Established 1951 March 2023 Swiss Review

Index 2023

Dates: April 18th to 21st, 2023.

Venue: Palexpo, Geneva, Switzerland.

Techtextil 2023 North America

Dates: May 10th to 12th, 2023

Venue: Georgia USA.

DOMOTEX asiaCHINAFLOOR 2023

Dates: May 29th to 31st 2023.

Venue: NECC, Shanghai, China.

FESPA 2023

Dates: May 23rd to 26th 2023.

Venue: Munich, Germany.

Istanbul Yarn Fair

Dates: June 1st to 3rd, 2023.

Venue: Istanbul, Turkey.

ITMA 2023

Dates: June 8th to 14th, 2023.

Venue: Milan, Italy.

PAKISTAN TEXTILE JOURNAL - March 2023

Johannesburg, South Africa !

Dates: June 18th to 20th, 2023.

Venue: Gallager Convention Centre.

The 92nd Textile Institute World Conference, UK.

Dates: July 3rd to 6th 2023.

Venue: Huddersfield, UK.

IGATEX Pakistan 2023, Karachi

Dates: September 7st to 9th 2023.

Venue: Expo Centre, Karachi.

iCADEX Pakistan 2023, Karachi

Dates: September 7st to 9th 2023.

Venue: Expo Centre, Karachi.

62th Dornbirn GFC Global Fiber Congress

Dates: September 13th to 15th 2023.

Venue: Dornbirn Austria.

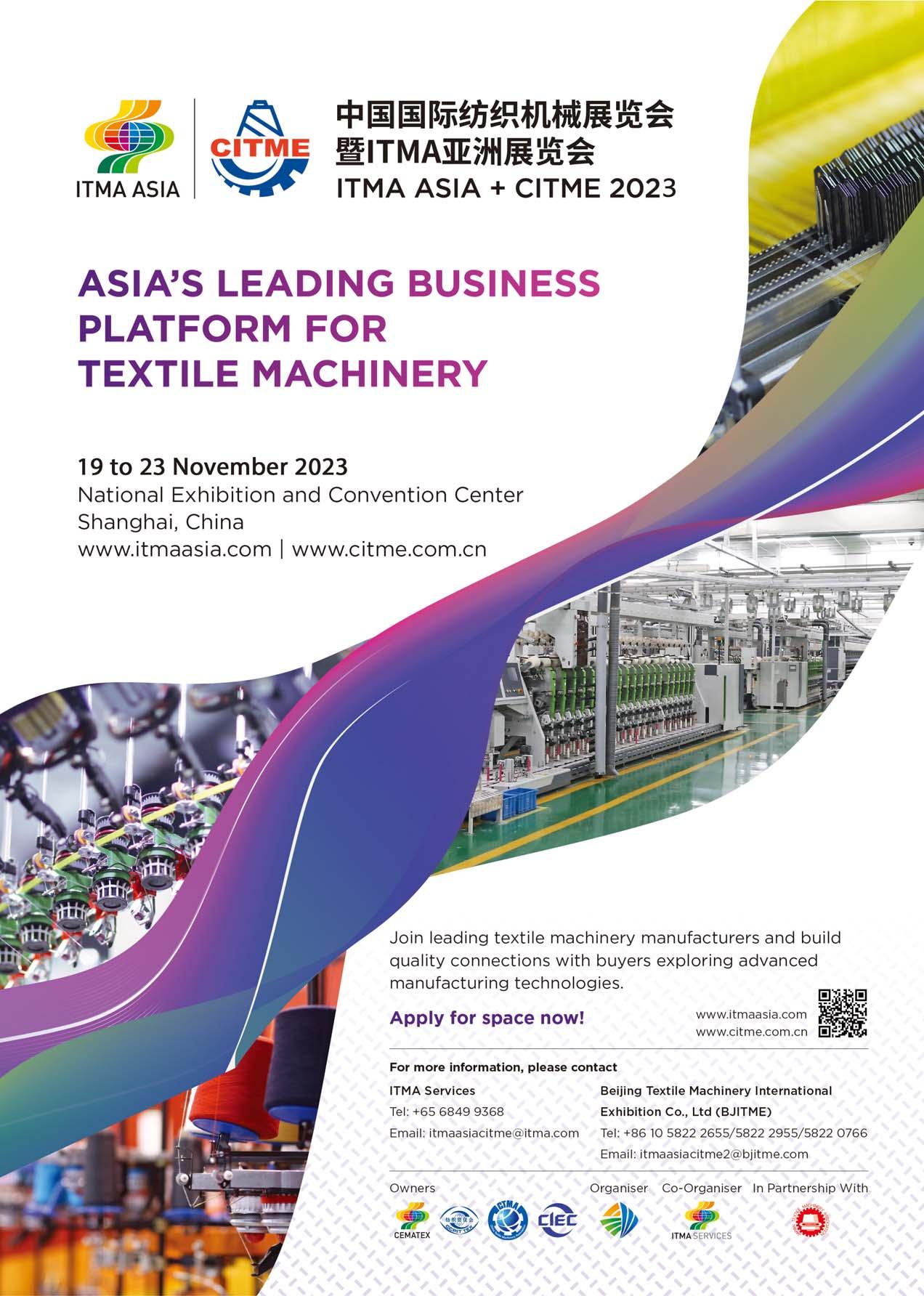

ITMA ASIA + CITME 2023

Dates: November 19th to 23rd, 2023.

Venue: NECC, Shanghai, China.

Heimtextil 2024, Frankfurt

Dates: January 09th, to 12th, 2024

Venue: Frankfurt am Main.

DOMOTEX Hannover 2024

Dates: January 11th to 14th 2024.

Venue: Hannover, Germany.

ITM 2024

Dates: June 4th to 8th, 2024.

Venue: Istanbul, Turkey.

HIGHTEX 2024

Dates: June 4th to 8th, 2024.

Venue: Istanbul, Turkey.

JIAM 2024 OSAKA

Dates: Nov. 27th to Nov. 30th 2024.

Venue: Osaka, Japan.

12th ITME

INDIA

2024

Dates: December 2024.

Venue: India Expo Centre & Mart. Noida, India.

2

Calendar of Events

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher

Nadeem Mazhar

Editor in Chief

Amina Baqai

Associate Editor

Nimrah Nadeem

Production Manager

Mazhar Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh

Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab

C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA)

Mian Iftkhar Afzal

B.S.N.C State, M.Sc. (Leeds)

C.TEXT.F.T.I (UK)

Dr. Zubair Bandukda

PhD (Textiles), CText ATI

Editorial & Advertising Office

B-4, 2nd Floor, 64/21, M.A.C.H, Miran M. Shah Road, Karachi - Pakistan

Tel: +92-21-34311674-5

Fax: +92-21-34533616

Email: info@ptj.com.pk

URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Correspondence & Mailing address: 93 Fleming Place, Bracknell, RG12 2GN, United Kingdom

Tel: +44 792 2228 721

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, UK

Registered no. 09141989

AROUND THE WORLD . . . . . . . . . . . . . . . . . . . . . .14 NEWS & VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . .10 EDITOR’S PAGE . . . . . . . . . . . . . . . . . . . . . . . . . . .7 Switzerland remains an important partner for Pakistan’s textile industry TEXTILE BRIEFS . . . . . . . . . . . . . . . . . . . . . . . . . . .8 Vol. LXXII No. 03 March 2023 Rs. 565.00

Printed at: Color Plus Korangi, Karachi. Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi. Available on Gale and Factiva affiliated international databases through Asianet Pakistan

CORPORATE NEWS Unique product created with Swedish innovation . . . . . . . . . . . . . . . . . . . . . .18 FEATURES U.S. Cotton Trust Protocol has tracked over 3 million kilograms of cotton . . . . .19 Groz-Beckert’s WarpMasterPlus – successful presentation in Asia . . . . . . . . . . .20 The LYCRA Company announces latest Higg achievements . . . . . . . . . . . . . . . .21 8 20 19

AND EXHIBITION

490

exhibitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22 18

FAIRS

FESPA Global Print Expo 2023 set to welcome strong line-up of

international

SWISS REVIEW

26 48 32 29

Acquisition of the Textile Effects business of Huntsman Corporation . . . . . . . .50 Archroma starts the FiberColors* revolution . . . . . . . . . . . . . . . . . . . . . . . . .52 Archroma Internship program completes 25 years . . . . . . . . . . . . . . . . . . . . .54 Tree Plantation Campaigns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55 Partnering for Educational Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55 Sustainable Neighborhood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56 Support towards Fire Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56 Emergency Response – Floods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57 Awards and Accreditations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58 50 24

SPECIAL REPORT

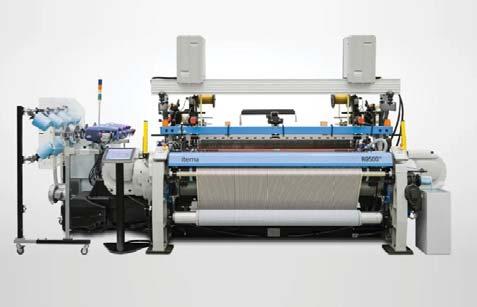

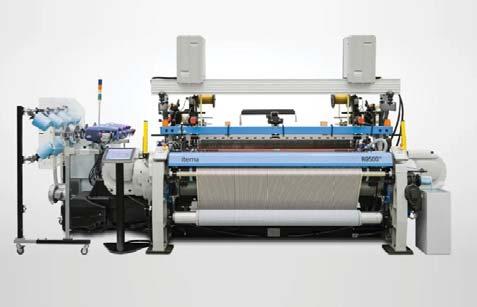

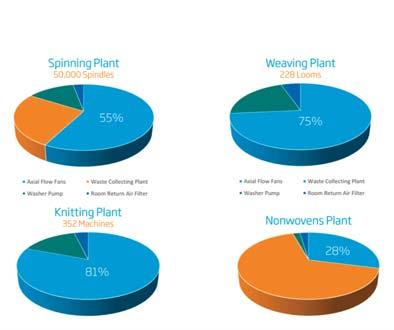

ITMA is the greatest show on earth? . . . . . . . . . . . . . . . . . . . . . . . . . . .24 Cornelia Buchwalder, Secretary General of the Swiss Textile Machinery Association. SSM offers sustainable and energy efficient processes . . . . . . . . . . . . . . . . . .26 Three Dedicated Card Clothing Packages by Graf . . . . . . . . . . . . . . . . . . . . . .26 Rieter: Mastering the Short Fiber Challenge . . . . . . . . . . . . . . . . . . . . . . . . .27 TexCircle: The Design of a Circular Ecosystem . . . . . . . . . . . . . . . . . . . . . . . .28 Itema Group offers

weaving solutions . . . . . . . . . . . . . . . . . . . . . . .29 Autefa: Sustainability at forefront with innovative solutions . . . . . . . . . . . . . .30 Bluesign Technologies offers sustainable solution systems . . . . . . . . . . . . . . . .31 SANTEX RIMAR technology for textile finishing of knitted fabrics . . . . . . . . . . .32 Heberlein: Expert for air interlacing and air texturing jets . . . . . . . . . . . . . . .33 Uster outlines the challenges, and solutions for Recycled yarn . . . . . . . . . . . .34 Jakob Müller Group – Gateway to Industry 4.0, the Fourth Industrial Revolution . . .35 Stäubli Textile exhibiting impressive innovations at ITMA 2023 . . . . . . . . . . . .36 Loepfe sensors avoid material and energy wastage . . . . . . . . . . . . . . . . . . . . .37 Swinsol Compact Spinning solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38 Luwa: New developments for Axial Flow Fan to reduce energy consumption . . .39 Retech innovations under the blue thread theme related to Sustainability . . . .40 Saurer: Autocoro with new patented rotor cleaning . . . . . . . . . . . . . . . . . . . .41 Steiger shares action plan for a sustainable future . . . . . . . . . . . . . . . . . . . . .42 Crealet presents individual and comprehensive solutions . . . . . . . . . . . . . . . .43 Benninger: Road to Net Zero in continuous wet processing & jet dyeing . . . . . .44 Swissmem Press Conference Glimpses . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46 Day out at the Cheese Factory and Berne city . . . . . . . . . . . . . . . . . . . . . . . .48

Why

advanced

important partner for Pakistan’s textile industry

Switzerland is known worldwide for its precision watches, cheeses and financial services. However, Swiss competence is not limited to these well known sectors. Equally strong are the Swiss companies in the textile technology, testing equipments, chemicals and service sectors. What differentiates Swiss companies from others is their tradition and passion for innovation, precision engineering as well as their focus on high productivity and respect for the environment.

In the world of textile chemicals, Archroma is another great example of the commitment of Swiss companies to Pakistan. With a firm commitment to the environment Archroma has developed world’s first Aniline free indigo, an achievement possible with the efforts of the dedicated team of Archroma.

Switzerland is one of the most competitive economies in the world. They have always strengthened their trade relations with Pakistan. The Swiss companies intend to increase their investments in Pakistan, while the current Government of Pakistan is continuously improving its imports policy to allow liberal imports of textile machinery, industrial raw materials, capital goods, and essential consumer goods. Over the centuries, the sheer innovative spirit of the Swiss has been demonstrated many times through inventions spanning various fields. Their impact on the global textile industry has been among the most notable, with continuous and significant developments.

Our current issue of March 2023, is devoted to Switzerland and in this special edition, our readers will find reports and news about Swiss companies and their innovative technological solutions for Pakistan’s textile industry. This edition also covers the Pre ITMA Press conference held during 17 to 18 March at Bern, organized by Swissmen.

Looking ahead to ITMA 2023 in Milan (June 8-14), Cornelia Buchwalder, Secretary General of the Swiss Textile Machinery Association explores the real importance of ITMA as a driver of global textile progress during an interview published here. Ernesto Maurer, CEMATEX and Swissmem President comments about the need for the industry to adopt sustainability business practices are also noteworthy. It's encouraging to see that Swiss companies are taking a leadership role in this area and that they are committed to making a positive impact on the environment as seen during the panel discussions. ITMA 2023 is perfectly timed to offer Swiss exhibitors an opportunity to showcase these new products and cutting-edge technologies.

The participation of various Swiss companies at the Swissmen conference, including Saurer, Steiger Participations, Autefa Solutions, Swinsol, Santex Rimar Group, Jakob Muller, Crealet, itema (Switzerland), Stäubli Sargans, Uster Technologies, Rieter, Rieter Components (incl. Bräcker, Graf, SSM), Luwa, Retech, Heberlein, Loepfe, Benninger, Bluesign and Texcircle Project, highlights the close partnership between Swiss and Textile Trade Press, such as Pakistan Textile Journal, the oldest textile trade publication in Pakistan. It's great to see that these companies are working together to bring innovative solutions to the textile industry.

Established 1951 March 2023 Swiss Review

Switzerland remains an

EDITOR’S PAGE 7

March 2023.

1

Textile industry has asked the State Bank of Pakistan to extend the moratorium on debt under TERF and LTFF from June 1, 2023, to December 2023 to avoid large-scale NonPerforming Loans (NPLs) and severe negative impacts on the banking sector.

taker Minister for Industry and Commerce SM Tanveer.

4

Amidst of government attempt to save every penny, Experts have raised concerns that cotton would also need to be imported as its production has fallen short of the target.

started to close all operations and decline in textile exports is increasing day by day.

7

APTMA patron-in-chief Gohar Ejaz alerts Prime Minister Shehbaz Sharif that 10 million textile workers will be unemployed in Punjab if the textile sector continues to suffer.

2

Textile exports continued a downtrend to a fifth consecutive month in February by falling 29.9 percent year-on-year to $1.18 billion, lowest in last 21 months, data from Pakistan Bureau of Statistics.

3

A delegation led by Hamid Zaman, Chairman All Pakistan Textile Mills Association commenced a meeting with care-

5

PTEA fears that it will not be possible to meet target of USD 25 billion in export for the year if the country’s financial conditions continues to decline.

6

Report by All Pakistan Textile Mills Association (APTMA) concludes that the country is struggling to support the backbone of the economy “The textile Industry” and outcome of this can be seen as mills have

Textile Briefs International

1

According to the official data released by General Administration of Customs China (GACC), the country shipped US $ 21.68 billion worth of apparel and accessory, falling by 14.70% on year to year basis in January to February period of 2023.

2

USA’s cotton consumption forecast is down more than 500,000 bales from the previous month due to lower consumption in Pakistan, Turkey, Bangladesh, and Indonesia due to an array of countryspecific factors.

North Carolina State University (United States) researchers discovered that the blended cotton and polyester fabric can be separated using enzymes .

3

China is important trading partner for Pakistan, with Chinese companies increasingly sourcing garments from Pakistan due to their competitive prices. In January- February of this year, men’s garments exports from Pakistan to China crossed $4.36 million while in 2022 in the same period, it was $3.21 million, showing an increase of 36%.

8

9

Pakistan’s textile industry adapting to Renewable Energy solutions is not only cost and resource effective but also enhances the sector’s overall compliance to the global standards on energy efficiency and industrial de-carbonization, such as those imposed by the European Green Deal.

10Pakistan and Uzbekistan signed a one billion dollar trade agreement to encourage exchange of goods and services. The deal was sealed at the 8th meeting of the Pakistan-Uzbekistan Intergovernmental Commission on Trade-Economic and Scientific-Technical Cooperation (IGC) held in Tashkent.

4

China exported US $ 40.84 billion textiles and apparel in JanuaryFebruary 2023 as compared to US $ 51.11 billion in January-February 2022 period, noting a 20.10% yearly fall.

5Bangladesh Bank has imposed restrictions on opening of letters of credit due to ongoing dollar crisis in the banking sector. "Declining stocks of raw materials amid commercial banks' unwillingness to open LCs might severely hamper production and exports of textile and apparel items," says Bangladesh Textile Mills Association.

6

Turkiye’s textile and apparel exports in 2022 were valued at

$35.25 billion. Turkiye has strong competitiveness in the global market in the apparel and home textiles segment. The Turkish clothing industry is the sixth largest supplier in the world with a share of 3.7%.

7

A fact-finding study of the use of secondhand clothing by Greenpeace found that Tanzania and Kenya are flooded with huge amounts of textile waste daily that have severe consequences for people and the environment. The findings were presented in a report titled Poisoned Gifts: From donations to the dumpsite: textiles waste disguised as secondhand clothes exported to East Africa.

8

The European Commission invests 16 million USD in textile recycling project in hope of a sustainable future.

The tExtended project is spearheaded by the stateowned- VTT Technical Research Centre of Finland. It intends to integrate recycling, waste valorization and data technologies and bring the current textile recycling from 1% to 80%, resolving an issue that’s been a challenge for a circular economy.

The Indian Institute of Technology has developed a green technology called “air nano-bubble” that can be a game changer for water requirements of the textile sector.

9

8 PAKISTAN TEXTILE JOURNAL - March 2023

Textile Briefs National

A Ray of hope for the muchneglected textile sector

A delegation led by Hamid Zaman, Chairman All Pakistan Textile Mills Association commenced a meeting with SM Tanveer, Caretaker Minister for Industries, Commerce and Energy. During the meeting the Minister was briefed on problems of electricity connections for textile sector, tax refund and social security.

APTMA chairman said that the policy of closure of markets should be made in consultation with the stakeholders regarding the saving of energy.

The Minister assured him of solving problems of the textile sector. The caretaker Minister SM Tanveer said that the textile sector has a key position in the national economy. The textile sector is also a major source of employment. He said this sector is important in the economy and the problems facing the sector will be solved on priority. SM Tanveer said that the government will not let stop the wheel of the industry in any case.

Cotton production fails to meet the set target

According to the figures by Pakistan Cotton Ginners Association (PCGA) the country produced over 4.76 m bales by Jan 31, against over 7.42 m bales produced by the same time last year - a dip of 35.8pc or 2.66m bales. This has raised many concerns regarding production and availability of raw cotton among the textile sector.

Experts in the field says that the requirement of raw cotton in textile sector is approximately 12 M bales but the country was only able to produce approximately 5 million bales and will need to import 7 million bales of cotton to meet the gap between demand and production.

Naseem Usman, Karachi Cotton Brokers Forum Chairman says, “The country will only able to produce approximately 5 million bales this year and the requirement of raw cotton in textile sector is approximately 12 million bales, so the country will need to import 7 million bales of cotton to meet the gap between demand and production.”

He further added, “Currently, agreements have been signed for the import of 5.5 million bales.”

Textile spinners have so far purchased 4.175 million bales, while in the previous year, they had bought over 7.233 million bales during this period.

Mr Usman said a further hike in rates and difficulty in importing white lint due to the US dollar’s appreciation against the rupee is another challenge. He concluded that the delay in the opening of letters of credit has already compounded supply chain issues.

Pakistan Textile Exporters Association fears for future of textile

The PTEA fears that meeting the export targets in the current fiscal would be more difficult in the prevailing circumstances. Worsening international economic situation, primarily because of the Ukraine crisis, combined with floods in Pakistan, had negatively impacted the already inefficient supply chain of the country. Textile items are the backbone of the country’s overall exports. The textile sector accounts for more than 50% of the industrial workforce in Pakistan. Textile exports in the previous financial

PAKISTAN TEXTILE JOURNAL - March 2023 10 News & Views

year contributed 60.92% of the country’s total exports of $31.76 billion. The textile exports target for the current fiscal has been set at $25 billion.

Textile sector continues to suffer

Pakistan’s textile sector exports witnessed a significant decline of 12.4%, clocking in at $1.36 billion in January 2023 in comparison to $1.55 billion recorded in the same month of the previous year.

According to report by All Pakistan Textile Mills Association (APTMA) the country is struggling to support the backbone of the economy “The textile Industry” and outcome of this can be seen as mills have started to close all operations and decline in textile exports is increasing day by day. The APTMA’s report raises concern within the country as textile exports in the first 7 months of FY23 decreased by 8% to $10.08 billion, declining from $10.93 billion recorded in 7MFY22.

During an interview recently Asif Inam, chairman APTMA said, “Worsening international economic situation primarily caused by the Ukraine crisis combined with floods in Pakistan has negatively impacted the already inefficient supply chains of the country. Flooding in dozens of districts of Pakistan has destroyed a wide swath of agricultural land.”

“While the industry requires 14 million bales, the country could only produce 5 million bales of cotton domestically, to meet this gap cotton needs to be imported; however, the Forex issues in the economy have curtailed imports of cotton and other essential inputs for exports. The issue of raw material clearance from the ports remains unresolved owing to unavailability of forex and therefore mills are currently unable to obtain cash against documentation and are closing down owing to the shortage of raw materials,” he concluded.

Pakistan and Uzbekistan sign trade deals

According to a Tweet, the Economic Affairs Division, Government of Pakistan, “Both countries signed a one billion dollar trade agreement to encourage exchange of goods and services.”

The deal was sealed at the 8th meeting of the Pakistan-Uzbekistan Inter-governmental Commission on Trade-Economic and Scientific-Technical Cooperation (IGC) held in Tashkent.

The meeting mainly focused on bilateral economic cooperation in various sectors, including commerce and trade, banking, industries and production, investment, textile industry, energy, oil and natural resources, transportation and communication, agriculture and tourism and culture development.

Finance Minister Ishaq Dar was leading the delegation to thrash out the trade agreements, which cover cooperation in fields, including trade, banking, industries, energy and agriculture, the ministry added.

The IGC meeting was co-chaired by Uzbek Minister of Investments, Industry and Trade, Laziz Kudratov and Dar.

The continuous efforts by both countries to encourage closer ties, especially in the fields of trade, transport, banking, and agriculture, were appreciated by the Uzbek side, the officials stated.

According to the statement, Dar appreciated the “deeper interests by the Uzbek side and strengthening the relationship and lauded progress already made” in the field of transport and trade. He also welcomed the Uzbek side to explore areas in automobiles, information technology and natural minerals.

“Textile sector on brink of default.” APTMA writes letter to the State Bank Of Pakistan

“The textile sector has reached the brink of default in the wake of its inability to service the loans it received under TERF (Temporary Economic Refinance Facility) and LTFF (long-term facing facilities) which may also lead to a possible banking crisis”, wrote APTMA to the State Bank of Pakistan.

The State Bank of Pakistan (SBP) during the PTI era provided the TERF and LTFF facilities to help industrialists to install more textile units and expansion of units for more growth in exports of the country. However, because of the ongoing LCs crisis, stuck-up consignments of imported cotton at the ports owing to the dollars liquidity crunch and withdrawal of RCET by the government in line with IFM diktat, all the new and expansion units in the sector have become non-functional. This has led

to immense pressure on export-reignited units which are unable to generate funds to pay even interest on the loans, leading to massive defaults, curtailment capacity and a possible banking crisis.

The textile industry has asked the State Bank of Pakistan to extend the moratorium on debt under TERF and LTFF from June 1, 2023, to December 2023 to avoid large-scale NonPerforming Loans (NPLs) and severe negative impacts on the banking sector.

APTMA further wrote, “Banks are not opening LCs or retiring cotton imports, which had led to the non-functioning of the textile units. Now loyal international customers are reluctant and asking Pakistani suppliers whether or not they will be able to meet deadlines and ship orders on time resulting in a loss of export orders.”

Garment exports to China register increase by 33% in 2022.

“Pakistan’s garment exports to China have seen a remarkable increase of 33% in the past year which is a significant achievement as it strengthening of economic ties between the two countries”, said Ghulam Qadir, Commercial Counsellor, Pakistan Embassy Beijing.Pakistani menswear popularity is growing day by day in China, this fashion trend is one of the reasons for this exceptional growth.

“Chinese manufacturers are increasingly trusting Pakistan as a source of quality textiles and garments at competitive prices, and this trend has also been bolstered by government initiatives such as free trade agreements that have facilitated increased trade between the two countries.” Ghulam said.

News & Views 12 PAKISTAN TEXTILE JOURNAL - March 2023

He further elaborated that Pakistani men’s garments annual exports to China in 2022 were $28.66 million, up from $21.62 million in 2021, a nearly 33% increase.

Men’s or boys’ cotton trousers, community code (61034200), worth $17.94 million, remained the top items, while it was $12.59 million in 2021. Similarly, men’s or boys’ trousers and breeches with community code 62034290 are worth $7.22 million, whereas this item exported from Pakistan was worth $6.55 million in 2021.”

This increase in exports is also beneficial for Pakistan’s economy, as it will bring more foreign exchange into the country and help boost its GDP.

Lastly he concluded, “This surge in exports is a testament to the strength of Pakistan’s garment industry and its ability to meet global standards. It also highlights how China is becoming an increasingly important trading partner for Pakistan, with bilateral trade between the two countries increasing rapidly over recent years.”

Men’s garments export to China rises 36pc in first two months of 2023.

Pakistani men’s garment export to China rose by 36% in the first two months of 2023 and this growth is attributed to the robust manufacturing capabilities and high quality of Pakistani men’s garments, said Ghulam Qadir, Commercial Counsellor, Pakistan Embassy Beijing.

China has been an important trading partner for Pakistan, with Chinese companies increasingly sourcing garments from Pakistan due to their competitive prices. The rise in exports is also attributed to the increased demand for Pakistani apparel from Chinese consumers, who have been looking for more stylish clothing options, he told China Economic Net (CEN). In JanuaryFebruary of this year, men’s garments exports from Pakistan to China crossed $4.36 million while in 2022 in the same period, it was $3.21 million, showing an increase of 36%.

The top products were men’s or boys’ trousers of cotton community code (61034200) worth $2.57 million whereas

January-February of 2022 was $1.27 million, he stated. It is worth mentioning that Pakistani men’s garments annual exports to China in 2022 were $28.66 million while in 2021 it was $21.62 million, an increase of nearly 33%.

Men’s or boys’ trousers of cotton, community code (61034200) worth $17.94 million remained the top items while in 2021 it was $12.59 million. Pakistan’s T-shirt exports to China also reached $5.53 million in the first two months of 2023, up more than 106% compared to the same period in 2022. Overall, Pakistan’s export to China crossed $446 million in the first 2 months of 2023.

News & Views 13

AFRICA

Textile waste to Africa have severe consequences

A fact-finding study of the use of secondhand clothing by Greenpeace found that Tanzania and Kenya are flooded with huge amounts of textile waste daily that have severe consequences for people and the environment. The findings were presented in a report titled Poisoned Gifts: From donations to the dumpster: textiles waste disguised as second hand clothes exported to East Africa.

The report mentioned: "In Kenya, 185,000 tons of second-hand clothes were imported in 2019, and according to Africa Collect Textiles and other local sources local sources, 30 to 40% of second-hand clothes are of such bad quality that it cannot be sold anymore. This means that 55,500 to 74,000 tons of it was actually textile waste. This amounts to about 150–200 tons of textile waste a day."

These countries do not have the requisite infrastructure to deal with these “poison gifts” and the results in textile waste dumped everywhere, some of it is burnt leading to air quality issues, and a lot of it is dumped in rivers and drains, clogging them right away.

That's not all. As the report points out, "The decomposing clothes release methane, a harmful greenhouse gas that contributes to climate change; synthetic fabrics like polyester and Lycra can take hundreds of years to biodegrade.”

Greenpeace Germany's toxics campaigner, Viola Wohlgemuth, who visited the two countries, wrote on the Greenpeace website: "Fast fashion brands are promoting circularity, but reality shows that this is still a myth. Nowhere is the failure of the fast fashion linear business model more visible than in the countries where many of these cheap clothes end up once their short lives are over: on huge dump sites, burnt on open fires, along riverbeds and washed out into the sea, with severe consequences for people and the planet."

It's also a question of trading practices which are weighed heavily in favour of the Global North. Wohlgemuth wrote: This effectively turns Global South

countries into dumping grounds for fast fashion waste, while doing little or nothing to support or develop the clean manufacturing of local textiles and garment production that is needed in these countries, using the same high standards and best practices that are required in Europe."

There are, of course, success stories in both Tanzania and Kenya where novel initiatives are creating positive solutions and developing their own form of circularity. Examples include: Anne Kiwia (Tanzania), Suave (Kenya), Mama Hokororo (Tanzania) and Africa Collect Textiles (Kenya).

BANGLADESH

Restrictions for the opening of LCs lead to downfall of textile industry

Bangladesh Bank has imposed restrictions on opening of letters of credit due to ongoing dollar crisis in the banking sector. The Bangladesh Bank, earlier in July 2022, imposed a 100% cash margin for opening letters of credit (LCs) on cars, electronics, gold, precious metals, RMG, and pearls, among other items, to discourage imports in a bid to keep the country's currency and debt management

more integrated and stable. This move has led to a decline in the imports, and in turn has increased the prices of all kinds of commodities in the country.

"Declining stocks of raw materials amid commercial banks' unwillingness to open LCs might severely hamper production and exports of textile and apparel items," says BTMA.

The Bangladesh Textile Mills Association (BTMA) recently expressed concern that the situation of most commercial banks being averse to opening letter of credit (LC) under the Export Development Fund (EDF), Usance Paid At Sight (UPAS) and deferredpayment systems due to dollar shortage may lead to suspension of production of basic raw material for apparel.

The domestic spinners may continue production activities for the next three months till the existing raw materials stock lasts, added BTMA.

The Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA) also expressed that they facing similar problems.

In a letter to the central bank, signed by BTMA president Mohammad Ali Khokon, the association said factories could not import required raw materials like cotton, polyester staple fibre (PSF) and Viscose staple fibre (VSF) to feed the readymade garment (RMG) exporters

Around the World 14 PAKISTAN TEXTILE JOURNAL - March 2023

despite receiving orders and warned that the production disruption would not only deepen the existing dollar crisis, but also hit export earnings, leading to massunemployment.

CHINA

Textiles exports in decline

According to the official data released by General Administration of Customs China (GACC), the country shipped US $ 21.68 billion worth of apparel and accessory, falling by 14.70% on year to year basis in January to February period of 2023.

China exported US $ 40.84 billion textiles and apparel in January-February 2023 as compared to US $ 51.11 billion in January-February 2022 period, noting a 20.10% yearly fall.

It is relevant to mention here that the China concluded 2022 with US $ 323.34 billion, witnessing an increase of 3.90 per cent over 2021 export values.

The decline in 2023 can be attributed to the holidays in the country on the occasion of the Chinese New Year, that’s a phenomenon every year. March 2023 will certainly be a month to watch out for that will define if China’s clothing and textile exports are getting back on track.

EUROPEAN UNION

EU aims to reduce textile waste by 80%

The tExtended project aims to reduce textile waste by 80% through developing and demonstrating recovery and recycling

processes. The European Commission invests USD 16 million in textile recycling project in hope of a sustainable future.

The tExtended project is spearheaded by the state-owned VTT Technical Research Centre of Finland. It intends to integrate recycling, waste valorization and data technologies and bring the current textile recycling from 1% to 80%, resolving an issue that’s been a challenge for a circular economy.

The project is supported by a Euro 15 Million (USD 16 Million) grant from the European Commission’s Horizon Europe program, with a total of 20 organizations from ten EU nations working together to create economically feasible and sustainable solutions to reduce waste in the textile field.

The four-year program intends to decrease textile waste, CO2 emissions, new job possibilities and develop a sustainable textile recycling industry.

Pirjo Heikkilä, project coordinator of VTT Technical Research Centre said: “The tExtended project will optimize textile flows and retain the value of materials in a safe and sustainable way. Through our extensive pilot studies, we will verify the repeatability of the tExtended solutions and their potential to reduce textile waste by 80%.”

With the help of digital tools, sensing systems, and data-driven solutions, tExtended aims to create and demonstrate efficient textile recovery, and waste valorization recycling processes.

Around the World

US cotton consumption in decline worldwide

Cotton consumption forecast is down more than 500,000 bales from the previous month due to lower consumption in Pakistan, Turkey, Bangladesh, and Indonesia due to an array of country-specific factors.

Both Pakistan and Bangladesh are experiencing issues opening and executing letters of credit along with declining profit margins amidst higher electricity costs. Turkey’s earthquake adversely affected mills in the area and Indonesia imports are forecast at the lowest level since 1990.

Global trade is forecast down roughly 800,000 bales from the previous month to 39.6 million bales, the lowest level in 6 years. This month’s adjustments are mostly attributed to lower global consumption.

Global ending stocks are forecast up more than 2.0 million bales to 91.1 million and mostly attributed to changes in China. China’s beginning and ending stocks were revised higher because of a downward revision to consumption in 2021/22 and higher 2022/23 production.

The U.S. balance sheet is unchanged from last month, and the projected U.S. season-average farm price is also unchanged at 83 cents per pound.

TURKIYE

Textile industry suffers as disasters hit hard

Turkiye has been rattled by the strongest earthquake in the history of the country since last century. The devastated nation suffered more than 20,000 deaths, a shattering impact on the country’s economy and a killer blow to country’s GDP.

Turkiye is one of the world’s major textile and apparel production and sourcing destinations, and the second largest source of textile and apparel exports to European Union countries. Turkiye’s textile and apparel exports in 2022 were valued at $35.25 billion. Turkiye has strong competitiveness in the global market in the apparel and home textiles segment. The Turkish clothing industry is the sixth largest supplier in the world with a share of 3.7%.

Turkiye has been a crucial sourcing destination for brands and retailers that represent the entire value chain of the textile and apparel industry. Since the earthquake has severely damaged production and logistics in Turkiye in many ways, manufacturers may look towards other countries for imports.

50% of total textile and apparel exports go to the EU countries. In 2022, it exported $20.64 billion worth of textiles and apparel to the EU, almost 25.60% up from $16.44 billion in 2020.

VIETNAM

Textile and garment exports statistics

According to the report of Vietnam’s export General Department of Customs two-way trade in February was up almost US$3 billion over January despite February being a slightly shorter month.

All-in-all Vietnam clocked-up over 46 Billion USD in two-way trade for the month with foreign direct invested enterprises accounting for a little over two-thirds.

The report mentioned that in the month of February Vietnam’s textile and garment exports grew by 1.94% (43.61 Million USD). Vietnam exported 2.29 Billion USD worth of textile and garments which is more than 2.25 Billion USD last month.

Moreover, Vietnam’s Textile industry for leather and foot-wear materials and auxiliaries showed a drastic growth of 35.41% (42.89 Million USD) with 164.047 Million USD worth of exports in February compared to 121.150 Million USD for the month of January.

The majority of these exports were destined to different Asian countries like China, Korea and Japan and a noticeable amount of textile were imported by the USA as well. Vietnam continues to be a major source of textile and garments in the challenging global markets and changing consumer preferences.

USA

16 PAKISTAN TEXTILE JOURNAL - March 2023

Around the World

Unique product created with Swedish innovation

Digitalisation and highly automated new technologies are enabling companies in high wage countries to competitively thrive in textile markets that for many years have been closed to them.

Just as significantly, these technologies are providing the tools to differentiate in highly competitive fields, as is demonstrated by a recent project initiated by TMAS – the Swedish Textile Machinery Association – for the highly automated production and decoration of a unique tote bag.

Plastic reduction

Back in 2015, the European Parliament reinforced legislation to encourage an 80% reduction in the use of conventional single-use plastic carrier bags by 2025.

The initiative immediately had broad public support, effectively encouraging a basic and widespread change in consumer behaviour. As a result, the consumption of disposable plastic bags has fallen significantly, along with a corresponding reduction in the waste they create.

There has also been a swing towards durable woven shopping bags which in the past have been labour-intensive to produce cheaply, as a result of the cutting and sewing involved.

Fully automatic

TMAS member Automatex has developed a fully automatic tote/consumer bag sewing unit which

can produce fully finished bags in heights of between 35-80 cm and widths of 3080 cm. The machine is configured to carry out all the necessary automated operations including hemming, handle insertion, cutting, labelling, bag forming and gusset forming, which previously had to be carried out manually.

Its output is some 540 units an hour, introducing a completely new cost paradigm.

The resulting bags, however, are still plain and uniform at this point, and with products that are intended to be used for as long as possible, personalisation is the key. Unique designs work to ensure purchasers are likely to become more attached to their products – and are happy to pay a little more for them in the first place.

Instant colouration

In order to add that another TMAS member company, Coloreel, became involved in the project.

Coloreel continues to secure multiple orders for its instant thread dyeing technology for high-speed decoration and embroidery – notably with the fastrising new generation of online merchandisers and brands for whom mass customisation and produce-ondemand sales are the key. The addition of a distinctive embroidered design to the tote bag using Coloreel’s technology took the product to a new level of attractiveness, as a further showcase for Swedish innovation.

The technology enables the highquality and instant dyeing of a textile thread while it is actually being used in embroidery production. It can be used with any existing embroidery machine without modifications. Additionally, this technology makes it

possible to produce gradients in an embroidery design, as demonstrated by the TMAS logo and the text in the image.

Advanced rapid colour formulation software and high-speed drive technology allow a single needle to carry out what it previously required many multiples of them to do – and with much more consistent stitch quality.

By instantly dyeing a recycled white thread during production, the system enables complete freedom to create unique decorations and embroideries without any limitations. Colour changes along the thread can either be made rapidly from one solid colour to another, or gradually, to make smooth transitions or any colouring effect desired.

This provides big benefits when it comes to both sustainability and design creativity.

Potential of Swedish innovation

“Coloreel’s designs on the batch of bags produced on the Automatex machine are truly outstanding and have been turning heads wherever they appear,” says TMAS secretary general Therese Premler-Andersson. “The collaboration really emphasizes the positive potential of the latest Swedish digital textile technologies which are enabling companies to generate new revenue streams wherever they happen to be located.”

18 PAKISTAN TEXTILE JOURNAL - March 2023 Corporate News

U.S. Cotton Trust Protocol has tracked over 3 million kilograms of cotton

The U.S. Cotton Trust Protocol (Trust Protocol) announced that it has now reached a critical milestone of tracking over 3 million kilograms of cotton through its proprietary Protocol Consumption Management Solution (PCMS).

This significant milestone was hit during the busiest fashion month - when all eyes are on the industry and the spotlight on its sustainability during the biennial fashion month which opened on February 9 with the New York Fashion Week and closes Paris Fashion Week on March 7.

As international brands and retailers seek to credibly and transparently demonstrate their own efforts and achievements in driving sustainability in the industry, the Trust Protocol’s announcement marks a significant achievement in its development since its inception in 2020.

The verified data released recently also shows that a total of more than 11 million units of finished products have been tracked through the PCMS system.

“Coming in the middle of the world fashion month, these figures are not only timely, but outstanding in terms of the progress that the U.S. Cotton Trust Protocol has achieved in the three short years since its inception”, said Dr. Gary Adams, President of the U.S. Cotton Trust

Protocol. “Using the PCMS, brand and retailer members can make a variety of claims, including on-product, that are based on data-backed, verified Protocol Consumption Units.”

“Providing transparency through the supply chain is one of the Trust Protocol’s core premises and we’re proud to be the world’s first sustainable cotton fiber program to offer its members article-level transparency”, he added.

This is possible because the PCMS leverages blockchain and other digital technologies to record and verify the movement of Protocol Cotton and U.S. Cotton at every stage of the supply chain in near real time. This requires all members of the supply chain – including

mills and manufacturers – to be a member of the Trust Protocol.

The Trust Protocol is also the only system that provides quantifiable, verifiable goals and measurement and drives continuous improvement in six key sustainability metrics: land use; soil carbon; water management; soil loss; greenhouse gas emissions, and energy efficiency.

The program captures key environmental and social data under a farm-level, science-based system and reports these annually on an aggregated basis.

To learn more about The Trust Protocol, visit TrustUSCotton.org.

19 Features

Critical milestone hit during busiest month for fashion industry when spotlight is on sustainability. Over 11m finished articles tracked through Protocol Consumption Management Solution (PCMS)

Groz-Beckert’s WarpMasterPlus –successful presentation in Asia

The latest generation of Groz-Beckert's fully automatic drawing-in machine –the WarpMasterPlus – was presented live on site for the first time in Asia during ITME INDIA exhibition. In addition, Groz-Beckert presented its knotting machine KnotMaster.

With the new WarpMasterPlus, GrozBeckert relied on the globally proven drawing-in concept, where the drawingin takes place via a single yarn package technology. Nevertheless, WarpMasterPlus is not simply a further development of the previous generation of machines: The system has been newly constructed from the scratch. The latest technologies were consistently used to bring a machine to the market that is already equipped today for future requirements with regard to increased automation in the course of Industry 4.0.

Maximum flexibility with minimum setup time were further focal points in the development, as well as maximized machine efficiency and simultaneously reduce the loading and unloading time. For this purpose, the number of cycles has been increased and sophisticated functions such as pre-setting drop wire magazines and CNC axes for adjusting the heald length have been added. Conversion times can be reduced to a minimum with different accessories.

Numerous visitors took the chance to experience one of the WarpMasterPlus demonstrations at the ITME. All those who were unable to attend a demonstration at ITME will have the opportunity to experience the WarpMasterPlus at the recently inaugurated showroom in Ichalkaranji in Kolhapur District of Maharashtra State in future. Among other things, Groz-Beckert offers individual customer trials and trainings on the machine here.

Other machines from the GrozBeckert’s Weaving Division portfolio are available for training, tests and demonstrations at the showroom too such as the KnotMaster. Tens of thousands of KnotMaster tying machines are successfully deployed worldwide.

Sophisticated technology and simple operation for a wide range of applications are considered the big advantages of the KnotMaster series. Customers benefit from rapid warp changes and reduced processing times for a more efficient and cost-effective weaving preparation. Regarding efficiency, the KnotMaster impresses with its high-performance achieving up to 600 knots per minute.

Intelligent technical features of the KnotMaster increase both process reliability and reproducibility. The yarn clamps with a separate clamping system for example: These special KnotMaster yarn clamps allow the clamping of different yarn thicknesses. Differences in thickness are automatically compensated. Thanks to the automatic repeater, the KnotMaster ensures highest process reliability. In case the separation unit cannot select a yarn on the first attempt, the control repeats the attempt by a predefined number of times. This happens at the full speed of the tying process.

WarpMasterPlus and the KnotMaster are the winning combination for weavers and the flagships of Groz-Beckert’s weaving preparation portfolio. The machines are characterized by their simple operation and great flexibility. Groz-Beckert is convinced that the machines with showing these advantages will improve quality and profitability in worldwide weaving mills in future.

Features 20 PAKISTAN TEXTILE JOURNAL - March 2023

Groz-Beckert WarpMasterPlus.

Groz-Beckert Weaving KnotMaster

The LYCRA Company announces latest Higg achievements

Multiple Sites Earn Independent Verification Results in Top Quartile

The LYCRA Company, a global leader in developing innovative fiber and technology solutions for the apparel and personal care industries, announced that several of its manufacturing sites had their Higg Facility Environmental Module (Higg FEM) and Higg Facility Social & Labor Module (Higg FSLM) selfassessments verified by an independent third party last year and achieved scores in the top quartile.

The LYCRA Company’s manufacturing sites in Waynesboro, Virginia; Maydown, Northern Ireland; and Foshan, China, completed verification for the Higg FEM module, while its Tuas, Singapore, and Maydown sites completed verification for the Higg FSLM module.. A copy of the verified reports for Higg FEM and Higg FSLM can be requested at communications@lycra.com.

Higg FEM reviews air emissions, energy use, environmental management systems, wastewater, waste, chemical management and water usage. The LYCRA Company’s six manufacturing sites have completed the selfassessment, with the three sites mentioned above securing verification. The company’s goal is to have sites representing 80% of LYCRA® fiber production to be Higg FEM verified by 2024.

“The LYCRA Company strives to be an industry leader for sustainability by utilizing credible and independently verified data,” said Alan McElreavey, operations sustainability program manager at The LYCRA Company. “The Higg Facilities modules are widely used within the apparel industry to assess the environmental impact of manufacturing facilities, to uncover opportunities for improvement, and to measure our progress against established baseline performance. Completing the Higg facility modules drives behaviors that become embedded in our company, enhancing our sustainability culture and creating measurable change.”

“Higg FEM is aligned with our goals in key impact areas and helps us improve our sustainability profile and operate as a good corporate citizen,” said Hector Chapa, business integration manager at The LYCRA Company. “It also supports two pillars of our Planet Agenda sustainability platform - corporate responsibility and manufacturing excellence.”

The LYCRA Company’s Tuas, Singapore and Maydown, Northern Ireland manufacturing sites also completed third-party

verification of their Higg FSLM, both with scores in the top quartile. The Higg FSLM self-assessment provides insights into social progress and labor conditions at each site, including compensation and health and safety, and identifies areas for continuous improvement.

“Our upstream and downstream customers are increasingly asking suppliers like us to provide independent certifications that assess the environmental impact of their facilities, as well as social and labor practices in the workplace,” said Kok Beng Chew, Asia Pacific Regional Operations Director. “The Higg Facility Tools are a must-have for business today because they enable us to stay on track and be a responsible Spandex producer.”

The LYCRA Company is a member of the Sustainable Apparel Coalition, a nonprofit alliance that developed the Higg Facility Tools. The global organization consists of over 280 stakeholders in the fashion industry.

To learn more about Higg assessments completed by The LYCRA Company, visit below: lycra.com/sustainability.

Features 21

The LYCRA Company’s manufacturing sites in Waynesboro, Virginia; Maydown, Northern Ireland; and Foshan, China, completed verification for the Higg FEM module, while its Tuas, Singapore, and Maydown sites completed verification for the Higg FSLM module.

FESPA Global Print Expo 2023 set to welcome strong line-up of 490 international exhibitors

More than 490 exhibiting companies are already confirmed to participate at FESPA Global Print Expo, European Sign Expo and Personalisation

Experience 2023, including 95 suppliers who were unable to attend the events in the last two years due to travel restrictions.

Exhibiting companies include DP Solutions, eurolaser, INX, Lüscher Technologies, Marabu, SPS TechnoScreen, Vastex International and Vivid Laminating Technologies. The lineup also features 78 new exhibitors, including Aerolam Decoratives, CarbonQuota, Duveholm Stallbacken, Magon, Newtown Packaging, Ronchini Massimo, Scandinavian Print Group, Toscana Systems and XEIKON.

Visitors to FESPA Global Print Expo 2023 will see solutions from event sponsors Durst, Surfex, Brother, Mimaki, Hanglory and HP and hardware from

leading suppliers including AGFA, Aeoon, Aleph, Canon, Epson, Fujifilm, HP, Kongsberg, Liyu, MHM, Sakurai, Swissqprint, Ricoh, Roland, ROQ and Zünd.

Confirmed automation and workflow software suppliers include Caldera, efi, Enfocus BV, OneVision and PrintFactory. Ahlstrom Munksjö, APA, Hexis, ImagePerfect/Berger Textiles, InkTec, Neschen, ORAFOL, Poli-Tape and Sun Chemical are also among the companies presenting media and consumables.

Head of FESPA Global Print Expo, Michael Ryan comments: “Exhibitors who haven’t been able to participate in FESPA events in the last few years can’t wait to share their innovations and expertise with our visitors. And we know that printers benefit hugely from being able to see products from many suppliers in one place, helping them to compare and evaluate the right investments for their

business. Our mission this year is to give valuable new perspectives to printers and signmakers. With the strongest line-up of FESPA exhibitors since 2019, we can guarantee that visitors to Munich in May will be in the best place to get the insight and advice they need to overcome their production challenges, access new opportunities and imagine their business future.”

Christoph Gamper, CEO & CoOwner, Durst comments: “Whereas there was a strong focus on faster production in recent years, digital printing is now no longer the new kid on the block. The emphasis is now on automation, efficiency, and an overall sustainable process in the various digital printing applications. We are pleased to have FESPA in our ‘neighbourhood’ this year and look forward to a lively exchange of applications and unique views, celebrating achievements and discussing

22 PAKISTAN TEXTILE JOURNAL - March 2023 Faris and Exhibitions

new perspectives. The best ideas are born in dialogue, and FESPA offers the ideal setting.”

European Sign Expo 2023, the leading European exhibition for signage and visual communications, will be co-located with FESPA Global Print Expo. With the support of Platinum Sponsor EFKA, the event will reunite key signage professionals with companies specialising in channel lettering, digital signage, dimensional signage, engraving and

etching, illuminated displays, out of home media, LED, outdoor systems, laser cutters and sign tools.

The brand new Personalisation Experience will give visitors the opportunity to learn more about personalisation, with specialist suppliers including Antigro, Brother, Dreamscape, Infigo, Optimus, Printbox, Print & Logistics, Taopix and XMPie showcasing products and solutions.

Registration for FESPA Global Print Expo, European Sign Expo and Personalisation Experience is now live. Entry to all three exhibition areas is free for members of a FESPA national Association or FESPA Direct. A four-day pass for the Personalisation Experience conference area will be priced at €495. Tickets to the PE conference are €225 for visitors who register before March 23rd using code PEX1.

and Exhibitions 23

Fairs

Why ITMA is the greatest show on earth?

Cornelia Buchwalder, Secretary General of the Swiss Textile Machinery Association

In the world of textile manufacturing, ITMA is really the ‘greatest show on earth.’ It’s where the progress of textile and clothing technology is measured and benchmarked against previous years, and vital contacts are made between customers and suppliers worldwide. Swiss companies are renowned for their innovative spirit and commitment to the four-yearly exhibition series. Looking ahead to ITMA 2023 in Milan (June 814), this interview with Cornelia Buchwalder, Secretary General of the Swiss Textile Machinery Association explores the real importance of ITMA as a driver of global textile progress.

How important is ITMA 2023 for Swiss Textile Machinery member companies?

Not only for us, but for the visitors from the textile manufacturers, ITMA is vitally important, and a major element in the overall development of the industry worldwide.

The 2023 ITMA is fully booked – clear evidence of its continued appeal as the essential marked place for textile machinery. And its importance is underlined by the participation of more than 50 Swiss exhibitors, most of which are members of the Textile Machinery Association. We will be there in Milan, because we know it’s the perfect opportunity to show the world what we offer.

Our Association is a major player in textiles. Established in 1940, it now includes 44 member firms, covering the entire textile value chain. Together, these companies have a total of more than 4,000 years of experience, and an unrivalled international reputation for innovation and quality.

Is ITMA really still a focus for the timing of major innovations in technology?

That is certainly the way the ITMA shows have been viewed in the past. Today it’s not the only forum for innovation, which is now more of an ongoing process of collaborative effort between machinery companies and their customers. But ITMA remains a fouryearly milestone in technology, where industry visitors rightly expect to see the best and latest ideas from their suppliers. It’s increasingly interesting to evaluate how innovations fit into the wider textile value chain, rather than in a company’s own specialized branch of the sector.

Obviously, Swiss Textile Machinery companies will want to use this big event to grow their business and expand sales. Are there other motivations for exhibiting at ITMA 2023?

Yes, that’s a primary goal for sure. But we don’t underestimate the superb networking opportunities it will bring, fostering shared knowledge and experience with both new and existing partners.

Significantly, 2023 will be one of the first really major shows for textiles since the coronavirus pandemic put a stop to personal business interactions. It will be great to enjoy face-to-face meetings again this time. We have a lot to talk about!

For our member firms, it’s also a chance to focus on how our products, components and services stack up against competitors’ offerings, and gauge the reaction from visitors to our booths.

24 PAKISTAN TEXTILE JOURNAL - March 2023

Swiss Review

What

actual innovations and novelties can we expect in Milan?

We will certainly be ready with a strong display of new Swiss developments, as each company presents its latest innovations. For the specifics, individual members companies will be delighted to provide more detailed information – and maybe even some surprises at the show itself.

What would the Swiss Textile Machinery Association aim to achieve at ITMA?

One of our key goals would be to assure visitors that Switzerland is seen in the vanguard of progress in both sophisticated digital solutions and sustainable solutions. Sustainability has a double meaning for us: the ability to offer continuing benefits and enduring performance for our customers, while embracing every aspect of sustainable production to the highest standards of environmental responsibility.

We achieve these standards through significant investments in R&D – a major slice of revenue for most of our members – and by close cooperation with experts in the leading products, components and services. ‘Innovation is in our DNA’ is more than a slogan: we have the history of achievements to prove it.

What is it that makes Swiss machinery so special?

Of course, there are respected textile machinery suppliers in other countries too! Switzerland though has the reputation, earned over many decades, of the highest levels of excellence and precision in all aspects of manufacturing and engineering. Textile machines, components and services rightly share that status. Our in-house production systems are cutting-edge and sustainable.

Customers say it for us: With Swiss companies, quality is guaranteed. Why should textile industry visitors go to ITMA 2023?

Couldn’t they just stay at home and get the info they need online? Well, maybe, but there is nothing quite like seeing a new machine or an exciting innovation up and running in the bustling halls of a major show. Live demonstrations at timed intervals are often crowded with eager visitors – for a good reason. It’s the way to be inspired, and find solutions that could literally change your business outlook, and actually grow your profits.

ITMA 2023 will also give visitors a chance to speak personally with the

experts from machinery companies, to ask those ‘difficult’ questions and get the full story behind a vital innovation. How will it fit into an existing production environment, will it help to reduce waste, will it help to improve profitability…?

Then there are the big questions, about investment costs and funding. Big deals are started at ITMA, and contracts are often finalized – admittedly sometimes as a publicity boost. Visitors can also compare offers from different providers. Obviously, we hope the choice is for the Swiss option! Ultimately, ITMA is a celebration of the achievements of the global textile community, and an opportunity to foster the kind of innovative developments that future generations will be proud of.

Swiss Review 25

SSM offers sustainable and energy efficient processes

SSM embodies sustainability by offering energy efficient technologies and processes to reduce energy consumption and lower carbon footprint. SSM promotes the concept of upgrading and retrofitting existing products and flexible machine concepts, serving maximum amount of applications.

The latest products and services at ITMA Milano 2023 include NEO-FW, NEO-FD and Nema – SSM Digital Suite.

SSM NEO-FW

The SSM NEO-FW precision package winder is set to make its worldwide market introduction at ITMA Milano 2023. This new product offers outstanding advantages, which include: Automatic doffer, which helps to reduce downtime. The NEO-FW is capable of winding at higher speeds than previous models, resulting in a 25% increase in productivity.

The NEO-FW features the most accurate length measuring system available, with a precision of ± 0.5%. This ensures that all packages are of consistent length, resulting in higher quality yarn.

Quick take-up change allows for fast and easy changeovers between different package types. Other advantages include: Digitens – yarn tension control and

Fastflex – electronic yarn laying unit. The NEO-FW is Nema ready, which means it can be integrated with the Nema-SSM Digital Suite, enabling manufacturers to digitize and optimize their production processes.

SSM NEO-FD

SSM NEO-FD precision assembly winder offers following advantages: Automatic doffer – maximizing productivity.

Increased speed by 25%.

Accurate length measuring (± 0.5%). Quick take-up change. digitens – yarn tension control. fastflex – electronic yarn laying unit. Integrated 2- or 3-ply creel. Nema ready.

Nema (IoT) solution for controlling and managing production (optimization means less energy consumption, less waste and increased machine efficiency).

Real-time insights provide transparency of the process performance

Stay in control easily – navigating from global overview to local insights within seconds

Engage key people with unlimited user access.

Ensure optimized machine operation with machine health indicators. Enjoy secure connection and safe data storage with state-of-the-art technology.

Connect to other MES or ERP systems with download event function. Nema, the Digital Suite of SSM, helps SSM customers navigate through complexity, uncover hidden issues and find the path to manufacturing excellence.

Three Dedicated Card Clothing Packages by Graf

Graf is considered as one of the market leaders in providing specialized solutions for the recycling of various fibers in the textile industry.

At the upcoming ITMA in Milan Graf shall present three dedicated Card Clothing Packages for recycled cotton, recycled cotton blends, and last, but not the least recycled man-made fibers (MMF). These three solutions allow for the production of yarn counts up to Ne 20 by limiting the short fiber content.

Additionally, Graf offers the option to customize more specific Card Clothing sets for all kinds of recycling applications with the help of their textile technology experts.

Swiss Review 26 PAKISTAN TEXTILE JOURNAL - March 2023

Nema – SSM digital suite

SSM NEO-FW precision package winder.

Per Olofsson, Managing Director, SSM.

Rieter: Mastering the Short Fiber Challenge

Rieter Machines and Systems Head

Marketing and Systems Franziska

Häfeli gave a presentation on Rieter’s strong position in the short fibre field and the increasing demand for recycled yarns. Following are the salient points of the presentation.

Recycling Industry Today

A significant growth potential

Nearly three quarters of all garments end up in landfills.

Out of the 89 million tones annual fiber production, only 1% is recycled from pre- or post-consumer textiles. The recycling potential is estimated to be more than 15%.

EU Strategy for Sustainable and Circular Textiles with ambitious goals.

Two Ways to Open Fibers

Chemical recycling and mechanical recycling are two ways to open fibers in textile recycling. The chemical recycling involves breaking down fibers into chemical building blocks, which can then be used to create new products. This process is particularly useful for cotton waste and blended waste, where separating fibers through mechanical means is challenging.

On the other hand, mechanical recycling involves tearing pre- and postconsumer goods into pieces and then torn by cylinders into fibers. This method has its roots in the downcycling business and is a more aggressive way of opening fibers. The main advantage of mechanical recycling is that it is a well-established and cost-effective process. However, the downside is that it can lead to a loss of quality and the resulting fibers are typically of lower quality than the original fibers.

In contrast, chemical recycling has the potential to create high-quality fibers that are equivalent to or even better than the original fibers. However, the process is currently more expensive and requires more research and development to become a viable commercial option. Overall, both chemical and mechanical

recycling have their advantages and limitations. The choice of method depends on the type of fiber being recycled, the desired quality of the resulting fibers, and the cost-effectiveness of the process.

Recycled Yarns

The typical spinning processes for Short Fibers include rotor and ring spinning system for recycling. It is important to note that both rotor and ring spinning have their advantages and limitations, and the choice of method depends on several factors, including the type of fiber being used, the desired quality of the resulting yarn, and the cost-effectiveness of the process.

In textile recycling, both rotor and ring spinning can be used to create new yarn from recycled fibers, reducing the amount of waste generated by the textile industry and promoting a more sustainable approach to manufacturing textiles.

Rieter Rotor spinning system for recycling

Spinners have been using the rotor spinning process for decades for recycled material.

Many did not even claim to use recycled material save raw material cost. Rotor spinning is best suited for processing material with a high shortfiber content.

Rieter Ring spinning system for recycling

Increasing demand also for recycled ring yarns (wider application range).

Higher tenacity of ring yarn go into weaving.

Different, softer touch, finer counts.

Possibility for core yarn (stretch) on the end spinning machine, but very challenging due to neps and high short fiber content.

Rieter is collaborating with a topquality denim manufacturer to test adaptations along the value chain. Denim Ne 7-12 with 80/20% virgin cotton/post-consumer (bleached) was used in the sample yarn. The progress with the sample yarns using the Rieter ring spinning system, shows improved yarn quality (reduced IPIs, lower shortfiber content), achieved through settings on card, draw frame, roving, and compact-spinning settings. The target of using a 50% share of recycling materials is ambitious , but trials and improvements continue to yield positive results along the entire spinning process.

Com4 recycling for Recycled Yarns

Com4® is a registered trademark by Rieter, and it is used for quality yarns spun on Rieter spinning systems and apparel made out of these yarns. Customers can participate in the Com4® licensee program. This program allows customers to use the Com4® trademark on their products, indicating that they are made from high-quality yarns spun on Rieter spinning systems.

27

Swiss Review

Franziska Häfeli, Head Marketing & Systems Rieter Machines and Systems.

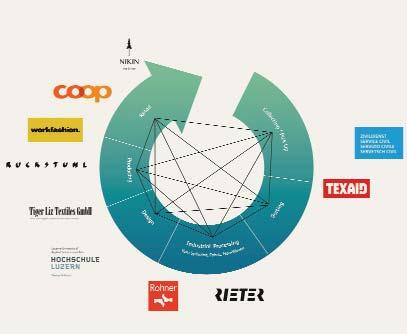

The Design of a Circular Ecosystem

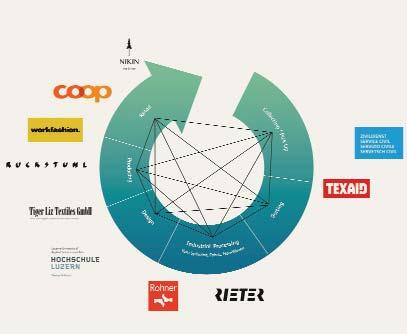

Brigitt Egloff, Researcher and Designer at Lucerne University of Applied Sciences and Arts and Franziska Häfeli, Head Marketing & Systems Rieter Machines and Systems explained the collaborative project TexCircle that is contributing towards the design of a circular economy.

Climate change and environmental degradation are some of the main concerns facing us today. With barely 1% of garments being recycled and three quarters of the world’s clothing ending up in landfill, the textile industry is actively seeking ways to make production

patterns more sustainable and pay more attention to the entire life cycle of items of clothing. Rieter is actively committed to a sustainable policy, using its technological expertise to offer a complete recycling spinning system for both ring and rotor spinning lines that enables customers to spin fibers from used garments and waste into yarns.

“TexCircle” cluster, consists of Swiss and international companies in the field of textile manufacturing and textile recycling. The project partners joined forces by contributing their know-how, areas of expertise, funding and materials. Contributors include Rieter, Coop, Rohner Socks, Ruckstuhl, Texaid and Workfashion. Other network partners include the Federal Office of Civilian Service (ZIVI), Nikin and Tiger Liz Textiles. The project has received additional support through collaborations with Swiss firms such as Jakob Härdi AG and international companies such as Marchi & Fildi. It is being funded by the Swiss Innovation agency Innosuisse.

By creating and testing prototypes, the project examined various circular value-added scenarios. The focus was on making the challenges of a future circular economy verifiable rather than developing prototypes as precursors to marketable products. Based on an inventory of material, 2.5 tonnes of textiles were collected in the cluster and developed into six prototypes over the two years.

Brigitt Egloff and Franziska Häfeli, showed the socks and other prototypes by Texcircle at the end of their presentations.

Swiss Review 28 PAKISTAN TEXTILE JOURNAL - March 2023

Brigitt Egloff, Researcher and Designer at Lucerne University of Applied Sciences and Arts

Itema Group offers advanced weaving solutions

Itema, the global leading provider of advanced weaving solutions, including weaving machines, OEM spare parts, weaving accessories, and integrated services, participated in the Swissmem pre-ITMA 2023 press conference in Bern on the 17th of March.

Matteo Mutti, Itema Switzerland Ltd Managing Director, first introduced the Group’s 2022 financial results and then focused on ITMA 2023.

In 2022, Itema recorded a sales revenue of EUR 337.6 million, up +10% over the previous year, thus continuing its path of constant growth.

Mr. Mutti continued by introducing the main highlights of the Itema Group’s participation in the upcoming ITMA 2023: “ITMA 2023 will take place in Milan, Italy, which is our Group home country. Therefore, we are excited to welcome visitors from all over the world and we are working to guarantee to them the best possible experience at the event.”

Itema is present at ITMA 2023 with the target to be a meeting point for the industry. The Itema Group booth in Hall 6 - B105 will offer all the latest innovations in the Itema weaving technology and also premium weaving accessories by the Group companies Lamiflex and Schoch to make the weaving process even more effective, sustainable, smart, and successful.

In Mr. Mutti’s words: “At ITMA, Itema will present a full range of solutions developed to make our customers’ life easier while providing them with tangible benefits in terms of textile mastery, ecoefficiency, digitalization and easy weaving.”

Itema is a leading global provider of advanced weaving solutions, including best-in-class weaving machines, spare parts and integrated services. Sixty per cent of Itema is held by Gianni Radici’s family heirs (the siblings Angelo, Maurizio, Paolo, Maria Grazia and Bruna) and 40% by the Arizzi and Torri families.

Itema Group business areas include also industrial and innovation. In fact, in recent years the Group diversified into complementary, high-growth markets through stakes in innovation driven companies, such as Lamiflex®, Schoch® and Itemalab®, the Itema advanced innovation hub created in 2014 that in 2021 evolved into a fully-fledged company dedicated to develop breakthrough textile and industrial

solutions. With more than 1.000 employees worldwide, world-class production sites in Italy, Switzerland, China and India (the latter for Schoch products, ndr), Itema features a global presence with commercial and after-sales services in Italy, Switzerland, China, India, Japan, USA, Hong Kong, Dubai, and Türkiye. More information about Itema can be found on the website www.itemagroup.com.

Matteo Mutti, Managing Director, Itema Switzerland Ltd.

Swiss Review 29

R9500 is ideal for various textile applications, such as shirting, wool, silk, furnishing, curtains, home textile, apparel and technical fabrics.

Sustainability at forefront with innovative solutions by Autefa

Autefa Solutions is one of the leading global suppliers of innovative and highperformance machines and systems. The company will be showcasing its latest developments at ITMA 2023, which runs from June 7-14.

The company operates in four main business areas: Nonwovens Technology, Baling Technology, Woollen/Worsted Technology, and Automation Technology.

Autefa's technology includes cardedcrosslapped needle punch lines, aero-dynamic web forming technology, thermo-bonding lines, and spunlace lines. As one of the market leaders in staple fiber and tow baling presses, the company offers everything from fiber transport to the baler to bale handling and storage. Autefa also offers OCTIR woollen carding sets for high-quality weaving and knitting yarns.

At ITMA 2023, Autefa will showcase its expertise in advanced materials, digital future, innovative technologies, and sustainability. The company's advanced Airlay technology delivers heavy and thick fibers mats by using natural or recycled fiber for the growing acoustic and thermal insulation market. The energy-saving Spunlace technology is designed to maximize efficiency while minimizing energy consumption. Lastly, the Needle Exchanger technology reduces downtime and increases productivity, making it a valuable addition to any production line.

Autefa Solutions offers a range of innovative solutions designed to process and reuse various types of fibers, including reclaimed, natural, and manmade materials. The Airlay KV12/K12 aerodynamic web forming machine in combination with Stylus Needle Loom or HiPerTherm Oven meets customer requirements for productivity and high quality.

The Needle Exchanger is an innovative solution to address the challenges of re-needling needle boards in needle punching nonwovens production.

30 PAKISTAN TEXTILE JOURNAL - March 2023

André Imhof, CEO, AUTEFA Solutions Switzerland and AUTEFA Solutions Austria.

AUTEFA Solutions Airlay Futura.

The machine replaces the physically tiring and risky manual process of needle insertion, exchange, and removal with an automated process that removes the risk of operator injury and minimizes the risk of board damage. The Automatic Needle Exchanger is equipped with adapted software to ensure reproducibility and safety at every needle exchange.

Autefa Solutions has also cooperated with PAMA Paper Machinery to offer Wetlaid-Spunlace technology, a process that combines fiber-based web forming, consolidation, and drying technology with the Wetlaid technology commonly used in the paper industry. The process improves the bulkiness and feel of the final product through Autefa carding and spunlace technology. Compared to the classic Wetlaid inclined wire technology, Autefa Solutions is focusing on innovative paper machine solutions with even better

performance, especially for CP products. The use of this technology reduces the amount of pulp fibers and energy required.

Further savings in power and water consumption are achieved with Autefa Solutions' V-Jet technology for hydroentanglement, effective dewatering with V-shaped suction slots, and the efficient SQ-V square drum dryer technology. This technology is designed to create a uniform pulp layer for optimal fiber distribution with the lowest fiber consumption.

Autefa Solutions offers automated bale warehousing solutions that optimize space and streamline operations. During ITMA, the company will unveil one of the largest PET fiber bale logistics centers in the world. The warehouse and logistics center will organize, press, form, package, strap, identify, label, stack, sort

and prepare the enormous fiber output of six new polyester staple fiber lines with specific fiber know-how for storage and further logistical actions.