Subscribe eNewsletter 23 195 Price in India Rs.100 volIssue23 01 January 2023 A monthly Publication from PRESSIdeas Publishing Pvt. Ltd. Convergence In Action 08 Gulf Print & Pack 09 Printpack India 2025 11 Winners of SA Digital Media Awards 14 Mitigate business risks 18 Photo Park’s new HP Indigo 7K .................... 20 Fine Digital Prints 23 Reign Green 29 Vol.23 Issue 01, 2023 digital printing signage printing

FROM THE EDITORS’ DESK

Convergence In Action- Visitors From Three MP Cities Meet-up At Indore

Gulf Print & Pack returns to Dubai in 2024

EFI announces appointment of new CEO and separation of fiery business unit into independent company

Vinsak’s participation at PLASTINIDA, Pragati Maidan, New Delhi

Overwhelming response to Printpack India 2025

Biodegradable packing for Bar-U-Eat products

HEIDELBERG turns print shops into pioneers of energy-efficient production

Obituary

Winners of the 2022 South Asian Digital Media Awards announced by WAN-IFRA

Hotpack Announces its Largest Manufacturing Plant in Dubai

For Flagship Press the answer was KODAK

MGI launches its own social network JETforce

Mitigate business risks with Digital

Photo Park adds two new HP Indigo 7K Pressesto expand its digital printing network

Next Level Automation at Hunkeler Innovation Days

Comexi launches into digital printing

Fine Digital Prints goes beyond CMYK with RICOH PRO C7200X

Canon at the CEIF 2023

Kodak to showcase PROSPER ULTRA 520 Press at Hunkeler Innovationdays 2023

FUJIFILM India at CEIF 2023

Monotech Systems woos photo labs at CEIF 2023

HP displays new

Jasmeet D. Editor & Publisher (jasmeet@pressideas.com)

Vineet K G. Associate Editor (vineetkg@pressideas.com)

Jasvinder S. Sub-Editor (jasvinder@pressideas.com)

Jacob George Marketing and Sales (jacob@pressideas.com)

M.S. Mukundan

Advertising and Sales Southern and Western India (aims@pressideas.com)

Graphic Designer Anil Kumar

Networking/ Hardware Consultant Sukhdeep Singh

USA Correspondents Tensi M., Preeti

European Correspondent Rimi, Yadhu Morphine

Production Thomas K Alex

Every effort has been made to ensure that credits accurately comply with information supplied. All material supplied is compiled from sources believed to be reliable or solely an opinion of the authors. PRESSIdeas is not responsible for any steps taken based on the information provided herewith.

4 January 2023

Contents

PRESSIdeas January 2023 Vol. 23, Issue 01 Printed by Jacob George and published by Jasmeet Singh on behalf of PRESSIdeas Publishing Pvt Ltd. Printed in India at Hues and Colors 363, Industrial Focal Point, Phase-IX Mohali, and published at PRESSIdeas, 437-A 1st Floor, Industrial Area, Phase-2 Chandigarh-160002 (India)

Subscription details/form on Page 06

6

8

9

10

10

11

11

12

13

14

15

16

17

18

20

21

22

23

24

25

26

27

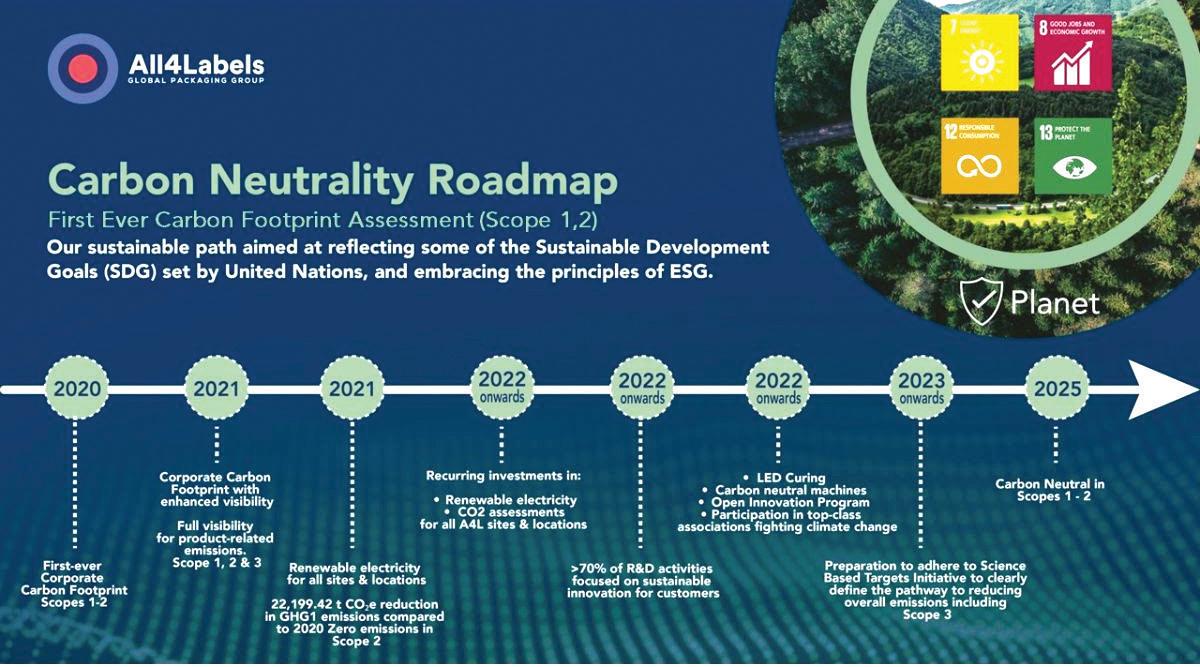

Indigo presses at the 2023 Photo Fair 28 Reign Green expands power of printing with RICOH PRO C5310S 29 Art & Air India Express 29 eProductivity Software @ Connect 2023 (Jan 23-26, Las Vegas) 30 Simultaneous printing and cutting with the new Mimaki CJV330-160 30 Amcor opens China’s largest flexible packaging plant, strengthening its position in Asia Pacific 31 Landa opens ink plant in Europe 31 Momentous GEW LED upgrade by All4Labels 32 Kingston Data Systems and Flexo Image Graphics team up for Indian market 33 ESKO 2023 Packaging Trends 33 LIS & VINSAK install Print Quality Inspection System at Aurobindo Pharma 34 Pankaj expects Union Budget 2023 to focus on industrialisation and technological innovation to support domestic businesses 35 Baumer hhs at FCBM conference at Indore 35 The XpertJet 1682SR Pro, the new high productivity printer from Mutoh 36 The XpertJet 1682SR Pro, the new high productivity printer from Mutoh 36 Second generation of the Karibu, the roll to roll printer from SwissQprint 37

FROM THE EDITORS’ DESK

Dear Readers,

Let us start with the feel-good news about the Economic Survey 2023 giving an idea of where India Inc is heading to in 2023-24 with the nation’s projected GDP growth pegged at about 6.5%. Our nation has already become the world’s fifth largest economy in the 75th year of Independence and will reach the $3.5 trillion mark by end-March, said the Economic Survey tabled in Parliament.

Now, hope that the budget will be tax payer friendly in terms of simplifying the taxes thus broadening the tax collection proportions and making India a charming destination for foreign investments.

As for our industry Pamex had their promotional roadshow at Indore details of which is there in the issue. Gulf Print pack reappears in 2024 in Dubai. The key trend in the MENA market is the transition to digital, not only in terms of print and post-print equipment, but also workflows, said the organiser.

EFI announced it’s new CEO and has shelved out their Fiery business as a separate entity in itself.

Meanwhile, Print Pack India, the premier show in the indian print industry’s itenerary announced 261 bookings as on date after bookings opened on 16th Jan 2023.

Heidelberg, the leading press manufacturer launched energy efficiency campaign for print shops thus bringing in more sustainability in the printing process.

We had two notable departures of friends from this world - Mr.PR Srinivas (Seep-O-Print) and Ramani Vishwanathan (Ex-Kodak/HP). Friends sent in their condilence messages whih we have reproduced in this issue.

We have also listed the Winners of the 2022 South Asian Digital Media Awards announced by WAN-IFRA in the issue along with the success story of Flagship Press with their Kodak ensemble. Kodak’s inkjet press portfolio and how it can help a printer in managing a successful transformation to digital is also included for your reading pleasure.

Photo Park Digital Press installed two HP indigo presses at their Thiruvananthapuram unit. “We want to be India’s preferred photo book production partners”, declared Mr Francis, the company’s owner.

Just a reminder about the Next Level Automation at Hunkeler Innovation Days at Lucerne has a mention too. We have also covered Canon, Fuji Film and Monotech at the Consumer Electronic Imaging Fair (CEIF) 2023 held at Jio WOrld Centre in Mumbai.

Talking of new acquisitions, Reign Green (Tirupur) with their RICOH PRO C7200X and Fine Digital Prints (Hyderabad) with their RICOH PRO C5310S, both from Mponotec have their stories too inside.

Amcor opened China’s largest (590,00 sq. ft.) flexible packaging plant thus strengthening its position in Asia Pacific region. Meanwhile there is an interesting news on Landa’s new ink plant in Europe.

In Vishakhapatnam, Lake Image Systems in partnership with Vinsak installed their inspection system for aluminium foil blister packs at Aurobindo’s Vizag facility.

To conclude, let us hope for a good growth oriented budget tomorrow from Nirmala Seetharaman ji!

- Jasvinder Singh, Sub-editor

6 January 2023 Subscription Form 1 Year (12 issues) 2 Years (24 issues) (For outstation cheques add Rs. 40/- extra) Rs. 750.00 Rs. 1250.00 5 Years (60 issues) Rs. 3250.00 1/2/5yrs. I am enclosing cheque/draft of

Promote for on our SOCIAL pages! FREE

We can be of help!

Each story we create, or for that matter, each press release that you share with us, not only goes on our popular website but also is shared on all above Social Media pages of PRESSIdeas.

Your social media content is the embodiment of your brand and each social network brings in it's own set of challenges. Well, we take of several factors that go into producing and publishing social media content.

We can help you not only in Content Creation - where and how to Start with but once created, to schedule them on the Social Media and then optimizing it to attain the expected success is also our job. Last but not the least, analyzing the results of the Social Media Campaign too shall be shared with you.

If you’re looking to get started, allow us to walk you through it. Allow us to hand hold you all along.

Write to digital@pressideas.com or WhatsApp on +91 9780036854 to know more!

Note: Our online editorial team holds the right to decide on the selection of posts to be included on our social media pages. The FREE offer is for a period of 45 days. It is advisable to have only a post in a week.

www.pressideas.com jacobpressideas jacob.pressideas only.pressideas +JacobGeorge-pressideas jacobgeorge1/

Convergence In Action- Visitors From Three MP Cities Meet-up At Indore

As the dates for PAMEX 2023 are coming closer, the growing enthusiasm around the industry in the country is discernible and was amply evident at the Indore event.

The PAMEX Road show reached Indore on its fourth stop on 24 January 2023 at the Brilliant Convention Centre with registrations crossing 300 in numbers. The event witnessed visitors in large numbers from Bhopal and Ujjain who all converged with local attendees of Indore for the afternoon to evening event, where the Table-top Exhibition started off at 2 PM and the Conference began at 4 PM.

The Indore event was a joint effort of All India Federation of Master Printers (AIFMP) and Indore Master Printers Association (IMPA) and was organised in association with Print-Packaging.com Private Limited and supported by Bhopal Master Printers Association, Indian Plastpack Forum, Federation of Corrugated Box Mfrs. of India (FCBM), Madhya Pradesh Corrugated Box Manufacturers’ Association and Ujjain Print & Media Association.

The Panel discussion was followed by a technical presentation by Rajesh Khatwani (VINSAK India) on ‘Connected Packaging’. Speaking about the importance of track and trace in today’s scenario, he gave a brief on how technology makes it possible to get full information of a product through a simple barcode.

Pawandeep Sahni (OMET India), who has been a part of all the four roadshows conducted gave a presentation on ‘The Convergence Mindset- How to encash on the biggest opportunity in Print’. Premchand Prajapati (Konica Minolta), spoke about ‘Digital printing & the way forward’.

The event concluded with a vote of thanks extended by Pritesh Jain, Vice President, Indore Master Printers Association, (IMPA).

The event included a panel discussion, a couple of technical presentations alogn with a table top exhibition and the last of the series is beign planned on 3rd March 2023 at Haridwar.

Key Notes :

> Over 300 visitors from three Madhya Pradesh cities

> This was the fourth show out of the five planned

> A table-top exhibition too ran parallel to the Conference

After the inaugural lamp lighting by Raveendra Joshi, President, AIFMP, Tushar Dhote, Co-chairman, PAMEX, AIFMP, then gave a presentation on PAMEX, talking about its history and the current status of the 15th edition of the Show which was followed by a Panel Discussion moderated by industry veteran, V Vaidyalingam of Suba Solutions raising some very relevant questions around ‘Convergence in Print - The Way Forward’. The panelists included Aditya Pahuja (Colours Packaging Solutions), Gaurav Nema (Pragati Graphics), Amit Shah (Spectrum Scan), and Amit Khurana (Technova).

A table-top exhibition, running parallel to the Conference, created an opportunity for the attendees to network and talk business. The evening ended with a networking dinner, which allowed the delegates and participants to interact in an informal ambiance. The next destination for PAMEX 2023 Roadshow is Bengaluru, where once again the table-top exhibition and conference will be held on 23 February 2023. The last venue of this series will be in Haridwar on 03 March 2023.

PAMEX 2023 is scheduled to be held from 27-30 March 2023 at Bombay Exhibi″on Centre, Mumbai.

8 January 2023

Gulf Print & Pack returns to Dubai in 2024

Gulf Print & Pack is back on the biennial calendar for the first time since the pandemic.

Gulf Print & Pack, the MENA region’s leading exhibition for the commercial and package printing industries, will take place at the World Trade Center in Dubai on 9-11 January 2024.

Barry Killengrey, Gulf Print & Pack event director, commented: “We’re delighted to be back on the biennial calendar for the first time since the pandemic. During this time, the print and package printing industry has evolved immensely, with exciting new trends such as digital embellishment emerging, and this has intensified the appetite to see more advances in digital technology, automation and workflow capabilities.”

The last Gulf Print & Pack event was held in June 2022, when it attracted leading graphic arts suppliers from across the globe and over 7,500 international visitors.

“With the milder climate, January is the ideal time to plan a business trip to Dubai and the best time to kick-start new business here,” says Killengrey. “Dubai is the most populous city in the UAE and has become a center of

trade and commerce for the Middle East.”

Gulf Print & Pack 2024 will give PSPs, commercial printers and packaging converters the chance to see a broad range of new technology in action including wide format printers, digital corrugated, cut sheet inkjet, package printing presses and digital embellishment systems.

“The key trend in the MENA market is the transition to digital, not only in terms of print and post-print equipment, but also workflows,” commented Andy ThomasEmans, Strategic Director of the Tarsus Labels and Packaging Group, which organizes Gulf Print & Pack.

“Conventional offset printers are now looking closely at cut sheet inkjet presses, while both flexo and conventional printers are seeing increased automation in plate making, fully integrated with end-to-end color management. Corrugated printers also have new digital options, both at the high volume end and in continued development of wide format presses and cutting tables.”

Thomas-Emans points out that although the commercial print market as a whole faces challenges, there are niche areas showing sustained growth, including on-demand book and photobook production and digital printing of fabrics and floor tiles. All these applications will be represented at Gulf Print & Pack 2024.

“Commercial printers are also looking at opportunities in the booming package printing market, particularly in folding cartons and labels,” said Thomas-Emans. “We expect to see suppliers of flexo converting equipment and digital presses and finishing equipment in force at the show.”

Another key trend to watch out for at the show is digital embellishment of cut-sheet commercial work, folding cartons and labels, said Thomas-Emans. “The replacement of conventional tooling by high build inkjet varnishing, laser die cutting and digital metalization technologies will transform the value proposition for both commercial and packaging printers.”

pressideas/ commercial printing 9 January 2023

EFI announces appointment of new CEO and separation of fiery business unit into independent company

Sharpens EFI’s focus as a leading industrial inkjet pure-play and Fiery’s position as the leading DFE provider

as an industrial inkjet leader and Fiery as the leading digital front end (DFE) provider. Jeff Jacobson, a 35-year veteran of the digital imaging sector who led EFI as CEO following its 2019 take-private by Siris, will remain Executive Chairman of each business.

EFI to Operate as an Industrial Inkjet Pure-Play

Electronics For Imaging, Inc. (EFI), a global leader in digital industrial imaging and portfolio company of Siris Capital Group LLC today announced the appointment of Frank Pennisi, a veteran of the industrial and technology sectors, as Chief Executive Officer. In tandem, EFI’s Fiery business unit has been separated as an independent company that will remain wholly owned by Siris.

As separate companies, EFI™ and Fiery® will have distinct areas of strategic focus that will enable them to serve their customers better and grow over the long-term, with EFI

Headquartered in Londonderry, N.H., EFI will be solely focused on driving the analog-todigital transition across the packaging and corrugated, display graphics, textile, and building materials/décor end-markets for industrial inkjet.

Mr. Pennisi comes to EFI from Orora Packaging Solutions, a leading provider of custom packaging solutions with an emphasis on corrugated. While managing Orora Packaging Solutions as its President and CEO, Mr. Pennisi was an EFI customer, using EFI’s industry-leading Nozomi singlepass inkjet, superhigh-speed digital printer. His experience with EFI solutions extends to the close collaboration and consulting he has done with Orora Packaging’s sister company, Orora Visual – a leading display graphics provider that is among the largest

North American users of EFI VUTEk® display graphics and EFI Reggiani industrial textile digital printers. Previously, Mr. Pennisi spent two decades in leadership positions at FLIR Systems (now Teledyne FLIR), Honeywell, and GE.

Fiery to Operate as Independent Company Driving Digital Print Innovation

As an independent company, the marketleading Fiery business will continue to provide industry-leading DFE technology for digital production and industrial printing. Toby Weiss, long-time Chief Operating Officer and General Manager of Fiery, will continue to lead the business as CEO of Fiery. “Fiery will remain focused on working closely with our OEM partners, including the EFI Inkjet business, to continue developing cutting edge technology that drives the next generation of automation, accuracy, and profit potential in digital printing,” said Mr. Weiss. “We look forward to accelerating our investment as a standalone company, while driving our expanding product portfolio, incorporating world-class color algorithms, and developing advanced cloud technology.”

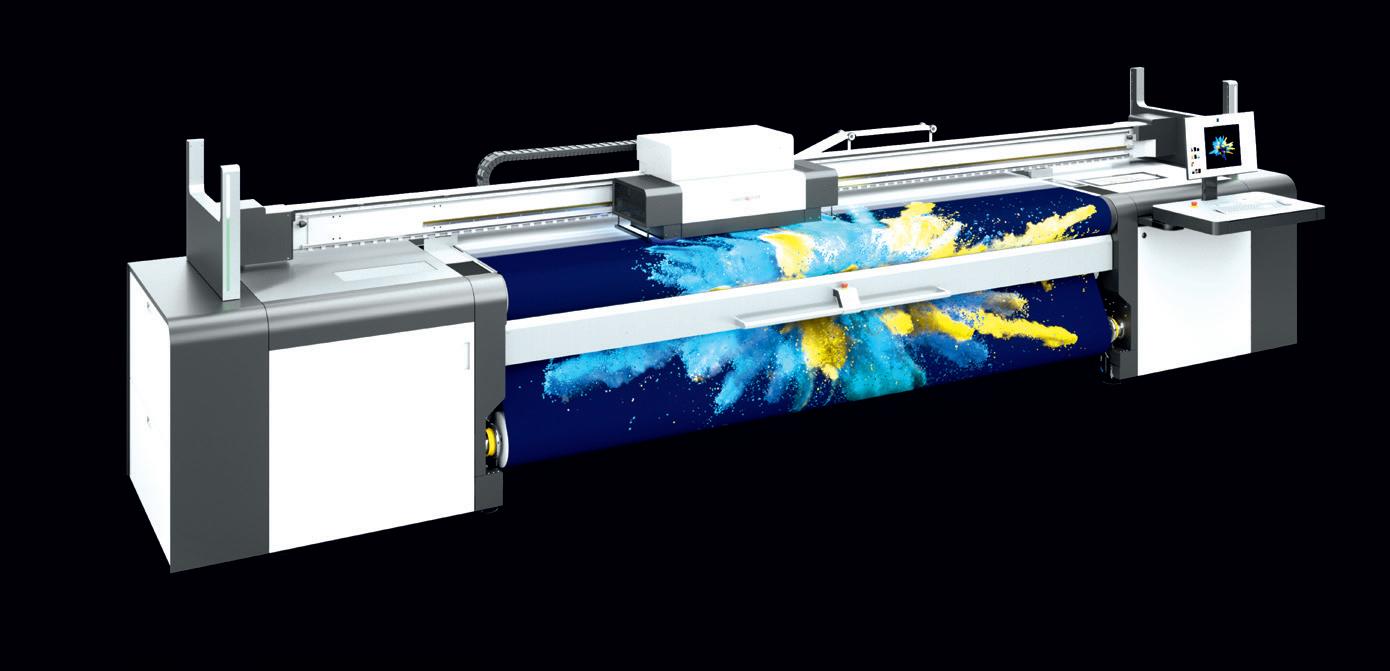

Vinsak’s participation at PLASTINIDA, Pragati Maidan, New Delhi

Vinsak is delighted to announce the launching of DIGI-Jet Wide Format Digital Printing System at PLASTINDIA, (01 TO 05 FEB 2023) @PRAGATI MAIDAN. AT Hall No.11 H, Stand No. B-3-A.

VINSAK’s mission is to design, manufacture and distribute products and services with emerging technologies that meet or exceed the unique needs and expectations of each customer. To be valued by our customers for bringing competitive solutions, reliability,

comfort and convenience to their lives and businesses. Our guiding principle remains ushering in an era of high technology in the packaging industry.

VINSAK Digi-Jet 1000 offers high printing speed, high quality results and the highest level of performance and production.The system can print in exceptional quality variable data matrix, QR codes, barcodes, texts, numbers, marking applications. This is the ideal solution for created “connected packaging“which the brands are demanding today.

UV Low Migration Inks enable jobs for food

applications to be carried out. Low migration inks allow the work to be printed on all surfaces and on previously printed material as well. Under special request, the system can also be created with Water based ink jets systems which offer direct food contact as well .

In addition to the this product launch, Vinsak will showcase it’s entire range of solutions for printing of short run flexible packaging as well as brand protection solutions. Looking forward to your visit to witness these relevant technologies.

pressideas/ commercial printing 10 January 2023

Overwhelming response to Printpack India 2025

64 Bookings in the first Minute, 198 bookings in the first hr & day 1 closed with 261 Bookings.

IPAMA started booking for the 16th PRINTPACK INDIA 2025 exhibition on 16th January 2023 and saw an overwhelming response from participants. The exhibition will be held at India Expo Centre, Greater Noida from February 1st to 5th in the year 2025.

64 companies booked their space within the first 60 seconds and 198 companies in 1 hr, and till the end of the day, a total number of 261 companies had already done the advance booking. The speed of booking shows the trust, popularity and the importance of PRINTPACK INDIA Exhibition amongst the companies representing manufacturing or dealing in printing, packaging, and allied machinery and solutions. The first day booking is 135% more than what it was for the last PRINTPACK INDIA.

The space will be allotted to the Exhibitors based on priority numbers generated on the basis of Bank Statement showing the receipt of the advance booking from the respective companies.

The profile of 16th PRINTPACK INDIA Exhibition includes Pre-Press, Press, Digital, Screen and Textile Printing, Label, Paper, Post-Press, Corrugation, Converting, Packaging, Service & Software, Consumables & Spares, Signage & LED and other related segments of the Graphic Arts Industry. The Halls will be earmarked segment wise, keeping in view the convenience of Exhibitors and Business Visitors. The Exhibitors will also be provided number of complimentary services during the Exhibition.

Mr. Rakesh Sodhi, President IPAMA said,

Biodegradable packing for Bar-U-Eat products

BAR-U-EAT, is now available in an all new wrapping which is Biodegradable Products Institute (BPI) Certified, which means that the entire packaging is able to break down properly in commercial compost systems.

The new packaging is composed of plant-based materials from FSC Certified sustainably managed forests. It additionally complies with the specifications established in the American Society for Testing and Materials (ASTM) D6400 to be aerobically composted and is biodegradable.

BAR-U-EAT is the first bar company in the world to offer packaging that is fully biodegradable, which puts the company in a rarified air when it comes to sustainability, as most energy bar companies still rely on

“PRINTPACK INDIA is poised to be unique, highly innovative and a trend setter. I am sure that PRINTPACK INDIA 2025 will showcase the world’s latest technologies. It will be a promising show with great opportunities.”

The last edition was organised at India Expo Centre from May 26-30, 2022, in which 487 Indian and Foreign companies had participated on a net area of 25342 Sqms. It was visited by 1,03,412 business visitors. IPAMA representatives will also visit some of the important foreign Exhibitions like Interpack, Drupa etc. to invite Exhibitors and Business Visitors for 16th PRINTPACK INDIA Exhibition. The Marketing Unit of IPAMA has already started attending Exhibitions, Conferences, Workshops etc., which are being organised by other domestic & international exhibition organisers to interact with the Exhibitors and the Business Visitors.

single-use plastics for their packaging.

Plastic waste has been an issue for energy bar companies, as it is estimated that millions of pounds of non-renewable, nonbiodegradable refuse are produced every year by the industry.

Consistent with the company’s mission to create food that is free of unhealthy oils and preservatives, BAR-U-EAT’s new packaging will allow the wrappers to become energy for the planet, just as the bars are for people.

pressideas/ commercial printing 11 January 2023

HEIDELBERG turns print shops into pioneers of energy-efficient production

Company launches energy efficiency campaign for print shops; brings more sustainability in the printing process.

Back in 1997, the Kyoto Protocol stipulated that, by 2020, industrial processes should be at least 20 percent more efficient than they were in 1990. Today, due to the general trend for more sustainability across the whole of society, ambitious climate protection targets, and the present energy crisis, there is growing pressure on the print media industry to make the entire production process even more energy-efficient – and to do so quickly.

Heidelberg has therefore launched a campaign for print shops featuring information, advice, and tips from experts on how to considerably increase energy efficiency in printing companies while simultaneously driving down costs. The company will be focusing on several headline issues in its communications over the next few months.

“The subject of sustainability and energy efficiency has become a crucial competitive and cost factor for suppliers in the print media industry – and that applies equally to our customers and to Heidelberg itself,” says Dr. Ludwin Monz, CEO of Heidelberg. “Alongside its customers, Heidelberg aims to extend its leading role in the industry to include energy efficiency as well. Due to our technological and data expertise, we are able to offer our customers attractive options for achieving energy-efficient production and can provide comprehensive advice and consulting. We all need to work on these

issues if we are to hit climate protection targets.”

Speedmaster XL 106 – energy efficiency as standard

To launch the campaign, Heidelberg is showcasing the energy efficiency of the Speedmaster XL 106. For example, a comparison between the Speedmaster CD 102-6+L from 1990 and the current Speedmaster XL 106-6+L reveals that energy consumption per 1,000 sheets has been reduced from 13.8 kWh to 8 kWh – a reduction of 40 percent. A whole range of innovations and improvements throughout the entire system is responsible for this achievement.

A printing press is at its most energy-efficient when running at full capacity, as this ensures its basic energy requirement is spread out over more printed sheets.

Besides investing in cutting-edge equipment, print shops can also further boost their energy efficiency by optimizing the way they use their equipment. This is where one principle in particular comes into play – one that highlights a key difference between printing presses and automobiles, for instance, which consume more energy the faster they travel. By contrast, a printing press has a basic level of energy consumption that covers the fundamental operating functions. Beyond this, energy consumption increases

in line with rising printing speed, but since the basic level of energy consumption is spread over more printed sheets, overall energy efficiency improves. This means a press is at its most efficient when a job is being printed at full speed – ideally on a fully automated basis – and when, after that job, the system either moves on immediately to the next job or switches to standby mode if there is nothing else to be printed.

“When it comes to energy efficiency in print shops, although the equipment being used is an important basis, operating that equipment in the best way possible is at least equally as important. This is often where companies can really make a big difference. It is at precisely this point that the Heidelberg campaign for greater energy efficiency comes in and creates a basis for fully utilizing pre-existing potential,” says Dr. Eva Boll, head of ESG at Heidelberg.

Speedmaster XL 106 with energy measuring device

Starting April 2023, the Speedmaster XL 106 will be supplied with an energy measuring device as standard, albeit only in Germany initially. This will enable users to permanently monitor the energy consumption of their press – measured in kilowatt-hours per 1,000 sheets – from the control station. This readout encourages operators to run the press in an energy-efficient way – in other words, at maximum speed. All in all, various energyefficiency measures also help print shops reduce the CO2 emissions associated with their industrial processes.

The second theme of the campaign highlights the potential in terms of savings offered by peripheral units for the Speedmaster, which makes energy-efficient production possible. Next, the campaign addresses the issue of “maintenance”, revealing the extent to which regularly maintained machine systems can conserve resources and improve the energy balance. To complement the campaign, Heidelberg offers relevant consulting services so it can work with customers to identify potential for energy savings in the print shop and draw up plans for leveraging that potential.

pressideas/ commercial printing 12 January 2023

Mr.P.R.Srinivas, a one of his kind personality who lead Speed-O-Graphics India to it’s heights, is no more. His brand of “Printorama” sheet fed offset machines has a place of it’s own in our country. The gentleman peacefully passed away yesterday night. Cremation is being done today in Bengaluru. Mr.Srinivas was a Past President (First President from southern part of India) of IPAMA and was decorated with the Lifetime Achievement awards in the year 2019.

Sharing his grief Mr.Rakesh Sodhi, President IPAMA said that it is indeed very heart wrenching to know of the demise of our respected Mr.P.R.Srinivas who was not only a leading manufacturer of sheet fed offset printing machines but also a past Preseident of IPAMA. “I pray to almighty to provide eternal peace to the departed soul and to give enough strength to his family and friends to bear the immense loss” he addded.

Mr.Dayakar Reddy Sripathi, immediate past-President of IPAMA said “Srinivas sir was a legend for the printing industry in general and a mentor for me in addition to being the first president of IPAMA from South India. “Even today as I travel across the coutry I see many satisfied users of his machines and have only heard praise from his customers not only about his machines but also about his humble dealings with them” he added.

Mr.N.S.Mankoo, the then General Secretary of IPAMA while Mr.Srinivas was the President said “Extremely sad and pained to learn that Sh.PR Srinivas has left for his heavenly abode. Having known him for over three decades, a man of few words, always very courteous & warm, I had the privilege of working under his Presidency as a General Secretary from 1996-98. It was his perseverance and sociopolitical networking

that the team then was able to successfully organise IPAMA’s – Printpack Expo’97 that too in an open palace grounds in Bangalore. Our heartfelt condolences to his wife, family and friends. Om Shanti Om.”

Ramani Vishwanathan – RIP our beloved friend! A gentle soul from our industry passes away in his sleep. We at PRESSIdeas were in touch with him during his Kodak days. An ireparable loss for the industry and for people near and dear to him. We pray to the almighty, to give strength to the family to carry on. A few friends from our industry shared their grief –

Bhalchandra Nikumb, Print Solutions

Sales Director – Kodak India Yesterday afternoon got the shocking news of Ramani’s sad demise & it disturbed me immensely. The gentle soul worked with Kodak for more than 4 years in the realm of Digital Printing and was very passionate about his job. A man very well versed with photo book industry & related business with compassionf or his colleagues. Aggressive in his sales approach but equally kindhearted with people in general and extremely popular with his office buddies and well accepted as a natural leader by the entire team. Me on behalf of entire Kodak team will always miss

him. May his soul rest in peace. Kodak family shall keep his family in our thoughts and prayers.

Abraham Prabhakar, Managing Director (Asia) – iMSGLOBALAlas my friend Ramani! He never knew the word NO, always said will do, can be done, not difficult, can get, can sell, will close the deal. What a practical optimist he was! Whether he won or lost, he used to try and always gave his best! Our prayers and sweet remembrance for the departed soul. Shall meet in the next world.

Arun Gandhi, Director – CGSASP I became friends with Ramani while working together on the project of Repro India together with Kodak in through Ajay Bhatia. Since then, we worked on many projects together and built a lifelong relationship. The gentle soul always developed close bonds with everyone he worked with in his entire career and had his own special way with his positive & happy personality and left an indelible impression on every life he touched. I was in touch with till he was with a print magazine based in Noida and thereafter suddenly lost contact because of his illness. When he recovered, he worked

with us at CGSASP as a consultant. He had a tough time in life with his health but was a true professional till his last day. He was one of the the few persons in the country who understood the Hunkeler Digital Business and that is where we used as his inherent strength. Very unfortunate to have lost him at such a young age. My heartfelt condolences to his family. May his soul rest in peace.

Ranesh Bajaj, MD – VINSAK India & UAE Ramani was a very gentle soul. Soft spoken and an excellant sales man, he was also an excellent human being. The industry surely will miss him.

Om Shanti

Jacob George, MD – PRESSIdeas

Knew the gentleman during his days at Kodak and then during his brief sojourn at IPP and later in CGSASP. A soft spoken and knowledgeable being, Ramani had his approach leave an indelible mark on any conversation we had in person with him. May almighty give courage to the bereaved family and provide eternal peace to the departed soul. Life goes on as it always does, but we all shall miss you RV!

pressideas/ commercial printing 13 January 2023

Winners of the 2022 South Asian Digital Media Awards announced by WAN-IFRA

The Quint, The Hindu, Prothom Alo, Indian Express emerged as the SDMA winners, from more than 100 entries from news publishers across South Asia.

The World Association of News Publishers (WANIFRA) announced the winners of the South Asian Digital Media Awards 2022, the sixth edition of digital media awards for South Asia. These prestigious awards recognise the outstanding digital media projects delivered by news publishers from across the region. An eminent panel of international judges evaluated the entries.

The winners are:

Best News Website

• Gold: https://www.thequint.com/, The Quint

The 2022 edition saw news publishers competing under 13 different categories for ‘Gold’, ‘Silver’ and ‘Bronze’ awards. The ‘Gold’ winners automatically enter WANIFRA’s World Digital Media Awards competition.

• Silver: Best News Website - Hindi, TV Today Network

• Bronze: Best News Website - English, TV Today Network

Best Use of Video

• Gold: ABP CENTENARY CAMPAIGN, ABP PVT. LTD.

• Silver: Rising Waters and Sinking City, The Quint

• Bronze: Dhal Char, Deutsche Welle

Best Newsletter

• Gold: Morning Expresso, The Indian Express

Best Data Visualisation

• Gold: Islamophobia 365, The Quint

Key Notes :

> The sixth edition of digital media awards for South Asia.

> An eminent panel of international judges evaluated the entries.

> The award ceremony will be held on 16 March 2023 at Delhi

• Silver: Seeds of Protest, The Quint

• Bronze: Artemis Moon Mission, India Today Group Digital

Best Digital Subscription Initiative

• Gold: Indian Express Subscription, The Indian Express

• Silver: TH Newsletters, The Hindu

• Bronze: New Subscription Model, The Daily Prothom Alo

Best Trust Initiative

• Gold: Women in Journalism, Afghanistan Women News Agency

• Silver: Sach Ke Sathi Flagship, Jagran New Media

• Bronze: BBC Young Reporter India, BBC News

Best Podcast

• Gold: Shet Market, Sakal Media Private Limited

• Silver: Ankahee Baatein, People Like Us Create (Pluc)

• Bronze: 3 Things, The Indian Express

Best in Audience Engagement

• Gold: ABP CENTENARY CAMPAIGN, ABP PVT. LTD.

• Silver: Padma Bridge Inauguration Campaign, The Daily Prothom Alo

14 January 2023

• Bronze: Kanneerakaruthu Kalyanam Campaign, M M Publications Limited (Vanitha)

Best ePaper-Concept

1. Gold: The Hindu e-Paper,The Hindu

2. Silver: Interactive epaper, DT Next

3. Bronze: The Daily Prothom Alo eEdition, The Daily Prothom Alo

Best Digital Advertising Project

1. Gold: Bkash Eid Ayojon, The Daily Prothom Alo

2. Silver: Abashon Mela (Real Estate Fair), The Daily Prothom Alo

Best special project for COVID-19 / Pandemic Reporting

1. Gold: India’s Girls Out Of School, The Quint

2. Silver: Breaking News, Dainik Jagraninext

3. Bronze: HH Covid Actions, Hindustan Media Ventures Limited

Best Use of Short Form Video

1. Gold: Trending & Current Affairs, The Hindu

2. Silver: Mini profiles during UP Election, BBC News

3. Bronze: Breaking News, Dainik Jagraninext

Best Native Advertising / Sponsored Content Campaign

• Gold: Banega Swasth India, NDTV Convergence

• Silver: COIMBATORE UNLIMITED, The Hindu

• Bronze: Ask Him Today, The Quint

Panel of jury

The entries were evaluated by an international panel of jury that included Corinne Podger (Director – Digital Skills Agency- Australia), Adam Tinworth (Consultant-Reed Business Information), Juan Velasco (5W Infographics LLC, USA), Simon Scarr (Singapore), Murdoch Davis (USA), Frank Denton (Vice President – Journalism, Morris publishing groupsUSA), Ola Henrikkson Independent media consultant (Sweden), Robb Montgomery (Mobile journalism author, Founder, USA), Kavita Chandran (Singapore), Dean Arnett(Independent and freelance-Video production specialist-UK) , Kevin Anderson (Director of professional services at PugPig- UK), Danny Spears (Chief Operating Officer, The Ozone Project), David Warmsley (Editor-in-

Chief, The Globe and Mail, Canada), Javier Garza (Editor, EnRe2 Laguna, Mexico), Kathy English VP (Content Integrity & Editorial Standards Dotdash MeredithCanada), Margret Muller (Director, Digital Publishing – RP Digital GmbH- Germany), Aileen Rae Perez (Social Media Manager – GMA Network Inc., Philippines), Cahyo Listyanto (GM Technology, Product & Data, Harian Kompas- Indonesia), Cherish Leow (Assistant VP, Branded Content & Editorial Solutions – Astro Awani Network Sdn Bhd-Malaysia), Chris Janz Media AdvisorAustralia), Lyn-yi Chung (Deputy Chief Editor, CNA Digital-Singapore), Karen Lim (Supervising Editor – Mediacorp, Singapore), Lee Williamson (Regional Editorial Director, Tatler Asia Limited, Hong Kong), Eoghan Weeney (Digital Media Consultant-Germany), Rebecca Skippage (Disinformation Editor BBC News– UK), and Kuang Keng (Data editor Pulitzer centre, Malaysia).

Award ceremony

WAN-IFRA congratulates all the winners. The award ceremony will be held on 16 March 2023 during the Digital Media India 2023 Conference in New Delhi.

Hotpack Announces its Largest Manufacturing Plant in Dubai

Hotpack Global, the UAE-based global leader in food packaging products, has launched its largest manufacturing plant in National Industries Park (NIP), Dubai. The company announced that it has invested an estimated AED 250 million into the facility. The new plant marks a significant step in Hotpack’s vision to emerge as the premier global food packaging manufacturer by 2030.

The purpose-built manufacturing plant will produce Hotpack’s high-performance and sustainable PET (Polyethylene terephthalate) packaging products. The facility is also going to function as a centre for various Hotpack arms with manufacturing, e-commerce, logistics, and marketing being localized in one building.

Hotpack Global is recently certified as a ‘verified exporter’ by Dubai Industries and Exports, the trade promotion entity of the Department of Economy and Tourism (DET). The NIP facility will further augment

Hotpack’s logistics capabilities and provide a major boost to its export growth strategy. In line with its global vision, Hotpack has exercised an aggressive expansion strategy in the Middle East. Most recently, the company opened its first manufacturing plant in Doha, Qatar to produce Hotpack paper products. Moreover, the company has also expanded its e-commerce store to all GCC countries and launched numerous sales

centres in Oman, Saudi Arabia, and Bahrain to augment Hotpack’s manufacturing and logistics operations.

Hotpack Global will continue expanding in the middle east with a focus on supply chain optimization. The company announced that it will soon be launching new manufacturing plants in Saudi Arabia, India, Malaysia, and Serbia in the coming months.

pressideas/ newspaper 15 January 2023

For Flagship Press the answer was KODAK

Flagship Press achieves efficiency and sustainability with KODAK PRINERGY, COLORFLOW Pro, and INSITE horsepower.

Flagship Press can do everything from books to direct mail, large format to promotional products because they embrace their range of offset and digital equipment. But their current workflow was beginning to let them down. It was slow, hard to maintain, and needed more of the features their volumes demanded. They started the search for a faster workflow that could enable more automation. They wanted a customer portal to enable 24/7 communication options throughout the job progression. And they wanted better colour management to support their G7 program. The answer was Kodak.

streamlined automation. As work volumes grew, the only answer was to add more staff, adding cost and complexity that wasn’t sustainable.

As business more than doubled, they were processing more than 2500 plates a month with hundreds of jobs moving through the workflow. Their processes took too long, often up to 30 minutes to get a single plate ready initially, and the same again if any changes were needed. They needed more efficiency to break the cycle of adding people to processes. They turned to Kodak for an integrated solution.

Flagship Press added KODAK COLORFLOW Pro for color management to support its G7 program, Kodak PREPS to create imposition and ganging layouts, and KODAK INSITE Prepress Portal and Creative Workflow to create a closed-loop file approval process with the customers.

Key Notes :

> The current workflow of Flagship was beginning to let them down.

> They started the search for a faster workflow for more automation.

> Installs KODAK COLORFLOW Pro, KODAK PREPS & KODAK INSITE Prepress Portal and Creative Workflow.

For over 70 years, Flagship Press has served its customers with the highest-quality print products. As their offerings expanded and their volumes grew, their existing workflow struggled to meet demands. It was challenging to use, and it created islands of production automation. Every task, including color management and correction, required a different software application, and there was no path to

Efficiency through Automation

The efficiencies gained with the Kodak solution eliminated the requirement to add people for new work. The new, slim team is six people where there had been 12, and each is handling 25% to 50% more work thanks to the automation. Growing the business no longer means expanding the staff to keep up, driving more revenue to the bottom line.

digital printing 16 January 2023

KODAK PRINERGY Workflow with RulesBased Automation (RBA) has been their new workflow solution. They added KODAK COLORFLOW Pro for color management to support their G7 program, Kodak PREPS to create their imposition and ganging layouts, and KODAK INSITE Prepress Portal and Creative Workflow to create a closed-loop file approval process with their customers.

Meredith Nichols, Director of Technology Development, stated: “The proof is in the numbers. For Flagship Press, PRINERGY balances the playing field between the newest and most experienced operators. Experienced staff learned what they needed in less than three days. The previous workflow servers were unplugged within a month of the PRINERGY installation, eliminating duplicated server and licensing costs. Some of the staff already had experience with Kodak solutions from previous jobs, leading to rapid acceptance. Everyone was involved from the start, contributing to the definition of rules for the workflow. Everyone had ownership, removing the fear of the unknown.”

The addition of KODAK COLORFLOW Pro allows them to do their colour management upfront before any other processes begin. They decided on COLORFLOW Pro because it integrates into the workflow and honors the client color profiles. As a G7 shop, they have a process to follow to ensure that every job meets specific colour guidelines, but the files arrive from clients and their

designers in many states with many colour models. COLORFLOW Pro automates the normalization processes so they can print the best color based on the substrate and the output device. And they can print it consistently within the job, as well as for every reprint, regardless of the output device.

COLORFLOW Pro also saves time and money by dramatically reducing the number of color corrections needed for each job. For customers, that means an equally dramatic reduction in color correction charges and faster time to print.

Savings in Every Step

By integrating PRINERGY and INSITE with their PrintMIS, Flagship Press enabled file uploads through the portal. Customers can

now preflight and correct their files, and soft proofs are automatically available as jobs move seamlessly from INSITE through prepress. No one touches a file unless an event triggers an email to the production manager to say something needs attention. Today it takes as little as five minutes to get from job entry to production-ready versus hours with their previous workflow. Waste is eliminated, operator time is reduced, and there is no more risk of mismatched job specifications.

Customers are happy, too! Firing up the INSITE portal saves Flagship Press hours of interaction, and saving time is saving money. Flagship Press made adoption as easy as possible by building Quick Start guides and offering demonstrations to show customers how the portal benefits them.

Moving to a PDF-centric workflow enabled by the INSITE portal, inbound PDFs now arrive ready to print. Working with Flagship Press is more accessible for clients because they have any time access through their desktop, laptop, tablet, or phone to approve files for production.

Flagship customers have embraced the power of the always open communication portal and the savings they get from reducing the number of proof and approval loops. Now there are fewer calls and emails, leading to faster progress into production. Every aspect of the PRINERGY, COLORFLOW Pro, and INSITE implementation brings savings to Flagship Press that will continue for years to come.

MGI launches its own social network JETforce

With thousands of users worldwide, MGI Digital Technology has decided to connect all of these graphic arts professionals by providing them with an official space for sharing and learning. JETforce is a kind of social network reserved exclusively for owners, operators and managers of its JETvarnish digital printing and finishing presses.

Translated into 19 languages, JETforce offers forums, regularly updated technical tutorials, monthly conference calls on practical topics in printing and finishing of packaging, labels and printed materials, downloadable content such as videos and images. It is possible to develop contacts like a social network.

“From passive, you become active, even proactive. You feel connected and your ability to learn and be creative is increased tenfold,” says Matt Redbear, one of the JETforce facilitators.

pressideas/ digital 17 January 2023

Mitigate business risks with Digital

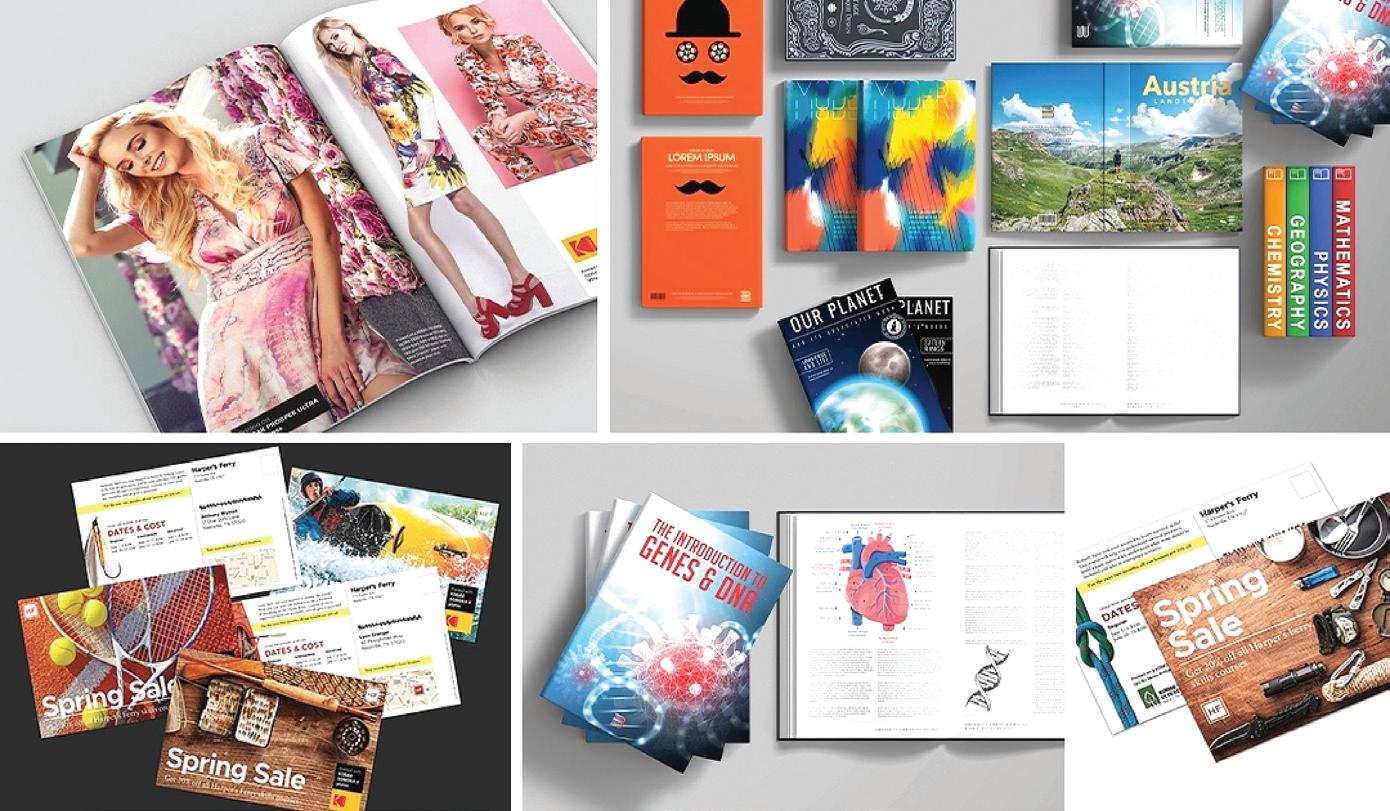

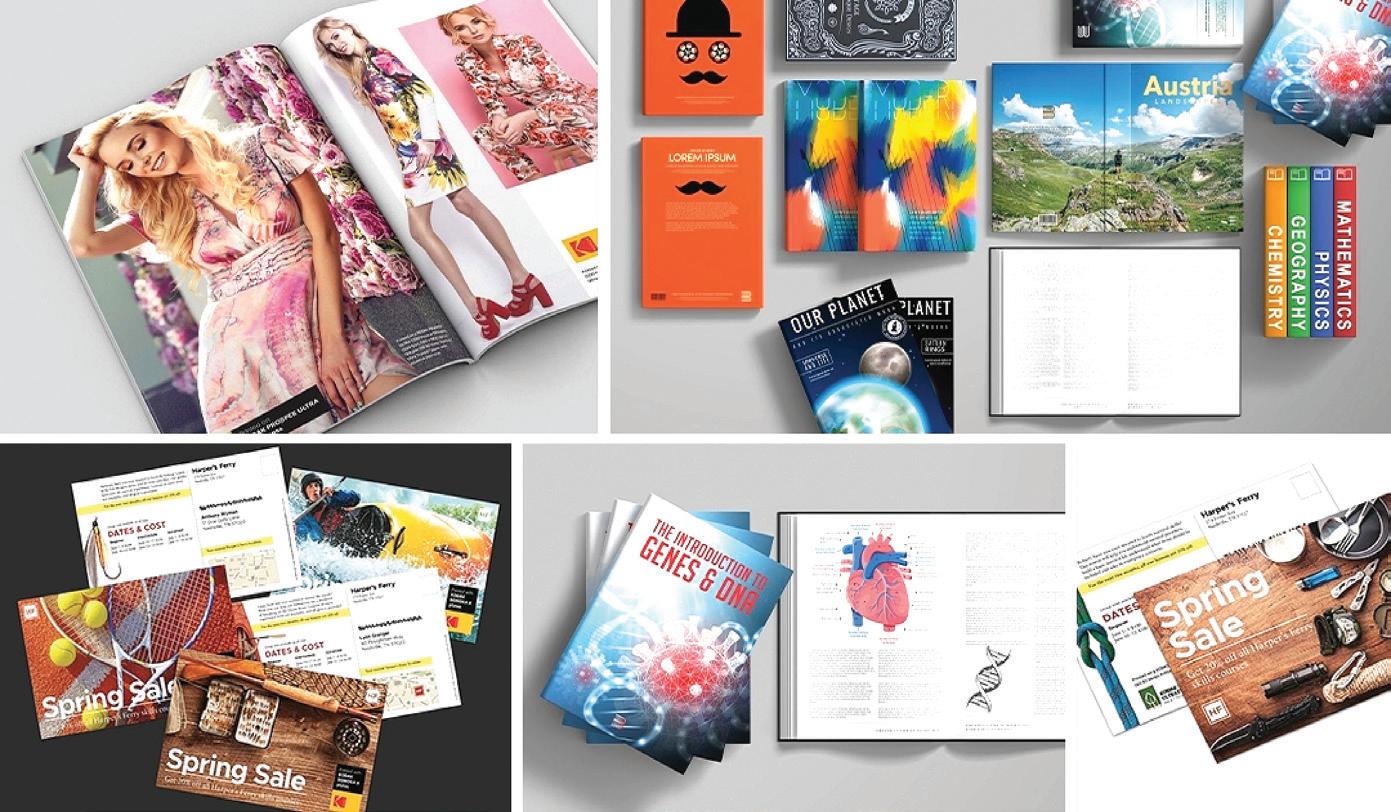

Kodak’s inkjet press portfolio provides more options for a successful transition to digital.

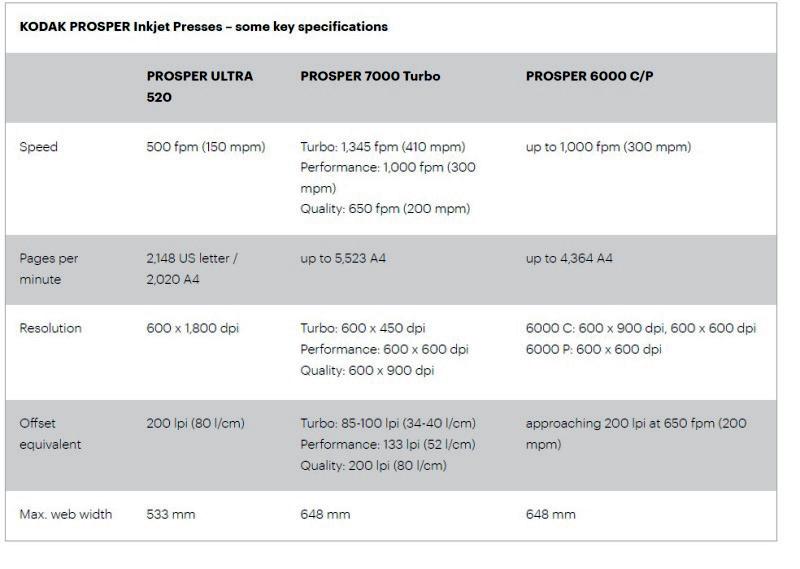

Kodak recently introduced the KODAK PROSPER 7000 Turbo Press. This new addition has expanded the company’s portfolio of high-speed inkjet web presses for an almost infinite range of commercial applications. Kodak is thus following its strategy of providing innovative printing solutions that enable customers to take advantage of diverse business opportunities in the commercial printing market, improve profitability and shift more jobs from traditional offset to digital.

With market trends towards shorter runs and tighter deadlines, KODAK PROSPER Presses require no lead time for platemaking, can start production with virtually no makeready, and provide advantages over offset in many applications. Furthermore, PROSPER’s streamlined press operation means fewer operators when compared to offset, resulting in tangible labor savings and enhanced productivity. And compared to sheetfed offset, PROSPER Presses score additional points in that they do not use paper sheets, but rather more cost-effective roll paper.

Powered by KODAK Stream Inkjet Technology, the presses use air deflection of the nonprint drops, generates 9 pL drops for printing and lays the foundation for the extremely high productivity of the presses.

In view of rising raw material costs, ongoing supply chain issues and the global trend toward greater sustainability, one aspect comes into focus: The transition to digital from offset can help printers avoid today’s aluminum supply issues and thus mitigate business risks. Unlike offset presses, PROSPER Digital Presses do not require printing plates, which are mainly made of high-quality aluminum – a valuable resource produced in an energy-intensive process. Likewise, the complex production as well as the transport and storage of printing plates are eliminated. Also, PROSPER Presses use water-based inks, eliminating oil-based inks as well as printing chemicals with problematic ingredients, chemical dampening additives or solvent-based ink train and blanket cleaning agents. This means the switch to digital brings sustainability improvements in addition to risk reduction.

Key Notes :

> Kodak introduces PROSPER 7000 Turbo.

> High-speed inkjet web press for unimaginable range of commercial applications.

> Switch to digital brings sustainability improvements in addition to risk reduction.

With some of the lowest operating costs and the fastest speeds on the market, KODAK PROSPER Presses are much more cost-effective and quicker to run than other digital presses, especially at larger volumes and high ink coverage.

Continuous inkjet technology from Kodak makes all the difference

All PROSPER Presses use Kodak’s continuous inkjet (CIJ) technology which provides high-quality, high-speed color printing with eco-friendly, waterbased inks. The advantages of CIJ result from the technology’s ability to control placement and dot uniformity extremely accurately at very high speeds. CIJ printheads produce a non-stop curtain of ink drops. The printing drops go directly onto the paper

digital printing 18 January 2023

and the non-printing drops are deflected and recirculated for reuse.

Kodak’s continuous drop generation practically eliminates clogged jetting modules and maximizes uptime and productivity of the press. Other benefits of CIJ include that drops travel to the substrate faster than with Drop-On-Demand (DOD) technology, which targets them exactly for better quality. Moreover, CIJ drops are round and precise, unlike DOD that creates misshapen drops and actually undesirable satellite drops, leading to jagged edges on text and lines and less sharp images.

KODAK ULTRASTREAM Inkjet Technology is Kodak’s latest generation of continuous inkjet technology. It provides the ultimate in

line straightness, highlights, detail and color fidelity as well as consistency over long runs. ULTRASTREAM works by electrostatically charging and deflecting the non-printing drops, creating tiny 3.75 picoliter (pL) drops that enable a high print resolution.

In contrast, the new PROSPER 7000 Turbo Press and the PROSPER 6000 C (Commercial) and P (Publishing) Presses are powered by KODAK Stream Inkjet Technology. Stream uses air deflection of the non-print drops, generates 9 pL drops for printing and lays the foundation for the extremely high productivity of the presses.

Universal water-based pigment inks

The properties of the inks used are a decisive

factor for the versatility, productivity, color quality and cost-effectiveness of an inkjet press. Kodak’s approach is to supply just one CMYK ink set for all presses and papers. Kodak utilizes proprietary micromilling technology to manufacture all of its inkjet inks. The water-based nanoparticulate pigment inks are optimized for maximum efficiency with ULTRASTREAM and Stream Inkjet Technology.

Kodak’s pigment milling process means the presses deliver a much larger gamut than heatset web offset and sheetfed offset and can match 93% of Pantone colours (within 4 dE). This enables PROSPER Presses to print vivid images with vibrant colours, reliably render the CMYK offset gamut, match brand colors and exceed customer expectations.

In addition, PROSPER inks have lower levels of humectants than inks from competitors. That translates into faster drying, even with high ink coverage on coated and glossy papers. The low humectant inks, together with interstation near-infrared (NIR) drying which is adjustable depending on volume and ink coverage are enablers for printing heavy ink coverage on coated and glossy papers at top speeds. This combination of fast-drying inks and efficient drying technology ensures that PROSPER Presses manage with comparatively low energy requirements for drying and thus lower energy costs, even at their highest speeds.

Optimizer Agents – the key to simple ink concept and substrate diversity

To offer commercial printers independence from expensive pre-treated inkjet papers and the ability to print on a wide range of substrates with the uniform ink set, Kodak supplies various ink-receptive primers known as Optimizer Agents, that have been optimized for PROSPER aqueous pigment inks. For example an Enhanced Optimizer Agent for coated papers and a Standard Optimizer Agent for uncoated papers are available. Precoating substrates with Optimizer Agents does not affect ink runability on press and ensures the best print quality in every application.

Precoating paper with Optimizer Agent, which can be done inline in the press or nearline, is a much more cost-effective option than printing on standard offset

pressideas/ digital 19 January 2023

Photo Park adds two new HP Indigo 7K Pressesto expand its digital printing network

HP Indigo’s unique Vivid Pink & Vivid Green inks allows users to have high-quality printing for photo applications.

Photo Park Digital Press, one of the largest colour labs in India, has become the first customer to purchase the two most recent HP Indigo 7K presses. With this, Photo Park Digital has expanded its use of the technology, taking the total fleet of HP Indigo presses to eight.

Established in 1979, Photo Park started the first color lab in 1983 in Trivandrum and for almost two decades, they did try every available technology in Photo printing space. But the quest for high quality printing and expanded colour gamut ended their search with HP Indigo Technology.

Photo Park is one of the biggest Photo printing companies in India today and have been continuously enhancing its expertise and capability. HP Indigo 7K presses have only helped them increase their reach both in terms of quality as well as quantity.

Key Notes :

> Established in 1979, Photo Park started the first color lab in 1983 in Trivandrum.

> Serving more than 25% of the photo industry requirement directly and indirectly in Tamil Nadu and Kerala.

> HP’s digital technology helps them achieve the highest standard of print quality.

“PHOTOPARK stands for “Symbol of Quality” which has helped us to serve more than 25% of the photo industry requirement directly and indirectly in Tamil N″du and Kerala. With the new technology growth, we have started to serve the domestic and international market too”, Mr. Francis, Managing Director, Photo Park Digital.

“Now with HP Indigo technology we have extended our service in the printing press industry with a real color printing solution, which is an all-new redefinition for offset printing solution. With the objective to be one of the highest quality printers of the industry,

offering uncompromising customer satisfaction and best-in-class robust services. Photo Park is one of the biggest Photo printing companies in India today and continuously enhancing its expertise and capability. We want to be India’s preferred photo book production partners”, added Mr Francis.

A Appadurai, Country Manager, Indigo & Inkjet Business Solutions, HP Indiasaid, “Over the last decade, the digital printing industry has undergone a tremendous transformation. With the revolution of HP’s digital printing press for photo and commercial printing industry, today, our customers can innovate and technologically advance their offerings to meet the evolving needs of the market. Photo Park is a classic example of how they have expanded over the years, and we are proud to collaborate with them once again. We are confident that their trust & faith in HP’s digital technology helps them achieve the highest standard of print quality, which will be their competitive differentiator.”

HP Indigo Digital Presses are designed to help print owners become the smart, industry-leading supplier that customers will prefer, with access to a wider variety of materials, more versatile media options, and an increased colour gamut beyond CMYK while

digital printing 20 January 2023

reducing waste. With advancements in A3 printing’s speed, adaptability, and operating efficiency, customers can now employ an HP Indigo Digital Press to meet any need - today, tomorrow, and years into the future.

HP Indigo 7K Digital Press is a printing solution providing printers with endless applications, premium quality, and colour for photo and commercial printing which lasts for 200 Years. As photographers are sensitive to facial tones, HP Indigo Digital Press usually prints using the 6-colour process to capture specific hues. Unlike conventional printing methods, HP Indigo 7K Digital Press allows high-quality printing for photo applications, allowing the users to achieve its maximum colour gamut using the most innovative invention of Vivid Pink and Vivid Green Inks. With the use of different papers and HP Indigo 7K Digital Press, Photo Park can produce the best quality albums that are Lightweight, Waterproof & Nontear, giving its customers memories they’ll cherish forever.

Next Level Automation at Hunkeler Innovation Days

Industry 4.0 is no longer a vision of the future, but already a reality in many production companies. Today, state-of the art information and communication technology networks people, machines and products. Thanks to new forms of organization and control of the entire value chain, experts forecast a productivity increase of up to 30 percent by 2025. Figures that no company in the digital printing industry can ignore.

So NEXT LEVEL AUTOMATION no longer just means the automation of machines, plants and systems, but the complete interlinking of all corporate processes and the challenges that the new reality also poses for people.

Consequently, NEXT LEVEL AUTOMATION is now the motto and dominant theme of the Hunkeler Innovationdays 2023, the international industry get-together of the digital printing industry. Live demonstrations and discussions with many implemented solutions will be held from February 27 to March 2, 2023 in Lucerne showing how fragmented processes can be combined by the intelligent linking of work steps and how this leads to greater efficiency, better quality

and absolute planning reliability.

Due to the different challenges and needs of companies in digital printing, there is no universal or general solution. The focus is therefore not on off-the-shelf technological solutions, but on the customer-specific use of current technology and information modules – jointly developed and tailored to the specific requirements of the individual company.

NEXT LEVEL AUTOMATION therefore always stands for scalable systems and the individual customer benefit that is noticeable throughout the entire value chain:

• through optimization and rethinking of all company processes

• through the ability to be more innovative

• through massive increase in efficiency

• through the creation and optimization of interfaces

• through production monitoring

• through the competence to react immediately to complex requirements, deviations or failures

and ultimately through enormous growth

opportunities and concrete competitive advantages

Solution providers like HP, Canon, Muller Martini, Kodak, Screen Hunkeler, Horizon, Ricoh, Xerox, Guk, Meccanotecnica, Xeikon, Duplo, Riso, W+D, Kyocera, Scodix, Fuji Film, Koyabashi, Contiweb, Baumer, Imaging SOlutions, Heidelberg amongst many others will be showing their latest innovations at the show. Experience the NEXT LEVEL AUTOMATION – the future of digital printing and finishing. Visit https://www. innovationdays.com/en for more details.

pressideas/ digital 21 January 2023

papers with so-called enhanced – and more expensive – ink sets, as promoted by some press manufacturers. And thanks to the unique nature and properties of KODAK inks, PROSPER Press users can achieve acceptable results in some applications on conventional offset papers even without a precoat.

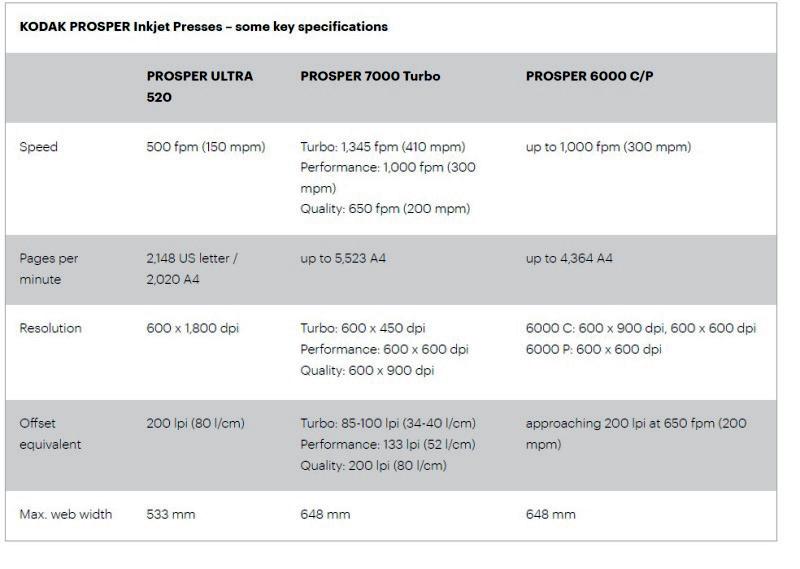

Top quality with maximum speed for all applications

Kodak’s PROSPER Press portfolio offers solutions across a broad range of applications from high end commercial work to publishing and also newspapers. The specific press a customer would be interested in will depend on their print volume, quality, and width requirements (see the table for some key specifications).

Taking full advantage of KODAK ULTRASTREAM Inkjet Technology, the KODAK PROSPER ULTRA 520 Press delivers outstanding, offset-quality print at speeds faster than competitive solutions. It is aimed at the mid-volume market segment and printers that would have production volumes around 10 million A4 images per month. Operating at top speed for all supported paper weights and grades, PROSPER ULTRA 520 provides the highest image quality.

It is available in two versions: PROSPER ULTRA P520 with two driers per side of the web is designed for transactional and transpromotional printing, publishing applications and commercial print up to moderate ink coverage. PROSPER ULTRA C520 (four dryers per side of the web) is

the perfect choice for applications such as direct mailings, inserts, catalogs, promotional brochures and books – even those with high ink coverage on coated and glossy papers.

Turbo speed and flexibility

The brand-new PROSPER 7000 Turbo Press and the PROSPER 6000 C (Commercial) and P (Publishing) Presses are powered by KODAK Stream Inkjet Technology. PROSPER 7000 Turbo offers unmatched flexibility to move between high quality applications and turbo speed productivity and anything in between. In addition to its Turbo mode, which is suitable for low ink coverage applications, the press offers Performance and Quality print modes to produce any application with the optimal combination of speed and resolution. Performance is ideal for textbooks, fiction books and other medium ink coverage applications while PROSPER 7000 Turbo’s Quality mode is perfect for direct mailings, brochures, catalogs and magazines.

One thing has become very clear: Today there are more arguments than ever for savvy commercial printers to base their production on a future-oriented platform with a PROSPER Press and to prosper with Kodak’s inkjet technology in the long term.

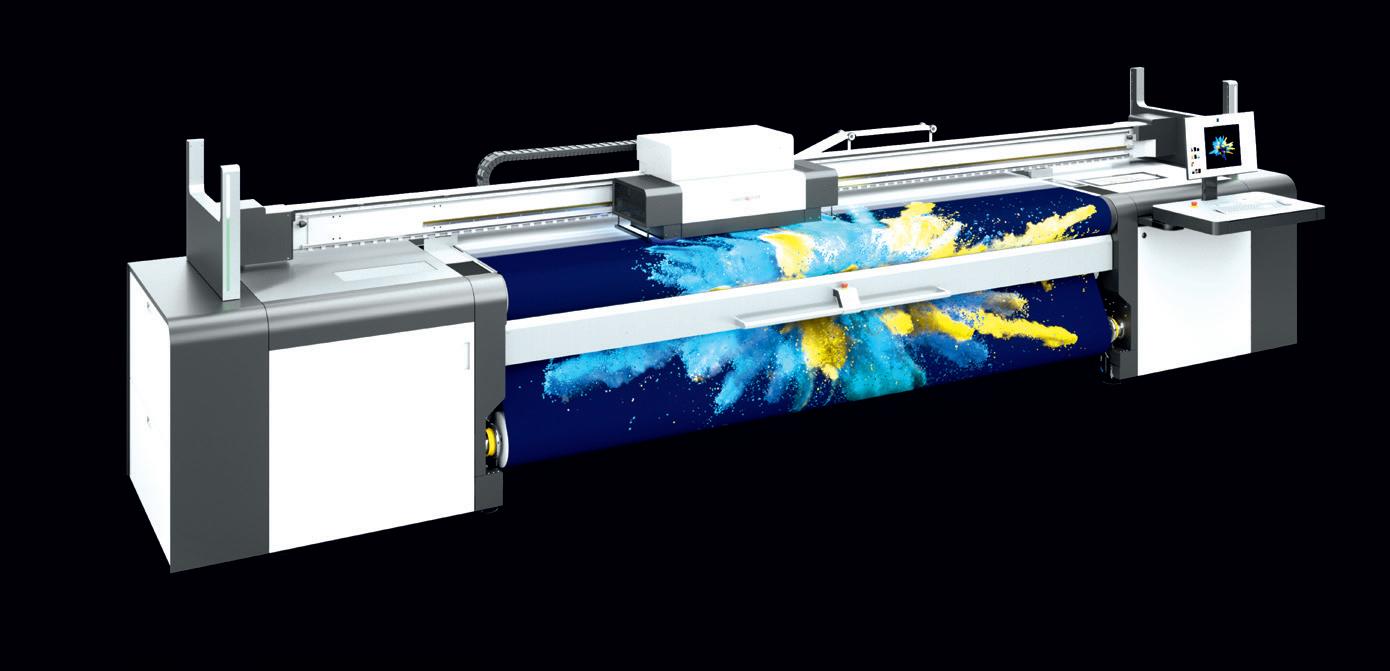

Comexi launches into digital printing

After 70 years in the manufacture of flexo and offset presses for the flexible packaging sector, the Spanish manufacturer Comexi launches its first digital press, the Digiflex machine. This UV press of 132 cm of width with black ink is conceived for the printing of variable data.

“The Comexi Digiflex is the machine that currently offers the best digital printing of variable codes, such as Datamatrix codes, QR codes, bar codes, alphanumeric text, as well as other numbering and marking applications with high quality requirements.” explains Pedro Jiménez, the digital technical sales manager at Comexi.

The Digiflex reaches a speed of 220 m/min and offers a print quality with a resolution of up to 1200 x 1200 dpi and a code size of up to 8 x 8 mm.

pressideas/ digital 22 January 2023

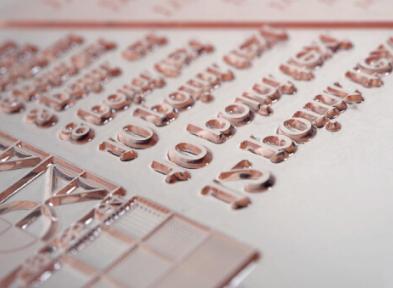

Fine Digital Prints goes beyond CMYK with RICOH PRO C7200X

Monotech installs RICOH Pro C7200X Digital Production Press at Hyderabad’s digital printing firm.

Monotech Systems has installed a new RICOH Pro C7200X Digital Production Press at Fine Digital Prints based in Hyderabad, Telangana. “The adoption of the new RICOH digital press has empowered us to leap into innovative graphics with a new colour gamut beyond CMYK,” says, J C Krishna Reddy Panyala, Managing Partner, Fine Digital Prints.

Since its inception in the year 2008, Fine Digital Prints has been one of the popular commercial printing corners engaging in the production of high-end commercial graphic prints as well as stunning graphic designing jobs. “We work for a huge population of customers who are from varied market segments, diverse walks of life, and different cities and towns of India,” mentions Mr, Reddy, adding, “Though we are based in Hyderabad, almost 90 percent of our customers are from the neighbouring and far-flung cities and towns.”

There are many reasons why Fine Digital Prints has become a hugely popular commercial printing corner that pulls the attention of customers from all over India. One main reason is the company’s production setup which keeps upgrading from time to time with the installations of new and ultra-modern machines with RICOH Pro C7200X being the latest addition to the portfolio. “The new RICOH digital press from Monotech Systems is indeed a ‘workhorse’

with which we are now galloping to discover the innovative range of new applications and colours beyond CMYK,” emphasizes Reddy.

He adds, “We have been working for several big corporate brands from every all across the country. Our customers are very quality conscious and often come to us for outof-the-box graphic ideas and applications. To meet their demands and expectations, we need to get equipped with high-end machines like RICOH Pro C7200X. The RICOH machine has advanced features that we don’t find in any other digital press in its class.”

Apart from the RICOH Pro C7200X, the production facility of Fine Digital Prints is equipped with other digital presses such as Xerox Versant 180 and Xerox B9100, backed by a strong team of 12 well-trained printing and graphic designing professionals. “Unlike the other digital presses we have used so far, our new RICOH Pro C7200X has the versatility to explore a new colour gamut comprising ‘white ink’ and use of a range of unconventional printing media like Tyvek and others,” informs Mr Reddy.

RICOH Pro C7200X can take up media up

to 360 gsm and it can run at speeds up to 85 ppm (pages per minute) in banner sheet duplex printing mode. “Other than the usual applications, we are now planning to change the game of commercial printing to another level using the 5th colour station of our newly adopted RICOH Pro C7200X. We have set a target of six months down the line to utilise the prowess of this RICOH digital press to explore all new possibilities of innovative applications,” says Mr Reddy.

Throughout Fine Digital Prints’ journey till date, they have established a firm foothold in the commercial printing arena with a vast customer base. “We are proud to be able to maintain a vast pan-India customer base, which continues to expand day by day,” says Reddy, adding that the role Monotech Systems plays by providing the highly versatile and advanced RICOH Pro C7200X digital press is vital to enhance the company’s overall production prowess and creativity to impress and attract customers from all over India.

pressideas/ digital 23 January 2023

MrJCKrishnaReddyPanyalawithRICOHProC7200X

Canon at the CEIF 2023

- exhibits its technology prowess across imaging and printing segments at the recent Consumer Electronic and Imaging Fair.

Digital imaging company, Canon India showcased its robust range of products across segments at the World’s largest, ‘Consumer Electronic and Imaging Fair’. Organized by ‘All India Photography Trade and Industry Association’, the interactive platform took place in the form of a mega three-day event at the Jio World Convention Centre from the 5th-7th of January 2023. The event targeted professionals, enthusiasts, filmmakers, students, and educators in the field of photography and videography.

Canon actively engaged with its customers via experiential demonstration zones incorporating the right amalgamation of technology showcase, educational sessions, and networking at the mega event. Keeping in mind the exponential growth of online content consumption, Canon’s latest range of cameras are set-up for consumers for an in-depth demo and experience, highlighting the brand’s true imaging potential across Wedding, Wildlife, Fashion and Vlogging depicting speed, slow-motion, action, and video capabilities, under different lights and moods. These include the most recent and game changing EOS R6 Mark II as well as Canon’s entrants into the APS-C Sensor market - the EOS R7 and EOS R10 alongside a special VR Zone for the RF5.2mm f/2.8L Dual Fisheye lens.

On the printers’ front, Canon displayed its wide range of printers be it for consumers or businesses through live product display. The two demo zones targeted photo studios and design shops and jobbers shedding light on product USP’s. The printing technology showcased at CEIF includes high performance Ink Tank G Series, as well as Canon’s flagship professional printers including the imagePROGRAF series –imagePROGRAF TM-5200, imagePROGRAF PRO-541, and imagePROGRAF GP-540.

Sharing his thoughts, Mr. Manabu Yamazaki, President, and CEO, of Canon India, said, “The Consumer Electronic and Imaging fair is one of the most opportune platforms for us to connect with our customers and exhibit our technological supremacy in imaging

and printing solutions. At Canon, it is our endeavour to make superior technology accessible to our customers and offer them product experiences that are par excellence. With the consumer landscape evolving at a rapid pace since the pandemic, we have strived to empower the growth of many segments especially those of vlogging, professional photography, videography cinema, OTT as well as cater to the printing needs for home and professional segments. As we continue to support growing segments, we aim to consistently connect with our customers face to face so that they get to truly experience the potential of our products. Over the past editions of the show, we have been overwhelmed with the positive response received and we look forward to marking yet another milestone through our

association with this premium interactive platform.”

The best companions for filmmakers and cinema enthusiasts, the Cinema EOS range with its star performers EOS R5C, EOS C70 and C300 MARK III were also showcased. On the other hand, Canon’s four new professional-use camcorders XA75, XA70, XA65 and XA60 that seamlessly fit into multiple professional workflows, were attractive highlight as well.

With this year’s exhibit, Canon created wider awareness about the brand’s extensive product portfolio through unique booth concepts to guide visitors about product potential that are inspiring, accurate, and cutting-edge.

pressideas/ digital 24 January 2023

Kodak to showcase PROSPER ULTRA 520 Press at Hunkeler Innovationdays

2023

Kodak’s latest technology for high-speed digital production printing & end-to-end workflow management on show at the event.

Hunkeler Innovationdays, Kodak, prosper ultra 520 pres, Kodak ultrastream, continuous inkjet technology, UW8 unwinder, RW8 rewinder, WI8 web inspection system, prosper 7000 turbo press, doxnet, Jim Continenza,

Kodak will showcase its latest technology for high-speed digital production printing and end-to-end workflow management at Hunkeler Innovationdays 2023 (February 27 to March 2, Lucerne, Switzerland).

The KODAK PROSPER ULTRA 520 Press will be the highlight at Kodak’s booth P5 in Hall 2. The recently launched inkjet web press will be on display for the first time in Europe. Taking full advantage of KODAK ULTRASTREAM Continuous Inkjet Technology, PROSPER ULTRA 520 delivers offset-quality print at high speeds, offers great application flexibility and enables printers to profitably shift more jobs from traditional offset to digital.

Kodak will present a roll-to-roll configuration in which PROSPER ULTRA 520 is integrated with a Hunkeler UW8 unwinder and RW8 rewinder along with the Hunkeler WI8 web inspection system via its open architecture interface. The press will print live three versions of a “magalog” (blend of magazine and catalog) with different editorial and marketing content. The demanding application includes large high resolution images and a compelling design that leverages PROSPER ULTRA 520 Press’s ability to print heavy ink coverage on standard offset paper at 150 mpm (500 fpm).

Show attendees can also expect to see an extensive collection of finished applications printed on the PROSPER ULTRA 520 Press as well as the PROSPER 7000 Turbo Press, the world’s fastest digital press with speeds of up to 1,345 fpm (410 mpm). The impressive range of samples on display will include trade publications, colour books, newspapers, catalogs, postcards, and direct mail.

To enable efficient and profitable production in the digital print environment and to realize a “smart factory” concept, a powerful overarching workflow is needed. Kodak will be demonstrating KODAK PRINERGY On Demand Business Solutions, the first end-to-end workflow solution for the printing industry. Powered by PRINERGY On Demand workflow automation and Microsoft Azure cloud, PRINERGY On Demand Business Solutions removes complexity by bringing together print-specific E-commerce, MIS/ERP, and collaboration software solutions, fully integrated and solely managed by Kodak. At Hunkeler Innovationdays, PRINERGY On Demand Business Solutions manages the digital print workflow and tracks the entire production process of the magalog job all the way to the saddle-stitched end product.

In addition to its activities on the exhibition floor, Kodak will talk about its solutions for

seamless and efficient workflow integration in the digital printing environment at the DOXNET on-site Conference, which will be held on February 28 as part of Hunkeler Innovationdays.

“We are excited to use Hunkeler Innovationdays for the European premiere of the KODAK PROSPER ULTRA 520 Press. This breakthrough inkjet press eases printers’ transition from offset to digital production with its quality, productivity and application capabilities,” said Jim Continenza, Executive Chairman and Chief Executive Officer, Kodak. “KODAK PROSPER Presses, with their highspeed architecture and use of proprietary water-based nanoparticulate pigment inks and optimizer agents, provide complete solutions for high-output, cost-effective printing of a broad range of applications in all segments of the print market.”

pressideas/ digital 25 January 2023

FUJIFILM India at CEIF 2023

At Consumer Electronic Imaging Fair 2023 Fujifilm showcases its wide range of imaging and other products and solutions.

FUJIFILM India exhibited its technologically advanced products at the Consumer Electronic Imaging Fair (CEIF) 2023. CEIF is one of the largest Imaging exhibitions across the World which witnessed participation and representation from top global brands in the field of imaging and photography. Starting on 5th January 2023, the exhibition continued till 7th January 2023 at Jio World Centre, Mumbai.

FUJIFILM India has a wide range of Imaging solutions, and it has positioned itself as one of the few manufacturers in the world which has created total solutions that can support professionals and businesses with end-toend solutions. Some of the key products and technologies displayed at the exhibition are:

Digital Still Camera & Instant Cameras: Fujifilm’s entire range of digital still cameras like the GFX and X series was on display. The versatile X-T5, an exclusive device for all the photography enthusiasts, X-H2S & X-H2 , a true hybrid for video and photography purpose along with high-resolution XF lenses like XF-30mm, XF18-120mm, XF 150-600mm, XF-56mm were also on display. From the GFX series the GFX 100s II, GFX 100 along with GF 20-35mm, GF Lenses were showcased. The entire range of INSTAX cameras along with the Smartphone Printers was also on display.

Graphic Arts Solutions: The Revoria Press PC 1120, a 6-colour print engine which brings unrivaled expressive power to digital printing was on display. The machine has garnered phenomenal traction among the photo lab community in the recent past with its ability to transform the production printing market with its functional efficiency, precision and the ability to create overlays and underlays with additional colours. Fujifilm’s Revoria Press PC 1120 is a high-definition, high-output resolution device which is a preferred choice among photo labs in India.

Photo Imaging Solutions: The ApeosPro for Photo C810 / C750 / C650 Printer which is built on a next-generation hybrid platform designed to enable businesses to print more

with outstanding quality on a wider range of substrates was on display, along with a versatile and long-lasting product Frontier DE100-XD which can meet the industry’s diversified needs. Also on display was the ASK-400 Dye-sublimation Printer which is a highly durable compact dye-sublimation printer, which has a compact size of 170mmhigh and 0.1m2 footprint and it has a High Speed of 8.4 secs which is majorly used for Sticker Printing