JIAM 2024 OSAKA

Dates: November 27th to 30th 2024.

Venue: Osaka, Japan.

Heimtextil 2025, Frankfurt

Dates: January 14th, to 17th, 2025

Venue: Frankfurt am Main.

FESPA 2025

Dates: January 20th to 22nd 2025.

Venue: Dubai Exhibition Centre.

Apparel Sourcing Paris Autumn

Dates: Feruary 10th to 12th 2025.

Venue: Paris

Istanbul Yarn Fair

Dates: February 13th to 15th, 2025. Venue: Istanbul, Turkey.

Intertextile Shanghai Apparel Fabrics

Dates: March 11th to 13th 2025. Venue: Shanghai, China.

Textile Asia 2025, Karachi

Dates: April 12th to 14th 2025.

Venue: Expo Centre, Karachi.

Textile Asia 2025, Lahore

Dates: November 22nd to 24th 2025.

Venue: Lahore Expo Centre.

DOMOTEX Middle East 2025

Dates: April 22nd to 24th 2025.

Venue: Dubai World Trade Centre.

IGATEX Pakistan 2025, Karachi

Dates: April 24th to 26th 2025.

Venue: Expo Centre, Karachi.

iCADEX Pakistan 2025, Karachi

Dates: April 24th to 26th 2025.

Venue: Expo Centre, Karachi.

FESPA 2025

Dates: May 06th to 09th 2025.

Venue: Messe Berlin in Germany.

DOMOTEX asiaCHINAFLOOR 2025

Dates: May 26th to 28th 2025.

Venue: NECC, Shanghai, China.

ITMA ASIA + CITME, Singapore 2025

Dates: October 28th to 31st, 2025. Venue: Expo Centre Singapore.

Techtextil 2026

Dates: April 21st to 24th, 2026 Venue: Frankfurt, Germany.

Index 2026

Dates: April 21st to 24th, 2026. Venue: Palexpo, Geneva, Switzerland.

ITM 2026

Dates: June 9th to 13th, 2026. Venue: Istanbul, Turkey.

HIGHTEX 2026

Dates: June 9th to 13th, 2026. Venue: Istanbul, Turkey.

ITMA 2027

Dates: September 16th to 22nd, 2027. Venue: Hanover, Germany.

PAKISTAN TEXTILE JOURNAL - November 2024

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher Nadeem Mazhar

Editor in Chief Amina Baqai

Associate Editor

Nimrah Nadeem

Production Manager Mazhar Ali

Layout & Design

Noor M. Jaan

Website / Social Media

Minhaj Ali

Hony-Editorial

Dr. Hafizur Rehman Sheikh Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA)

Dr. Zubair Bandukda PhD (Textiles), CText ATI

Engr. Naeem Ilyas Khanani

Editorial & Advertising Office

B-4, 2nd Floor, 64/21, M.A.C.H, Miran M. Shah Road, Karachi - Pakistan

Tel: +92-21-34311674-5

Fax: +92-21-34533616

Email: info@ptj.com.pk URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, United Kingdom.

Registered no. 09141989 Tel: +44 792 2228 721

Available on Gale and Factiva affiliated international databases through Asianet Pakistan

Printed at: Color Plus Korangi, Karachi.

Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi.

eVent Fabrics signs new talent to meet increasing demand, assist with global expansion into Korea

Rieter places bond for a total of CHF 65 million

Textiles Intelligence partners with the ASBCI to analyse the role of artificial intelligence (AI) in the fashion industry

Officina39 on stage at La Scala Theater for the CNMI sustainable fashion awards . .24

ARCHROMA announces leadership and organizational changes .

Rajiv Sharma assumes the role of Archroma CEO as Mark Garrett transitions to the Board of Directors

Dr. Christian Rink becomes new CFO of the CHT Group

Dr. Christian Rink will take over the position of global CFO of the CHT Group held by Prof. Dr. Klaus Müller on an interim basis

Archroma introduces breakthrough in bio-based textile

Archroma

FESPA Middle East advances regional printing industry through global expertise and reinvestment programme

Functional contract textiles: The multi-talents at

U.S. Cotton Trust Protocol achieves record growth, reinforcing commitment to sustainable practices and traceability

Monforts is 140 and looking to the future

The LYCRA Company publishes its 2023 Sustainability Update, reports on progress versus 2030 goals

Trützschler: Joining forces for Europe’s biggest multi-purpose plant

Trützschler Nonwovens and Texnology to supply complete needle-punching line to O.R.V. Manufacturing S.p.A., Italy

JigMaster – The most gentle and versatile jigger of the industry

Benninger’s high-tech jigger is the perfect choice for demanding dyers

Rieter ring spinning system powers Beste’s fully traceable supply chain

Asia Pacific Rayon (APR) organized its first customer meet in Pakistan . . . . . . . .46

6th DPS World Pakistan 2024: Pakistan’s leading exhibition for digital printing and signage industry

ITMA ASIA + CITME 2024 enjoys strong local attendance .

VDMA companies at ITMA ASIA + CITME 2024: Smart technologies for green textile production

.50

ACIMIT (Association of Italian Textile Machinery Manufacturers) at ITMA ASIA + CITME 2024 in China .

Trützschler and Murata celebrated their partnership at ITMA ASIA 2024

SAVIO showcased its latest automatic winder and air-jet spinning machine during ITMA ASIA+CITME 2024

.55

.56

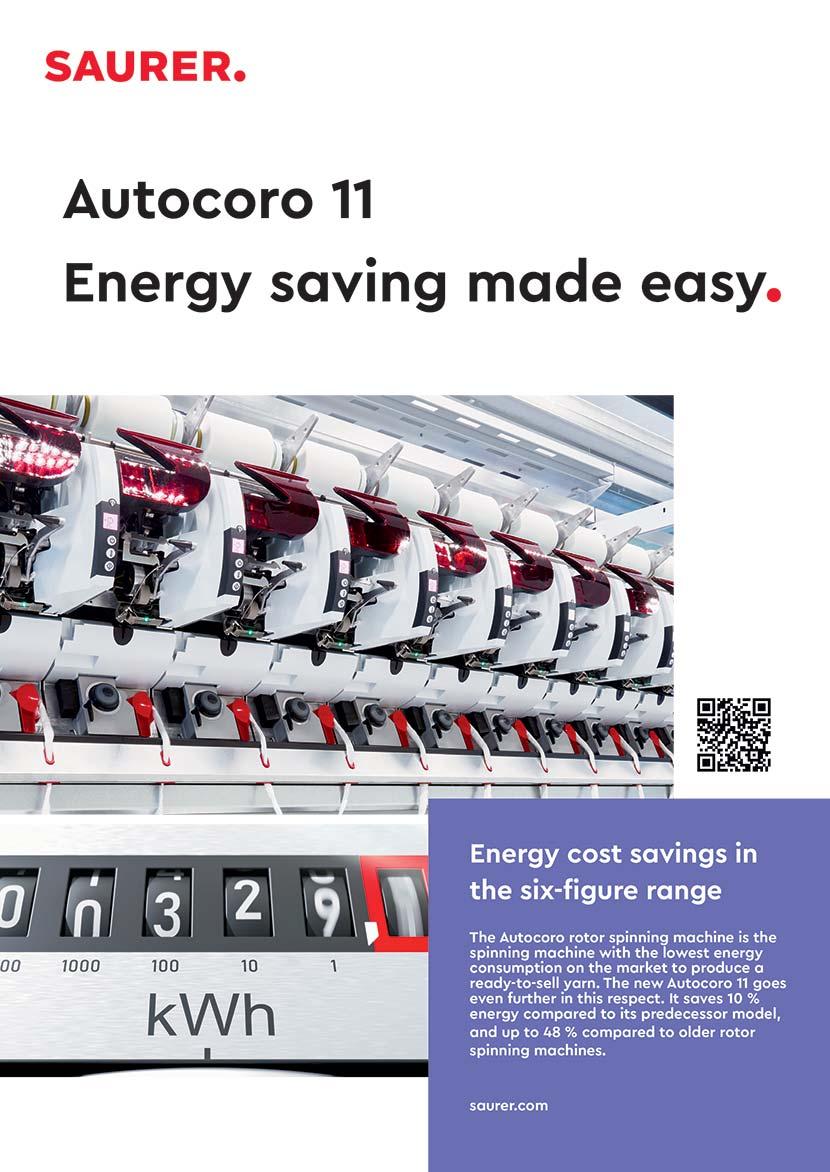

Successful at ITMA ASIA 2024 – Saurer’s technology highlights . . . . . . . .58

ITMA ASIA + CITME Glimpses 2024

The recent surge in Pakistan's textile exports brings a wave of cautious optimism to an industry vital to the nation's economic health. A 10.44% increase in the first four months of FY25, reaching $6.146 billion, signals a promising trajectory. This growth, coupled with the current economic stability marked by a record-breaking stock exchange, controlled inflation, and a steadied PKR, paints a picture of resilience and potential.

However, it's crucial to acknowledge this growth within the larger context of the challenges that continue to plague the sector. While the overall export figures inspire confidence, a closer look reveals a concerning decline in cotton yarn exports, down by 45.59% in the same period. This disparity highlights the complexities of the textile value chain and the urgent need for a multifaceted approach to sustain and enhance this positive momentum.

One of the most persistent hurdles remains the high cost of production, primarily driven by exorbitant electricity prices. This issue has long cast a shadow over the industry's competitiveness in the global market. Addressing this requires a concerted effort from the government to implement policies that ensure affordable and reliable energy access for textile manufacturers. Investing in renewable energy sources, improving energy efficiency, and rationalizing tariffs are crucial steps in this direction.

Furthermore, diversification of products and markets is essential to mitigate risks and capitalize on emerging opportunities. While the growth in readymade garments and knitwear is encouraging, exploring new avenues within the textile sector, such as technical textiles and non-woven fabrics, can unlock further potential. Similarly, reducing reliance on traditional export markets and actively seeking new partnerships in regions like Africa and South America can enhance resilience and boost export volumes.

The current economic stability provides a fertile ground for implementing muchneeded structural reforms. This includes streamlining bureaucratic processes, facilitating access to finance, and promoting innovation and technology adoption within the textile industry. Investing in skill development and training programs for the workforce is equally important to enhance productivity and meet the evolving demands of the global market.

The government's role in fostering a conducive business environment cannot be overstated. Policy consistency, transparency, and efficient regulatory frameworks are vital to attract investment and encourage sustainable growth in the textile sector. Moreover, promoting collaboration between industry stakeholders, research institutions, and the government can facilitate knowledge sharing, innovation, and the development of a robust textile ecosystem.

In conclusion, the recent surge in textile exports is undoubtedly a positive development, offering a beacon of hope for Pakistan's economic recovery. However, sustaining this growth requires a comprehensive strategy that addresses the persistent challenges of high production costs, market diversification, and technological advancement. By capitalizing on the current economic stability and implementing prudent policies, Pakistan can unlock the full potential of its textile industry and pave the way for sustained economic prosperity.

1

A workshop hosted by the Sustainable Development Policy Institute (SDPI), in collaboration with the United Nations Environment Programme (UNEP) and the European Union, gathered industry leaders and policymakers to develop criteria for Pakistan’s expanding trade in used textiles. The event aimed to lay a foundation for sustainable practices in second-hand textile trade as part of Pakistan’s broader commitment to a circular economy.

2

Pakistan’s textile industry maintained its upward momentum in September 2024, recording a significant 17.9% increase in export earnings compared to last year. Total textile exports

hit $1.605 billion, up from $1.36 billion in September 2023, according to data from the Pakistan Bureau of Statistics (PBS).

3

The Pakistan Textile Exporters Association (PTEA) has identified alarming concerns regarding substantial delays in the disbursement of Rs328.5 billion in refunds, critically affecting the liquidity and operations within the textile industry. Despite multiple government assurances, exporters continue to experience financial strain due to these outstanding refunds, jeopardizing the sector's growth potential.

4

The International Monetary Fund (IMF) has called on Pakistan to promptly eliminate prefer-

1

A recent study titled “Regulatory Framework to Enable Recycling of Post-Industrial Waste (Jhut) for the RMG Industry in Bangladesh,” conducted by GIZ GmbH in collaboration with Swedish retailer H&M, has revealed that Bangladesh is missing out on a lucrative export market worth $4-5 billion annually due to inadequate regulatory frameworks surrounding the recycling of post-industrial textile waste, known as Jhut.

2

India's textile and apparel exports experienced a notable increase of 5.13%, reaching $17.66 billion during the first half of the fiscal year 202425 (April to September 2024). September 2024 was particularly strong, with over-

ential treatment, tax exemptions, and other protective measures for its agriculture and textile sectors, which the organization claims have hindered its economic growth for decades. In a staff report analysing the underlying factors of Pakistan's economic struggles, the IMF highlighted that these sectors not only fail to contribute significantly to national revenue but also consume substantial public funds while remaining inefficient and uncompetitive.

5

In a joint statement, PTEA Patron-in-Chief Khurram Mukhtar and Chairman Sohail Pasha have expressed strong opposition to the government’s decision to halt gas supplies to highly efficient Captive Power Plants

(CPPs) starting January 1, 2025. They warned that this policy change poses a significant threat to the stability and growth of the country’s textile industry, which relies heavily on CPPs for consistent power and operational efficiency.

6

Pakistan is facing a troubling forecast as its cotton import bill for the current fiscal year (FY25) which is projected to soar to $1.9 billion, a significant increase from $448 million last year, according to a report from Arif Habib Limited (AHL). This anticipated rise is largely due to a dramatic drop in local cotton production, which has seen a staggering 48.3% decrease compared to the previous year.

all shipments rising by 12.38%, while apparel exports surged by 17.30%, signalling a robust recovery in the sector following a prolonged period of sluggish foreign trade.

3

In a ground-breaking development for the sustainable fashion sector, researchers in Japan have introduced an innovative decolorization technique aimed at reducing the environmental footprint of textile dyeing processes. This new approach addresses the widespread water pollution and ecological damage linked to the use of synthetic dyes, which have long been a staple in the fashion industry.

4

The UK manufacturing sector experienced a robust increase in pro-

duction volumes towards the end of Q3 2024, according to S&P Global's latest report. Both output and new orders continued to rise, primarily driven by domestic demand.

5

The United States, the largest global apparel importer, saw its apparel imports soar to $79.3 billion in 2023, predominantly from Asian suppliers, according to a recent report by the US International Trade Commission (USITC). This report, requested by the US trade representative, highlights key trends in the apparel import landscape.

6

The Uzcharmsanoat Association from Uzbekistan recently held discussions with Musa Jamanbayev, the Kyrgyz Republic's Ambassador to

Uzbekistan, to explore avenues for expanded cooperation and joint investments in the leather industry.

7

Vietnam's garment exports to the Middle East fell by 25% in the first nine months of 2024, driven by heightened competition and shifting market dynamics. Countries like Bangladesh, India, and Turkey have gained ground by offering competitive prices and a broader range of products, presenting a challenge for Vietnamese exporters. At the same time, economic uncertainties in the Middle East, including fluctuating oil prices and geopolitical tensions, have weakened consumer purchasing power, leading to reduced apparel demand.

A workshop hosted by the Sustainable Development Policy Institute (SDPI), in collaboration with the United Nations Environment Programme (UNEP) and the European Union, gathered industry leaders and policymakers to develop criteria for Pakistan’s expanding trade in used textiles. The event aimed to lay a foundation for sustainable practices in second-hand textile trade as part of Pakistan’s broader commitment to a circular economy.

The workshop, titled “Criteria and Guideline Development for Used Textiles Trade,” addressed the role of Pakistan’s textile industry in global circular trade and underscored the sector's importance. UNEP representative Asad Naqvi emphasized the need to strengthen supply chains from the ground up, beginning with local farmers, while SDPI’s Zainab Naeem pointed out Pakistan’s role as a leading importer of used textiles from the European Union.

With the country’s second-hand clothing imports rising by 17% to over 433,000 metric tons in the past year, the sector’s value has grown significantly, generating over $40 million in revenue. Mustafa Sattar, CEO of Retex Global, shared insights into the recycling process, noting that 90% of clothing is recycled without using water or gas—a vital step towards reducing environmental impact.

The workshop also addressed issues such as microplastic pollution, with UNEP’s Beatriz Fernandez stressing the importance of the textile sector for employment, especially for women, who make up 45% of the workforce. Government officials, including Ministry of Commerce representative Umar

Farooq, highlighted ongoing regulatory efforts to create a sustainable framework for textile trade.

Pakistan’s textile industry maintained its upward momentum in September 2024, recording a significant 17.9% increase in export earnings compared to the same month last year. Total textile exports hit $1.605 billion, up from $1.36 billion in September 2023, according to data from the Pakistan Bureau of Statistics (PBS).

This growth, largely fuelled by demand for finished products, signals a strategic shift within the sector towards exporting higher-value items, while shipments of raw materials, such as cotton yarn, saw marked declines. Readymade garments led the surge, with exports rising by 35%—a standout performance across the sector.

Other finished textile categories also saw impressive gains: knitwear exports

jumped 29.57% to $448.3 million, bedwear rose 24.8% to $290.2 million, and cotton cloth exports increased by 15.33% to $201 million. Exports of towels increased by 7.35%, amounting to $90.55 million.

The strategic shift away from raw materials is evident in the sharp drop in cotton yarn exports, which fell by 54.22% to $52 million. Meanwhile, raw cotton exports plummeted to zero, reflecting the sector’s focus on value addition.

For the fiscal year 2023-24, Pakistan’s textile exports totalled $16.65 billion, showing a modest annual growth of 0.9%. Industry stakeholders see this trend as part of a long-term pivot towards higher-value products, aiming to boost profitability and global competitiveness.

The Pakistan Textile Exporters Association (PTEA) has identified alarming concerns regarding substantial delays in the disbursement of Rs 328.5 billion in refunds, which are critically affecting the liquidity and operations within the textile industry. Despite multiple government assurances, exporters continue to experience financial strain due to these outstanding refunds, jeopardizing the sector's growth potential.

A detailed views of records indicates that the refunds include Rs 55 billion related to sales tax, Rs 105 billion for

deferred sales tax, Rs 25 billion under duty drawback, and Rs 100 billion from income tax refunds. Additional amounts are pending under the Drawback of Local Taxes and Levies (DLTL/DDT), Technology Upgradation Fund (TUF), and markup subsidies.

The PTEA has pointed out that the delays in processing these refunds have worsened liquidity issues, preventing exporters from expanding their businesses and managing increasing financial pressures. The high-interest rates associated with these pending refunds further complicate the situation for textile manufacturers, who play a pivotal role in Pakistan's foreign exchange earnings.

Current regulations, notably the Sales Tax Act of 2006, require refunds to be processed within 72 hours; however, many refunds are now taking over 200 days. For instance, the most recent payments addressed only Refund Payment Orders (RPOs) up to late August, with delays in processing extending well into the fall.

Adding to the concerns, the allocation for DLTL/DDT refunds was only set at Rs 10 billion, significantly lower than the Rs 38 billion liability that exporters claim is due. The PTEA warns that such underfunding restricts reinvestment and growth opportunities, making it difficult for exporters to compete on the global stage.

Although the textile sector has shown a 15% growth month-on-month since August, with exports totalling between $7 to $8 billion, the association cautions that failure to resolve these refund delays could undermine this positive trend. PTEA emphasizes that they are not seeking special treatment, but rather a resolution to the government’s financial commitments.

The International Monetary Fund (IMF) has called on Pakistan to promptly eliminate preferential treatment, tax exemptions, and other protective measures for its agriculture and textile sectors, which the organization claims have hindered the country’s economic growth for decades. In a staff report analysing the underlying factors of Pakistan's economic struggles, the IMF highlighted that these sectors not only fail to contribute significantly to national revenue but also consume substantial public funds while remaining inefficient and uncompetitive.

As part of a recently approved $7 billion Extended Fund Facility, the IMF stressed the importance of moving away from long-standing economic practices to avoid cyclical downturns. The report pointed out that Pakistan's economy is lagging behind similar nations, leading to stagnation and increased poverty levels, with over 40.5% of the population living below the poverty line.

The IMF's findings indicated that Pakistan has not developed a diverse range of sophisticated export goods, with a heavy reliance on agriculture and textiles, particularly in products like cotton yarn, rice, and woven fabrics. Despite exporting some high-value items such as medicines and medical instruments, these sectors operate

under a distorted economic framework, constrained by tariffs on intermediate and final goods, which inhibit competitiveness and growth.

The report noted a significant tax gap in the textile sector, where between 2007 and 2022, it received various subsidies and preferential tax treatments. With 70% of concessional loans from the central bank tied to this sector, the IMF urged the government to simplify trade policies and avoid using tariffs to protect inefficient sectors, warning that such practices lead to resource misallocation.

To enhance economic development, the IMF recommended that Pakistan integrate more effectively into global trade, which would require removing barriers to imports and ensuring a level playing field for businesses. The report suggested that various complex goods could potentially be developed within Pakistan's technological proximity, including chemicals and industrial fabrics, provided that government interventions that lock resources into low-productivity activities are eliminated.

In a joint statement, PTEA Patron-in-Chief

Khurram Mukhtar and Chairman Sohail Pasha have expressed strong opposition to the government’s decision to halt gas supplies to highly efficient Captive Power Plants (CPPs) starting January 1, 2025. They warned that this policy change poses a significant threat to the stability and growth of the country’s textile industry, which relies heavily on CPPs for consistent power and operational efficiency.

The PTEA officials pointed out that substantial investments have been made in gas-based CPPs, with 480 plants connected to the SNGPL network and 800 to the SSGC network. These facilities are essential for ensuring stable and uninterrupted power, which is critical to prevent costly voltage fluctuations that

could disrupt highly automated textile machinery.

The association cautioned that depending solely on the national grid— which is plagued by transmission and distribution losses—would fail to meet the industry's energy demands and risk damaging sensitive equipment across the textile value chain. CPPs allow for the simultaneous generation of power and steam, which is vital for industrial operations, and are deemed more efficient than government-owned plants.

significant losses, with production dropping from 3,452,986 bales in 2023 to 1,916,096 bales in 2024, marking a 44.5% decrease.

Experts attribute this decline to “poor farmer economics and the delayed planting of the cotton crop.” AHL estimates that local production may reach 6 million bales this fiscal year, necessitating the import of approximately 5.4 million bales to meet demand. This heavy reliance on imports poses a significant risk for Pakistan, particularly given that textiles account for over 60% of the country's total exports.

Concerns have been raised about the inadequacy of grid-supplied power, especially given the frequent outages, which could severely hinder industrial productivity. Additionally, large manufacturing units requiring more than 10 MW per hour would face considerable costs and delays if forced to establish their own energy grids, further exacerbating production challenges.

The PTEA also warned that the government’s decision could deepen the financial woes of Pakistan's gas sector, which is already grappling with a circular debt of Rs2,700 billion.

Pakistan is facing a troubling forecast as its cotton import bill for the current fiscal year (FY25) which is projected to soar to $1.9 billion, a significant increase from $448 million last year, according to a report from Arif Habib Limited (AHL). This anticipated rise is largely due to a dramatic drop in local cotton production, which has seen a staggering 48.3% decrease compared to the previous year.

As of mid-October 2024, the Pakistan Cotton Ginners Association (PCGA) reported cotton arrivals totalling 3,101,743 bales, down from 5,996,086 bales recorded on the same date in 2023. The decline is particularly pronounced in key producing provinces. In Punjab, cotton production has plummeted from 2,543,100 bales last year to just 1,185,647 bales this year, reflecting a 53.4% reduction. Sindh has also faced

The situation is further complicated by the potential exacerbation of Pakistan's balance of payment crisis, as rising imports may strain the nation's foreign exchange reserves and complicate efforts to manage external debts.

Kamran Arshad, the newly-elected Chairman of the AllPakistan Textile Mills Association (APTMA) has made a strong appeal to policymakers for urgent reforms to stimulate the struggling sector. Addressing the Association's Annual General Meeting in Lahore, Arshad emphasized the need for a reduction in electricity tariffs and the restoration of the Regionally Competitive Energy Tariff (RCET). He also urged the government to reverse its decision to curtail gas supply to captive consumers starting January 1, 2025, and to include local yarn supply in the Export Facilitation Scheme (EFS).

These initiatives, according to Arshad, are essential to revitalizing the textile sector, driving economic growth, and creating job opportunities. He further advocated for a reduction in interest rates to support industrial expansion.

During the meeting, the election results were announced, confirming Kamran Arshad as the central Chairman, with Muhammad Jameel Qasim as Senior

Vice Chairman and Siddique Javed Bhatti and Shahzad Ahmed Shaikh serving as Vice Chairmen for the 2024-26 term. The Northern Zone also saw a new leadership team elected, including Asad Shafi as Chairman.

Arshad praised the efforts of Dr. Gohar Ejaz, APTMA's Patronin-Chief, for securing member confidence and leading the Association to its 16th consecutive election victory. He highlighted the severe challenges faced by the textile sector over the past year, marked by tight monetary policies, rising energy costs, and political instability, all amid a global economic downturn.

The chairman noted the negative impact of the withdrawal of the RCET in 2023 and energy tariff disparities on the industry, particularly in Punjab. He expressed concern over the misuse of the EFS following the withdrawal of sales tax zero rating on local inputs, which has led to a significant increase in yarn imports.

Dr. Gohar Ejaz, commending the new leadership, expressed optimism about their potential to enhance the country’s export capacity and collaborate with the government to foster a supportive business environment. Asad Shafi, the newly-elected Northern Zone Chairman, encouraged members to invest in the value-added sector to capitalize on Pakistan's demographic advantage, suggesting that such investments could significantly boost exports.

CEM Altan, President of the International Apparel Federation (IAF) at a recent press conference highlighted that Pakistan’s garment and textile exporters must be encouraged to diversify their markets and focus on high-value products. Altan emphasized the importance of exploring emerging markets such as Russia, Central Asia, and the Middle East, moving beyond the current reliance on low-cost textile exports.

During his address, Altan, who represents 42 countries, stressed the need for Pakistani exporters to shift towards value-added offerings like garments, fast fashion, sportswear, and medical wear. He pointed out that the ongoing political instability in Bangladesh presents an opportunity for Pakistan to capture export orders, as global fashion brands seek reliable, compliant production partners.

To remain competitive, Altan urged textile manufacturers to digitize their supply chains by implementing tools like ERP systems, blockchain technology for enhanced transparency, and IoT solutions for better production planning and inventory management. He also called for established brands to bolster their ecommerce platforms and support local manufacturers in accessing global marketplaces such as Amazon, Alibaba, and Etsy.

Ijaz Khokar, former chairperson of the Pakistan Readymade Garment Manufacturers and Exporters Association

(PREGMEA), echoed Altan’s sentiments, indicating that the exploration of new markets, particularly Russia, could yield export values comparable to North America, contingent on establishing banking channels between the countries. He noted an uptick in orders from South Asian buyers and expects this trend to continue.

In an effort to strengthen the local textile industry, PREGMEA is planning to host the World Fashion Convention in Pakistan in 2026, following its successful inaugural event in 2019. Khokar emphasized the necessity of government support in creating research and development centers, textile clusters, and fashion design hubs to enhance the capabilities of garment producers.

With strong interest shown at Texpo Pakistan, Khokar believes this will translate into increased export values. He also suggested that Pakistan should consider launching its own Texpo in Dubai to attract a broader range of buyers.

A recent study titled “Regulatory Framework to Enable Recycling of PostIndustrial Waste (Jhut) for the RMG Industry in Bangladesh,” conducted by GIZ GmbH in collaboration with Swedish retailer H&M, has revealed that Bangladesh is missing out on a lucrative export market worth $4-5 billion annually due to inadequate regulatory frameworks surrounding the recycling of postindustrial textile waste, known as Jhut.

The report emphasizes the urgent need for a comprehensive policy framework to unlock the potential of the largely overlooked informal Jhut sector, which currently captures only 5-7% of the significant waste generated each year. With modest recycling capacity for apparel-grade recycled yarns, Bangladesh is positioned to enhance its recycling efforts substantially.

To address these challenges, the study proposes several critical policy solutions. Establishing a national Jhut database is vital for improving data accuracy and traceability, which will aid better decisionmaking and resource management. The introduction of standardized management and recycling guidelines is also necessary to streamline processes and boost overall efficiency within the sector.

Moreover, the report advocates for revisions to VAT and tariff regulations related to Jhut transactions to create a

more favourable economic environment for recycling activities. Financial incentives are essential to encourage the formalization of Jhut collection, handling, and sorting processes, fostering investment in this sector.

The establishment of cluster-based sorting hubs is recommended to promote decent work, social inclusion, and improved waste management practices. Additionally, enhancing the investment landscape for advanced recycling technologies is crucial for driving innovation and expanding Bangladesh's recycling capabilities.

The findings of the study highlight the critical need for policymakers to implement these recommendations to capitalize on the economic, social, and environmental benefits of a formalized Jhut recycling industry. As Bangladesh aims to position itself as a leader in sustainable textiles, these reforms could

significantly strengthen its economy while promoting a circular textile economy.

India's textile and apparel exports experienced a notable increase of 5.13%, reaching $17.66 billion during the first half of the fiscal year 2024-25 (April to September 2024). September 2024 was particularly strong, with overall shipments rising by 12.38%, while apparel exports surged by 17.30%, signalling a robust recovery in the sector following a prolonged period of sluggish foreign trade.

In detail, textile exports grew by 2.76% to $10.155 billion, compared to $9.882 billion during the same period last year. Apparel exports also rose significantly, up 8.51% to $7.505 billion, from $6.916 billion in the previous fiscal year. As a result, the share of textiles and apparel (T&A) in India's total merchandise exports increased to 8.28%, according to the Ministry of Commerce and Trade.

Key sectors within textiles saw varied performance: exports of cotton yarn, fabrics, made-ups, and handloom products experienced a modest rise of 0.79% to $5.946 billion. Man-made yarns, fabrics, and made-ups grew by 2.95% to $2.405 billion, while carpet exports rose by 11.41% to $745.74 million.

In September 2024 alone, T&A exports amounted to $2.923 billion, with textile exports increasing by 9.56% to $1.813 billion, and garment shipments seeing a significant rise to $1.110 billion from $946.35 million in September 2023. Under textiles, exports of cotton yarn, fabrics, made-ups, and handloom products rose by 3.48% to $1.053 billion, while man-made products surged by 11.41% to $415.28 million.

On the import side, India witnessed an 18.74% increase in raw cotton and waste imports, totaling $477.38 million, alongside a 3.45% rise in imports of textile yarns, fabrics, and made-ups. However, imports of textile yarn, fabrics, and made-ups decreased by 1.80% in September 2024.

Despite a decrease in the previous fiscal year, where total textile and apparel exports fell by 3.24% to $34.43 billion, industry leaders are optimistic about the upward trend. Sudhir Sekhri, chairman of the Apparel Exports Promotion Council (AEPC), highlighted India's unique position in the global market, attributing the growth to low import intensity, a comprehensive ecosystem and a young labour force.

In a ground-breaking development for the sustainable fashion sector, researchers in Japan have introduced an innovative decolorization technique aimed at reducing the environmental

footprint of textile dyeing processes. This new approach addresses the widespread water pollution and ecological damage linked to the use of synthetic dyes, which have long been a staple in the fashion industry.

By employing advanced methodologies, the team has effectively extracted dyes from various fabrics without sacrificing their integrity. This enhancement not only curtails the negative environmental effects associated

with textile production but also significantly improves the feasibility of recycling worn garments. By streamlining the decolorization process, the researchers are promoting a circular fashion model that emphasizes reuse and repurposing, thereby minimizing waste.

The potential impact of this research is far-reaching. As consumers increasingly prioritize sustainability in their purchasing decisions, fashion brands that implement environmentally conscious practices are likely to attract a more discerning clientele. This shift could catalyse a broader transformation in manufacturing practices within the industry, steering it toward greener alternatives.

As the global emphasis on sustainability intensifies, this pioneering decolorization method stands to significantly influence the textile industry, advocating for both ecological integrity and economic sustainability. The findings signal a hopeful trajectory for responsible fashion, setting the stage for a cleaner, more sustainable future in textiles.

The UK manufacturing sector experienced a notable increase in production volumes towards the end of Q3 2024, according to S&P Global's latest report. Both output and new orders continued to rise, primarily driven by domestic demand.

However, the anticipation of the upcoming Autumn Statement has led to a more cautious approach among manufacturers, resulting in slower growth in production and new business, alongside a decline in future expectations that have dropped to a nine-month low.

The seasonally adjusted S&P Global UK Manufacturing Purchasing Managers' Index (PMI) registered at 51.5 in September, down from August’s 26month high of 52.5, marking five consecutive months above the neutral threshold of 50. Three of the five PMI sub-components—output, new orders, and suppliers' delivery times—indicated favourable operating conditions for manufacturers.

Conversely, employment levels and purchase stocks decreased, as firms sought to control rising input costs by cutting expenditures elsewhere. September marked the fifth month of rising manufacturing production as businesses adapted to increased new orders.

Despite the overall growth, there was a notable decline in new export business for the thirty-second straight month,

attributed to lacklustre market conditions in Europe, particularly concerning demand from France and Germany. Lower orders from U.S. clients also contributed to this trend.

The month saw heightened uncertainty affecting manufacturers and their clients, reflected in slower growth in new orders and output compared to August. Business confidence regarding future production fell to its lowest point in nine months, with the decline in the future output index marking the secondlargest drop on record since March 2020.

Concerns over potential government policy changes, particularly surrounding October’s Autumn budget, combined with subdued global market conditions, are dampening the outlook for the next year. Nevertheless, about half of those surveyed—down from over 60% in August—still anticipate increased output, motivated by new projects and planned product launches.

September also witnessed a decrease in manufacturing employment following two months of increases, while input prices rose at their fastest rate since January 2023.

The United States, the largest global apparel importer, saw its apparel imports soar to $79.3 billion in 2023, predominantly from Asian suppliers, according to a recent report by the US International Trade Commission (USITC). This report, requested by the US trade representative, highlights key trends in the apparel import landscape.

Among the notable suppliers, Bangladesh, Cambodia, India, Indonesia, and Pakistan ranked in the top 10 apparel exporters to the US, collectively accounting for 27% of the country’s apparel imports last year. Over the past decade, the market shares of these suppliers have shifted significantly. While China, the leading exporter, experienced a decline in its share, Vietnam, Bangladesh, Cambodia, and Pakistan saw their shares rise.

Bangladesh, as the second-largest apparel exporter globally, excels in manufacturing basic garments in bulk, thanks to its low labour and input costs, along with duty-free access to key markets outside the US. Cambodia's apparel sector thrives on foreign direct investment and focuses on cut, make, and trim production, utilizing imported materials. Its commitment to social responsibility further enhances its appeal as an alternative sourcing option to China.

India stands out for its high-quality production, characterized by detailed finishing and a vertically integrated industry. In contrast, Indonesia, although a higher-cost supplier, specializes in highvalue garments such as business attire and athletic wear. Lastly, Pakistan leverages its strong cotton sector to support its apparel industry, particularly in producing high-quality denim, though geopolitical risks remain a concern for buyers.

Discuss

The Uzcharmsanoat Association from Uzbekistan recently held discussions with Musa Jamanbayev, the Kyrgyz Republic's Ambassador to Uzbekistan, to explore avenues for expanded cooperation and joint investments in the leather industry. During the meeting, the two sides assessed the current state of bilateral relations in the sector, evaluating past efforts and setting new priorities. Ambassador Jamanbayev expressed interest in learning from Uzbekistan's

advancements in leather production and suggested collaborative projects involving Uzbekistan’s key industry players in Kyrgyzstan.

Discussions also covered potential partnerships in wool processing and raw leather collection, with Jamanbayev highlighting Kyrgyzstan's need for improved leather processing capabilities to reduce wastage.

As a result, both parties agreed to establish a platform to facilitate business tours and negotiations, enabling entrepreneurs from both nations to foster stronger ties in the leather sector.

Vietnam's garment exports to the Middle East fell by 25% in the first nine months of 2024, driven by heightened competition and shifting market dynamics. Countries like Bangladesh, India, and Turkey have gained ground by offering competitive prices and a broader

range of products, presenting a challenge for Vietnamese exporters. At the same time, economic uncertainties in the Middle East, including fluctuating oil prices and geopolitical tensions, have weakened consumer purchasing power, leading to reduced apparel demand.

Industry experts attribute this downturn not only to increased competition but also to a shift in consumer spending habits in the Middle East, where retailers have responded to economic pressures by tightening budgets and scaling back on orders from Vietnamese suppliers.

In light of these developments, Vietnamese garment leaders are urging manufacturers to innovate, focusing on sustainability, quality improvements, and supply chain efficiency to regain market share. Diversifying export destinations and strengthening partnerships within the Middle East are also seen as crucial strategies for maintaining resilience and adapting to the evolving global apparel market.

The decline signals the need for Vietnam’s garment industry to adopt a forward-thinking approach, emphasizing adaptability and strategic planning to navigate an increasingly competitive environment.

New Senior Sales Manager, Textile Engineer, and Korean Market Consultant bring key skills to industry-leading brand

eVent® Fabrics, a global leader in waterproof and breathable laminates, is proud to announce the recent hiring of three key team members to assist with growing demand for the brand’s expanding line of performance laminates and recent expansion into the South Korean market.

Recent hires include Bartosz Lassak to the US sales team and Xie Yi to engineer the next generation of eVent textiles. For the recent expansion into Korea, Terry Kim will assist as eVent’s Korean Market Consultant.

“We are taking a range of steps now to position eVent for future growth. Our newest hires and work in the Korean market are just two of our most recent efforts to meet increasing global demand,” said Chad Kelly, President of eVent Fabrics. “Additionally, with increasing regulatory pressures and elevated consumer demand for PFAS-free technologies such as our alpineST and BIO laminates, we are well positioned for future success.”

eVent’s recent expansion into the Korean market includes a new strategic partnership with GEO International Co., LTD, a leading Korean company in the textile industry. This collaboration will introduce eVent’s high-performance waterproof breathable laminate solutions for apparel, footwear, and accessories to the Korean market, catering to the increasing demand for premium outdoor and performance apparel.

eVent’s newest team members include:

Based in Washington D.C., Bartosz is a Senior Sales Manager for the Eastern U.S. region and will help expand eVent’s sales footprint as new customers are added to the eVent portfolio. Bartosz brings 20 years of global industry experience and has a deep knowledge of outerwear materials, end use applications, and component brand sales. Most recently, Bartosz was a Territory Sales and Marketing Manager for Primaloft, managing ingredient brand distribution in the UK, Germany, Eastern Europe, Russia, Turkey, and North America.

Having recently graduated with a double Master’s Degree in Textile Materials and Product Design from the highly regarded Donghua University, Xie joins the eVent team full time as a Textile Engineer. Xie will be integral as eVent continues to enhance product strategy and new product introductions. Throughout her academic career, Xie worked as a Production Assistant for Oya Jacquard Belt limited and a Research and Development Assistant at Atelier LUMA. Terry Kim – Senior Consultant in Korea

Terry will support the expansion of eVent’s global footprint into Korean markets and assist with marketing efforts in the Korean market as well. Terry has significant experience in the industry including 20 years working in roles such as Sales Director and New Business Development Director in his time at Gore-Tex. In his most recent role, Terry was the Managing Director of Fabric Division for Gore-Tex.

WEKO is the official sales & service partner in North America for PLEVA Sensors and Controls. Mr. Terence McGee (General Manager WEKO North America) and his team represent PLEVA in the USA and Canada.

After a successful technology training at PLEVA headquarters Empfingen in Germany, Terence McGee (General Manager WEKO North America) and Daniel Forbes (Service Technician) are ready to support and advise the customers in USA and Canada.

WEKO is worldwide known for high quality minimal spray dyeing and finishing technology. This in combination with PLEVA high precision sensors and controls will give many advantages in terms of improving efficiency and sustainability in industrial production. Significant reduction in water, energy and chemical consumption can be achieved. In addition, new functional effects can be created for technical textiles, paper, nonwovens and more.

“WEKO is a great partner for us. We are looking forward to the co-operation in North America and are ready to start new, exciting projects. Together we make the industry more sustainable.” states Kathrin Pleva, Member of Management.

As a starting point, PLEVA and WEKO presented themselves together on a common exhibition booth at Techtextil North America, which took place from 20 to 22 August in Raleigh, North Carolina.

Rieter Investor Update 2024Order intake of CHF 226.4 million in the third quarter, CHF 629.8 million after nine months

Sales of CHF 163.3 million in the third quarter, CHF 584.3 million after nine months

Order backlog of around CHF 690 million as of September 30, 2024 Outlook for the full year 2024

The market environment in the reporting period was characterized by restrained investment in new machinery in almost all regions except China. Demand for consumables, wear & tear and spare parts weakened slightly due to the low spinning mill capacity utilization. The noticeable downturn in consumer sentiment had a further dampening effect throughout the entire textile value chain.

Despite this challenging market environment, the Rieter Group recorded a gratifying order intake of CHF 629.8 million in the first nine months of 2024 (2023: CHF 452.2 million) in all market regions. In the third quarter of 2024, orders increased by 78% year-on-year to CHF 226.4 million (2023: CHF 127.2 million). This means that the order intake has increased for the third quarter in a row.

Rieter’s cumulative sales in the first nine months of 2024 amounted to CHF 584.3 million (2023: CHF 1 092.9 million), a decrease of 47% compared to the prior-year period. Sales in the third quarter of 2024 were CHF 163.3 million (Q3 2023: CHF 334.7 million).

The Business Group Machines & Systems generated total sales of CHF 264.1 million in the first nine months of 2024 (-65% compared to the same period of the previous year). The Business Group Components posted sales of CHF 184.5 million, 11% lower than in the corresponding period of the previous year, while the Business Group After Sales recorded a slight decline of -1% to CHF 135.7 million in the first nine months of 2024.

As of September 30, 2024, Rieter has an order backlog of around CHF 690 million (September 30, 2023: CHF 900 million).

The transfer of resources and responsibilities to India and China to

enable the key markets to respond in a more agile way to customer needs and cycles in the machinery business is on track. The planned cost savings were achieved. Rieter continues to consistently implement the action plan to increase profitability.

Due to the overall geopolitical situation and the general deterioration in consumer sentiment, the market recovery is proving to be more restrained than previously forecast. The first signs of a recovery in financial year 2024 have emerged in the key markets of China and India.

For the full year 2024, Rieter now anticipates sales in the range of CHF 900 million and an EBIT margin remaining at 2% to 4%.

Rieter has today placed a bond of CHF 65 million with a term of five years and a coupon of 3.5%. The net proceeds of the issue will be used for general corporate purposes. “The bond also extends the maturity profile of our debt financing and increases the diversification of the investor base as well as our strategic flexibility,” said Oliver Streuli, Rieter Group CFO.

The bond was issued by UBS, Zürcher Kantonalbank, Commerzbank and Basler

Kantonalbank. The bond will be listed on the SIX Swiss Exchange.

Rieter is the world’s leading supplier of systems for manufacturing yarn from staple fibers in spinning mills. Based in Winterthur (Switzerland), the company develops and manufactures machinery, systems and components used to convert natural and man-made fibers and their blends into yarns in the most cost-

efficient manner. Cutting-edge spinning technology from Rieter contributes to sustainability in the textile value chain by minimizing the use of resources. Rieter has been in business for more than 225 years, has 18 production locations in ten countries and employs a global workforce of around 4 800, about 16% of whom are based in Switzerland. Rieter is listed on the SIX Swiss Exchange under ticker symbol RIEN.

Textiles Intelligence is the official media partner of a forthcoming industry conference which will analyse the challenges and opportunities of artificial intelligence (AI) in the textiles and clothing industries. The conference is being hosted by the Association of Suppliers to the British Clothing Industry (ASBCI) and it will take place in Halifax, UK.

AI tools are poised to disrupt the entire fashion value chain—from trend prediction, product development and stock optimisation to personalised marketing, customer journeys and retail design.

In particular, they are set to drive innovation, create competitive advantages, give rise to new risks and raise ethical questions as to how this new technology can be exploited.

The ASBCI conference will explore how the textile and clothing industries can harness the rewards of AI while mitigating the risks and fulfilling its responsibilities to businesses, people and the planet.

At the conference, technologists, experts at the forefront of AI innovation and retailers pioneering AI tools will provide use cases, highlight the potential benefits, and consider the legal, ethical and sustainability risks associated with AI innovations.

The keynote presentation will be delivered by Dr Ahmed Zaidi, a visiting AI researcher at the University of Cambridge and the chief executive officer (CEO) and co-founder of Hyran Technologies—an AI platform which helps brands and suppliers respond to consumer demand, increase profitability and reduce waste.

Dr Zaidi will address how AI can help the textile and clothing industries to meet their core, long-standing challenges by exploring the intersection of fashion and AI.

Jack Stratten—the head of trends at the retail trendspotting agency Insider Trends—will provide an overview of innovation and AI in retail and will highlight the positives and negatives of AI in the real world and in real time. Insider Trends works with a number of major retail brands—including Galleries Lafayette, Tommy Hilfiger and Westfield—to identify the key trends in retail.

Nick Eley, the head of digital creation at ASOS, will provide the retailer’s perspective on the rise and integration of AI in product design and presentation. He will explain how the use of three-

dimensional (3D) software, AI and emerging technology is driving innovation and efficiencies at ASOS, enhancing creativity, streamlining workflows and reducing time to market.

The power of AI to improve real-time supply chain transparency and actionable insights will be explored by Cedric Hoffman, the co-founder of the AIpowered supply chain platform Ameba. He will highlight how AI can automatically extract and structure relevant product and supplier information from existing communication flows and how this is helping businesses to improve their operational efficiencies and make space for innovation and growth. And Andrew Dalziel, from software provider Infor, will consider how AI could revolutionise areas such as demand prediction and inventory optimisation in order to enhance the customer experience.

Focusing on the creative process, Peter Gallagher-Witham and Jon Smith, the co-founders of The Fashion Guild, will explore the benefits and threats of AI in the design process and share their experiences of AI image generation

software—asking whether it will lead to revolution or redundancy.

Personalisation expert Sarah McVittie, from Dressipi, will explain how harnessing AI insights can help brands and retailers to combat overproduction. Ms McVittie is passionate about reducing the terminal stock waste which results from overproduction. She will explore the size of the waste problem, the changes required, and how to achieve the changes using AI tools.

Linked to this problem is AI’s potential to tackle another intractable industry issue—size and fit. Jason Wang, the chief operating officer of Alvanon, has been pivotal to the company’s AI developments in this field, and he will share his expertise on how emerging technologies can help brands and retailers to cater better to their customers’ fit requirements.

Meanwhile, Norv Bell, the founder of The Bureau model agency, will discuss AI’s legal minefield when it comes to intellectual property rights and HR, and Simon Platts—the co-founder and board advisor at Recomme.co and an ASBCI director—will share his expertise on the

use of AI along the supply chain, and in sustainability and double materiality assessment.

Further exploring the sustainability angle will be James Omisakin, the cofounder of Compare Ethics— an organisation which deals with issues that include the environment, human rights, compliance, and AI technology.

Two panel discussions—moderated by Jenny Holloway from Fashion-Enter and Simon Platts, respectively—will consider the risks, rewards and responsibilities of generative AI and AI for data analysis.

Announcing the conference, the chair of the ASBCI, Julie King, said: “Understanding the risks and potential of AI is a key priority for the fashion industry and one that touches on so many of the challenges our members are facing.

“But with so many tools under the AI umbrella, and such rapid and far-reaching change, it can be challenging to keep on top of developments and cut through the noise to understand what we should and should not be doing, when and how. This conference is an unmissable opportunity to explore the topic from all angles and perspectives at what is a pivotal moment for the industry.”

A prestigious recognition for the Biella-based company and its product Recycrom™, the dyestuff derived from textile waste that allows fashion brands to responsibly dye their garments.

One might say that La Scala Theater has seen it all over its centuries-long history, but it is safe to say that this is the first time a dye made from only textile scraps has been in its spotlight. In fact, in Milan’s most famous theater, on the evening of Sunday 22nd September 2024, Officina39 took part in the Sustainable Fashion Awards 2024 organized by the Camera Nazionale della Moda Italiana. Despite not winning, the company, founded in 1992, was nominated among the three finalists of the Groundbreaking Award with its patented dye Recycrom™

Inspired by Italian craftsmanship and creativity, Officina39 researches and develops sustainable chemicals for the textile, apparel and denim industries, creating technologies with low environmental impact, reducing the use of resources and raw materials. Six years ago, these goals led to the creation of Recycrom™, a range of pigment powders derived 100% from used clothing, fibrous material, and textile scraps through a patented mechanical upcycling process. These fibers produce exceptionally even dyes that can be used on fabrics and garments made of cotton, wool, nylon, or other natural and synthetic fibers, either by dyeing, printing, coating, or spraying.

Participating at the CNMI Sustainable Fashion Awards 2024 is a recognition that rewards the efforts of Officina39. The company has been developing and improving this technology for years by working closely with brands, which often provide the garments to be recycled for unique, custom-made dyes. Blue of a Kind, Calvin Klein, Flavia La Rocca, G-Star Row, H&M Group, OVS, Pangaia, Stella McCartney, Tommy Hilfiger are just some of the partners who have joined the Recycrom™ journey.

To make this color revolution even more accessible and impactful to the

market and the industry, last year Officina39 also launched Recycrom™ Ready to Dye, a range of 15 ready-instock colors made from a minimum of 65% recycled pre- and post-consumer textile materials, offering brands the ability to choose and create their own dyes from a standard color chart.

Moreover, Officina39 is, for all its purposes, a laboratory and workshop

where new solutions are experimented every day to meet the needs of fashion and the environment. Here, the key word is Trustainable, a mix of passion, innovation, sustainable practices, transparency and social responsibility. The CNMI Sustainable Fashion Awards 2024 is a milestone to remember in Officina39’s journey, but the path to a less impactful industry is still long and full of innovation.

Rajiv Sharma assumes the role of Archroma CEO as Mark Garrett transitions to the Board of Directors

Archroma, a global leader in specialty chemicals towards sustainable solutions, has announced that Rajiv Sharma has been appointed as the new Chief Executive Officer (CEO) with key responsibility for the Textile Effects business, effective October 1, 2024. Current Group CEO Mark Garrett will transition to the Archroma Board of Directors.

Miguel Kohlmann, Chairman of the Board of Directors of Archroma, said: “We would like to thank Mark for his strategic leadership throughout a period of transformation and for enhancing the company’s growth trajectory. Mark brings a great deal of expertise and experience to the Board and joins us in welcoming Rajiv Sharma. In Rajiv, we have an inspiring global leader with proven experience in delivering long-term growth.”

“It has been an honor to lead Archroma at such an exciting time, as the company has delivered substantial growth in sales and profitability and successfully integrated the Huntsman Textile Effects business. We have become the clear market leader, with the most comprehensive set of solutions to support our customers in helping reshape our industry for a more sustainable future,” Mr. Garrett said. “Rajiv is a proven visionary with a track record of generating global growth through sustainability, innovation and sound financial management. He is the ideal leader for a forward-looking company with roots that go back more than two-and-a-half centuries.”

Rajiv Sharma comes to Archroma following a 14-year tenure with Coats Group plc (LSE: COA.L), where he was Group Chief Executive for the last eight years. As head of the UK-listed company, which is the world leader in thread manufacturing and structural components for apparel and footwear, Mr. Sharma created a platform for profitable growth

and shaped a company culture based on customer centricity, innovation, digitalization and sustainability.

“I feel very privileged to be given the opportunity to lead this dynamic business at a pivotal time of transformation,” Mr.

Sharma said. “We have an incredible opportunity to support the textile and apparel industry on a sustainability journey that will redefine what’s possible and touch the lives of people all around world.”

Barry Siadat, Archroma Board member and co-Founder of SK Capital Partners, said: “Rajiv brings an ideal set of experience which will support Archroma as it continues to play a key role as the global leader in color and specialty textile chemicals with the industry’s broadest product portfolio and expertise in manufacturing, research and technology, operations and technical customer support that spans the globe. In addition to welcoming Rajiv, we wholeheartedly thank Mark Garrett for the instrumental role he played in serving the company by executing Archroma’s successful acquisition and integration of Huntsman Textile Effects and for delivering substantial growth for Archroma. We are also grateful for his ongoing service as an active Board Member.”

In parallel with these leadership changes, Archroma’s Packaging Technologies business is established as a focused business activity from October 1, 2024, with the aim of increasing its focus on the packaging business and accelerating its development. It will continue under the proven leadership of its CEO, Sameer Singla, who will report directly to the Archroma Board of Directors. Packaging Technologies has also delivered substantial growth with more dedicated leadership over the past two years and the organizational changes will help both Textile Effects and Packaging Technologies continue to focus on best serving their respective customers and markets.

Archroma is a global, diversified provider of specialty chemicals serving the branded and performance textiles,

packaging and paper, and coatings, adhesives and sealants markets. Headquartered in Pratteln, witzerland, Archroma operates with more than 5,000 employees located in 42 countries and with 35 production sites.

Archroma is passionate about delivering leading and innovative solutions, enhancing people’s lives and respecting the planet. The company is committed to the principles of "The Archroma Way to a Sustainable World: Safe, Efficient, Enhanced. It's our nature!"; an approach reflected in its innovations, world-class quality standards, high service levels and cost-efficiency.

Dr. Christian Rink will take over the position of global CFO of the CHT Group held by Prof. Dr. Klaus Müller on an interim basis.

Dr. Christian Rink will form the Management Board together with CEO Eva Baumann. In this role, he will be responsible for Finance & Controlling, Information Technology, Digitalization, Compliance Management and Project Management.

Dr. Rink has gained extensive experience in various functions within the Bosch Group, where he held management positions in Logistics and Finance & Controlling. Among other things, he was Commercial Head Asia Pacific for the Bosch Home Comfort Group in Shanghai, China, and most recently Vice President Finance and Controlling of the Business Unit Electric Solutions which was responsible for building up the Bosch Group's heat pump business.

Eva Baumann comments: “We are firmly convinced that Dr. Rink will make an important contribution to the future success of the company and the achievement of our goals in this crucial position. On behalf of the entire

workforce, I would like to welcome Dr. Christian Rink to the Management Board!”

Johan de Ruiter, Chairman of the Foundation, is certain: “With Dr. Christian Rink, we have appointed a CFO for the CHT Group who will lead the company into a successful future. His many years of experience as CFO of another foundation-managed company and his diverse activities in the industry make him the ideal choice. In these challenging times, we are confident that this will secure and further expand the long-term success of the CHT Group.”

“The Management Board has big plans for the future,” confirms Eva Baumann and clarifies: “We are facing challenging but promising times of change. As a company owned by two foundations, we have strong backing. Nevertheless, we bear a great responsibility for the continued existence of the company and for our employees worldwide. As a manufacturer in the chemical industry, we want to further establish and expand our leading role in

the field of sustainability in the future. With Christian Rink, we form an ideal team to realize our ambitious plans.”

Dr. Christian Rink supplements:

“Together with Eva Baumann, our Management team and the entire workforce, we will continue to expand the CHT Group as a successful and profitable group of companies in the specialty chemicals sector. Prof. Dr. Klaus Müller has shown exemplary commitment and a great sense of responsibility for the CHT Group over the past months as interim CFO. With competence, vision and empathy, he has made a decisive contribution to creating stability and preparing CHT for its future tasks in the best possible way. I would like to express my sincere thanks to him for this.”

The CHT Group pursues important corporate principles: a value-based corporate management, a high level of innovation and a continuous commitment to sustainability.

Utilizing renewable materials* and formaldehyde-free chemistries, the industry-first Archroma NTR Printing System combines newly created pigment black and customized auxiliaries for enhanced sustainability, comfort and durability

Archroma, a global leader in specialty chemicals towards sustainable solutions, has introduced the NTR Printing System to make bio-based pigment printing commercially possible for the first time. Based on renewable raw materials* and designed for safer chemistry, it helps apparel and textile brands reduce their environmental footprint while producing brilliant black shades on garments that deliver both comfort and durability.

Bio-based pigment printing is an emerging technology that is attracting major interest from brands that want to use pigments derived from natural sources, such as plants, in the production of environmentally conscious textiles. Until now, however, bio-based pigments have not delivered color fastness that is comparable to synthetic pigments, and color quality and production performance have not been sufficient to support commercial-scale production.

Archroma’s NTR Printing System is the first to utilize renewable feedstock* across pigment dispersion, binder and fixing agent. Crucially, it ensures good wet-rubbing and dry-rubbing fastness, with outstanding softness on all kinds of fabrics. Furthermore, it is suitable for most popular application technologies, including printing, coating and

continuous pigment dyeing, with outstanding runnability for production efficiency.

“These properties make the new NTR Printing System ideal for the highly competitive denim market, where sustainability, comfort and durability are important; for knits, where very soft handfeel is essential; and on babywear, where both exceptional softness and safety are required,” Joaquin Femat, Market Segment Director for Printing, Archroma, said.

“This latest breakthrough is another example of innovation under Archroma’s “PLANET CONSCIOUS+” roadmap. We develop revolutionary products, systems, and technologies with increased sustainability features than available market alternatives and enhanced value so that brands and mills can differentiate themselves with solutions that meet their business goals and sustainability targets,” he continued.

The result of more than two years of research and development, the innovative new NTR Printing System required Archroma to create customized binding and fixing agents to ensure fastness for the pigment black dispersion comparable to current petroleum-based printing systems. All three printing elements are partially based on renewable feedstock to reduce reliance on non-renewable petrochemicals. Archroma also developed the new system to avoid toxic input streams and impurities, including formaldehyde. Two successful bulk trials were conducted with Textprint S. A. and Jeanologia.

The NTR printing system comprises the following highly efficient and robust printing elements:

PRINTOFIX® BLACK NTR-TF: A nongelling pigment black with 79% renewable carbon content**, designed for use in textile applications with no impact on fastness levels.

HELIZARIN® NTR-SS: A formaldehyde-free super-soft binder with 40% renewable carbon content**, designed to ensure very good overall fastness levels.

FIXING AGENT NTR-HF: A formaldehyde-free fixing agent with 40% renewable carbon content**, designed for high wet fastness in rubbing and laundry.

All three elements are currently being evaluated for compliance with globally accepted standards like bluesign®, the Global Organic Textile Standard (GOTS) and Zero Discharge of Hazardous Chemicals (ZDHC). The system also supports major industry restricted substances list (RSL) requirements.

“With the launch of the bio-based NTR Printing System, Archroma can now draw on the industry’s most complete portfolio of innovative printing solutions to tailor systems for individual customer needs,” Mr. Femat said. “We remain the global leader in pigment printing, with a history of innovation that includes the first formaldehyde-free pigment printing system, introduced in 2012.”

* The NTR printing system utilizes partially renewable raw materials.

**Based on ASTM D6866 bio-based product testing using radiocarbon analysis.

Deeper commitment to innovation and partnership; sharper focus on consumers and the environment

Archroma, a global leader in specialty chemicals towards sustainable solutions, has honed its vision of the future of the apparel and textile industry with the announcement of “PLANET CONSCIOUS+”, a roadmap designed to support brands and mills to chart their sustainability journey.

“Over the past decade, Archroma has been on a mission to lead the textile industry towards a more sustainable future. But the world’s challenges are escalating – from climate change to economic and geopolitical instability. We believe that the time is right for us to realign our vision to guide the next phase of our development. ‘PLANET CONSCIOUS+’ encapsulates both our responsibility and our potential as a company that touches and colors people’s lives every day, all around the world,” Mark Garrett, Group CEO, Archroma, said.

“With the industry’s most extensive product portfolio and a comprehensive global footprint, Archroma has the resources and drive to go beyond the status quo and advance what’s possible for apparel and textile brands on multiple fronts at the same time,” Paul Cowell, Vice President of Innovation, Marketing, Brand Engagement and Sustainability for Archroma Textile Effects, explained. “The introduction of ‘PLANET CONSCIOUS+’ deepens our commitment to innovation and partnership and sharpens our focus on consumers and the environment to bring about meaningful change with pace and at scale.”

“PLANET CONSCIOUS+” has six dimensions, the first four of which have been rolled out over the past few months:

SUPER SYSTEMS+: Powerful end-to-end systems that combine processing solutions and intelligent effects, SUPER SYSTEMS+ deliver measurable environmental impact, more durable colors and effects, and cleaner chemistry as compared to the current market offering. This allows brands and mills to select the impact they want to achieve in line with their sustainability goals.

SAFE EDGE+: Groundbreaking initiative represents a major commitment to providing a roadmap for compliance and cleaner chemistries for use in the textile industry by combining The Safe Edge platform with Foundation+. Foundation+, Archroma’s beyond-compliance portfolio, is a curated selection of Archroma products that utilize innovative technologies to either design out hazardous or regulated substances or reduce them by more than 95% compared to the current industry standard limits.

ONE WAY+: Combining Archroma’s One Way Impact Calculator, a world-first online tool for sustainable value chain mapping, with its expert-led Sustainability Improvement Program (SIP), ONE WAY+ helps mills and brands overcome their specific challenges with products and tools that offers the highest operational excellence and productivity, achieves savings of resources such as water, energy, and creates differentiation with value-added end-products.

COLOR MANAGEMENT+: An advanced color design and development solution, COLOR MANAGEMENT+ helps mills and brands work together for improved sustainability. It incorporates the industry’s largest off-the-shelf color atlas selection alongside color standards created with Archroma’s SUPER SYSTEMS+ for reduced environmental impact and consistent and accurate color reproduction.

The remaining two pillars of “PLANET CONSCIOUS+” are being introduced now that continuesto underscore that innovation and transparency are the cornerstones of the Archroma way of working.

INNOVATION+: Archroma brings together science, their technological expertise and in-depth market, customer, and regulatory knowledge to create groundbreaking solutions that have a positive environmental impact. To accelerate the shift to a circular economy and help manufacturers use resources more efficiently, Archroma’s research and development teams across Americas, Asia and Europe focus on innovating for cleaner chemistry and durable effects.

COMMUNICATION+: By providing authentic, fact-based information to all stakeholders, Archroma helps improve transparency across the value chain. This enables mills and brands to communicate their sustainability goals and achievements with confidence and navigate issues like regulatory complexity and consumer skepticism.

“To truly make a difference in our fast-paced world, innovation must be accompanied by accountability and trust. We work with brands and manufacturers to develop and produce end-products that are safer than available market alternatives and made in a more sustainable and efficient way— and we give them the tools to measure their environmental impact and talk about their contribution with evidence-backed data,” Mr. Cowell said.

Following a successful launch in Dubai in 2024, FESPA Middle East is gearing up for its second edition from 20-22 January at the Dubai Exhibition Centre. As a global federation of associations for the digital printing, textile and screen-printing community, FESPA is a non-profit organisation that has reinvested US$9 million into the printing industry worldwide since 2015 through its Profit for Purpose programme.

Profit for Purpose is an international reinvestment initiative designed to channel revenue from FESPA events into supporting the sustainable and profitable growth of the global speciality print community. The programme fosters the development of print businesses by providing market insights and facilitating valuable networking opportunities.

Some of the actions it undertakes to deliver this reinvestment initiative, include: the production of technical guides and sustainability guides which offer advice for business owners and are

available to FESPA members; the FESPA Print Census report giving insights on trends and long-term growth; funding for association projects who deliver localised activities; as well as bespoke events to connect key stakeholders such as the FESPA Leadership Exchange (FLEX) which was hosted in Dubai in 2023 and at

FESPA Middle East 2024 to share knowledge and discuss future trends.

"As a not-for-profit organisation, FESPA has a unique focus, driven by a mission to promote growth and knowledge-sharing in the printing sector and provide ongoing support to the industry worldwide. FESPA Middle East is

an important addition to our global portfolio and highlights our commitment to promoting the region’s thriving print sector, making us very different to other trade exhibition organisers," said Bazil Cassim, Regional Manager (Middle East and Africa), FESPA.

With a global network of over 14,000 members worldwide, FESPA has created a range of exclusive benefits to support those within the industry, including preferential access to exhibitions, networking opportunities, and expert industry insights in multiple languages and a host of informational guides and white papers. Industry professionals within the MENA region can sign-up to FESPA Direct membership in order to access the curated materials and forum.

Visitors to FESPA Middle East 2025 will also have access to a wealth of content when the event returns to Dubai in January next year, with a dynamic showcase of live competitions, learning opportunities, and business-building sessions. On the exhibition floor, you will be free to attend FLEx (FESPA Leadership Exchange), a range of conferences featuring international speakers and experts from across the printing industry covering topics such as Business Building, Personalization, New Technology/Future Vision, Brand Perspective, Sustainability in print.

The event will also host the popular World Wrap Masters – Middle East, part of a global competition series in which wrap installers demonstrate their proficiency, expertise, and technique. In addition, FESPA Middle East will feature Wrap Demos in collaboration with official Learning Partner, The Wrap Institute, providing valuable techniques, tips, and guidance on maximising profits for professionals in the vinyl wrapping industry.

The Sustainability Spotlight stand feature is also set to return, allowing attendees to explore a unique showcase

of 100+ sustainable print material samples with data sheets for sourcing, ideas on reducing waste and optimising resource use.

The sectors featured at FESPA Middle East include digital printing, textiles, signage (including digital signage) and screen printing. The inaugural edition featured over 150 brands and exhibitors, and over 3,000 visitors had the opportunity to explore thousands of products on display.

Registration for FESPA Middle East is now open at www.fespamiddleeast.com, and visitors can register for free entry using promo code FMEM501.

Functional, reliable and innovative – this is how the products for the contract sector are presented at Heimtextil in Frankfurt from 14 to 17 January 2025. Interior designers, architects and hospitality experts awaits a broad and international range of textiles, specifically for use in public buildings and facilities.