DOMOTEX asiaCHINAFLOOR 2024

Dates: May 28th to 30th 2024. Venue: NECC, Shanghai, China.

drupa 2024

Dates: 28th May to 07th June 2024. Venue: Düsseldorf, Germany.

ITM 2024

Dates: June 4th to 8th, 2024. Venue: Istanbul, Turkey.

HIGHTEX 2024

Dates: June 4th to 8th, 2024. Venue: Istanbul, Turkey.

INTEX SOUTH ASIA 2024

Dates: August7th to 9th 2024. Venue: Colombo, SriLanka.

Textile Asia 2024, Lahore

Dates: August 03rd to 05th 2024. Venue: Lahore Expo Centre. Textile Asia 2025, Karachi

Dates: April 12th to 14th 2025. Venue: Expo Centre, Karachi.

DPS World Pakistan 2024

Dates: August 16th to 18th 2024. Venue: Lahore Expo Centre.

Dates: September 11th to 13th 2024. Venue: Dornbirn Austria.

International Trade Fair for Technical Textiles and Nonwovens

Dates: September 19th 21st, 2024. Venue: Shanghai New International Expo Centre, Shanghai, China

ITMA ASIA + CITME 2024

Dates: October 14th to 18th, 2024. Venue: NECC, Shanghai, China.

Dates: November 27th to 30th 2024. Venue: Osaka, Japan.

Heimtextil 2025, Frankfurt

Dates: January 14th, to 17th, 2025

Venue: Frankfurt am Main.

DOMOTEX Hannover 2025

Dates: January 16th to 19th 2025. Venue: Hannover, Germany.

FESPA 2025

Dates: May 06th to 09th 2025. Venue: Messe Berlin in Germany.

IGATEX Pakistan 2025, Karachi

Dates: April 24th to 26th 2025. Venue: Expo Centre, Karachi.

ITMA ASIA + CITME, Singapore 2025

Dates: October 28th to 31st, 2025. Venue: Expo Centre Singapore.

Index 2026

Dates: April 21st to 24th, 2026. Venue: Palexpo, Geneva, Switzerland.

ITMA 2027

Dates: September 16th to 22nd, 2027. Venue: Hanover, Germany.

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher

Nadeem Mazhar

Editor in Chief Amina Baqai

Associate Editor

Nimrah Nadeem

Production Manager Mazhar Ali

Layout & Design

Noor M. Jaan

Website / Social Media

Minhaj Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab

C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA)

Dr. Zubair Bandukda PhD (Textiles), CText ATI

Editorial & Advertising Office

B-4, 2nd Floor, 64/21, M.A.C.H, Miran M. Shah Road, Karachi - Pakistan

Tel: +92-21-34311674-5

Fax: +92-21-34533616

Email: info@ptj.com.pk

URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Registered Office:

Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, United Kingdom.

Registered no. 09141989

Tel: +44 792 2228 721

Available on Gale and Factiva affiliated international databases through Asianet Pakistan

Printed at: Color Plus Korangi, Karachi.

Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi.

Two young ITM scientists awarded the Sustainability Prize of the German Textile Machinery Industry 2024 .

Archroma and DMIx collaborate to inspire fashion's digital workflow with more color and sustainability

Meisheng expands production with third ANDRITZ needlepunch line

Peru’s Nuevo Mundo continues sustainability journey with Archroma

Exploring Innovation and Sustainability in the Textile Industry: A Seminar Hosted by iTextiles .

Energizing Industry: National Textile University and Rastgar Group launch pioneering center of excellence in Compressed Air

Eagerly awaited ITMA ASIA + CITME exhibition in Singapore gears up for opening of space application

Exploring the Dynamics of DOMOTEX Middle East: An Interview with Sonia WedellCastellano, Global Director

Rieter Autoconer X6: The open prism OZ2 is the new allrounder in splicing . . .34

U.S. Cotton Trust Protocol Announces Expanded Board of Directors

Successful collaboration: Groz-Beckert and Santoni develop innovative INNOTAS knitting system

Biancalani: Crazy for artificial fibers

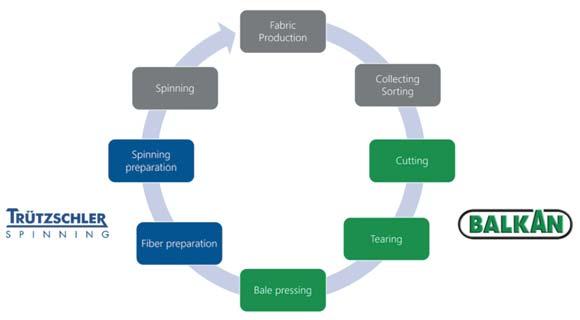

TRUECYCLED: A holistic approach to textile recycling success

Beacon Impex is revolutionizing sustainable knit production in Pakistan

Mr. Israr Hussain Zaidi, Director Operations at Beacon Impex

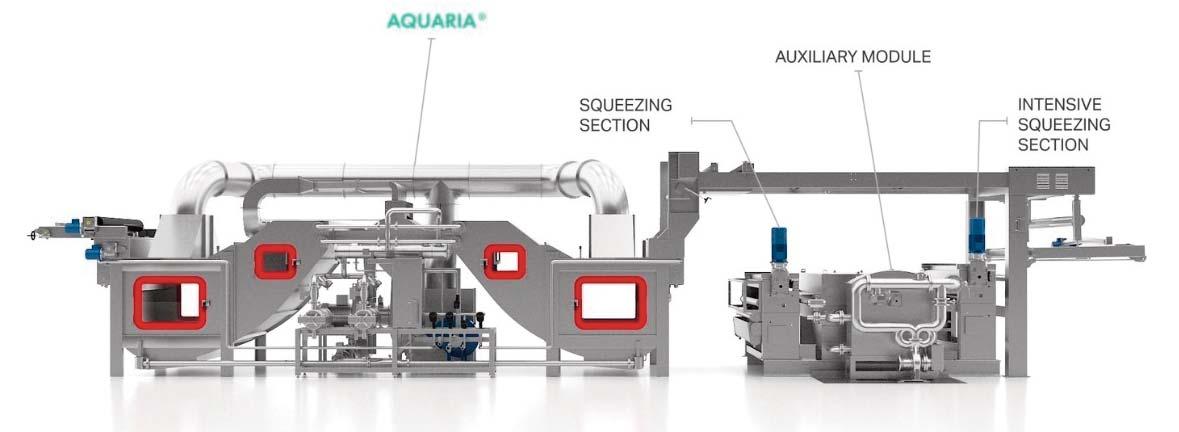

ERBATECH modern concepts for washing, bleaching and dyeing

Pakistan-Germany Trade Relations Remains Healthy and Growing

.36

.46 by Nadeem Mazhar, Managing Editor, Pakistan Textile Journal. BRÜCKNER’s 75 years of tradition and innovation

Ms. Regina Brückner, CEO of Brückner “BRÜCKNER ensures sustainable and efficient production.”

Mrs. Verena Ruckh, Head of Marketing Department at Brückner

Change in the management board - Eva Baumann becomes the new CEO of the CHT .50

Monforts automation reinvigorates Pincroft line

ITM 2024 all set to break records

Italian Trade Agency to exhibit at ITM 2024 with Italian pavilion

Heberlein AG: ‘Stunning’ evenness in filament yarns

Itema to showcase its latest weaving innovations and HelloItema at ITM 2024

KARL MAYER Technische Textilien at ITM 2024 in Istanbul

Merhaba Istanbul: Trützschler Group at ITM 2024

Oerlikon to show sustainable way to produce manmade fibre at ITM 2024

.63

Rieter: Raising the Bar on Performance with Automation, Digitization and Recycling .64

Mayer & Cie. to bring a new vision to circular knitting at ITM 2024

Spin box SE 21 in the new Autocoro 11 Programmed for sustainability

.68

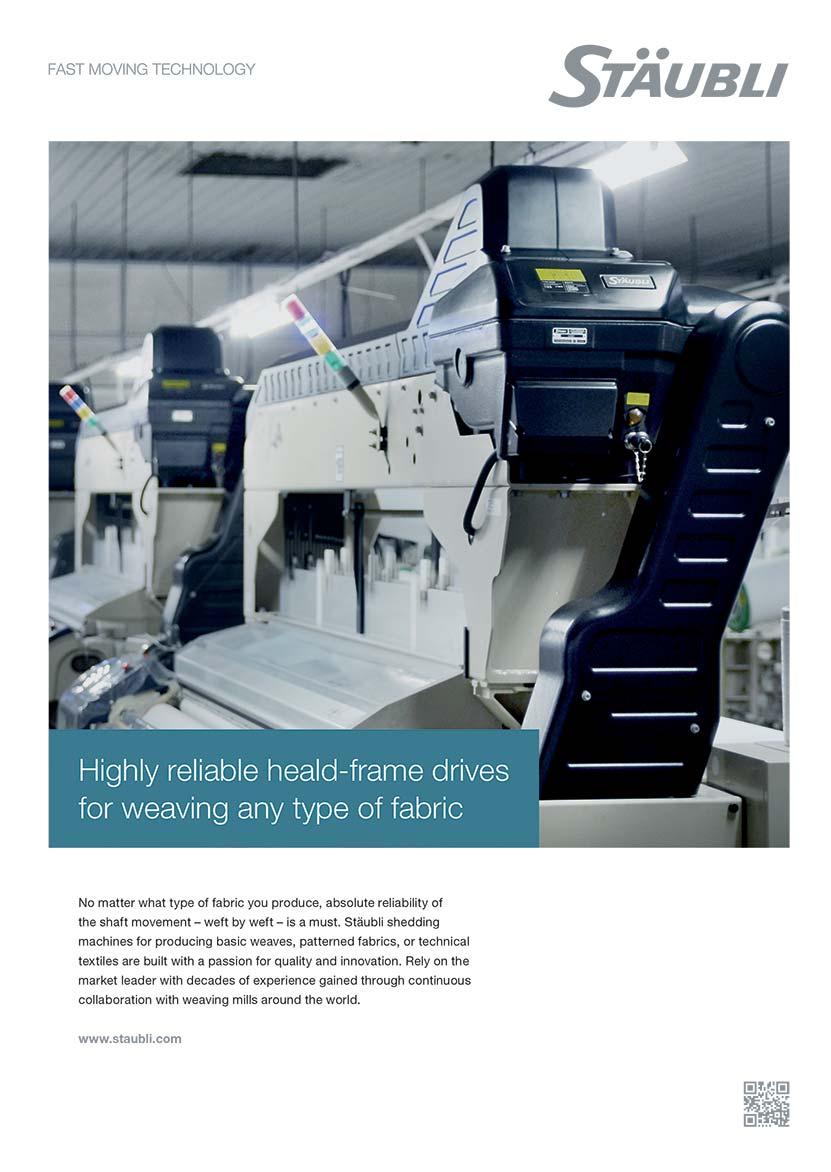

Stäubli at ITM 2024 – Redefining efficiency: with speed and quality processing . . .70

Picanol to showcase the all-new Ultimax rapier weaving machine

Erhardt+Leimer at ITM 2024 .

Color Service srl: accuracy and sustainability in the made-in-Italy dosing automation

Jakob Müller Group - CEO Andreas Conzelmann has been in his position for 100 days

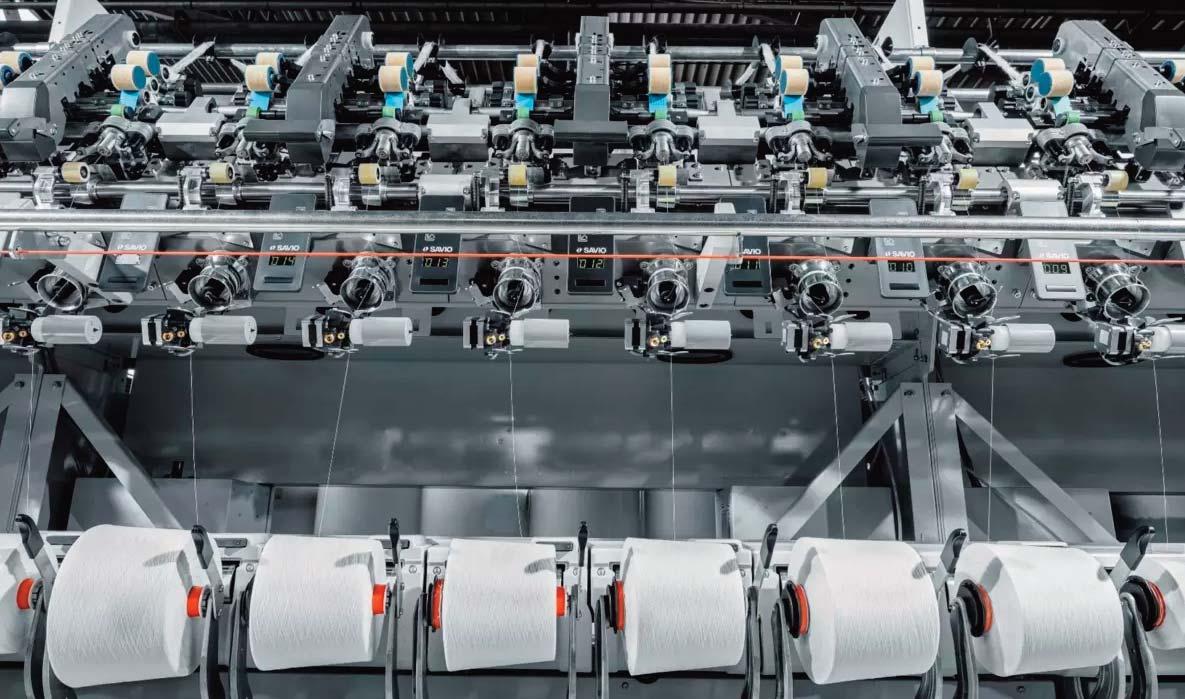

Savio’s next destination: ITM 2024

Mesdan at ITM 2024

EDITOR’S PAGE

Germany continues to be a strong partner for Pakistan's textile industry. The growth of Pakistan's textile sector has been greatly influenced by the innovative technological solutions provided by German textile machinery suppliers. Companies like Saurer Group, Schlafhorst, Truetzschler, Monforts, and Karl Mayer have played a crucial role by supplying advanced machinery and offering extensive after-sales support. Furthermore, German chemical suppliers such as Bayer and DyStar have been vital partners in supplying quality chemicals and promoting sustainable production practices.

For over seven decades, the Pakistan Textile Journal has fostered engagement between German companies and the Pakistani market, demonstrating a lasting commitment from these companies. As the industry encounters new challenges, German firms are well-positioned to support Pakistan's textile sector through technological advancements and expert guidance. Strengthening trade relations between Pakistan and Germany in the textile sector remains essential for driving innovation, productivity, and sustainable development. The Pakistan Textile Journal is dedicated to promoting this partnership and supporting the industry's growth. In this month's issue, we have included the statistics of Pak-German trade relations, which indicate a healthy relationship between the two countries. Key exhibitions like Heimtextil, Techtextil, Texprocess, Domotex, ISPO, and DRUPA regularly take place in Germany, providing great relevance to Pakistan's textile industry. Additionally, the next ITMA exhibition in 2027 is scheduled to be held in Hannover.

ITM and DOMOTEX asia/CHINAFLOOR

In this month's issue, we also highlight two important upcoming exhibitions: DOMOTEX asia/CHINAFLOOR, taking place from May 28th to 30th at NECC, Shanghai, and ITM 2024, taking place from June 4th to 8th in Turkey. ITM 2024 is one of the most significant events for the textile industry. Visitors and trade delegates from around the world gather here to seek and provide solutions for the rapidly growing textile sector.

During the last edition of ITM, the exhibition experienced a record-breaking number of exhibitors and visitors, turning it into a textile feast that attracted global investors and trade delegations. A total of 64,500 people from 102 countries visited ITM, with 44% of visitors coming from international locations and 56% from domestic locations. Manufacturers from various countries, including Egypt, Iran, Pakistan, Russia, Uzbekistan, Bangladesh, India, Italy, Algeria, and Tunisia, attended the exhibition, securing promising deals to enhance their business capabilities.

DOMOTEX asia/CHINAFLOOR is a leading flooring exhibition in the Asian-Pacific region and the second-largest flooring show worldwide. As part of the DOMOTEX trade event portfolio, the 25th edition of DOMOTEX asia/CHINAFLOOR serves as the primary business platform for the global flooring industry. Industry professionals from China, the fast-growing markets of South and Southeast Asia, Oceania, and beyond, attend this show each year to connect with suppliers and manufacturers, purchase flooring products, establish partnerships, and network with industry leaders.

The upcoming edition of DOMOTEX asia/CHINAFLOOR expects more than 1,600 exhibitors and 85,000 visitors from around the world, exploring the future of the flooring industry. Pakistan Textile Journal will provide firsthand reports on these exhibitions in upcoming issues and on our website.

1

Pakistan earned $ 13,683.251 million from exports of textile products during the first 10 months of the current financial year (2023-24), the Pakistan Bureau of Statistics (PBS) report said. The exports of the textile products however, witnessed a slight decline of 0.19 percent during July-April (2023-24) when compared to the exports of $ 13,709.246 million during July-April (202223).

2

The Pakistan Textile Exporters Association (PTEA) has voiced grave concerns over the prevailing economic uncertainty, citing high interest rates and constrained access to funds

as significant hurdles to the expansion of industrialization and exports in the nation.

Khurram Mukhtar, Patron-inChief of PTEA, advocates the adverse effects of the economic slowdown on the textile industry, which stands as Pakistan’s largest manufacturing sector.

3

During a pre-budget seminar organized by the commerce ministry, the textile and apparel industry presented a detailed roadmap aimed at addressing pressing challenges and unlocking the sector's growth potential in the upcoming fiscal year.

4

Deputy Director Agriculture (Extension) Multan, Dr. Azwar Raza

1

According to a quarterly review report by the Bangladesh Bank, value addition in the country's ready-made garment (RMG) sector saw a notable increase of 3.66 percentage points in the second quarter (October-December). However, despite this uptick in value addition, the sector's export earnings experienced a decline of 7.46 percent during the same period.

2The report highlights that the import value of essential raw materials for the RMG industry, including raw cotton, synthetic fiber, yarn, and textile fabrics, amounted to $3.37 billion in the October-December period of FY24. Meanwhile, total RMG export earnings stood at $11.77 billion, resulting in net export earnings of $8.40 billion for the sector. Notably, local value

Gilani, has emphasized the crucial role of adopting certified seeds of approved BT varieties of cotton to achieve heightened production levels.

5

Power Minister Sardar Awais Ahmad Khan reiterated the government's commitment to revitalizing Pakistan's textile sector during a meeting with All Pakistan Textile Mills Association (APTMA) officials.

6

Sindh Irrigation

Minister, Jam Khan Shoro, has called upon Islamabad to ensure uninterrupted water supply to the province, stressing the importance of sufficient water availability for crop production.

7

Stress on Pakistan’s textile industry listed at the capital market continued in the first quarter of 2024 as the sector grappled with challenges not only in exports but also in domestic markets.

8Representatives from the pesticide industry extended their support and presented a set of suggestions to the Punjab government for the restoration of the cotton crop in the province. In a meeting with Secretary Agriculture Punjab, Iftikhar Ali Sahoo, held on Monday, industry representatives offered technical assistance and guidance throughout the crop's growth stages.

addition accounted for 71.35 percent of these earnings in the second quarter of FY24, reflecting a slight increase compared to the same period in FY23.

3

EDANA, the foremost global association advocating for the benefits of nonwovens, shared a comprehensive overview of key figures from the EDANA Statistics Report on Nonwovens Production and Deliveries for 2023.

4

In 2023, nonwovens production in Greater Europe experienced a slight decline compared to 2022, with a decrease in volume by 5.7% to 2,864,840 tonnes and a 5.5% reduction in surface area, resulting in the manufacture of 81.7 billion square meters of nonwovens. However, nuanced variations

were observed at both national and process-specific levels across Greater European countries.

5

The French textile industry association, UIT, has put forward six proposals to candidates in the country's EU elections, following the approval of a first set of measures aimed at regulating fast fashion by the French Parliament. While UIT welcomed these measures, it expressed concerns about their effectiveness.

6

Despite numerous intervention efforts, the Nigerian textile industry continues to grapple with significant hurdles, as importation of textile products into the country surged by 106.7 percent over four years, reaching N377.1 billion in 2023.

7

In Tanzania, a four-day conference will bring together researchers and representatives from African cotton companies to delve into crucial topics such as soil health, environmental pest management, and optimization of cultivation techniques for African cotton farmers.

8

A coalition of US apparel and textile trade bodies, including the American Apparel and Footwear Association (AAFA), the National Retail Federation (NRF), the Retail Industry Leaders Association (RILA), and the United States Fashion Industry Association (USFIA), is urging the Department of Homeland Security (DHS) to collaborate with stakeholders to combat illicit textile trade practices.

Pakistan earned $ 13,683.251 million from exports of textile products during the first 10 months of the current financial year (2023-24), the Pakistan Bureau of Statistics (PBS) report said.

The exports of the textile products however, witnessed a slight decline of 0.19 percent during July-April (2023-24) when compared to the exports of $ 13,709.246 million during July-April (2022-23).

Raw cotton exports grew by 319.91 percent, from $13.357 million last year to $15.944 million this year.

Exports of cotton yarn increased by 32.83 percent, from $ 636.832 million last year to $845.923 million this year and bed wear by 1.82 percent, from $ 2,249.778 million to $ 2,290.796 million.

Exports of towels increased by 4.81 percent from $824.879 million to $864.547 million while exports of madeup articles were up by 0.67 percent to $589.026 million from $585.102 million.

Cotton cloth exports declined by 7.53 percent, from $ 1,684.724 million to $ 1,557.909 million. Yarn other than cotton yarn witnessed a decline of 20.76 percent, from $36.302 million to $28.766 million while knitwear exports declined by 3.92 percent, from $3,712.066 million to $3,566.624 million.

Similarly, exports of tents, canvas and tarpaulin decreased by 16.52 percent, from $116.959 million to $97.632 million, ready-made garments by 0.57 percent, from $ 2,904.693 million to $ 2,888.177 million.

The exports of art, silk and synthetic textiles also decreased by 12.08 percent declining from $342.917 million to $301.496 million, whereas the exports of all other textile materials also went down by 0.87 percent, from $600.642 million to $595.432 million.

Meanwhile, on a year–on–year basis, the textile exports in April increased by 0.37 percent going up from $ 1,232.803 million in April 2023 to $ 1,237.316 million in April 2024.

On a month-on-month basis, the textile exports, however, decreased by 4.84 percent when compared to the exports of $1,300 million in March 2024.

The Pakistan Textile Exporters Association (PTEA) has voiced grave concerns over the prevailing economic uncertainty, citing high interest rates and constrained access to funds as significant hurdles to the expansion of industrialization and exports in the nation.

Khurram Mukhtar, Patron-in-Chief of PTEA, underscored the adverse effects of the economic slowdown on the textile industry, which stands as Pakistan’s largest manufacturing sector.

Mukhtar highlighted the decline in textile exports, plummeting from a peak of $1.74 billion in April 2022 to a low of $1.18 billion in February 2023, subsequently stagnating at approximately $1.4 billion per month, marking a $600 million shortfall from the installed production capacity.

Pointing to the record-high interest rate, currently at 22%, Mukhtar underscored its detrimental impact on Pakistan's export sectors. He juxtaposed Pakistan's policy rates with those of regional counterparts like Bangladesh, India, Vietnam, and Sri Lanka, ranging from 4.5% to 11%, underscoring the disadvantage faced by Pakistan.

The elevated interest rates foster an environment of uncertainty, impeding long-term planning and investments due to exorbitant borrowing costs. Moreover, exporters grapple with challenges as their funds remain tied up in the refund regime, compelling them to seek loans at

steep interest rates, thus inflating the cost of business operations and rendering them less competitive within the region.

Mukhtar stressed the pivotal role of the Large-Scale Manufacturing sector, contributing nearly a quarter of the country’s GDP. He lamented the sector's marginal growth in output, decreasing by less than 1% during the July-January period of the fiscal year 2023-24.

This decline, compounded by other pressing issues such as high inflation, burgeoning current account deficit, dwindling foreign exchange reserves, fiscal disparities, and waning foreign direct investments, poses a grave threat to the economy's stability and growth trajectory.

During a pre-budget seminar organized by the commerce ministry, the textile and apparel industry presented a detailed roadmap aimed at addressing pressing challenges and unlocking the sector's growth potential in the upcoming fiscal year.

Central to the industry's proposals is a strategic plan to alleviate cross subsidies and stranded costs in the prevailing power tariff structure, with the goal of reducing industrial tariffs from the existing 14 cents per unit to 9 cents per unit. This initiative, if implemented, is anticipated to catalyze sustainable growth in exports, positioning Pakistan's industry competitively on the global stage.

Furthermore, the industry advocates

for the establishment of business-to-business (B2B) electric power contracts to procure green energy at competitive rates. By setting an upper cap of 1,000 MW/annum for these contracts, the sector aims to manage financial implications effectively while fostering an environment conducive to export expansion.

In addition to these measures, the industry underscores the imperative of augmenting the cap on solar net-metering for industrial consumers from 1 MW to 5 MW, aligning with global trends towards sustainable practices and positioning Pakistan towards a net-zero future.

Highlighting the recent decline in exports, the All Pakistan Textile Mills Association (APTMA) emphasized the critical need to address prohibitive energy costs, hindrances in tax refunds, and an adverse duty structure for key raw materials. APTMA also recognized the looming threat posed by the EU's Carbon Border Adjustment Mechanism (C-BAM) and stressed the urgency of transitioning to green energy to maintain export competitiveness.

Moreover, the industry calls for the rationalization of tax rates, deepening of the stock market, and incentivizing exports to stimulate financial rejuvenation. It advocates for a robust National Compliance Center (NCC) to ensure adherence to sustainability standards and emphasizes the importance of diversifying export products beyond cotton to tap into burgeoning global markets for man-made fiber textiles.

To bolster the textile sector's global position, APTMA recommends the removal of import duties on raw materials such as Purified Terephthalic Acid (PTA) and Polyester Staple Fiber (PSF), while also proposing the revision of anti-dumping duties on PSF. Additionally, the industry urges the withdrawal of customs duty on industrial spare parts and gas generators, along with zero-rating duties on dyes and chemicals essential for downstream industries.

Furthermore, APTMA calls for the expansion of the Export Facilitation Scheme to encompass the entire value-added chain of the textile sector, advocating for revisions in the Sales Tax Return provisions to facilitate indirect exporters.

Deputy Director Agriculture (Extension) Multan, Dr. Azwar Raza Gilani, has emphasized the crucial role of adopting certified seeds of approved BT varieties of cotton to achieve heightened production levels.

During his visit to Qasba Ayazabad Marral and suburban areas to assess early sown cotton, Dr. Gilani engaged with local farmers, urging them to refrain from pesticide application during the initial 60 days of crop growth. He advised farmers to treat seeds with appropriate insecticides before sowing to safeguard

against sap-sucking insects, particularly whiteflies, for approximately a month.

Highlighting the significance of land preparation, Dr. Gilani stressed the importance of sub-soiler plowing to break the soil's hard layer, enhancing water retention capacity, and facilitating root nourishment. He recommended maintaining a distance of two and a half feet between rows if planting by drill method. Additionally, he advised leaving one line of plants and spreading soil on the other line when the crop reaches a height of one and a half to two feet.

These measures, Dr. Gilani explained, would optimize fertilizer usage, conserve water, and mitigate losses in case of rainfall. He specified that for crops cultivated between April 1 to 30, the optimal plant population should be 17,500 plants per acre, while for those sown from May 1 to 30, farmers must ensure a plant population of 23,000 per acre.

Power Minister Sardar Awais Ahmad Khan reiterated the government's commitment to revitalizing Pakistan's textile sector during a meeting with All Pakistan Textile Mills Association (APTMA) officials.

Concerns were raised by APTMA regarding the declining exports within the textile industry, exacerbating issues like unemployment and poverty. Minister Khan assured the delegation of the government's steadfast support, emphasizing ongoing efforts to implement a comprehensive wheeling policy aimed at boosting exports.

The proposed policy, coupled with regionally competitive tariffs tailored for the textile sector, aims to unleash the industry's full potential. Minister Khan underscored the urgency of the situation, highlighting swift actions to improve the operations of DISCOS (Distribution Companies) to provide immediate relief to the textile sector.

With these strategic initiatives in place, the government aims to significantly increase textile exports by up to $2 billion, fostering economic growth and employment opportunities in Pakistan.

Sindh Irrigation Minister, Jam Khan Shoro, has called upon Islamabad to ensure uninterrupted water supply to the province, stressing the importance of sufficient water availability for crop production.

Highlighting the disparity in water distribution, Minister Shoro expressed concern over the shortage of water in several canals, despite the Nara and Rohri canals receiving adequate supply. He emphasized the government's efforts to maintain crop and drinking water supply through a rotation programme.

Additionally, Minister Shoro announced plans for a separate scheme aimed at draining rainwater from key drainage systems, including the Left Bank Outfall Drain (LBOD), Dhoro Puran Outfall Drain (DPOD), and Hakro drain. The installation of a large gate at RD 210 is part of this scheme, with reports being sought from concerned deputy commissioners to address the issue.

However, concerns have arisen over the potential impact of water releases from the Tarbela Dam on the sowing of main Kharif crops, such as cotton and rice, in Sindh. Wapda's request for water release beyond the storage level of 1,420 feet for tunnel construction has raised apprehensions about crop production in the region.

Sindh has emphasized the need for maximum water releases from the Tarbela reservoir to facilitate timely sowing of crops, highlighting the critical importance of early Kharif water releases for cotton and rice cultivation. Minister Shoro underscored the province's reliance on sufficient water supply in adherence to the water accord, urging equitable distribution among provinces in case of shortages.

As discussions continue in the advisory committee meeting scheduled for April 2, Sindh remains steadfast in its pursuit of maximum water releases during the early Kharif period to mitigate potential losses in crop production. Minister Shoro reiterated Sindh's stance against excessive water storage and advocated for fair distribution in accordance with the water accord to safeguard agricultural livelihoods in the region.

Stress on Pakistan’s textile industry listed at the capital market continued in the first quarter of 2024 as the sector grappled with challenges not only in exports but also in domestic markets.

It is surprising that at a time when KSE-100 has broken all the records butTextile Composite sector suffered a 64.2 percent YoY decline in net profit during the quarter, declining to Rs5.27

billion against Rs14.72bn in the same period last year.

In view of global economic slowdown demand for textile products remained subdued in the international market as the overall exports of the textile industry have remained stagnant.

On the domestic front high energy costs, costly financing, and the imposition of government taxation have escalated the cost of doing business. As per the results available at PSX web page, sales revenue of textile sector worth worth Rs133.27bn as against Rs108.48bn during corresponding period of last year. This translated into an increase of 22.9 percent YoY.

But the increasing energy costs and escalating raw material prices compressed the profit margins significantly. The cost of sales ballooned by 35.0 percent YoY, depressing the gross profit by 16.1 percent YoY to Rs21.63bn during the period under review. Other income of the sector declined by 20.8 percent to stand at Rs2.79bn in Q1 2024 as compared to Rs3.52bn.

The selling and distribution expenses fell 27.9 percent YoY to Rs2.33bn depicting less efforts at sales level, administrative expenses fell 52.1 percent YoY to Rs1.55bn, while other operating expenses surged 379.1 percent YoY to Rs5.76bn.

Due to high policy rate the financial costs increased by 37.1 percent YoY to

Rs7.18bn as compared to Rs5.24bn earlier. Moreover, the sector paid a higher tax worth Rs2.33bn against the Rs1.68bn paid in the corresponding period of last year, depicting a rise of 38.7 percent YoY.

Experts say the next quarter would be challenging for the textile sector in view of current global economic situation and local pressures on costs

The sector result includes all big names like GATM, ILP, KTML, and NML. Most of these companies anticipate further pressure. With real GDP expected to grow at 2 percent this fiscal the overall economic activities are would remain subdued.

Representatives from the pesticide industry extended their support and presented a set of suggestions to the Punjab government for the restoration of the cotton crop in the province. In a meeting with Secretary Agriculture Punjab, Iftikhar Ali Sahoo, held on Monday, industry representatives offered technical assistance and guidance throughout the crop's growth stages.

Expressing gratitude to the private industry owners, Secretary Agriculture Punjab emphasized the collective effort required from all stakeholders to achieve the target of cotton cultivation and

production. He outlined the Agriculture Department's commitment to running a more diligent cotton campaign compared to the previous year, including issuing crop advisories to farmers and utilizing various media channels, particularly social media, for effective dissemination.

Secretary Sahoo stressed the importance of deploying maximum technical staff in allotted tehsils to provide necessary guidance to farmers. Furthermore, digital monitoring of field activities by Agriculture Department staff will commence from May 1st to ensure accountability and efficiency.

Highlighting the crucial role of industry owners, Secretary Sahoo emphasized the need for them to fulfill their responsibilities effectively to achieve desired results for the cotton crop in the province.

It was hoped that decisions made in the meeting between the Agriculture Department and the private sector would be implemented for the welfare of cotton farmers, fostering public-private sector cooperation for mutual prosperity and economic stability.

A committee, led by Secretary Agriculture South Punjab Saqib Ali Ateel, Consultant Dr. Anjum Ali, and Director General Pest Warning and Quality Control Punjab Dr. Amir Rasool, was formed to finalize the tehsil adoption programme through negotiations with the private sector.

Experienced a decline of 7.46%

According to a quarterly review report by the Bangladesh Bank, value addition in the country's ready-made garment (RMG) sector saw a notable increase of 3.66 percentage points in the second quarter (October-December). However, despite this uptick in value addition, the sector's export earnings experienced a decline of 7.46 percent during the same period.

The report highlights that the import value of essential raw materials for the RMG industry, including raw cotton, synthetic fiber, yarn, and textile fabrics, amounted to $3.37 billion in the October-December period of FY24. Meanwhile, total RMG export earnings stood at $11.77 billion, resulting in net export earnings of $8.40 billion for the sector. Notably, local value addition accounted for 71.35 percent of these earnings in the second quarter of FY24, reflecting a slight increase compared to the same period in FY23.

The primary markets for Bangladesh's RMG exports continue to be the US, Germany, the UK, and several other European countries, collectively contributing nearly 68 percent of total exports during October-December of FY24. However, the RMG sector has encountered various challenges, including the Russia-Ukraine conflict, currency depreciation, weak global demand, and high global inflation, leading to a marginal decline in exports during this quarter.

Looking ahead, the report cautions that the RMG sector may face further challenges in the upcoming months due to subdued economic activities, uncertainties in the global economic landscape, and weak productivity growth. To address these challenges and boost export earnings, the government and the Bangladesh Bank have implemented several initiatives, including pre-shipment credit, export incentives, and funds for export development and green transformation.

Furthermore, the report emphasizes the importance of inter-apparel diversification, reducing lead time, enhancing efficiency, investing in research and development, exploring new global markets, and modernizing production processes as priority areas to stimulate RMG export earnings in the future.

Despite these challenges, Bangladesh remains a significant player in the global apparel market, with apparel exports reaching $46.99 billion in the last fiscal year.

Production Decreased by 5.7% in 2023

EDANA, the foremost global association advocating for the benefits of nonwovens, shared a comprehensive overview of key figures from the EDANA Statistics Report on Nonwovens Production and Deliveries for 2023.

In 2023, nonwovens production in Greater Europe experienced a slight decline compared to 2022, with a decrease in volume by 5.7% to 2,864,840 tonnes and a 5.5% reduction in surface area, resulting in the manufacture of 81.7 billion square meters of nonwovens. However, nuanced variations were observed at both national and process-specific levels across Greater European countries.

Jacques Prigneaux, EDANA’s Market Analysis and Economic Affairs Director, provided additional insights into the data, noting a second consecutive decline in European nonwovens production since its peak in 2021. Prigneaux emphasized the importance of examining trends across different production processes, highlighting notable double-digit declines in thermally and chemically bonded nonwovens. Despite this, some processes, such as drylaid-hydroentangled and short-fibers airlaid, maintained stability or slight growth compared to the previous year.

From an end-use perspective, analysing 2023 data by market segment revealed varied trends in European manufacturers' global sales. While segments like hygiene, medical, and construction experienced decreases compared to 2022 levels, certain segments such as wipes, automotive interiors, agriculture, and personal protective garments displayed resilience or growth, reflecting evolving consumer demands.

Prigneaux emphasized that surface area data may yield different insights due to varying product weights, underscoring the continued importance of EDANA's square meter figures as a crucial business tool for member companies.

Acknowledging the invaluable contribution of member companies to the annual survey, EDANA expressed gratitude and highlighted the significance of an expanded membership base in enriching industry monitoring and analysis.

While the detailed data remains internal, Prigneaux will present a comprehensive overview of key findings at the upcoming EDANA Innovation Forum in Munich, Germany, scheduled for June 2024. Meanwhile, a summary report – "2023 European Nonwovens Markets Insights" – will soon be available for EDANA members.

The Innovation Forum aims to explore the essence of innovation in the nonwovens sector, emphasizing collaboration and knowledge sharing while preserving confidentiality and intellectual property. Participants can expect engaging discussions, networking opportunities, and insights into driving innovation amidst dynamic industry landscapes.

Nigerian Textile Industry Facing Challenges as imports rise 106.7%

Despite numerous intervention efforts, the Nigerian textile industry continues to grapple with significant hurdles, as importation of textile products into the country surged by 106.7 percent over four years, reaching N377.1 billion in 2023.

Data from the National Bureau of Statistics (NBS) highlights a consistent rise in textile imports from 2020 to 2023, indicating a pressing need for effective strategies to revive the sector.

Despite initiatives by the Central Bank of Nigeria (CBN), including financial support, training programs, and foreign exchange restrictions, the textile industry's revival remains elusive.

Nigeria holds substantial potential in the textile and apparel sector, with a rich history of production and a large domestic market capable of driving employment and economic growth.

However, challenges such as smuggling, unreliable power supply, policy inconsistencies, and insecurity have led to the decline of once-thriving textile mills.

In a recent interview, Hamma Kwajaffa, Director General of the Nigerian Textile Manufacturers Association, lamented the industry's high

production costs, hindering competitiveness and deterring investments.

At the 13th National Delegates Conference of the National Union of Textile Garment and Tailoring Workers of Nigeria (NUTGTWN), former President John Adaji highlighted that 90 percent of textile products in Nigerian markets are imported, underscoring the urgent need for government intervention to create jobs and reduce import bills.

Adaji emphasized the necessity of infrastructure development and energy cost reduction to lower production costs. He cited South Africa's successful revival of its textile sector through targeted government campaigns as a model for Nigeria.

Adaji applauded Executive Order 003, urging government agencies to prioritize locally produced goods, as a step toward bolstering the manufacturing sector and the economy at large, stressing the importance of full implementation for sustained growth.

African Cotton Conference in Tanzania to Focus on Sustainable Agriculture and Earth Day Initiatives

In Tanzania, a four-day conference will bring together researchers and representatives from African cotton companies to delve into crucial topics such as soil health, environmental pest management, and optimization of cultivation techniques for African cotton farmers.

Aligned with Earth Day celebrations across 175 countries on April 22, the event will feature renowned figures like Dr. Adam Cobb from the Soil Food Web School and Keshav Kranthi from the International Cotton Advisory Committee (ICAC), alongside agricultural managers, consultants, and stakeholders.

Rather than just theoretical discussions, the conference will integrate practical activities. Participants, including 40 cotton industry representatives, will partake in hands-on demonstrations aimed at implementing sustainable agricultural practices and soil carbon sequestration techniques.

Belinda Edmonds, Managing Director of the African Cotton Foundation, highlighted the significance of a holistic approach that combines scientific expertise with the practical challenges faced by cotton farmers and stakeholders. She emphasized bridging the gap between theory and practical implementation.

The workshop will feature the planting of fruit trees, symbolizing the collective efforts of African cotton companies to plant over 520,000 crop trees in CmiA cotton-growing regions by 2025.

A coalition of US apparel and textile trade bodies, including the American Apparel and Footwear Association

(AAFA), the National Retail Federation (NRF), the Retail Industry Leaders Association (RILA), and the United States Fashion Industry Association (USFIA), is urging the Department of Homeland Security (DHS) to collaborate with stakeholders to combat illicit textile trade practices.

Emphasizing the importance of input from all parties and coordinated efforts with importers for effective enforcement, the coalition calls for DHS to partner with its associations and members for a successful enforcement plan. Many members are Tier 3 participants in Customs-Trade Partnership Against Terrorism (C-TPAT) and are trusted traders with safe and secure supply chains.

The enforcement plan should include input from all stakeholders, ensure clear communication with the trade, and facilitate coordinated activities with imports, especially when DHS identifies illicit trade activities within the supply chain. Sharing results of any illicit activities is crucial for quick action by members and other imports to address the issue.

Meanwhile, the National Council of Textile Organizations (NCTO) CEO Kim Glas welcomed DHS Secretary Alejandro Mayorkas's announcement of an enhanced strategy to combat illicit trade, emphasizing its critical role in combating import fraud and circumvention of free trade agreement rules and trade laws.

The plan focuses on cracking down on small package shipments, conducting

joint CBP-HSI trade special operations, better assessing risk through customs audits and foreign verifications, building stakeholder awareness, leveraging partnerships, and expanding the Uyghur Forced Labor Prevention Act (UFLPA) Entity List.

Secretary Mayorkas stressed the importance of a fair and level playing field for American businesses, highlighting the detrimental impact of forced labor and illegal practices on the US textile industry. The implementation of the enforcement plan has already begun, with ongoing efforts to ensure compliance.

Additionally, Vice President Kamala Harris announced a new initiative between the US and Guatemala to advance secure trade in textiles and apparel, encouraging engagement with existing government-to-industry stakeholder partnerships.

President Shavkat Mirziyoyev chaired a government meeting on April 16 to discuss strategies for increasing exports and investments in Uzbekistan’s textile industry, which currently comprises over 6,000 enterprises and has a workforce of 570,000.

Investments and the adoption of new technologies have led to a 4.2-fold increase in productivity over the past seven years. In 2023, the manufacture of textiles, clothing, and knitwear amounted to $8.2 billion, with exports reaching $3.1 billion.

Despite these achievements, the share of high-value-added products in finished goods exports remains low, with nearly 80% of exports going to traditional markets and European exports falling below expectations. Only 175 Uzbek enterprises possess the international certifications required for export to developed countries.

An analysis by the Boston Consulting Group highlights Uzbekistan’s potential to provide products worth at least $15 billion and create 500,000 new jobs using domestic raw materials. The country holds a significant competitive advantage, with the cost of one kilogram of yarn being 28% cheaper than the world average. However, access to raw materials remains a key challenge, as Uzbekistan currently processes only about 1 million tons of cotton fiber out of its capacity of 1.3 million tons due to high cultivation costs.

President Mirziyoyev stressed the need for Uzbekistan’s textile industry to focus on complete processing of existing raw materials to create high added value and shift from exporting to traditional cheap markets to more lucrative alternatives.

The awards ceremony of the Walter Reiners Foundation of the VDMA Textile Machinery Association to students and young engineers from German universities for outstanding achievements in their studies took place at Techtextil 2024 in Frankfurt/Main. The nationwide awards were presented by Mr. Peter D. Dornier, Chairman of the Board of the Walter Reiners Foundation, at the VDMA trade fair stand.

M. Sc. Katharina Maria Ernst developed a process for the thermal stabilization of chitosan filament yarn on the basis of thermoanalytical investigations and batch tests.

The aim of the Euros 3500 project was to investigate chitosan as an alternative raw material for carbon fiber production. Up to now, the petroleumbased precursors PAN and pitch have mainly been used. Due to the increasing demand for carbon fibers, new precursors

based on renewable raw materials are being sought. In contrast to cellulose and lignin, chitosan has not yet been extensively investigated and could also be suitable for carbon fiber production due to its chemical similarity to cellulose. Chitosan was thermoanalytically investigated in the thesis and a stabilization process with several heating zones was developed in which stabilized fibres based on chitosan could be successfully produced. With the thermal stabilization processes developed, no positive influence on the carbon yield could be demonstrated. However, the investigations of the conversion processes form a good basis for adapting and optimizing the stabilization process accordingly so that more sustainable carbon fibres can be produced from chitosan in the future.

Lena Fink was awarded the sponsorship prize in the category "Project work in German textile mechanical engineer-

ing" for her work entitled "Development of a device for changing bobbin lace spring tensioning systems".

The project work, worth Euros 3,000, was completed as part of a specialist internship at ADMEDES GmbH. The aim of the project work was to develop a new device for changing the flat springs of the clapper spring assembly. To this end, the existing assembly process was analyzed and then the entire design development process was run through. The preferred variant identified was manufactured, assembled and tested. The device developed enables the safe and timeefficient changing of spring tensioning systems for the braided bobbins used. It meets all safety and quality requirements. The use of the device reduces the risk of injury and accidents for production employees and increases the effectiveness of the changing process.

The employees of ITM are proud and congratulate the award winners.

Archroma, a global leader in specialty chemicals focused on sustainable solutions, and ColorDigital GmbH, the company behind DMIx, a pioneer in textile supply chain digitalization, are joining forces to bring the textile industry’s largest library of engineered color standards to the DMIx ecosystem of fashion brands and suppliers.

All 5,760 color references in the Color Atlas by Archroma® will be integrated into ColorDigital’s DMIx interactive collaboration platform, enabling brands to embrace almost unlimited color creativity with an assurance of color precision. Based on digital twin technology, the DMIx solution ensures that color choices are aligned across design, sourcing and production, reducing sampling costs and collection development time as well as improving color accuracy and end-product quality. In short, DMIx marks a significant step forward in enhancing color management processes for both digital product creation (DPC) and physical production.

Sustainability is an essential factor for both Archroma and DMIx. Colors in the Archroma Color Atlas are formulated to comply with leading eco-standards while

also delivering consistent and accurate color reproduction. This complements the DMIx ImpAct approach, which provides data on the environmental impact of raw materials to enable brands to select inputs that meet their sustainability targets.

“Archroma takes a ‘Planet Conscious’ approach to color. Like DMIx, we want to empower designers to make sustainable choices from color inspiration to execution. That’s why we build achievability criteria into our colors standards, considering eco-compliance, fastness performance, color consistency and resource efficiency, and why we offer global technical support,” Chris Hipps, Global Head of Archroma Color Management, said.

Gerd Willschütz, COO and CoFounder of ColorDigital, said: “Strategic color management can transform textile and fashion businesses and drive commercial success. We are delighted to collaborate with Archroma to help make color development and production more creative, efficient and accurate, and more environmentally responsible too.”

A new feature on the DMIx platform is DMIx eXcite, an inspirational material and color-trend hub that uses interactive moodboards to share new color and

material scenarios ahead of each season. Designers and colorists will be able to directly use colors presented in the eXcite trend reports, including colors from the Color Atlas by Archroma®, across the DMIx color and 3D technology tools.

The Color Atlas by Archroma® is part of the Archroma Color Management+ design and development solution for more sustainable textiles and fashion through fast color selection and creation, consistent and accurate color reproduction, and reduced environmental impact.

Meisheng Group has started up a new ANDRITZ needlepunch line at its facility in Shaoxing City, Zhejiang Province, China. It is the third line supplied by ANDRITZ to the renowned manufacturer of high-end nonwoven synthetic leather. This expansion will enable Meisheng to address the growing demand for synthetic suede in the automotive industry, particularly for New Energy Vehicles (NEVs).

Mr. Qian Guochun, CEO of Meisheng, commented: “In view of the

strong demand for our premium synthetic suede, especially for NEVs, we have placed our trust in ANDRITZ for the third time. With the new needlepunch line we are expanding our capacity while maintaining our high quality standards.”

The advanced line is equipped with a ProWid™ system that allows Meisheng to ensure an optimum web weight regularity across the full product width. As a result, the web distribution is drastically improved, which reduces material consumption (fibers) and

improves web weight evenness (CV%) –factors that are particularly important in synthetic leather manufacturing for automotive applications.

Founded in 1994, Zhejiang Meisheng New Material Co., Ltd. is an internationally renowned maker of highend textiles and nonwoven synthetic leather. Through a consistent focus on R&D, Meisheng has established itself as a pioneer in the production of nonwoven microfiber synthetic leather in China.

Integrated textile mill Nuevo Mundo is partnering with Archroma, a global leader in specialty chemicals focused on sustainable solutions, to offer collections utilizing Archroma’s EarthColors® agricultural waste based dyes and produced with zero liquid discharge and substantial resource savings.

A strategic partner of apparel brands, Nuevo Mundo is a market leader in South America with a 75-year history. It helps brands expand into new markets with value-added products that capture growing consumer demand for quality and sustainability. The company is a pioneer in the adoption of water-saving processes and chemicals that have minimal impact on the environment.

Working with its longstanding partner Archroma, Nuevo Mundo is now reinforcing its commitment to sustainability with the creation of new collections that utilize Archroma’s biowaste-based EarthColors® dyes. Based on patented Archroma technology, these high-performance dyes are from non-edible agricultural or herbal industry waste in a process that helps to reduce the negative impact on water footprint, natural resources and climate change compared to conventional synthetic dye production where toxic and nonrenewable oil derivative products are used as raw material.*

The organic raw materials used for the dyes created for Nuevo Mundo include residues from cotton plants, beets and saw palmetto. In addition to using these biowaste-based dyes, the EarthColors® collections will be produced in Nuevo Mundo’s zero liquid discharge facilities, providing savings in time, water and energy, as well as emissions.

Umberto De Vita, Director, Denim Market Segment, Archroma Textile Effects, said: “Like our partner Nuevo Mundo, Archroma is passionate about working with brands to move our industry towards a future where businesses can thrive and care for people and the planet at the same time. This approach is captured in our ‘Planet Conscious+’ vision of deeper collaboration, supported by breakthrough technologies like EarthColors®.”

Boris Schwartzman, Nuevo Mundo, said: “With the trend towards nearshoring gaining momentum in the U.S., now is the ideal time for South American brands to capture demand for high-quality clothing and textiles that deliver the sustainability that the American market demands. Our partnership with Archroma and the introduction of EarthColors® into our collections creates a real opportunity for growth.”

Nuevo Mundo and Archroma intend their alliance to be a long-term collaboration, with plans to release new collections based on EarthColors® in the coming year and beyond.

iTextiles recently hosted an insightful seminar that delved into the realms of innovation and sustainability within the textile industry. Held on May 3, 2024 at Nishat Hotel Lahore, the seminar brought together industry leaders and experts to discuss the latest advancements and trends shaping the future of textiles.

The seminar commenced with a warm welcome from iTextiles' CEO, Mr. Mujeeb Ullah Khan, who emphasized the importance of collaboration and knowledgesharing in driving positive change within the industry. Attendees were then treated to a lineup of esteemed speakers, each bringing their unique insights and expertise to the table.

Fabrizio Maggi, the Apparel Commercial Director South Asia and EMEA Distribution at The LYCRA Company, set the tone for the seminar by introducing the audience to the next generation Bio-Derived LYCRA® Fiber made with QIRA®. This revolutionary step in the

textile industry promises to boost sustainability and pave the way for eco-friendly textile solutions. Fabrizio further presented the latest sustainable LYCRA technologies for the denim segment, highlighting the brand's commitment to driving sustainable innovation across the market.

Oguzhan Gumuskaya, the European Account Manager for CORDURA® at INVISTA, took the stage next to discuss the importance of durability in performance textiles. He emphasized how durable choices are inherently sustainable for the planet, aligning with INVISTA's core values and culture.

Taqerrub Raza Sayeed, the Global Product Development Manager for CORDURA® Brand, discussed the brand's innovative products and their applications in both consumer and military segments.

Samuel Goldstein is a circular materials technologist and entrepreneur, working as Chief Operating Officer at Earth ProtexTM captivated the audience with insights into the company's innovative product, Tex2TexTM. This revolutionary textile-to-textile recycling model moves beyond single-use plastics downcycling and towards upcycling textile-to-textile recycling. Samuel showcased the significant impact of Tex2TexTM on CO2 reduc-

tion, energy consumption, water usage, and solid waste disposal, highlighting its role in achieving the sustainable goals of the textile industry.

Adeel Anwar, GM Sales at iTextiles®, shared valuable insights into Naia Renew, an innovative fiber that is making waves in the textile industry. Adeel discussed Naia's applications in home textiles and apparel, emphasizing how Naia is making fashion sustainable without compromising on style, comfort, and hand feel. His presentation underscored the importance of sustainable fiber choices in driving positive change within the industry.

Aamir Pingal, the Regional Sales Manager for IFF, concluded the presentations by sharing insights into IFF's sustainability journey and the development of sustainable enzymes for the textile industry. His presentation underscored IFF's commitment to sustainability and its efforts todrive positive change within the industry.

The seminar drew attendance from major textile industries across Karachi, Lahore, Faisalabad, and Multan, including renowned Mills such as Reliance Mills, Kay & Emms, Masood Textile Mills, Interloop, Shahire Textile Mills, Naveena Denim, Nizam Sons, and many more. Their presence underscored the significance of the seminar in the textile industry landscape.

Throughout the seminar, attendees had the opportunity to engage in interactive discussions and networking sessions, fostering collaboration and idea exchange.

The event concluded on a high note, with attendees expressing their appreciation for the valuable insights shared by the speakers.

As the curtains closed on the seminar, it was evident that the event had succeeded in its mission to inspire, educate, and empower industry professionals to embrace innovation and sustainability in their respective roles. iTextiles looks forward to continuing the dialogue and driving positive change within the textile industry.

In a landmark initiative for Pakistan's industrial sector, the National Textile University, Karachi Campus, together with the Asian Institute of Industrial AirAIIA and its main sponsor, the Rastgar Group, proudly announces the inauguration of the new Center of Excellence in Compressed Air (CECA). This center is poised to dramatically enhance the competitiveness and sustainability of industries throughout the southern region of Pakistan.

Located in the bustling industrial hub of Karachi, CECA was established by the Asian Institute of Industrial Air with substantial support from its main sponsor, the Rastgar Group. The center is committed to:

Providing Specialized Employee Training: CECA delivers expert training in compressed air system optimization. Through targeted workshops and real-world applications, employees gain critical skills to enhance system efficiency, leading to reduced operational costs and better resource management.

Boosting Productivity and Environmental Sustainability: Effective management of compressed air systems helps minimize downtime and energy waste, contributing to greater productivity and environmen-

tal sustainability. The center trains technicians to swiftly troubleshoot and maintain systems, ensuring continuous industrial operations.

Enhancing Industry Competitiveness: With reduced operational costs and improved system reliability, businesses equipped with skills from CECA are better positioned to compete in both local and international markets. This heightened competitiveness is essential for fostering long-term industrial growth.

Following the successful model established by its Faisalabad counterpart, CECA Karachi is designed to replicate and expand upon these achievements. It specifically serves the burgeoning needs of the southern industrial sector, setting a new standard for training excellence in the region.

Quotes:

Dr. KHALID PASHA, Director, NTU Karachi Campus: "Through the collaboration with the Asian Institute of Industrial Air and the generous sponsorship from the Rastgar Group, CECA Karachi is set to revolutionize how our industries operate, making them more competitive and sustainable."

Syed Johar Ali Qandhari, President, Korangi Association of Trade & Industry

(KATI) : "The establishment of CECA here in Karachi is a strategic boost to our local industries, providing them with the tools to thrive in an increasingly competitive global marketplace."

The partnership between NTU, the Asian Institute of Industrial Air, and the Rastgar Group exemplifies the synergy that is essential for fostering a skilled and innovative workforce. This collaborative effort underscores a commitment to industry-leading training and development.

The inauguration of CECA Karachi marks a significant milestone in industrial training and development in Pakistan. This initiative not only enhances operational efficiencies but also paves the way for sustainable industrial practices across the region.

The ITMA ASIA + CITME, Singapore 2025 exhibition has attracted heightened levels of interest since it was launched in Milan last June. Drawn by the regional market opportunities, many leading textile technology brands are looking forward to apply for their booth space when online space application opens from 9 April 2024.

The Singapore edition is scheduled to be held at Singapore Expo from 28 to 31 October 2025. It is owned by CEMATEX (the European Committee of Textile Machinery Manufacturers), China Textile Machinery Association (CTMA) and SubCouncil of Textile Industry, CCPIT (CCPIT-Tex).

According to the show owners, there is a huge increase in enquiries from machinery manufacturers as the Singapore exhibition targets not only South and Southeast Asia, but also from very important markets in the Middle East.

Mr Ernesto Maurer, president of CEMATEX, explained, “These regions present vast opportunity for our members as technology buyers from these textile and garment hubs are sourcing costeffective and sustainable solutions to modernise and upgrade their production.

“The Singapore exhibition complements our ITMA exhibition in Europe and the ITMA ASIA + CITME exhibition in China. The platform will help to broaden our exhibitors’ market focus and diversify their reach, enabling them to effectively engage with many of

the buyers who were not able to attend these two exhibitions previously. For these buyers, we are convinced, Singapore is more accessible due to its closer proximity to their home countries, but even more so due to its visa-friendly policy.”

Mr Gu Ping, president of CTMA, said: “The combined exhibition in Singapore has opened a new phase of development for CITME. We are excited to bring our members along as we ride the wave of regional opportunities through the Singapore edition.”

Ms Chandrima Chatterjee, secretary general of the Confederation of Indian Textile Industry (CITI), welcomed the staging of the exhibition in Singapore. She said: “This expansion of the exhibition from Shanghai to Singapore recognises the growing needs of the Asian textile industry, especially India. The industry today is looking for technologies to meet its need for optimising production, minimising supply chain risks, better control of quality and finishes, and enhancing sustainability in all aspects of production.”

She added: “We look forward to the Singapore exhibition to address these needs and help this biggest textile manufacturing and exporting region of the world leverage the latest in technology and innovations.”

To mark the opening of space application, a webinar titled Springboard

to Regional Markets will be held on 9 April 2024 (Tuesday) at 3pm SGT. To register for the live session, visit https://www.itmaasiasingapore.com/web inar/9apr.

Billed as The Leading Textile Technology Exhibition Driving Regional Growth, ITMA ASIA + CITME, Singapore 2025 is expected to gross 60,000 square metres. It aims to attract over 600 exhibitors and a visitorship of 30,000. The combined exhibition is organised by ITMA Services and co-organised by Beijing Textile Machinery International Exhibition Co., Ltd.

Mr Daisuke Murata, president of Japan Textile Machinery Association (JTMA), said: “We congratulate the ITMA ASIA + CITME owners for making the decision to have a second exhibition in Asia. The Singapore exhibition will be useful for our members to better penetrate other regional textile hubs in Asia, and as far as the Middle East.”

Prominent textile technology providers are also eagerly eyeing the start of space application for the combined exhibition.

Ms Rebekka Dilo of Dilo Systems GmbH shared that the group is looking forward to the Singapore edition of ITMA Asia + CITME 2025. She enthused, “As an important gathering of the whole textile industry, it is a great opportunity for us to present our latest innovations.”

Welcome to our interview with Sonia Wedell-Castellano, the Global Director of DOMOTEX at Deutsche Messe AG. With DOMOTEX Middle East returning to Dubai, we have the opportunity to gain insights into the rationale behind this decision and what attendees can expect from this prestigious event.

DOMOTEX Middle East is making its comeback to Dubai. Could you kindly provide insight into the rationale behind this decision to return to the region, as well as the selection of Dubai as the show’s location?

Despite global economic challenges, the construction sector in the Middle East and North Africa (MENA) region has not only proved remarkably resilient, but is continuously growing.

These regions were forecasted to be among the best performing regions for construction activity in 2023 and beyond, according to GlobalData’s Global Construction Outlook to 2027 report, which was published in early 2023.

With more and more specific construction projects in Dubai, such as Dubai Creek Harbour and other Emaar projects, in Abu Dhabi on Saadiyat or Yas Island or in the KSA, such as NEOM, THE LINE and GIDORI in the pipeline, the Middle East will continue to be an absolute boom region for all companies involved in building and furnishing for decades to come.

Exploring the Dynamics of DOMOTEX Middle East: An Interview with Sonia Wedell-Castellano, Global Director

This positive outlook has a knock-on effect on related sectors such as real estate, interior design, furnishings and flooring. Therefore, the demand for carpets and floor coverings is constantly growing. The Middle East floor coverings and carpets market is expected to grow at a CAGR of 7.2 percent from US$8.6 billion in 2022 to around US$14.55 billion by 2030.

As the epicenter for business and tourism, Dubai is known for its inclusivity and diversity and as such, presents an ideal setting for DOMOTEX Middle East. With an exceptional business and trade infrastructure, a global aviation hub connecting the world as well as efficient public and private transportation, Dubai guarantees effortless and convenient access to the show for both, exhibitors and visitors alike.

I am very pleased with our determination and courage to provide the industry a highly attractive platform in this fast growing market with its incredibly promising potential.

DOMOTEX Middle East offers the perfect opportunity to gain a comprehensive overview of the market, discover and compare trends and innovations and to engage with other participants, exhibitors and visitors alike. We are looking forward to welcome everyone in Dubai in just a few weeks’ time.

What factors influenced the decision to hold DOMOTEX Middle East at the Dubai World Trade Centre (DWTC), and in what ways does this venue contribute to enriching the exhibition experience for participants?

The DWTC is the perfect venue for DOMOTEX Middle East as we have had good experiences in the past. It is one of the largest venue operators and home to the region’s leading convention and

exhibition centre, offering a dynamic calendar of international trade shows with an unrivalled line-up of leading exhibitions and conferences across all industries.

With decades of experience in organising events in the Middle East, DWTC will help us ensure an enjoyable and seamless experience for all attendees of DOMOTEX Middle East.

What can attendees expect regarding exhibitors and product showcases at DOMOTEX Middle East?

DOMOTEX Middle East is the first event to bring together the leading global brands Merinos, Oriental Weavers, Solomon Carpet and Al Abdullatif at a single show in Dubai. The commitment of these leading brands is not only an important gesture for us as organizers, but for the entire industry. Being in Dubai in April is everything!

Visitors can look forward to even more excellent exhibitors such as Farrahi Carpets, Almas Kavir Carpet, Standard Carpets, Abu Dhabi National Carpets, Heritage Carpet, Madhu India, Nirmal International, Extraweave, Dodhia Synthetics Limited, Nayyer Industries, Indian art Gallery, Card Monroe and many more. All of them will be showcasing their top products and latest innovations – including contemporary designs, unique pieces and superb craftsmanship. The show offers an unparalleled variety of flooring products, styles and materials, from handmade and machine-made carpets and rugs to antique carpets and floor coverings.

One of my personal highlights of the show will be presented by Iranian manufacturer Azim Silk Carpet Trading. As well as being an outstanding piece of art and craftsmanship, it’s also the largest carpet ever shown at a DOMOTEX event.

It measures 600 m² and is part of the Tabriz Premium Silk Warp, which consists

of four carpets that together form a carpet covering an area of 2,000 m². These carpets have been meticulously handcrafted by 230 weavers over a period of seven years. I’m looking forward to seeing it live in April, as the Tabriz Premium Silk Warp is an excellent example of the outstanding quality of handmade carpets produced in the Middle East.

As a leading international trade fair company, how does Deutsche Messe envision the future of DOMOTEX Middle East? What are the expectations for future editions of the event?

Naturally, we would like to become the leading event for carpets and floor coverings in the Middle East. Our next editions will be even bigger than this year’s. We already have a ton of ideas for special displays and collaborations in mind. For now, though, we’re going to focus on the first show. Never take the second step before you’ve taken the first.

What are the competitive advantages of the DOMOTEX brand compared to other events in the flooring sector?

DOMOTEX is the world’s leading brand of trade fairs for the carpet and floor coverings industry and has been at the forefront of strong, exceptional events since 1989. For us, carpets and floor coverings are not just one of many exhibition areas – as is the case at other events – but the centre of attention. DOMOTEX is entirely dedicated to the flooring industry.

In addition to our many years of experience as organisers and hosts of events for this unique industry, another strength of the DOMOTEX brand is the fantastic team. We are flooring enthusiasts and very passionate about what we do.

We love DOMOTEX and we love the community. I believe whenever we approach potential exhibitors and visitors, they can sense our enthusiasm and trust us to organise and stage great events for

them as we share a passion: A passion for carpets and flooring!

What are you looking forward to the most at DOMOTEX Middle East?

I am looking forward to the conversations with exhibitors, partners and visitors alike. They are the essence of each DOMOTEX event, the essence of what makes it the home of the entire industry and the reason why we are doing what we are doing.

There is nothing better than the opportunity to engage on a professional and personal level with all of them – and see them all leaving the fairgrounds with a big smile on their faces.

Sonia Wedell-Castellano has been with Deutsche Messe since 2011, where she has served as Sales Director and Global Director of Hannover Messe. In 2018, she took over responsibility for DOMOTEX as Global Director. Before moving to Hannover, the industrial and multi-language specialist was Marketing Manager Europe for the DMG Mori Group, a global manufacturer of machine tools.

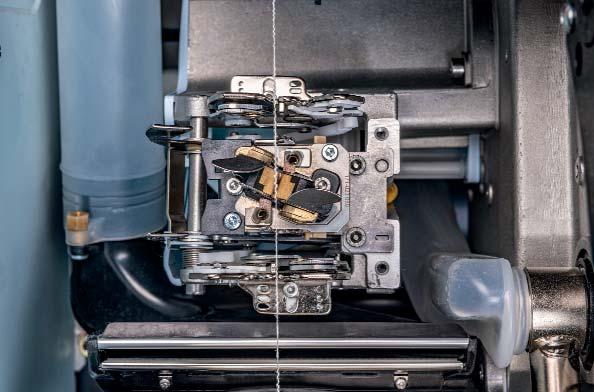

Demand for the Autoconer X6’s new open prism technology is accelerating across markets globally. The open prism OZ2 covers a wider application range and is a gamechanger for spinning mills. This new technology can process standard, elastic and multicore yarns based on improved splice quality and splice process.

The open prism splice technology is designed to cover nearly the complete material and yarn spectrum with a minimum number of prisms. Having started with applications limited to single yarns made of 100% cotton and blends with more than 30% cotton, the material range was rapidly expanded in the last two years due to intensive technological testing. Now spinning mills can cover the entire spectrum of cotton yarns and cotton blends with the open prism technology. In addition, elastic yarns in a wide variety of material combinations consisting of cotton, polyester, viscose, and blends as single, duo or multi-core yarns are possible.

The prism OZ1 is recommended for yarn count Ne 30 to Ne 120 and finer. With the all-new OZ2 prism, customers can widen the application range down to Ne 4. Because of its versatile application in coarser yarn count ranges, the prism OZ2 is particularly well-suited and recommended as an all-rounder for duo or multi-core yarns.

Rieter customers can take an application-oriented decision: spinning mills which focus on a yarn count range finer than Ne 30 and process cotton yarns, cotton blends or cotton-elastane blends select the standard version OZ1. For spinning mills with the widest application ranges and with different yarn structures and material combinations (cotton, polyester, elastane, viscose), Rieter recommends the optional prism OZ2 (Fig. 1).

The production of modern denim fabrics requires both coarse single yarns and high-elastic core yarns, such as single, duo-core or multi-core yarns, with very different material combinations. This is where the open prism technology is unique and unbeatable: all types of yarns can be processed with one splicing system. Customers can easily switch between elastic and standard yarn processing. The splicing parameters are almost the same. This is a big advantage compared to competitor splicing systems which have

limitations in terms of universal applicability.

For a very large variety of elastic yarns dry splicing is possible and will lead to yarn-like splice results (Fig. 2). For applications which need highest yarn strength and thus splice strength as well (average splice strength > 90-95%), the use of a very small amount of water is recommended to be on the safe side. Due to a minimized amount of water, drastically less cleaning is required. The splice process itself is more stable, while the fault rate and number of splice cuts are reduced to a minimum.

Open prism technology guarantees elasticity of the splice zone right through to the finished fabric including dyeable splice joints for uniform dyeing process and embedded elastic filament ends. This results in reduced splice failure rates in weaving and knitting by approx. 50-70% and, thus a higher quality of the finished products.

The universality of the Autoconer splice technology makes the use of the innovative open prism splice technology not only possible for new machines but it can also be retrofitted on all machine generations down to the Autoconer 338. In future the application range of the open prism splice technology will be expanded to S-twisted yarns with the prism OS.

The U.S. Cotton Trust Protocol has today announced the appointment of a refreshed and expanded Board of Directors. The refreshed board comes with the appointment of 11 new board members and expands the board from the previous 16 to now 22 members.

The appointment of the new board comes as part of a governance review four years into the successful development of the program, and at a natural inflection point in the Trust Protocol’s evolution. The board has been expanded in particular to give greater and more equal representation to international stakeholders and across the entire supply chain, while enhancing its diversity.

The U.S. Cotton Trust Protocol Board of Directors announced today includes:

four growers, each representing one of the four U.S. cotton-growing regions;

three representatives of gins and cottonseed producers; four merchants and cooperatives; four mills and manufacturers; three representatives from NGOs and academia, and four brand and retailer members

The refreshed board is structured to deliver on the Trust Protocol’s emphasis of further connecting the supply chain from the farm to end user, driving demand from all segments, and seeking to improve impact, as well as building program understanding amongst growers to drive continued enrollment.

With a view to ensuring fresh perspectives while retaining institutional knowledge, board members are appointed for a period of two years renewable once. An Advisory Council with a fluctuating number of seats complements the board by providing adhoc expertise on specific topics.

Commenting on the board appointments, Daren Abney, Executive Director of the U.S. Cotton Trust Protocol, said:

“I’m thrilled about the formation of our newly refreshed Board of Directors.

Comprised of exceptional experts and leaders spanning the global supply chain, this board represents a significant milestone in the governance of the U.S. Cotton Trust Protocol. By incorporating a blend of domestic and international voices, this board will ensure a diversity of perspectives that will drive value for all members across the supply chain, while ensuring that cotton growers remain at the very heart of the program.”

The new board members are:

Cotton Growers

Sam Whitaker, Partner, Whitaker Farms Gins and Cottonseed

Larry Black, General Manager, Central Rolling Plains Gin Coops and Merchants

Krista Rickman, Commercial Strategic Lead, Cargill Cotton

Carlos Garcia, Director of Sales, Plains Cotton Cooperative Association

Mills and Manufacturers

Adolfo Kalach, Vice President, Kaltex Manufacturing Group

Saima Chowdhury, Founder and CEO, Noi Solutions LLC

NGOs and Academia

Suzy Friedman, Senior Director of Food Policy, World Wildlife Fund

Tyson Raper, Associate Professor, Pettigrew Cotton Specialist, University of Tennessee Brands and Retailers

Katherine “Katie” O’Hare, Senior Director, Sustainability, J. Crew Group

Agata Smeets, Head of Environment and Product Sustainability, Gap Inc.

Virginie Cayzeele, Head of Raw Materials, Kiabi

They join existing members:

Cotton Growers

Aaron Barcellos, Partner, A-Bar Ag Enterprises

Dahlen Hancock, Owner, DK & J Farms

Matt Coley, Owner, Coley Farms

Gins and Cottonseed

Fred Serven, General Manager of Cotton, Archer Daniels Midland

David Blakemore, President, Blakemore Cotton and Grain, LLC

Coops and Merchants

Henry “Hank” Reichle, President and CEO, Staple Cotton Cooperative Association

William “Buddy” Allen, President and CEO, American Cotton Shippers Association

Mills and Manufacturers

Jim Martin, Executive Vice President of Cotton Operations, Parkdale Mills, Inc.

Mike Quinn, Vice President of Cotton Operations, Gildan yarns, LLC.

NGOs and Academia

Kris Johnson, Director of the North America Agriculture Program, The Nature Conservancy

Brands and Retailers

Hitesh Sharma, Senior Lead, Sustainable Sourcing and Traceability (Global Sustainability), Levi Strauss & Company

In recent years, Italian circular knitting machine manufacturer Santoni (part of the Lonati Group) and Groz-Beckert have worked together to develop a new self-cleaning knitting system for the INNOTAS circular knitting machine. The knitting system is also called INNOTAS and consists of the circular knitting machine needle SANTM DUO and the corresponding sinker SNK DUO-OL.

Driven by the increasing demands on sustainability aspects and the desired increases in efficiency, Groz-Beckert had the goal of developing a new, energyefficient knitting system. Groz-Beckert approached Santoni with a corresponding cooperation request. Following various preliminary investigations, the go-ahead was finally given in January 2015 for the joint development of a self-cleaning system in the needle area with side-byside needles and a low shank.