FROM THE EDITORS’ DESK 6

Highest Industry Honour for Harveer Sahni 8

Building Bridges to Japan........................................................................................................................................................................................................... 12

Global print and packaging sector banks on drupa 2024 14

Provin Technos installs RMGT at Multivista Global 16

PAMEX 2023 – to be Bigger, Better and Busier 17

Epson relaunches SurePress range in India 18

Polyart showcases extended portfolio 19

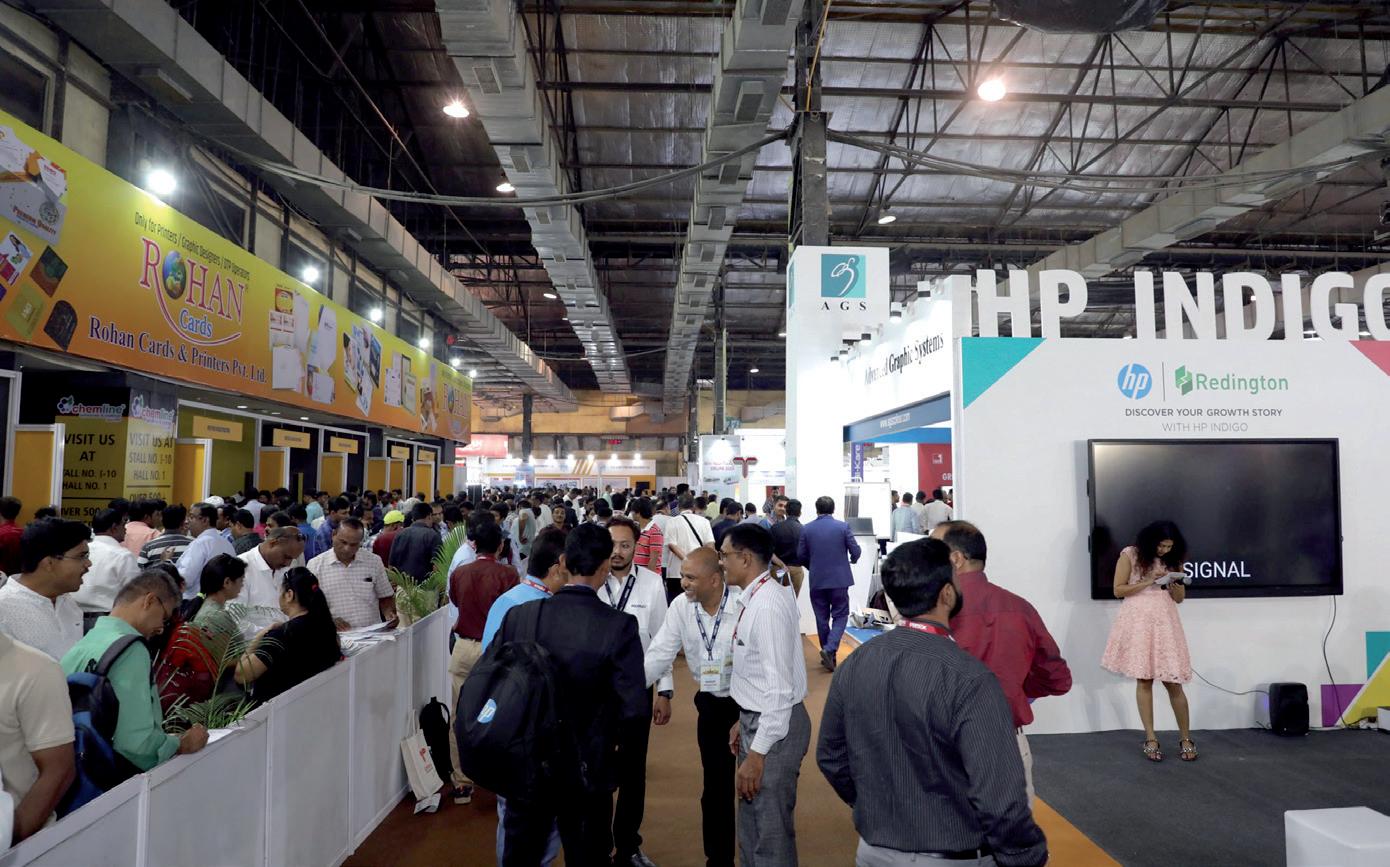

Labelexpo India 2022 showcases technology by 250 exhibitors 20

Monotech Systems scores the first ColorAQUA Hybrid sale within hours of show opening 23

New partnerships for academi a. at Labelexpo 24

Newgen Printronics has a great Labelexpo 24

The 8th Global Trends Report is a Must-Have! 25

Live demo by AL230 digital press from Konica Minolta 26

Lombardi: United we can make the difference 26

Multitec debuts new press features 27

Optashield by Holostik offers high security features 27

UFlex’s holographic solutions at Labelexpo 28

Esko showcases benefits of plate room automation and inline print inspection ................................................................................................. 28

GEW emphasizes UV LED models 29

UV Graphics grows with Vetaphone 30

Dow unveils new coating 30

UV Graphic Technologies partners Domino 31

Cosmo First quarterly financial results 31

MM Graphics Digital Press invests in AccurioPrint C4065 32

Ludhiana’s Foil Printers upgrades with RICOH Pro C5310S 33

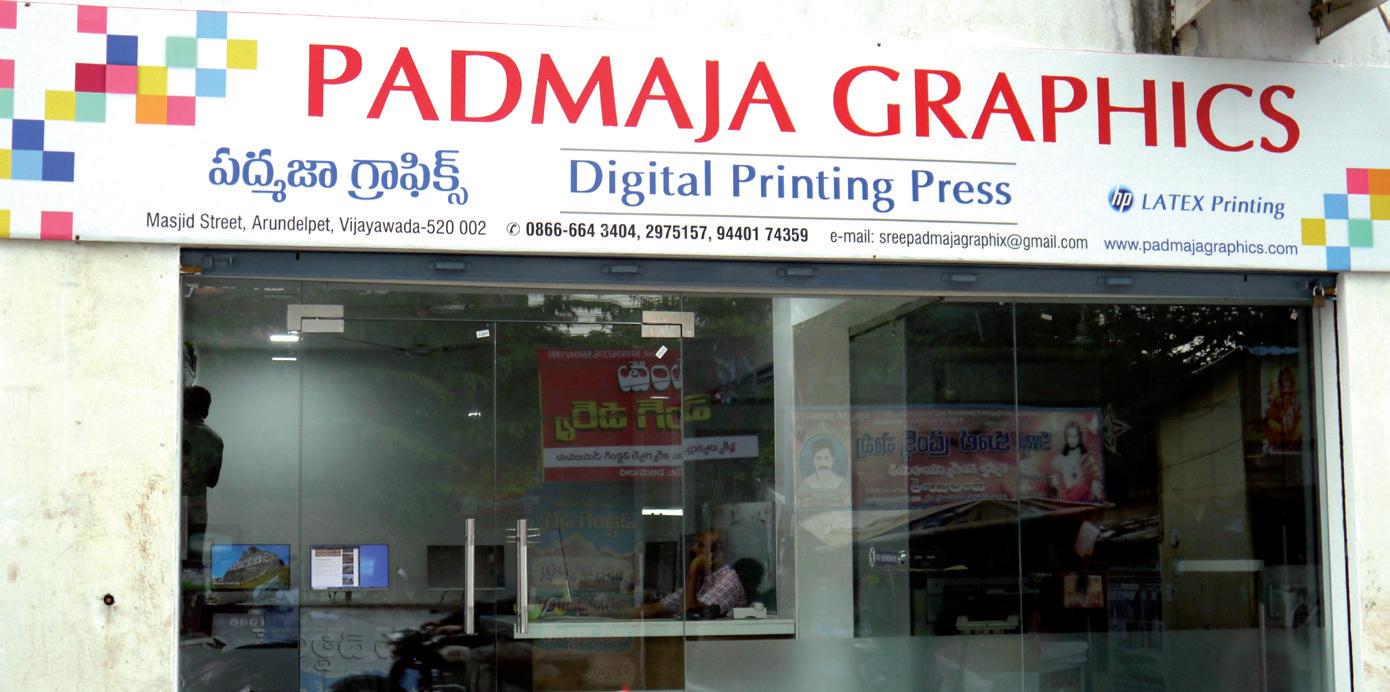

Padmaja Graphics goes for Canon imagePRESSC10010VP Print Quality 34

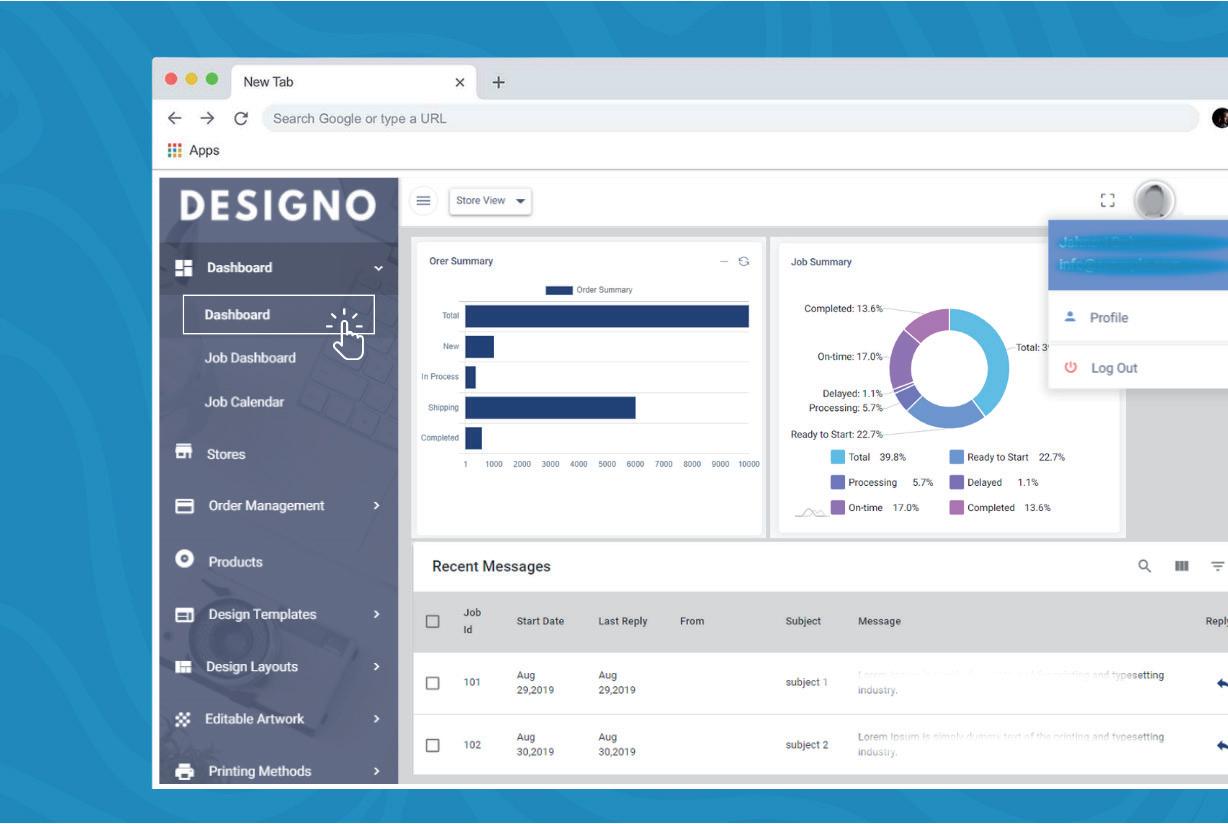

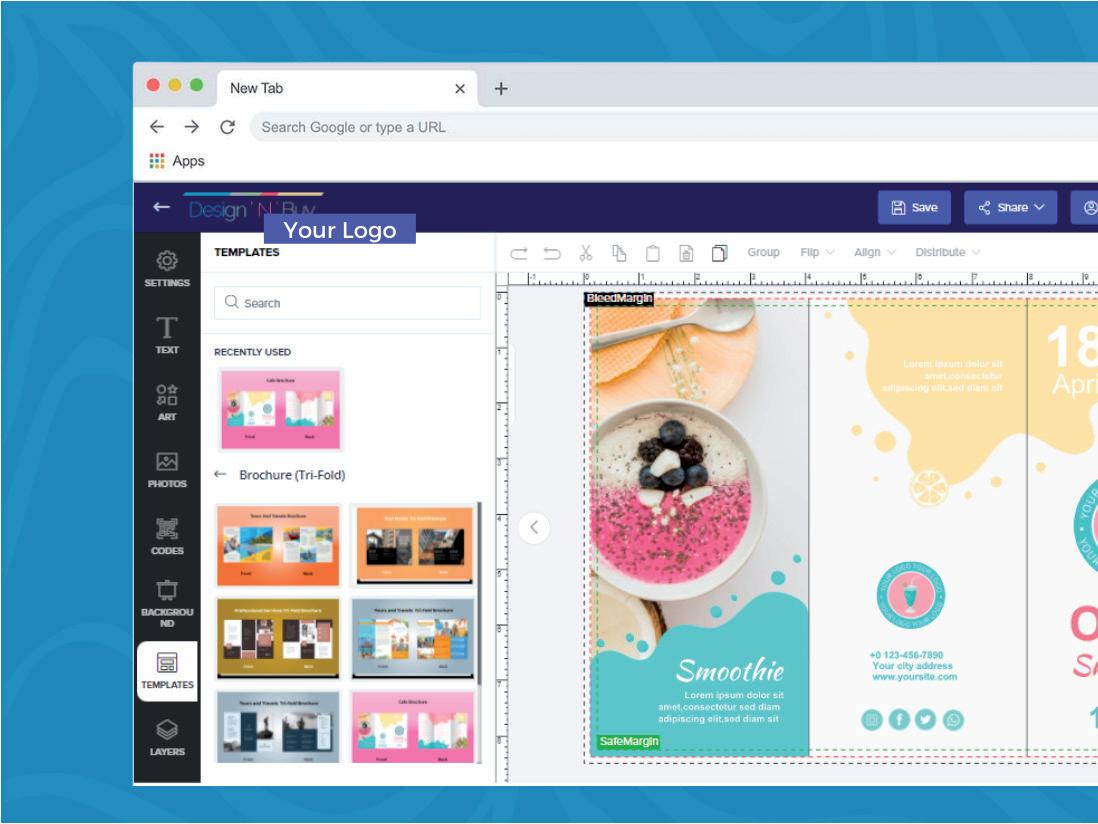

The DesignO Plugin makes its way to OpenCart 35

BOBST celebrates eight decades of success for its folder-gluers 36

Vinsak installs second Lombardi at Mudrika 38

Labelexpo Asia postponed until 2023 38

Print quality, productivity and waste reduction with Baldwin’s Guardian OLP for Kumar Labels 39

Esko releases latest software version 22.11 40

SOMA releases next-generation of Venus Slitters 41 HP displays Jet Fusion and Metal Jet capabilities .............................................................................................................................................................. 42

HP Latex: disruptive fleet graphic technology making advertisement on wheel more effective 44

Sun Up buys HP Latex 3600 from Insight 45

Jasmeet D. Editor & Publisher (jasmeet@pressideas.com)

Vineet K G. Associate Editor (vineetkg@pressideas.com)

Jasvinder S. Sub-Editor (jasvinder@pressideas.com)

Jacob George Marketing and Sales (jacob@pressideas.com)

M.S. Mukundan Advertising and Sales Southern and Western India (aims@pressideas.com)

Graphic Designer Anil Kumar Networking/ Hardware Consultant Sukhdeep Singh

USA Correspondents Tensi M., Preeti

European Correspondent Rimi, Yadhu Morphine

Production Thomas K Alex

PRESSIdeas November 2022 Vol. 22, Issue 11 Printed by Jacob George and published by Jasmeet Singh on behalf of PRESSIdeas Publishing Pvt Ltd. Printed in India at Hues and Colors 363, Industrial Focal Point, Phase-IX Mohali, and published at PRESSIdeas, 437-A 1st Floor, Industrial Area, Phase-2 Chandigarh-160002 (India)

Every effort has been made to ensure that credits accurately comply with information supplied. All material supplied is compiled from sources believed to be reliable or solely an opinion of the authors. PRESSIdeas is not responsible for any steps taken based on the information provided herewith.

R.Stanton Avery Global Achievement Award is international label industry’s most coveted award. Indian Label Industry veteran Harveer Sahni is the first Indian to achieve the highest honour. We cruised along him as he shares his exciting journey from inheriting a family stationery business to innumerable milestones that marked innovations to accolades. He is one of the most recognized faces of Indian Printing and Labels industry and is equally revered wherever he goes, be it his own exploit or as an industry representative. He has been associated with the Indian version of industry’s premier exhibition from the first day. In our cover story this time we have Mr.Harveer Sahni sharing his personal bits with our readers.

With 900 exhibitors from 45 countries already on board and 100,000 sqm of exhibition space already booked, drupa remains the favourite among top technology providers just as it remains among the inquisitive customers and users. Forums like the drupa cube, drupe next age, the exhibition area for Newcomers, Startups, Young Talents, touchpoint ‘packaging’, touchpoint ‘textile’ and the touchpoint ‘sustainability’, all provide highly relevant and valuable insights into tomorrow’s high-potential themes at the event. With around 75% international attendance on the exhibitor side, drupa occupies an outstanding position by global standards. A showcase of innovations, technology trends, product portfolios and global launches will take place from 28 May to 7 June 2024 in Düsseldorf.

The recently concluded Labelexpo India 2022 showcased technology by 250 exhibitors with more than 40 new exhibitors showcasing on the 2022 edition showfloor. This year’s Labelexpo India show had more new technology than ever before and proved an unmissable opportunity to experience the latest launches from leading industry names including Avery Dennison, BST, GEW, HP, Konica Minolta, Bobst, DuPont, Esko, Miraclon, Monotech Systems, Lucky Graphics, Popli Graphics and more. Find a detailed review in the inside pages.

There have been numerous sales reported from Labelexpo showfloor. Apart from them, the industry is abuzz with quite an encouraging atmosphere as regards technology investment. Provin Technos has installed an RMGT 8-colour perfector press at Multivista Global. It is Multivista’s second RMGT. MM Graphic Digital Press has invested in an AccurioPrint C4065 from Konica Minolta stable. The firm chose the press for its reliability, robustness, colour consistency and after-sales support. Ludhiana’s Foil Printers has upgraded with a new RICOH Pro C5310S. Padmaja Graphics has gone for Canon imagePRESSC10010VP. Vinsak has installed second Lombardi at Mudrika Labels. Kumar Labels has opted for a Baldwin Guardian OLP. Bhopal based Sun Up Autopack has added ‘Print Faster’ capability to its ‘Print Smarter’ motto with the latest HP Latex technology.

There is a lot more in this issue of PRESSIdeas. Just go through the inside pages and enjoy reading.

- Jasvinder Singh, Sub-editor

1/2/5yrs. I am enclosing cheque/draft of

Each story we create, or for that matter, each press release that you share with us, not only goes on our popular website but also is shared on all above Social Media pages of PRESSIdeas.

Your social media content is the embodiment of your brand and each social network brings in it's own set of challenges. Well, we take of several factors that go into producing and publishing social media content.

We can help you not only in Content Creation - where and how to Start with but once created, to schedule them on the Social Media and then optimizing it to attain the expected success is also our job. Last but not the least, analyzing the results of the Social Media Campaign too shall be shared with you.

If you’re looking to get started, allow us to walk you through it. Allow us to hand hold you all along.

Write to digital@pressideas.com or WhatsApp on +91 9780036854 to know more!

Note: Our online editorial team holds the right to decide on the selection of posts to be included on our social media pages. The FREE offer is for a period of 45 days. It is advisable to have only a post in a week.

We can be of help!

R.Stanton Avery Global Achievement Award is the top international Label Industry recognition and Harveer is the first Indian stalwart to achieve the feat. He speaks in detail with PRESSIdeas about his eventful journey and the latest achievement.

Harveer has been instrumental in the establishment of Labelexpo in India – in 2001 he helped his friend Anil Arora establish the India Label Show, which later in 2007 got purchased by the Tarsus Group and got its new name, Labelexpo India.

> Harveer Sahni, Weldon Celloplast receives Avery supported top honour, awarded to either an individual or team.

> The award recognizes an innovation or idea that has helped transform and progress the label industry across the world.

> Among other criteria, Harveer acting as an influential ambassador on the world stage, helped the judging panel to come to their decision.

Label Industry veteran, Mr. Harveer Sahni who built his Weldon Celloplast Ltd. with his own hands and has remained an inspiration for generations of label producers and printers who ever knew him. A jovial personality, as we all know him, has remained at the central stage of leading forums of our evolving industry. He has been the predictable face of Indian Label Industry across the globe at hundreds of international events that took place in the country as well as overseas. He has been bestowed with as much top awards as he has been showered accolades for his achievements which are numerous. The recent feather in his cap is the most prestigious recognition – the R. Stanton Avery Global Achievement Award. The decision was made by the Global Awards judging panel, consisting of Lori Campbell, chairman TLMI, Linnea Keen, president TLMI, Philippe Voet, FINAT president, Greg Hrinya, editor Label & Narrow Web, James Quirk, content director Labels & Labeling and Jean Poncet, editor-inchief Etiq+Pack. The award is a top honour, awarded to either an individual or team, and is supported by Avery Dennison. In memory of Stan Avery’s pioneering spirit and values, this award recognizes an innovation or idea that has helped transform and progress the label industry across the world.

It has been a long journey full of inspiring experiences in the label industry for Harveer Sahni.

“It has been a long journey! I entered business in 1971 and stepped into labels industry in 1978,” says Harveer Sahni. “Life has had its ups and downs, but I remained focused in always striving to do something different. This award is the biggest in the world for our

labels industry. I feel elated. My endeavors have been rewarded. There is immense satisfaction,” he admits.

Andy Thomas-Emans, Labelexpo Global Series strategic director and chair of the judging panel, commented, “The judges felt Harveer Sahni met all the criteria for excellence demanded by the industry’s most prestigious award for an individual’s global contribution to the growth and development of the labels industry. His history in building a company to manufacture self-adhesive labels in India, through to his central role in building the Indian label association and then acting as an influential ambassador on the world stage, all helped the judging panel to come

to their decision amongst a field of excellent candidates.”

The BSc Chemistry background came in handy

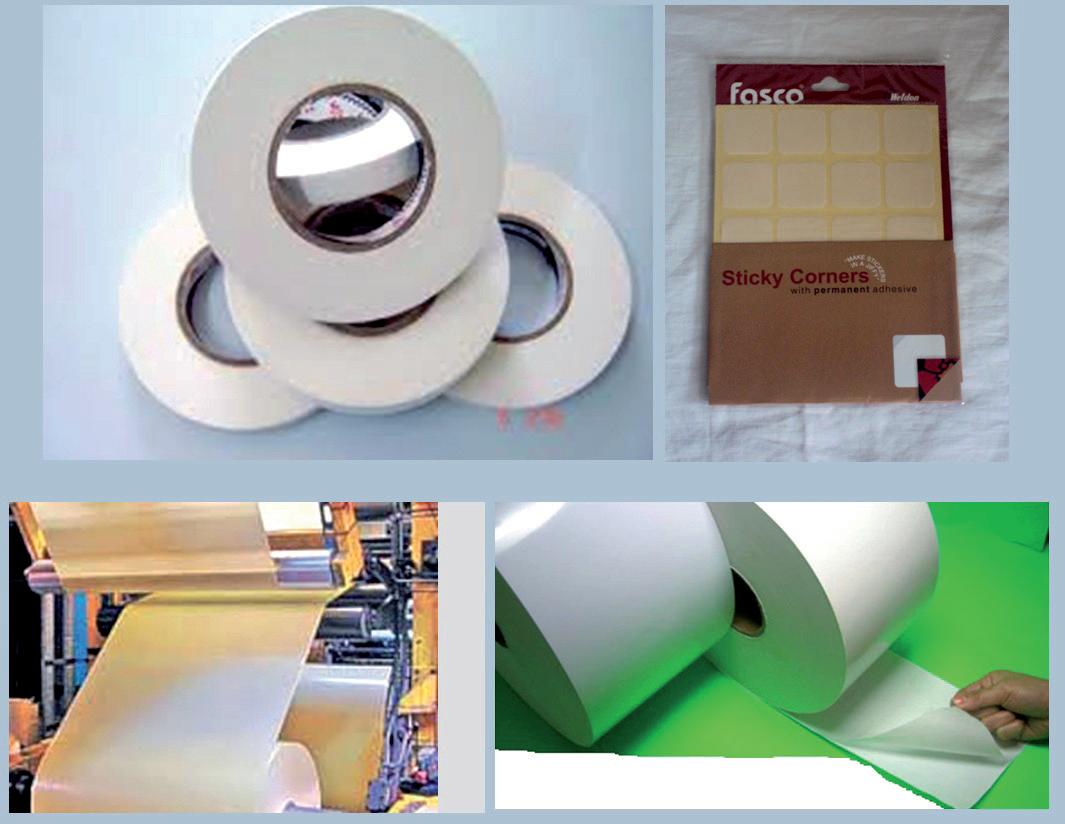

Working in his father’s stationery company, Weldon Sales Corporation, Harveer Sahni started his career in 1971. In 1978, as part of expanding the company’s stationery product range, Sahni set up a 20-inch coater to manufacture self-adhesive BOPP tapes - one of the first to do so in India. From inheriting his family stationery business to all the way to develop pioneering products for the upliftment and growth of the industry and leading from the front, he shares how his initial learnings came in handy during

his labels journey, “Having been in the manufacturing of packaged consumer products from the very beginning in the family business, all learnings contributed to knowledge that eventually came in handy for the requirements of label laminates and eventually labels. Given my background of being a chemistry graduate and understanding the needs of labelling, it was normal for me to undertake new developments and diversifications. My ability to cater to a steadily maintained customer base helped me maintain a focus to the advancements in label industry.”

Making full use of his BSc Chemistry background, Sahni used the Weldon laboratory to research development of new products including inks, adhesives and coatings. At this time he also ventured into industrial adhesives, plastic blow molding and injection molding.

“It is really a very vast change from the earliest days of self-adhesive labels,” remembers Harveer. “It may be difficult for our younger generation to imagine how labels were produced in those early days and how they have evolved to present day manufacturing processes – the start was all manual when screen printers would print, dry, follow it by applying adhesive on the reverse again with screen, dry and apply silicon release paper. Then, finishing the label by half cutting with shaving blade and a steal ruler; every process from printing, labelstock manufacturing, siliconizing technology, converting, embellishing to label applications have all undergone a sea change,” he continues.

With demand for self-adhesive stickers starting to take off in India through the 1970s, in 1978 Harveer invested in a siliconizing line, developing and producing poly-coated release liners and later a barrier coating for uncoated woodfree or brown sack kraft papers that could accept silicone release coating. In 1984, he made his own way to London for a surprise visit to ‘Label Guru’ Mike Fairley, gaining inspiration and useful insights into label converting trends. In the late 1990s a one-meter coater was installed to carry out both silicone coating and to produce release liners, and in 1997 Weldon Celloplast started manufacturing self-

adhesive labelstock, soon adding another coater to focus on liner manufacture.

With the dawn of the 2000s, Harveer moved the business from coating tin catalyst-based silicone chemistry to a solvented platinum catalyst system and then on to solventless silicone coating – a line which is still in use. In 2003 he again was a pioneer setting up the first Nordson Hotmelt adhesive coating line in India.

There have been technological developments in the labels world all these years that have a significant impact on the future course of the industry. “Labels have diversified into many tangents,” says Harveer. “Their production, embellishing, converting and application technologies have transformed immensely.

What was once just wet glue and later largely became self-adhesive of Pressure Sensitive labels, have now moved into multiple segments like wrap around labels, shrink sleeves, in-mold labels and direct on product labels. Label printing has also evolved from just letterpress to flexo, digital to hybrids or combination of flexo, screen, offset, rotogravures, etc. with foiling, varnishing, embossing, etc. The future is a time for ongoing continuous transformation; printers who are quick to adapt to changes as they happen, will excel. A very disruptive change that I expect is when technology for directly printing and embellishing directly on product will evolve as a largely usable one, that will be sustainable as there will not be any waste generation as regards paper, adhesive, silicone or liners,” lucidly explains Harveer.

The Award is Precious!

For anybody who knows about the award’s high pedestal, it means no less than an honour. For Harveer, the award is especially precious: “The award accords global recognition and connect! As for our domestic labels industry, I am sure it will generate inspirations and aspirations for other peers to reach out to have presence and recognition on global scenario.”

Harveer’s individual contribution to the global label fraternity is unmatched. He has always shared his knowledge whether it was chronicling the history of Indian Labels Industry, or sharing technical learnings, networking within the Indian and global labels industry or by being a bridge between the Indian and global label fraternity. With his indulgence in India’s label manufacturers association (LMAI), he supported organizing seminars for the benefit of label printers and also being the connect between brand owners and label manufacturers.

Harveer’s achievements are more of a dream for others in the industry. But the expert tips to the achievements are no more secret with Harveer revealing them himself, “Always endeavour to acquire knowledge by keeping abreast with news about labels, network with peers to exchange views, be willing to share knowledge. The biggest one is in times of pressures or challenges, be prepared to move out of your comfort zone and travel into newer fields.”

Speaking about the latest Labelexpo India 2022 and Weldon’s offerings, Harveer informs, “Since Manufacturing was always dependent on me and for a host of reasons, we have stepped back from manufacturing.” However, Weldon Celloplast brings the best technologies in the world through its many principals and retains its enviable customer base. “In times of intense competition, for example,” explains Harveer, “there is dire need for the leaders or those aspiring to reach leadership position to adapt innovative printing and converting technologies. For this reason, we presented, through our Italian principals and embellishment experts CARTES, their digital screen and laser converting technologies. This is one of the many new developments that we brought

to our Labelexpo audience besides many others.”

It was a good show for Weldon. “Labelexpo India 2022 proved the yearning the industry had to meet, network again and learn about the new developments to ascertain the way forward. All those who mattered in the industry, marked their attendance. It was a well-attended show. Our stand was very busy, we displayed Brotech’s digital finishing machine which attracted a lot of printers. All principals present at Weldon stand were happy by the attendance and enquiries received. Visitors were satisfied and appreciative,” says Harveer.

“Digital label printing is a sought-after capability. There is a lot of interest amongst the fraternity looking at options to implement digital label printing,” he adds to say about what inspired him at this edition of Labelexpo.

Actually, Harveer has been instrumental in the establishment of Labelexpo in India – in 2001 he helped his friend Anil Arora establish the India Label Show, which later in 2007 got purchased by the Tarsus Group and got its new name, Labelexpo India.

Apart from producing world class products, Weldon Celloplast has brought world’s best technologies to the Indian market. Most of the associations have been for long years, some more than 15 years. Weldon’s long represented Italian press manufacturer Omet now has its own subsidiary Omet India Pvt. Ltd. The company is headed by Harveer’s elder son Pawandeep Sahni as its Managing Director. All other agencies are also internationally reputed and Harveer’s younger son K D Sahni takes care of that part of the business. “Another example is Vetaphone Corona treaters, the promoter family are actually the inventors of Corona treatment. Spilker Germany manufacturers are OEM to leading press manufacturers. Lartec Spain another family managed company making flexible dies has grown manifold and was our very first agency and remains bonded with us,” proudly shares Harveer.

In the late 1990s when Harveer welcomed the entry of ‘big brother’ Avery Dennison to India, he recognized that it would help drive development of the entire Indian label converting industry. This also pushed him

into developing export markets, and Weldon was soon selling to over 30 countries.

Harveer suggests that today innovation and creativity are the key to the growth of the label companies and Indian industry. “Besides having a quality control department as R&D endeavor, there is now an imperative need for all progressive label companies to have a dedicated innovation and creativity department that will devise new label products that will fetch higher returns and will enable the end-products an impulsive lift-off from the shelves, contributing a higher sales revenue for brand owners. Simple labels do not stand you out of the crowd and are intensely competitive, giving low margins,” he declares.

Harveer is at the helm of India’s premier Label association LMAI (Label manufacturers association of India). “LMAI strives and is successful in driving value for its members. In the domestic space it organizes seminars, technical sessions and presentations from experts with brand owner presence along with networking. On the sidelines of Labelexpo India LMAI has been organizing LMAI Avery Dennison Labels Awards night, a highly successful event attended by the who’s who of the industry. The award winners have the option to participate in world label awards. Similarly, every alternate year LMAI organizes the LMAI conference, a much sought-after event where label printers and suppliers attend with families. The conference is always held at interesting tourist destinations. As for the international connect, LMAI is a part of L9 which is the association of world’s leading nine associations that includes FINAT and TLMI. LMAI hosted the L9 meet in NOIDA India in 2018 where international delegates networked with Indian counterparts.

Sharing the priceless knowledge Harveer Sahni’s informative Blog is highly popular among the label industry peers. “Giving and sharing valuable knowledge benefits the industry. It gives me immense satisfaction of giving back to the industry that gave me so much. The Blog is read in all the five continents around the world. Besides, serving the industry’s growth by being an informative platform, it provides inspiration and connect. It is about success stories and news, and most importantly, has become a reference point for technical articles,” he

elaborates. The Blog, “Self Adhesive Labels Industry In India and The World” is nearing half a million page-views.

Among a long list of laurels, Harveer’s presentation on the Indian self-adhesive labels market received great admiration and he became a part of the international Cham Paper pressure sensitive symposium at St. Moritz Switzerland in 2003. Also, Weldon Celloplast was the first Indian label industry constituent to exhibit at Labelexpo Europe in Brussels. He has been writing regularly for national and international magazines. In 2017 he became the first recipient of the LMAI award for lifetime support to the Indian Label Industry.

Harveer wishes and plans to continue sharing his learnings and stay connected to the world of labels that, he says, led him to this award. He is concentrating on his book on labels which he hopes to bring out soon. He wishes to start a training program and working on the idea to finalize a proper shape.

Harveer admits that the R. Stanton Avery Global Achievement Award is his greatest achievement. “There are numerous association and country specific awards, but the R Stanton Avery Global award is the biggest in the world for labels,” he states. He sums up by reiterating his favourite words we heard him say at Chicago while accepting the award, “I Live Labels, I Love Labels!”

Interview with Aki Ohno, Organizer of the Japan Inkjet Technology Trade Fair.

The Japan Inkjet Technology Trade Fair is held in Tokyo. As a special partner of this exhibition, drupa interviewed the organizer Aki Ohno, who gave some information on his career and an overview of the trade fair and the Japanese printing market.

I want to touch and feel the print sample, I want to hug old friends whom I may meet by chance at Messe, and I want to go to Uerige in Altstadt to enjoy Altbier together! Only having online events is somehow “imbalanced”. We should smartly use both online and live events case by case.

Key Notes :

> Aki Ohno – an independent consultant promoting inkjet technology and business.

> Seeing himself as a bridge between Germany and Japan, he has made it his mission to support drupa.

> Will introduce companies that have not yet had a relationship with drupa to Sabine and the Messe Dusseldorf office to develop future business relations.

Being the world’s leading trade fair for the printing industry, drupa is pleased to be a special partner of the Japan Inkjet Technology Trade Fair (JITF2022). Aki Ohno, an independent consultant promoting inkjet technology and business and head of the JITF2022, not only has a long career in the printing industry but also strong connections to Germany and drupa. As a Germanophile who has a very personal connection with Messe Dusseldorf’s home base country, he sees himself as a bridge between Germany and Japan and in this context has also made it his mission to support drupa – especially since we have declared sustainability to be one of the main topics at drupa 2024. After all, he sees inkjet technologies as an important building block for a sustainable future.

In an exclusive interview with drupa he shared his thoughts not only on JITF2022 but also on the Asian printing market.

Drupa: First of all, we would be pleased to hear what brought you to the printing industry and what role you play there?

Aki Ohno: I have been working for Konica Minolta (KM) for 39 years, 22 years for the copier and printing division, and 17 years for the inkjet division. My last title was that of an executive officer: the division director inkjet. Now, after working for KM, I am acting as an independent consultant, head of the OIJC (Ohno Inkjet Consulting), and a professor at Yamagata University Inkjet Development Center

to promote the inkjet industry from both the business and technology side.

Drupa: With your expertise and by representing the first Japan Inkjet Technology Trade Fair, you can surely give us an insight into the Japanese or rather Asian printing industry.

Aki Ohno: I see the worldwide inkjet industry as follows: The Japanese develop devices (inkjet heads), Europeans develop printing machines to use these, then the Chinese follow what the Europeans are doing. Japan is closed off, and the Japanese tend to stay in Japan and would not see what is happening overseas. We have eight inkjet head manufacturers, but the application is not as active as in Europe and China. I want to build a bridge between Japan and overseas for the sleeping Japanese to wake up.

“Japan Inkjet Technology Fair 2022 is not the typical trade fair for printing machines but more for its elements, including inkjet head, ink, material, parts, software, and integrators.”

Drupa: drupa is the leading international trade show for the printing industry. So it is no surprise that you are quite familiar with it as well. Having said that, what led to your strong link with drupa?

Aki Ohno: As explained before, I once worked for the copier and printer division at KM, the main exhibition of which was CeBIT. Meanwhile, CeBIT shifted from office printing to software and communication technology, and drupa became the perfect alternative not only for KM but also for Ricoh, Canon, etc., which wanted to expand their focus from just office printing to cover commercial printing.

Later, I moved from the copier and printing

division to the inkjet division. I met Ms. Sabine Geldermann in person at an inkjetrelated conference and learned that drupa is also expanding from conventional offset printing to the toner-based digital printing technology to cover the inkjet technology as well. The header photo shows a picture of our first encounter.

Drupa: drupa is a special partner of the Japan Inkjet Technology Trade Fair. Which connection exists between the two print fairs?

Aki Ohno: Japan Inkjet Technology Fair 2022 is not the typical trade fair for printing machines but more for its elements, including inkjet head, ink, material, parts, software, and integrators.

I am inviting CEOs and board member classes of major companies that are involved in the inkjet business such as Epson, Fujifilm, Konica Minolta, Komori, etc. In order to offer an opportunity for Ms.Geldermann and her team to warm up their long-term relations and friendship, I invited them together with some staff of Messe Dusseldorf Japan to join the Japan Inkjet Technology Fair 2022.

I will also introduce many other companies that have not yet had a relationship with drupa to Sabine-san and the Messe Dusseldorf office to develop future business relations.

“I want to touch and feel the print sample, I want to hug old friends whom I may meet by chance at Messe, and I want to go to Uerige in Altstadt to enjoy Altbier together!”

Drupa: As the very first print trade show in Japan, there will definitely be a lot of new exhibits at the front. What trends and key areas of focus

will be featured at the trade show?

Aki Ohno: Inkjet is expanding its possibilities and opportunities in various directions. Replacing conventional printing has been the main direction so far. I would focus on some future-oriented directions, including “digital manufacturing” and “additive manufacturing”, which are still new and on the way to growing.

Of course, I will not forget the big market to replace the existing market by emphasizing the sustainability inkjet could offer.

Drupa: Online events have become more popular in recent years. What made you decide in favor of a presence trade fair? What advantages do you see in face-toface exhibitions compared to online ones?

Aki Ohno: We have learned enough about the positive and negative sides of online events. In the early phase of COVID, we had no alternative to online meetings and events.

The positive point we found was that we could save the cost and time of traveling. We could have meetings or join events without emitting CO2 by flights. I believe you know another 100 positive points from your own experiences.

The most negative points of online are the missing of “touch and feel”, “excitement and attraction” and “by chance”. Two and half years of a long period without “touch and feel”, “excitement” and “by chance”, we are all bored and eagerly expecting live events to happen.

I want to touch and feel the print sample, I want to hug old friends whom I may meet by chance at Messe, and I want to go to Uerige in Altstadt to enjoy Altbier together! Only having online events is somehow “imbalanced”. We should smartly use both online and live events case by case.

Thanks to Aki Ohno for the inspiring insights and new knowledge about the Japanese printing industry and the Japan Inkjet Technology Trade Fair.

900 exhibitors from 45 countries already on board; over 100,000 sqm of exhibition space already booked.

Some one and a half years before the start of the trade fair, drupa has reached an important milestone: over 100,000 sqm of net exhibition space have already been booked by around 900 exhibitors from 45 nations. This clearly underlines the relevance and the USP of drupa as the world’s No. 1 trade fair for print technologies.

Special forums like the drupa cube, drupa next age, the exhibition area for Newcomers, Startups,Young Talents, touchpoint ‘packaging’, touchpoint ‘textile’ and the touchpoint ‘sustainability’, all provide highly relevant and valuable insights into tomorrow’s high-potential themes at the event.

From renowned global players to up-and-coming new entrants – the list of registered exhibitors is impressive and reads like the ‘Who’s Who’ of the print and packaging industry along the complete value chain. Well-known and longstanding exhibitors like Bobst, Comexi, Duplo, EFI, Epson, ESKO, Fujifilm, Heidelberg, Horizon, Koenig & Bauer, Kolbus, Komori, Konica Minolta, KURZ, Landa, Müller Martini, Screen, Windmöller & Hölscher, to name but a few, have registered and will be showcasing their innovations, technology trends, product portfolios and global launches in Düsseldorf from 28 May to 7 June 2024. So already today, participants can look forward to a unique customer journey because complex, automated workflows, processes and new machinery will again be presented in operation.

An overview of all exhibitors registered so far is available at the drupa website.

Even after the official deadline for registrations at

> A showcase of innovations, technology trends, product portfolios and global launches in Düsseldorf from 28 May to 7 June 2024.

> drupa 2024 will again be the world’s most important industry meeting place.

> With around 75% international attendance on the exhibitor side, drupa occupies an outstanding position by global standards.

the end of October, Messe Düsseldorf continues registering a strong demand for exhibition space, which can still be accommodated. At present, Germany is again the strongest exhibiting nation among the top 10 followed by such countries as Belgium, China, India, Italy, Japan, the Netherlands, Spain, Switzerland, Turkey, the United Kingdom and the USA.

“Current booking levels and the positive verdict received by exhibitors make us very confident and optimistic – despite the geopolitical and economic challenges – that drupa 2024 will again be the world’s most important industry meeting place,” confirms Sabine Geldermann, Director drupa, Portfolio Print Technologies Messe Düsseldorf, and adds: “With around 75% international attendance on the exhibitor

side, drupa occupies an outstanding position by global standards. The range, variety and staging of innovations are unique and will once again provide a glimpse into the future of this industry. With ideal prerequisites for exhibitors and visitors to network intensely and drive forward-looking projects.”

The in-depth knowledge transfer and interaction with experts from all over the world on the impacts of global megatrends and the associated new business models as well as opportunities for the sector will be in focus here. Special forums like the drupa cube (conference area), drupa next age (dna), the exhibition area for Newcomers, Startups, Young Talents alongside long-established exhibitors of cross-sectoral technologies as well as the touchpoint ‘packaging’ for

visionary and smart packaging solutions, the touchpoint ‘textile’ including the installation of a textile micro-factory, and the touchpoint ‘sustainability’, which is dedicated to sustainability and circular economy themes, all provide highly relevant and valuable insights into tomorrow’s high-potential themes at the event. With its agenda, drupa hits the tempo of the time and reflects an industry that is highly creative and constantly taps into new vertical markets in the field of industrial and functional applications and solutions – thereby bearing witness to its high degree of future proofness.

In addition to this, the drupa blog (https:// blog.drupa.com) allows industry people to take a glance at industry trends, solutions and inspiring best cases from throughout the

world. Furthermore, interested parties can subscribe to the drupa Newsletter featuring exciting news and stories from the drupa blog plus the latest news related to drupa in Düsseldorf and the international trade fairs forming part of the drupa Global Portfolio.

Ken Hanluec, VP of Worldwide Marketing, Electronics For Imaging: “EFI delivers vital innovations and opportunities for customers through digital print and, for us, drupa is a venue for digital’s best ideas. At drupa 2016, we launched a Nozomi single-pass inkjet press that is transforming the corrugated space. The 2024 show will be just as important for anyone seeking the next level of success in many segments of digital print.”

Dirk Schröder, Sales Division Manager Paper / Film / Special Markets, Erhardt+Leimer:

“‘We create the future’ – the drupa slogan is also our claim. As a leading process automation provider, we are constantly working on forward-looking solutions. We can hardly wait to present to trade fair visitors our new EL.NET-technology based on a digital, connectable, IoT-enabled and web-based system architecture in addition to our drive technology or inline inspection products.”

Markus Gorlt, Head of Global Marketing & Network, Ferag Deutschland GmbH: “In our view the situation of the industry is currently very tight due to the higher costs of materials and energy, for example. Precisely for this reason our objective and message for the coming drupa 2024 is clear: our customers should feel that Ferag is a reliable and innovative partner in the long term especially in the fields of service, support and spare parts supplies. The trends and innovations driving us include flexible and sustainable manufacturing technologies, new disruptive business models, automation and increased efficiency for our customers as well as future leasing models for our plants.”

Ken Zhao, Co-founder of HanGlory Group: “drupa is a very important event for HanGlory Group, which helps us to stand on the big stage of the printing industry to show the world our development and achievements in the field of digital inkjet printing. Now, facing the constantly changing and evolving future, HanGlory Group has decided to participate in drupa 2024 again, which is a very valuable

opportunity for us to further integrate into the international market of digital inkjet printing to create more excellent products, services and solutions that are more in line with international market requirements. Seizing opportunities to embrace the potential future, HanGlory Group sincerely looks forward to communicating and cooperating with you on site!”

Dr. Ludwin Monz, Board Chairman/CEO, Heidelberger Druckmaschinen AG: “For us, drupa is a showcase for our leading technologies and innovations in commercial and packaging printing. HEIDELBERG wants to continue to shape the future of the print media industry and we look forward to seeing our customers again in Düsseldorf in 2024 under the motto ‘we create the future’.”

Dr. Andreas Pleßke, Spokesman of the Board/CEO at Koenig & Bauer AG and Chairman of the drupa Committee: “2024 still sounds far away but drupa is already pretty near for Koenig & Bauer. There is great anticipation to be able to experience exciting innovations hands-on again at the world’s most relevant industry trade fair. Many things have changed compared to planning in previous years. The gap between the digital world and the machinery in operation needs to be bridged. For visitors this means new worlds to be experienced. As an exhibitor we

will do our utmost to make the leading topics Digitalisation and Sustainability graspable. Fortunately, the industry is pulling in the same direction here and Messe Düsseldorf sets the stage for this.”

Olaf Lorenz, General Manager Global Brand Management, Konica Minolta, Inc.: “drupa is the bedrock for our industry. Educational, informative and inspirational – there is a real appetite for live events, and we can’t wait to be there. As a global technology leader, Konica Minolta will again have a major presence at the exhibition. With our commitment to sustainability and social responsibility goals, we are looking forward to welcoming visitors to our stand to help them rethink possibilities, ignite their creative ideas, and see the potential in print. drupa provides a perfect platform for us to demonstrate the latest technology and improvements to further identify and unlock the digitalisation potential for our customers.”

Mr. Swapnil Patel, Management Executive, Line O Matic Graphic Industries: “drupa 2024: The world’s leading trade fair for Printing & Packaging provides an excellent networking opportunity. We expect groundbreaking innovations and sustainable solutions in line with global challenges. We are already counting the days and are excited to showcase our new range

Offering superior cost performance, RMGT 9 series continues to dominate the A1-size press market with Multivista Global installing their second RMGT 9 Series 8-colour convertible perfector. The solutions has been provided by Provin Technos.

After investing in their first RMGT 8-color convertible perfector in 2018, Multivista yet again invests in a brand new RMGT press.

Multivista Global, a family owned printing house founded in 1976 has made a name for themselves in the printing and distribution of educational books. The printing facilities are housed in a state-of-the-art manufacturing plant that boasts an end-t-end system for manufacturing books. Their journey with

of products to the world market at drupa 2024. Our product range will help our customers gain high production volume with lower running costs. In a way, it will create a competitive edge to sustain a highly competitive world market!”

Hermann Veismann, General Manager Business Unit Printing and Finishing, Windmöller & Hölscher: “drupa is the most important leading trade fair for the print industry. Which is of course why we will also be present in Düsseldorf in 2024 again. There, W&H will be showcasing innovative solutions for a wide variety of challenges on the basis of its unique printing press portfolio. In addition to launching new products we will demonstrate how much print technology contributes to greater sustainability and flag up the potential digitalisation holds.”

drupa welcomes Cornelia Tautenhahn as a new member to the drupa press team as Senior Manager Marcom. As press officer for interpack, the world’s leading trade fair for processing and packaging, she will contribute her experience and expertise to drupa with immediate effect and strengthen the team. She has been with Messe Düsseldorf since February 2022 and was previously responsible for press relations at several trade fairs at Reed Exhibitions for 13 years.

RMGT presses commenced in 2008 when they installed their first RMGT 920 multicolour press. Impressed with the machine’s capability and flexibility, they added another RMGT within 6 months. In the year 2019 they installed their first 8-colour 920PF-8 which was also India’s first RMGT 8-colour convertible perfector. The highly capable RMGT 920PF-8 improved productivity

for Multivista from 20 to 25 percent. The machine was able to do up to 64 jobs in a single day. The machine chiefly catered to printing textbooks for publications in Europe and Africa. Though the plan was to add another RMGT 920PF-8 in 2020, they have finally installed their second RMGT 920PF-8 recently.

PAMEX Promotional Events planned in SIX cities of India.

PAMEX 2023 the global business platform for print, label, converting and corrugation industry, is highly awaited not only by the suppliers and exhibitors but also by the buyers and visitors who are ready to scale up the already substantial market.

The Show, scheduled to happen from 27-30 March 2023 at Bombay Exhibition Centre, Mumbai- has already surpassed the total booked area of last edition. By the end of October, more than 270 companies were on board, with many more in the stage of finalisation.

The highlight of 2023 edition is the theme of the Show, which is Convergence in Print! Convergence, basically, is a phenomenon that has been happening over the past few years. It has gained tremendous momentum in the recent times and is very pronounced today as we come out of the unprecedented global pandemic while merging the technologies seamlessly.

At one end, it is driven by the printers and converters who are looking to diversify into an industry segment beyond their primary focus. On the other, the emerging technologies make it possible for printers and converters to offer newer applications, enhancements and embellishments from their equipment.

These technologies and trends will be witnessed through the exciting display at PAMEX 2023, with convenience to interact with technology leaders.

PAMEX will play host to a glittering awards ceremony at the Gala Exhibitors’ Evening on the 29 March 2023.

AIFMP has decided to institute several new awards to add to the prestigious National Awards for Excellence in Printing (NAEP) and Viren Chhabra Print Leadership Award (VCPLA) that were extended in the last edition. The new categories will include International Awards for Excellence in Printing (IAEP) and Top 10 of Indian Printing Industry.

The categories under top 10 awards will include Commercial/Book Printer, Packaging Printer, Label Printer, Print Exporter, Machinery Manufacturer, Inks/chemical Manufacturer, Paper Mill, Machinery Exporter, Allied Material Manufacturer and Woman Entrepreneur.

The promotional road show of PAMEX 2023 planned for six cities in India will also see events circled around the theme of Convergence in Print!

The expo team had formed a core group of the leading industry players and stakeholders from Indian Printing and Packaging fraternity to help design and finalise the locations of the promotional event.

With the feedback from group members Raveendra Joshi, President, AIFMP, Ranesh Bajaj, Vinsak India; Deepak Chawla, Technova; Tushar Dhote, Dhote Offset; Amit Sheth, Intergraphic Sales & Services; HarveerSahni, Weldon Celloplast; Abhishek Bhatnagar, HP; Manish Desai, Mudrika Labels; Hemanth Paruchuri, Pragati Pack; PawandeepSahni, Omet India; Nitin Vani, Print Consultant; Sonal Khurana, S Media Group- Print & Publishing and Anil Arora, Print-Packaging.com (P) Ltd.- the promotional events are being planned in Guwahati, Ahmedabad, Pune, Haridwar, Indore and Bangalore.

These cities that serve as the regional hub for the industry, will see PAMEX led one day table-top exhibition and half-day conference in coming months. Organized in partnership with local associations, these events will see printers, converters and suppliers openly discuss the pros and cons of adopting ‘Convergence in Print’ and map the tangible benefits thereby boosting the confidence for new investments in these equipments and technologies.

The first promotional event is scheduled to happen in Guwahati on the 27th of November, co-located with NorthEast Print Tech 2022, at Maniram Dewan Trade Center. Ahmedabad will be the next stop, where the table-top exhibition and conference is planned for 9th December 2022, to be followed by Pune in the same month on 23rd December 2022.

The dates of other cities will soon be announced and details of the same will be available on www.pamex.in

Epson India is relaunching its SurePress range of digital label presses in the local market after a four-year break.

Epson has announced its decision to relaunch its successful SurePress digital label press in the Indian market. Vasudevan, General Manager - Large Format Printers/Industrial Equipment says: “Even though we were not directly present in the market for the last few years, we were getting enquiries for our label press. We have now relaunched these products in the Indian market, and we are confident that we will get a positive response from the market.”

for adapting to new technologies then.”

Another reason for discontinuing the products was converters were comparing digital productivity with analog.

When Epson launched the printers earlier in 2014, market was not fully ready for adapting the technology – the converters were comparing digital productivity with analog. With the relaunch, Epson answers both cost and productivity needs of Indian customers.

He adds that the adaptation from analog to digital technology for labels has been slow in India, despite India being a big market in comparison to other western countries such as Europe and US where label converters are actively adopting digital technologies.

“In India, the label printing cost is extremely important. Converters prefer to use analog presses to compete on pricing deterring the adoption of digital technologies. When we had launched the printers earlier in 2014, we were ahead of time in the market, but still we managed to sell these digital presses in India. We realized that the market was not fully ready

“Earlier we just had one model to offer and its productivity was not comparable with analog presses. Even the customers’ expectation was the printing speed to be at least 45-50mts/min. With the launch of the new product – the Epson SurePress L-6534VW, we should be able to meet customers’ expectations on productivity,” Vasudevan says.

The company has started its promotional activities including reaching out to customers to assess their requirements and showcasing how digital can support their existing setup.

Satyanarayana, Director - Visual products and Robots, Epson India says: “We have started speaking to the customers. We are also in the process of rebuilding our ground-level activities to reach out to new customers. We will be actively present in the

Notes :

> Slow adaptation of digital from analog for labels in India.

> Converters prefer to use analog presses to compete on pricing, deterring the adoption of digital technologies.

> With the launch of the new product – the Epson SurePress L-6534VW, Epson aims to meet customers’ productivity expectations.

market by the end of this quarter. We expect the sales to begin starting from this year.”

Epson has built a new demo center in Japan in May 2022 equipped with its latest SurePress label printer.

“The potential customers are taken to Japan to visit the demo center for a product demo and those unable to travel are provided an option of the virtual demo. When customers request for print samples, we arrange the same from our demo center in Japan. As we progress, we could tie up with one customer in India and set-up a demonstration center in the future,” Satyanarayana explains.

The company will primarily sell the label press directly to end customers and are also open to partnering with distributors.

Vasudevan says that label converters in India are happy with their current analog presses. Epson intends to show how digital presses can offer value-added services and business expansion opportunities to customers.

“We will attempt to identify the unproductive process in the current analogue label

printing set-up at the customers place and suggest how they can be improve efficiency by adding with digital print machines along with analog machines. Our whole idea is to create a model where both analog and digital printers work parallelly thus improve efficiency and profits analog to the customers.”

Primarily aimed at short-run jobs and variable data printing, digital presses can support new start-up brands to connect and engage with customers.

“If a brand wants to run a campaign for high customer engagement, then digital presses can play a major role in that. It can also help start-up brands to conduct market research and test their products in certain demography,” Vasudevan explains.

For example, brands could produce limited edition and customizable products targeting individual cities and markets. Such campaigns help them understand what products are preferred by customers and perform well. With digital printing, brands can make these products available in the market in a short span of time.

The Polyart Group launches new sustainable portfolio at the Labelexpo.

Polyart group, a producer of speciality solutions on papers and films and synthetic paper, showcased its new extended portfolio at Labelexpo India 2022 for the first time in Asia. Its extended line of papers and films ranges from specialty facestocks to tag material and in-mold label material for blow molding.

During Labelexpo India, Polyart group launched two new sustainable substrates r-Polyart and Fiberskin.

r-Polyart is a synthetic paper made of 30 percent post-consumer recycled material. r-Polyart looks and prints like 100 percent virgin material, and has the same mechanical properties, but a lower carbon footprint. Applications include industrial, VIP and prime labels.

Fiberskin is a weather resistant paper, recyclable and biodegradable, printable by

dry toner, for short term outdoor exposure. Applications include outdoor tags, labels and signages.

The company demonstrated Polyart IML film, the HDPE based film for in-mold labels blowmolding applications. For tag applications

“I want to encourage customers to use digital machines along with analog printers. We don’t expect them to move away from analog but co-exist so that they can improve efficiency & provide customized solutions to their customers. It gives them the freedom to accept all kinds of jobs, both from take short and long-run jobs from their clients. The idea is to increase the awareness the benefits of digital printing and how it can add value to the existing lineup,” Vasudevan highlights.

“Even today some of the Epson customers have been using our product for the last 5-8 years which implies reliability of the machine. Epson is committed to co-creating sustainable and enriched communities by addressing solutions to environmental problems and other societal issues. This commitment is aligned with the 17 sustainable development goals (SDGs) adopted by the United Nations. By 2030, we aim to achieve sustainability in a circular economy and advance the frontiers of the industry through creative and open innovation,” concludes Satyanarayana.

the company showcased its Satinex range of HDPE based, highly resistant and 100 percent recyclable material for outdoor labels. Printable by flexo and thermal transfer printing, Satinex offers mechanical properties in one or both directions and is compliant for direct food contact.

More than 40 new exhibitors at Labelexpo India 2022 show floor – bustling with new technology, new faces and new engagements.

Printers, Kamal Mohan Chopra, president, World Print & Communication Forum, AVPS Chakravarthi, Global Ambassador of World Packaging Organisation, Mohammad Shamsul Islam senior vice chairman of Printing Industry association of Bangladesh, Peter Deckker, president of Sri Lanka Association of Printers and Andy ThomasEmans, strategic director of Tarsus Labels, Packaging and Brand Print Group.

Saroha said, “We are very happy to be back at with Labelexpo India after a gap of four years. Despite the challenges of Covid, the label and package printing industry did not stop innovating in the past couple of years. We are thankful to all of our exhibitors for their unwavering support for Labelexpo India. This year’s show is packed with innovation and technology developments that took place in the past four years.”

Labelexpo India 2022 show floor bustled with new technology and new faces both on the visitor and exhibitor side. The show was packed with more than 250 exhibitors out of which 40 were first-time exhibitors.

South Asia’s leading exhibition for labels and packaging printing industry took place at India Expo Mart & Centre, Greater Noida. This year’s Labelexpo India show had more new technology than ever before and proved an unmissable opportunity to experience

the latest launches from leading industry names including Avery Dennison, BST, GEW, HP, Konica Minolta, Bobst, DuPont, Esko, Miraclon, Monotech Systems, Lucky Graphics, Popli Graphics and more.

The show was opened by Pradeep Saroha, event director of Labelexpo India, Rajesh Nema, president of Labels Manufacturers Association of India (LMAI), Jaideep Singh, honorary secretary, LMAI, Raveendra Joshi, president of All India Federation of Master

Rajesh Nema, president of Labels Manufacturers Association of India, said: “I am very happy to be a part of the Labelexpo India 2022 and meeting the whole label fraternity during the four-day show. The show is a crucial event for growth and development of the labels and packaging printing industry. The Tarsus team has done an excellent job of organizing the show.”

The Labelexpo India 2022 showcased new technologies and products from the leading manufacturers in the industry. Here are the

synopsis of some of the attractions at this years Labelexpo:

Self-adhesive labelstock and silicone liner manufacturer MLJ Industries launched and showcased a host of release liners and labelstock materials at their booth B9 in Hall 1. The release liners by the company include glassine, paper, CCK, SCK, recycled PE liner yellow and white, MG kraft and PE. Among labelstocks, MLJ showcased semi gloss, PP white, PP silver, PP clear, DT, silver MET paper and removable silver PP. It launched clear on clear, battery, tire, pharma, specialty labels for corrugation, wash off, PET clear, PET white label, PE clear, PE white and repositionable labels and PET liner.

Stamping foil provider Shaharaji Associates showcased ITW ShineMark range of cold foils under the name of its new firm Sharjun India – an affiliation between Shaharaji Associates and Arjuna Global Impex.

Bhatia Graphica exhibited at booth J3 in Hall 5. Bhatia is a pre-press service provider based in Mumbai. It offers prepress and printing plates for the flexo, dry offset and letter-press industries using HD CTP technology and the plates are used for printing aluminum cans, aluminum collapsible tubes, lamitubes, seamless tubes, plastic cups, liquor caps, labels and embossing.

Gujarat-based flexo press manufacturer AKO Flexo also participated for the first time at Labelexpo India 2022. The company displayed its 330mm 8-colour flexo printing machine with add-on features. Flexo press and label finishing equipment manufacturer AKO Flexo showcased its latest offerings to the show visitors.

HP had on display its Indigo 6K which got purchased by Sonipat-based Wonderpac which aims to increase its product range

with the new increased capabilities of the HP Indigo technology. The company will target applications such as shrink sleeves, pouches, and self-adhesive labels and VDP with the new digital press.

Veepee Graphics Solutions has launched Ensure. The software is aimed at product authentication and augmented reality (AR). VeePee also launched the process of producing flexo plates using hybrid screening.

Esko sold CDI Spark 4260 to Alpha Flex at Labelexpo. Alpha also invested in Crystal XPS 4260 from Esko.

Monotech Systems showcased its digital label printing solutions under JETSCI Global brand. The company launched ColorAqua Hybrid at Labelexpo. The machine was purchased by Wonderpac, one of the prominent manufacturers and exporters of an

exclusive range of labels and holograms.

UFlex showcased its wide range of holographic products and solutions and printing cylinders at Labelexpo India 2022. Vinsak’s digital label finishing that can print QR codes, high-build varnish and digital cold foil on display at the Labelexpo India stand will be installed at UFlex’s Noida plant.

Daya Printograph showcased reel-toreel thermal lamination machine with inline embossing feature at Labelexpo India 2022. The show experience for Daya was full of technical discussions, customization and signing deals. Kolkata base label manufacturer bought a reel to reel high

speed Thermal laminator with texture. Kaushalya Art Press, Ludhiana bought 600mm high speed reel to reel thermal laminator.

Holostik, manufacturer of holographic labels and security hologram sticker printing service provider, launched a range of anticounterfeiting products.

Printing and converting specialist NBG showcased its Starflex S430 machine at the show. Starflex 430 is a modular multisubstrate press with cold foil and LED UV Label Printing capabilities.

Flexo Image Graphics sold five Rotoflex

VSI 330 slitter rewinder machines with 100 percent fault detection systems at Labelexpo India. The machine showcased at the show floor will be installed at Jain Transfer Products based in Noida.

Many deals have been reported finalized by Newgen Printronics during the show. All of their showcased products and solutions generated enthusiastic visitor interest. They finalized deals for their Durst Industrial UV Inkjet digital press, Polly Automatics, Packers and many more.

“We have been well-received by the industry and established ourselves as partners of some of the best in the business,” says Namah Raval, COO, academi a. The partnerships include – Harper, Troika Systems, Flexo Concepts, AlphaSonics, ALE and Keencut.

UV Graphic Technologies and Domino partnered to launch a new hybrid press at Labelexpo.

Epson India has relaunched its SurePress range of digital label presses in the local market after a four-year break. The company has started its promotional activities including reaching out to customers to assess their requirements and showcasing how digital can support their existing setup.

Konica Minolta offered live demonstrations of the AccurioLabel 230 digital label machine along with the DPR digital die-cutting machine at Labelexpo India 2022. The company also showcased print samples of its upcoming press MGI JETvarnish 3D Web to be launched in early 2023.

Multitec displayed its S1 full servo press in an 8-colour 450mm configuration. The company also showcased new E4 press with twin servo technology and a full LED UV configuration.

During Labelexpo India, Polyart group launched two new sustainable substrates: r-Polyart synthetic paper and Fiberskin, a weather resistant paper. Applications for r-Polyart include industrial, VIP and prime labels and for Fibreskin the applications are outdoor tags, labels and signages.

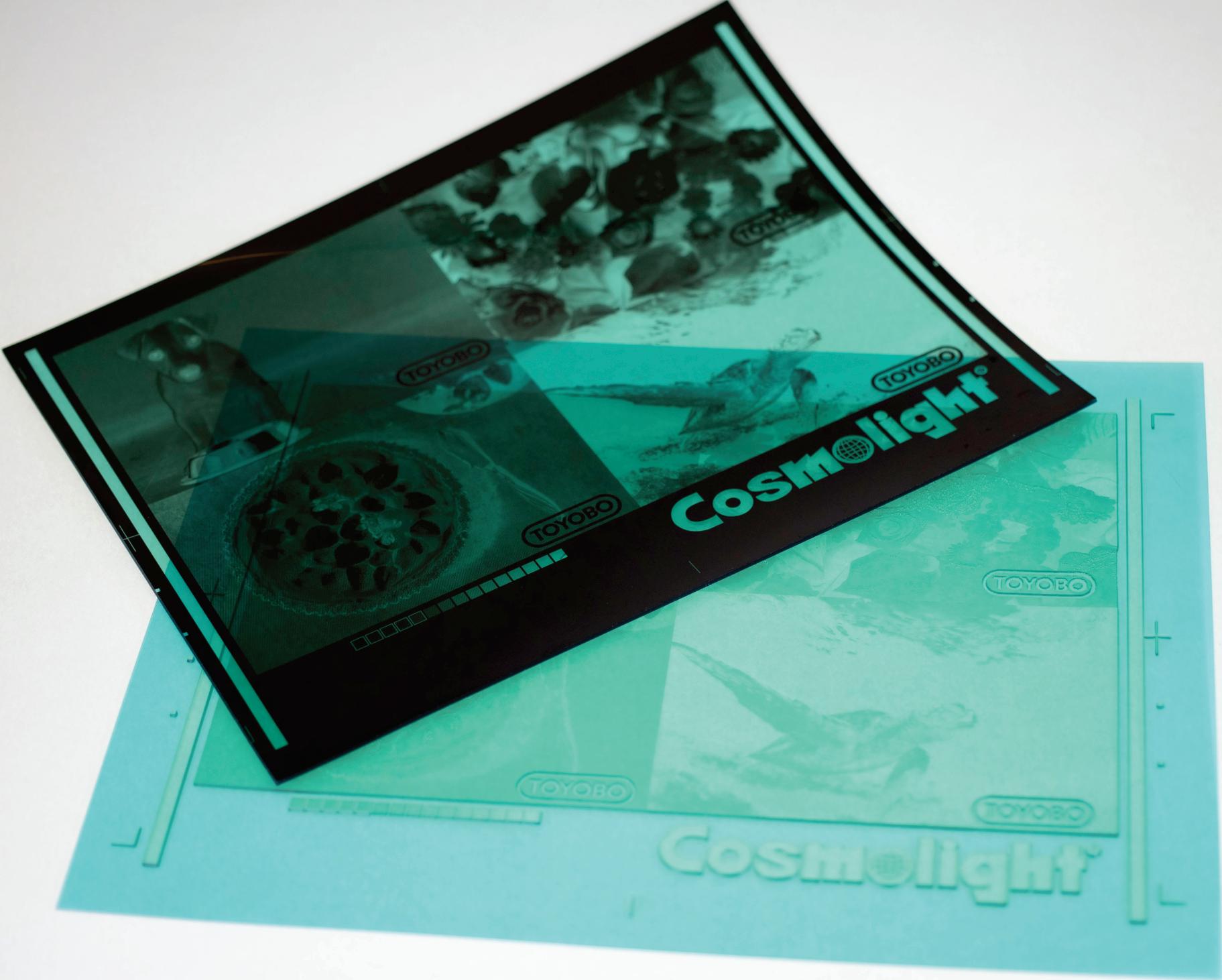

Lucky Graphics conducted live demos of its innovative cost-efficient Pre-Press

Printing solutions at Labelexpo India. It showcased Cosmolight Waterwashable Flexo Plates QZ Series at its Stall No k -30 Hall No 5. Cosmolight by Toyobo was the show highlight by Lucky Graphics. It also presented its 3ES-PROIII-Water Flexo Machine, the inline machine produced for water-washed flexo plates.

DuPont Cyrel Solutions highlighted Cyrel Fast thermal plate-making technology for flexographic printing at its booth L20 in Hall 5 during the show. The company promoted the new DuPont Cyrel Lightning UV LED exposure optimized plates and demonstrated live flexo platemaking with the entire Cyrel Fast thermal workflow technology.

Popli Graphics introduced the Sitexco Label L10 Anilox Cleaning System. The laser system targets narrow web printers and gives unique benefits like cleaning times of 5 to 15

minutes with no water or chemicals needed and no waste produced. It was demonstrated live at the Labelexpo India show at the company’s Stall L- 30 Hall no 5. The awardwinning Sitexco technology comes from the house of TEG Technologies, Spain. “After two long and uncertain years, we were able to re-connect with our partners, peers and customers in-person and face to face. We would like to express thanks and gratitude for yet another world-class exhibition season that brings us back to innovating solutions together, experiencing state-of-art technology , meeting the brightest minds of the industry and most of all - watching the printing industry grow,” says Sanjeev Popli, Director at Popli Graphics.

VINSAK presented the Flexo Label Printer of the Year Awards alongside Nicola Lombardi Alberto Redaelli at the LMAI Awards Show 2022. Lombardi honoured the leading

convertors in India. LMAI hosted its label awards ceremony during the second night of Labelexpo India, 2022. VINSAK reported to have a wonderful time at Labelexpo, receiving numerous inquiries and having an excellent footfall.

Pulisi displayed AOBEAD digital press model DPIM330 for the first time after recent global launch in Korea and USA and China, its home country.

Manufacturer of release coatings and adhesive films for the pressure-sensitive industry Dow launched SL 184 SYL-OFF SL 184 coating at Labelexpo India 2022 at its stand E3.

UV curing systems manufacturer GEW highlighted how UV LED technology enables narrow web printers to make energy savings and reduce their carbon footprint.

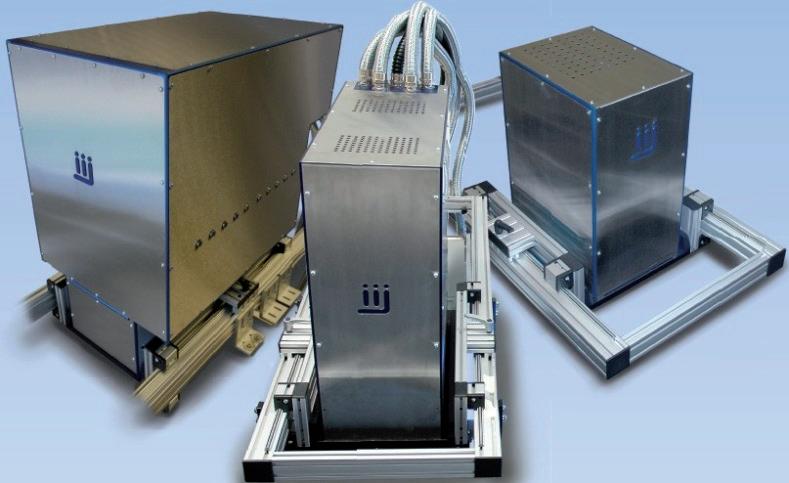

Within a few hours of the opening of the Labelexpo India 2022, Monotech SystemsJETSCI Global sold their ColorAQUA Hybrid to Wonderpac.

JETSCI Global ColorAQUA hybrid is a Mid-Level Label Printing Production Press that enables label printers to adopt digital workflow in label printing. ColorAQUA is loaded with attractive features like high definition 1600 dpi full-color CMYK waterbased inkjet printing. Based on Memjet Duraflex Inkjet printhead, the solution is equipped with Pre inkjet flexo for water-based primers /coating/white and post inkjet flexo with Water Based/ UV curable coatings and movable cold foil station. The machine is especially suited for Pharma jobs and

is evenly capable of producing flawless flexibles for food-grade applications. The Print quality is unmatchable at 1600 dpi where customers can print very sharp micro text and high-quality images.

During the launch of the machine at Labelexpo India, Mr. Trilok Mittal and

Minakshi Mittal of Wonderpac saw the machine live and had no two thoughts about the digital production press of their choice which they were looking for. They immediately booked the ColorAQUA Hybrid on the spot after discussing it with the Monotech-JETSCI team present at the show.

academi.a participation at the Labelexpo India 2022 has been successful. “We have been well-received by the industry and established ourselves as partners of some of the best in the business,” says Namah Raval, COO, academi a. The partnerships include – Harper, Troika Systems, Flexo Concepts, AlphaSonics, ALE and Keencut.

“It was great meeting the industry under one roof and seeing new innovations that will further the label market,” adds Namah. Some of our academi a. new additions are Polymount Self Adhesive Sleeves, Troika FlexoCAM and Keencut Flexo Plate Cutter.

academi a. has also started dealing in Etirama and received a great interest for the same. “We expect an Etirama machine installation in 2023,” says Namah.

and many more.

We also generated a very good amount of inquiries which we are confident in converting to business,” shares Selvaraj Venkatesh, Newgen Printronics.

Newgen Printronics is one of the leading providers of machineries and equipment pertaining to labels and packaging segments. Newgen Printronics provides highly competitive, fast and professional services to match the specific requirements of clients across a multitude of verticals. With a collective experience of over 90 + years in

the industry, Newgen Printronics facilitates services in Narrow Web & Wide web Flexo press, Narrow web digital press, pre-press hardware and software for Flexo and offset applications, sheet fed offset, web offset, signage and POP applications.

It was a great show for Newgen Printronics at LabelExpo India 2022 wherein they not only met customers and visitors from across the country and overseas but also presented the latest solutions from their stable.

Many deals have been reported finalized by Newgen Printronics during the show. All of their showcased products and solutions generated enthusiastic visitor interest. They finalized deals for their Durst Industrial UV Inkjet digital press, Polly Automatics, Packers

Industry Voices on the 8th drupa Global Trends Report.

The 8th drupa Global Trends Report has now been available for a month. This is the first edition since the survey 2019, with industry experts from manufacturers, suppliers and print service providers worldwide contributing to the otherwise annual report. Anyone who wants to gain insights into technology trends, market developments, investment plans is well served by our Global Trends Report. For this edition, it can be said that the global print industry is recovering from the effects of the pandemic and that confidence levels are recovering across the globe as economic momentum builds post-Covid, but that major socio-economic challenges lie ahead for all.

But what does the printing industry think about our 8th Global Trends Report? Is it worth investing in the report to get access to insights and relevant market developments? We have collected some expert comments for you.

“Information

- François Martin, Marketing & Communication, BOBST

“The relevant content, layout and graphs of drupa Global Trends Report are an effective way to get, in a short amount of time, the pulse of the industry. Accessing printers and converters data across all regions of the world is a great addition to analyst’s reports and social media posts. Information requires diversity and drupa reports contribute to it.” -

“Our industry thrives not only on technology, but above all on people” - Sandra Küchler, Chief Editor, Druck & Medien Magazin

“The drupa Global Trends Report provides a comprehensive orientation for the industry. Taking stock of the situation after the toughest years of the Corona pandemic is elementarily important in order to obtain an up-to-date picture of the printing industry. I was impressed by the fact that printers worldwide now assess their situation as being even better than before the pandemic. This shows how resilient the printing industry is and how innovative it is. The current challenges posed by the war in Ukraine are

also reflected in the drupa Global Trends Report, including increased costs for materials and energy. However, the report also shows that print shops are successful if they plan ahead and strategically. This includes investing in machinery and in employees. After all, our industry thrives not only on technology, but above all on people.”

“The 8th drupa Global Trends Report again lives up to its reputation as a guiding force for the print industry” - Jacob George, PRESSIdeas, India.

“It’s very encouraging that the industry’s confidence levels are high and printers and suppliers report strong capital expenditure plans in the coming time. Packaging confidence drives growth for offset, flexo and finishing while digital boosts the segments of cut-sheet colour. Meanwhile, the web-toprint shows equally encouraging growth.

The point that print is still a central means of communication as confirmed by the world’s most comprehensive and precise report is indeed very promising. The 8th drupa Global Trends Report again lives up to its reputation as a guiding force for the print industry.”

“This is the time to invest and be prepared to grow” - Claudia Benelli, General Manager, Ferrarini & Benelli Srl

“Ferrarini & Benelli srl in Italy is a supplier working in the packaging market. We

produce corona and plasma surface treatment systems. The result of the report gives us a positive outlook for the future and makes us feeling part of the global market, as we recognize ourselves and our thoughts in the report results.

We are facing a very difficult and unprecedented period, due to the Covid pandemic, global supply chain difficulties, regional wars, rising inflation, labour shortage and climate change, as most of the companies in the world, as the report confirms. However, it is good to know that our resilience and optimism for the future is shared with most of the companies of the packaging market.

The report also confirmed our overlook of the packaging market especially in Asia and South America. Hopefully Europe will become more optimistic in the near future once the Russian-Ukraine war will finally get to an end. Regarding print technology in the packaging market, the report confirms our view and trust in the flexo technology. The report assesses flexo investment is a clear winner for packaging (39%) and gravure and hybrid offset/flexo/digital should not be overlooked for the same market (both 14%). This is the time to invest and be prepared to grow.”

You can purchase the 8th Global Trends Report or browse through the free Executive Summaries available in seven languages.

Requires Diversity and drupa Reports Contribute to it”

Soon to be launched MGI JETvarnish 3D Web gets highlighted at the show.

Konica Minolta offered live demonstrations of the AccurioLabel 230 digital label machine along with the DPR digital die-cutting machine at the recent Labelexpo India 2022.

The company also showcased print samples of its upcoming press MGI JETvarnish 3D Web to be launched in early 2023. The JETvarnish 3D Web allows printers of labels, sleeves, flexible packaging, or flexible cartons to apply a 100 percent digital finishing on rolls ranging from 100mm width to 420mm, on media previously printed in offset, flexo and digital. This equipment applies selective UV varnish and hot foil stamping, in 2D/3D, on all types of labels or light cardboard, using MGI inkjet technology. The selective UV varnish and the hot foil stamping adds sensory and tactile dimension to labels.

The 100 percent digital technology of the JETvarnish 3D Web applies these coatings in fixed or variable data to enable different hot foil patterns or selective varnish on each label/sleeve or packaging coated. On-the-fly registration, controlled by artificial intelligence (AIS Smartscanner), allows perfect registration of the varnish and the gilding,

by adapting their application to the defects observed in real time on the printed roll.

The implementation of JETvarnish 3D Web does not require any tooling, plate or cliché, and helps reducing costs of finishing and allows mass production, prototyping and versioning. Flexible packaging and heat-

shrinkable sleeves are key segments of the packaging world, in markets as varied as food, consumer products, pharmaceuticals, cosmetics and industry. MGI offers a range of digital printing and finishing presses, adapted to the different formats of packaging such as sleeve Shrink sleeves, tubes, flexible barrier packaging, pouches and bags.

On the occasion of Labelexpo India, Lombardi Converting Machinery S.p.A., in collaboration with VINSAK, launched a live streaming transcontinental link regarding demos for the midweb and the narrowweb. “Directly connected from our headquarters in Europe to the led wall in India, making our own the technology learned in recent years and inaugurating a new type of hybrid approach for trade fairs all over the world,” informed Nicola Lombardi, Marketing Manager at Lombardi Converting Machinery S.p.A. Manufacturer of flexographic printing machines for narrow web and mid web.

Lombardi: United we can make the differenceLombardi Studios, Service, Sales force and Partners all unite for exciting project.

Displays S1 full servo 8-colour press; showcases new E4 with twin servo technology.

Multitec displayed its S1 full servo press in an 8-colour 450mm configuration. The press is equipped with a combination of LED and UV dryers, a multi-layer coupon label kit, and new operator-friendly features.

The company also showcased its new E4 press with twin servo technology and a full LED UV configuration.

Amit Ahuja, CEO of Multitec, said: “This is an interesting launch for the market as it is a new concept of an economical press with the advantage of dual servo technology.”

QSR Slitter rewinder with 100 percent defect detection ran live at the show. All the machines on Multitec stand were on live demonstration. Live demonstrations of printing on thin substrates including 12 micron PET, 2-layer labels and features such as auto-registration were on display. The company also introduced several new features in its presses at the show.

With over 450 installations in more than 35 countries over the world, Multitec has been

serving the needs of label printers with innovative and cost-effective equipment.

Holostik highlights new security label products, Nano Optical Image OVDs, Optashield, Half Scratch QR Code and much more.

Nano Optical Image OVDs (optically variable devices) are secure and technologically advanced OVDs or security holograms. The master of these OVDs is shot at a resolution above 6,00,00 DPI. It can include nano text (up to 5 microns), nano images and microstructure.

Optashield, based on custom holographic technology, displays two different colours at two different viewing angles. It is among the most secure and convenient authentication device in the anti-counterfeit industry, the company said.

3D labels (printed OVDs) are embedded with aesthetic elements, designs and security features. 3D labels amplify a product’s visibility on the shelf and adds premium appeal to the brand.

Half Scratch QR Code comes with half

scratch layer over the QR code, preventing replication and tampering of the QR code. It can be embedded in both OVDs (holograms) and labels.

Paper Label with Holographic Strips are

secure and visually appealing paper labels with holographic strip transferred over it. The strip embedded with multiple security features offer safety of the product from tampering and counterfeiting.

Uflex showcases holography products and printing cylinders at Noida show.

UFlex Limited, multinational flexible packaging materials and solutions provider exhibited its wide range of holographic products and solutions and printing cylinders at LabelExpo India 2022.

Today, brand owners scout for product enhancements and customised solutions to enable their brands to stand out on retail shelves, prevent counterfeiting, and fulfill consumers’ demand for sustainable products, packaging and processes. At LabelExpo India 2022, the UFlex Holography business exhibited its product portfolio including registered foil stamping solutions, cold foil solutions, hybrid security labels, holographic sterling lens effects, and 3D optics labels. These products serve the dual purpose of brand enhancement and anticounterfeiting for a large number of brands across industries globally.

In addition, the UFlex Printing Cylinders business division also displayed its wide range of products and solutions including flexo plates, elastomer plates, and photopolymer plates. The UFlex Cylinders business division manufactures Flexo

KodakNX printing plates that are popular worldwide owing to its excellent print quality. Flexo KodakNX printing plates are the preferred choice for flexo printing on account of their laser square spot imaging technology. The print efficiencies and compatibility of these plates with sustainable inks (water-based inks) enable printers and brand owners to step closer to their sustainability goals, in addition to delivering supreme quality print impressions.

The Holography business of UFlex offers advanced anti-counterfeiting solutions with unique security features and brand enhancement features to its customers. Its client range includes pharmaceutical, automotive, FMCG, consumer electronics, F&B, textiles, and more. The business offers an array of holographic solutions to brand owners to help their brands stand out on retail shelves, distinguish their products from fake products, and authenticate legitimate transactions and returns - thus promoting safe business practices.

The Printing Cylinders Business of UFlex traverses the complete print life-cycle from