3 minute read

New innovations for precise bending from Aliko

Finnish Press brake manufacturer Aliko is known for innovative product development and flexible design. Aliko’s Finnish made Press brakes and tooling solutions present cutting edge technology and quality. The customers benefit from the advanced and comprehensive solutions for machining heavy materials. Aliko press brakes are manufactured in Finland according to customers’ specifications and requirements.

This article highlights couple of the latest innovations. These are Aliko KMJ Angle measuring devide, Aliko CNC Vario crowning 400 and Aliko CNC Vario die.

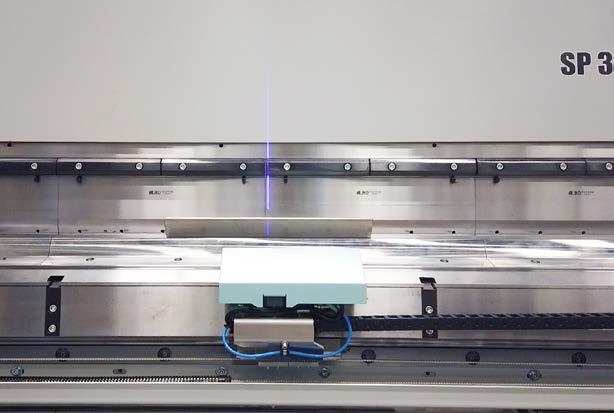

CNC controlled and servo driven measuring with Aliko KMJ Angle Measuring Device.

When the bending pressure is released from the material, it will tend to return to its original shape. This effect, which will result as a bend that isn’t at the desi¬red angle, is called the springback. This makes overbending necessary in order to achieve desired angle. With an CNC controlled Aliko KMJ angle measuring device it is possible to measure the springback effect and automatically calcula¬te a correction in real time to reach the desired angle.

• Typical measurement accuracy better than +/-0.1 °

• Can be used with 1V lower tools or CNC vario dies

• Can be cleaned pneumatically

• Change of lower tool won´t affect the measuring nor does it make moving the measuring necessary.

• A covered parking space at the bending table.

• Has a blue beam, making all the lights on the bending bed to be in diffe¬rent colors

• Collission protection for safety

Aliko CNC vario crowning 400 makes adjusting crowning easy

Aliko CNC vario crowning 400 is construction of servo driven self-locking wedges. These wedges are adjusted by servomotors from the control panel. The wedges are located every 500 mm, and each can be managed with the accuracy of 0,01 mm. Being able to adjust crowning in this detail is ideal when bending demanding materials and when aiming for flawless bending result.

Due to the deflection that occurs on upper and lower beam when pushed against each other, the accuracy of bending angle will be affected. Aliko cro¬wning system is designed to compensate the deflection of upper and lower beam, so that accurate bending angle can be achieved throughout the length of the bending material. CNC control calculates needed compensation automati¬cally after which operator can make adjustments based on the bending result. With Aliko vario crowning 400 those adjustments can be made with uttermost precision.

Fast V-opening adjustment straight from CNC control

Aliko has developed a very durable and fast CNC lower tool for press brakes. With the CNC lower tool, the V-opening change occurs in seconds and is completely automatic through the CNC control of the press brake. Due to the speed of the adjustment, the production of small series is cost-effective and much preferable compared to standard bending tool solutions.

The design of the tool pays special attention to durability and precision control. V-opening adjustment range and tool length can be customized according to customer needs:

• Motorized V-opening adjustment, precise positioning every 10 mm

• Fast v-opening adjustment straight from CNC-control

• Strong and durable construction; excellent load resistance

• Possible to add rollers at the corners of the V-opening

For more information about Aliko go to www.aliko.fi