Smart-Indigo™ makes the difference for the denim world. Offering a liquid-indigo production where the only waste product is oxygen! A revolutionary technology, which protects the environment, creates safer and healthier workplaces and offers a optimized production.

63rd DORNBIRN-GFC Call For Papers

Dates: September 11th to 13th 2024. Venue: Dornbirn Austria.

CAITME 2024

Dates: September 11th to 14th, 2024.

Venue: Tashkent, Uzbekistan.

Cinte Techtextil China

International Trade Fair for Technical Textiles and Nonwovens

Dates: September 19th 21st, 2024.

Venue: Shanghai New International Expo Centre, Shanghai, China

HVACR Trends 2024

Dates: October 04th to 5th, 2024. Venue: Karachi Marriott Hotel

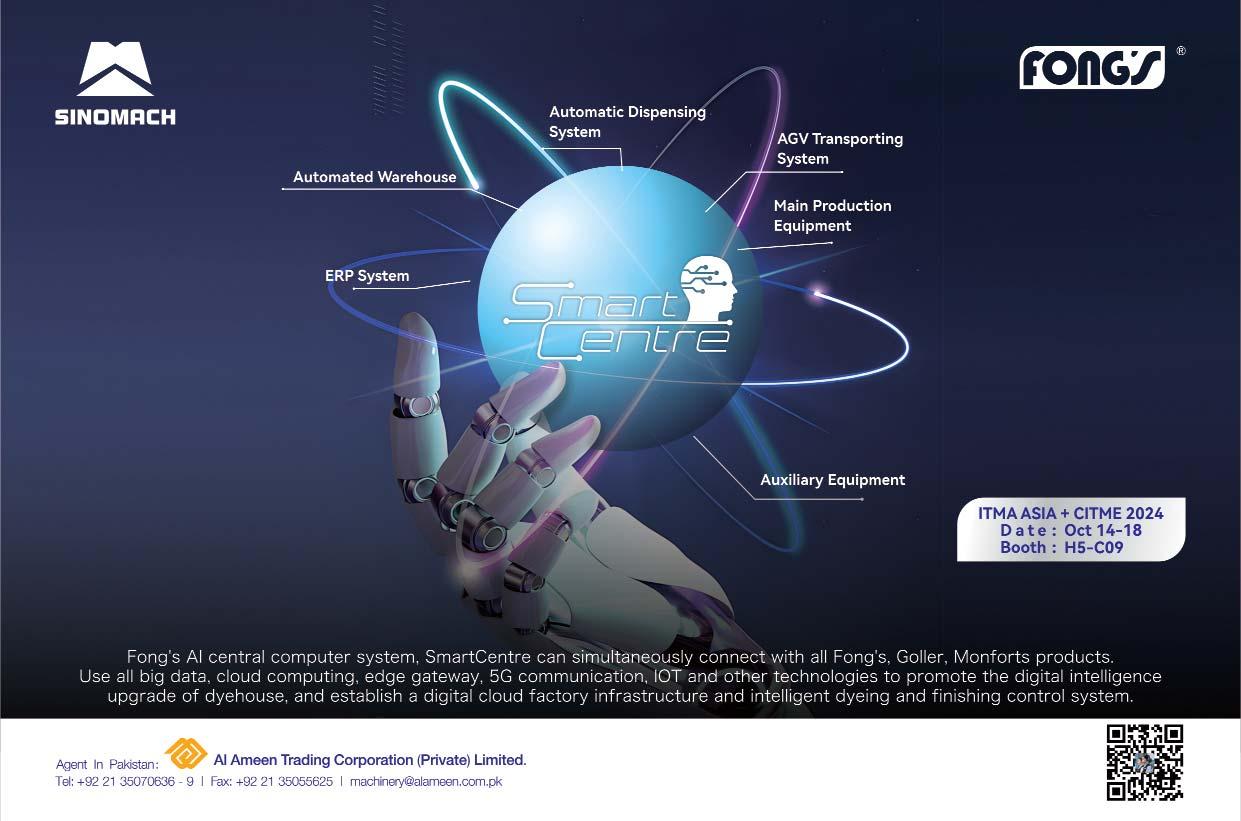

ITMA ASIA + CITME 2024

Dates: October 14th to 18th, 2024. Venue: NECC, Shanghai, China.

JIAM 2024 OSAKA

Dates: November 27th to 30th 2024. Venue: Osaka, Japan.

Heimtextil 2025, Frankfurt

Dates: January 14th, to 17th, 2025

Venue: Frankfurt am Main.

DOMOTEX Hannover 2025

Dates: January 16th to 19th 2025.

Venue: Hannover, Germany.

Istanbul Yarn Fair

Dates: February 13th to 15th, 2025.

Venue: Istanbul, Turkey.

Textile Asia 2025, Karachi

Dates: April 12th to 14th 2025. Venue: Expo Centre, Karachi.

Textile Asia 2024, Lahore

Dates: August 20th to 22nd 2024. Venue: Lahore Expo Centre.

IGATEX Pakistan 2025, Karachi

Dates: April 24th to 26th 2025. Venue: Expo Centre, Karachi.

iCADEX Pakistan 2025, Karachi

Dates: April 24th to 26th 2025. Venue: Expo Centre, Karachi.

FESPA 2025

Dates: May 06th to 09th 2025. Venue: Messe Berlin in Germany.

DOMOTEX asiaCHINAFLOOR 2025

Dates: May 26th to 28th 2025. Venue: NECC, Shanghai, China.

ITMA ASIA + CITME, Singapore 2025

Dates: October 28th to 31st, 2025. Venue: Expo Centre Singapore.

Techtextil 2026

Dates: April 21st to 24th, 2026

Venue: Frankfurt, Germany.

Index 2026

Dates: April 21st to 24th, 2026. Venue: Palexpo, Geneva, Switzerland.

ITMA 2027

Dates: September 16th to 22nd, 2027. Venue: Hanover, Germany.

PAKISTAN TEXTILE JOURNAL - September 2024

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher Nadeem Mazhar

Editor in Chief Amina Baqai

Associate Editor Nimrah Nadeem

Production Manager Mazhar Ali

Layout & Design

Noor M. Jaan

Website / Social Media

Minhaj Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA)

Dr. Zubair Bandukda PhD (Textiles), CText ATI

Engr. Naeem Ilyas Khanani

Editorial & Advertising Office

B-4, 2nd Floor, 64/21, M.A.C.H, Miran M. Shah Road, Karachi - Pakistan

Tel: +92-21-34311674-5

Fax: +92-21-34533616

Email: info@ptj.com.pk

URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, United Kingdom.

Registered no. 09141989

Tel: +44 792 2228 721

Available on Gale and Factiva affiliated international databases through Asianet Pakistan

Printed at: Color Plus Korangi, Karachi. Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi.

eVent Fabrics® prepares for a PFAS-free future, offers eVent BIO and eVent alpineST laminates .

ITMA: Living with blends and looking beyond the backyard

RE&UP wins ITMF Start-up Award 2024

Smart fibers and fabrics for cool and restful nights .

VDMA members participated in CAITME expo in Uzbekistan

.23

Archroma introduces Color Management+ to elevate color development and execution for more sustainable textiles and fashion

DyStar publishes integrated sustainability report for FY2023/24

From lab to label: The chemistry between production and catwalks is finally right .28

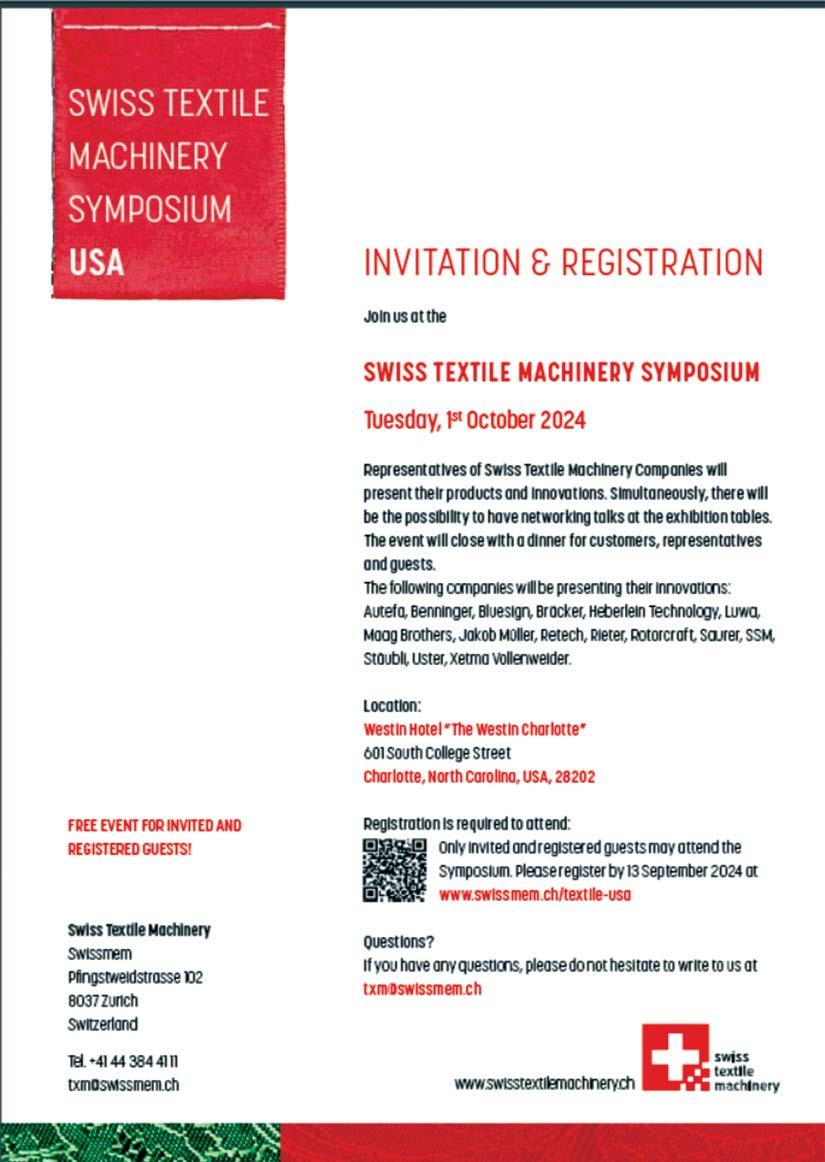

Swiss Textile Machinery Manufacturers on tour: Innovations to be presented at Symposium in Charlotte, N.C. .

“JIAM 2024 OSAKA” reveals promising signs for increasing number of exhibitors and size of exhibition space covered 6 months prior to the show .

.32

Yarn Expo Autumn facilitates global eco-transition with increased international participation and wider product offering

4th HVACR Trends Expo & Conference to be held on 4-5 October 2024 at the Karachi Marriott Hotel

Benninger’s FabricMaster revolutionizes textile dyeing in India

Discover Stäubli technical weaving solutions at techtextil North America

Biancalani Textile Machinery: Textile lovers fabric quality preservation

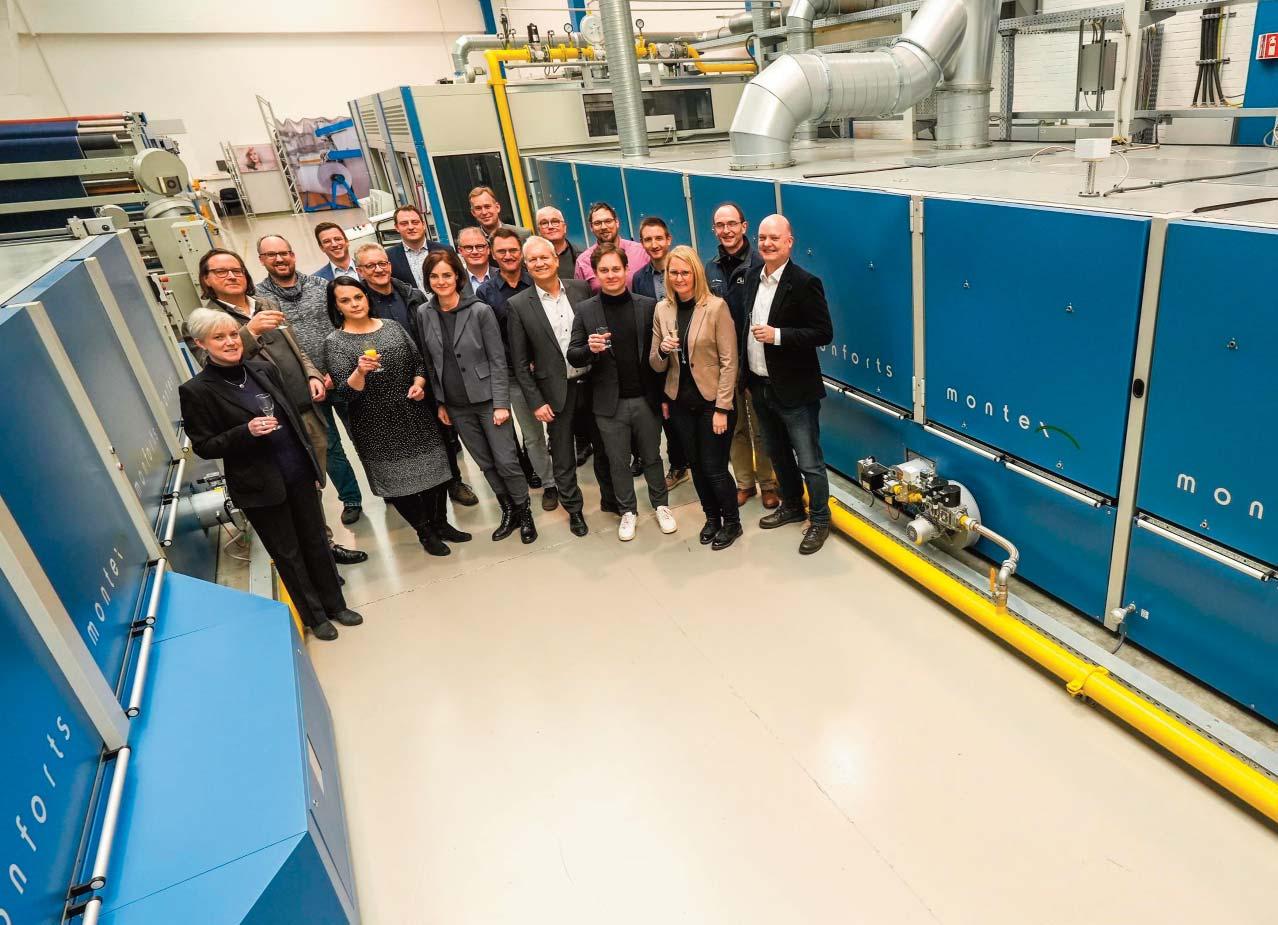

Monforts: Latest on hydrogen finishing at Dornbirn 2024

BRÜCKNER: Energy costs, security of supply and the future of EU textile industry .44

Trust protocol grower enrollment climbs for fifth straight year

Oerlikon Neumag: Automotive supplier Sailuda integrates backwards in BCF yarn production

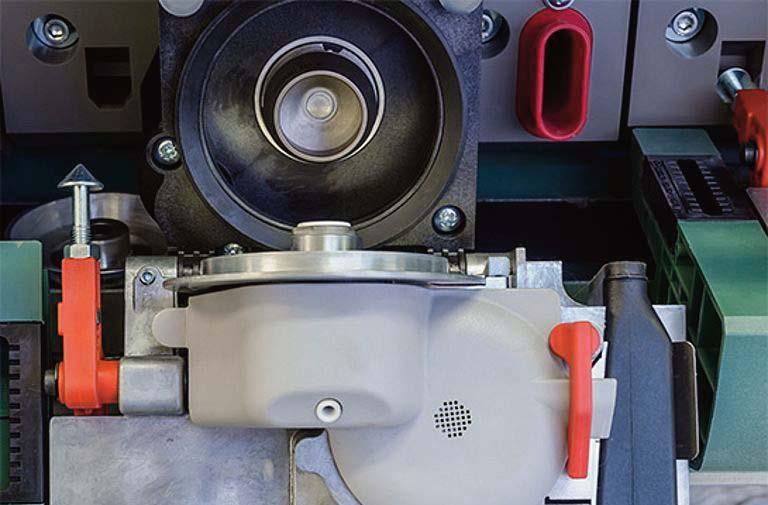

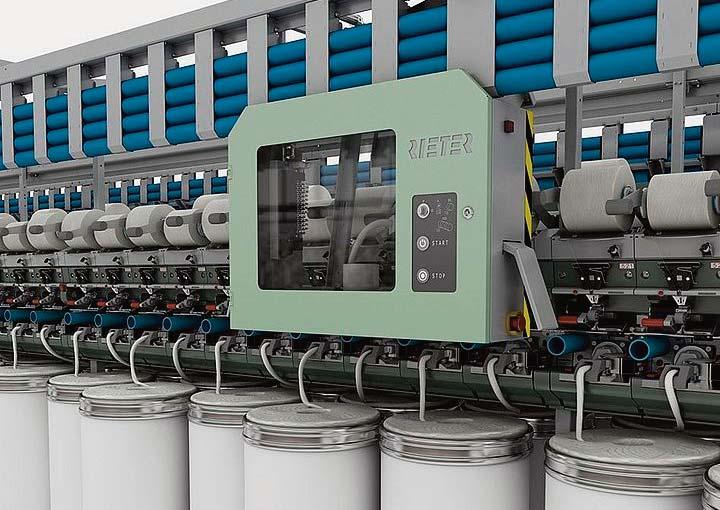

Rieter: Semi-automated rotor spinning machine R 37

Santoni announces Sao Paulo flagship store grand opening: A pivotal step of the global expansion

Trützschler’s IDF in India: Flexibility for the upcycling of textile waste

iTextiles® and LYCRA® envision innovative, creative thoughts at Create2Inspire

The 28th Textile Asia International Exhibition and Conferences 2024

Glimpses of Textile Asia 2024

Roadmap for a sustainable textile industry in Pakistan to capitalize true textiles export potential

By Engr. Naeem Khanani, Associate Editor, Pakistan Textile Journal; Director, Fahim, Nanji & deSouza FND Consulting Engineers; Co-Author: Engr. Najib Rehman, Associate FND Consulting Engineers

The evolving textile trade dynamics between Pakistan and China .

.61 by Nadeem Mazhar, Managing Editor, Pakistan Textile Journal.

48

The recent approval by the International Monetary Fund (IMF) of a $7 billion Extended Fund Facility (EFF) for Pakistan marks a pivotal moment for the nation’s economic landscape. While this decision aims to stabilize the country’s economy amidst mounting challenges, its repercussions will undoubtedly ripple through various sectors. Among them, the textile industry — a cornerstone of Pakistan's economy — stands to experience significant impacts, both positive and negative.

For decades, textile and apparel manufacturing has been the backbone of Pakistan's economy, accounting for approximately 60% of the country’s total exports and employing millions. However, the industry has faced a series of challenges, including escalating energy costs, outdated technology, and stiff international competition. The infusion of funds from the IMF presents a crucial opportunity for Pakistan to address these systemic issues.

The EFF program stipulates rigorous economic reforms, primarily targeting the fiscal deficit, exchange rate stabilization, and structural reforms. For the textile sector, this could mean increased investments in technology and innovation, as the government may be compelled to allocate resources towards modernizing textile plants and enhancing productivity. Such developments are essential if Pakistan aims to compete effectively in the global market, particularly amidst rising production costs in traditional manufacturing hubs.

Moreover, the IMF’s requirements for fiscal discipline could lead to a reevaluation of subsidies for the textile industry. Historically, these subsidies have helped manufacturers maintain competitiveness. However, should the government reduce or eliminate such financial support, textile producers may face more significant operational challenges. The impending pressure on margins could strain businesses that are already struggling with liquidity issues.

Meanwhile, the devaluation of the Pakistani Rupee, a likely scenario under the IMF's program, could provide a dual-edged advantage for the textile sector. While it may raise the cost of imported raw materials and machinery, it also makes Pakistani textiles more affordable in international markets, potentially boosting export sales. If leveraged correctly, Pakistan could enhance its market share, particularly in high-demand regions where competitive pricing is vital.

Additionally, the textile sector must prepare for a shifting global landscape. Consumers increasingly seek sustainable and ethically produced goods. This societal shift presents an opportunity for Pakistan’s textile industry to invest in sustainable practices, aligning with global trends while enhancing brand appeal. Funds from the IMF could help facilitate this transition, allowing for eco-friendly technologies and practices.

In conclusion, the IMF’s approval of the EFF program presents both challenges and opportunities for Pakistan’s textile industry. Stakeholders must remain vigilant in navigating these turbulent waters, embracing reforms while simultaneously investing in modernization and sustainability. By fostering resilience and adaptability, the textile sector can emerge stronger from the economic storm, safeguarding its vital role in Pakistan’s economy and reinforcing its position on the global stage.

As the implementation of the EFF program unfolds, the focus must remain not just on immediate financial stabilization but also on the long-term growth and competitiveness of one of Pakistan's most crucial industries.

1

The All-Pakistan Textile Mills Association (APTMA) has called on the federal government to renegotiate agreements with Independent Power Producers (IPPs) to lower exorbitant electricity tariffs. These high costs have severely impacted industrial operations and led to widespread job losses.

2

The Punjab government has embarked on a mission to enhance cotton plantation across the province. Provincial Minister of Agriculture, Syed Ashiq Hussain Kirmani, announced this initiative during a conference on cotton research and

development held at Agriculture House earlier this month. He emphasized that Chief Minister Punjab Maryam Nawaz is committed to reforming the research and development system to meet contemporary needs.

3

Pakistani entrepreneurs with investments in Bangladesh’s textile sector are increasingly worried about the recent turmoil and unrest in the country. The potential imposition of martial law in Bangladesh raises concerns about similar instability as seen in Pakistan, which could adversely affect their operations.

1

The Bangladesh Garment Manufacturers and Exporters Association (BGMEA) has called on ready-made garment (RMG) factory owners to ensure timely wage payments to workers in response to recent unrest in the sector. Protests by garment workers demanding better wages and improved working conditions have disrupted operations in several factories, escalating tensions within the industry.

2

Wage negotiations for Cambodia’s garment sector have commenced, bringing together government officials, labor unions, and industry employers to determine the minimum wage for 2025. This process is pivotal for the sector, which employs over 700,000 workers and is a

4

Textile and clothing exports in Pakistan saw a modest growth of just 0.93% in FY24, highlighting the challenges the sector faces in staying competitive with regional rivals. The implementation of stringent taxation measures during the current fiscal year appears to be a key factor hampering growth. The impact of soaring energy costs has also been significant, with export figures for June 2024 reflecting a 3.91% decline compared to the previous year, according to data released by the Pakistan Bureau of Statistics.

5

Pakistan's textile and leather industry has raised alarms over escalating electricity tariffs, unsustainable taxation, and a growing liquidity crunch, citing these as major obstacles to boosting exports.

6

In August 2024, Pakistan’s textile sector demonstrated a strong resurgence, with exports increasing by 13% to $1.64 billion compared to $1.45 billion in August 2023, according to the Pakistan Bureau of Statistics (PBS). Compared to July 2024, August's textile exports saw a notable 29.4% increase.

major contributor to Cambodia’s economy, generating substantial export revenue annually.

3

In the first seven months of 2024, China’s textile and garment exports exhibited a modest yet notable growth, reaching $186.25 billion. This represents a 1.1% year-onyear increase. Specifically, textile exports rose by 3.7% to $88.54 billion, while garment exports experienced a slight decline of 1.2%, totalling $97.71 billion.

4Germany’s economy has contracted by 0.3% in the second quarter of 2024, marking the second consecutive quarter of negative growth. This persistent downturn highlights the challenges facing Europe’s largest economy, including sluggish industrial performance, high

inflation, and weakened export demand.

5

An international textile exhibition is currently underway in Tehran, featuring over 290 domestic and foreign companies from 13 countries. The event, known as the Iran International Textile Industry Exhibition (IRANTEX), provides a platform for showcasing industry advancements, exploring investment opportunities, and discussing business and trade prospects.

6

South Korea has unveiled an extensive plan to elevate its textile and fashion sector with the launch of the Textile and Fashion Industry Competitiveness Strategy. This initiative aims to significantly enhance Korea’s global market share in industrial and eco-friendly textiles from the

current 2-3% to 10% by 2030, and to increase digital transformation levels from 35% to 60%.

7

In the first half of 2024, the United States saw a 3.17 percent drop in textile and clothing exports, totaling $11.5 billion. This decrease continues a trend that began in the first quarter and accelerated throughout 2023, reflecting ongoing challenges in the global market. Imports have also decreased, driven by persistent inflationary pressures.

8

In the first half of 2024, Uzbekistan’s textile exports totaled $1.5 billion across 55 countries, reflecting a 5.3% decrease compared to the same period last year, according to official data.

The All-Pakistan Textile Mills Association (APTMA) has called on the federal government to renegotiate agreements with Independent Power Producers (IPPs) to lower exorbitant electricity tariffs. These high costs have severely impacted industrial operations and led to widespread job losses.

In a statement earlier this month, APTMA Chairman highlighted the stark discrepancy between Pakistan’s installed generation capacity, which exceeds 40,000 MW, and its peak demand and transmission capacity, which is only 25,000 MW. This imbalance has resulted in significant excess and underutilized generation capacity. Despite this, the government is obligated to make Rs. 2 trillion in capacity payments to 40 IPP companies annually, even when no electricity is generated or supplied, placing a heavy economic burden on the country.

The Chairman emphasized that capacity charges make up two-thirds of the total cost, with fuel costs accounting for the remaining one-third.

Investigations have revealed that IPPs have been enjoying returns exceeding 73 percent in dollar terms, far higher than international standards. These unfavorable contractual arrangements, rooted in the 1994 Power Policy, have contributed to a spiraling circular debt, which reached Rs. 2.64 trillion in February 2024.

He also pointed out that guarantees indexed to the US dollar mean any depreciation of the Pakistani rupee increases returns for IPPs, further straining the government’s finances. Initially, the return on equity for IPPs was set at 18% and later reduced to 12% in the 2002 Power Policy, still high by global standards. Comparisons with similar projects in other countries suggest many IPPs were funded through inflated invoicing on capital goods, leading to perpetual returns on non-existent equity.

The Chairman noted that the tariff for coal-based plants in Pakistan is 9 cents, significantly higher than the 5.6 cents for similar plants in Bangladesh. For FY25, imported coal-based plants have the highest capacity charge of Rs. 60.48/kWh compared to Rs. 26.01/kWh for the second-highest capacity charge among all thermal generation.

He also mentioned frequent misreporting and overbilling by IPPs under take-or-pay contracts protected by international law. Actual oil consumption of several oil-based plants is reportedly less than billed, and attempts to audit discrepancies are often obstructed legally. Operation and maintenance costs are similarly overstated, with actual expenses billed at significantly higher rates.

The Chairman warned that the recent surge in electricity rates could lead to civil unrest and discontent among the business community. He stressed the need for a comprehensive review of IPP agreements, price re-evaluation within legal bounds, and improved oversight to prevent over-invoicing. He called for examining the energy infrastructure for clauses related to misinformation and fraud, urging the federal government to devise a strategy to address IPP issues and ensure affordable electricity prices for the industry in the national interest.

The Punjab government has embarked on a mission to enhance cotton plantations across the province. Provincial Minister of Agriculture, Syed Ashiq Hussain Kirmani, announced this initiative during a cotton research and development conference held at Syed Ashiq Hussain Kirmani, Punjab Agriculture Minister

Agriculture House earlier this month. He emphasized that Chief Minister Punjab Maryam Nawaz is committed to reforming the research and development system to meet contemporary needs.

Minister Kirmani highlighted the decline in cotton cultivation due to the unavailability of quality seeds, which has confined cotton farming primarily to South Punjab. He stressed the necessity for collaboration between the public and private sectors to rejuvenate cotton production, noting that reviving the silver fiber industry would significantly boost the national economy.

The program's primary goal is to leverage the expertise of both public and private sectors to produce high-quality cotton seeds. The Minister underscored the urgent need to discover climate-smart cotton varieties with high productivity to address current challenges.

Secretary Agriculture Punjab Iftikhar Ali Sahu acknowledged the persistent

issues faced by the cotton crop over the past decade. He called for practical proposals from both sectors to tackle these challenges and emphasized the importance of developing a comprehensive plan of action based on the conference's recommendations. He assured that the technical opinions of all participants would be thoroughly considered.

Pakistani entrepreneurs with investments in Bangladesh’s textile sector are increasingly worried about the recent turmoil and unrest in the country. The potential imposition of martial law in Bangladesh raises concerns about similar instability as seen in Pakistan, which could adversely affect their operations.

Secretary Sahu also mentioned that the provincial government would seek support from the federal government to address issues requiring federal intervention.

The conference saw participation from notable figures, including Agriculture Secretary South Punjab Saqib Ali Attil, Dr. Muhammad Anjum Ali, former caretaker federal minister Kausar Abdullah Malik, Director Generals Agriculture Extension Chaudhry Abdul Hameed, Javed Salim Qureshi, Dr. Khalid Hameed, Asif Majeed, Saad Akbar Khan, Syed Hasan Raza, Dr. Sagheer Ahmed, along with other government officials and representatives from the private sector.

In recent years, several Pakistani textile entrepreneurs relocated their operations to Bangladesh, driven by factors such as lower production costs, preferential trade agreements, and improved infrastructure. Bangladesh, currently the world’s second-largest apparel exporter after China, has been making significant inroads into markets traditionally dominated by China, which faces sanctions from Western nations. Many of these entrepreneurs established their operations in Bangladesh’s special export processing zones, where they have benefited from a cost-effective production environment.

Notable Pakistani textile firms that have moved or expanded their operations to Bangladesh include Soorty Enterprises, which invested $35 million to establish a garment factory employing around 6,000 Bangladeshis. Other major names include Interloop Limited, Pak Denim Limited, Crescent Textile Mills, Gul Ahmed Textile Mills, Kohinoor Textile Mills, Al-Karam Textile Mills, Nishat Mills Limited, Artistic Milliners, and Masood Textile Mills.

The decision to relocate was influenced by Bangladesh’s strategic advantages, including lower labor costs and favorable trade agreements with the European Union and the United States. These agreements provide Bangladesh with better market access and lower tariffs compared to Pakistan. Despite Pakistan’s GSP+ status from the European Union since 2013, Bangladesh’s incentives have made it an attractive destination for Pakistani textile firms seeking to maximize profits and expand market reach.

Balwani, a textile industry leader, shared concerns about the reception of Pakistani firms in Bangladesh under the long tenure of Prime Minister Hasina Wajid, whose policies were perceived as pro-India. With the recent political upheaval, there is hope that a new military government may respect antiIndian sentiments, potentially fostering a more welcoming environment for Pakistani investors.

MI Khurram, a leading exporter of knitwear and yarn, noted that the high costs of power and energy in Pakistan make it challenging for textile mills to operate domestically. He suggested that if relations between Pakistan and Bangladesh improve post-military takeover, many mills might prefer to relocate their operations to Bangladesh.

Historically, smaller Pakistani textile units relocated to Bangladesh around 15 years ago but faced challenges due to unfavorable public opinion and government policies that favored Indian interests. Larger enterprises, however, have invested in export processing zones with better planning. Despite this, the cumulative investment of Pakistani textile entrepreneurs remains significantly lower than that of Bangladesh’s top local textile groups.

Textile and clothing exports in Pakistan saw a modest growth of just 0.93% in FY24, highlighting the challenges the sector faces in staying competitive with regional rivals. The implementation of stringent taxation measures during the current fiscal year appears to be a key factor hampering growth.

The impact of soaring energy costs has also been significant, with export figures for June 2024 reflecting a 3.91% decline compared to the previous year, according to data released by the Pakistan Bureau of Statistics.

Gohar Ejaz, a former commerce minister, expressed concerns over the stagnant state of textile and clothing exports, despite the sector having a $25 billion installed capacity. He pointed out that export levels have remained unchanged over the past two years, underscoring the need for government intervention. According to Ejaz, offering competitive energy rates, tax incentives, and timely sales tax refunds are essential steps to boost the country's export performance.

The outlook for 2024-25 remains uncertain, with further taxation measures potentially impacting the sector's performance. In absolute terms, textile and clothing exports reached $16.55 billion in FY24, slightly up from $16.50 billion in the previous year.

In June alone, export proceeds dropped to $1.41 billion, a decrease of 3.91% from $1.47 billion in the same

month last year. On a month-to-month basis, exports fell by 9.23%.

The government's decision to increase the tax rate on exporters' personal income in 2024-25 may further strain the sector, with the full impact of these measures likely to become apparent in the coming months.

The PBS data also revealed mixed performance across different product categories. Exports of readymade garments increased by 2.05% in value and 1.99% in quantity in FY24, while knitwear saw a slight decline of 0.66% in value but a significant 41.44% increase in quantity. Bedwear exports grew by 4.12% in value and 15.27% in quantity, and towel exports rose by 5.55% in value and 14% in quantity. However, cotton cloth exports fell by 7.72% in value despite a 16.15% rise in quantity.

Additionally, the import of textile machinery plummeted by 54.52% in FY24, indicating that expansion or modernization efforts are not currently a priority for the industry.

Pakistan's textile and leather industry has raised alarms over escalating electricity tariffs, unsustainable taxation, and a growing liquidity crunch, citing these as major obstacles to boosting exports.

In a virtual meeting held earlier with Commerce Minister Jam Kamal Khan and his team, representatives from the textile

sector voiced their concerns. The meeting included members of the Council for Apparel, Made-ups, and Technical Textiles, as well as other councils representing Textile Fibers, Yarns, and Fabrics, with a shared focus on critical issues plaguing this key economic sector.

Industry representatives highlighted a range of challenges, including high energy costs, complex taxation policies, liquidity shortages, and difficulties related to Statutory Regulatory Orders (SROs). They also pointed to the limited availability of export financing and high borrowing costs as barriers to maintaining export momentum. The participants urged the government to address these concerns urgently, stressing the importance of removing these obstacles to keep the sector competitive on a global scale.

The discussions also emphasized the need for supporting small and medium enterprises (SMEs) and establishing new plug-and-play garment cities, which are seen as vital for the industry's growth.

Council members stressed that Pakistan has a unique opportunity to capture a larger share of the international market, especially given the current geopolitical climate. They called on the government to implement policies that would enhance the country's valueadded textile exports.

Commerce Minister Jam Kamal acknowledged the industry's concerns, emphasizing the need to streamline the sector to enhance global competitiveness and boost exports. He recognized Pakistan's status as one of the few countries with a complete textile and apparel value chain, underscoring the sector's contribution to the country's socioeconomic development.

The minister assured the council members that their issues would be brought to the attention of the highest levels of government. He also committed to reviewing the recommendations from the 16 sectoral councils, highlighting the importance of private sector representation in these discussions.

"The prime minister is continuously exploring ways to facilitate exporters and increase trade volume," said the minister. He praised the private sector's input, noting that it would play a crucial role in shaping future policies. The

recommendations from these meetings will be compiled and presented to the National Export Development Board (NEDB) for final consideration by the prime minister.

In a related development, Jam Kamal Khan also met with the Pakistan Leather and Footwear Council, marking the first time a federal minister has actively engaged with this sector's council. He encouraged the council and the other 15 sectoral councils to submit their proposals and recommendations, which will be reviewed by the National Export Development Fund, chaired by the Prime Minister, for consideration and approval.

Surge by 13% in August 2024

In August 2024, Pakistan’s textile sector demonstrated a strong resurgence, with exports increasing by 13% to $1.64 billion compared to $1.45 billion in August 2023, according to the Pakistan Bureau of Statistics (PBS). This marked the first rise in three months, following export declines in June and July. Compared to July 2024, August's textile exports saw a notable 29.4% increase.

Within the sector, ready-made garments were the standout category, recording an impressive 28% growth. Other major textile components also saw growth: cotton cloth exports increased by 14% to $182.5 million, knitwear by 15.4% to $462.9 million, bedwear by 15.2% to $290.45 million, and towels by 15.7% to $100.67 million. Ready-made garment exports also climbed by 27.8%, reaching $363 million compared to the previous year.

However, there was a notable decline in exports of unfinished products like cotton yarn and raw cotton, signalling a strategic shift within the industry. Cotton yarn exports fell by 47.7%, down to $54.8 million, while raw cotton exports dropped to zero, indicating a growing focus on using these materials domestically to produce higher-value finished products.

For the fiscal year 2023-24 (JulyJune), total textile exports posted a modest 0.9% year-on-year increase, reaching $16.65 billion. This highlights the resilience of Pakistan's textile sector despite earlier challenges.

The Bangladesh Garment Manufacturers and Exporters Association (BGMEA) has called on ready-made garment (RMG) factory owners to ensure timely wage payments to workers in response to recent unrest in the sector. Protests by garment workers demanding better wages and improved working conditions have disrupted operations in several factories, escalating tensions within the industry.

BGMEA President Faruque Hassan stressed the critical role of the garment sector in Bangladesh’s economy, which employs over 4 million workers and contributes more than 80% to the country’s export earnings. Hassan highlighted those delays in wage payments not only breach labor laws but also exacerbate worker dissatisfaction, potentially damaging the global reputation of Bangladesh’s garment industry.

The BGMEA has urged factory owners to comply with labor rights and enhance communication with workers to address grievances effectively. Timely and fair compensation is crucial for maintaining a motivated and productive workforce, especially as international scrutiny over labor practices intensifies.

To support factory owners, BGMEA has suggested discussions with the government to explore financial

assistance or policy adjustments to alleviate the financial pressures on factories facing rising production costs and fluctuating global demand.

This appeal underscores the need for a unified effort from all stakeholders to protect worker welfare and sustain the growth of Bangladesh’s RMG sector in a highly competitive global market.

Wage negotiations for Cambodia’s garment sector have commenced, bringing together government officials,

labor unions, and industry employers to determine the minimum wage for 2025. This process is pivotal for the sector, which employs over 700,000 workers and is a major contributor to Cambodia’s economy, generating substantial export revenue annually.

The discussions come in response to increasing living costs and worker demands for higher wages. Currently, the minimum wage for garment workers is set at $200 per month, following a $6 increase in 2024. Labor unions are advocating for a more substantial wage increase, citing inflation and the need to improve living standards as key factors. They argue that the current wage is insufficient to meet the rising costs of food, housing, and healthcare.

Conversely, garment manufacturers and industry representatives express concerns about the impact of significant wage increases on their competitiveness. They highlight challenges such as fluctuating global demand, rising raw material costs, and the importance of maintaining Cambodia’s status as a lowcost manufacturing hub. Employers are calling for a balanced approach that considers both the industry’s financial health and workers’ needs.

The government is working to mediate between these competing interests, aiming to find a consensus that addresses both worker demands and industry sustainability. The outcome of these negotiations will be closely monitored, as it will influence labor relations and economic stability in Cambodia’s garment sector. A final decision is anticipated by the end of the

year, with any changes set to take effect in January 2025.

In the first seven months of 2024, China’s textile and garment exports exhibited a modest yet notable growth, reaching $186.25 billion. This represents a 1.1% year-on-year increase. Specifically, textile exports rose by 3.7% to $88.54 billion, while garment exports experienced a slight decline of 1.2%, totalling $97.71 billion.

This growth occurs despite facing global challenges such as inflation, geopolitical tensions, and a slowdown in demand from key markets. The data underscores the resilience of China's textile sector, which remains a crucial component of the country's trade portfolio. The decline in garment exports may reflect changing global consumption patterns and intensified competition from other manufacturing regions.

China’s textile and garment industry continues to be a vital player in the global supply chain, though it is under increasing pressure to adapt to evolving market dynamics and sustainability demands. The increase in textile exports suggests persistent global demand for Chinese textiles, driven by the need for raw materials and semi-finished goods. As the industry navigates these challenges, its ability to sustain even

modest growth highlights its strategic importance to China’s overall economic performance.

These figures also point to the necessity for the industry to innovate and diversify to maintain its competitive edge in a complex and shifting global market.

Germany’s economy has contracted by 0.3% in the second quarter of 2024, marking the second consecutive quarter of negative growth. This persistent downturn highlights the challenges facing Europe’s largest economy, including sluggish industrial performance, high inflation, and weakened export demand.

The GDP decline is primarily due to a slowdown in the manufacturing sector, adversely affected by rising energy costs and ongoing supply chain disruptions. Key industries such as automotive and machinery have reported reduced production outputs, with industrial orders falling by 1.7% from the previous quarter. Additionally, global economic uncertainties and tightening monetary policies have further strained exportdependent sectors, diminishing Germany’s competitiveness internationally.

Consumer spending, a vital component of the economy, has remained subdued. Persistent inflation has eroded household purchasing power, leading to cautious spending despite a slight decrease in inflation rates compared to earlier in the year. The cost of living continues to be a significant concern for German consumers.

The construction sector has also experienced a slowdown, contracting by 2.5% due to higher interest rates and increased material costs, leading to a reduction in investment in construction and infrastructure projects.

Economic analysts caution that Germany may face a prolonged period of stagnation if these trends persist. There are calls for the German government to implement supportive fiscal measures, such as investment incentives and relief for energy-intensive industries, to stimulate economic activity and prevent a deeper recession in the upcoming quarters.

An international textile exhibition is currently underway in Tehran, featuring over 290 domestic and foreign companies from 13 countries. The event, known as the Iran International Textile Industry Exhibition (IRANTEX), provides a platform for showcasing industry advancements, exploring investment opportunities, and discussing business and trade prospects.

Among the exhibitors, 170 are from Iran, and 120 represent international entities from countries including Germany, Italy, Taiwan, Uzbekistan, Tajikistan, South Korea, Turkey, Pakistan, Austria, Switzerland, India, Japan, and China. Notably, three of the world's top textile and apparel exporting nations— China, India, and Turkey—are

prominently featured, with 100, 18, and 12 companies respectively participating.

Iran’s textile industry benefits from several inherent advantages, including easy access to raw materials. The country produces 50 percent of its cotton domestically, a significant decrease from full self-sufficiency two decades ago. Additionally, Iran supplies over 50 percent of its silk needs from local production, with potential for complete selfsufficiency through targeted support and planning.

The nation’s abundant oil and gas resources bolster its production of synthetic fibers, further strengthening the textile sector. Iran’s domestic market, with a population of 85 million and a turnover of $30 billion, serves as a key driver for the industry. The neighboring Central Asia and Caucasus region, with a combined population of 400 million, also represents a significant market opportunity.

Iran’s textile history spans at least 10,000 years, with its ancient Persian textiles and carpets renowned for their intricate designs and vibrant colors.

However, over the past three decades, the industry has struggled, with its contribution to the country’s GDP dropping from 6.4 percent to under 1 percent, largely due to the influx of imported goods, both legal and illegal.

South Korea has unveiled an extensive plan to elevate its textile and fashion sector with the launch of the Textile and Fashion Industry Competitiveness Strategy. This initiative aims to significantly enhance Korea’s global market share in industrial and ecofriendly textiles from the current 2-3% to 10% by 2030, and to increase digital transformation levels from 35% to 60%.

The strategy emphasizes technological advancements in highperformance materials such as aramids, carbon fibers, and electronic textiles. To support this, a substantial fund of KRW 2.9 trillion will be allocated to assist companies in integrating industrial textiles into their products. The plan also includes the establishment of an Industrial Textile Alliance and a Tech Textile Product Certification Evaluation Support Center.

Addressing environmental sustainability, the strategy involves an investment of 31 billion in initiatives like fiber-to-fiber recycling, plant-based vegan leather, and biodegradable fibers. Over 200 SMEs will benefit from waste heat recovery facilities, and new carbon emissions standards along with ecodesign guidelines will be implemented.

In terms of digital transformation, the strategy sets ambitious goals including reducing product design times by over 80% and developing a Connected Micro Factory for agile production. Automation facilities will be provided to more than 250 companies by 2028, and the expansion of Meta Fashion Playgrounds is also on the agenda. Furthermore, the plan includes training 1,000 professionals in eco-friendly and digital technologies by 2028 and pursuing global sustainability certifications.

In the first half of 2024, the United States saw a 3.17 percent drop in textile and clothing exports, totaling $11.5 billion. This decrease continues a trend that began in the first quarter and accelerated throughout 2023, reflecting ongoing challenges in the global market. Imports have also decreased, driven by persistent inflationary pressures.

Mexico and Canada remain the leading destinations for American textile and clothing exports, purchasing $6.1 billion and $4.2 billion worth of goods, respectively. The European Union, however, faced a significant 11.2 percent drop in apparel consumption, with orders totaling $1.2 billion, as inflation continued to affect its market.

Other notable markets include Honduras and China, each maintaining a steady order volume of $361 million. These figures place them ahead of the Dominican Republic, the UK, and Japan in terms of market size.

On the import side, the US experienced a 3.58 percent decline in textile and apparel imports, totaling $49.3 billion during the first half of the year. This contraction, largely attributed to inflation, has raised concerns among consumers and brands, despite signs of a slowdown since July. China remains the largest supplier with $11.1 billion worth of goods, followed by Vietnam ($7.2 billion), India ($4.7 billion), and Bangladesh ($3.5 billion), which saw a 10.6 percent decline.

The European Union ranks fifth among suppliers with $2.8 billion in imports, reflecting a 2.9 percent drop. It is followed by Indonesia, Mexico, Cambodia, and Pakistan.

These developments are set against the backdrop of a 22 percent decline in US garment imports observed in 2023, which somewhat excluded European luxury products. Additionally, rising freight prices are affecting trade levels. Lower water levels in the Panama Canal have increased transportation costs and transit times between Asia and the American East Coast, while security concerns around the Suez Canal have further driven up container rates.

In the first half of 2024, Uzbekistan’s textile exports totaled $1.5 billion across 55 countries, reflecting a 5.3% decrease compared to the same period last year, according to official data. The export portfolio primarily included finished products, which made up 38.1% of the total, and yarn, which accounted for 46.2%.

Yarn exports notably rose to $708.6 million, up from $658 million in the previous year. However, the value of finished textile products fell to $584 million, down from $662.6 million in 2023. Exports of knitted fabrics decreased to $114.1 million from $173.9 million, while fabric exports declined to $75.1 million from $92.2 million. Sock exports also saw a reduction, totaling $20.5

million compared to $31.4 million last year, as reported by domestic media.

While the overall export figures reflect a downturn, the increase in yarn exports signifies a bright spot in Uzbekistan’s textile industry, pointing to a sector with ongoing potential for growth.

Vietnamese textile exporters are facing severe financial strain as shipping costs for their goods have surged by up to 20%. This significant increase in shipping expenses is severely impacting profit margins, with reports indicating a reduction of up to 30% in profitability across the industry.

The sharp rise in shipping costs is not only eroding profits but also leading to a noticeable drop in new order volumes. Some exporters have experienced a decline of up to 15% in the number of new orders, exacerbating the financial pressures on the sector.

In response to these challenges, some companies are exploring alternative shipping routes and negotiating with logistics providers to secure better rates. Despite these efforts, the rising shipping costs present a formidable obstacle for the Vietnamese textile industry, which is heavily dependent on exports.

This situation highlights the growing financial pressures faced by exporters as they navigate an increasingly volatile global shipping environment, striving to maintain their competitive position in the international market.

eVent Fabrics® prepares for a PFASfree future, offers eVent BIO and eVent

With pending legislation and changing consumer sentiment, eVent is positioned to deliver performance without PFAS “forever chemicals”

eVent Fabrics, a global leader in waterproof and breathable technologies, is looking to the future and offering their partner brands eVent BIO and eVent alpineST technologies. Both are made without PFAS and are compliant with regulations requiring the removal of PFAS chemicals from many consumer products.

As the European Union and a growing list of US states phase out PFAS, eVent is uniquely positioned to offer a high level of breathable waterproof performance that will comply with new regulations.

“We look at sustainability as a journey, more than a destination,” said Chad Kelly, President of eVent Fabrics. “We continuously pursue the most sustainable options possible while ensuring our laminate fabric technologies deliver the high level of performance our customers demand. We are proud to report that eVent BIO and alpineSTboth made without the use of PFASaccomplish exactly that.”

PFAS-compliant eVent BIO and alpineST both provide long-lasting solutions for demanding apparel, footwear, and accessory applications.

eVent BIO is a bio-based membrane technology that uses sustainable materials to provide the all-weather protection and performance users have come to expect from eVent fabrics. At the

laminate technology’s core are highly renewable plant-based and biomass elements paired with smartly-sourced or recycled face and backer fabrics. Light, tough and flexible, eVent BIO has a reduced carbon footprint and is recyclable when it reaches the end of its lifecycle.

alpineST is a sustainable alternative to ePTFE products that provides first-rate waterproofness, breathability, and protection in the harshest environments. Created with the planet in mind, alpineST products are built around a fluorine-free membrane laminated to recycled face fabrics. With an initial waterproofness of 25K, alpineST maintains a water column of 20K after dozens of washes.

eVent Fabrics offers a full range of PFAS-free laminate options for apparel,

footwear and accessories to help ensure trusted performance in the field and compatibility with global textile recycling standards. All laminate materials are smartly sourced and feature a C0 DWR finish.

eVent® Fabrics, founded in 1999, revolutionized the industry with the first air-permeable 100% waterproof membrane and continues to innovate with sustainable, high-performance textiles. The company is globally recognized for its breathable waterproof solutions and commitment to reliable, high-performance laminates. Trusted by leading brands, eVent® Fabrics sets the standard for performance and sustainability in outerwear, footwear, and accessories.

Despite the many difficulties of sorting and recycling of post-consumer waste textiles, fibre blends are an indispensable facet of today’s market, and their use may actually increase going forward.

This was one of the key takeaways from the ITMAconnect Sustainability and Circularity webinar of the Innovator Xchange Virtual Edition series. The webinar was chaired by Karla Magruder, founder and president of Accelerating Circularity, the organisation working with multiple companies to drive forward the industry’s transition to textile-to-textile circular systems.

That blends don’t cause difficulties in recycling was disputed by Annabelle Hutter, managing director of Säntis Textiles. She said that they caused significant problems on her company’s proprietary RCO 100 system for the production of high-quality recycled cotton and questioned whether they need to be used to the extent that they currently are.

“In fashion, complex blends can sometimes be unnecessary, and we are working extensively with designers to make them aware of the problems they

cause,” she said. “Often blends can be avoided and it’s about making conscious decisions at the design stage.”

Alan Hudd, founder and CEO at digital dyeing company Alchemie Technology said recyclers and dyeing and finishing companies faced similar difficulties.

“Blends certainly make things more complicated for us too,” he said. “All parameters have a big impact on the quality of coloration and the devil is in the detail. Variability is huge in terms of physical and chemical properties in dyeing, and these properties are changed again in recycled fibres. There is in any case, no such thing as a single polyester and the dye properties change from one fibre to another.”

Jean-Francois Gryspeert, sales and business developer for Belgian sorting and baling technology specialist Valvan, observed that for the textile waste sorter, blends extended to accessories such as buttons, zippers, pocket linings and stitching, which all have to be separated from mixed bales of waste, but working out the percentage of polycotton with NIR (near infrared) technology was relatively easy.

Valvan is currently involved in a major project in the Prato region of Italy

involving a supply chain-wide push to establish circular textile manufacturing.

In defence of blends, Toby Moss, business development director at Worn Again Technologies, representing EuRIC, the largest industry association of waste and recycling companies in the EU, compared restricting manufacturers to single fibres to asking the art world to only use the colour blue.

“Blends provide a fantastic complexity and wide functionality that we wouldn’t have with a single fibre, or a single dye or finish,” he said. “Today there are seventeen different fibres used in making clothing, some of them natural, but most synthetic, and the synthetics are growing in popularity because they can provide both cost efficiency and functional properties that natural fibres can’t.

“We should be very cautious about saying that the fibres we’ve got today are the best ones or that any single one of them should be chosen to be used exclusively for making clothing. That could send us down a relatively dangerous path in terms of both sustainability and the cost of clothing, which is really important, especially for people in the developing world.”

He cited the example of the workwear industry’s reliance on polycotton blends which are crucial in providing a range of necessary functions with the durability and cost efficiency that pure cotton or pure polyester can’t.

“We need to live with the fact that these blends are going to be with us and get even more complex,” Moss said. “Our job as recycling innovators is to create better solutions so that we can deal with that complexity. At Worn Again our core technologies are about polycotton recycling, but we’re not stopping there. ”

Price levelling

In looking at the broader picture, Jean-Francois Gryspeert observed that the European Union’s ban on the landfilling or incineration of textile waste from January 2025 will oblige the major brands to put their waste feedstocks on the market and this should go some way to levelling up the price difference between virgin and recycled fibres.

“There is so much additional processing involved in recycling fibres which means they are currently much more expensive than either virgin cotton or synthetics, which both have longestablished and cost maximised manufacturing chains,” he said. “The introduction of the extended producer responsibility (EPR) scheme by the EU will introduce fees to help organise the

structure for economical recycling and lower its processing costs as the European recycling industry scales up to meet these new regulatory measures.”

Encouraging legislation

Alan Hudd welcomed the upcoming EU legislation but said that when European governments talked about getting to net zero they were often only looking at their own countries and in this respect were adopting something of a NIMBY – Not In My Backyard – attitude to the problems created by the globalised textile industry.

“We would encourage legislation, and more of it, and especially to stop or to tax the products that we are importing

that are causing a lot of pollution somewhere else in the world,” he said. “But bringing about the changes necessary to become a cleantech industry has to be supported by serious investment. We need to be investing US$20 billion every year for the next ten years and that investment needs to be coming from both brands and governments. Realistically, it needs governments to come together because the only way this can really be done is on a global stage with global policies.”

A recording of the webinar is available on ITMAconnect on-demand for subscribers. If you are not a subscriber, register for an ITMAconnect visitor account now for just Euro 25 (plus applicable VAT).

The circulartech company reshaping the traditional textile-to-textile paradigm brings home its first accolade.

RE&UP Recycling Technologies, a leading innovator in scalable recycling solutions for Next-Gen fibers, proudly announced its recognition as one of the winners of the prestigious ITMF Startup Award 2024. This esteemed accolade highlights RE&UP's commitment to advancing more sustainable practices in the textile industry through groundbreaking recycling technologies.

The ITMF Start-up Award, presented annually by the International Textile Manufacturers Federation (ITMF), aims to honor start-ups that showcase innovative and transformative ideas poised to make a significant impact on the textile sector. This year’s award ceremony was held during the ITMF & IAF Conference 2024 from September 8-10 in Samarkand, Uzbekistan, co-hosted by the Uzbek Textile & Apparel Industry Association (UZTS).

"We are incredibly honored to be recognized by the ITMF with this award," said Andreas Dorner, General Manager of RE&UP. "Our mission is to revolutionize

the textile-to-textile recycling paradigm by making it more efficient, scalable, and accessible. This award validates our efforts and commitment to the cause and the industry.”

As one of the four winners of the ITMF Start-up Award 2024, along with Sci-Lume Labs, Sycoretec CAS, Syre Impact, RE&UP received the opportunity to present its business model and technological advancements at the conference, where leaders from across the global textile value chain gathered. This platform enabled RE&UP to connect with established companies and explore collaborative opportunities to further integrate sustainable practices in textile manufacturing.

RE&UP is the circulartech company reshaping the traditional textile-to-textile paradigm. By producing Next-Gen Cotton and Next-Gen Polyester that maintain the same performance as virgin fibers, it brings sustainable solutions to

life, addressing the planet's most pressing challenges. Enriched by SANKO’s centenary knowledge in textile innovation, RE&UP creates a seamless circular ecosystem that transforms endof-life textile waste into high-quality raw materials at scale: a commitment to opening up a more responsible and technologically evolved future for textiles and fashion.

Sleep is essential for our well-being, yet temperature fluctuations often disrupt our ability to fall and stay asleep, leading to restless nights. The solution? Outlast's temperature-regulating bedding fabrics and fibers. These advanced materials minimize heat peaks, ensuring you stay comfortable and maintain a stable microclimate all night long.

Outlast® Thermo-Technology was originally developed by NASA to protect astronauts from the extreme temperature fluctuations in outer space. Recognizing its potential, the founders of Outlast have dedicated themselves to making this innovative technology accessible for a variety of uses, including clothing, seating, medical equipment, footwear, safety and bedding. With a wide range of products, Outlast allows you to integrate this advanced technology into nearly any textile, significantly enhancing comfort and well-being.

The Heart of Outlast® ThermoTechnology: Microencapsulated Wax

At the core of all Outlast® ThermoTechnology products is micro encapsulated wax, typi-cally derived from rapeseed oil. This natural wax can change

its physical state—melting when warm and solidifying when cold—enabling temperature regulation in fabrics and fibers. It reacts to environmental or body temperature changes proactively, preventing you from starting to sweat. During these state changes, the temperature stabilizes, as thermal energy is absorbed or released to melt or solidify the wax. This process maintains the body's microclimate, keeping the user comfortable and within their thermal comfort zone.

Using products with Outlast® Thermo-Technology while sleeping helps maintain a stable micro-climate, reducing both heat peaks and freezing. Laboratory tests prove that this technology can reduce sweat production by up to 48%* and extend periods of deep sleep. It

Martin Bentz, CEO of Outlast®

creates an improved sleep setting and helps put an end to restless nights. People who suffer from sleep disorders can greatly benefit from temperatureregulating products, but everyone can use them to improve their quality of sleep. Help your customers sleep better by offering bedding fabrics and fibers from Outlast, providing additional value and functionality.

CEO Martin Bentz has been running the company successfully for over 20 years and remains enthusiastic about the technology: "I love the 'wow' effect when customers experi-ence Outlast® Thermo-Technology for the first time. The technology really speaks for itself, and we hardly have to do any convincing anymore."

Would you like to experience Outlast® Thermo-Technology firsthand? Visit booth no. S475 at the SLEEP Expo Middle East in Dubai and meet the team. Enhance your product offerings with superior performance by incorporating Outlast® Thermo-Technology!

CAITME, which took place from 11 to 14 September in Tashkent, Uzbekistan, saw a strong participation of VDMA member companies. About 25 VDMA members took part in the event. Among the numerous VDMA companies present at the trade fair with their own booth or through agents, 13 companies exhibited in the area of the official German Pavilion, organised by the German Federal Ministry for Economic Affairs and Climate Action and initiated by VDMA: Brückner Textile Technologies, Erbatech, Georg Sahm, Groz-Beckert, Heusch, KARL MAYER STOLL Textilmaschinenfabrik, KURIS Spezialmaschinen, Lindauer DORNIER, Oerlikon Textile, Stäubli Bayreuth, STC Spinnzwirn, THIES, Xetma Vollenweider.

At CAITME, VDMA member companies showcased the most advanced technology for the textile sector. The exhibiting companies were at the forefront, especially in sustainability and digitisation of production processes.

With exports of textile machinery and accessories worth 85 million euros in 2023, Germany was once again the second biggest supplier to the Uzbek

textile sector, surpassed only by China. Uzbekistan is one of the largest producers and exporters of cotton. In the cotton sector, Uzbekistan already has a fully integrated production chain. Almost the entire cotton fibre is spun in the country. The Uzbek government has pushed ahead with extensive economic reforms in recent years. The textile industry is one of the top investment sectors in the manufacturing industry. Besides cotton spinning, the textile sector is enlarging its

capacities in the downstream production steps of the textile chain, such as fabric making, finishing and dyeing.

Dr. Harald Weber, Managing Director of the VDMA Textile Machinery Association, stated: “To compete globally in the textile industry, companies must prioritise technology updates. CAITME is a perfect platform to intensify the collaboration between our industry and the Uzbek textile sector and to set up new contacts.”

“Planet Conscious” approach to color from inspiration to execution

Archroma, a global leader in specialty chemicals towards sustainable solutions, today introduced COLOR MANAGEMENT+, an enhanced color design and development solution that helps textile and fashion brands and mills work together for improved economic and environmental sustainability.

Archroma Color Management+ incorporates the industry’s largest off-theshelf color atlas selection, market-leading design tools and customized services for fast color selection and creation. It combines these with engineered color standards created with Archroma’s Super Systems+ for reduced environmental impact and consistent and accurate color reproduction.

With these end-to-end capabilities, brands and designers can focus on their color inspiration and on the required functionality and sustainability for their end article, with the assurance that their inspiration can be precisely communicated and efficiently executed at the mill.

“Selecting the perfect color is a vital part of the creation of textiles and fashion, but it is not simple. Beyond aesthetics and consumer appeal, today’s designers also have to consider fastness performance, eco-compliance, color consistency and resource efficiency,” Chris Hipps, Global Head of Archroma Color Management, said. “Archroma’s COLOR MANAGEMENT+ builds these considerations into engineered color standards and provides the recipes and references that colorists and technical specialists need to bring colors to life in economical and resource efficient bulk production.”

Within Color Management+, the Color Atlas by Archroma® offers access to a collection of more than 5,700 unique colors for cotton, polyester and blends, both as a physical library and searchable online library. Designers also have the option to create custom colors.

Most importantly, achievability criteria are available for each color standard, whether in the Color Atlas or provided as an Engineered Color, at the selection phase. This includes information about the technical and economic feasibility of the selected color, along with a commitment to sustainability build on the foundation of the Zero Discharge of Hazardous Chemicals (ZDHC)

Manufacturing Restricted Substances List (MRSL) Level 3.

The COLOR MANAGEMENT+ color standards provide clear color communication to mill colorists, textile technologists and quality control specialists, helping them deliver the right color faster and achieving reproducible colors across countries and mills. Clear communications can also eliminate excessive lab dipping, shorten approval times and improve first-time-approval rates.

The color standards in COLOR MANAGEMENT+ are created with Archroma’s powerful Super Systems+ solutions for bulk production in mind. Offering end article-specific processing solutions, durable colors and intelligent effects, the Super Systems+ suite allows brands to achieve measurable environmental impact, eliminate harmful or regulated chemicals, and add value and longevity to the end product.

The solution is further supported Archroma’s ONE WAY+ Impact Calculator and Sustainability Improvement Program (SIP), and SAFE EDGE+ compliance-data platform. Global technical support is provided to help the supply chain deliver the right colors with consistency and reduced environmental impact.

Archroma’s COLOR MANAGEMENT+ is a core pillar of the company’s “Planet Conscious+” vision. With the industry’s most extensive product portfolio and a comprehensive global footprint, Archroma has the expertise and drive to accelerate the textile and fashion industry’s transition to the most sustainable processes and lead it towards a more sustainable future.

DyStar, a leading specialty chemical company with a heritage of more than a century in product development and innovation, has published its Integrated Sustainability Report for FY2023/24. For the past 14 years, DyStar has formally reported on its sustainability performance in accordance with the Global Reporting Initiative (GRI) Standards. This report also adopts the Integrated Reporting <IR> framework, which outlines the company’s environmental, social, and governance (ESG) practices through the lens of six major capitals.

Despite a year of change, DyStar has remained resilient in its commitment to Sustainability.

Mr. Xu Yalin, Managing Director and President of DyStar Group said, “In FY2023, DyStar capitalized on growth momentum and embraced strategic changes. We are pleased to report, DyStar is on track to meet our 2025 targets. Today, DyStar remains committed to enhancing our environmental performance and seeking innovative solutions to address future challenges,

thereby creating long-term value for all our stakeholders and the global supply chain.”

DyStar has successfully demonstrated the effectiveness of its strategy in the latest report. For instance, our efforts in implementing energy-efficient initiatives across its operations have started to yield credible results. DyStar’s Scope 1 and Scope 2 emissions totaled 42,084 tCO2e, representing a 67% decrease from 2011’s baseline year and a 26% decrease compared to FY2022. Scope 3 accounted for 8.2% of DyStar’s total emissions profile, with over 80% primarily stemming from the transportation of goods and services.

In terms of energy management, the Group has increased its use of renewable energy by 20%. Additionally, several energy conservation initiatives have been implemented as part of a concerted effort to reduce energy consumption globally.

Operationally, there have been several improvements to procedures aimed at boosting water efficiency and achieving cost savings at all manufacturing sites.

Wastewater discharge was reduced by 37%, improving the intensity level to 8.04 m³ per ton of production compared to 8.71 m³ per ton the previous year. This improvement is also partially due to some of our sites operating under a “Zero Liquid Discharge Scheme” mandated by local authorities.

Key highlights of FY2023 include:

Participated at ITMA Milan, where DyStar introduced a new range of bio-based DyStar products, dyes and auxiliaries containing renewable feedstock, as well as the EcoAdvanced Indigo Dyeing process.

Recognition by the Institute of Public & Environmental Affairs (IPE), achieving second place on IPE’s Green Supply Chain Corporate Information Transparency Index (CITI).

Celebrating diversity and inclusivity through global campaigns.

As we move towards a low-carbon future, DyStar decarbonization strategy roadmap will be crucial in supporting DyStar’s efforts to improve productivity and optimize cost in the name of Sustainability.

bluesign and SCTI donate the pioneering Sustainable Chemistry Index (SCI) Methodology to ZDHC aiming to advance sustainable chemistry within the textile industry.

The textile industry is taking a great step forward in sustainable practices as bluesign and SCTI donate the pioneering Sustainable Chemistry Index (SCI) Methodology to ZDHC. This collaboration aims to revolutionize chemical management in the textile, leather and fashion industries, while addressing environmental impact in a holistic manner.

The Challenge of Harmful Chemicals in Fashion:

For decades, the use of hazardous chemicals in clothing has been a major challenge. Despite industry efforts with numerous overlapping standards and voluntary schemes - the textile, leather and fashion industries struggle with varying regulations, inconsistent data and a lack of common action. Inconsistent

regulations, limited transparency, and little coordinated action hinder progress, while consumers do not receive information about the overall environmental impact of these industries.

A Unified Effort for Sustainable Solutions:

Leading organizations in the textile sector are elevating the conversation to tackle these issues head-on with converging assessment tools.

SCTI, a group of innovative and pioneering chemical manufacturers, aims to bring positive change to the textile industry and make sustainable chemistry the norm. bluesign, a renowned sustainability solutions provider, has extensive experience in ensuring safe and responsible chemical management, environmental and worker safety as well as resource efficiency in the production of textiles. The ZDHC Foundation, driven by major fashion brands, is on a mission to detox the fashion industry by providing tools and guidelines for sustainable chemical management.

The Start of the Sustainable Chemistry Index (SCI):

In 2022, SCTI and bluesign announced the development of the first comprehensive Sustainable Chemistry Index (SCI) for the textile industry. The pioneering work leverages best available technologies, while transcending existing chemical assessments, and introduces a one-stop-shopping tool for a broader assessment of environmental impact. Such an approach was missing. Now, the SCI introduces a standard common language for convergence and alignment throughout global textile.

The SCI brings new parameters to assess how chemical products improve resource utilisation in the processes they are used along the life cycle of a garment. Key building blocks include supply chain transparency, responsible sourcing, feedstock reducing fossil dependency, product carbon footprint, resource

consumption, efficiency in use during textile production, end use impact and end-of-life of consumer applications. This transparent framework makes it easier for the industry to evaluate the sustainability impact of chemicals present in a garment and promote circularity.

A Collaborative Donation to Advance the Industry:

To advance and foster industry-wide collaboration, SCTI and bluesign are donating, the SCI to ZDHC as the cornerstone of its Chemicals to Zero (CTZ-A) program. CTZ-A represents the highest level of sustainable chemistry within ZDHC. In 2024, the SCI content will undergo ZDHC's stakeholder engagement and consultation processes, aiming to enhance the Roadmap to Zero Program by addressing sustainability and circularity. ZDHC will make the SCI content freely available to the public, enabling widespread adoption and impact.

Wolfgang Schumann, Managing Director of RUDOLF, Chairman of SCTI and ZDHC board member, stated, "We have been partnering with all stakeholders involved for some time and recognized that our market has been operating with multiple isolated approaches. Within SCI content, we are converging several approaches, while raising sustainable chemistry to the benefit of our community’

Daniel Rüfenacht, CEO of bluesign, said “As a contributor in the development of Sustainable Chemistry Index, we are glad to continue the journey we have started in 2022 with this initiative, and look forward to working with our partners to further move sustainability forward in our industry.”

Isabella Tonaco, SCTI Executive Director, added "Our initiative elevates collective action to new heights and enables the textile and fashion industries to make sustainable choices by taking full advantage of what solidarity can do to power change."

Frank Michel, ZDHC CEO, continued. “At ZDHC, our mission is to build a dynamic platform that highlights the transformative journey of sustainable chemistry in the fashion industry. By integrating the SCI as the cornerstone of Chemicals to Zero Aspirational Level and

releasing it into our publicly available ZDHC Framework, we’re showcasing true thought leadership essential for driving positive change and engage our wider community of stakeholders on our way forward.”

The ZDHC program is well-positioned to complement the expertise of bluesign and SCTI and to scale its impact within a multistakeholder structure. This collaboration empowers manufacturers and brands to make informed, responsible choices in terms of chemicals and processes, committing to sustainable chemistry and benefiting society.

Founded in October 2020, Sustainable Chemistry for the Textile Industry (SCTI) is an alliance of leading chemical companies that strives to empower the textile and leather industries to apply sustainable, state-ofthe-art chemistry solutions that protect factory workers, local communities, consumers and the environment. It has six founding members: Archroma, CHT Group, Kyung-In Synthetic Corporation (KISCO), Pulcra Chemicals, Rudolf and Tanatex Chemicals. In 2022, SCTI teamed up with bluesign to create the Sustainable Chemistry Index (SCI) that enables stakeholders to assess the sustainability of textile chemical products.

The bluesign® SYSTEM is the solution for sustainable textile production. It eliminates harmful substances right from the start of the manufacturing process,

and it sets and controls standards for environmentally friendly and safe production. This not only ensures that the final textile product meets very stringent consumer safety requirements worldwide but also gives consumers confidence in purchasing sustainable products. bluesign technologies ag was founded in 2000. Since then, the bluesign® SYSTEM has been adopted by worldwide leading textile and accessory manufacturers. Various significant key players in the chemical and machine industry rely on the bluesign® SYSTEM, and well-known brands in the outdoor, sportswear and fashion industry trust the extensive knowledge and services of bluesign.

The ZDHC Foundation leads the fashion industry in preventing hazardous chemicals from being used in fashion production. It unites over 300 Signatories and develops guidelines, platforms and solutions that empower brands, suppliers, and chemical formulators to implement safer and sustainable chemical management.

This enables large-scale change towards zero hazardous chemical discharge across complex global supply chains. By creating the collaborative Roadmap to Zero Programme and equipping the fashion ecosystem with solutions, ZDHC plays an instrumental role in advancing the industry towards responsible chemical use that protects people and the planet.

The Swiss Textile Machinery Association (Swissmem) is presenting special events in key markets worldwide. The next stop is Charlotte, N.C., where 16 association member companies will present their latest innovations at a one-day symposium on 1st October 2024

In global business, not even the latest communication systems can replace personal relationships. To members of the Swiss Textile Machinery Association, it’s vital making contact with customers old and new. “That’s what motivates our members to take their latest innovations

right into the biggest textile manufacturing markets — along with a friendly handshake,” said Cornelia Buchwalder, the association secretary general.

The Swiss Textile Machinery Association warmly invites textile professionals to a special symposium in the heart of the North American textile sector. A total of 16 association member firms will be on hand to answer any questions about the technology, the products and more. Participating companies are:

Autefa Solutions

Benninger

Bluesign Technologies

Bräcker

Heberlein Technology

Jakob Müller

Luwa Air Engineering

Maag Brothers

Retech

Rieter

Rotorcraft

Saurer

SSM – Schärer Schweiter Mettler

Stäubli

Xetma Vollenweider

North America is a well-chosen tour destination, because it has become an increasingly interesting market for Swiss textile machinery and component manufacturers, as well as service providers.

“North America has a large and diverse textile market, with a strong technical textiles sector, covering a vast range of applications. This means demand for advanced textile machinery is at a high level,” Buchwalder said.

The event will start with insights into the latest developments from the Switzerland-based companies, as the delegates showcase their innovations for the U.S. manufacturers. There will also be the chance for networking, at the exhibition tables and at a joint dinner for customers, representatives and guests. The free-ofcharge event takes place at the Charlotte Westin Hotel.

Please visitSwissmem’s website for further information and registration.

The host at the event will be Cornelia Buchwalder, secretary general, Swiss Textile Machinery Association (part of Swissmem). Ralf Heckner, Ambassador of Switzerland to the United States; Charles Poston, chairman, Southern Textile Association; and Ernesto Maurer, president, Swiss Textile Machinery, will also welcome the guests.

The Swiss Textile Machinery Association is the representative body for Switzerland’s producers of textile equipment, systems and services. Currently 45 companies are affiliated, including manufacturers of machines and components, and service providers, for the textile industry. The companies offer solutions covering the entire textile value chain, from spinning to weaving, knitting, finishing, embroidery and quality control.

Founded in 1940, Swiss Textile Machinery Association is the oldest industry sector of Swissmem.

Swissmem is the leading association for SMEs and large companies in Switzerland's mechanical and electrical

engineering (MEM) industries and related technology-oriented sectors. Swissmem enhances the competitiveness of its 1,200

or so member companies both at home and abroad by providing needs-based services.

increasing number

The 13th JIAM 2024 OSAKA - Japan International Apparel & Non-Apparel Manufacturing Technology Trade Show (organised by the Japan Sewing Machinery Manufacturers Association (JASMA)) will be held at Intex Osaka for four days from 27 (Wed) - 30 (Sat) November 2024. OSAKA. After an interval of two years, the fair is expected to attract approximately 160 exhibitors from 10 countries and regions, which exceeds the previous edition (as of 6 June)

Increase of number of oversea exhibitors and exhibitors from nonapparel sector.

Influenced by the re-energized global economy, the show will welcome more oversea exhibitors than 2022. Germany led by VDMA, China led by CSMA and Taiwan will organize national pavilion at JIAM 2024 OSAKA, and individual exhibitors will join from Italy, UK, India, Sri Lanka, hailand, Hong Kong and China. In total exhibitors from 10 countries / regions will gather from all over the world with high expectation towards the show as an international business platform.

In addition, the number of nonapparel related products has increased,

since the 2024 edition added ‘nonapparel’ to the exhibition name and invited companies dealing with hardware, software and services, respectively to participate. In particular, the number of exhibitors of automotive, aerospace and aviation-related products more than doubled compared to the previous edition.

Organiser JASMA decide to expand space in response to unrelenting demand for exhibitors.

As of the end of April, the official deadline for exhibitor applications, the show scale had already been confirmed to be larger than the previous edition. In

response to continuing enquiries for exhibiting the show from companies even after deadline of application, the organiser, JASMA, has decided to expand the exhibition space and will continue to accept exhibitor application. Due to limited space extension, earliest contact to organiser is recommended for further inquiry of exhibitor application.

Exhibiting at JIAM 2024 OSAKA, one of the world's leading trade fairs for sewing equipment, is an excellent opportunity not only to attract new customers and strengthen relationships with existing customers, but also to build networks with business partners in Japan and abroad.