Subscribe eNewsletter 23 197 Price in India Rs.100 volIssue23 03 March 2023 A monthly Publication from PRESSIdeas Publishing Pvt. Ltd. Efficiency through CountWONDER 08 DIC’s new Indian facility 12 Heidelberg SM CX104@Kumar Printers 14 4th Suprasetter A 106 for Prakash 18 All new imagePRESS by Canon 20 PAMEX 2023: Mega live show....................... 23 Print Xpress by Konica Minolta 32 Digital, hot topic in tube printing 36 Vol.23 Issue 03, 2023 digital printing signage printing

Contents

FROM THE EDITORS’ DESK

Automatic machine data collection leading to productivity enhancement

BMPA introduces ASCENT to the print allied fraternity

16th PRINTPACK India books 81% space within two months .......................................................................................................................................

DIC India inaugurates new state-of-the-art manufacturing facility

Aurelius closes the acquisition of Agfa Offset Solutions

Kumar Printers to explore the unexplored with Heidelberg Speedmaster CX 1047 + L UV

HBD Packaging installs India’s first RMGT 970

4th Heidelberg Suprasetter A 106 for Prakash

FESPA launches new Middle East event to serve growing print and signage market

Canon India reinforces proven imagePRESS with New Generation V Series

Glimpses of Pamex 2023

PAMEX 2023 greets an enthusiastic industry to a mega live show!

Pamex 2023 justifies theme; “Convergence of print.”

‘Print

brings new business opportunities with latest digital solutions

In which direction will tube printing develop?

SISTRADE expands into Chinese market with successful participation in Printing South China 2023

Jasmeet D. Editor & Publisher (jasmeet@pressideas.com)

Vineet K G. Associate Editor (vineetkg@pressideas.com)

Jasvinder S. Sub-Editor (jasvinder@pressideas.com)

Jacob George Marketing and Sales (jacob@pressideas.com)

M.S. Mukundan Advertising and Sales Southern and Western India (aims@pressideas.com)

Graphic Designer Anil Kumar

Networking/ Hardware Consultant Sukhdeep Singh

USA Correspondents Tensi M., Preeti

European Correspondent Rimi, Yadhu Morphine

Production Thomas K Alex PRESSIdeas March 2023 Vol. 23, Issue 03 Printed by Jacob George and published by Jasmeet Singh on behalf of PRESSIdeas Publishing Pvt Ltd. Printed in India at Hues and Colors 363, Industrial Focal Point, Phase-IX Mohali, and published at PRESSIdeas, 437-A 1st Floor, Industrial Area, Phase-2 Chandigarh-160002 (India)

Every effort has been made to ensure that credits accurately comply with information supplied. All material supplied is compiled from sources believed to be reliable or solely an opinion of the authors. PRESSIdeas is not responsible for any steps taken based on the information provided herewith.

4 March 2023

Subscription details/form on Page 06

6

8

10

11

12

13

14

17

18

19

20

............................................................................................................................................................................................................. 22

23

29

Highlights 30 Konica Minolta flags off

Xpress’ 32 eProductivity Software acquires Tharstern Group 33 Canon India launches

new

printers 34

35

PAMEX

16

advanced

Konica Minolta

36

37 Parksons acquires MK Printpack 38 Parksons

acquires Fortuner

39

Packaging

Packaging’s Business

FROM THE EDITORS’ DESK

Dear Readers,

PAMEX 2023 displayed the print industry’s optimism through enthusiastic exhibitor showcase and even greater visitor response. New product launches, live demos, public meetings, business deals and innovative solutions were abuzz all through the four days at the Bombay Exhibition Centre, Goregaon, Mumbai, the venue for this edition of PAMEX. “It’s not unusual to see happy exhibitors at the end of the first day of the exhibition. I’m seeing happy exhibitors even before the show has started,” wonders Prof. Kamal Chopra, Past President, AIFMP. The show grew by over 25% over the previous edition and boasted of over 450 exhibitors. Many products were launched for the first time in the Indian market. All the action was captured on the four large screens adorning the exhibition for all the visitors and exhibitors to witness.

Key highlights at PAMEX 2023 included: Xerox showcasing scalable specialty colour digital print technologies; Fujifilm showcasing flagship Revoria Press PC 1120; Autoprint launching two new machines; BOBST demonstrating its advanced NOVAFOLD 50, 80 & 110 folding gluing and folding carton system; TPH bagging order for two Orient folder gluers; Insight Communications introducing Atexco VegaPress - 440/660 industrial inkjet commercial printer; Megabound launching Quick Box carton box making machine; Hubergroup showcasing its sustainable solutions; HP India demonstrating its flagship Indigo 7K Digital Press; Line O Matic launching automatic flexo printing machine; Monotech Systems launching PixelFoil –foiling solution designed specifically for screen printers; VINSAK displaying the USAR with semi-rotary die-cut, Table Top Rewinder with Inkjet system and Roll Lifter; and the key highlights of Kunal Enterprise at PAMEX 2023 stall were: Functional Inks & Application; Foiling by Screen printing; Screen printing + inkjet printing + Foiling in one go; Natgraph electronic UV, Heat exchanging & Reel-to-Reel dryer; Computer to Screen by CST; Glass printing; Pad printing for uneven surface by Teca print; Special Clean room material; and Contract manufacturing by Sakurai.

On the penultimate evening Pamex 2023 played host to a glittering awards ceremony at the Gala Exhibitors’ Evening. AIFMP decided to institute several new awards to add to the prestigious NAEP and VCPLA Awards that were given away in the last edition. The awards function saw full attendance with printers and suppliers networking and celebrating the togetherness.

There are hundreds of other highlights of the show of which many others can be found in our review section. A few of them are about DGM Automation, Sangeeta Poly Pack, Ashwin Enterprises, Minosha, Konica Minolta, Cron, Komori and of course Canon - introducing the all new imagePRESS V1000 and imagePRESS V900 Series at the PAMEX 2023.

Our cover story this time is about Kumar Printers – the company explores the unexplored with their new Heidelberg Speedmaster CX 104 7 + L UV. The Manesar-based Kumar Printers has installed Heidelberg Speedmaster CX 104 seven-colour coater with UV to answer the premium print segment and to magnify opportunities. The story shares insights from an exclusive interview with Mr. Sandeep Bhargava, MD, Kumar Printers.

Enjoy reading all this along with our other regular updates from the printing, packaging and graphic arts industry.

- Jasvinder Singh, Sub-editor

6 March 2023 Subscription Form 1 Year (12 issues) 2 Years (24 issues) (For outstation cheques add Rs. 40/- extra) Rs. 750.00 Rs. 1250.00 5 Years (60 issues) Rs. 3250.00 1/2/5yrs. I am enclosing cheque/draft of

Promote for on our SOCIAL pages! FREE

We can be of help!

Each story we create, or for that matter, each press release that you share with us, not only goes on our popular website but also is shared on all above Social Media pages of PRESSIdeas.

Your social media content is the embodiment of your brand and each social network brings in it's own set of challenges. Well, we take of several factors that go into producing and publishing social media content.

We can help you not only in Content Creation - where and how to Start with but once created, to schedule them on the Social Media and then optimizing it to attain the expected success is also our job. Last but not the least, analyzing the results of the Social Media Campaign too shall be shared with you.

If you’re looking to get started, allow us to walk you through it. Allow us to hand hold you all along.

Write to digital@pressideas.com or WhatsApp on +91 9780036854 to know more!

Note: Our online editorial team holds the right to decide on the selection of posts to be included on our social media pages. The FREE offer is for a period of 45 days. It is advisable to have only a post in a week.

www.pressideas.com jacobpressideas jacob.pressideas only.pressideas +JacobGeorge-pressideas jacobgeorge1/

Automatic machine data collection leading to productivity enhancement

Any discrepancy in manually collected data can lead to deviant results and negatively impact your business. CountWONDER enables efficient automated data collection.

Almost all companies big, medium or small today use software in one way or the other to run their businesses, be it an Enterprise Resource Planning (ERP) or a Management information System (MIS) or a Manufacturing Execution Systems (MES). The real issue with these ERP/MIS/MES systems for each organisation is their reliance on production data collected from the shop floor which is mostly collected manually and entered into the system by a human operator.

Common Problems of Manual Data Collection

table stakes in the manufacturing business, where OEE equals availability multiplied by quality multiplied by performance”.

Key Notes :

> The issue of manually collected data with ERP/MIS/MES systems.

> Manually collected data pose problems like incompleteness, untimeliness, inaccuracy and bias etc.

> The biggest challenge that a printer faces in automated data collection is finding a way to communicate with many different types of equipment.

The common problems one faces with manually collected data include untimeliness, inaccuracy, and bias. Considering that this raw data forms the basis for all subsequent production reports—and that important decisions are made based on those reports—any discrepancy in the collected data can lead to deviant results and negatively impact your business. Typically we see this manually collected production data is entered into the system only at predetermined times, such as at the end of a shift or job. The data then is made available in the form of reports and used for analysis. For long term analysis this data is usually sufficient but knowing what has already happened after the occurrence has little significance and mostly detrimental to productivity, considering the dynamic environment of the factory floor.

Another problem with the manually entered data is:

it can be incomplete. This is because the actual data entry task usually falls to someone with many other responsibilities. Generally speaking, in a number of presses we visited and observed, data entry is a task that is often put off for as long as possible and it is not uncommon for raw data to sit around for hours, if not days before being entered into the system. As a result, reports don’t show the latest data. Additionally, the data must be written down first and later entered into the system—sometimes by a different person than the one who recorded it in the first place. Typographical and transcription errors are common.

8 March 2023

“The Overall Equipment Effectiveness [OEE] metric is now

- Madan Singh, Pentaforce Software

Once these errors become part of the data set, they become difficult to detect and eradicate, making all the resulting reports suspect.

Solution – Automated Data Collection

When we explore possible solutions to these problems, automated data collection is an obvious one. Automated Data Collection is collecting production data automatically, as it happens. Until recently, commercially available data collection software tended to be vendor-specific, especially if it collected data from proprietary machine controllers. And, if you had several different types of machinery and controllers, you would need several different data collection systems that would have to be custom-integrated by a third-party software writer which is in fact not a viable proposition.

Today, in India, the emergence of highspeed Ethernet as the de facto standard for local area networks has decreased the cost of network cards, adapters, and other hardware, allowing Ethernet to replace dedicated serial networks. Data collection software now can use a Web browser to display and manipulate data and e-mail to distribute reports.

Now if you look at it, the biggest challenge amongst many – that a printer faces in automated data collection – is finding a way to communicate with many different types of equipment. Today the maturation and widespread use of communication protocols have provided the means to move raw data in and out of many proprietary controllers, programmable logic controllers (PLCs), and other devices.

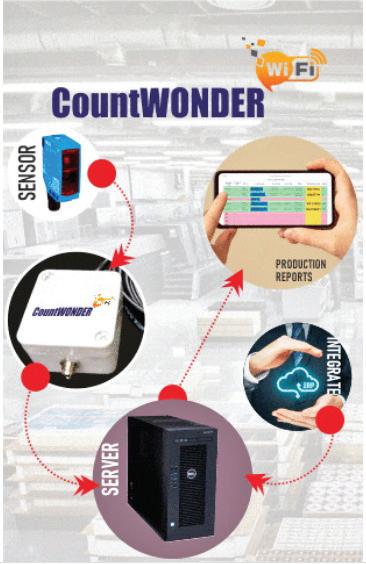

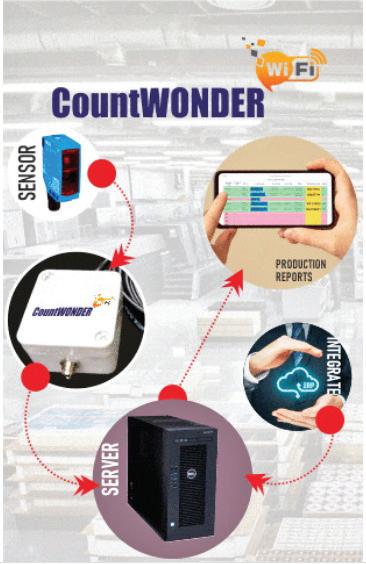

CountWONDER – Automatic production monitoring, OEE update & more

The Automated Data Collection solution from Unico Tech Solutions (UTS) (the agents for Pentaforce Software in India) is its CountWONDER. The key feature of this data collection and analysis system includes a sensor which collects data from the machine and passes it to the CountWONDER hardware which in turn passes it to the Data Logger via WiFi. The Data Logger has the proprietary analytics software which converts the received data into readable reports with options to even customise as may be required for individual customers.

The reports generated would include figures to enumerate the current condition of the machine like running, idle, unplanned down, planned down, changeover/setup etc. and many more. While part count and

machine state can be usually collected without operator input, the exact reasons for downtime can be entered with the Operator Interface when it comes to Downtime Reasons.

It may be possible to collect some downtime reasons automatically. If a machine is equipped with an “intelligent” controller or monitoring device and the controller initiates the machine stop, the reason can be reported back to the data logger automatically in the form of an error code.

However, if the machine is stopped by the operator or by a piece of ancillary equipment, the data collection software will not be able to determine the reason for stoppage. When this is the case, the transaction manager is forced to log this time as idle time. Since one of the main benefits of a data collection system is to identify reasons for productivity loss, simply logging idle time is unhelpful. The most effective way to enable an operator to specify the cause of a machine stoppage is to provide a pull-down menu of choices from which the operator selects the appropriate downtime reason.

One of the most important metrics that can be created with the data is overall equipment effectiveness (OEE). This is a simple percentage that shows the ratio of actual equipment output to its theoretical maximum. OEE factors in equipment availability, speed performance, and quality and is based on the premise that all production losses on machines and processes can be measured and quantified.

Over time data collection software will measure the production rate for every machine as it produces every part. In

pressideas/ commercial printing 9 March 2023

addition, it can track the changeover time for each machine as it changes from one part to the next. This data becomes more accurate the longer the system tracks it.

If you look at the machines on the shop floor of an average middle level printing press, many of the disconnected machines are bound to be older legacy equipment representing a huge investment, and these machines can require more technology than a standard MTConnect adapter to fully implement modern data collection, monitoring and analysis systems. And this is

exactly where CountWONDER comes as an affordable and reliable partner in action.

Reliable costs and quality are achieved by data-driven awareness on the shop floor, said Madan Singh of Pentaforce Software. “The Overall Equipment Effectiveness [OEE] metric is now table stakes in the manufacturing business, where OEE equals availability multiplied by quality multiplied by performance”. OEE is an ideal, industry-accepted metric, Mr.Sachin Kala of UTS added. “An OEE of 80% or more is achievable by most manufacturing

industry shop floors and the ‘money people’ understand this, yet the majority of shop floors can’t produce this measurement on any kind of consistent basis.

Well, you can arrange for an online demo by requesting your preferred timing by clicking here. You also have the option to visit UTS stall at PAMEX (Hall 1 Stall 6C) being held at the Bombay Exhibition Center from 27 – 30 March 2023. You may also write to unicotechsolution@gmail.com or visit www. unicotechsoution.com

BMPA introduces ASCENT to the print allied fraternity

BMPA has partnered with ASCENT Foundation, started by Harsh Mariwala (Chairman, Marico Limited) in 2012, to support the journey of growth-ready entrepreneurs through peer learning and experience sharing.

Designed as a peer-to-peer platform, ASCENT leverages the “Power of Collectives” and enables entrepreneurs to share experiences, ideas, insights to learn from each other through self-facilitated Trust Groups and an extended network of Enablers. In the last 10 years, ASCENT has selected over 860 entrepreneurs as members (from more than 3000 applications received) who are part of 74 operational Trust Groups in Mumbai, Chennai and All India Chapters. The composition of these members is quite diverse with a 46:54 split between Manufacturing and Services Industries; 44% Family Businesses; 7% Women

Entrepreneurs and in all about 65+ diverse industries represented. The aggregate annual turnover of the ASCENT members is more than Rs. 53,000 crores with individual member turnover ranging from Rs. 1 crore to Rs. 3500+ crores. For more details, Click here

ASCENT Foundation is a not-for-profit expression of Harsh Mariwala’s personal passion to identify and enable high-potential growth-stage entrepreneurs in their journey to grow both as Entrepreneurs and their Enterprises. ASCENT creates a close-knit Trust Group of non-competing entrepreneurs who believe in Learning from Doers. A few of BMPA members are ASCENT members as well; and they benefit by actively participating thereat.

“I am a second generation, family managed business entrepreneur. There are tasks of continuing the legacy, commanding respect rather than demanding it, dealing with family dynamics, getting modernisation in the daily operations and my ASCENT Trust Group which I call my Sounding Board have really helped me navigate through these

challenges effectively and efficiently which has helped me make a remarkable mark on my business and it continues to do so even today!”

- Ankit Tanna, Director, Printmann Group (ASCENT member for last 5 years and whose business is a BMPA member).

pressideas/ commercial printing 10 March 2023

16th PRINTPACK India books 81% space within two months

Overwhelming response shows the trust, popularity and importance of PRINTPACK INDIA exhibition.

The Indian Printing Packaging & Allied Machinery Manufacturers’ Association (IPAMA) had announced the dates of 16th PRINTPACK INDIA Exhibition which will be organised at India Expo Centre, Greater Noida, NCR Delhi from February 01-05, 2025.

IPAMA had reserved all the available Exhibition ground floor Halls of India Expo Centre, having 51,000 Square Meters of gross space. Within two months from the date of announcement of the Exhibition, till date 351 Companies have already reserved their space by depositing the token amount of Rs.25,000/-. The total useable space (Net area) of the Halls on the ground floor works out to 26,000 Square Meters out of which, as on date, around 21000 Square Meters of space has already been booked by the Exhibitors. Since the stands have not been allotted, the calculation is based on the area taken by the exhibitors in the last edition of PRINTPACK INDIA. Therefore, only 5,000 Square Meters of useable space is available for allotment to the prospective exhibitors. Major players of the industry have either reserved the space or being reserved.

The details of 351 Companies have been uploaded on the Website along with the Priority Numbers. The Priority Numbers are generated on the basis of the Bank Statement, containing the date and time of the receipt of the token amount, duly certified by the Chartered Accountant of the Association. Complete transparency is being observed in generating the Priority Numbers on the basis of which the space will actually

be allotted to the Exhibitors ad seriatim in the respective Halls. Keeping in view the practice and convenience of the Exhibitors & the Business Visitors, some of the Halls will be reserved segment-wise. Separate halls have been earmarked for Label, Corrugation, Screen Printing, Paper, Signage & LED and rest of the printing segments including digital, Offset, Packaging and allied products/ Machines.

The last date for availing of the Early Bird Discount, Rs. 1600/- Per Sq. Mtr, has also been uploaded on the Website. The special motivational discount, Rs. 1500/- and Rs. 500/- per sq.mtr will be provided to IPAMA Members, as per the existing policy, including the new Members. And at last but not least, membership discounts will also be provided as per the tenure of membership.

Mr. Rakesh Sodhi, President IPAMA said, “IPAMA is striving hard to make PRINTPACK INDIA, a next level exhibition. Our purpose

is not make profit from the exhibition, it is only for the benefit of the Indian machine manufacturers who are working hard for the growth and development of the Indian industry, and IPAMA is whole heartedly supporting them.”

The Companies, who have not yet booked space and are interested to participate in the Exhibition can do so by depositing a token amount of Rs.25,000/-. On receipt of the remittances, the Priority Numbers will be generated and communicated to the respective Companies and also simultaneously uploaded on the Website. The space will be allotted on the basis of “First Come First Served” basis.

IPAMA is expecting more than 1,25,000 business visitors to visit the Exhibition. The last edition of this Show was visited by 1,03,412 business visitors which provided an unmatched business platform. DON’T MISS THIS MEGA EVENT!

pressideas/ commercial printing 11 March 2023

DIC India inaugurates new state-of-the-art manufacturing facility

Invests INR 1100Mn in the new plant in Saykha, near Bharuch city in Gujarat.

Manufacturer of printing and packaging inks, innovative packaging solutions, and allied material, DIC India (part of DIC group), has inaugurated its advanced and latest Toluene free plant ‘Optima’ for Liquid Ink manufacturing at Saykha in Bharuch district, Gujarat. Spread across a vast area of 92,500sqm, the plant has the capacity to manufacture over 10,000+ Tonnes of TF, KF/NTNK (Toluene Free/ Ketone Free) liquid inks in two shifts in phase -I . The plant will be further augmented to produce value added and specialty products for domestic and export markets.

The new plant set up has been constructed using leading technological features to modernize as well as to increase production efficiencies. This plant is a completely Toluene free plant for DIC India.We are optimistic that the manufacturing facility will help in catering to both domestic as well as international demand and expand our footprint in India.”

Mr. Manish Bhatia, MD & CEO, DIC India

Key Notes :

> Targets to meet increasing demand with its 5th plant in India.

> To generate 100 + direct employment.

> Installed production capacity of 10,000 T + of TF, KF/NTNK liquid inks.

Set up with a total investment of INR 1100Mn for phase -I the new plant will provide direct employment to more than 100 associates with the aim to cater to the growing demand of toluene free and ketone free based inks in the country.

With this new plant, DIC India will now have an expanded footprint in India. Its other four plants are at Kolkata, Uttar Pradesh, Gujarat (Ahmedabad), Karnataka.

Established at the center of the chemical hub of India, the strategic location gives the company close access to the Northern and Western markets that drive majority of the demand in the segment. The

plant boasts of a bulk line manufacturing facility for supplying standard and specialty TF, KF/NTNK inks.

Constructed with care, the plant, called OPTIMA plant is laden with latest technological features to cater to the growing demand in the country at present. The plant has also been designed to accommodate future expansion needs of the company. The Optima plant will also work towards strengthening the company’s business in export markets.

Speaking on the occasion, Mr. Paul Koek, Regional Managing Director, DIC Asia Pacific said, “The Indian market is a priority market for DIC group and this new manufacturing facility has been established with the vision of catering to the new demand as well as usher in new growth prospects for us in the country. As a market leader in printing ink manufacturing,

12 March 2023

we are bringing more advancement in our manufacturing processes to augment our quality and customer service, meet the rising demand and maintain global standard at all our touch points. This facility , with a strong inbuilt design features which will expand sustainability footprint of DIC India will benefit customers, generate employment as well as solidify our over 75 years presence and leadership in India.”

Mr. Manish Bhatia, MD & CEO at DIC India Limited, said, “India is a strategic market for us and our long standing journey in the country is a testimony to the success we have achieved over the years. The market is witnessing increased demand for technological superior and specialty printing inks for packaging. The inauguration of the new facility is another stepping stone for the company’s future expansion plans here. The new plant set up has been constructed using leading technological features to modernize as well as to increase production efficiencies. This plant is a completely Toluene free plant for DIC India. We are optimistic that the manufacturing facility will help in catering to both domestic as well as international demand and expand our footprint in India.”

Out of the plant’s 92,500 sqm, 45,000sqm has already been constructed under Phase 1. The area will be used for consolidation

of different plants and different types of products of DIC Indian Operations.

DIC is in the process of getting green certification for the site. This will be probably the first plant in India to achieve this accreditation. Optima site, as the plant is called, produced TF and KF products, also in compliance with international regulations. The company also aims to achieve ISO and OSHAS certification for the Optima plant by the year 2023-34.

Known as COATES OF INDIA LIMITED at the time of its inception, DIC India came into existence on April 2nd, 1947. Nearly 71.75%

of the company’s shareholding belongs to DIC Japan through DIC Asia Pacific Ltd. Singapore.

What started out with a single service center in Kolkata, today it has evolved into a number of factories and logistics centers strategically placed all across the country. DIC India Limited has a Broad Network of printing ink suppliers throughout the Country. The company has a well-spread distribution network that covers the length & breadth of the country for the range of offset ink suppliers and gravure ink suppliers as well for the betterment of Product Understanding & On-site Products Demo.

Aurelius closes the acquisition of Agfa Offset Solutions

Overwhelming response shows the trust, popularity and importance of PRINTPACK INDIA exhibition.

AURELIUS has announced the successful completion of the acquisition of Agfa Offset Solutions from the Agfa-Gevaert Group. The division is one of the leading global suppliers of prepress solutions to the offset printing industry. In FY22, Agfa Offset Solutions generated EUR 779m in revenues which translates into a global market share of roughly 20 percent.

The company supplies the offset printing industry with prepress solutions like offset plates, graphic films or software and

is commercially active in more than 75 countries worldwide. The firm is present across all steps of the prepress valuechain, offering a portfolio of offset plates, graphic film, equipment & services, as well as software and chemicals. Agfa Offset Solutions reached a market leading position in Europe and LATAM and ranks among the top players in other markets.

Under the terms of the share purchase agreement with AURELIUS Group, the Agfa-Gevaert Group will continue to provide certain consumables (including film) and services to its former division.

“The sale of our Offset Solutions division is an important step in our transformation journey. I want to thank all Offset Solutions employees for their professionalism, dedication and loyalty over the years and

wish them all the best in the future. I am confident that with AURELIUS, they will continue a track record of innovation and leadership.

In turn, this transaction will allow Agfa to focus on other growing market segments, which is crucial for our future success,” said Pascal Juéry, President and CEO of the AgfaGevaert Group.

The Agfa-Gevaert Group is a leading company in imaging technology and IT solutions with over 150 years of experience. The Group holds three divisions: Radiology Solutions, HealthCare IT and Digital Print & Chemicals. They develop, manufacture and market analogue and digital systems for the healthcare sector, for specific industrial applications and for the printing industry.

pressideas/ commercial printing 13 March 2023

Kumar Printers to explore the unexplored with Heidelberg Speedmaster CX 1047 + L UV

Manesar-based Kumar Printers installs Heidelberg Speedmaster CX 104 seven-colour coater with UV to answer the premium print segment and to magnify opportunities.

Kumar Printers, a flag bearer in the Indian print industry, has inspired the printers with its technology adoption motivation, innovative solution offerings, efficient business management, and growth-focused leadership.

“The Heidelberg Speedmaster CX 104 is a big investment for us, as it offers topnotch print quality.The next-generation CX 104 press, has a fully loaded AI-driven operation that speeds up make-ready, reduces waste, minimizes operator interference, and increases OEE (Overall Equipment Efficiency).

The Speedmaster CX 104 focuses on enhanced productivity and takes care of print complexity and job intricacy with ease.” - Sandeep

Bhargava, MD, Kumar Printers

Key Notes :

> The latest Heidelberg Speedmaster CX 104 at Kumar Printers is a sevencolour workhorse specializing in UV and coating applications.

> The CX 104 strength is: production of specialized packaging printing for premium market segments.

> High-quality standards; necessitates unique product ideas; gives the finest quality; and opens up diverse possibilities.

Kumar Printers have been adding high-end presses from Heidelberg to bolster the company vision. Apart from the other presses at Kumar Printers’ which has up to six-colour presses; the latest Heidelberg Speedmaster CX 104 is a highly capable sevencolour workhorse specializing in UV and coating applications. The CX 104 achieves high print quality at a faster speed which is a perfect complement to Kumar Printers’ existing presses. The strength is the production of specialized packaging printing for premium market segments with high-quality standards and necessitates unique product ideas, the finest quality, and diverse possibilities.

Sandeep Bhargava, Managing Director at Kumar Printers is an alumnus of IIT Chennai, and after joining the printing business, he also completed a printing management course. “The Heidelberg Speedmaster CX 104 is a big investment for us, as it offers topnotch print quality. The next-generation CX 104 press,

has a fully loaded AI-driven operation that speeds up make-ready, reduces waste, minimizes operator interference, and increases OEE (Overall Equipment Efficiency). These are the features that every print shop is searching for. The Speedmaster CX 104 focuses on enhanced productivity and takes care of print complexity and job intricacy with ease,” said Sandeep.

14 March 2023

Mr.SandeepBhargava,ManagingDirector,KumarPrintersandMr.HarshBhargava,withtheSpeedmasterCX104sevencolourpress.

Possession of New Heidelberg Speedmaster CX 104 7 + L UV

Having scrutinized other supplier models before finalizing on the Heidelberg SM CX 104 seven-colour plus coater, it was easy for Sandeep and his team to opt for the CX 104. The installation of Heidelberg Speedmaster CX 104 at Kumar Printers is the first in Northern India.

“Kumar Printers is known for its premium printing quality with reputed clientele in the pharmaceutical, liquor, garments, engineering industries, and personal care segment. With the enhanced technological press at Kumar Printers, the team would be exploring new possibilities of expanding into mass production and different geographies,” added Sandeep Bhargava.

Heidelberg Prinect Image Control 4

The Speedmaster CX 104 focuses on increasing efficiency with all user-friendly software features like Intellistart, Intelliline, Intelliguide, and Intellirun. With the simplified changeover process; the changeover time should be lower with the software assistance. With this investment, Kumar Printers is looking to overcome the efficiency challenges which every packaging converter is going through.

Kumar Printers had been using the IntelliTrax device for a long time. Kumar Printers used Spectrophotometers, bought in 1995, along with ink formulation software. Kumar Printers were the second company in the country to use a spectrophotometer and the first printing company to use ink formulation software in India. Sandeep had seen the ‘Prinect Image Control’ working in the USA and Germany.

He wondered, if people there can produce such huge volumes on a single machine, then why can’t we do it in India? When Sandeep decided to buy the Speedmaster CX 104, he was aware of the capabilities of the press and knew that it could deliver wonders to them. “Once we are used to getting our jobs done in a particular way, it will not only be giving amazing output and result but will also reduce additional efforts,” says Sandeep. The Speedmaster CX 104 with Prinect Image Control has delivered on all three segments – increased output, quality results, and reduced efforts for Kumar Printers.

‘Prinect Image Control 4’ spectrally scans the whole print sheet and balances out even the minute deviations in the print image automatically. It detects all measuring elements and solid areas using the pre-press data and incorporates them into the control process. CMYK images and halftone areas can be corrected using print samples and proofs. A high resolution of 50 million pixels or CIEL*a*b values with the proof match for a faster alignment of the finished print.

“We expect an ROI for one year as this is a technological press and has a specific procedure to follow to get it to work to get desired results. We are open to the required learning curve; and time to get used to the entire process. It takes a while to get things

going in the right direction.”

Challenges and Opportunities

After returning to the usual working atmosphere, the industry continues with just a few good things. Sandeep says, “The business is back on its feet with a huge opportunity in the paper packaging segment in volumes. India has increased its consumption, and the quality of the consumption in terms of consistency and performance of the pack leaves are desired,” added Sandeep.

The FMCG products that may usually sell on display shelves – the quality of packaging and their appearance play a crucial role in buying decisions. But when it comes to

pressideas/ commercial printing

(InPicture):Mr.SandeepBhargava,inspectingaprintedsheetonthePrinectImageControlstation

(FromLeft)Mr.HarishGogia,ClusterSalesHead–North&East,HeidelbergIndiawithMr.SandeepBhargava,MD–KumarPrinters,Mr.HarshBhargava–KumarPrintersalongwithMr.SonuGujjar,ProductionManageratKumarPrinters.

engineering goods like automobile and electronics parts, retailers and consumers hardly care for the quality of packaging, and it looks. They are not even concerned about its functionality.

“There is a huge potential in the market, if the quality of the packaging is taken care of, then the issue of counterfeit can be resolved, which are highly affected by this issue,” observes Sandeep while discussing the opportunities.

According to Sandeep, the factor affecting the efficiency of the printing industry is the unemployment of the skilled workforce. Sandeep stresses on, there may be skilled people employed as replacements, but there is a terrible shortage of people combining the correct type of skill with the right attitude. Sandeep suggested industry-varsity tie-ups to guide and motivate students to develop the right attitudes with skills.

Advantages of the Speedmaster CX 104

Kumar Printers has a significant capability to boost with the addition of the seven-colour Speedmaster CX 104, which offers enormous possibilities with the additional colour station; they had been using six-colour before the latest press installation. The Speedmaster CX 104 is the cross-segment straight-printing press for commercial, packaging and label printing. “The press offers more numbers of colours, and the possibilities are vast – we can print three special colours, metallic colours; we have limitless options to blend and combine colours and effects to our premium offerings. We wanted to print a

pressideas/ commercial printing 16 March 2023

(InPicture)SpeedmasterCX104’sinnovativewallscreenanduser-friendlytouch-screendisplay.

carton with metallic look and not MET PET; we were in dire need of the flexibility and the facility to print metallic ink first and rest of the six colours over. It’s the special value addition that we will be presenting and promoting to our customers. The first market segment on our target for this application is the cosmetics sector. Subsequently we will expand to garments and alcobev cartons etc,” envisages Sandeep.

The Speedmaster CX 104 opens completely new range of possibilities - including navigated print production. It is ensured by intelligent support systems such as Intellistart 3 and the unique Intelliline. With the intuitive touch operation, settings can be done with an ease of a click, and the operation can be managed with the required profile.

The patented Intellistart 3 defines all the steps required for the job change without an operator intervention. Intelliguide simulates the time-optimized sequence live and, if necessary, also includes the steps to execute manually. The Speedmaster CX 104 has a wall screen setup for the control, and the 24 inches multi-touch screen offers intuitive operation like a smartphone.

Expansion plans with Heidelberg Speedmaster

Kumar Printers has rented premises of 30,000 sq/ft., where they would be shifting their corrugation facility to accommodate capacity expansion enabled by their new Heidelberg. Sandeep looks forward to at least a 60 percent combined capacity expansion with his latest set-up. “We have enough post-press capability to handle our target expansion for the future. We had bought folder-gluer before purchasing a printing press; we added die-cutting and more,” added Sandeep.

Circular Economy and Kumar Printers

Kumar Printers started recycling their trade discharge in the year 2008, and by 2012 they were recycling it 100%. It has been over ten years since Kumar Printers had 0% water discharge from any trading process. For solid waste management, they have been disposing of it through a state-appointed authority. Apart from these measures to contribute towards a circular economy, they are offering alternative solutions to their clients, who seek materials in place of their MET PET products. Considering the

complexity of recycling MET PET, they have alternatives for clients seeking UV printing directly onto the product. Kumar Printers has mastered the process of UV printing and have been doing it for a long time.

International Association of Printers

Kumar Printers is part of a global alliance of printers with six partners across the international markets. The alliance members are from Brazil, Mexico, USA, China, and Korea. “The way of working with overseas partners is very different from that we work in India. For example, the Mexican partner, while putting up his factory with three printing line, they knew that in next 8-9 month, he would be adding two more printing lines. They had calculated the period in which his existing capacity would exhaust and will expand to a certain level. The whole approach towards business in those markets is different from what we have here. We don’t have such a market; they have contracts with the customer, decide the demand and supply equation beforehand and plan the capacity to meet those demands. Product pricing plays a crucial role in India despite the quality of products and service.” However, it’s not crucial in the premium segment which Kumar Printers chiefly caters. Sandeep wishes for the day when Indian print industry will be more organized to have customer contracts

and enable printers here too sail in a similar fashion.

A Complete Packaging Solution

In India, Kumar Printers is one of the top manufacturers of paperboard packaging, converting over 12,000 tons of paper and paperboard per annum. The state-of-theart infrastructure, world-class quality, and a highly skilled and dedicated team led by Sandeep Bhargava have combined Kumar Printers as the supplier for premium packaging. With two sites for manufacturing, one in Manesar and another in Indore, Kumar Printers can provide five product lines of paperboard packaging to its customers across India and foreign markets: Mono cartons, rigid boxes, corrugated cartons, blister cards, and insert and outserts. The client list of Kumar Printers includes Nestle, Volkswagen, Jockey, Adidas, Duracell, Gillette, P&G, Sun Pharma, Teachers, Dr. Reddy’s, and Colgate.

Sandeep’s decision to go with Heidelberg was influenced by the fact that the entire team was well-versed in Heidelberg technology, there would be little of a learning curve, Heidelberg India provided excellent service support, and the press had a solid reputation for its build quality and production ability. “Heidelberg has always been a reliable name,” concluded Sandeep.

HBD Packaging installs India’s first RMGT 970

HBD PACKAGING welcomes a brand new RMGT 970 Series 7 colour plus coater press!

RMGT’s first 38” inch press in India has just been installed at HBD Packaging. This press is equipped with a host of performance enhancing automations and labour saving mechanisms which makes it a SMART packaging press. Its Retractable coating unit, Predictive density control system, Program inking, Feeder Air presetting, Automated operator assist functions coupled with superior economy are just a few of the points which gives this press a competitive edge over others.

The RMGT 970 at HBD has been provided by Provin Technos.

pressideas/ commercial printing 17 March 2023

4th Heidelberg Suprasetter A 106 for Prakash

Mangalore’s Prakash Offset Printers installs fourth Heidelberg Suprasetter A 106 CtP equipment.

Mangalore-based renowned printing firm Prakash Offset Printers has invested in a brand-new Heidelberg Supertaster A 106 CtP. Prakash Offset Printers established in 1983 to cater to their in-house print requirements with complete pre-press, press, and post-press setup. Today, Prakash Offset Printers has an immense reputation and standards in the print industry.

The Suprasetter A 106 CtP was installed at Baikampady unit at Mangalore in December 2022. The relationship between Heidelberg and Prakash Offset Printers is of more than three decades, like their experience in the industry. It’s the fourth Heidelberg Suprasetter A 106 CtP at Prakash Offset Printers.

Prakash Offset Printers has an array of Heidelberg presses from Heidelberg M offset

to Speedmaster XL 75 and Speedmaster SM 102. Also, Prakash Offset Printers had installed India’s first Heidelberg SX 52 Anicolor press in 2014; and a complete range of Polar cutting and Stahlfolder folding machines at their shopfloor with three Suprasetter equipment.

Prakash Offset Printers has two units at Mangalore, the pre-press unit located at the heart of the city with a spread across 5,000 sq/ft area, and the production unit located at Baikampady industrial estate has a 35,000 sq/ft operational area, catering to commercial, book publishing, packaging, printing, and folding carton conversion.

P R Nayak, Director at Prakash Offset Printers, said, “We were certain about our investment right from day one. The Heidelberg Suprasetter A 106 is a rewarding

equipment. We have been using Heidelberg Suprasetter CtP equipment for over a decade, and the performance and quality are exemplary.”

“The Heidelberg Suprasetter A 106 is known for its proven record-breaking performances. We are very sure about the investment as it will enable us to grow and give amazing services to our valuable customers,” added Nayak.

Heidelberg Suprasetter A 106 supports the firm for its upgradations and growth. It has boosted productivity and has given Prakash Offset Printers a more advanced pressroom. The modular design of the Suprasetter A 106 provides maximum flexibility for the mediumsize print format. The patented laser system by Heidelberg offers an excellent imaging quality. The production reliability is ensured through the Intelligent Diode System (IDS), it means that if a diode fails, the operation can continue.

The Suprasetter offers a consistently high depth of focus to compensate for unevenness in the plates.The temperature of all the components relevant to imaging is maintained at constant levels. The imaging of the printing plates always take place under the same condition – a performance feature particularly beneficial for plate remake. Any deviations caused by ambient temperature change are avoided, as this maintains the high register accuracy with the printing plates allowing a faster makeready on press and a minimum of waste.

The Suprasetter A 106 CtP has a dimension of 84.65 widths × 58.82 depth × 60.47 height (inches), with a minimum plate format of 370 height x 323 widths (mm); and a maximum plate format of 930 height × 1,060 widths (mm) and has a resolution of 2,400 dpi.

Heidelberg India is delighted to be part of this eminent journey of Prakash Offset Printers and will continue. “We believe in Heidelberg and are sure about the Suprasetter A 106 CtP as it will help us to reach new heights,” concluded Nayak.

pressideas/ commercial printing

(Picture:MrP.R.Nayak,DirectoratPrakashOffsetPrinters,withtheHeidelbergSuprasetterA106CtPequipment)

FESPA launches new Middle East event to serve growing print and signage market

FESPA has launched FESPA Middle East, a new event serving the speciality print, signage and visual communications community in the Middle East and Africa regions. The first edition of the annual exhibition will take place at Dubai Exhibition Centre, United Arab Emirates, from 29 to 31 January 2024.

The exhibition is expected to welcome over 100 global brands. At the event, FESPA will host the first World Wrap Masters competition in the Middle East, a Sustainability Spotlight educational feature, a conference and technical training programme and a Club FESPA Lounge for FESPA Direct (MEA group) members to network.

FESPA CEO Neil Felton comments: “Major vendors have been expressing a strong appetite for a content-led FESPA event in the Middle East for some time, matched by demand from the leading speciality print service providers. It’s a market that continues to show solid year-on-year growth, with key sectors such as tourism and property demonstrating healthy post-COVID recovery, alongside the region’s renowned core industries. Landmark events have recently showcased the region’s capacity to serve international visitors with world-class facilities. Through our recent FLEX Summit and our increasing FESPA Direct membership in MEA, we’re establishing FESPA’s brand in this region, and we believe that now’s the perfect time to inspire and stimulate the Middle Easts’ print, signage and visual communications community with a FESPA event.”

Regional print industry stakeholders at

the recent exclusive FESPA Leadership Exchange (FLEX) Summit in Dubai responded enthusiastically to the idea, commenting: “There’s a lot of development in this region which leads to new opportunities in the print field. FESPA’s experience and know-how will complement that”; “FESPA Middle East will be an important training and learning event for printers in this region, and it will be a great chance for us all to share and connect”; “We’re excited for the event to come to the Middle East to help lift the industry, increase education and make a difference in the market”; “The new event will lead to a lot of new opportunities for us as printers”.

Like FESPA’s established regional events in Eurasia (Istanbul), Africa (Johannesburg), Central America (Mexico City) and Brazil (Sao Paolo), FESPA Middle East will provide an important, targeted sales and marketing platform for exhibitors including principal suppliers and distributors of equipment, software, media and consumables for digital, screen, textile printing and sign-making.

The visitor audience will comprise of large format digital printers, textile printers, print service providers, fleet graphics producers, sign-makers and fabricators, brand owners and creative agencies, interior designers and architects, and visual communications professionals from the Middle East, Africa and South Asia.

FESPA has selected the location of the Middle East event to attract the regional print industry from a wide geographical area, including the Gulf Corporation Council countries (UAE, Saudi Arabia, Oman, Qatar,

Kuwait and Bahrain), which have a combined population of over 57.2 million and a GDP of over $4.37 trillion. Dubai is also an accessible location for visitors from the wider Middle East, North and Central Africa, and South Asia.

Centrally located for this region, Dubai is the choice of many global brands seeking to establish a direct presence in the Middle East, including multiple major print equipment and materials vendors. It also serves as a commercial gateway to Africa for many industries.

The city’s well-developed infrastructure and excellent travel and logistical connections via air, sea and land make it an appealing host city for an international event of FESPA’s calibre. Jabel Ali Port serves as the 9th busiest port in the world and Dubai International Airport (DXB) is the #1 international airport in the world serving more than 240 destinations via over 100 airlines connecting Dubai to a third of the global population within four hours’ flying time. Dubai also has an interlinked road network connecting the wider region.

FESPA has appointed an experienced exhibitions team in Dubai to sell and promote the new FESPA Middle East event, supported by the resources and expertise of the global sales teams based out of UK, USA, Brazil, Mexico, Turkey, South Africa, Thailand and China.

pressideas/ commercial printing 19 March 2023

Canon India reinforces proven imagePRESS with New Generation V Series

Introduces all new imagePRESS V1000 and imagePRESS V900 Series at PAMEX 2023.

“Innovation stays core to all product development at Canon. Hence, with transformation as a key strategy for us this year, we are proud to unveil the new imagePRESS V series that also reflects our commitment to aligning products and solutions with customers’ changing expectations and industry trends.”

- Manabu Yamazaki, President and CEO, Canon India

Key Notes :

> A perfect synergy of superior technologies with enhanced media flexibility and higher productivity.

> The new series is suitable for Light and Mid Production Print Environment.

> Will offer users features such as Versatility, Viability, High-Volume Printing and Vibrant Print quality.

Canon India, one of the leaders in the digital imaging industry, has launched a new generation of the imagePRESS series, comprising V1000 and V900, at PAMEX 2023 in Mumbai. The latest digital colour press printers exhibit a perfect synergy of superior technologies, incorporated over well-established previous models, with enhanced media flexibility and higher productivity. The new series, suitable for Light and Mid Production Print Environment will offer users features such as Versatility, Viability, High-Volume Printing, Vibrant Print quality, and is a perfect Visionary Print partner for business growth, thereby empowering businesses to #BeVictoriousWithVSeries.

PAMEX is a premier printing exhibition and global business platform for the print, label & converting industry, held at Bombay Exhibition Centre, Goregaon from 27- 30 March. Centred on the theme of #BeVictoriousWithVSeries, the Canon stall was also exhibiting other marquee products, including upgraded wide format printers like imagePROGRAF TM, TZ & GP Color Series, and the recently launched imagePROGRAF TC series.

Speaking on the occasion, Mr. Manabu Yamazaki, President and CEO, Canon India, said, “In the ever-

evolving landscape of business with technology at the forefront, innovation stays core to all product development at Canon. Hence, with transformation as a key strategy for us this year, we are proud to unveil the new imagePRESS V series that also reflects our commitment to aligning products and solutions with customers’ changing expectations and industry trends. As industries increasingly move towards automating their tasks, the focus has shifted from not only increasing productivity, but also increasing flexibility and quality in the output. By creating a technological synergy in the new futuristic printers, we are unlocking new opportunities for success and growth, for both Canon and our customers. We are excited to be pushing the boundaries in printing technology and enable our customers to #BeVictoriousWithVSeries.”

Event Review 20 March 2023

Sharing his thoughts on the exhibition, he further stated, “PAMEX has always provided us with an appropriate platform to demonstrate some of our marquee offerings, amidst a large gathering of jobbers, commercial printers, and book printers. Hence, we expected a good footfall yet again at the event, providing us the opportunity to demonstrate the unique capabilities of the new V-series.”

The Versatile imagePRESS V series is equipped to handle a wide range of printing tasks, ranging from simple documents to topnotch marketing materials on varying types of substrates. The excellent efficiency and cost-effectiveness make the V1000 and V900 Viable choices, empowering businesses to grow and succeed. The printers’ ability to produce high Volume prints and smoothly switch between different papers allows busy print shops and in-house printing departments to increase their production capacities. Furthermore, the new series has exceptional quality prints that are teeming with Vibrant colours while being sharp and detailed. Overall, the new generation offers Visionary technology to long-term growth driven businesses and customers, in mid and Light-production segments.

Commenting on the launch, Mr. C Sukumaran, Senior Director, Products & Communication, Canon India said, “As we launch a new generation of imagePRESS

V series, we at Canon India are thrilled to be equipping businesses with cutting-edge technology that enables them to unlock new levels of productivity and efficiency. The new V1000 for the mid-production segment, and V900 for the light-production segment, provide users with increased flexibility to handle diverse applications with a very broad media capability, thereby empowering them to explore new business avenues. Combining various productivity-enhancing features to help operators tackle day-to-day production challenges, these digital colour press printers will ensure that customers can boost both quality and quantity of their output and also meet demanding timelines. Overall, the new series exhibit the power of V- providing users with increased versatility, viability, high volume and vibrant print quality, all coupled with visionary technologies. Our endeavour of best-in-class innovation and customer satisfaction remains unwavering, and we look forward to helping businesses achieve greater heights with our latest offering.”

Key features of imagePRESS V1000

Effective Task Automation

With a strong emphasis on task automation, the imagePRESS V1000 helps PSPs ensure colour repeatability and registration alignment effortlessly. The Inline Spectrophotometers (ILS) allow operators to easily perform advanced colour adjustments

such as engine linearisation, colour profile creation, calibration, and colour validation in a short span of time with minimal operator intervention. In addition, a new Precision Registration Technology helps operators ensure the alignment of duplexed sheets remains accurate and consistent during long production runs.

The imagePRESS V1000 also has a strong front-end controller options: the imagePRESS Server D3000.Powered by the Fiery FS500 Pro system software, the imagePRESS Server D3000 adds new functionalities, including familiar workflow and prepress features. In addition, the Express Media Colour Manager and Auto Recall combined with the ILS deliver swift colour management on an intuitive interface.

Productive Print Operations

Integrated with POD-SURF (Surface Rapid Fusing), the imagePRESS V1000 effectively maintains a consistent print speed of 100 ppm on coated and heavy media types up to 400g/m2(gsm), sustaining high efficiency when printing complex and mixed media jobs. When used with the Bypass trays, the optional Multi-Drawer Paper Deck boost the paper input capabilities to create a wide array of premium applications. With remote alerts, operators can change media and toner and remove toner waste while keeping the imagePRESS V1000 running for maximum productivity.

High Quality and Reliability

The imagePRESS V1000 features an innovative cooling system that cools paper immediately after fixing it. Minimising the risk of warping, sticking or bricking, the new cooling system ensures optimum print quality and avoids potential waste for the best cost-efficiency. Moreover, a new transfer technology creates the ideal transport path for each sheet of paper during the printing process and ensures even colour distribution when operators switch between media types with different weights during printing.

pressideas/ event review 21 March 2023

The imagePRESS V900 Series –Versatile Entry-Level Models

Perfect for light volume production, the imagePRESS V900 series produces monthly print volumes of up to 500,000 A4 pages, and consists of three different entry-level models, the V900, V800 and V700 with print speeds of up to 90/80/70 A4 pages/minute respectively. Built to meet the needs of varied production environments, the imagePRESS V900 series delivers superb versatility by incorporating the latest technology that adjusts the suction force before fixing according to different paper weights, stabilising the transport of thick paper.

The imagePRESS V900 series also includes feed rollers and strengthened transport rollers to improve the transport stability for thin, thick, and short paper, expanding the variety of high-quality applications printable on the press. The versatile series supports

a wide array of media ranging from 52g/ m2 (gsm) plain and 70g/m2 (gsm) coated to 350g/m2 (gsm) thick media, narrow envelopes, auto-duplex 762mm and simplex 1.3m banners, as well as embossed and synthetic paper.

Eliminating the need for highly skilled operators, the imagePRESS V900 series incorporates new time- and labour-saving automation features that ensure ease of use. The inclusion of an optional Duplex Colour Image Reader Unit allows the press

Glimpses of Pamex 2023

to make rapid pre-print adjustments to front and back registration, colour gradation and density, as well as secondary transfer voltage to ensure high-quality production even on textured media. PSPs can simply run printed adjustment charts through the Automatic Document Feeder, a part of the Duplex Colour Image Reader Unit, and the press makes the required adjustments automatically. Other time-saving features on the imagePRESS V900 series include remote alerts that inform operators when consumables run low.

pressideas/ event review 22 March 2023

PAMEX 2023 greets an enthusiastic industry to a mega live show!

Receives an overwhelming visitor response for a live showcase by over 450 exhibitors; running machines, innovative products & solutions demo, special zones, on the spot order bookings and expert meetings being the key highlights.

PAMEX 2023 attracted thousands of serious quality visitors throughout the four days of the grand show representing the Printing, Packaging and allied industries. PAMEX 2023 was officially declared open amidst a host of dignitaries and who’s who of the industry. The industry leaders at the inauguration included Raveendra Joshi, President AIFMP & Chairman of PAMEX; Prof Kamal Chopra, Past President, AIFMP & President, WPCF; Manoj Mehta, Past President AIFMP & President FAPGA; Raghabendra Baruah, General Secretary, AIFMP; P Chander, Imm & Past President, AIFMP; and Anil Arora, Director, Print-Packaging.com Private Limited.

In his inaugural speech, Raveendra Joshi appreciated the overwhelming industry

response received on the very first day of the show by way of number of visitors reaching the venue. Referring to the revival of the market and return of normalcy in business post-pandemic, Prof Kamal Chopra, Past President AIFMP & President of WPCF, said, “Post pandemic, we are now on the growth path and now is the time to get up and do profitable and successful business.”

While, Manoj Mehta, in his inaugural address, mentioned that the expo has expanded its show floor and increased the number of halls as compared to the previous editions. He added that the expo is featuring special zones for special products and technologies such as Artificial Intelligence (AI), flexible packaging, among others. Featuring more than 450 exhibitors, the show is presenting a

largest gamut of live running machines and innovative products and solutions for the industry.

Many key dignitaries were commemorated during the opening of the landmark expo. They included Nitin Narula, Vice President (North), AIFMP; Bidyut Ranjan Nag, Vice President (East), AIFMP; Anant Vishwanath Joshi, Vice President (West), AIFMP; Rahul Mahajan, Joint Secretary, AIFMP; Rakesh Sodhi, President, IPAMA; Sandesh Tere, President, Screen Printer Association of India (SPAI); Manish Shah, Vice President, ICPMA; and Manish Jain, Vice President, FCBM. Tushar Dhote, Co-Chairman, PAMEX 2023 presented bouquets to all dignitaries at the inaugural session.

pressideas/ event review 23 March 2023

At PAMEX 2023, the visitors witnessed live demos of more than 250 machines and launches of more than 100 new products. Many exhibitors sealed deals for their machines on the jam-packed four days of the show.

Building up on the strong visitor response on the first day, the second day picked up steam with the show witnessing more visitor footfalls compared to its first day (the first day welcomed around 7000 people as per official record of All India Federation of Master Printer (AIFMP), the organiser of the show). Meanwhile, more than 20,000 business visitors had registered for the show so far. According to the organisers, the event this year broke all previous records with more than 425 exhibitors showcasing their products and services.

The exhibition is hosted demos of at least 250 big machines and 700 small machines.

Show highlights:

TPH bags order for two Orient folder gluers

The Printers House (tph) was giving live demo of Orient folder gluers at the show. The company bagged order for two Orient folder

gluers. They also received good response for their newly launched digital book printing machine at the show, said Pankaj Jha, GM –International Business, TPH.

BOBST demos advanced NOVAFOLD 50, 80 & 110 folding gluing and folding carton system

BOBST advanced NOVAFOLD 50, 80 & 110 folding gluing and folding carton system pulled crowd to their demonstration at the show.

Autoprint launches two new machines

Autoprint Machinery Manufacturers launched two new machines at the show – Autoprint Fine Coat 105 Drip Off and Dextra 80 HF. “This is the first time a drip off product is available in India for the size of 105. In fact, we would be the first in South East Asia to make this product. It took us 18 months to develop this product,” says CN Ashok, Managing Director, Autoprint Machinery Manufacturers. “We have already sold the machine displayed here and got as many as 10 strong leads,” shares KG Suresh, Jt Managing Director. “Even Dextra 80 HF is the first machine in India which is an automatic punching and hot foiling machine. We got good response for this machine and have

sold the machine displayed at the show. We got strong leads for the machine as well,” adds Ashok.

Another new product at their stand is Autoprint Prinsor which prints variable data, inspects it and sorts between good and bad. It can be retrofitted to existing lines or used as a standalone machine. Its 1-inch printhead, which enables to print 1 inch QR code, adds to the uniqueness of the machine. Besides these, the company displayed a range of products at the show. “The response at PAMEX has been very encouraging and the footfalls are very good,” says Ashok.

Fujifilm showcases flagship Revoria Press PC 1120

Fujifilm focused on solutions for both analogue and digital printing at the PAMEX show. The company showcased its extensive line of offerings, including the flagship Revoria Press PC 1120, a 6-colour print engine which brings unrivaled expressive power to digital printing. The machine has garnered phenomenal traction within the printing industry. It is a 6-colour print engine with a high-speed printing of 120 ppm, printing full colours. It supports a broad range of stocks: 52 gsm lightweight paper,

pressideas/ event review 24 March 2023

400 gsm heavyweight paper, minimum 98 x 148 mm and up to 330 x 1200 mm.

The company also launched the ZX Superia Processless Plates and showcased the Flenex Water Washable solutions at the exhibition in India, with an eye on the changing market trends in analogue printing domain. FUJFILM India’s Graphic Arts product portfolio includes more than 30 products ranging from High Quality Thermal Plates, Toner & Inkjet Digital Presses, Wide format UV Inkjet systems, Water washable flenex technology, PWB Films to Press Room Chemicals.

Priyatosh Kumar, Head of Department, Graphic Arts Division Fujifilm India Pvt Ltd said, “At Fujifilm, we have always focused on bringing better and smoother systems that empower our customers and helps them to produce high quality results. Our strength lies in our diversified portfolio catering to all ends of the printing industry. We are entrenched in the graphic arts industry, where we offer both analogue and digital printing solutions.”

Xerox showcases scalable specialty color digital print technologies

Xerox presented its end-to-end production

technologies ranging from the Xerox flagship Iridesse Production Press with the ability to print 10 colours and six in a single pass, Versant 280 and PrimeLink C9070 both with 11 colours options and 4 specialty colours in a single pass that redefine the Digital Color prints with stunning fluorescent colours complemented with brilliance of white and metallic hues of gold, silver enhanced with clear output. The machines are backed with the benefits of automated workflows resulting in lower cost and optimum utilization of customers’ invaluable time.

The company also offered XMPie software platform which drives more effective audience engagement with personalizing and automating campaigns—using print and digital media—to provide complete omni-channel consistency. Also on offer was FreeFlow Core Digital Workflow Collection, which optimizes production and eliminates costly touch points throughout the value chain.

First time exhibitor OMET impressed with show response

OMET SRL offers flexographic narrow web label and packaging printing press and combinated flexo / offset /rotogravure / inkjet / silk-screen narrow web label and packaging

printing press.

“We are exhibiting for the first time at PAMEX and we are really happy with the response. Printers are coming to us with relevant questions and they are happy to find the printing solutions here,” confirms Pawandeep Sahni, Managing Director, OMET India.

Insight introduces industrial inkjet printer

At PAMEX 2023, Insight introduces Atexco VegaPres s - 4 4 0/6 6 0 industrial inkjet commercial printer for the on-demand book printing market. On the newly launched inkjet printer, Ajay Aggarwal, Managing Director & CEO, Insight Print Communication, says, “The machine is a game changer in book printing and it gets great achievements of comprehensive book printing and production.”

Megabound launches carton boxmaking machine

At PAMEX, Megabound launched Quick Box carton box making machine. The multifunctional packaging machine with horizontal slotting and scoring, features vertical slitting and creasing, horizontal trimming. “Compared with traditional packaging equipment, it has a flexible

pressideas/ event review 25 March 2023

dimension adjusting system. All settings can be entered directly through a touchscreen panel within one minute,” informs Srinivas Reddy. The company also displayed its complete hard case binding solutions –casemaker, casing in, joint forming, case corner rounding, head & tail, perfect binding and rigid box complete solution.

HP India demonstrates Indigo 7K Digital Press

HP India demonstrate its flagship Indigo 7K Digital Press at PAMEX 2023. Jaipur Printers has recently installed an HP Indigo 15K Digital Press with OneShot to cater to the digital and packaging segments. With their new HP Indigo Digital Press, the company aims to expand into the digital domain to tap into the upcoming trends of personalised and variable data printing. Alok Jain of Jaipur Printers says that ‘quality’ is one of the primary aspects that made them get the new HP Indigo Digital Press.

The HP Indigo Digital Presses offer media versatility and can deliver a gamut of specialised applications on commercial printing, photo printing and packaging. Apart from running art paper on the new HP Indigo

Digital Press Jaipur Printers can now also print on plastics for packaging, non-tearable media and canvas for photo, and coloured paper and textured paper for brochures.

HP presented the HP Indigo 7K in collaboration with Redington. The stand had on display an array of print samples.

HP already has close to 60 machines of the 7000 series presses in India. Over the period, tremendous improvements have been made to the 7000 series technology.

Award Offset Printers & Packaging chooses Ample Graphics corrugation machine

Ample Graphics sold a corrugation machine to Award Offset Printers & Packaging on the first day of the PAMEX show. The Silvassa-based Award Offset purchased the B-flute corrugation machine which is its 10th machine from Ample. Installation of the B-flute corrugation machine is expected to take place by the end of May 2023 at Award Offset’s Silvassa plant.

Ample demonstrated two machines at PAMEX 2023 — the film lamination machine

and the high-speed corrugated flute laminator. The film lamination machine is its flagship product, which has over 50 installations in India. The new model KFM106MCZ features a special delam unit. The high-speed corrugated flute laminator is an improved version of the earlier machine which also got showcased in PrintPack 2022. With similar speed, the machine now comes with improved paper handling which translates to reduced wastage and increased pasting accuracy.

Calprin invests in Esko and Macdermid

Kolkata-based Calprin ADS has invested in flexo pre-press and platemaking technology from Esko and Macdermid. The company invested in top-of-the-line ArtPro Plus workflow from Esko along with the highresolution CDI prepress system and the latest XPS 4835 UV LED exposure on the first day of the PAMEX show. Along with that, the company also invested in the latest thermal technology Lava from Macdermid. It is the first installation of the Lava thermal technology in India and it is also the first system by Macdermid which is completely solvent-free.

Over the years, Calprin has invested in a series of Esko software, including ArtPro Plus, flexo engines and now high-resolution CDI with UV LED exposure XPS Crystal and colour engine. Calprin was into offset printing and recently added a vertical consisting of flexo printing to its profile.

Creofoil inks a deal for Smartfoil

Another first day deal at PAMEX was by Creofoil, which announced the deal for its newly inaugurated Smartfoil machine. The 36-inch machine was sold to Award Offset Printers.

pressideas/ event review 26 March 2023

With a wide embellishment range from 5 to 500 microns, Smartfoil is a smart answer to cracking issues in foiling. It can print on substrates of 25 to 300 microns and is capable of running a minimum of 57-gsm paper and maximum 10-mm acrylic. Apart from state-of-the-art machines, Creofoil also supplies foils and chemicals.

Hubergroup showcases sustainable solutions

Hubergroup Print Solutions presented its MGA (low-migration and low-odour) inks at PAMEX. The MGA inks ensure safety and sustainability in food packaging and the portfolio includes the sheet-fed series MGA Natura as well as the direct food contact series MGA Contact.

The MGA Natura is designed for safe printing on the outside of food packaging and the MGA Contact allows safe and vivid printing on the inside of the paper and cardboard food packaging. The newcomer series MGA Food News and MGA Evolution, on the other hand, are aimed at web offset printers who want to establish a new business with the printing of food packaging. These first are low-migration and low-odour coldset and

heatset inks to produce food-compliant paper packaging in large quantities using four-colour printing. Food manufacturers can thus make their packaging more colourful, for example, by reproducing their products’ true-to-life on it.

When it comes to non-food packaging, Hubergroup also presented its ink series Rapida Eco and Eco-Perfect-Dry which both combine fast and sustainable printing. Rapida Eco is one of the fastest vegetablebased inks for sheet-fed printing available on the market. Eco-Perfect-Dry is convinced through the combination of fast setting with high resistance, mechanical stress, and ecofriendliness.

Boxtech Bangalore closes deal for 5 orders

PAMEX was a great success for Boxtech Bangalore. The company closed deals for 5 orders at the show. The company has completed over 640 installations in India and overseas. Boxtech has been into manufacturing of folder gluers for over two decades.

The Velocity Plus machine by Boxtech can

handle different designs, such as straight line, lock-bottom, double wall, partition carton, dangler cartons and specialised cartons. The model is quite popular with Indian converters. It is the highest-selling machine in their line-up in recently and comes in different sizes range starting from 450-mm to 1100-mm maximum open blank. Their Ecomatic model is another costeffective product suitable for startups and small-scale businesses in the folding-gluing segment. The product on display by Boxtech at PAMEX included Ecomatic, Velocity, Veocity Plus and Ecomatic Essence.

Line O Matic launches automatic flexo printing machine

At PAMEX 2023, Line O Matic presented its cutting-edge solutions for the printing and packaging industry. Getting an overwhelming response from the show visitors, Line O Matic had a great show with its range of products garnering a lot of visitor interest.

“Visitors were thrilled with our innovative features & advanced technology. We’re proud to be at the forefront of the industry, providing cutting-edge solutions that help our customers,” says Swapnil Patel.

The Ahmedabad-based company launched an automatic flexo printing machine, the STM 125, for full colour printing on paper at Pamex. The machine incorporates a closedloop chamber doctor blade system which ensures printing sharpness and registration. This combination can produce halftone printing, line-printing and also special dotprinting.

The company also highlighted its square bottom paper bag machine, the Crown RB200. The company, which recently completed 25 years of its inception, has

pressideas/ event review 27 March 2023

Monotech Systems launches

PixelFoil

Monotech Systems launched PixelFoil –foiling solution designed specifically for screen printers – at the recent Pamex show. The official unveiling of PixelFoil was done at Monotech’s Pamex booth in Mumbai.

PixelFoil is a cutting-edge solution that provides screen printers with the ability to produce stunning and intricate foiling effects on a wide range of substrates, including paper and plastic. With its user-friendly interface and advanced technology, PixelFoil makes it easy for screen printers to create high-quality foiling effects quickly and efficiently.

One of the key features of PixelFoil is its ability to create variable data foiling effects. This means that screen printers can easily produce personalized and customized foiled designs for their clients, which is a valuable advantage in today’s competitive printing market.

“We are thrilled to introduce PixelFoil to the screen printing industry,” said Tej Prakash Jain, MD of Monotech Systems. “With its advanced technology and user-friendly interface, PixelFoil is a game-changer for screen printers who want to add foiling effects to their designs. We believe that