Established 1951 May 2023 German Review / ITMA 2023 Preview

Techtextil 2023 North America

Dates: May 10th to 12th, 2023

Venue: Georgia USA.

DOMOTEX asiaCHINAFLOOR 2023

Dates: May 29th to 31st 2023.

Venue: NECC, Shanghai, China.

FESPA 2023

Dates: May 23rd to 26th 2023.

Venue: Munich, Germany.

Istanbul Yarn Fair

Dates: June 1st to 3rd, 2023.

Venue: Istanbul, Turkey.

ITMA 2023

Dates: June 8th to 14th, 2023.

Venue: Milan, Italy.

Johannesburg, South Africa !

Dates: June 18th to 20th, 2023.

Venue: Gallager Convention Centre.

The 92nd Textile Institute World Conference, UK.

Dates: July 3rd to 6th 2023.

Venue: Huddersfield, UK.

62th Dornbirn GFC Global Fiber Congress

Dates: September 13th to 15th 2023.

Venue: Dornbirn Austria.

Textile Asia 2023, Lahore

Dates: October 13th to 15th 2023.

Venue: Expo Centre, Lahore.

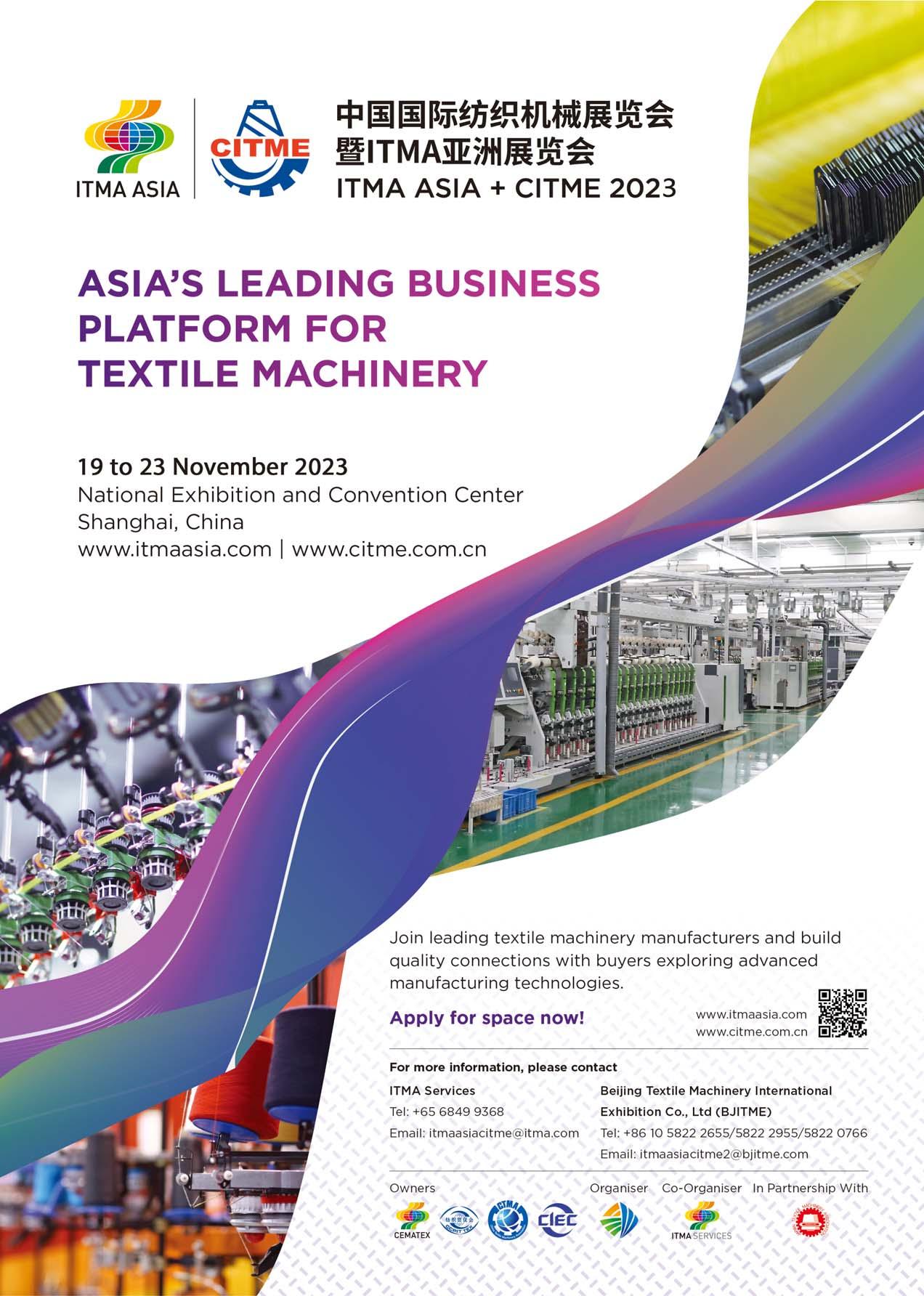

ITMA ASIA + CITME 2023

Dates: November 19th to 23rd, 2023.

Venue: NECC, Shanghai, China.

Heimtextil 2024, Frankfurt

Dates: January 09th, to 12th, 2024

Venue: Frankfurt am Main.

IGATEX

Pakistan 2024, Lahore

Dates: May 1st to 4th 2024.

Venue: Expo Centre, Lahore.

iCADEX

Pakistan 2024, Lahore

Dates: May 1st to 4th 2024.

Venue: Expo Centre, Lahore.

ITM 2024

Dates: June 4th to 8th, 2024.

Venue: Istanbul, Turkey.

HIGHTEX 2024

Dates: June 4th to 8th, 2024.

Venue: Istanbul, Turkey.

JIAM 2024 OSAKA

Dates: Nov. 27th to Nov. 30th 2024.

Venue: Osaka, Japan.

DOMOTEX Hannover 2024

Dates: January 11th to 14th 2024.

Venue: Hannover, Germany.

12th

ITME INDIA 2024

Dates: December 2024.

Venue: India Expo Centre & Mart. Noida, India.

2

Calendar of Events

PAKISTAN TEXTILE JOURNAL - May 2023

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher

Nadeem Mazhar

Editor in Chief

Amina Baqai

Associate Editor

Nimrah Nadeem

Production Manager

Mazhar Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh

Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab

C.TEX, F.T.I (U.K), B.Sc.

Fellow I.C.T.T Atlanta, GA; (USA)

Mian Iftkhar Afzal

B.S.N.C State, M.Sc. (Leeds)

C.TEXT.F.T.I (UK)

Dr. Zubair Bandukda

PhD (Textiles), CText ATI

Editorial & Advertising Office

B-4, 2nd Floor, 64/21, M.A.C.H, Miran M. Shah Road, Karachi - Pakistan

Tel: +92-21-34311674-5

Fax: +92-21-34533616

Email: info@ptj.com.pk

URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Correspondence & Mailing address: 93 Fleming Place, Bracknell, RG12 2GN, United Kingdom

Tel: +44 792 2228 721

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, UK

Registered no. 09141989

AROUND THE WORLD . . . . . . . . . . . . . . . . . . . . . .14 NEWS & VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . .10 EDITOR’S PAGE . . . . . . . . . . . . . . . . . . . . . . . . . . .7 German Textile Machinery: A seven-decade commitment to Pakistan's textile industry TEXTILE BRIEFS . . . . . . . . . . . . . . . . . . . . . . . . . . .8 Vol. LXXII No. 05 May 2023 Rs. 565.00

Printed at: Color Plus Korangi, Karachi. Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi. Available on Gale and Factiva affiliated international databases through Asianet Pakistan

NEWS ANDRITZ: Novafiber starts

& airlay lines from ANDRITZ . . . .18 VDMA: Way2ITMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 New set-up of Mayer & Cie. representation in Bangladesh and Nepal . . . . . . . .21 FEATURES The edie23 highlights the importance of data & transparency in sustainability .26 Earth Protex Corporation partners with iTextiles® . . . . . . . . . . . . . . . . . . . . .28 FAIRS AND EXHIBITIONS Texworld Paris celebrates 25 years! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22 Heimtextil 2024: Demand exceeds exhibitor number of previous event . . . . . .24 DYES AND CHEMICALS Archroma puts sustainability in the spotlight at Bangladesh Denim Expo 2023 . .34 18 MILL REPORT SSM: Irreproachable Quality with XENO-AC . . . . . . . . . . . . . . . . . . . . . . . . . .30

HINTS Atlas Copco's tips on how to size pneumatic conveying systems . . . . . . . . . . . .32

CORPORATE

up textile recycling

PRACTICAL

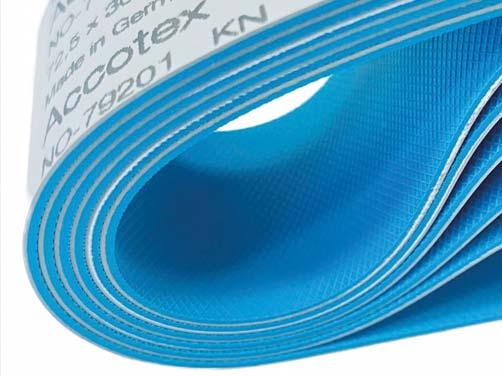

GERMAN REVIEW + ITMA 2023

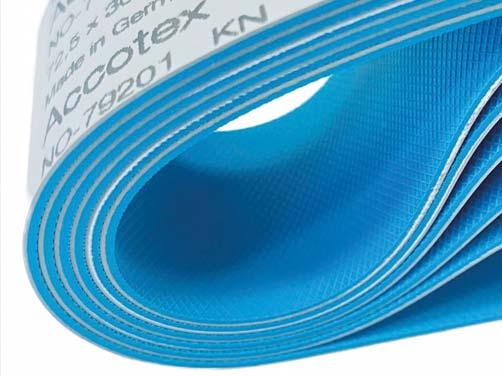

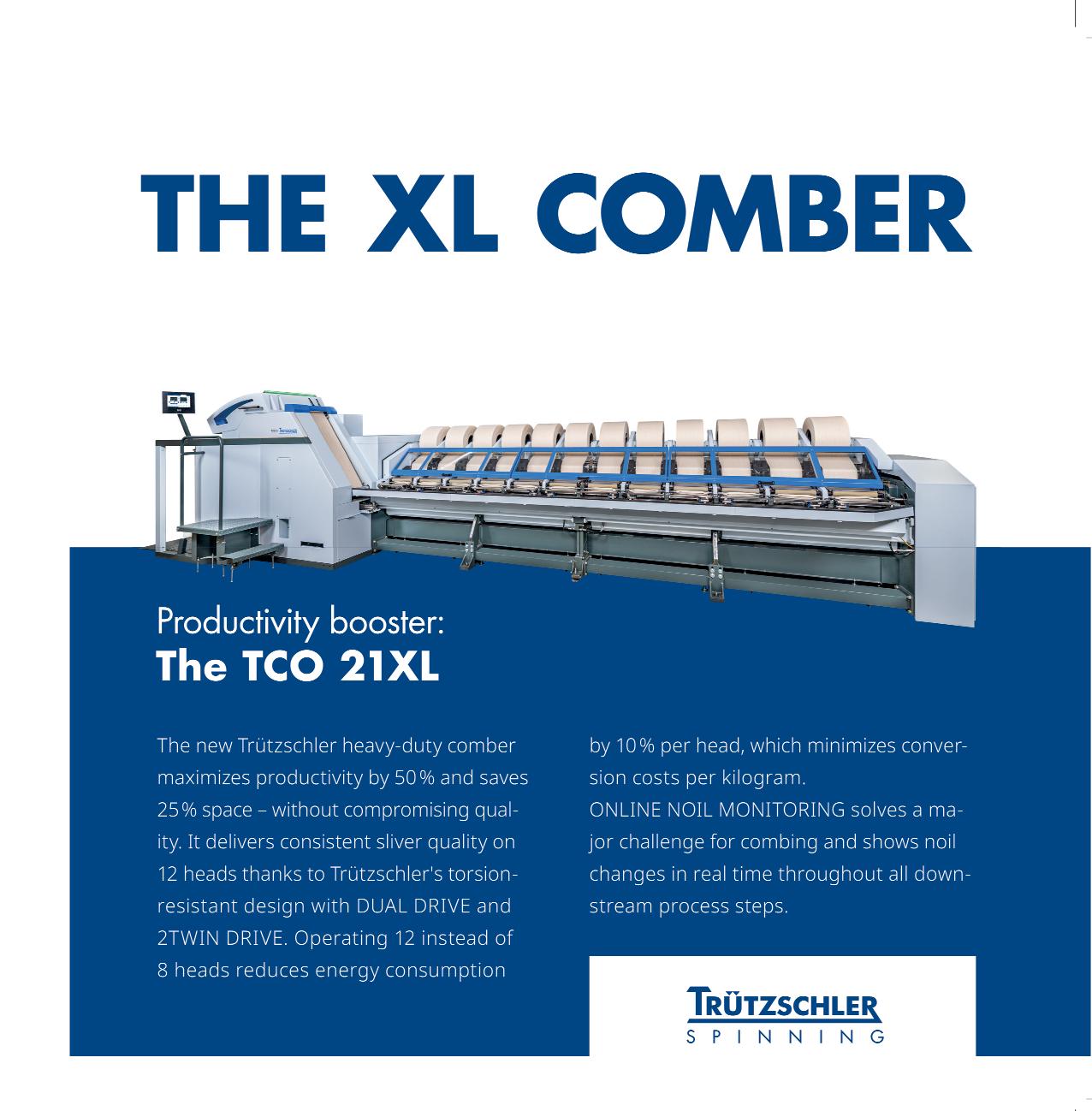

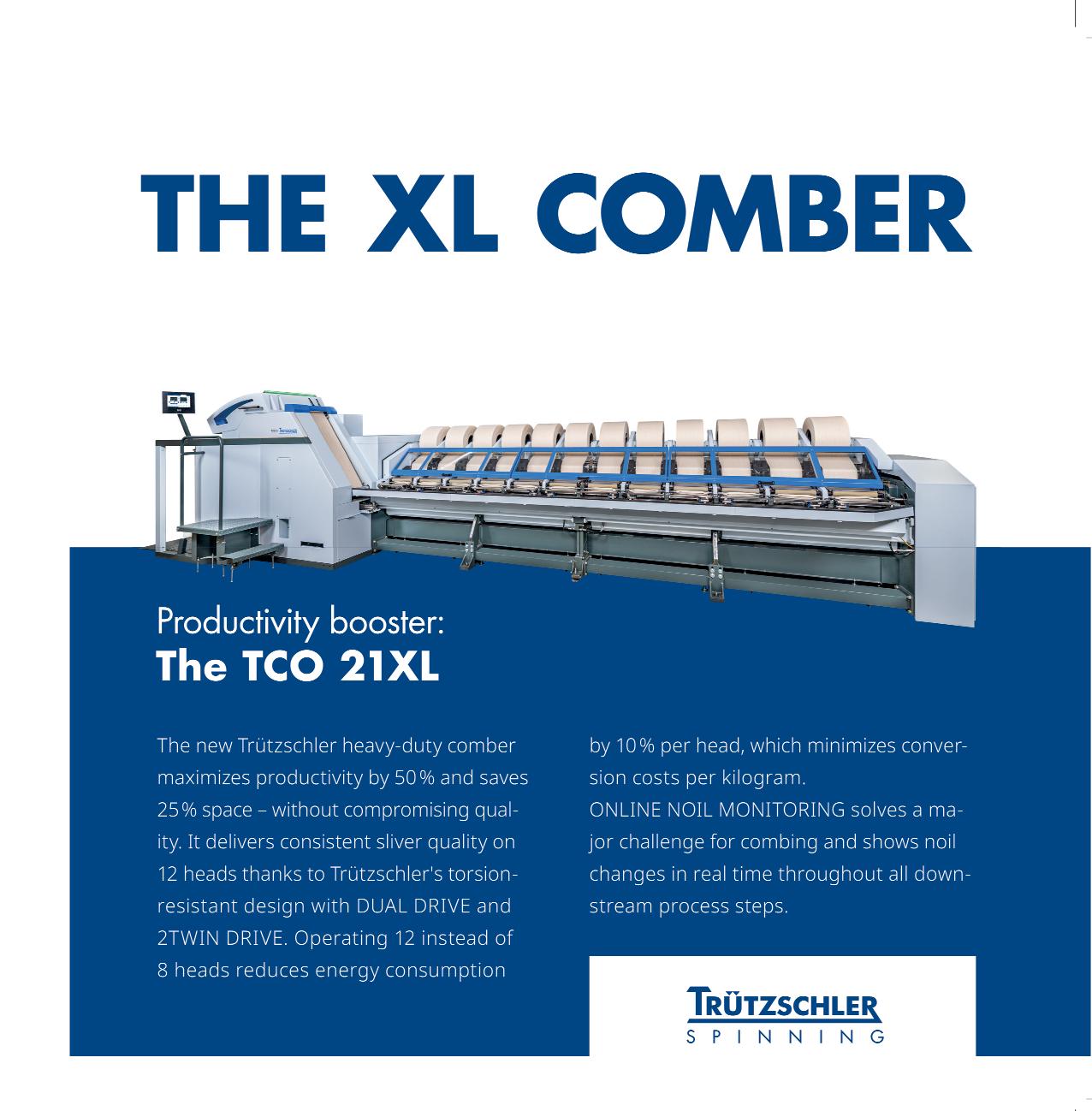

Pakistan-Germany Trade: A Fruitful and Growing Partnership . . . . . . . . . . . . . .36 Contribution of German Machinery in the World of Textiles . . . . . . . . . . . . . . .40 Sustainable & innovative solutions are building blocks of a quality product . . . .42 Latest machines & technologies from the Trützschler Group . . . . . . . . . . . . . .44 Monforts displays Montex®Coat coating unit . . . . . . . . . . . . . . . . . . . . . . . . . .46 Weko & RotaSpray to exhibit at ITMA Milan in June . . . . . . . . . . . . . . . . . . . . . . . . .48 New Accotex Aprons: Field tests confirm high Performance . . . . . . . . . . . . . . . . . . .50 AUTEFA Solutions: Pioneer in sustainability with innovative solutions . . . . . . . . . . . .51 Oerlikon with world premieres at ITMA Milan 2023 . . . . . . . . . . . . . . . . . . . . . . . . .52 Erhardt+Leimer: New inspection technologies for improved production processes . . .54 Groz-Beckert presents its highlights and innovations . . . . . . . . . . . . . . . . . . . . . . . .55 PLEVA showcases technology for energy-efficiency processes . . . . . . . . . . . . . . . . . .56 KARL MAYER GROUP mastering the future with sustainability . . . . . . . . . . . . . . . . . .58 DiloGroup: MicroPunch line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59 SETEX is shaping the future of Industrial Automation . . . . . . . . . . . . . . . . . . . . . . . .60 Mahlo highlights latest developments for process optimization . . . . . . . . . . . . . . . . .61 Thies: Signature technology transforms dyeing . . . . . . . . . . . . . . . . . . . . . . . . . . . .62 KERN-LIEBERS Textile at ITMA-2023 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63 42 46 44 50 55 36 62

German Textile Machinery: A seven-decade commitment to Pakistan's textile industry

Pakistan's textile industry has thrived over the years, and its success owes a great deal to the innovative technological solutions provided by German textile machinery suppliers. The strong foundation of the Pakistani textile industry can rightfully be attributed to the technological prowess of German companies. Pakistani textile entrepreneurs and industrialists have embraced the acquisition of cutting-edge global technology to remain competitive in the global textile market.

German textile machinery suppliers have played a pivotal role in the development of Pakistan's textile industry. Companies and brands such as Schlafhorst (Saurer Group), Suessen (Rieter Components), Truetzschler, Dornier, Monforts, Osthoff-Senge, Goller, Brueckner, Thies, Groz Beckert, Mayer & Cie, Stoll, and Karl Mayer have been instrumental in shaping the textile sector in Pakistan. These companies have not only provided state-of-the-art machinery but have also demonstrated a strong commitment to the Pakistani market through extensive after-sales support.

Furthermore, the contribution of German chemical suppliers cannot be overlooked. Companies like Bayer, CHT, DyStar, and many others have been reliable partners, supplying quality chemicals and auxiliaries to Pakistan's textile finishing industry. With the increasing demand for sustainable and eco-friendly textiles, the role of chemical suppliers has become even more vital. These companies have not only provided suitable chemicals but have also played a crucial role in educating the Pakistani textile industry on techniques to achieve sustainable and profitable production.

Pakistan Textile Journal has been a key medium for German companies to engage with and address the rapidly evolving textile industry in Pakistan for over six decades. Some of the earliest advertisers in our publication are still actively present, demonstrating their long-term commitment to the Pakistani market. The journal has witnessed the growth of Pakistan-Germany trade relations through thick and thin, and continues to serve as a platform for disseminating valuable information and promoting industry advancements.

In these challenging times for the Pakistani textile industry, German companies have an opportunity to demonstrate their support and solidarity with their customers. By providing guidance and support, German companies can assist the Pakistani textile industry in navigating new challenges and diversifying into new areas. With their expertise and technological advancements, German companies are well-positioned to guide Pakistan's textile industry towards sustainable growth and profitability.

As the Pakistan-Germany trade partnership in the textile industry continues to evolve, it is crucial for both countries to foster open lines of communication, encourage collaborations, and create a conducive business environment. Through mutual cooperation and shared knowledge, Pakistan and Germany can further strengthen their trade ties, driving innovation, productivity, and sustainable development in the textile sector.

The Pakistan Textile Journal remains committed to promoting the PakistanGermany trade relationship and serving as a reliable source of information for the textile industry. We look forward to the continued collaboration between Pakistani and German companies, driving progress and prosperity in the textile sector for years to come.

7 Established 1951 May 2023 German Review ITMA 2023 Preview

EDITOR’S PAGE

May 2023.

Schlafhorst (PTJ 1956).

Monforts (PTJ 1956). Truetzschler (PTJ 1964).

Karl Mayer (PTJ 1958).

Suessen (PTJ 1956).

1Pakistan Hosiery Manufacturers & Exporters Association (PHMA) asked the Federal Board of Revenue to speed up releasing value-added knitwear industry’s sales tax refunds to help ease up its cash flow, especially for wages to its workers. 2

The exporters are complaining about the inordinate delays in the payment of sales tax refund claims, as the government has stopped releasing all the sales tax refund claims. Thus exporters’ precious liquidity worth billions is compromised, stated Naseer Butt Chairman PHMA North Zone.

3

Mr. Sohail Nisar, Senior Vice Chairman, of Pakistan Yarn Merchants Association (PYMA) earlier this month rejected the recent hike in electricity and gas tariff, and protested against this antibusiness and anti-industry initiative. 4

The Senior Vice Chairman raised concern that in such circumstances, an increase of more than 400 percent in electricity and gas tariff would increase the cost of doing business to an unbearable extent, having disastrous effects on the industries and domestic exports.

Textile Briefs International

1

Bangladesh is the second largest readymade garments exporter in the world but the country’s own fashion industry is suffering due to lack of government support among other factors. Maheen Khan founder-president of the Fashion Design Council of Bangladesh while sharing her concerns said, “Lack of proper planning, work environment, investment, and policy support is the main hurdle for local fashion producers.”

from child labor in China. Mei Feng, chairman of the National Advanced Functional Fiber Innovation Center said his organization will collaborate with all parties to develop China’s recycled fibre industry. He was confident that the platform will function well and promote the high-quality development of the textile industry.

3

China has launched a new digital platform to help identify and trace textile products throughout the supply chain. Possibly to address the concerns of Western buyers on the use of cotton produced allegedly

2

The Hong Kong Research Institute of Textiles and Apparel Limited (HKRITA) and The International Iberian Nanotechnology Laboratory (INL) signed a Memorandum of Understanding with the intention of exchanging knowledge about wearable technology and fostering developmental research.

The 4th International Textile Exhibition, also called TEXPO 2023 attracts textile industries all over the world with many industries leaders already committed to visit TEXPO during May. Among which China who is one of the industry leader worldwide has shown a keen interest in the TEXPO as more than 100 Chinese companies has shown interest and made commitment to visit it next month. 6

5

price for cotton is to be fixed at Rs 8,500 per 40kg to give relief to farmers, so that they can begin to cultivate more and more cotton as soon as possible. 7

Mr. Iftikhar Ali Sahu, Secretary of Agriculture, Punjab, at a recent high-level meeting announced that the support

Hugo Boss has signed the Pakistan Accord, underscoring its commitment to the protection of health and safety of garment workers. “At Hugo Boss, we are committed to respecting human rights and safe working standards along our entire value chain and apply this throughout our organization,” said Yves Müller, CFO and COO of Hugo Boss.

4Continuous poor demand for cotton yarn in the local Weaving Industry and global market has started having negative effects on cotton prices throughout India. Many Weaving plants within the country are halting production for 2 -3 days every week because the poor demand has put pressure on the entire value chain and the entire market is facing a payment crisis.

Wash Lab was successfully launched on 20th April 2023 after facing a delay since 2020 because of the global pandemic and other related factors.

6

The University of London and Denim leader Lane Ateliers have launched what they are claiming to be the country’s first state-of-the-art sustainable Research and development washing facility. The sustainable R&D Denim

With the global decline of demand for textiles, the US has also seen a decline in the imports of its textile and apparel industry with Apparel imports declining by 19.7%, while nonapparel imports decreased by 20.7% in the first three months of 2023.

5

7

Vietnam’s exports to the Association of Southeast Asian Nations (ASEAN) hit $10.85 billion in the first four months this year, accounting for 10 per cent of the country’s total.

8 PAKISTAN TEXTILE JOURNAL - May 2023

Textile Briefs National

Pakistan's exports continue to decline, raising concerns of layoffs in the export sector

Pakistan's merchandise exports have experienced a seventh consecutive monthly contraction, with a year-on-year dip of 14.76% to $2.36 billion in March. This decline, coupled with a 9.87% decrease in exports during the first nine months (July to March) of the fiscal year 2022-23, paints a concerning picture for the export sector, fueling fears of potential massive layoffs.

The decline in export proceeds can be attributed to both internal and external factors, leading to apprehensions about the closure of industrial units, particularly in textiles and clothing. Furthermore, imports have also seen a significant drop, falling by 40.25% to $3.82 billion in March and 25.34% to $43.94 billion during the first nine months of the fiscal year.

The trade deficit, however, showed a deceleration of 35.5% between July and March of FY23, amounting to $22.9 billion compared to $35.50 billion during the corresponding period last year. In March, the trade deficit witnessed a substantial decline of 59.75% year-onyear, totaling $1.46 billion.

The downward trend in exports, particularly in textiles and clothing, raises concerns about achieving the export target for the current fiscal year. According to industry leaders, the federal

government's lack of strategy and failure to address crucial issues such as working capital shortages and delayed refunds, including sales tax and technology upgradation funds, have contributed to the export decline. The promised faster refund system has also suffered from significant delays, taking several months to process instead of the initially advertised 72 hours.

High financial and energy costs have further added to the challenges faced by the textile industry. Exporters emphasize the need for dialogue with the government to identify and address priorities, as neglecting the sector will hamper its competitiveness and hinder export recovery.

Exporters also cite hurdles in opening letters of credit and political and economic uncertainties as factors deterring buyers from placing orders. They urge the government to provide clear statements to assure foreign buyers that orders will be delivered on time, as building foreign exchange reserves depends heavily on increasing exports.

Exporters predict a 17% decline in exports for April, pointing to the discontinuation of subsidies on electricity and gas for the export sector as a reason for reduced competitiveness in global markets. Additionally, exchange rate instability has been identified as a significant factor contributing to falling exports.

In summary, Pakistan's export sector faces significant challenges, including declining export figures, delayed refunds, rising costs, and exchange rate instability. Urgent attention and effective measures are needed to address these issues and revive the industry to meet export targets and safeguard employment opportunities.

PHMA requests the Federal Board of Revenue for speedy release of value-added knitwear industry’s sales tax refunds

Pakistan Hosiery Manufacturers & Exporters Association (PHMA) has urgently requested the Federal Board of Revenue (FBR) to expedite the release of sales tax refunds for the value-added knitwear industry. The association emphasizes that the timely release of these refunds is crucial for easing the industry's cash flow and ensuring the payment of workers' wages.

Mr. Naseer Butt, Chairman of PHMA North Zone, has raised alarm over the dire financial situation faced by the export-oriented industry. The delay in the release of sales tax refunds has resulted in significant liquidity losses amounting to billions of rupees. Exporters have expressed their discontent with the prolonged processing times and inconvenience caused by the FBR's halt on releasing the refunds.

PAKISTAN TEXTILE JOURNAL - May 2023 10 News & Views

Despite repeated appeals for assistance, the government's failure to address these issues has exacerbated the challenges faced by the textile industry. The industry has already experienced a sharp decline in exports and foreign exchange earnings, leading to reduced production.

Mr. Butt warns that the government's inaction has pushed the textile industry to the brink of collapse.

Previously, the FBR introduced the FASTER system, which aimed to process refund claims electronically and without delays. The knitwear industry initially welcomed this system, but recent changes, including the involvement of FBR officials in the process, have raised concerns about potential corruption and compromised efficiency.

Mr. Butt urges the FBR Chairman to rectify the technical glitches and flaws in the FASTER system, which have caused substantial delays in the processing of sales tax refunds. The current situation has resulted in significant losses and hindered timely exports, rendering the textile export industry financially unsustainable.

The PHMA Chief highlights various flaws and discrepancies in the refund procedure, exacerbating the grievances of textile exporters. Unfortunately, the FBR has not responded adequately to the demands presented by PHMA. Mr. Butt expresses his disappointment with the government's disregard for the export sector, particularly the value-added textile industry.

He laments the lack of attention from the Prime Minister, emphasizing that textile exports have plummeted by approximately 28% in February 2023. Moreover, during the first eight months of the fiscal year 2023, there has been an overall decline of around 11%, primarily attributed to reduced exports of value-added textile products such as ready-made garments and knitwear. Specifically, there has been a decrease of 16% in knitwear exports, 10% in towel exports, and 9% in bed-wear exports.

The situation calls for urgent intervention and support from the government to revive the struggling textile industry and prevent its imminent collapse.

PYMA rejects government’s recent increase of tariffs

"This significant increase in electricity and gas tariffs is an alarming and detrimental move against businesses and industries," expressed Sohail Nisar, Senior Vice Chairman of the Pakistan Yarn Merchants Association (PYMA). He firmly rejected the recent tariff hike and vehemently protested against what he referred to as an anti-business and antiindustry initiative.

Mr. Nisar highlighted the existing challenges faced by importers of raw materials, particularly the difficulties arising from the increasing dollar rate. Importers have encountered

Sohail Nisar, Senior Vice Chairman of PYMA.

significant losses due to the unavailability of dollars, resulting in the containers of imported raw materials being stuck at ports and incurring heavy demurrage and detention charges.

Given the industry's already severe liquidity crunch and the recent factors affecting exports, the government's decision to increase tariffs by more than 400% could prove to be a fatal blow to an industry that is already suffering greatly.

The Senior Vice Chairman expressed concern that in such circumstances, the exorbitant increase in electricity and gas tariffs would make the cost of doing business unbearable. This would have disastrous effects on industries and domestic exports. Mr. Nisar appealed to Prime Minister Shehbaz Sharif and Federal Minister of Energy Power Division Khurram Dastgir Khan to address the economic crisis by reducing the cost of doing business. Failure to take action would make it exceedingly difficult to conduct business and operate industries, ultimately leading to a negative impact on the country's exports and causing unemployment for millions of workers.

Pakistan faces steep decline in cotton production, imports expected to rise

Pakistan's cotton production has declined by 34% this year, reaching the lowest level in four decades, according to data from the Pakistan Cotton Ginners Association (PCGA). The country produced 4,912,069 bales compared to 7,441,833 bales in the previous season. This significant drop poses challenges for the textile industry, which will need to import approximately 10 million bales to meet its annual demand of 15 million bales.

Import financing issues have further hindered the textile mills, resulting in the lowest mill consumption in over 20 years, at 8.8 million bales. To bridge the gap, mills have signed import agreements for 5.5 million bales and purchased 4,605,449 bales locally. Last year, mills had procured 7,332,000 bales from the domestic market. Additionally, ginners currently hold 301,720 bales in their inventory, significantly higher than the previous year's stock of 93,833 bales.

The decline in cotton arrival is attributed to the devastating impact of flash floods and heavy rains during the last monsoon season, particularly affecting agricultural land in Sindh and Balochistan provinces.

Despite strong international demand, Pakistan's cotton exports have decreased by over 69% this year, with only 4,900 bales of white lint exported compared to 11,000 bales in the previous year. The main destinations for Pakistan's raw cotton exports include the Philippines, Italy, Bangladesh, Greece, and France.

Analyzing the data province-wise, Punjab has witnessed a year-on-year decline of over 32% in cotton output, producing 3,033,050 bales this season compared to 3,928,690 bales in the previous season. Sindh reported a substantial year-on-year loss of over 46%, with lint production totaling 1,879,019 bales this year compared to 3,513,143 bales last year.

Pakistan's cotton production has experienced a downward trend over the years, with the country's per-acre yield contracting to half of the productivity seen in other regional countries. In an effort to reverse this trend, the Economic Coordination Committee (ECC) expressed concern and approved an intervention price of Rs8,500 per 40kg as proposed by the Ministry of National Food Security and Research.

The intervention aims to attract growers towards cotton cultivation. The ECC also formed a cotton price review committee responsible for assessing

market prices and proposing interventions on a fortnightly basis.

Punjab to take aggressive measures in hopes of boosting cotton production

The Secretary of Agriculture, Punjab, Mr. Iftikhar Ali Sahu, announced that the support price for cotton will be set at Rs 8,500 per 40kg in order to support farmers and encourage increased cotton cultivation. The decision was made during a high-level meeting attended by various agricultural officials and experts.

During the meeting, Dr. Anjum Ali, Director General Agriculture (Ext & AR), led discussions on the reasons behind the significant decline in cotton production in the province. A strategy was devised to address this issue by promoting cotton cultivation and offering incentives to farmers interested in growing cotton.

Mr. Iftikhar Ali Sahu emphasized the need for effective research and development to develop climate-smart cotton varieties that can withstand the challenges posed by climate change and insect infestations. He also highlighted the importance of utilizing print, electronic, and digital media to raise awareness among farmers about modern cotton production techniques.

To further support cotton farmers, the Punjab government is providing a subsidy of Rs 1,200 per bag on certified seeds of approved cotton varieties. Additionally, biocards will be distributed to farmers through the established bio lab in Punjab to assist in controlling harmful insects.

News & Views 12 PAKISTAN TEXTILE JOURNAL - May 2023

Hugo Boss signs Pakistan Accord on safety in textile industry

Hugo Boss has signed the Pakistan Accord, underscoring its commitment to the protection of health and safety of garment workers.

As a binding agreement of company and trade union signatories, the Pakistan Accord is an extension of Bangladesh’s 2021 International Accord for Health and Safety in the Textile and Garment Industry. The International Accord is based on the Bangladesh Accord on Fire and Building Safety, established in 2013, resulting from the dramatic tragedy of the Rana Plaza building collapse.

“At Hugo Boss, we are committed to respecting human rights and safe working standards along our entire value chain and apply this throughout our organisation,” said Yves Müller, CFO and COO of Hugo Boss. ”We take the fair and ethical treatment of our employees, suppliers, and partners worldwide very seriously and look forward to supporting the improvement of labour conditions in Pakistan through implementing the Pakistan Accord.”

In the past, Hugo Boss signed the International Accord together with about 190 other garment brands and unions and now additionally committed to the Pakistan Accord, the company said in a press release.

The Pakistan Accord includes all key International Accord features, and promotes workplace and building safety for an initial period of three years through independent inspections,

remediation, an independent complaints mechanism and training programmes for employees.

Together with its fellow signatories, Hugo Boss will provide funds to support the successful implementation of the Pakistan Accord and help uphold and improve occupational health and safety measures in Pakistan’s garment and textile sector.

News & Views

BANGLADESH

Bangladesh’s local Industry suffers due to lack of attention from Government

Bangladesh is the second largest readymade garments exporter in the world but the country’s own fashion industry is suffering due to lack of government support among other factors.

The local fashion industry is not growing also due to the lack of proper planning, absence of research and development, low design quality, lack of government policy support and absence of quality teachers and curriculums in the country’s fashion design schools.

Maheen Khan founder-president of Fashion Design Council of Bangladesh while sharing her concerns said, “Lack of

proper planning, work environment, investment, and policy support are the main hurdle for local fashion producers.”

Many shopping malls and markets in the country are selling clothing items imported from all over the world, with a large number of smuggled products coming through land ports evading taxes.

SK Saifur Rahman, General Secretary of National Crafts Council of Bangladesh added to this matter and stated, “Bangladesh produces the world’s finest denim and other clothing items. But local fashion houses import fabrics from China and India. Most players in our local fashion industry hanker after making money. Some claim that they make 100 per cent local items, but it is false and they deceive the buyers.”

‘We are now treated like losers. But once, our saris were exported to Indiawe had such a rich tradition and glory.’

Mohammad Kashem, Banarasi Palli

Shop Owners Association secretary said, ‘We are not in a position to save our rich tradition of banarasi saris due to lack of government patronage, including a place for weavers and necessary assistances. We are not happy to sell Indian products, while once, even in the 90’s, we used to export our saris to India. Weavers and handloom industries are on the decline.’

He disclosed that many weavers had, meanwhile, switched to other professions for survival.

‘The Indian government provides subsidy to weavers in the form of subsidised electricity for power looms, but in Bangladesh they fall in the category of commercial use paying high tariff for electricity,’ he despaired.

There is no alternative to government support for reviving the glory of the country’s high quality banarasi saris, he went on to say.

CHINA

China to digitalize their entire supply chain

China has launched a new digital platform to help identify and trace textile products throughout the supply chain. Possibly to address the concerns of Western buyers on the use of cotton produced allegedly from child labor in China.

Around the World 14 PAKISTAN TEXTILE JOURNAL - May 2023

The online platform will be managed by the China Chemical Fibre Association and National Advanced Functional Fibre Innovation Centre. It will operate under guidance from the Department of Consumer Goods Industry of Ministry of Industry and Information Technology and Suzhou Market Supervision Administration.

Mei Feng, chairman of the National Advanced Functional Fiber Innovation Center said his organization will collaborate with all parties to develop China’s recycled fibre industry. He was confident that the platform will function well and promote the high-quality development of the textile industry.

Adding to this He Yaqiong, director of the Department of Consumer Goods Industry said, “building a certification platform traces the entire life cycle of green fibre products that are conducive to promoting the low-carbon, environmentally friendly and circular development of the industry. He further said that the Ministry would take steps to quickly promote the popularity and recognition of the platform in the industry.”

HONG KONG: HKRITA Signs MoU with INL for a Research on sustainable Future using bio-tech

The Hong Kong Research Institute of Textiles and Apparel Limited (HKRITA) and The International Iberian Nanotechnology Laboratory (INL) signed a Memorandum of Understanding with the intention of exchanging knowledge around wearable technology and fostering developmental research.

The MoU was signed at HKRITA’s Hong Kong seminar, entitled “Smart Manufacturing: A Revolutionary Transformation of the Fashion Industry,” by Paulo Freitas, deputy director-general of INL, and Edwin Keh, chief executive officer of HKRITA.

“Sensor and IoT technologies are already leading to wearable devices that allow monitoring of a variety of biosignals and body related data. INL will work with HKRITA to further exploit new wearable concepts, fabrication, and integration routes aiming at increasing wearable solutions and their wide spread utilization,” Freitas penned at the signing.

The ultimate goal of the partnership is to develop new devices and methods of testing to enhance the performance of wearable tech, which is increasingly becoming an integral part of the lives of many consumers, both socially and occupationally.

HKRITA’s Keh added that “sensor and wearable technologies will make a great impact on our social development, allowing us to explore more possibilities. Our collaboration will generate useful and productive innovations for industry and society.”

The organization has been leading the charge with sustainable textile innovations in Hong Kong, and last year they developed a solution to break up post-consumer cotton-and-polyesterblended fabrics into their constituent fibers which was considered an impossible thing to achieve back then, but HKRITA scientists developed a process that uses only heat, water and less than 5 percent of biodegradable green chemicals to degrade the cotton fibers into cellulose powder and separate them from their polyester counterparts.

INDIA

Textile production halts as demands continues to weaken for Cotton Yarn

The continuous poor demand for cotton yarn in the local weaving industry and the global market is having negative

effects on cotton prices across the country. Export demands are declining every day, and the local weaving market is showing little interest in purchasing new stock. Existing stock is not being utilized as before due to the weak global market demand. As a result, major markets in the country, such as the Delhi market and the Ludhiana cotton market, have witnessed a significant price drop of 70 cents USD per kilogram of cotton. With the ongoing weak demand from the weaving industry, many experts believe that the situation is deteriorating.

Numerous weaving plants within the country have been forced to halt production for 2-3 days every week due to the poor demand, which has put pressure on the entire value chain and led to a payment crisis in the market.

Traders in Delhi expressed their concerns, stating that there is no indication of improvement in demand from the weaving industry. The weak demand has created pressure throughout the value chain and has caused a payment crisis, limiting the purchasing capacity of buyers.

Trade sources believe that the weaker sentiment in Indian cotton prices is a result of the global cotton downturn and reduced demand from spinners. The arrival of cotton was observed at 5,000 bales (170 kg each). In Punjab, cotton is being offered at $74 USD per maund, in Haryana at $72 USD per maund, and in upper Rajasthan at $76 USD per maund. In lower Rajasthan, it is sold for $71 USD per candy (356 kg).

Around the World 16 PAKISTAN TEXTILE JOURNAL - May 2023

UNITED KINGDOM

State-of-the-art sustainable R&D washing facility launched in partnership with the University of the Arts London

The University of London and Denim leader Lane Ateliers have launched what they are claiming to be the country’s first state-of-the-art sustainable Research and development washing facility.

The sustainable R&D Denim Wash Lab was successfully launched on 20th April 2023 after facing a delay since 2020 because of the global pandemic and other related factors.

The sustainable lab which is located at Blackhorse Lane Ateliers aims to bring an expertise that has been missing in the country while offering a space to develop unique UK denim aesthetic. The lab will be accessible to students, start-ups, and established brands to explore more sustainable denim wash methods.

The much needed project is backed by local councils including Waltham Forest, Haringey, and Enfield, as well as the London Mayor’s Office.

USA

US records decline in imports of textile and apparel by 19% in the first quarter of 2023

With the global decline of demand for textile US has also seen a decline in the imports of its textile and apparel industry with Apparel imports decline by 19.7%, while non-apparel imports decreased by 20.7% in the first three months of 2023.

According to the latest reports released by the US department of commerce, both segments experienced a decline, in the first quarter (January till March) of 2023, the US textile imports of apparel peaked at 19.472 billion USD, while non-apparel imports made up to 6.400 billion USD.

Apparel imports recorded a dip of 19.73% compared to the 24.259 billion USD traded in JanuaryMarch 2022, while non-apparel imports declined by 20.71% from 6.4 billion USD for the same duration following year.

It should also be taken into the account that among the top apparel suppliers to the US, the import from any country did not improve. The imports from China dipped by 34.89%, following Vietnam by 24.25%, Pakistan 26.9%, Honduras 15.84%, Bangladesh 13.34% and India 11%.

Novafiber starts up textile recycling and airlay lines from ANDRITZ at its mill in Palín, Guatemala

Novafiber, a prominent company in Guatemala specializing in the production of nonwovens from post-industrial textile waste, has successfully established a textile recycling line and an airlay line at its mill in Palín, Guatemala. These cutting-edge technologies, delivered, installed, and commissioned by international technology group ANDRITZ, have been in operation since December 2022, enabling Novafiber to achieve sustainable production at high throughputs.

The recycling line, the second tearing line supplied by ANDRITZ to Novafiber, is dedicated to processing post-industrial textile waste from Central America. By utilizing this line, Novafiber efficiently recycles fibers, which are then fed into the state-of-the-art Flexiloft airlay line provided by ANDRITZ. The airlay line is responsible for manufacturing nonwoven end-products utilized in the bedding and furniture industries. This integration of the tearing and airlay lines exemplifies a circular textile-to-nonwoven approach, ensuring optimal material usage. Notably, any waste generated during the production process is redirected back into the tearing and/or airlay line via an advanced edge trim recycling system.

The combination of ANDRITZ tearing and airlay lines empowers Novafiber to process substantial quantities of postindustrial garments while maintaining control over the entire supply chain, from raw material to final product. Moreover, this implementation allows for energy savings and a reduced carbon footprint by minimizing shipments.

The commissioning process, facilitated through close collaboration between Novafiber and ANDRITZ Laroche, was completed within a remarkably short timeframe. Jean Philippe Bernard, CEO of Novafiber, expresses his satisfaction with the project, stating, "It has been a great pleasure to collaborate with ANDRITZ again on a waste-to-value project. Seven years ago, we launched our first textile recycling and nonwovens production project together with ANDRITZ Laroche. Our new project has also been a perfect opportunity to take advantage of ANDRITZ's technological innovations to achieve an even better fiber opening quality along with higher capacity."

Novafiber, located in Palín, Guatemala, is renowned for its leadership in the production of nonwovens derived from post-industrial textile waste. The company caters to both the domestic market and export demands.

In summary, Novafiber's adoption of ANDRITZ's textile recycling and airlay lines in Palín, Guatemala, has paved the way for sustainable and efficient production processes. This collaboration not only enables the processing of significant textile waste but also demonstrates Novafiber's commitment to the circular economy and reducing environmental impact in the textile industry.

18 PAKISTAN TEXTILE JOURNAL - May 2023 Corporate News

Novafiber CEO and Head of Production together with ANDRITZ technicians and project manager in front of the newly installed 6-cylinder EXEL line.

Inside of a mattress made with Novafiber endproducts from ANDRITZ airlay line.

VDMA: Way 2 ITMA

100 days before ITMA 2023 in Milan, VDMA Textile Machinery launched its “Way2ITMA” webinar series. “Transforming the World of Textiles: efficient – digital – circular”. Under this heading, VDMA technology providers will present their solutions along the value chain.

Speakers of the virtual event were Dr. Janpeter Horn, Chairman of the VDMA Textile Machinery Association and Managing Director of August Herzog Maschinenfabrik, Dirk Vantyghem, Director General, EURATEX, Francis Elias Junker, Area Sales Manager, Andritz Laroche and Tanja Karila, Chief Marketing Officer, Infinited Fiber Company.

With regard to the EU strategy for sustainable and circular textiles, Dr. Horn said:

“This topic concerns all of us, consumers and producers. We as machinery builders position ourselves as enablers. We want to be part of the solution of this ambitious project”.

Dirk Vantyghem introduced the core issues of the EU textile strategy launched in 2022, which is the most ambitious plan ever, to push the textile sector towards sustainability and transparency, and promote a new circular business model. If wrongly designed, that new framework may collapse the European textile value chain. But if done rightly, the changes ahead could bring a paradigm shift in the sector, where competitiveness is no longer based on price only, but also on

sustainability and innovation, explained Vantyghem.

Francis Elias Junker showed high level of expertise for mechanical textile recycling for both spinning and nonwovens industries that Andritz has. The company has a diversity of solutions to offer and several cooperation partners, covering the value chain from recovery of fiber to the chemical modification and preparation for the production of yarn.

Tanja Karila gave an overview of how Infinited Fiber is turning textile waste into new fibers. Patented technology turns post-consumer textile waste into brand new premium quality fibers for the textile industry. The textile-to-textile recycling technology captures the value in waste that would otherwise be landfilled or burned.

Next topic: Energy management

In the run-up to ITMA, taking place in Milan in June, VDMA will continue the

“Way2ITMA” webtalk series. Topic of the next event will be “Intelligent production and energy management for textile dyeing and finishing processes” with presentations from Sedo Treepoint, Brückner and Thies.

The VDMA represents more than 3,500 German and European mechanical and plant engineering companies. The industry stands for innovation, export orientation and SMEs. The companies employ around 3 million people in the EU-27, more than 1.2 million of them in Germany alone. This makes mechanical and plant engineering the largest employer among the capital goods industries, both in the EU-27 and in Germany. In the European Union, it represents a turnover volume of an estimated 770 billion euros. Around 80 percent of the machinery sold in the EU comes from a manufacturing plant in the domestic market.

20 PAKISTAN TEXTILE JOURNAL - May 2023 Corporate News

New set-up of Mayer & Cie. representation in Bangladesh and Nepal

Sales and service of Mayer & Cie. circular knitting machines in Bangladesh have been under new management. A new dynamic team “Mayer Bangladesh” has been formed. Mayer & Cie.’s long standing Indian representative Batliboi has joined business activities in Bangladesh since the beginning of the month, supported by the team of Brady Services and by Almani Biz. The synergies created by the partnership with Batliboi, Brady Services, and Almani Biz. will allow Mayer & Cie. representations to combine their strengths and expertise to better serve customers.

New & well-known faces in Bangladesh

In Batliboi, Mayer & Cie. has set up a business partner of many decades standing as its representative in Bangladesh. For around 40 years Mumbai-based Batliboi has overseen sales and service of Mayer & Cie. circular knitting machines in India. Abhay Sidham heads Batliboi’s Textile and Machinery Group. He and his team have many years of experience in strategic marketing, and a focus on sustainability and processing recycled raw materials is part of Batliboi’s expertise.

These competences are of relevance in the Bangladesh market because “we

face strong competition from Asian manufacturers here,” Wolfgang Müller, Mayer & Cie.’s sales director, explains. The premium market was growing smaller, and the trend was toward specialities – value-added fabrics, spacer fabrics and athleisure with a high proportion of elastic. Mayer & Cie. sees in these requirements significant potential for its machines – and in Batliboi a partner able in view of its experience to put them to optimal use.

Best possible combination of new and tried and trusted

One building block in the set-up of Mayer & Cie. representatives is unchanged. Brady Services will continue with Batliboi to contribute its close ties with the local market. A significant number of existing companies will continue to be looked after by Brady Services.

The new member in Mayer Bangladesh team is Dhaka-based Almani Biz. A lubricants specialist for circular knitting machines Almani Biz has a wide network with Bangladesh knitting industry.

Mayer & Cie. feels well positioned by this new set-up. Wolfgang Müller says, “

We are of the opinion that the market for machinery in Bangladesh will continue to grow and we are confident that by strengthening our sales, service and marketing team we will be able to make good use of this opportunity.”

A market with great potential

Customers in Bangladesh have placed large orders in the past. The latest, placed in January, was for several dozen machines to be delivered this autumn. Further orders from Apex and BEXIMCO (Bangladesh Export Import Company) are also scheduled for delivery in the second half of 2023.

Nepal represented by Batliboi

While reorganising the set-up of its representatives in Bangladesh Batliboi has also taken over as Mayer & Cie.’s representative in Nepal, where the company had previously had no local representative. There is a demand for machines for interlock, 8-lock and single jersey, but sales are still in single figures. “Nepal has long been served from India, specifically by Batliboi,” Wolfgang Müller says. “So, we have now formalized the existing practice.”

21 Corporate News

Fairs and Exhibitions

Texworld Paris celebrates 25 years!

The anniversary edition of Texworld Evolution Paris will take place this summer from 3 to 5 July 2023 at the Porte de Versailles Exhibition Centre. For the first time, this event will be held downtown Paris. 1,300 exhibitors from some twenty countries have already confirmed their presence.

More services, easier access to the heart of Paris, the fashion capital, and finally a return to its pre-crisis level...The July edition of Texworld Evolution Paris will be in many ways a special gettogether for buyers and exhibitors.

1,300 exhibitors expected in Paris for 3 days

This summer the trade fair for the fashion industry will once again bring together all the Texworld Evolution Paris components (Texworld, Texworld Denim, Apparel Sourcing, Avantex and Leatherworld Paris). The exhibition is also set to be the largest event since the end of the Covid-19 health crisis, with more than 1,300 manufacturers expected in Hall 1 of the Porte de Versailles Exhibition Centre, representing a 40% increase in participation compared to last February. Chinese manufacturers are almost back to their pre-crisis level, with the number of exhibitors doubling at Apparel Sourcing Paris and increasing very strongly at Texworld Paris. Manufacturers from India, Turkey, Korea and Taiwan have confirmed their attendance. This anticipation is explained by the very good results of the winter session and the desire of exhibitors to maintain close contact with the market.

25 years: An extraordinary session

The celebration of the 25th anniversary of Texworld Paris will be an opportunity to offer visitors special events, entertainment, but also innovative services and networking. The T-Club area will strengthen its business-oriented services to exhibitors and visitors. This will also be an opportunity for Avantex Paris to reinvent itself and broaden its offer around a Hub dedicated to innovative solutions and companies: performance textiles, solutions for a more sustainable fashion and Web3 players will be present at Porte de Versailles.

Strategic meeting point for the fashion industry

This new configuration, both spatial and temporal, will make it possible to offer visitors two days in common with Curve and Interfilière Paris (organised by WSN Dévelopement) the meeting place for committed professionals from the lingerie, loungewear, swimwear and activewear community, which will be held from 2 to 4 July in Hall 5. The combination will offer an expanded fashion platform and will also lead to shared news and promotion.

Providing maximum convenience for visitors, Apparel Sourcing and Texworld Paris belong to the cluster of related trade fairs organised by Messe Frankfurt France

(alongside Avantex which takes place only once a year during July session), held in one and the same location, on the same dates and where entry is free upon presentation of professional credentials. Texpertise, the textile business network, stands for Messe Frankfurt's entire textile commitment. With a unique portfolio currently comprising around 50 international trade fairs in 11 countries, the company is the world market leader in trade fairs for the textile industry. Texpertise Network covers the entire value chain of the textile industry and, as a central communication platform, provides valuable information on the textile trade fair brands.

22 PAKISTAN TEXTILE JOURNAL - May 2023

Heimtextil 2024: Demand already exceeds exhibitor number of previous event

For upcoming Heimtextil 2024, over 2,500 exhibitors are already planning to take part in January next yearincluding top players such as A.S Création, Bedding House, Corn. van Dijk, Elastron, Graham & Brown, JBY Creation, Lameirinho, Libeco Lagae, Masureel International, Marburger Tapetenfabrik, Traumina and Wendre. The home and household textile segments Asian Excellence and Asian Selection are also experiencing high demand and are composed of a broad range of high-quality high-volume suppliers from Asia.

Strong registration figures provide tailwind for Heimtextil 2024: more than 2,500 exhibitors have already announced their participation in the world's leading trade fair for home and contract textiles from January 9 to 12, 2024.

"The demand already exceeds the number of exhibitors at the previous event. We are very pleased with the positive response across all product segments – both globally and nationally. In 2024, we will be expanding our range further, especially for the contract business as well as fibers and yarns for home and household textiles," says Olaf Schmidt, Vice President Textiles & Textile Technologies at Messe Frankfurt.

Cross-segment: Strong national and global demand

Heimtextil 2024 is proving very popular with wallpaper suppliers. Here, renowned brands such as A.S. Création (Germany), Graham & Brown (UK), Kinland Decor (Hong Kong), Marburger Tapetenfabrik (Germany) and Masureel International (Belgium) have announced their return.

"At Heimtextil, we start the new year with momentum with our customers from Germany and abroad who are looking for high-quality and innovative wallpapers, 100% made in Germany. We are positioned worldwide. Nevertheless, every year Heimtextil offers new opportunities and possibilities to get in touch with new customers in an uncomplicated way and to meet existing customers again. We regard having the leading trade fair in our own country as an invaluable competitive advantage," says Wolf Kappen, Managing Director Marketing / Sales at Marburger Tapetenfabrik.

In halls 4.1 and 4.2, exhibitors such as Elastron (Portugal), Libeco Lagae (Belgium), Martinelli Ginetto (Italy) and Vanelli Tekstil (Turkey) have announced to show their latest decorative and upholstery fabrics.

24 PAKISTAN TEXTILE JOURNAL - May 2023 Fairs and Exhibitions

In hall level 3.1 (Window & Interior Decoration), curtain exhibitors such as JBY Creation (France) as well as German suppliers such as Albani, Eustergerling and Neutex Home Deco are signaling their interest in participating.

In the Smart Bedding product area in hall 11.0, almost all market leaders are expected to present their latest collections of bedding, mattresses and sleep systems at Heimtextil, the biggest trend platform for textile materials and textile design. Among the announced participants are German suppliers such as Badenia Bettcomfort and Traumina, as well as European manufacturers such as Wendre AS (Finland). A wide range of the latest bedding designs can be expected in hall 12, with suppliers such as Bedding House (Netherlands), Corn. van Dijk (Netherlands), Estamparia Textil Adalberto Pinto (Portugal), Klaus Herding (Germany), Lameirinho (Portugal), Nile Linen Group (Egypt) and Wülfing (Germany) planning to participate here. With the latest range of terry products, Fabrica de Tecidos do Carvalho (Portugal), Mundotextil Industrias Texteis (Portugal), Veritas Tekstil (Turkey) and Welspun (UK), among others, announce their participation.

Contract range in hall 4.0: all exhibitors from the last edition are registered Exhibitors for the contract sector successfully presented themselves in hall 4.0 at the last Heimtextil. Thus, the range of outdoor fabrics, artificial leather and functional textiles for the contract

sector will be further expanded at Heimtextil 2024 and will be more international in scope. In addition, all contract exhibitors from the previous event have already announced their participation at Heimtextil 2024including German leather supplier mah-ATN:

"We are looking forward to presenting many innovative products at Heimtextil 2024. Especially in the field of artificial leather, leather, fabrics as well as cork, we show sustainable and environmentally friendly articles. At Heimtextil, we reach our target group and can present our range directly and personally to a knowledgeable audience. Our presence at the fair allows us to expand our network and strengthen existing customer relationships. We are convinced that this will enable us to further improve our market opportunities," explains Angelika Delalle, Head of Marketing at mah-ATN.

Fully booked: qualitative high-volume suppliers and high-end halls from Asia

The six hall levels "Asian Excellence" and "Asian Selection" are already fully booked - both in the house textile (10.010.3) and home textile (6.0, 5.0, 6.1) areas.

Trade buyers of large volumes will find a unique Asian range of industrial to hand-crafted goods in these hall levels. Here, volume-oriented external and wholesale traders as well as representatives of department stores meet manufacturers who enable orders in medium and high volumes to be placed on schedule. The Asian Excellence range in hall levels 6.1 and 10.2 is composed of high-quality producers with export experience, selected by an independent panel of experts. Among others, D Decor, G. M.Fabrics, G. M Syntex, Grasim Jana Seva Trust from India and Karupannya Rangpur from Bangladesh will be represented in hall 6.1.

“Heimtextil offers us an excellent opportunity to showcase hand-woven and centuries-old techniques from the important weaving mills in Varanasi, Bhuj, Pochampally and Kashmir - in a new guise, with global flair. With the handloom as the backbone of our collection and with a social enterprise model as our main objective, we are creating a new range of rugs, cushions, throws and bed covers for buyers seeking variety and exclusivity,” says Manish Saksena, Lead Advisor at Aadyam Handwoven / Grasim Jana Seva Trust.

In the home textiles section (hall 10.2), selected suppliers such as Al-Karam Textile Mills (Pakistan), Gul Ahmed Textile Mills (Pakistan) and Trident Limited from India will be presenting their high-quality products.

Fairs and Exhibitions 25

Angelika Delalle, Head of Marketing at mah-ATN.

The edie23 event highlights the importance of data and transparency in sustainability

The U.S. Cotton Trust Protocol recently attended and actively participated in edie23, an event held in London by the purposedriven business media brand edie. Formerly known as the Sustainability Leaders Forum, the event, now in its 13th year, focuses on driving tangible environmental and social change through business leadership. Over the course of two days, attendees had the opportunity to listen to experts and sustainability professionals discuss the challenges we face and innovative solutions that can help companies become more responsible and transparent.

This year's theme, "Leadership Through Crisis," centered around the transition to net-zero and sustainability strategy. The event featured multiple tracks and sessions aimed at educating and inspiring participants by providing insights and opportunities to learn from others' experiences.

One noteworthy session explored the importance of transparent communications and the need for companies to be honest with their customers. In an era of greenwashing, consumers are more likely to trust a brand that not only celebrates its successes but also openly acknowledges the work that still needs to be done and the challenges ahead. The Director of

Consumer Protection from the Competition and Markets Authority in the UK emphasized the necessity for increased confidence in tackling greenwashing and greenhushing publicly.

As a program dedicated to contributing to the protection and preservation of the planet through sustainable and responsible techniques, the Trust Protocol was proud to present a case study during the conference. Tara Luckman, Special Advisor to the U.S. Cotton Trust Protocol, delivered a presentation titled "Measuring and improving the environmental footprint of cotton in the U.S." Tara emphasized the significance of environmental data in avoiding greenwashing and stressed the need for metrics and transparency in the fashion industry's supply chain.

During her presentation, Tara highlighted two key issues within the fashion industry. Firstly, the lack of verified data hinders the ability to make informed decisions regarding where efforts and resources should be invested to align with global goals on climate change and sustainable development. Secondly, the lack of transparency in the

supply chain prevents brands from guaranteeing factual information about their products if they do not have knowledge of their origin and route.

Throughout the conference, participants engaged in detailed discussions and sought input from peers and colleagues to address tough questions about sustainability.

The event underscored the importance of industry collaboration as we strive to continually improve our environmental footprint, and the Trust Protocol takes pride in being a part of this collective effort.

26 PAKISTAN TEXTILE JOURNAL - May 2023

Earth Protex Corp partners with iTextiles®

Earth Protex and iTextiles® join in partnership to bring new generation recycled polyester technology to Pakistan.

Earth Protex and iTextiles® announced today that the companies have entered into a strategic partnership that will focus on the distribution of ground breaking textile-to-textile recycled polyester fiber, Tex2Tex™ to major Pakistan manufacturers and brands.

Tex2Tex™ is an important solution as the textile industry needs to move away from single-use plastics such as PET bottles in the circular economy. PET bottles recycled into textile products are generally considered ‘downcycled’. Tex2Tex™ is also a solution in response to

the forthcoming bottle shortage of 10 million metric tons/year by 2025 as the beverage and fashion industry start competing for this limited feedstock.

Tex2Tex™ is a textile-to-textile recycling technology for synthetic textile waste. Through their low impact thermomechanical reactor (TMR) process, Tex2Tex™ converts textile waste into recycled polyester staple fiber and filament. The Tex2Tex™ LCA demonstrates that the process uses less energy and water, and has less carbon emissions compared to virgin polyester,

as well as mechanically and chemically recycled RPET from bottles.

The agreement brings together the innovative technologies of Earth Protex and the strong distribution network and credibility of iTextiles®, and enable the integration of Tex2Tex™ fibers into many top global brands supply chains in the region. The partnership will focus on circular knits, warp knits, denim and socks, however Tex2Tex™ is also suitable for home textiles, suiting, flannels, shirting, and countless other applications.

iTextiles® is a multi-disciplinary textile solutions company that creates and manages, entire value chains in performance textiles. The company has rapidly evolved to become a leading value chain manager in the region, representing some of the biggest international companies and their brands. iTextiles® has aways been known for introducing Innovative textile solutions and is looking forward to work in alliance with Earth Protex to bring more sustainable products to Pakistan.

For Sourcing:

www.itextiles.com.pk

info@itextiles.com.pk +9221-35147784-92.

Features 28 PAKISTAN TEXTILE JOURNAL - May 2023

Irreproachable Quality with XENO-AC

Bishnu Texport Pvt. Ltd. is one of the pioneers in Spandex yarns and manufactures extra fine deniers of air covered yarns. Founded in 2003, the company rapidly grew and expanded its portfolio to include conventional single covered yarns and double covered yarns. Renowned for its high quality, Bishnu is dedicated to customer success and constantly expands its portfolio to serve its customer needs.

The Challenge

Bishnu Texport Pvt. Ltd. is one of the pioneers in Spandex yarns and manufactures extra fine deniers of air covered yarns. Founded in 2003, the company rapidly grew and expanded its portfolio to include conventional single covered yarns and double covered yarns. Renowned for its high quality, Bishnu is dedicated to customer success and constantly expands its portfolio to serve its customer needs.

To better answer customer needs in a timely manner, Bishnu Texport Pvt. Ltd.

decided to produce its own air covered yarns. Switching from a trading company to a manufacturing one does not come without challenges. While it improves delivery time and reduces import costs, achieving the same, or even better, quality is ambitious.

In search for the best air covering machines on the market, Bishnu turned to SSM. While cheaper alternatives were available, the company trusted that the original investment for SSM air covered machines would result in a better return on investment and better fit their motto “No compromise on quality”

The Solution

In 2012, Bishnu acquired 15 spindles of SSM DP3-C machine for its factory located in the northern part of India, near Delhi, where temperature can vary from 3 to 45 degrees Celsius – a real challenge when producing super fine yarns of 10/10 den, polyamide and elastane. With the right airconditioning system and the support of SSM experts, Bishnu successfully set up the

machines and reached a smooth and reliable production.

In 2020, the company owned 90 spindles of SSM air covering machines XENO-AC and its brand has been recognized as high-quality air covered yarns.

The Customer’s Benefits

The main advantage with XENO-AC machines is the quality of the final product. From the yarn quality to the runnability on other machines and the package appearance, everything is optimized. Bishnu and its customers have been enjoying consistent high quality for 10 years and the company’s customer base is growing.

Bishnu is currently exporting its air covered yarns to Japan and Sri Lanka and is expecting long-term business in Japan. Consequently, the company plans to expand its existing capacity of spindles of SSM air covering to 200 spindles by the end of year 2025.

30 PAKISTAN TEXTILE JOURNAL - May 2023

Success story Bishnu Texport Pvt. Ltd.

Mr. Mani Kant, Managing Director of Bishnu Texport Pvt. Ltd.

The air covering machine XENO-AC has no equal when it comes to quality.

Atlas Copco's tips on how to size pneumatic conveying systems

Discover new 5-18kW VSDs air compressors; find out how compressor room could benefit from an inspection plan

Top Tip: Pneumatic conveying systemsRight-sized, every time

Choosing the most suitable systems and components for pneumatic conveying can have a significant impact on operational performance. We can help determine the right solution for the pneumatic conveying process – whatever the application.

Our GA VSDs screw compressor range now comes in 5-18 kW sizes

The most energy-efficient, sustainable, and smart compressor range on the market is getting bigger by going smaller. Atlas Copco’s nextgeneration VSD technology is now available in compressors as small as 5kW, offering smart operation and energy savings of 60% even to smaller air users.

Get a thorough check-up of your compressor room with Inspection Plan

An inspection plan complements your own technical people. A trained Atlas Copco engineer can analyse your

compressed air system and spot problems early. You receive a comprehensive report with recommended actions to keep your equipment running in the most optimal way.

Do you have the right aeration blower for your site?

Air blowers use up to 70% of the energy consumption in a wastewater treatment plant - a good reason to check for any hidden costs and ways to increase efficiency.

We can advise on air blower solutions which offer clean air technology with high energy efficiency and a low total cost of ownership, for both industrial and municipal sites.

Get superior performance and reliability with the NGP+ nitrogen generators

Atlas Copco has announced the addition of the NGP 130+ model to its PSA nitrogen generator line-up. We have also introduced next-generation control and automation technology to all of our smaller (8-130) NGP+ units.

Practical Hints 32

TEXTILE JOURNAL - May 2023

PAKISTAN

Archroma puts sustainability in the spotlight at Bangladesh Denim Expo 2023

Archroma, a global leader in specialty chemicals towards sustainable solutions, is set to showcase its range of ecoconscious denimwear solutions at the upcoming Bangladesh Denim Expo. Brands and textile mills visiting the international fair in Dhaka from May 16 to 17 will be able to explore the company’s full suite of denim solutions, including an innovative new black coloration system.

Demand for denimwear continues to grow globally, but traditional denim production is at odds with modern consumers’ expectations for sustainability. Brands that aim to compete in this growth market need to be able to produce denimwear that not only delivers sought-after functional capabilities and desirable aesthetics, but that also comes with low environmental impact.

“Sustainability is a top priority for many brands, and consumers are increasingly conscious of the environmental impact of their choices,” said Umberto De Vita, Denim Segment Director, Textile Effects Division, Archroma. “Archroma is challenging the status quo to help denim manufacturers upgrade to more environmentally sustainable solutions while enhancing their competitiveness at the same time. Our innovations make it possible to benefit from efficiency gains and resource

savings in the factory as you deliver products that stand out in the market. Because it’s our nature.”

Sustainable denim solutions

Archroma is showcasing a comprehensive range of sustainable system solutions at the Expo. Among the highlights are DEEP SOUL, a system for overdyeing denim and woven fabrics with low water and energy consumption without compromising the look; PURE INDIGO ICON, an aniline-free* indigo system that produces authentic denim without harming the environment; and INDIGO REFLECTION, a coloration system that behaves like indigo but with a more sustainable and efficient process.

Innovation in black coloration

The company is also introducing its latest addition to the denim systems solution, EVOLUTION BLACK, a groundbreaking black coloration system that

delivers authentic black denim effects with huge resource savings.

The 14th Bangladesh Denim Expo will take place from May 16 to 17, 2023 at the International Convention Center (ICCB) in Dhaka. You are invited to visit the team in person at Hall 4, Booth 57. * Below limits of detection according to industry standard test methods.

34 PAKISTAN TEXTILE JOURNAL - May 2023

Pakistan-Germany Trade: A Fruitful and Growing Partnership

Introduction

Pakistan and Germany have enjoyed a strong and friendly relationship since establishing diplomatic ties in 1951. Their relations are built on shared values of democracy, human rights, cultural diversity, and economic liberalism. Over the years, both countries have fostered close cooperation in various sectors, including trade and development. In this report, we will explore the dynamics of Pakistan-Germany trade, highlighting the historical background, current trade volumes, key sectors, and the role of organizations like GIZ in promoting bilateral development initiatives.

by Nadeem Mazhar, Managing Editor, Pakistan Textile Journal.

Historical background and diplomatic relations

Pakistan-Germany relations have consistently grown since their establishment. In 1959, the two nations signed the world's first bilateral investment treaty, signaling their commitment to fostering economic cooperation. West Germany, now the Federal Republic of Germany, became a member of the consortium providing development assistance to Pakistan in 1961. And later in 1962, the PakistanGerman Forum was established to facilitate dialogue and exchange between the two countries.

Today, Germany maintains a strong diplomatic presence in Pakistan with an embassy in Islamabad and consulates in Karachi, Lahore, Peshawar and Quetta. German investments and business presence in Pakistan

Germany is the eighth-largest investor in Pakistan, with several German multinationals operating in the country. Approximately 35 German companies have a presence in Pakistan, primarily in Karachi and Lahore.

36 PAKISTAN TEXTILE JOURNAL - May 2023 German Review

Table 1: Pak - German Trade

Year Exports Imports Balance of Trade 2017-18 1,365 1,097 +268 2018-19 1,307 1,089 +218 2019-20 1,301 949 +352 2020-21 1,512 1,148 +364 2021-22 1,747 837 +910 Source: State Bank of Pakistan Annual Reports.

Value: US$ Million

Ambassador Alfred Grannas.

The majority of these companies are engaged in industries such as machinery, chemicals, pharmaceuticals, automotive, and related equipment and services. Notably, around 55% of multinational companies in Pakistan are from the pharmaceutical and chemical sectors. The services sector comprises 15% of companies, followed by transportation and textile machinery sectors with 5% each. The German government has committed substantial financial support for development projects in Pakistan, with approximately 3.5 billion euros pledged, a significant portion of which has already been disbursed.

GIZ: German Cooperation with Pakistan

The Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH, working on behalf of the German Federal Ministry of Economic Cooperation and Development (BMZ), plays a vital role in supporting Pakistan's development initiatives. GIZ focuses on priority areas such as sustainable economic development, good governance, crisis prevention and stabilization, and energy. The organization has been actively involved in technical and vocational education and training (TVET) reforms, promoting private sector-led and demand-driven training systems for improved employability prospects. GIZ also supports poverty alleviation efforts by improving access to needs-based social protection services.

Trade volume and sectoral analysis

Germany is Pakistan's largest trading partner within the European Union, accounting for a significant portion of Pakistan's exports to and imports from the EU. In the fiscal year 2019-20, bilateral trade between Pakistan and Germany amounted to US$ 2.25 billion, with Pakistan enjoying a trade surplus. Germany has been a significant market for Pakistani textile products, particularly readymade garments, bedwear, cotton fabrics, and knitwear. The export of textiles and other related products from Pakistan to Germany has been steadily increasing.

On the other hand, Pakistan imports various goods from Germany, including chemical products, textile machinery, electrical goods, motor vehicles, and iron goods. German imports of textile machinery have been crucial for Pakistan's value-added textile sector, enabling manufacturers to improve product quality and reduce business costs. Pakistan's major imports from Germany also include machinery, electrical machinery and equipment, vehicles, mineral fuels, pharmaceutical products, plastics, optical instruments, organic chemicals, iron, and steel.

Prospects and Challenges

The Pakistan-Germany trade relationship holds significant prospects for further growth and cooperation. Both countries can explore new avenues of collaboration and diversify their trade beyond the existing sectors. Germany's expertise in renewable energy, engineering, and high-tech industries can contribute greatly to Pakistan's goal of achieving sustainable development.

German Review

Furthermore, the collaborative projects and technology transfer in these areas can foster knowledge exchange, promote innovation, and drive long-term economic growth for both nations. Moreover, the establishment of joint ventures and partnerships between Pakistani and German companies can create new business opportunities and boost two-way investments. This not only strengthens economic ties but also promotes employment opportunities and skill development in Pakistan. By creating a favorable business environment and offering incentives, both countries can attract more German businesses to invest in Pakistan, further enhancing economic cooperation.

Additionally, the implementation of trade facilitation measures, including the simplification of customs procedures, harmonization of quality standards, and streamlining certification requirements, can remove non-tariff barriers and promote smoother trade flows. Strengthening transportation infrastructure and logistics will also contribute to improved trade facilitation and efficiency. Despite the positive outlook, there are challenges that need to be addressed to fully harness the potential of Pakistan-Germany trade. Non-tariff barriers continue to pose obstacles, including complex customs procedures, stringent quality standards, and certification requirements.

In this context, both countries need to engage in dialogues and negotiations to streamline trade processes and reduce the associated costs for businesses.

Source: Trade Development Authority of Pakistan.

Furthermore, while Germany is a significant investor in Pakistan, there is room for further investment and diversification of sectors. Encouraging more German companies to explore investment opportunities in sectors beyond machinery, chemicals, and pharmaceuticals would contribute to a more balanced trade relationship.

Another challenge lies in promoting awareness of business opportunities and potential collaborations. Efforts should be made to organize trade fairs, exhibitions, and business forums that bring together Pakistani and German companies, facilitating networking and partnership building. This would create a conducive environment for exploring new avenues of trade and investment.

Conclusion

As the partnership continues to evolve, it is essential for Pakistan and Germany to maintain open lines of communication, engage in regular dialogue, and foster a business-friendly environment. By leveraging each other's strengths and working together, Pakistan and Germany can forge a more robust and mutually beneficial trade relationship, bringing about shared prosperity for both nations.

References

1.German Textile Machinery Association (VDMA).

2.Pakistan Bureau of Statistics.

3.State Bank of Pakistan-Annual Reports.

4.Trade Development Authority of Pakistan.

5.Various press releases.

38 PAKISTAN TEXTILE JOURNAL - May 2023

(Major Items) Value : US$ 000 Items 2021-22 2020-21 2019-20 Cotton fabrics 48,185 91,457 75,277 Readymade garments 671,347 567,217 278,997 Knitwear (Hosiery) 671,347 567,217 253,117 Bedwear 349,892 286,867 241,620 Towels 55,097 49,950 36,978 Textile made ups 45,144 38,233 38,641 Tents and canvas 692 487 442 Rice 11,120 14,899 15,917 Leather tanned 2,721 4,477 6,743 Leather garments 58,076 114,043 69,795 Leather gloves 33,094 27,999 21,144 Footwear 9,084 35,217 34,260 Sport goods 7,933 41,105 28,399 Carpets and rugs 4,152 5,486 4,185 Surgical instruments 48,394 64,910 48,572 Fruits 5,826 5,671 7,645 Other items 548,154 92,430 125,850 Total 2,606,258 2,007,665 1,365,000

Table 2: Export of textile and other products from Pakistan to Germany