7 minute read

DRIVING SECTOR RESILIENCE

Australian Made to drive sector resilience

IN THE FACE OF SUPPLY CHAIN DISRUPTIONS, WASTE MANAGEMENT REVIEW EXPLORES HOW ONSHORE PROCESSING AND LOCAL MANUFACTURING WILL PLAY AN INCREASING ROLE IN BUILDING A RESILIENT WASTE SECTOR.

“ T his isn’t about being insular or shutting ourselves off to the rest of the world. This is about embracing the incredible quality of

Australian-made products – products that nations around the world associate with being top-notch,”

Karen Andrews, Federal Industry

Minister says.

During the COVID-19 pandemic businesses around the globe faced massive disruption to their supply chains. For companies dependent on products coming in from overseas, the halt of imports and exports sent a domino of delays through various industries across the nation.

Now, Australian businesses understand the complexities of the

Island’s oceanic location more than ever.

The need to diversify supply chains is shaking up Australia’s manufacturing sector as more companies explore onshore processing and leveraging the benefits of local manufacturing.

On June 1 this year, a multi-media campaign was launched by Australian

Made Campaign Limited to promote local manufacturers and brands to capitalise on a renewed interest in their products.

So, where does the waste management sector sit in Australia’s

Federal Industry Minister Karen Andrews says the sector should prioritise value over cost.

manufacturing capacity?

According to Andrews, Australia has historic strengths in mining and resources, which has boosted development in a number of other industries.

In her address to the National Press Club on May 20, Andrews said that includes plastic and waste recycling.

She is encouraging sector decision makers to have comparative and competitive strengths. “The focus is to grow the Australian manufacturing sector, and by doing that, they will need to focus on the value concept rather than the cost focus themselves,” she says.

One of the big trends in Australian manufacturing over the last decade has been the sheer difficulty of competing with China on cost.

However, when China and other neighbouring Asian nations stopped the import of contaminated recycling, industry and governments across the world had to look within their borders to find solutions for ever growing waste management needs. Federal and state governments have offered incentives to encourage

By choosing products containing recycled Australian materials, individual consumers can generate larger markets for recycled goods.

high quality recycling, including the Federal Government’s $4.9 million export hub grants scheme, which will advance manufacturing and capitalise on new onshore capabilities by establishing a stronger market beyond the nation’s border.

“In my time as a minister, I’ve never had as many people contact me as I have in recent weeks supporting our government’s push to grow Australian manufacturing,” Andrews says.

She believes it’s important to shift the mindset so that Australia is not trying to compete on cost.

Andrews says Australia’s niche is its capability to transform quickly and make manufacturing agile and nimble.

“So, for us to be competitive, we have to start looking at manufacturing on value, not on cost. Price is a part of the value equation, but it is not the only part of it,” she says.

Waste manufacturers are critical for driving markets and designing products that maximise recycling opportunities, which can be translated to export success.

From February this year, all Cleanaway Daniels’ reusable sharps collectors and related spare parts are now 100 per cent Australian-made.

The complete onshoring of manufacturing capabilities represents the single largest investment made by Cleanaway Daniels last year, and is an example of re-shaping operations onshore to enable rapid production, more flexibility to meet changes in customer demand and supporting and driving the local economy.

Larger commercial businesses like Cleanaway have the advantage of already beginning onshore investments, but the opportunity is present for small and medium sized manufacturing businesses too.

Trends indicate that local manufacturing can also improve recovery rates and reduce contamination through single-stream recycling.

By choosing products that contain Australian recycled materials, individual consumers can also generate bigger markets for recycled goods.

Refashioning waste manufacturing post COVID-19 calls for recognising and protecting value drivers, prioritising breakthroughs, collaborating on shared problems, mitigating risk through co-funding programs and building resiliency through local supply chains.

And while COVID-19 has created new optics through which the community needs to view both risk and opportunity, there has arguably not been a more compelling time to build a resilient waste sector, with a new, attractive and outward local manufacturing future.

Not just another oil company

PETER MCCOLL OF GULF WESTERN OIL EXPLORES THE ROLE OF EFFECTIVE LUBRICATION TOWARDS THE DEVELOPMENT OF A MORE SUSTAINABLE AND ROBUST WASTE SECTOR.

While the full ramifications of COVID-19 are not yet fully understood, conversations around post-pandemic recovery are largely focused on building on-shore manufacturing and domestic markets.

In the waste and resource recovery sector, much of this discussion has centred on building new facilities and processing capacity.

According to Peter McColl of Gulf Western Oil (GWO), while this macro focus is important, building a sustainable and resilient waste sector also requires a micro approach. He explains that without steady machine operations on the ground, large scale facility investments might fall short of their intended objectives.

GWO has been supplying lubricant solutions to waste and recycling facilities for over 30 years, and in the process, has developed an extensive range of purpose-built products for various applications within the sector.

As one of the largest Australian owned lubricant manufacturers, GWO operate a comprehensive distribution network throughout Australia and the Pacific Rim.

“The waste sector, as with all industries, relies on its machinery to ensure efficient operations, and that requires lubrication,” McColl says.

“That is what GWO does every day – we work hard to constantly improve

Gulf Western Oil’s five warehouses are fully stocked with millions of litres of lubricants ready for dispatch. the longevity and service times of operators equipment.”

McColl adds that lubricants are often first off the mark when budget cuts are made, which is a common mistake.

“Lubricant replenishment costs are relatively minor when compared to the initial infrastructure cost, and the expense and consequences of unplanned equipment failure will not only be inconvenient, but can lead to a greater environmental footprint,” he explains.

“A major emphasis for GWO is to provide waste and recycling plants less downtime of machinery by creating longer lasting, higher load bearing products. The intention is to enable recycling plants to operate as efficiently as possible by protecting machinery life and saving clients money.”

GWO offer a range of five different hydraulic blends, with more than 30 different grades carried in stock.

“In fact, we have 88 different part numbers specific to hydraulic applications and our laboratory can custom formulate blends to specific customer applications,” McColl says.

Furthermore, GWO offer unique products such as a Super Clean Hydraulic cleaner, which removes varnishes and other foreign matter from hydraulic systems to extend service life.

“Beyond these initiatives, GWO also make environmentally sound products. We have a large range of biodegradable hydraulic fluid,” McColl says.

McColl highlights the Gulf Western Biodraulic range, which is a series of hydraulic fluids designed to operate under high operating temperatures and extended service applications.

“The range provides superior oxidation resistance, allowing longer service life and a very high natural viscosity index, which means that the oil remains more constant in viscosity across a wider temperature range as found in high-stress applications.”

Extending the range is Superdraulic Indestructible, the first of its kind within the Australian market to offer a 6000-hour oil life, McColl says. He adds that the product is formulated with full synthetic base oil technology, the latest ultra-sheer stable viscosity modifiers and enhanced levels of antiwear and antioxidants. Superdraulic Hi Temp is another product in GWO’s range of premium grade, high viscosity index, anti-wear hydraulic oils.

“The range has been formulated for use in hydraulic power or control systems, either mobile or stationary, which are subject to temperature extremes, or are particularly sensitive to changes in temperature,” he says.

With an array of equipment including gearboxes, pumps, chains, blowers, compressors, slides and guides, McColl says it’s important to get lubrication right. He adds that this is especially significant in severely corrosive environments such as those common to the waste industry.

“Our diesel family includes Top Dog Indestructible, a heavy-duty diesel engine oil containing the latest in indestructible additive technology designed to protect high-powered, heavy-duty diesel engines,” he says.

“The unique formulation contains performance enhancing and superior wear protection technology that exceeds the requirements of the current lubricant specifications. This allows improved efficiencies.”

Striving to stand out from their competitors, GWO offer next day delivery to Sydney, Melbourne and Brisbane’s greater metropolitan areas. The company also operate a night shift service, meaning orders can be taken and processed up to 9pm for next day delivery.

“Our five warehouses located across Australia are fully stocked with millions of litres of lubricants ready for dispatch. GWO strives to offer un-paralleled service to our customers and make doing business with us as seamless and easy as possible.”

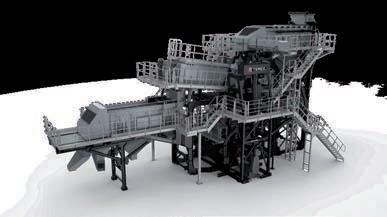

GAME CHANGER FOR WASH RECYCLING

aggwash 300

6 300 UP TO PRODUCTS TONNES PER HOUR 1 MACHINE

Engineered Washing and Water Mangement Solutions for the waste recycling industry

AGGWASH 60

AGGWASH 300