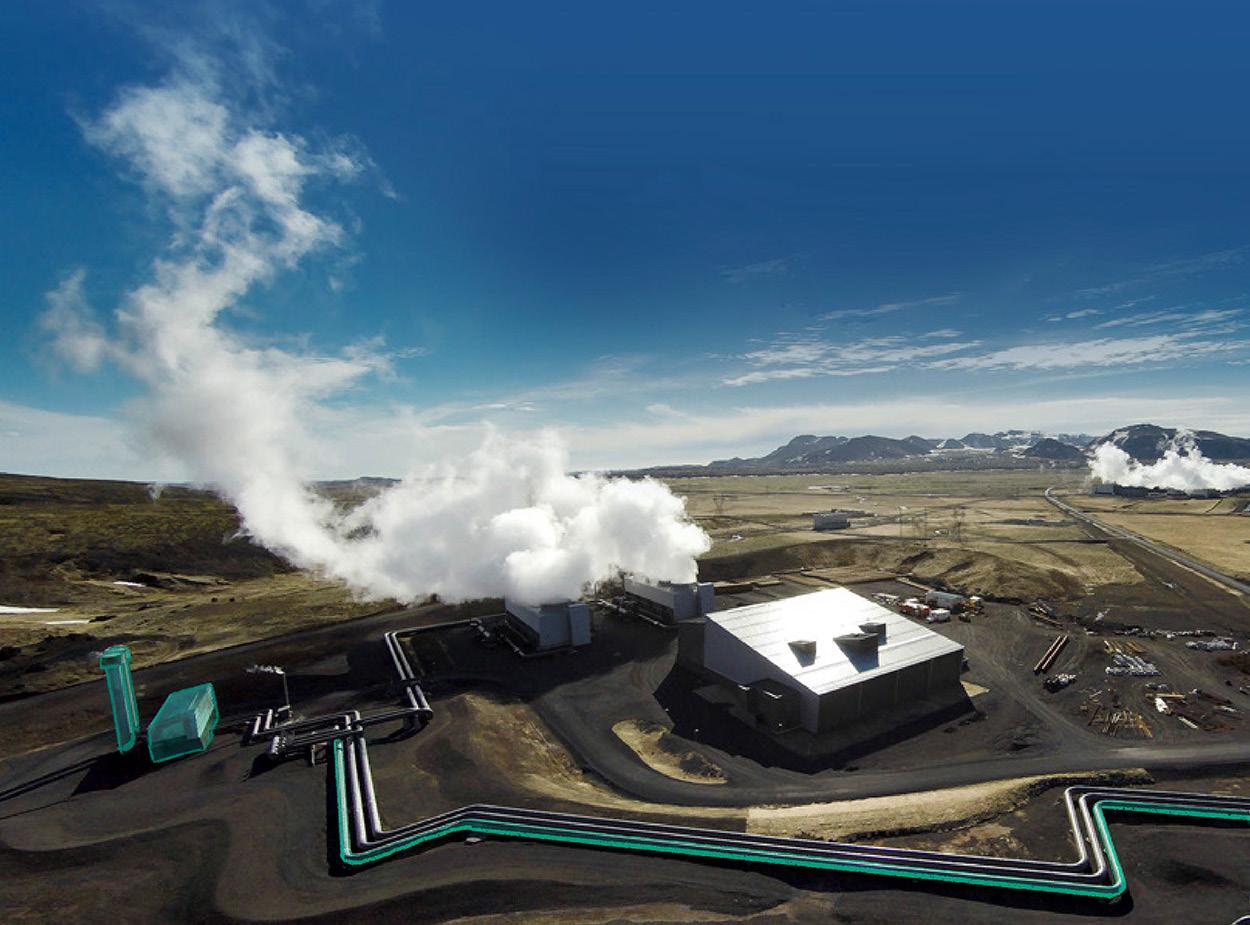

Case study: Iceland and El Salvador

As early as 2014, crypto currencies, such as Bitcoin, were being mined in Iceland, where the combination of cool, year-round temperatures and an abundance of geothermal energy create ideal conditions for low-carbon power and the need for server cooling. In fact, so many datacentres are rushing to take advantage of these conditions that some in the tech industry are calling it a ‘digital arms race’.

Figure 2 Using the Earth’s own heat means geothermal energy is ‘always on’ and not dependent on the wind blowing or the sun shining.

Baker Hughes is well-positioned to assist in this effort, with an historic presence in Iceland, in addition to a portfolio of technology for geothermal well drilling and construction. As part of this portfolio, the company has

drilled a well for the Icelandic Deep Drilling Project 2, which is the hottest and deepest geothermal well ever drilled in Iceland.

While Iceland’s cool climate is highly advantageous when it comes to cooling servers, it is not a requirement. For example, on the opposite end of the spectrum, there has been significant crypto currency mining in El Salvador, powered by geothermal energy. Specifically in the region around the Tecapa volcano, a number of Bitcoin mining operations are active, using geothermal power produced by the 109 MW Berlin geothermal field. In 2021, El Salvador’s president announced a new project called ‘Bitcoin City’, which will be developed at another volcano approximately 100 km from Berlin. The Berlin geothermal power plant has been using a flash steam turbine from Baker Hughes since 2004.

Utilising renewable energy

When considering the wider topic of using renewable energy for datacenter or crypto farming, the key to success is secure, reliable, and competitively priced power. There have been some attempts at vertically integrated wind, solar, or hydroelectric power plants for 100% offtake for datacentres. But delivering this key element to the

table is difficult and costly. The capacity factor of these technologies can barely reach 50%, unless a costly storage system is built as well.

Since geothermal is a baseload energy source with more than 95% capacity, a vertically integrated power solution is highly attractive, as it can bring competitive, consistent, renewable power to the datacentre.

Baker Hughes has developed a unique geothermal solution, as its modern technology and capabilities range from reservoir engineering to an understanding of the geothermal resource, to the drilling and construction of wells, to accessing the resource, to the turbines needed for power generation. This portfolio stretches across the entire scope of geothermal project development and minimises the cost, risk, and time required to get the power or the heat online.

Conclusion

Overall, the use of geothermal for datacentres and crypto mining is still considered new, but as more players in this space work to achieve their net zero carbon emission goals, this is an area of the market that is projected to grow rapidly.

Figure 3 . Geothermal energy has been used to generate heat and power for more than 100 years.•

•

Benefits Challenges and Solutions

•

n these challenging and unpredictable times – climate change, rising energy costs, financial instability, and the uncertainty of the geopolitical landscape – the energy the world uses and the security around this has become ever more important.

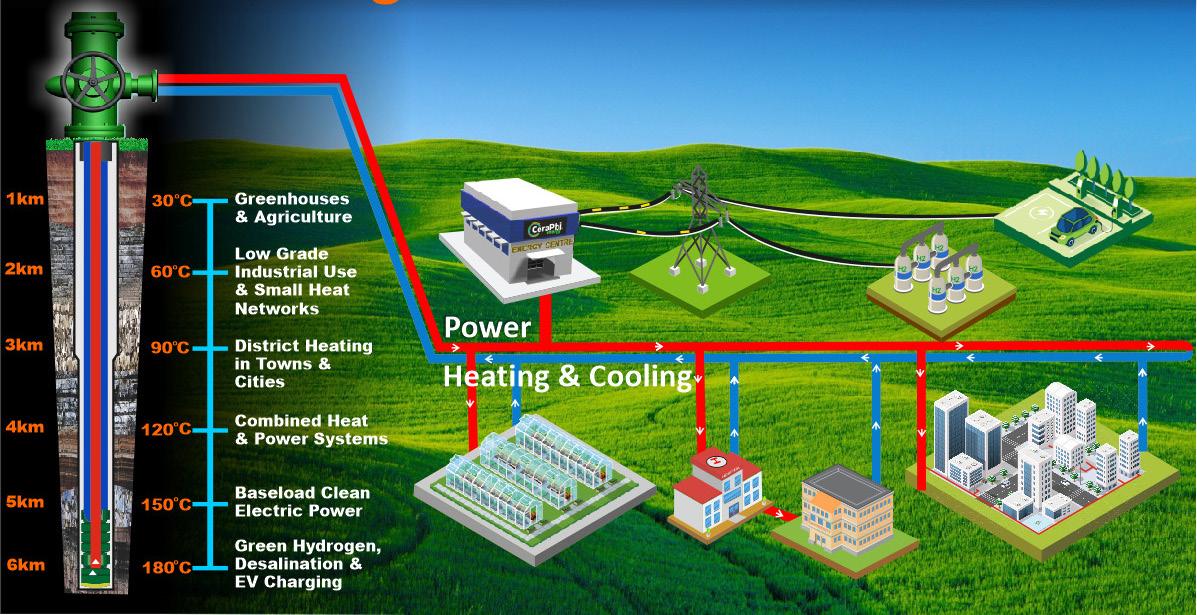

Geothermal as an energy source has been available for centuries, and is the only true baseload energy. Available everywhere and anywhere – and with 99% of the Earth’s volume having temperatures exceeding 1000˚C – geothermal is a baseload energy, meaning it provides 24/7 energy and can be viewed as one giant battery with enough clean renewable energy to help meet the 2050 Paris Agreement’s net zero targets, and to potentially last billions of years.

What is geothermal energy, and how does it fit into the energy mix?

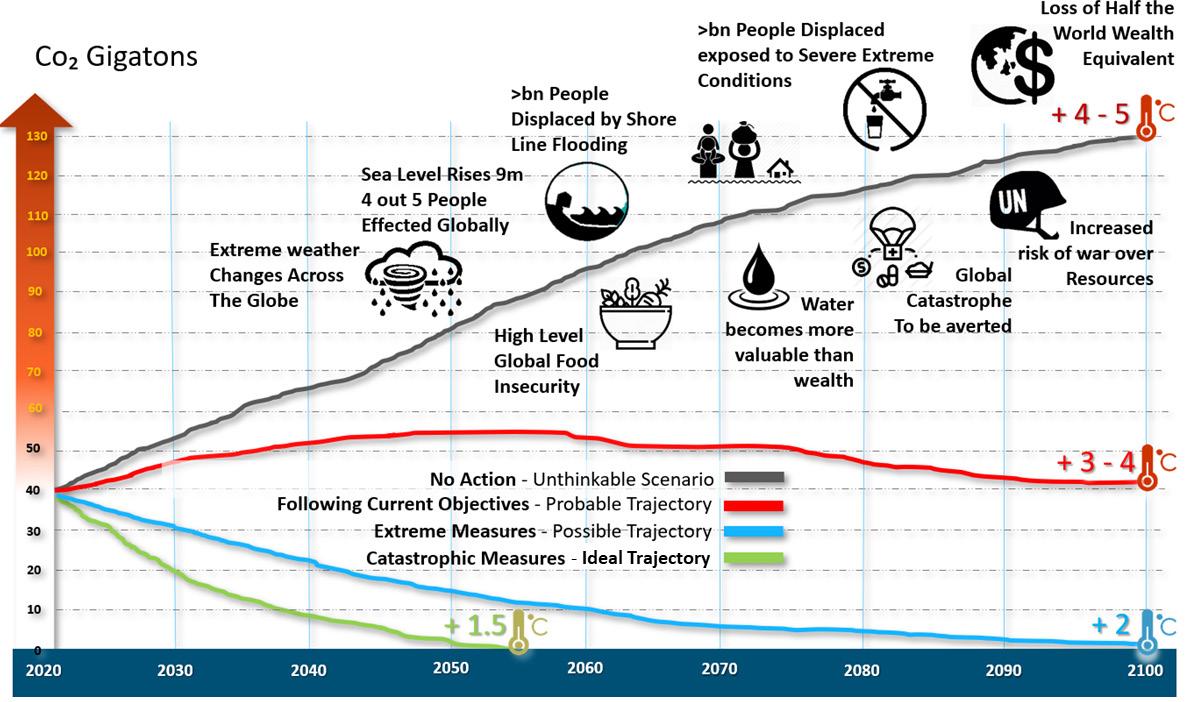

To meet the Paris Agreement targets and set a global warming target of 1.5˚C, global energy use must transition from oil and gas to cleaner and more sustainable energy sources.

Realistically, no one source of renewable energy can completely replace the current energy supply from

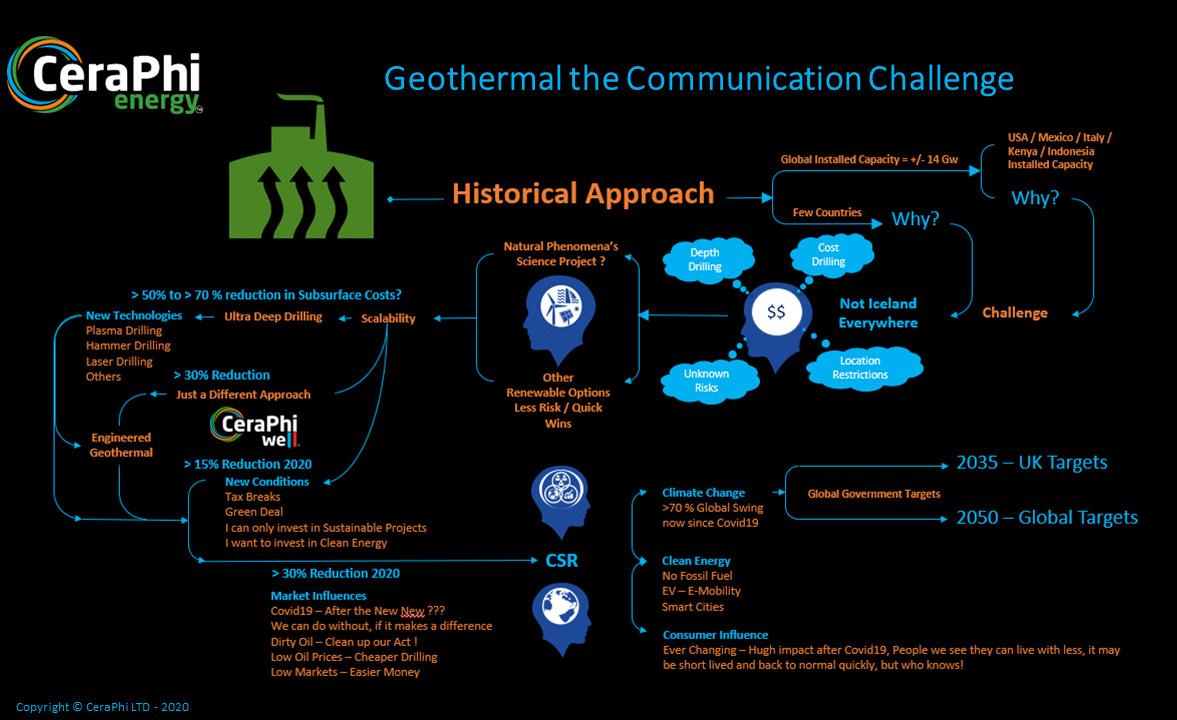

Karl Farrow, Founder and CEO of CeraPhi Energy, UK, talks about the opportunity geothermal and gas sector could be harnessedgeothermal presents as a viable and realistic part of the energy mix, and how the skill set of the oil harnessed in this transition.

fossil fuels such as oil and gas – and it is a blend of all energy sources that will enable this transition to happen. But, what needs to be grasped is that geothermal energy is always available, unlike solar and wind (which are discontinuous and require ancillary systems to operate), or biomass and hydrogen (which require feed stock from fossil fuel or cultivated source, in turn having a damaging environmental impact). Furthermore, a key benefit of geothermal is that it provides heat directly.

Geothermal energy is heat created from radioactive decay penetrating through the sub-surface of the earth.

Different geothermal technologies with distinct levels of maturity exist. Technology for direct use including district heating, geothermal heat pumps, greenhouses, and other such applications are widely used and already considered mature. Technology for electricity generation from hydrothermal reservoirs has been used commercially for more than 100 years, and is completely reliable. Yet, despite the staggering amount of geothermal energy contained within the Earth’s sub-surface, only 16 GWe of energy is currently being commercially produced from this source globally.

Many of the world’s continents are already utilising geothermal energy to meet their energy needs and there is, undoubtedly, huge potential in this sector; however, the UK and the world needs to ramp up use of this viable and natural energy resource in order to remain serious about hitting the global environmental targets.

How can the transition be achieved?

There are two strands to energy transition:

F The movement of energy resourcing from non-renewable energy resources to renewable energy solutions.

F The repurposing of oil and gas wells for geothermal, and the utilisation of an already highly-skilled existing oil and gas work force who can seamlessly make the transition into the geothermal energy space.

There are currently an estimated >20 million oil and gas wells across the world, with an estimated 3.2 million located in the US. Many of these are end of life and non-producing. Acknowledging there are some differences between oil and gas and geothermal energy production – geothermal requires deeper accessibility and functions at higher temperatures – the expertise and services from the oil and gas sector can access it easily.

Couple this with the existence of an already skilled work force, in the hundreds of thousands of people who work in the global oil and gas sector, and the geothermal energy industry has a ready-made, hugely skilled work base that already uses much of the technology and work practices that would seamlessly transition into this renewable energy space.

What does the future look like for geothermal energy?

A huge challenge for the geothermal energy industry is perception. Drilling in geothermal needs to be looked at in the same way as in oil and gas. The only difference being, with oil and gas the requirement is to get the resource as quickly as possible and then shut down the field. Geothermal is about getting the fuel for as long as possible, at a lower but longer rate of return – a baseload replacement for heat that can be monetised with a bottom line of double digits.

Wider political and funding support and a commitment to the development of geothermal technology as a viable part of the new renewable energy mix is also much needed and – working with, and as a founding member of the Geothermal Energy Advancement Association (GEAA) – CeraPhi Energy is already starting to make significant headway accelerating the development of geothermal solutions.

Similarly, the company is already well underway advocating and initiating the migration and application of oil and gas expertise. Earlier this year, CeraPhi appointed Petrofac to support it on a ‘first of its kind’ study that will evaluate whether

Figure 3 The communication challenge for geothermal. Figure 2 The CeraPhi geothermal energy cascade.oil and gas wells in the North Sea can be repurposed for geothermal energy. The work on the Enquest Magnus will determine whether heat from the wells can be used as a direct power and/or as a heating or cooling for services and utility.

The opportunities for geothermal energy as a viable, clean, continuous, and secure part of the energy mix are considerable. The resources are already there in the millions of unused oil and gas wells across the world. The skill set of oil and gas professionals is already there to draw on, with engineering skills in well integrity management, root cause analysis, corrosion and erosion, wellbore management, fracturing, and stimulation of all areas of expertise transferable to the geothermal energy sector.

The technology

Technology is key in the production of geothermal energy, and CeraPhi Energy are already well advanced in the development and utilisation of it. One of these technologies is CeraPhiWell TM , which enables the recovery of commercially useable heat energy from the sub-surface virtually anywhere in the world. A downhole heat exchanger, CeraPhiWell is designed to circulate proprietary working fluids, moving the heat to the surface where it can then be processed into direct heat or power use before being returned to the well.

Additionally, the technology offers a ‘fall back’ for those wells that fall short of production expectations

and where retrofit architecture can be installed to leverage some commercial return as opposed to a costly well abandonment.

CeraPhi Energy is well positioned to advance the use of geothermal energy both across the UK and the world and to demonstrate the real viability of this energy source as a key player in the energy mix. The company’s turnkey capabilities and highly skilled team are already operational on projects across the globe and continue to advocate geothermal energy as the cleanest, cheapest, and most efficient 24/7 baseload energy.

Figure 5 A geothermal hot spring.use of geothermal energy is not new. People have been using the hot water and steam emanating from natural pools and hot springs for thousands of years for heating their homes, bathing, and cooking. Of course, these uses were limited to areas having hot springs. In more recent times, with the advent of modern technologies, the use of geothermal energy has begun to expand. In fact, although not widely used until the late 19th Century, the world’s first district heating system was installed at Chaudes-Aigues, France, in the 14th Century. Geothermal district heating systems are now used in many places around the world.

The use of geothermal energy to produce commercial power first occurred in 1911 in the very first geothermal power plant built in the Devil’s Valley in the Larderello, Italy, dry steam field. This plant provided electricity for the Italian railway system. In 1958, New Zealand’s Wairakei power station became operational. This power plant was the first in the world to make use of flash steam technology. Since the 1980s, the use of binary and organic rankine cycle (ORC) power production technologies has grown, especially when harvesting power from lower temperature geothermal resources. Over the next couple of decades, many countries including the US, Iceland, Turkiye, Kenya, Indonesia, the Philippines, New Zealand, Italy, Germany, and Mexico, have invested

in geothermal power technologies. Today, a total of 17.4 GW of electric power is generated from geothermal energy sources.

Generation one: Hydrothermal systems

Until recently, other than the use of modern technologies, the harvesting of geothermal energy for heating and power production has not changed all that much. Essentially, the majority of the 17.4 GW of electricity that is being generated around the world is still being done in areas where hot water and steam are close to the surface. These are areas around the plate boundaries, known for volcanic activity (such as the Ring of Fire, New Zealand, Indonesia, and Iceland). These plants take advantage of existing natural hydrothermal systems –heat close to the surface (magma), underground fractures (plumbing system), water (oceans) – bringing that water and steam to the surface for district heating or to run power plants.

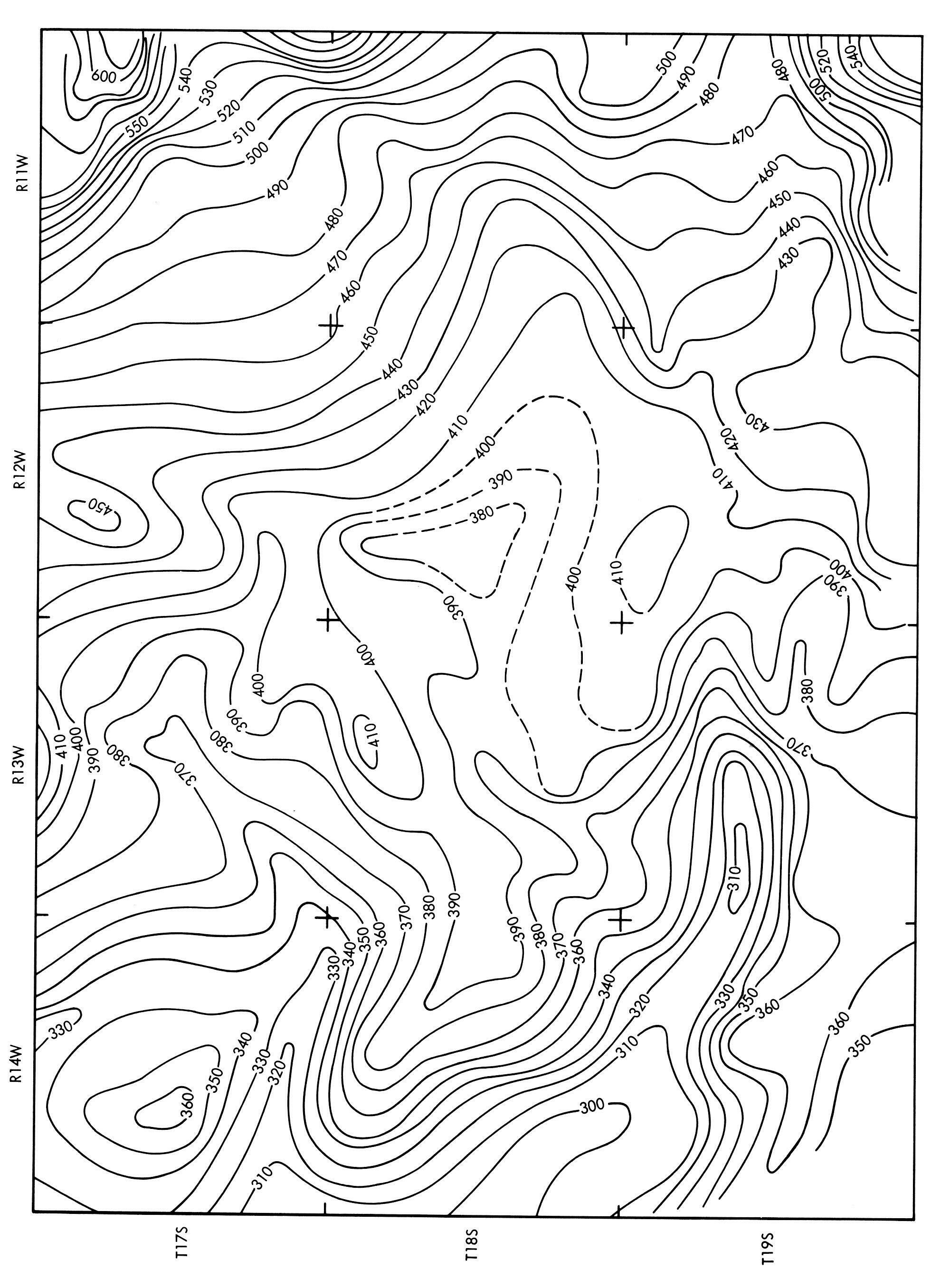

All good, except for the fact that natural hydrothermal systems are rare, representing only approximately 2% of the Earth’s surface (Figure 1). While a great approach, this first generation of geothermal energy is simply not scalable.

Generation two: Hot dry rock, enhanced geothermal systems

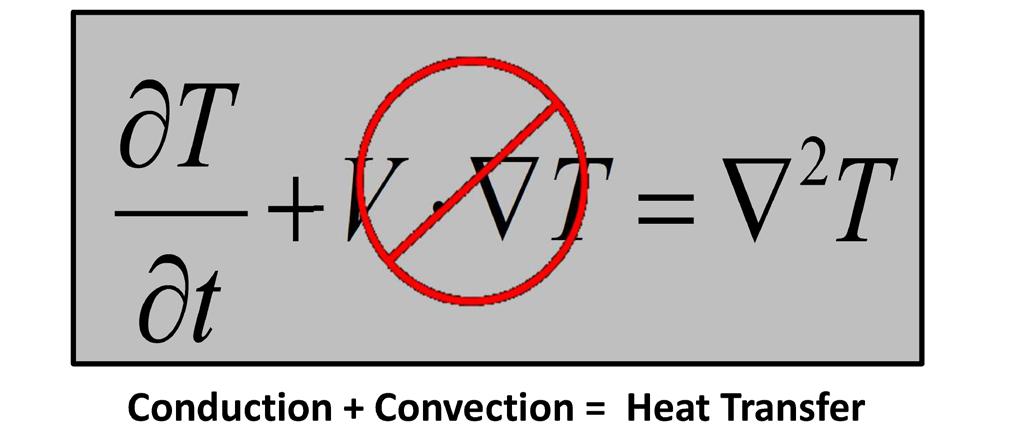

Acknowledging this geographical limitation, and knowing that basement rock is very hot, scientists and engineers began working on creating an engineered system to harvest the heat from hot dry rock (HDR). Such a system can be constructed virtually anywhere. The deeper you drill, the hotter it gets. The first enhanced geothermal systems (EGS) effort took place at Fenton Hill, New Mexico, the US, with a project run by the US’s federal Los Alamos laboratory. It was the first attempt to make a deep, full scale EGS reservoir (Figure 2). Since then, billions of US dollars have been invested in the development of EGS systems in Australia, France, Germany, Japan, Switzerland, and the US. To date, this approach has proven unsuccessful. The reasons are four-fold: (1) The water that is pumped into the injection well sometimes finds its way into the HDR’s natural fracture system and disappears; (2) The water that does make its way to the production well leaches minerals from the rock, corroding pipes and causing numerous maintenance and operational problems; (3) The basement rock is very dense and cannot be adequately imaged using existing technologies. Therefore, drilling operations are often ‘wildcatting’, with drillers hoping to hit a suitable fracture system; (4) Rock is an insulator, not a conductor. It has a very low thermal diffusivity. Because the process is dealing with rock, conduction is the only mechanism for heat transfer to occur (Figure 3), as convection only occurs in liquids and gases. Therefore, the geothermal resource is quickly exhausted as the rate of heat extraction exceeds the rate of natural heat recharge (conduction through the rock).

Much work is being done to address these problems. In the US, for example, the Department of Energy has funded the FORGE project which is looking to find solutions.

Generation three: Closed loop systems

In recent years, new technologies have been emerging which address many of the problems in these second generation EGS systems. These are the closed loop designs. There are several companies commercialising closed loop systems, including Eavor Technologies, GreenFire Energy, and Sage Geosystems. All have a different approach, but all involve circulating a heat exchange fluid in an underground closed loop system to harvest the heat from the geothermal resource. With these systems, there is no loss of water (circulation), there are no leaching/corrosion problems, and imaging/wildcatting is not an issue. If used for district heating purposes, these technologies are certainly up to the task. What remains to be seen is how these technologies will be able to overcome the problem of the exhaustion of the geothermal resource that will occur due to the rapid heat extraction that is required to produce economic power.

Generation four: Hot sedimentary aquifers

Hot sedimentary aquifiers (HSAs) have been used in various places around the globe for district heating, but due to various

Figure 1 . Existing geothermal power plants (2021) are geologically and geographically very rare. Figure 2 . Hot dry rock (HDR)/enhanced geothermal systems (EGS) system. Source: Department of Energy.temperature and flow rate limitations, have found minimal use for large scale power generation. However, recent advances in oil and gas exploration and production technologies are about to change this dynamic. Novel approaches to mining the heat from HSAs are now being taken in an attempt to address the problems of the first three generations of geothermal power production. Several companies, such as Geothermal Technologies, Inc. (GTI) in the US and DEEP in Canada, are working in the area and are bringing these new technologies to bear. HSAs are an interesting geothermal resource because:

1. HSAs are globally abundant, existing in many areas of the world – solving the scalability problem of first generation geothermal power production.

2. HSAs contain large volumes of hot water that can be harvested. And, that water will not be wandering off through the natural fracture system – solving the loss of water problem. In fact, the fractures will help with the circulation of water within the aquifer, thereby bringing water/heat to the system from the far field.

3. The water in the aquifer is at chemical equilibrium with the surrounding sandstone – eliminating the water leaching/corrosion problem. The composition of the water is constant and predictable, allowing for proper metallurgy selection in the facility’s design.

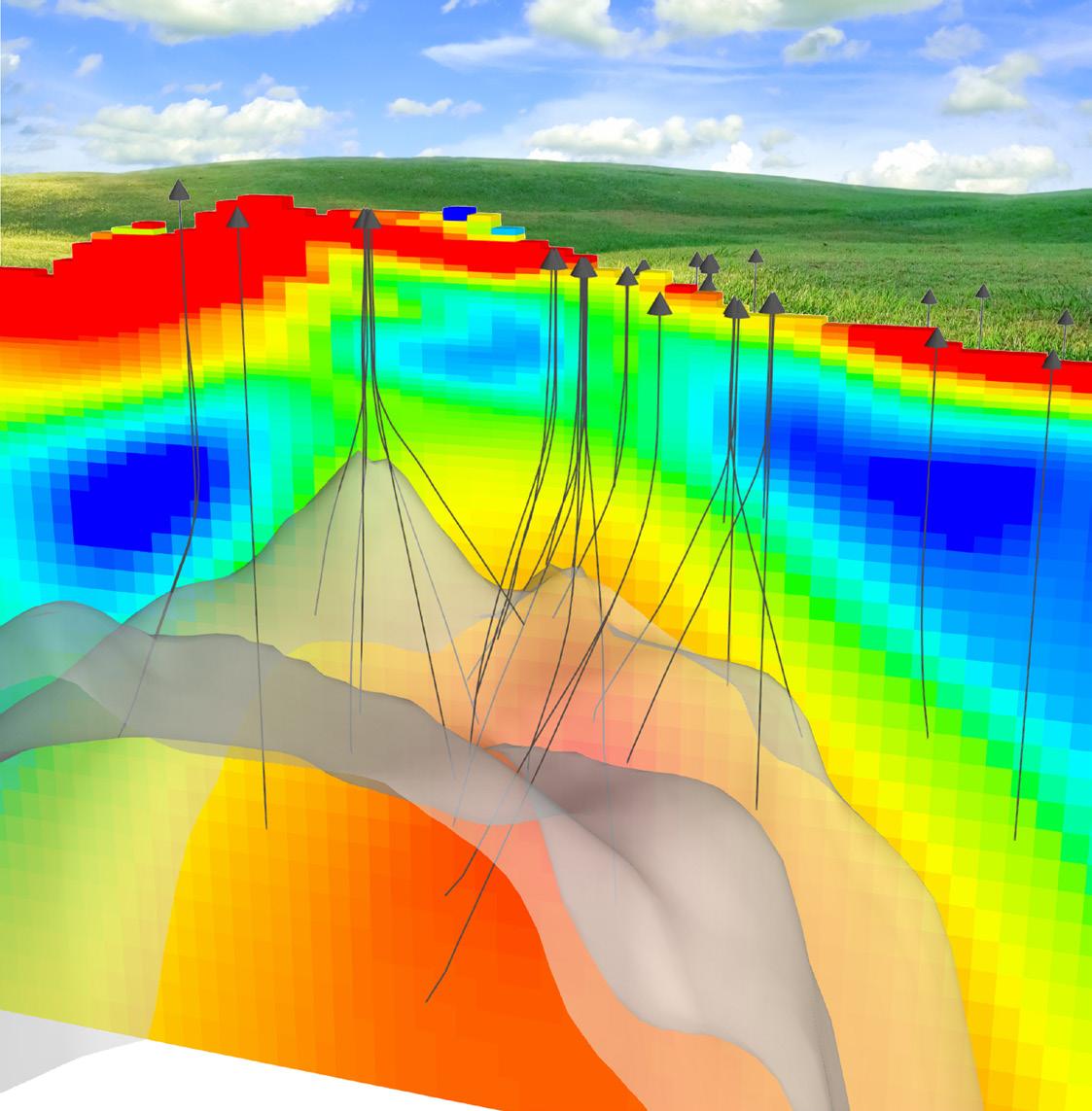

4. The geology of these reservoirs consists of sandstones which can be thoroughly imaged with the 3D seismic, passive seismic, and electromagnetic imaging technologies that have been developed for the oil and gas industry – solving the wildcatting problem and enabling the placement of the wells in locations for optimum system performance.

5. Water, being a liquid, allows for both convective and conductive heat transfer. This combination maximises the heat transfer within the system – eliminating the exhaustion of the geothermal resource due to the convective recharge that occurs (Figure 4).

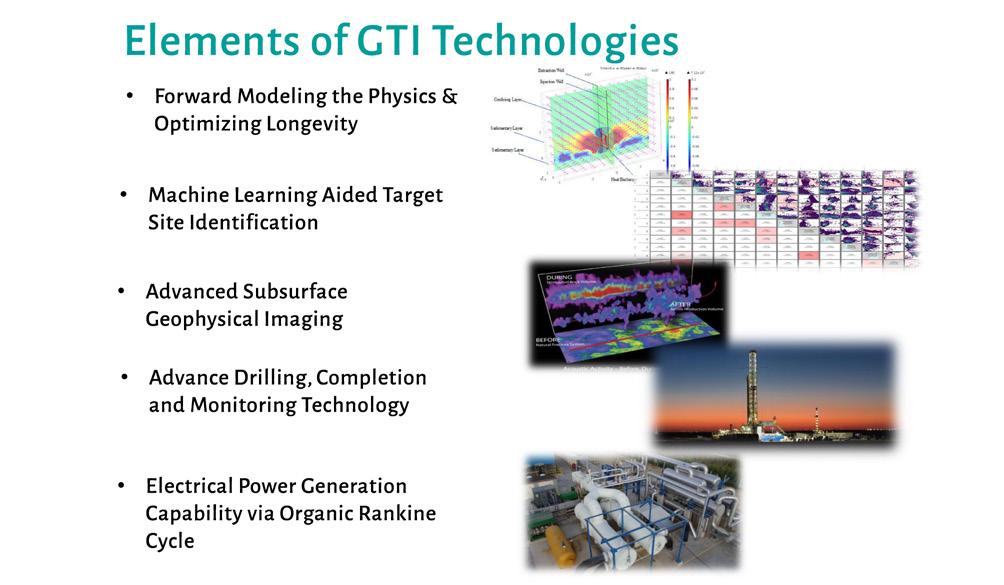

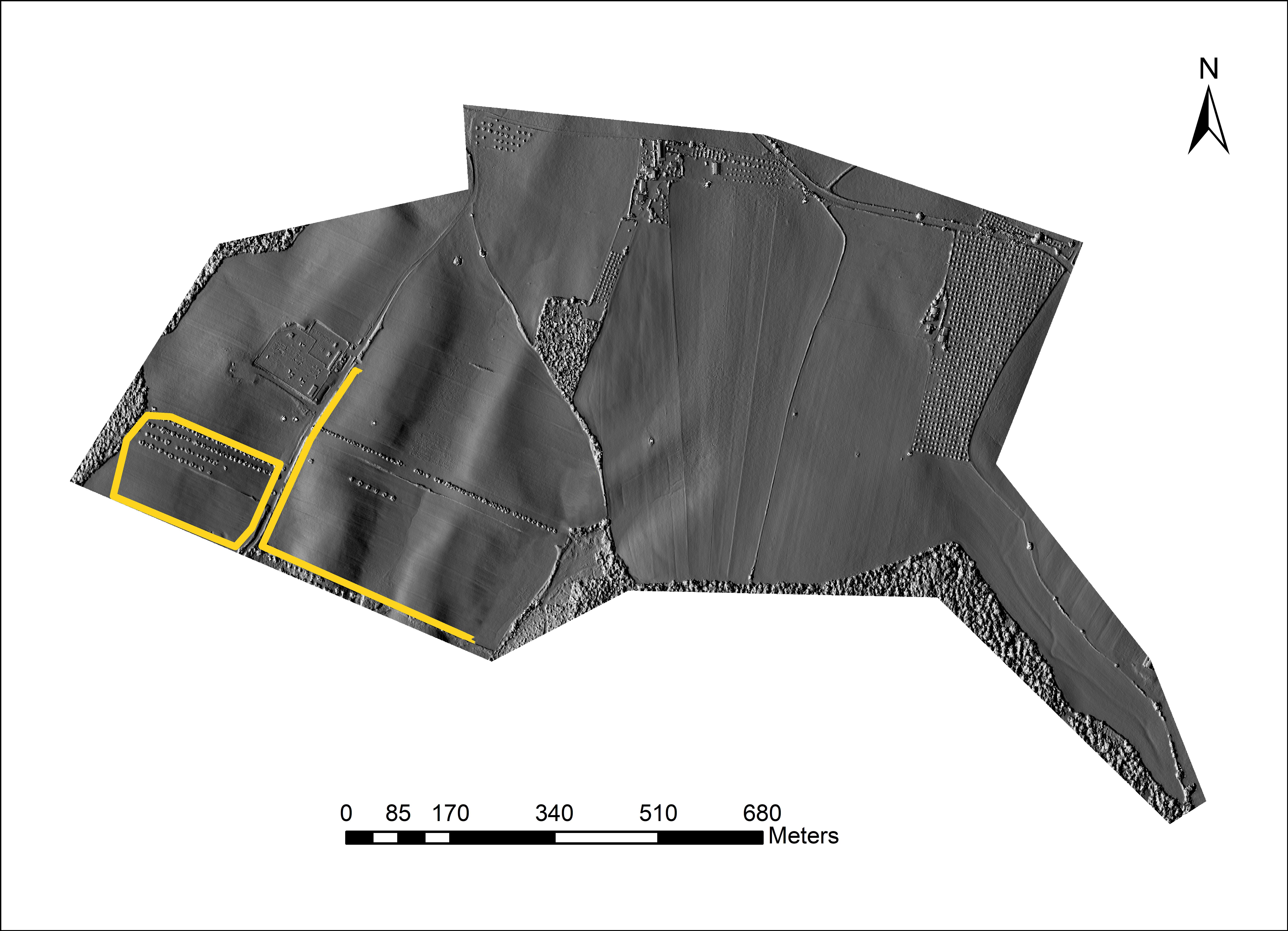

Case study: GTI’s geothermal power plant development in Colorado

GTI is currently developing a GenaSys geothermal power plant within the sedimentary basin not far from the US city of Denver, Colorado. Much is known about the subsurface geologic formations from the decades of oil and gas exploration that continues to this day. Beneath the oil and gas fields lies a hot (approximately 135˚C), saline non-potable aquifer that is contained within a permeable sandstone formation. GTI has been able to repurpose many of the technologies developed recently to explore for hydrocarbons. Proprietary technologies have also been developed that are focused on optimising the geothermal power system for longevity and for reducing the cost of the electricity.

Some of the key technologies applied by GTI in the development of the Denver-Julesburg Basin GenaSysTM geothermal plant are summarised in Figure 5. Forward modelling that incorporates the geoscientific data obtained from oil and gas developments and other sources allows GTI scientists and engineers to optimise the

Figure 4 Illustration of Geothermal Technologies, Inc.’s GenaSysTM Convective Recharge.

Figure 5 Key technologies incorporated in identifying optimised GenaSys geothermal plant locations and optimising power generation.

design of the underground power system. GTI’s forward modelling efforts are coupled with proprietary machine-learning algorithms that facilitate the fusion of multiple data layers that parameterise the geology of the underground power system. GTI is in the process of leveraging subsurface imaging technologies – both active and passive seismic to not only better understand the subsurface structure, but also the magnitude and velocity of the convective heat recharge system.

GTI has secured the surface and subsurface rights to drill and construct a power plant from a local landowner and is in the process of receiving a permit from the State of Colorado to begin drilling operations.

In addition to the application of geoscience technologies, GTI is collaborating with many of the world’s experts from the oil and gas industry, including Helmerich and Payne (H&P), an experienced and technically advanced drilling company based in the US, and the global oil field services company Halliburton who will lead the effort of completing and instrumenting the wells in preparation for power production. The above ground system will be provided by one of the many ORC power generation system vendors who GTI is in the process of vetting. Considering the permitting and construction time, GTI expects to be making clean, baseload, economic power by 2024 and supplying that power to either a local customer or to the electrical grid that supplies Denver and its neighbouring cities for decades.

For decades, it was almost a certainty: energy was available when it was needed. The price: negligible to acceptable. Be it coal, oil, or natural gas, these cheap fossil fuel energy sources have been powering production around the world since the Industrial Revolution.

If one looks back at the history of the industries, the last two centuries in particular have been characterised by constant increases in the speed, efficiency, and capacity of production. On the one hand, this development has brought wealth and the convenience of a modern lifestyle to many areas of the world. On the other hand, burning fossil fuels to power modern industry is the main cause of climate change, experienced in extreme weather, poor air quality, and species extinction.

But something is happening, and not only since recent climate demonstrations have put greater pressure on decision-makers and supervisory boards. For the first time in modern history, the goals of many politicians, industrial decision-makers, and climate activists are narrowing: “Things cannot stay the way they are” is the mantra. Admittedly, the individual motivations may be different, with one group more concerned about protecting the planet, for example, and another more concerned about the continued existence of a business or business model. Whatever the reasoning, the aim is greater sustainability.

Energy independence

The most recent geopolitical developments of 2022 have further revealed the dangers of countries depending on fossil fuels for energy: the intensive interdependence of the energy markets make fossil fuels highly susceptible to international crises. Without a constant supply of energy sources, the lights literally go out. This dependency not only makes national economies vulnerable to crises, but also, to a certain extent, it makes them externally determined.

So, it is not just the idea of sustainability that is leading to a rethink across many political parties; it is also about

efforts to minimise the effect of crises, volatile prices, and imports.

Green hydrogen, widely praised as an energy game-changer, appears in many industries as a simple and pragmatic solution to help end dependence on fossil fuel energy sources. However, it is produced from electricity with high energy losses and requires greater efficiencies before its wide scale deployment. Moreover, for ordinary applications, heat pumps can do the job as good as hydrogen, and increases in electrolyser efficiency will not change this fact.

Of course, there are many industrial applications for which hydrogen can be used sensibly – in particular, applications that require high temperatures for combustion, a direct chemical reaction, or for long-term energy storage. Examples of this are in steel production, cement production, the glass industry, or hydrogen as a feedstock in the chemical industry.

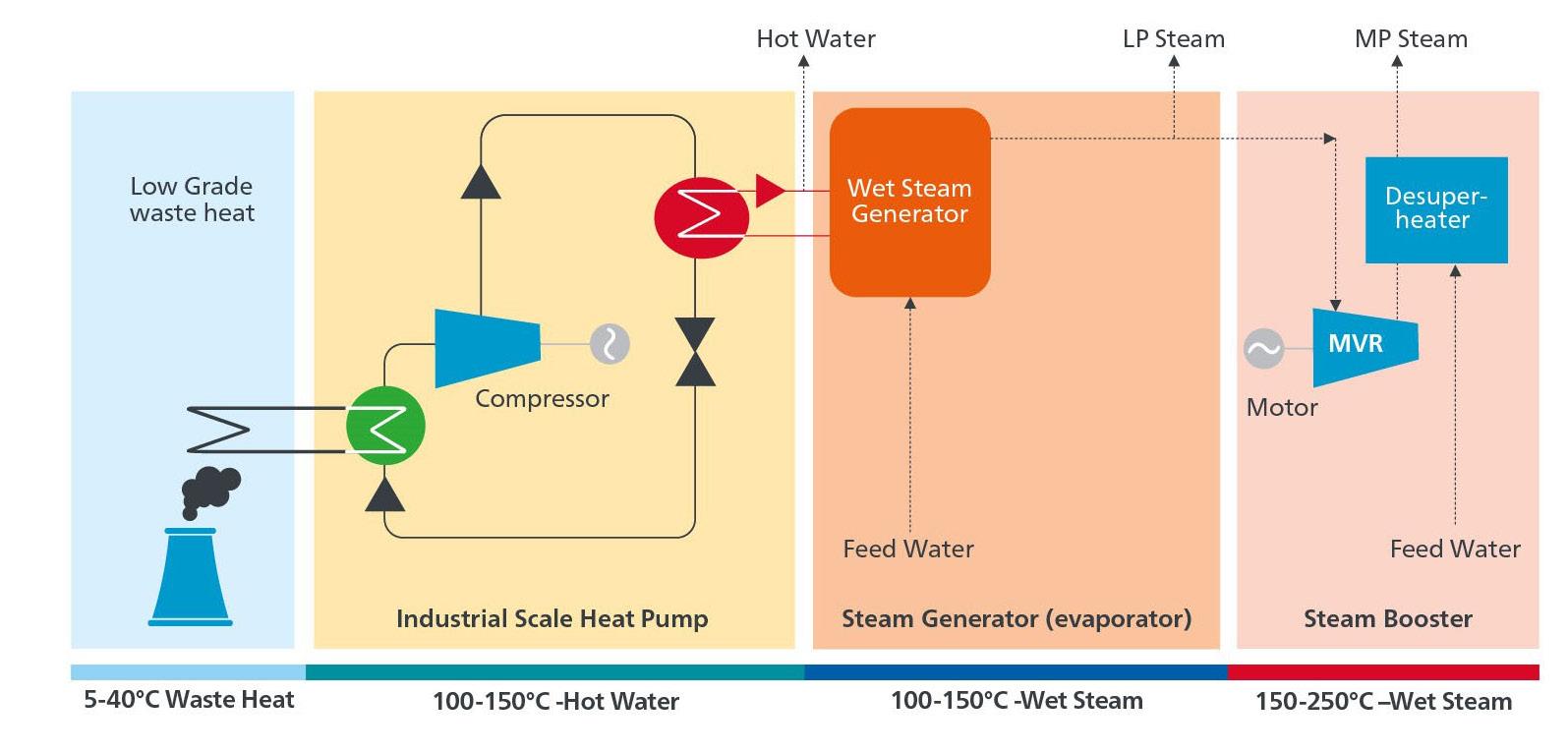

Temperatures – only as high as necessary

As well as these example industries, there is a lot of energy demand below the high-temperature level. Still, even low temperatures are generated with extremely hot flames, something that is not technically necessary. In paper production, the food industry, parts of the chemical industry, and also district heating, temperatures of only approximately 100 – 250˚C are required.

Reflecting the recognition that in many situations, lower temperatures are sufficient to produce the required energy or fulfil process needs, a technology that is now almost a century old is gaining greater attention: the heat pump.

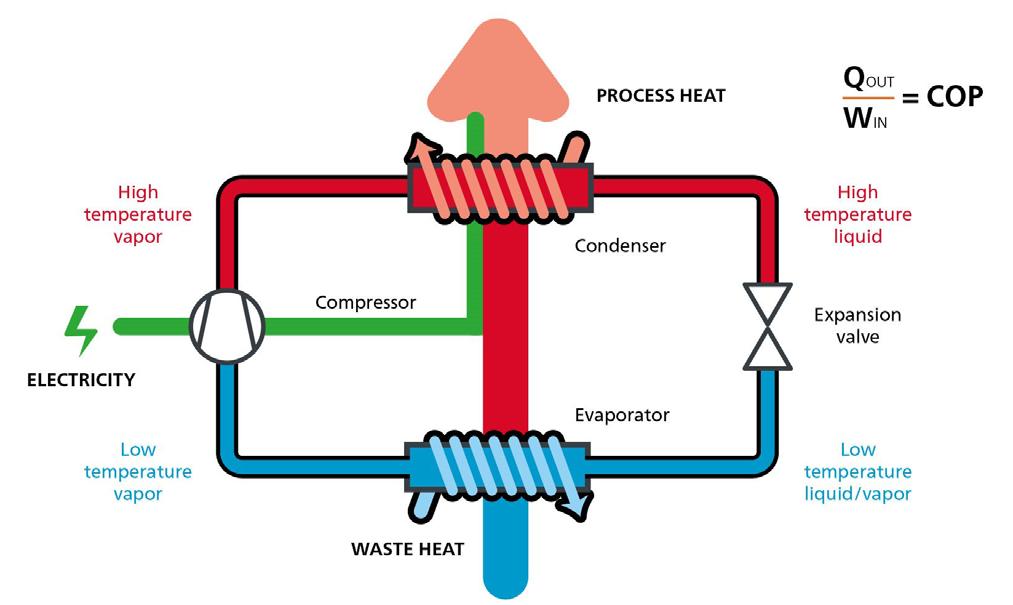

Technically, heat pumps are comparable to the working principle of a normal refrigerator: a liquefiable gas, the so-called refrigerant, is evaporated in a cyclic process at low pressure, compressed in a compressor, and condensed at higher pressure. The cycle is closed by a pressure reduction component, usually an

expansion valve. During evaporation, the refrigerant absorbs heat, such as from inside the refrigerator or from a low-temperature environmental or process heat source. The gaseous refrigerant condenses after compression at high pressure and high temperature. In the case of the refrigerator, this heat is released into the ambient air. With a heat pump, this heat is used for something useful, such as heating, district heating, or process heat.

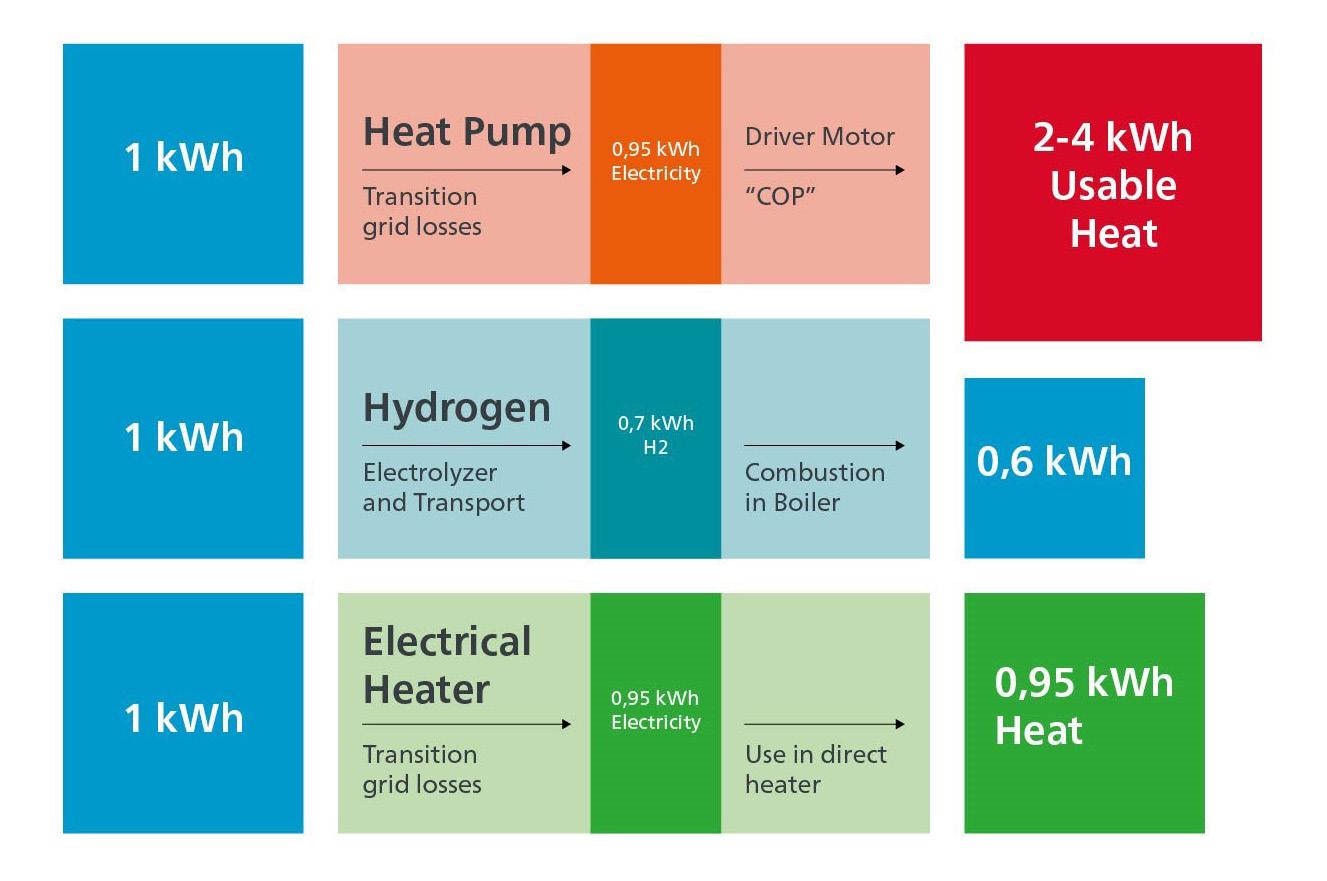

COP, and getting the most from the electricity

The magic of the heat pump lies in precisely this trick: the heat is loaded into a refrigerant and raised to a higher temperature level using additional energy. This means that typically 2 – 4 kWh of heat can be pumped with 1 kWh of electricity. This ratio of electricity used to usable heat is referred to in technology as co-efficient of performance (COP).

Electric heaters have a COP of 1, and the electrolysis and combustion of hydrogen is typically 0.6, mainly due to losses in electrolysis.

A heat pump, therefore, generates much more usable heat from the same amount of electricity compared to other technologies. Furthermore, no carbon dioxide (CO 2 ) is emitted if climate-neutral electricity from the sun, wind, water, nuclear power, or other sources is used,

though even operated with electricity from efficient gas- and coal-fired power plants may save CO 2

Farewell to fossil fuels

While the technology has long lived in the shadows of cheaply available fossil fuels, the current extremely high fuel prices and the lack of security of supply in parts of the world now finally seem to be setting the stage for the heat pump’s grand entrance. It seems ironic that the first large scale installations in Switzerland, dating back to 1938, were installed with the same motivation of minimising dependence on imported coal.

Several large Atlas Copco Gas and Process heat pumps with turbocompressors have been in operation in Scandinavia since the 1980s, which speaks for the longevity of the technology. The heat source is cleaned waste water from a sewage treatment plant, and the heat sink is the urban district heating system. The systems achieve thermal outputs of over 60 MW per unit.

Regarding CO 2 savings, heat pumps in industry offer enormous potential: two Atlas Copco Gas and Process heat pumps installed in Stockholm’s heating network, each with 40 MW thermal output, save 90 000 tpy of CO 2 emissions (compared to the previous use of heating oil). To achieve a comparable saving in road traffic, it would mean that the average Swedish gasoline-powered cars would have to drive 500 million km fewer every year (approximately 400 times to the moon and back).

The high impact areas of industry

There are five areas of production in particular that stand out for the use of heat pumps: paper production, food production, chemical/petrochemical, general production, and the aforementioned production of district heating.

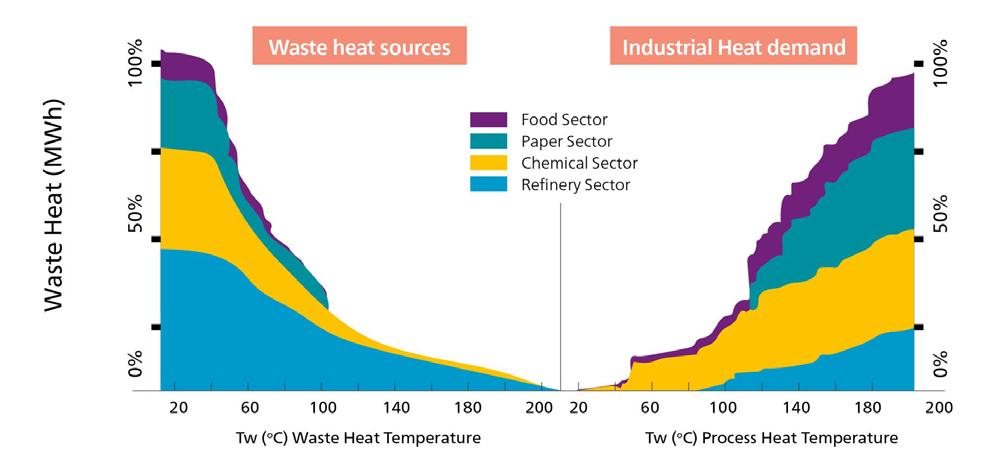

Figure 1 . Cumulative amount and temperature levels of waste heat/process heat demand in the EU. The total amount of available waste heat adds up to 314 000 GWh/y. Data source: TNO 2021.

In these sectors, a large part of the required heat is used at temperatures between 80 – 250˚C. At the same time, low-temperature waste heat is available in all production plants, which is rejected via cooling towers. From an energy point of view, this conventional use of heat is an open process that can be converted into an energy circular economy by using a heat pump.

As well as from industrial production, there are more heat sources that are readily available which may not be immediately recognisable as such: municipal sewage treatment plants and hydrogen electrolysis plants represent a continuous flow of low-temperature heat that can be made usable again (similarly, river and sea water).

Example: Chemical industry

Figure 2 Basic principle of a heat pump. Here, a single stage, subcritical cycle is shown. The co-efficient of performance expresses the efficiency of the heat pump at given temperature lifts and temperatures.

Using an example from the chemical industry, the possibility of seamless integration of a heat pump into existing systems becomes clear. In the industrial production of bioethanol, the ethanol/water mixture obtained through fermentation is separated by a multi-stage distillation at approximately 80 – 100˚C. The distillation column is usually heated with low-pressure steam, which is generated from natural gas in a power plant or boiler. After separation, the purified ethanol

steam is condensed in a water-cooled condenser and the heat is released into the environment via cooling towers. However, if the heat of condensation of the ethanol is transferred into the circuit of a heat pump, the heat from the distillation can be fed back in as usable heat.

Such a system with a temperature rise from 70˚C to 110˚C may achieve a COP of 4, while thermal outputs of up to approximately 50 MW can be achieved per machine.

Example: Food production

In the production of sugar, large amounts of heat are required to first produce syrup and then crystal sugar from the aqueous sugar extract of the beets or sugar cane.

In conventional systems, the waste heat of the first apparatus is already used several times to heat the downstream processes, but eventually, it becomes waste heat at approximately 50˚C, which can no longer be used economically and is rejected via a cooling tower. This lost heat must be replenished by fresh energy, which is usually generated from fossil fuels.

A heat pump can be used here instead of the cooling tower. Since the sugar production apparatus is an expensive, specially manufactured component, the heat pump has to meet the existing requirements for the available heating medium, which is usually water vapour at low pressure.

A heat pump with an oil-free integrally geared turbocompressor can easily achieve the necessary temperature rise from 50˚C to 140˚C to produce the required steam at 2.5 bar. Due to the higher temperature range, the COP is lower, but it still achieves good values of approximately 3, depending on how low the cooling water is to be cooled.

Example: Hydrogen electrolysis

No system has perfect efficiency, and this is especially true for large scale electrolysis for the production of green hydrogen. The prevailing polymer electrolyte membrane (PEM) technology achieves 60 – 70% efficiency. With a 100 MW electrolysis, approximately 30 MW waste heat is generated at a level below 80˚C. In industry in particular, upcycling this waste heat represents an easy way to exploit the full potential of the hydrogen economy: on the one hand, replacing fossil fuels with hydrogen where really necessary (such as in furnaces, cement, and metallurgy), and on the other hand, replacing fossil-fuel generated steam with hydrogen ‘green steam’ from the waste heat of the electrolysis.

Proven turbocompressor technology

The optimisation of industrial heat pumps represents a system with a number of variables. Larger outputs generally require high-performance turbomachines, while continuously operating production processes in industry require maximum reliability and economy.

Integrally geared turbocompressors represent a technology that has been tried and tested for decades, and they can be ideally combined with the above-mentioned requirements for performance, reliability, and economy. Due to the possibility of

Figure 4 Integrally geared turbocompressor as part of the industrial heat pump for district heat generation at Hammarbyverket, Sweden.

Figure 4 Integrally geared turbocompressor as part of the industrial heat pump for district heat generation at Hammarbyverket, Sweden.

flexible arrangements of up to eight individual compressor stages on a gearbox, there is the possibility of multiple inter-stage cooling. The COP benefits enormously, especially in the case of heat pumps with a large temperature lift, but the setup of the machine remains simple because only one drive motor is required.

To compensate for fluctuations in heat demand, the compressor stages can be precisely controlled via inlet guide vanes. Due to this entirely mechanical control, expensive power electronics for speed control can be dispensed with in most cases. Especially in critical applications in large production plants, a simple, mechanical power and capacity control is usually a preferred option.

Customised systems welcome

Figure 5 . By combining heat pumps and steam compression systems, steam generation from even very low grade temperatures is possible.

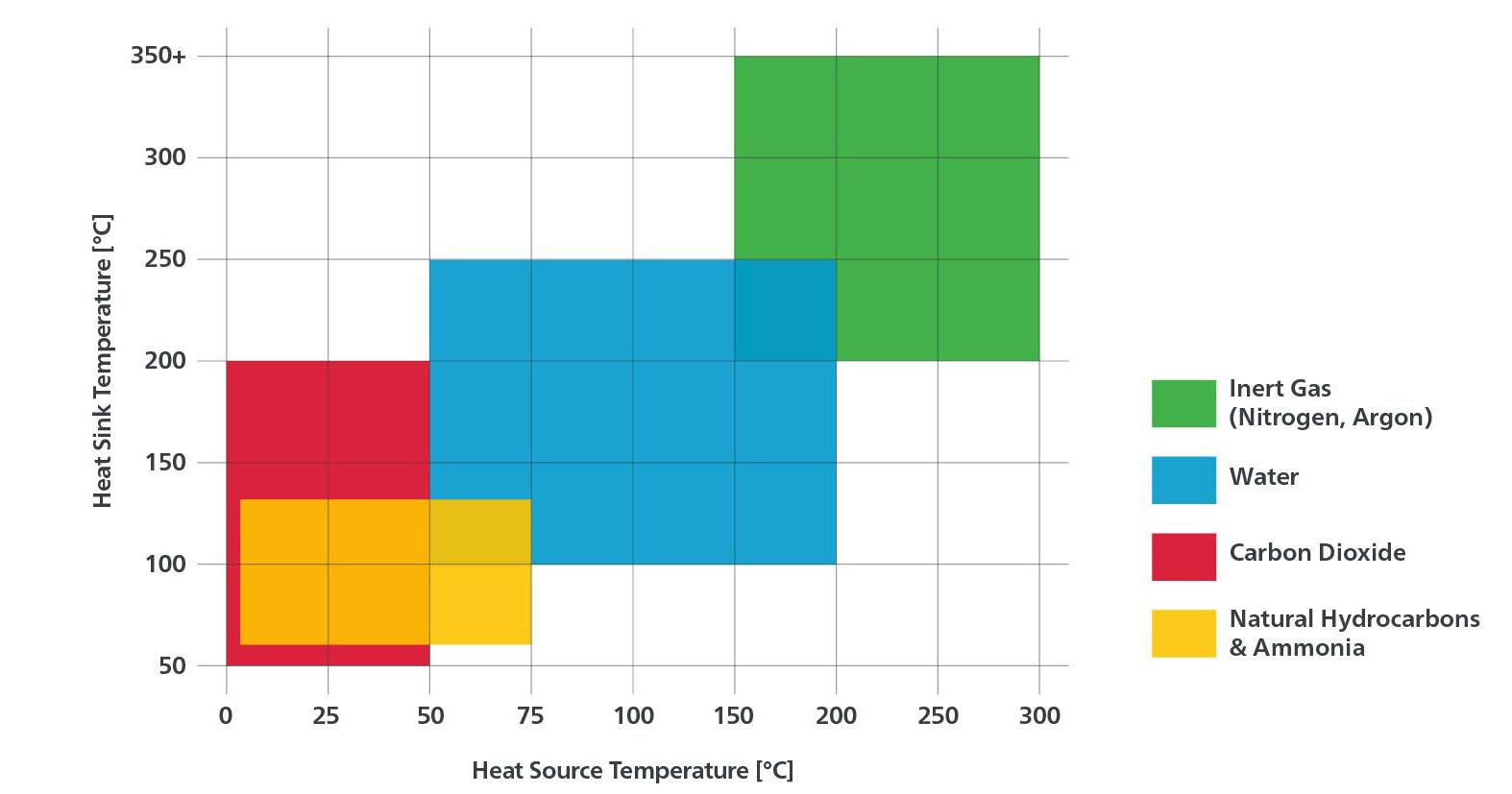

However, the secret star of the heat pump is the refrigerant. Without beneficial properties, no heat pump can achieve high COP values. Many systems with lower performance use components from the heating, ventilation, and air conditioning (HVAC) industry, which is why established refrigerants such as hydrofluorocarbons (HFCs) of the latest generation (such as R1233zee and R1234yf) are also used here. Manufacturers promote these refrigerants as a future-proof choice, with no negative impact on the ozone layer and very low global-warming potential. However, long-term consequences, such as the environmental impact of the degradation-product trifluoroacetic acid (TFA), raise legitimate questions and become more important given the normal service life of Atlas Copco Gas and Process compressors is over 30 years. With filling-quantities in the ton scale, the high price of HFCs is accompanied by its high weight, while natural hydrocarbons in the form of LPG are freely available and at low cost.

Figure 6 . Depending on the heat source and sink temperature, Atlas Copco Gas and Process heat pumps can use a wide range of suited fluids for the given application.

construction of the core component of the heat pump: the centrifugal compressor.

Because of these points, Atlas Copco Gas and Process heat pump compressors use natural refrigerants, specifically hydrocarbons, water, inert gases (nitrogen and argon), and carbon dioxide. Of course, machines with HFCs and ammonia as the working fluids are also available.

As an expert for turbomachinery in oil and gas processing, the handling of combustible gases is an everyday task for Atlas Copco Gas and Process that fits into any machine concept without problems. A suitable configuration can be created from the modular range of machines for applications up to 500˚C, with the different temperature ranges requiring different refrigerants and designs.

Focus on the core know-how: Integrally geared turbocompressors

Reflecting on one’s strengths is a good way to be sustainable and successful in life. And true to this motto, Atlas Copco Gas and Process focuses on the design and

This means that a strong engineering/EPC partner is needed to build a complete heat pump system. Based on many years of experience in working with internationally active EPCs, Atlas Copco Gas and Process selects the optimal partner depending on the requirements of the project. For projects in Europe, for example, it has an exclusive partnership with EPC STRABAG Environmental Technologies.

Summary

There are three obvious reasons for using heat pumps: CO 2 emission reduction, cost reduction (fuel savings, CO 2 emission certificates, tax breaks, and so on), and security of supply.

The heat pump as an industrial technology has been mature for decades, but it has existed for years in the shadow of fossil fuels due to a lack of need. Now, however, with sustainability demands and the price of fossil fuels, it is fair to say that the age of the heat pump is beginning.

Regardless of the motivation behind the investment decision for an industrial heat pump, in the end it is a further step towards the decarbonisation of industry, something that is urgently needed to meet the climate goals of the Paris climate agreement.

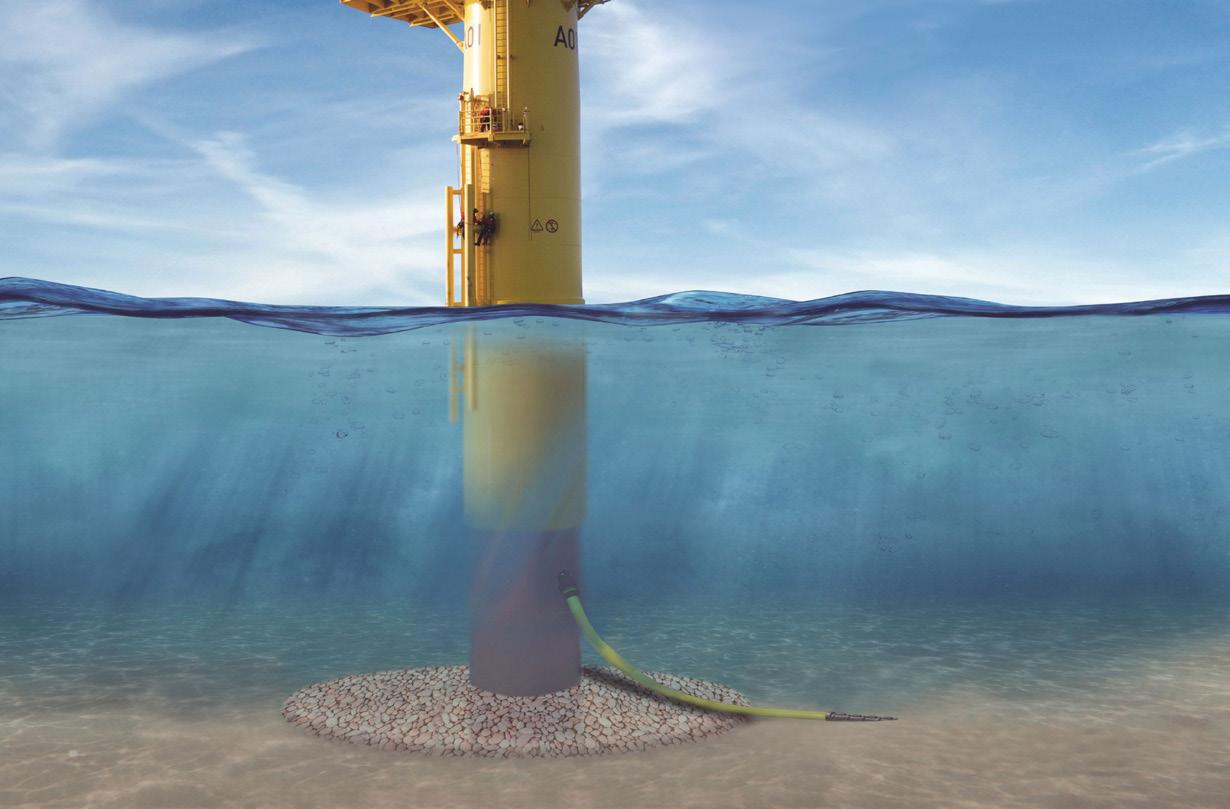

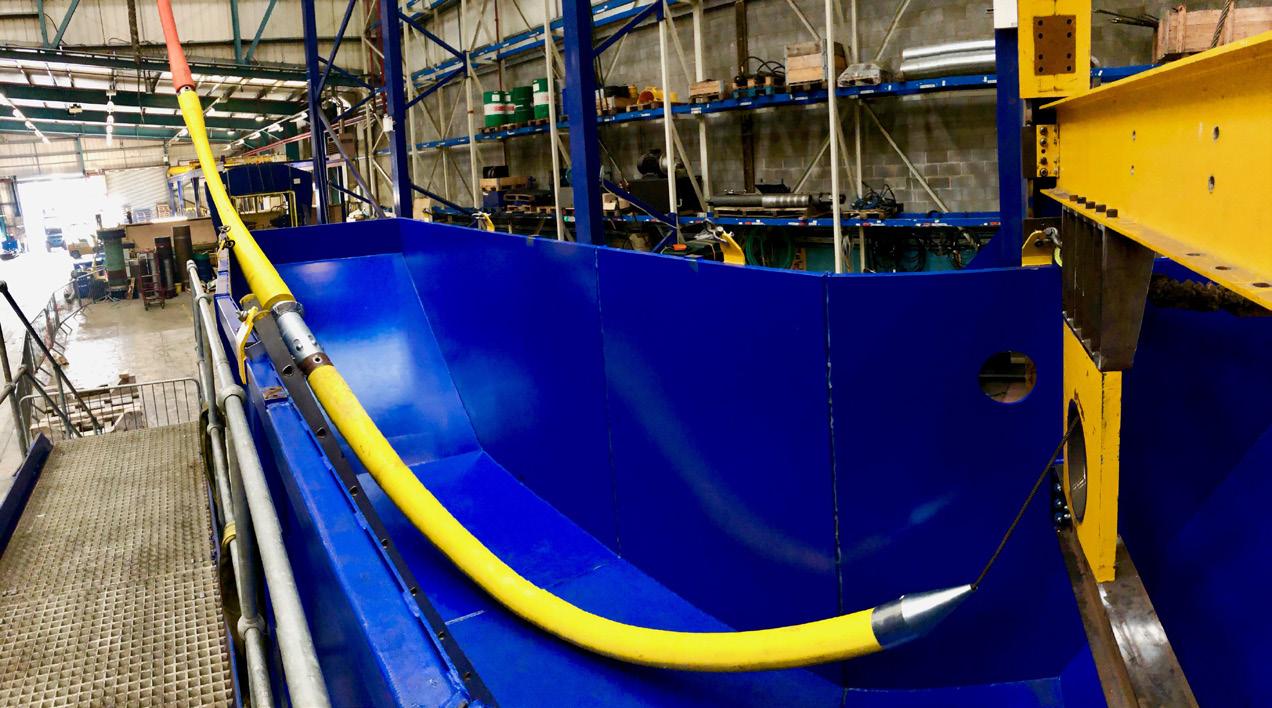

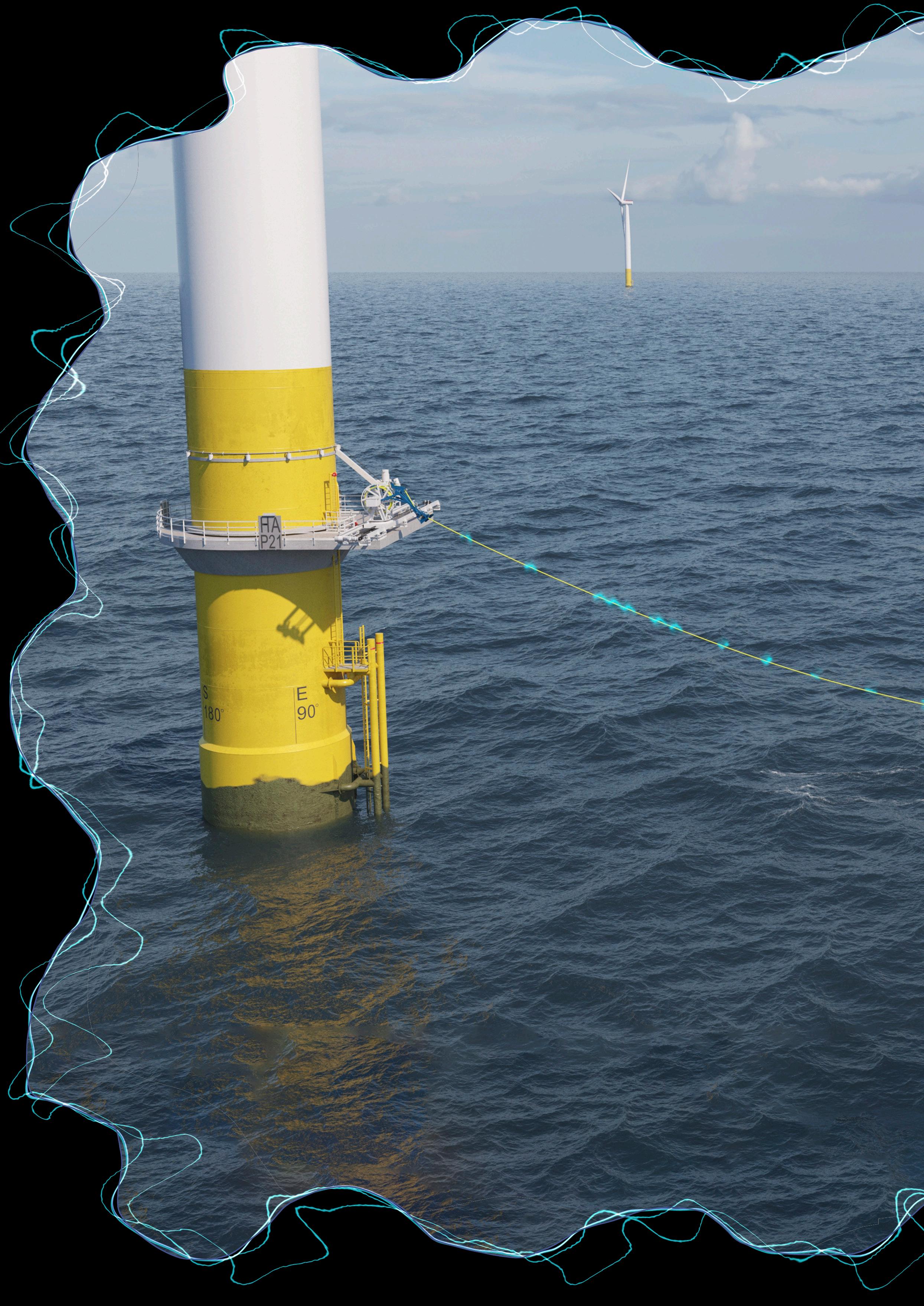

Austin Harbison, Smart Technology Manager, CRP Subsea, UK, talks about the importance

of safely

protecting subsea electrical cables in the shallow waters of offshore wind farms.

s the world balances its transition from fossil fuels to renewable sources of energy, the changing tide of supply will inevitably lead to unforeseen industry challenges and failures, resulting in new approaches and improvements to support further growth and cost-effectiveness in these sectors. These lessons must be learnt in order to see how best to identify and adapt so as to guarantee reliable energy supply and security in the future.

Over 30 years ago, offshore wind farms started to emerge in Europe, with slow adoption through the turn of the millennium, to almost meteoric growth over the past decade, and ever more coming online as 2030 comes closer.

Development focus has led to great gains in the most visible part (the turbine and its blades), but as a result, is the whole system being mistakenly labelled a mature technology not in need of further investment and improvement?

As with any system, it is only as strong as its weakest link, and some are beginning to argue that its very connection to people’s homes might just be that. Given the environment in which these systems are immersed, and the unforgiving nature of coastal waters, small risks are being exacerbated, but through the lessons of failure, new approaches are uncovered to mitigate, analyse, and eliminate them.

To facilitate the world’s burgeoning thirst for renewable electricity, submarine cable production has been increasing like never before to meet with the demand for offshore wind, with the cumulative deployed length of cables now exceeding the diameter of the planet, and an eight-fold increase coming online within the decade. Thus, any risk to their integrity could impact the

entire industry and, without cable redundancy on most fields, any single point failure could lead to considerable loss of power to homes and businesses.

Cable protection products