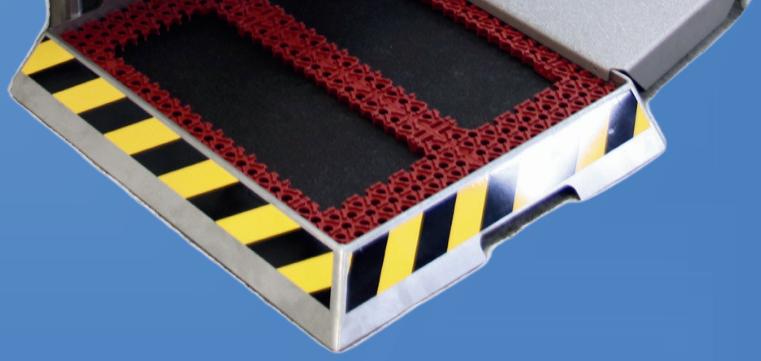

We have introduced a more cost effective and sleeker design version of our Outrunner Spiral. When your product is just a little bit on the smaller side, we are now introducing our latest innovation: a spiral conveyor that’s not only sleeker but also more budget-friendly! Engineered for optimal efficiency, this new design enhances your workflow with a compact footprint, reducing space requirements and maintenance costs. Whether you’re in manufacturing, packaging, or logistics, our spiral conveyor delivers superior performance without breaking the bank.

Sleeker more compact design for an even smaller footprint.

TURNKEY: Spiral + Conveyors + Transfer Technology available.

NO Conveyor Chain Tension Device required.

Stainless Steel Design equipped with Modular Plastic Chain that is washdown capable perfect for direct food contact.

Each tier is individually driven and pushed or pulled by a single gearmotor

SCAN TO LEARN MORE

Contract manufacturer’s new Rotary Batch Mixer from Munson Machinery slashes cycle times, overages for dry product operation.

How Bettaway Supply Chain Services turned a warehouse into a value-added repacking operation for Nestlé’s San Pellegrino brand.

In the heart of Northern Kentucky, just ten minutes south of Cincinnati, Camco Chemical has quietly grown into a powerhouse of contract chemical manufacturing.

Joseph Derr EDITOR jderr@pmmi.org

Kim Overstreet DIRECTOR OF CONTENT

David Bacho CREATIVE DIRECTOR

sales@pmmimediagroup.com

Courtney Nichols DIRECTOR, CLIENT SUCCESS & DEVELOPMENT cnichols@pmmimediagroup.com

Lara Krieger SENIOR MANAGER, PRINT OPERATIONS lkrieger@pmmimediagroup.com

Janet Fabiano FINANCIAL SERVICES MANAGER jfabiano@pmmimediagroup.com

David Newcorn PRESIDENT

Elizabeth Kachoris VICE PRESIDENT, DIGITAL

Kelly Greeby SENIOR DIRECTOR, MEDIA OPERATIONS

Trey Smith SENIOR DIRECTOR, EVENTS

Jen Krepelka DIRECTOR, DIGITAL MEDIA

Amber Miller DIRECTOR OF MARKETING

Joan Jacinto DIRECTOR, AD TECH AND SEARCH

Have a question or an idea for an article? Contact Joseph Derr, Editor. Contract Manufacturing and Packaging magazine prefers to receive press releases by e-mail. Send to jderr@pmmi.org.

PMMI MEDIA GROUP 500 W. Madison, Suite 1000, Chicago, IL 60661 WEB www.pmmimediagroup.com

PMMI THE ASSOCIATION FOR PACKAGING AND PROCESSING TECHNOLOGIES 12930 Woodgate Dr., Suite 200, Herndon, VA 20170 PHONE 571/612-3200 • FAX 703/243-8556 WEB www.pmmi.org

PUBLICATIONS MAIL AGREEMENT NO. 40064408

Return undeliverable Canadian addresses to Express Messenger International, P.O. Box 25058, London Brc, Ontario, Canada N6C 6A8

Questions about your subscription or wish to renew? Contact circulation@pmmimediagroup.com.

Contract Manufacturing and Packaging magazine is the official publication of the CPA, The Association for Contract Packagers and Manufacturers. The association provides business development support, industry education, networking opportunities, and industry intelligence for contract packagers and contract manufacturers. For more information on becoming a CPA member, contact Paige Jarvi, 571/287-6818, pjarvi@contractpackaging. org, or visit www.contractpackaging.org

BY JOSEPH DERR, Editor

I

just got back from ENGAGE 2025 in Clearwater, Fla., and I don’t know about you, but I left the meeting feeling energized about CPA and optimistic about our industry.

What struck me most at this, my first ENGAGE, were the stories I heard—not just onstage but in the hallways and during networking breaks.

There were stories of CPA members stepping in to help brands in tight spots when other co-mans couldn’t. Stories of

family businesses growing, expanding facilities, and the dedication it took to get there. I also heard stories of challenges still waiting for solutions. No matter the subject, they all reflected an industry in motion—one that makes an impact 365 days a year.

I was inspired by the work you do.

This month, I’ve edited a few stories that I hope will inspire you too.

Our cover story and Plant Profile highlights Camco Chemical, a Cincinnatiarea co-man that transformed from a gas station into a chemical manufacturing powerhouse—all after an unexpected knock on the door (p. 10). Brand expert Robby Martin shares his story of building

strong brand relationships by learning to “know what you don’t know” (p.3).

Bettaway Supply Chain Services also has a compelling story about how they found the right time and the right place (their warehouse) to enter the repacking space for beverage fulfillment (p. 8).

There’s plenty more in this issue you won’t want to miss, so dive in. And if you have a story to share, I’d love to hear it.

Drop me a line at jderr@pmmi.org

Happy reading.

Delivering

With Heat and Control, you have a partner with the scale to support your

the innovation to advance your operations, and a commitment to

that will help you offer

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

products for consumers. We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

BY ROBBY MARTIN, Principal, 3-Fold Consulting

There was a time when our brand decided to try moving faster in our innovation. We had used a formal process up to that point, but it seemed the process often helped us decide why not to do things far more than it helped us actually try new things!

So, our CEO had us staffed and focused on getting ideas to a “good enough” state to at least conduct an in-store limited trial or mini-launch—to see if we could find success with less wasted effort. This led to some pretty awesome days of working nimbly and included things like sitting in a room with the whole team on a Friday afternoon, with folks rearranging travel for the next week because of things learned late in the current week.

It was in this environment that we developed some refrigerated products for trial—the first time in our company’s history. One group of products was being manufactured by a co-manufacturer (coman) in the Southern California area— L.A., to be exact. We were finally done with development and starting production to support test markets in two locations in the Midwest and Mid-South. We were in L.A. for the production startup, and as we completed production on the first day, someone came into the room where our team was situated and asked what should have been an easy question:

“Where do you want the product shipped?”

“I’m sorry, what did you just ask me?”

You guessed it. That was the first time the idea of needing a cold storage facility had even crossed my mind. Well, it didn’t just cross my mind—it was forced right to the front and center!

Now, that’s just one of several stories I could tell you. Most of them have pretty good outcomes, too—primarily because I’ve worked with many, many incredible folks throughout my career.

Even so, there have been a lot of situations, CM/CP providers, and projects that have combined to create interesting—and sometimes even funny— stories. Those situations have also led to a lot of valuable lessons. Here are a few that go beyond just the technical aspects of an engagement.

1. Relationships can become the most important aspect of CM/CP and brand-owner partnerships. Companies building a CM/CP sourcing strategy should prioritize the relationships that seem to form early in the evaluation process. This isn’t always about people simply “getting along.” It can be about the

“There have been a lot of situations, CM/CP providers, and projects that have combined to create interesting—and sometimes even funny—stories. Those situations have also led to a lot of valuable lessons.”

transparency experienced, the connection observed, or even a “feeling” that is hard to describe—but that several members of your evaluation team can recognize.

2. Capability confirmations should go beyond just understanding what unit operations a provider offers. True capability includes the service provider’s ability to flex those unit operations. It should also include the provider’s ability to talk about their “sweet spots” and explain how they handle opportunities that may require a “stretch” for them.

3. Be honest about the engagement. A final key area blends the first two

together. Can the teams on both sides connect well enough to be honest about what feels right and what doesn’t in the engagement being considered? Will the engagement start with “eyes wide open” and stay that way moving forward?

The more innovative or technically challenging a project is expected to be, the more critical these questions become.

Here’s a somewhat typical example of what I’m talking about.

As we visited a potential supplier in the refrigerated space, my product developer, food safety person, and I were welcomed by the entire leadership team at the provider. In fact, they sat in the conference room with us the entire time we weren’t on the floor touring the facility—probably an hour and a half or more. The facility was small, with two to three small lines, only one of which was running the day of our visit. We talked about the products we wanted to make, and we were assured that the provider could do the work.

On the way back to the airport, I asked my colleagues what they thought. They said they believed the provider could meet our needs. Then I asked if they had noticed that the entire leadership team seemed to have time to sit with us that morning. I pointed out that some of them should not have had that kind of time on their hands. My colleagues didn’t think it was that big of a deal.

“Okay,” I said. “Consider this. Six to eight weeks from now, our president calls you and says he’ll be in the provider’s area sometime in the next week or so, and he’d like to visit our new co-man.”

“Oh!” they both painfully echoed, suddenly realizing they might not feel great about such a visit.

“Well,” I said, “doesn’t that tell you something?”

And just like that, we quickly agreed— our provider search was not over. CM+P

The 2025 CPA ENGAGE annual meeting was a resounding success. Held February 4-6 at the Sheraton Sand Key Resort in Clearwater, Fla., the event welcomed 220 attendees, including CPA members, brand representatives, and industry newcomers interested in external manufacturing.

Highlights included economist Connor Lokar of ITR Economics’ data-driven outlook on inflation, interest rates, and market forces shaping external manufacturing.

Nulogy CEO Jason Tham moderated a panel on supply chain efficiency, featuring speakers from Sunsweet Growers, Mark Anthony Brewing, and a cosmetics industry consultant.

On the tech side, Adam Griffen of ei3 Corporation discussed AI’s role in facility optimization, and attendees got an exclusive look at the new CoPack Connect tool (see below). The event wrapped up with a tour of Polypack’s end-of-line machinery facility in nearby Pinellas Park.

With engaging sessions, sponsor booth exhibits, and networking opportunities, ENGAGE lived up to its name. Mark your calendar for ENGAGE 2026, set for February 24-26 in Las Vegas!

After ENGAGE, CPA launched into a busy event season, hitting major industry shows, including PACK EXPO Southeast in Atlanta, Natural Products Expo in Anaheim, and SNAXPO in Orlando, where CPA members showcased their capabilities in the expanded Co-Man Central pavilion, part of the Tower Sponsor program. First introduced in 2023, the pavilion provides a cost-effective way for members to exhibit.

This spring and summer, CPA expands further into the cosmetic industry, with appearances at the NYSCC annual event in New York (June 3–4) and Cosmoprof North America in Las Vegas (July 15–17). CPA initially partnered with the Independent Beauty Association at Cosmoprof but will now have its own booth to better serve members in non-food sectors.

For details on becoming a Tower Sponsor at upcoming events, email info@contractpackaging.org or log in to InfoHub at contractpackaging.org.

Contact us for more information. 269-637-1121 / 1-800-426-4822

sa les@do-it.com

www.do-it.com

BY MICHAEL COLLINS, President, CPA

I’m thrilled to address you for the first time as the president of CPA, the association for contract manufacturing and packaging. It’s an honor to step into this role, and I’m excited about the opportunities ahead of us.

Balancing this volunteer role with my day-to-day responsibilities as vice president of sales and marketing at Sterling Contract Packaging Inc. in Spartanburg, S.C., is no small task. But I’m eager to take it on because I’ve seen firsthand how much CPA can benefit those who engage with it.

I joined CPA in 2007 and quickly realized the value of involvement. When Sterling participated in the Tower Sponsorship program at PACK EXPO, we gained tremendous exposure. Later, through committee work, I built friendships and connections that wouldn’t have been possible otherwise. I encourage you to dive deeper into our association—you’ll gain more than you expect, both professionally and personally.

There are two exciting CPA initiatives you should know about. First, we’ve opened membership to CPG brands, creating opportunities for co-manufacturers, co-packers, and brands to collaborate and address industry challenges. This move strengthens the supply chain, driving growth and innovation.

Second, our CoPackConnect tool is live! This RFQ platform simplifies how brands connect with you, the best external manufacturers and packaging service providers. It does the heavy lifting for brands and delivers quality leads quickly to co-man and co-pack experts. But we need your participation. If your company hasn’t yet created a profile, I urge you to do so now (see below).

Your ideas matter. Reach out, share your thoughts, and let us know how CPA can better serve you.

Here’s to a great year ahead!

Michael Collins is vice president of sales and marketing for Sterling Contract Packaging Inc.

Don’t miss out on CoPack Connect!

Matching brands with external providers, this AIdriven RFQ tool increases visibility for CPA members and delivers quality leads at no extra cost, as it’s included in membership dues. Set up your profile today to start receiving priority RFQs from brands at CoPackConnect.com CM+P

Contract manufacturer’s new Rotary Batch Mixer from Munson Machinery slashes cycle times, overages for dry product operation.

BY JOSEPH DERR, Editor

When Rob Lonas founded EW Packaging in 2001, he started it as EW Trading, a business that outsourced packaging and printing. Over time, Lonas decided to bring these services in-house, rebranding as EW Packaging.

Today, the company has grown into a versatile operation, manufacturing and packaging powder, tablet, and capsule products for customers ranging from national warehouse clubs to dietary supplement retailers and government contracts.

the contract manufacturing sector for dry products, EW Packaging prides itself on machining its tooling, enabling faster turnaround times and cost savings for its clients.

By 2016, EW Packaging had expanded to include blending dietary supplements and food powders, as well as manufacturing tablets and capsules. However, its V-cone blender needed attention.

“The V-cone blender we used was a lot of work and there was a lot of

From its 30,000-squarefoot facility in Los Angeles, EW Packaging handles everything from protein powders to energy drink mixes and sports nutrition products, including the EarthNutri.com nutraceutical line.

With more than 50 employees, EW Packaging runs six blister-filling lines, four bottle-filling lines, and in-house flexographic printing for custom pouches and blister foils. Carving out a niche in

The Rotary Batch Mixer discharges to a screw conveyer, which transfers mixed powder products to an auger filling machine (left).

An operator empties a scoop of hand-weighed powder into the mixer intake, which remains stationary as the vessel turns.

EW Packaging produces sports nutrition products, energy drink mixes, food powders, dietary supplements in tablet, capsules, and powders.

downtime,” Lonas explains. “It took at least 30 minutes to get a load in and out, plus another 15 to 20 minutes of actual mixing.”

Next, he tried a ribbon blender, which reduced loading and unloading times but compromised blend quality. “The ribbon blender has corners, dead zones, where the powder isn’t mixed,” he says.

Sometimes EW added as much as 10 percent more active ingredient to the products than required for HPLC testing to confirm that the product met the label claim. In addition, the ribbon blender’s impeller put product quality at risk, Lonas says. “It chops up the ingredients and damages the product at the same time.”

In search of a solution to improve its blending operation, EW found Munson Machinery online. That led to Lonas purchasing a 15-cu ft (425 L) Munson Rotary Batch Mixer machine that loads, blends, and discharges in about 15 minutes—half the time of the previous blenders.

The unit’s horizontal vessel rotates on external trunnion rings located at each end, handling ingredients gently because it has no agitators. Instead, the vessel has internal flights that create a fourway tumble-turn-cut-fold mixing action, producing homogenous blends without generating heat, shear, or stratification. Lacking internal shafts, the mixer has no seals that are in contact with the product.

To initiate a blending cycle, operators hand weigh ingredients into a drum. A plant-based protein product may contain up to eight ingredients, while a flavored creatine product may contain up to four. The drum containing the weighed batch is then lifted onto a mezzanine and dumped through a security screen into a hopper that discharges into the mixer’s stationary inlet. A collection hood contains fugitive dust during the loading process, while a single external seal prevents the escape of dust during vessel rotation.

Lonas highlights the Rotary Batch Mixer’s gentle mixing action in his business conversations. “It’s part of my sales pitch for whatever the job is — encapsulation, tableting or just blending a powder,” he says. “This mixer just folds in the ingredients. It’s not smashing them or pounding them together.”

EW Packaging says its mixer’s gentle four-way action leaves almost no residue, simplifying cleaning between batches.

Blends are discharged from the mixer through a stationary outlet. Batches destined for encapsulation or tableting flow into mobile hoppers that are rolled into the adjacent room for those processes. Powder products are discharged into a screw conveyor that transports the batch to the feed hopper of an auger filling machine, which dispenses it by weight into bottles, canisters, tubs, or most any container.

The vessel leaves almost no residue following discharge. “There aren’t any

corners or pockets that can collect powder,” Lonas says. Between blending campaigns and when switching products, operators wash, rinse, and swab-test the vessel interior in accordance with GMP.

Lonas says that the blends are always on-spec, and overages range between 2 percent and 3 percent instead of 10 percent previously. “I sold my V-blender and my ribbon blender. The Rotary Batch Mixer gives us a perfect HPLC test every time.”

Despite its modest volumetric capacity, the mixer outputs high volumes because it loads and discharges quickly and blend times are short, as little as 3 to 6 minutes, Lonas says. “When we started getting bigger orders, we got nervous at first thinking our mixer wasn’t big enough, but we ran some big orders with no problems.” In one case, EW Packaging blended some 80 batches of a protein powder over four days, filling all of it into 5 lb (2.3 kg) tubs.

“The future for us is growing the powder business because we have our powder lines so dialed in. It’s a profitable and a fast way to fill bottles,” says Lonas.

EW fills as many as 50,000 bottles a day, which includes capping, induction sealing, metal detecting, checkweighing, labelling, lot coding, and neck banding.

Lonas says that EW Packaging seldom tells customers ‘no’ unless they come to them with a liquid.

“If we don’t have the right machinery, we buy it. Our niche is getting new products going for people and cranking it out, getting them into the market fast. We get a lot of business because of our blister and short-run capabilities. There aren’t many other places on the West Coast that can do that.”

Lonas calls the mixer his workhorse. “I think we changed a seal once. There’s not much maintenance to do on it. It’s one of our most reliable machines.” CM+P

This mobile pail filler was created for batch filling operations at multiple locations. It is top and sub-surface pail filler that moves around on casters. This filler will handle 1 to 7 gallon containers and only requires 25 lbs. of inertia to move it.

» User Friendly Benefits

» Improved Efficiencies & Accuracy

» Increase Production & Maximize Uptime

» Heavy-Duty & Long Lasting

This solution has a variety of product options available to meet your needs. To learn more, contact us by calling 833-467-3432.

We also provide installation, parts and field service 833-467-3432

www.specialtyequipment.com

How Bettaway Supply Chain Services turned a warehouse into a value-added repacking operation for Nestlé’s San Pellegrino brand.

BY JOSEPH DERR, Editor

Bettaway Supply Chain Services is a name synonymous with growth.

The Vaccaro family founded the company in 1960 as a soda business in Brooklyn, bottling its own brand in glass bottles distributed in plastic crates. By the late 1970s, the family stayed in the beverage industry but pivoted away from manufacturing to beverage logistics and distribution, acquiring a fleet of trucks. By the 1990s, Bettaway expanded

Econocorp’s Dual Infeed Beverage Spartan cartoner was recommended by Nestlé for Bettaway’s repacking operation. The cartoner was built to handle various configurations, such as 24-, 18-, 15-, or sixpacks. Infinity Photography Inc.

yet again, offering national third-party logistics and a national pallet program for brands (see sidebar on facing page).

In 2020, the New Jersey-based company had already added supply chain consulting, a new distribution center, e-commerce fulfillment, and a 300,000-sq.-ft. mega plant in Edison, N.J. As it expanded its services and capacities, it never lost its connections to the beverage industry, with clients including Arizona Tea, Snapple, Monster Energy, and Nestlé.

Bettaway’s next move came in 2021 when it ventured into variety packing—a logical progression given its strategic location near major ports in South Plainfield, N.J.

“We saw that in order to become more valuable to our customers, there was a need for warehousing and repacking,” says John Vaccaro, president of Bettaway Supply Chain Services and son of its founder. “Most of our customers do repacking, and with our location in the Northeast, there’s a large consumer market around us, so it was the right spot.”

While warehousing alone can be unsustainable due to its costs, Bettaway wanted to take a value-added services approach, offering a compelling reason for customers to store products in its warehouse.

“No one wants to pay for warehousing—customers want to be in and out as quickly as possible,” says Vaccaro.

To add value, Bettaway introduced repackaging and variety packing to its portfolio. Not only did this diversify its offerings, but it also strengthened relationships with clients.

“We wanted to provide more services

to our long-term customers so that we would be more integrated and ‘sticky’ with them,” Vaccaro says.

The move also made sense for Bettaway’s operations and strategy.

“We weren’t looking to become the biggest or greatest variety packer, but we had this great building, and we wanted to make sure it stayed full,” Vaccaro says.

Igor Katsman, vice president of operations, sums up Bettaway’s one-stop-shop approach for beverage clients like this:

“We’ll store it in our warehouse, and then we’ll do the packaging for them in a variety pack. Instead of dealing with five different vendors, they can just come to us for a customized solution.”

The right cartoner for the job

After opening up their new space and having some discussions with Nestlé, Bettaway landed a contract for repacking Nestlé’s San Pellegrino Essenza mineral water, imported from Italy. To launch its repacking operations—which today make up about 5% of Bettaway’s service portfolio— it needed the right cartoner for the job: a highly specialized and flexible system.

Econocorp’s Dual Infeed Beverage Spartan cartoner—a model recommended by Nestlé—was chosen for its versatility and reliability. Econocorp partnered with Bettaway to install the machine for one of its two cartoning lines. Katsman praises Econocorp’s support during the setup phase.

“Their team was responsive and transparent, with no hidden costs or agendas,” he says. “They even took us to another facility in New York to see the machine in action.”

Imported from Italy, the 12-ounce

slim cans of San Pellegrino Essenza mineral water arrive in work-in-progress (WIP) packaging—loose shrink-wrapped cartons. Workers manually unpack and sort the cans by flavor before feeding them into the Econocorp machine.

The system forms cartons from Smurfit Westrock ’s glossy, metallized carton flats, fills them, and seals them for retail. Bettaway’s automated TopTier palletizer then stacks and prepares the cartons on pallets destined for major club stores like Costco and BJ’s.

“Econocorp’s machine is highly flexible,” says Katsman. “It can produce three different package styles: front-load, sideload, and perpendicular.”

Econocorp built Bettaway’s cartoner to handle various configurations, such as 24-, 18-, 15-, or six-packs. The customized cartoner is now running at 18 carton cases per minute, equating to one pallet every three and a half minutes, says Vaccaro. On a single shift, that line churns out nearly 10,000 carton cases.

“From the day we brought the machine in, it’s been running almost flawlessly,” Vaccaro notes.

Previously, Bettaway relied on older,

Bettaway has multipurposed its warehousing area for repacking operations with two cartoning lines. Infinity Photography Inc.

unreliable machines, but the Econocorp cartoner has exceeded expectations.

“When you’re in the service business, you want to turn the key every morning and produce. That’s what’s important,” Vaccaro says.

The variety pack operation has also created opportunities for the 35 Bettaway employees who work in repacking. Many have transitioned from manual roles, such as forklift operators, to skilled positions operating the cartoner and palletizer, Katsman says.

Vaccaro’s commitment to inclusion in the workforce is another hallmark of Bettaway’s repacking operation. With a son on the autism spectrum, Vaccaro saw variety packing as an opportunity to provide meaningful employment for individuals with disabilities. Today, Bettaway partners with organizations like We Make and Rutgers Center for Adults with Autism to offer these opportunities on the repacking line for tasks such as carton preparation.

“We’re proud to have 20 to 25 individuals with mixed abilities contributing to our operations,” Vaccaro says.

With two variety pack lines running, Bettaway plans to add a third, further solidifying its position as a value-added logistics provider.

“My vision is to make this building more reliant on variety packing and less dependent on traditional storage,” Vaccaro says.

The company’s proximity to New York-area ports and its integrated service model make it a preferred partner for beverage giants like Nestlé.

Bettaway’s automated TopTier palletizer stacks and prepares cartons of Nestlé’s San Pellegrino Essenza mineral water on pallets destined for club stores. Infinity Photography Inc.

“We’re positioned well logistically— we’ve got trucking, logistics, repackaging, and palletizing all under one roof,” Vaccaro explains.

It’s an approach that gives Bettaway a competitive edge in the hot Northeast beverage market. CM+P

Drawing upon its expertise in beverage distribution, Bettaway Supply Chain Services reimagined pallet management when it created Pallet Trader (www.pallettrader. com), a platform for buying, selling, and managing pallets.

Unlike traditional pallet systems, Pallet Trader is an online marketplace dedicated to pallet transactions. Operating through a network of 700 depots nationwide, Bettaway’s system ensures that companies can source pallets efficiently

without the burden of ownership.

“Pallet Trader streamlines operations by providing a singlesource solution for national brands,” says John Vaccaro, who founded Pallet Trader. “We handle everything from supplying grade-specific pallets to retrieving and repairing used ones.”

The closed-loop system is tailored to beverage and consumer packaged goods (CPG) companies, which rely on standardized pallets for seamless distribution. CM+P

In the heart of Northern Kentucky, just ten minutes south of Cincinnati, Camco Chemical has quietly grown into a powerhouse of contract chemical manufacturing.

BY JOSEPH DERR, Editor

From its beginnings in making surface treatment chemicals, Camco Chemical, in Florence, Ky., has stayed true to its bread-and-butter core of dry and liquid soaps, detergents, and related products while also diversifying to package synthetic lubricants, car wash liquids, and even aircraft deicing fluids.

Today, a Rolodex of 75 customers relies on Camco’s services for manufacturing, packaging, and distributing commercial, institutional, and industrial chemicals that touch lives every day.

“I tell our employees that we are the silent partner,” says President and CEO Adrian Hothem. “You won’t see us in Super Bowl commercials, but if we do our

job right, our customers’ products are in the market, on shelves, and being used every day.”

Now, with a major expansion and an increasing focus on contract packaging, Camco is positioning itself for the next era of growth.

Founded in the early 1960s, Camco began with a simple entrepreneurial vision of Richard “Dick” Rolfes, the company’s founder, who started mixing and selling concrete floor degreaser out of his family’s service station.

Then, a group of executives from a leading consumer products company, just across the Ohio River in Cincinnati, came knocking on Rolfes’ door in search of a facility to conduct R&D batches. It was an unexpected encounter that ended up sparking a shift in Camco’s business model—one that remains at the core of its operations today: manufacturing as a service.

Over the decades, Camco evolved from a modest service station operation into

a 700,000-square-foot manufacturing and distribution hub spread across four buildings on 50 acres. In Q4 of 2024, Camco continued to expand, acquiring 18 acres of property that includes a 170,000-square-foot facility in Florence, in close proximity to its 40-acre main campus.

Despite its phenomenal growth, Camco remains a family-owned business run by the third generation, with Hothem at the helm alongside Dick’s grandson Jason Theissen (VP of Operations), Anthony Colley (Director of Purchasing), and Tommy Cropper (Bulk Operations).

Camco’s expertise spans a wide range of chemical manufacturing and packaging services, from blending soaps and detergents to industrial lubricants. With roughly 40% of its business in commercial and institutional products, 40% in consumer goods, and the remaining 20% in industrial and intermediate products, the company offers a full spectrum of chemical solutions.

Hothem says he thinks customers turn to Camco because they trust the co-man’s expertise and its turnkey approach of handling everything from raw material sourcing to packaging, warehousing, and distribution. “Many of our customers outsource 100% of their manufacturing to us,” explains Hothem. “They focus on sales and brand-building while we take care of production, quality, and fulfillment.”

Camco’s recent expansion underscores its commitment to growth, driven by one thing: providing greater efficiency and increasing capacity across both liquid- and dry-filling operations for its customers—whether their container is a pouch or a railcar—based on a core set of principles: safety, quality, and efficiency.

“If you go too fast and get out of sequence, you’re going to miss an important step, so we always ask, ‘Is it safe?’ first,” says Hothem. “We produce quality products consistently day in and day out, and if we can do those first two, we’re pretty confident that we’re going to find ways to do it efficiently.”

Camco has 25 packaging lines across its dry and liquid filling operation. Camco packages a broad range of products, from quarter-pound pouches of liquid to various liquid bottle sizes and styles, as well as industrial containers such as pails,

drums, totes, tank trucks, and rail cars.

To meet the diverse needs of its customers across a range of markets, Camco has partnered with leading equipment suppliers over the years to maximize its flexibility, quality, and operational performance. Those equipment partners include All-Fill , Viking Masek , Inline Filling Systems, Crandall , SureKap, Pack West , Universal Labelers, Nita , Wipotec , Enercon, Wexar, Keyence , Combi, and many others.

Camco’s investments over the years remain focused on maximizing flexibility

while delivering consistent outcomes of service and quality for its customers, says Hothem.

“We blend and package everything from water-thin glass cleaners to high-viscosity waxes,” says Hothem. “Our flexibility is a huge advantage.”

Expecting the unexpected

Camco’s ability to pivot quickly has made it a trusted partner for brands facing urgent challenges. Hothem remembers an automotive client whose previous contract manufacturer shut down, leaving them scrambling to relocate production for 30 different products within 12 weeks.

Camco stepped in, built out a dedicated manufacturing space, secured bulk storage, and set up fully operational packaging lines before the deadline. “We move as fast as our customers need us to,” says Hothem. “But it starts with structured planning and a collaborative approach to understand the requirements, needs, and pain points, and develop solutions that will result in long-term, safe, quality product.”

Another client, a Fortune 500 company, needed to shift the production of 130 products in just 90 days. Camco successfully onboarded the entire portfolio, validating each product’s manufacturing process with a meticulous approach working hand-in-hand with the

Headquarters: Florence, Kentucky

Founded: 1960

Core Services: Contract chemical manufacturing, contract packaging, warehousing, fulfillment

Facility Size: 700,000 square feet across 50 acres

Key Capabilities: Blending, dry and liquid filling, packaging, labeling, kitting, and bundling

Certifications: ISO 9001, EPA Registered, Kosher, Halal, USDA Organic

Customers Served: About 75, ranging from startups to Fortune 500 brands

Website: www.camco-chem.com

customer. “We believe in going slow to go fast,” says Hothem. “That’s how you ensure quality and consistency at scale.”

At the core of Camco’s success are its people. With 200 full-time employees complemented by contract workers, the company fosters a culture of internal growth and development. Hothem recounts the story of an employee who started as a contract worker more than 30 years ago and now serves as vice president of purchasing. “He’s lived every part of this business,” says Hothem. “That kind of institutional knowledge is irreplaceable, and we are fortunate to have a number of 25-plus year employees across our entire operation that have helped Camco become what it is today.”

Joe Bricking, Director of Business Development, brings a unique perspective, having transitioned from a large corporate environment to Camco’s familyowned structure. Rather than pushing a sale that doesn’t fit, Bricking says Camco prioritizes the customer.

“Relationships here are different,” he says. “If something isn’t a good fit for the customer, we’re upfront about it. That kind of honesty builds long-term partnerships.”

Hothem says more customers are coming to Camco with requests for

Some 75 customers in commercial, institutional, and industrial chemicals rely on Camco for their services. Photo courtesy of Camco Chemical.

sustainable packaging options. Camco’s vast portfolio and experience mean that it can help brands transition to post-consumer recycled (PCR) plastics, alternative packaging materials, and more sustainable chemical formulations on existing equipment. As any good co-man would, Camco also keeps a close eye on regulations, proactively adapting to shifts to ensure its processes align with changing environmental and safety standards.

Looking ahead, Hothem says e-commerce fulfillment is a key growth focus for Camco. With its expanded facilities, Camco sees itself as ready to take on the challenge of streamlining direct-to-consumer and Amazon-ready packaging solutions.

“E-commerce presents an exciting opportunity for us,” says Hothem.

“Consumers want products faster, and brands need partners who can keep up. That’s where we come in.”

Along with its capabilities and experience, Camco’s location in Northern Kentucky—just 10 miles from Cincinnati— offers a strategic advantage, Hothem says.

“We are blessed to have been founded and grown in this region where a strong product and brand ecosystem combined with the infrastructure for chemicals manufacturing and modern-day logistics and fulfillment enable Camco to continue to best serve the needs of our customers.”

Camco Chemical’s commitment to agility, trust, and quality has made it a preferred partner for some of the biggest brands in the world. As the industry shifts toward more flexible, responsive supply chains, Camco is well-positioned to lead the charge—silently, but powerfully. CM+P

in packaging & processing

Break out of the ordinary and discover your next big idea at PACK EXPO Las Vegas 2025. Explore the eye-opening show floor, go hands-on with new tech, collaborate with experts and uncover game-changing solutions that can transform your operations.

MACHINERY IN ACTION and materials to explore

NEXT-LEVEL TECHNOLOGY from 2,300 exhibitors

IDEAS & CONNECTIONS spanning 40+ industries

VISIONARY EXPERTISE shared in free on-floor sessions

GRAB AN ALL-ACCESS BADGE FOR JUST $30!

American-Made Automated Boot Scrubbers with Easy-to-Clean Design

Brush heights for laced street shoes or up to 9" on the sides of boots.

Compact or high-throughput models available with easy-to-clean design.

On-site service and fast shipping available for brushes and parts.

®

CleanTech Automated Handwashing Stations with Footwear Sanitizing Pan

Simultaneous footwear sanitizing with fast-drying solution.

No touch points and no crosscontamination between users.

Self-cleaning cycle for a deep clean of the system on your schedule.