Established 1951 April 2023 ITMA 2023 Preview I - Dyeing, Printing and Finishing I

Index 2023

Dates: April 18th to 21st, 2023.

Venue: Palexpo, Geneva, Switzerland.

Techtextil 2023 North America

Dates: May 10th to 12th, 2023

Venue: Georgia USA.

DOMOTEX asiaCHINAFLOOR 2023

Dates: May 29th to 31st 2023.

Venue: NECC, Shanghai, China.

FESPA 2023

Dates: May 23rd to 26th 2023.

Venue: Munich, Germany.

Istanbul Yarn Fair

Dates: June 1st to 3rd, 2023.

Venue: Istanbul, Turkey.

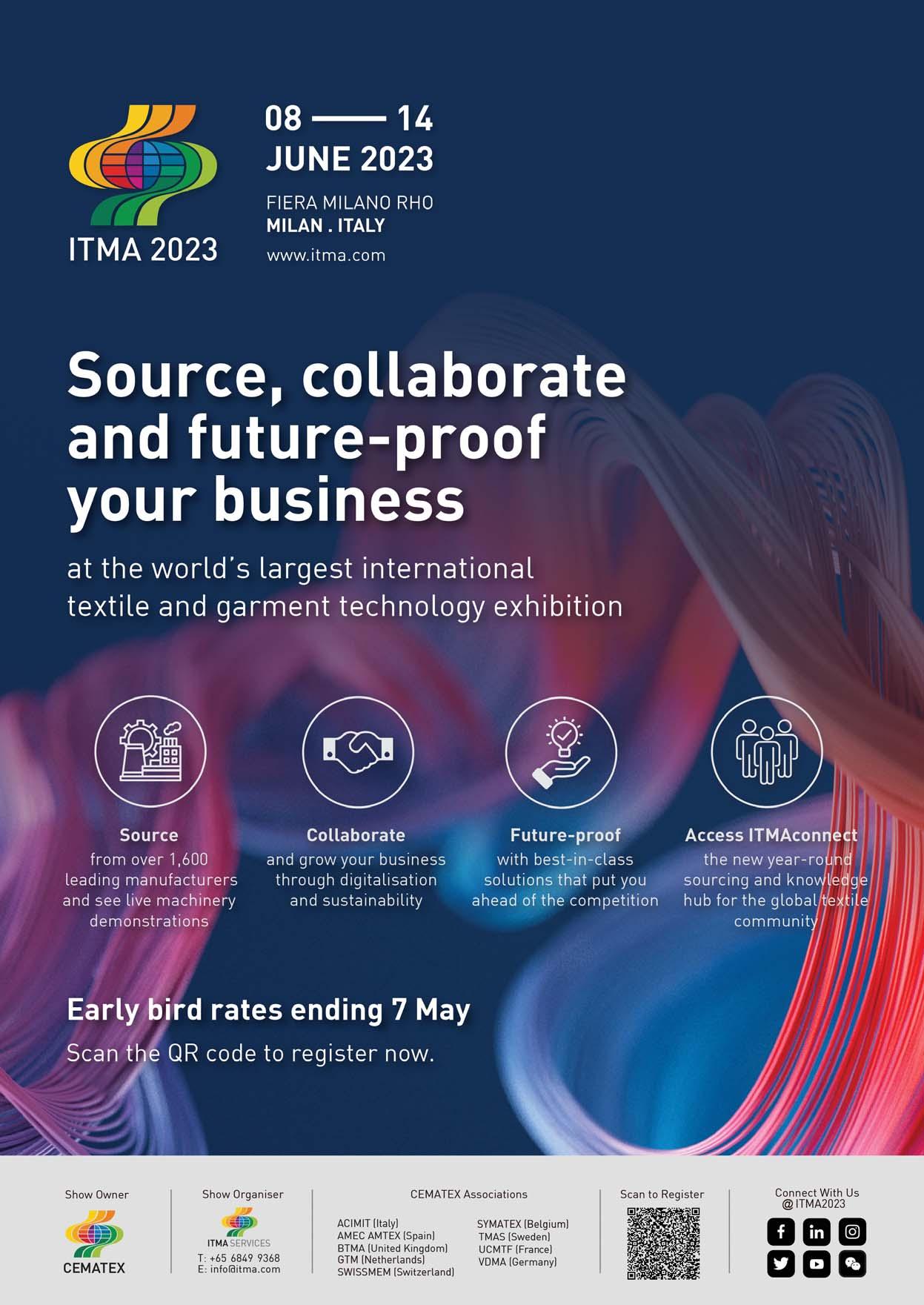

ITMA 2023

Dates: June 8th to 14th, 2023.

Venue: Milan, Italy.

PAKISTAN TEXTILE JOURNAL - April 2023

Johannesburg, South Africa !

Dates: June 18th to 20th, 2023.

Venue: Gallager Convention Centre.

The 92nd Textile Institute World Conference, UK.

Dates: July 3rd to 6th 2023.

Venue: Huddersfield, UK.

IGATEX Pakistan 2023, Karachi

Dates: September 7st to 9th 2023.

Venue: Expo Centre, Karachi.

iCADEX Pakistan 2023, Karachi

Dates: September 7st to 9th 2023.

Venue: Expo Centre, Karachi.

62th Dornbirn GFC Global Fiber Congress

Dates: September 13th to 15th 2023.

Venue: Dornbirn Austria.

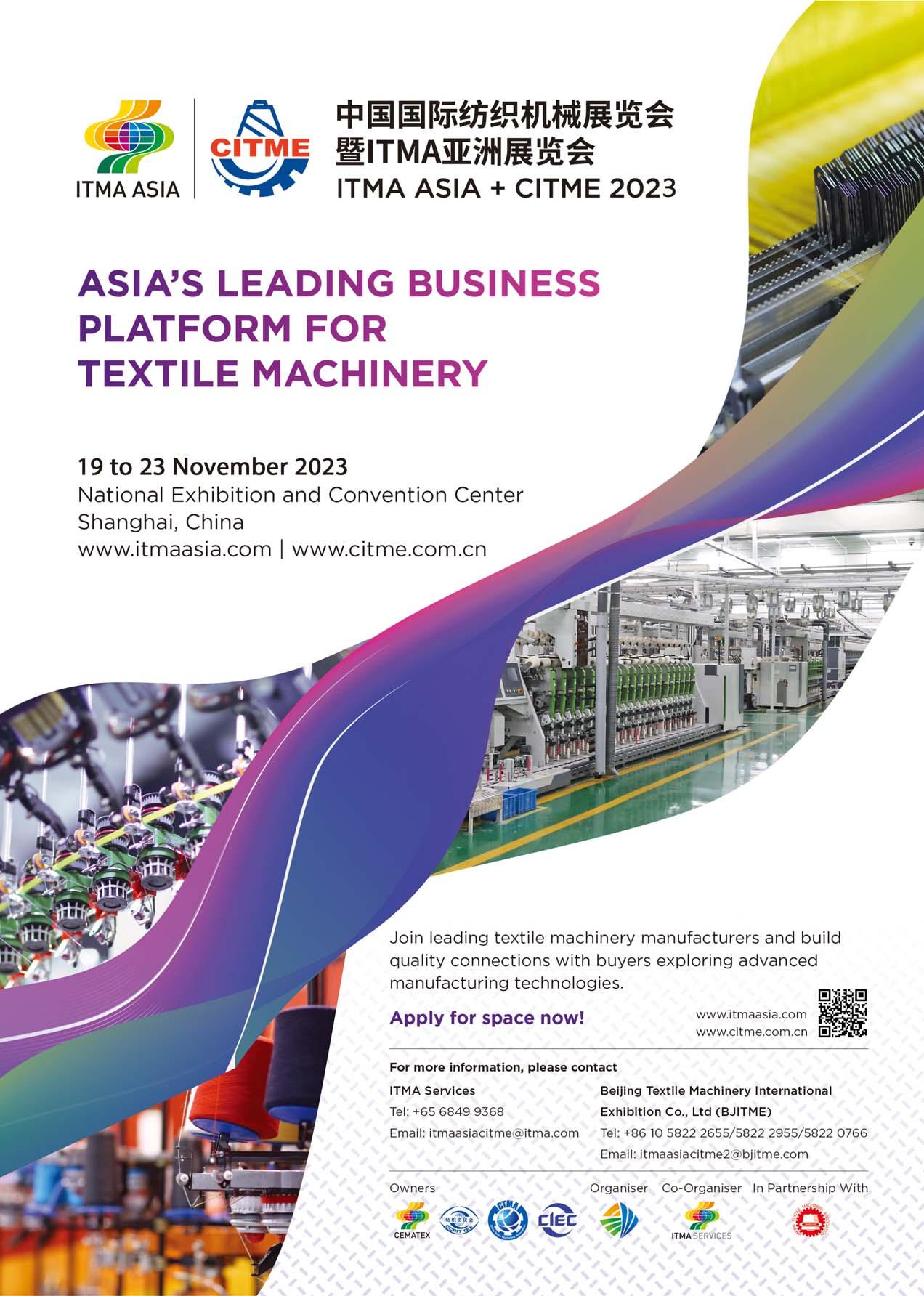

ITMA ASIA + CITME 2023

Dates: November 19th to 23rd, 2023.

Venue: NECC, Shanghai, China.

Heimtextil 2024, Frankfurt

Dates: January 09th, to 12th, 2024

Venue: Frankfurt am Main.

DOMOTEX Hannover 2024

Dates: January 11th to 14th 2024.

Venue: Hannover, Germany.

ITM 2024

Dates: June 4th to 8th, 2024.

Venue: Istanbul, Turkey.

HIGHTEX 2024

Dates: June 4th to 8th, 2024.

Venue: Istanbul, Turkey.

JIAM 2024 OSAKA

Dates: Nov. 27th to Nov. 30th 2024.

Venue: Osaka, Japan.

12th ITME

INDIA

2024

Dates: December 2024.

Venue: India Expo Centre & Mart. Noida, India.

2

Calendar of Events

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher

Nadeem Mazhar

Editor in Chief

Amina Baqai

Associate Editor

Nimrah Nadeem

Production Manager

Mazhar Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh

Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab

C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA)

Mian Iftkhar Afzal

B.S.N.C State, M.Sc. (Leeds)

C.TEXT.F.T.I (UK)

Dr. Zubair Bandukda

PhD (Textiles), CText ATI

Editorial & Advertising Office

B-4, 2nd Floor, 64/21, M.A.C.H, Miran M. Shah Road, Karachi - Pakistan

Tel: +92-21-34311674-5

Fax: +92-21-34533616

Email: info@ptj.com.pk

URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Correspondence & Mailing address: 93 Fleming Place, Bracknell, RG12 2GN, United Kingdom

Tel: +44 792 2228 721

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, UK

Registered no. 09141989

SPECIAL REPORT

Italian Textile Machinery at ITMA 2023:

and Digitalization a winning asset for Italian

AROUND THE WORLD . . . . . . . . . . . . . . . . . . . . . .14 NEWS & VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . .10 EDITOR’S PAGE . . . . . . . . . . . . . . . . . . . . . . . . . . .7 Pakistan's textile industry crisis: An urgent wake-up call TEXTILE BRIEFS . . . . . . . . . . . . . . . . . . . . . . . . . . .8 Vol. LXXII No. 04 April 2023 Rs. 565.00

Printed at: Color Plus Korangi, Karachi. Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi. Available on Gale and Factiva affiliated international databases through Asianet Pakistan

CORPORATE NEWS Oerlikon’s

. . . . . . . . . . . . . . . . . . . . . .18 Radici EcoMaterials means 360-degree sustainability . . . . . . . . . . . . . . . . . . .20

Shareholders approved all resolutions

Sustainability

Technology . . . . . . .24 Excursion: Borromees Islands, Lake Maggiore. . . . . . . . . . . . . . . . . . . . . . . . .27 20

AND EXHIBITIONS Textile Institute World Conference: Sustainability of the Textile and Fashion Supply Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 Texworld Evolution Paris to return with large participation from around the world .32 18 PERSONALIA Archroma announces Mark Garrett as CEO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22 24

FAIRS

FEATURES

DYEING, PRINTING AND FINISHING

39 40 42 44

Women making their mark in cotton industry on International Women’s Day . . .36 Rieter: COMPACTdrum – Outstanding efficiency with up to 26,000 RPM . . . . . .39

JK GROUP @ FESPA GLOBAL PRINT EXPO 2023 is where image matters . . . . . . . . . . .52 Jeanologia reduces water consumption from 100 to 1 liter in garment finishing . . . .54 EFI Reggiani hosts ecoTERRA live show . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56 BRÜCKNER Textile Technologies highlights Co2 Neutral Textile Finishing . . . . . .57 Grupo Kaltex benefits from Monforts upgrades . . . . . . . . . . . . . . . . . . . . . . .58 Zero finishing chemical discharge with TexCoat G4 from Baldwin . . . . . . . . . . .59 48 24 ITMA 2023 CHTC Fong’s Group: Forging ahead with innovation . . . . . . . . . . . . . . . . . . . . . . . . .40 Expert treatment for sensitive synthetics with the THEN Supratec LTM . . . . . . . . . . .42 Biancalani presents advanced technology of sustainable textile finishing machines . .44 Santex & Cavitec brands: Breathable, soft, and stable finishing touch for textiles . . .46 Epson Monna Lisa: Fusion of excellence linking Italy and Japan . . . . . . . . . . . . . . . .47 SPGPrints offers complete range of digital printing solutions . . . . . . . . . . . . . . . . . .48 BTMA welcomes digital dyeing and finishing pioneer Alchemie . . . . . . . . . . . . . . . . .50 INDITEX recognizes TVE ESCALE among the best washing technologies . . . . . . . . . . .51 57

Pakistan's textile industry crisis: An urgent wake-up call

The textile industry, the backbone of Pakistan's economy, finds itself amidst an alarming crisis that is wreaking havoc not only on the industry but the entire country. Textile exports, contributing to 60% of Pakistan's total exports, have recorded a staggering decline for seven months in a row, slumping by 30% in February and 21% in March 2023 year-on-year. This situation poses a serious threat to the country's depleting foreign reserves, potentially destabilizing its economic stability.

Adding to the alarm is the distressing picture painted by the All Pakistan Textile Mills Association (APTMA), highlighting the grave challenges the industry is facing. The key among these challenges is the acute shortage of cotton and restrictions on the procurement of raw materials, making it nearly impossible for the industry to sustain operations.

Cotton, the lifeblood of the textile industry, has seen a significant 34% reduction in output due to unprecedented floods. This sharp decrease has led to a massive unavailability of raw materials, driving a crippling blow to the sector.

The escalating crisis in the textile sector has already resulted in dire human consequences, with seven million people losing their jobs. The predicament is particularly devastating for women and vulnerable communities who rely on the sector for their livelihoods. The majority of the workers in the industry are informal or hired through thirdparty agencies, making them even more susceptible to workplace abuses and leaving them with limited avenues to raise their concerns or seek legal redress.

The ongoing power crisis in Pakistan is adding fuel to the fire. Frequent and prolonged power outages coupled with spiraling energy costs have forced many businesses to close, causing an estimated loss of USD 70 billion to the textile industry alone.

The list of woes does not end here. The industry is also grappling with the closure of manufacturing units, lower sales due to surging inflation, a significant drop in exports, and unsuitable government policies, all contributing to the weakening of this vital sector.

Indeed, the textile industry in Pakistan has been in distress for several years, but the current crisis is unprecedented in scale and impact. If the current trend continues, observers warn of long-term damage to Pakistan's economy due to the crippled textile sector.

This crisis situation is not only an urgent wake-up call for the industry but also for the government. It necessitates immediate and comprehensive measures to address the root causes of the crisis and put the industry back on track.

Revisiting unsuitable policies, ensuring a stable power supply, safeguarding workers' rights, mitigating the impact of natural disasters on cotton production, and easing restrictions on raw materials procurement are some of the steps that need to be taken. The government, industry stakeholders, and international partners must come together to navigate this crisis before it's too late.

With strategic planning and decisive action, it's not too late to reverse the damage and restore the glory of Pakistan's textile industry, a sector integral to the country's economy and the livelihoods of millions.

Established 1951 April 2023 ITMA 2023 Preview - Dyeing, Printing and Finishing

EDITOR’S PAGE 7

April 2023.

Textile Briefs National

1During the month of April despite the low trading of cotton, the spot rate of cotton progressed smoothly and remained unchanged at Rs 20,000 per maund even though minimal trading was witnessed thorough out the starting days of April. The rate of cotton in Sindh was in between Rs 17,000 to Rs 20,000 per maund for the month of April. The rate of cotton in Punjab was also in between Rs 18,000 to Rs 21,000 per maund for the same month. 2

The Pakistan Institute of Development Economics (PIDE) – in collaboration with the Research for Social

Transformation & Advancement (RASTA) program and the Pakistan Society of Development Economists (PSDE) organized its first-ever Economy Festival (EconFest) at Lahore, Pakistan. Dr Gohar Ejaz, Patron-in-Chief APTMA along with Senior Economist of the World Bank Group (Pakistan) Gonzalo J. Verala, Advocate Salman Akram Raja, Mr Aamir Fayyaz, Mr Hamid Zaman & Ali Khizar presented their opinion and views during a session on Sustainable Growth and Role of Textile Sector.

In this way, they could increase their cotton production by 25-30 per cent per acre.” Says a spokesman for Agriculture (Extension) Department. 4

3

Farmers should get analysis of their soil first and then use fertilisers according to needs of crops.

Textile Briefs International

Swag Kicks, which is one of Pakistan’s leading preloved (secondhand) fashion store for items including, sneakers, bags, apparel to accessories on its digital platform, recently celebrated a successful seed round funding of $USD 1.2M. The Swag Kicks CEO plans to utilize this funding in expanding their business by occupying new warehouses and offices in different parts of Pakistan.

5For the first time in the history of the Pakistani fashion industry, a Pakistani brand is to be featured on the list of international brands’ collections and be worn by supermodels and showcased at the London Fashion Week (LFW) 2023.

6

The Lahore University of Management Sciences (LUMS) via their official twitter account tweeted, “The LUMS leadership visited Interloop Ltd. in Faisalabad, with the shared vision of making higher education accessible to all, Interloop has sponsored 14 students at LUMS.

1

In March, the uncertainty of the world economy led to a decrease in liquidity as well as decreases in prices for agricultural commodities and cotton is at particular risk from inflation and income issues. In Brazil, Center for Advanced Studies on Applied Economics (CEPEA) collaborators reported difficulties in selling cotton products, resulting in even steeper price drops for the raw material. 2

A team of researchers from Khalifa University has developed a new material that can remove dyes from industrial wastewater. Inspired by mussels, the new material is made from a polymer called polydopamine, modified with an ionic liquid. This creates a

new adsorbent material for the removal of anionic pollutants from water.

3

Many textile manufacturers in India are moving to polyester and viscose fabrics. Last year India’s textile sector witnessed blending in cotton and now several players in the value chain have moved to polyester and viscose 4

Cotton picking has started in most of Australia, and so far the numbers are showing that the country’s fear of underperforming from last year numbers due to flooding and farm damage late last year may not have been as devastating as first feared. Australia is now forecasting the crop being picked at 5.2 million bales, up from around

5Mb forecast in December, both well below the 5.6Mb crop picked last year. “This will result in around 1.2 million tonnes of fibre and 1.4 million tonnes of cottonseed,” Cotton Australia chief executive officer Adam Kay said.

5

Amid the trade tensions between Australia and China, Australia has started to explore new markets for its cotton. As a result, Vietnam has emerged as the number one importer of Australian cotton, replacing China. Vietnam has a number of other advantages over China that Australian cotton producers are able to take advantage of, such as free trade agreements, a convenient location, and a huge appetite of cotton apparel manufacturers.

6Tunisia has shown an exceptional growth of exports in textile sector by managing to reach 14.61% in terms of exports when compared to the same period of 2022 and grew up to USD $ 865.6 Million, or an estimated coverage rate of 145%.

7International technology group Andritz has joined Pellenc ST and Nouvelles Fibres Textiles to produce the first industrialscale automatic textile sorting line in France. The collaboration combines the expertise of the three partners in sorting technologies, textile machinery, and post-consumer textile value chains, respectively.

8 PAKISTAN TEXTILE JOURNAL - April 2023

Cotton spot rate remains steady despite low trading

During the month of April despite low trading of cotton, the spot rate of cotton progressed smoothly and remained remained unchanged at Rs 20,000 per maund even though minimal trading was witnessed thorough out the starting days of April.

The rate of cotton in Sindh was in between Rs 17,000 to Rs 20,000 per maund for the month of April. The rate of cotton in Punjab was also in between Rs 18,000 to Rs 21,000 per maund for the same month.

The rate of Phutti in Sindh was between Rs 5,500 to Rs 8,300 per 40 kg while the rate of Phutti in Punjab was in between Rs 6,000 to Rs 8,500 per 40 kg. Polyester Fiber was also available at Rs 375 per kg during the same month.

APTMA, EconFest and opinion on the textile sector’s growth

The Pakistan Institute of Development Economics (PIDE) – in collaboration with the Research for Social Transformation & Advancement (RASTA) program and the Pakistan Society of Development Economists (PSDE) organized its first-ever Economy Festival (EconFest) at Lahore, Pakistan.

The two-day event Turned out to be a crucial need for today’s industry as it

offers mind opening and vision expanding sessions by more than 100 distinguished speakers.

On the first day, Dr Gohar Ejaz, Patron-in-Chief APTMA along with Senior Economist of the World Bank Group (Pakistan) Gonzalo J. Verala, Advocate Salman Akram Raja, Mr Aamir Fayyaz, Mr Hamid Zaman & Ali Khizar presented their opinion and views during a session on Sustainable Growth and Role of Textile Sector.

The session included discussions on Pakistan’s productivity challenges, Agricultural productivity and the challenge of climate change, Textile Industry & Social-Economic Significance, RCET: Competitive Energy Essential to Sustain & Grow Exports, among other important topics.

At the onset, the importance of the textile industry was highlighted since it is the biggest industrial sector in the economy of Pakistan. However, due to the recent political instability, the textile sector is facing a decline in its sustainable growth.

Dr Gohar Ejaz shared that Pakistan needed a little over $6.8 billion annually to set the economy back on the right track. Adding that annual revenue of $6.8 billion from textile exports could have easily paid off the debt of the last fourteen years.

“We could have decreased our imports by increasing our agricultural production. We could have increased our exports by $6.8 billion. We could have created an environment for foreign direct investment of $6.8 billion or curtailed our

PAKISTAN TEXTILE JOURNAL - April 2023 10 News & Views

expenses in dollars by 6.8. All options were available,” Dr Gohar Ejaz said.

He then shared that APTMA went to the government saying the economic issue can be resolved with the $6.8 billion but the textile industry needs government support in the form of a Regional Competitive Energy Tariff (RCETs) instead of 6% duty drawbacks on exports and local taxes which have added no value to exports.

The government had agreed and gave the textile industry an RCET of 7.5 cents which resulted in an investment of $5 billion by the textile industry as the textile exports rose from $12.3 billion to $19.3 billion in 2022.

“We need to take our country’s economy seriously. The policies need to be homegrown.” Dr Gohar Ejaz commented on the importance of RCET.

Government advises Farmers to use balanced fertilizers for cotton crops

“Farmers should get analysis of their soil first and then use fertilisers according to needs of crops. In this way, they could increase their cotton production by 25-30 per cent per acre.” Says a spokesman for Agriculture (Extension) Department.

Further categorizing the soil of different regions for cotton production in Pakistan he said, “Multan, Khanewal, Vehari, Lodhran, Bahawalnagar, Bahawalpur, Dera Ghazi Khan, Rajanpur, Muzaffargarh, Layyah, Sahiwal and Rahim Yar Khan were the main cotton areas while soil of Faisalabad, Toba Tek Singh, Jhang, Bhakkar, Mianwali, Kasur, Okara and Pakpattan had secondary level for the crop.”

He said that farmers should use two bags of DAP, 3.5 bags of Urea and 1.5 bags of SOP or 1.25 bag of MOP fertilisers per acre for weak soil in main cotton belt areas, whereas 1.5 bags of DAP, 3.25 bags of Urea and 1.5 bas of SOP or 1.25 bags of MOP fertilisers were enough for middle-level soil. Similarly, 1.25 bags of DAP, 3 bags of Urea and 1.5 bags of SOP or 1.25 bags of MOP fertilizers should be used for cotton crops in heavy soil, he added.

He advised growers to use 1.75 bags of DAP, 3.25 bags of Urea and 1.25 bags of SOP or 1 bag of MOP fertilizers for weak soil in Faisalabad like areas whereas 1.5 bags of DAP, 3 bags of Urea and 1.25 bags of SOP or 1

bag of MOP fertilizers were enough for average level soil. Similarly, the farmers should use 1.25 bags of DAP, 2.5 bags of Urea and 1.25 bag of SOP or 1 bag of MOP fertilizers for per acre cotton crops cultivated in heavy soil in secondary level areas.

He concluded by saying that the farmers should follow these suggestion in order to boost the cotton production and to get exact need for the soil they should consult the agriculture experts or field staff of Agriculture (Extension) Department before use of any fertilizers comprising of phosphorus, potassium and nitrogen.

Swag Kicks, Pakistan’s 'sustainable fashion' platform raises USD $1.2M seed funding

Swag Kicks, which is one of Pakistan’s leading preloved (secondhand) fashion store for items including, sneakers, bags, apparel to accessories on its digital platform, recently celebrated a successful seed round funding of 1.2M $ USD.

Swag Kicks, a name which is not new to Pakistanis said in their official statement that they have successfully closed a funding round of 1.2 M $ USD with International venture capital (VC) firms Techstars Toronto, CrossFund HongKong, Rose Lake Ventures, i5 Capital, STAK group and other angels.

The CEO of Swag Kicks, Nofal Khan when asked the reason of their popularity in Pakistan said, “In Pakistan, if you want to purchase a branded shoe i.e. Adidas or Nike, the customer can purchase them from their outlets, which is very costly. The options available in the market are very limited, and the products offered are not very durable or appealing design-wise. There is a gap in the local market.”

Pakistan is one of the largest importers of used clothes and imported 186,299 metric tons of preloved clothing in 2021, registering a growth of over 283% as compared to the same period in 2020. Moreover, the field experts have

stated that the international secondhand market is growing everyday and is likely to grow 127% by 2026 to an estimated $218 billion.

But there are numerous thrift stores throughout Pakistan and the concept of secondhand or preloved cloths isn’t new to Pakistanis, when asked that what makes Swag Kicks unique, their replied, “Products available at thrift markets are mostly C-category, whereas, we offer Agrade products, which are re-exported to countries as well.”

The Swag Kicks CEO plans to utilize this funding in expanding their business by occupying new warehouses and offices in different parts of Pakistan.

“We need a bigger facility to process our growing inventory. We would set up a larger inbound facility. Moreover, the funds would be spent on marketing, inventory procurement etc,” Khan added.

The company’s CEO when asked that how will they scale their brand as numerous thrift stores have tried to do that in the secondhand market in Pakistan but failed, their CEO Nofal Khan replied, “Unlike others, which struggle with scaling their operations, Swag Kicks intends to expand and offer its services worldwide using its propriety technology ThriftOps, an inventory-management software developed by Swag Kicks. ThriftOps allows us to unlock our scalability potential, the software allows us to access preloved fashion markets globally, while also carrying out tasks of

inventory management, warehousing, and purchasing as well.”

Pakistan’s fashion industry shines bright at International Fashion Week held in London

For the first time in the history of the Pakistani fashion industry, a Pakistani brand is to be featured on the list of international brands’ collections and be worn by supermodels and showcased at the London Fashion Week (LFW) 2023.

Rastah, which was founded in 2018 by cousins Zain, Ismail, and Adnan Ahmad, who are based out of Lahore, Pakistan, was invited to showcase their trendy Fashion wear at the London Fashion Week (LFW) held in mid of February.

This achievement of ‘Rastah’ shows how much potential Pakistan’s fashion industry holds that it was invited to be part of such prestigious event and to present with other top brands from all over the world.

Rastah showcased their Volume IX during the event, which according to them is a “deeply personal story, inspired by concepts of conflict, desire and the human condition. It explores what it means to suffer in a largely material world.”

Their Volume XI collection consists of jackets, patterned trousers, pants, embroideries and unconventional pairings featuring an array of colours and

News & Views 12 PAKISTAN TEXTILE JOURNAL - April 2023

Nofal Khan, CEO of Swag Kicks.

textures, patterns and cuts against unique silhouettes.

Rastah is constantly raising bar for other Pakistani brands and making Pakistan proud In International events and occasions, earlier this year they received a chance to work with Marvel (A popular comic and Movie Studio that has taken the world of cinema by storm) on their TV series called “Ms. Marvel” to produce clothing for the series. Beside this Rastah is also getting very popular

with International celebrities as celebrities like Riz Ahmed (An Academy Award Winner), popular Bollywood Director and producer Karan Johar and Veteran actor Anil Kapoor have opted for Rastah’s trendy fashion in recent events.

LFW takes place in London twice a year, in February and September and showcases over 250 designers to a global audience of influential media and retailers.

Interloop with LUMS sponsors 14 students

The Lahore University of Management Sciences (LUMS) via their official twitter account tweeted, “The LUMS leadership visited Interloop Ltd in Faisalabad, with the shared vision of making higher education accessible to all, Interloop has sponsored 14 students at LUMS.”

The LUMS delegation travelled to Faisalabad to meet with Interloop Limited and discuss the future of textile and learn about the growing demands of the industry. During the meeting various research options and collaboration opportunities were discussed and the meeting end at a positive note with Interloop sponsoring academics of 14 Students at LUMS.

The LUMS Rector Mr. Shahid Hussain and other members met Mr. Musadaq Zulqarnain, Chairman Interloop Holdings; Col. Ijaz Ahmad Nasir, Special Assistant to Mr. Musadaq Zulqarnain, and Mr. Zeeshan Akram, Deputy Manager CSR.

News & Views

AUSTRALIA

Australia to harvest 5.2 Million bales worth of cotton this season

Cotton picking has started in most of Australia, and so far the numbers are showing that the country’s fear of underperforming from last year numbers due to flooding and farm damage late last year may not have been as devastating as first feared. Australia is now forecasting the crop being picked at 5.2 million bales, up from around 5Mb forecast in December, both well below the 5.6Mb crop picked last year.

“This will result in around 1.2 million tonnes of fibre and 1.4 million tonnes of cottonseed,” Cotton Australia chief executive officer Adam Kay said.

While the impact of rain and flooding varied between regions, some farmers were forced to scale back their plantings, particularly in the Southern Valleys and Macquarie Valley of New South Wales, where farmers could not get on their paddocks to plant and subsequently missed their window of opportunity.

Mr. Kay further added, “To appreciate where we are now you first have to acknowledge where we were. Last November, every inland river catchment was full or flooded from the Queensland border to Victoria and around 100 active warnings were in place.”

“With favourable conditions across most of the 65 plus local government areas growing cotton this year, growers were reassessing yield and quality. One

area impacted by the wet weather is the Southern Valleys, where defoliation is just starting after late planting, wet weather at planting stage resulted in a one-third reduction in crop planted”, he concluded.

BRAZIL

Cotton’s prices crisis to be expected due to instability of global economy

In March, the uncertainty of the world economy led to a decrease in liquidity as well as decreases in prices for agricultural commodities and cotton is at particular risk from inflation and income issues. In Brazil, Center for Advanced Studies on Applied Economics (CEPEA)

collaborators reported difficulties in selling cotton products, resulting in even steeper price drops for the raw material.

“As sales of finished cotton products face challenges, cotton processors purchased only small volumes of the material, aiming to meet urgent demands or replenish inventories. These buyers offered lower prices for cotton”, CEPEA mentioned in its latest fortnightly report on the Brazilian cotton market.

The CEPEA/ESALQ Index for the month of March experienced a 10% decrease, closing at BRL 4.6572/pound on March 31.

In terms of buyers, the national spot market has increased its supply of cotton due to the approaching 2022-23 crop and a need for cash flows among some farmers. Farmers were more willing to lower their offer prices for these cases, especially if the quality was not so good. However, in particular when the quality was high and the supply was low, some farmers remained firm and refused to negotiate.

INDIA

Textile units are abandoning cotton and shifting to polyester

Many textile manufacturers in India are moving to polyester and viscose fabrics. Last year India’s textile sector

Around the World 14 PAKISTAN TEXTILE JOURNAL - April 2023

witnessed blending in cotton and now several players in the value chain have moved to polyester and viscose.

Dhruv Patel Managing Director of Diamond Textile Mills Pvt Ltd commented, “We had a thriving cotton textile business for more than five decades with integrated spinning, weaving and processing facilities but for the last nine months, we have completely shifted to polyester yarn and viscose.”

According to industry estimates, at least 5% of the entire industry which were entirely into cotton have adopted man-made fibres. Last year, cotton prices reached a record high of Rs 1.10 Lac per candy (356kg). This year, prices have come down to an average of Rs 60,000 per candy. However, recently experts have concluded that the Cotton Association of India (CAI) report suggests lower crop output and thus there will be more volatility in cotton prices.

He further said, “We source the fibre, manufacture yarn, and weave it into fabric. We’re also supplying yarn to manufacturers in Surat. We had no choice but to shift to polyester and viscose due to high cotton prices, which

affected our viability. We have not exited the cotton business entirely, but feel the time is not right for cotton and thus chose to diversify.”

Saurin Parikh, president of the Spinners Association Gujarat (SAG), said, “Gujarat is hub of cotton textiles but in the last year, more than 5% of its cotton capacity has been replaced by polyester and viscose.”

Akash Sharma, director of Akash Fashion Pvt Ltd, said, “We began

polyester and viscose printing three years ago. We were into 100% cotton fabrics, but of late have begun blending. There is blending of up to 65% polyester because it is at least 25% cheaper than pure cotton. We used to print 12 Lac metres of cotton shirting every month earlier, however, capacity utilization dropped due to high cotton prices. We now print seven Lac metres of blended shirting fabric while our volume of pure cotton shirting fabric is only one Lac metres a month.”

Around the World

Inditex, H&M, Mango, Primark and Uniqlo form ARTE to represent the Spanish textile sector

The Inditex group (Bershka, Massimo Dutti, Oysho, Pull&Bear, Stradivarius, Kiddy's Class, Zara, and Zara Home), H&M, Mango, Primark, Iberian Sports Retail Group (JD Spain, JD Canarias, Sport Zone, Sprinter), and Uniqlo have formed the business association Asociación Retail Textil España (ARTE) to represent the entire textile sector at the national level.

These textile firms, which account for a third of the sector, constitute a new employers' association in the fashion sector to give voice to the points of view of the industry in the face of the challenges it faces in the economic, sociolabor, and regulatory spheres.

In this way, its statutes - which initially establish a minimum threshold in terms of employment, commercial space, and territorial presence - provide for the possibility of incorporating more companies in the textile sector that have common interests, regardless of their size.

ARTE seeks to represent the general and common positions of the sector in the institutional sphere, and in particular, in its relationship with public administrations at different levels and the union organizations representing their workers.

Its founding members also have the purpose of promoting the freedom of business and establishment, as well as trade and business hours, market unity, and commitments in terms of social and environmental sustainability.

In this way, the association's board of directors, which is made up of all the founding groups and has a four-year mandate, has set as a goal for 2023 the implementation of its "ambitious work agenda with which it was born".

TUNISIA

Textile and apparel exports grew by 16.78% in 2023

Tunisia has shown an exceptional growth of exports in textile sector by managing to reach 14.61% in terms of exports when compared to the same period of 2022 and grew up to USD $ 865.6 Million, or an estimated coverage rate of 145%.

With the demand of Tunisian readyto-wear clothing in rise among European countries like France, Italy, Germany, Belgium, Portugal and Netherlands, the country is expected to increase its textile export even more in the coming years.

Turkiye has been a dominant supplier of textiles throughout the Europe but due to recent catastrophes faced by the country the European market has not

been fully satisfied of it needs for textiles hence an opportunity has emerged for the countries around the World to try their luck in European market and many countries like India and China has already tried to seize this opportunity and put their best efforts to capture this market, similarly Tunisia has tried their luck here and so far the country’s textile goods have been received warmly by the European Union as the demand is increasing day by day.

The country managed to achieve USD $ 703.3 million in the first quarter of 2023 in terms of textile exports, up by 19.80% compared to 2022 and accounting for 81% of the sector's total exports.

USA

Home textile imports for US showing continuing downtrend

In 2022, the US imported home textiles worth US $ 22.025 billion, marking the second year of a declining trend. Due to personal preferences and economic concerns, home textiles segment, after a steep rise in imports during 2020, is facing hurdles.

The Asia-Pacific region accounted for 81 per cent of the US imports amounting to US 18 billion, making it the largest supplier.

Record growth in imports was seen in 2020, reaching US $ 32 billion, up from US $ 18 billion in 2019, largely due to lockdowns related to Covid, making people stay at home and making demands surge.

SPAIN

Around the World 16 PAKISTAN TEXTILE JOURNAL - April 2023

Imports have been on a downward trend since 2021, where imports dropped to US $ 24 billion and due to changing consumer preferences the downward trend continues since people preferred to buy garments instead of home textiles as lockdowns eased.

High inflation and unemployment in the latter half of 2022, dried up consumers’ pockets so that discretionary purchases like home textiles and garments became less viable. Brands also struggled to clear stock in their showrooms and had to slow down sourcing, with some even postponing or cancelling purchase orders.

VIETNAM

Vietnam ditches China for Australian cotton amid trade tensions between Australia and China

Amid the trade tensions between Australia and China, Australia has started to explore new markets for its cotton. As a result, Vietnam has emerged as the number one importer of Australian cotton, replacing China.

The worsening trade relations between Australia and China since 2020 has resulted Australia exploring alternative markets for its cotton, among the potential new clients for the Australian cotton Vietnam has emerged as the number one market for their cotton with imports of raw cotton from Australia increased by 899 percent or US$555 million between 2020 and 2021.

But this phenomenal growth is not solely due to the worsening trade relationship between Australia and China. Vietnam has a number of other advantages over China that Australian cotton producers are able to take advantage of, such as free trade agreements, a convenient location, and a huge appetite of cotton apparel manufacturers.

With the demand of raw cotton in rise within Vietnam, Vietnam’s textile and garment industry is expected to export in the vicinity of US$46-47 billion of clothing and apparel in 2023.

Oerlikon’s Shareholders approved all resolutions

Annual General Meeting of Shareholders 2023

Dividend payout of CHF 0.35 per share was approved.

Prof. Dr. Michael Suess was reelected as Chairman of the Board Inka Koljonen was elected as a new Board Member.

All Board Members who stood for reelection were voted in.

All members of the Human Resources Committee (HRC) who stood for reelection were voted in. Inka Koljonen was elected as a new member of the HRC.

Improved on all environmental 2030 targets in our operations.

403 shareholders attended Oerlikon’s 50th Annual General Meeting of Shareholders (AGM) at the KKL Luzern in Lucerne, Switzerland, and 66.01% of the total share capital was represented.

All resolutions proposed by the Board of Directors were approved, including the revisions to Oerlikon’s Articles of Association, the maximum aggregate amount of total compensation of the Board for their term of office (AGM 2023 to AGM 2024), the maximum aggregate amount of fixed compensation of the Executive Committee (EC) for the period July 1, 2023 to June 30, 2024, and the retrospective variable compensation of

the EC for 2022, as well as the dividend payout of CHF 0.35 per share.

All members of the Board of Directors and all members of the Human Resources Committee (HRC) who were standing for (re-)election were voted in. Following the (re)-election, the Board of Directors comprises of Prof. Dr. Michael Suess as Executive Chairman, Gerhard Pegam as Vice-Chairman, Paul Adams as Lead Director and Jürg Fedier, Inka Koljonen, Irina Matveeva, Alexey V. Moskov and Zhenguo Yao as members of the Board of Directors. All elected Board members will serve a one-year term.

Following these elections, the majority of Oerlikon’s Board of Directors will be independent and its committees will be composed as follows:

Paul Adams, Inka Koljonen, Alexey V. Moskov, Gerhard Pegam and Zhenguo Yao will serve as members of the Human Resources Committee. Paul Adams, Jürg Fedier, Inka Koljonen and Irina Matveeva will be members of the Audit & Finance Committee, and the Governance Committee will comprise of Paul Adams, Gerhard Pegam and Zhenguo Yao.

At the AGM, Oerlikon provided an update on the improvement on its 2030

environmental targets in its operations. In 2022, Oerlikon implemented energy management systems at 25 sites, bringing the total to 55, which represents 33% of its operational sites and accounts for 70.5% of Oerlikon’s total energy consumption. Compared to the baseline, Oerlikon increased its purchased electricity from renewable sources by 8% points, leading to a total of 30% of electricity consumed in 2022 stemming from renewables. Oerlikon also decreased the amount of waste disposed by from 42% to 28% of total waste.

Pertaining to its climate neutral target, Oerlikon reduced its greenhouse gas emissions intensity by 16.9% from 60.9 to 50.6 tons of CO2 equivalents per million of sales in Swiss francs. Following a number of rating upgrades in 2022, Oerlikon is now among the top 10% of the best-rated companies in the industrial sector in terms of sustainability.

The Oerlikon Sustainability Report 2022 will be published at the end of March, in which Oerlikon will provide details on its sustainability progress, actions and initiatives, as well as sustainability case studies and examples.

18 PAKISTAN TEXTILE JOURNAL - April 2023 Corporate News

Radici EcoMaterials means 360degree sustainability

A recycling production site offering the market traceable, high-quality, environmentally friendly materials.

A little over three years have passed since RadiciGroup announced the acquisition of Zeta Polimeri, an Italian company headquartered in Buronzo (VC) with over 30 years' experience in the recovery of pre- and post-consumer synthetic fibres and thermoplastic materials. Today, the company has become a full member of the Group with its new name Radici EcoMaterials Srl.

The name quite aptly describes the nature of the company’s activities: indeed, Radici EcoMaterials occupies a position in RadiciGroup at the forefront of the recycling field, thanks to its cutting-edge technology that optimizes its high value-added sorting and recovery processes.

The new company’s long-standing know-how, combined with RadiciGroup’s as a whole, will create a virtuous production system that recovers wornout materials (fabric, yarn and granules), or otherwise unusable materials, and processes them into raw materials available for other production cycles by taking advantage of industrial synergy.

“This is truly a circular economy business,” Angelo Radici, president of RadiciGroup, emphasized. “We collect scraps and waste from our Group plants,

as well as from external companies, and determine the most appropriate recycling destinations. RadiciGroup has already had some forty years of experience in recovering post-industrial waste from all its processing activities and giving it a second life in the world of engineering polymers. Now, with the expertise of Radici EcoMaterials, we can also produce recovered materials of very high quality, nearly equal to virgin raw materials, ready to be used by our spinning lines to manufacture products that meet the textile market’s demand for low-emission, sustainable products.”

Radici EcoMaterials is a strategic production site because it handles all the preliminary recovery stages: the sorting, processing and pre-treatment of materials, including those used for the

production of post-consumer yarns and engineering polymers. In this sense, Radici EcoMaterials is fully in line with the most recent European policies on sustainable textiles, which address minimizing the share of materials destined for disposal sites, favouring instead more structured recycling solutions.

“We can call our strategy a 360degree approach to sustainability,” Maurizio Radici, vice president of RadiciGroup, added. “In fact, owing to Radici EcoMaterials, we can now handle both pre- and post-consumer recovery activities and optimize the materials in a “zero waste” operation. During the last few months, we have also invested in new technologies to further improve the quality of the products headed for our spinning lines – for both carpeting and textile applications – and to double the production capacity of the site.”

Radici EcoMaterials is also GRS certified. GRS certification ensures the complete traceability of its materials, which are made in a safe plant that meets the highest environmental and social certification standards.

The company is also equipped with a state-of-the-art photovoltaic system and, for the portion of its energy needs not covered by the photovoltaic source, it partially relies on renewable energy. The goal is to use 100% green energy in the next few years, in accord with RadiciGroup's goals.

Corporate News 20 PAKISTAN TEXTILE JOURNAL - April 2023

Archroma announces Mark Garrett as CEO

Archroma, a global leader in sustainable specialty chemicals and solutions for the textiles, packaging & paper, paints and coatings industries, announced its transition plan for the role of Chief Executive Officer (CEO). Heike van de Kerkhof, CEO of Archroma since January 2020, will step down effective April 30, 2023, to focus on other career opportunities. Mark Garrett, a seasoned industry executive, will assume the role of interim CEO. Archroma’s Board of Directors has initiated a comprehensive search process for installing a permanent CEO and has retained a leading executive search firm to evaluate both internal and external candidates.

Miguel Kohlmann, Chairman of the Board of Directors of Archroma, said “On behalf of the Board of Directors, I would like to thank Heike for her leadership and tireless dedication to Archroma. Heike joined the company in January 2020 as CEO and has meaningfully advanced the company’s sustainability, innovation, and customer-focused business model, while also successfully closing the transformational acquisition of Huntsman’s Textile Effects business, which will substantially enhance Archroma’s capabilities in serving its customers and markets. We would like to thank Heike for her great contributions

through this substantial period of growth and wish her continued success in her next endeavors.”

Kohlmann continued, “The Board remains committed to accelerating the growth of Archroma and to continuing to provide our customers with the systems, solutions, innovation and technical support that they have come to expect from us, while providing enhanced opportunities for Archroma’s employees. We are enthusiastic about Mark Garrett joining Archroma as interim CEO, a seasoned executive who brings substantial industry experience which encompasses directly relevant knowledge of Archroma’s product portfolio and end markets. Mark has served in the capacity of Chairman and CEO and in senior executive leadership roles with companies such as OMV/Borealis, Marquard & Bahls, Ciba Specialty Chemicals and DuPont. He is a proven leader and the perfect choice to serve as Archroma’s interim CEO. The Board has strong confidence in Archroma’s leadership team

and is focused on continuity during this period of transition.”

Heike van de Kerkhof said, “It has been an honor and a privilege to lead Archroma. I am proud of the tremendous progress the company has made over the past three years, both organically and through the acquisition of the Huntsman Textile Effects business. I want to thank the Archroma leadership team and employees for their commitment to the company, our customers, brands and industry partners around the world. As I transition at this phase of my career, I look forward to seeing Archroma realize its full growth potential.”

Mark Garrett stated, “I am excited to join Archroma and lead the company at this time. Over the course of my career, I have long admired Archroma for its focus on innovation, sustainability and customer solutions. I look forward to working with the talented leadership team and employees to flawlessly execute on our growth opportunities, as well as completing the seamless integration of the Huntsman Textile Effects business.”

22 PAKISTAN TEXTILE JOURNAL - April 2023 Personalia

Mark Garrett, CEO.

Miguel Kohlmann, Chairman of the Board of Directors of Archroma. Heike van de Kerkhof.

Italian Textile Machinery at ITMA 2023: Sustainability and Digitalization a winning asset for Italian Technology

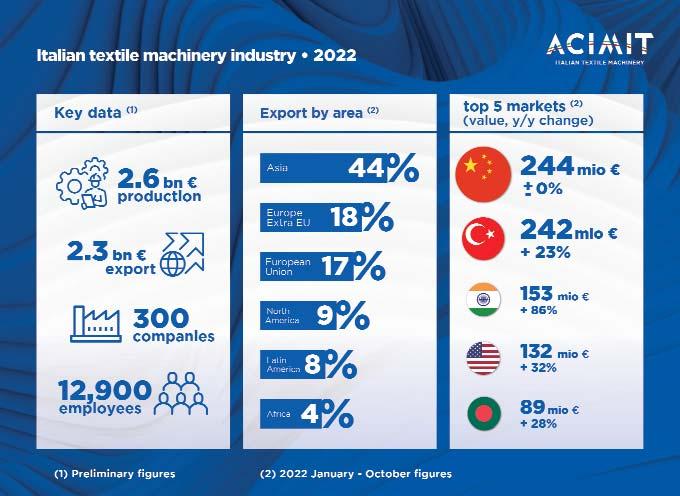

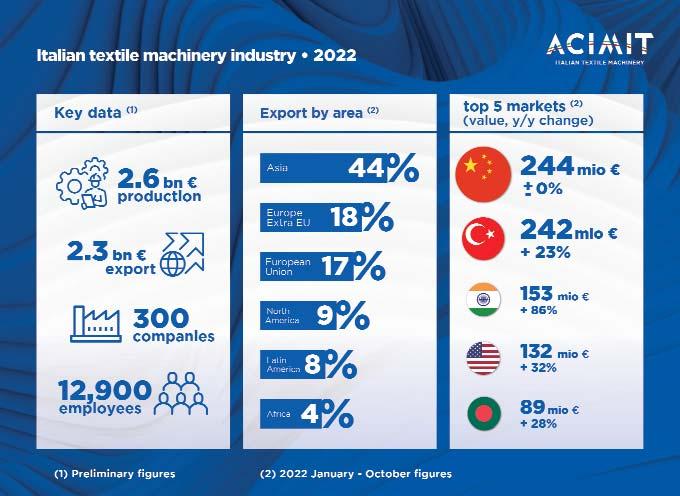

Promoted by ACIMIT, the Association of Italian Textile Machinery Manufacturers, a press conference was held on 15 March at Villa Frua (Stresa, Italy) to unveil Italian participation in ITMA, the leading textile machinery exhibition, scheduled from 8 to 14 June at Fiera Milano - Rho.

During the event, Alessandro Zucchi, President of ACIMIT, showed the preliminary figures for 2022. Both Italian production and exports of textile machinery increased by more than 10% compared to the previous year. The production value exceeded 2.6 billion euro. Of this value, 87%, or around 2.3 billion euro, was realised abroad. Italian exports went mainly to Asia and Europe. Overall, the two areas absorbed 79% of foreign sales. China, Turkey, India and the United States of America were the main destinations of Italian sales abroad in 2022.

Alessandro Zucchi: "The positive results do not, however, cancel out the obstacles that companies still face in this period. The critical issues following the Covid-19 pandemic have been amplified by the ongoing Russian-Ukrainian conflict. Even in this early 2023, unfavourable conditions to business still exist, Such as high inflation, constraints on the functioning of value chains, and energy commodity prices above the average of recent years. However, forecasts prepared by our Economic Office show an improvement in the second half of the year and in the 202426 period, which gives us hope."

With these forecasts, ITMA 2023, the leading trade fair for the textile machinery industry, to be held in June in Milan, could be the driving force able to stimulate investment in the textile sector, not only the Italian one. Zucchi

commented: "Our manufacturers are very confident about next June's event. As shown by the figures on the Italian presence at the event: almost 400 Italian exhibitors, about 36,000 square metres, with an increase in the occupied surface area of over 20% compared to the

previous edition held in Barcelona. 30% of the total exhibition area at ITMA 2023 will be taken up by Italian machinery manufacturers."

During the press conference, the various initiatives that ACIMIT, with the support of Italian Trade Agency (ITA), has put in place to promote Italian participation in ITMA were announced. Roberto Luongo, the General Director of ITA, stated: "The Italian textile machinery industry represents one of the leading production sectors for our country due to its strong projection on international markets. Our textile technologies are considered to be of a high quality level, and for us at ITA this represents an element of great pride and satisfaction, which pushes us to support Italian companies in an increasingly convinced and decisive manner, through an effective

24 PAKISTAN TEXTILE JOURNAL - April 2023 Special Report

After a positive 2022, the Italian textile machinery industry looks with optimism to the current year. In 2023, after eight years, ITMA, the most important trade fair in the sector, returns to Milan. It is an opportunity to highlight the excellence of Italian technology and stimulate new investments in the textile industry.

Alessandro Zucchi, President of ACIMIT.

collaboration, now consolidated and tested, with ACIMIT. ITMA is a unique opportunity for the Italian textile machinery industry, due to the high number of exhibitors and the tens of thousands of visitors it usually attracts. As ITA we have therefore prepared, in accordance with ACIMIT, an extensive project aimed at promoting the Italian textile machinery sector through the enhancement of the three drivers that distinguish it: technology, digitalization and sustainability. We will have an incoming of 140 top foreign buyers from 25 different Countries; this will be accompanied by an intense and widespread communication campaign in Italy and abroad that will significantly contribute to increasing the presence at the event of professional operators from all over the world. There will be several training events, focusing mainly on the innovations presented by Italian companies at ITMA 2023, with a special focus on sustainable technologies and digitisation processes. And then there will be the Italian Textile Technology Awards, organised by ITA and ACIMIT.

Prizes will be awarded to the 18 most deserving students from textile universities in those Countries where Italian Textile Technology Training Centres are active or are being set up: Bangladesh, India, Mongolia, Pakistan, Peru and Vietnam'

The promotional campaign through social and traditional channels was also particularly significant. The concept that distinguishes ACIMIT communication activities towards ITMA 2023 is SHAPING

THE FUTURE. "The Italian textile machinery sector, explains the president of ACIMIT, has shown in recent years

that it knows how to look ahead to create innovation and strengthen a technological leadership that is now established and recognised internationally. Shaping the future is a concept that aims to show how Italian manufacturers are key players in the development of the entire textile supply chain, able to outline virtuous paths that testify to the proactive nature of the entire sector and that enable the future of the sector to be shaped through the three

pillars, technology, digitalization, and sustainability, which are also the key themes of ITMA 2023".

At the Milan edition of ITMA, a trade show that has always been characterised by the high level of innovation of its technological proposals, sustainability and digitalization will be the main topics of discussion. Alessandro Zucchi: "The textile supply chain is moving towards increasingly competitive production processes, where the reduction of

25 Special Report

Roberto Luongo, the General Director of Italian Trade Agency (ITA).

production costs, through lower consumption of water, energy and raw materials, is combined with attention to the environment. Equally important is the ongoing digital transformation of companies, a process that will enable technology suppliers and their customers to operate more and more constructively and efficiently."

During the conference on the topic of sustainability and digitalization, five ACIMIT member companies also spoke, bringing their company experiences: Flainox, Itema, Marzoli, Salvadè and Sperotto Rimar. Their contributions highlighted the validity of the projects that ACIMIT has been pursuing for some years now in the field of sustainability and digitalization, namely the Sustainable Technologies project, with the Green Label as the core of the initiative, and the digital certification called ACIMIT Digital Ready. Both projects testify to the commitment of Italian manufacturers in two areas of strategic significance to consolidate the leadership of Italian textile technology also in the future. With the Green Label, certifying the environmental and economic performance of textile machinery, member companies undertake to reduce the C02 emissions of their machines through constant technological improvement. With Digital Ready, on the other hand, the aim is to standardize the production and management data of Italian textile machines and their ability to be digitally integrated at the customer's plant. Alessandro Zucchi concluded: "We believe that the future of textiles that we

want to shape lies in a sustainable and digitised technological supply.'

ACIMIT, the Association of Italian Textile Machinery Manufacturers, represents an industrial sector that comprises roughly 300 manufacturers (employing around 73,000 people), which produce machinery for an overall worth of around 2.6 billion euro, of which 8796 are exported. Creativity, sustainable technology, reliability and quality are the hallmarks that have made Italian textile machinery worldwide leaders.

ITA - Italian Trade Agency is the Governmental agency that supports the business development of our companies abroad and promotes the attraction of foreign investment in Italy.

With a motivated and modern organization and a widespread network of overseas offices, ITA provides information, assistance, consulting, promotion and training to Italian small and medium-sized businesses. Using the most modern multi-channel promotion and communication tools, it acts to assert the excellence of Made in Italy in the world.

26 PAKISTAN TEXTILE JOURNAL - April 2023 Special Report

Valentina Brignoli, Itema Group.

Marco Salvade.

Andrea Bozzo, Flainox.

Cristian Locatelli, Marzoli.

Federico Businaro, Santex Rimar Group.

Excursion: Borromees Islands, Lake Maggiore.

27

28 PAKISTAN TEXTILE JOURNAL - April 2023 Special Report

Sustainability of the Textile and Fashion Supply Chain – Transitioning to Zero Carbon and Zero Waste

The 92nd Textile Institute World Conference (TIWC) 2023 will be hosted by the University of Huddersfield on 3-6 July 2023.

The 92nd Textile Institute World Conference (TIWC) 2023 will be hosted by Conference Chairman Prof Parik Goswami CText FTI, the Department of Fashion and Textiles, and the Technical Textiles Research Centre (TTRC) at the University of Huddersfield. The conference theme, ‘Sustainability of the Textile and Fashion Supply Chain –Transitioning to Zero Carbon and Zero Waste’, is focused on identifying the current scenario as well as emerging sustainable practices and solutions throughout the whole supply chain of textile and fashion products, starting from raw materials to manufacturing processes, distribution and retailing, use by consumers and up to the end-of-life phases.

Furthermore, the conference will address various strategies to manage the impact of the textile and fashion supply chain on the environment and climate change. The theme directly aligns with the worldwide initiatives being undertaken in moving toward zero carbon emission. Divided into several sub-themes and organised by academic and industrial experts, the conference

will cover the latest developments and inventions towards achieving reduced carbon emissions in the apparel and fashion sectors and high-end and specialised technical textile products. This conference aims to demonstrate how the triple helix model of the academic–industry-government dialogues could benefit the industry and create a meaningful roadmap towards achieving zero carbon ambitions before 2050.

The conference will also include but not be limited to the following subthemes:

Future Fashion. Composites.

Green Skills. Dyes, Pigments, and Polymers. Nonwovens.

Technical Textiles.

The textile industry is by its nature diverse and multi-disciplinary. Therefore while the key theme for The 92nd TI World Conference is ‘Sustainability of the Textile and Fashion Supply Chain –Transitioning to Zero Carbon and Zero Waste’, the conference will wholeheartedly welcome papers discussing specific topics encompassing:

Advanced Fibres and Materials Manufacture, Biomaterials, Business, CAD/CAE Technology, Circularity and New Business Models, Clothing,

Coloration and Finishing, Comfort Science, Composites, Costume, Craft, Design, Economy & Supply Chain Management, Fashion, Fibre and Fabric Functionalisation, Floorcovering, Footwear, Industry, Household/Interiors, Innovative Fabric Structures/Products, Leather, Modelling & Simulation, Nanotechnology, Printing, Retailing & Branding, Smart Textiles, Sustainability, Technical Textiles, Testing and Materials Analysis, Textile Machinery, Textile Manufacturing – Knitting, Nonwovens and Weaving, Textile Recycling, Textile Cultural Heritage Science, Textile Education, Yarn Structures and Spinning.

30 PAKISTAN TEXTILE

- April 2023

Fairs and Exhibitions

JOURNAL

Conference Chairman Prof Parik Goswami CText FTI, the Department of Fashion and Textiles

Texworld Evolution Paris to return with large participation from around the world

Texworld Evolution Paris received nearly 8,000 visitors from some twenty countries during its February 2023 edition, a sign of the resumption of business between the European fashion industries and the major sourcing countries. The date is set for the summer edition, which will take place from 3 to 5 July at the new venue in Paris, Porte de Versailles Expo Centre with some 1,300 exhibitors.

Strong growth in attendance

After three years of crisis, the alleys of Texworld Paris and Apparel Sourcing Paris have finally returned to a level of attendance and activity comparable to the great editions of Texworld Evolution Paris. Nearly 8,000 professional buyersa near three-fold increase compared to February 2022 - came to meet the 750 exhibitors grouped together in Hall 4 of the Paris - Le Bourget Exhibition Centre. This significant increase demonstrates

Texworld Evolution Paris' ability to respond to the reopening of business flows with the major textile sourcing countries.

This edition, which was very international, was highlighted by the return of Chinese exhibitors. After a 3year absence, nearly 450 companies, weavers and garment makers, came to meet international and especially European buyers. Overall, it was an edition that reflected the long awaited reopening to the world with the comeback of Indian, Indonesian, but also Korean or Bangladeshi manufacturers. Turkish manufacturers, with 122 companies present this year, including 94 grouped under the national pavilion led by the Istanbul Chamber of Commerce (ITO), were also prominent.

Leading actors

The expansion of the offer was also reflected in the structure of the visitor base, which was very international: the

proportion of foreign visitors reached 85%, compared to 65% a year ago. If the French remain the most important presence, English, Turkish, Italian, Spanish and Dutch buyers dominate the Top 5 of foreign visitors, ahead of Germans and Americans. Another sign of this renewed atmosphere was the presence of major stakeholders such as the Inditex group, River Island, Marks&Spencer, Mango, ASOS or C&A, who came to discover the displayed offer and negotiate contracts for the next season.

Dynamic exchange

From the first day, the dynamics of the trade were perceptible. Buyers, who have tended to reorient their sourcing strategy since the arrival of inflation over the long term by sourcing more from Asia and the Mediterranean region, came to get inspiration for trends and finalise their collections. Turkish weaver Segovin, which offered a wide range of silky fabrics at the Elite area of Texworld Paris,

32 PAKISTAN TEXTILE JOURNAL - April 2023

had three very busy days. At Apparel Sourcing Paris, ReshaMandi, the Indian specialist in natural fibre for Womenswear, saw more customers in a single day than at the show last July. Sesil, the Pakistani manufacturer of technical sportswear and supplier to a major French sports brand, was quite popular among buyers of major European brands when presenting its new casual range.

1,300 exhibitors are expected from 3 to 5 July at the Porte de Versailles

As part of this strategy - to make the offer more accessible - Texworld Evolution Paris has decided to move all its summer editions to Paris intra-muros: From 3 to 5 July, Apparel Sourcing Paris, Avantex Paris, and Texworld Paris as well as the Leatherworld offer will be held on 45,000 m² in Hall 1 of the Porte de Versailles Exhibition Centre (compared to 25 000 m² for the February 2023 edition). Nearly 1,300 exhibitors are expected, with an increased participation of Chinese, Indian, Turkish, Korean, Vietnamese, Ghanaian and Ethiopian manufacturers.

Providing maximum convenience for visitors, Apparel Sourcing,and Texworld Paris belong to the cluster of related trade fairs organised by Messe Frankfurt France (alongside Avantex and Leatherworld which take place only once a year during July session), held in one and the same location, on the same dates and where entry is free upon presentation of professional credentials.

Texpertise, the textile business network, stands for Messe Frankfurt's entire textile commitment. With a unique portfolio currently comprising around 50 international trade fairs in 11 countries, the company is the world market leader

Frédéric Bougeard, President of Messe Frankfurt France

in trade fairs for the textile industry. Texpertise Network covers the entire value chain of the textile industry and, as a central communication platform, provides valuable information on the textile trade fair brands.

The success of this edition shows our ability to adapt, underlines Frédéric Bougeard, President of Messe Frankfurt France. It also shows that our fairs are open international sourcing platforms. And they will remain so. The offer must stay organised according to the expectations of buyers, who come here to find quality industrial know-how to produce their collections in the best conditions and at the best price. Our objective is to always make this offer accessible and visible.

Apparel Sourcing,and Texworld Paris belong to the cluster of related trade fairs organised by Messe Frankfurt France (alongside Avantex and Leatherworld which take place only once a year during July session. This configuration will also offer two days in common with the dates of the International Lingerie trade show & Interfilière organised by WSN (Who’Next), the professional platforms for the sourcing of materials and accessories for the lingerie, sportswear and swimwear markets, which will be held from 2 to 4 July.

This strategic choice was made in response to strong demand from buyers, who want to be able to take advantage of an extended sourcing platform at this time of year, just minutes from Paris. This will be an opportunity for us to celebrate our 25th anniversary in a new arrangement, with more services, which will bring emulation to the market, concluded emphasises Frédéric Bougeard.

Fairs and Exhibitions 33

Highlighting women making their mark in the cotton industry on International Women’s Day

When it comes to working in the cotton industry, it’s all about getting the job done. It doesn’t matter who you are as it all boils down to quality, passion and sustainability to ensure the job gets done right every time. On this International Women’s Day, we are proud to highlight a few of the women who are making their mark.

Rachel Lee is a county executive director for the United States Department of Agriculture’s (USDA) Farm Service Agency (FSA). She didn’t grow up farming but received encouragement from her family to follow her passion and pursue a career in agriculture. She attained multiple degrees from Mississippi State University in agriculture and extension education and after marrying her husband, Kellon, they moved to Louisiana to help on his family farm. The Lee’s are members of the U.S. Cotton Trust Protocol and have been enrolled since the program’s pilot.

Jacyln Dixon Ford is Vice-President and Chief Operating Officer, Dixon Gin

Co., Inc., in Georgia and also works with her brothers on their family’s farm. She returned home to run the family’s newly acquired gin one year after graduating from the University of Georgia and marrying her husband. Dixon Farms won the 2010 Cotton Marketer of the Year Award, the first time in the award’s history that the winning operation was run in part by a woman. Their farm and gin are members of the Trust Protocol.

Larkin Martin of Alabama has managed her family farm, serving as principal, over the

Ms. Rachel Lee.

Ms. Larkin Martin.

Ms. Rachel Lee.

Ms. Larkin Martin.

36 PAKISTAN TEXTILE JOURNAL - April 2023

Photo credit Jim Hannon

past three decades. Martin is highly active within the cotton industry and became the first female Chair of the Cotton Board in 2009. In addition to being active in the cotton industry, she is also past Chairman of The Farm Foundation, The Public Affairs Research Council of Alabama (PARCA), and the Federal Reserve Bank of Atlanta She has served as a director of the Kenya based NGO Africa Harvest and was named an Eisenhower Agricultural Fellow in 2012. She is a graduate of Vanderbilt University. Her family farm is enrolled in the Trust Protocol and are implementing regenerative agriculture practices.

Q. What motivated you to have a career in the cotton industry?

Rachel: It was my mom who encouraged me to pursue a career in agriculture. She thought that agriculture would be something I would be interested in. Now, being involved in the production side of our food and fiber system for our family farm helps to feed that passion. In my current role as county executive director with FSA, I am the lead for our county aiding our staff in training and implementation of programs that serve our local farmers, ranchers and agricultural partners. USDA FSA provides a strong safety net of conservation, disaster, and commodity programs.

Jaclyn: I always knew I wanted to return home to the farm. After I graduated from the University of Georgia with a degree in Agricultural Communications, I started my career at Georgia Farm Bureau where I learned more about agriculture politics. I enjoyed lobbying at the state level but also missed the farm. When my family bought a cotton gin, my dad asked me to oversee it. I started running the gin in 2001. Today I am responsible for ginning, shipping, pricing and contracting cotton. I also market cotton on behalf of our grower customers.

Larkin: My father’s family has always farmed in the same area of Alabama. In my generation there are only daughters. I am the oldest and was always interested in the farm growing up. I drove tractors and evaluated cotton fields for other growers for summer jobs in high school and college, but I did not have plans for a career in farming or for cotton industry

involvement until my father was diagnosed with cancer when I was in my late 20s, working in Washington, D.C and considering graduate school. When he was diagnosed, I postponed graduate school and moved home to help while he underwent treatment. I enjoyed the work and have never left. My father was very involved in the cotton industry, so I had his example to follow as I assumed responsibility for the farm.

Q. What do you think are the most important issues facing the industry today?

Rachel: Providing data and metrics that support our farming practices is extremely important. I work with growers every day to help them ensure they have the data they need to make informed decisions for their operation. Before I worked at FSA, I worked at USDA’s Natural Resources Conservation Service (NRCS). In both roles I’ve worked with farmers on a daily basis. For them, it’s about the long game and making the best decisions today for the next generation to carry on the farm. Sustainability is constantly top of mindwhether that be financial sustainably, or more field-level sustainability to ensure growers are being the best stewards of the land.

Jaclyn: As a ginner and marketer, we’re responsible for helping the growers who use our gin. This means I have to be knowledgeable about the issues impacting our industry. We know that our end use customers: brands and retailers— need transparent supply chains and access to sustainably grown cotton that today’s consumers demand. Continuous education and improvement are key to ensuring we’re using all the best technologies so we can document, measure and quantify our sustainable practices - whether that be at the field level or throughout the ginning process as we look to get our cotton to consumers.

Larkin: Cotton faces profitability challenges on farms and stiff competition globally from other kinds of fibers. Cotton has the advantage of being a natural, versatile, renewable and biodegradable fiber. Textile brands and retailers are looking much further back into their supply chains than they have in the past. They want to understand the environmental impacts of every step, including raw material production. The whole industry faces the challenge and the opportunity of answering those questions. Constant improvement in production methods with an eye towards adopting agronomic practices that reduce soil erosion and capture and store moisture and soil carbon, adoption of mechanical/technical/genetic advances are all parts of meeting that challenge. Increased transparency and traceability in marketing and manufacturing pathways can increase the value of that responsibly grown cotton.

Q. What does sustainability mean to you and why is Trust Protocol membership important?

Rachel: Sustainability is an important topic for agriculture. For decades the U.S. cotton industry has employed sustainable farming practices - however, we knew we had to document and verify at the field

Features

37

Ms. Jaclyn Dixon Ford.

level. This is where the Trust Protocol comes in, as the initiative is a farm-level science-based sustainability program that provides data led assurances, measurements and outcomes to help meet the needs of brands and retailers; something that has been lacking in the industry to date. For both growers and brands and retailers, the Trust Protocol bridges the gap. The program allows growers to access data so they can continually improve their sustainable growing practices.

Jaclyn: As a ginner, it’s also our job to ensure sustainability as we prepare cotton for our end use customers. We clean the cotton and then separate out the leftover leaves and stems, as well as the cotton seeds from the lint to make bales of cotton that are ultimately shipped. The ginning process is extremely efficient. We don’t waste anything. Cotton seed is either sold to be crushed into oil or used for livestock feed. What we call gin trash - the sticks and leftover stems- are composted. Nothing is wasted. We’re as efficient as we can be to ensure sustainable production throughout the cotton production supply chain. From the point of view of our family farm and as ginners, I’m pleased we have the Trust Protocol so we can document our sustainability throughout the entire supply chain.

Larkin: Our farm has worked hard to adopt practices that are considered sustainable or regenerative. For us it meant moving from an almost monocrop cotton operation to a multi crop farm, annually growing cotton, corn, soybeans and wheat in rotation. We have tried other crops, including canola,

peanuts, sorghum, sesame and barley as a way to increase the soil health benefits that come from additional crops in the rotation. It has also meant intensive soil testing and variable rate applications of inputs whenever possible, minimizing tillage and planting cover crops. We plant our cotton right in the residue from the cover crop because it provides a mulching effect to build organic matter, aids with erosion control and soil moisture infiltration during rains and moisture retention in the hot summers. We don’t have a lot of irrigation. Everything we implement ties back to sustainability, either environmental or economic. The Trust Protocol is a great step for the cotton industry to take to help farms have data to evaluate what we are doing in the fields and how our practices have improved or can improve further.

Q. What advice do you have for other women who are interested in careers in the cotton and agriculture industry?

Rachel: I’ve seen more women becoming involved in agriculture in the past few years, which is very encouraging to me. I urge women beginning to farm and women who own land to always be open-minded, take every opportunity to learn something new, ask questions and be willing to grow. It can be intimidating to enter a historically male-dominated industry, but I encourage women new to the field to take this feeling and use it as motivation to work harder and succeed. We can inspire other women to enter this field that is challenging but rewarding.

Jaclyn: While it can certainly feel uncomfortable being a minority in a male-dominated field, it feels good to see

that more women are getting involved in agriculture and in leadership positions in the industry. I also think it’s important to delegate work and thankfully I have a lot of support from my family and my coworkers As a mother, this is helpful because I can spend more time with my two children. I’m proud that they’re invested in our farm too, although I want them to do what makes them happy. I have a feeling that at least one of my children will come back to the family farm someday and I want to do all I can to prepare them to be successful.

Larkin: Women have always been involved in farming, often serving in families and companies in crucial roles, but often supporting roles. When I assumed responsibility for our farm in 1990, like it or not, I immediately became the principal. I did not have to work my way up a ladder in an organization. I just had to prove to the people watching, both inside and outside the farm, that I could get the job done. What I needed and was lucky to find were several good mentors/supporters/advisers who took the time to help me. Almost all of them were men, both on our farm and in the cotton industry. That would be my best advice to anyone. Look for and appreciate good mentors. I also think it was important that being female was not something I saw then or now as defining my ability to do the work or serve as a leader. Projecting that point of view probably allowed others to see the same thing. A good thing for anyone to remember as they build a career is that it is hard for others to imagine you in roles you do not project for yourself.

38 PAKISTAN TEXTILE JOURNAL - April 2023 Features

Rieter: COMPACTdrum – Outstanding efficiency with up to 26,000 RPM

Sri Jayajothi and Company Private Ltd., a quality yarn spinner from South India, produces cotton and synthetic yarns with a daily production capacity of 55 tons. Jayajothi invests in the latest technology to be able to produce at highest speed without compromising on quality. To help meet the growing market demand, the company opted for the Rieter ring spinning machine G 37 with the semi-electronic drafting system together with the compacting device COMPACTdrum.

The Rieter ring spinning machine G737 with the compacting device COMPACTdrum runs with excellent spinning stability and ensures highest productivity.

Jayajothi operates the machines at a maximum spindle speed of 26000 rpm producing a very fine yarn (Ne 60) from 100% cotton with 100 grams per spindle (GPS). This is far above the industry benchmark. The energy efficient components such as the 75 kW IE4 main motor, the LENA spindles and the optimized suction systems reduce the energy consumption by up to 7% compared to the previous model.

Best performance in downstream processes with COMPACTdrum

The compacting device COMPACTdrum reduces long protruding fibers of the yarn to an absolute minimum which increases the acceptance in downstream processing. This enables Jayajothi to supply highly demanding customers in the global market. The yarn produced with this Rieter solution achieves the best performance in downstream processes: virtually no other system can spin a yarn that reaches a value below 0.20 warping breaks per million meters. The durable technology components of COMPACTdrum ensure that the yarn quality remains consistently

high over the long term. In addition, the unique SERVOgrip system eliminates the need to underwind the yarn for doffing preparation. This reduces fiber fly and ensures high yarn quality.

K Gokul, Managing Director at Sri Jayajothi, summarizes: “We are very satisfied with the performance of the ring spinning machine G 37 with the compacting device COMPACTdrum. The machine runs at an exceptionally high spindle speed of 26000 rpm and produces consistently high yarn quality.”

Highest flexibility for constantly changing trends