DPS World Pakistan 2024

Dates: August 16th to 18th 2024. Venue: Lahore Expo Centre.

63rd DORNBIRN-GFC Call For Papers

Dates: September 11th to 13th 2024.

Venue: Dornbirn Austria.

CAITME 2024

Dates: September 11th to 14th, 2024.

Venue: Tashkent, Uzbekistan.

Techtextil China

International Trade Fair for Technical Textiles and Nonwovens

Dates: September 19th 21st, 2024.

Venue: Shanghai New International Expo Centre, Shanghai, China

HVACR Trends 2024

Dates: October 04th to 5th, 2024. Venue: Karachi Marriott Hotel

ITMA ASIA + CITME 2024

Dates: October 14th to 18th, 2024. Venue: NECC, Shanghai, China.

Dates: November 27th to 30th 2024.

Venue: Osaka, Japan.

2025, Frankfurt

Dates: January 14th, to 17th, 2025

Venue: Frankfurt am Main.

Hannover 2025

Dates: January 16th to 19th 2025.

Venue: Hannover, Germany.

Textile Asia 2025, Karachi

Dates: April 12th to 14th 2025. Venue: Expo Centre, Karachi.

Textile Asia 2024, Lahore

Dates: August 20th to 22nd 2024.

Venue: Lahore Expo Centre.

IGATEX Pakistan 2025, Karachi

Dates: April 24th to 26th 2025.

Venue: Expo Centre, Karachi.

iCADEX Pakistan 2025, Karachi

Dates: April 24th to 26th 2025. Venue: Expo Centre, Karachi.

FESPA 2025

Dates: May 06th to 09th 2025. Venue: Messe Berlin in Germany.

DOMOTEX asiaCHINAFLOOR 2025

Dates: May 26th to 28th 2025.

Venue: NECC, Shanghai, China.

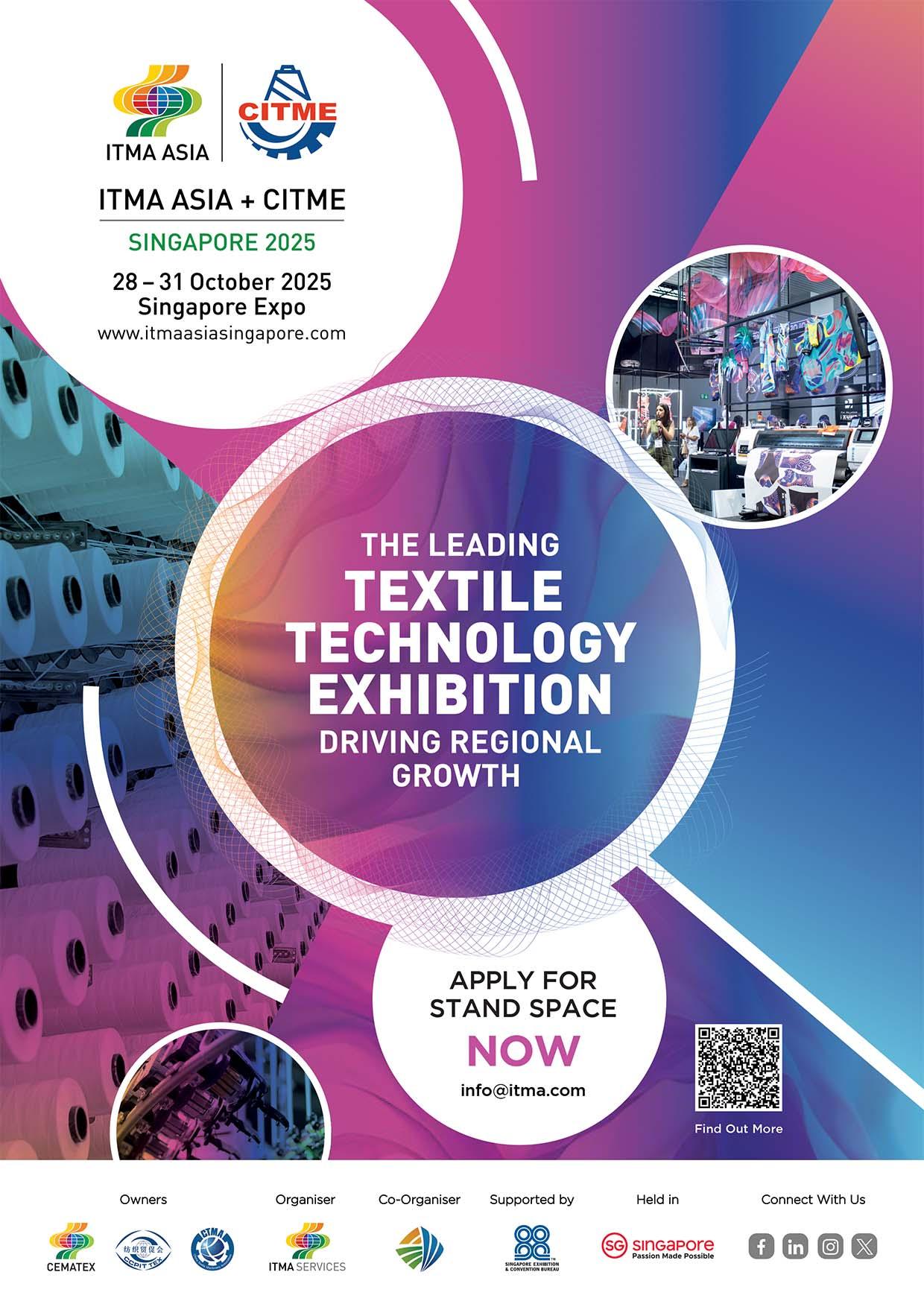

ITMA ASIA + CITME, Singapore 2025

Dates: October 28th to 31st, 2025. Venue: Expo Centre Singapore.

Techtextil 2026

Dates: April 21st to 24th, 2026

Venue: Frankfurt, Germany.

Index 2026

Dates: April 21st to 24th, 2026. Venue: Palexpo, Geneva, Switzerland.

ITMA 2027

Dates: September 16th to 22nd, 2027. Venue: Hanover, Germany.

PAKISTAN TEXTILE JOURNAL - August 2024

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher Nadeem Mazhar

Editor in Chief Amina Baqai

Associate Editor

Nimrah Nadeem

Production Manager Mazhar Ali

Layout & Design

Noor M. Jaan

Website / Social Media

Minhaj Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab

C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA)

Dr. Zubair Bandukda PhD (Textiles), CText ATI

Editorial & Advertising Office

B-4, 2nd Floor, 64/21, M.A.C.H, Miran M. Shah Road, Karachi - Pakistan

Tel: +92-21-34311674-5

Fax: +92-21-34533616

Email: info@ptj.com.pk URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Registered Office:

Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, United Kingdom.

Registered no. 09141989

Tel: +44 792 2228 721

Available on Gale and Factiva affiliated internat ional databases through Asianet Pakistan

Printed at: Color Plus Korangi, Karachi.

Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi.

Mahlo to present cutting-edge straightening and process control technologies at Febratex .

Luxembourg-EIB Climate Finance Platform supports BlueOrchard’s climate insurance equity fund with the backing of the government of Luxembourg

.20 eVent Fabrics Partners with Formidable Media for Strategic Communications and Brand Elevation Services

Sapphire Mills to leverage Life Cycle Assessments and digital

S&P Global Inc. joins ITMF as

Ground-breaking ceremony for new container cleaning and recycling plant in Dusslingen

CHT Germany raises container management to a sustainable level and increases the use of reusable packaging ARCHROMA and VIVID CLM TEAM up to advance color matching for textile printing with the industry’s largest color library

Leadership transition at Loepfe

Markus Kleindorp; New CEO of Loepfe

Brückner, Groz-Beckert, Karl Mayer and Thies to hold joint warp knitting symposium in Brazil

Karachi to host landmark ASHRAE RAL CRC 2024 and 4th HVACR Trends Expo . . .31

Heimtextil 2025: Carpets & Rugs is booming – and makes Frankfurt an annual fixed point for the global carpet industry

Functional natural materials in high demand: real all-rounders for the industry in focus at Techtextil 2026

ITMA ASIA + CITME 2024: Road shows conducted in Pakistan

Road shows were concluded successfully in Pakistan’s economic and cultural hubs: Lahore and Karachi, respectively on, 23th–26th July 2024.

Rieter wins major follow-up order from DIW

Carhartt Inc. joins U.S. Cotton Trust Protocol as part of its strategy to source more responsibly grown cotton

Discover Saurer's innovations at Febratex 2024

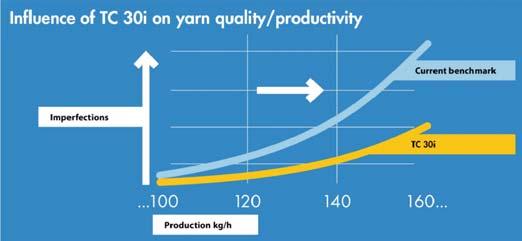

Trützschler’s TC 30i: Convincing customers with strong

The Potential of China-Pakistan Cooperation in the Textile Sector.

by Prof. Engr. Zamir Ahmed Awan, Founding Chair GSRRA, Sinologist, Diplomat, Editor, Analyst, Consultant, Advisor, and Non-Resident Fellow of CCG.

CHTC Fong’s International Co.,Ltd. Allwin Plus high temperature package dyeing machine

RIFA Textile Machinery revolutionizes fabric production with superior technology .52

China Texmatech Co., Ltd: World class textile engineering solution

Mayer & Cie.’s kniting solutions at ITM

Picanol showcased ultimax rapier weaving machine at ITM, a valuable alternative for airjet weavers

Saurer showcased new machines and technology at ITM 2024

Stäubli’s SAFIR PRO S67 captured visitors’ attention during ITM 2024

Trützschler ended ITM 2024 with new partnerships

Glimpses of ITM 2024

China’s textile and garment sector showed resilience with a 1.1% growth in exports, totaling $186.25 billion from January to July 2024. Textile exports rose by 3.7%, reaching $88.54 billion, while garment exports saw a slight decline of 1.2%. Despite challenges such as inflation, geopolitical tensions, and reduced demand from key markets, China’s textile sector continues to play a critical role in the global supply chain, highlighting its economic importance.

The China-Pakistan Economic Corridor (CPEC) has strengthened the economic partnership between the two nations, with textiles emerging as a key area for collaboration. Pakistan’s textile industry, which contributes 8.5% to its GDP and employs over 15 million people, remains a cornerstone of the country’s economy. However, to stay competitive, Pakistan needs to modernize its textile sector and expand its market reach. China, as the world’s largest textile producer, is well-placed to assist Pakistan in this process by offering technology transfer, advanced machinery, and training.

Chinese investment in Pakistan’s textile sector is also expected to rise, especially through the development of special economic zones (SEZs) under CPEC. These zones could attract Chinese textile companies, creating jobs and boosting Pakistan’s export capacity. Strengthened trade ties between the two countries, where Pakistan imports textile machinery and exports cotton yarn and fabrics, could further enhance economic collaboration.

Joint research and development initiatives between China and Pakistan could lead to innovations in sustainable textiles, product diversification, and improved production methods. Additionally, China’s vast domestic market offers Pakistan the chance to diversify its exports and access new markets, reducing its reliance on traditional buyers.

The upcoming ITMA ASIA + CITME 2024 exhibition in Shanghai provides a critical platform for Pakistani textile companies to explore new business opportunities, discover advanced textile machinery, and form international partnerships. Such events are essential for Pakistan’s textile sector to stay competitive globally.

The China-Pakistan partnership in textiles offers significant potential for both countries. By leveraging China’s technological expertise and Pakistan’s rich natural resources, this collaboration can drive mutual growth, innovation, and sustainability in the textile industry, strengthening both nations’ positions in the global market.

1

The government has announced plans to introduce a track and trace system in Pakistan’s cotton and ginning industry to combat tax evasion, as revealed by Rana Tanveer Hussain, the Minister for Industry and Production, National Food Security and Research. This decision was shared during a meeting with a delegation from the Pakistan Cotton Ginners Association on Friday.

2

The Pakistan Central Cotton Committee (PCCC) has announced plans to integrate digital tools and technologies into cotton farming to enhance per-acre yield and overall production potential. This initiative aims

to leverage modern technology to address agricultural challenges and improve efficiency in cotton cultivation.

3

The Punjab government has embarked on a new initiative to explore and implement strategies for improving cotton plantation across the province. This effort is aimed at addressing the challenges faced by the cotton industry and rejuvenating its production capacity.

4

On Thursday, the All Pakistan Textile Mills Association (APTMA) called on the government to significantly lower interest rates to 6 to 7% to better align with regional economies. The association

1

Amid escalating uncertainty within the nation across Bangladesh, the country's apparel and textile manufacturers have decided to suspend operations indefinitely. The Bangladesh Garment Manufacturers and Exporters Association (BGMEA), representing the readymade garment sector, issued a request on Sunday for all its members to shut down their production units until further notice due to the increasingly volatile situation that has resulted in numerous fatalities.

2

China’s textile exports reached a remarkable $42 billion in the first half of 2024, reaffirming the nation's continued dominance in the global textile

argues that reduced interest rates would create a more competitive environment for export-oriented industries, which are currently suffering under high rates that are stifling growth.

5

Earlier this month, Federal Minister for Industries, Production, and National Food Security, Rana Tanveer Hussain, reaffirmed the government's dedication to advancing the cotton industry. His remarks came during a meeting of the Pakistan Central Cotton Committee (PCCC) governing body, as detailed in a recent news release.

6

Suzhou, once renowned as China’s traditional textile hub,

is now presenting a wealth of opportunities for Pakistani businesses, according to China Economic Net (CEN) on Monday. Known historically as a center for textile production, Suzhou has evolved into a significant industrial and economic hub within China. This transformation was highlighted during the recent Pakistan Investment and Trade Conference, which was organized by the Consulate General of Pakistan in Shanghai, alongside local authorities and enterprises in Suzhou last Thursday. The event showcased Suzhou’s potential for fostering Pakistan-China collaborations across various sectors.

market. Fabric exports played a significant role, contributing to 80% of the total export value, which underscores China's crucial role in supplying textiles to international markets despite facing numerous challenges.

3Germany's exports dropped by 3.4% month-over-month in June, reflecting ongoing difficulties in the global trade environment. This downturn has also led to a reduction in Germany’s trade surplus, raising concerns about the country's economic stability. According to the Federal Statistical Office, the value of German exports saw a substantial decline, affecting multiple sectors. This decrease is attributed to

weakening demand in key international markets, persistent supply chain disruptions, and geopolitical uncertainties that continue to strain global trade.

4

The future of India’s textile industry is marred by significant challenges, despite government efforts and attempts to embrace innovation. The sector, which has traditionally been a cornerstone of employment and economic growth, now faces a series of obstacles that could hinder its potential. India's textile industry has been struggling with a troubling decline. From 2018 to 2023, the industry saw a significant drop of 11.69%, with revenues falling from $16.24 bil-

lion to $14.34 billion. This downturn reflects deeper issues within the sector, which has been unable to capitalize on its previously robust production base, including natural fibers such as cotton, jute, silk, and wool, as well as synthetic fibers like polyester and nylon.

5

The Indonesian textile industry is grappling with a significant crisis due to the recent release of 26,000 containers filled with illicit imports that had been languishing at the port, according to the Indonesian Filament Fibre & Yarn Producers Association (APSyFI). This influx has led to widespread job losses and ongoing factory closures.

The government has announced plans to introduce a track and trace system in Pakistan’s cotton and ginning industry to combat tax evasion, as revealed by Rana Tanveer Hussain, the Minister for Industry and Production, National Food Security and Research. This decision was shared during a meeting with a delegation from the Pakistan Cotton Ginners Association on Friday.

Minister Hussain shared the vital role of the cotton industry in the rural economy, noting its potential to provide employment opportunities for a significant portion of the skilled and semiskilled workforce. He explained that the new track and trace system will be applied to locally produced cotton bales to prevent tax evasion, thus safeguarding local farming communities and the industrial sector. The initiative aims to enhance transparency and accountability within the industry, potentially boosting government revenues by curbing illegal trade practices.

In addition, Hussain highlighted that the enforcement of the Cotton Control Act (CCA) will be carried out in collaboration with provincial governments. He assured the delegation that their concerns regarding the new taxation measures on seed cotton and

cottonseed cake would be reviewed. The minister committed to discussing these issues further with the Finance Division and the Federal Board of Revenue to address the challenges faced by the local ginning industry.

Representatives from the Cotton Ginners Association raised concerns about the heavy taxation on cotton products, which they believe is impacting the production capacity of the cotton ginning industry. They called for a rationalization of taxes on these commodities to benefit the local industrial sector and promote increased cotton crop output.

The delegation argued that rationalizing sales tax would improve tax compliance and help reduce tax evasion. They noted that over 8.4 million cotton bales were produced last season and expressed optimism that, with supportive government policies, production could

rise to 20 million bales. They also suggested that the government should consider providing subsidies and other incentives to boost production and encourage investment in modern ginning technologies.

The Pakistan Central Cotton Committee (PCCC) has announced plans to integrate digital tools and technologies into cotton farming to enhance per-acre yield and overall production potential. This initiative aims to leverage modern technology to address agricultural challenges and improve efficiency in cotton cultivation.

Dr. Yusuf Zafar, Vice President of PCCC, emphasized the transformative impact of digital technology on crop management. He noted that advancements such as digital tools in cotton sowing have proven highly beneficial, significantly boosting production outcomes. According to Dr. Zafar, modern technology has revolutionized farming practices, making it easier for farmers to achieve better results from their crops.

During a recent meeting, Dr. Zafar discussed digital agriculture technologies with Prof. Dr. Ishtiaq Rajwana, Vice Chancellor of Muhammad Nawaz Sharif

Agricultural University Multan. The discussion covered various digital innovations including tools, sensors, drones, and artificial intelligence. Dr. Zafar highlighted that the Digital Agriculture Alliance would provide farmers with advanced technology and valuable insights, expected to drive production growth and contribute to the stability of the national economy. He stressed the importance of collaborative partnerships and knowledge exchange between the PCCC and Nawaz Sharif Agricultural University, particularly for advancing cotton research and development.

Prof. Dr. Rajwana supported this view, pointing out that ongoing collaboration between the institutions and the adoption of advanced technologies are crucial for advancing and stabilizing the country’s agriculture sector. He explained that digital technologies such as soil analysis and crop monitoring systems enable farmers to tailor their practices to specific field conditions through precision agriculture. Prof. Rajwana also highlighted the use of automated devices like Smart Siphons and Leaf Temperature Sensors, which provide real-time data on soil moisture and plant water stress, further aiding in efficient cotton production.

The Punjab government has embarked on a new initiative to explore and implement strategies for improving cotton plantation across the province. This effort is aimed at addressing the challenges faced by the cotton industry and rejuvenating its production capacity.

During a recent conference on cotton research and development held at Agriculture House, Provincial Minister of Agriculture Syed Ashiq Hussain Kirmani emphasized that Punjab Chief Minister Maryam Nawaz is committed to reforming the research and development system within agriculture. Kirmani highlighted that various measures are being undertaken to modernize agricultural research to meet contemporary needs.

Syed Ashiq Hussain Kirmani; Punjab Agriculture Minister

He pointed out that the scarcity of quality seeds has led many farmers to abandon cotton cultivation, which is why cotton farming is predominantly concentrated in South Punjab. To revive cotton production, both public and private sectors must collaborate effectively. Kirmani stressed that restoring the production of cotton, often referred to as "silver fiber," is crucial for the economic prosperity of the country.

The primary goal of the program is to leverage the expertise and experiences of both public and private sectors to produce high-quality cotton seeds. Kirmani emphasized the need for developing climate-smart cotton varieties with high productivity to address the current challenges in cotton farming.

Punjab Agriculture Secretary Iftikhar Ali Sahu outlined that the cotton crop has faced numerous challenges over the past decade. He called for actionable proposals from both sectors to tackle these issues and stressed the importance of creating a comprehensive plan based on the conference’s discussions. He also mentioned that the technical opinions of all conference participants would be crucial in formulating this plan.

Sahu added that the federal government would be consulted to address issues at the national level. The conference saw participation from notable figures including South Punjab Agriculture Secretary Saqib Ali Attil, Dr. M. Anjum Ali, former caretaker federal minister Kausar Abdullah Malik, DG Agriculture Extension Chaudhry Abdul Hameed, Javed Salim Qureshi, Dr. Khalid Hameed, Asif Majeed, Saad Akbar Khan, Syed Hasan Raza, Dr. Sagheer Ahmed, and other government officials and private sector representatives.

On Thursday, the All Pakistan Textile Mills Association (APTMA) called on the government to significantly lower interest rates to 6 to 7% to better align with regional economies. The association argues that reduced interest rates would create a more competitive environment for export-oriented industries, which are currently suffering under high rates that are stifling growth.

During a press conference, APTMA South Zone Chairman Zahid Mazhar highlighted the severe impact of high energy costs and steep interest rates on the textile sector. He revealed that over 30% of textile mills have shut down due to these financial pressures, and many others have reduced production by up to 50%.

Mazhar underscored the sector's critical role in the economy, contributing 60% of total exports and 12% to GDP. He expressed concern over the declining export figures, with textile exports falling from $19.33 billion in FY22 to $16.5 billion in FY23. This decline is particularly troubling given the government's ambitious target of $60 billion in textile exports over the next three years.

The APTMA Chairman attributed the rising production costs to the challenging business environment and called for an export-friendly policy framework. He cited Bangladesh as an example, where lower production costs have led to increased textile exports, contrasting this with Pakistan's higher production costs.

Mazhar noted that despite the State Bank of

Pakistan's recent reductions in the interest rate, it remains high at 19.5%. He warned that if the current policy persists, exports will struggle to grow.

He also criticized the high cost of electricity, attributing it to Independent Power Producers (IPPs). He highlighted that capacity charges for IPPs have reached Rs2,000 billion, and despite a national electricity production capacity of 43,000 MW, only 23,000 MW is being supplied.

The APTMA has urged the government to re-evaluate its contracts with IPPs and expressed concern over the proposed plan to cut gas supply to captive power plants by January 2025. Mazhar argued that the national grid is not capable of meeting the electricity needs of the textile sector, which exacerbates the industry’s difficulties.

Earlier this month, Federal Minister for Industries, Production, and National Food Security, Rana Tanveer Hussain, reaffirmed the government's dedication to advancing the cotton industry. His remarks came during a meeting of the Pakistan Central Cotton Committee (PCCC) governing body, as detailed in a recent news release.

Minister Hussain underscored the vital role of cotton production in Pakistan’s economy, highlighting its significant impact on the textile industry. He

emphasized that a strong link exists between high cotton yields and the growth of the textile sector.

To support this, the government has introduced a Rs 10 per unit subsidy on electricity for the textile industry. This initiative is expected to provide considerable financial relief, easing some of the sector's ongoing challenges.

The minister also stressed the importance of prioritizing research and development. He assured that the government is committed to offering comprehensive support to farmers, ginners, and all stakeholders involved in the cotton industry.

Currently, Pakistan’s annual cotton production is at 8.4 million bales, with a target to increase this figure to 15 million bales by 2025. Hussain noted that modern agricultural practices and technology are key to enhancing yield per acre.

Additionally, recommendations for restructuring the PCCC, based on a report from the Food and Agriculture Organisation, are being considered. The next meeting to discuss these recommendations is scheduled for next week.

Suzhou, once renowned as China’s traditional textile hub, is now presenting a wealth of opportunities for Pakistani

businesses, according to China Economic Net (CEN) on Monday.

Known historically as a center for textile production, Suzhou has evolved into a significant industrial and economic hub within China. This

transformation was highlighted during the recent Pakistan Investment and Trade Conference, which was organized by the Consulate General of Pakistan in Shanghai, alongside local authorities and enterprises in Suzhou. The event showcased Suzhou’s potential for fostering Pakistan-China collaborations across various sectors.

Shehzad Ahmad Khan, Consul General of Pakistan in Shanghai, praised Suzhou as a city that exemplifies rapid urbanization and economic development. He noted, “Suzhou, a historic gem located near Shanghai, has emerged as a beacon of modern development and international collaboration. My first impression of Suzhou was remarkable—it is a testament to China’s swift economic progress and its pivotal role in manufacturing.” Khan highlighted Suzhou’s strategic importance due to its

robust flow of human resources between Shanghai and itself.

Recent data from the Suzhou Statistics Bureau revealed that the city’s economy performed exceptionally well in the first half of 2024. Suzhou reported a gross domestic product (GDP) of RMB 1.2059 trillion, marking a substantial 6.2% increase compared to the previous year. Additionally, the city’s manufacturing sector saw significant growth, with a total industrial output value of RMB 2.2253 trillion, reflecting a 5.5% year-on-year rise. Khan emphasized the strong potential for collaboration between Suzhou and Pakistani businesses, particularly in the textile industry, as well as in renewable energy, electric vehicles, and medical devices.

The Consul General underscored the potential for various forms of cooperation, including industry relocation, joint ventures, and foreign direct investment from China to Pakistan. He pointed out the historical ties between the two countries, rooted in their shared silk and textile production heritage. Additionally, he highlighted Pakistan’s growing role as a gateway to the European Union for exports and its substantial consumer market.

The conference concluded with B2B networking sessions and individual meetings, offering a valuable opportunity for businesses from both nations to explore potential partnerships and collaborative ventures.

Bangladesh apparel and textile manufacturers halt production indefinitely

Amid escalating uncertainty within the nation across Bangladesh, the country's apparel and textile manufacturers have decided to suspend operations indefinitely. The Bangladesh Garment Manufacturers and Exporters Association (BGMEA), representing the readymade garment sector, issued a request on Sunday for all its members to shut down their production units until further notice due to the increasingly volatile situation that has resulted in numerous fatalities.

Simultaneously, members of the Bangladesh Textile Mills Association (BTMA) have also agreed to halt production during the three-day general holiday that has been declared. The decision to close was reinforced by an incident where one of its member mills in Gazipur was set on fire.

In Narayanganj, production in most ready-made garment factories has been suspended as the unrest continues. Factory owners reported that workers initially started their shifts, but were provoked by external agitators to abandon their work and take to the streets. This led to several factories in Narayanganj BSCIC and Fatullah closing operations to protect their facilities.

Fazle Shamim Ehsan, Vice President of the Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA), confirmed that production was halted in various factories after workers were influenced to leave their posts.

Abdullah Hil Rakib, Vice President of BGMEA, reported that by 3:00 pm, workers in some Gazipur factories had left their workplaces, leading to a halt in production. He acknowledged the fatalities resulting from clashes between protesters, law enforcement, and ruling party members across the country.

Despite the challenges, Rakib mentioned that efforts would be made to continue operations, similar to previous instances

during holidays, by using workers' identity cards as curfew passes.

Rakib also noted that while most factories in Gazipur were still operational, BGMEA plans to seek a meeting with the government to request permission to continue production during the curfew and general holiday

Fabrics contributed 80% to China's textile exports of $42 billion in H1 2024

China’s textile exports reached a remarkable $42 billion in the first half of 2024, reaffirming the nation's continued dominance in the global textile market. Fabric exports played a significant role, contributing to 80% of the total export value, which underscores China's crucial role in supplying textiles to international markets despite facing numerous challenges.

The strong performance of the fabric export sector has been fueled by steady demand from major global markets such as Europe, the United States, and Southeast Asia. China’s ability to offer competitive pricing and consistently highquality products has helped solidify its standing as a leading exporter, particularly in the fabric segment.

However, the industry is encountering significant hurdles. Rising labor costs and stringent environmental regulations are

compelling manufacturers to innovate and adopt more sustainable practices. Moreover, ongoing geopolitical tensions and shifting trade policies are encouraging Chinese textile exporters to diversify their markets and seek new opportunities.

As the global textile landscape continues to shift, China’s textile industry remains a cornerstone of the global supply chain. Industry stakeholders are closely monitoring market trends and policy changes that could influence future export growth and the sustainability of this vital sector.

Tensions among Germans rise as exports show decline by 3.4% in June

Germany's exports dropped by 3.4% month-over-month in June, reflecting ongoing difficulties in the global trade environment. This downturn has also led to a reduction in Germany’s trade surplus, raising concerns about the country's economic stability.

According to the Federal Statistical Office, the value of German exports saw a substantial decline, affecting multiple sectors. This decrease is attributed to weakening demand in key international markets, persistent supply chain disruptions, and geopolitical uncertainties that continue to strain global trade.

While imports to Germany also experienced a slight decline, it was not sufficient to counterbalance the drop in exports. Consequently, the country’s trade surplus—the gap between exports and imports—has narrowed, indicating potential challenges ahead for Germany's export-driven economy.

Economic analysts are closely observing these developments, noting that Germany’s economic health is closely tied to its trade activities. If the decline in exports persists, it could hamper overall economic growth.

In response, the German government and industry leaders are considering strategies to mitigate the impact, such as diversifying export markets and bolstering domestic industries. However, the global

economic landscape remains uncertain, and the success of these measures will depend on various external factors.

The future of India’s textile industry is marred by significant challenges, despite government efforts and attempts to embrace innovation. The sector, which has traditionally been a cornerstone of employment and economic growth, now faces a series of obstacles that could hinder its potential.

India's textile industry has been struggling with a troubling decline. From 2018 to 2023, the industry saw a

significant drop of 11.69%, with revenues falling from $16.24 billion to $14.34 billion. This downturn reflects deeper issues within the sector, which has been unable to capitalize on its previously robust production base, including natural fibers such as cotton, jute, silk, and wool, as well as synthetic fibers like polyester and nylon.

The sector’s contribution to India’s GDP, which stands at 2.3%, and its role in exports and industrial production are under threat. Despite being a major contributor to the economy, the industry is grappling with persistent problems that overshadow its potential benefits.

The Indian government has announced plans to adjust its Production Linked Incentive (PLI) scheme, adding product lines like innerwear and t-shirts to the scheme. However, these measures have been criticized as insufficient to address the industry’s deep-rooted problems. The scheme's focus on labor-

intensive sectors may not be enough to counteract the broader decline and market instability.

The anticipated growth in the textile market, projected at a 10% compound annual growth rate (CAGR) to reach US$ 350 billion by 2030, may not be realistic given the current challenges. India’s position as the world’s third-largest exporter of textiles is precarious, with exports projected to hit US$ 100 billion, yet the industry struggles with diminishing returns and increasing competition.

The textile sector, which employs around 45 million workers, including 3.5 million handloom workers, faces significant employment challenges. Despite its size, the industry’s inability to maintain growth is raising concerns about job security and the sustainability of employment levels.

India’s status as the world’s largest producer of cotton and its potential in the technical textile sector, including medical textiles and composites, are overshadowed by ongoing difficulties. The industry's efforts to embrace sustainability and innovation may not be enough to overcome the fundamental issues affecting its performance.

The challenges facing India's textile industry highlight broader issues within the sector, including infrastructure bottlenecks, environmental concerns, and skill gaps. These problems threaten to undermine the industry’s global standing and economic contribution, casting a shadow over its future prospects.

The Indonesian textile industry is grappling with a significant crisis due to the recent release of 26,000 containers filled with illicit imports that had been languishing at the port, according to the Indonesian Filament Fibre & Yarn Producers Association (APSyFI). This influx has led to widespread job losses and ongoing factory closures.

Farhan Aqil Syauqi, APSyFI's executive secretary, has criticized Coordinating Minister for Economic Affairs Airlangga Hartarto and Finance Minister Sri Mulyani for their role in the situation. "It appears that illegal imports are being effectively legitimized in our country," Syauqi remarked.

Syauqi also expressed concerns over the lack of public information regarding the containers' contents, alleging that the ministers in charge of trade and industry were also unaware of what was inside.

The association is demanding greater transparency and a clear explanation of the container contents. "In light of these troubling developments, APSyFI calls for decisive government action to protect the domestic textile industry from the flood of illegal imports," Syauqi urged.

In a recent meeting with the International Cotton Advisory Committee (ICAC), Nigeria’s Vice President announced a bold initiative aimed at rejuvenating the country’s textile industry, a sector that has historically played a crucial role in Nigeria's economy but has faced numerous challenges in recent years.

The Vice President outlined a comprehensive strategy for this revival, which includes upgrading existing textile facilities, investing in cutting-edge technologies, and introducing supportive government policies. These measures are intended to boost production efficiency, enhance competitiveness, and generate new employment opportunities within the sector.

The ICAC mission responded positively to Nigeria’s commitment, expressing confidence in the potential benefits for the local economy. They underscored the need for a united effort between the public and private sectors to ensure the long-term sustainability and growth of the textile industry.

This initiative is a key component of Nigeria’s broader economic diversification plan, which aims to lessen the country’s reliance on oil and stimulate growth in other sectors such as agriculture and manufacturing. By revitalizing the textile industry, Nigeria hopes to provide a stable source of income and job opportunities for many of its citizens.

Turkey’s apparel exports see 10% drop due to ongoing global economic challenges

In the first half of 2024, Turkey's apparel exports fell sharply by 10%, totaling $8.5 billion. This decline underscores the difficulties the Turkish apparel sector is facing in the midst of a global economic slowdown and shifting trade dynamics.

Several factors have driven this drop. A reduction in consumer spending worldwide has led to decreased demand for apparel in major markets. Additionally, heightened competition from other apparel-exporting nations and fluctuations in currency values have exacerbated the situation.

Despite these setbacks, Turkey's apparel industry remains a vital

component of the national economy. Efforts are underway to counteract the negative impact of the export downturn. Industry players are actively seeking new market opportunities and working on improving production efficiencies to regain their competitive edge. Furthermore, the government is implementing supportive policies to bolster the sector’s resilience and encourage innovation.

The future performance of Turkey’s apparel exports will largely depend on the successful execution of these strategies and the evolution of global market conditions in the second half of 2024.

seizes opportunity as

Vietnam's apparel sector is experiencing a notable upsurge as Australia diversifies its sources of apparel imports away from China. This shift,

prompted by geopolitical tensions and trade disruptions, has created a significant opportunity for Vietnamese textile and garment producers.

Over the past year, Australia has reduced its apparel imports from China by 25%, falling from around $4.5 billion to $3.4 billion. This substantial reduction has opened a gap in the market that Vietnamese manufacturers are rapidly filling. During the same period, Vietnam’s apparel exports to Australia have surged by 40%, increasing from $1.2 billion to $1.68 billion.

Vietnamese textile companies are benefiting from a surge in orders from Australian retailers and brands. In response, these manufacturers are scaling up production, with several major firms planning to expand their production capacity by up to 30% in the coming year.

Australian retailers have welcomed this shift, appreciating the greater flexibility and reliability offered by Vietnamese suppliers. This trend reflects a broader global movement towards diversifying supply chains amid international uncertainties.

The realignment of trade patterns portrays the evolving dynamics of global commerce and highlights the rising significance of Southeast Asian economies. As Vietnam takes advantage of this opportunity, it strengthens its position as a key player in the global apparel market and a vital supplier for major international buyers.

Mahlo GmbH + Co. KG, a global leader in measuring, control, and automation systems for the textile and finishing industry, is pleased to announce its participation in the Febratex trade show from August 20 to 23, 2024. The event will take place in Blumenau, Brazil, a hub for textile and garment production.

Visitors can find Mahlo at Sector 01 / Space 20 - 22, where the company will present its latest advancements in straightening technology and process control. The booth will be jointly hosted by Mahlo’s sales agency MBR Textile and Christian Matthias, the head of Mahlo’s application department. They will be available to provide in-depth knowledge and demonstrations of Mahlo's state-ofthe-art solutions.

Mahlo’s technology addresses the critical needs of textile manufacturers, ensuring high-quality production with minimized distortion and optimized processes. The company’s automatic straightening system guarantees threadstraight fabric across various applications,

thanks to its modular design that can be tailored to individual production environments. Additionally, Mahlo offers several process control systems designed to optimize stenter frame operations by measuring and controlling parameters such as dwell time, thread density, and residual moisture. These systems help manufacturers improve textile quality, save raw materials, and reduce energy costs.

“Brazil hosts all industries needed for textile and garment production, from fiber to final product, making Mahlo’s diverse solutions highly relevant and essential for many manufacturers,” said Christian Matthias. “Our technologies help producers achieve their goals of high-quality goods and optimized processes that balance quality and economy.”

The Luxembourg-EIB Climate Finance Platform (LCFP) will provide EUR 5 million for impact investor BlueOrchard's innovative USD 100 million climate insurance fund, with the backing of the government of Luxembourg.

The LCFP seeks to catalyse private and public sector investment into highimpact companies in emerging markets involved in insuring climate change mitigation and adaptation projects, including projects addressing losses and damages caused by climate change.

Gilles Roth, Luxembourg Minister of Finance said: “Protecting communities from the social and economic impact of climate change is crucial and can be enhanced through climate insurance and better understanding of the local impact of extreme and more uncertain weather. Luxembourg is pleased to support the new BlueOrchard Insurance resilience fund as part of our impact focused

climate cooperation with the European Investment Bank. This cooperation demonstrates how private and public finance, climate expertise and climate insurance can mitigate the impact of climate change on vulnerable regions.”

Serge Wilmes, Luxembourg Minister of the Environment, Climate and Biodiversity said “Luxembourg is committed to climate action and is

pleased to support improved access to climate insurance to effectively protect vulnerable communities in developing countries from losses and damages caused by climate change, including extreme weather events and slow onset events. Unlocking private and public investment is critical to tackling the climate crisis in developing countries. The new support for the BlueOrchard

InsuResilience Fund II by the Luxembourg-EIB Climate Finance Platform will help vulnerable communities to be better prepared for climate risks and recover more quickly from climate disasters.”

The BlueOrchard managed InsuResilience Investment Fund Private Equity II (IIF II) will contribute to increasing access to affordable insurance and expanding the provision of climate insurance by providing equity investments in fast-growing companies that provide and support climate insurance, including insurance technology providers and specialist insurance companies and brokers.

New investment backed by the BlueOrchard managed InsuResilience Investment Fund Private Equity II will help to enhancing climate resilience in Asia, Africa, and Latin America by providing coverage against unavoidable climate related losses and damages in developing countries, including extreme weather events and slow onset events. By doing so it effectively offers an effective means to reduce financial risks and ensure rapid recovery following extreme weather events.

"The European Investment Bank is committed to fostering climate resilience around the world and our latest collaboration with BlueOrchard will help to address barriers holding back access to climate insurance in countries most impacted by climate change. Investing in adaptation and resilience is not only a necessity but a strategic imperative for the insurance industry in the face of climate change. The InsuResilience Investment Fund II will support equity investments in climate insurance technology, to empower insurers to better manage climate risks and better protect vulnerable communities across Asia, Africa, and Latin America from extreme weather events and climate change." said Ambroise Fayolle, Vice President.

"Our latest partnership with the EIB reflects our shared dedication to building resilience against the consequences of climate change and supporting the most vulnerable regions and households. The InsuResilience Investment Fund Private Equity II will drive high-impact equity investments to enable companies to

harness technological innovation and improve access to affordable climate insurance solutions." said Philipp Mueller, Chief Executive Officer of BlueOrchard.

Overcoming barriers to climate insurance in developing countries

Specialist investment is a critical component in providing insurers with the necessary climate data and expertise to encourage risk-reducing activities. The InsuResilience Investment Fund Private Equity II aims to enable more resilient communities by directly investing in expanding resilience insurance, covering agricultural and natural catastrophe risks.

Currently, many vulnerable communities and economic activities in climate change-affected countries remain uninsured, highlighting the need for greater industry involvement. The insurance industry is uniquely positioned to support and reward investment in climate adaptation and resilience, it therefore plays a pivotal role in transferring risk and providing rapid recovery funding for households, businesses, and communities after disasters.

Unlocking investment to improve climate monitoring technology will help insurance companies to better understand what can go wrong before a disaster occurs aided by insurance industry best practice expertise, analytics, and risk modelling. The fund will also help to drive sustainable development by speeding up recovery, encouraging financial inclusion,

and freeing up capital to invest in crucial areas from a family’s financial security to vital healthcare and education. Perhaps most importantly, we are helping to transfer risk away from families, businesses, and countries, through a variety of insurance products and tools.

Yet lack of insurance can tip hundreds of thousands of people into poverty as disasters strike given that many people living in developing countries have little or no means to recover and rebuild.

Additional equity capital provided by InsuResilience Investment Fund II will strengthen capabilities along the insurance value chain to better cover weather-related losses through improved access to climate data, expertise, and distribution, allowing stakeholders to manage climate risk effectively and on a commercial basis. This will facilitate improved coverage of losses and expand climate insurance to farmers and communities in Asia, Africa, and Latin America.

The cooperation between the EIB, BlueOrchard, and the Government of Luxembourg follows the successful deployment of the predecessor strategy, the InsuResilience Investment Fund.

To date, the predecessor fund has made 9 investments across emerging markets, reaching nearly 58 million beneficiaries in underserved and economically vulnerable communities to mitigate the effects of climate change (as of Q3 2023) with the objective to reach 70-110 million beneficiaries by 2025.

Widely embraced throughout the outerwear, footwear, and tactical markets, eVent Fabrics is preparing to increase global brand visibility

eVent Fabrics, a global leader in highperformance waterproof and breathable technologies, is partnering with Formidable Media, a public relations agency with deep roots in the textile and apparel industries, for strategic communications and brand elevation services.

Effective immediately, Formidable Media will assist eVent Fabrics with a wide range of communications and public

relations efforts to increase global brand visibility.

“For the past 25 years, eVent has led the way in breathable waterproof technology, and thanks to recent advances in performance and sustainability, we’re ready to embrace our next round of growth in the market,” said Chad Kelly, President of eVent Fabrics. “We’re looking forward to having Formidable help us gain brand recognition and market share.”

eVent’s list of technologies includes waterproof, windproof, and professional options, providing solutions for demanding apparel, footwear, and accessory applications.

eVent’s comprehensive list of weatherproof technologies includes the new sustainablyminded solutions alpineST and eVent BIO.

“eVent is an ideal partner for Formidable Media,” said Scott Kaier, Founder and President of

Scott Kaier; Founder and President at Formidable Media

Formidable Media. “A highly technical and well-respected material supplier, eVent offers brands some of the best performing waterproof/breathable laminates on the market. Couple that with several PFAS-free offerings, and this is a brand that is well positioned for serious growth.”

eVent Fabrics will join Formidable Media’s growing list of prominent textile and apparel industry clients, including ALLIED Feather + Down, Green Theme Technologies, and Active Apparel Group.

Sapphire Mills collaborates with Green Story for enhanced transparency

In line with its commitment to sustainable business practices, Sapphire Mills has partnered with Green Stor y, an environmental footprint intelligence platform, to conduct comprehensive Life Cycle Assessments (LCAs) at scale across its product line.

This collaboration aims to quantitatively measure and communicate the environmental impact of Sapphire Textile Mills' products using Green Story's advanced technology, including unique QR codes and digital product passports (DPP).

Sapphire Mills, part of the prestigious Sapphire Group, is a leading vertically integrated textile producer and exporter based in Pakistan, renowned for producing high-quality woven, dyed, and printed fabrics, as well as garments.

Sapphire Mills has long been committed to sustainability through its core pillars: People, Planet, and Prosperity. The company has invested heavily in these areas, including a state-of-the-art effluent treatment plant, a biomasspowered cogeneration plant, and the development of various recycled and biodegradable polyester products. Now, Sapphire Mills is taking a step further by accurately quantifying the environmental footprint of each product in their portfolio.

Green Story is a leading Environmental Footprint intelligence platform and one of the few official Higg FEM Verifier bodies globally. This accreditation ensures that every piece of primary data collected during verifications adheres to stringent protocols, guaranteeing high-quality and credible environmental assessments.

"We are proud to partner with Sapphire Mills, marking a pivotal moment in advancing sustainability transparency in the textile industry. By quantifying their environmental impact through our platform, Sapphire Textile Mills is setting new benchmarks for accountability and driving positive change," shares Akhil Sivanandan, CEO, Green Story.

Through this partnership, Sapphire Mills will leverage Green Story's platform to present environmental data in a clear and interactive manner across methodologies such as PEF, EPD and ISO 14047. Each product will be accompanied by a digital product passport accessible via QR codes, enabling customers to

trace their environmental journey from raw materials to finished goods. This initiative underscores Sapphire Mills' commitment to transparency and accountability in their sustainability practices.

"Our partnership with Green Story is not just about advancing our sustainability practices at Sapphire Mills; it’s about transforming the fashion industry and empowering consumers with transparent, ethical choices. Through rigorous Life Cycle Assessments and Digital Product Passports, we provide clear and accessible data about the environmental impact of our products. This collaboration enhances the value of our products by ensuring they meet the highest standards of environmental responsibility, driving industry-wide change, and supporting eco-conscious choices. We are proud to lead by example and offer our customers the confidence to make informed, sustainable decisions,” says Yousuf Abdullah, CEO, Sapphire Mills.

By quantifying their environmental impact through LCAs, Sapphire Mills can set Science Based Targets (SBTs) and gain insights into their Scope 3 emissions. This data-driven approach not only strengthens their commitment to sustainable manufacturing but also enables informed decision-making that drives positive environmental outcomes.

At the upcoming Kingpins event (July 17-18, 2024) in New York, Sapphire Mills will showcase its collaboration with Green Story. Visit Sapphire Mills it the Green Area, Booth #8, to see firsthand how this innovative technology works for Sapphire Mills.

S&P Global provides essential intelligence – analytics and workflow solutions in the global capital, commodity and automotive markets. One of the five business divisions - S&P Global Commodity Insights’ coverage includes chemicals & fibers, oil and gas, power, metals, agriculture and shipping. S&P Global Commodity Insights comprises well-known and market leading brands following the merger of IHS Markit with S&P Global in March 2022. S&P Global Market Intelligence delivers leading data sources and technologies about macroeconomy, regions and sectors and partners with customers to broaden their perspective and operate with confidence.

Mr. Christian Schindler, Director General of ITMF, stated that “ITMF is very pleased to welcome S&P Global as the latest corporate member.

S&P Global is a renowned company that is providing valuable data across regions and industries that is now also covering the upstream fiber and textile industry. It is mutually advantageous if companies

from the entire textile industry and from affiliated sectors are coming together at ITMF to meet and discuss issues related to the entire value chain. S&P Global has a lot of expertise to offer but can also benefit from being closer to the industry and thus from a better understanding of the dynamics shaping it.”

Ms. Tatiana Bondar, Associate Director of S&P Global Inc., pointed out that “by having joined ITMF the S&P Global will now

have access to a lot of valuable reports, statistics, and surveys that help to further improve the understanding of fibre and textile industry. Taking part in excusive ITMF activities like the ITMF Annual Conferences, special workshops and webinars provides access to in-depth knowledge and to being closer to market. In today’s interwoven and ever more complex world it is important to be embedded in the industry you serve and to have easy access to both information and industry experts from around the world. I believe that by staying tuned our fibers team, represented in EMEA, Asia and America, will be able to bring value to the ITMF and its members.”

CHT Germany raises container management to a sustainable level and increases the use of reusable packaging CHT Germany GmbH is successfully on its way to a sustainably acting chemical company.

With a corporate strategy consistently geared towards sustainability and a clearly defined path towards climate neutrality, CHT Germany are approaching their goal step by step.

An important milestone on the way is resource-optimized production and the use of the latest technologies to save as many resources as possible.

The comprehensive analysis of CHT’s processes has led the company to raise container management to a sustainable level and increase the use of reusable packaging.

The necessary packaging is kept directly in circulation and the overall amount of needed material is reduced. The energy required to clean and reuse existing packaging is less than that needed to recycle and produce new containers.

CHT is saving on raw materials by building a resource-efficient new container washing system and recycling the residual materials and waste that still

accumulate.

With the new system, the increase in the reuse of existing containers can significantly reduce the procurement of new packaging (drums and IBCs). By cleaning on site, CHT saves on transportation and thus further resources.

With the investment of almost 5 million Euros at the Dusslingen site, CHT is making a significant contribution to reducing their carbon footprint.

It goes without saying that the new state-of-the-art plant will be operated with maximum resource efficiency using

heat from the renewable local heating network. The water circulates and comes from rainwater and the roof is used to generate renewable electricity. The PV system is dimensioned to its maximum size so that it generates more electricity than the container washing system below it needs.

At an official ground-breaking ceremony, representatives of public administration and the press were able to see this construction project for themselves and make direct contact with the company representatives.

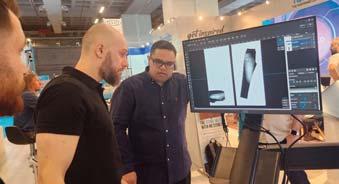

Archroma, a global leader in specialty chemicals towards sustainable solutions, is collaborating with Zydat Inc. to bring the complete Color Atlas by Archroma® color library to the Vivid Color Library Management (CLM) color-matching platform for faster and more accurate inkjet digital printing of fashion and textiles.

Archroma’s Color Atlas is the textile industry’s largest library of engineered color standards, with more than 5,760 color references formulated to comply with leading eco-standards and deliver consistent and accurate color reproduction.

With these colors available within Vivid CLM’s online color palette optimization and correction tools, designers can more quickly and easily create and share their color palettes for more accurate inkjet printing. This can reduce the burden of pre-production color proofing and streamline the color management process to help deliver

high-quality printed fabric and apparel in a fast and economical way.

Vivid CLM was launched by Zydat in February 2024. It offers a unique and designer-oriented solution to color matching with a proprietary algorithm that translates complex spectral data into a Red-Green-Blue workflow and allows the user to print, scan and check the color, with automatic adjustments to improve accuracy. The solution’s palette storage system allows colorists to share palettes across the ecosystem.

“Digital workflows and inkjet printing present an opportunity for designers and brands to embrace both their creative vision and their sustainability principles,” Chris Hipps, Global Head of Archroma Color Management, said. “Our partnership with Vivid CLM reflects Archroma’s ‘PLANET CONSCIOUS+’ commitment to innovation and partnership that supports a more sustainable textile ecosystem.”

Matthew Forman, President of Vivid CLM by Zydat Inc., said: “Archroma and

Vivid CLM have come together to revolutionize color palette selection, creation and inkjet printing for fashion designers. By integrating the Archroma Color Atlas into the Vivid CLM workflow, we are giving designers access to thousands of ready-made digital colors and enabling swift and seamless color matching for their particular inkjet printing system.”

In addition to accessing all of the 5,760 colors in the Archroma Color Atlas portfolio as digital standards within Vivid CLM, users of the software may also choose to refer to Archroma’s physical color library in multiple formats. They can also tap into Archroma’s expertise around the world for technical support with sustainable coloration systems and achievability on alternate substrates.

The Color Atlas by Archroma® is part of the Archroma Color Management+ design and development solution for more sustainable textiles and fashion through fast color selection and creation, consistent and accurate color reproduction, and reduced environmental impact.

Loepfe Brothers Ltd. has embarked on a new chapter with the appointment of Markus Kleindorp as the new CEO, ushering in a fresh era of leadership. Former CEO Ralph Mennicke's departure prompts restructuring, including the addition of Gregor Stalder as CFO. With this seasoned team, Loepfe aims to maintain its excellence in the textile industry.

Since the beginning of May, Loepfe Brothers Ltd. has been led by a new management team. The Board of Directors has appointed Markus Kleindorp as the new CEO of Loepfe.

Markus Kleindorp brings a wealth of experience from his tenure within the Vandewiele Group and as the former CEO of MEMMINGER-IRO GmbH, offering deep insights into the textile industry.

After four years of dedicated service, the former CEO of Loepfe, Ralph Mennicke, has decided to embark on new professional endeavors, signaling a change in leadership for the company. The Board of Directors acknowledges Mennicke's resignation and extends gratitude for his contributions to Loepfe's journey.

Furthermore, Loepfe is seizing this moment to restructure its management team, reinforcing it with an individual possessing extensive business expertise, and are delighted to introduce Gregor Stalder as the new CFO of Loepfe. Gregor Stalder is a proven expert in finance and has long-term experience in the position of a CFO.

With this accomplished leadership team in place, Loepfe is poised to continue its trajectory of excellence in the textile industry. Loepfe expressed gratitude to their stakeholders for their ongoing support and partnership as they embark on this exciting journey together.

The German companies Brückner, Groz-Beckert, the Karl Mayer Group and Thies invite representatives of the Brazilian textile industry to a symposium with presentations and discussion panels in Blumenau, Brazil, on August 21, 2024. The event will be held at NS Armazém, Fortaleza, Blumenau and will focus on the current demand trend for warp knitted elastic fabrics.

The demand for warp knitted elastic fabrics has increased rapidly in the past two to three years. On the one hand, this offers the Brazilian textile industry new growth opportunities and the chance to establish itself in a leading position in the growing market. On the other hand, the turnaround also holds challenges as the production steps involved in manufacture of warp knitted elastic fabrics are strik-

ingly different from the conventional methods.

In order to provide the Brazilian warp knitting industry with optimum support in this change, Brückner, Groz-Beckert, Karl Mayer and Thies are inviting participants to a specialist symposium on the subject of "Production of Warp Knitted Elastic Fabric". Industry experts, stakeholders and textile visionaries are invited to share their insights and experiences with the guests.

The aim of the symposium is to provide a platform where knowledge can be exchanged and cooperation intensified. The symposium offers a wide variety of technical presentations as well as best practice examples and showcases cuttingedge technologies and innovations in warp knitting technology. Interactive sessions and discussion rounds promote exchange among participants and provide

networking opportunities. The event language is Portuguese.

This is how the German companies Brückner, Groz-Beckert, Karl Mayer and Thies would like to provide their Brazilian customers with optimum support in adapting to rapidly changing trends and benefiting from the current trend in warp knitted elastic fabrics.

Those interested in attending the symposium may contact the sales representatives: Frank Bernhard or Fabricio Rampani (Brückner, Thies & Karl Mayer), or Diomar Gomes Vieira (Groz-Beckert) to register: frank.bernhard@mbrtextil.com.br, fabricio.rampani@mbrtextil.com.br, malharia.sudeste@ns.com.br.

Venue: NS Armazém, Fortaleza, Blumenau BR 470, 7109 CEP 89058-020Fortaleza Blumenau, SC- Brasil

Date: August 21, 2024

10.00 a.m.–11.40 a.m.

The ASHRAE Pakistan Chapter is proud to announce that Karachi will host two major international events: the ASHRAE Region-At-Large (RAL) Chapter Regional Conference (CRC) 2024 and the 4th HVACR Trends Expo and Conference. These events will take place from October 4-7, 2024, marking a significant milestone for Pakistan’s HVACR industry.

ASHRAE RAL CRC 2024 will be held at the Movenpick Hotel, Karachi from October 4-7, 2024. This prestigious conference will attract over 300 delegates from 21 member chapters of ASHRAE RAL, including participants from the Middle East, Africa, Pakistan, and Turkey. The four-day event will feature business sessions, training programs, and networking opportunities aimed at advancing the HVACR field. Highlights include a cultural dinner at the prestigious Governor's House, a sports night dinner, and a Presidential Lunch with the ASHRAE President.

Muhammad Abbas Sajid, General Chair of ASHRAE RAL CRC, shared his excitement, stating, “This CRC is a unique opportunity to bring together the best minds from across the region. We look forward to fruitful discussions, knowledge sharing, and building stronger connections within the ASHRAE community.”

Simultaneously, the 4th HVACR Trends Expo and Conference will take place at the Marriott Hotel, Karachi on October 4-5, 2024. This year’s expo focuses on the theme ‘Sustainable HVAC Design and Systems for Textile and Garments Industry.’ The event aims to spotlight innovative HVACR solutions that address energy efficiency and sustainability challenges in Pakistan’s textile sector, a vital part of the nation’s economy.

Mahmood Ahmed, President of ASHRAE Pakistan Chapter, emphasized

the importance of this expo, saying, “The 4th HVACR Trends Expo is a critical platform for showcasing cutting-edge technologies and sustainable practices. With a focus on the textile and garments industry, this event will help shape the future of HVACR systems in Pakistan, driving efficiency and environmental responsibility.”

Both events are expected to draw significant participation from local and international delegates, providing a unique platform for knowledge exchange, professional development, and business networking.

For more information, please contact: Communications Chair, ASHRAE Pakistan Chapter, Email: communication@ashraepakistan.com

Even bigger, even more international, even higher quality: this is how the successfully established product group Carpets & Rugs presents itself at Heimtextil 2025. The segment will be even stronger at the upcoming event: Carpets & Rugs already has twice as many exhibitors, an additional hall level and new highlights. Strong brands, exciting new products and content formats await the international carpet industry at Heimtextil 2025 in Frankfurt.

Carpets & Rugs on course for growth: At Heimtextil 2025, the successfully established product segment grows in quality and quantity – and is already

recording an enormous increase in exhibitors six months before the upcoming event: more than twice as many companies have already registered compared to the previous year. “We are very pleased about this signal from the market. It clearly reflects the industry's need for a strong, international and central carpet platform. This is exactly what we offer with Heimtextil in Frankfurt: a comprehensive market overview and a bundled product range combined with the highest quality. We have listened to the market and taken on board the feedback. Now it's a matter of expanding the range, organising it in a structured way and presenting it to

visitors in a structured manner”, explains Bettina Bär, Director Heimtextil. In 2025, the segment grows by an entire hall level: the expanded range of high-quality hand-woven carpets and the international country pavilions are located in the additional Hall 5.0. Once again, Hall 5.1 is home to the growing segment of machine-woven carpets and also brings together the enlarged preproduction offer with fibres and yarns as well as technologies specifically for the carpet industry. Hand-knotted carpets and unique pieces, doormats and cleanoff systems as well as textile solutions for outdoor areas and contract business round off the unique range. Another

highlight: a new carpet area is being planned together with the exhibitor Ragolle Rugs and the Belgian association Fedustria. The association will be exhibiting together with well-known exhibitors from Belgium in a high-quality joint presentation. Strong resonance from the industry: these exhibitors are taking part

Numerous renowned companies have already confirmed their participation at Heimtextil 2025. Among them are big international names such as Bhadohi Carpets (India), Balta Home (Belgium) und Kaleen Lifestyle (India), who will exhibit for the first time at the upcoming Heimtextil. Renowned brands like Lalee OHG (Germany) and strong returnees like Heritage Overseas (India), Mittal International (India), Oriental Weavers Group (Oriental Weavers Carpets, EFCO, MAC Carpet, Egypt), Ragolle Rugs (Belgium), Rugs in Style (India), The Rug Republic (India), Tufko International (India), Universal XXI (Spain) and Vini Décor (India) have also signed up. Within the Decoteam, the carpet supplier InfloorGirloon (Germany) and the manufactory Paulig (Germany) with unique handwoven products will present themselves. In addition, the member companies of the Belgian association Fedustria and, for the first time, the Tunisian association Office National de L’Artisanat will show their high-quality carpets at Heimtextil.

The exhibitors confirm the successful establishment of the new product area and the role of Heimtextil as a global

industry meeting point and showcase for new trends, collections and products: “Our first participation in this year's Heimtextil was a success; Heimtextil represents a destination for textile innovations in the home textiles industry, trends, sustainable impulses, and a variety of unique opportunities for our business. We benefited from excellent introductions and numerous new international contacts. We look forward to participating again in 2025”, says Yasmine Khamis, Chairwoman Oriental Weavers Group.

Mittal International emphasises the joint industry presence in the Carpets & Rugs product segment as well as the Frankfurt location as a new anchor point for the carpet industry: “We really appreciate the initiative taken by Messe

Frankfurt in launching the Carpets & Rugs segment at Heimtextil. The concept was convincing across the board and met the needs of the industry. We had a successful start, a good influx of customers and also received orders from the USA and Mexico. Carpets & Rugs as a new platform for the carpet industry is a great advantage for us, as we can focus on all segments at Heimtextil. We are even expanding our stand space in Frankfurt for 2025. We are looking forward to participating again in order to continue shaping the new product area for the future,” says Manmohan Sharma, Founding Partner Mittal International.

The additional hall level not only offers an expanded range of exhibitor presentations and product innovations –an extensive content programme also awaits visitors on the two Heimtextil stages: With business-promoting specialist presentations on current industry topics, stimulating panel discussions and exciting guided tours, Heimtextil 2025 positions itself even stronger as a valuable knowledge platform for the carpet industry. The popular Carpet Lounge in the foyer of Halls 5.1/6.1, equipped with high-quality exhibitor products, will once again bring unusual designs and new carpet trends to life in 2025 – and invites visitors to linger and network.

Natural yet high-performing fibres are game changers for many branches. Nature and performance come together in new, innovative solutions – a real milestone towards sustainability. At Techtextil 2024, international exhibitors showed future-proof developments for numerous industries in the ‘Nature Performance’ area. For Techtextil 2026, functional natural materials will become even more of a focus.

Functional and natural at the same time – innovative natural fibres manage the link between performance and sustainability and are developing into real all-rounders. They are in high demand for application in numerous industries worldwide. The market for natural fibres alone is expected to grow to around USD 103 million in 20311. As demand for natural materials increases, innovations are also being developed to improve their performance. New materials, finishing and processing methods increase the performance of sustainable textiles –

whether natural, bio-based, degradable or man-made. This was also evident at Techtextil in April, which dedicated a separate ‘Nature Performance’ area to the future topic.

"The industry is ready to provide a range of functional textiles on a natural basis. Whether in the automotive or construction industry, the demand for natural materials is increasing rapidly. We

are pleased to see that forward-looking solutions are being presented and welcomed by the branches. In April, more than 15% of exhibitors were already showing natural fibres and materials. Due to the high demand and ongoing developments, we expect an even larger range of natural performance materials at the next Techtextil," says Sabine Scharrer, Director Brand Management Technical

Textiles & Textile Processing at Messe Frankfurt.

The exhibitors presented a whole range of fibre and material exhibits with functional properties to the trade visitors, ranging from natural insulating materials to circular polyester fibres.

Among them was the Canadian startup Vegeto, which presented degradable thermal insulation based on milkweed, biopolymer fibres made from corn starch and kapok, a natural fibre from the silk tree. A jacket with a non-woven inner lining based on the new milkweed insulation apparently attracted a lot of attention at the Vegeto stand in the Nature Performance area. “People came to our stand and were really amazed that a plant-based insulating material of this quality even exists,” reports Vegeto General Manager Ghyslain Bouchard.

Anatolian Colors from Turkey showcased innovative natural dyes that can compete with chemical dyes in terms of quality and durability. “The Nature Performance Area was an excellent platform for us, which fits perfectly with our vision of environmentally friendly and sustainable textile production,” says Sophia Merve Ince, founder of Anatolian Colors. Participation in Techtextil has noticeably increased awareness of the new plant dyes and helped to reach a larger international audience. Talks were held on site with representatives from various industries – from fashion to automotive. “It was particularly pleasing that a leading fashion brand showed

interest in a pilot project with our products for its own collection,” reports the CEO. Due to its great success, the company is already planning to take part in Techtextil 2026.

The Swiss start-up OceanSafe presented a polyester material that, according to the company, is just as durable, functional and scalable as conventional polyester. The highlight: it is also said to be completely biodegradable. The circular polyester was very well received by trade visitors: “The feedback was amazing,” says CMO Matthias Fuchs, summarising the company's first Techtextil appearance. “We had significantly more visitors than expected.” According to Fuchs, the variety of

contacts ranged from automotive, medical and clothing to workwear, construction and public procurement. Overall, the quality of the visitors was “excellent”.

The increasing usage of natural fibres in the textile industry was also the central theme of the ‘Discover Natural Fibres Initiative’ (DNFI) at Techtextil. The international alliance of over 40 associations, organisations, natural fibre manufacturers and research institutes aims to raise awareness of the importance of natural fibres and promote their application. Looking back, Sandra Bohne, Managing Director of DNFI member ‘Fibral Material Alliance’, is very satisfied with the DNFI participation in the Nature Performance area. “Many companies that have not yet used natural fibres before visited our booth to find out about alternatives to man-made fibres,” says Bohne. Overall, it was a very successful event at which the DNFI representatives received many questions about potential applications for natural fibres from a wide range of industries, including fashion, home textiles, construction, automotive and composites.

The innovative companies demonstrate this: nature and performance are a sustainable match. At Techtextil 2026, the focus will be even more on natural fibres, yarns and materials.

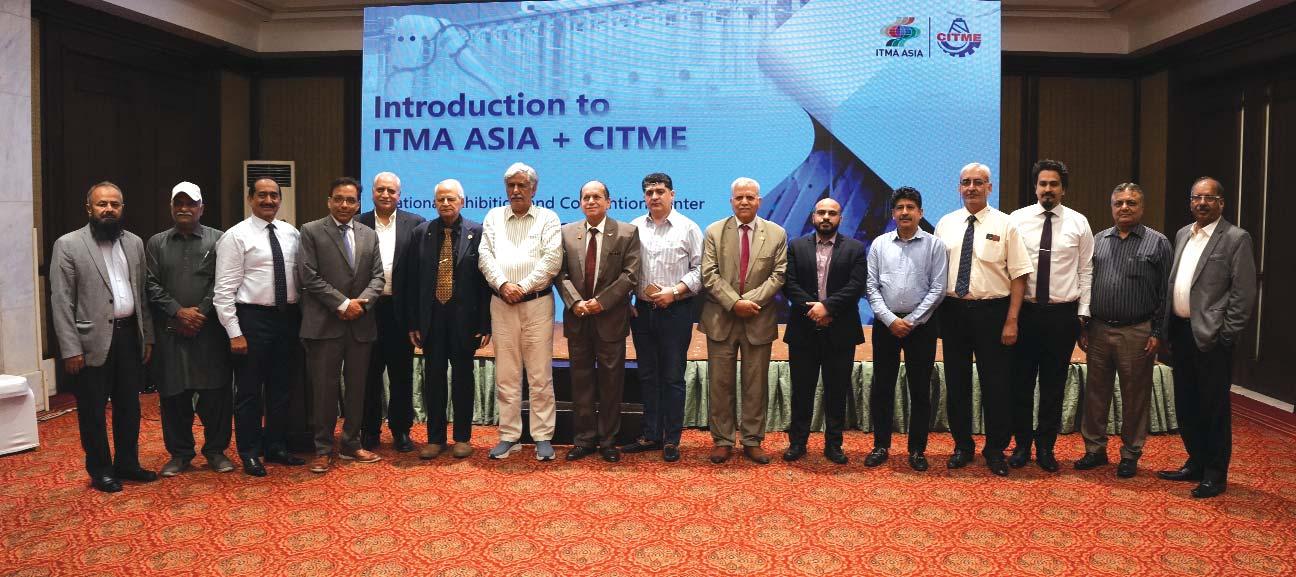

Road shows were concluded successfully in Pakistan’s economic and cultural hubs: Lahore and Karachi, respectively on, 23th–26th July 2024.

The Pakistan Textile Journal, in collaboration with ITMA ASIA + CITME, proudly hosted two highly successful Pre ITMA ASIA + CITME 2024 Road Shows in Lahore and Karachi. These events, held at the PC Hotel in Lahore on July 23, 2024, and at the Movenpick Hotel in Karachi on July 26, 2024, brought together over 280 professionals from Pakistan's textile industry. The strong turnout and engaging discussions at both seminars underscore the unity and shared commitment of the textile sector as it prepares for the upcoming ITMA ASIA + CITME Exhibition in Shanghai, China.

Lahore Seminar

The Lahore seminar set the stage for collaborative growth, with more than 130 industry leaders coming together to share insights and expectations for the ITMA ASIA + CITME Exhibition. The event began with a warm welcome from Mr. Nadeem Mazhar, who emphasized the importance of unity within the industry. Distinguished guests, including Mr. S.M. Qutab, Chairman of the Textile Institute, and Mr. Zameer Ahmad Awan, a China

specialist, highlighted the opportunities for collaboration between Pakistan and China in the textile sector.

Keynote speeches by Mr. Khalid Mahmood, Director of Master Textiles, and Mr. Muhammad Atta, Regional Head at Gerry's Visa, reinforced the message of collective progress. A significant highlight was a video message from Mr. Zhen Shen, Deputy Secretary of CCPIT TEX and Vice President of BJITME, which under-

scored the exhibition’s potential and its significance for Pakistan's textile sector. Additionally, a virtual address by Mr. Alex Zucchi, President of CEMATEX, emphasized the exhibition’s critical importance for Asian markets, reinforcing why Pakistan can’t afford to miss it. The seminar concluded with a strong sense of unity, as attendees received awards in recognition of their contributions to the industry.