Subscribe eNewsletter 23 198 Price in India Rs.100 volIssue23 04 April 2023 A monthly Publication from PRESSIdeas Publishing Pvt. Ltd. MMS LAA for Anand Limaye 08 VCPLA for Dr. Anayath 13 69 printers receive NAEP 14 Kodak VERISET at Druck Media 18 Xeikon’s toner technology TITON 22 IPAMA launches IntraPac India..................... 24 SHENGTU at Print China 30 Sustainability by Scodix 38 Vol.23 Issue 04, 2023 Cover Picture : Print China 2023, Dongguan, China Page 08 Page 20 Page 22 Page 36 Page 18 digital printing signage printing

manrolandsheetfed.com A Langley Holdings plc company. The Evolution of Print. MR SHEETFED INDIA PVT LTD A-7, Phase – II Community Centre, Naraina Ind. Area, New Delhi – 110028 T: +91 11 4557 7393 / 394 For more details, please contact PETER REGO, M: 9820089274, E: peter.rego@manrolandsheetfed.com ROLAND Evolution. Delivering the perfect package of quality and productivity. Our valued new customer Sain Packaging Pvt Ltd will soon experience the benefits of the their new ROLAND 700 Evolution.

Contents

FROM THE EDITORS’ DESK

Anand Limaye receives MMS Lifetime Achievement Award

Dr. Rajendrakumar Anayath, VC DCRUST awarded VCPLA

69 distinguished printers receive NAEP honours

DPA holds AGM of 2023

Kodak appoints Print & Finishing Solutions as new Channel Partner

Consistent launches Copier Powder for major printer brands across India

Insight Print Communications installs Kodak VERISET at Druck Media

Key message from Digital Media India 2023: Collaborate to innovate, prioritise audience

Promising versatility like never before

Monotech installs RICOH Pro C7200X at Kamala Press

Digital printing scores with heat-sealable, food-safe barrier paper based packaging

IPAMA launches IntraPac India

Labelexpo Europe 2023 registration opens

New LFH Plate extends DuPont Lightning platform

Monotech installs JETSCI YUV system in South Africa

Nestlé Certifies Scodix PS850 Polymer for Compliance with Packaging Inks

RICOH Pro C7200X empowers Ajanta to deliver the best quality wedding photos

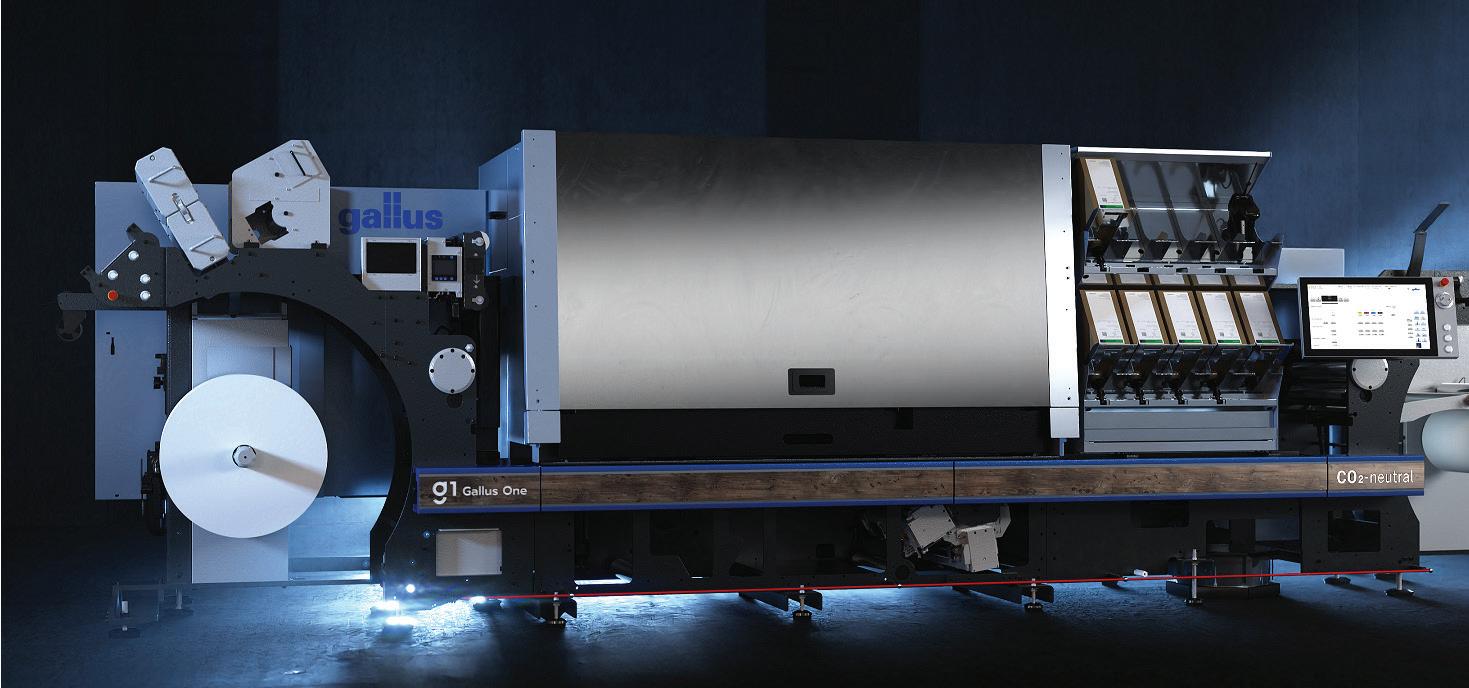

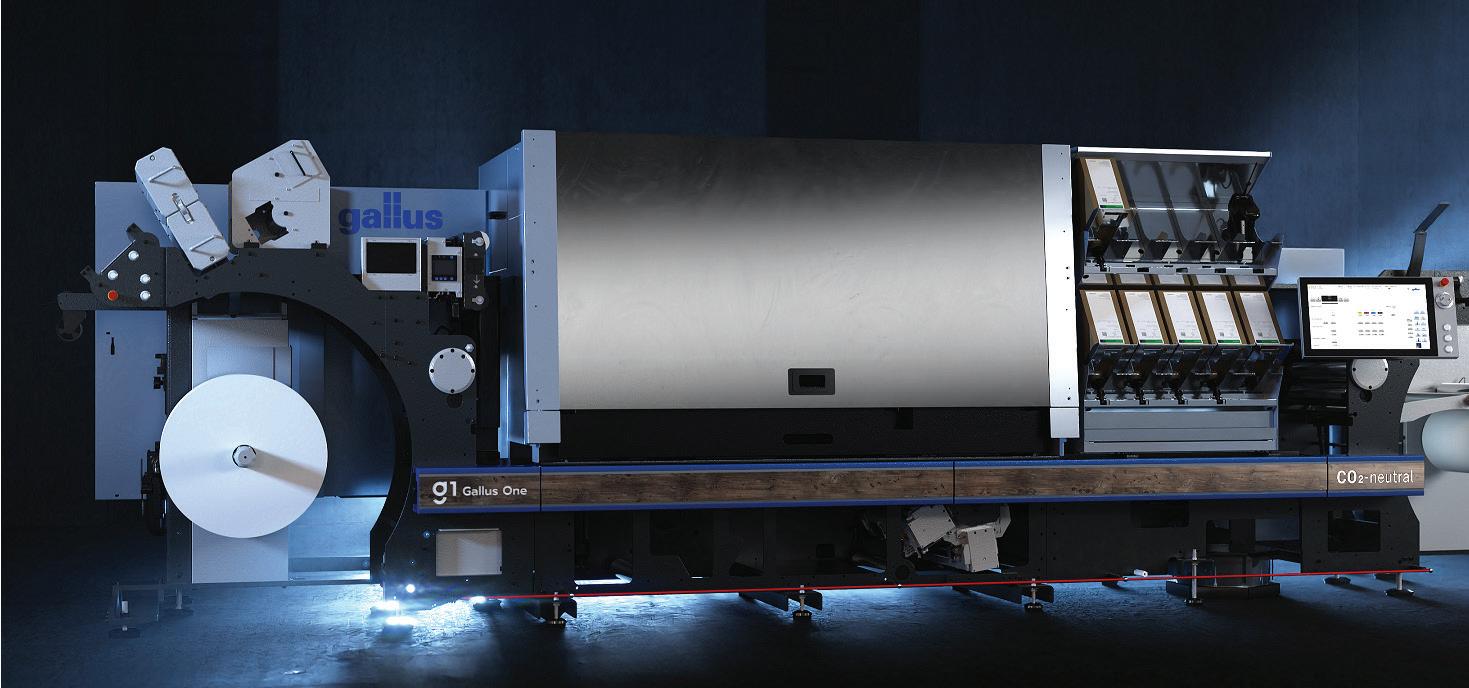

Gallus to debut new foldable ink set at Interpack 2023

Hard Case Making machine manufacturer, SHENGTU has a successful Print China 2023

DGM has a successful Print China 2023 participation

Koenig & Bauer experiences a successful Print China 2023

LongXingSheng (LXS): Futuristic Engineering, Simplistic Design, Minimum Steps to Rigid Box Making

Massivit at Rapid + TCT

Xeikon goes to Fespa with end-to-end digital solutions for sustainable growth

Sustainability benefits in comparison to traditional Print Enhancement

Jasmeet D. Editor & Publisher (jasmeet@pressideas.com)

Vineet K G. Associate Editor (vineetkg@pressideas.com)

Jasvinder S. Sub-Editor (jasvinder@pressideas.com)

Jacob George Marketing and Sales (jacob@pressideas.com)

M.S. Mukundan Advertising and Sales Southern and Western India (aims@pressideas.com)

Graphic Designer Anil Kumar

Networking/ Hardware Consultant Sukhdeep Singh

USA Correspondents Tensi M., Preeti

European Correspondent Rimi, Yadhu Morphine

Production Thomas K Alex

Every effort has been made to ensure that credits accurately comply with information supplied. All material supplied is compiled from sources believed to be reliable or solely an opinion of the authors. PRESSIdeas is not responsible for any steps taken based on the information provided herewith.

4 April 2023

PRESSIdeas April 2023 Vol. 23, Issue 04 Printed by Jacob George and published by Jasmeet Singh on behalf of PRESSIdeas Publishing Pvt Ltd. Printed in India at Hues and Colors 363, Industrial Focal Point, Phase-IX Mohali, and published at PRESSIdeas, 437-A 1st Floor, Industrial Area, Phase-2 Chandigarh-160002 (India)

Subscription details/form on Page 06

6

8

13

14

16

....................................................................................................................... 17

17

18

19

20

21

22

24

25

25

26

27

28

29

30

32

33

34

36

37

38

PRINT THAT PAYS

At Kodak we’re focused on delivering solutions that help printers succeed as the industry evolves. That means increasing your productivity while reducing costs so you can capitalize on opportunities for growth. From traditional offset to leading-edge digital, we offer a complete portfolio of cutting-edge products supported by outstanding service that will help increase your profitability taking you to the next level.

Find out more at kodak.com/go/pressideas

© 2023, KODAK. Kodak and the Kodak logo are trademarks of Kodak.

© 2023, KODAK. Kodak and the Kodak logo are trademarks of Kodak.

FROM THE EDITORS’ DESK

Dear Readers,

Mr.Charming Cao, entered the machinery industry in 2006 and created the brand LongXingSheng, which today is considered as one of the leading rigid box making machinery manufacturer in China. Since its establishment, LXS has obtained many patents which include 5 practical patents, 4 invention patents, and 5 appearance patents. Besides, all LXS models are developed in-house yet independently. What makes the performance of the LXS Rigid box production line unique is LXS’s commitment to develop and produce stable and interconnected modular production lines. More about the company and its products can be explored in an exclusive interview we had with Mr.Charming Cao during recent Print China.

In another Print China interview, Mr.Tuo speaks about his company, Shengtu, its product range and latest offerings. Shengtu’s ST case making machines are known for speed, stability and durability. Speaking about the machines, Tuo says, “The success of these machines can be guessed by the fact that our ST case making machines have been robustly running at customer facilities for more than 10 years and boast more than 20 million cases produced to date.”

With more than 30 years of continuous research, development and innovation, Degang Machinery (DGM) has become a major supplier in the high-end packaging market with sales in more than 75 countries including Europe, America and Southeast Asia. Besides the China facility, DGM’s automated factory in India is an independent production base aims to strengthen the development layout for the company in the South Asian subcontinent. PRESSideas had an exclusive interview with Mr.Puneet Aggarwal.

MMS has conferred the Lifetime Achievement Award on the veteran printer and industry leader Mr. Anand Limaye of India Printing Works (IPW). Mr. Limaye popularly known as “The Master Book Printer” for his passion and dedication in nurturing and taking the 91 year young legacy of IPW to greater heights. Mr. Limaye is a true visionary and dynamic printer in the industry and is recognized for one of the many qualities he possesses that is clearly TIME MANAGEMENT for which

the industry stalwarts are envious to know the secret that he continues to follow even today.

Another print industry stalwart, Dr. Rajendrakumar Anayath, VC DCRUST has been honoured with Viren Chhabra Print Leadership Award for his exceptional achievements and performances for the growth and welfare of the printing and packaging industry. Mr. Raveendra Joshi, President, AIFMP, presented the award to Mr. Anayath in the presence of the permanent members of the ‘Viren Chhabra Foundation’ and industry leaders in a recent glittering ceremony in Mumbai.

It has been awards galore with 69 distinguished printers receiving NAEP honours. 12 eminent printers received GPEA at the Print Excellence Award ceremony.

Key installations in recent days include Insight Print Communication installing Kodak VERISET at Druck Media, Greater Noida; installations by Monotech Systems – Varanasi’s Kamala Press adding RICOH Pro C7200X; Avocet Scales & Labels of South Africa installing JETSCI YUV Inkjet Imprinting System; and Ajanta Digital World installing RICOH Pro C7200X.

Key new launches this time include CONSISTENT Copier Powder, which is compatible with laser printers of different brands – Canon, Ricoh, Kyocera Mita, Xerox, Konica Minolta, Sharp, and many more. With sharp and high page yield, the 100% printer-friendly Copier powder also provides crisp and extra prints for long last effects and maximum enhancement of work.

Canon has launched imagePROGRAF TC-20M multifunctional machine. Addressing the requirements of remote working professionals, the new multifunctional machine allows them to print, scan and copy large format prints, even without accessing a workstation. DuPont Cyrel Solutions has launched the newest member of the Cyrel Lightning plate family. The new Cyrel Lightning LFH plate delivers quick access times, consistent printing results, and a reduced environmental footprint.

Along with our regulars, don’t miss the article on Xeikon’s toner technology TITON, the food-safe sustainable packaging solution by Dieter Finna.

- Jasvinder Singh, Sub-editor

1/2/5yrs. I am enclosing cheque/draft of

6 April 2023

Subscription Form 1 Year (12 issues) 2 Years (24 issues) (For outstation cheques add Rs. 40/- extra) Rs. 750.00 Rs. 1250.00 5 Years (60 issues) Rs. 3250.00

Anand Limaye receives MMS Lifetime Achievement Award

MMS Round Table Conference & Lifetime Achievement Award 2023.

MMS conferred the Lifetime Achievement Award on the veteran printer and industry leader Mr. Anand Limaye of India Printing Works (IPW). Mr. Limaye popularly known as “The Master Book Printer” for his passion and dedication in nurturing and taking the 91 year young legacy of IPW to greater heights. Mr. Limaye is a true visionary and dynamic printer in the industry and is recognized for one of the many qualities he possesses that is clearly TIME MANAGEMENT for which the industry stalwarts are envious to know the secret that he continues to follow even today.

The Association also organized its marquee Round Table Conference, bringing forward-looking printers and technology providers.

This year, the committee members celebrated the deserving person amongst their own— Mr. Anand Limaye—and delivered the day-long knowledge-sharing event worthy of the stature of the stalwart who initiated it.

Key Notes :

> Celebrating legacy, deliberating on the future of print.

> Informative 90-minute Round Table discussion with loud and clear views put forwarded by the panelists.

> The discussion underlines the importance of database management, especially for effective digital asset management.

The flagship events were held at MCA Club in Bandra-Kurla Complex, Mumbai. In the sixth edition of the MMS Round Table Conference was conducted with over 200 delegates across tables themed around Digital Labels, Print on Demand, MIS and Print Management, Digital Packaging, Corrugation in Design and Packaging, Design Automation, Monocartons by Narrow Web Flexo, and High-Value Digital Short Run.

A peer-to-peer knowledge-sharing platform

The concept of the MMS Round Table is simple: eight thematic tables. Each table comprises one industry expert, one or two print experts, and 8-10 delegates. The group conducts a free-flowing 90-minute discussion on the theme of the table. Later a representative from each table participates in a moderated panel discussion that sums up the

discussions, insights, and critical lessons from each table.

“Digital Packaging table” According to the print expert Mr. Saifee Makasarwala of Silverpoint, the technology allows highly customized & personalized packaging designs catering to brand and customer preferences.

Mr. Sanjay Nagrani of Sanjay Arts, and member of the Digital Packaging table, said, “Thanks, Team MMS, for a wonderful opportunity to explore and get insights into digital packaging. He thanked Mr. Saifee Makasarwala for patiently clarifying all their concerns and doubts during the Round Table discussion.”

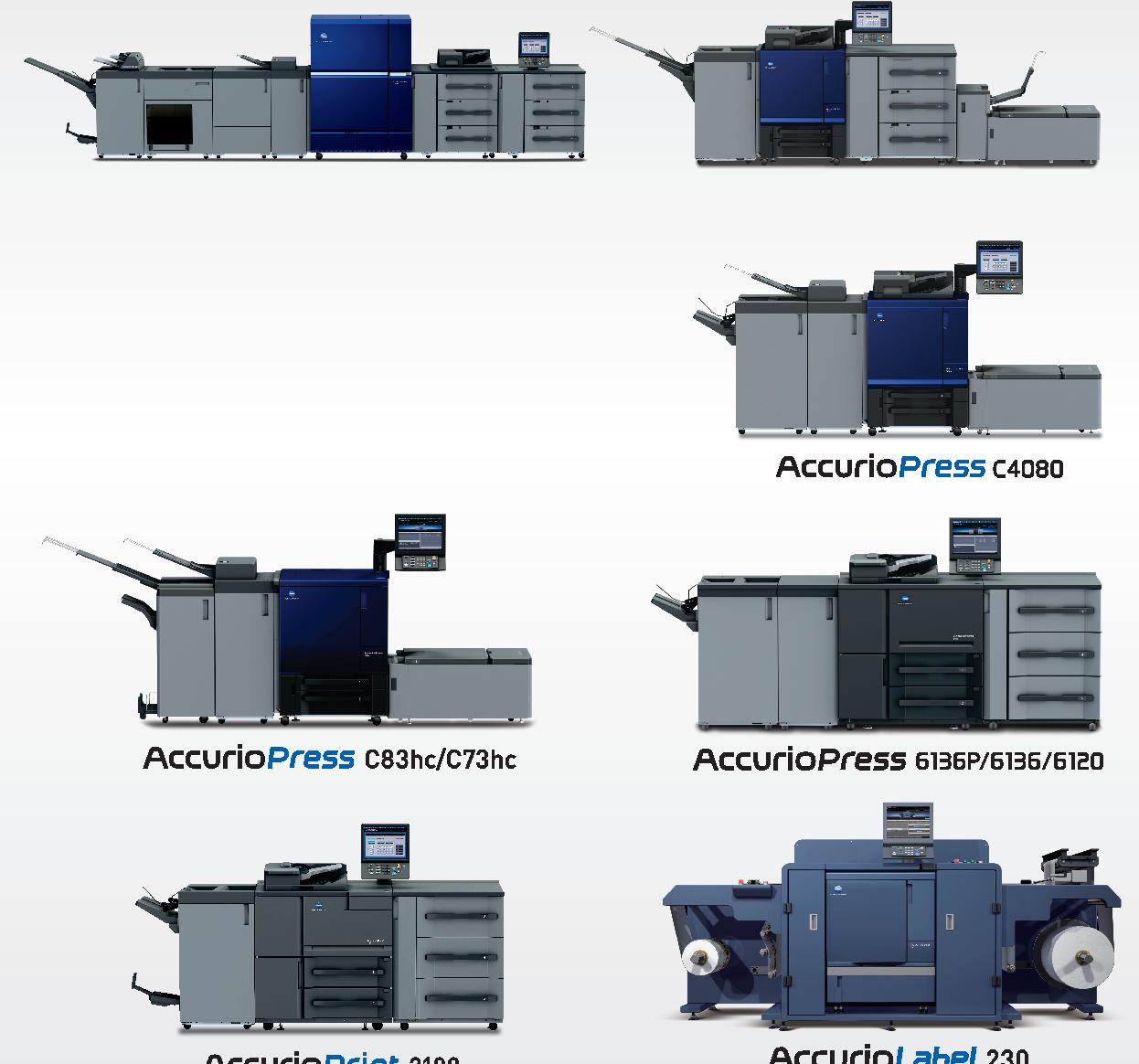

‘Digital Labels’ have witnessed growing demand over the past decade due to shorter turnaround times and the possibility of many value additions. Konica Minolta’s representative on the table highlighted that digital technology enhances cost control by effectively controlling waste and missed registrations. “The only wastage on a digital press is after the initial set-up.

‘Print On Demand’ (POD) has become popular amongst authors and publishers, especially in the growing market of self-published books. However, as Mr. Mehul Desai pointed out, the “POD model

8 April 2023

pressideas/ commercial printing 9 April 2023

cannot work in India. One-book print is still not feasible for most printers. We carry out short runs, for example, 10-20 copies, to deliver it in a few days.” The table delegates unanimously agreed that all the POD business models in India have made the adoption difficult for the conventional bookmakers, while the photocopy and short-run service providers are finding it easy to enter the POD market.

‘Monocartons Narrow Web (Flexo)’ Mr. Nitin Shah of Award Offset Printers and Packaging is a mono-carton packaging specialist, primarily using offset. The industry specialist echoed this dichotomy in the current market. He said, “95% of the narrow-web presses are used for label production in India.” One of the delegates at the table, highlighted the advantage of the flexo presses—printing, embellishments, and die-cutting are all possible in one go.

Mr. Amit Shah of Spectrum Scan, print expert at the ‘Corrugation in Design and Packaging’ table believed in the sustainable growth of corrugation in packaging. Mr. Shah firmly believes that the demand for corrugated boxes in India is primarily driven by their advantages, such as lightweight construction, cost-effectiveness, easy recyclability and versatility of applications

Mr. Sumit Lad, the print expert at the ‘MIS in Print Management’ table, highlighted many benefits for a print company—from efficient inventory and management to operational planning to achieve better resource planning.

Mr. Tushar Bhotica of Shree Arun Packaging Company underlined the significance of choosing the right people to operate and manage MIS. He highlighted a

key point: “Not just data collection and entry, but extracting insights from MIS and implementing changes is the key” to successful and long-term system implementation in any organization.

At the table ‘High-value digital printing’, the industry expert from Fujifilm, Mr. Madhav Bharule, highlighted that digital presses have become more productive and operationally viable with the broader installation base and reducing the cost of consumables & production for the printers. These factors, coupled with the rapidly changing mix of retail and e-commerce, are driving the greater demand for short-run prints.

The print expert Mr. Shailesh Sharma, explained, “It can be variable data printing, customization, quick turnarounds and reduced setup costs. High-value digital printing can be a way to expand their service offerings and meet the changing demands of their customers.”

Mr. Pratik Shah of Corel Insight, the industry expert at the ‘Design Automation’ table found this experience inspiring and humbling, as it reminded him of the power of collective intelligence and the importance of continued learning and growth.”

Mr. Suhas Mulam, the printer expert at the Design Automation Table, highlighted how simple scripts in Corel Draw can make the design process much more efficient. He also highlighted how pre-media, package design, and data management processing could be efficient and effective with design automation interventions.

The 90-minute discussion at the table particularly underlined the importance

of database management, especially for effective digital asset management.

Commenting on the MMS Round Table Conference, President of AIFMP and PPOA Mr. Raveendra Joshi said, “It was well organized, well attended, very informative and inspiring. I congratulate Team MMS for its exemplary work for the benefit of the print fraternity. The 90-minute Round Table discussion was informative, and all the panelists put forward their views very loud and clear.”

The President of MMS opened the MMS Lifetime Achievement Award ceremony. He shared, “Since its inception, this Award ceremony has been held to mark the Printers’ Day Celebrations to honor Johannes Gutenberg, the father of printing. The last four awardees were Mr. Pranav Parikh, Mr. Uday Patel, Mr. Ramesh Kejriwal and Mr. CN Ashok, among many others. Similarly, the distinguished speakers who graced the Award ceremony were Sadhvi Bhagwati Saraswatiji, Mr. Deepak Ghaisas, Padma Shri. Deepak Bhaskar Phatak and Mrs. Anuradha Prabhudesai, among others.”

Senior parliamentarian and former Governor of Uttar Pradesh, Shri Ram Naik, the chief guest of the LTA ceremony, conferred the LTA on Mr. Anand Limaye. He said, “I have known Mr. Limaye for the last 15 years, and he has been instrumental in turning me into a writer.” In his unique style, Shri. Naik shared many stories from his long political career and his association with Mr. Limaye. “My writing began with a column for a Marathi newspaper. And I contributed some articles with two other senior politicians from Maharashtra. People liked my articles, and many years later, upon Mr. Limaye’s perusal, I turned them into a book. That became my first book. Until then, I had only written some press notes and annual work reports for the people I represented and served.”

In his speech, the former Governor of Nagaland, Shri. Padmanabha Acharya, and the guest of honor for the LTA ceremony urged the printers to contribute more to nation-building by publishing more educational and inspiring materials. Mr. Pranav Parikh, Chairman, TechNova Imaging Systems in his message congratulated both Mr. Anand Limaye on receiving the prestigious MMS Lifetime Achievement

pressideas/ commercial printing 10 April 2023

Award and MMS for bestowing this honor on a true champion of our industry.

Mr. Anand Limaye expressed deep gratitude as he delivered the award acceptance speech in Marathi, his mother tongue. He said, “I am overwhelmed with the love and honor. I am deeply grateful.” He told the audience that his company, India Printing Works, established by his father, completed 91 years in business in March this year. “During this period, we have seen many ups and downs and have been able to face those situations with strength. The most important factor for their success is their labour brothers, staff, clients and vendors,” he added.

While speaking at the Award ceremony, Mr. Limaye reminisced, “Starting with treadle and hot metal composing, the printing business has changed with the times today. We are surviving in this business because we have built the latest digital, offset and web printing systems in all three sections pre-press, press and post-press, all under one roof.”

Mr. Limaye added, “It is indisputable that I could do whatever work I did because of the faith shown in me by my former colleagues and their cooperation. I do not consider my work for the printing industry as social work. Because I am also a printing professional, I am also the benefactor of the work. Like the rest of the industry, I enjoyed the fruits of my work. To do real social work, I work with likeminded people, my Rotary Club members or school friends.”

“I am delighted to see the gathering of the family members, friends, members of various printing associations and printing machinery manufacturers, and raw material providers who all love Anand and came specifically to

bless him from different places from across India,” President of AIFMP Mr. Raveendra Joshi said at the ceremony. He shared how Mr. Anand Limaye encouraged, inspired and guided him to do better at the organizational level as a karyakarta. “Mr. Limaye has singlehandedly filed so many writs for our industry that I often say he will soon file a writ against himself in the court,” jokingly said Mr. Joshi as he highlighted the many battles Mr. Limaye had fought for the print industry in Maharashtra and at the national level.

Mr. Ramu Ramanathan, Group Editor of PrintWeek, hosted the LTA ceremony. He engaged the audience at LTA with anecdotes—from books to theatre, actors to printing and publishing and his friendship with Mr. Anand Limaye. Mr. Ramanathan shared stories of Mr. Limaye’s pursuit of perfection, dedication and passion for printing and the significant impact Mr. Limaye has had on his personality.

MMS’ Printers’ Day celebrations came full circle with the Round Table and Lifetime Achievement Award to Mr. Anand Limaye. This year, the committee members celebrated the deserving person amongst their own— Mr. Anand Limaye—and delivered the day-long knowledge-sharing event worthy of the stature of the stalwart who initiated it.

Two students each from GIPT, Mumbai Ms. Aanchal Mehra & Mr. Devang Malhara and from PVG COET, Pune - Mr. Dnyaneshwar Bhor & Mr. Sanmay Jain were felicitated with certificate and a cheque for excelling in their academics with persistent growth as a student and also in curricular and extracurricular activities. The certificate and cheque was presented to the students at the hands of Prof. (Dr) Anjan Kumar Baral,

Former Director, GJUS&T & Prof. Madhurima Mahajan, Head of Printing Dept. Pune Vidyarthi Griha.

worldprinthub.com

MMS’s World Print Hub aims to actively enhance interaction among printers of diverse cultures living in different states of India and printers from across the globe.

• The platform gives access to reach out and share technology-driven information, journals, blogs, important documents and many other options leading to business growth and brand awareness.

• A panel of experts are handy to answer and collectively resolve your business queries.

• Webinar jam is another feature that allows one-to-one knowledge sharing on varied subjects that save your time and money looking for unknown sources. You also can replay and visit the recordings of the training sessions you might have missed out.

• Marketplace is your trading point to acquire new technology in terms of machinery, consumables etc or you can dispose your additional capacity

• Business growth is possible due to networking that is available here in the form of joining or creating groups for focused discussions of your interest. You can create photos and photo albums in groups

• One can directly connect and chat realtime with others similar to your posts on facebook

• Job Board assists you in uploading the CV of the employee you are relieving in the golden handshake scenario and you can also hire trained professionals who have applied for a vacancy.

• Profile integration makes it possible to display your blog posts in your own profile as well

• With admin help you can create polls

Interested members can log into the portal and sign up for the membership. To learn more about how you too can benefit, sign in at www.worldprinthub.com.

The WorldPrintHub.com portal saw almost 2500 registrations during Pamex 2023. The above features were explained to those who registered and they appreciated the services that were offered on MMS’s digital portal.

pressideas/ commercial printing 12 April 2023

Dr. Rajendrakumar Anayath, VC DCRUST awarded VCPLA

Dr Anayath honoured with Viren Chhabra Print Leadership Award for his exceptional achievements and performances for the growth and welfare of the printing and packaging industry.

Col. Comdt. Prof (Dr) Rajendrakumar Anayath, Vice Chancellor at DCRUST, Murthal was awarded the coveted ‘Viren Chhabra Print Leadership Award’ (VCPLA) on 29 March 2023 at Mumbai, for his exceptional achievements and performances for the growth and welfare of the printing and packaging industry. The award was presented by Mr. Raveendra Joshi, President of the All India Federation of Master Printers (AIFMP) in the presence of the permanent members of the ‘Viren Chhabra Foundation’ in a glittering ceremony, in the presence of print leaders of the globe at JW Marriott Mumbai.

Viren Chhabra Print Leadership Award (VCPLA) is the highest honour for a person-in-print, is given to a veteran who has devoted himself/herself consistently to the field of printing for the development and growth of the industry and welfare of the printing community and have achieved something exceptional substantive during his/her work-span. The award is instituted by the AIFMP in the name of veteran stalwart of printing industry of India and the ‘Ambassador of Indian Printing Industry to the World’ - Viren Chhabra. He was the founder editor of Printing Times, man behind 5th World Print Congress and the 1st South Asia Print Congress (SAPC) at New Delhi. The peer of Graphic Arts Technical Foundation (GATF) also remained the president of AIFMP, Mr. Chhabra worked for the promotion of printing industry without any selfish goals.

Speaking about the concept and reasons for VCPLA, Prof. Kamal Chopra, convener

of VCPLA forum said, Printing is mother of all revolution and is the greatest invention of mankind till date. Several technicians fine-tuned this art to use it according to the changing times. No effort was made to honour to honour the technicians responsible for revolution of printing in India and to remember the contributions of the masters of this great art. Such recognition is necessary to perpetuate the spirit of doing something unique for the growth of the trade and industry. Because, in the absence of bestowing due honour to the deserving, the society is taken over by unscrupulous elements. The award carries a Citation, Shawl, Memento and Cheque of Rs. One Lakh together with the biodata and Photo of Mr. Viren Chhabra.

Dr Anayath attained the distinction of being a true doctor, a professor of the Indian printing industry, as well as a torchbearer for the print worldwide. His drive for excellence, pursuit of scientific advancements, and faith in technology have emanated new energy and confidence that the print community has been able to seize and capitalise on. His words of wisdom provided many people with fresh perspectives, served as a warning to those who resisted change, and motivated countless printing students to continue working on this industry with commitment. He elevated the stature of print technology by gliding into the top echelons of academic leadership, at the highest levels of government with ease.

Accepting the award, Dr Anayath urged the printers to keep eyes and hearts open to the future and to feet on the ground. He

expressed his thanks to the AIFMP leaders, members of the forum constituted, and judges to be the first winner of the VCPLA. He said, “From the Independence Day to till today, during the past 75 years, India attracted 950 Billion USD of FDI and you know, it is interesting to note that out of that 532 Billion USD hascome in the last 90 Months. What a wonderful time!The next revolution in the Indian Print &Packagingindustry would be in Agriculture, Food products, Mobile & Allied Equipment and Pharma.” He suggested five important points to the printers for becoming successful &responsible Printer.

• Environmental Impact of Raw Materials and Processes: Incorporate reused materials andcircularity potential at the design phase itself.

• Sustainability Through Circular Economy: Have a serious concern on the end life of all products you print. Design to minimise energy use, emissions, consumables, and product failure.

• Societal Responsibilities: Health, Safety and Welfare of all stake holders of print industry.Use data to develop service innovations. Maximise ease of recycling and recycled value of components.

• Values, Ethics and Legal Compliances: It is not an option anymore, but mandatory for the future due to transparency in everything you do and the deep global awareness on nature and systems.

• Handling Technology: There are much more better ways to do it with the help of digitalisation. 3D Printing, Big Data, AI, ML, AR, VR, METAVERSE, Cloud Computing are going to make everything fast, simple, and precise including ultimate accuracy in decision making.

pressideas/ commercial printing 13 April 2023

69 distinguished printers receive NAEP honours

12 eminent printers receive GPEA at the Print Excellence Award ceremony.

During a glittering ceremony at JW Marriott Mumbai, National Awards for Excellence in Printing (15th NAEP) were presented to 69 distinguished printers of India. During the same Print Excellence Award Ceremony Global Print Excellence Awards (GPEA-2023) were also conferred to 12 eminent printers. The top winner in both the competitions remained JAK Printer from Mumbai.

Organized by the All India Federation of Master Printers, NAEP is the biggest and most recognised awards for the printing sector. AIFMP has been the torchbearer of the Printing Industry in India since decades. They have been doing a great service to millions of printing and packaging stakeholders in the country – Let it be Entrepreneurs, Employees, or anyone associated with this industry. Receiving recognition for their talent, hasn’t been easy for the printers, majorly due to Government of India’s (GoI) halt in giving the National Awards for Excellence in Printing (NAEP) in 1985. AIFMP took the challenge and started

bestowing NAEP from 1999 from the little resources available with them.

In all 69 Gold, 66 Silver, 59 certificates of merit and 9 Special jury awards were distributed to the winner of 15th NAEP 2023.The major winners of this year were: National Star Printer of the year 2023: JAK Printers, Mumbai; Best Printer of the year 2023 (supported by DRUPA): Pragati Offset, Hyderabad; Best Packaging Printer of the year 2023: Parksons Packaging, Mumbai; Best Digital Printer of the year 2023 (supported by BINDWEL): Avantika Printers, New Delhi and Best Screen Printer of the year 2023: DRS Arts Company Ahmedabad.

Speaking on the occasion, Prof. Kamal Mohan Chopra, organising secretary said, the 15th edition of coveted print awards was conducted under the guidance and control of its Chairman, Padmashree Vijay Kumar Chopra, Former President of AIFMP. Combining the NAEP and GPEA, we have received 1833 entries from 162 printers. For

NAEP, region wise 71 printers from the North, 29 from the West, 26 from the South and 4 from the East took part in this competition. Taking into consideration the number of entries, the maximum entries, 596 were received from the North followed by 459 from the West, 323 from the South and 64 from the East. Talking city wise, New Delhi with 211 entries remained at top, followed with Mumbai (160), Ahmedabad (157), Kolkata (64) and Hyderabad (57) and so on.

“Karigari” was, once again, the theme of 15th NAEP 2023, because, printing though a centuries old technique, is considered a mechanical, almost robotic, process or reproducing ideas on paper. It is, however, much more than merely pressing buttons on sophisticated printing machines. It is an art comparable to the weaving of rich brocade, the painting on exquisite canvasses, the sculpting of rock. A printer is, therefore, nothing less than an artist, and only the exceptionally skilled one can produce some brilliant examples of print. This Karigiri needs

pressideas/ commercial printing 14 April 2023

to be dignified with recognition, and it is the mission of AIFMP, I believe, Mr. Chopra added.

In his report Mr. Chopra mentioned that to widen the peripheral of awards an international competition was also arranged alongside the NAEP for the first time ever. Global Print Excellence Awards (GPEA) were introduced to recognize excellence in printing world over. Though GPEA just made its debut, I am glad to mention that the message was taken earnestly and all the leading trade magazines from around the globe covered it in their print and online editions. For this first edition of GPEA we received 391 entries of 32 printers from 6 countries. 241 entries were received from India, 160 from Sri Lanka, 6 each from Bangladesh and Bhutan, 4 from UAE and one from Indonesia.

In Global Print Excellence Awards (GPEA 2023) 24 Gold, 20 Silver, 18 Certificates of Merit and 5 special jury awards were conferred during the magnificent 29th March evening at Mumbai.The prominent winners in Global

competition remained: Best of GPEA 2023 and Best Offset Printed Products: JAK Printers, India; Best Digital Printed Products: Printcare PLC, Sri Lanka; Best Screen-Printed Products: Archana Advertising, India; Best Flexography Products: Kumar Labels, India.

For the very first-time judging was streamed live to be viewed throughout the globe. Special software was prepared, and technical tools were provided to facilitate the judging. To get the unbiased decision even the judges were not allowed to discuss each other on any entry. The judges touched each entry we received, and they evaluated it individually as per their opinion.

Judging was conducted at the committee room of OPA at Ludhiana, special white lighting was arranged so that constant and same light must be maintained throughout the timings of the judging. For true and unbiased evaluation judges were intimated to evaluate each sample individually taking in view the factors like i) Aesthetic and visual

appeal ii) Colour rendering, image def and appearance iii) Quality print iv) Registration

v) Finishing vi) Use of technology and media

vii) Degree of difficulty and creativity and viii) Innovations.

Based on evaluation of the judges 5 top entries were selected as nominated entries and these were put on display at the ‘Hall of Fame’ on 27, 28, 29 and 30 March during PAMEX 2023 at hall no 3. The award gallery was unique and was appreciated by one and all.The Print Excellence Award Ceremony held at JW Marriott (Sahar) Mumbai remained a roaring success, for the first time to entertain the audience a mind reader and magician was invited to show his talent. It is again for the first time ever that eminent printers and top award winners in the past were invited to give away the awards to the winners, so that they may get inspired to adopt their footprints. Prominent exhibitors of PAMEX 2023 were also invited for the purpose so that they all must feel involved in the award ceremony.

pressideas/ commercial printing 15 April 2023

DPA holds AGM of 2023

The Annual General Meeting of Delhi Printers’ Association was held at Harkishan Singh Surjeet Bhawan on April 15, 2023.

At the Annual General Meeting of Delhi Printers’ Association held at on April 15, 2023, former President Mr. Sunil Jain welcomed the members. President Mr. Atul Goel, Hon. General Secretary Mr Prakash Dass and Treasurer Mr Puneet Talwar took the seats on the dais. In his welcome address Mr. Atul Goel who got elected as President for the year 2022-2023 highlighted the main activities including, celebration of Azadi Ka Amrit Mahotsav, organization of seminar on GST, and celebration of Printers’ Day.

Mr. Prakash Dass read out his Annual Report for the outgoing year. Mr. Puneet Talwar presented the Statement of Annual Accounts for the year 2021-2022. The Returning Officer Mr. Mukesh Kaushik read out names of the unanimously elected new team for 2023-2024 and invited them to assemble at the dais for a group photograph. The new team were individually introduced briefly and felicitated with garlands by the outgoing Office Bearers and senior former Presidents.

The outgoing President for 2022-2023 Mr. Atul Goel was honoured with a memento and a shawl by former Presidents in recognition of his exemplary stewardship, farsighted vision and for raising the benchmark of remarkable

achievements for the printing fraternity.

Later on, a memento was given to Mr. Uma Maheshwar Rao, Sr. Manager - Tech Sales & Mktg., of Chemline Adhesives and Coatings in gratitude of their support to the AGM. Mr. Rao promised to work out an economic package for DPA members.

Sr. former President Mr. Arun Berry congratulated the new team for 2023-2024. He praised the role of DPA as an important platform to reach out to various Government departments for resolution of different issues, such as NCERT print jobs, affecting the printing fraternity. The meeting ended with high tea.

pressideas/ commercial printing 16 April 2023

Kodak appoints Print & Finishing Solutions as new Channel Partner

PFS to distribute Kodak’s complete current range of products and system solutions for the printing industry.

Kodak has expanded its Channel Partner network with the latest appointment of Print & Finishing Solutions (PFS) as its new reseller. To under the agreement, PFS will distribute Kodak’s complete current range of products and system solutions for the printing industry throughout its sales territory. As a KODAK Channel Partner, PFS will sell KODAK PROSPER Inkjet Presses and Imprinting Systems, KODAK PRINERGY Workflow Software Solutions, KODAK Offset CTP Systems and KODAK Printing Plates.

Established in 2000 and headquartered in Placentia, California, PFS has grown to a team of nearly 40 employees and today is one of the largest independent distributors of commercial printing equipment in the western United States. The company covers 18 states with its sales and service activities

and operates out of 4 facilities for increasing its regional proximity to a growing customer base. A “Business Partner in Print and Finishing”, PFS offers a comprehensive product portfolio that includes offset presses, digital printing systems, wide format printing solutions, a wide range of post-press and finishing equipment as well as consumables.

“This new distribution partnership with Kodak provides an ideal complement and extension to our existing range of products. The KODAK PROSPER Presses enable us to expand our digital offering with high-volume production printing solutions that are on par with traditional offset in terms of quality and productivity. We are excited to have the opportunity to offer high-speed continuous inkjet to clients that are ready to move up from toner-based systems or that need to reduce labor costs and increase capacity in their offset operations without compromising on quality,”said Christian Stauss, CEO, Print & Finishing Solutions. Kian Hemmen, Western Regional Sales Manager RMGT, Print & Finishing Solutions, added: “Furthermore,

KODAK PRINERGY Workflow automation software fills a gap in our existing offering, and of course, KODAK CTPs and plates are a perfect fit for our offset press business as we must meet our customers’ desire to be a one-stop shop for all their needs.”

“We are delighted to welcome Print& Finishing Solutions as a new KODAK Channel Partner. PFS has 23 years of expertise as a trusted sales and service organization focused on the printing and graphic arts industries. With its professional consulting approach, PFS is ideally positioned to help printers benefit from the capabilities and advantages of Kodak’s innovative solutions,” commented Jeff Zellmer, VP Sales & Strategy, Kodak.

Consistent launches Copier Powder for major printer brands across India

100% printer-friendly Copier Powder is crisp and ideal for offices and homes.

Consistent Infosystems has launched CONSISTENT Copier Powder. Available in Moisture Free Pouch, the powder is compatible with laser printers of different brands that include Canon, Ricoh, Kyocera Mita, Xerox, Konica Minolta, Sharp, and many more. With sharp and high page yield, the 100% printer-friendly Copier powder also provides crisp and extra prints for long last effects and maximum enhancement of work.

Founded by Nitin Bansal and Yogesh Agarwal in 2011, Consistent is a key player in the Security, Surveillance Networking and Print consumables domain.

Highlighting the ideation of the CONSISTENT Copier Powder, Mr. Yogesh Agarwal, CEO and Co-founder of CONSISTENT Infosystems said, “We are delighted to launch our Copier Powder and since it is just an ideal product for offices and homeowners, we are sure it

will aid them in their productivity. Additionally, it is a very cost-effective ink solution. We are looking forward to it being used by everyone!”

Recently, Consistent Infosystems participated in 30th Convergence India Expo 2023 held from 27th to 29th March 2023 at Pragati Maidan, Delhi.

The newly launched copier powders can be purchased through all Consistent branches. Price list:

• Royal Magic (1Kg) – INR 1,850

• XEROX Premium Powder (1Kg) – INR 1,950

• Magic Canon Universation (1Kg) – INR 1,550

• Richo Aficio (1Kg) – INR 1,950

• SHARP Powder (1Kg) – INR 2,250

• Super Magic Canon Copier (1Kg) – INR 2,050

Consistent has grown successfully over the years and has increased its footprint across all major states in India. Today the company has 20+ branches, a portfolio of 275+ products, 55+ Service centers and more than 3500+ channel partners PAN India ensuring quality service to customers.

pressideas/ commercial printing 17 April 2023

• Konica Minolta (1Kg) – INR 2,050

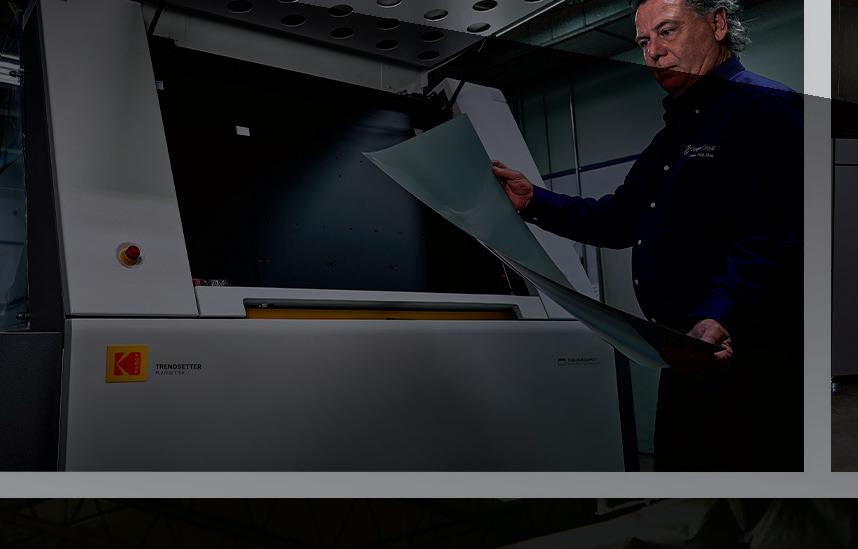

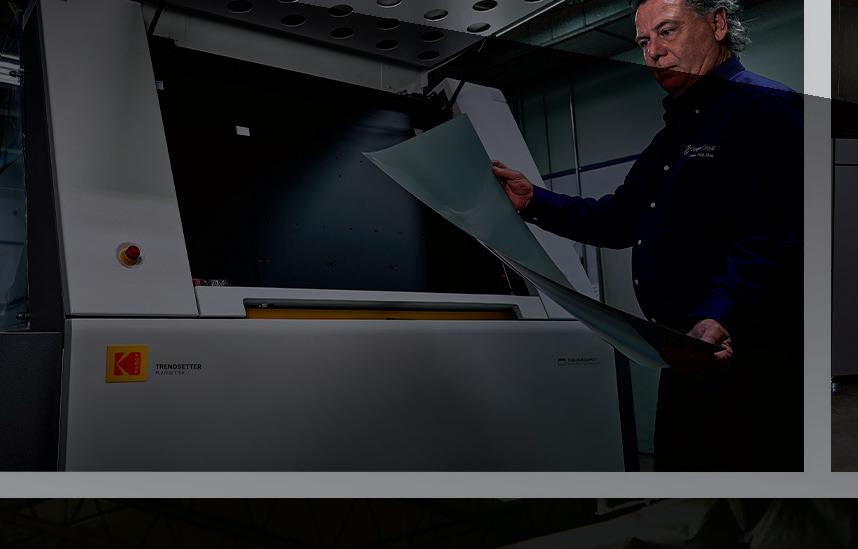

Insight Print Communications installs Kodak VERISET at Druck Media

“The combination of Kodak’s technology and excellent service support backed by Insight was the driving factor of our purchase.” - Achal Aggarwal, Druck Media

“After thorough research and analysis, we chose Kodak, and we couldn’t be happier with our decision. Their thermal technology is second to none, and the CTPs they manufacture are top-of-the-line, providing us with the precision and accuracy we need to produce flawless prints,” says Achal Aggarwal Founder & Director of Druck Media, commenting on their recent Kodak VERISET installation.

With its advanced capabilities, Kodak’s VERISET Platesetter ensures superior tonal stability and exposure uniformity, resulting in outstanding print quality and exceptional consistency across every job. Kodak’s proprietary light valve imaging technology achieves unparalleled precision and accuracy in dot placement.

Greater Noida based Druck Media is one of the largest providers of commercial Printing, Binding, and Prepress services in India with FSC COC, ISO 9001, 14001 & 45001 certifications. Their state-of-the-art manufacturing plant is spread across 20,000 sqm to cater to worldwide customers with massive print and post print capacities. Founded in 2008 Druck Media has 120 employee’s strengths. Incorporated as HT Burda Media Ltd. was a joint venture between BurdaDruck GmbH and Hindustan Times Media Ltd. In 2013 BurdaDruck GmbH became the sole owner of the company

and company name was changed to BurdaDruckIndia Pvt Ltd. which was later renamed to Druck Media in 2021.

The VERISET Platesetter is an open CTP system that accommodates a wide range of thermal plates, providing users with the flexibility to choose the most suitable option for their specific needs. Furthermore, this innovative Lens Contamination Avoidance (LCA) technology enables compatibility with low to medium debris-generating plates, thereby reducing plate costs while eliminating the need for an expensive debris removal system. The LCA technology incorporates an active air curtain and a removable, easy-toclean window, which effectively keeps debris away from the imaging laser, guaranteeing optimal performance.

VERISET Platesetter is the perfect solution for businesses that demand reliable and high-quality plate making and with smaller footprints. This is ideal for businesses of all sizes, including those with limited space. VERISET Platesetter delivers impressive results, with the capacity to produce up to 22 8-page plates per hour. This outstanding performance is made possible by TH5 thermal head, which offers exceptional robustness and reliability, ensuring you can depend on it for every job.

“At Druck Media, We believe in providing

our customers with the best quality, and we knew that investing in low-budget, low-quality machines would not meet our standards hence Kodak CTP was the only suitable solution,” adds Achal Aggarwal.

Ajay Aggarwal MD & CEO at Insight says, “We’re dedicated to providing innovative solutions that empower our customers to achieve their goals in a sustainable way. We promote Veriset CTP bundled with Sonora process-free plates to reduce environmental footprints for companies that are committed to green printing solutions like Druck Media.”

Furthermore, VERISET comes with an innovative cooling system that not only guarantees optimal performance but also results in significant energy savings. With power consumption reduced to only 380 watts while imaging, this platesetter offers savings of up to 95% compared to some competitor CTP devices.

“We have a very good experience with the installation and service team. The Kodak team is very reachable and helped us not only with the installation but making our team comfortable in operating the machine efficiently. The combination of Kodak’s technology and excellent service support backed by Insight was the driving factor of our purchase,” states Achal Aggarwal commending Insight’s service support.

18 April 2023

TeamInsightwithDruckMediaandnewlyinstalledKodakVeriset

Key message from Digital Media India 2023: Collaborate to innovate, prioritise audience

Now in its 12th year, Digital Media India took place in-person in New Delhi from 16 to 17 March, with more than 140 news media executives from over 35 organisations taking part.

WAN-IFRA’s Digital Media India (DMI) conference, back in its physical form, was held in New Delhi on 16 and 17 March. It also featured the South Asian Digital Media Awards 2022 ceremony, with The Quint bagging the Champion Publisher Award.

The goal of the conference this year was to expand on discussions related to various modern business, editorial, and digital issues. The theme of the event was “Drivers of digital revenue and technology,” and featured a program aimed at facilitating learning and networking opportunities.

The two-day conference kicked off with a keynote address by Lucio Mesquita (Senior Consultant, Innovation Media Consulting Group, United Kingdom), who shared the findings of the “Innovation in News Media –World Report 2023.”

“News publishers worldwide have come out of the tough pandemic years with renewed optimism and healthy digital gains despite the ongoing geopolitical challenges. Innovation is a key common thread for their success. Above all, news brands that are doing well are investing in and focusing on developing content worth paying for as, in the end, only journalism can save journalism,” said Mesquita.

Day 1 of the conference featured sessions on sustainability, subscription insights and trends, digital revenue, and artificial intelligence, a trending top for publishers globally.

Bharat Gupta, CEO, of Jagran New Media, kicked off the first panel discussion on digital priorities and diversified business strategies by listing out three things he is optimistic about the future of digital publishing in India.

“With over 650 million users, India is the second largest internet population, and that’s only 55 per cent of the penetration rate. Second, the ad to GDP ratio is only about 0.7 per cent, instilling confidence about monetisation. Third, India is the youngest country globally,” said Gupta. “More than 60 per cent of the population is under 35 years of age. Consumption patterns are changing and all these three things put together spell out great opportunities for publishers.”

The panel also comprised LV Navaneeth (CEO, The Hindu Group), Mariam Mammen Mathew (CEO, Manorama Online), and was chaired by Ritu Kapur (Co-Founder and CEO, The Quint).

“Indian publishers have traditionally been good with content and journalism. We are going back to basics both in terms of the product and the business model, and this is what 2023 is going to be about,” said Mathew.

“Healthy digital news business is 40 per cent reader revenue, and The Hindu is 50 per cent currently. In the next 2-3 years, I expect that to grow to 60-65 per cent while advertising continues to grow,” said LV Navaneeth. “There will be a time in the next 3-5 years where digital revenues may not grow enough to offset the organic decline in the print business if that were to happen, but the growth will be enough to be more profitable.”

The day closed with the presentation of

the South Asian Digital Media Awards 2022 (SDMA). From new approaches to digital subscriptions to impactful native advertising campaigns, the awards presented projects that inspire us all.

This edition of the SDMA, which recognises and lauds publishers in South Asia, recorded more than 100 entries, and The Quint, The Hindu, Prothom Alo, and Indian Express emerged as the winners. The Quint also bagged the overall ‘Champion Publisher’ Award.

Day 2 of the conference saw sessions on short-form video, retaining GenZ news subscribers, more subscription success stories, and data in journalism.

“The media today is seeing a shift towards synthetic media, driven by artificial intelligence and mixed reality – AR/VR, Deep Fakes, NLP and interactive media. We have to be careful how this will disrupt our news industry. Don’t be afraid to experiment, and make sure to keep an eye on the future so that we can take part in leading the disruption, rather than being disrupted,” Kaythaya Maw, Chief Technology Officer, SPH Media said, addressing the concluding session of the conference on future technologies that can sustain the diverse, trusted, and vibrant publishing ecosystem audience demand, virtually from Singapore.

Quintype, Chartbeat and ConsCent sponsored the conference. It was supported by gxpress.net, Indian Printer and Publisher and RIND Survey.

The complete details of the programme are available at https://wan-ifra.org/events/ dmi2023/?pagetype=programme

More information from the conference can be found on Twitter with the hashtag #DMI2023. For a calendar of upcoming WAN-IFRA events, please visit events.wan-ifra.org. (by NEHA

GUPTA – WAN-IFRA)

pressideas/ newspaper 19 April 2023

WinnersoftheSouthAsianDigitalMediaAwards2022gatherfora groupphotographafterthepresentation.

Promising versatility like never before

Canon India launches All-In-One A1 size desktop Multi-Function Printer.

and multifunctional machine allows them to print, scan and copy large format prints, even without accessing a workstation. It is an all-in-one product that seamlessly fits into tight spaces to cater to the large-format printing industry’s versatile output requirements. We are confident that this revolutionary product will build upon the TC-20 series’ legacy and set new standards in the industry.”

Create a Variety of Output Applications Without a PC

Addressing the requirements of remote working professionals, the new multifunctional machine allows them to print, scan and copy large format prints, even without accessing a workstation.

Key Notes :

> Canon imagePROGRAF

TC-20M – offering allin-one print, scan and copy capabilities.

> Applications across industries – architects, retail, food and beverages, schools or travel agencies.

> Allows users to print and scan directly with a USB memory stick without accessing a workstation.

Canon has announced the launch of imagePROGRAF TC-20M, a compact 4-colour pigment ink all-in-one large format printer in India. Fitted with an A4 flatbed scanner, the printer allows users to seamlessly make copies from cut sheets and roll papers. Designed to provide optimal productivity, the versatile printer is ideal for remote worksites, small offices and retail outlets.

Equipping users with enhanced capabilities, with this new printer, A4 documents can be easily enlarged and copied. It is specially suited for printing educational material, official notices and promotional posters for retail outlets and restaurants and also enables remote site offices to smoothly create largeformat prints and copies of engineering drawings.

Sharing his thoughts on the launch, Mr. Manabu Yamazaki, President and CEO, Canon India, said, “We are committed to advancing productivity and creativity with cutting-edge technology at Canon India and continuously strive to develop specialized products that cater to modern needs. Driven by our pursuit of innovation, we are proud to add the imagePROGRAF TC-20M to our expansive printer portfolio. Addressing the requirements of remote working professionals, the new space-efficient

TC-20M can easily enlarge copies of A4 documents to A3 cut sheets, A2 or A1 roll papers and even to the full width of roll paper. Portrait or landscape orientation of the output copies can be selected from the user panel easily. ‘Repeated copy’ feature enables an original document to be copied and printed repeatedly using roll paper. This can be used for various applications such as wrapping paper or retail stores banners. By using ‘Enlargement copy’ function, A4 handheld leaflets and handwritten manuscripts can be scaled to large size posters to be used in travel agencies or food and beverage outlets. With the flatbed scanner, thick booklets or brochures can be converted to hard or soft copies for distributions. Apart from copy function, TC-20M supports JPEG & PDF file format for direct printing and scanning with USB memory stick without having to access a workstation.

Space-saving To Meet Users’ Needs

Similar to TC-20, TC-20M fits easily in tight spaces to meet various printing needs for remote worksites, small offices and retail outlets. With the front access of the printer, all daily print-related operations such as loading of paper, refilling of ink, and replacing of maintenance cartridge can be performed conveniently. The printer supports roll paper of up to

digital printing 20 April 2023

A1 plus width and is equipped with standard auto sheet feeder that can load A3 or A4 cut sheets, hence making copies, scanning and printing can all be done on one machine.

Designed to Be Productive and Environmentally Friendly

For increased productivity, TC-20M is equipped with 70ml ink bottles for four colours (cyan, magenta, yellow & black) for continuous printing, which is useful for

CAD drawings and posters printing. Every colourinklet on the printer is designed uniquely to prevent incorrect loading of ink bottles. With the large ink tank capacity system, it reduces time and effort when it comes to ink refilling. Vibrant red colour can be produced in lines and texts commonly used in technical drawings, graphics and flyers. Large format prints and long banners can be collected and held with optional desktop basket .

TC-20M achieves low power consumption of less than 26W during operation and 1.9W during standby. With high environmental performance, the TC-20M has been registered as a gold product under U.S. environmental assessment system EPEAT .

Customise Prints with PosterArtist Web V1.1

With the upgraded PosterArtist V1.1 web application, eye-catching posters can be designed and printed with TC-20M to cater to various needs. Users can choose from an expanded range of new and trendy design templates to create their own flyers, food menus and marketing collaterals to meet business needs or customise calendars and photo collages for personal use. With the variable printing function, users can customise text data through an excel sheet, which would be useful for printing certificates in A4 or A3 sizes, as well as posters for various purpose, up to A1 size on the TC20M.

Monotech installs RICOH Pro C7200X at Kamala Press

Varanasi’s Kamala Press switches to RICOH for enhanced digital prints.

Installation of a new RICOH Pro C7200X has accelerated the overall competency of Varanasi-based Kamala Press to another level. Their new RICOH digital production press is engineered to print and produce gamut of outstanding graphic prints making it a highly versatile new-generation production press. The press has been supplied and installed by Monotech Systems.

Established in the year 1990, Kamala Press has been a trusted name in the commercial printing market of Varanasi, serving a host of clients from the Holy City as well as many other parts of eastern Uttar Pradesh. The company boasts a production facility equipped with arrays of pre-press, press and post-press machines and equipments.

“In addition to offset printing, we have been quite active on the digital short-run front as well,” says Mr. Anjani Kumar Singh, Founder & Managing Director of Kamala Press.

Mr. Singh adds, “Our recent investment in the RICOH Pro C7200X has intensified our capability to produce enhanced graphics for our customers who particularly come for high-gloss photos, corporate brochures and such other items.” He further mentions that they help enhancing corporate image and branding of some elite corporate companies in Varanasi and around, using the advanced features of the newly installed RICOH digital press, which delivers premium-quality prints on SBS and high-GSM substrates.

Prior to the purchase of RICOH Pro C7200X from Monotech Systems, Kamala Press used to run a Konica Minolta bizhub PRESS C8000 for the digital short-run photos and other commercial print applications. In this respect, Mr. Singh comments, “We deliberately choose RICOH for its advanced features, high production speed, unique print quality,

and media versatility over any other digital press available in its class.”

This new RICOH Pro C7200X running currently at the production facility of Kamala Press is a Graphic Arts Edition, which has advanced features such as ‘fifth toner station’ for print beyond the usual CMYK. It gives the option to print metallic, neon, clear, white and security colours.

Kamala Press serves its customers from graphic design all the way through to final print and production of finished items. “We usually offer products such as brochures, catalogues, posters, leaflets, folders, wobblers, newsletters, menu cards, greeting cards, calendars, corporate stationery, utility boxes & envelopes. In addition, we progressively function in the post-press, engaging in cutting, folding, stitching, adhesive binding, die cutting, thermal laminating, UV coating, etc,” tells Mr. Singh.

“As we constantly upgrade our facility with the latest machines and technologies to meet the new demands for quality prints from our customers, so is our recent installation of the RICOH Pro C7200X,” says Mr. Singh, adding that they look forward to further strengthening tie with Monotech Systems for more valuefor-money machines and all-time satisfied after-sales service.

pressideas/ digital 21 April 2023

Digital printing scores with heat-sealable, foodsafe barrier paper based packaging

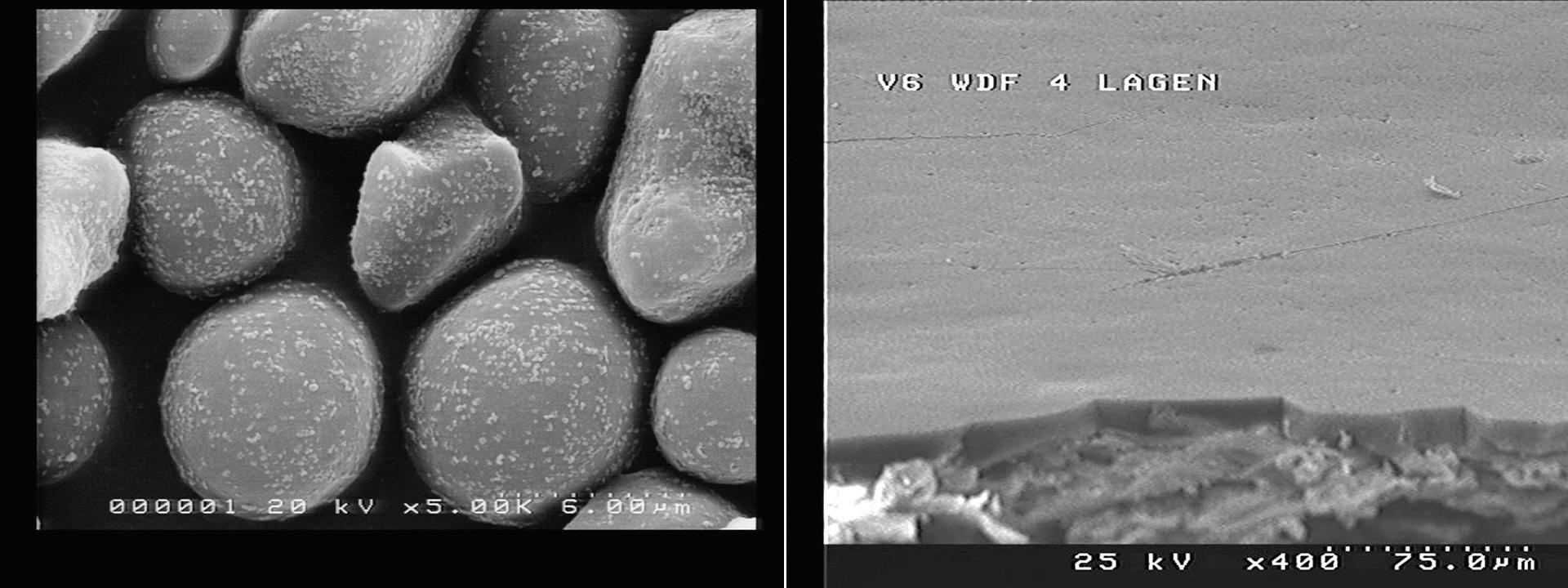

Dieter Finna writes about Xeikon’s toner technology TITON, the food-safe sustainable packaging solution.

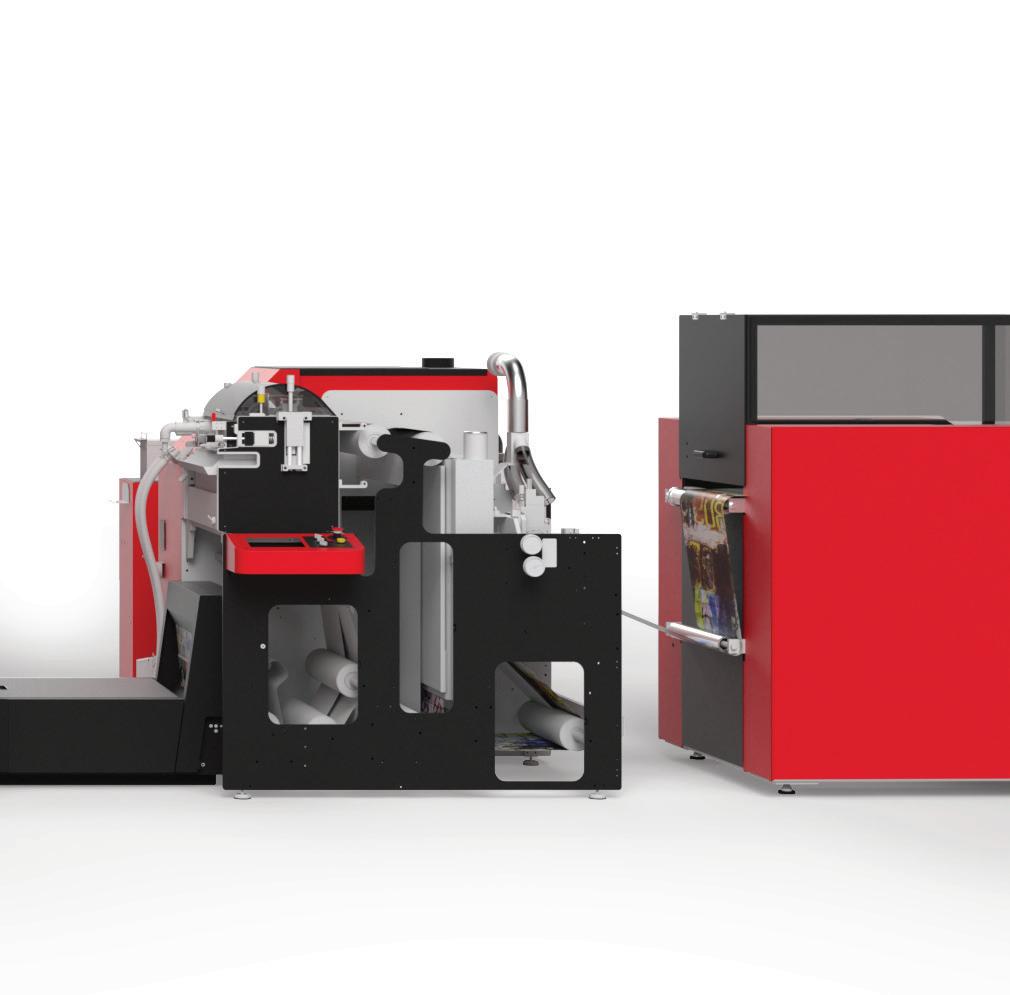

While food-safe and at the same time sustainable flexible packaging solutions have not previously been one of the strengths of digital printing, the toner technology of Xeikon TITON has brought progress in this area of application. Barrier papers printed with dry toner offer flexible packaging solutions that open up new opportunities. Exactly at the right time because pressure on the industry to offer such solutions in digital printing is on the rise.

Digital printing with TITON toner is a foodsafe technology.The barrier papers made from renewable resources stand for the sustainability of the packaging solution. In this combination, there is a broad potential for their further development in flexible packaging.

Key Notes :

> Pressure on the industry to offer sustainable food safe packaging solutions in digital printing is on the rise.

> Food-safe sustainable flexible packaging solutions have not previously been one of the strengths of digital printing.

> However, Xeikon TITON dry toner technology.

The packaging industry faces the enormous challenge of redesigning its packaging solutions for a circular economy. An inventory published by Systemic in April 2022 shows that in 2020 only around 19% of the packaging volume in Europe was mechanically recycled. One reason for this low recycling rate lies in the large number of composite materials in use, consisting of aluminium and plastic multi-layer laminates. These composite films can only be separated into usable fractions with great effort and are therefore usually thermally recycled. This is one of the reasons why the most common method of disposing of plastic packaging materials in Europe is energy recovery (incineration). In second place is disposal in landfill and only in third place is material recycling. The latter is undoubtedly propagated by

all those involved as the most meaningful solution, keeping the carbon cycle going and continuing to use the currently available carbon without adding new fossil carbon or converting it to CO2.

In order to change this situation and make recycling easier, a rethink in packaging development is required. One approach for a circular solution is the use of monofilm laminates or monofilm made of oriented polyethylene (MDOPE), on which, depending on the design, a barrier white and an oxygen barrier varnish are applied in reverse or frontal printing. With this structure, remarkable oxygen transmission rate (OTR) values can be achieved for oxygen

22 April 2023

impermeability, which already covers a wide range of requirements for various fatty foods.

However, packaging solutions made of fibre-based materials are also on the rise in flexible packaging and are being given new tasks, and not just because of their high recycling rate or because they are made from renewable resources. The current portfolio of heat-sealable barrier papers is constantly being expanded by all the well-known speciality paper manufacturers, both for food and non-food applications. It now covers numerous product protection requirements in terms of water vapor, oxygen and fat barriers as well as puncture resistance. In combination with such barrier papers, dry toner-based digital printing is gaining in importance.

Packaging printing with TITON dry toner technology

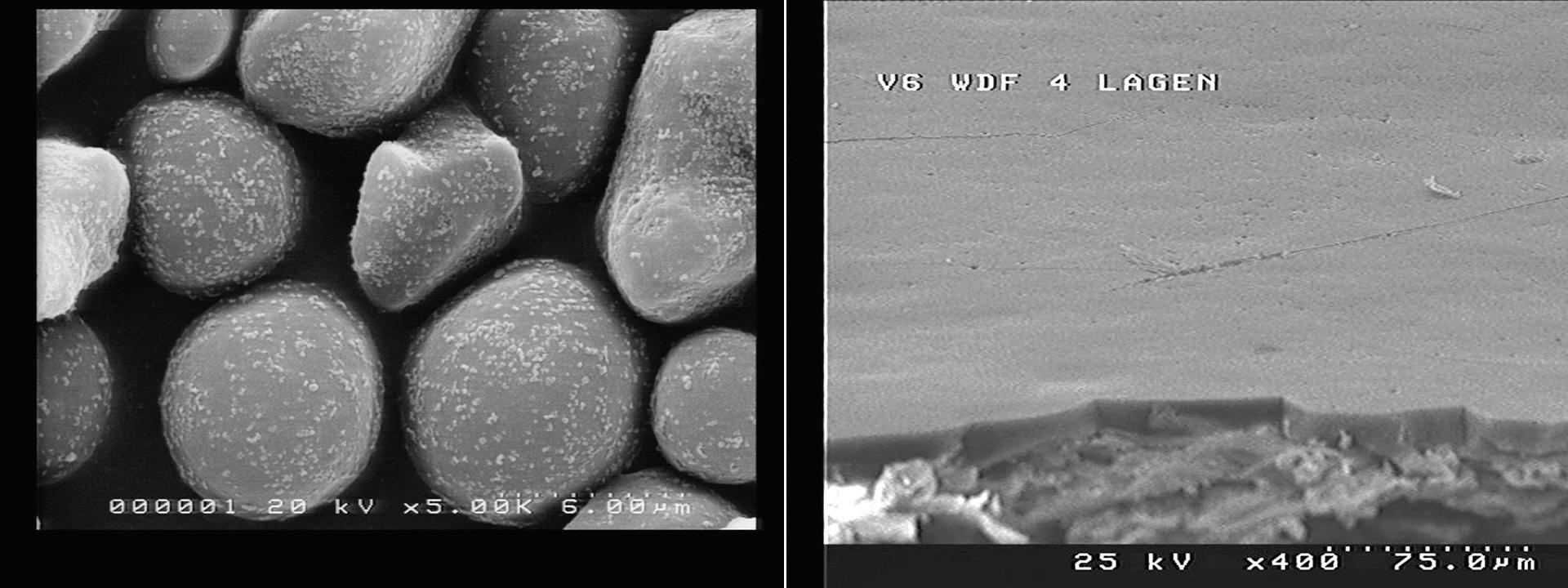

The fact that digital printing with dry toner printing presses can be used for flexible packaging is due to the further development of dry toner technology. Xeikon introduced it to the market under the name “TITON”. Compared to conventional dry toner types, barrier papers that are printed with it have the necessary seal resistance when the printed packaging is closed in the filling machines.

The seal resistance achieved in this way opens up the use of dry toner in flexible packaging. And this is where this toner process can demonstrate a general strength over other digital ink systems – its food safety properties as well as its non-melting

and image quality on paper. While liquid toner, water-based inkjet or UV-inkjet have significant limitations in their compatibility with these kinds of applications, there is also a very low risk of food migration due to the specific composition of TITON toners based on the very high molecular weights of the ingredients used.

TITON Dry Toner

The Xeikon Titon toner consists of crosslinkable polymers, pigments, charge control agents and other additives. In contrast to conventional dry toners, the TITON toner molecules can be cross-linked with an extra LED curing step resulting in very high molecular weights. As a consequence of the curing step the TITON toner becomes resistant to mechanical and thermal stresses, giving the toner the necessary properties for use in flexible packaging.

After the imaging process in the printing press, the powder image is transferred to the substrate and the particles are then fixed to the substrate using a temperature of approximately 110°C. The toner particles melt and coagulate to form a homogeneous film with a thickness of up to 4 µm per toner layer. In addition, the Xeikon CX500t digital printing press is equipped with an LED curing unit. The LED radiation initiates the cross-linking process of the toner polymers. Eventually all the TITON toner polymers are then cross-linked to form a matrix with unique properties. Since the molecular weight of the toner layer and the matrix structure in which the components are embedded are the decisive factors for migration behaviour, the components in the polyester layer are practically immobile. For this reason, the migration risk of the dry toner is extremely low. This is unique in digital packaging printing, especially since the solid layer is completely odourless and also prior to printing, completely solid and safe to handle.

Additional Features of TITON Toner

The cured, cross-linked polymers in the toner layer not only make it heat-resistant when sealing a package. They also give it its mechanical properties in terms of scratch and abrasion resistance, as well as chemical resistance. In addition, this dry toner has a high light-fastness due to the choice of pigments. When looking at the printed packaging, one notices the velvety sheen of the solids resulting from the closed toner surface, which means that no decorative overcoating is required.

Application in Flexible Packaging

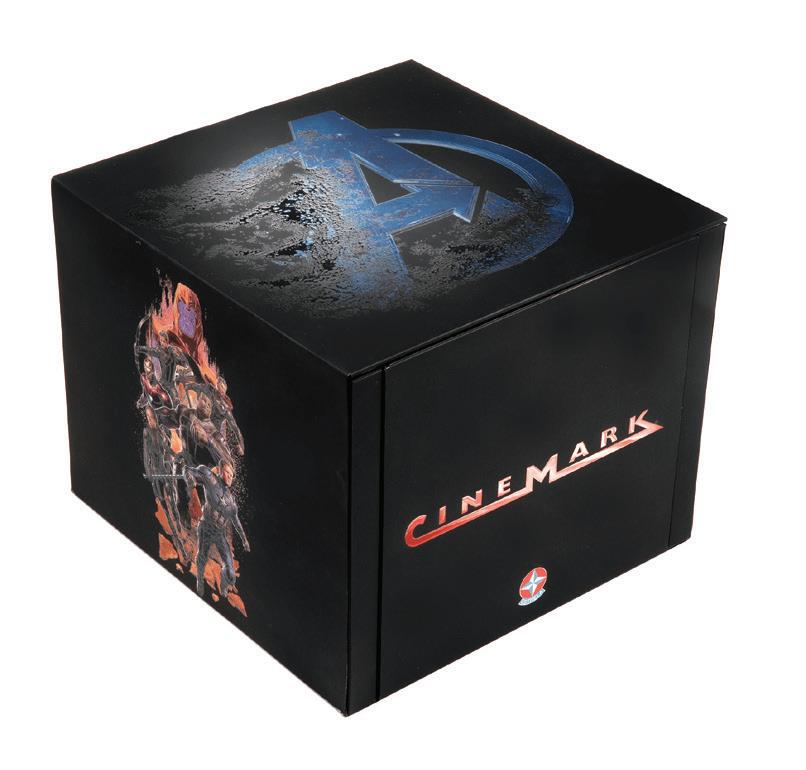

With the increasing use of barrier papers in flexible packaging, the possible applications of digitally printed packaging with dry toner are also growing. The pasta manufacturer Bschüssig in Frauenfeld was the first manufacturer in Switzerland to switch its 33 different pasta packages to barrier paper. For their recently added green packaging line, they preferred digital printing as it was ideal for the initial production at launch. The packaging was printed with TITON toner on kraft paper, without overprint varnish. The fact that the packaging in this design cannot be stored in a damp environment is not an issue for Bschüssig customers. In return, they can dispose of the packaging through the normal waste paper stream after use.

For packaging printer ACM in Cremosano, Italy, the reason for printing packaging digitally is its run length. The company is geared toward the production of short-run pouches. ACM is one of the first to use a Xeikon CX500t press for this purpose. The company’s key selling points for the dry toner printed paper pouches are that they are food safe and sustainable.

Both are criteria that are required more than ever in flexible packaging. Packaging solutions that meet these criteria cover today’s requirements. In digital printing with TITON toner, it is the food-safe technology due to the absence of any liquid, low molecular weight (mobile) substances. And the barrier papers made from renewable resources stand for the sustainability of the packaging solution. In this combination, there is a broad potential for their further development in flexible packaging.

pressideas/ plc 23 April 2023

IPAMA launches IntraPac India

An exclusive Packaging Exhibition to meet the demand of the Packaging Machine Manufacturers and the Companies dealing in Allied Products.

On 24th April 2023, Indian Printing Packaging & Allied Machinery Manufacturers’ Association (IPAMA) launched “IntraPac India” Exhibition. The bookings of IntraPac India have started. IPAMA promises it to be a complete solution for Packaging Industry Companies. Heads of different Associations, IPAMA Governing Council Members & Staff and Distinguished Media Personnel were present at the launch.

After years of organizing the largest fair in the country biennially on graphic arts industry, “PRINTPACK INDIA”, the Indian Printing Packaging & Allied Machinery Manufacturers’ Association (IPAMA) has now decided to organize an exclusive Packaging Exhibition to meet the long outstanding demand of the Packaging Machine Manufacturers and the Companies dealing in Allied Products.

IPAMA, since its inception in the year 1988, has been promoting Printing and Packaging industry at different platforms, including organizing of PRINTPACK INDIA biennially which is the most prominent exhibition of Printing Industry in India. IPAMA has also been providing necessary inputs relating to the industry to various Government organisations, including the Ministry of Heavy Industry, Bureau of Indian Standards, CII, FICCI, PHD, EEPC etc. IPAMA is also working in tandem with other Associations/ Federations for redressing the grievances of the Industry and its Member companies.

The last edition of PRINTPACK INDIA Exhibition was organised at India Expo Centre, Greater Noida from May 26-30, 2022, on a net area of 25,342 Square Meters in which 487 Indian and foreign Companies had participated. It was visited by a record number of 1,03,412 business visitors. The space charges were kept at the minimum level so that the MSME Units could participate with ease and in an effective manner with minimal financial constraints.

IPAMA, being an Association of both Printing and Packaging Machine Manufacturers and also responsible to support the industry by providing a unique platform so that

the maximum number of companies can participate and promote themselves at a very affordable rate, the Governing Council of IPAMA had decided to create such a platform in the form of IntraPac India, exclusively for the Packaging Industry, on the pattern of PRINTPACK INDIA Exhibition. The packaging sector has a much wider exposure in comparison to other sectors of our economy. India is a developing country, and the people are now aware about food hygiene, living standards, health consciousness along with adoption of next gen digital technologies.

IntraPac India will be organised at IICC, Dwarka, New Delhi from 14 – 16 March 2024. The profile of the Exhibition includes all packaging solutions, machinery, and allied products inclusive of plastic packaging, metal packaging, glass packaging, paper packaging, filling, capping, filling & sealing, biodegradable packaging, protective packaging, automation and robotics, tube packaging, mono cartons, die-casting, traceability & tracking, logistics, film, moulding, and many more relating to Packaging Industry. Initially the space charges will be kept between Rs.9,000/to Rs.10,000/- per Square Meter. For subsequent editions, these will be reviewed and kept at the minimum level so that more and more MSME Units could participate in the Exhibition. IPAMA is also in the process

of forming an Advisory Committee to rope in important industry players who can guide and give their valuable contribution in implementing the project. Some of the important and prominent industry players have already been approached for this. Within a couple of months, the Advisory Committee will be in position to support.

While announcing the dates and the venue of IntraPac India, Mr. Rakesh Sodhi, President, IPAMA said that “The Packaging Sector in India is the 5th largest in its economy and one of the highest growing Sectors in the country. We are making endeavours to promote this sector at different platforms so that the industry can get further momentum. We are also making efforts to increase the exports of packaging machinery and related products to different destinations in the global market. We are happy to say that the industry has successfully come out of the grip of COVID-19. With the legacy of PRINTPACK INDIA, IPAMA will be able to serve the Packaging Industry in a better way.

pressideas/ plc 24 April 2023

Labelexpo

Europe 2023 registration opens

Latest equipment, masterclasses, special events on automation and flexible packaging, world premiers and cutting edge technology showcase.

Tarsus Group, organizer of the Labelexpo Global Series, has announced the opening of registration for Labelexpo Europe 2023. The show takes place between 11-14 September at Brussels Expo.

This will be the first Labelexpo show in Europe since 2019. Along with demonstrations of the latest printing and converting equipment there will be masterclasses and special events focused on Automation and Flexible Packaging.

Tickets to the show cost Euro 95, with an early registration rate of Euro 75 until 25th August at 18.00 CET.

New equipment to be seen at Labelexpo Europe includes the world premiere of the

HP Indigo 200K press, the Xeikon CX500t Titon toner press and the Screen Truepress PAC520P water-based packaging press.

Commented Jade Grace, portfolio director of Labelexpo Global Series, “We are delighted to be running Labelexpo Europe again, and can promise visitors an extraordinary show across nine halls. We will see an explosion of cutting-edge technology launched at the show, everything from pre-press to materials, and digital and conventional print and converting technology. Add to this a world-leading series of educational events and our focus on Automation and Flexible Packaging for label converters and you have an unmissable Labelexpo experience.”

Andy Thomas-Emans, strategic director

New LFH Plate extends DuPont Lightning platform

at Labelexpo Global Series, added, “We are already seeing key technology themes emerging at Labelexpo Europe 2023. Diversification across labels and flexible packaging technologies, digital embellishment, workflow and machine automation, real-time data collection over the Cloud and sustainability across multiple fronts from LED-UV to more new materials and adhesives choices. This will be a landmark show for the future direction of our industry.”

DuPont launches the UV-LED optimized photopolymer for thermal processing at the FTA Forum & INFOFLEX 2023.

unique stability of LED exposure with the quick, easy and solvent-free platemaking of Cyrel FAST helps our customers produce high-end printing plates quickly and efficiently,” explains Tucker Norton, Global Business Leader, DuPont Cyrel Solutions.

DuPont Cyrel Solutions has launched the newest member of the Cyrel Lightning plate family at the FTA Forum & INFOFLEX 2023. The new Cyrel Lightning LFH plate delivers quick access times, consistent printing results, and a reduced environmental footprint.

The Cyrel Lightning LFH plate was built on the technology of the award-winning Cyrel Lightning plates, which received the FTA Technical Innovation Award in 2022. “This new plate is optimized for the latest UV-LED exposure technology, such as the Esko XPS Crystal, and was designed for the sustainable thermal Cyrel FAST process. Combining the

The new plate allows for the use of the latest screening technologies for enhanced print quality, making it ideal for tradeshops and converters seeking to produce high-quality plates. The workflow is simple to use and results in outstanding prints.

“We are confident that converters that are thinking about running platemaking operations in-house as well as other flexographic plate providers will appreciate the ease of use and the high quality printforms that this workflow provides. Combining UV-LED exposure and thermal Cyrel FAST processing offers repeatable and sustainable platemaking combined with a small operational footprint,” adds Norton.

In conclusion, Cyrel Lightning LFH offers a

quick, sustainable, and efficient solution to significant platemaking challenges. The new Cyrel Lightning LFH is available in 1.14 mm and 1.7mm (0.045’’ and 0.067’’) thicknesses.

“We are proud to keep innovating for our customers for improved print quality and productivity using our sustainable Cyrel FAST process. The Forum and INFOFLEX show provide a great opportunity to meet people, learn and share experiences, explore new technologies, and find innovative solutions. As a long-time sponsor of this show, DuPont values the contribution of these events to the flexography industry, which is aligned with our commitment to developing innovative solutions for our customers to thrive”, concludes Norton.

pressideas/ plc 25 April 2023

Monotech installs JETSCI YUV system in South Africa

Avocet Scales & Labels, a South African-owned company installed JETSCI YUV Inkjet Imprinting System.

Avocet Scales & Labels, Uwe Bögl, Neeraj Thappa, JETSCI Global, packwise-africa, Monotech Systems, JETSCI YUV system,

Neeraj Thappa, Vice President of Sales at JETSCI Global, expressed gratitude to Mr. Uwe Bögl, Director of packwise-africa, for placing his trust in JETSCI, a global brand of Monotech Systems, and helping them penetrate the South African market. He announced that this is the first global installation of JETSCI in the international market for this year, and there are other installations in the pipeline. Thappa added that the JETSCI YUV system is a tested and validated solution for variable data printing, and can be easily integrated into existing web offset, flexo machines, slitters, rewinders, and more. Thappa also mentioned that as the system has just been installed, Avocet expects it to meet their business needs by

allowing for inspection and customization of finished products.

“Avocet Scales & Labels conducted thorough research to find a solution for printing variable data on labels with high speed and quality, and the JETSCI YUV system was identified as one of the most viable solutions due to its exceptional productivity and print quality,” said Uwe Bögl, Director of packwiseafrica.

Bögl further added that the JETSCI YUV system is versatile and can be modified to work with various conventional printing systems, making it suitable for a wide range of applications. JETSCI Global offers customization options for bespoke applications, including fully integrated inkjet systems and standalone printing technology. (L—>R:Mr.UweBögl,TeamAvocetScales&Labels,andMr.NeerajThappa)

pressideas/ plc 26 April 2023

Nestlé Certifies Scodix PS850 Polymer for Compliance with Packaging Inks

Accreditation makes the Scodix Ultra 6000 digital embellishment press even more compelling for packaging producers.

After extensive testing, the Scodix Polymer PolySense850 (PS850) has been certified to be in compliance with Nestlé’s Guidance Note on Packaging Inks. Suitable for indirect food contact, PS850 is the latest Scodix polymer to be released, for exclusive use with the Scodix Ultra 6000 system. The polymer is suitable for embellishments including Scodix High Definition, Scodix Sense, Scodix Metallic, Scodix Foil, Scodix VDE and Scodix Cast&Cure, taking brands to new, heightened levels of impact for their food packaging.

As the largest publicly held food company in the world, Nestlé is committed to delivering its food products in safe packaging materials and, in turn, maintains strict and stringent testing of all vendor components in the supply chain. Achieving Nestlé compliance means that Scodix Polymer PS850 has passed migration tests for secondary