Established 1951 September 2022

Dornbirn GFC Global Fiber Congress

Dates: September 14th to 16th 2022. Venue: Dornbirn Austria.

INTEX SOUTH ASIA 2022

Dates: December 8th to 10rd 2022. Venue: New Delhi, India.

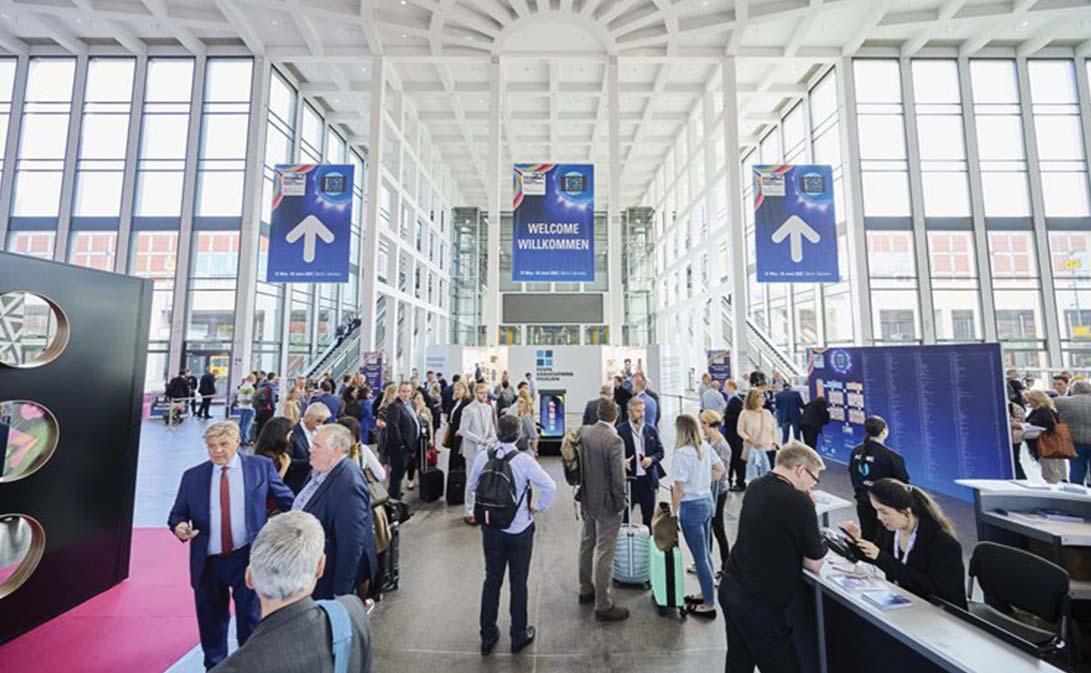

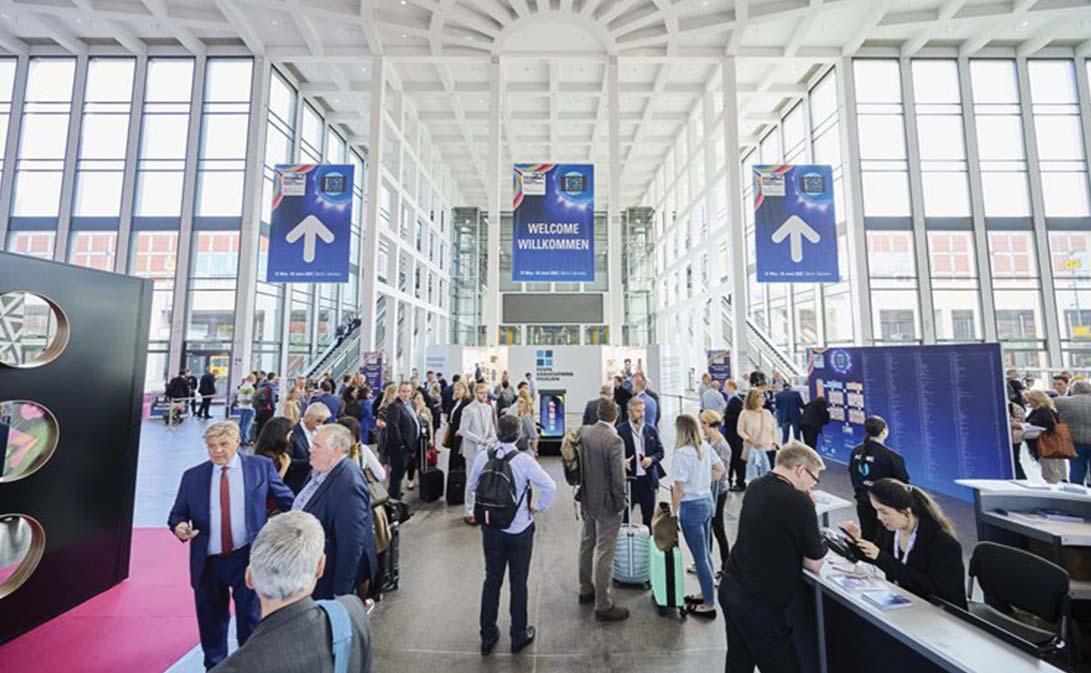

FESPA 2023

Dates: May 23rd to 26th 2023. Venue: Munich, Germany.

Index 2023

IGATEX Pakistan 2022, Lahore

Dates: April 18th to 21th, 2023. Venue: Palexpo, Geneva, Switzerland.

IGM 2022

Dates: September 8th to 6th 2022. Venue: Istanbul, Turkey.

Textile Asia 2022, Faisalabad

Dates: October 29th to 31th 2022.

Venue: Quilim Marquee, Canal Road Faisalabad, Pakistan

Textile Asia 2023, Karachi

Dates: March 11th to 13th 2023. Venue: Expo Centre, Karachi.

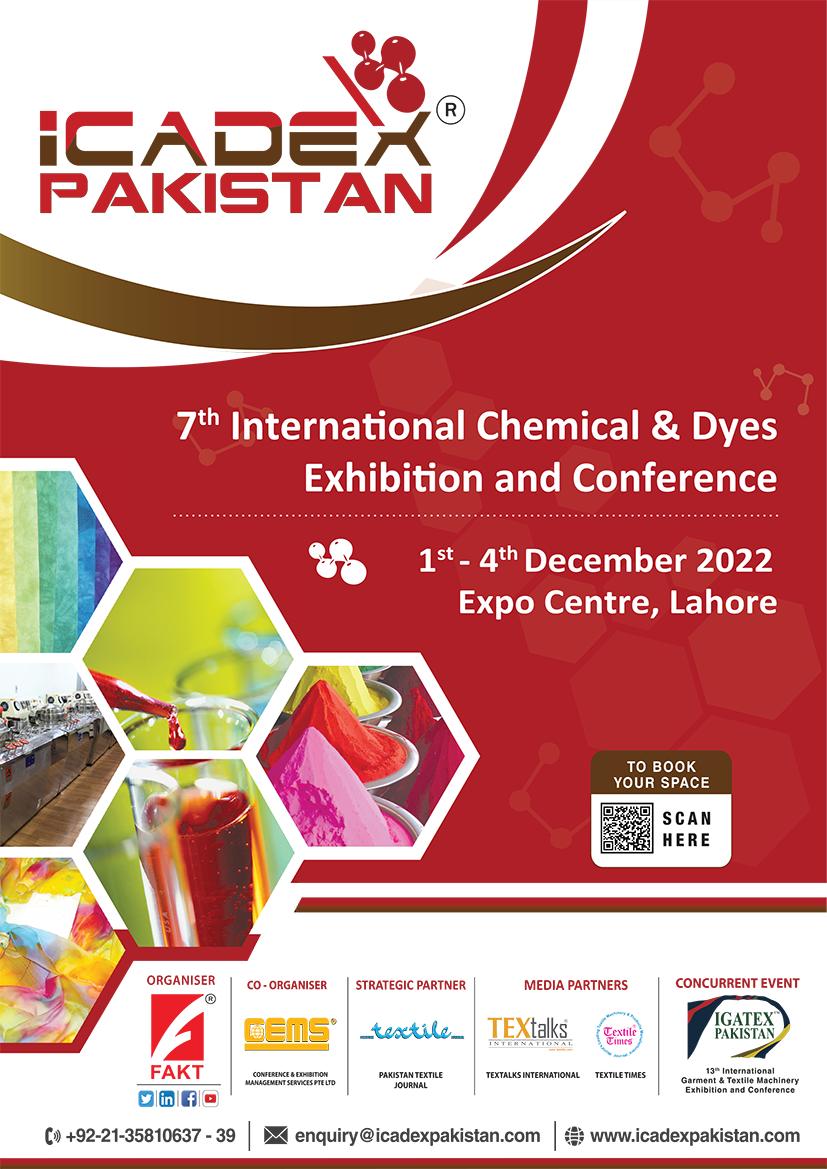

Dates: December 1st to 4th 2022.

Venue: Expo Centre, Lahore.

Intertex Tunisia

Dates: October 6th to 8th 2022. Venue: Tunisia.

iCADEX Pakistan 2022, Lahore

Dates: December 1st to 4th 2022. Venue: Expo Centre, Lahore.

Heimtextil 2023, Frankfurt

Dates: June 10th, to 13th, 2023 Venue: Frankfurt am Main.

ITMA 2023

Dates: June 8th to 14th, 2023. Venue: Milan, Italy.

ITMA ASIA + CITME 2023

Dates: November 19th to 23th, 2023. Venue: NECC, Shanghai, China.

JIAM 2022 OSAKA

Dates: Nov. 30th to Dec. 3nd 2022. Venue: Osaka, Japan.

DOMOTEX Hannover 2023

Dates: January 12th to 15th 2023. Venue: Hannover, Germany.

ITM 2024

Dates: June 4th to 8th, 2024. Venue: Istanbul, Turkey.

Istanbul Yarn Fair

Dates: February 16th to 18th 2023. Venue: Istanbul, Turkey.

HIGHTEX 2024

Dates: June 4th to 8th, 2024. Venue: Istanbul, Turkey.

2 Calendar of Events

PAKISTAN TEXTILE JOURNAL - September 2022

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher

Nadeem Mazhar

Editor in Chief Amina Baqai

Associate Editor

Dr. Noor Ahmed Memon

Associate Editor

Nimrah Nadeem

Associate Editor

Shahnawaz Khan

Production Manager

Mazhar Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA)

Mian Iftkhar Afzal B.S.N.C State, M.Sc. (Leeds) C.TEXT.F.T.I (UK)

Dr. Zubair Bandukda PhD (Textiles), CText ATI

Editorial & Advertising Office B-4, 2nd Floor, 64/21, M.A.C.H, Miran M. Shah Road, Karachi - Pakistan Tel: +92-21-34311674-5 Fax: +92-21-34533616 Email: info@ptj.com.pk URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Correspondence & Mailing address: PTJ Europe Ltd. 93 Fleming Place, Bracknell, RG12 2GN, United Kingdom Tel: +44 792 2228 721

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, UK Registered no. 09141989

Available on Gale and Factiva affiliated internat ional databases through Asianet Pakistan

Printed at: Color Plus Korangi, Karachi.

Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi.

Vol. LXXI No. 09 September 2022 Rs. 565.00

EDITOR’S PAGE . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Textile sector loses US$ 1 billion export orders 2022

TEXTILE BRIEFS . . . . . . . . . . . . . . . . . . . . . . . . . . .8

NEWS & VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . .10

AROUND THE WORLD . . . . . . . . . . . . . . . . . . . . . .14

CORPORATE NEWS

Parkdale Selects Datatex NOW ERP system to replace TIM solution . . . . . . . . . .18

Oerlikon Group: Strong Q2 performance confirming growth strategy . . . . . . . .20

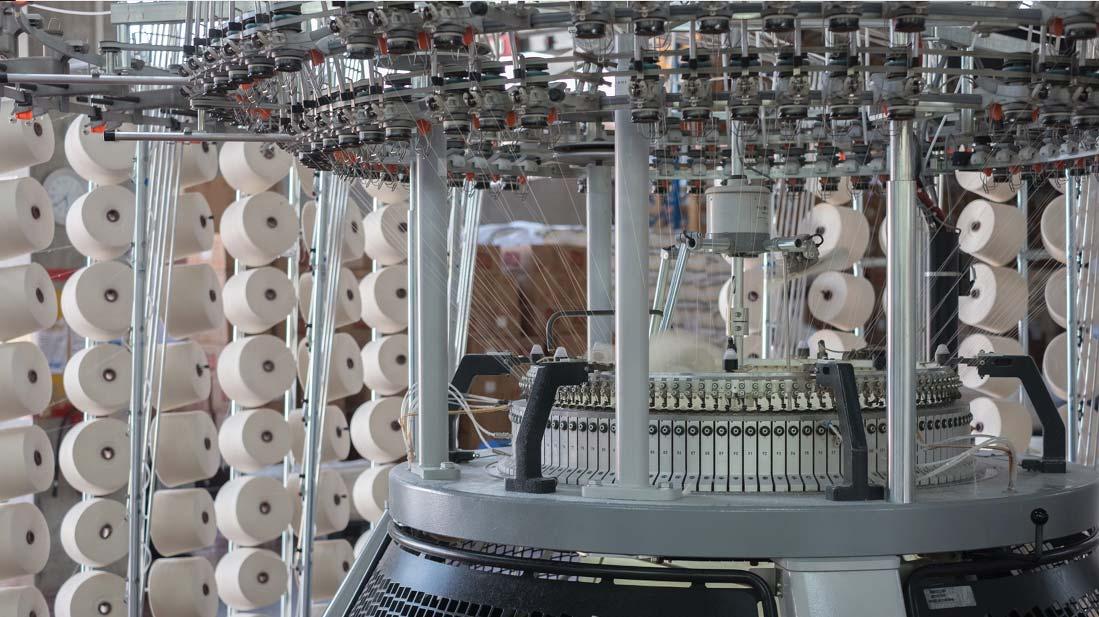

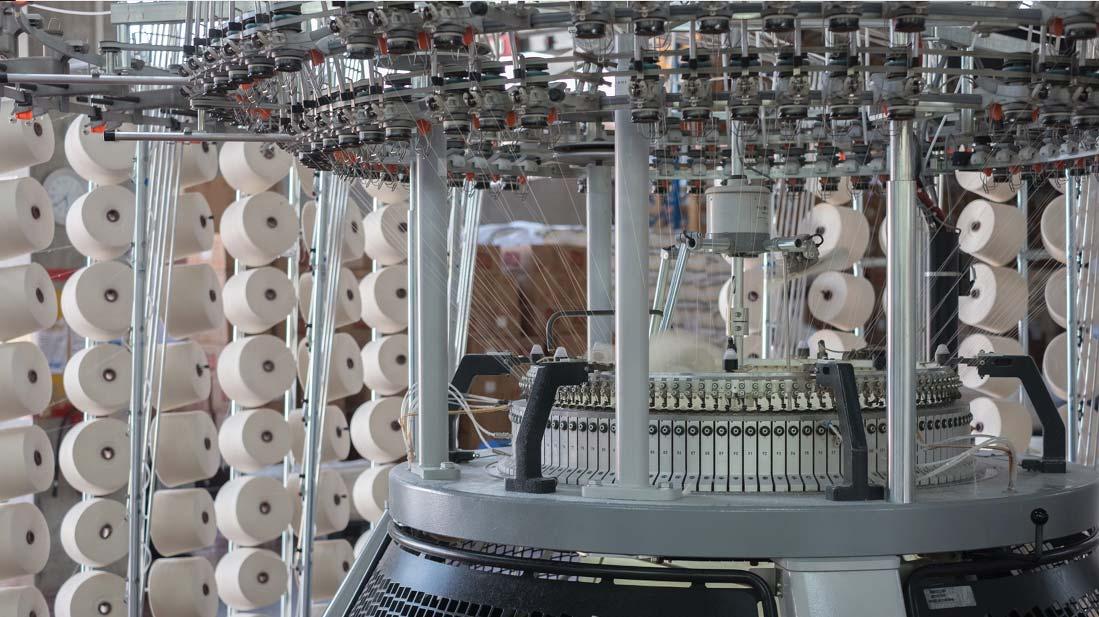

Top circular knitting and braiding machine manufacturer Ranga Yogeshwar presents third top 100 award to Mayer & Cie. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Pakistani textile manufacturers learning more about U.S.Cotton fiber’s value . .24 Lacoste’s commitment to sustainability includes science-based traceability technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Print Against War: Delivering support to Ukraine . . . . . . . . . . . . . . . . . . . . . . . .28

Sustainable Specialty Chemicals provider Perstorp Group to be acquired by PETRONAS Chemicals Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

DYES AND CHEMICALS

Huntsman textile effects introduces new PFC-free durable water repellent in performance breakthrough . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Bluesign defines “sustainable attributes” for approved chemicals within its bluesign® FINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

18 22

33

FAIRS AND EXHIBITIONS

61st Dornbirn GFC Global Fibre Congress 2nd Dornbirn GFC Startup Days . . . . . . . . . .36

FESPA Confirms European Event Calendar to 2024 . . . . . . . . . . . . . . . . . . . . . . . . .37

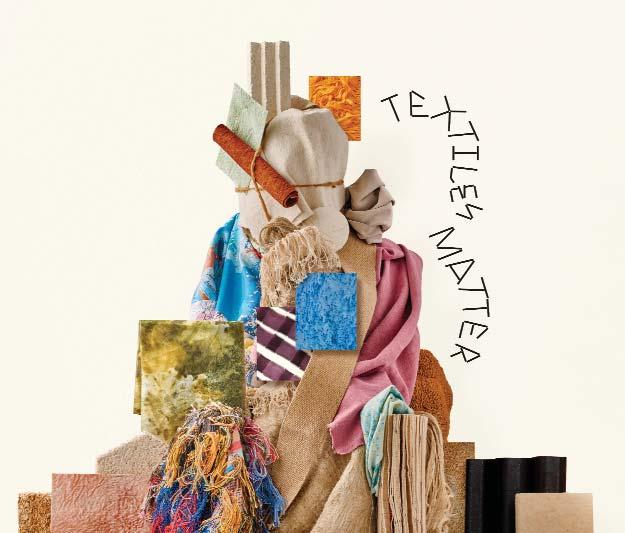

Textiles Matter: Heimtextil Trends 23/24 define the future of home . . . . . . . . . . . . .38

Intertex Tunisia: 4th International Exhibition of Textile Idustry . . . . . . . . . . . . . . . . .40

9th Intex South Asia - Bangladesh Edition in physical format concludes . . . . . . . . . . .41

Sewing industry to converge at JIAM 2022 OSAKA – equipment and expert insights top the agenda . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

FEATURES

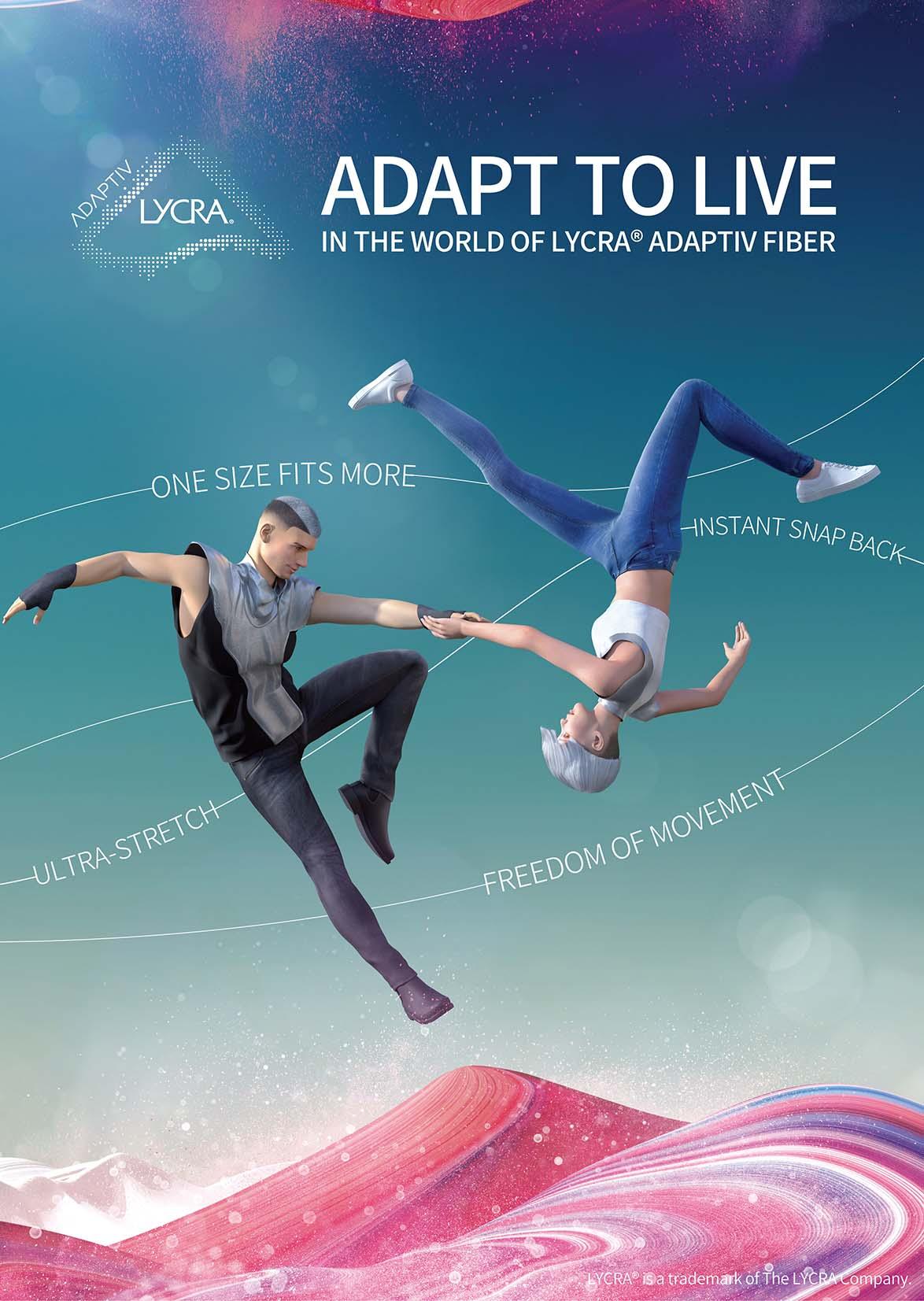

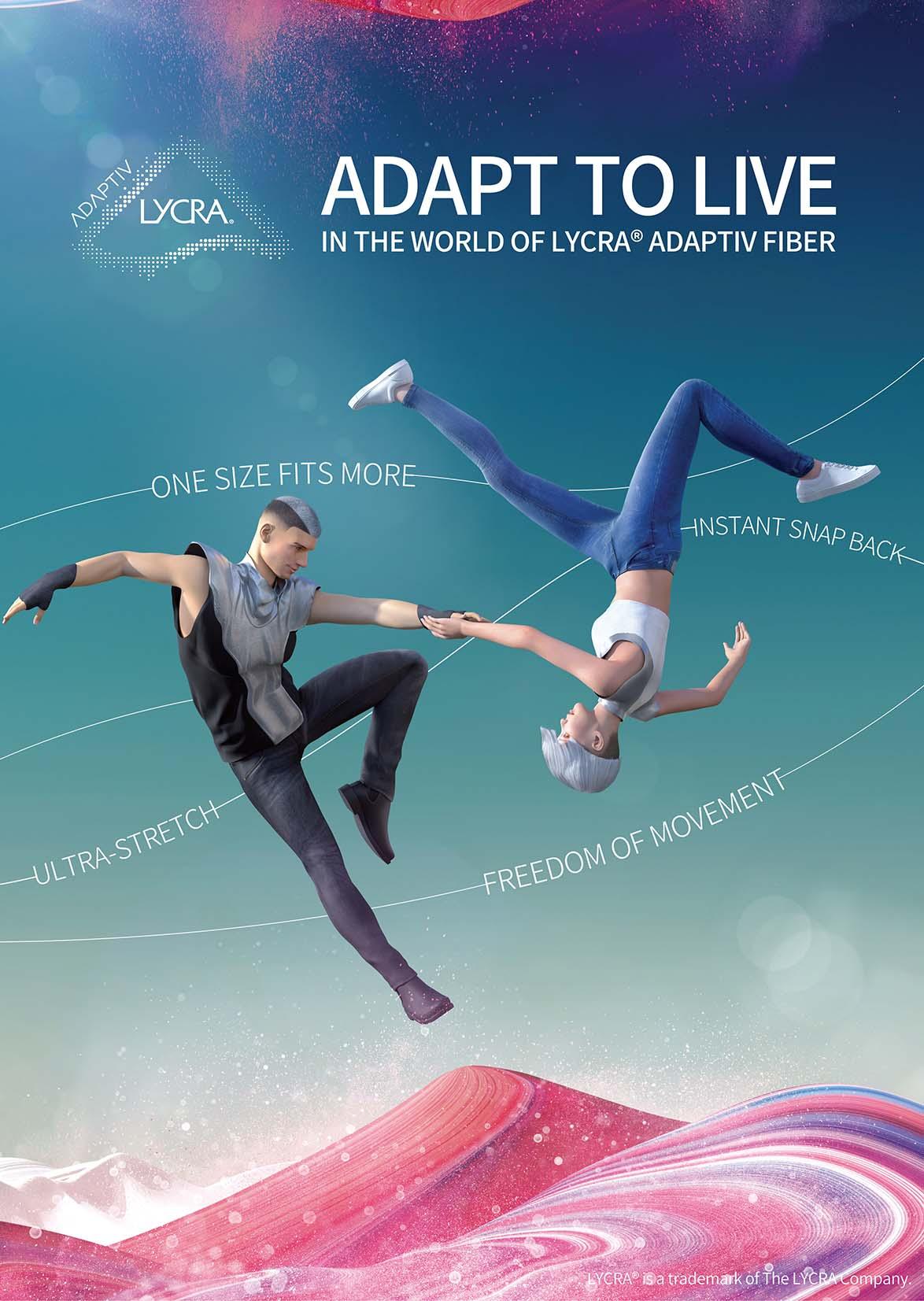

The LYCRA Company introduces LYCRA® ADAPTIV fiber . . . . . . . . . . . . . . . . . . . .44

Allowing garments to adjust to each person’s needs, movements, lifestyle and body fluctuations for a better wearing experience

iTextiles® Welcomes representatives from The LYCRA Company to Pakistan . . . . . .45

“I feel at home here”: Nazer’s Akbar Affandi about his time at Mayer & Cie . . . . .46

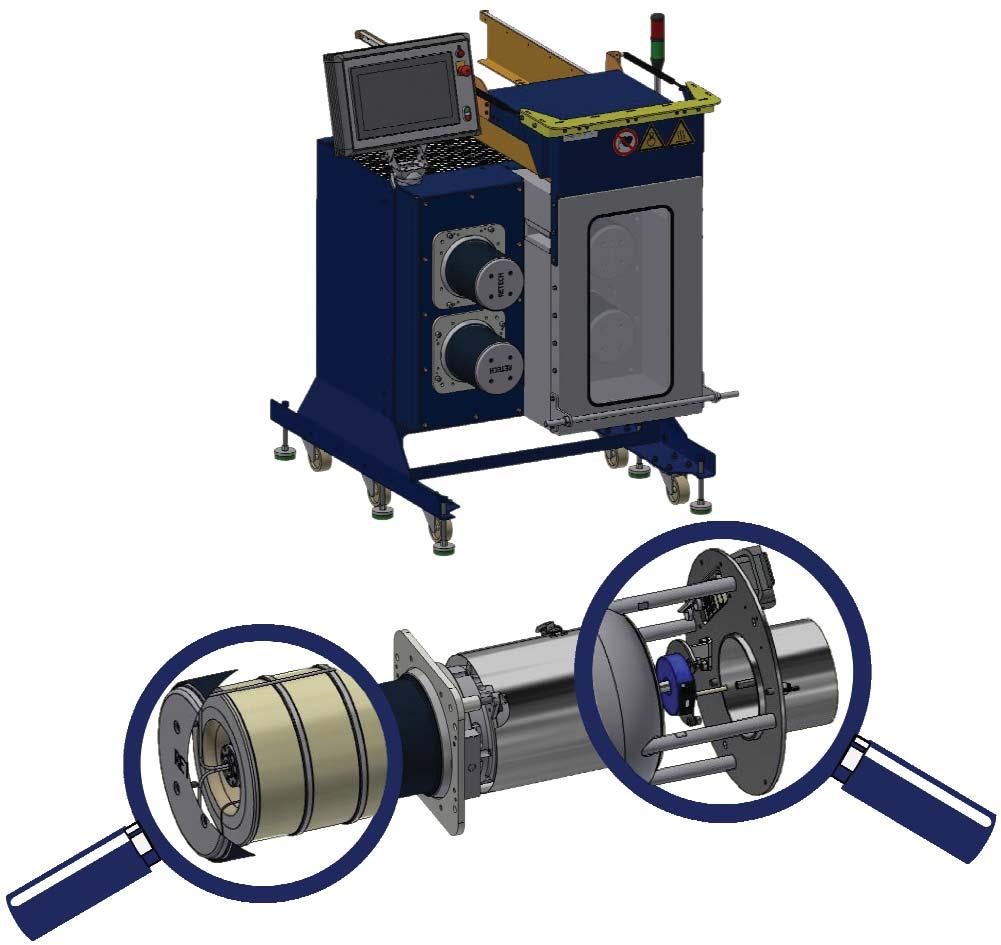

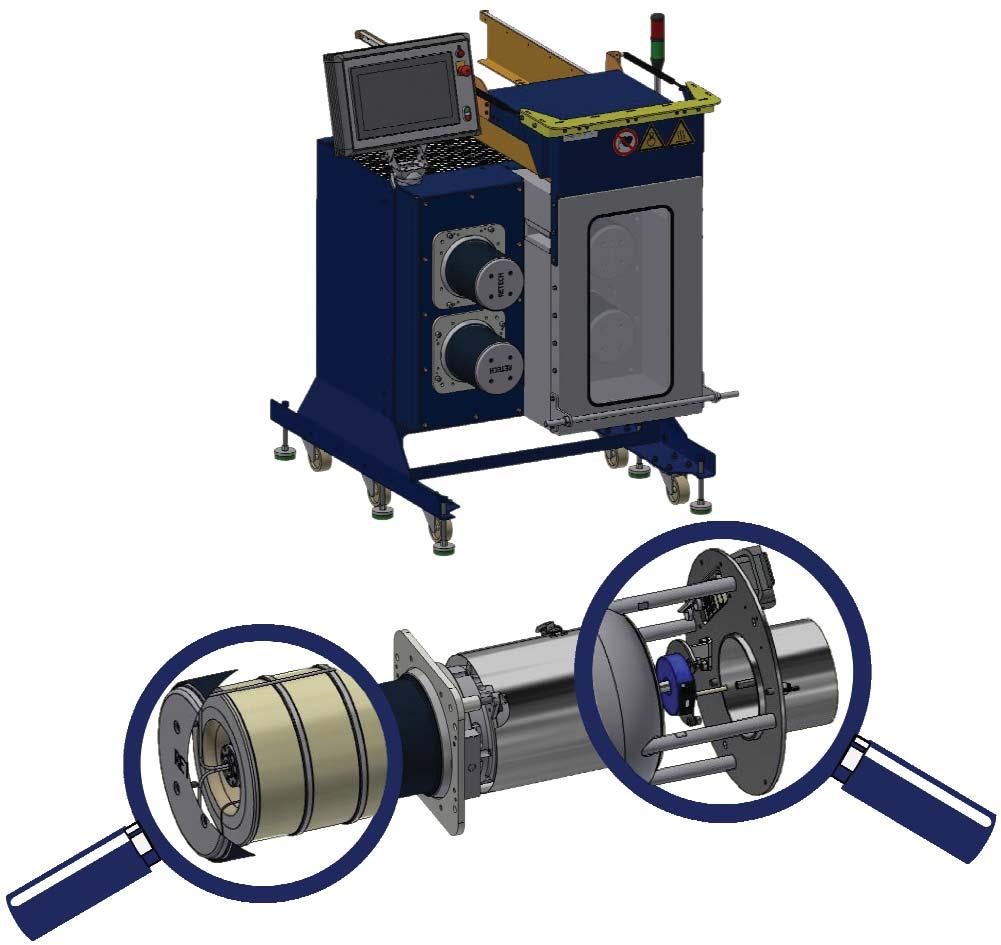

Zero-tolerance contamination control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Uster solution gives nonwovens producers total confidence in demanding applications

Retech technology innovations underline its expertise in filament production . . . .50

Worldwide Shipments of New Textile Machinery 2021 were as High or Higher than Pre-Pandemic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Further successes for FET at Techtextil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

U.S. Cotton: Healthy soil is the basis of our growers’ livelihoods . . . . . . . . . . . . .56

MILL REPORT

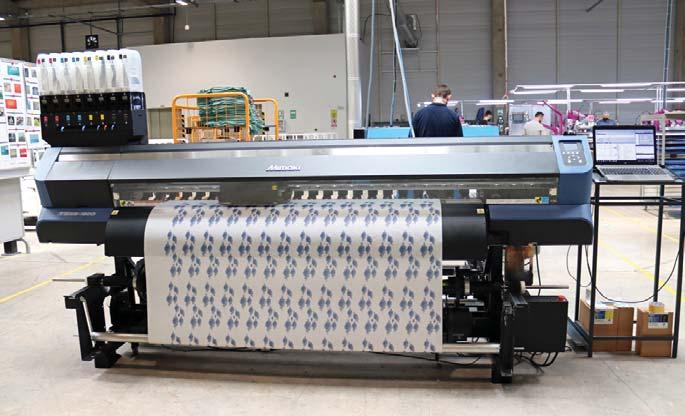

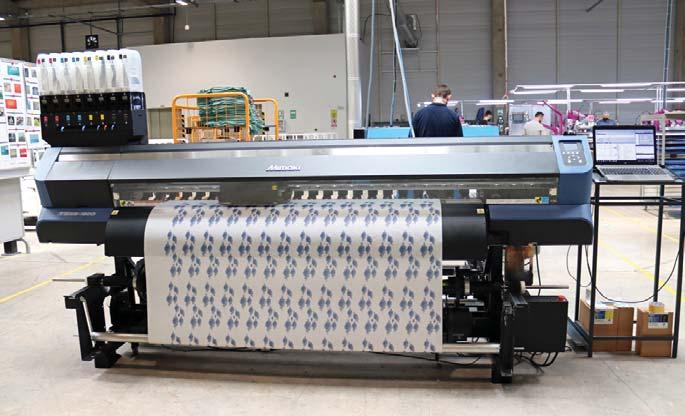

Mimaki: Kardem Tekstil manufactures with Mimaki TS55-1800 for fashion giants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

45

44

37 38

50

48

46

Textile sector loses US$ 1 billion export orders 2022

Claiming that over 300 textile mills have been closed due to a cut in gas supply, All Pakistan Textile Mills Association (Aptma) Chairman Abdul Rahim Nasir on Wednesday urged the federal government to restore gas supply to the textile industry on an urgent basis, stressing that a loss of almost $1 billion in exports has already been incurred because of it.

Accompanied by Aptma North Zone Chief Hamid Zaman and Senior ViceChairman Kamran Arshad at a press conference, he said the 26 per cent upsurge in the export of textiles during fiscal year 2021-22 was made possible only due to the supply of energy at a regionally competitive tariff.

He stated that the textile industry performed admirably, increasing textile exports from $12.5bn in 2020 to nearly $20bn in 2022, a 60pc increase.

He claimed that the exponential growth in the textile sector has promoted investment of over $5bn and the establishment of 100 new textile units, which, after becoming operational, would result in fetching additional exports of $6.0bn per annum.

Mr Nasir pointed out that gas supply to the industry was suspended for a week, almost halting production in the whole value-added industry and causing a colossal loss to the economy.

He added that the large-scale closure of mills has resulted in massive layoffs and unemployment, spreading economic chaos.

He believes it is inexplicable that the exporting sector, which has pledged to increase textile exports to $25bn by 2022-23, is being denied energy and gas. He said that an incessant supply of gas was imperative for the industry to maintain momentum in exports.

Mr Zaman said that the textile sector has repeatedly delivered on its commitment to enhance exports and proven that they are a viable and longterm solution provider for the economic stability of the country.

He warned that more than 50pc of output would be lost this month, with a very high risk of permanent order loss and buyer diversion from Pakistan to its competitors.

He stated that the textile industry is currently producing goods for the upcoming Christmas, and any delay in the delivery schedule risks losing export markets for an indefinite period with little chance of recovery.

“If this momentum is lost due to energy supply and cost constraints, Pakistan will be forced to seek an additional $6bn in loans from abroad, which under the circumstances may not even be possible,” he said, stressing the immediate restoration of gas supply to the export-oriented industry.

Highlighting the importance of the textile sector in the mainstay of the country’s economy, Mr Arshad said that textiles have a 61pc share in the country’s exports and 40pc of manufacturing sector employment. The fragile economy of the country cannot sustain the consequences of the closure of mills in the wake of non-supply of gas

7

Established 1951 September 2022 September 2022.

EDITOR’S PAGE

1In a meeting to review about the current situation of cotton the Ministry of Agriculture discussed the severity and nature of control of pests attacking on the cotton crop including IPM plots was reviewed.

2Country exported textile products worth $19.33 billion during fiscal year 2021/2022, showing an increase of 25.53 per cent when compared with $15.4 billion in the preceding fiscal year, according to data released by Pakistan Bureau of Statistics (PBS).

3The All Pakistan Textile Mills Association (Aptma) believes export proceeds of the textile sector will go down by up to $3 billion in the current fiscal year because of the government’s policies that have “strangu-

lated” the largest dollar-earning sector of the economy.

4Finance Minister Miftah Ismail assured the Hosiery Manufacturers and Exporters Association that their tax and other issues would be resolved soon, urging them to expand their export base. The (PHMA) apprised the Minister of the issues related to taxation, refund of sales tax, electricity, and gas tariff, etc.

5Readymade garments exports during the twelve months of fiscal year of 2021-22 grew up by 28.75 percent as compared to the exports of the commodity during the corresponding period of last year.

6The exports from the country in rupee term witnessed an increase of 40.11 per cent during the

Textile Briefs International

1Australians buy 14.8kg of clothing, or 56 new items, every year, a new report has found, making Australia one of the highest consumers of textiles per capita in the world. There are 1.42bn pieces of clothing –amounting to 373,000 tonnes of fabric – arriving in Australia each year, the report by the Australian Fashion Council (AFC) has revealed.

2Bangladesh's textile industry is currently facing major challenges due to the global recession and inflation as retailers in both European and US markets are either deferring the shipments of finished products or delaying orders due to soaring inflation.

3According to the Center for Advanced Studies in Applied Economics

(Cepea/Esalq-USP) , which calculates the indicator together with the Confederation of Agriculture and Livestock of Brazil (CNA), the Gross Domestic Product of Brazilian agribusiness dropped 0.8% in the first quarter of this year.

4President Abdel Fattah Al-Sisi expressed his support towards the promotion of Egypt’s textile and readymade clothing industry at a recent meeting with his ministers. The country’s minister of public enterprise Hisham Tawfik also assessed their plans to set up the largest spinning factory in the world in the city of Mahalla.

5The minister of labour and vocational training announced that the pension scheme, which is a part of the National Social

current fiscal year 2021-22 as compared to last year, Pakistan Bureau of Statistics (PBS) reported.

7The export of Pakistani textile commodities surged by 25.5 per cent during the fiscal year 202122 (FY22) as compared to the preceding fiscal year. These exports were recorded at $19,329.9 million in JulyJune (2021-22) against the exports of $15,399m JulyJune (2020-21), showing growth of 25.5pc, according to the latest data released by (PBS).

8Xinjiang cotton has comparative advantage and befitting lessons for Pakistan. Furthermore, adopting Chinese techniques of intercropping and double cropping is the way forward for Pakistani cotton farmers.

9Pakistan might have to import up to six million bales of cotton as domestic output would likely fall short of target mainly due to inclement weather and high cost of inputs over the last several weeks. Official cotton sowing data for 202223 season showed national level cultivated area at 2.01 million hectares, around 20 percent less than the target of 2.53 hectares.

10The APTMA has indicated that the Pakistan Textile Industry is expecting a notable increase in exports during FY23 with a growth rate above 20 percent given that the Government continues with the Policy of ‘Regionally Competetive Energy Tariffs’ for exports.

Security Fund (NSSF), The rate increases to 4 percent from the employee and 4 percent from the employer respectively. An additional 2.75 per cent will be added to the employee and employer’s contribution respectively for each subsequent 10 years.

6Rising costs and increasing competition will, in coming years, reduce the dominance that China has enjoyed in the cotton industry since joining the WTO in 2001, said an Agriculture Department report.

7India’s struggle to win global textile market is dependent on imported raw materials like man-made fibre (MMF), extra-long staple (ELS) cotton and raw materials for technical textiles. Government’s initiative of

Production-Linked Incentive (PLI) scheme can fill the gap for only technical textiles.

8A textile industry group in Japan has said it has created guidelines encouraging companies to pay more attention to human rights abuses in supply chains. The Japan Textile Federation’s guidelines include a checklist for company executives to ensure their supply chains are free of various types of rights.

9Hyosung TNC Corp., a South Korea-based comprehensive fibre manufacturer, has reported a net income of 42.9 billion won in the second quarter (Q2) of fiscal 2022 (FY22), down by 85.7 per cent from a year earlier. The company’s sales increased 19.7 per cent to 2.56 trillion won in the second quarter of fiscal 2022.

8 PAKISTAN TEXTILE JOURNAL - September 2022

Textile Briefs National

Pakistan textile exports have fallen around twelve percent so far in the month of September compared to the same month of the previous year.

Textile millers have been struggling to increase their exports because of a host of issues, especially the non-opening of letters of credit for the import of spare parts and machinery.

This was disclosed by the textile industrialists in both Karachi and Faisalabad, the two main textile making centres of the country, when they were approached about hindrances in exports.

The high cost of cotton after its crop was severely damaged in Sindh because of flood has been also contributing to the hardships of the sector.

“Textile exports are down by 12 percent in the current month of this year over the corresponding month of last year,” Asif Inam, chairman of All Pakistan Textile Mills Association (APTMA)-South Zone told The News.

Faisalabad-based Patron-in-Chief of Pakistan Textile Exporters Association (PTEA) was worried about the fall in the exports, while Karachi-based Zubair Motiwala, a textile miller, also predicted the downfall in exports in view of the crisis in the textile industry.

Pakistan’s textile sector was on a growth trajectory for the last few years, and even survived the onslaught of Covid19 when it managed to post growth in that difficult time.

But now, Inam said the textile sector was not only facing a liquidity crunch, but also problems in opening letters of credit, as banks were reluctant to issue the necessary guarantee documents for the import of spare parts, machinery and raw materials. He pointed out that the issues were worse for the spinning sector, with units being closed down.

Motiwala also reiterated that letters of credit were not being opened for raw materials and spare parts, which was hurting the expansion and modernisation plans of the sector. If expansion was not taking place that meant growth has halted, and it would also decreased the exports of textile goods, he said.

Gas crisis and high electricity bills were also to blame for the textile sector woes, he pointed out. “Textile exports can’t growth in the face of shortage and expensive gas and power,” he added.

Khurram Mukhtar, however said that matters regarding HS code 84 and 85 have been resolved by holding meetings with the State Bank of Pakistan, and it would pave way for the clearance of spare parts.

During the first two months of the current financial year, the textile sector’s total exports increased by 4.2 percent to $3.056 billion from $2.93 billion in the same period last year. In the financial year ended on June 30, 2022, the country’s textile exports registered 26 percent growth to $19.3 billion over the corresponding month of the previous year.

Pakistan’s textile exports hit record high at $19.33 bn in FY22

The country exported textile products worth $19.33 billion during fiscal year 2021/2022, showing an increase of 25.53 per cent when compared with $15.4 billion in the preceding fiscal year, according to data released by Pakistan Bureau of Statistics (PBS). In terms of value, the export of knitwear recorded an increase of 34.23 per cent to $5.12 billion during the fiscal year 2021/2022 as compared with $3.81 billion in the preceding fiscal year.

Meanwhile, foreign buyers purchased Pakistani cotton cloths worth $2.44 billion during the fiscal year under review as compared with $1.92 billion in the preceding fiscal year, showing an increase of 27 per cent. Similarly, the export of bed wear recorded an increase of 18.8 per cent to $3.29 billion in the fiscal year 2021/2022 as compared with $2.77 billion in the preceding fiscal year.

10 PAKISTAN TEXTILE JOURNAL - September 2022

Textile exports show a declining trend in September 2022

Zubair Motiwala,

The export of readymade garments exhibited an increase of 28.75 per cent to $3.9 billion during fiscal year 2021/2022 when compared with $3.03 billion in the preceding fiscal year. The textile exports contributed around 61 per cent to the total exports of $31.8 billion during the fiscal year 2021/2022.Textile sector plays a significant role in supporting the economy of Pakistan and continue to be in the spotlight owing to country’s dependence on foreign exchange. Pakistan has exported textile products worth $19.33 billion during the fiscal year 2021/2022 making a record high on annual basis. The analysts said that some factors are posing threat to the textile industry for the current fiscal year such as i.e., increase in export refinance rate.

In the fiscal year 2021/2022, cotton production stood at 8.3 million bales, which is 2.2 million bales lower than the targeted production. The government was eyeing to fetch textile exports of $25 billion for the fiscal year 2022-2023. Moreover, cotton shortage remains the key concern for the country as the demand for textile industry grows but cotton production has declined substantially over the last decade, mainly due to fall in cultivation area followed by lower yield resulting from water shortage and inconsistent rainfall. “Thus, due to the supply and demand gap, textile industry has to rely on imported cotton to meet the country’s demand, putting pressure on country’s import bill,” the analysts added. However, production has increased by 1.3 million bales compared to last year.

Textile exports to dip by $3bn due to govt policies, warns Aptma

The All Pakistan Textile Mills Association (Aptma) believes export proceeds of the textile sector will go down by up to $3 billion in the current fiscal year because of the government’s policies that have “strangulated” the largest dollar-earning sector of the economy.

“I can’t see (us) getting out of this perfect storm. It’d be a miracle if we’re able to retain our exports at the current level,” said Aptma Secretary General Shahid Sattar while speaking at a seminar organised by the Pakistan Institute of Development Economics recently. Textile exports increased almost 26 per cent to $19.3bn in 2021-22, according to the Pakistan Bureau of Statistics. Mr Sattar said the textile sector performed “pretty well” in the last two years as its foreign earnings increased by roughly $7bn. However, he said he’s become a “big sceptic” with regard to the immediate future of the textile sector given the severity of its working capital crisis. The national currency has lost more than two-thirds of its value of late, which means the pre-existing limits on textile mills’ working capital

Shahid Sattar; Secretary General, APTMA

have become redundant. “Exporters are facing huge issues in financing the export cycle, which lasts four to six months. You need double the amount of currency now to finance that cycle,” he said while criticising the sales tax that’s meant for domestic sales but results in mopping up liquidity from the export-oriented segment of the textile sector. “You collect Rs300-350bn a year and retain up to Rs60bn (and refund the rest). This has soaked up liquidity the Export Finance Scheme just doesn’t cover the lack of working capital. How can our exports grow if we don’t have working capital?” he said.

Pakistan Hosiery Association Discusses Tax Issues with Miftah Ismail

Finance Minister Miftah Ismail assured the Hosiery Manufacturers and Exporters Association that their tax and other issues would be resolved soon, urging them to expand their export base. The finance minister also directed the relevant authorities to resolve the issues discussed with the representatives of the hosiery and knitwear industries. A delegation of the Pakistan Hosiery Manufacturers and Exporters Association (PHMA) apprised the Minister of Finance and Revenue, Miftah Ismail, of the issues related to taxation, refund of sales tax, electricity, and gas tariff, etc.

Miftah met with the delegation of the PHMA headed by its Chairman, Mian Kashif Zia, at the Finance Division on August 10. The delegation highlighted the contribution of the hosiery and knitwear industries to accelerating and providing growth in all sectors of the economy. Moreover, issues pertaining to the response of commercial banks to the opening of letters of credit (LCs), the drawback of local tax and levies (DLTL), and the Pakistan Single Window (PSW) were also discussed in the meeting. The Deputy Governor of the State Bank of Pakistan (SBP), a member of the Federal Board of Revenue (FBR), and senior officers from the Finance and Commerce

Ministries attended the meeting. Mian Farrukh Iqbal, Dr. Khurram Tariq, Rana Altaf Ahmed, Hafiz Rashid Mehmood, and Mr. Tahir Rehman participated in the delegation. The Finance Minister, Mr. Miftah Ismail, expressed the resolve of the present government to promote business activities and facilitate the business community to attain sustainable growth in the country.

Meanwhile, on year-on-year basis, the exports during the month of June 2022 increased by 39.98 per cent as compared to the exports of same month of last year.

Readymade garments exports during the twelve months of fiscal year of 202122 grew up by 28.75 percent as compared to the exports of the commodity during the corresponding period of last year. During the period from July-June 2021-22, Tobacco worth US $3,904,658 were exported as compared to the exports of US $ 3,032,812 during the same period of last year. According to the data released by the Pakistan Bureau of Statistics, the exports of Knitwear increased by 34.23 percent, worth US $ 5,120,973 as compared to exports of $3,815,000 during the same period of last year.

Exports increase 40 per cent to Rs5.663 trillion in FY2022

The exports from the country in rupee term witnessed an increase of 40.11 per cent during the current fiscal year 202122 as compared to last year, Pakistan Bureau of Statistics (PBS) reported. The exports during July–June (2021–2022) were recorded at Rs. 5,663,089 million as against Rs. 4,041,927 million during the corresponding period of last year showing an increase of 40.11 per cent, according to provisional data released by PBS.

The exports in June 2020 were recorded at Rs. 596,433 million as compared to exports of Rs. 426,080 million during June, 2021.On month-onmonth basis, the exports increased by 16.16 when compared to the exports of Rs.513,475 million in May 2022.Main commodities of exports during June, 2022 were knitwear (Rs. 97,063 million), readymade garments (Rs. 75,350 million), bed wear (Rs. 58,049 million), cotton Cloth (Rs. 41,082 million), rice other than Basmati (Rs.35,268 million), cotton yarn (Rs.19,236 million), towels (Rs.18,643 million), madeup articles excluding towels and bedwear (Rs.14,089 million), rice Basmati (Rs.12,838 million) and fruits (Rs.9,699 million)On the other hand, imports, imports during July–June, 20212022 totaled Rs.14,281,447 million as against Rs. 8,982,442 million during the corresponding period of last year, showing an increase of 58.99%. Imports into Pakistan during June, 2022 amounted to Rs. 1,610,327 million as against Rs. 1,325,001 million in May, 2022 and Rs. 991,914 million during June, 2021 showing an increase of 21.53% over May, 2021 and of 62.35% over June, 2021.

Textile exports surge by 25.5pc in FY22

The export of Pakistani textile commodities surged by 25.5 per cent during the fiscal year 2021-22 (FY22) as compared to the preceding fiscal year. These exports were recorded at $19,329.9 million in July-June (2021-22) against the exports of $15,399m July-

Readymade garments exports witness 28.75 pc increase

News & Views 12 PAKISTAN TEXTILE JOURNAL - September 2022

Miftah Ismail; Finance Minister

June (2020-21), showing growth of 25.5pc, according to the latest data released by Pakistan Bureau of Statistics (PBS). Commodities that contributed in trade growth included cotton cloth, the exports of which increased by 26.9pc to $ 2,437.9m during FY22 as compared to the exports of $1,921m in FY21.Other commodities that witnessed growth in trade included cotton, the exports of which grew by 18.67pc from $1,016.9m to $1,206.8m and raw cotton which grew by 714.9pc from 0.807m to $6.6.

Likewise, the exports of carded cotton increased by 2,450pc from $0.06m to $1.632m, and yarn other than cotton yarn by 98.4pc, from $33.4m to $66.2m whereas the exports of knitwear increased by 34.23pc, from $ 3,815m to $5,120.973m.Similarly, exports of bed wear increased by 18.8pc from $2,771.786m to $3,292.9m, towels by 18.5pc from $937.5m to $1,111.3m, tents, canvas and tarpaulin by 0.02pc from $110.389m to $110.4m, ready made garments by 28.75pc from $3,032.8m to $ 3,904.7m, art, silk and synthetic textile by 24.2pc from $370.4m to $460.1m, made up articles excluding towels and bead wear by 12.2pc from

$756.4m to $849.1m whereas the exports of all other export materials increased by 20.4pc from $632.5m to $761.4m. Meanwhile, on a year-on-year (YoY) basis, textile exports from the country increased by 2.86pc by growing from $761.5 in June 2021 to $1,706.3m in June 2022.On a month-on-month (MoM) basis, textile exports from the country declined by 3.93pc during June 2022 as compared to the exports of $1,641.9m recorded in May, the PBS data revealed.

It is pertinent to mention here that exports from the country witnessed an increase of 25.5pc during FY22 as compared to the corresponding period of last year. PBS data shows that exports were recorded at $31.8bn during FY22 against the exports of $25.304 billion recorded during FY21, showing growth of 25.5pc. However, on the other hand, imports during the year under review also went up by 41.93pc by growing from $56.4bn in FY21 to $80 billion in FY22.Based on the data, the trade deficit during the period under review was recorded at $48.3bn, showing an increase of 55.29pc over the deficit of $31.076 billion recorded during last year.

Pakistan to see over 20% growth in exports: APTMA

Patron in Chief All Pakistan Textile Mills Association (APTMA) Dr. Gohar Ejaz in his statement has indicated that the Pakistan Textile Industry is expecting a notable increase in exports during FY23 with a growth rate above 20 percent given that the Government continues with the Policy of ‘Regionally Competetive Energy Tariffs’ for exports.

Textile Industry has posted record exports of $4 billion in FY22 with its expansion and investment plans of about $5 billion under LTFF and TERF schemes –YOY growth of 25 percent up till June 30, 2022.Earlier, APTMA stated that the growth was only possible due to the supply of energy at regionally competitive tariffs. Currently, textile is the only sector that continues to grow and bring foreign exchange to the country, gearing up to close at $20 billion in June 2022 compared to $15.4 billion in June 2021In Pakistan, Cotton yields have fallen by 26 percent from 880 kgs/hectare to 652 kgs/ hectare over the last 10 years, while in Punjab the decline has been more pronounced and productivity has fallen by 36 percent from 814 kgs per hectare (2012) to 520 kgs per hectares (2022).

News & Views

AUSTRALIA

Australia has among the highest number of consumers of textiles per capita in the world

Australians buy 14.8kg of clothing, or 56 new items, every year, a new report has found, making Australia one of the highest consumers of textiles per capita in the world. There are 1.42bn pieces of clothing – amounting to 373,000 tonnes of fabric – arriving in Australia each year, the report by the Australian Fashion Council (AFC) has revealed. The report, funded by the Australian government, said the annual cost to consumers was $9.2bn, meaning Australians were paying on average just $6.50 for each item of clothing. The AFC has used the findings to call for a levy on clothing imports to reduce textile waste. The volume of clothing imports dwarfs local production, which sits at 38m units of clothing a year – or 3% of the import market.

At the other end of the fashion cycle, roughly 260,000 tonnes, or 10kg a person, reaches landfill each year, the lead author of the report, Peter Allan, said. “And in addition, all that we export, which is around four kilos per person, eventually reaches the same end of life,” he said. The report was launched by the AFC at the second town hall for the National Clothing Product Stewardship Scheme – which is tasked with halving

national textile waste by 2030. Speaking at the meeting, the AFC chief executive, Leila Naja Hibri, said the fashion industry added $27b to the Australian economy each year and had a “deserved” reputation for its negative impact on the environment. “There needs to be a change in the way we design, produce, use and dispose of products,” she said. On top of the huge amount of landfill, the textile industry also relies heavily on fossil fuels and other chemicals. Globally, 98m tonnes of nonrenewable resources are used in the fashion industry, including oil to produce synthetic fibres, fertilisers to grow cotton, and chemicals to produce dye.In Australia, two-thirds of clothing is made up of synthetic fibres, which are often derived from petroleum.

BANGLADESH

& Mauritz AB claims that it depends on generators for at least 3 hours a day to power its dyeing and washing units in the manufacturing hub of Gazipur on the outskirts of Dhaka.

The cost of electricity from generators is three times more than power from the regional grid. At the onset of the Covid19 outbreak, Bangladesh garment orders worth USD 2.87 billion were cancelled as of March 31, 2020, according to a Bangladesh Garment Manufacturers Association (BGMA) estimate.

Bangladesh's textile industry is currently facing major challenges due to the global recession and inflation as retailers in both European and US markets are either deferring the shipments of finished products or delaying orders due to soaring inflation. The energy crisis in Bangladesh has increased the cost of the business in the country. One of the leading exporters that supply to Gap Inc. and H&M Hennes

This affected about 2.09 million workers and over 1,048 factories. In the first week of April 2020, RMG exports declined by almost 84 per cent. Since then the RMG exports could not pick up to the desire level of growth due to constricted demand and radical shifts in consumer tastes apart from Covid-19related obstacles. According to Policy Insights, a flagship publication of the Policy Research Institute in Bangladesh, the country's RMG has considerably grown in recent decades increasing from USD 120,000 in FY 1985 to about USD 34 billion in 2019.

However, all the growth came in with massive over concentration in a few products and few markets. According to the Bangladesh Bureau of Statistics (BBS) estimate, Bangladesh's growth, which had declined to 3.5 per cent in 2020 due to covid-19 led disruptions recovered to 6.9 per cent in 2021.

14 PAKISTAN TEXTILE JOURNAL - September 2022

Bangladesh textile faces major challenges amid global recession

EGYPT

President El-Sisi keen to develop Egypt’s textile industry

President Abdel Fattah Al-Sisi expressed his support towards the promotion of Egypt’s textile and readymade clothing industry at a recent meeting with his ministers. The country’s minister of public enterprise Hisham Tawfik also assessed their plans to set up the largest spinning factory in the world in the city of Mahalla. The factory will be inaugurated in 2023 and will cover an area of 62,000 sqm. The factory in Mahalla will be equipped with the latest industrial machinery similar to what major international companies use and deal with different types of cotton, especially long staple and extra-long cotton. It is intended to leverage Egypt’s competitive advantage in global cotton production thanks to its high quality and demand in international markets.

At the meeting, Tawfik mentioned in detail about a company formed by his ministry that was established especially

for the marketing, sales, and supply chain management of Egyptian textile products. President Al-Sisi also reviewed samples of the luxury cotton textiles presented to him that the company had been marketing. There were also discussions about implementing a bidding system for Egyptian cotton in collaboration with the Egyptian Commodity Exchange at the meeting.

CHINA

Rising After Reaching ‘PEAK COTTON,’ A Declining Role for China

Rising costs and increasing competition will, in coming years, reduce the dominance that China has enjoyed in the cotton industry since joining the WTO in 2001, said an Agriculture Department report. China is the world’s largest cotton grower, importer and consumer at present, but other Asian countries are growing in importance as importers. At the end of this decade, Vietnam, Bangladesh, Indonesia, Turkey and Pakistan would account for a

combined 47% of world cotton imports, according to USDA’s long-term baseline. China’s share would be 24%, about the same as in recent years. Imports crested at 24.5 million bales in 2011, fell to 5 million bales in 2015 and are projected by USDA for 10 million bales in the trade year that began on August 1.

“China’s cotton production, consumption and imports peaked between 2005 and 2013,” wrote ERS economists Fred Gale and Eric Davis. Beijing uses a tariff-rate quota (TRQ) to restrict imports, as a step to avoid reliance on foreign-grown cotton, and it depends heavily on production in the Xinjiang region, more than 2,000 miles from textile manufacturers in coastal and central China. Some Chinese officials envision cotton production and consumption holding steady in the near term.

“China shifted cotton production to Xinjiang as growers abandoned the laborintensive crop in eastern and central China in favor of more profitable crops or higher-paying jobs in factories. About 12 million Uyghurs, an ethnic minority, live in Xinjiang. Human rights groups accuse China of abuses that include unfairly

Around the World

detaining more than a million Uyghurs. Complaints include conscripting Uyghurs to harvest cotton. “China’s use of forced labor in Xinjiang attracted more attention to the textile industry,” said the ERS report. During 2020-21, the United States barred imports of cotton and cotton products from entities in Xinjiang using forced labor, and in January, the Uyghur Forced Labor Prevention Act instituted a broader ban on cotton grown in Xinjiang and on products made with the cotton.

INDIA

raw material

India’s struggle to win global textile market is dependent on imported raw materials like man-made fibre (MMF), extra-long staple (ELS) cotton and raw materials for technical textiles. Government’s initiative of ProductionLinked Incentive (PLI) scheme can fill the gap for only technical textiles. Such schemes are the need of hour for Indian textile sector. According to statistics imports of raw materials increased in previous years with the rise in exports. It means the country spent large amount of foreign currency on raw materials to sustain export growth. Therefore, net export earnings reduced which could be avoided. India’s textile & apparel imports reached $8.1 billion in 2021 from $5.5 billion of 2020. It is pertinent to mention

that foreign trade was disrupted in 2020 due to COVID-19.

The imports were $8.3 billion in 2019, $7.3 billion in 2018 and $6.6 billion in 2017. The import was $3 billion in January-April 2022.India’s exports performance was similar in the previous years. The exports of textile and apparel reached $41.5 billion in 2021 from $29.7 billion of 2020. The export was $35.5 billion in 2019, $37.2 billion in 2018 and $37.4 billion in 2017. The export figure was recorded at $15.8 billion in first four months of 2022. India secured fourth position in global textile exports in 2021 with the market share of 4 per cent. China is still dominating player in the market despite its soared relation with the western world, which is the largest market for the sector.

JAPAN

Japan’s textile industry urges firms to pay close attention to human rights in supply chains

A textile industry group in Japan has said it has created guidelines encouraging companies to pay more attention to human rights abuses in supply chains. The Japan Textile Federation’s guidelines include a checklist for company executives to ensure their supply chains are free of various types of rights abuses, such as forced labor, child labor and harassment. Specifically, the checklist said that attention needs to be paid to long working hours and delays in wage payments.

The guidelines also said it is important that textile companies make internal rules and human rights policies. The guidelines came amid allegations of forced labor over cotton production in China’s Xinjiang region. “We hope that the guidelines will be used to make the industry more attractive for workers,” Masanao Kanbara, president of the industry group, told a virtual news conference. The government plans to draw up guidelines this summer on human rights due diligence. The textile industry is lagging behind in addressing human rights abuses. In textile manufacturing in Japan, which is costly compared with foreign rivals, the way in which some foreign technical trainees are treated has raised concerns over human rights abuses.

India needs more schemes to enhance production of textile

Around the World 16 PAKISTAN TEXTILE JOURNAL - September 2022

KOREA

South Korean firm Hyosung’s net income down 85.7% in Q2

Hyosung TNC Corp., a South Koreabased comprehensive fibre manufacturer, has reported a net income of 42.9 billion won in the second quarter (Q2) of fiscal 2022 (FY22), down by 85.7 per cent from a year earlier. The company’s sales increased 19.7 per cent to 2.56 trillion won in the second quarter of fiscal 2022.

In the textiles division, Creora profits fell due to higher downtime at customers amid COVID-19 lockdown in China, further hit by one-off charges.

The division witnessed a steadily strong price of major raw materials in the second quarter of fiscal 2022. PET/NY remained in the red mainly on strong raw material cost, the company said in a release.

TAJIKISTAN

Tajikistan's cotton exports to Uzbekistan increase

Tajikistan's cotton exports to Uzbekistan vastly increased from January through June 2022, Trend reports with reference to the Customs Service of Tajikistan.

According to the agency, cotton exports from Tajikistan to Uzbekistan in the reporting period amounted to $17.3 million, which is almost 3.3 times higher than in the same period of 2021 ($5.3 million).Tajik exports of cotton to Uzbekistan from January through June 2022 reached 6,607 tons, which is an increase of 23.4 percent compared to the corresponding period of last year (5,352 tons).

The main Tajikistan's export goods to Uzbekistan in the first half of 2022 were: Cotton ($17.3 million), Cement ($14.1million), electricity(12.2 million), aluminum($10.6 million). At the end of June, the Uzbek delegation of Uztekstilprom, as part of a working visit to Tajikistan, discussed with the heads of local authorities of Khatlon and Sughd regions the prospects for creating a joint venture for processing cotton.

USA

66.2% of USA clothing import comes from top six countries (all Asian) in H1 ’22

During the first half of 2022, the USA sourced garments worth US $ 49.58 billion, noting 40.14 per cent yearly growth. The demand for clothing in the country outpaced the growth attained in the same period of 2021 signaling the minimal impact of inflation on the consumers’ spending on garment products.

Particularly in June ’22, the imports valued US $ 8.64 billion, up 40.30 per cent on Y-o-Y basis, while the growth noted on monthly basis over May ’22 was 1.52 per cent. As per OTEXA data, analysed by team Apparel Resources, top six Asian countries (China, Vietnam, Bangladesh, India, Indonesia and Cambodia) together supplied US $ 32.82 billion worth of garments to USA in H1 ’22, which is 66.20 per cent of total import values of the USA.

China remained the top shipper to the USA in the period with US $ 10.25 billion worth of apparel exports, growing by 40.15 per cent on yearly basis.

Vietnam shipped US $ 9.19 billion worth of apparels to USA in H1 ’22, noting 35 per cent yearly growth, while Bangladesh (US $ 5.02 billion) and India (US $ 3.20 billion) upped their shipment by 60.30 per cent and 57.27 per cent, respectively.

Indonesia stayed on fifth position and couldn’t surpass India despite a flurry of orders the country has witnessed in 2022. The South-East Asian nation shipped US $ 3 billion worth of garments to USA, noting 60.27 per cent yearly jump.

VIETNAM

Vietnamese textile exporters to focus on traceability

The textile industry in Vietnam is busy adapting to new requests from international clients related to traceability of raw materials as companies right now are facing much difficulty with the rise in such demand. A lot of global brands are now requesting that all their products

have to be produced with sustainable cotton materials by 2030.Cotton traceability is something that every company must account for when bringing their product to the world, according to Vo Manh Hung, head representative of Cotton Council International (CCI) in Vietnam.

Nguyen Thi Tuyet Mai, deputy general secretary of the Vietnam Textile and Apparel Association (VITAS) told a recent conference in Ho Chi Minh City that more and more international textile and apparel companies are pursuing green production and that is posing a big challenge to Vietnam’s textile firms, which also need to satisfy transparency requirements related to origin, domestic material use, labour, and environment commitments. Companies trading in markets with whom Vietnam has signed a free trade agreement (FTA) have to ensure that the materials used to make their products are in line with the FTA’s environmental regulations in the importing countries. Officials of the textile industry are now working with the country’s ministry of industry and trade to build industrial compounds with wastewater treatment systems to ensure environmental protection. Textile firms, especially original design manufacturers (ODM), should carefully research Vietnam and the importing countries' traceability rules and standards, the conference was told. The conference was held as part of the International Exhibition of Textile and Garments and Fabric and Garment Accessories (SaigonTex and SaigonFabric), which continues until August 6.

Around the World

17

Parkdale selects Datatex NOW ERP system to replace TIM solution

Datatex is happy to announce that Parkdale Inc. has selected NOW as its next generation ERP solution.

Parkdale is a leading manufacturer of spun cotton yarns and cotton consumer products. Parkdale’s success hinges on its ability to deliver customer value through exceptional yarn quality, unparalleled service and innovation.

Parkdale’s culture of embracing innovation, continuous improvement, and lean manufacturing is fundamental to its future, hence the decision to replace its ERP system from the Datatex TIM solution of more 15 years to Datatex NOW ERP.

“We are excited about our investment in NOW as we believe it gives

us a competitive advantage in productivity and cost containment — while improving our capabilities to meet our customers’ needs” says Parkdale Inc. Chairman and CEO Anderson D. “Andy” Warlick.

Warlick further explained: “Datatex has been a valued partner to Parkdale over the past 15 years. After thorough market due diligence, we felt like Datatex NOW was the best enterprise system in the market for our future needs.“

“Parkdale is an innovation leader in the industry.” said Datatex CEO Ronen “Ronnie” Hagin. “This vote of confidence in our systems, people, and our technology direction with web-based solutions, confirms to us that we made

and continue to make the right investment to remain the leading supplier of software solutions to the textile and apparel industries.”

Parkdale also will implement the Datatex NOW solution in its U.S. Cotton LLC business — a manufacturer of cosmetic and beauty aid products all made in the U.S.A.

Datatex is happy to represent the best enterprise system in the market for Parkdale’s future needs as well as to keep on supporting the optimization of the innovative American textile industries, providing them the best of breed solutions using the latest technologies.

18 PAKISTAN TEXTILE JOURNAL - September 2022

Corporate News

Strong Q2 performance confirming growth strategy

Second-Quarter and Half-Year 2022 Results

Group orders +19%, sales +17%, operational EBITDA +15% vs. prior year.

Polymer Processing Solutions orders significantly increased by 40%, sales by 24% and operational EBITDA by 33% year-over-year, driven by strong execution.

Surface Solutions sales increased by 10% vs. prior year. Operational EBITDA improved by 4%. 2022 Group guidance confirmed.

Pfäffikon, Schwyz, Switzerland –August 3, 2022 – “Our strong growth confirms the strategy of focusing on innovative and sustainable solutions,” said Michael Süss, Executive Chairman, Oerlikon Group.

“In Surface Solutions, we experienced improved demand, even as many of our end markets still face supply chain challenges. While macroeconomic uncertainties increase, we have not seen any unanticipated impacts to date. We are closely monitoring the situation and focusing on further improving our cost competitiveness,” added Süss. “Polymer Processing Solutions continued to execute and delivered another strong quarter of sales growth and margin improvement, driven by filament and non-filament.”

Strong second quarter

Group orders increased by 19.5% to CHF 773 million, driven by strong demand in both the filament and nonfilament business in Polymer Processing

Solutions. Group sales increased globally by 16.9% to CHF 734 million, attributed to growth in both Surface Solutions and Polymer Processing Solutions. At constant exchange rates, Group sales increased by 19.7%.

The operational EBITDA for the second quarter improved by 15% yearover-year to CHF 128 million, corresponding to a margin of 17.4%.

Operational EBIT for Q2 2022 was CHF 72 million, or 9.8% of sales (Q2 2021: CHF 58 million, 9.2%). Q2 2022 EBITDA was CHF 125 million or 17.0% of sales (Q2 2021: CHF 112 million, 17.8%), and EBIT was CHF 68 million, or 9.3% of sales (Q2 2021: CHF 56 million, 9.0%).

Oerlikon Group 2022 half-year overview

In the first half of 2022, the Group’s order intake increased by 21.2% year-onyear to CHF 1 563 million, and sales were up 19.7% to CHF 1 432 million. Operational EBITDA for the half year amounted to CHF 247 million, corresponding to a margin of 17.2%. Operational EBIT was CHF 135 million, or 9.4% of sales. EBITDA was CHF 237 million, or 16.6% of sales (HY 2021: CHF 200 million, 16.7%), and EBIT was CHF 125 million, or 8.7% of sales (HY 2021: CHF 95 million, 7.9%). The reconciliation of the operational and unadjusted figures can be found in the tables below.

The net result for the first half of the year increased by 23% to CHF 88 million, driven by EBITDA growth. As of June 30,

2022, Oerlikon had CHF 513 million of net debt, representing a net debt to operational EBITDA ratio of 1.0. Cash flow from operating activities for the first half of the year was CHF 22 million, compared to CHF 36 million in 2021, mainly due to the increase in inventories.

The Surface Solutions Division saw a 10% increase in sales, driven by general industries, energy and aviation. Automotive continued to be impacted by supply chain shortages, particularly in China and South Korea. Shortages are expected to moderate in the second half of the year. The division’s order intake slightly increased in the second quarter by 1% to CHF 348 million, while orders for the half year increased by 8% to CHF 724 million.

Q2 operational EBITDA improved by 3.6%, corresponding to a margin of 17.7%. The margin was impacted by transitory shortages in high-margin businesses, temporarily offsetting positive operating leverage and cost efficiency. Operational EBIT was CHF 24 million, or 6.8% of sales. EBITDA was CHF 61 million or 17.3% of sales (Q2 2021: CHF 62 million, 19.2%). EBIT was CHF 22 million, or 6.2% of sales (Q2 2021: CHF 20 million, or 6.1%).

The Polymer Processing Solutions Division continued to grow profitably in the second quarter. Q2 2022 order intake increased by 40% to CHF 425 million. Sales increased by 24% to CHF 383 million yearover-year, driven by structural

20 PAKISTAN TEXTILE JOURNAL - September 2022 Corporate News

the

as of June

2022

Q2 2022 Q2 2021 Δ H1 2022 H1 2021 Δ Order intake 773 647 19.5% 1563 1289 21.2% Order backlog 838 705 18.9% 838 705 18.9% Sales 734 628 16.9% 1432 1196 19.7% Operational EBITDA1 128 111 15.0% 247 202 22.2% Operational EBITDA margin1 17.4% 17.7% -30 bps 17.2% 16.9%

Operational EBIT1 72 58 24.6% 135 99

Operational EBIT margin1 9.8% 9.2% 60 bps 9.4% 8.3

Net result 88 72

1For the reconciliation of operational and unadjusted figures, please see table I and II on page

of this release.

Key figures for

Oerlikon Group

30,

(in CHF million)

30 bps

36.9%

110 bps

23.4%

2

demand for filament equipment, flow control systems, plant engineering solutions and a recovery in demand in the U.S. carpet yarn market.

Operational EBITDA improved by 34% to CHF 65 million, or 17.1% of sales, driven by positive operating leverage, cost control and the INglass acquisition. Operational EBIT was CHF 51 million, or 13.3% of sales (Q2 2021: CHF 38 million, 12.2%). Second-quarter EBITDA was CHF 65 million, or 17.0% of sales (Q2 2021: CHF 49 million, 15.8%), and EBIT was CHF 50 million or 13.1% of sales (Q2 2021: CHF 38 million, 12.2%).

Additional information

Oerlikon will present its results during a conference call today beginning at 10:30 CEST. To participate, please click on this link to join the webcast.

About Oerlikon

Oerlikon (SIX: OERL) is a global innovation powerhouse for surface engineering, polymer processing and additive manufacturing. The Group’s solutions and comprehensive services, together with its advanced materials, improve and maximize the performance, function, design and sustainability of its

Table I: Reconciliation of Q2 2022 and H1 2022 Operational EBITDA and EBITDA1

In CHF Million

Q2 2022 Q2 2021 H1 2022 H1 2021

Operational EBITDA 128 111 247 202

Income/expenses related to restructuring 0 1 -1 1

Expenses related to discontinued activities -1 -3 Expenses related to acquisition and integration costs -2 -1 -5 -3 EBITDA 125 112 237 200

Table II: Reconciliation of Q2 2022 and H1 2022 Operational EBITDA and EBITDA1

In

CHF

Million Q2 2022 Q2 2021 H1 2022 H1 2021

Operational EBIT 72 58 135 99

Income/expenses related to restructuring 0 1 -1 1 Expenses related to discontinued activities -1 -4

Impairment charges 0 -2 0 -2 Expenses related to acquisition and integration costs -2 -1 -5 -3

EBIT 68 56 125 95

customers’ products and manufacturing processes in key industries. Pioneering technology for decades, everything Oerlikon invents and does is guided by its passion to support customers’ goals and foster a sustainable world. Headquartered in Pfäffikon, Switzerland, the Group

Division Overview, Surface Solutions Division

operates its business in two Divisions –Surface Solutions and Polymer Processing Solutions. It has a global footprint of more than 12 000 employees at 202 locations in 37 countries and generated sales of CHF 2.65 billion in 2021.

Key figures for the Surface Solutions Division as of June 30, 2022 (in CHF million) Q2 2022 Q2 2021 Δ H1 2022 H1 2021 Δ

Order intake 348 345 1.1% 724 672 7.8% Order backlog 219 168 30.4% 219 168 30.4% Sales (to third parties) 352 320 10.0% 680 624 8.9%

Operational EBITDA 63 60 3.6% 121 115 6.1%

Operational EBITDA margin1 17.7% 18.8% -110 bps 17.8% 18.3% -50 bps

1Based on unrounded figures and total sales, including intercompany sales.

Polymer Processing Solutions Division

Key figures for the Polymer Processing Solutions Division as of June 30, 2022 (in CHF million) Q2 2022 Q2 2021 Δ H1 2022 H1 2021 Δ

Order intake 425 302 40.4% 839 618 35.9%

Order backlog 619 537 15.3% 619 537 15.3% Sales (to third parties) 383 309 24.0% 752 572 31.5%

Operational EBITDA 65 49 33.5% 124 82 51.2%

Operational EBITDA margin1 17.1% 15.9% 120 bps 16.4% 14.3% 210 bps

1Based on unrounded figures and total sales, including intercompany sales.

Corporate News 21

Top circular knitting and braiding machine manufacturer Ranga Yogeshwar presents third top 100 award to Mayer & Cie.

Albstadt-based Mayer & Cie. has been named a Top 100 award-winner for the third time as one of Germany’s most innovative small and mid-range businesses. The jury made special mention of the circular knitting and braiding machine manufacturer’s innovative processes. At the centre of the family firm’s further digital development is on the aim to boost its customers’ productivity. Last Friday, members of the Mayer & Cie. management received the award from the science journalist Ranga Yogeshwar at the SMB summit in Frankfurt am Main.

Claim to leadership a deliberate decision

“We are delighted to receive the Top 100 award for the third time this year,” said Sebastian Mayer, Chief Digital

Officer and member of the Mayer & Cie. management. “2019 and 2020, characterised by a slump in demand and the pandemic, were not easy years for our company. Yet we deliberately worked on improving our processes in order to hit the ground running once the market recovered.

We thank all of our employees for supporting this development and driving the change forward.”

Progress is digital for SMBs too

For some time now, the focus of development work at Mayer & Cie. has been on lean management in assembly processes, on optimisation of aftersales service, including setting up an online shop for spare parts, and on product lifecycle management, or PLM, which

stands for a concept of seamless integration of all the information that arises during a product’s lifecycle.

A clean data structure is the basis for these measures. Sebastian Mayer likes to call it the “digital backbone”. “Basically, what it means is that all product data is processed in he same database and all information is available only once and can be downloaded immediately,“ he explains.

Boosting the customer’s productivity

Customer benefit is the sense and purpose of Mayer & Cie.’s digital development work. “Our aim is to boost the productivity of customers who work with our circular knitting machines,” as Sebastian Mayer puts it. Their main point of access to the company’s development

22 PAKISTAN TEXTILE JOURNAL - September 2022

Benjamin Mayer (left) and Sebastian Mayer (right) are receiving the award from Ranga Yogeshwar in Frankfurt/Main on Friday.

work is the “knitlink” IIoT platform, where machine data is to be recorded and evaluated. Spare parts sales is then automated via the online shop and support is available from the platform round the clock. In future, a 3D model of every machine – a kind of digital twin – is to be available on “knitlink”.

Mayer & Cie. in award-winning company

In all, 436 companies, including about ten per cent from machinery and plant engineering, competed for the Top 100 seal of innovation this year. Nearly 300 were successful and were congratulated in person by Ranga Yogeshwar at the SMB summit. He noted that the award winners set a role model example. “Innovators are thought leaders; they are always pioneers too,” said Yogeshwar, who mentors the competition. “They put their products to the test and ask themselves what an ecological society and a climate-oriented world will require of them. And they check the opportunities and challenges that increasing digitisation will bring for forms of cooperation, social relationships and, with them, for employee retention.”

About Mayer & Cie.

Mayer & Cie. (MCT) is a leading international manufacturer of circular

knitting machines. The company offers the entire range of machines required for making modern textiles. Fabrics for home textiles, sportswear, nightwear and swimwear, seat covers, underwear and technical uses are made on MCT knitting machines. Furthermore, Mayer & Cie. regularly develops new approaches underlining its leadership in technology.

Since 2019, Mayer & Cie. has augmented its portfolio by braiding machines which produce sheathings for hydraulic tubes used in aviation,

automotive industry as well as in further, very specific fields of applications.

Founded in 1905, Mayer & Cie. generated sales of EUR 103 million in 2021 with about 450 employees worldwide, according to preliminary figures. In addition to its headquarters in Albstadt, Germany, where around 350 people work, and subsidiaries in China and the Czech Republic, sales partners for circular knitting and braiding machines in around 80 countries represent Mayer & Cie.

Corporate News 23

The Mayer & Cie. assembly line in AlbstadtTailfingen Photo: Ralph Koch for Mayer & Cie.

The development department at Mayer & Cie. in Albstadt-Tailfingen: with around 50 of the firm’s 400 employees Sebastian Mayer drives the SMB’s digitisation forward. Photo: Ralph Koch for Mayer & Cie.

Pakistani textile manufacturers learning more about U.S. Cotton fiber’s value

Textile executives representing 21 companies from Pakistan should gain a deeper understanding of why U.S. cotton is the world’s preferred fiber when they travel across the U.S. Cotton Belt.

This COTTON USA Special Trade Mission is coordinated by Cotton Council International (CCI), the National Cotton Council’s (NCC) export promotions arm. With total cotton consumption estimated at 11.1 million bales in 2021-22, Pakistan is the third largest cotton consuming country after China and India.

This trade mission’s participating companies collectively consume about 4.4 million bales annually. For the 2021-

22 marketing year, U.S. cotton export sales (as of mid-July) to these tour participants is 1.5 million bales.

CCI President Carlos Garcia, a Texas cooperative executive, noted that many of the mills on this tour have expansion plans, so the COTTON USA Special Trade Mission “is an ideal opportunity to grow U.S. cotton sales now and in the years ahead in this important market. We also want these textile executives to see firsthand U.S. cotton’s first-class production and processing operations and efforts on environmental responsibility and continuous improvement.”

The Pakistan delegation will begin its tour in Savannah, Ga., with briefings

from CCI and Cotton Incorporated staff before touring the Port of Savannah and a local cotton farm. Later, they will tour the USDA cotton classing office in Bartlett, Tenn., and visit a cotton farm, gin and warehouse in South Texas.

The group also will meet with exporters in the Cotton Belt’s four major regions and with these other industry organizations: AMCOT; American Cotton Producers; American Cotton Shippers Association; Southern Cotton Growers; Lubbock Cotton Exchange; the NCC; Plains Cotton Growers, Inc.; Texas Cotton Association; Western Cotton Shippers Association; and Supima.

24 PAKISTAN TEXTILE JOURNAL - September 2022

Corporate News

Lacoste’s Commitment to Sustainability Includes ScienceBased Traceability Technology

Building on its current sustainable development strategy, Lacoste partnered with Oritain, global leader in forensic verification of origin as part of its efforts to sure up its supply chain.

Lacoste’s mission towards Durable Elegance focuses on three core areas: people, communities and planet. Each is guided by a sustainable development strategy and helps to improve the social and environmental impact of their products, ensuring local prosperity and benefiting populations on the ground. With all this effort in place, Lacoste wanted to find a way of protecting it and supporting it through irrefutable evidence.

As Lacoste started looking for a way to prove the traceability of their supply chain, it came across Oritain: everything that is grown, reared, or made, absorbs a unique ratio of isotopes and trace elements. This is what Oritain measures; using world leading-edge science and statistical models to analyse the data and create an ‘Origin Fingerprint’ for each product.

The Origin Fingerprint enables brands to test their products and raw materials

both for provenance and for the absence of provenance, to monitor and verify compliance with their supply chain. In the case of Lacoste, they can ensure their products are made from the high-quality cotton they source, whilst remaining free of high-risk cotton—a particularly important attribute considering the prevalence of forced labour in some supply chains.

“Oritain uses science to help truly committed brands continuously evolve in their value chain transparency journey. We are proud to have been working with Lacoste for the past 2 years, helping them

verify the origin of their cotton to guarantee that it is not only the highest quality, enables them to accurately monitor the sustainability impacts at the raw material level, but are also free from unethical labor practices.” Oritain’s Chief Commercial Officer, Rupert Hodges.

Through concrete knowledge, comes accountability and real, long-lasting change—something Lacoste is driving in order to prove that elegance really can be durable.

About Oritain

Oritain is a world leader in using forensic science to trace the origin of products. It works with Mother Nature and doesn’t rely on barcodes, packaging or other tracer systems. Everything that is grown, reared, or made, is a product of its environment, absorbing a unique ratio of elements and nutrients depending on where in the world it comes from. This is what Oritain analyses, using a unique combination of forensic science and statistics to accurately verify the origin of products.

26 PAKISTAN TEXTILE JOURNAL - September 2022 Corporate News

Print Against War: Delivering support to Ukraine

The Russian invasion of Ukraine has triggered a catastrophic humanitarian crisis with lives being lost and thrown into turmoil, properties and infra-structures destroyed, and millions of livelihoods being threatened every day. It is our duty as humans to provide support and assistance as best we can to the citizens of Ukraine in their deepest time of need.

This new initiative, Print Against War, is calling upon printers and converters, pub-lishers, influencers, and suppliers to the printing and packaging industry to join forc-es to support their colleagues during this incredibly difficult time. Beyond the war in Ukraine, the organization’s goals extend to an ongoing ability to help restore the socioeconomic fabric of printing in any region affected by war.

What is Print Against War?

Print Against War, a nonprofit initiative of the Meaningful Print Foundation, will help Ukrainian printing and packaging companies continue to operate, or provide support when they can again start up their productions. Together, Print Against War and the Meaningful Print Foundation are designed to mobilize the global printing and pack-aging industry to help stakeholders cope with wars, natural disasters, epidem-ics/pandemics, and other damaging and disruptive occurrences. In addition, the Meaningful Print Foundation will work on long-term projects empowering the printing industry to make a positive impact on the planet by addressing gender equality, car-bon neutralization, sustainable manufacturing,

education for students in need, and inclusion of people with disabilities in the workforce.

How will Print Against War raise resources?

The program is open to offers of help from vendors, printers, and any other printing community members. To encourage the collection of donations from a broad base of users, Print Against War proposes that online printing and packaging businesses add a voluntary checkout donation option to their eshops. This will allow a broad base of designers, agencies, print-service providers and individuals around the world to contribute. In addition, you can make direct donations or offer other forms of material help (e.g., provide

Corporate News 28 PAKISTAN TEXTILE JOURNAL - September 2022

consumables, paper, etc., for free or at special pric-es). Finally, Print Against War is working to create alliances between printers in the European Union and those in Ukraine so that the former can share jobs with the latter, making their survival possible.

How will Print Against War allocate resources?

The Meaningful Print Foundation is setting up an application system to make re-source allocation transparent. Through its supervisory board, it will evaluate case by case the eligibility of the applicant and the goodness of the projects to be support-ed. All funded projects will be made visible.

Print Against War testimonials

Within the initiative and on the website, Print Against War intends to make visible reports from the field, give voice to Ukrainian printers through written and video interviews, and collect messages of solidarity from personalities, print champions, and print enthusiasts.

Among them:

WhatTheyThink, a leading independent US-based printing industry media organization — “We stand in solidarity with those who are trying to fight this kind of war and oppression, and we stand for democratic values. Free speech, communication, and print have always been a huge part of that.”

Marcus Timson, co-founder of Future Print — “We encourage anyone in

the printing sector, anywhere in the world, to help our brothers and sisters in Ukraine rebuild their businesses and get behind this fantastic initiative.”

Alon Bar-Shany, chairman of Highcon and former general manager of HP Indigo — “Because in the end, the war ends. And life comes back. As a print industry, I think we want to help our colleagues.”

The organization has also asked duomedia, a leading PR agency, to help increase its visibility and gain additional support.

“Beyond the humanitarian efforts that individuals, families, and businesses are mak-ing to support the Ukrainian population and refugees, we believe that an industry-wide response is essential,” says Lorenzo Villa, co-founder of the Meaningful Print Foundation. “Print Against War is the first global outreach and support project to a regional printing and packaging market in need. We count

it as just the first that the Meaningful Print Foundation will be able to coordinate in the future.”

The platform has already engaged in conversations with several Ukrainian opera-tions. We invite you to read more about their stories here.

To lend your support, please join the Print Against War global community here.

About Print Against War

Print Against War is a nonprofit initiative aimed at helping Ukrainian printing and packaging companies continue to operate or providing support when they can again start up their productions. Soon it will be backed by the Meaningful Print Founda-tion, managed and overseen by a group of respected global print enthusiasts.

29 Corporate News

Sustainable Specialty Chemicals provider Perstorp Group to be

acquired by PETRONAS Chemicals Group

Perstorp Group, a leading sustainability-driven global specialty chemicals company, today said that it is to be acquired by PETRONAS Chemicals Group Berhad (PCG). PCG announced today that it has signed a Securities Purchase Agreement on 14 May 2022 to acquire the entire equity interest in Perstorp Holding AB. The agreement was signed with Financière Forêt S.à.r.l, a company under PAI Partners, a European private equity firm.

Jan Secher, President and CEO of Perstorp said, “We are excited to become part of the PETRONAS family. I see a strong commonality in values and priorities for how to take our respective businesses forward, meeting the challenges and opportunities of the

future. By tapping into PCG’s strength and market leading position in the Asia Pacific region, we are confident that Perstorp can continue to develop into its next phase of growth. Being part of PCG means Perstorp gets the scale to increase the pace of innovation and accelerate our sustainable transformation, which is at the forefront of the chemical industry. PCG’s and Perstorp’s businesses complement each other very well.”

“Perstorp is an outstanding strategic fit for PCG and enables us to participate in attractive end-markets such as paints and coatings, construction, plastic additives, personal care and food, feed & nutrition, paints and coatings that share a robust growth outlook. This acquisition will also provide us critical talent, know-

how, technological platforms and proven customer channels to address the pressing needs of the market for more eco-friendly and sustainable solutions,” said PCG Managing Director and CEO, Ir. Mohd Yusri Mohamed Yusof.

Established more than 140 years ago, Perstorp is a leading niche specialty chemicals player that develops sustainable solutions with focus on the Resins & Coatings, Engineered Fluids and Animal Nutrition markets. The company has a global sales presence, seven stateof-the art manufacturing sites in Europe, US and China (the 8th plant will be ready in India in 2023) and three research and development (R&D) centres worldwide with approximately 1,500 employees serving more than 2,600 customers

30 PAKISTAN TEXTILE JOURNAL - September 2022

globally. Perstorp is highly regarded among its customers for its product quality and application expertise, supply reliability, customer centricity and ProEnvironment products and solutions.

“We find Perstorp attractive for their expansive range of products, established customer base as well as their market leadership in selected chemicals, which are complementary to PCG. It is our intention to make Perstorp our growth platform into the Specialty chemicals field. With Perstorp’s holistic and innovative approach to reduce environmental impact in line with PCG’s aim for positive environmental and social contribution, we are confident that together we can accelerate our sustainability journey towards circular economy and carbon neutrality by 2050,” concluded Ir. Mohd Yusri.

PCG’s journey to achieve its vision of becoming the preferred chemical company providing innovative customer solutions is based on a clear strategy; to strengthen its basic petrochemicals portfolio, and to selectively diversify into derivatives, specialty chemicals and solutions.

In the execution of this strategy, the acquisition of Perstorp group marks the creation of a significant specialty

chemicals portfolio, while enhancing PCG’s overall earnings. This transaction follows the acquisition of BRB Group in 2019, a leading global independent producer and formulator of silicones, lube oil additives and chemicals, which launched PCG into new areas aligned with its long-term growth ambitions.

“I am convinced that Perstorp and PCG can learn from each other’s capabilities to ensure we bring the best of our two companies to our customers and our employees. I am confident that PCG will provide the best possible ownership for Perstorp in the years to come,” concluded Jan Secher.

The acquisition values Perstorp Group at an enterprise value of EUR 2,300.0 million.

The completion of the acquisition is subject to relevant regulatory and shareholders’ approvals.

Corporate News 31

Huntsman textile effects introduces new PFC-free durable water repellent in performance breakthrough

SINGAPORE – Huntsman Textile Effects has released PHOBOTEX® R-ACE, a breakthrough PFC-free durable water repellent (DWR) that makes it possible for mills and brands to deliver highperformance outdoor and extreme sports apparel and everyday wear while meeting stringent environmental standards and optimizing production flow.

PHOBOTEX® R-ACE delivers excellent water repellence on all types of fibers. In addition to its outstanding performance on synthetic fibers and blends, PHOBOTEX® R-ACE offers excellent compatibility with resin finishing to ensure even application with unmatchable performance on cellulosic fibers. It offers outstanding rain and splash protection for garments that are water repellent and windproof, even under the toughest conditions. Additionally, it repels everyday stains, such as mud, coffee, ketchup and juice, so that garments stay cleaner for longer. Textiles treated with PHOBOTEX® RACE are breathable, retain their soft handle and continue to look good and perform well through repeated laundering and drying.

“There is growing worldwide demand for garments that deliver highperformance weather protection and stain-resistance with improved sustainability. Achieving these attributes in concert has been challenging, as traditional non-fluorinated DWR technologies can have undesired side effects that impact fabric quality. Drawing on Huntsman Textile Effects’ research expertise and global operational experience, PHOBOTEX® R-ACE is a true breakthrough that helps mills and brands deliver excellent water repellence with minimal impact on fabric performance,” said Lutfu Okman, Vice President of

Global Revenue, Huntsman Textile Effects.

The robust chemistry of PHOBOTEX® R-ACE achieves high repellency with significantly less chemicals added on to the fabric as compared to the typical PFC-free DWRs in the market. This helps mills minimize unwanted consequences like chalk marks, seam slippage issues and harsh handle. The breakthrough DWR also offers best-in-class runability, for faster trouble-free production and good reproducibility. Its excellent compatibility with resin finishing ensures even application with unmatchable performance on cellulosic fibers.

Critically, PHOBOTEX® R-ACE meets current and upcoming industry standards. The new DWR is PFCfree and formaldehyde-free PHOBOTEX® R-ACE meets the bluesign® criteria (imminent approval pending) and will be published on the ZDHC Gateway with

Conformance Level 3, and suitable for STANDARD 100 by OEKO-TEX® certified textile products. It also meets new bluesign® restrictions on 2Butanone oxime in chemical products, which will come into effect in June 2022.

Textiles treated with PHOBOTEX® RACE qualify for the High IQ® Repel Performance Assurance scheme.

With PHOBOTEX® R-ACE, Huntsman Textile Effects is affirmed as the leader of the industry’s DWR transition. The innovation continues more than a decade of DWR breakthroughs from the Huntsman research labs team and partners, including PHOBOTEX® R, a pioneering PFC-free C0 technology introduced in 2010; ZELANTM R3, Chemours’ renewably sourced PFC-free DWR, launched in 2015; and the marketleading PFC-free PHOBOTEX® RSY range, introduced in 2017 for extreme DWR performance.

32 PAKISTAN TEXTILE JOURNAL - September 2022

Dyes and Chemicals

PHOBOTEX® R-ACE Raises the Bar for DWR Performance and Trouble-free Production

Bluesign defines “sustainable attributes” for approved chemicals within its bluesign® FINDER