APRIL 2020

& INFRASTRUCTURE

RESILIENT ROADS Cross River Rail Delivery Authority’s Graeme Newton on supporting the road network with major projects.

Official media partners of

LOW TRAFFIC ROADS New crumb rubber specifications CONEXPO WRAP-UP All the latest construction news

AUSTRALIA’S ONLY SPECIALIST ROAD MANAGEMENT, CONSTRUCTION AND CIVIL WORKS MAGAZINE

C

M

Y

M

Y

Y

Y

K

Industrial Special Plant and ProCon underwritten by QBE Insurance (Australia) Limited. ABN 78 003 191 035, AFSL 239545. Underwriting Agencies of Australia Pty Ltd. ABN 86 003 565 302 AFS Licence 238517. Underwriting Agencies of New Zealand Limited (UAA). 4758199, NZBN: 9429040999678. J6663

APRIL 2020 CONTENTS

& INFRASTRUCTURE 4 Editors letter 6 News

COVER STORY

14 Cross River Rail Roads & Infrastructure looks at the requirements for Brisbane’s largest transport project.

AAPA

18 AAPA Member Profile Scott Dornan at Action Line Marking reflects on growing the business. 20 Circular thinking AAPA’s Peter Damen explains what’s pushing the road industry towards circular economy practices.

ASPHALT IN ACTION

23 Purchasing pavers When purchasing a paver there are important factors to consider. 24 Mixing time tech Ciber’s Marcelo Zubaran explains how controlling mixing time can improve material adhesion.

ENVIRONMENT & SUSTAINABILITY

26 Crumb rubber bitumen OLEXOCRUMB, a bitumen blend created by Puma Bitumen, contains 10 per cent crumb rubber with no need to change mix design. 28 A new era for crumb An Australian-first specification is set to inform the use of crumb rubber in asphalt on low-traffic roads. 32 Freeway foundations ResourceCo has been contracted to supply soft rock materials to the Mordialloc Freeway in Melbourne.

34 Greener roads Moreton Bay Regional Council is using substantial volumes of recycled product used in its resurfacing program.

TECHNOLOGY & EQUIPMENT

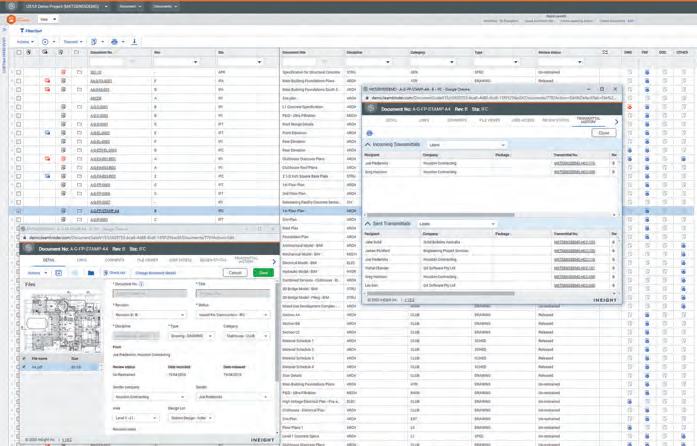

36 Roundabout revolution TORUS 6.0 is enabling designers to analyse and design noncircular roundabouts and generate 3D roundabout designs. 38 Document controls Major projects are using InEight Document, a project-centric solution that organises documents and makes them available to teams in real-time. 40 Assets on track Ctrack by Inseego has launched a new asset tracking range with supporting web and mobile applications. Conexpo featured more than 2.7 million square feet of exhibits.

42 In-stock batch plants In a company-first, Gough Industrial Solutions is keeping a concrete batching plant in stock in Australia. 44 Introducing Hiway Group Since establishing itself in Australia in 2008, Hiway Group has grown to become a major road stabilisation contractor.

SAFETY

46 Edge protection NON-DRILL is helping major projects increase on-site productivity and safety. 48 Motorcycle barriers Ingal Civil has created two different road safety solutions for motorcyclists. 50 Cyber safety Troy Filipcevic from Emergence Insurance highlights the importance of insurance in the event of a cyberattack.

EVENTS

52 Conexpo Roads & Infrastructure details one of the largest construction equipment exhibitions in the world. 56 Queensland major projects The 2020 Queensland Transport and Infrastructure Conference will present a holistic update of infrastructure across the growing state.

THOUGHT LEADERSHIP

58 ARRB thought leadership The Australian Road Research Board discusses why it’s critical to get the basics right as we head towards a connected and automated transport future.

roadsonline.com.au

3

& INFRASTRUCTURE

IS CRUMB BACK IN VOGUE? AT LAST YEAR’S AUSTRALIAN ASPHALT PAVEMENT ASSOCIATION CONFERENCE, stakeholders at each end of the tyre-derived product supply chain got together to discuss the progress and barriers to crumb rubber uptake. Those in the audience answered a series of questions about what was preventing them from increasing crumb. More than 60 participants were involved, with road owners/government making up around 40 per cent of the audience, followed by contractors and binder suppliers. Of those participants, more than 80 per cent were using crumb, but the barriers were seen to be a lack of infrastructure/supply, followed by specifications, guidelines and cost. The message from the broader conversation was clear: crumb is back in vogue. We know that crumb rubber modified binder has been used since the 70s, mainly in spray sealing. Moreover, it’s not as if crumb hasn’t been explored in asphalt applications or as if we’re reinventing the wheel, but what is clear is that companies are once again looking at it. For example, Puma Bitumen, featured on page 26, has developed OLEXOCRUMB, a crumb rubber binder that will be used on Australia’s first large-scale trial of crumb rubber asphalt on an arterial road. Over on the low-traffic side, the Department of Transport in Victoria has just released an Australia-first specification for crumb rubber asphalt in this proven application, detailed on page 28. As the Department’s Arthur Apostolopoulos explained, low-traffic applications of crumb rubber don’t have to compete with polymer modified binders. Stakeholders, including the Institute of Public Works Victoria, are excited about how this new specification will give local governments the confidence to explore crumb rubber usage in asphalt. It’s the backing of the Department that will help get councils over the line to using more crumb. The fact that the application has been proved means that expressions of interest will soon be released for up to 10 participating councils. This could be a mix of urbanised, coastal, desert and mountainous environments to demonstrate tangible outcomes across a number of applications. Over in South Australia, a handful of councils have agreed to take part in a trial using crumb rubber for asphalt derived from end-of-life truck tyres. It’s particularly timely as the practice of sending whole baled tyres overseas becomes unsustainable, making the economics of the practice increasingly unviable and opening up the risk of stockpiling. According to the Federal Government’s export ban discussion paper, 47 per cent of Australia’s 101,806 tonnes of tyre exports go to India. Although tyres only comprise seven per cent of the export tonnage, India’s National Green Tribunal has directed the Central Pollution Control to regulate the import of waste tyres. A ban on whole baled tyres is also expected next year. To that end, it’s an opportune time to get crumb back on the scene, providing occupational health and safety concerns can be allayed through evidence-based practice.

Toli Papadopoulos Managing Editor, Roads & Infrastructure Magazine 4

ROADS APRIL 2020

PUBLISHER Christine Clancy christine.clancy@primecreative.com.au MANAGING EDITOR Toli Papadopoulos toli.papadopoulos@primecreative.com.au JOURNALISTS Lauren Jones lauren.jones@primecreative.com.au Holly Keys holly.keys@primecreative.com.au DESIGN PRODUCTION MANAGER Michelle Weston michelle.weston@primecreative.com.au ART DIRECTOR Blake Storey DESIGN Kerry Pert, Madeline McCarty BUSINESS DEVELOPMENT MANAGER Zale Thurgood zale.thurgood@primecreative.com.au CLIENT SUCCESS MANAGER Justine Nardone justine.nardone@primecreative.com.au HEAD OFFICE Prime Creative Pty Ltd 11-15 Buckhurst Street South Melbourne VIC 3205 Australia p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.roadsonline.com.au SUBSCRIPTIONS +61 3 9690 8766 subscriptions@primecreative.com.au Roads & Infrastructure Australia is available by subscription from the publisher. The rights of refusal are reserved by the publisher. ARTICLES All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Roads & Infrastructure Australia is owned and published by Prime Creative Media. All material in Roads & Infrastructure Australia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without the written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Roads & Infrastructure Australia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

A WIRTGEN GROUP COMPANY

STRONG LIKE A SPECIALIST. VERSATILE LIKE AN ALL-ROUNDER. MOBIREX MR 110/130 EVO2

MOBIREX MR 110/130 EVO2

YOUR PERFECT PERFORMER IN PROCESSING OF RECYCLING ASPHALT, KLEEMANN… THAT’S A RAP. The MOBIREX MR 110 & MR 130 EVO2 mobile impact crushers feature a powerful diesel-direct-drive – for high throughput, combined with broad range of Wear Items to optimised output and reduce cost. The flexibility in these units allows Multi Stream Material processing for all Road construction materials, Demolition Waste and Naturally occurring virgin materials. With their compact design, the plants are easy to transport and as quick to set up. The MR 110/130 EVO2 – versatile and part of the road to the future . www.kleemann.info WIRTGEN AUSTRALIA PTY LTD · Lot 2 Great Eastern Highway (Off Ivy St) South Guildford WA 6055 T: +61 8 6279 2200 · www.wirtgen-group.com/australia

NEWS

$17.6B STIMULUS PACKAGE SET TO BOOST CONSTRUCTION BUSINESSES The Federal Government has announced a $17.6 billion stimulus package to keep businesses running, support households and the Australian economy in the face of challenges posed by the spread of the coronavirus. The package will focus on keeping Australians in jobs and helping small and medium sized businesses to keep running. It will be split into the following four parts: supporting business investment, providing cash flow assistance for small and medium sized businesses, targeted support for the most severely affected sectors, regions and communities and household stimulus payments. To support businesses the Federal Government will commit $700 million to increase the asset write off threshold from $30,000 to $150,000. It will also expand access to include businesses with aggregated annual turnover of less than $500 million (up from $50 million) until 30 June 2020. An example of an asset that may be able to be immediately written off would be a concrete tank for a builder. There will also be a commitment of $1.3 billion to help small businesses in supporting the jobs of around 120,000 apprentices and trainees. Eligible employers can apply for a wage subsidy of 50 per cent of the apprentice or trainee’s wage for up to nine months, from 1 January 2020 to 30 September 2020. If a small business is not able to retain an apprentice, the subsidy will be available to a new employer that employs the apprentice.

The Federal Government will commit $700 million to increase the instant asset write-off.

Master Builders Australia have backed the stimulus package. CEO Denita Wawn said the industry needs confidence and this is a clear signal from the government they are determined to do whatever it takes. “There are more than 380,000 small building businesses and tradies in our industry, more than any other sector of the economy, that will benefit from the government’s strong focus on backing small businesses,” Ms. Wawn said. Ms. Wawn said incentives to invest in business assets are well targeted to the construction industry. She said there is no doubt builders and tradies will be encouraged to invest in new plant and equipment. “However, if there is a major contraction in building activity then the benefit of these

measures will be blunted. The government must take a strong leadership role in ensuring that construction of government projects currently underway continue and that projects scheduled to commence are not delayed or withdrawn,” Ms. Wawn said. “Our industry also remains nervous about how protracted the inevitable shortage and delayed delivery of imported building products will be. “This is a hit to our industry that is looming over the next few months and additional measures and extensions of some of stimulus measures may be required to help the industry weather that storm,” she said. Prime Minister Scott Morrison said as part of the plan up to 6.5 million individuals and 3.5 million businesses would be directly supported by the package. “Just as we have acted decisively to protect the health of the Australian people, based on the best evidence and medical advice, our support package responds to the economic challenges presented by this pandemic in a timely, proportionate and targeted way,” Mr. Morrison said. “Our targeted stimulus package will focus on keeping Australians in jobs and keeping businesses in business so we can bounce back strongly.” “The economy needs temporary help right now to bounce back better so the livelihoods of all Australians are protected,” he said.

AIRPORT CENTRAL STATION, PERTH NEARS CONSTRUCTION COMPLETION Construction of the new Airport Central Station in Perth has reached 70 per cent completion. Majority of the works at the site have been underground with significant excavation involved to build the three-level railway hub. Above-ground construction has now begun with the first step to start building the roof structure. The first girders of the 137-tonne roof structure are being craned into place. The steel girders were fabricated locally by 6

ROADS APRIL 2020

Naval Base company Pacific Industrial Co. Constructing the roof structure is expected to take three months. Then, specially designed sheeting will be installed. which will help to reduce glare for pilots flying in and out of Perth Airport. The 280-metre Skybridge between Airport Central Station and Perth Airport is also close to completion. The walkway features travelators and information screens and will provide a seamless connection between the

station and Terminals One and Two. Tunnel boring machine Sandy, the second tunnel boring machine on the project, is due to arrive at Bayswater Junction in the middle of the year. Her arrival will mark the end of tunnelling on the project. Once operational in late 2021, the Forrestfield-Airport Link will provide a 20-minute direct route between the eastern foothills and the CBD as well as the wider public transport network via the airport.

Low-cost level measurement. Radar sensor for water management. Reliable level measurement in water treatment facilities, pump stations and rain overflow basins. Open channel flow measurement and water level monitoring.

VEGAPULS WL S 61 ▪ Measuring range up to 8 m

▪ Can be used outdoors without restriction ▪ Flood-proof IP 68 housing

▪ Operation via Bluetooth with Smartphone, tablet or PC

Further information: www.vega.com/wls61

Phone 1800 817 135

NEWS

CROSS RIVER RAIL OPPORTUNITIES FOR SUBCONTRACTORS TO BE ANNOUNCED With more than 200 companies across South East Queensland already securing Cross River Rail Contracts, a wave of sub-contractor opportunities for the tunnels and stations work package will be released. Cross River Rail Minister Kate Jones said the Cross River Rail project would create thousands of construction jobs over the next five years. “We’re working hard to make sure that local subbies and workers benefit from the biggest infrastructure project in Queensland’s history,” she said. “We’ve already seen iconic Queensland company Wagners awarded a $40 million contract to supply precast concrete segments and we want companies asking themselves ‘could we be the next ones to win?’” Ms. Jones met with Multhana Property Services, an indigenous company from Eight Mile Plains, which is contracted to deliver cleaning and maintenance services at the project’s worksites. “Multhana is a great example of a proud Queensland company benefiting from Cross River Rail,” she said. “They’re doing a great job and already

have eight staff working on the project, with that number set to grow as more worksites are established.” Ms. Jones revealed a new website is now live for companies to register their interest to apply for contracts through the main contractor. “This will be the one-stop shop for anyone who wants to work on Cross River Rail,” she said. “If you’re a local subby with the right expertise, we want you to apply to work on the biggest project in Queensland’s history.” This announcement comes alongside a major reform package announced by Ms. Jones to ensure contractual commitments on the Cross River Rail project are delivered as the project moves into construction phase. Ms. Jones said her priority was to ensure that Pulse consortium and head contractor CPB Group complied fully with their contract with the state government. “Since coming into the role at the end of last year, I have been reviewing the structure of the Cross River Rail Delivery Authority.” She said it is clear to her and the cabinet

that now the project has moved from procurement to construction, compliance will need to be strengthened. “Our government has made strong commitments to Queenslanders to deliver long-term benefits to the state’s future through our record investment in infrastructure,” Ms. Jones said. “This includes more jobs for locals, more training for young apprentices and trainees and better workplace health and safety, delivering real opportunities for local Queensland businesses to get contracts as well as fair industrial relations practices and environmental compliance.” Ms. Jones announced that cabinet had agreed to the following reforms: 1. The Cross River Rail Delivery Authority will report directly to the Minister 2. A Compliance Unit will be established to ensure all commitments made by the contractor are met during the construction of the project 3. The board will be restructured once the current term expires in April this year in line with the transition from procurement to construction. Ms. Jones said that the Compliance Unit would be established immediately.

AUSTRALIAN ASPHALT PAVEMENT ASSOCIATION RELEASES NEXT INTERNATIONAL CONFERENCE DATE

AAPA’s next international conference will be held in Brisbane in 2021.

8

ROADS APRIL 2020

Every two years, the Australian Asphalt Pavement Association (AAPA) hosts its international flexible pavements conference and exhibition. The next will be held at the Brisbane Convention and Exhibition Centre from 16 to 18 August 2021. The title of the conference will be “Roads going full circle” with key themes around sustainability and asset management. In a statement, the AAPA said the title refers to the need for the infrastructure sector to become circular and incentivise circular economy solutions to respond to the challenges of climate

change, carbon emissions and decrease of natural resources. The four key themes for the conference will be: • Sustainable future pavements • Trends in the bitumen and asphalt industry – development and innovation • New technologies/continual improvement • Retaining asset value. Following the success of the 2019 conference and exhibition, AAPA members are advised to save the date and keep an eye out for more updates.

WITH

OLEXOCRUMB Trusted PMB grades now incorporating 10% recycled tyre rubber

pumabitumen.com

Reducing temperature and emissions in asphalt production and placement

ÂŽ

Every tonne of OLEXOCRUMBÂŽ binder repurposes the equivalent of 15 locally sourced passenger tyres

Complies with existing Austroads specifications for A10E, A15E and A20E

Follow us on LinkedIn PUMA ENERGY

ENGINEERED FOR THE DEMANDS OF THE COMMERCIAL PAVING MARKET WITH

SUPPORT YOU CAN RELY ON As the exclusive distributor for Weiler road construction machinery in Queensland and the Northern Territory, Hastings Deering offers a range of end-to-end road construction solutions. The new P385B commercial paver is engineered and built to produce in a wide range of applications, providing performance, reliability and outstanding mat quality for the commercial paving market, backed by uncompromising service you can rely on, wherever you are.

TO FIND OUT MORE CALL US ON 1300 186 250 OR VISIT HASTINGSDEERING.COM.AU/ROADS

NEWS

CONTRACTORS DELIVER $137M SCONE BYPASS IN NSW The new Scone Bypass will soon open to traffic, enabling faster drive times along the New England Highway in NSW. Daracon Group was contracted to construct the 5.5-kilometre bypass in March 2018. With construction complete, a community walk was held to celebrate the new route. Deputy Prime Minister and Federal Minister for Infrastructure, Transport and Regional Development Michael McCormack said the entire region would benefit immensely from the bypass opening. “[The] community walk is a fitting way to mark the completion of the project, which follows many years of planning, consultation and construction,”

Mr. McCormack said. NSW Minister for Regional Transport and Roads Paul Toole said the bypass would change the way people moved in and around Scone. “Until now, highway traffic passed through Scone along the main road access to the town, which is also the main street through the central business district,” Mr. Toole said. Some 8400 daily vehicles will no longer need to travel through the town centre on the New England Highway south of Scone. The grade-separated intersection at the southern end of the bypass, which crosses over the rail line and Kingdon and Liverpool Streets, will allow uninterrupted access to the bypass at the north and south of town

Some 8400 daily vehicles will no longer need to travel through the town centre.

and in the middle at Aubins Street. On this section of the highway, there were 26 crashes in the five years to December 2015, and the upgrade is hoped to improve road safety in the area.

VIC INFRASTRUCTURE PROJECTS TO PRIORITISE RECYCLED MATERIALS Recycled First, a new initiative from the Victorian Government, is set to boost the use of recycled and reused materials in construction projects. According to Transport Infrastructure Minister Jacinta Allan, Recycled First brings a uniform approach to the existing “ad hoc” use of recycled products on major transport infrastructure projects. “We’re paving a greener future for

Recycled First is set to bring a uniform approach to recycled products in infrastructure.

Victoria’s infrastructure, turning waste into vital materials for our huge transport agenda and getting rubbish out of landfills,” Ms. Allan said. “Recycled First will boost the demand for reused materials right across our construction sector, driving innovation in sustainable materials and changing the way we think about waste products.” The program will incorporate recycled and reused materials that meet existing standards for road and rail projects, with recycled aggregates, glass, plastic, timber, steel, ballast, crushed concrete, crushed brick, crumb rubber, reclaimed asphalt pavement and organics taking precedence over brand new materials. “Companies interested in delivering major transport infrastructure projects will be required to demonstrate how they will prioritise recycled and reused materials, while maintaining compliance and quality standards,” Ms. Allan said. Additionally, contractors will need to report on the types and volumes of recycled products used. The policy will not set mandatory minimum requirements or targets, Ms. Allan said. Instead, a project-by-project approach

will allow contractors to liaise with recycled materials suppliers to determine if there are adequate supplies of the necessary products for their project. “Work is already underway with current construction partners to ensure more recycled content is being used on major projects, in addition to the new Recycled First requirements,” Ms. Allan said. “The M80 Ring Road, Monash Freeway and South Gippsland Highway upgrades will use more than 20,000 tonnes of recycled materials, and 190 million glass bottles will be used in surfaces on the $1.8 billion Western Roads Upgrade.” According to Ms. Allan, recycled demolition material was also used to build extra lanes along 24 kilometres of the Tullamarine Freeway, as well as the Monash Freeway and M80 Ring Road. “The state government is also reusing materials created by its own projects, with 14,000 tonnes of soil excavated from the Metro Tunnel site in Parkville now being used in pavement layers on roads in Point Cook,” she said. “This material weighs as much as 226 E-class Melbourne trams and would otherwise have gone to landfill. roadsonline.com.au

11

NEWS

CONTRACTOR TO BEGIN CONSTRUCTION OF $60M MELBOURNE AIRPORT EXPRESS ROAD Contractor Seymour White is set to start construction on the $60 million project linking the Tullamarine Freeway to the Terminal Four car park at Melbourne Airport. The T4 express link will aim to make it faster for drivers to reach Terminal Four and is expected to carry 5000 vehicles per day when completed. Melbourne Airport Chief Commercial Officer of Landside Access Lorie Argus said the airport was proud to invest in road access and cater to forecast passenger growth. A further $260 million is earmarked for stage two of the road upgrade which may include a second elevated link to facilitate

better connections to Terminals One, Two and Three. “We’re focused on improving the traveller experience from freeway to runway and the elevated loop road is going to make it easier and faster for people to reach Terminal Four, which services Jetstar, Tigerair and REX travellers,” Ms. Argus said. Melbourne Airport passenger numbers are predicted to grow from 37 million to 70 million people per year by 2038 and the new road will help to move traffic around the precinct efficiently. “Our data shows that if we do not add more roads by 2025, drivers could be stuck in traffic for around 30 minutes on the doorstep of the airport,” Ms. Argus said.

“Our elevated loop road upgrades will future-proof Melbourne Airport for international and domestic traveller growth while reducing stress for passengers.” Seymour Whyte CEO and Managing Director John Kirkwood said he was looking forward to working on the project to deliver the first stage of the airport’s major development plan. “We are committed to ensuring that the project’s planned operational, social and economic benefits are achieved through innovative and sustainable solutions, and that we deliver a quality asset of longterm value for Melbourne Airport and the people of Victoria,” Mr. Kirkwood said.

INFRASTRUCTURE AUSTRALIA NOTES ENVIRONMENTAL CONCERNS IN 2020 PRIORITY LIST Environmental changes headline the 2020 Infrastructure Priority List released by Infrastructure Australia. The latest Priority List presents 147 infrastructure proposals of national significance, the most since the list’s inception. The list introduces five new high-priority national initiatives covering water, the nation’s rapidly growing waste problem, coastal inundation and road maintenance. Infrastructure Australia Chief Executive Romilly Madew said the Infrastructure Priority List reflects both the diversity and urgency of the nation’s future infrastructure needs. “Resilience was a key theme of our 2019 Australian Infrastructure Audit and this focus continues to be reflected in our latest edition of the Infrastructure Priority List,” Ms. Madew said. “Compounding issues of unprecedented infrastructure demand, severe drought and other environmental changes require a focus on our resilience strategies and a consensus on where to invest now for our nation’s future prosperity.” Infrastructure Australia specifically identified a new high-priority initiative for a 12

ROADS APRIL 2020

The latest edition presents 147 infrastructure proposals of national significance.

national water strategy and a town and city water security strategy. The report notes that demand for water systems is increasing and the water cycle is being altered by changing climate, changes to run-off and evaporation due to land and forest management. “In response to this call to action, we’re expecting a range of solutions to be considered for capturing, managing and

distributing water, along with improvements in reporting and use of data in the water sector,” Ms. Madew said. Regional Australia also emerged as a focus of this edition of the Infrastructure Priority List with a call to improve mobile telecommunications coverage in remote areas and improve regional road safety. “Truly staying connected requires not only safe and efficient transport options, but also ensuring our towns and regional communities have the same access to telecommunications as the rest of Australia. This is to also provide people with reliable access to electronic payment systems, emergency alerts and other critical services,” Ms. Madew said. In total, the latest edition of the Priority List identifies a project pipeline worth more than $58 billion. It is a collaborative document developed using data from the 2019 Australian Infrastructure Audit and submissions from government, industry and the community. “The Priority List has a strong record of driving national investment and has become a key reference point for all levels of government,” Ms. Madew said.

A NEW WAY TO BUILD Finally, take control of your projects at every phase of construction. Find out how with InEight software.

InEight.com/road

TURN UP

AND GO

CROSS RIVER RAIL IS SET TO EASE THE STRAIN FROM QUEENSLAND’S ROAD TRANSPORT NETWORK WITH A GOAL OF TAKING 47,000 CARS OFF THE ROAD BY 2036.

A

s Queensland’s biggest infrastructure project, Cross River Rail is more than just a rail project. By offering a new 10.2-kilometre rail from Brisbane’s Dutton Park to Bowen Hills, including 5.9 kilometres of twin tunnels under the Brisbane River and CBD, the project will alleviate stress from the transport network. In making public transport a more attractive option, the project is looking to take around 47,000 cars off the road by 2036. Of course, as a rail project, unlocking the bottleneck at the core of the rail network is a key element. With the current rail network nearing capacity and constrained by a single river crossing and four Brisbane stations in the CBD, the Cross River Rail will alleviate the bottleneck. Likewise, providing more trains to run across the complete South East Queensland network and integrating with new roads and bus services is another important benefit, not least revitalising 14

ROADS APRIL 2020

multiple inner-city precincts. Put in perspective, the Cross River Rail Business Case, released in August 2017, found the project benefits would exceed the costs by $1.9 billion. At a glance, the project comprises four underground stations at Boggo Road, Woolloongabba, Albert Street and Roma Street. It also covers two upgraded stations at Dutton Park and Exhibition and six upgraded stations from Salisbury to Fairfield on Brisbane’s southside. Moreover, the project includes the development of three new Gold Coast Stations at Pimpama, Helensvale North and Merrimac. Cross River Rail has been more than 10 years in the making, with the Newman Government bringing in an expert panel in 2012 to review the business case. Former Transport Minister Scott Emerson had remarked at the time that the earliest possible project delivery would be 2020. Almost a decade later, as predicted, more than 200 companies across South

East Queensland have already secured Cross River Rail contracts, with more opportunities for the tunnels and stations works package set to be released. At least seven construction sites are currently active, with more to open. It’s even inspired the appointment of a ministerial portfolio in Kate Jones, who is also the Tourism Industry Development Minister, with the Queensland Government investing $5.4 billion to deliver the project. Graeme Newton, Chief Executive Officer of the Cross River Rail Delivery Authority, says that what is perhaps underestimated is the power of this project to truly transform the region. “The fact that Cross River Rail will help more trains get around the network, create new stations in Brisbane and the Gold Coast and upgrade eight others is only one part of the story,” he says. Mr. Newton says the other part of the story is that Cross River Rail will act as a catalyst to change the urban landscape for the better.

COVER STORY

The Woolloongabba Station Precinct will be transformed into a vibrant mixed-use hub.

He cites the Precinct Delivery Strategy that outlines the vision and path forward for the precincts that will be built at five of its station locations. “For example, at Woolloongabba, there is an opportunity to give the suburb a real town heart, with the potential for public spaces, as well as new hospitality, retail, residential and office spaces,” Mr. Newton says. Roma Street sees buses, coaches, city trains and regional trains all forming a transport hub along with Cross River Rail. As such, Mr. Newton says that there is potential to revitalise an underutilised part of the city and create a vibrant gateway to Brisbane. Not least of all, he says, this includes an option to progress plans for Brisbane Live. If built, the 18,000-capacity indoor entertainment arena would attract major events and generate economic and social benefits for the region. Mr. Newton says that creating better connectivity and interesting spaces that help Brisbane evolve as a world-class city is a key part of the project. This encompasses making it easy to hop from one part of the city to another, right through to

The master alignment map highlights the scale of community change that will emerge from the project.

a turn-up-and-go rail system. He adds that a number of industries have already expressed an interest in setting up near or as part of these precincts, as they understand how the project will transform the city and how people move around within it. EARLY WORKS PROGRESSES Early works have been underway for a few years, with a geotechnical investigation and survey program beginning in 2017. Borehole drilling was conducted at more than 50 locations across the proposed Cross River Rail corridor, with the deepest hole drilled at Kangaroo Point which went 66 metres down. As part of the early works program, project participants have also cleared the four-hectare site at Woolloongabba. This will form the launch site for the Cross River Rail tunnel boring machines and road headers. The preparation of the

site included the demolition of three government-owned buildings and the removal of 45,000 tonnes of building waste, 95 per cent of which was recycled. Site remediation works then began on the Woolloongabba site, removing 138,000 tonnes of contaminated materials and their respective bulking factors. A temporary coach terminal has also been built at Roma Street which opened in September last year. Mr. Newton says the new terminal will provide continuity for long-haul coach services previously housed in the Brisbane Transit Centre. He says this is arguably Brisbane’s ugliest building and will be demolished this year to make way for a new underground Roma Street station. Mr. Newton says that since appointing primary contractors, the design and construction phase is progressing well. “Projects of this size are complex creatures, but we’re pleased with the work roadsonline.com.au

15

Roma Street is poised to become one of the state’s most significant transport interchanges.

from our contractors so far to align our three major works packages and keep things on track,” he says. The Cross River Rail Delivery Authority has released the Fairfield station concept design with major construction at Fairfield station scheduled in mid-2020. Site survey and geotechnical investigations are continuing from Fairfield to Salisbury station and will continue throughout early 2020. The authority has also released the Exhibition Station concept design, with major construction expected in late 2020. One of the innovative aspects of the project is Project DNA (Digital Network Approach) – a digital twin bringing Building Information Modelling, Geographic Information System and realistic visualisations of the project in a single, federated model. Mr. Newton says it is used by many Cross River Rail teams. For example, engineers look at how to refine designs, while the project controls team tracks project progress. Planners aim to see how the precincts can knit into Brisbane’s urban fabric. In addition, the community information team use it for visualisations and virtual reality to bring the project to 16

ROADS APRIL 2020

life for the public. “Project DNA also helped us streamline our bidding process with major contractors for the project submitting their bids in a format that we could plug into our model,” Mr. Newton says. “It meant that once contracts had been awarded, we could hit the ground running without the need for extensive and expensive rework.” One of the three main works packages is the delivery of the European Train Control System (ETCS) – Level 2, which is widely used in Europe but a first for Queensland. The ETCS is a signalling technology that removes the need for trackside signalling and relays information continuously between the rail management centre and the driver’s on-board computer. “Because this gives us a greater ability to track and control train movements, it allows trains to operate more safely. It will also add capacity to and increase the efficiency of our rail network,” Mr. Newton says. He says that in addition to Brisbane’s rail line, the Cross River Rail will also be installing the technology on the Cross River Rail line. In terms of community feedback, Mr.

Newton says the project has, overall, been well received. He says the Cross River Rail is on schedule for completion by 2025 and is currently hitting all of its milestones. Critical to the project will be minimising community disruption during the plan and build phase and when selecting construction methodologies. “Now that we’re into the constriction phase, it’s critical that we keep the community informed of what is happening,” he says. “Most importantly, we work very closely with our stakeholders, including residents and business owners, local and state government agencies and other major projects.” Mr. Newton says that by 2025, Brisbane will be completely transformed by the likes of Cross River Rail. This will complement the Brisbane Metro, Herston Quarter and the Dexus Waterfront development. “However, for all of these projects to be a success, there will be some disruption, which is why it’s so important that we work with these projects that will change the face of Brisbane. We’re all aiming to mitigate disruption as much as we can,” he says.

EXCELLENCE FROM THE GROUND UP Hiway Group has been delivering innovative ground improvement solutions since 1986. Our reputation for quality performance has been built upon our drive and commitment to safe work practices, innovation, environmental sustainability, leadership and excellence. It is our commitment to innovation, environmental sustainability and industry leadership that has seen us introduce cutting edge technologies into Australia and develop our own advanced methodologies and stabilising products. With a proven track record of ensuring high quality, lasting outcomes – even in challenging conditions – our in-house design and contracting teams are industry experts.

OUR ADDED VALUE

We work across all sectors of industry specialising in fill drying saturated ground; treating and remediating soil contaminated sites; design, supply and laying of foam bitumen; aggregate modification; subgrade and subbase improvement. As well as the cost savings they generate our innovative solutions reduce construction time, increase strength and durability, and are more environmentally sustainable.

OUR CAPACITY

Hiway Group has operations in NSW, Queensland, Victoria, SA, Tasmania and WA, as well our original operations continuing in New Zealand and the Pacific Islands. We have a large fleet of well-maintained and modern plant which is continually being augmented as new technologies become available and as we expand our operations. Many of our in-situ stabilisers are equipped for foamed bitumen works.

OUR CAPABILITY

Our expert team also provides a proven one-stop-shop for design and construction. Our site operational staff are supported by a team of experienced professional engineers, pavement designers and project managers. Our experience covers all forms of in-situ stabilization basecourse modification services that are more cost effective than traditional road construction and rehabilitation methods.

Paul Rhoden

Mark Large

Mark Filsall

M. +61 455 677 665 T. +61 755 412 074 E. paulr@hiways.com.au

M. +61 477 990 500 T. +61 8 9258 4488 E. m.large@hiways.com.au

M. +61 428 803 001 T. +61 3 9730 2020 E. mark.f@hiways.com.au

GM NORTHERN REGION

GM WESTERN REGION

GM SOUTHERN REGION

www.hiways.com.au

AAPA MEMBER PROFILE: SCOTT DORNAN ACTION LINE MARKING SA Q: WHY DID YOU DECIDE TO BECOME AN AAPA MEMBER? A: I have been associated with or a member of APPA since around 2008. I decided to join AAPA to get a better understanding of the industry that supports us as a key stakeholder. Q: HOW DID YOU START YOUR CAREER IN THE ROAD CONSTRUCTION INDUSTRY? A: I joined Action Line Marking (SA) Pty Ltd around 1992 as a 33 per cent shareholder. My father, Jim Dornan, and Paul Wheeler previously started the company. Q: WHAT IS YOUR CURRENT ROLE AND WHAT DOES IT INVOLVE? A: I am one of the two owners and the Managing Director of Action Line Marking (SA) Pty Ltd. My role is business development and I assist with potential growth and understanding of our market trends. This ensures Action Line Marking remains an innovative company at the forefront of the line marking industry and my main focus is the South Australian market. We are extremely customerfocused and proud of our ability to react to market needs and ensure our client’s needs are met. Q: WHAT IS THE BEST THING ABOUT YOUR CURRENT ROLE? A: I really enjoy seeing how the company has evolved from humble beginnings to now being the leader in the marketplace. A major standout for Action Line Marking is our ability to employ full-time employees. We are a true South Australian company that not only employs South Australians, but also trains them and provides them with job security and satisfaction. With

18

ROADS APRIL 2020

full-time, highly trained staff and a business that has been running for over 25 years, we can deliver any size of project with precision and quality. Q: WHAT IS YOUR BIGGEST ACHIEVEMENT IN THE INDUSTRY? A: Designing and building the majority of our bespoke equipment in-house is by far one of the most rewarding achievements we have accomplished in the industry. I believe we have some of the best equipment in the country and it has been proudly developed by us. Action Line Marking has five custom-built paint vehicles with the capacity to carry 1000 litres of paint. The business also has custom trailers and hand spray or ride on vehicles for a wide range of jobs. Q: WHAT IS A RECENT CHANGE YOU HAVE SEEN IN THE INDUSTRY AND HOW ARE YOU/THE COMPANY PREPARED FOR THAT? A: The biggest change I have seen in the industry is with regards to the safety aspects of the tasks we undertake daily. Action Line Marking is proud to be at the forefront of our industry with truckmounted attenuators. We have heavily invested to increase our current fleet number. I believe we now have five of the best attenuators in the country, which are used to protect our workers when working in live traffic environments. Q: WHAT DO YOU THINK IS MOST INTERESTING ABOUT THE ROAD CONSTRUCTION INDUSTRY? A: I think evolving industry practices are very interesting, for example, using recycled materials in pavements.

C

M

Y

CM

MY

CY

CMY

K

Scott Dornan has enjoyed seeing Action Line Marking SA evolve over the years.

Q: HOW HAS BEING A MEMBER OF AAPA BENEFITTED YOU IN THE INDUSTRY? A: Being a member of AAPA has enabled me to receive a better understanding of the sealing companies’ contractual arrangements and assist with supplying them with the required data. Q: WHAT ARE YOUR GOALS FOR THE FUTURE? A: My goals are to keep strengthening the business, continue to gather knowledge, show initiative in the industry and to keep our current and future clients’ needs at the forefront of the business’s priorities. Action Line Marking has a commitment to customer service, ensuring products and service continue to exceed expectations through innovation and state-of-the-art equipment.

A WIRTGEN GROUP COMPANY

Performance with special mixes and fuel efficiency delivering higher results

iNOVA 2000 · Australia

CIBER iNOVA SERIES

THE MOST ADVANCED TECHNOLOGY WITH HIGH PRODUCTION CAPACITY AND MOBILITY. With production capacity of up to 100t/h , 150 t/h or 200 t/h in 1 or 2 mobilities, the CIBER iNOVA Series line of asphalt plants are perfect for all types of works. When high production, best performance with special mixes and greater efficiency in fuel consumption are required, Ciber iNOVA plants deliver excellent results to your business. www.ciber.com.br

ciberoficial

WIRTGEN AUSTRALIA PTY LTD · Lot 2, Great Eastern Highway (off Apac Way) · South Guildford WA 6055 · Australia · T: +61 (0) 8 6279 2200

ON THE ROAD TO A

CIRCULAR ECONOMY

AAPA’S EXECUTIVE DIRECTOR FOR WESTERN AND SOUTH AUSTRALIA PETER DAMEN EXPLAINS HOW CHANGES TO THE INTERNATIONAL EXPORT MARKET ARE DRIVING THE ROAD INDUSTRY TOWARDS CIRCULAR ECONOMY PRACTICES.

T

he circular economy is an economic system aimed at eliminating waste and the continual use of resources. It is based on keeping products, equipment and infrastructure in use for longer. Circular systems adopt a hierarchy of reduce, reuse, repair, recycle and recover or refurbish to create a closed loop system. This minimises resource inputs and the creation of waste, pollution and carbon emissions. The circular economy can apply to the roads industry with typical solutions. The first is reduce. The roads industry can strive to achieve increased durability, quality management and asset life. This can be done through better design, construction quality, reduction of energy, waste and resource usage (for example, warm mix asphalt) and the use of renewable energy (such as solar power). The industry can also look to repair its pavements by resurfacing, rehabilitating, rejuvenating and restoring road pavements using best practice maintenance techniques.

Recycling is the third solution, with a focus on upcycling. This involves using materials such as crumb rubber that provide performance benefits. Lastly, recovery can be applied by reprocessing road pavements at the end of life, such as using reclaimed asphalt pavement. Sustainability is a major focus of the flexible pavements industry, and the Australian Asphalt Pavement Association (AAPA) membership is leading best practice on how roads can contribute. The association and its members recognise there is an increasing demand for the use of recycled products in roads and are continuing to investigate whether this is the right circular economy answer. Until recently, Australia exported a substantial amount of waste overseas. In 2016-17, Australia recycled 37 million tonnes of waste, with 746,000 tonnes exported to China. However, on 1 January 2018, the China

In February an industry forum featuring experts from around Australia shared the latest thinking on the circular economy.

20

ROADS APRIL 2020

Sword Policy came into effect, resulting in restrictions on the importation of 24 categories of solid waste into China. It further constrained any remaining materials being imported to China to less than 0.5 per cent of contaminants. During the financial year 2017-18, the quantity of waste exports from China to Australia fell dramatically, but was largely offset by higher exports to other countries, according to Blue Environment’s analysis “Data on exports of Australian wastes”. Nevertheless, the report highlights that a significant proportion of the overseas waste exports tap could soon be turned off. On 1 March 2019, this move was followed by a complete ban on solid plastic waste to India. Reports indicate several Asian countries are also reviewing their waste import policies. The Blue Environment report highlighted that if Malaysia, Vietnam and Thailand enacted waste import bans similar to China’s, Australia would need to find sustainable domestic or export markets for around 1.2 million tonnes, or $530 million per annum, based on 2017-18 export amounts. But despite all this, governments have responded with a collaborative approach across Australia. Most state governments pledged to support local governments and the industry financially, temporarily allowing an increase in stockpiling limits. In November 2019, at a meeting of environment ministers, the ministers agreed that waste plastic, paper, glass and tyres that have not been processed into valueadded material should be subject to an export ban. In addition to a host of policy pledges, all ministers committed to identify any procurement opportunities in major road

projects that could use significant amounts of recycled materials. They determined that the ban should commence on 1 July 2020 for all waste glass, with a phased approach that will see waste plastics, whole baled tyres and mixed paper and cardboard banned by the end of 2022. How the policy will be enforced remains to be seen, but one thing is certain: this has accelerated the challenge for industry, and the pressure is on to come up with new and innovative solutions. Roads have been targeted as potential homes for many recycled products, including plastic and glass. However, we need to be careful that we are not turning our roads into waste dumps and, in doing so, reducing their durability and performance, which would be contrary to circular economy outcomes. When used, recycled materials should enhance the performance of Australia’s most valuable asset – our roads.

P L A N T

.

Glass, for example, can involve much more energy to transport and reprocess into sand than using available natural materials in a wide radius. However, it can be recycled into glass in perpetuity which provides a quality circular economy outcome. Crumb rubber and some plastics can also enhance the performance of bituminous products. Therefore, in approaching the challenge, we need to ensure that the numbers stack up and the use of recycled materials does not reduce durability or long-term performance of road pavements but, rather, improve it. On 11 February 2020, an industry forum was convened on this topic in Perth. The forum brought together close to 100 people from state and local government and industry. The forum featured six leading experts from around Australia to share the latest thinking on the topic of circular economy

E Q U I P M E N T

.

P A R T S

.

from a range of different perspectives. It aimed to help encourage greater uptake of circular economy principles in the flexible pavements industry. The speakers were from Main Roads Western Australia, the City of Canning, Loop Platform, Tyre Stewardship Australia, Puma Energy and AAPA. It was very clear that industry is doing its part to achieve better outcomes. Materials such as crushed concrete, fly ash, recycled glass, reclaimed asphalt product, industrial slag and crumbed rubber are already being used routinely. In fact, the roads industry has many great examples of how it is reducing resource usage, energy and waste, reusing, repairing, and reprocessing at end of life, and recycling waste, much of it from other industries. While their success to date has been good, more can be done, and there was a very strong commitment in the room for that to happen.

S E R V I C E

&

S U P P O R T

ASTEC AUSTRALIA PAVING SOLUTIONS

EQUIPMENT TO BUILD AND RESTORE THE WORLD’S INFRASTRUCTURE ASTEC AUSTRALIA.

an Astec Industries Company

PO BOX 142, ACACIA RIDGE, QLD, 4110 • 1300 278 322 • astecaustralia.com.au

An asset solution for every application Introducing Ctrack Asset, the real-time tracking of assets combined with dynamic reporting. Whether you require tracking outdoors, indoors or underground, Ctrack’s newest solution will keep your assets visible through a range of easily self-installed devices.

For more information, call us today or visit ctrack.com/au 1300 304 033

With options for a range of vehicles or smaller items such as tools, you can protect your powered and non-powered resources from theft or unauthorised use. Simply set up movement alerts through app, mobile or email notifications. Ctrack Asset has a number of flexible solutions to keep track of your assets, so you can keep your site running.

Always Visible.

ASPHALT IN ACTION

PAVER PURCHASING

CONSIDERATIONS

WITH MANY SIZES AND ADDITIONAL FEATURES, CHOOSING THE RIGHT ASPHALT PAVING MACHINE REQUIRES EXTENSIVE RESEARCH. ASTEC’S JORGE BOIL EXPLAINS THE KEY CONSIDERATIONS WHEN PURCHASING AN ASPHALT PAVER.

O

ne of the earliest reports of an asphalt paving machine dates back to the 1930s when Harry Barber, of Barber-Greene Company, invented an asphalt mixing and spreading machine. Close to 100 years later, asphalt pavers have progressed in leaps and bounds while still containing those original features. Purchasing an asphalt paver is a large investment, and with so many different features and functions that have developed over time, it is important to know what will best suit the work being produced. Jorge Boil, Astec Business Line Manager for Infrastructure, says there are a variety of additional paver features to consider to ensure you have the right asphalt paver for the job. “First, you will need to consider where and how the paver will be used. Be sure to factor in the application, budget, size of job, environment and crew’s experience and skill, as well as preferences,” Mr. Boil says. “If you are considering doing smaller city jobs, you are probably looking at either a 1.8-metre basic width or 2.5-metre basic width paver which is easy to transport, but if you are looking at a major highway construction job, you will need a paver that has a 3.0-metre basic width which can hydraulically extend to 6.0 metres or more.” The thickness of the asphalt laid for each job can also require some extra features for the paver. With high-volume asphalt jobs where you are creating a new road, a material transfer vehicle or shuttle buggy may be required to supply more of the asphalt material into the paver. “Shuttle buggies are a great addition to a paving train that must be considered. These are helpful when you are transporting asphalt across long distances for jobs,” Mr. Boil says. Asphalt mix comes out of the asphalt plant at the correct temperature, and parts of the mix can cool down when being transported. Mr. Boil says a shuttle buggy remixes the

Roadtec offers a variety of features in its asphalt pavers to maximise productivity.

material before it is put through the paver so it can be laid at an even temperature, avoiding temperature segregation and giving you more even compaction. Mr. Boil says one of the most important things to understand when buying a paver is the maintenance and cleaning requirements. “This is extremely important because, for example, if you don’t clean a paver at the end of each shift, the asphalt will cool down and stick to the machine and this puts the machine at risk of failures during the next day’s shift. When you start the machine on the next shift, you might break chains on the conveyors because the mix had dried onto them,” he says. Cleaning can also help to extend the life of a paver because if another issue arises, you can quickly identify the problem and start repairs. “While it’s important to visually inspect a machine, it’s also imperative to monitor the systems using telematics such as Roadtec’s Guardian System. This data can help you see when maintenance is needed,” Mr. Boil says. The Roadtec Guardian telematics system is a standard feature in most Roadtec pavers. The system allows users to view aspects of the paving machine in operation from the office. “You are able to see where the machine is, how much fuel is burning, you can tell whether the paver is on paving mode or if

the machine is idle and you can see if there are any issues with the machine and locate those issues,” Mr. Boil says. He says if a service department is based in a major city and the paver is working regionally, when an issue arises, the team can identify it from afar through the Guardian System. This way, Mr. Boil says, if repairs are needed, the service person can travel to the location prepared with the right parts and tools to fix the issue quickly. In some instances, the team can correct issues remotely without having to travel to the paver. Roadtec’s Paver Production Reporting is another added feature that allows operators to view the performance of a paver as it relates to real productivity. “You can see asphalt tonnes laid per day, the day’s total paving distance, the live speed and the total tonnes for the life of the machine, which can help to speed up productivity on site,” Mr. Boil says. Roadtec also offers dedicated features to its asphalt pavers such as floatation tyres for better traction, flow gates for better control of material head and two dedicated operator stations which hydraulically extend beyond the edge of the paver for better vision during operation. “Making sure you do the research to find the right paver features suited to your job is important for maximising productivity and minimising downtime,” Mr. Boil says. roadsonline.com.au

23

MIXING FOR HIGH

PERFORMANCE

TO CREATE A HIGH-PERFORMANCE ASPHALT MIX, THE AGGREGATES AND BINDER NEED TO BE SEAMLESSLY BLENDED. CIBER’S MARCELO ZUBARAN EXPLAINS HOW MIXING TIME CONTROL CAN HELP IMPROVE THE ADHESION OF ASPHALT MIXES.

The first image shows an iNOVA 1500 plant by Ciber with different filling levels, from 30 to 70 per cent. In this case, the best mix had 60 per cent of the filling level.

A

s the chemical bond between aggregates and bitumen depends heavily on the minerals that constitute the aggregates, quality asphalt relies on these materials being well mixed. For aggregates that are more challenging to bond with bitumen, such as granite, mixing control can play a key role in ensuring the final asphalt mix is of a high quality. Ciber Equipamentos Rodoviários, commonly known as Ciber, has been making asphalt plants for around 60 years. The company has delivered more than 1800 asphalt plants across the globe, including in Australia. Marcelo Zubaran, Ciber Product and Application Specialist, says the company has been exploring ways to improve mix adhesion. To that end, Ciber has found certain factors can influence the final product. The first is applying high shear mixing force between the materials, which ensures the aggregates are coated. “Once the mixing project requirements are defined with inputs and proportions of material, it is possible to enhance adhesion between materials in the asphalt plant through mixers,” Mr. Zubaran says. “Granite, for example, has clay minerals, which do not bond well with bitumen. Instead, granite attracts water, and if water comes between the bitumen and the aggregate, the final mix will be poorly bonded and may result in quicker pavement degradation.” If mixers provide a high shearing rate, this can help guarantee the final asphalt mix is bonded well and will 24

ROADS APRIL 2020

perform to a high standard. To achieve high shearing rates, an external pug mill mixer can be used. Although this is traditionally used on batch plants, Ciber has refined its pug mill mixer to operate on continuous plants. “Batch plants were the first to use pug mill mixers because the production is cyclic. This means there is no need for a specific material movement in the mixer as afterwards the mix falls down, by gravity, towards the truck bucket or to a storage silo,” Mr. Zubaran says. “Conversely, the continuous mixer must project the mix forward in a continuous flow to avoid material sticking to the plant in the process.” Because a pug mill mixer consists of a double axis mixer, with arms and paddles that rotate and strike the material continuously, it helps to force the adhesion of the binder and aggregates. “The pug mill mixer helps to make certain all surfaces of the aggregate are coated with bitumen, but it also ensures the bitumen is injected into the mix at a controlled temperature,” Mr. Zubaran says. The burner and the pug mill mixer are separate components, so this eliminates any chance that the bitumen will be heated by the burner flame before being added to the mix. “In some asphalt plants without pug mill mixers, the bitumen is injected inside the drum and close to the flame, and this can cause the binder to prematurely oxidise and affect pavement performance,” Mr. Zubaran says.

He says that in addition to high shear force, Ciber has found mixing time to be an important factor that can influence the adhesiveness of the asphalt mix. “In general terms, the longer the mixing time, the larger the capacity to homogenise the materials,” Mr. Zubaran says. In batch plants, he says, the production rate depends on the size of the mixer, how much material it can mix for each cycle and on the cycle time. However, the only variable in batch plants is the mixing time. The material quantity or filling level inside the mixer will normally be the maximum capacity of the plant. In a continuous plant, the amount of material cannot surpass the limit of the asphalt plant, so the mixing time is adjusted depending on the type of mix and the amount of material. “If the mixer is too empty, the aggregates are projected too far to the front, not mixing enough for sufficient homogeneity. When it is too full, movement from the bottom of the mixer up does not happen, also affecting homogeneity,” Mr. Zubaran says. In a mixer, the aggregates should be thrown up from the bottom to contact with the paddles. They are then cushioned by the mixer structure and, by gravity, fall into the lower portion of the mixer to be thrown upwards again. “This movement allows for an intense shock between the different sizes of aggregates with bitumen making the mix homogeneous,” Mr. Zubaran says. Modern Ciber continuous plants with a pug mill mixer can adjust the mixing

ASPHALT IN ACTION

This image shows the mixer operating with a filling level of 60 per cent and different production rates: 75, 112 and 150 tonnes per hour.

time, which is controlled by plant automation, eliminating the need for mechanical intervention. The company has been refining its mixing time control technology since 2017 to further improve asphalt adhesion. “It is possible in both continuous and batch plants to adjust the mixing time to achieve better adhesiveness, even at maximum plant production,” Mr. Zubaran says. The filling level for the pug mill mixer will be indirectly controlled by the continuous plant through the position of a gate placed between the mixer and the drag elevator. “The gate will work automatically according to the filling level that is determined by the plant operator,” Mr. Zubaran says.

In a test using an iNOVA 1500 plant by Ciber, Mr. Zubaran says the best mix had a 60 per cent filling level, after testing filling levels from 30 to 70 per cent. However, this will vary on a case by case basis. Importantly, Mr. Zubaran says the best filling rate for each plant and mix type needs to be determined for optimum production. “Once the ideal filling level is defined and maintained, if the production rate of the plant is reduced, the technology will increase the mixing time at the same proportion,” he says. “In this case, the maximum production capacity in the plant was 150 tonnes per hour, a filling level of 60 per cent was found as the best mix performance,” Mr. Zubaran says.

Furthermore, with increased filling levels, the standard mixing time will be increased and the production will decrease. “These components and technologies, when applied to a mixer in continuous and batch plants, enhance the adhesiveness of the asphalt mix dependent on the way the characteristics of the materials react with each other,” Mr. Zubaran says. Mr. Zubaran says customisation of mixing time is essential to the production of special mixes, ensuring they perform to a high standard in construction. He says Ciber aims to achieve the result of quality mixing by the attainment of a highperformance asphalt mix as projected in a lab, where the environment is controlled and there is a much smaller production rate.

CONQUERING A CRUMB

RUBBER CHALLENGE PUMA BITUMEN’S NEW CRUMB RUBBER MODIFIED BINDER IS SET TO BECOME A STANDOUT IN ITS SUITE OF HIGH PERFORMANCE ROAD BINDERS. MEETING AUSTROADS BINDER SPECIFICATIONS, IT HAS BECOME ONE OF THE FIRST CRUMB RUBBER BINDERS THAT REQUIRES NO CHANGES TO A STANDARD ASPHALT MIX DESIGN.

I

n 2019, the Victorian Department of Transport, Tyre Stewardship Australia and the Australian Road Research Board set the road construction industry a challenge. As part of a plan to accelerate crumb rubber asphalt, industry was asked to create a high-performance mix equivalent to their current stone mastic asphalt with polymer modified binder. Consequently, the Department of Transport and Tyre Stewardship Australia announced tenders in 2020 for up to six variations of high-performance asphalt. These asphalt mixes will make up a largescale trial of crumb rubber asphalt on an arterial road, taking place in Melbourne. Results from the trial will be used to inform Victorian crumb rubber specifications for arterial roads. By giving

authorities and end-users the confidence to incorporate crumb rubber in high-traffic applications, its usage will continue to grow and subsequently reduce the environmental impact of end-of-life tyres. It has now been four months since the trial was announced, and the road construction industry has been prepping its rubber asphalt mixes for implementation. Partly inspired by the Department of Transport’s challenge, major bituminous product supplier Puma Bitumen developed OLEXOCRUMB, a crumb rubber binder that will be used in the trial. “Going further for better-performing roads” is not just a tag line, but an ethos deeply embedded in the character of the Puma Bitumen team. This ethos is shown in their latest creation, OLEXOCRUMB,

“Going further for better performing roads” is not just a tag line, but an ethos deeply embedded in the character of the Puma Bitumen team.

26

ROADS APRIL 2020

which conforms to the Austroads polymer modified binder specification and can, therefore, be used in existing contracts. The binder incorporates 10 per cent recycled tyre rubber and can be incorporated into asphalt mix designs as a direct substitute for conventional polymer modified binders. As the rubber provides elastic properties to the binder, the mix represents a highvalue application of the waste material, with every tonne produced repurposing the equivalent of 15 passenger tyres. Erik Denneman, Puma Bitumen Technical Manager – Middle East and AsiaPacific, says the initiative to develop OLEXOCRUMB came from the challenge society and governments are facing in finding beneficial uses for waste tyres. With countries like India clamping down on used tyre exports, the export of whole baled tyres is increasingly becoming unsustainable. Over the past five years, Australia generated 56 million equivalent passenger units annually, with used tyres that are not recovered often sent to landfill or stockpiled. Dr. Denneman says that OLEXOCRUMB will help reduce Australia’s tyre burden by demonstrating performance outcomes that can compete with existing options. “The performance of OLEXOCRUMB is equivalent in all aspects of performance to our existing polymer modified binders,” Dr. Denneman says. OLEXOCRUMB is a hybrid binder, containing both tyre-derived rubber and styrene-butadiene-styrene rubber. The key benefit to this particular crumb rubber binder is that the asphalt mix design does not have

ENVIRONMENT & SUSTAINABILITY

Puma’s OLEXOCRUMB range will make up a large-scale trial of crumb rubber asphalt on an arterial road.

to be altered to accommodate the binder. “Normally when you put rubber into bitumen, it leaves residual rubber parts and you then have to change the mix design to make space for it in the asphalt. With OLEXOCRUMB, there is negligible residual rubber, so you don’t have to change the mix design,” Dr. Denneman says. “Changing a mix design is a timeconsuming and costly exercise and if you have to change it to allow for residual rubber, that has a significant impact.” Puma Bitumen, in partnership with Boral Asphalt, has already completed a trial with a Victorian local council, where a section of OLEXOCRUMB asphalt was laid on 2 March 2020. “The binder complied with all requirements of the Austroads specification and that was our main goal. The contractor was also able to place the asphalt successfully and it behaved just like a normal binder would on the rollers and paver, which is what we expected,” Dr. Denneman says. “This binder can be used immediately and on a large scale, so potentially we could see a lot more rubber used in more asphalt, very quickly.” Dr. Denneman says Puma’s production method for OLEXOCRUMB resulted in negligible crumb rubber residue, meaning it can be used in the same way as conventional bituminous binders. He

says the support of industry-leading manufacturing equipment allowed the speciality binder to become a reality. “We have very efficient, high-powered production facilities which were designed for our premium polymer modified binders in our OLEXOBIT range that have proved highly successful in the past,” he says. “That same equipment, which is unique to Puma, is also uniquely suited to make this type of crumb rubber binder.” Added to the environmental benefits is the use of a warm mix additive, which allows the asphalt to be produced at lower temperatures. “We decided to produce this product with a warm mix as for every 12 degrees of temperature reduced in the production of asphalt, the level of emissions is halved,” Dr. Denneman says. The asphalt will be produced at temperatures below 165 degrees Celsius in line with the Australian Asphalt Pavement Association’s recommendation for crumb rubber. Puma Bitumen performed laboratory asphalt and binder testing to ensure the binder met all requirements in the Austroads specifications. Puma’s OLEXOCRUMB binder was laid as part of the VicRoads demonstration overnight on 18 March in partnership with Boral (weather permitting). The mix laid in the demonstration trial

was a stone mastic asphalt mix using OLEXOCRUMB as the binder. The Australian Road Research Board monitored emissions on the night the asphalt was laid and will monitor the pavement’s condition over two years. Dr. Denneman says emissions monitoring is one of the most important parts of the trial, as it will be key to demonstrating that the asphalt mixes being laid do not expose workers to harmful emissions. He adds that Puma Bitumen expects that the results of the trial will confirm with work done elsewhere. Dr. Denneman says that in line with that work, it will show that if placed at warm mix temperatures, the amount of emissions from crumb rubber modified asphalt are on par with conventional asphalt. Puma Bitumen expects to be able to offer this binder as part of its product offering in Victoria, NSW and Queensland later this year. The company could also potentially look at offering binders with crumb rubber as a standard, in place of traditional binders, to the industry in the future. “We are fully expecting to be laying more of this bitumen very soon, in states across the country,” Dr. Denneman says. “I believe the industry should be focusing on products that give us improved performance, not just reducing waste to landfill, and OLEXOCRUMB undoubtedly meets both these criteria.” roadsonline.com.au

27

Having a document endorsed by the Department of Transport aims to give councils the confidence they need to specify crumb rubber asphalt in low-traffic roads.

A NEW ERA

FOR CRUMB

AN AUSTRALIAN-FIRST SPECIFICATION IS SET TO INFORM THE USE OF CRUMB RUBBER IN ASPHALT APPLICATIONS ON LOW-TRAFFIC ROADS.

F

or the past six months, Liam O’Keefe, Senior Strategy Manager at Tyre Stewardship Australia (TSA), has been travelling from state to state on an education mission. Going beyond platitudes about the circular economy, Mr. O’Keefe has been focused on supporting the product pull-through of tyre-derived product in roads. It’s a simple strategy – change the specifications, demonstrate benefit, create demand and subsequently enable supply. From last year’s Australian Asphalt Pavement Association (AAPA) followed by the Institute of Public Works Engineering 28

ROADS APRIL 2020

Australasia (IPWEA) Conference, Mr. O’Keefe has been a busy man. He’s since presented at the Major Roads Project Victoria Forum, the Australian Local Government Association Roads Congress in SA, the Local Government Association of Queensland Waste Forum and an AAPA Breakfast in Perth. Around three months ago, when trawling through his notes at the Australian Local Government Association conference for yet another presentation, the dot points evoked a simple yet impactful message. “The reality is that the best proponents of councils to build roads with tyre-derived

product are councils who have built roads,” he recalls. “The message has much more resonance when it comes from fellow practitioners than people like myself.” While crumb in spray sealing is well known and used across Australia, notably in Victoria, it’s tyre-derived product asphalt applications that are once again back on the agenda. “When Russell King from the City of Mitcham gets up and says ‘I’ve done it, I’ve built it!’, it just cuts through. So what we want to do is create an army of council proponents, advocates or representatives

ENVIRONMENT & SUSTAINABILITY

who have done it themselves on their own roads,” Mr. O’Keefe says. In looking at Queensland, Mr. O’Keefe is talking real numbers and tangible outcomes. “What we’ve seen in Queensland is we have reports of significant declines in polymer modified binder usage of around 30 to 40 per cent in some regions,” he says. With that in mind, the “we’re doing it!” battle cry of crumb rubber asphalt in roads has taken more than five years to hold such significance – but a distinct shift is evident. TSA worked collaboratively with major road authorities to change the specifications. These were predominately around open and gap graded asphalt, including the Victorian Department of Transport, Main Roads WA and Department of Transport and Main Roads Queensland. Over that time, TSA accelerated uptake in the market in 2018 when it shifted focus for its market development fund from research and development to demonstration and infrastructure. However, a clear piece of feedback was that councils have their own nuances, and so a customised set of specifications was needed. “What we’ve found is the local government sector has different requirements for the way in which they manage their assets to road authorities,” Mr. O’ Keefe says. He says that part of the reason TSA has traditionally focused on the road authorities is that councils defer to the road authority specifications. “It’s kind of like a default to manage risk, but in reality, the specifications and the recipes for building roads for road authorities are somewhat different to local government,” Mr. O’Keefe explains. “So now we’re really focusing on giving local government what they need to build rubberised roads – that’s the priority.” In November, the Department of Transport in Victoria released the light traffic crumb rubber asphalt specification. The specifications are a collaborative effort between Sustainability Victoria – which co-funded their development – the Department, AAPA, the Australian Road Research Board and IPWEA Victoria. Arthur Apostolopoulos, Manager Pavement Technology at the Department of Transport, says the key driver of the

specifications was to increase the use of crumb rubber in asphalt. “While there are specifications out there for the use of crumb rubber, it was usually focused on heavy traffic roads, which makes [crumb rubber] asphalt expensive,” Mr. Apostolopoulos says. He says that with an appetite from the local government sector for greener infrastructure, the Department saw an opportunity to increase crumb rubber uptake in a low-traffic landscape not competing with polymer modified binders. A submission was put to Sustainability Victoria at the start of 2019 to develop a specification. From there, the Australian Road Research Board conducted laboratory tests to ensure the crumb rubber asphalt was comparable to conventional light traffic asphalt mixes. The results went out to industry for public comment in the middle of the year, and a formal specification was

“THIS VALUE PROPOSITION IS AN EASY SELL FOR A LOCAL GOVERNMENT TO ITS COMMUNITY, ESPECIALLY WHEN THEY CAN STATE THAT THEY ARE ASSISTING WITH THE SUSTAINABILITY OF THE ENVIRONMENT THROUGH REDUCED STOCKPILING OF A WASTE PRODUCT.”