Established 1951 June 2023 Weaving / ITMA 2023 Preview

Istanbul Yarn Fair

Dates: June 1st to 3rd, 2023.

Venue: Istanbul, Turkey.

62th Dornbirn GFC Global Fiber Congress

Dates: September 13th to 15th 2023.

Venue: Dornbirn Austria.

Textile Asia 2023, Lahore

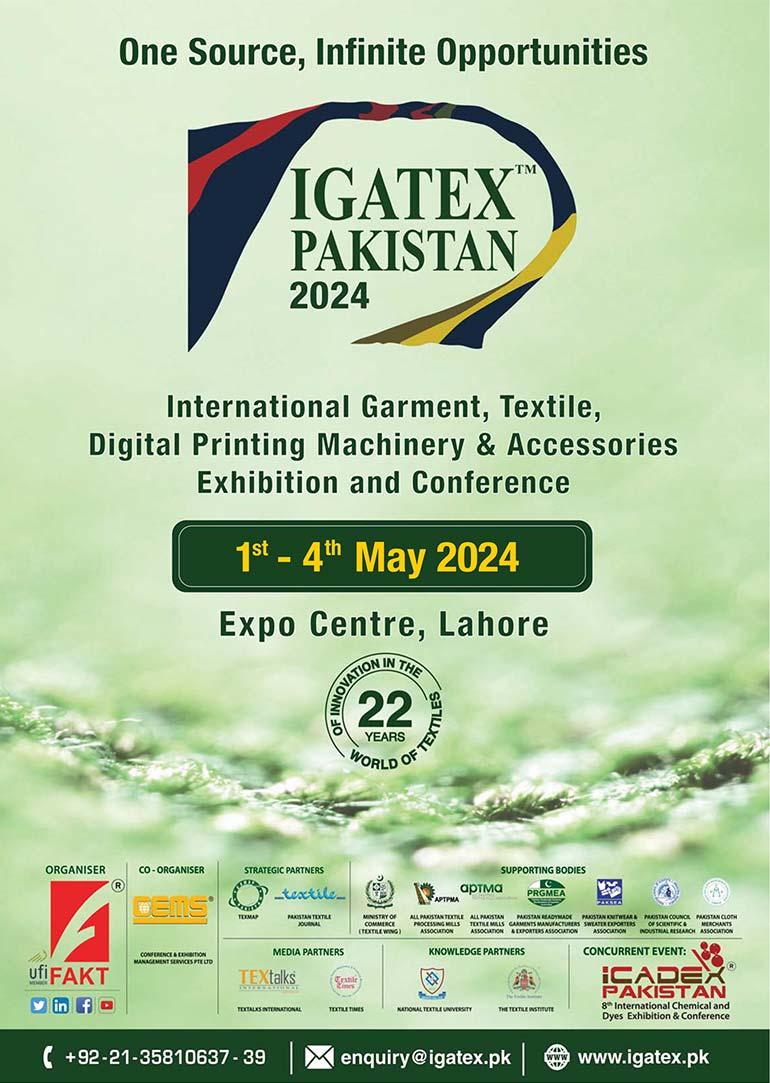

IGATEX Pakistan 2024, Lahore

Dates: May 1st to 4th 2024.

Venue: Expo Centre, Lahore.

ITM 2024

Dates: June 4th to 8th, 2024.

ITMA 2023

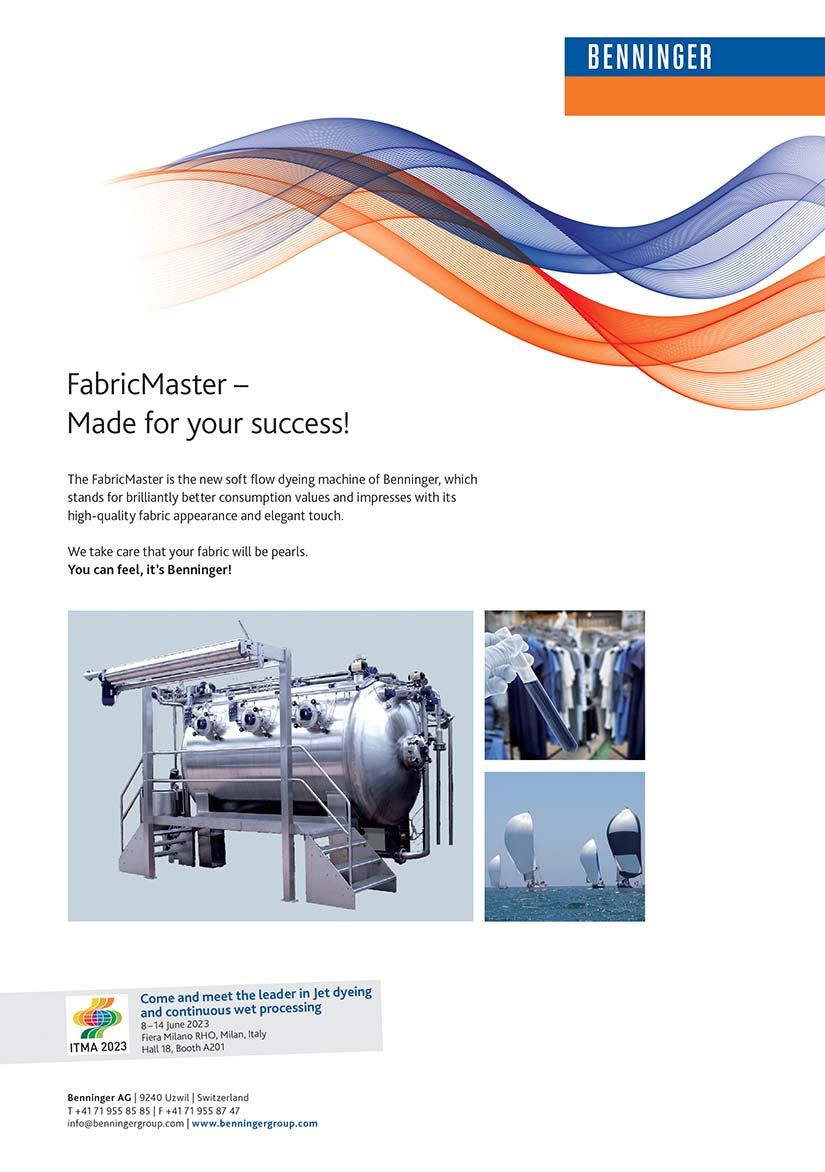

Dates: June 8th to 14th, 2023.

Venue: Milan, Italy.

Johannesburg, South Africa !

Dates: June 18th to 20th, 2023.

Venue: Gallager Convention Centre.

The 92nd Textile Institute World Conference, UK.

Dates: July 3rd to 6th 2023.

Venue: Huddersfield, UK.

DOMOTEX asiaCHINAFLOOR 2023

Dates: July 26th to 28th 2023.

Venue: NECC, Shanghai, China.

Dates: October 13th to 15th 2023.

Venue: Expo Centre, Lahore.

ITMA ASIA + CITME 2023

Dates: November 19th to 23rd, 2023.

Venue: NECC, Shanghai, China.

Heimtextil 2024, Frankfurt

Dates: January 09th, to 12th, 2024

Venue: Frankfurt am Main.

DOMOTEX Hannover 2024

Dates: January 11th to 14th 2024.

Venue: Hannover, Germany.

iCADEX Pakistan 2024, Lahore

Dates: May 1st to 4th 2024.

Venue: Expo Centre, Lahore.

Venue: Istanbul, Turkey.

HIGHTEX 2024

Dates: June 4th to 8th, 2024.

Venue: Istanbul, Turkey.

JIAM 2024 OSAKA

Dates: Nov. 27th to Nov. 30th 2024.

Venue: Osaka, Japan.

12th ITME INDIA 2024

Dates: December 2024.

Venue: India Expo Centre & Mart. Noida, India.

Index 2026

Dates: April 21st to 24th, 2026.

Venue: Palexpo, Geneva, Switzerland.

2

Events

Calendar of

PAKISTAN TEXTILE JOURNAL - June 2023

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher

Nadeem Mazhar

Editor in Chief

Amina Baqai

Associate Editor

Nimrah Nadeem

Production Manager

Mazhar Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh

Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab

C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA)

Mian Iftkhar Afzal

B.S.N.C State, M.Sc. (Leeds)

C.TEXT.F.T.I (UK)

Dr. Zubair Bandukda

PhD (Textiles), CText ATI

Editorial & Advertising Office

B-4, 2nd Floor, 64/21, M.A.C.H, Miran M. Shah Road, Karachi - Pakistan

Tel: +92-21-34311674-5

Fax: +92-21-34533616

Email: info@ptj.com.pk

URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Correspondence & Mailing address: 93 Fleming Place, Bracknell, RG12 2GN, United Kingdom

Tel: +44 792 2228 721

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, UK

Registered no. 09141989

INTERVIEW Gul Ahmed Textile Mills invests in Bruckner Stenters for sustainable growth . .

Ahmed, Director Operations, Gul Ahmed Textile Mills

AROUND THE WORLD . . . . . . . . . . . . . . . . . . . . . .14 NEWS & VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . .10 EDITOR’S PAGE . . . . . . . . . . . . . . . . . . . . . . . . . . .7 ITMA 2023: Unveiling the Future of Textile Technology TEXTILE BRIEFS . . . . . . . . . . . . . . . . . . . . . . . . . . .8 Vol. LXXII No. 06 June 2023 Rs. 565.00

Printed at: Color Plus Korangi, Karachi. Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi. Available on Gale and Factiva affiliated international databases through Asianet Pakistan

SEMINAR ITMA 2023: Visitor promotion presentations in Pakistan . . . . . . . . . . . . . . . . .23 Lahore Event Glimpses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24 Karachi Event Glimpses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 FAIRS AND EXHIBITION IGATEX PAKISTAN – International Garment, Textile, Digital Printing Machinery & Accessories Exhibition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22 23 20

Zaheer

.20

ITMA

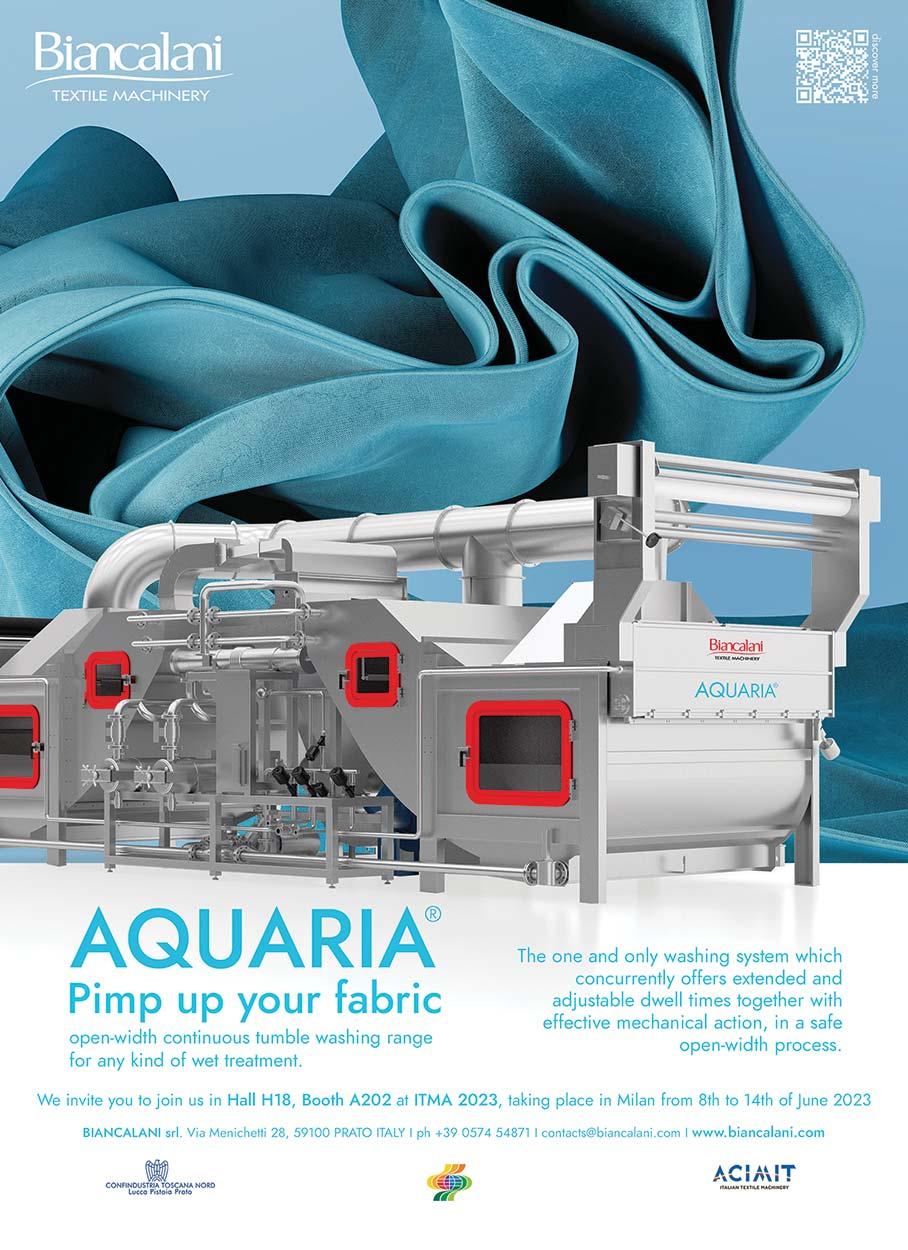

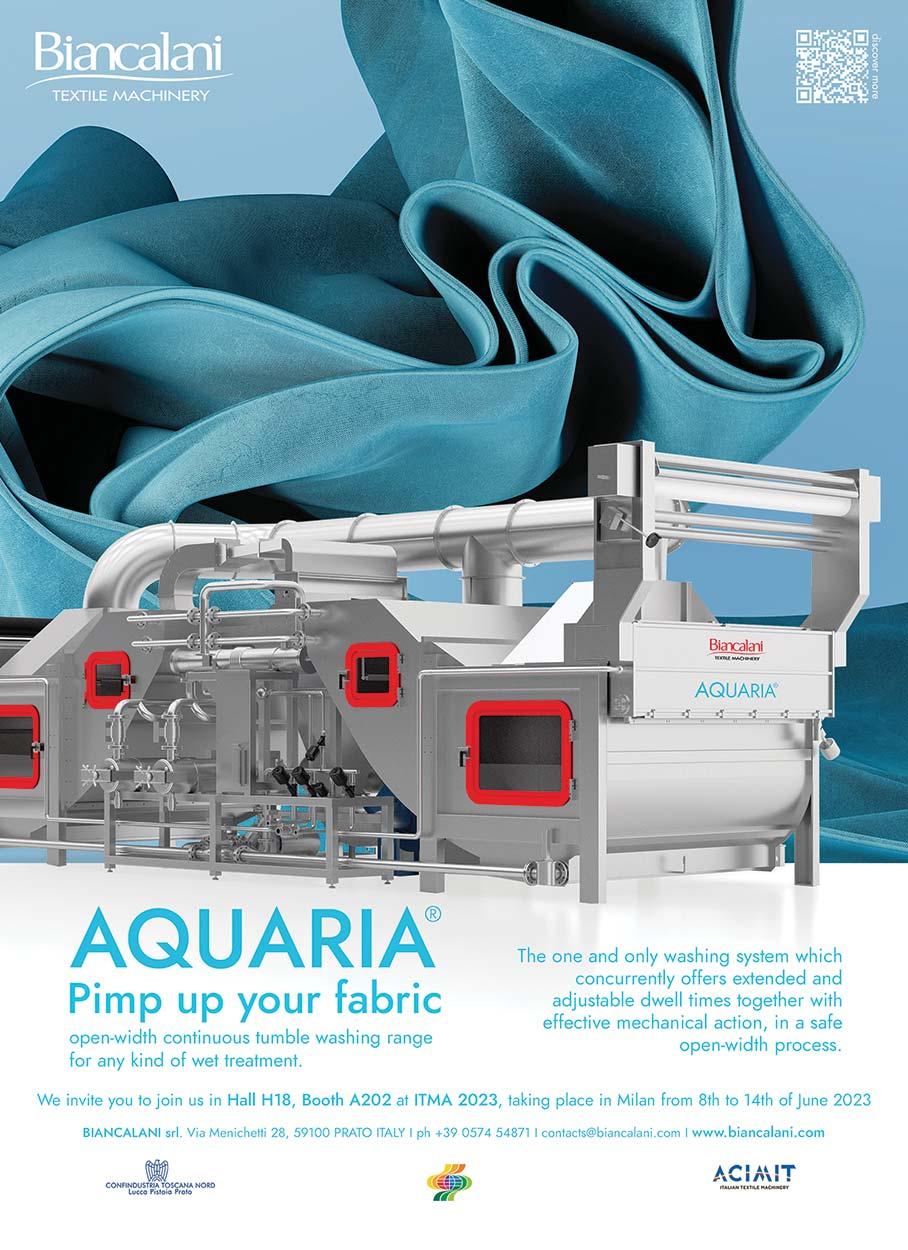

Way2ITMA: Recycling Technologies offered by VDMA members . . . . . . . . . . . . .30 UCMTF: French Textile Equipment Manufacturers’ Association . . . . . . . . . . . . .32 Swiss textile machinery companies focus on environmental priorities . . . . . . .34 Jakob Müller presents mymueller and mymuenet . . . . . . . . . . . . . . . . . . . . . .35 Automation is central for Swedish textile machinery . . . . . . . . . . . . . . . . . . .36 TMAS: Weaving remains the bedrock of the textile industry . . . . . . . . . . . . . .38 DyStar features new product & process innovations . . . . . . . . . . . . . . . . . . . .39 TOYOTA showcases three JAT 910 airjet weaving machine models . . . . . . . . . .40 Itema displays new EVO range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42 Crealet introduces narrow weaving warp tension control system . . . . . . . . . . .43 Picanol to unveil revolutionary rapier machine at ITMA 2023 . . . . . . . . . . . . .44 Uster Fabriq Assistant automates data preparation for key decisions . . . . . . . .46 MEMMINGER-IRO latest developments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47 PROTECHNA Herbst . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47 VANDEWIELE: Expert in carpet weaving machines . . . . . . . . . . . . . . . . . . . . .48 MESDAN yarn splicing technology & laboratory testing equipment . . . . . . . . . .50 Sedo Treepoint Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 SAVIO presents PROXIMA Smartconer® automatic winder . . . . . . . . . . . . . . . . .51 TITAN for carpet sewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51 Santex Rimar Group: Green ambitions with environmental - friendly machinery . .52 Saurer at ITMA 2023 – Shaping the future of textiles . . . . . . . . . . . . . . . . . . .54 Latest THEN Airflow developments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56 XORELLA: New XO AUTOMATION system . . . . . . . . . . . . . . . . . . . . . . . . . . . .57 JK Group & MS Printing Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58 TOMSIC Nep & Trash tester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60 REVECOL® by ERCA, the circular revolution takes a step forward . . . . . . . . . . .60 Loepfe: YarnMaster® PRISMA Autoclearing . . . . . . . . . . . . . . . . . . . . . . . . . . .62 Biancalani: AQUARIA® revolutionary finishing process . . . . . . . . . . . . . . . . . . .63 35 40 38 42 44 52 34 54

2023

ITMA 2023: Unveiling the future of textile technology

As the global textile industry gears up for one of the most eagerly anticipated events in its calendar, ITMA 2023 promises to be a game-changer for textile professionals from Pakistan. From June 7-14, Milan will host this prestigious exhibition, showcasing the latest technological developments that are set to revolutionize the textile and garment sector. Pakistan Textile Journal is proud to be a longstanding participant, having reported on every ITMA event since its inception in 1951, and we are excited to bring our readers the news and reports on the cutting-edge technologies that will shape the industry's future.

ITMA has consistently held its position as the world's largest textile and garment technology exhibition, and this year's edition is no exception. Boasting an impressive lineup of 1570 exhibitors from 42 countries, the exhibition will cover a sprawling gross exhibition space of 200,000 square meters. With 12 halls dedicated to showcasing a complete range of textile machinery solutions, ITMA 2023 truly serves as a one-stop sourcing platform for the entire textile and garment value chain.

For textile professionals from Pakistan, attending ITMA 2023 holds immense benefits. Firstly, it provides a unique opportunity to witness firsthand the latest technological advancements that are revolutionizing the industry. The exhibition will feature cutting-edge machinery, equipment, and software solutions that will enhance productivity, efficiency, and sustainability across the textile manufacturing process. By exploring these innovations, Pakistani professionals can gain a competitive edge and identify the technologies that best align with their specific needs and goals.

Furthermore, ITMA offers an unparalleled platform for knowledge sharing and networking. Visitors can participate in conferences, panel discussions, and product demonstrations, where industry experts will share insights and expertise on key topics shaping the textile landscape. This exchange of knowledge not only fosters professional growth but also facilitates valuable connections with international counterparts, paving the way for potential collaborations and business opportunities.

The importance of ITMA cannot be overstated, especially for textile professionals from Pakistan. Attending this event held every four years enables them to stay at the forefront of industry trends, gain exposure to innovative solutions, and foster invaluable connections. With Pakistan's textile industry playing a significant role in the country's economy, embracing technological advancements showcased at ITMA will help ensure its continued growth and competitiveness on the global stage.

As Pakistan Textile Journal, we are committed to keeping our readers well-informed about the latest happenings at ITMA 2023. Our dedicated team will be on the ground, reporting on the groundbreaking technologies, trends, and success stories emerging from the exhibition. We are excited to bring these insights back to our readers, empowering them with the knowledge they need to navigate the ever-evolving textile landscape.

In conclusion, ITMA 2023 is poised to be an unmissable event for textile professionals from Pakistan. By attending, they will gain access to a wealth of knowledge, cutting-edge technologies, and invaluable networking opportunities. Pakistan Textile Journal is honored to be part of this prestigious exhibition once again, and we look forward to delivering comprehensive coverage that will inspire and inform our readers, as we have done since the very first ITMA event. Together, let's embrace the future of textile technology and shape a vibrant and prosperous textile industry for Pakistan.

7 EDITOR’S PAGE

Established 1951 June 2023 Weaving / ITMA 2023 Preview

June 2023.

June 8th to 14th,2023 Milan, Italy

Textile Briefs National

1The 4th International Textile and Leather Exhibition, TEXPO was held at the Expo Centre in Karachi in the last week of May. TEXPO 2023 hosted more than 300 domestic and International buyers consisting of exhibitors, Pakistan’s leading designers, and industry specialists from around the world. The event showcased the textile and leather industry’s offerings from all across Pakistan, ranging from leather garments, footwear, cotton, readymade garments, home textiles, denim, knitwear, sportswear, among others. 2

The first cargo ship containing goods in more than 2000 transshipment containers has set sailed from Russia’s Saint

Petersburg Port which will be docking at Pakistan’s Karachi Port within 19 – 24 days.This new trading route is going to be very crucial for quick delivery of goods like textile, machinery and other important goods from European side of Russia, as well as Asian side to Pakistan and vice versa.

ment and demurrage charges, recovery of RCET, administration-based tax, sensible open access (wheeling) charges, and end to the uniqueness in costs and accessibility of gas between send out areas of Punjab and Sindh. 4

3

The All Pakistan Textile Mills Association (APTMA) has proposed a budget draft for 2023-24, which includes the recovery of energy and other subsidies, deferred sales tax refunds, service-based tariff, and restoration of zero-rating status for the export sector. It also sought discounts of conceded deals charge, continuation of long haul supporting office, discount of confine-

Textile Briefs International

Mango, A Barcelonabased fashion group has recently joined hands with Pakistan to ensure the workers safety in the garments and textile Industry. Mango was one of the earliest members to join the Accord on Fire and Building Safety in Bangladesh, which was signed by Mango in 2013.

ments in an effort to reduce the exchange rate gap between the official and kerb markets.The move also followed the International Monetary Fund’s demand that Pakistan fixes its currency market prior to resuming a $6.5 billion bailout programme. 6

1

The central bank on Wednesday permitted banks to buy dollars from the interbank market to settle international card pay-

5

The data released by the Pakistan Bureau of Statistics (PBS) indicates a significant decline of approximately 14% in Pakistan's textile exports during the 10-month period of fiscal year 2023. The total textile exports dropped to $13.7 billion, compared to $15.9 billion in the previous year.In April 2023, textile exports experienced a yearon-year decrease of 29%, amounting to $1.23 billion.

Farmers in Indian state of Maharashtra has called a protest

Despite USA efforts and protests at international level, the Chinese Import Export Fair also known as Canton Fair turned out to be a success for Chinese Cotton Industry as they successfully closed deals worth about 82 Million US Dollars. The fair was attended by domestic and International buyers from all over the World and among them more than 100 domestic and foreign buyers have closed the deals worth 82 Million US Dollars for the cotton textile product sourced from the Northwest China's Xinjiang region. 2

against the government and its anti-farmer policies, veteran farmer leader Vijay Jawandhia have asked each farmer in Yavatmal city to come with at least 10kg of cotton which is lying useless in their home and dump in the open ground of protest area where it will all be burned to show the un-satisfaction, disappointment and protest against the government’s anti-farmer policies.

because of the ULEFA bill which requires proving that the products being exported to USA specially do not contain cotton obtained by means of forced labours and other inhumane practices.

Government the cotton industry of Zimbabwe has started to yield a positive change after continuous negative trends since past few years.

4

Vietnam which took the global textile industry of apparel and sneakers by storm and has been crowned World’s hub for apparel and sneakers is recently under a tremendous pressure

3

From the recent statistics of the U.S Customs and Border Protection, it was observed that so far (till the month of April 2023) 43% of the total textile products imported to USA from Vietnam has been denied entry with 10.04 Million US Dollar worth of products still waiting to be cleared by the US customs.

5With foundation of positive initiatives last year and ongoing efforts of current

6

“We have been making efforts to ramp up the cotton sector and this has seen some positive performance within the sector. From being a ‘dead sector’ in 2015/16 to a US$90 million (137 000 tonnes) cotton export sector and this is a positive stance towards achieving glory days,” said Lands, Agriculture, Fisheries, Water and Rural Resettlement permanent secretary John Basera.

8 PAKISTAN TEXTILE JOURNAL - June 2023

Cotton Action Plan 2023-24 to harvest USD 3 billion foreign exchange

The announcement of the "Cotton Action Plan 2023-24" in Pakistan, aimed at boosting cotton cultivation and earning $3 billion in foreign exchange, has significant implications for the textile and garment exports industry.

The plan, as expressed by Mr. Iftikhar Ali Sahoo, Punjab Agriculture Secretary, emphasizes the importance of cotton cultivation and its potential to contribute to the country's foreign exchange earnings. By preparing nearly 0.971 million acres of land in the Dera Ghazi Khan division solely for cotton cultivation, the government aims to increase cotton production and exports.

Cotton is a critical raw material for the textile and garment industry, and Pakistan has traditionally been a significant player in the global cotton market. Increasing cotton production through initiatives like the Cotton Action Plan can strengthen the domestic supply chain for textile manufacturers, ensuring a stable and sufficient raw material supply.

The $3 billion target for foreign exchange earnings from cotton exports demonstrates the government's focus on leveraging the textile sector to boost exports and stabilize the country's economy. The textile and garment industry is a major contributor to

Pakistan's exports, and cotton exports play a crucial role in its success.

To support the implementation of the Cotton Action Plan, the government is taking practical measures to maximize cotton growth in the region. This includes close collaboration with the irrigation department to ensure sufficient water supply for crop cultivation and motivating farmers through initiatives like the Cotton Growing Competition, which offers attractive prizes.

The plan's successful implementation can have several positive implications for the textile and garment exports industry. A higher domestic cotton production will reduce the industry's reliance on imported raw materials, potentially lowering production costs and enhancing competitiveness in the international market.

Moreover, increased cotton production can lead to higher textile exports, generating more foreign exchange earnings for the country. This can help address the trade imbalance with countries like Russia, as mentioned by Mr. Abdullah Farooq, CEO of Pak Shaheen Private Limited. The availability of a direct shipping service to Russia is expected to boost Pakistani exports to the country by $2.5 billion, opening up new opportunities for the textile and garment industry.

Overall, the Cotton Action Plan 202324 has the potential to significantly impact the textile and garment exports

industry in Pakistan. By focusing on increasing cotton cultivation and foreign exchange earnings, the plan aims to strengthen the industry's supply chain, improve competitiveness, and tap into new export markets.

APTMA presents various budget proposals in hopes of boosting exports

The budget draft presented by the All Pakistan Textile Mills Association (APTMA) for 2023-24 highlights several measures that the organization believes are necessary to support the textile sector and enhance its competitiveness. These measures primarily focus on the recovery of subsidies, refunds, and the restoration of favorable policies for the export sector.

APTMA emphasizes the importance of recovering energy and other subsidies, as well as deferred sales tax refunds. These financial incentives can help reduce production costs for textile mills and improve their profitability. Additionally, the organization calls for the restoration of the zero-rating status for the export sector, which would exempt exports from sales tax, further supporting the industry.

The draft also suggests measures to address challenges faced by textile exporters, such as the recovery of the Research and Development Cess (RCET), administration-based tax, and equalization of gas prices between export areas in Punjab and Sindh.

PAKISTAN TEXTILE JOURNAL - June 2023 10 News & Views

These measures aim to create a more favorable business environment for textile exporters and enhance their competitiveness in both domestic and international markets.

APTMA highlights the issue of port detention and demurrage charges, which have significantly increased the costs for the industry. The organization asserts that these charges should not be borne by importers, as they result from a lack of foreign currency reserves. APTMA proposes that these charges be refunded from the Export Development Fund (EDF), thereby relieving the financial burden on exporters.

Overall, the budget draft presented by APTMA reflects the challenges faced by the textile sector in Pakistan and outlines measures that can support its growth and competitiveness. The recovery of subsidies, refunds, and the restoration of favorable policies can help reduce production costs and enhance profitability. Addressing issues related to port detention and demurrage charges can alleviate financial burdens on exporters, ensuring a more viable and competitive industry.

Textile Group Exports decline by 14.22% during 10 months of current FY 2022-23

The data released by the Pakistan Bureau of Statistics (PBS) indicates a significant decline of approximately 14% in Pakistan's textile exports during the 10-month period of fiscal year 2023. The total textile exports dropped to $13.7 billion, compared to $15.9 billion in the previous year.

In April 2023, textile exports experienced a year-on-year decrease of 29%, amounting to $1.23 billion. The decline in textile exports was observed both in US dollar terms and Pakistan

rupee terms, with a 29% and 9% decrease, respectively.

The decline in textile exports can primarily be attributed to a drop in the value-added and basic segments. The value-added segment, which includes products like bedwear, knitwear, readymade garments, and towels, witnessed declines of 22%, 34%, 29%, and 26%, respectively. Similarly, the basic segment, including cotton cloth and cotton yarn, experienced a 32% decline.

In a month-on-month comparison, textile exports for April 2023 stood at $1.23 billion, showing only a 2% decrease. The value-added textile exports remained stable, with stability observed in

News & Views

bedwear and knitwear, while readymade garments witnessed a 10% decline. The basic textiles decreased by 7%, with declines observed in cotton cloth and cotton yarn. In terms of volume, bedwear and knitwear showed positive trends with a 9% and 3% increase, respectively, compared to the previous month. However, towels decreased by 3%, and readymade garments remained flat.

Textile manufacturers in Pakistan have observed improved orders from Europe and the United States for the valueadded segment, indicating some resilience in volumes.

However, challenges such as unavailability of locally produced cotton, delays in clearance of imported cotton and other inputs, elevated gas and electricity tariffs, and increased finance

Mango joins Pakistan Accord

Since the devastating incident of Karachi’s garments factory, Pakistan have paid a great interest in the safety of the factory workers and has developed many promising policies around it, these policies and regulations have been warmly welcomed by the Pakistan’s Textile Industry.

Almost all top manufacturers have already equipped their production houses with all the modern safety equipments and are taking strict safety measures to ensure the safety of the workers and many more manufacturers are following the footsteps and joining these policies.

One of the more greater initiative by the policy makers in this regard is International Accord which is also very popular by the name of Pakistan Accord, Pakistan Accord came effective on September 2021, since then it has been highly appreciated by the global Textile community and many top brands have

joined Pakistan in ensuring the safety of the workers, one signature a time.

Many popular brands like Hugo Boss, Adidas, American Eagle Outfitters, Asos, Boohoo Group, Marks & Spencer and Puma have already signed the Accord and has ensure that they will take all modern safety measures and regulations needed to ensure the safety of their workers in Pakistan.

Barcelona-based fashion group Mango has recently joined hands with Pakistan to ensure the workers safety in the garments and textile Industry. Mango has always been a supporter of workers safety and healthy work environment for workers, Mango was one of the earliest members to join the Accord on Fire and Building Safety in Bangladesh, which was signed by Mango in 2013. This Accord was established after the incident at the Rana Plaza building, which resulted in the loss of 1,133 lives and hundreds of injuries.

Mr. Toni Ruiz, CEO of Mango said, “At Mango, we firmly believe in the

costs continue to hinder the textile industry.

It is important to note that the decline in product prices may have offset the impact of decreased volumes to some extent. However, the overall decline in textile exports and the challenges faced by the domestic economy pose ongoing obstacles for textile players in Pakistan.

transformative power of collaboration, which is why we consider it necessary to join forces with other companies in the Pakistan Accord. We are delighted that these types of agreements are being extended to new countries since it represents a major step forward in our journey towards greater protection in textile and garment factories.”

More than 50 brands and retailers have added their names to the Pakistan Accord since January, according to the International Accord secretariat, which expects more to follow in the following weeks.

Together, the International Accord’s 187 brand signatories source more than $2.6 billion worth of garments and textiles from Pakistan.

The secretariat said it expects all 110 signatories with operations in the country to eventually participate, covering 500 to 700 facilities and tens of thousands of workers.

News & Views 12 PAKISTAN TEXTILE JOURNAL - June 2023

Mr. Toni Ruiz, CEO of MANGO.

SBP allows credit card settlements using interbank exchange rate

The recent decision by the State Bank of Pakistan (SBP) to allow banks to purchase dollars from the interbank market for settling international card payments has implications for the textile and garment exports industry in Pakistan.

One of the key challenges faced by exporters in Pakistan is the exchange rate gap between the official and kerb markets. The official exchange rate is typically lower than the rate in the kerb market, which is where most exporters source their foreign currency. This exchange rate disparity creates difficulties for exporters in accurately pricing their products and managing their foreign currency transactions.

By allowing banks to buy dollars from the interbank market for settling international card payments, the SBP aims to reduce the exchange rate gap. This move will provide exporters with access to dollars at a more favorable exchange rate, which can help them in pricing their exports competitively and improving their profitability.

The textile and garment industry is a significant contributor to Pakistan's exports, and any measures that improve the ease of doing business for exporters in this sector can have positive implications. The ability to settle card-based cross-border transactions using a more favorable exchange rate can reduce the cost of doing business for exporters, making their products more affordable in international markets.

Furthermore, the increasing use and acceptance of digital instruments, including debit and credit cards, in Pakistan can facilitate international transactions for textile and garment exporters. It opens up opportunities for exporters to tap into online platforms and reach a wider customer base globally.

Overall, the SBP's decision to allow credit card settlements using the interbank exchange rate can have a positive impact on the textile and garment exports industry in Pakistan. It can enhance the competitiveness of exporters, reduce transaction costs, and facilitate smoother international trade in the sector.

BANGLADESH

Bangladesh apparel export to the US surge by 51 percent

Bangladesh’s apparel shipment to US, the country’s single largest export destination, increased by about 51 percent compared to last year. In the first 9 months of this year, the country has exported a record of more than 7.5 billion US dollars in clothing. Noteworthy, Bangladeshi apparel makers are getting a strong foothold in the United States of America market as exports posted robust growth in recent times. Despite the global recession, the export of Bangladeshimade garments to the United States has increased at a significant rate.

According to “The Office of Textiles and Apparel (OTEXA)”, Bangladesh’s garment exports to the US market dropped slightly to $690 million last July but rose again to over $900 million in the next two months. During the last nine months of the current fiscal year, Bangladesh fetched billions from the US market by exporting primarily trousers, Tshirts, sweaters, blouses, underwear, etc. With an 8.54 percent export share, the country remained the third largest apparel import source for the US.

The United States of America is the single largest export destination for Bangladesh. Over 21.50 percent of apparel export earnings came from this huge market. Bangladesh supplies quality goods at affordable prices, while the US buyers are happy with the safety standard of the industry.

The surge in the export earnings comes at a time when the Western

countries, the main buyers of Bangladesh apparel, are fighting a depressed demand mainly due to the energy crisis caused by the Russia-Ukraine war. The USA also is facing the effect of a global economic recession as interest rates in the country are going high, and energy prices also have gone up. But people are still buying clothes there. The import figures indicate that USA’s retail industry is witnessing a fast recovery from the Covid-19 crisis.

Earlier last year, Bangladesh exported 7.15 billion dollars worth of ready-made garments to the US market, which was about 37 percent more than in 2020. The better-than-expected growth came as consumer spending increased more than in the government’s previous reading, while the value of imports was revised down. Imports are subtracted from GDP, which is the broad measure of economic activity within the country.

CHINA

Textile manufacturers acquired business worth USD 82 Million at Canton Fair

The Chinese Import Export Fair, also known as Canton Fair, proved to be a success for the Chinese cotton industry as deals worth approximately USD 82 million were closed. The fair attracted domestic and international buyers, and more than 100 buyers, both domestic and foreign, finalized deals for cotton textile products sourced from Xinjiang region in Northwest China.

Xinjiang region is responsible for nearly 90% of China's cotton production. However, China has faced accusations, particularly from the USA, regarding forced labor and other issues. The Uyghur Forced Labor Prevention Act (UFLPA) was passed by the USA, which criticizes Chinese cotton and manufacturers and requires brands using Xinjiang-produced cotton to prove it was not acquired through inhumane practices. This act has put pressure on Chinese brands, leading to strong responses against it. Some experts in China view this bill as "EvilBill" and have boldly opposed it. Mr. Wang Jiang, an expert at the Institute of China's Borderland Studies at Zhejiang Normal University, stated that despite the USA's attempts, the Canton Fair demonstrated that the US abuse of its financial power and market dominance

Around the World 14 PAKISTAN TEXTILE JOURNAL - June 2023

could not hinder the sale of Xinjiang products in the global market. He emphasized that Chinese people have the right to sell their products on platforms like the Canton Fair, as these products are the result of honest and diligent work.

Despite the USA's campaign, more than 30 Xinjiang-based companies promoted 300 cotton textile products to both domestic and foreign buyers. The majority of the foreign buyers were from Asian, African, and Latin American countries, which are less affected by the UFLPA.

Mr. Liu Haifeng, Chief Scientist and President of China National Color Cotton Corp, mentioned that many clients expressed interest in their products, and initial contacts were established, particularly with buyers from Asian, African, and Latin American countries who are less impacted by the UFLPA.

Overall, the Canton Fair proved successful for the Chinese cotton industry and appeared to be relatively unaffected by the USA's campaign. Furthermore, Chinese companies are working on digitizing their entire production line to minimize the negative effects of the UFLPA.

INDIA

Farmers decide to burn 1000 quintal of raw cotton to protest against anti-farmer policies

Farmers in Indian state of Maharashtra has called a protest against the government and its anti-farmer policies, veteran farmer leader Vijay Jawandhia have asked each farmer in Yavatmal city to come with at least 10 kg of cotton, which is lying useless in their home and dump in the open ground of protest area, where it will all be burned to show their disappointment and protest against the government’s anti-farmer policies.

Over 8 million farmers are engaged in cotton cultivation in the state and last year, it was grown on a record 10.20 million hectare when the prices had touched Rs 14,000/quintal,

However, this year, the cotton prices have crashed by nearly 50 per cent –from Rs 14,000/quintal to barely Rs 7,000/quintal now.

The cotton exports had tumbled from 6 million bales to just 2 billion bales, pushing the cultivators across India into a fresh debt trap, said Vijay Jawandhia.

Kishore Tiwari, Shiv Sena (UBT)’s farmer leader says, “this year, the state has already reported more than 3,300 suicides of cotton-growers in Vidarbha, Marathwada and north Maharashtra regions.”

He further warned the government, “We are demanding a compensation of Rs 5000/quintal for the losses suffered by the cotton farmers failing which they could resort to extreme mass action.”

He explained that besides the crisis in the field, the Centre has added fuel to the fires to permit a record import of three million bales of cotton to protect the interests of the textile mill industry while the farmers languish under loan burdens.

The duo claimed that even the prevailing rate of cotton (Rs 7,000/quintal) is only due to a strong US Dollar against the Indian Rupee, or else the prices would have collapsed even below Rs 6,000/quintal or less than the MSP.

Around the World

USA

USA shows decline in apparel import values

After hitting the highest-ever apparel import values in 2022 (USD 99.93 billion), the USA has seen a decline in its apparel imports – both in values and volumes, on yearly basis.

As per the data released by OTEXA, the country imported USD 7.27 billion worth of apparel in the first month of the year, falling by 3.44 per cent on yearly note; however, the imports grew on monthly basis by 9.16 per cent as compared to December 2022 when it imported USD 6.66 billion worth of apparel.

Markedly, all major apparel export destinations (except for Indonesia) fell substantially in their volume-wise shipment to the USA during January 2023 on Y-o-Y basis; whereas India, Bangladesh, Indonesia and Sri Lanka increased their apparel shipments to the USA in value terms.

As per an analysis done by the data team of Apparel Resources, China’s share of the USA’s apparel import values declined to 19.83 per cent, possibly for the first time ever in the first month of a Calendar Year. China shipped USD 1.44 billion worth of apparel to the USA during January 2023, declining massively by 24.61 per cent on Year-on-Year basis.

Vietnam too fell marginally by 0.50 per cent to export USD 1.27 billion worth of apparel to the USA market, while Bangladesh seemed to be tapping China’s (and somehow Vietnam’s) share to export USD 867.64 million worth of apparel to the USA, growing 15.43 per cent on yearly basis.

China secured its top rank with USD 19.33 billion worth of garments entering the USA from the Asian giant at a growth rate of 20.76 per cent. However, the value-wise share has come down to 22.19 per cent from 23.92 per cent a year earlier.

India and Indonesia continued their tug of war as the former exported USD 485 million (up 9.77 per cent) worth of garments to the USA, while shipments from the latter to the USA were valued at US $ 453.84 million (up 4.73 per cent).

VIETNAM

Textile Industry on brink of collapse as US bans products made from Chinese cotton

Vietnam is recently under a tremendous pressure because of the ULEFA bill which requires proving that the products being exported to USA specially do not contain cotton obtained by means of forced labours and other inhumane practices.

Vietnam sources majority of the cotton for production in of various textile like apparel, sneakers, fashion and much more from China.

China is facing allegation from USA that the Chinese uses forced labour in the cultivation of cotton in the region of Xinjiang.

The Xinjiang region produces 90% of total cotton of the country and because of the UFLPA bill which requires China to prove that it’s cotton production is not obtained through sources of forced labour.

Many countries around the world are suffering because of all this in terms cotton products imports and exports among which Vietnam has been hurt more severely.

Many USA based global brands like Adidas, Nike, H&M, Armani, Lacoste and many other high end fashion brands sources their product from Vietnam for their stores in USA (majority) and worldwide, but because of the ULEFA bill,

Fashion brands among other textile brands and manufactures are suffering a lot.

To put in perspective every 1 of 3 pairs of Nike and Adidas sold, 1 is produced by Vietnam and roughly 26% of their sportswear is produced by Vietnam

From the recent statistics of the U.S Customs and Border Protection, it was observed that so far (till the month of April 2023), 43% of the total textile products imported to USA from Vietnam has been denied entry with USD 10.04 Million worth of products still waiting to be cleared by the US customs. Because of all this Vietnam’s exports are declining tremendously with 11.9% drop recorded in the country’s first quarterly exports report and a record 2.3% decline in terms of year to year basis.

Experts are saying that if this continues on and Vietnam’s continues to use Xinjiang cotton in their products, the country’s entire textile industry for apparel and sportswear could be on a brink of collapse.

Around the World 16 PAKISTAN TEXTILE JOURNAL - June 2023 Come and visit Pakistan Textile Journal at ITMA 2019 Milan, Italy. 8-14, June 2023

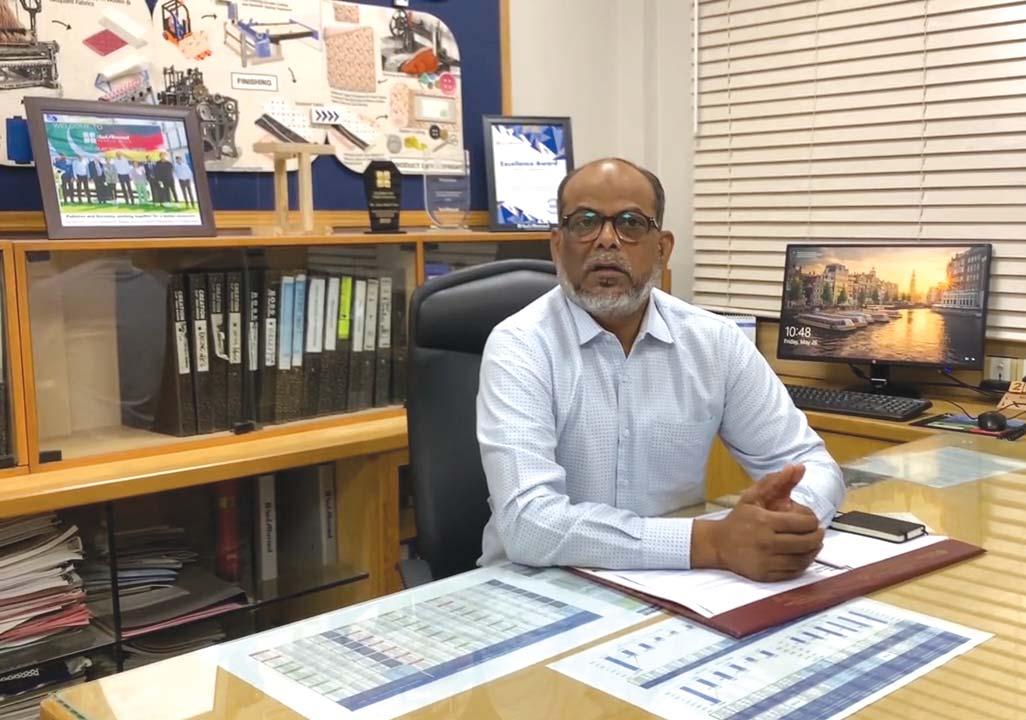

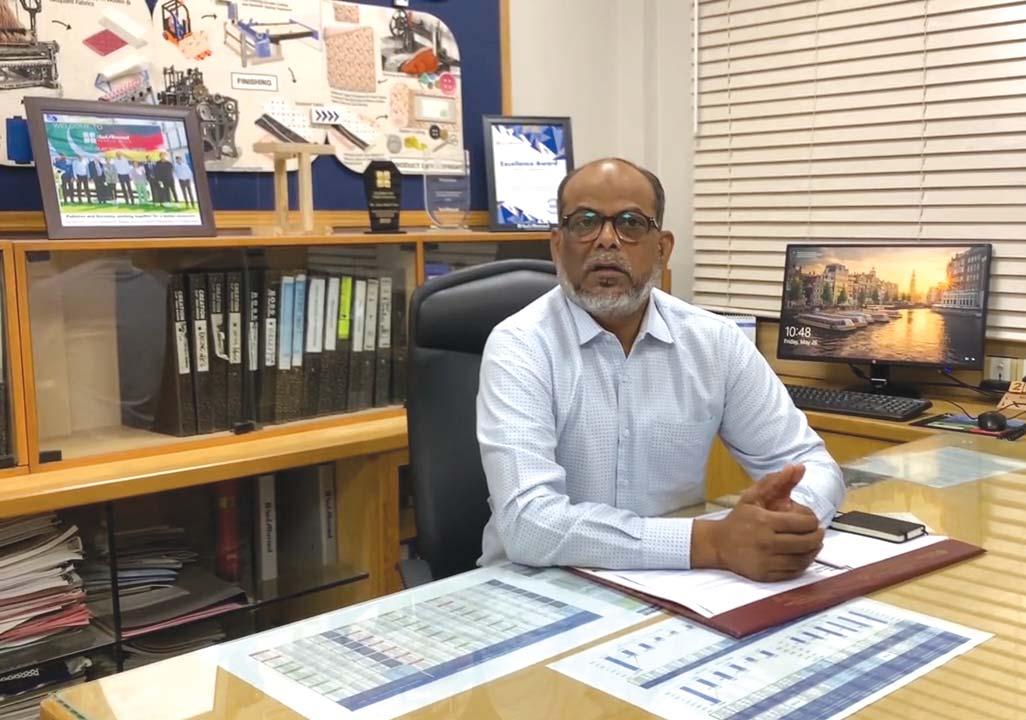

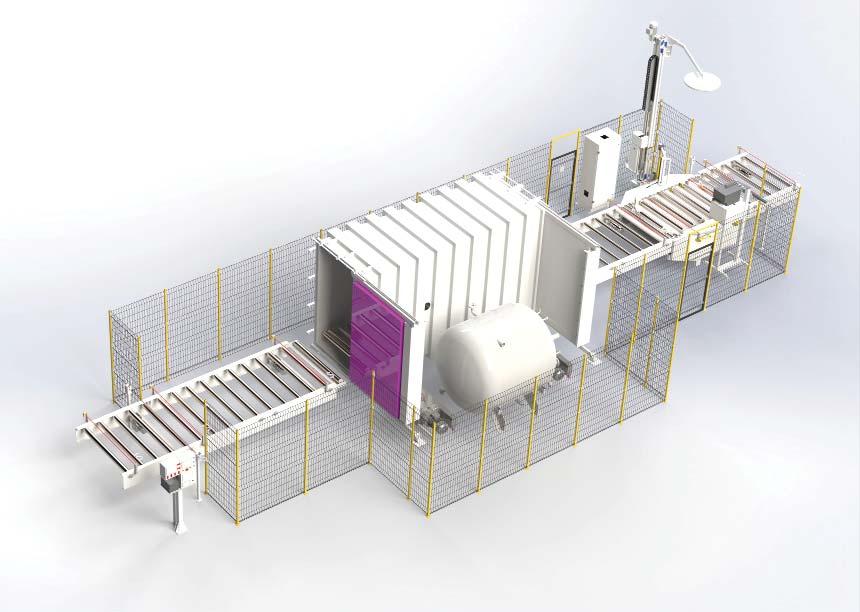

Zaheer Ahmed heading the processing division of Gul Ahmed Textile Mills as Director Operations shared his views about the growth of Gul Ahmed Group. Gul Ahmed Textile Mills was established in 1953. It is a vertically integrated textile company with weaving, spinning, processing and printing, yarn dyeing, fiber bleach as well as knits and apparel divisions.

According to Zaheer Ahmed, Director Operations at Gul Ahmed Textile Mills, the company has a strong belief in sustainable growth. Over the past seven decades, they have continuously invested in the latest technology to ensure their competitiveness and reliability as suppliers of high-quality textiles. Zaheer Ahmed emphasizes that investing in the best processing technology has been the key to their success.

In recent years, Gul Ahmed has made significant advancements in processing capacity, increasing it from 10 million meters to 11 million meters, depending on the product mix. They have incorporated advanced machinery such as five rotary printing machines, eight digital

printing machines, and a large setup for dyeing, including stenter dyeing, pad batch dyeing, thermosol dyeing, and pad steam dyeing.

Zaheer Ahmed highlights the importance of sustainable growth and continuous improvement, which led them to invest in Bruckner stenters. Over the last six years, they have acquired six Bruckner stenters, known for their ability to process various fabric types and consistently achieve the highest production quality. These stenters are equipped with efficient moisture control

and a state-of-the-art airflow duct system, ensuring consistent shrinkage and fabric quality. The burners in these stenters also contribute to costeffectiveness and reduced energy consumption.

To further enhance their dyeing capabilities, Gul Ahmed has added a Bruckner dyeing stenter with double IR. This stenter can produce a significant quantity of dyed fabrics per day, and the incorporation of a Thermex chamber enhances the fastness of light, medium, and dark shades.

20 PAKISTAN TEXTILE JOURNAL - June 2023

“Gul Ahmed Textile Mills invests in Bruckner Stenters for sustainable growth.”

Zaheer

Ahmed, Director Operations, Gul Ahmed Textile Mills

The reliability of Bruckner stenters is commendable, with minimal downtime or breakdowns, enabling Gul Ahmed to consistently deliver excellent quality production and meet diverse client requirements. The low energy costs associated with these stenters contribute to the company's competitiveness.

Apart from technological investments, Gul Ahmed also emphasizes the development of human resources and skill enhancement. Zaheer Ahmed himself is an example of this commitment, having joined the organization as a management trainee in 1990 and now serving as the Director of Operations.

The company believes in enriching lives and inspiring change, with a focus on sustainability. "Think Green, Act

Green" is not just a slogan for Gul Ahmed but a testament to their dedication as a sustainable and environmentally conscious company.

In conclusion, Gul Ahmed Textile Mills has demonstrated its commitment to sustainable growth through investments in the latest technology, such as Bruckner

stenters, and a strong emphasis on human resource development. Their focus on consistent quality, reliability, and customer satisfaction has been key to their success as a competitive player in the textile industry.

Power-Colortherm Hotflue

The BRÜCKNER hotflue is the heart of a continuous dyeing range and depending on the customers’ requirements it can be supplied with oil or gas heating. Due to the intelligent drive concept and a sophisticated air flow control an exact shade homogeneity is achieved across the length and the width of the fabric. Tailing and migrations are prevented and the dyeing results are 100% reproducible.

Advantages & technical data

Best dye uniformity over the complete length and width.

No tailing.

No migration.

Crease-free production.

100% reproducible dyeing results. Minimum consumption of thermal and electrical energy.

Tailor-made solutions for a maximum productivity even with small quantities. Easy access for cleaning and maintenance due to large doors.

Interview 21

IGATEX PAKISTAN - International garment, textile, digital printing machinery & accessories exhibition

FAKT Exhibitions (Pvt.) Ltd. will be organizing IGATEX PAKISTANInternational Garment, Textile, Digital Printing Machinery & Accessories Exhibition and Conference. The pioneer event of its kind will mark its presence at Expo Centre, Lahore from 1- 4 May 2024.

IGATEX PAKISTAN has successfully completed its 22 years making it an increasingly significant event with its scale setting records every year. The tradeshow will introduce high level garment, textile, and digital printing machinery and accessories which will provide business opportunities and add value to our exports hence, will increase the product worth that will have positive impact on the economic well-being of Pakistan. The event is known to not only introduce newest expertise, but also improvise trade benefits, increase foreign investments and spending through business visits by international delegates.

This edition of IGATEX PAKISTAN along with its concurrent event ICADEX PAKISTAN - International Chemical & Dyes Exhibition and Conference promises

to be bigger, better, and more impactful than ever before. We have curated a diverse range of exhibitors who will showcase their latest machinery, cuttingedge technology, and sustainable solutions. An informative conference will take place along the exhibition which will feature renowned industry experts who will share their insights on the latest trends, challenges, and opportunities in the industry.

IGATEX PAKISTAN being the biggest garment, textile, and digital printing industry tradeshow in Pakistan, gathers more than 500 exhibiting companies

from 30 countries including Austria, Belgium, China, France, Germany, Italy, Japan, Korea, Pakistan, Spain, Switzerland, Taiwan, Turkey, UK, USA etc. with a number of innovative and versatile machinery models to be debuted at the event.

IGATEX PAKISTAN has always played a pivotal role in development of the garment and textile industry by introducing efficient machinery and accessories to local manufacturers and is bound to yield success and growth for the industry.

22 PAKISTAN TEXTILE JOURNAL - June 2023

ITMA 2023: Visitor promotion presentations in Pakistan

A series of presentations were organized by Pakistan Textile Journal in association with ITMA Services during February 2023 and March 2023, in Lahore and Karachi respectively for the promotion of ITMA 2023, Milan Italy - the world’s largest textile machinery exhibition to be held from 08th to 14th June 2023 at Fiera Milano Rho, Milan, Italy.

The two successful events took place in Lahore, and Karachi in February and March 2023. The presentations covered topics such as the impact of digitalization and sustainability on the Pakistani textile industry, as well as updates on ITMA 2023.

The Lahore and Karachi events began with a welcome address by Alex Zucchi, the President of the Italian Textile Machinery Manufacturers Association, expressing gratitude to the hosts and guests. Ms. Eileen Ng, the Deputy Project Director of ITMA Services, delivered a presentation on the significance of ITMA as a platform for showcasing new technological developments and innovations in the textile sector. She highlighted the exhibition's role in facilitating direct interaction between visitors and manufacturers, providing live machinery demonstrations, and offering opportunities for collaboration and knowledge sharing.

In the Lahore event, Mr. Pervez Lala, Chairman of the All Pakistan Textile Processing Mills Association, served as the Chief Guest and emphasized the importance of ITMA 2023 for the textile industry. He highlighted the exhibition's value in showcasing advancements in textile manufacturing technology and providing valuable insights to improve business operations.

The Lahore event, attended by approximately 150 representatives from the textile industry of Pakistan, was greatly facilitated by the involvement of the Textile Institute Manchester. The Chairman, S.M. Qutab, and Secretary General, Nusrat Ali Chishti, played key roles in ensuring the success of the event. Their presence and contributions were essential in making the Lahore event a significant and well-received gathering.

The involvement of the Textile Institute Manchester's Lahore section and its members greatly contributed to the event's success. Their expertise, support, and active participation added value to the presentations and discussions related to ITMA 2023. The Textile Institute Manchester's role in supporting the event highlights the collaborative efforts to promote the textile industry and foster knowledge sharing and networking opportunities.

The Karachi event featured Mr. Danilo Giurdanella, the Counsel General of Italy in Karachi, as the Chief Guest. Mr. Aarij Iqbal, President of the Italian Development Committee, discussed the special procedures established in collaboration with Gerry's and the Italian Consulate to facilitate the visa process for Pakistani visitors attending ITMA 2023. Sophie AlKhawar from Gerry's International presented the visa application procedure to prospective visitors.

Mr. Sohail Tabba, a founding member of the Italian Development Committee, highlighted the significance of Pakistan as a key market for global textile machinery.

Mr. Danilo Giurdanella, the Consul General of Italy in Karachi, emphasized the value of Italian production and exports of textile machines, particularly to the Pakistani market. He encouraged the textile industry in Pakistan to participate in ITMA 2023, emphasizing the strong ties between Italy and Pakistan and committed the support by the Italian government to make participation from the textile industry of Pakistan possible. Special procedures were to be implemented to ensure smooth process of the issuance of visas and overall experience throughout the exhibition.The events were huge success and concluded on a positive note with high spirit of participation from the attendees of both events, at Karachi as well as Lahore.

23

Aarij Iqbal, President IDC.

Eileen Ng.Alex Zucchi.Pervez Lala. Danilo Giurdanella.

Sohail Tabba, LCI.

Lahore Event Glimpses

24 Seminar PAKISTAN TEXTILE JOURNAL - February 2018

Karachi Event Glimpses

25 Seminar

Way2ITMA: Recycling technologies offered by VDMA members

In the run-up to ITMA, VDMA is presenting an overview of the textile recycling technologies offered by member companies exhibiting at ITMA. VDMA and its members are committed to a responsible use of all resources used in textile production.

VDMA members create the technical prerequisites for the efficient reuse and recycling of textile raw materials.

In the spirit of the circular economy, VDMA companies offer solutions for the entire processing and production chain. The production programme and services include equipment and technologies for recycling textile production waste, textiles, textile auxiliaries or waste heat and for processing recycled materials into textiles.

An overview of the available technologies is provided here: Way2ITMARecycling (vdma.org/itma). The short descriptions of the solutions offered by the member companies are structured according to the following headings:

Recycling of textile production waste and textiles.

Recycling of caustic soda and waste heat.

Processing of recycled materials.

All VDMA members are looking forward to welcoming visitors from all around the world to their booths at ITMA in Milan. A pocket guide, listing all exhibiting VDMA member companies, will be available at the fairgrounds.

The VDMA represents more than 3,600 German and European mechanical and plant engineering companies. The industry stands for innovation, export orientation and SMEs. The companies employ around 3 million people in the EU-27, more than 1.2 million of them in Germany alone. This makes mechanical and plant engineering the largest employer among the capital goods industries, both in the EU-27 and in Germany. In the European Union, it represents a turnover volume of an estimated 860 billion euros. Around 80 percent of the machinery sold in the EU comes from a manufacturing plant in the domestic market.

30 PAKISTAN TEXTILE JOURNAL - June 2023

UCMTF: French Textile Equipment Manufacturers’ Association

French Textile Equipment

Manufacturers are particularly strong in long fibre spinning (wool, acrylic …), yarn twisting and control (including technical yarns), space-dyeing, heat setting for carpet yarns, carpet systems, bleaching and hydro-extractor equipments, dyeing and finishing, felts and belts for finishing processes, precision machining and textile ERP.

Christian Guinet, the Secretary General of their association states: Driven by their entrepreneurial spirit, our members embrace innovation to shape together and achieve a perfect alignment between their future and the future of their customers.

ITMA 2023 is a great opportunity to meet in person, at the highest level, to find solutions. Of course, there are some main trends: sustainability, raw materials, energy and water savings, recycling, digitalization, Internet of Things, cloud

computing, artificial Intelligence, cost cutting etc. Another main trend is to be service oriented and act as a local partner wherever the customers are located.

Before welcoming our customers at ITMA, I would like to share with you a proud moment for the French textile equipments. Kristian Blummenfelt, the Norwegian athlete won the Men’s Triathlon Olympic Gold Medal. The Trimtex Skinsuit he was wearing for swimming, cycling and running was made of a fabric designed and produced by a French company. To produce the very fine and technical fabric which incorporates an unusually high percentage of elastane covered polymer, a specific equipment from one of our members was needed. A highly technical finishing equipment for a highly technical fabric and, at the end of the story, a Gold Medal!

Our members will deserve many such medals at ITMA in Milano. Let’s tell all our visitors that we will be very honored to welcome them, concluded Christian Guinet.

32 PAKISTAN TEXTILE JOURNAL - June 2023

Message from Christian Guinet, the Secretary General, UCMTF

Christian Guinet, Secretary General

Swiss textile machinery companies focus on environmental priorities

Visitors to ITMA 2023 will see significant innovations from members of the Swiss Textile Machinery Association – with a special focus on solutions for a more sustainable future in the textile industry. Details of planned exhibits reveal how Swiss companies have been acting in specific technology developments, as well as multi-faceted business strategies to meet their own sustainability targets and those of their customers.

Some of these actions go beyond products and applications to take in ‘behind-the-scenes’ measures such as improving internal ecosystems and streamlining manufacturing. Activities covered by the Swiss firms’ technology embrace the concept of safeguarding a ‘livable planet’ for future generations, and

this policy starts within the companies themselves, as they commit to careful management of their businesses to protect the environment and conserve global resources. Real outcomes are already being proudly presented as visible progress for the benefit of customers.

Sustainable production

Swiss textile machinery manufacturers apply their innovative power to make production as sustainable as possible –tackling issues such as saving water, chemicals, raw material waste and energy, as well as improving hardware life-cycles. Machine developments empowering more environmental production are continually growing in importance, as producers invest in them enthusiastically.

Sustainable solutions for cotton spinners include mechanical compacting systems by Swinsol. These units need no

electricity and are therefore CO2 neutral in operation. The company also offers recycling of used components.

Loepfe provides yarn clearers with latest technologies enabling settings to balance the required yarn quality against contingent productivity losses. The results avoid waste of both yarn and energy.

Retech develops solutions to improve the footprint of mills spinning man-made fibres. State-of-the-art heating godets with energy-optimized motor technologies and heating systems enable energy savings of up to 35%.

For Stäubli, sustainable investment also means ensuring its machinery is reliable enough to allow continued production over many years, even under harshest and most demanding conditions. Customers can rely on the firm’s equipment, services and support for an impressively long life-cycle.

34 PAKISTAN TEXTILE JOURNAL - June 2023

Innovation in change

The idea of a circular economy promises a massive leap forward for global sustainability goals. Using recycled fibres is a good start for the textile industry, and Swinsol systems make it possible to spin 100% recycled fibres – even without adding new fibers due to a high short fibre distribution. Jakob Müller provides technologies in narrow weaving that enables the processing of sustainable yarns and therefore the manufacture of closed-loop products.

Serious rethinking of business models is clearly essential if long-term sustainability goals are to be met. In synthetic spinning, a completely new production line might not be needed when the extrusion process is still working perfectly. But it could well be the drawing and heat treatment system that is limiting the production of the yarns customers demand today – in which case Retech has the answer, with its ability to upgrade or rebuild existing lines, including providing new and energy-optimized drawing systems.

The idea of converting or retrofitting machines and systems often develops in

response to changing customer requirements. Specifications in such cases are already well defined in advance.

Tracking fibres, and many other aspects of traceability, are further topics of innovative developments currently with Swiss textile machinery companies.

Most sustainable solutions show an additional benefit: cost saving. Costumers’ investments therefore empower the protection of the environment and prosperous business. Machine manufacturers committing to the various sustainability aspects are actually generating value for customers, organisations, wider society, and the environment.

The internal ecosystem

Machine manufacturers must also focus on managing their own ecosystems in a sustainable way. Jakob Muller for example wants to be a role model in handling its own system according to best practices. At its headquarters in Frick, Switzerland, various projects significantly reduce the consumption of gas, oil, and most of all electricity. Also, the production area was challenged for more sustainability. The space for machine manufacturing

was optimized first, greatly reducing the energy consumption needed for climate control.

Stäubli installed photovoltaic systems in its premises around the world, also taking the opportunity to generate local and sustainable electricity and lower the carbon footprint. The reduction of CO2 emission is one of its key focuses and identifying the carbon footprint of all main production units is among the priorities for 2023. The company is designing a sustainability roadmap to determine actions, resources, and a timeline, working on a long-term vision with tangible benefits for the environment and society.

Swiss Textile Machinery members take center stage at ITMA because of their innovative reputation – but a closer look at latest developments will show these world-class suppliers of machinery, components and services are themselves striving, as are their customers, to have the best partners for sustainability in components, raw materials and services. The ultimate goal is the same: business success with environmental responsibility for themselves, their customers and the world.

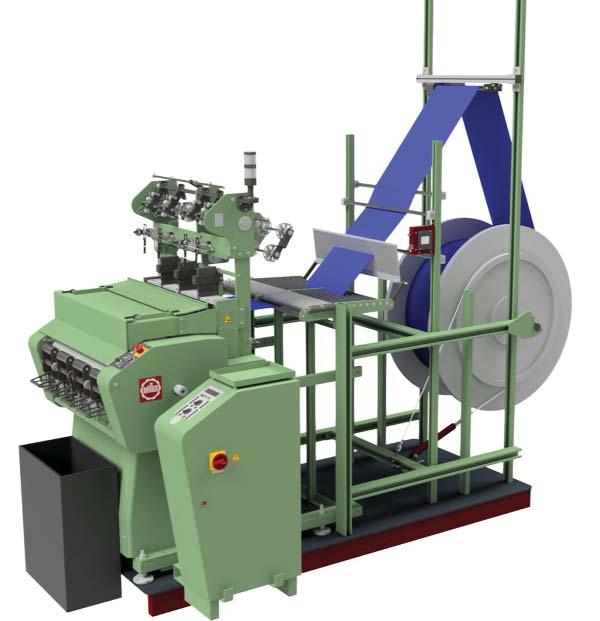

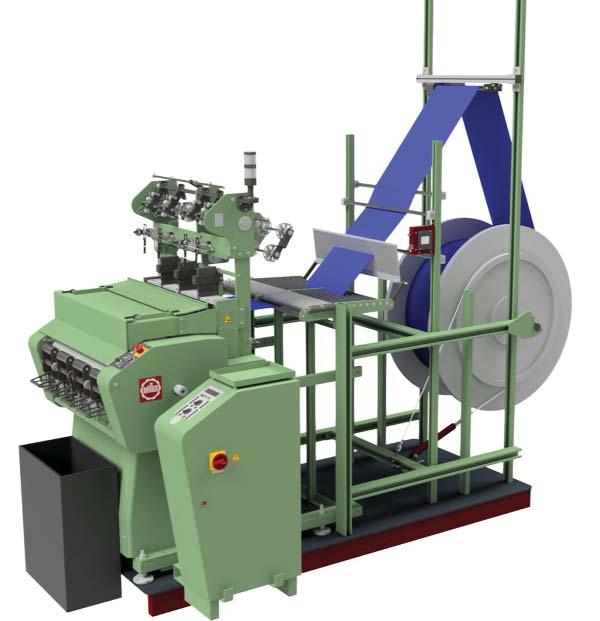

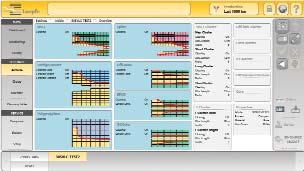

Jakob Müller presents mymueller and mymuenet

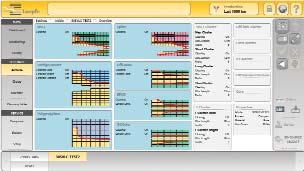

Jakob Müller Group will showcase its latest innovations in hall 6, booth A102. The Switzerland based textile machinery manufacturer offers mymueller, a service portal for ordering spare parts, and mymuenet, a production data acquisition and transfer system for Industry 4.0.

Switzerland-based textile machinery manufacturer Jakob Müller Group will be participating at ITMA 2023, which will be held in Fiera Milano Rho, Milan, Italy. The company recently participated in Swissmem's Pre-ITMA 2023 press conference.

Jakob Müller Group is a leading supplier of systems and solutions for the ribbon and narrow fabrics industry, providing everything from warp

preparation to the final product on a one-stop shop basis, the company said in its presentation at the Pre-ITMA conference.

The group delivers a variety of digital concepts. mymueller is a service portal for ordering spare parts and technical topics. It offers a browserbased solution and automatic freight and packaging calculator.

mymuenet enables production data acquisition and transfer. It provides the gateway to Industry 4.0 with OPC/UA interface, enabling performance

monitoring, data management, and a clear and transparent overview on production locations and machines.

The company will be showcasing its latest innovations in hall 6, booth A102 at ITMA 2023.

35

Automation is central for Swedish textile machinery

Fully integrated technologies with up-to-the-minute automated features for the end-to-end production of fully-finished garments and home textiles will be demonstrated by members of TMAS – the Swedish Textile Machinery Association.

“Technologies such as artificial intelligence (AI), machine learning and automation are becoming increasingly important in the textile industry and in Milan, Swedish companies will showcase new machines and software that can help streamline production and improve efficiency,” says TMAS secretary general Therese Premler-Andersson.

For example, ACG Kinna (Hall 9, stand C108) drew considerable crowds to demonstrations of its robotic pillow filling system at the last ITMA in 2019.

With the ability to fill and finish some 3,840 pillows per eight-hour shift, automated units cover the entire process –from the opening and weighing of the fibre to the filling of the product and on to the sewing and packing processes.

The system has been further developed to include new features including an integrated marking solution which allows the customer to print QR codes, batch

numbers and dates on the pillows’ labels, and a unique software for automatically detecting pre-programmed faults.

Single source potential

In addition, following its acquisition of the portfolio of Nowo, Kinna is now a single-source supplier of such lines. Nowo’s portfolio of textile production machinery, primarily for fibre processing and quilting, is well established and includes the Nowo Vac pillow filling system and the Noworoll ball fibre machine.

“The integration of Nowo’s range into our portfolio enables us to now oversee complete projects from start to finish for the highly automated production of pillows, quilts and other finished products,” says the company’s sales and marketing manager Tomas Aspenskog. “This provides our customers with a number of advantages in terms of transparency and the elimination of bottlenecks. When multiple suppliers are involved in building a line, it can often be difficult for customers to keep them aligned and ensure the construction of one line component is not holding back the completion of others.”

Materials handling

Eton Systems (Hall 9, stand B202)provides automated material handling systems consisting of individually addressable product carriers designed to eliminate manual transportation and minimise handling, radically increasing the time for adding value to garments and other finished items.

Eton will launch its new software platform, ETONingenious™ which is a real-time system used to manage, control and follow up on production in the Eton system. ETONingenious™ continuously gathers, processes and presents

powerful, value-adding product information to operators, supervisors, quality control personnel and management.

Utilizing the latest development environment, it features a web-based user interface and runs on any browser – laptops, PCs, tablets and even mobile phones – without any client installation requirements. It is also easy to integrate with any existing ERP system and is industry 4.0 compatible. Dashboards provide a clear and easy overview of production.

“ETONingenious™ will help companies reach their production targets, freeing up more time for supervisors, reducing throughput time, identifying bottlenecks and helping to adapt production in real time,”says CEO Jerker Krabbe.

Major benefits

For Premler-Andersson, the AI and advanced automation already being used in a number of ways by TMAS members such as ACG Kinna and Eton has the potential to revolutionize the textile industry, improving production efficiency, quality control and design processes. “AIpowered systems can, for example, help detect defects in fabrics and garments during manufacturing processes,” she explains.

“By using computer vision in the machinery, different defects such as stains, holes and uneven stitching can be rapidly identified and corrected at an early stage. Predictive maintenance is another benefit. AI is being used to monitor machines and predict when they are likely to need maintenance. This can help prevent breakdowns and reduce downtime, improving overall efficiency. AI is also proving valuable in R&D for TMAS companies, enabling data from different sources to be coordinated in order to optimize product design and reduce time and costs via the sensor-controlled optimization of a host of different parameters,”concluded Premler-Andersson.

36 PAKISTAN TEXTILE JOURNAL - June 2023

Therese Premler-Andersson, Secretary General.

ETON TEAM: ETONingenious™ software system frees up time for supervisors, reduces throughput time and identifies bottlenecks.

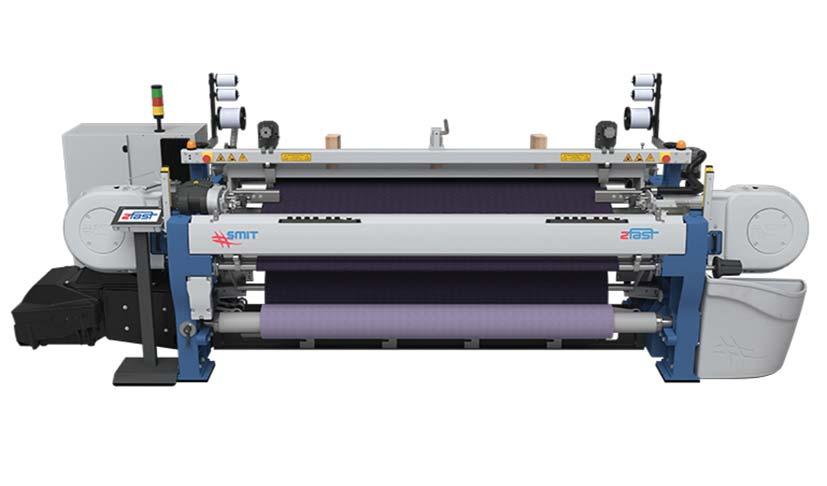

TMAS: Weaving remains the bedrock of the textile industry

Members of TMAS – the Swedish textile machinery association – will be introducing significant new automation concepts for weaving at the forthcoming ITMA 2023.

“Today, everyone is talking about digitalisation, but there is a strong case for considering the weaving process as the digital forerunner over 200 years ago,” says TMAS secretary general Therese Premler-Andersson. “When Joseph-Marie Jacquard invented his loom controlled by perforated cards and the first automated machine for which elaborate patterns were stored on them in ones and zeros, he arguably set the ball rolling for binary computer programming and all that has followed. There is certainly a direct line from Jacquard’s lightbulb moment to the latest innovations that will be displayed by our weaving technology members at ITMA 2023.”

Know-how from Vandewiele Sweden

Vandewiele Sweden AB, for example, benefits from all of the synergies and accumulated know-how of the Belgiumheadquartered Vandewiele Group – one of the market leaders in comprehensive weaving technologies (Hall 10, stand B201). This TMAS member has been the market leader in weft yarn feeding and tension control units for weaving looms for many years, supplying systems to the majority of the leading weaving machine manufacturers, as well for retrofitting in working mills around the world.

In Milan, Vandewiele Sweden will present its latest X4 yarn feeders with integrated accessory displays with which current settings and any alarms can be easily monitored and any required changes seamlessly carried out.

X4 feeders are available in three different versions – with an integrated tension display (TED), with integrated active tension control (ATC), or with quick release, which enables weft tension settings to be transferred from one machine to another, enabling a fast start-up the next time the same article is woven. The position of the S-Flex Tensioner is constantly monitored by an internal sensor –even if adjustment is made during power off.

With the ATC-W active tension control, the required tension is easily set and monitored on the integrated display. Once set, the system constantly regulates itself, ensuring consistent yarn tension during the weaving process which is constantly and accurately measured by the ATC sensor unit, sending a signal to the ATC operator unit resulting in consistently stable yarn tension at the required level.

Quick release meanwhile provides a quick and easy way to change the brushring or tensioner.

Vandewiele Sweden is also launching its own e-commerce platform for ordering the market’s leading range of textile accessories at ITMA 2023.

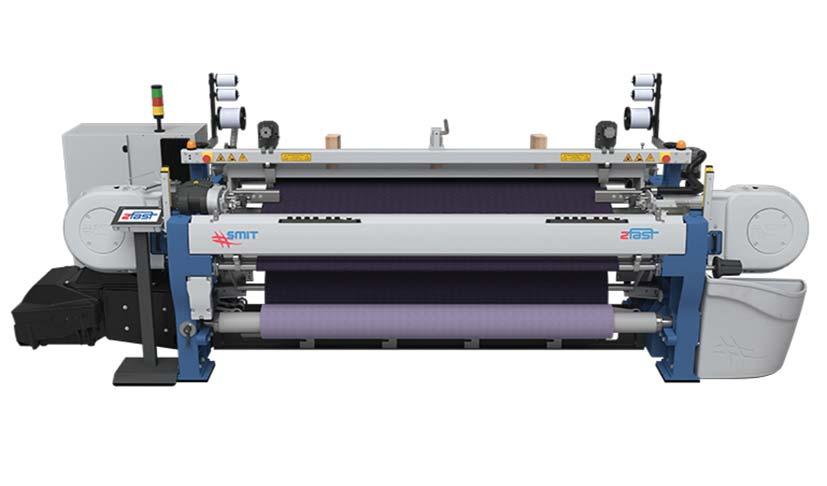

Wide width from Texo AB

TEXO AB (Hall 6, stand B301) has meanwhile seen a surge in the demand for its Compfelt weaving looms for press felt base fabrics.

“These are far from standard machines,” explains TEXO president Anders Svensson. “Off-the-shelf industrial weaving machines generally range in their working widths from 1.9 to 3.2 metres, with those purpose-built for technical applications such as geotextiles extending to wider widths of six metres and beyond. Meanwhile, one of the machines we have recently successfully delivered and commissioned has a working width of 23 metres.”

The demand for such machines comes from the suppliers of paper machine clothing (PMC) to paper mills, who in turn operate colossal machines for paper manufacturing.

All paper machines require a regular supply of PMC fabrics which are employed in three separate areas of the

38 PAKISTAN TEXTILE JOURNAL - June 2023

TEXO AB reports a surge in the demand for its Compfelt weaving looms for press felt base fabrics.

Vandewiele Sweden will present its latest X4 yarn feeders with integrated accessory displays.

paper machine – the forming section, the press section and the drying section.

“Although the PMC business represents a small proportion of the total cost of manufacturing paper, it can have a significant impact on the quality of the paper, the efficiency of a machine and machine production rates,” Svensson explains.

TEXO Compfelt weaving machines are specifically employed for the production of endless (tubular) woven base fabrics for the press section of paper machines, where water is mechanically removed from the newly formed sheet of fibres.

Eltex EyETM

Eltex of Sweden AB will be running live demonstrations of the latest version of EyETM – a versatile multi yarn tension monitoring system – at ITMA 2023, in Hall 6 at stand A210.

The Eltex EyETM system is being widely adopted by weavers, but unlike weft break sensors that are fitted solely on the weft insertion systems of weaving machines, it monitors the warping process prior to weaving. This means that instead of monitoring only the six-to-eight weft yarns fed by the weft insertion system,

the EyETM system is monitoring literally hundreds of yarns in real time on a warping creel.

“Several hundred yarns can be fed from the creels during the warping process compared to only a few weft insertion yarns during weaving,” says Peter Wiberg, responsible for marketing at Eltex. “Our motto is ‘No Loose Ends’ and that’s exactly what we can guarantee with our system.”

With warping that can operate at speeds of 500 metres a minute, the yarn tension values from all yarns are continuously updated and displayed on a screen with pre-set warning levels indicated in red. When tension reaches outside the pre-set stop level, the machine is immediately halted, with indications both on the sensor’s LEDs as well as on the screen.

Bedrock

“Weaving remains the bedrock of the textile industry and the potential for continuously improving the process remains virtually limitless,” concludes PremlerAndersson. “This is a key area for specific TMAS members, as will be demonstrated in Milan.”

DyStar features new product and process innovations

DyStar one of the leading specialty chemical companies with a heritage of more than a century in product development and innovation, will be exhibiting at ITMA in Hall 5, at Stand H5-B201.

DyStar is proud to be part of this prestigious global trade event which is well trusted by the textile and chemical manufacturing supply chain.

Mr. Eric Hopmann, Chief Commercial Officer of DyStar Group said it is great that members of the global supply chain can finally meet to exchange ideas at ITMA post-pandemic.

“The energy crisis, inflation, and climate impact have accelerated the pace of the textile supply chain’s transformation. DyStar’s innovations will help global manufacturers and producers, Brands and

Retailers continue creating value-added confidence and assurance, while keeping up with transformational needs to deliver quality products without compromising sustainability.” Eric said.

DyStar’s product innovations are backed by our unwavering commitment to Sustainability, and our expertise in reducing the environmental impact of the products. Our econfidence® program creates fundamental value for our customers.

At ITMA, DyStar will be featuring a suite of product and process innovations which include Cadira®, Dianix®, Evo®, Indigo, Jettex®, Levafix®, Procion®, Remazol® and more.

All customers and stakeholders can expect to connect with DyStar’s subject matter experts who will be available at the stand, to provide customers with indepth knowledge of our products and

answer any questions they may have during the seven-day event, as they learn more about DyStar’s latest innovations.

Visitors to our stand can also take advantage of getting instantaneous product information digitally in a few clicks.

39

Eltex of Sweden AB will be running live demonstrations of the latest version of EyETM – a versatile multi yarn tension monitoring system.

Eric Hopmann, Chief Commercial Officer of DyStar Group

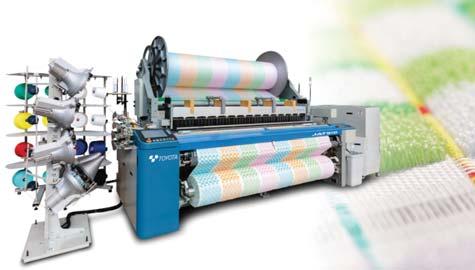

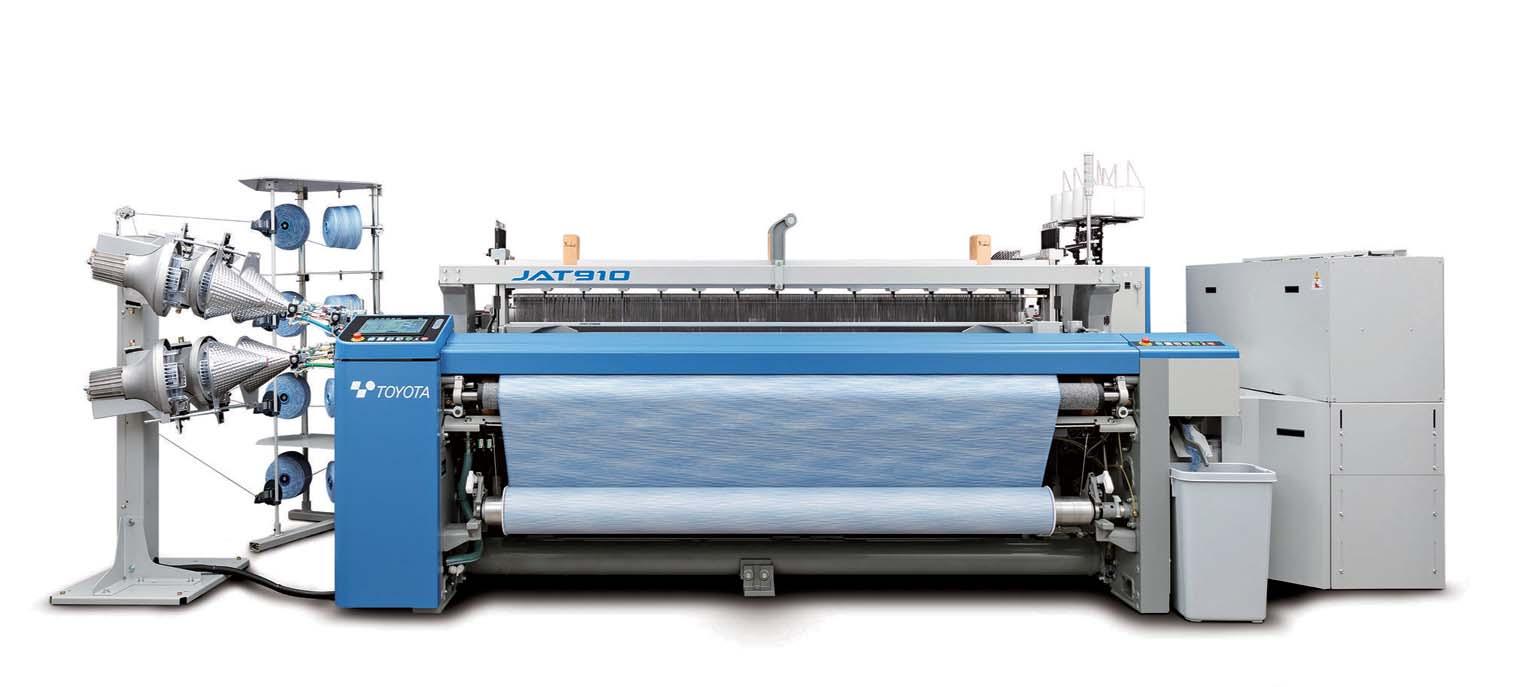

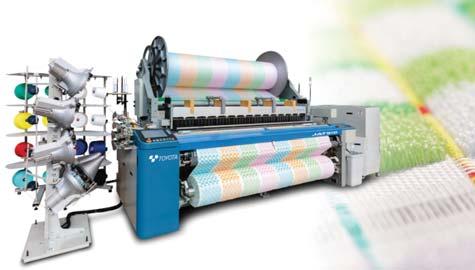

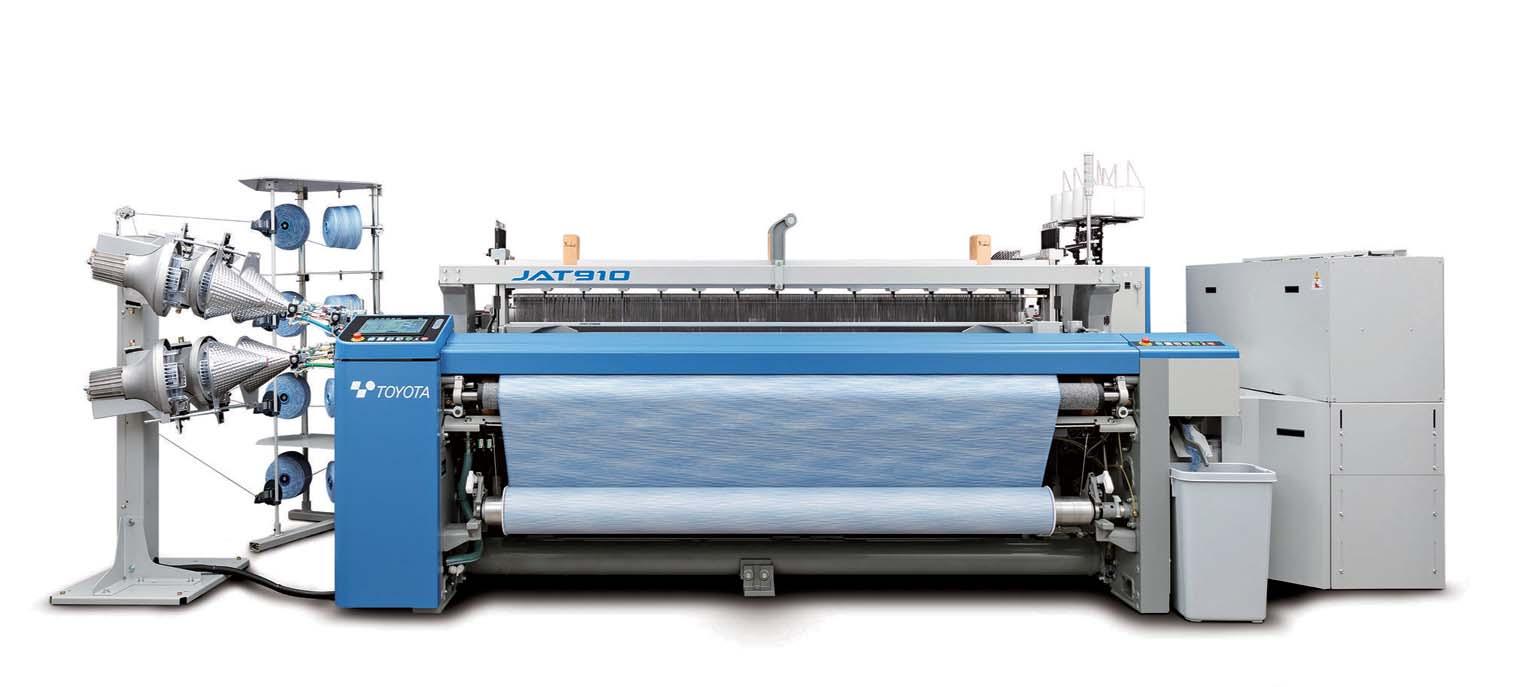

TOYOTA showcases three JAT 910 airjet weaving machine models

Toyota will exhibit and demonstrate a new model air-jet loom JAT910 at Hall 10, Booth B-104.

The company will highlight three Air-jet weaving machines of Model JAT910.

Electronic Shedding E-shed: Double face with Super-fine stretch yarns. Crank Shedding C-shed: Sheeting and pillow cover, double panels. Jacquard Shedding: Bath towel with various kinds of piles.

JAT910 is Toyota's new model with the latest technology, which has achieved further energy-saving and efficient weaving performance through the adoption of a newly developed weft insertion system and a new main motor.

In addition, Toyota will also introduce the development progress of the innovative spinning machine "Helix", which was very well received at ITMA 2019, toward the realization of new spinning technology in the future.

40 PAKISTAN TEXTILE JOURNAL - June 2023

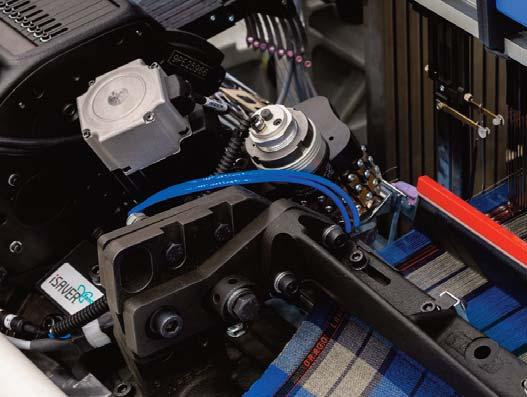

Itema displays new EVO range

Itema Group, the Italian global leading provider of advanced weaving solutions, participates at ITMA 2023 in Hall 6 – B105 with tangible and significant innovations for the weaving industry.

With a total of 12 Itema EVO weaving machines on show (7 in the Itema booth and 5 in the partners’ booth –Staübli, Van De Wiele, MEI, and Julibao), Itema confirms its attitude in exhibiting weaving machines running innovative, complex, and challenging fabrics to demonstrate its superior textile mastery.

At ITMA 2023, Itema brings on stage sophisticated, diversified styles, designed in cooperation with leading textile companies – all Itema customers - such as ISKO, Mantero Seta, Drago Lanificio in Biella, Tessitura Marinoni, Frau Pérez Textiles, and Finsa Textil.

ITMA 2023 comes back in Milan, and Itema takes advantage of this prestigious stage to introduce its new EVO Weaving Range for the first time.

The new EVO weaving range features significant innovations designed to raise the bar in terms of textile mastery, ecoefficiency, performance, and easy weaving.

Ugo Ghilardi, Itema Group CEO comments: “The new Itema EVO Weaving Range answers to concrete weavers’ needs. Our vision is to offer to our worldwide customers tangible innovations that, based on the most advanced engineering principles, can improve their productivity, competitiveness on the market, and user experience.”

New Itema EVO Weaving range includes:

Advanced solutions for the weft transfer to enhance versatility and machine performance.

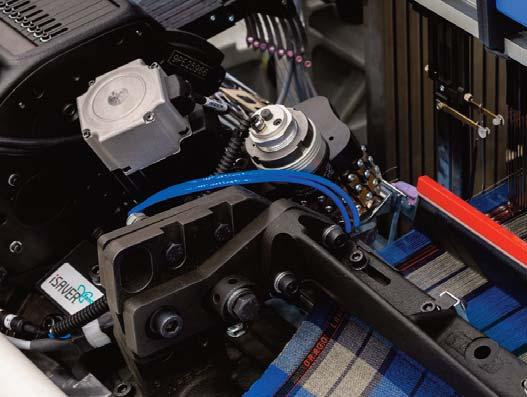

New iSAVER® range which, following its undisputed market success in denim weaving, is now available in up to 6 colors and for many more fabrics, thus significantly increasing the applications of sustainable weaving.

Innovative digital software to enhance user experience and optimize textile production, such as iKNOW™the innovative tool that contains all the Itema textile experts' know-how collected on the field over the years - and MyWeave™ the new, advanced mill monitoring system.

Optimization of key machine components to further improve machine performance, ensure the best possible machine accessibility, and reach unbeatable reliability while preserving the renowned compactness of the Itema weaving machines, which provides weavers with valuable additional space in the weaving floor to install more looms.

New digital solutions, such as the brand-new Itema Customer Portal HelloItema, further enriches the visitors’ experience.

Moreover, besides the unmissable weaving innovations on stage, the Itema Group booth hosts all the Group companies and solutions. Itema Group companies Lamiflex® and Schoch® with their advanced accessories for weaving machinery have dedicated corners in the Itema Group booth, and Itema and previous brands’ OEM spare parts are exhibited, including upgrade kits to optimize machine performance and retrofit latest Itema innovations on existing looms. Itemalab®, the Itema advanced innovation hub, has a special environment inside the booth to boost the innovation mission of Itema.

The range of nylon and polyester yarns from RadiciGroup, a leading group in the production of textile solutions for numerous markets such as apparel, furnishings, and automotive will be on display. In particular RadiciGroup presents products with a reduced environmental impact, both from recycling and made with raw materials of bio origin.

Itema Group welcomes visitors with a product line-up designed to demonstrate its dedication to innovation & the Made in Italy excellence in the weaving sector.

42 PAKISTAN TEXTILE JOURNAL - June 2023

The iSAVERfancy - the new iSAVER up to 6 colors.

R9500EVOdenim,

Crealet introduces narrow weaving warp tension control system

KAST ERC – automation for quality and productivity

A new fully-automated solution for electronic warp feeding of narrow fabrics is being presented for the first time at ITMA 2023 by Crealet. The new KAST ERC system is designed to offer best results in quality, productivity and profitability.

Crealet’s mission is to empower highperformance weaving with a consistent high-quality level. Minimum faults can only be achieved with optimum warp feeding. Its warp supply options – for beams or creels – focus on the key areas of maintaining constant warp tension and reducing thread breaks. The new KAST ERC (Electronic Rope Control) solution builds on Crealet’s unrivalled expertise and innovative know-how to raise productivity and optimize automation for narrow fabric weavers through ingenious tensioning concepts.

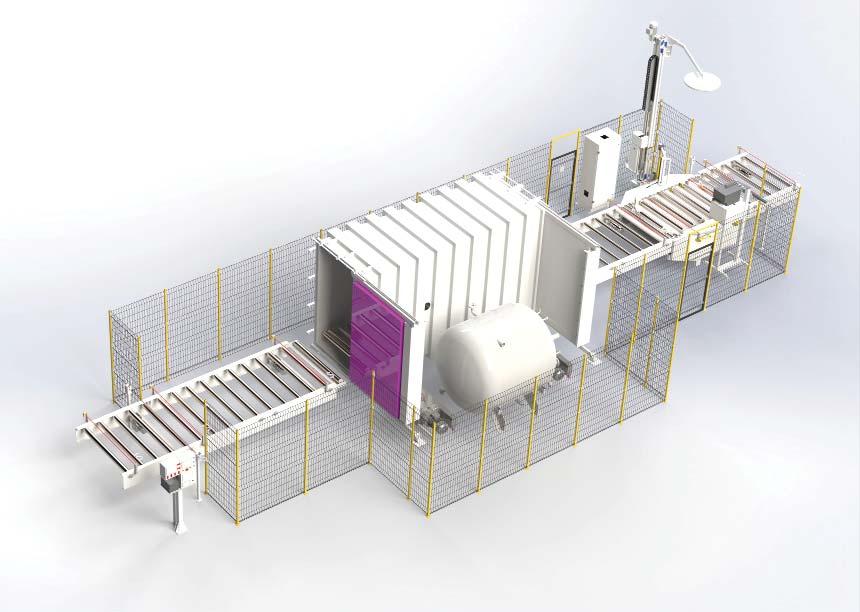

Enabling best narrow weaving through technology