Established 1951 January 2023 Apparel and Knitwear

Heimtextil 2023, Frankfurt

Dates: January 10th, to 13th, 2023

Venue: Frankfurt am Main.

DOMOTEX Hannover 2023

Dates: January 12th to 15th 2023.

Venue: Hannover, Germany.

Textile Asia 2023, Karachi

Dates: March 11th to 13th 2023.

Venue: Expo Centre, Karachi.

Index 2023

Dates: April 18th to 21st, 2023.

Venue: Palexpo, Geneva, Switzerland.

Techtextil 2023 North America

Dates: May 10th to 12th, 2023

Venue: Georgia USA.

DOMOTEX asiaCHINAFLOOR 2023

Dates: May 29th to 31st 2023.

Venue: NECC, Shanghai, China.

FESPA 2023

Dates: May 23rd to 26th 2023.

Venue: Munich, Germany.

Istanbul Yarn Fair

Dates: June 1st to 3rd, 2023.

Venue: Istanbul, Turkey.

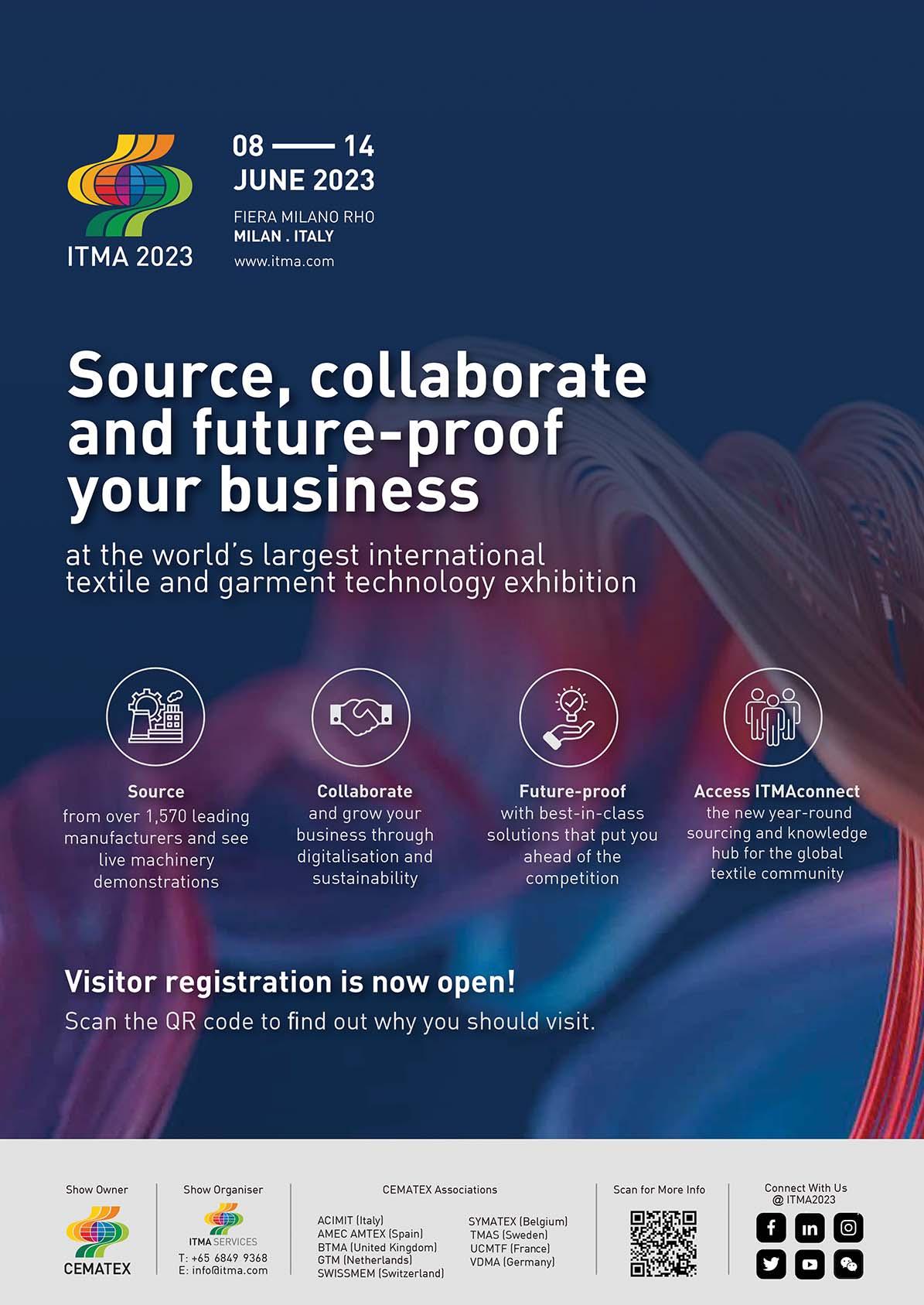

ITMA 2023

Dates: June 8th to 14th, 2023.

Venue: Milan, Italy.

ITMA ASIA + CITME 2023

Dates: November 19th to 23rd, 2023.

Venue: NECC, Shanghai, China.

Johannesburg, South Africa !

Dates: June 18th to 8th, 2023.

Venue: NECC, Shanghai, China.

IGATEX Pakistan 2023, Karachi

Dates: September 7st to 9th 2023.

Venue: Expo Centre, Karachi.

62th Dornbirn GFC Global Fiber Congress

Dates: September 13th to 15th 2023.

Venue: Dornbirn Austria.

ITM 2024

Dates: June 4th to 8th, 2024.

Venue: Istanbul, Turkey.

HIGHTEX 2024

Dates: June 4th to 8th, 2024.

Venue: Istanbul, Turkey.

JIAM 2024 OSAKA

Dates: Nov. 27th to Nov. 30th 2024.

Venue: Osaka, Japan.

iCADEX Pakistan 2023, Karachi

Dates: September 7st to 9th 2023.

Venue: Expo Centre, Karachi.

12th ITME INDIA 2024

Dates: December 2024.

Venue: India Expo Centre & Mart. Noida, India.

2

Calendar of Events

PAKISTAN TEXTILE JOURNAL - January 2023

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher

Nadeem Mazhar

Editor in Chief

Amina Baqai

Associate Editor

Nimrah Nadeem

Associate Editor

Shahnawaz Khan

Production Manager

Mazhar Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh

Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab

C.TEX, F.T.I (U.K), B.Sc.

Fellow I.C.T.T Atlanta, GA; (USA)

Mian Iftkhar Afzal

B.S.N.C State, M.Sc. (Leeds)

C.TEXT.F.T.I (UK)

Dr. Zubair Bandukda

PhD (Textiles), CText ATI

Editorial & Advertising Office

B-4, 2nd Floor, 64/21,

Tel: +92-21-34311674-5

Fax: +92-21-34533616

Email: info@ptj.com.pk

URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Correspondence & Mailing address: 93 Fleming Place, Bracknell, RG12 2GN, United Kingdom

Tel: +44 792 2228 721

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, UK

Registered no. 09141989

AROUND THE WORLD . . . . . . . . . . . . . . . . . . . . . .13 NEWS & VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . .10 EDITOR’S PAGE . . . . . . . . . . . . . . . . . . . . . . . . . . .7 Overcoming Challenges: Embracing Innovation in Pakistan's Textile Industry TEXTILE BRIEFS . . . . . . . . . . . . . . . . . . . . . . . . . . .8 Vol. LXXII No. 01 January 2023 Rs. 565.00

Printed at: Color Plus Korangi, Karachi. Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi. Available on Gale and Factiva affiliated international databases through Asianet Pakistan

M.A.C.H, Miran M. Shah Road, Karachi - Pakistan

NEWS Texcom invests in state-of-the-art Brückner Power-Frame Stenter . . . . . . . . . . . . .18 Loepfe expand globally creating local business units in China, India and Turkey . . .19 U.S. Cotton Trust Protocol Welcomes American Eagle Outfitters, Inc. as a Member . .20 Monforts marks 40 years of advanced manufacturing in Austria . . . . . . . . . . . .21 Oerlikon signs agreement to acquire Riri; Builds leadership position . . . . . . . .22 Trützschler Card Clothing expands its site in Neubulach . . . . . . . . . . . . . . . . .23 Zünd establishes new subsidiary in Spain . . . . . . . . . . . . . . . . . . . . . . . . . . .24 18 21 DYES AND CHEMICALS Archroma Awarded EcoVadis Platinum rating for 2nd consecutive year . . . . . . . .25 Consolidating its position amongst top 1% best rated companies PERSONALIA Nicole Spencer Appointed to FESPA board to represent the UK . . . . . . . . . . . . . . .26 FAIRS AND EXHIBITIONS 2nd International Conference on Knowledge Based Textiles . . . . . . . . . . . . . . . . . . . .27 10th INTEX, Delhi (India) Concludes Successfully in Delhi . . . . . . . . . . . . . . . . .28 Texworld Evolution Paris, 2023 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29 Empowering Textiles - India ITME 2022 8th December – 13th Dec. 2022 . . . . . . .30

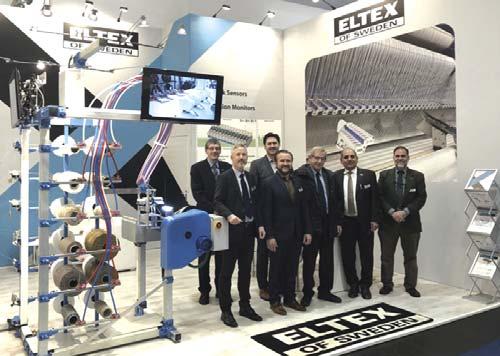

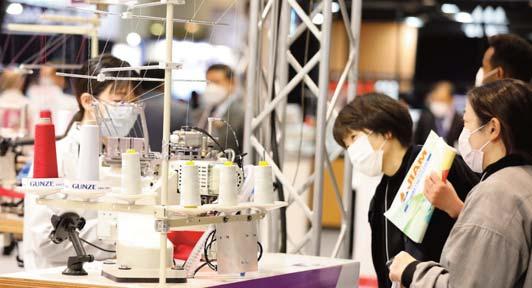

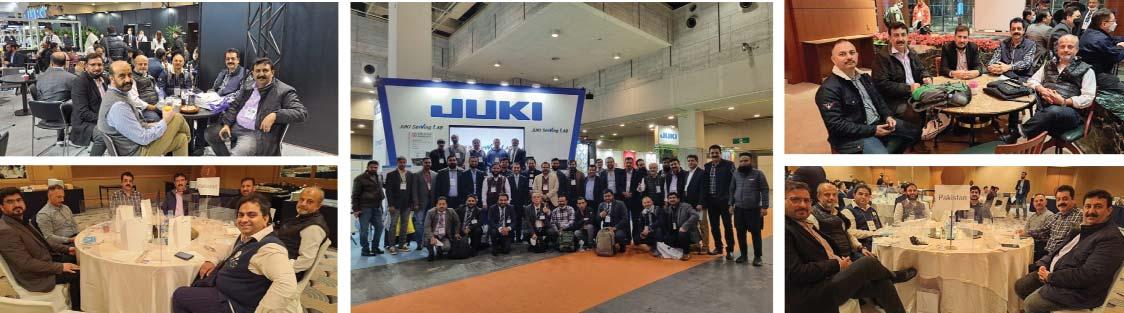

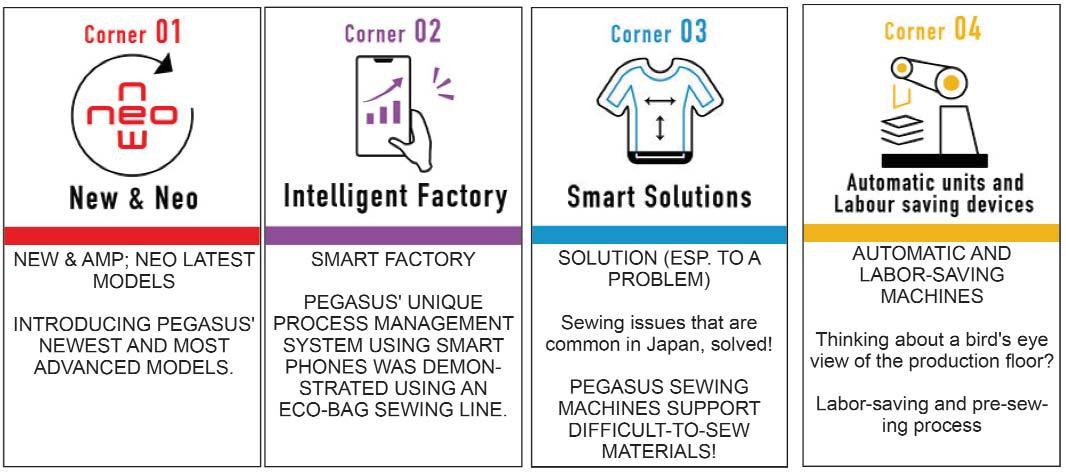

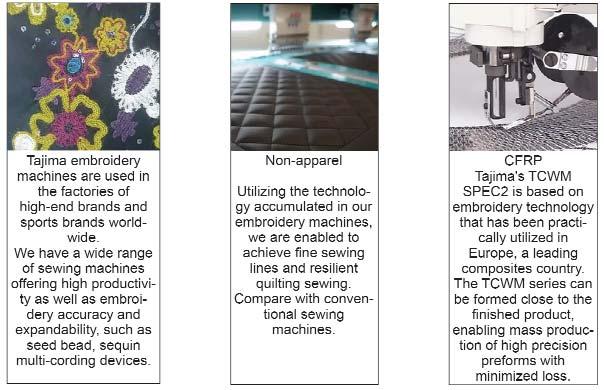

CORPORATE

35 37 40 42 62 56 INTERVIEW RF Systems highlights Smart thermal processes for the textile sector . .42 EVENT Textile Institute Lahore Section: . . . . . . . . . . . . . .55 Professional Qualifications Certificates Award Ceremony 44 FEATURE Introducing the new status symbol of Sustainability, Conscious Fashion and Innovation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 that runs in our DNA. DOMOTEX Domotex world’s leading trade fair for Carpets and Floor Coverings opens successfully . .34 Sustainable carpet trends at DOMOTEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37 Oriental Weavers Savio Textile machinery at Domotex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38 Stäubli Carpet Weaving solutions ELTEKSMAK Machinery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39 Eltex of Sweden . . . . . . . . . . . . . . . .39 XETMA VOLLENWEIDER Carpet Finishing for woven velours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 Exhibitors from Pakistan Visitors Comments at Domotex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41 IGATEX PAKISTAN 2022 . . . . . . . . . . . . .44 IGATEX PAKISTAN Exhibition celebrated its 20th anniversary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45 IGATEX PAKISTAN Conference 46 IGATEX ORIGIN dedicated for sustainable materials & apparels display and fashion show Glimpses of IGATEX PAKISTAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48 JIAM 2022 OSAKA + APPAREL AND KNITWEAR . . . . . . . . . . . . .56 JIAM 2022 OSAKA concludes successfully; new technological Juki Smart solutions: Innovation with our best global support . . . . . . . . . . . . .59 Pegasus Sewing Machine Mfg. Co., Ltd. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60 TAJIMA: Manufacture of embroidery machines and multi-function sewing machines .61 . . . . . . . . . . . . . . . .62 JAM International: The automatic unit JT882H machines 63

Overcoming Challenges: Embracing Innovation in Pakistan's Textile Industry

The textile industry in Pakistan has been facing a myriad of challenges in recent times, including rising energy costs, inflation, a severe shortage of cotton, and a ban on all imports of machinery and chemicals. These challenges have put immense pressure on the industry and threatened its survival. However, there is a glimmer of hope on the horizon - by embracing man-made fibers and exploring new areas of value addition such as technical textiles and performance textiles, the industry can overcome these challenges and emerge stronger than ever before.

One of the most promising solutions for the textile industry is to shift towards man-made fibers, primarily polyester. Polyester is a versatile material that is widely used in a range of applications, from clothing to home textiles. By using polyester, the textile industry can reduce its reliance on cotton, which is currently facing severe shortages, and tap into a new market that is in high demand. Additionally, polyester has the added advantage of being costeffective, which can help to reduce the production cost of textiles.

Another promising solution for the industry is to explore new areas of value addition such as technical textiles and performance textiles, including sportswear. Technical textiles are fabrics that are designed to provide specific functionalities such as flame resistance, UV protection, and water resistance, among others. Performance textiles, on the other hand, are fabrics that are designed to enhance athletic performance by providing moisture management, breathability, and other benefits. By focusing on these areas of value addition, the industry can tap into new markets and diversify its product offerings.

Cotton alternatives such as viscose should also be considered. Viscose is a type of rayon that is made from natural materials such as wood pulp. It has a similar texture to cotton and is a cost-effective alternative that can help to alleviate the shortage of cotton in the market.

The last eight months have been very challenging for the industry, with the increase in production costs and lost orders due to the recession in the West. However, by embracing man-made fibers, exploring new areas of value addition, and considering alternatives to cotton, the industry can weather the storm and emerge stronger than ever before.

In conclusion, the challenges facing the textile industry in Pakistan are complex and require a comprehensive approach from the government and relevant stakeholders. By embracing innovative solutions such as man-made fibers and exploring new areas of value addition, the industry can overcome these challenges and emerge as a competitive player in the global market. It is imperative that the government and relevant stakeholders work together to support the industry and help it to achieve its full potential.

7 Established 1951 January 2023 Apparel and Knitwear January 2023

EDITOR’S PAGE

Textile Briefs National

1

APTMA in a letter to PM warned that the country’s textile exports could fall below US$1 billion a month from January 2023 onwards. It further informed that a substantial number of jobs have already been lost and many more are to follow if remedial measures are not undertaken urgently.

2

Pakistan records over 4.6 million bales of cotton production during the calendar year 2022 against more than 7.3 million bales produced during the previous year, a massive shortfall of 37.23 per cent.

3

Pakistan's textiles exports declines for the second consecutive month in November 2022, dropping 18.15% to US$1.42 billion from US$1.736 billion in the corresponding month last year.

4

APTMA urges Govt. to support imports of inputs for export-oriented sectors, whether against Letter of Credit (LCs) or cash against documents. On liquidity constraints, APTMA said that a quantum of funds is stuck in work in progress as a consequence of a 17% sales tax and devaluation on all inputs.

Textile Briefs International

1

Industry body Cotton Australia has projected around 5 million bales of cotton crop in 2023. In addition, the (ABARES) is forecasting a 22-23 gross value of cotton production at around US$3.4 billion with expectations that exports will reach a value of US$5.1 billion.

3According to Brazil’s cotton producers’ association ABRAPA, cotton represents Brazil’s seventh-largest export product in terms of value and in the marketing year 2021-22, 1,680 tonnes were exported and generating more than US$3.2 billion.

2

Readymade garment (RMG) exports from Bangladesh increased by 15.56 per cent to US$ 22.996 billion in the first six months of fiscal 2022-23 (July-June) compared to exports of US$19.900 billion in July-December 2021, as per provisional data released by the Export Promotion Bureau (EPB).

5

Pakistan’s value-added textile sector has expressed fear that more industries would shut down in the coming days in addition to the ones already out of business, increasing the number of layoffs.

pared to the past year. The primary reason for this year’s situation is the devastating monsoon floods that damaged major cotton-growing regions of Sindh and Balochistan.

6

Korea International Cooperation Agency (KOICA) will provide a Grant-in-Aid of US$7 million for the Strengthening of the Pak-Korea International Cooperation Agency at NTU, Faisalabad.

7Cotton production for the year 2022-23 was estimated to suffer a historic slump of 43% com-

9

Pakistan’s textile sector is experiencing a rising demand from the international community of buyers to ensure compliance with international standards on human and labour rights. The continuity of the EU GSP+, which is crucial for the country’s socioeconomic development, also demands the industry to strengthen its workplace safety principles.

5

The latest Covid outbreak sweeping China has begun impacting the global textile and apparel supply chain, an industry expert has warned, raising uncertainty over production delays and factory closures.

50 per cent share in the total exports and manmade fabrics taking up the second place with 35.33 per cent share.

8

China’s exports of textiles, apparel and clothing accessories increased to US$297.629 billion in the first eleven months of the current year, registering a growth of 4.57 per cent year-on-year. The data released shows that the country’s garment exports grew by 4.3 per cent in the same period.

4

6

India's US$200 billion textile and apparel industry is facing a crisis as consumers in the United States, Europe and other big markets have cut spending on clothing following a surge in inflation after the war in Ukraine.

The assistance, included in the FY23 omnibus spending package, includes US$3.74 billon for disaster assistance for US ranchers and farmers, including cotton and other row crop producers.

9

Turkiye’s apparel exports to UK stood at US$1,513.857 million in the first nine months of 2022, with cotton apparel dominating with more than

7

Recognizing the green production trend, the Vietnam has built factories, equipped them with modern machinery by European standards and convert production activities accordingly. They now have a global organic and recycled fabric product certification.

8 PAKISTAN TEXTILE JOURNAL - January 2023

Pakistan's textile exports may fall below $1 billion a month from Jan 2023

The All Pakistan Textile Mills Association (APTMA) in a letter to Prime Minister Shehbaz Sharif warned that the country’s textile exports could fall below $1 billion a month from January 2023 onwards. The letter highlighted a range of issues facing the textile sector which is currently operating at less than 50 per cent capacity. "A very substantial number of jobs have already been lost and many more are to follow if remedial measures are not urgently undertaken," APTMA’s Patron-in-Chief Gohar Ejaz said in the letter.

Ejaz said that the international economic situation “primarily caused by the Ukraine crisis combined with the floods in Pakistan have combined to formulate the perfect storm for our economy”. APTMA attributed the decline to supply chain disruptions, liquidity constraints, energy shortages, and the non-functioning of new projects in the letter.

It said that recent floods destroyed the cotton crop with only five million bales available this year whereas the industry required 14 million bales. Meanwhile, it added, foreign exchange

issues have curtailed the import of cotton and other essential inputs for exports. "The cost has increased by 20% due to demurrage/detention and delays," it said.

APTMA urged the premier to clear all imports of export-oriented sectors which have arrived at parts whether against Letter of Credit (LCs) or cash against documents. On liquidity constraints, APTMA said that a much higher quantum of funds is stuck in work in progress as a consequence of a 17% sales tax and devaluation on all inputs.

APTMA called for the restoration of SRO 1125, zero rating for the textile value chain while collecting sales tax on domestic sales at the point of sale. It urged to immediately refund all deferred sales tax, tuff and other dues.

The textile association said that the government should also provide the textile sector with a moratorium on capital repayment from July 1, 2022 to June 30, 2023. "Due to marked differences in RLNG/gas rates being offered to textile mills in Sindh and Punjab, Punjab-based industries are no longer viable and have no option but to close down as they are no longer competitive and available orders are shifting or in process of shifting to the cheaper alternatives internationally and within Pakistan."

APTMA requested the implementation of Weighted Average Cost of Gas while extending Regionally Competitive Energy Tariffs (RCET), across the country to enable new industrial units, expansions and Punjab-based industries to compete.

The association also said that the textile sector invested $5 billion, in the past two years, in setting up new factories. “Some of the machinery of new plants/ expansions is still stuck at ports, LCs are being delayed for spare parts, and electricity and gas are not being provided to these new units.

Cotton arrivals plunge to 4.6 million bales

Pakistan records over 4.6 million bales of cotton production during the calendar year 2022 against more than 7.3 million bales produced during the previous year, a massive shortfall of 37.23 per cent.

Market observers put heavy monsoon rains and river floods, which washed away standing crops, particularly in the cotton belts of Sindh and Punjab, as the main reason behind the decline in cotton yield. Both provinces could not also meet the cotton sowing target as the crop had been planted only on 2.01 million hectares against the target of 2.53 million hectares this season.

PAKISTAN TEXTILE JOURNAL - January 2023 10 News & Views

The data released by the Pakistan Cotton Ginners Association (PCGA) has revealed that 4,612,687 cotton bales arrived by Jan 1, 2023, while the figure stood at 7,312,537 bales on Jan 1, 2022. The white lint output even fell short by 0.2 million bales than the estimates of 4.8 million bales made by the industry a month ago.

Cotton arrivals in Sindh have been reported at 1,850,400 bales this year against 3,508,602 bales last year, a decline of around 47pc. The drop in output in Punjab has been estimated as 28pc as the province harvested 2,762,287 bales this year as compared with 3,838,808 bales last year.

This means the country will need to import more than 9.4 million bales of cotton to meet the demand of 14 million bales of the local textile industry as per the estimate of the All Pakistan Textile Mills Association (Aptma). Whereas the foreign exchange reserves position is so weak that letters of credit (LCs) of even the pharmaceutical industry are not being opened.

In a letter to the prime minister on Dec 23, Aptma leaders warned that the textile industry was already working at less than 50pc of its installed capacity and a large number of workers had already been retrenched and many more employees would lose their jobs if immediate steps were not taken to keep the textile units running.

They held the unavailability of lint, liquidity crunch and energy shortages as the reasons behind falling textile exports. Concerned about falling local cotton production, Aptma is already approaching the countries, including the USA, China, Brazil and Turkiye, which have developed new cotton varieties with better yields to improve the local cotton seeds. It is also establishing a ‘cotton secretariat’ for focused work on the crop.

Pakistan's textiles exports drop by 18.15% in November

Pakistan's textiles exports dropped for the second consecutive month in November, dropping 18.15% to $1.42 billion from $1.736 billion in the corresponding month last year, the Pakistan Bureau of Statistics (PBS) said recently.

According to the latest data, exports of components like cotton cloth, knitwear, bedwear, and towels shrunk while readymade garments exports remained unchanged from the last year.

The PBS said, compared with the previous month, Pakistan's exports were up 4.7% over November 2021's exports of $1.357 billion. The textile sector's total exports were down 5.1% from July to November, to $7.36 billion from $7.76 billion during the same period last year.

Cotton cloth exports dipped by 25% to $153.7 million in November 2022 compared to $204.85 million in November 2021, while exports decreased by 9.45% over the previous month's exports of $169.6 million. However, compared to October, knitwear exports surged 2.17% to $400.2 million, bedwear 2.45% to $222.5 million, towels exports spiked 16.4% to $92.65 million, while exports of readymade garments increased 18.55% to $326.7 million.

Likewise, over the corresponding month of last year, knitwear exports declined 12.8%, bedwear exports slashed 29.4%, and towels sales abroad went down 12%, while readymade garments exports were the same as recorded in November 2021.

Textile sector is Pakistan's top exporter, occupying over 60% of the country's total exports. In FY22, total textile exports were at a record high of $19.35 billion, with an increase of over a quarter over FY21's exports of $15.4 billion.

Textile bodies term‘ imbalance of payments’ main problem

All textile associations, in the joint press conference, held at the Pakistan Hosiery Manufacturers and Exporters Association (North Zone) office recently, appealed to the government to resolve the problems and said the main problem of the country is the imbalance of payments.

In the joint press conference of all textile associations, Muhammad Amjad Khawaja, Senior Vice Chairman, PHMEA (North Zone), Dr Khurram Tariq President FCCI, Arif Ehsan Malik APBUMA, Waheed Khaliq Rame Power Loom Owners Association, Chaudhry

Muhammad Nawaz and Chaudhry Ijaz

Ahmad Nagra Power Loom Association, Hafiz Muhammad Asghar APTPMA, Mian Kashif Zia, Zanoon Nazir, Hazar Khan And other industrialists also participated.

PHMEA (North Zone) Senior Vice Chairman Muhammad Amjad Khawaja said Pakistan was currently suffering from severe economic problems due to which not only the factory owners but also millions of workers and employees were suffering from severe problems.

Referring to the circular of SBP, he said the government had placed the import of the textile sector at the third level, adding “if the import of raw materials is not allowed, the exporters will not be able to fulfill their orders.” He said the economy would get improve only when the wheel of the industry ran.

11 News & Views

President FCCI Dr Khurram Tariq said: “In exchange of 100 percent value of export, exporters should be allowed to import raw material equal to 35 percent value because without raw material we cannot export.”

He said that putting the burden of line losses and recovery of any DISCO on the customers of other DISCOs is excessive.

Value-added textile sector warns of closure, job losses

Pakistan’s value-added textile sector has expressed fear that more industries would shut down in the coming days in addition to the ones already out of business, increasing the number of layoffs. Not only textiles, but other exports have declined sharply, with the likelihood of further declines to the lowest ebb amid dangerously low foreign exchange reserves, associations representing the value-added textile sector said at a joint presser.

Participants included Value-Added Textile Forum Coordinator and Pakistan Apparel Forum Chairman Muhammad Jawed Bilwani, Pakistan Hosiery Manufacturers and Exporters Association Chairman Muhammad Babar Khan, PHMA Zonal Chairman Khizer Mehboob,

Pakistan Knitwear and Sweater Exporters Association Chairman Rafiq Godil, Pakistan Cloth Merchants Association former chairman Abdul Samad, and chairman of the Towel Manufacturers Association of Pakistan. Lamenting the current economic crisis and unresolved problems, they pointed out that industries were compelled to shut down and lay off around 7 million workers, of which 4 million was the textile sector’s workforce.

Raising the matter of letters of credit, the industry representatives said that import of necessary raw materials and accessories with even nominal values such as $5,000 were denied, which dented export orders. This caused severe disruption and delays in completion and even cancellation of export orders. This situation also led to port demurrage of various consignments, which exceeded the cost of those materials that were damaged and would now be auctioned as they were of no use to export industries.

Recently, textile exporters were also deprived of their remittances to participate in a global textile exhibition scheduled in Germany and barred from sending exhibition materials via an international courier. Participation only became possible after the intervention of

the Trade Development Authority of Pakistan, which sought special permission from the State Bank of Pakistan for the purpose.

Lamenting the delay in the release of sales tax refunds, they asked the government to disburse the amount in 72 hours after approval of eRPOs instead of delaying it for two months. Industrialists have lost faith in the government because of its failure to strengthen the economy. It was impossible to operate under extreme financial stress and an economic crisis. All priority should be given to the value-added textile exporters, the presser participants demanded. The government should allow exporters to spend 20 percent of their foreign remittances on the import of raw material and accessories.

SBP has already allowed exporters to retain 10 percent of their export proceeds in Exporters Special Foreign Currency Account to spend these US dollars on various purpose e.g. foreign consultant payment, hotel booking and travelling, payment for IT equipment and software, lab testing charges, audit/ inspection/ certification charges etc. Talking about the gas crisis, the industrialists said that amid the gas crisis in the country, particularly in Karachi, they felt deprived of a level playing field and a viable business environment.

News & Views 12 PAKISTAN TEXTILE JOURNAL - January 2023

AUSTRALIA

Cotton production to reach 5 million bales in 2023: Cotton Australia

Industry body Cotton Australia has projected around five million bales of cotton crop in 2023. In addition, the Australian Bureau of Agricultural and Resources Economics and Sciences (ABARES) is forecasting a 22-23 gross value of cotton production at around $3.4 billion with expectations that exports will reach a value of $5.1 billion because of prior shipping delays for the 2022 crop.

ABARES is also pointing to a possible recovery in cotton prices as buyers look for quality sustainable cotton combined with crop decreases and low stock levels in the US, said Cotton Australia.

“The industry is now forecasting a 5 million bale crop despite some of the wettest conditions and major flooding across much of New South Wales,” said Cotton Australia CEO Adam Kay.

BANGLADESH

Garment exports increase by more than 15% in July-Dec

2022

Readymade garment (RMG) (Chapter 61 & 62) exports from Bangladesh increased by 15.56 per cent to $22.996 billion in the first six months of fiscal 2022-23 (July-June) compared to exports of $19.900 billion in July-December 2021, as per provisional data released by the Export Promotion Bureau (EPB). Woven RMG exports grew at faster pace than knitwear.

RMG exports from Bangladesh were 4.81 per cent higher than the target of $21.940 billion for July-December 2022, as per EPB data.

Exports of knitwear (Chapter 61) increased by 13.42 per cent to $12.659 billion in July- December 2022, as against exports of $11.161 billion during the same months of the previous fiscal.

Exports of woven apparel (Chapter 62) increased by 18.29 per cent to $10.337 billion during the period under

review, compared to exports of $8.739 billion during July-December 2021.

Home textile exports (Chapter 63, excluding 630510) decreased by 16.02 per cent to $601.26 million during the period under review, compared to exports of $715.95 million during JulyDecember 2021. Woven and knitted apparel, clothing accessories and home textile exports together accounted for 86.84 per cent of Bangladesh’s total exports of $27.311 billion during JulyDecember 2022.

Bangladesh had achieved an all-time high in terms of value of RMG exports in 2021-22, at $42.613 billion, registering an increase of 35.47 per cent compared to exports of $31.456 billion in fiscal 2020-21. However, the growth in RMG exports has slowed down during the recent months due to global economic challenges.

BRAZIL

Cotton exports worth $3.4 million in Jan-Nov 2022

Cotton represents Brazil’s seventhlargest export product in terms of value and in the marketing year 2021-22, 1,680 tonnes were exported, generating more than $3.2 billion, according to the country’s cotton producers’ association

ABRAPA. Cotton exports were worth $3.4 million between January and November 2022, up by 15 per cent yearon-year.

Brazil provides a fifth of the world’s cotton supply, making it the second largest cotton exporter in the world.

ABRAPA said Asia imports 99 per cent of the output, with China (27 per cent), Vietnam (16 per cent), Turkey (13 per cent) and Bangladesh (12 per cent) being the main costumers, followed by Pakistan, Indonesia, Malaysia, South Korea, India and Thailand.

“Through research, technology, genetics, field management, and precise laboratory verification equipment, we have improved the quality of our products every year. Today we can say that we are on the same level as the best kinds of cotton in the world, with largescale production”, said ABRAPA director of international relations Marcelo Duarte.

Along with ABRAPA, the country’s export promotion agency ApexBrasil runs Cotton Brazil, a programme to promote Brazilian cotton globally and supports cotton producers in reaching foreign markets. More than 70 per cent of the cotton exported in the first eleven months of last year came from companies supported by Cotton Brazil.

Around the World 13

CHINA

China's textiles & apparel exports at $297 billion in JanNov 2022

China’s exports of textiles, apparel and clothing accessories increased to $297.629 billion in the first eleven months of the current year, registering a growth of 4.57 per cent year-on-year. The latest monthly data released by the General Administration of Customs of China shows that the country’s garment exports grew by 4.3 per cent in the same period.

Garments and clothing accessories exports reached $160.703 billion in the first eleven months, which was 4.3 per cent higher than the same period of last year. China’s textile exports, including yarn, fabrics, and others, registered a growth of 4.7 per cent year-on-year and the shipment reached $136.926 billion in January-November 2022.

Textile and apparel exports during November 2022 amounted to $24.385 billion. Out of this, textile, yarn, and articles exports earned $11.266 billion, while garments and clothing accessories fetched $13.119 billion in November this year, as per the data.

China Covid outbreak threatens apparel supply chain

The latest Covid outbreak sweeping China has begun impacting the global textile and apparel supply chain, an industry expert has warned, raising uncertainty over production delays and factory closures.

The Omicron variant of the Covid virus is making its way across several big cities in China after President Xi Jinping made a U-turn on his former zero-Covid policy of containment earlier this month. The spread of infections, which has hit China’s capital city Beijing the most, is threatening widespread business disruption to the world’s second-largest economy and largest apparel exporter. According to figures from the Financial Times, more than half the 22 million population is infected.

The increase in infection rates means industry across China is facing disruption

such as staffing shortages, which is leaving businesses vulnerable to closures, while sickness in the logistics sector is causing supply chain chaos.

Dr Sheng Lu, associate professor of fashion and apparel studies at the University of Delaware: “The latest Covid outbreak in China has started affecting the global textile and apparel supply chain and deserves a close watch. One imminent challenge is a nationwide labour shortage, production delays, and even factory closures as Covid cases surge. When Covid-19 first broke out in China in early 2020, garment-exporting countries in Asia struggled to get enough raw textile materials as China was their top supplier. The same situation could repeat this time.”

Lu says another big concern is new uncertainties. “How soon would China’s Covid situation stabilise? Shall we worry about a severe economic recession in China? Will China’s Covid outbreak result in new variants that complicate the world’s pandemic situation? Will the Chinese government have another U-turn in its Covid policy?

“Given these mounting uncertainties, fashion brands and retailers are likely to accelerate their “China exit” strategy and prioritise mitigating supply chain risks in their sourcing decisions.”

According to the FT, companies have now been left with no direction on how

to handle the sudden surge in cases, after previously operating under strict guidelines handed down by local governments. Some factory bosses have dropped restrictions such as PCR testing and fencing off workers from the wider population. Experts have said factories could face worker shortages until February, after the lunar new year. The Omicron outbreak has brought forward the annual movement of more than 290 m migrant workers from the coastal provinces back to poorer regions in the west, which occurs ahead of the festive period.

INDIA

Textile industry faces tough times as consumers cut spending

India's $200 billion textile and apparel industry is facing a crisis as consumers in the United States, Europe and other big markets have cut spending on clothing following a surge in inflation after the war in Ukraine.

While the overall economy is relatively strong and is outperforming major economies, the textile sector is a notable exception and orders suggest the downturn will continue well into 2023, raising the risk of layoffs in an industry

Around the World 14 PAKISTAN TEXTILE JOURNAL - January 2023

that employs more than 45 million people.

Exports, which constitute about 22% of the industry, have fallen for five months in a row - declining over 15% year-on-year in November to $3.1 billion. Domestic sales are sluggish despite strong growth in the overall economy because of high costs and cheap imported garments, manufacturers say.

After bumper sales earlier this year, local textile factories are now cutting production - contributing to a 4.3% contraction in manufacturing output in July-September quarter that has raised concerns among policymakers.

The shock comes as Prime Minister Narendra Modi's government struggles to create employment for millions of youngsters entering the job market each year. After 18 months of robust growth through mid-2022, global retail sales of clothing have been dragged down by high inflation and depressed consumer sentiment, and prospects for 2023 look gloomy, a McKinsey report said last month.

In India, the manufacturing sector, contributing 16% of GDP, has been hit by rising raw material costs and weak demand, despite bright growth elsewhere. Manufacturing showed no signs of growth in the first half of the current April-March fiscal year while the overall economy, helped by agriculture and services, expanded 6.3%.

TURKIYE

Cotton apparel make up more than half of Turkiye's total exports to UK

Turkiye’s apparel exports to UK stood at $1,513.857 million in the first nine months of 2022, with cotton apparel dominating with more than 50 per cent share in the total exports and manmade fabrics taking up the second place with 35.33 per cent share. Turkiye’s cotton apparel exports amounted to $794.245 million in the period under review.

The export value of cotton apparel was 4.26 per cent lower in January to September 2022 than the value in the same period of last year. Turkiye had exported cotton apparel worth $829.542

million to the UK in January-September 2021, 35.37 per cent higher than the exports during the corresponding period of 2020, as per data from statistics.

As for manmade apparel, Turkiye exported these products worth $534.846 million in January-September 2022. In the total apparel exports, the share of apparel made of wool/animal hair was 0.82 per cent ($12.397 million), while silk accounted for merely 0.01 per cent ($81,127).

Turkiye’s apparel exports constituted 69.41 per cent ($1,050.770 million) knitted fabric and 30.59 per cent ($463.087 million) woven fabric. Unisex apparel made up for 47.26 per cent ($715.485 million) of the exports, followed by womenswear at 37.04 per cent ($560.718 million) and menswear at 14.28 per cent ($216.198 million).

USA

US cotton sector benefits from 2023 government spend package

The assistance, included in the FY23 omnibus spending package, includes US$3.74bn for disaster assistance for US ranchers and farmers, including cotton and other row crop producers. It will also aid producers who have suffered losses of revenue, quality or production losses of crops (including crops prevented from planting in 2022), due to droughts,

wildfires, hurricanes, floods, thunderstorms, excessive heat, tornadoes, winter storms, freeze, including a polar vortex, smoke exposure, and excessive moisture occurring last year.

The package also provides $100 million for United States Department of Agriculture (USDA) to make payments to cotton merchandisers who have experienced economic losses.

Schneider, a Louisiana producer, said the industry appreciates that the package includes US $15.45 million for cotton pest management activities, US $ 4 million for USDA’s cotton classing laboratories, and increased funding for cotton genetics and fibre quality research programmes within the Agriculture Research Service.

The agreement also directs USDA’s National Agricultural Statistics Service to continue to work with stakeholders to better understand how to capture supplemental information for certain crops to help offset data losses from the discontinuation of agricultural statistics district level estimates.

NCC Chairman Ted Schneider said: “The US cotton industry is grateful that Congress approved this much needed legislation. This relief will help stabilise the cotton sector as many producers suffered devastating losses from this season’s extreme drought and other weather events and merchandisers who suffered economic loss during the pandemic.”

Other bill provisions include: Growing Climate Solutions Act — Incorporates

Around the World 15

Around the World

updated language from the Growing Climate Solutions Act, which directs USDA to establish a programme to register entities that provide technical assistance and verification for farmers, ranchers and foresters who participate in voluntary carbon markets with the goal of providing information and confidence to producers.

Pesticide Registration Improvement Act (PRIA 5) Reauthorisation — Reauthorises pesticide registration and review process user-fee programmes administered by EPA and increases registration and maintenance fees to support a more predictable regulatory process, create additional process improvements, and provide resources for safety, training, bilingual labelling, and other services to advance the safe and effective use of pesticides.

Pesticide Registration Review Deadline Extension — Extends deadline for Environmental Protection Agency (EPA) to complete registration review decisions for all pesticide products registered as of 1 October 2007. EPA is facing a significant backlog of pesticide registrations due to a variety of factors over the past several years, which raises potential implications for continued access to numerous crop protection tools. With this extension, EPA will be allowed to continue its registration review work through 1 October 2026.

VIETNAM

Vietnam aims to make textile industry ‘greener’

Recognizing the green production trend, this company has built factories, equipped them with modern machinery by European standards and convert production activities accordingly.

It now has a global organic and recycled fabric product certification, thanks to sustainable production process, strict process regulation and raising employees’ awareness.

Tran Van Quy, Chairman of BOD, General Director, Trung Quy Group said that the process though challenging, has produced great results. We can improve product quality, expand market, gain customers’ trust and affirm the company’s value in the textile industry.

Applying green production is a prominent goal for the domestic textile industry to keep up with the global trend. However, some still face many difficulties in this transition because it requires changing the whole production chain. The successful businesses show the potential of Vietnam’s textile industry for green growth.

16 PAKISTAN TEXTILE JOURNAL - January 2023

Pham Xuan Hong, Chairman of HCM City Textile and Embroidery Association said that in order to meet the requirements of trade agreements, it is necessary to make the environment greener and improve the quality of raw material sources.

“Businesses need to ensure transparency alongside their growth. The company’s green efforts such as using renewable energy, and saving water must be shown through digital management to be of value to consumers,” said the chairman of Vietnam Textile and Apparel Association, Vu Duc Giang.

The textile and garment industry will continue to develop the value chain for all processes, from yarn production to fabric and apparel, and apply green production methods. Their goal is to reach 47 billion USD in exports by 2023 and transform Vietnam into a global textile and garment hub.

Vietnam textile exports seen rising to more than US$ 45 bil

The Vietnam Textile and Apparel Association (Vitas) forecasts garment exports to reach more than US$45bil (RM198bil) in 2023, higher than last year’s US$44bil (RM194bil), driven by opportunities provided by new free trade agreements (FTAs).

Vitas president Vu Duc Giang said that although difficulties would remain for textile and garment exports in the first half of 2023, there were factors it could

pin hopes on in the second half. The United States and European Union (EU) markets were expected to warm up in the second half of 2023, together with the opportunities provided by new FTAs, Giang said.

For example, under the EU-Vietnam FTA, many products exported from Vietnam would enjoy zero tariffs as of 2023. The visit of Prime Minister Pham Minh Chinh to Europe would also open up significant opportunities for attracting investment in the garment and textile industries, especially in the production of raw materials.

The Vietnam National Textile and Garment Group (Vinatex) said its members were surprised by some developments in 2022, such as the Russia-Ukraine conflict and surges in oil

prices, inflation and interest rates, which caused demand to nosedive. Vinatex estimated its 2022 revenue at over 19.53 trillion Vietnamese dong (RM3.6bil), up 15% on the year prior, and 8% higher than the target, and a consolidated profit of more than one trillion Vietnamese dong (RM186.97mil), up 14.6% on the target.

Pointing out three scenarios, Vinatex chairman Le Tien Truong said in the bestcase scenario, the global economy will become stable and geopolitical conflicts will be over by the end of the second quarter, meaning exports in 2023 may go up 4% to 5% on 2022. In a middle-case scenario, instabilities will linger, inflation will remain, and interest rates will increase until the third quarter, where exports may stay unchanged compared to last year.

Around the World 17

Texcom invests in state-of-the-art Brückner Power-Frame Stenter

The Argentine textile industry is booming, which means a prosperous period for investment, increased production and therefore the creation of new jobs, which greatly benefits the development of the national industry.

TEXCOM - as Texameri S.A. with headquarters in Buenos Aires is officially called - is one of the leading companies in Argentina with more than seventy years of experience in the market. With 3 production plants, a commercial office and 6 sales stores distributed around the country, TEXCOM manufactures and distributes knitted fabrics for a highly demanded market, where sports, technical, fashion and workwear fabrics stand out. The company's own developments, such as Twintex, Polisap, Neodry, Sense, Texcom antibacterial, among other brands, are perfect for sports and leisure due to their technical attributes. The company attaches great importance to the fact that all processed materials have the appropriate current environmental certificate (Öko Tex Standard 100, BlueSign and ZDHC). The efficient and responsible use of chemicals is also a matter of course.

Texcom has become a strategic partner for its customers, basing its operation on 3 pillars: Market Focus, Innovation, Sustainability.

These pillars position the company one step ahead of the needs and demands of the market through technology and development. With more than 100 circular knitting machines and a wide range of possibilities for rotary printing, sublimation, lamination as well as special finishes such as antibacterial or hydrophilic, TEXCOM produces premium sports and leisure wear. This includes the official jersey of one of the world's most successful national soccer teams, the white and sky-blue striped Albiceleste jersey of the Argentines.

TEXCOM has recently started up two new BRÜCKNER POWER-FRAME stenters for knitted fabric with 8 compartments and lubrication-free

vertical chain and direct gas heating. This is already the 5th BRÜCKNER line purchased by TEXCOM and the successful continuation of the cooperation with BRÜCKNER since 1979. The third member of this successful alliance is the commercial agency, MAPEKO, which has been active for BRÜCKNER for several decades and in the 3rd generation.

The partnership between the German market leader in textile finishing machinery and the customer has always been trustful and good over the changeful development of the Argentine textile industry and several generations on both sides.

Highest drying capacity and the technically proven split-flow ventilation system, the extremely homogeneous air volume and temperature distribution due to countered thermo zones were decisive for the customer. The low specific energy consumption of the direct gas heating and the maintenance-friendly components, such as the completely lubrication-free vertical circulating chain and width adjustment spindles, help to save production costs, especially in economically difficult times. Especially in the premium sector, the exactly

reproducible finishing results due to full automation as well as recipe management of the line are appreciated.

Mr. Esteban Scigliano, Industrial Manager (Gerente Industrial) at TEXCOM is confident: "With the energy-efficient high-tech machines by BRÜCKNER we follow the continuous changes in Argentina and will be part of the upswing of the domestic textile industry. We invest in innovation to promote the sustainability of our processes by an optimal use of the thermal energy consumption and a maximum saving of electrical energy. The technology of these machines ensures us a higher quality and the ability to produce in a sustainable and efficient way, reducing energy consumption. We thank the whole team of BRÜCKNER who made this possible!"

Regina Brückner, CEO of the German market leader is pleased about these positive impulses for the Argentinian textile industry: "Especially in a crisis, companies are in demand which look ahead and go their way future-oriented. TEXCOM is setting a good example and setting standards. We are pleased to be a long-standing partner and friend of the innovative and ecologically oriented TEXCOM Group."

18 PAKISTAN TEXTILE JOURNAL - January 2023 Corporate News

Photo from left to right: Ronaldo Huber (MAPEKO), Esteban Scigliano (TEXCOM) and Rodrigo Huber (MAPEKO) in front of one of the two new BRÜCKNER POWER-FRAME stenters

Loepfe creates local business units in China, India and Turkey

The integration of trusted service partners strengthens relationships with local customers and creates opportunities to collaborate on future product development.

As part of their ongoing commitment to customer-centricity, Loepfe Brothers Ltd. have announced their expansion into China, India and Turkey. The strategic integration of key service partners creates dedicated business units that can provide a local service to customers, while drawing on the international support within the Vandewiele group.

Decades spent as trusted service partners ensures continuity and stability for clients during the integration period, with experienced and knowledgeable staff continuing to provide customer service and technical support. Further, clients will have the opportunity to

impact the company’s future product portfolio more directly. Direct feedback will lead to clients being a key part of solution testing and development, and to products being more closely aligned to their needs.

These strategic moves have been undertaken as part of Loepfe’s long-term goal to provide more direct operational and strategic support to customers in the key markets, Turkey, India and China. The Loepfe business units remain independent within the Vandewiele structure.

Jürg Schneider, Head of Sales & Service at Loepfe Brothers Ltd. said: “By being much closer to our customers, we’re able to offer even more effective local installation, training and troubleshooting services. We want to thank our integrated service partners,

who have successfully served our customers in key markets for years, for the smooth integration process. Every member of staff will continue to play an integral part in this transition, ensuring stability for our customers.”

Dr. Ralph Mennicke, CEO of Loepfe Brothers Ltd. states: “This strategic move reinforces our commitment to the three markets, Turkey, India and China. Our teams on the ground will provide product updates, upgrades and trainings, while collecting invaluable customer feedback. We warmly welcome each individual within our new business units to the Loepfe family. Their expertise and local insight are key to the success of Loepfe and play an essential part in our ongoing transformation.”

19 Corporate News

Local business units in China, India and Turkey

U.S. Cotton Trust Protocol Welcomes American Eagle Outfitters, Inc. as a Member

The U.S. Cotton Trust Protocol “Trust Protocol” is pleased to announce the membership of American Eagle Outfitters, Inc. (AEO). AEO is a leading global specialty retailer offering high-quality, on-trend clothing, accessories and personal care products through its American Eagle, Aerie, OFFL/NE by Aerie, Todd Snyder and Unsubscribed brands.

Trust Protocol membership will support AEO in its continued efforts to provide greater transparency, communication and standardized reporting of its ESG progress. Underpinned by a focus on optimism, AEO’s Building a Better World ESG strategy is centered on three key areas: planet (environment), people (social) and practices (governance). Notably, the company has set specific goals to achieve carbon neutrality in its owned and operated locations and significantly reduce water use, among other sustainability initiatives.

“AEO is excited to partner with the Trust Protocol as we work to move our sustainability practices forward, preserve

our planet and meet the ambitious targets we have set on our journey to build a better world,” said Mark Rose, SVP, Production and Sourcing, AEO. “The Trust Protocol will help provide AEO the opportunity to further verify our responsible sourcing practices and demonstrate the progress we’re making toward meeting our environmental targets.”

The Trust Protocol is the only sustainable cotton system that provides quantifiable, verifiable goals and measurement and drives continuous improvement in six key sustainability metrics – land use, soil carbon, water management, soil loss, greenhouse gas emissions, and energy efficiency. The Trust Protocol integrates these sustainability metrics from Field to Market’s Fieldprint® Platform, enabling enrolled growers to measure the environmental impacts of their operation and identify opportunities for continuous improvement.

“The demand for verified data to credibly demonstrate progress on sustainability targets is representative of a clear need across the retail industry: the Trust Protocol is uniquely positioned to meet that need and is setting a new standard in sustainable cotton production where full transparency is a reality,” said Dr. Gary Adams, President of the U.S. Cotton Trust Protocol. “We look forward to working with AEO to demonstrate tangible and continuous improvement across the six key sustainability metrics we track.”

The Trust Protocol is aligned with the UN Sustainable Development Goals, recognized by Textile Exchange and Forum for the Future, and part of the Sustainable Apparel Coalition, Cotton 2025 Sustainable Cotton Challenge, Cotton 2040, and Cotton Up initiatives. It has also been recognized and published in the ITC Standards Map,recognized as a standard for sustainable cotton by the Partnership for Sustainable Textiles, and confirmed as an ISEAL Community Member.

20 PAKISTAN TEXTILE JOURNAL - January 2023

Monforts marks 40 years of advanced manufacturing in Austria

Montex Maschinenfabrik – the key site for the manufacturing of Monforts finishing machines in Austria – has celebrated its 40th anniversary in 2022.

Located in St. Stefan, in the centre of Austria’s Lavant Valley in Carinthia, the advanced manufacturing hub was founded by Monforts in 1982.

“From the outset, we have specialised in all aspects of machine production, including high-precision sheet metal working, laser cutting and welding, and the pre-assembly of machines and components, , along with a wellorganised quality management and spare parts service,” says Montex plant manager Gert Hanzl.

“We work very closely with the Monforts research and development team in Mönchengladbach, Germany, to take the latest new ideas through testing and prototyping, in readiness for future series production,” Hanzl says. “We are fully exploiting the many new possibilities in the continuous development of design and manufacturing methods. The respective electrical switch cabinets for the machines are delivered just-in-time from Monforts in Germany according to our production schedules.”

Bespoke machines

While there is standardisation in series-produced Monforts machines,

Montex is also increasingly called upon to construct bespoke machines with unique designs, according to the special needs of customers in technical textile or special textiles, he adds.

“We aim for the best combination of already-proven components and carefully-tested special constructions and we are equipped to handle large projects.”

The core Monforts machine range, including the industry standard Montex stenters, along with relaxation dryers, Thermex dyeing ranges, Monfortex compressive shrinking ranges and

Montex®Coat coating units is built at the Austrian site.

“We have employees who have worked at this site long time, some even since the foundation of Montex Austria, but it’s very important that we train apprentices at the same time, in order to pass on our know-how and ensure the high standard that customers expect from Monforts systems is maintained going forward,” Hanzl says. “One of the key advantages of being here in the heart of Europe is the Dual Training System – one of the best training systems in the world. It combines theoretical instruction in a vocational school with practical training both within the company and in training workshops.

“Established staff also train regularly to develop new skills and everyone is involved at all stages of production and trained to multi-task. This gives us flexibility and strength.”

“Colleagues from Mönchengladbach heartily congratulate the Montex team on its 40th company anniversary,” adds Monforts Managing Director Stefan Flöth. “We would like to thank the company for the decades of good and successful cooperation we’ve had and wish the operation continued success in working with us for the next 40 years.”

Montex specialises in all aspects of machine production, including high-precision sheet metal working, laser cutting and welding.

21 Corporate News

Electrical switch cabinets are delivered just-in-time from Monforts in Germany according to production schedules.

Oerlikon signs agreement to acquire Riri; Builds leadership position in luxury market

Oerlikon has signed a definitive agreement to acquire Riri, a leading provider of coated metal accessories for the luxury fashion industry. This transaction marks a milestone in Oerlikon’s growth strategy and diversifies Surface Solutions’ offerings and market access. The transaction is expected to close in the first quarter 2023, subject to regulatory approvals and standard closing conditions.

“Riri is highly complementary to our existing luxury business and will reinforce our fashion jewelry and metallic components for leather goods. It is the ideal next step after our acquisition of Coeurdor in 2021 and will make us a market leader and an integrated provider with a complete offering of coated luxury metalware for high-end fashion brands,” said Michael Suess, Executive Chairman, Oerlikon. “The acquisition will drive cross-selling and strengthen our footprint in the global luxury metalware market, which sees mid- to-high single-digit growth rates annually.”

“Our portfolio, particularly in zippers and buttons, is an excellent fit to Oerlikon’s strengths in coated metalbased fashion components. Together, we are ideally positioned in Italy and France –the two major European fashion hubs –and can provide a complete offering to fashion customers,” said Renato Usoni, CEO, Riri. “We are excited to join Oerlikon as it will allow us to accelerate the luxury goods industry’s sustainability transition to greener technology by applying technologies such as Oerlikon’s PVD.”

Riri, headquartered in Mendrisio, Switzerland, is a market leader in metal accessories manufacturing, with a wide product range and unique offering. The company supplies global leading brands in the luxury fashion industry and has a strong foothold in the Italian luxury market. The company has more than 1100 employees and expects to generate sales of EUR 170 million (CHF 165 million) in 2022.

Headquartered in Pfaeffikon, Switzerland, the Oerlikon operates its business in two divisions – Surface Solutions and Polymer Processing Solutions.

22 PAKISTAN TEXTILE JOURNAL - January 2023

Michael Suess, Executive Chairman, Oerlikon.

Corporate News

Renato Usoni, , CEO, Riri.

Trützschler Card Clothing (TCC), one of the technology leaders in the manufacture of high-performance card clothings for textile yarn processing, is expanding its site in Neubulach, Germany.

With the twelve-million-euro investment, the supplier for the international textile machinery industry is expanding its production, warehouse and office capacities. A groundbreaking ceremony will take place during the coming winter.

The move into the new building is planned for 2024. TCC will also expand the range of services and the production intensity at the site, while optimizing the process flows. Trützschler intends to recruit the additional employees required within a short time frame by hiring new staff and offering apprenticeships at the Neubulach site. TCC employs more than 130 people in Germany, with a further 220 people employed worldwide at locations in Brazil, China, India, Mexico, Turkey and the USA.

Strengthening the site

"By expanding our business here in Neubulach, we are strengthening our presence in this area and our leading global market position too," says Managing Director Peter Gäbler.

Trützschler Card

The Trützschler Group SE is also investing in India to build a new site with over 100,000 square meters for the Spinning, Card Clothing and Nonwovens business units. "It is important to be close to the customer worldwide because our foreign companies make a significant contribution to the success of the Group," says Gäbler.

TCC achieved another record sales result in 2021. Demand for the technology components for carding fibers in spinning mills and for carding in nonwovens production has increased significantly. The steel sawtooth wires, which are wound onto coils and produced for customers around the globe, eventually get worn down by use in production processes – so it is necessary to replace them regularly. For this reason, further growth is expected in 2022 and beyond.

The new building will expand the warehouse and logistics area by 600 square meters, to make a total area of 2,800 square meters. In the optimized cube of the new hall, a modern warehouse system will double the storage capacity. There will also be a fully automated warehouse for coils for sawtooth wires. During the construction phase, logistics and shipping will be temporarily outsourced to PforzheimBüchenbronn.

Good integration into the region

Overall, the production area will be expanded from 4,000 to 5,400 square meters. This will enable the process flows to be optimized. The office space will be increased to 1,000 square meters. An additional level of the building will provide modern workplaces for administration and sales.

The new building will also improve access and exit routes for truck traffic. This will provide considerable relief for the local neighborhood in terms of noise emissions and other factors. Good integration into the region is very important to Trützschler. All contracts for planning, construction and air conditioning technology have been awarded to local companies.

In the future, TCC will operate its production facility in Neubulach in a climate-neutral manner. This will contribute important progress toward achieving the ambitious climate goals of the Trützschler Group. The new production facility will meet the highest requirements for energy efficiency and climate protection. Heating is provided by process heat recovery and geothermal energy. In addition, the company produces green electricity via its own solar panels.

23 Corporate News

Clothing expands its site in Neubulach

Zünd establishes a new subsidiary in Spain

Zünd Systemtechnik AG is moving even closer to its customers on the Iberian Peninsula. As of the beginning of 2023, Zünd acquired its long-standing sales partner Sign-Tronic S.A, which is based in Barcelona.

Sign-Tronic S.A. has been a wholly owned subsidiary of Zünd Systemtechnik AG since the start of 2023 and now operates under the name Zund Ibérica. Sign-Tronic S.A. was established in 1990 and has been an official sales and service partner of Zünd Systemtechnik AG since 1994. Zund Ibérica serves numerous customers in Spain, Portugal and Andorra.

Jordi Lorente is the new CEO of Zund Ibérica. For the time being, he will be actively supported by the previous coowner and Managing Director Flemming Jensen. Rosa Miralles, also a co-owner, will continue to work in an executive capacity at Zund Ibérica.

Zund Ibérica currently employs 15 people. With more than 1,000 cutters installed, Zund Ibérica is one of the most experienced distributors of both digital cutting systems and software and

workflow solutions on the Iberian market. It has its own showroom, which allows customers and interested parties to experience the many possibilities of Zünd’s digital cutting technology in person. Its staff consists of proven experts in consulting, training, installation, and service.

The Zünd name has represented Swiss quality, reliability, and technically advanced digital cutting systems for almost 40 years. As both an innovation and market leader, Zünd Systemtechnik AG repeatedly sets the pace in the development of multifunctional cuttingsystem solutions. Zünd’s eleven subsidiaries and network of dealers spanning the globe underline its international orientation as systems manufacturer.

Oliver Zünd, CEO of Zünd Systemtechnik AG: “We are thrilled to welcome Zund Ibérica to our global group of companies. Working closely with our new subsidiary will allow us to further strengthen our business in Spain and expand our customer base. I am convinced we will continue to be able to provide our Spanish customers with the

best possible service in the long term. The resources at our disposal and our new subsidiary’s extensive experience will allow us to grow further and continue optimizing our customer support.”

About Zünd Systemtechnik AG

Zünd Systemtechnik AG, a global, family-owned Swiss company, specializes in digital cutting systems. The Zünd name stands for Swiss quality and is synonymous with precision, performance, and reliability. Zünd has been developing, producing, and marketing modular cutting systems since 1984.

The Zünd customer base includes service providers and manufacturers in the graphics, packaging, garment, and leather industries as well as in textile and composites applications. Zünd maintains headquarters in Altstätten, Switzerland, where the company’s R&D, marketing, and production facilities are located, Besides Zünd’s own international sales and service organizations, the company relies on a worldwide network of longstanding, independent distribution & service partners.

24 PAKISTAN TEXTILE JOURNAL - January 2023 Corporate News

Archroma Awarded EcoVadis Platinum rating for 2nd consecutive year

Consolidating its position amongst top 1% best rated companies Archroma, a global leader in specialty chemicals towards sustainable solutions, announces the renewal of its EcoVadis “Platinum” status and further improvement of its overall rating.

Following an in-depth assessment by EcoVadis, covering 21 criteria grouped into 4 themes - Environment, Labor & Human Rights, Ethics, and Sustainable Procurement - Archroma further improved its score by 4 points (from 78/100 to 82/100), thanks in particular to its ongoing efforts in sustainable procurement, focusing on supply chain transparency and best practice sharing with suppliers and industry peers.

More details on Archroma’s sustainable sourcing activities can be found in the company’s Sustainability Report for its fiscal year 2022, just released on 8 December 2022. The Report includes an assurance report by KPMG, who conducted a limited assurance on several core ESG metrics, including CO2 emissions, water intake, occupational safety and gender diversity. Archroma passed the audit successfully, providing yet another third-party validation of the company’s deep commitment to its ESG objectives and roadmap.

“Our purpose is to lead our industry towards a more sustainable future for our customers and markets, and we are doing everything we can at Archroma to deliver on that ambition”, comments Danielle Blomert, Archroma’s Chief Sustainability Officer.

Daniel Madueno, Global Head of Quality Management adds: “We see sustainability as a true team effort, and the renewed EcoVadis recognition as a tribute to the hard work and ambition of all my colleagues to achieve and maintain the highest ESG standards every day, everywhere.”

Dyes and Chemicals 25

Nicole Spencer appointed to FESPA board to represent the UK

Nicole Spencer has been appointed to the FESPA Board to represent the UK. The decision was endorsed by representatives of FESPA’s National Associations at the recent FESPA General Assembly in Madrid, Spain.

As President of the FESPA UK Association since 2018, Nicole has been instrumental in supporting wide-format digital, textile, industrial and specialist printers in the UK. In 2020, Nicole became Managing Director of RMC Digital Print, where she had been Operations Director since 2011. Located in Hull, England, the company produces wide format applications for the signage, events, display and set design industries.

FESPA President Christophe Aussenac comments: “With over eleven years of direct experience in the speciality print industry, Nicole has been invaluable in diversifying and expanding the range of insight and support the FESPA UK association offered its members over the past five years.”

Lascelle Barrow has stepped down from his regional FESPA Board responsibilities representing the UK and has been awarded the life-long status of Honorary Board Member, in recognition of his outstanding personal contribution to the development of FESPA and the speciality printing community.

The FESPA Board is now composed as follows:

Christophe Aussenac – President. (France)

Olaf Skilbred – Vice President. (Norway)

Christian Duyckaerts – Asia. Ambassador (Belgium)

Daniel Sunderland – Treasurer & Americas Ambassador. (Latin America)

Nicole Spencer. (UK)

Gyorgy Kovacs. (Hungary)

Thomas Struckmeier. (Germany) Wouter van As. (Netherlands)

Alberto Masserdotti. (Italy)

Lascelle Barrow. (Honorary Member)

MS Printing Solutions and JK Group

MS Printing Solutions and JK Group announce the appointment of Christopher Bernat as General Manager of North America and the Caribbean markets. He will be the main point of contact for overall business in the region. Chris joins MS Printing Solutions and JK Group with over 20 years of industry experience.

He was Director of Sales at Sawgrass Technologies prior to starting Vapor Apparel in 2004. He currently serves on the Executive Committee and Board of Directors of Printing United and resides in Charleston, South Carolina.

26 PAKISTAN TEXTILE JOURNAL - January 2023 Personalia

Lascelle Barrow (Honorary Member).

Christophe Aussenac –President (France)

Nicole Spencer will focus on signage community and youth engagement.

Christopher Bernat General Manager of North America and the Caribbean markets, JK Group & MS Printing Solutions.

The 2nd International Conference on Knowledge based Textiles

The “2nd International Conference on Knowledge-based Textiles” will be held during February 14–15, 2023 at the “National Textile University, Faisalabad, Pakistan”. This conference is hosted by the School of Engineering and Technology, under the umbrella of the Grand Challenge Fund (Project KnowTex).

KnowTex is a research project designed to uplift the whole value chain of Pakistan’s textile industry by indigenization, introducing knowledgebased textiles, productivity enhancement, branding, showcasing, and policy recommendations. The main objective of this conference is to review the status of value addition in textile products and to devise a scientific strategy for product diversification to achieve sustainable growth in textile exports. This conference will bring prominent academic scientists,

research scholars, and industry experts together to discuss and share their expertise, experiences, and research findings in all areas of textiles. This year’s conference will cover a broad range of topics, including Sustainability and Circularity in Textiles, Innovations in Textile Processes, Advanced Textiles, Economy and Textile Business, etc.

The primary goal of this conference is to review the current status of value addition in textile products and to devise a scientific strategy for product diversification to achieve sustainable growth in textile exports. In addition, this conference will bring prominent academic scientists, research scholars, and industrial

experts together to discuss and share their expertise, experiences, and research findings in all areas of textiles.

This conference will also identify and develop interdisciplinary collaborations, as well as encourage textile-related research and creative work. It will serve as a premier multidisciplinary forum for educators, academics, and practitioners to share and showcase their most recent innovations, trends, and concerns.

Fairs and Exhibitions 27

10th INTEX, Delhi (India) concludes successfully in Delhi

The 10th edition of Intex India concluded successfully at Pragati Maidan, New Delhi with textile manufacturers and suppliers from over eight countries. The exhibitors showcased innovative, fashionable, and sustainable textiles. Traders and buyers from over 22 countries visited the show. The three-day sourcing event took place from 8 to 10 December, 2022.

A busy show that generated good business

Buyers’ delegations from over 22 countries including Italy, Spain, the US, Canada, and Russia among others attended the show. Over 4,252 trade buyers from across India and the world were present. More than 150 companies from over eight countries exhibited and with business over $650 million business expected to have been generated. As Arti Bhagat, Executive Director, Worldex India and organiser of Intex India said, “We are pleased to launch Intex in India and to see the participation of many high-caliber exhibitors and large numbers of international buyers here.

India today is a world leader in textiles, a key element of the global value chain being the world’s fifth-largest exporter of apparel, home, and technical textile products. India is targeting growth at 8 percent CAGR reaching $100 billion by 2030. This target would help India double its share of the global textile and apparel trade from the current level of 5per cent.

Aims to accelerate growth

With a growing demand for manmade fibre (MMF) textiles as a substitute for cotton amid changes in global fashion trends, the Intex India exhibition offered international manufacturers and suppliers opportunities to explore new business and investment avenues in India under this sector and increase their supply-chain to fulfill the demand for sourcing innovative, eco-friendly and functional textiles which is much needed by the Indian apparel and fashion industry. Further, to increase its global market

share, Indian manufacturers are producing a value-added range of garments and fashion accessories for global buyers to increase their sourcing from India and reduce their dependency on China.

Also, the Intex platform assists the domestic apparel industry to offer highvalue and sustainable garments to fashion-conscious and high-spending Gen Z and millennial consumers.

Buyer-seller meets a high point

The 10th edition was jointly organized by the Federation of Indian Chambers of Commerce and Industry (FICCI) under the aegis of the Department of Commerce, Ministry of Commerce along with the Worldex India Exhibition and Promotion. A ‘Reverse Buyer Seller Meet’ (RBSM) was jointly organized offering Indian exhibitors a platform to promote.

Over 500 B2B meetings were organized between international buyers and Indian exhibitors over three days. These will give a boost to India’s textile exports by $650 million in coming years; increasing our export base and creating employment opportunities by supporting the ‘Make in India’ program.

In order to boost micro and small entrepreneurs in the textile sector, the Ministry of Micro, Small, and Medium Enterprises (MSME) extended their support to qualified MSMEs at Intex India. More than 48 exhibitors joined the show to promote their textile and apparel strengths and expand their domestic and international presence.

Participants at the MSME Pavilion were overwhelmed with the sale enquiries they received from international and domestic buyers. Some leading Indian exhibitors were: Reid & Taylor, and Alok Industries amongst others. ReshaMandi was the official online sourcing partner of Intex India 2022. Over 85 percent of participating exhibitors were satisfied with buyers’ footfalls.

Some Leading international buyers that attended the show included KOMAR Brands from the US, TWO MAD from Switzerland, Sewkit from Russia, NUNINE from France, Hela Clothing and TESCO Sourcing from Sri Lanka.

B2B meetings, trends, and knowledge sessions were organised at the Interactive Business Forum (IBF) Seminar Series and ‘Trendz Now’ – the colour, fabric, and fashion forecast showcase.

Presentations were made by Italtex (Italy), Pantone (USA), and Orsha Linen Mills (Belarus) that offered valuable insights from the industry experts on 2023-24 fabric and fashion trends, colour trends, and working of Pantone Connect as well as new market opportunities in India for sustainable textiles.

Intex South Asia is now well established as the region’s premier international textiles sourcing platform, which is successfully held in key markets of South Asia like Bangladesh, Sri Lanka, and India and would become the annual calendar event for South Asia’s textile and apparel industry.

The 2023 edition will be Intex South Asia in Bangladesh, Sri Lanka, and India.

Fairs and Exhibitions 28 PAKISTAN TEXTILE JOURNAL - January 2023

Texworld Evolution Paris, 2023

Texworld Evolution Paris, which will be held at the Parc des Expositions de Paris-Le-Bourget from 6 to 8 February shows promising prospects: with 750 companies expected, overall bookings have reached 70% of the pre-pandemic level of February 2019. Among the major sourcing countries present in Paris on this occasion, Chinese exhibitors will affirm their physical presence.

Asia is coming to Paris in February!

Signs are good! The February edition of Texworld Evolution Paris is expected to approach the pre-crisis levels. With nearly 750 companies from some twenty countries, these three days will be an opportunity for visitors to renew their acquaintance, after three years of instability, with the offer of the great Asian weavers, embroiderers, and garment makers in particular.

Pre-crisis levels confirmed