JIAM 2022 OSAKA

Dates: Nov. 30th to Dec. 3nd 2022.

Venue: Osaka, Japan.

DOMOTEX Hannover 2023

Dates: January 12th to 15th 2023. Venue: Hannover, Germany.

FESPA 2023

Dates: May 23rd to 26th 2023.

Venue: Munich, Germany.

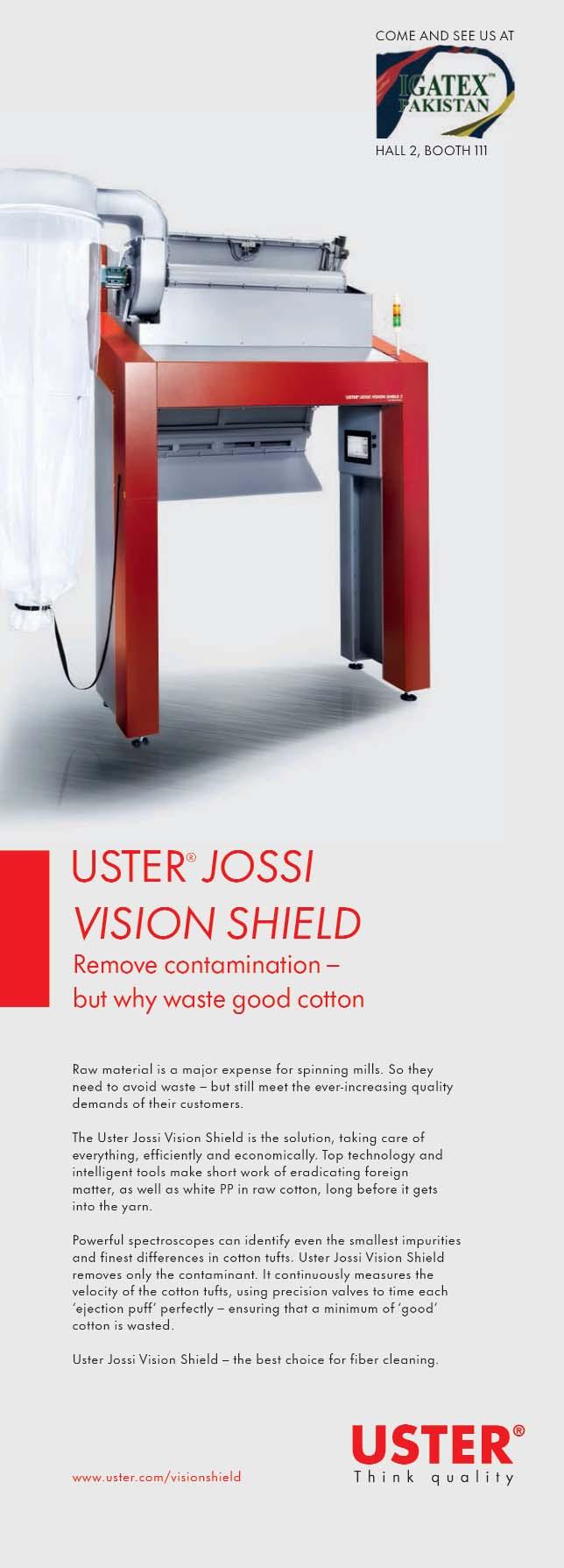

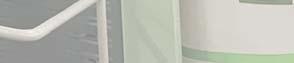

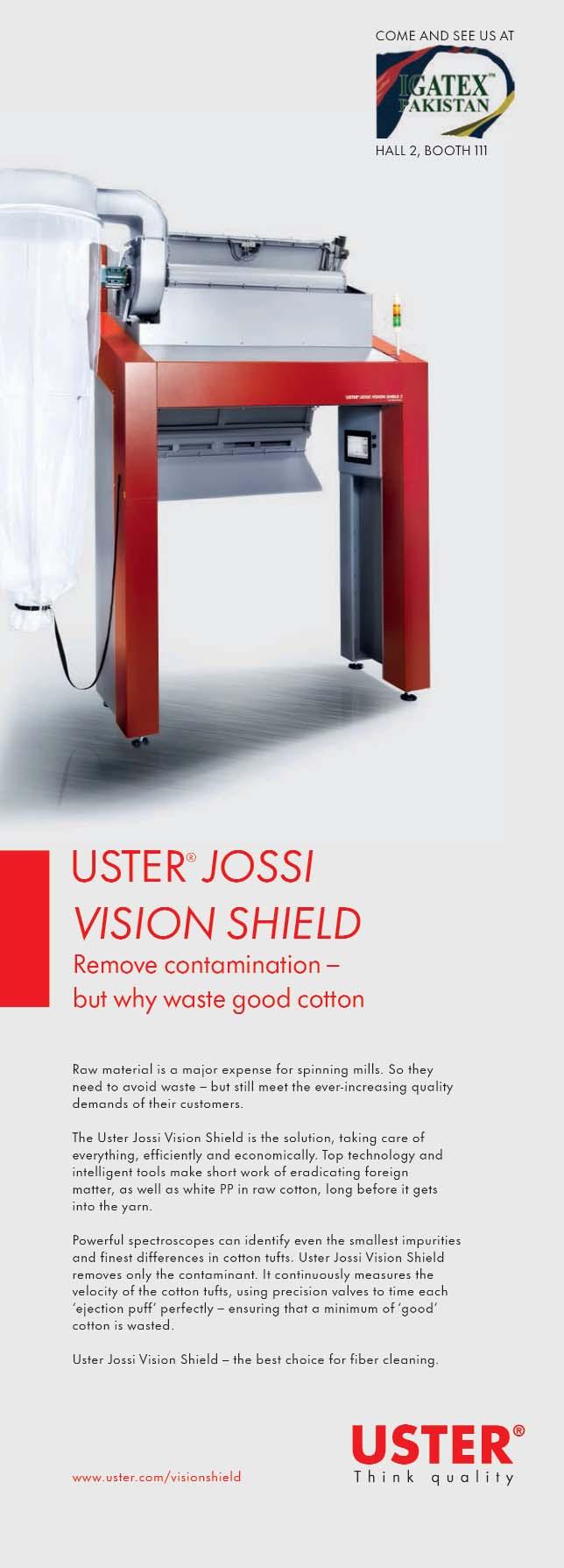

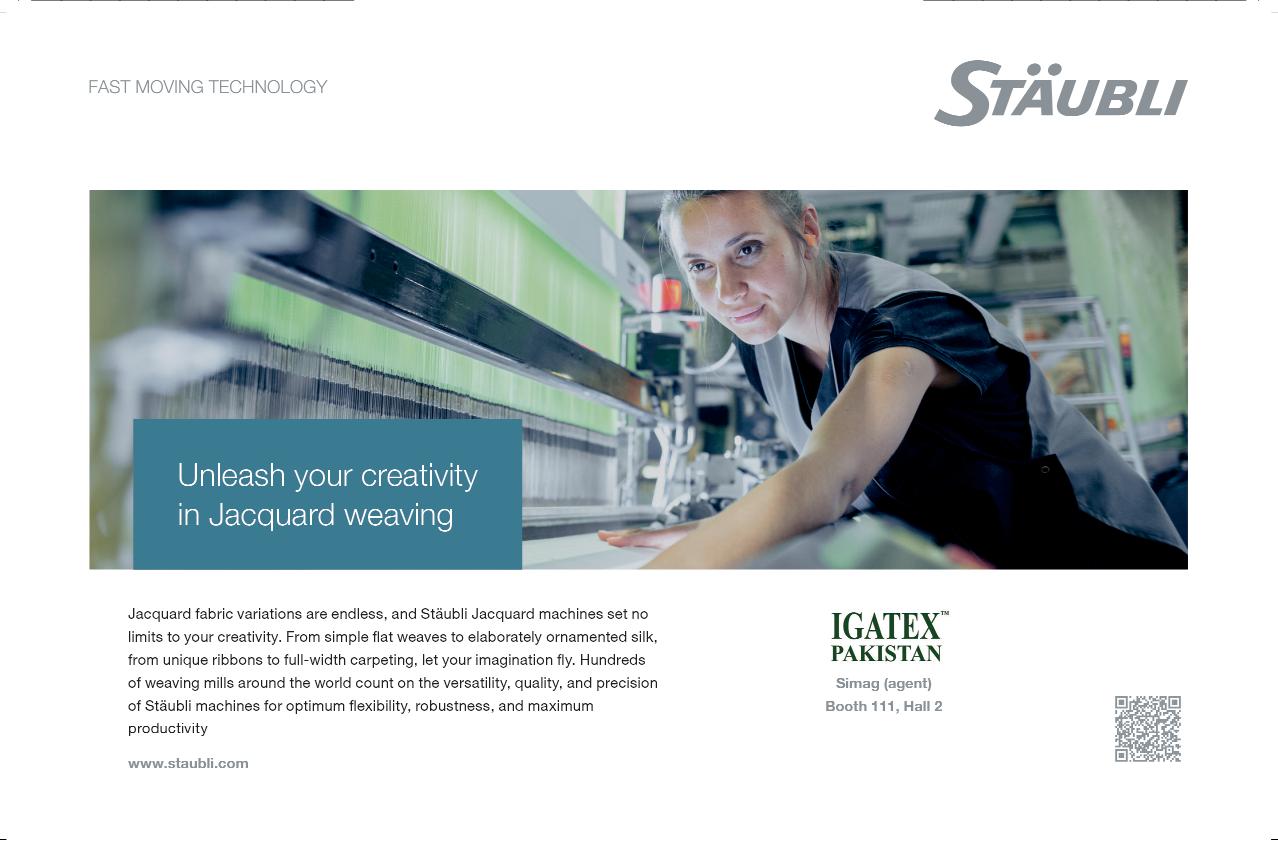

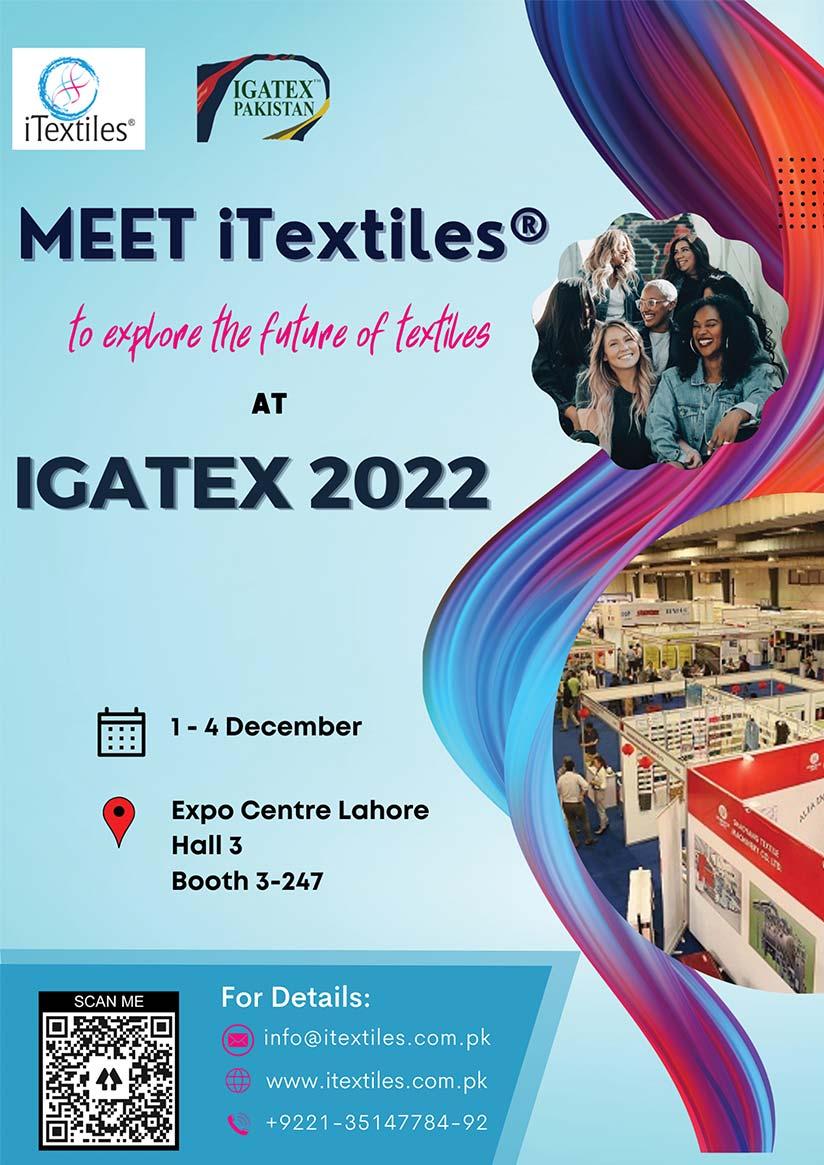

IGATEX Pakistan 2022, Lahore

Dates: December 1st to 4th 2022.

Venue: Expo Centre, Lahore.

Istanbul Yarn Fair

Dates: February 16th to 18th 2023.

Venue: Istanbul, Turkey.

ITMA 2023

Dates: June 8th to 14th, 2023. Venue: Milan, Italy.

iCADEX Pakistan 2022, Lahore

Dates: December 1st to 4th 2022. Venue: Expo Centre, Lahore.

Textile Asia 2023, Karachi

Dates: March 11th to 13th 2023. Venue: Expo Centre, Karachi.

INTEX SOUTH ASIA 2022

Dates: December 8th to 10rd 2022. Venue: New Delhi, India.

ITME INDIA 2022

Dates: December 8th to 13th 2022. Venue: India Expo Centre & Mart. Noida, India.

Index 2023

Dates: April 18th to 21th, 2023. Venue: Palexpo, Geneva, Switzerland.

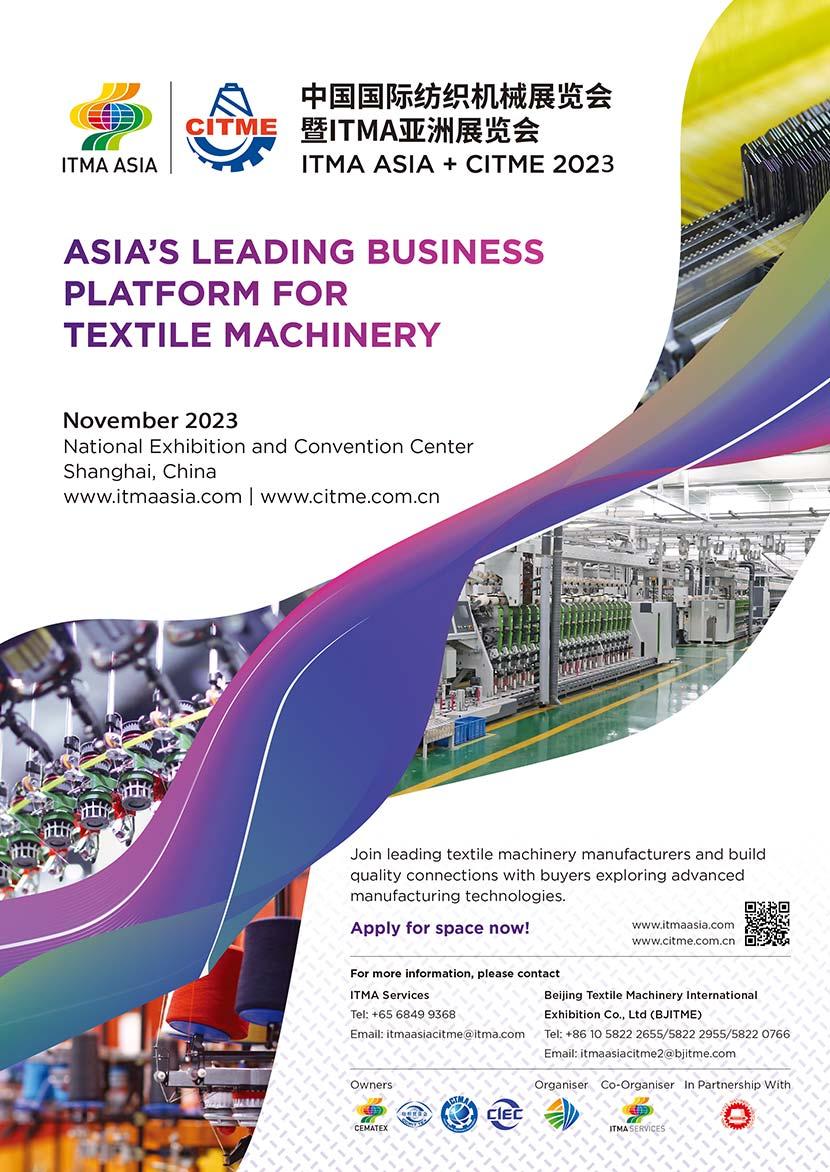

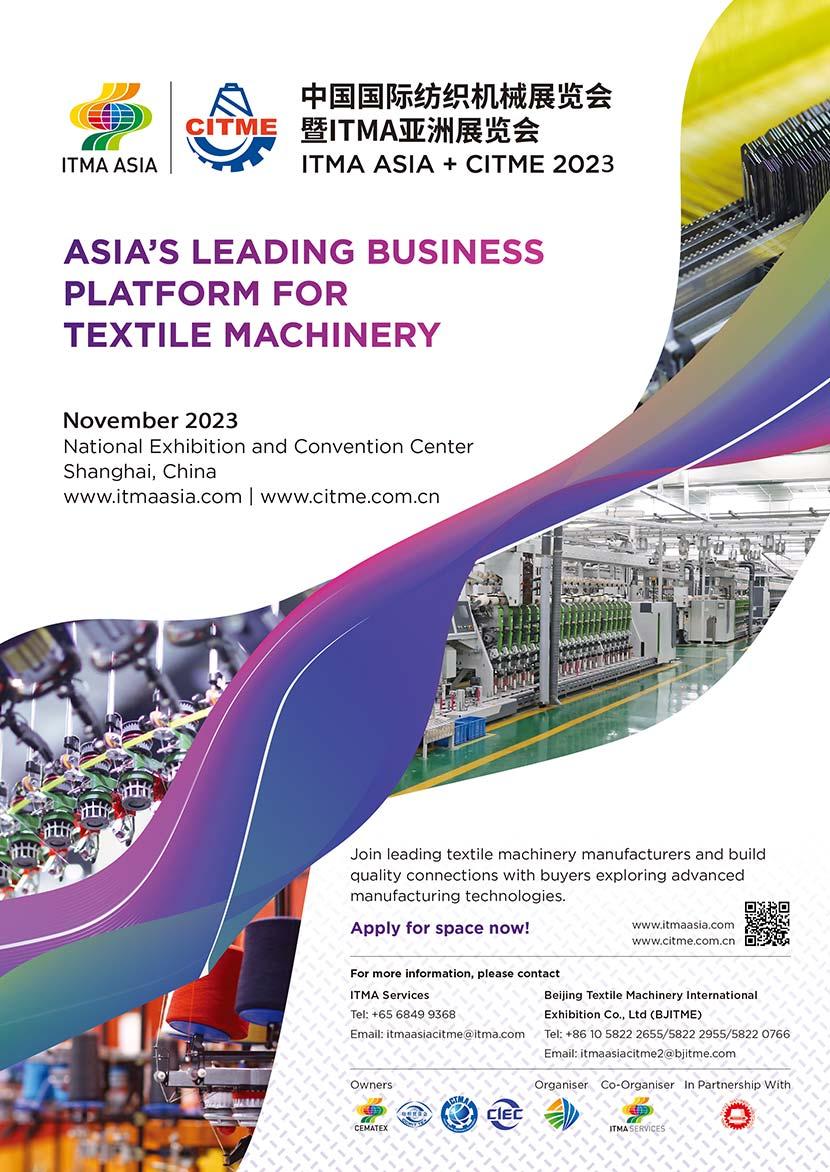

ITMA ASIA + CITME 2023

Dates: November 19th to 23th, 2023. Venue: NECC, Shanghai, China.

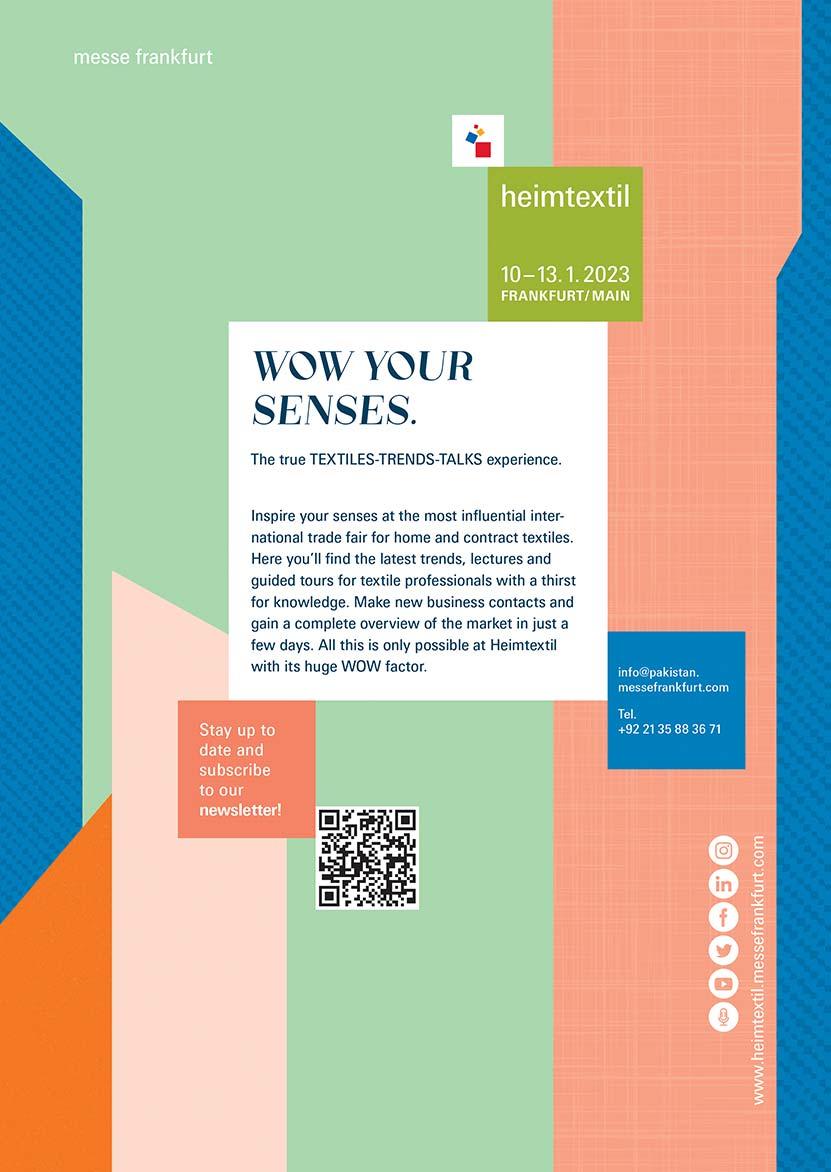

Heimtextil 2023, Frankfurt

Dates: January 10th, to 13th, 2023

Venue: Frankfurt am Main.

Techtextil 2023 North America

Dates: May 10th to 12th, 2023 Venue: Georgia USA.

62th Dornbirn GFC Global Fiber Congress

Dates: September 13th to 15th 2023. Venue: Dornbirn Austria.

ITM 2024

Dates: June 4th to 8th, 2024. Venue: Istanbul, Turkey.

DOMOTEX asiaCHINAFLOOR 2023

Dates: May 29th to 31st 2023. Venue: NECC, Shanghai, China.

HIGHTEX 2024

Dates: June 4th to 8th, 2024. Venue: Istanbul, Turkey.

2 Calendar of Events

PAKISTAN TEXTILE JOURNAL - November 2022

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher

Nadeem Mazhar Editor in Chief Amina Baqai

Associate Editor Dr. Noor Ahmed Memon

Associate Editor

Nimrah Nadeem

Associate Editor Shahnawaz Khan

Production Manager Mazhar Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA)

Mian Iftkhar Afzal B.S.N.C State, M.Sc. (Leeds) C.TEXT.F.T.I (UK)

Dr. Zubair Bandukda PhD (Textiles), CText ATI

Editorial & Advertising Office

B-4, 2nd Floor, 64/21, M.A.C.H, Miran M. Shah Road, Karachi - Pakistan Tel: +92-21-34311674-5 Fax: +92-21-34533616 Email: info@ptj.com.pk URL: http://www.ptj.com.pk

PTJ Europe Ltd. Correspondence & Mailing address: 93 Fleming Place, Bracknell, RG12 2GN, United Kingdom Tel: +44 792 2228 721

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, UK Registered no. 09141989

Available on Gale and Factiva affiliated international databases through Asianet Pakistan

Printed at: Color Plus Korangi, Karachi.

Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi.

Vol. LXXI No. 11 November 2022 Rs. 565.00

EDITOR’S PAGE . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Textile-producing nations unite to reduce chemical waste

TEXTILE BRIEFS . . . . . . . . . . . . . . . . . . . . . . . . . . .8

NEWS & VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . .10

AROUND THE WORLD . . . . . . . . . . . . . . . . . . . . . .14

SPECIAL REPORTS

U.S. Cotton Trust Protocol attends Sustainable Brands Flagship Conference . . . .20 TENCELTM launchesTree Climate Fabric Collection . . . . . . . . . . . . . . . . . .21

CORPORATE NEWS

Rieter donates CHF 100,000 to support flood victims in Pakistan . . . . . . . . .22

DYES AND CHEMICALS

LAB102 – Blue veins of CHT as new brand for the jeans and garment treatment24 Archroma to acquire the Textile Effects Business of Huntsman Corporation . . . .26

FIBRES AND YARNS

PERSONALIA

VDMA: Dr. Harald Weber new Managing Director of the Textile Machinery . . . . .30

28

22 24

Gleaming

for

and

uses

. . . . . . . . . . . . . . . .

Marchi & Fildi Group introduces

line range of coloured, reflective yarns

technical, safety

stretch

.

. . . . . . . . . . . . .28

FAIRS AND EXHIBITIONS

FEATURES

MILL REPORTS

IGATEX PAKISTAN

38 40

46 46 52 56

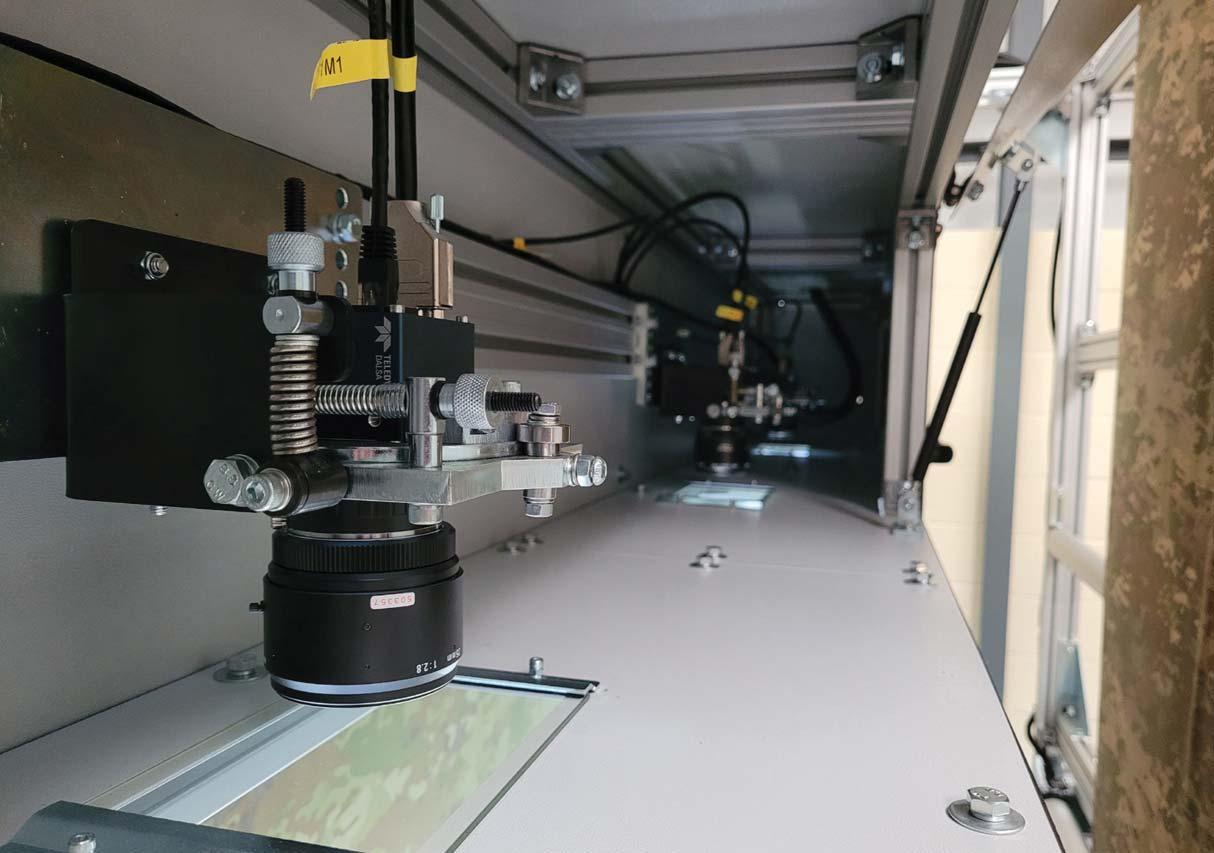

Terrot celebrates its 160th anniversary . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 The LYCRA company publishes sustainability update . . . . . . . . . . . . . . . . . . .36 Uster: Cotton – the unique natural fiber . . . . . . . . . . . . . . . . . . . . . . . . . . . .38 Sellers Textile Engineers: Hybrid Shear for carpet manufacturing . . . . . . . . . . .40 Seeing beyond the patterns with Shelton Vision . . . . . . . . . . . . . . . . . . . . . . .42

trade fair for home and contract textiles . . . . . . . . . . . . . . . .

International

. . . . . .31 Textile machines from Sweden at new local industry fair . . . . . . . . . . . . . . . . . . . . .32 Texworld, Apparel Sourcing fairs to be held in February 2023 in France . . . . . . . . . .34

.46

SSM air texturing machine DP5-T offers flexible production with high quality . .44 Perfect fiber and spinning preparation for Air-Jet Yarn . . . . . . . . . . . . . . . . .

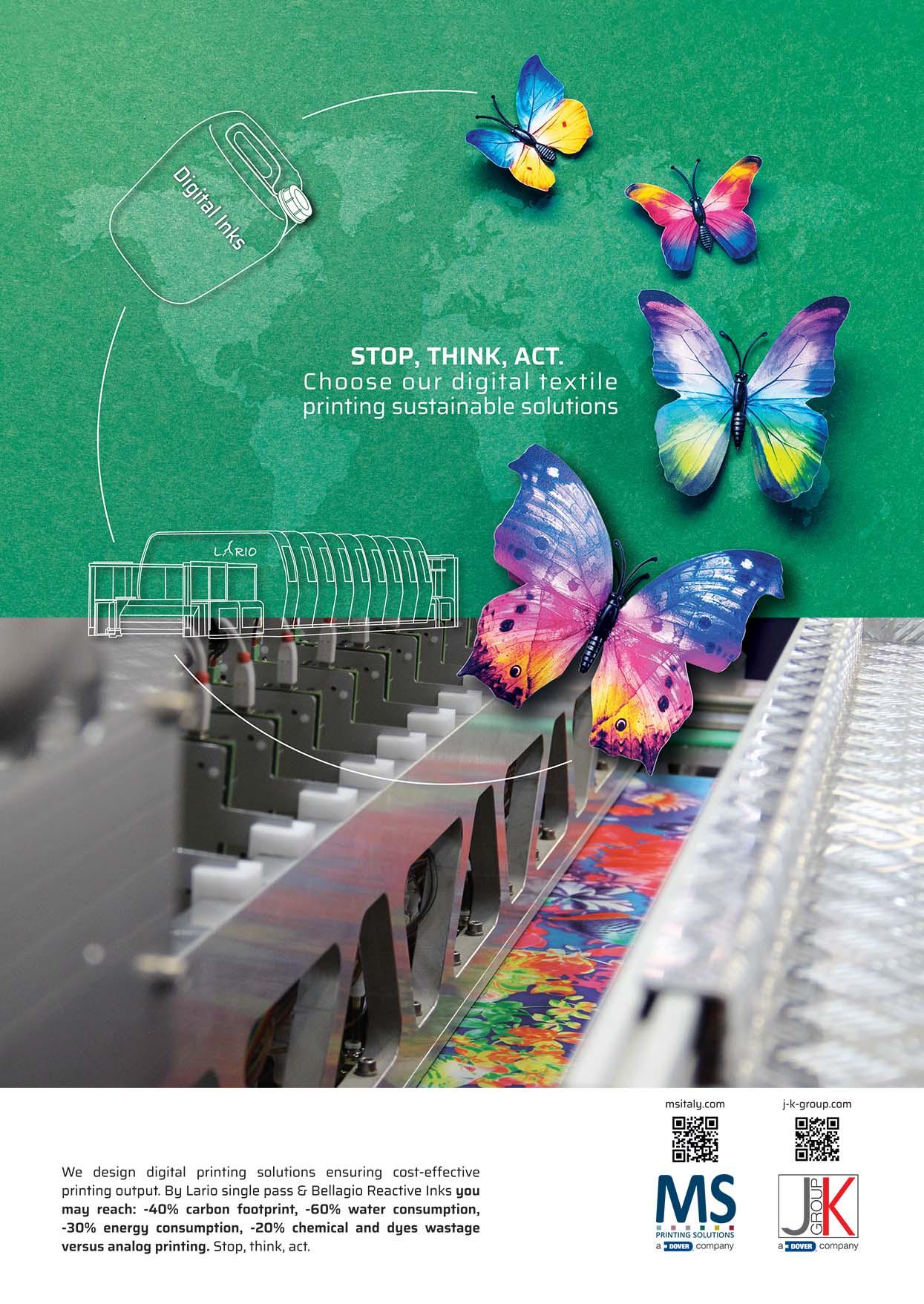

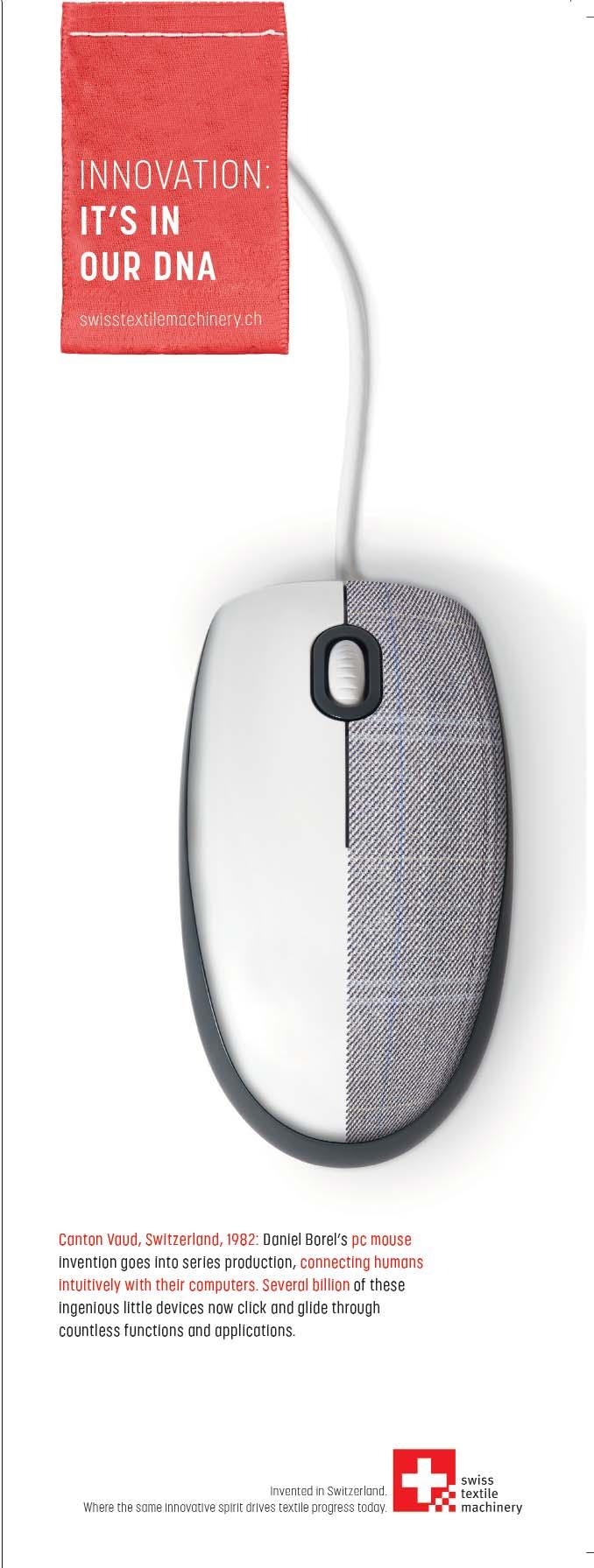

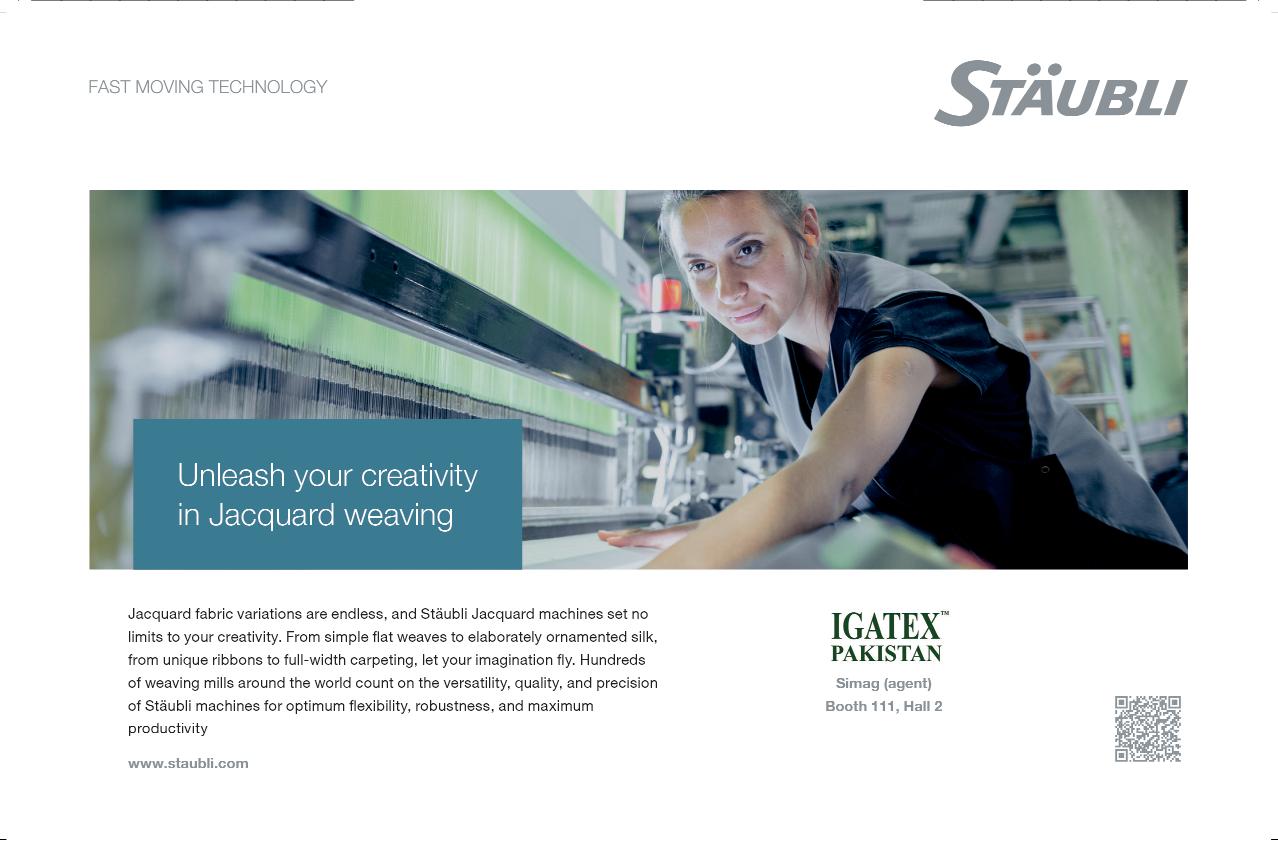

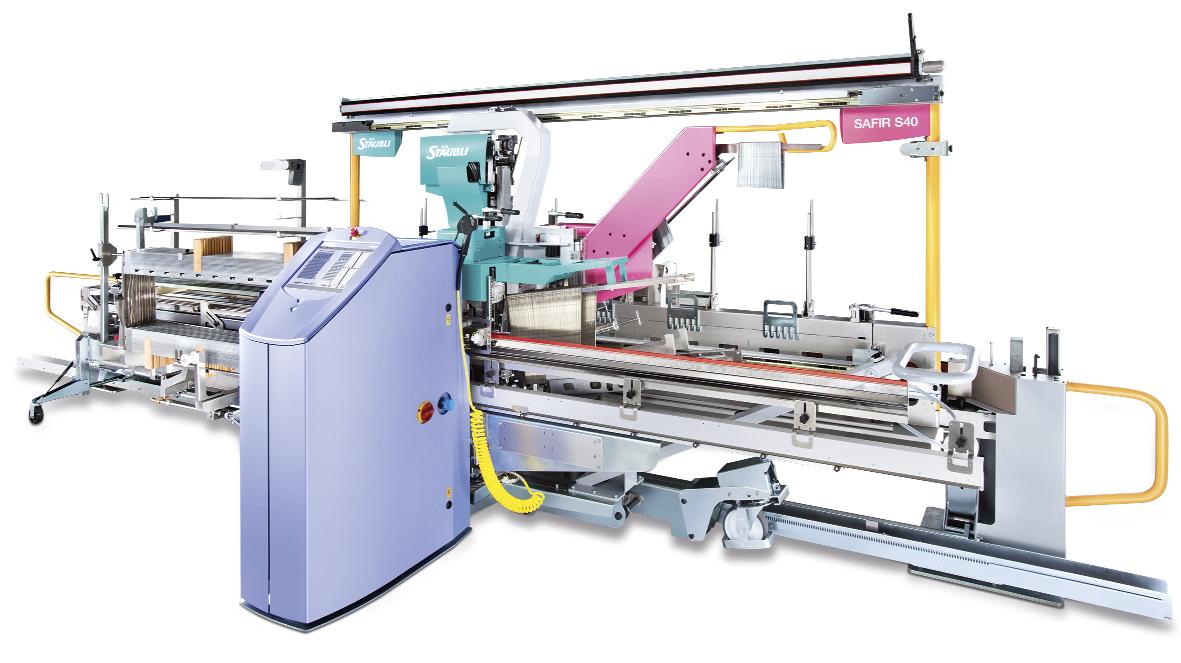

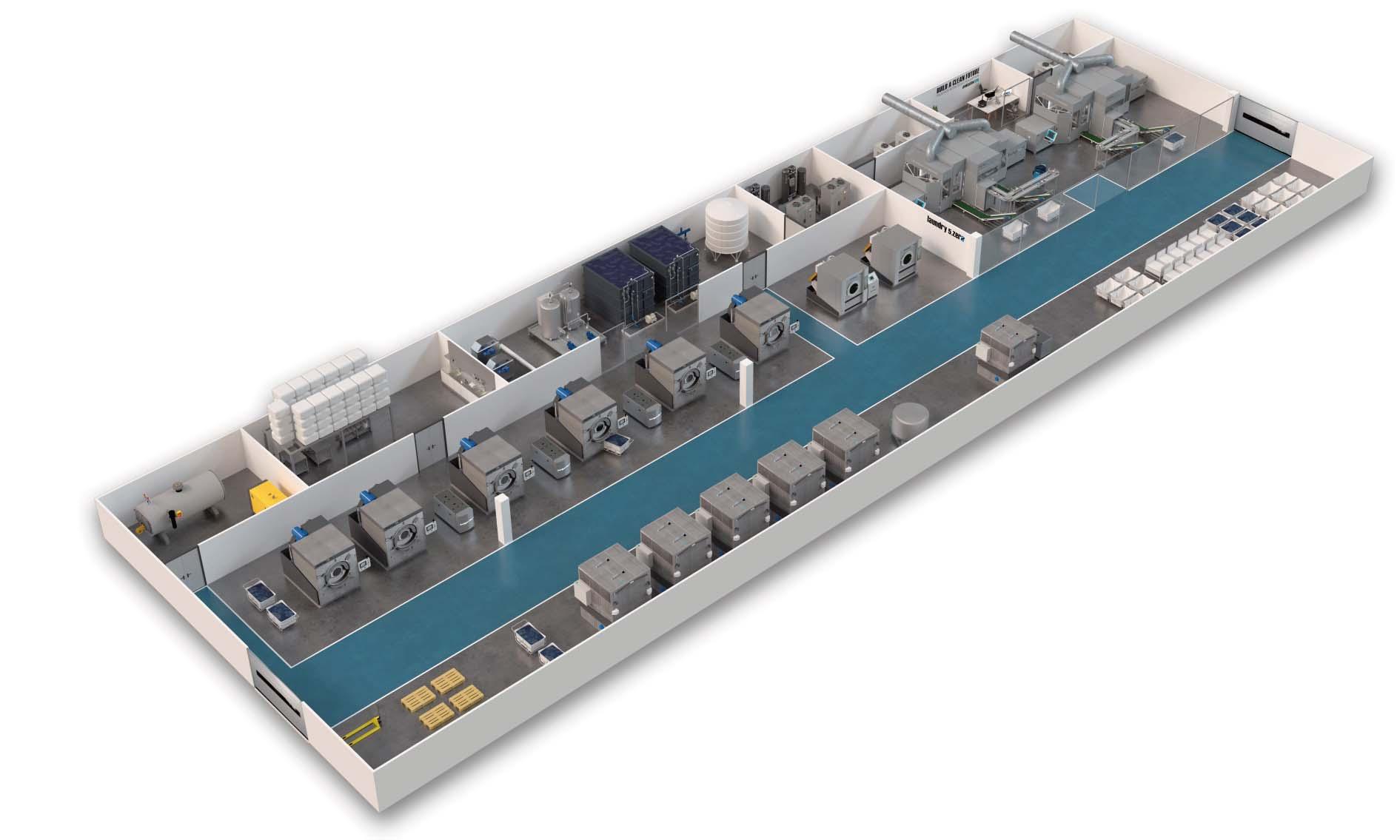

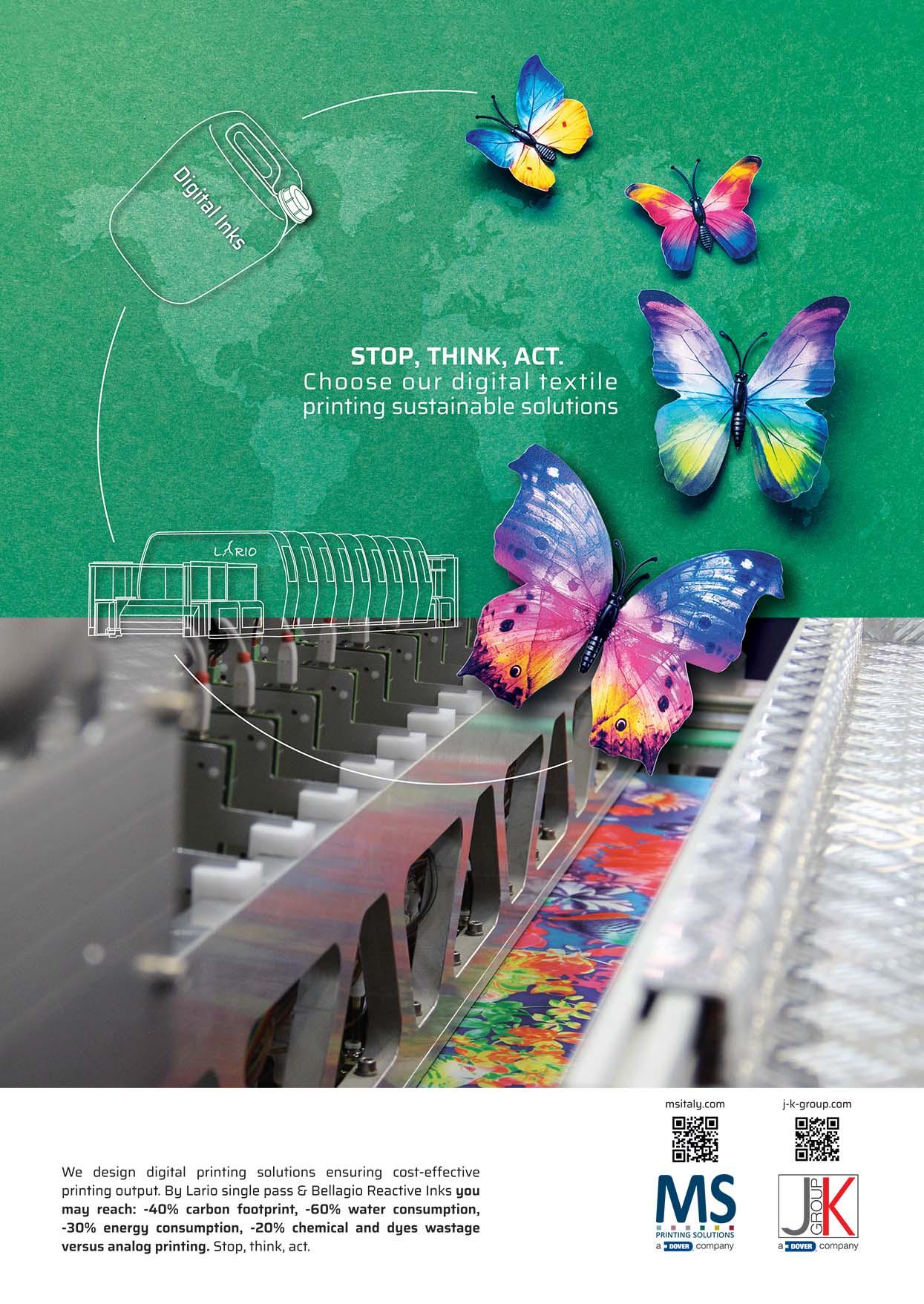

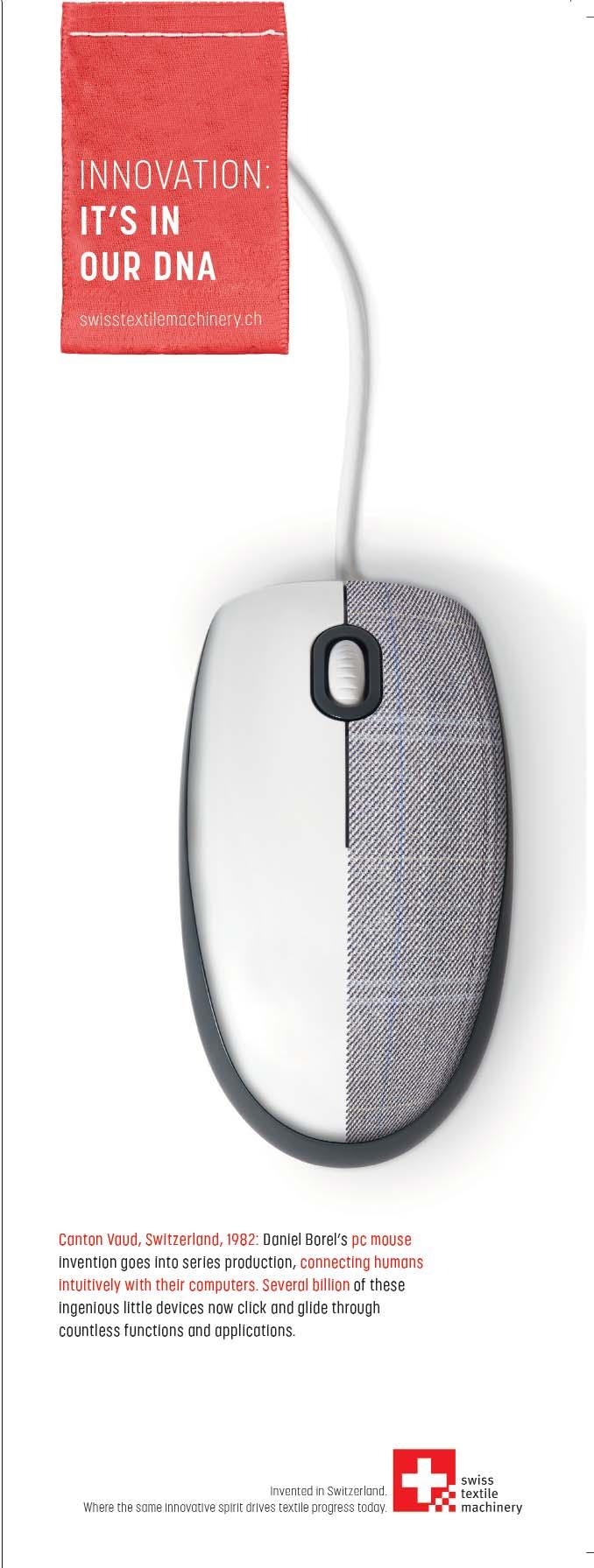

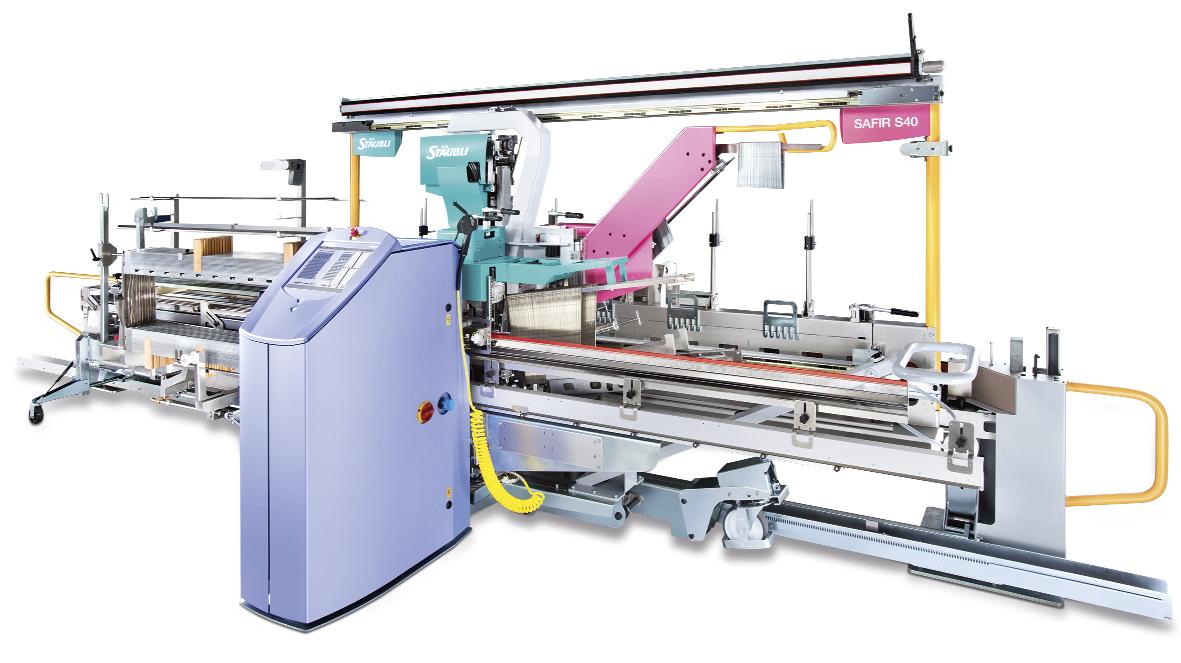

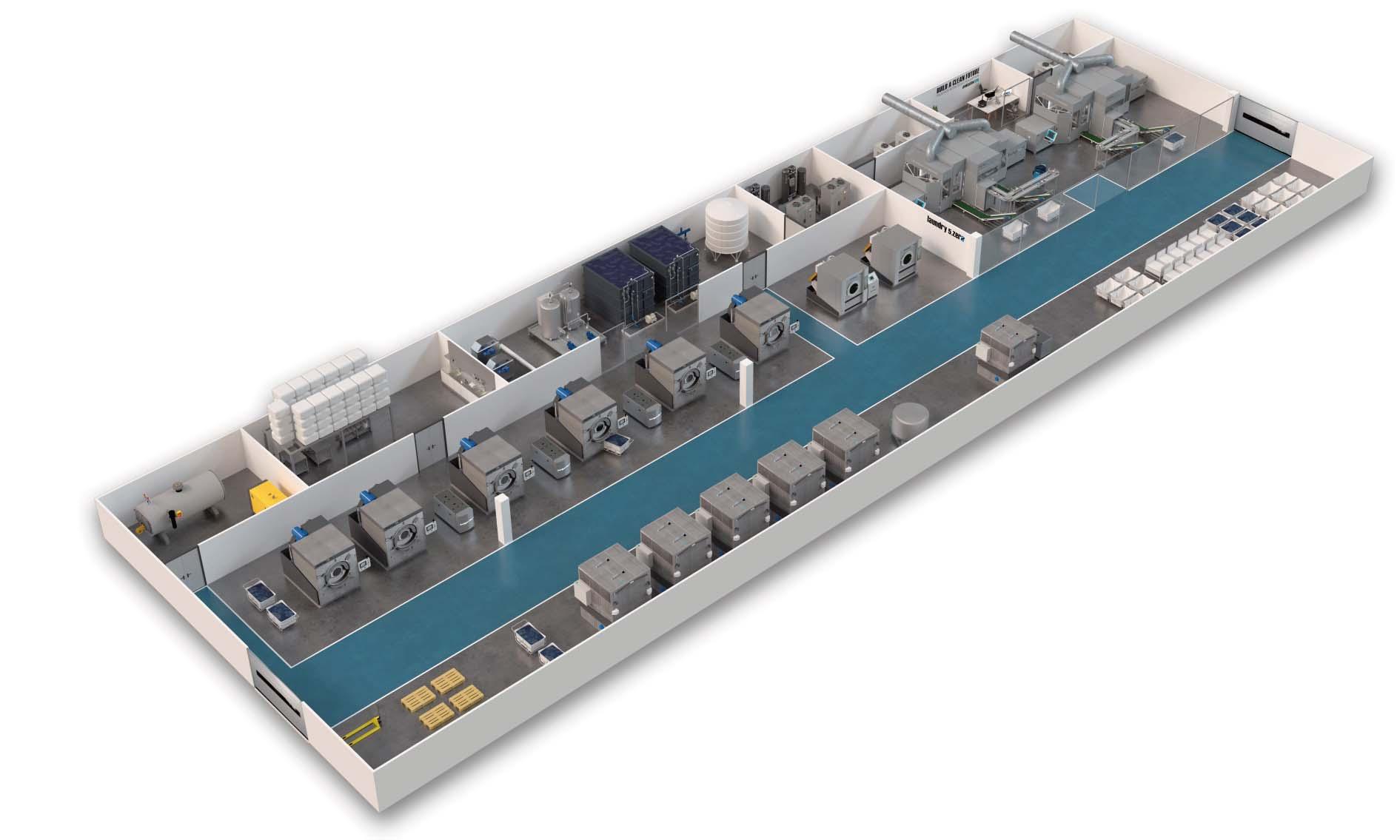

International Garment & Textile Machinery Exhibition & Conference . . . . . . . . . .48 IGATEX PAKISTAN 2022 – Celebrating 20 years of innovation in the world of textiles .49 Interview of Mr. Saleem Khan Tanoli, CEO, FAKT Exhibitions (Pvt.) Ltd.. Montex stentering equipment, Monfortex sanforizing units & Thermex dyeing . .50 CHTC FONG'S highlight: Smart Dyeing & Finishing innovations . . . . . . . . . . . . .52 Stäubli highlights the brand new SX PRO Jacquard machine . . . . . . . . . . . . . .54 Saurer: Sustainable spinning with Autocoro and BD 7 . . . . . . . . . . . . . . . . . . .56 Jeanologia presents efficient and competitive sustainable production models . .58 Baldwin teams up with Al Ameen for Sustainable TexCoat G4 Finishing System .60 EFI Reggiani presents sustainable solutions . . . . . . . . . . . . . . . . . . . . . . . . . .61 MS Printing & JK Group highlights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63 48 60

2022

Textile-producing nations unite to reduce chemical waste

The Governments of Bangladesh, Indonesia, Pakistan and Viet Nam have joined forces to fight chemical pollution, launching a joint $43million programme to manage and reduce hazardous chemicals in their textile industries.

Employing over 10 million people, the four nations’ textile sectors account for near 15% of global clothing exports. However, the economic benefits of the industry come at a cost, with the sector being one of the world’s major users of Persistent Organic Pollutants (POPs) and per- and polyfluoroalkyl substances (PFAS), a family of approximately 12,000 synthetic chemicals which do not break down and accumulate in the environment, threatening human and ecosystem health.

Wet processing factories, where materials are turned into fabrics through bleaching, printing, dyeing, finishing and laundering typically use 0.58 kg of chemical inputs for every 1 kg of fabric produced. These compounds leak into the environment at all phases of the textile lifecycle, from production to use, disposal and recycling.

Led by the UN Environment Programme (UNEP), with the financial backing of the Global Environment Facility (GEF) and the support of the Basel & Stockholm Convention Regional Centre SouthEast Asia and the Natural Resources Defence Council, the Reducing uses and releases of chemicals of concern in the textiles sector programme will provide technical support and tools for SMEs and manufacturers to improve their knowledge and management of hazardous chemicals, guiding them to manage risks to workers, and eventually eliminate the worst chemicals from their production processes.

“The textile sector is a major user of toxic ‘forever chemicals’ which pollute local and global ecosystems,” UNEP Chemicals and Waste Programme Officer Eloise Touni said.

“While governments have agreed global bans of the worst chemicals through the Stockholm Convention on POPs, value chains still use thousands of hazardous chemicals like PFAS. UNEP is proud to work with governments and front-runner companies to scale up best practices and phase out chemicals of concern across the whole sector”.

The five-year programme will bring the four countries together to align public policy on the textile sector with international best practice, including on supply chain transparency, investment for chemical management and eco-innovation, and occupational health and safety, creating the enabling environment needed to phase out PFAS and other chemicals of concern.

General Manager of Corporate Sustainability and Chemical Management at Pakistani textile manufacturer Interloop Limited Fauz Ul Azeem said processing mills often lack the awareness and technical expertise needed to manage chemicals according to best practices.

“For any production facility, phasing out any chemical from the running inventory is a painful task,” Mr Ul Azeem said. “They need to realign all the running processes after a careful analysis of quality, regulatory and cost impacts.”

“This project will help stakeholders to understand upcoming global mandatory requirements and how a pro-active approach can help them avoid a business impact. It will help them learn that considering environmental impacts in their decision making can lead to long term benefits”.

Senior Joint Secretary of the Ministry of Climate Change in Pakistan, Syed Mujtaba Hussain said the country was keenly aware of the need to reform the textile industry in order to reduce its environmental impacts and meet Pakistan’s international obligations.

“The textile wet processing stage is an environmental ‘hotspot’ in terms of water pollution, ecosystem, human health and climate impacts due to the high use of chemicals and of fossil fuel-derived energy,” Mr Hussain said.

“We welcome this project, which will help this important sector to reduce its pollution while accessing new markets for continued growth.”

Global Environment Facility

The Global Environment Facility is the world’s largest funder of biodiversity protection, nature restoration, climate change response, and pollution reduction in developing countries. It finances international environmental conventions and country-driven initiatives that generate global benefits. The GEF partnership connects 184 member governments with civil society, Indigenous Peoples, and the private sector, and works closely with other environmental financiers for efficiency and impact. To date, the GEF has provided more than $22 billion in grants and blended finance and mobilized another $120 billion in co-financing for more than 5,000 national and regional projects, plus 27,000 community ventures through its Small Grants Programme.

About the UN Environment Programme (UNEP)

UNEP is the leading global voice on the environment. It provides leadership and encourages partnership in caring for the environment by inspiring, informing and enabling nations and peoples to improve their quality of life without compromising that of future generations.

7 Editorial Article

1Pakistan’s exports of textile and clothing post a negative growth of 15.23 per cent in October from a year ago, data compiled by the Pakistan Bureau of Statistics (PBS) showed. High energy cost was one of the reasons for the slowdown in textile exports besides the non-disbursement of refund payments.

2Finance Minister Ishaq Dar has announced a power subsidy package for Pakistan’s export industries with per unit electricity cost set at Rs19.99.

3The deputy head of Belarussian mission in Pakistan, Ilya

Kanapliou, has said that Pakistan and Belarus are moving towards greater economic cooperation, which will have positive impact on the relations between the two countries in the long term.

4Pakistan’s textile industry’s battle with global environmental challenges. The recent countrywide floods are evidence of Pakistan bearing someone else’s emissions burden. The global GHG emissions data indicate that Pakistan contributes around 1% to these emissions.

5Senior Vice Chairman, (PHMA) has said that immediate restoration of old electricity tariff for textile sector is imperative to save national exports which were already in declining mode.

6The Governments of Bangladesh, Indonesia, Pakistan and Vietnam have joined forces to fight chemical pollution, launching a joint $43-million programme to manage and reduce hazardous chemicals in their textile industries.

7US Ambassador to Pakistan Donald Blome says he looks forward to expanding agricultural

trade between the two countries. He said that the US is looking forward to introducing high-yield cotton seed technology in Pakistan.

8Ambassador of the European Union Dr Riina Kionka has called for effective implementation of the 27 labour and human rights conventions as Pakistan’s current GSP plus status would be reviewed in December 2023. The ambassador said that more labour and human rights conventions would be added for implementation.

1Bangladesh Textile Mills Association (BTMA), states that almost 60 per cent of Bangladesh’s textile mills are at risk of closure due to the ongoing severe shortage of gas.

2China’s apparel exports to India increased by two and a half folds in August compared to March 2022. Monthly exports rose to $131.555 million in August from $53.275 million in March 2022. Although, the trade value is insignificant for both nations.

3India’s textiles sector aims to hit $100 billion exports in 5-6 years, which would take the indus-

try’s combined domestic and international economic value to USD 250 billion, Union minister Piyush Goyal.

4The weight of exports from Iran’s clothing and textile industries increased by 12 percent in the first six months of the current Iranian calendar year (March 21-September 22), compared to the figure for the preceding year’s first half.

5The Revenue Commissioners and the Irish customs authorities are obliged by law to ban cotton imports from China which, it is claimed, are being produced using forced labour, as stated by rights groups.

6According to statistics the Italian textile and garment industry is expected to make a complete recovery in 2022 to pre-pandemic levels of 2019, and then return to growth in 2023.

7The imports of clothing and accessories by Japan increased by 29.8 per cent year-on-year to 1,794,366 million yen during April-September 2022. The import was 3 per cent of total import of 60,590,442 million yen during the first six months of this year.

8The export forecast for cotton in the US for 2022-23 is 100,000 bales lower at 12.5 million

bales, while ending stocks are 100,000 bales higher.

9Vietnam's textile and garment industry is investing in sustainable and eco-friendly technologies to be on the same page as several global companies.

10Sri Lanka’s garment exports stood at $4215.9 million during JanuarySeptember 2022 which grew by 18.9 per cent over the exports of $3,544.3 million in the same period of the previous year, as per statistics released by the Central Bank of Sri Lanka. Sri Lankan managed a 5 per cent growth in garment exports in September 2022 due to grim the economic scenario.

8 PAKISTAN TEXTILE JOURNAL - November 2022

Textile Briefs National

Textile Briefs International

Textile exports drop by 15.23% in October 2022

Pakistan’s exports of textile and clothing post a negative growth of 15.23 per cent in October from a year ago, data compiled by the Pakistan Bureau of Statistics (PBS) showed.

High energy cost was one of the reasons for the slowdown in textile exports besides the non-disbursement of refund payments. Refund payment orders for Sept 16 to Oct 17 period are still unpaid and if the situation continues the November textile export may dip further, feared exporters.

In absolute terms, the export proceeds of textile and clothing fell to $1.35bn in October from $1.60bn over the corresponding month of last year.

Between July and October, exports of textile and clothing fell by 1.34pc to $5.94bn against $6.02bn over the corresponding months of last year.

The exports of value-added products posted negative growth across the board while exports of cotton recorded a 100pc growth in October. The exports of raw cotton stood at 1,725 tonnes in October from a year ago.

Data showed that ready-made garments exports jumped 2.46pc in value and 58.79pc in quantity in July-October. However, on a year-on-year basis exports shrank by 7.36pc in October.

The exports of knitwear edged up 6.92pc in value and 47.06pc in quantity in 4MFY23 while it dipped by 14.32pc in October on a year-on-year basis. The bedwear exports dipped by 8.64pc in value and 23.30pc in quantity in the four months from a year ago.

Readymade garments sector facing liquidity crunch

Readymade garments industry has been facing a severe liquidity crunch with exporters unable to procure raw materials amidst undue delay in release of sales tax refunds by the Federal Board of Revenue (FBR).

This has adversely impacted the sector’s export growth, as the country’s textile exports have declined by 15.23 percent in October 2022 to $1.35 billion,

The export of readymade garments exhibited an increase of 28.75 percent to

$3.9 billion during last fiscal year of 2021-2022, which has now started to decline due to multiple reasons, including liquidity issues. The value-added garments sector is the major taxpayer and largest employment generator in the whole textile chain.

Pakistan Readymade Garments Manufacturers and Exporters Association (PRGMEA) Central Chairman Mubashar Naseer Butt has said that liquidity crisis also started impacting the export volume, as exporters’ liquidity took a strong negative hit from ongoing global recession.

The value-added textile exporters were facing problems regarding sales tax refund payment orders (RPOs) which were issued after October 3, 2022, besides waiting for those deferred amounts, which were processed under the previous FASTER system.

Textile exporters’ sales tax refunds amount has risen to billions of rupees, and was now hampering business activities, reversing the progress in exports made in the last fiscal year. The latest data shows that textile exports have dropped to $1.35 billion in October 2022 from $1.60 billion of the corresponding period of last fiscal year.

PRGMEA lamented that despite commitment made by the government that RPOs would be issued in 24 hours, while the payments would be cleared within 72 hours, the government was not releasing the refunds. The original 72

hours have now extended to several weeks, the association said.

“Despite all the commitments, FBR has failed to pay the sales tax refunds of zero-rated export sector within 72 hours. Consequently, exporters are unable to procure raw materials and other accessories to execute their export orders and this will ultimately affect the country’s foreign exchange reserves, which are constantly declining,” the PRGMEA chairman added.

Pakistan must implement 27 conventions before GSP+ review

Ambassador of the European Union Dr Riina Kionka has called for effective implementation of the 27 labour and human rights conventions as Pakistan’s current GSP plus status would be reviewed in December 2023.

The ambassador said that more labour and human rights conventions would be added for implementation. Dr Kionka visited a number of garments’ manufacturing units along with Pakistan Readymade Garments Manufacturers & Exporters Association (PRGMEA) executive committee members and others.

She appreciated their performance and called for product diversity and more value-addition to exploit the full potential of market access to the countries under the present regime of the GSP plus.

PAKISTAN TEXTILE JOURNAL - November 2022 10 News & Views

Later in a meeting, both sides discussed in detail the role of the small and medium enterprises in economic growth, technical education, skills development, EU support for Pakistan in TVET sector and promotion of women skilled force.

PRGMEA and the EU agreed to work on women entrepreneurship, better labour laws and promotion of SME sector along with other projects.

The ambassador discussed various ideas for providing support to the SME sector, with the focus on creating linkages within the EU to open new markets for the products.

Dr Kionka said that the EU was the biggest export market for Pakistani goods, as it accounts for about onethird of all Pakistani exports. She said the EU can assist Pakistan to expand its exports and uplift its industry through collaboration with PRGMEA.

The ambassador appreciated the role of PRGMEA in boosting industrial activities in the region and added that her embassy would be in touch to increase the bilateral ties.

PRGMEA Central Chairman Mubashar Naseer Butt and Zonal Chairman Waseem Akhtar Khan said that GSP plus has increased EU-Pakistan bilateral trade; valued at €12.2 billion 2021 as compared to €6.9 billion, representing an increase of 78 percent.

“The scheme has a positive synergy with government’s social agenda. As a result of improved market access, Compound Annual Growth Rate (CAGR) for Pakistan’s exports to EU increased to 7 percent in the post GSP plus period as compared to 4 percent in the 5 years preceding GSP,” he added.

PRGMEA zonal chairman said that the tariff free access to the largest market for textile and apparel under the GSP plus status provided a solid platform and incentive structure to drive further reforms in the industry and the country.

“In the same way, the benefits to EU are reliable, cost competitive supply of textiles to EU businesses and consumers and a sustainable, ethical and increasingly traceable textile value chain. EU-Pakistan GSP plus relationship has the power to transform Pakistan’s economy and society while delivering on EU goals,” he added.

PHMA for restoring old electricity tariff for textile sector

Immediate restoration of old electricity tariff for textile sector is imperative to save national exports which were already in declining mode, said Muhammad Amjad Khwaja Senior Vice Chairman, Pakistan Hosiery Manufacturers & Exporters Association (PHMA).

Addressing a joint press conference of the textile sector in PHMA house, he said that our total exports were 31 billion dollars, out of which 22 billion dollars are contributed by the textile sector alone.

He said that the share of the apparel sector was around 9 billion dollars which is represented by PHMA and Pakistan Readymade Garments Manufacturers & Exporters Association (PRGMEA). He said that during corona national exports recorded an increase of 37% only due to the pro-industry policies.

Dr. Khurram Tariq, President Faisalabad Chamber of Commerce & Industry (FCCI) said that the industrial sector was forced to purchase costly electricity only due to the wrong decisions of successive governments. Presenting comparative electricity tariff of regional countries, he said that it is costlier in Pakistan as compared to the other countries.

He said that the electricity tariff was fixed in textile policy. “Similarly, former Finance Minister Miftah Ismail had also assured to maintain this tariff for a period of one year”, he said and added that surprisingly it had been changed without any consultation with the stakeholders.

He said that local industry is facing closure while export units have also cut down their production as compared to their installed capacity. He said that the crime rate in Faisalabad has jumped due to the increase in unemployment. He warned that workers would come on the road if more industrial units were closed due to the unbearable cost of electricity.

(PTEA) in Islamabad, he termed the demand for energy subsidies “just” and promised that the government would bear the difference between the new fixed price and the actual per unit production cost.

“I expect the industries to now increase Pakistan’s exports.” Dar said the annual burden of the subsidy would amount to around Rs 90-100 billion, adding that the “all-inclusive” package was announced for the five major exporting sectors, and not just the textile sector.

He denied that the subsidy would have any impact on the primary or budget deficit, assuring that “everything will be taken care of”.

Meanwhile, in response to a question on whether the International Monetary Fund (IMF) was taken into confidence on the package, the finance minister said: “I don’t need to take the IMF into confidence, when I know what I am doing then it is my responsibility to create [fiscal] space for it and I have done so.”

Media had earlier reported that the minister was considering a hefty package of energy subsidies for the textile sector to help it compete with regional countries.

head of Belarusian mission in Pakistan, Ilya Kanapliou, has said that Pakistan and Belarus are moving towards greater economic cooperation, which will have positive impact on the relations between the two countries in the long term.

“We have taken initiatives to boost our trade and economic ties,” he said. Speaking at a meeting with textile exporters during his visit to offices of the Pakistan Textile Exporters Association (PTEA), he said that Belarus considered Pakistan as an important country and wanted to increase trade with it.

“All-out efforts are being made to add new dimensions to the bilateral relations between the two countries. Belarus is striving to develop business-tobusiness and people-to-people contacts to boost mutual trade ties,” he added.

Pakistani textile exporters have great potential to explore and capture the Belarusian market as there exist lucrative new business opportunities in Belarus, he said. The Belarusian diplomat said there are bright opportunities for setting up joint ventures in different fields by Pakistani and Belarusian investors and businessmen. Terming Pakistan an ideal place for foreign investment, he said that Belarusian investors are visiting Pakistan to explore opportunities in different fields.

Govt is considering duty on man made filament yarn

Finance Minister Ishaq Dar has announced a power subsidy package for Pakistan’s export industries with per unit electricity cost set at Rs19.99.

In a media talk after negotiations with the Pakistan Textile Exporters Association

Belarussain diplomat visits Pakistan Textile Exporters Association

Other participants of the meeting included PRGMEA ex-chairman Sajid Saleem Minhas, Dr Mufeez ul Islam, Ahmad Hanif, Irfan Khurshid, Muhammad Ali and Hina Asif. The deputy

Despite a gap of over three-fourths between the demand and supply of manmade fabric, the government is considering imposing a 5% regulatory duty on the import of filament yarn, apparently to give protection to the local manufacturers.

Pakistan Yarn Merchants Association (PYMA), a body largely representing the

PAKISTAN TEXTILE JOURNAL - November 2022 12 News & Views

Govt announces ‘all-inclusive’ power subsidy for export industries

Ishaq Dar; Finance Minister

importers, has appealed to Prime Minister Shehbaz Sharif to intervene and stop the increase in tax burden.

The association has written to the premier that the imposition of 5% regulatory duty on the import of yarn, which is a raw material for the textile sector, on the pretext of discouraging imports will increase the cost of production.

Cotton has been replaced with yarn across the world and most of Pakistan’s textile industry depends on the imported yarn.

About 500,000 power looms and knitting machines use yarn as a raw material for the manufacturing of textile products. Commercial importers also import yarn for consumption by such manufacturers.

The association claims that the demand for yarn for local consumption stands at approximately 450,000 tons per annum, of which 350,000 tons are imported, which shows a gap of 78%.

Yarn demand cannot be fulfilled in any way through local supplies, which raises questions over the motive behind imposing the regulatory duty to discourage imports.

The association also points out that the local yarn manufacturers are still using outdated machines, which are not energy efficient. Such energy losses are built into yarn prices.

Currently, there is a gap of at least 8.5% in the duty structure on the import of raw material of yarn and the import of yarn and any increase in the duty will give undue advantage to the local manufacturers.

Despite the huge gap in supplies, the yarn manufacturers could not tap the market due to the low quality of their product and high cost of production. Efforts should be made to increase the efficient production capacity instead of imposing the regulatory duty.

Textile products produced from the imported yarn are mostly used by the ordinary people due to their affordability. The duty imposition will directly impact the inflation reading and will further worsen the situation.

On the other hand, the yarn manufacturers will also increase prices in line with the landed cost of imported yarn which will, in turn, raise the cost of finished textile products. The impact on inflation will be twofold.

Moreover, the export of textile will be no more competitive due to the high cost, resulting in possible closure of small and medium enterprises (SMEs).

The association has appealed to the PM that in light of the facts and in order to save hundreds of thousands of power looms from closure, the existing duty structure may at least be left unchanged if the duty gap is not reduced.

It has also demanded that no regulatory duty should be imposed on the import of yarn to provide undue protection to the local textile industry that is not able to meet the entire consumer demand.

BANGLADESH

As per BTMA, around 60% textile mills in Bangladesh at risk of closure due to gas crisis

Textile mill owners’ association in Bangladesh – the Bangladesh Textile Mills Association (BTMA), states that almost 60 per cent of Bangladesh’s textile mills are at risk of closure due to the ongoing severe shortage of gas.

This was underlined by media reports which added BTMA President Mohammad Ali Khokon, at a recent press conference, reportedly claimed a massive 90 per cent of the textile mills had been facing shortage of gas since March 2022 even if the situation had deteriorated since July with the production in the sector decreased to 35-40 per cent while the millers failed to entertain export orders worth US $ 1 billion in recent months, owing to the gas crisis, as per the trade body.

Presenting a paper titled Energy issue particularly overall scenario and its impact on the textile sector, Mohammad Ali Khokon underlined the primary textile sector was facing an intense gas crisis by receiving supply for only 12 hours a day, which increased the production cost of yarns by twofold to US $ 2.5 per kilogramme, while adding, ‘due to falling competitiveness, there is a chance of shutting down of many factories,’ which may create new bank defaulters and unemployment, the BTMA President felt.

CHINA

China's apparel exports to India rise 2.5x in Aug over March 2022

China’s apparel exports to India increased by two and a half folds in August compared to March 2022. Monthly exports rose to $131.555 million in August from $53.275 million in March 2022. Although, the trade value is insignificant for both nations, the trend is important as it indicates that more and more Indian buyers are importing cheaper Chinese garments.

A lot of speculations are floating in the Indian yarn market regarding the steep rise in imports of cotton garments from China which is seen as the main cause for low demand in the entire textile value chain in the country. “All the items in the garment category are being imported as they are cheaper than the garments made in India. If garments are imported from China, nobody will buy yarn or fabrics. Therefore, demand is not improving even during the festival season,” a trader from Ludhiana told to media.

Monthly garment exports from China increased consistently during the last six months. The exports grew to $77.066 million in April, $87.901 million in May, $109.995 million in June, $129.678 million in July and $131.555 million in August 2022, according to statistics. The data shows that garment exports grew in July 2022 over June 2022 when the US banned cotton and cotton products originating from the Xinjiang region of

China. Cotton and yarn prices declined in the Chinese market after the ban.

Chinese exports to India increased to $274.963 million in the second quarter from $184.135 million in the first quarter of this year. Annually, the exports rose to $1,145.475 million in 2021 from $838.195 million in 2020. The exports were at $720.332 million in the first eight months of the current year.

Chinese apparel exports were at $448.821 million in the first half of this year. Trousers and shorts contributed 22.61 per cent ($101.491 million) in the total supply. Jackets and blazers (18.17 per cent), accessories (15.27 per cent), socks (7.06 per cent) and dresses (5.78 per cent) were the other top products exported to India.

INDIA

India’s textiles sector aims to hit $100 billion exports in 5-6 years, which would take the industry’s combined domestic and international economic value to USD 250 billion, Union minister Piyush Goyal said recently. Outbound shipments from the country’s textiles segment stood at around USD 42 billion in 2021-22.

Addressing members of Export Promotion Councils through video conference in New Delhi, the Minister of Textiles, Consumer Affairs, Food and Public Distribution and Commerce & Industry said manufacturers should start

14 PAKISTAN TEXTILE JOURNAL - November 2022

India’s textiles sector eyeing $100-billion exports in 5-6 years

securing cotton to meet their demands. Besides, all those involved with cotton industry should meet to discuss the strategy to trace cotton and ensure value of the cotton products.

The minister said that last year, textile export was approximately USD 42 billion, while the target is to achieve USD 100 billion by next 5-6 years. He said that if achieved, the economic value of the sector will be worth USD 250 billion collectively, including its domestic as well as international markets.

Production of cotton is estimated at 34.19 million bales (of 170 kg each) in the 2022-23 crop year (July-June) as against 31.20 million bales in the previous year, as per the agriculture ministry’s latest data.

Cotton is one of the major Kharif (summer-sown) crops. The harvesting of cotton crops has begun from October. Goyal said that funds are available under the Textile Mission and should be utilised in new projects, adding that the potential of textile sector may be showcased in G20. Participation of industry representatives in the shopping festivals recently announced by the finance minister may also be pursued, the minister said.

The virtual meeting was convened with senior representatives of all the 11 Export Promotion Councils under the Ministry of Textiles, including the Apparel Export Promotion Council, The Cotton Textiles Export Promotion Council, the Carpet Export Promotion Council, the Export Promotion Council for Handicrafts.

In addition, representatives of industry associations, including the Confederation of Indian Textile Industry, Tiruppur Exporters Association and The Southern India Mills’ Association also participated in the meeting.

Goyal observed that a two-day meeting should be organised to discuss new ideas on strengthening the textile sector. At least 50 per cent of participants should be youngsters and there should be involvement of Quality Control of India (QCI), commerce, DPIIT, finance, banking export insurance for holistic engagement so that overarching themes may be discussed.

IRAN

Exports from textile, clothing industries up 12% in H1

The weight of exports from Iran’s clothing and textile industries increased by 12 percent in the first six months of the current Iranian calendar year (March 21-September 22), compared to the figure for the preceding year’s first half, a deputy with the Ministry of Industry, Mining and Trade said.

Mohammad-Mehdi Baradaran said the country’s petrochemical plants have increased their production of raw materials for the clothing industry and that has resulted in increasing the production of clothing and garments in the country, IRIB reported.

“According to the agreements made with the Textile Industries Association,

National Petrochemical Company (NPC) increased its production, which reduced the price of yarn. However, since the cost of production in the clothing industry is high, each of this industry’s chains must reduce their costs in order for the final product, which is clothing, to become more competitive [considering foreign commodities],” Baradaran said.

Referring to the job-creating potential of clothing production units, the official said: “In the current year, over 422,000 jobs have been created in various industries, and some clothing units have seen a 20 percent increase in employment.”

He considered the export of clothing and the competitiveness of this industry as one of its advantages and said: “We will not let this industry go stagnant due to imports.”

The textile industry in Iran has a long history and is one of the most important sectors for employment. This industry has a high employment potential, and the amount of foreign currency investment to create a job in the textile industry is very low compared to some industries such as automotive. The value of exports from Iran’s clothing and textile industries in the previous Iranian calendar year 1400 increased by eight percent compared to the figure for the preceding year.

IRELAND

backdrop of crimes against humanity and forced labour,” said Gearóid Ó Cuinn, director of the Global Legal Action Network (Glan), which has offices in Galway and London. “Retail stores are selling these goods in the full knowledge of what is going on” in Xinjiang.

The effort to have a ban imposed on cotton imports that may be linked to the use of forced labour in the Chinese province of Xinjiang, is being taken by Glan and the Munich-based World Uyghur Congress (WUC).

ITALY

“Entrepreneurs in the textile industry have realised the urgency of enacting the digital transformation of their businesses and this is precisely why ACIMIT has accelerated its Digital Ready project for certifying Italian textile machines that adopt a common set of data, in order to more easily integrate with the operating systems of their client businesses,” Alessandro Zucchi, president of the Association of Italian Textile Machinery Manufacturers (ACIMIT).

Despite 2020 being a particularly difficult year for the textile and clothing industry, the textile machinery sector remained resilient, particularly in exports. Italy is the fourth country in the world for textile machinery exports, with a 10 per cent share.

in 2022

labour’ in China

The Revenue Commissioners and the Irish customs authorities are obliged by law to ban cotton imports from China which, it is claimed, are being produced using forced labour, rights groups have said.

In a submission to the Revenue, two groups say they will refer the issue to the Court of Justice of the European Union in Luxembourg if the Revenue does not impose such a ban. They plan to seek a ruling that would “re-write the relationship between retail stores and goods produced through forced labour” across the EU.

“The status quo is that we are open for business for goods produced against a

The Italian textile and garment industry is expected to make a complete recovery in 2022 to pre-pandemic levels of 2019, and then return to growth in 2023, according to industry watchers and players. However, the structure of the textile and clothing industry in Italy will have to undergo a profound transformation in the coming five years.

The Confindustria Moda (Italian Federation of Textiles, Fashion, and Accessories) has defined this transformation as a cultural change. There is a need for Italy’s textile industry to address two crucial issues: the evolution towards a production system that is more environmentally sustainable, and digitisation of the supply chain, which must include SME players.

In the coming years, industry associations in the sector will continue to support the development of clusters through vertical and horizontal integration among companies and the building of business networks within the districts. This will make it possible to pool resources for the purchase of new machinery and the employment of specialised human resources. The Recovery and Resilience Plan (RRP) under the Next Generation EU programme put in place by the European Union to respond to the crisis caused by the COVID-19 pandemic, amounts to €235 billion for Italy in funding over a six-year period.

Some of the funds will provide the resources for the technological and cultural change of the Italian textile and clothing industry. With this and other

Around the World 16 PAKISTAN TEXTILE JOURNAL - November 2022

Ireland urged to ban imports of cotton produced using ‘forced

Italy's textile industry projected to make full recovery

programmes in place or in the pipeline, the Italian textile and clothing sector will be able to ride on new opportunities and offer increasingly innovative products, beyond the classic and popular fashion and clothing market, the report added.

“We are looking forward to the staging of ITMA 2023 in Milan. Our members, together with many of the leading brands from Europe and the rest of the world, will be able to leverage this global textile and garment technology exhibition to launch our latest innovations, especially those that will help the industry to digitalise and be more productive, as well as those that help us build a more sustainable and circular economy,” added Zucchi.

ITMA is the world’s largest international textile and garment technology exhibition. ITMA 2023 will be held at Fiera Milano Rho, Milan, Italy from June 8-14, 2023.

JAPAN

Japan's clothing imports increase 29.8% in Apr-Sept 2022

The imports of clothing and accessories by Japan increased by 29.8 per cent year-on-year to 1,794,366 million yen during April-September 2022. The import was 3 per cent of total import of 60,590,442 million yen during the first six months of this year, according to the provisional trade statistics released by the Far Eastern country's ministry of finance.

According to the latest data, the import of textile yarn and fabrics were valued at 647,725 million yen in AprilSeptember 2022, which was 30.8 per cent higher than the same period of last year. The import was 1.1 per cent of the total imports by Japan.

Japan's export of textile yarn and fabrics was worth 389,659 million yen during the first half of fiscal 2022, with an increase of 17 per cent year-on-year. The export was 0.8 per cent of the total export of 49,577,804 million yen from Japan during the April-September 2022.

Japan exported textile machinery valued at 145,877 million yen, which was 20.2 per cent higher than AprilSeptember 2021. It contributed 0.3 per cent to total export.

During September 2022, Japan's imports of clothing and accessories increased by 40 per cent year-on-year to 401,740 million yen. Clothing imports accounted for 3.7 per cent of the country's total imports of 10,914,496 million yen during the month under review. The imports of textile yarn and fabrics were valued at 110,920 million yen in September 2022, which is 33.5 per cent higher than the same month of last year.

Japan exported textile yarn and fabrics worth 64,808 million yen, an increase of 21.3 per cent year-on-year. The textile yarn and fabric exports accounted for 0.7 per cent of the total exports of 8,820,212 million yen from Japan during September 2022. Japan exported textile machinery worth 24,868 million yen, which was 28.8 per cent higher than August 2021.

PHILIPPINES

Philippines' handloom weaving industry still alive: official

Contrary to some fears and beliefs, the country's handloom weaving industry is still alive and undergoing a resurgence, according to an official.

"Many have been saying that this is a dying sector. But we are not discounting the fact that there is a resurgence, a renaissance of interest coming into play," said Dr. Enrico Paringit, executive director of the Philippine Council for Industry, Energy and Emerging Technology Research and Development of the Department of Science and Technology.

Paringit said this during the launch of the first Philippine Handloom Weaving Conference of the DOST's Philippine Textile Research Institute (DOST- PTRI).

The conference aims to put a spotlight on what handloom weaving is all about, including its purpose, significance, art designs, the meaning behind those designs and its relationship to the country’s indigenous people.

The presence of the handloom textile is not only gaining ground locally as it is also starting to get more exposure abroad with initiatives from the private sector.

"We connected the weavers… to different global market places specifically in Paris, in Paris Fashion Week and in New York Fashion Week. We also promoted weaves specifically the concept

“The fact that the commercial viability is something that the weavers are seeing… the sustainability market is growing, we have a lot of conscious consumers in first world countries and even in the Philippines, more people who are leading towards more sustainable practices and lifestyle… We also have a lot of Filipinos who are in the diaspora who are, who want to have, you know, feel of home and who want, you know, like more of Philippine cultural items," he added.

According to Dr. Norma Respicio, professor emeritus of the University of the Philippines - Diliman, some designs are meant to convey one's social class or protect wearers from bad luck.

USA

US cotton export forecast for 2022-23 slashed to 12.5 mn bales: USDA

With world trade projected lower, the export forecast for cotton in the US for 2022-23 is 100,000 bales lower at 12.5 million bales, while ending stocks are 100,000 bales higher. Production is virtually unchanged at 13.8 million bales, less than 1 per cent lower than September 2022, according to a report by the United States Department of Agriculture (USDA).

The 2022-23 US cotton supply and demand estimates show slightly lower exports and higher ending stocks compared with September 2022, as per the ‘World Agricultural Supply and Demand Estimates’ October report by the USDA.

The 2022-23 season-average price for upland cotton is forecast at 90.0 cents per pound, 6 cents lower than last month and slightly below the final 2021-22 record-high price of 91.4 cents. In the 2022-23 world balance sheet this month, consumption is 3.0 million bales lower and ending stocks are 3.1 million bales higher.

China’s historical consumption estimates are revised back to 2019-20, with the largest change in 2021-22, which is revised down 2.0 million bales. China’s projected 2022-23 consumption is 1.0 million bales lower this month, as is India’s.

Pakistan’s is 500,000 bales lower, and consumption is also lower for Turkey,

of an indigenous feature in Vogue Italia with Pia Wurtzbach as our model," Chief Executive Officer and Creative Director of Kandama Social Enterprise Victor Baguilat Jr. said.

Around the World 18 PAKISTAN TEXTILE JOURNAL - November 2022

Mexico, and Vietnam. World trade is projected nearly 1 million bales lower than it was in September, with declines in imports by China, Pakistan, Mexico, Turkey, and Vietnam. Exports are lower for Australia, Brazil, India, Benin, Cote d’Ivoire, Greece, and Mexico, as well as the United States. World production in 2022-23 is projected nearly 400,000 bales lower than it was a month ago, largely reflecting lower crops in Pakistan and Benin.

VIETNAM

Danish-owned Specter's new green apparel factory in the An Giang province started operation on September 30, specialising in outdoor sportswear for export and will be partly powered by renewable energy.

Vietnam's textile and garment industry is investing in sustainable and eco-friendly technologies to be on the same page as several global companies. This has become a necessity for suppliers as the European Union (EU), a big market for Vietnamese businesses in this sector, has proposed new environmental requirements for imported textiles till 2050.

The facility, which has received a Gold LEED certificate, uses solar energy and contemporary architecture to cut its annual carbon dioxide emissions by around 1,600 tonnes. This is Specter's third facility in Vietnam.

Hanoi Textile and Garment JSC (Hanosimex) and South Korea's Hansae Group signed an agreement earlier this month for a project in Vietnam for recycled textiles for export. Both will be the first in Vietnam's textile sector to develop a comprehensive distribution network from yarn to weaving, dying and

sewing, entirely for recycled goods, Kyung Kim, senior vice president of Hansae Group, was quoted as saying by a Vietnamese media outlet. About 4,000 tonnes of recycled fabric for the EU market are expected to be manufactured.

“The signing of a strategic collaboration agreement between Hanosimex and Hansae will assist both parties in increasing the volume and percentage of knitted goods of recycled origin and eco-friendly fashion items,” said Le Tien Truong, chairman at Vinatex, the parent business of Hanosimex.

Vietnam's textile-garment firms opt for green push to achieve targets

Around the World

U.S. Cotton Trust Protocol attends Sustainable Brands Flagship Conference

Recently, the U.S. Cotton Trust Protocol attended and participated in the Sustainable Brands Flagship Conference in San Diego (SB22), which enjoyed its first fully in-person event in the last couple of years.

The conference theme was ‘Recenter and Accelerate,’ hosted hundreds of people from global brands to thought leaders and industry organizations. Attendees were given key insights about consumers from recent research and studies and were able to listen to influential industry leaders such as Caitlin Harren, Director of Sustainability Solutions, Social Responsibility & Product Sustainability at Amazon, and Amanda Nusz, Senior Vice President of Corporate Responsibility at Target.

Caitlin Harren spoke of how sustainability as a concept can be overwhelming for consumers, but seem achievable as a community or collective. She emphasized the importance of science-based commitments, which was echoed by her fellow speakers.

In fact Amanda Nusz and Stephanie Grotta, Vice President of Owned Brand Connected Capabilities at Target, agreed that products need to be traced back to the farm in order to understand the impact of the supply chain, as well as remember where products originate. They agreed that sustainability strategies and practices should follow the steps of test, learn, iterate and scale.

As a program focused on setting a new standard in more sustainable cotton production, the Trust Protocol was excited to host a session at SB22. The discussion, named “Harnessing FieldLevel Data to Measure and Improve Environmental Footprint,” explored themes of aggregated data, verification, sustainable growing practices, and supply chain transparency.

The session featured Dr. Deepika Mishra who is a sustainability manager for the National Cotton Council, Byron Rath from the Soil Health Institute and Barry Evans, a Trust Protocol grower from Texas.

The three panelists had a dynamic conversation about the importance of data, sustainable growing practices and transparency.

“The data means we can measure and improve our growing practices,” said Barry Evans. “With the data that we receive, I can look at the way I’m doing things, and I can compare to the aggregated data to other sustainable practices from

growers within Texas and nationwide. The program provides a lot of encouragement to continue to improve.”

Echoing Barry’s thoughts, throughout the conference participants spoke about the need for and importance of data. As the saying goes, you can’t improve what you don’t measure.

The event was a valuable opportunity to hear from people throughout the industry, and a chance for the Trust Protocol to highlight key perspectives from growers and experts.

20 PAKISTAN TEXTILE JOURNAL - November 2022

TENCEL™ launches Tree Climate Fabric Collection

Lenzing launched the Tree Climate fabric collection by TENCEL™, curated by outdoor fabric innovators David Parkes and Marco Weichert. The new Tree Climate outdoor fabric collection features the wide range and versatility of Tencel branded lyocell fibers. It displays a great variety of base, mid, and outer layer fabrics each offering a range of inherent performance qualities, as well as waddings made of wood-based Tencel lyocell fibers for outdoor applications.

The three-fold collection allows the creation of synthetic free and enhanced synthetic content layering solutions for different weather conditions. The environmental impact of the fibers is amongst the lowest of all materials. In addition to the clear sustainability benefits, the collection demonstrates the versatility of Tencel lyocell fibers in functional outdoor applications. Wind and water resistant, with optimum

breathability and thermal regulation, makes the fabric ideal for outdoor sports lovers all year round. The fibers, which are gentle on skin, also blend well with natural fibers such as wool and hemp.

Andreas Gürtler, senior manager of Global Business Development Active Sportswear at Lenzing says. “We are extremely proud of what we have created with the help of renowned curators David and Marco. The fibers, which have highperformance attributes and super soft feel, are also biodegradable. Coupled with carbon-zero fibers, this fabric collection is poised to bring a wave of positive change to the outdoor apparel and the environment.”

“Sustainability has become a minimum requirement in the outdoor market. The industry is in need of climate neutral fibers, that are nature-based and can claim a function out of nature. Lenzing is providing some of the best

fibers for the active market with its Tencel Tree Climate collection. It offers nature based, biodegradable fibers with superb functional attributes such as climate control and moisture management. I am thankful that I had the chance to participate in this project and I am confident that it will do well,” said Marco Weichert, CEO of Weichert Agencies.

“Performance apparel defines itself through innovative and practical textiles, and the consumer has recognized this for several decades. It is a leader in textile development, and has assumed that role, with accountability, in textile sustainability and environmental awareness. I have been inspired by the sustainability of this generation of Tencel fibers, their attractive aesthetics and impressive thermal and comfort characteristics,” added David Parkes, founder and CEO of Concept III.

Special Reports

Rieter donates CHF 100,000 to support flood victims in Pakistan

Rieter is donating CHF 100,000 to support relief efforts for victims in Pakistan following the devastating floods of the 2022 monsoon season. Aid will focus on rebuilding schools and helping local healthcare clinics to protect those who are most vulnerable.

The disastrous floods have displaced nearly eight million people, killing more than 1500 people – including hundreds of children – and has put millions of lives at risk of health hazards, according to the United Nations.

The money will be donated in equal shares to two local non-government organizations, Citizens Foundation and ZMT clinics. Citizens Foundation was

founded in 1995 with the mission to provide education to children who are less privileged. The Foundation is now helping to rebuild the schools destroyed by the floods. ZMT clinics aim to support the development of a comprehensive primary health care system in Pakistan. They are now setting up clinics to provide medical aid to flood victims.

Rieter has selected these organizations together with its partners in Pakistan. Both aid organizations were chosen based on their ability to provide fast and effective relief where it is needed most. Pakistan is an important textile hub, with textiles making up 60% of the country’s exports. Rieter has been present in Pakistan since 1969.

About Rieter

Rieter is the world’s leading supplier of systems for manufacturing yarn from staple fibers in spinning mills. Based in Winterthur (Switzerland), the company develops and manufactures machinery, systems and components used to convert natural and manmade fibers and their blends into yarns in the most costefficient manner. Cutting edge spinning technology from Rieter contributes to sustainability in the textile value chain by minimizing the use of resources. Rieter has been in business for more than 225 years, has 18 production locations in ten countries and employs a global workforce of around 5 590, about 16.4% of whom are based in Switzerland.

22 PAKISTAN TEXTILE JOURNAL - November 2022

Corporate News

CHT Group launches "LAB102 – Blue veins of CHT" as new brand for the jeans and garment treatment

The ecological and social conditions in the production of textiles are coming to the fore and into the consciousness of industry and end customers. With the new LAB102 brand, the "Jeans & Garment" team of the CHT Group wants to give the development towards sustainability in the denim industry its own name.

LAB102 – the blue veins of CHT. Under this brand name and slogan, the group of companies wants to offer its global denim customers sustainable chemical solutions and technologies in the future.

Where does the name "LAB102 - Blue veins of CHT" come from?

LAB was chosen not only because the English word for laboratory fits perfectly with a chemical company, but also

24 PAKISTAN TEXTILE JOURNAL - November 2022

Dyes and Chemicals

because it stands for innovation, development, and discovery. The digits 102 in the name refer to the house number of CHT's corporate headquarters in Tübingen.

The slogan "Blue veins of CHT" maintains the connection to the name CHT which is well-known in the industry. Moreover, the denim or jeans industry is traditionally and historically indigo - thus blue. Through its developments for the denim industry, the CHT "Jeans & Garment" team has this blue dye quasi in its blood, flowing through its veins - Blue veins of CHT.

Focus on sustainability

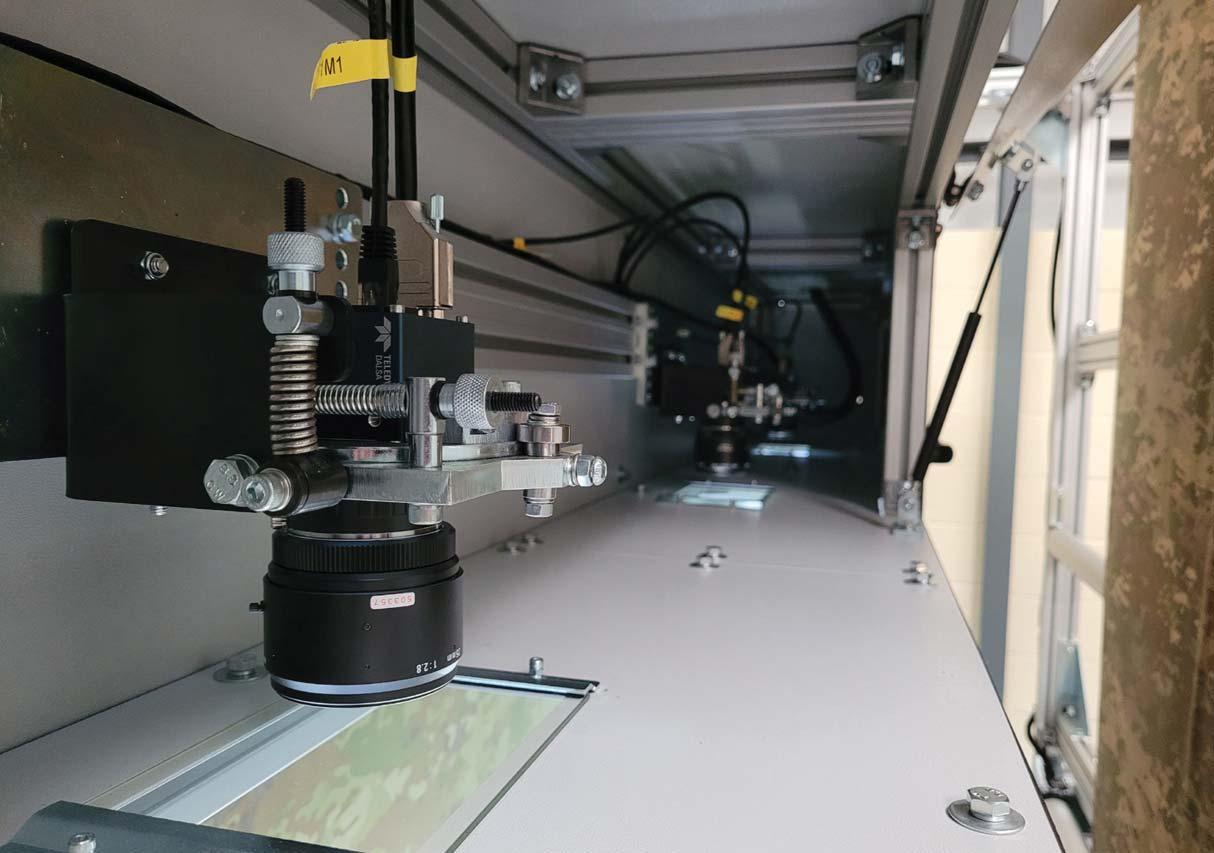

LAB102 focuses not only on chemistry, but also on technology. Fogging, laser, and ozone technologies are innovations that currently enable new approaches in jeans and garment treatment and are at the highest ecological level.

Their Group's "Jeans & Garment" team works with the leading machine manufacturers on new developments.

With these new processes and recipe changes towards sustainable products

LAB102 provides many new possibilities to achieve conventional effects with more sustainable components. In addition to innovative products to support the new machine technologies, LAB102 also provides ongoing development of new fashion effects.

The orientation of the brand launch is international. Over the years, the CHT Group has built up a strong network of experts in the most important locations of

the denim industry. The CHT "Jeans & Garment" team is therefore where its customers are to support them and exploit both local conditions and technical possibilities. And not only virtually and in terms of sales, but also with high technical expertise.

The official launch of CHT's new LAB102 denim brand took place on 19 October 2022 at the trade fair Kingpins Show in Amsterdam.

Archroma to acquire the Textile Effects Business of Huntsman Corporation

Archroma, a global leader in sustainable specialty chemicals and solutions and a portfolio company of U.S. based private investment firm SK Capital Partners announced it has entered into a definitive agreement to acquire the Textile Effects business from Huntsman Corporation.

The combined company will continue to lead the textile industry in sustainability, innovation, and performance offering fashion brands, automotive, technical and home textiles the best-in-class cost performance whilst respecting natural resources and the planet.

Since its formation in 2013, through a series of mergers & acquisitions, as well as internal investments in R&D, manufacturing and service capabilities, Archroma has been building a comprehensive portfolio of solutions to serve the emerging needs of the textile industry. The combination with Textile Effects and its rich historical roots of Huntsman and Ciba Specialties will create a technology power house that will include Archroma’s legacy heritages of Sandoz, Hoechst, Clariant, BASF and Dohmen who have been at the cutting edge of the textile industry for decades, and together will continue to serve customers for years to come.

Both Archroma and Huntsman Textile Effects are founding members of Sustainable Chemistry for the Textile Industry (SCTI), an alliance of leading chemical companies that strives to empower the textile and leather industries to apply sustainable, state-ofthe-art chemistry solutions that protect factory workers, local communities, consumers and the environment.

Both companies have been recognized by the industry and are each recipient of multiple awards for supplying sustainable systems and solutions in dyes and chemicals that enable fashion brands,

retailers, and textile manufacturers to create articles that are better for consumers and the planet.

“I am thrilled to see the combination of Huntsman Textile Effects and Archroma”, said Barry Siadat, Co-founder of SK Capital Partners and Chairman of Archroma. “Finally, we have achieved a dream of combining the technologies, products and capabilities of the legacy pioneers of the textile industry, namely Ciba, Sandoz, Hoechst and BASF, into a modern and cohesive enterprise that is focused on delivering innovative and sustainable systems and solutions to serve the evolving needs of today’s textile industry.”

“We at Archroma are so very excited to announce what we see as a merger of equals”, comments Heike van de Kerkhof, CEO of Archroma. “With this agreement, two committed leaders in sustainable and innovative solutions unite to pave the way towards a more sustainable textile industry. We are delighted to welcome a team of highly talented people”, adds Heike van de Kerkhof. “Innovative and transformative leadership is not built overnight, and we are eager to work together with the

people who made that happen at Huntsman Textile Effects.”

“The combination of Archroma and Huntsman Textile Effects is transformational, bringing together two highly complementary organizations with strong cultures of innovation and a shared commitment to inspire advancements in the textile industry. We are excited by what we will be able to achieve together. At a time when we are seeing robust growth trends in sustainability, the merger will position us firmly to accelerate growth and drive significant value for our customers, employees, and stakeholders,” said Rohit Aggarwal, President of Huntsman Textile Effects.

Closing of the transaction is subject to customary conditions and approvals and is expected to take place in the first half of 2023. Citi served as financial advisor to Archroma. Latham & Watkins LLP provided corporate legal advice and Kirkland & Ellis LLP provided financing legal advice to Archroma. BofA Securities served as Huntsman Corporation’s financial advisor and Kirkland & Ellis LLP acted as their legal counsel.

Dyes and Chemicals 26 PAKISTAN TEXTILE JOURNAL - November 2022

Heike van de Kerkhof, CEO of Archroma.

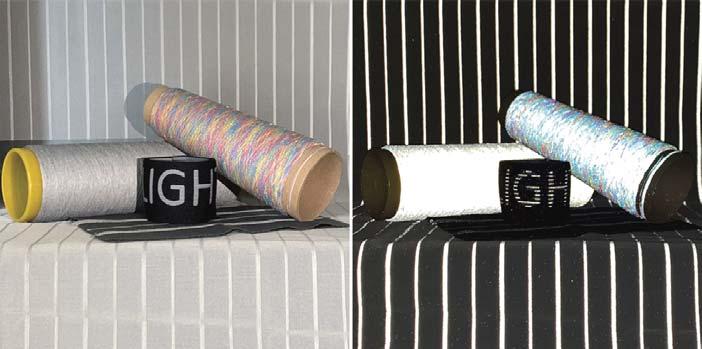

Marchi & Fildi Group introduces Gleaming line range of coloured, reflective yarns for technical, safety and stretch uses

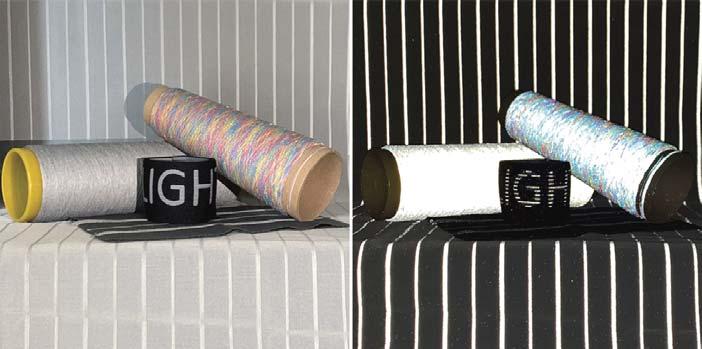

The Gleaming line by the Marchi & Fildi Group includes a wide range of metalloplastic yarns for the most varied of uses.

In addition to uses in the worlds of fashion and furnishings, for fancy yarns, decoration and accessories, an important application for the Gleaming collection is in the sector of technical clothing with high-visibility features.

The new range of reflective yarns Reflex, used for the production of fabrics and tapes, able to reflect the light and ensure good visibility for people wearing them in low-light situations, is augmented by new colour shades in addition to the traditional greys.

The innovative reflective yarns in white, black, and light and dark multicolours offer new possibilities for: Tapes, external labels and accessories;

Technical fabrics for work clothing with specific safety standards; Uniforms, sports clothing and accessories;

Hosiery, gloves, bibs and hats for night use, for winter clothing and for northern markets.

The latest addition to the range, with important new functionality, is the Reflex stretch yarn, which, apart from in the sectors described above, also finds application in flat bed or circular knitting and sewing. Its particular composition makes it softer and more versatile in comparison to traditional reflectives.

The Gleaming line, composed of articles which are mostly available in stock service, represents a completion of the range of yarns produced by the Marchi & Fildi Group. The Gleaming yarns are available in various thicknesses, widths and types in both metallised and

transparent versions, and iridescent, reflective and phosphorescent effects. The offer also includes articles with particular features of resistance to chemical and dyeing treatments.

Amongst the most recent innovations is the line of metalloplastic yarns in 100% polyester obtained from post-consumer recycling with GRS (Global Recycle Standard) certification.

The Marchi & Fildi Group

Marchi & Fildi Spa was established in 2007 from the fusion of the spinning companies Filatura Marchi and Fildi, in the ownership of the Marchi and Dissegna families.

Filidea is the younger company in the Group and was established in 2008. Marchi & Fildi Group’s offer for the fashion world includes yarns for both flat bed and circular knitting, weaving and hosiery. The distinctive element of the collection is represented by the focus on sustainability, starting with the selection of raw materials through to the Ecotec® brand, owned by Marchi & Fildi. The Filidea brand represents a selection of natural, sustainable and certified yarns for

a high-prestige market sector. Filidea is also specialised in the production and development of technical yarns for protective and work clothing, for the automotive branch and for various industrial purposes.

The modern dyeing department and the pilot research and development plant enable the creation of new yarns for the collection, the collaboration with universities and research centres, and with various partners for the development of special projects. Now that the third generation of entrepreneurs have joined the company, Marchi & Fildi Spa is a group which is internationally known and which has a constant rate of growth.

Ecotec® is the patented production process developed by Marchi & Fildi to bring new yarns into being by means of the upcycling of pre- and post-consumer waste and post-consumer PET. The Ecotec® range ensures a reduction in environmental impact: Up to 46.9% savings in terms of energy consumption, up to 46.6% reduction of CO2 and up to 61.6% reduction of water consumption along the entire supply chain.

44 PAKISTAN TEXTILE JOURNAL - November 2022 Fibre and Yarns

VDMA: Dr. Harald Weber new Managing Director of the Textile Machinery Association

Dr. Harald Weber will become the new managing director of the VDMA Textile Machinery Association on 1 January 2023. The 44-year-old industrial engineer succeeds Thomas Waldmann, who has held the position since 1991 and will retire at the end of the year.

After completing his doctorate at the Technical University of Darmstadt and working as a lecturer at the University of Applied Sciences Mittelhessen (THM), Dr. Weber joined the VDMA in 2011. Since then, he has been responsible for the topics of technology and innovation in the Plastics and Rubber Machinery Association.

Dr. Janpeter Horn, Chairman of the VDMA Textile Machinery Association and Managing Director of August Herzog Maschinenfabrik, commented on the change of personnel: "From his previous work in the plastics industry, Dr. Weber has profound knowledge and experience in topics that are also gaining in importance in textile machinery manufacturing. Examples include recycling and the circular economy, as well as digitalisation and especially the communication standard OPC UA."

Dr. Horn added: "We combine our warm welcome to Dr. Weber with a big thank you to Thomas Waldmann. After

30 years as managing director at the Textile Machinery Association also stand for constantly changing framework conditions. Mr. Waldmann has always had his finger on the pulse of the industry and, together with his team, has represented the special interests of the member companies: From technology policy to challenges of market access to the leading trade fair ITMA and the European association CEMATEX. ITMA 2007 in Munich was certainly a highlight. The executive board of the association wishes Mr. Waldmann all the best for the new phase of his life that is now beginning."

30 PAKISTAN TEXTILE JOURNAL - November 2022

Personalia

Caption: (from left to right): Dr. Harald Weber and Thomas Waldmann.

International trade fair for home and contract textiles

An internationally unique platform for home and contract textiles: from January 10 to 13, 2023, the next Heimtextil will present a global range of product innovations in textile interior design. As the leading global trade fair, it also maps market changes with its focus themes on Interior.Architecture.Hospitality, the range of products for interior designers and hospitality experts, and on the megatrends of sustainability and healthy sleep - and is the most important trend platform for textile materials and textile design.

The biggest international trade fair for home and contract textiles.

Heimtextil is the industry's most important global event for interior textiles, interior design and interior trends. With its new products and trends, it kicks off the upcoming

season and gives important views to both exhibitors and visitors.

There were more than 2,918 exhibitors and around 62,970 buyers and trade visitors from across the world in 2020 edition.

Yunus, Gohar, Towellers, Sitara, Sapphire and other premium exhibitors are located in hall 10 and over 220 exhibitors are participating from Pakistan.

Chinese exhibitors will also return along with exhibitors from Hong Kong and Taiwan.

Exhibitor are expected from France, India, China, Germany, Pakistan, Italy, Spain, Portugal, USA and many more.

Themes and Events:

Heimtextil Conference "Sleep & More”: Numerous keynotes will highlight important issues in the

green future of the hotel bed. The new concept format "Sleep & More" also provides valuable orientation for hotel industry decision-makers and sheds light on hospitality trends, particularly from the perspective of sustainability.

Heimtextil Trends 22/23 lectures: Under the motto "Next Horizons“ designers will present their visions of a textile future.

Green Tours: Consultants for sustainable textiles and fashion will guide visitors to selected exhibitors. The tours will end in the Green Village. Here one can talk to certification bodies and quality mark organisations and find out about the latest developments in the green segment.

Interior.Architecture.Hospitality LECTURES: Interior architects, architects and hotel experts present their work and discuss current industry topics such as building culture and design.

31 Fairs and Exhibitions

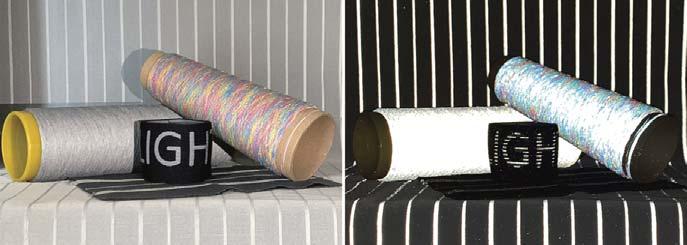

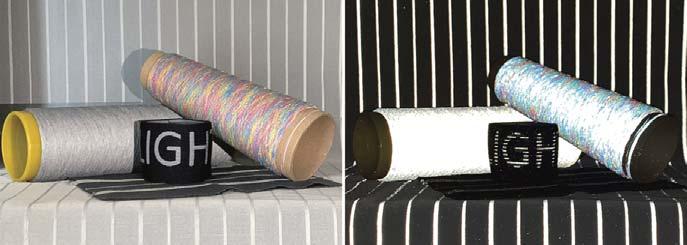

Textile machines from Sweden at new local industry fair

Svenska Textilmaskinsmässan (The Swedish Textile Machinery Fair), a new meeting place for sustainable textile production will run for the first time on October 13-14, 2022. The organiser of the fair is the University of Textiles in Borås. The Textile Machinery Association of Sweden (TMAS) and its member companies will showcase innovation and textile machines from Sweden – technology that enables local production.

The interest in local textile production in Sweden is growing as a result of the need for more sustainable production chains which need to be implemented in everything from material selection to production and distribution, providing good conditions for moving all or parts of the production home.

"TMAS members help automate and streamline textile production, reduce waste and emissions and contribute to increased quality and flexibility,” says Therese Premler-Andersson, general secretary of TMAS. “These requirements are crucial to respond to a market undergoing the transition towards circularity and sustainable business models. The initiative for the fair comes at the right time when local production is something more people are considering and it will be exciting to present Swedish solutions in Sweden."

The Swedish company Värnamo of Sweden has manufactured bed and decorative textiles of the highest quality in Sweden since 1951. With the support of the Swedish machine manufacturer ACG Kinna Automatic, it has established a modern facility in Sweden which has enabled it to compete with production in low-cost countries.

"Following the machine investments we have made in recent years, we can manufacture and sell to major players in both retail and hotel operations,” says Martin Åhlander, CEO of Värnamo of Sweden.

“New investments have meant that we have been able to break new ground

and bring in larger players such as Jysk and Mio among others."

ACG Kinna Automatic was founded in Sweden in 1977 and is one of the world's most experienced manufacturers of textile machines. The project together with Värnamo of Sweden is an excellent example of how it helps its customers to increase automation and thereby save costs.

"We are great at helping our customers to increase automation,” says Christian Moore, CEO ACG Kinna Automatic and board member of TMAS. “At Värnamo of Sweden, where the production has been placed in Sweden since the start, this meant that our machines could support the company in gearing up its production, which we are proud of."

Over 40 exhibitors will participate in the Swedish textile machinery fair, of which almost 30% are TMAS members

with machines manufactured in Sweden and with Swedish expertise. Between 300-400 visitors are expected. The fair is free of charge for visitors.

Participating TMAS member companies are ACG Nyström, ACG Kinna Automatic, Baldwin, Coloreel, Eltex of Sweden, ES Automatex Solution, Eton Systems, Imogo, Svegea of Sweden, Texo and Vandewiele Sweden.

The Textile Machinery Association of Sweden (TMAS) are made up of the leading Swedish companies within textile technology, automation and production processes. The expertise of our members ranges from advanced systems for yarn fault detection and tension monitoring, to yarn feeding technology for weaving, automated sewing production lines, cutting machines, embroidery technology, effective material handling systems, spray application system for fabric finishing and much more.

Fairs and Exhibitions 32 PAKISTAN TEXTILE JOURNAL - November 2022

Martin ÅhlanderVärnamo of Sweden.

Texworld, Apparel Sourcing fairs to be held in February 2023 in France

Trade fair Texworld Evolution Paris will open its doors from February 6-8, 2023, at the Paris-Le Bourget Exhibition Centre in France. For three days, Apparel Sourcing Paris and Texworld Paris will highlight global offerings for fashion brands, from ready-to-wear to luxury. For this edition, accompanying the recovery of international business, event organiser Messe Frankfurt France anticipates a participation close to pre-crisis levels for most of the major sourcing countries.

Texworld Paris, which brings together textile offerings, as well as for Apparel Sourcing Paris, focused on finished products, the commitments in terms of sqm are, at this stage, higher than the levels reached last July, according to a press release by Messe Frankfurt group.

The signs of recovery from the major Asian countries are therefore very positive. As far as China is concerned, the gradual lifting of health constraints on travel is encouraging the already strong demand from exhibitors and manufacturers from this key international sourcing area. Despite the uncertainties of the health situation, the desire to come is there, and the presence of more than a hundred Chinese companies is already confirmed.

At Texworld Paris, Turkish manufacturers will once again be strongly represented this year. Loyal partners of the Messe Frankfurt France trade fairs, they will be more than 100 presents, divided between the Turkish national pavilion, which is well developed this year, the Elite area, where they have always been very visible, and in the area dedicated to denim offerings. The Korean pavilion, supported by the Korea Federation of Textile Industries (KOFOTI), is also expanding. India, absent last February due to the pandemic, will be making a comeback, as will Indonesia and Taiwan, with leading companies that have, for the most part, been absent from Europe since 2021.

Similar trends will be seen at Apparel Sourcing Paris, where many Chinese and Hong Kong companies have already confirmed their attendance. Pakistan has confirmed its return, as has Bangladesh, whose representatives seemed satisfied with the activity generated last February. India is also back in force with a selection of very good companies. Sri Lanka and Mongolia renewed their presence with their exceptional know-how. For all these major sourcing countries, the trade fair should return to its pre-crisis level.