Finding solutions for real world challenges

― Engineering

UML Perry, above and far right, combines historic features with cutting edge technology. →

A view of the corridor outside the RoboHub, the robotics research lab at University of Waterloo. ←

A great example of “Science on Display.” The giant LED wall on the side of University of Michigan’s G.G. Brown Lab Building shows abstract examples of active lab work within.

Contents Introduction ― 4 Selected Projects ― 10 Our Team ― 58

↑

4

Passion and innovation are built into every design

Creating a culture of interest, transparency, and teamwork delivers results. It’s what’s inside and outside that counts. How does the space allow people to move around, share concepts, and work together to create the next big idea? Perceiving what doesn’t exist yet, that’s our asset.

5

― Engineering

Maximizing those “a-ha” moments

Engineering 6

The power of applied intelligence is becoming more and more crucial to successful partnerships in industry and academia. Internships and research experience allow students and faculty to draw on real world situations presented by their industry partners, gaining hands-on skills and direct expertise in their field of interest. Whether it’s refining the use of AI in healthcare, finding a new way to harvest energy, or creating a robot for the future, we know you like to think big, and we do too. For over 80 years, we’ve been helping institutions and corporations find smart solutions to take their programs to the next level.

7

Our Science and Technology practice

Engineering

Global Reach Research Labs

With 26 studios worldwide, we have an expansive network of people available to you. Our expertise serves clients in nearly every corner of the globe providing a creative knowledge base and industry-specific experience from people who are truly excited about the scope of work.

Words we live by are conducting practice-informed research for a research-informed practice. From developing a tool to help project teams quantify a zoned approach to reducing energy intensity in laboratory buildings, to using a robotic arm to measure ability for precision and automation in construction—we aim to break the mold and provide realworld insights.

Benchmarking

The technical demands of today’s science environments require the highest standards of design and expertise. Our active benchmarking tool allows us to not only understand singular building parameters, but also to create custom comparative analysis scenarios, provide the ability to include building performance analysis, and represent the data in easily understood graphic formats.

9

10

Selected Projects ― Engineering

11

Cornell University Upson Hall

Ithaca, New York

Client: Cornell University

Size: 160,000 square feet (14,864 square meters)

Completion Date: 2017

Sustainability: LEED Platinum ® Awards:

Award of Merit, AIA New York Design Awards, 2018 Architecture, Biennale Honor Award, 2018

― WHAT IT IS

←

The building serves as a “living sustainability lab,” enabling mechanical and aerospace engineering students to work, learn, and study in a high-performance, technologicallyadvanced facility.

→

Through an integrated approach to facade design combined with energy modeling, the climate specific response of a “transparent blanket” was developed. Calibrating open-glazed areas to maximize daylight in Ithaca’s overcast environment was balanced with heavily insulated walls to perform within its cold winter climate.

The engineering building, originally built just after World War II, has been fully renovated into a state-of-the-art research and teaching facility.

13

― WHAT MAKES IT COOL

A highly innovative, collaborative, and performative facility that sets a new standard for the re-invention of mid-century campus buildings.

Cornell University Upson Hall

Cornell’s objective was to “remove the veil from science” and create a visually transparent, dynamic, and connected engineering building. Research clusters were created and the entire lower floor of the building is dedicated to maker labs, where students work togethr to design and build new, experimental projects as part of their introduction to engineering.

UCSD Franklin Antonio Hall Engineering Interdisciplinary Building San

Diego, California

Client: University of California San Diego

Size: 200,000 square feet (18, 581 square meters)

Completion Date: 2021

― WHAT IT IS

16

A living laboratory for advanced research in critical areas related to the digital future.

17

18

Specific research will

↑

The building will integrate into its surroundings atop a hillside with bike lanes, pedestrian paths, and site landscaping.

←

The open atria design puts engineering on display and shows off the work of approximately 11 research collaboration labs.

→

These highly flexible and adaptable teaching labs will improve the facultystudent ratio in every department.

― WHAT MAKES IT COOL

include AI, cyber security, autonomous vehicles, smart grids, and drones.

UCSD Franklin Antonio Hall

Engineering Interdisciplinary Building

Electrical Engineering and Computer Science Building

Bellingham, Washington

Client: Western Washington University

Size: 55,800 square feet

Completion Date: 2023

Sustainability: Targeting LBC 3.1 - Energy, Equity, and Beauty petals

Mass Timber Structure to achieve Zero Carbon Certification

Supporting State-Wide Goals for STEM Education

Western Washington University (WWU) has experienced unprecedented growth in enrollment for almost every STEM major, and the University continues to develop new degree programs in the STEM field. Western's growth, combined with the state of Washington's goals to expand opportunities in science, technology and engineering education created a need for a new engineering and computer science facility on the WWU campus.

The new building brings together electrical engineering and computer science in one space, creating a multi-disciplinary learning environment.

A connecting bridge links the existing Computer Science spaces in the Communications Facility with the new building.

Electrical Engineering and Computer Science Building

Clockwise from Top Right: Computuer Science Robotics Laboratory

View of Active Learning Classrooms

Electrical Engineering Teaching Lab

Louisiana State University

Patrick F. Taylor Hall

Baton Rouge, Louisiana

Client: Louisiana State University

Size: 438,000 square feet (40, 692 square meters)

Completion Date: 2017

Awards:

ABC Merit Award, Excellence in Construction, 2018

― WHAT IT IS A larger, more welcoming space to encourage learning and engagement. 22

23

― WHAT MAKES IT COOL

As one of the largest engineering buildings in the U.S., its model promotes research focused on sustainable solutions for global challenges.

Louisiana State University Patrick

F. Taylor Hall

↑

Daylighting is included throughout the entire design. We positioned a window at the end of every corridor and used glass extensively to allow natural light to travel into the building and bring the outdoors in.

←

“Engineering on Display” allows incoming students and guests to get involved with current projects and initiatives.

University of Waterloo Engineering Buildings 5 and 7

London, Ontario

Client: University of Waterloo

Size: 39,484 square meters (425,000 square feet) Completion Date: 2018

Awards:

IES Illumination Award, Toronto Section Award, 2011 WAN Interiors + Design Lighting Award, Lighting Project Category, 2011

A six-story atrium with a unique LED lit feature stair ties each department into the social spaces.

From transforming AI technology to locking down cybersecurity solutions, innovative discoveries are in the works. Research partnerships include almost 800 Canadian companies and 300 international companies.

←

→

― WHAT IT IS Fully adaptable labs and dramatic public spaces combined to create an “academic mixer” and a showcase for students.

27

The building was conceived as a creative incubator that would draw researchers, faculty, and undergraduate students together around the building’s public spaces. Transparency and overlook promote a shared experience and a culture of teamwork.

As the largest engineering school in Canada, it is home to more than a dozen research centres and institutes.

University of Waterloo Engineering Buildings 5 and 7

University of Waterloo Engineering Buildings 5 and 7

― WHAT MAKES IT COOL

28

At the heart of the building is the Student Design Centre, where instructional space and design studios overlook high concrete framed work bays and shops supporting fabrication and display of student projects.

29

University of Michigan

Nano-Mechanical Science and Engineering Center

Ann Arbor, Michigan

Client: University of Michigan

Size: 275,700 square feet (25,595 square meters)

Completion Date: 2014

―

IT IS

The building is programmed for labs requiring ultra-low vibration, minimal electromagnetic interference, biosystems research, and core interdisciplinary space.

←

→

WHAT

A new front door to the mechanical engineering department through a three-story atrium provides a direct connection between the new research building, the existing programs, and the campus beyond. Modern, student-centric instructional space that combines core mechanical engineering with emerging technologies.

31

University of Michigan Nano-Mechanical Science and Engineering Center

University of Michigan Nano-Mechanical Science and Engineering Center

― WHAT MAKES IT COOL

Much

of the research coming out of this building is funded by major sponsors such as NIH and NSF.

University of Massachusetts Lowell Francis College of Engineering Perry Hall

Lowell, Massachusetts

Client: University of Massachusetts Lowell

Size: 53,425 square feet (4,963 square meters)

Completion Date: 2019

“Perry Hall exemplifies the interdisciplinary approach required to match the life sciences industry’s burgeoning need for convergent thinking leaders trained in engineering and the biological sciences.”

- Travis McCready, Massachusetts Life Sciences Center President and CEO

- Travis McCready, Massachusetts Life Sciences Center President and CEO

WHAT IT IS A full core and shell upgrade along with expansion to support new, flexible labs for a variety of programs.

―

University of Massachusetts

Lowell Francis College of Engineering Perry Hall

Lowell Francis College of Engineering Perry Hall

To encourage proximity and interaction, programs are organized thematically so that researchers with similar interests can work together. These focus areas include groups in alternative energy, biomedical engineering, manufacturing, material synthesis, and engineering teaching, which includes a three-story distillation column.

36

― WHAT MAKES IT COOL

After opening in 1968 and sustaining a fire many years later, this gut renovation has become a vibrant and diverse setting for teaching and research.

37

Fermilab―Integrated Engineering Research Center

Batavia, Illinois

U.S. Department of Energy Size: 90,000 square feet Completion Date: 2022

The Integrated Engineering Research Center (IERC) is a new laboratory, technical and office building with a focus on collaboration spaces for the Fermilab scientific and engineering community. The IERC will be located to the northeast of historic Wilson Hall and will connect directly to the Wilson Hall ground floor and atrium.

With the IERC positioned adjacent to Wilson Hall, it collocates engineering and technical staff in the laboratory’s central campus, which is where most of the scientific user community is located. Wilson Hall is highly valued as an architectural icon within Fermilab and the DOE laboratory community as a whole. While the IERC must also be a signature building, its design requires a sensitive and artful approach to its architectural configuration, scale and proportion in response to this proximity to Wilson Hall. This also complements the ongoing and planned renovations of Wilson Hall and establishes the central campus as the anchor point of the site.

Client:

Fermilab―Integrated Engineering

Client:

Fermilab―Integrated Engineering

The IERC is envisioned as a new, state-of-the-art building with laboratories equipped to deliver on major initiatives in particle physics. The purpose of the IERC project is to construct a building that provides laboratory space for facilities needed for particle physics detector research, development and detector construction for the Department of Energy projects.

Western University Amit Chakma Engineering Building

London, Ontario

Client: Western University

Size: 9,290 square meters ( 100,000 square feet)

Completion Date: 2018

Awards:

Excellence Award, New Construction, CaGBC Ontario, 2018

living

Electrochromatic glass, a “smart building” technology, allows the glazing to automatically self-shade, increasing occupant comfort and reducing the building’s cooling load.

― WHAT IT IS

A

laboratory and showcase for intelligent and sustainable design.

Design labs, classrooms, computer teaching facilities and fabrication project space were all designed to allow for creative collisions in which new ideas, prototypes and software are developed. Social spaces and lobbies are meant to be places of exchange, education and exhibition.

41

42

Expanded experiential learning spaces engage students earlier and expose them to the newest advances from research.

↑

The building serves as a practical and inspiring place where students integrate classroom theory with hands-on learning as they design, build, test and refine ideas.

←

The west corridor is the social spine for each level. It is programmed with integrated laptop tables along its entire length.

― WHAT

IT

MAKES

COOL

Western University

Amit Chakma Engineering Building

Wichita State University Experiential Engineering Building

Wichita, Kansas

Client: Wichita State University

Size: 142,661 square feet (13,254 square meters)

Completion Date: 2016

Awards:

Excellence in Architecture, Honor Award, AIA Wichita Design Awards, 2017

As the first of four future buildings, the Experiential Engineering Building offers high visibility to attract donors, draw expertise, and inspire the university’s youth.

― WHAT IT IS A co-location for partnerships between students, faculty, the university, private businesses, and public organizations.

46

Wichita State University Experiential Engineering Building

Programs held here include the Technology Transfer program, allowing for expansion support for entrepreneurial development of technology-based businesses, and the Experiential Learning program, essential to support and grow Wichita as an engineering hub for the United States.

― WHAT MAKES IT COOL

Hubs here encourage working across disciplines from aerospace prototyping to metallurgy testing, or flight simulation and astronomic mission planning to biomedical discovery. 47

The Ohio State University Mars G. Fontana Laboratories

Columbus, Ohio

Client: The Ohio State University

Size: 124,000 square feet

Completion Date: 2020 Cost: $43 million

Sustainability: Tracking LEED Silver ®

The Biomedical and Materials Engineering Complex is a complete interior and exterior renovation of the two adjoining Koffolt and Fontana Laboratories, and a new building addition replacing the Koffolt Laboratory high bay wing. Upon completion, the project will create a 127,000 gross-square-feet collaborative teaching and research facility for Biomedical Engineering (BME) and Materials Science and Engineering (MSE). The existing buildings adjoin MacQuigg and Watts learning and research buildings, and consider these buildings, in both form and function, as a part of the exploration of the program.

Materials Science thematic functions include corrosion, biomaterials and functional materials research and hybrid engineering research space with associated lab support space and post-doc and grad student write-up space.

Robert W. Plaster Center for Advanced Manufacturing

Springfield, Missouri

Client: Ozarks Technical Community College Size: 117,000 square feet

Completion Date: In-progress (Est July 2022)

Sustainability: In-progress

The Future is Here

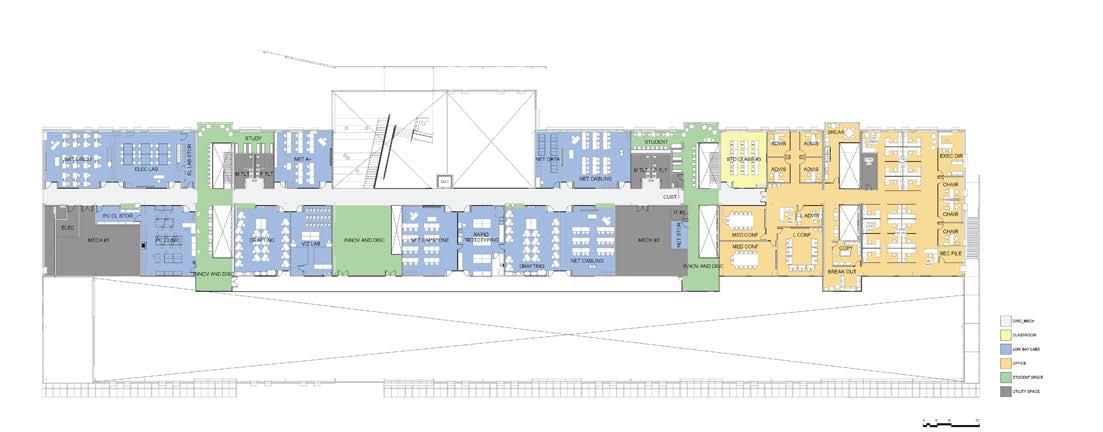

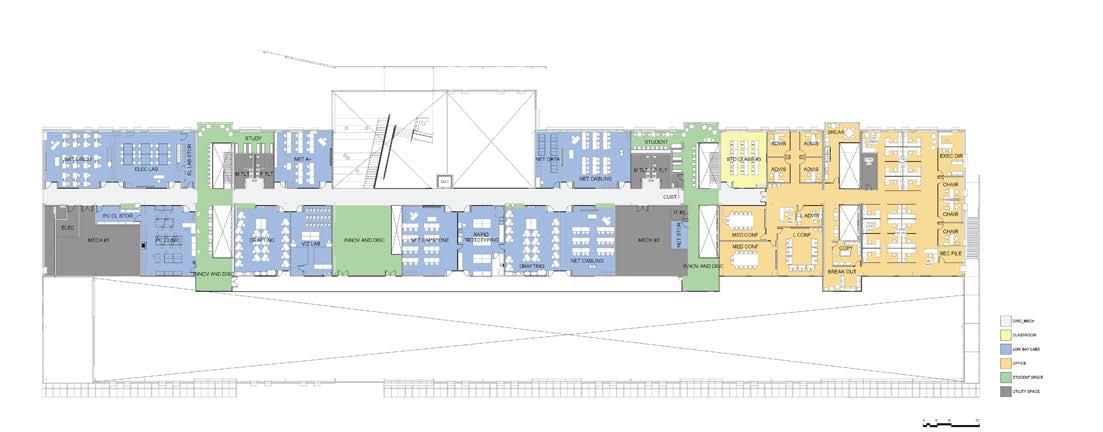

A new 117,000 square foot, two-story Robert W. Plaster Center for Advanced Manufacturing (PMC) is currently being designed for the OTC’s Springfield campus. The facility will serve as the regional hub for advanced manufacturing and technology-related education and training. The design for the PMC includes specialized hands-on learning environments, flexible and collaborative classrooms, customizable simulation training centers, long-distance learning space, research and development labs, designated process-improvement space, business incubation test centers, and a large high-bay environment for industry-led projects. The PMC will offer short- and longer-term training opportunities that cover a breadth of industry specializations, and focus on the future of the advanced manufacturing industry, highly technical processes, and employment.

― WHAT IT IS

A regional hub for advanced manufacturing and technologyrelated education and training.

Robert W. Plaster Center for Advanced Manufacturing

Fronting one of Springfield’s main thoroughfares, the 500’ long high-bay space will offer views into PMC’s main programs including Industrial Systems, Precision Manufacturing, Collaborative Projects, and Industry Partner Space. Alongside the high-bay, a two-story wing accommodates other lab space including Network Technologies, Digital Design, and Rapid Prototyping. To enhance the visitor experience, a choreographed “parade route” will help OTC lead prospective students and industry recruiters through the facility.

Above: High-bay and adjacent labs

Left: Visitor experience was a main driver to attract prospective students and industry recruits

― WHAT MAKES IT COOL

The proposed building will serve as a testimonial to OTC’s role in nurturing skilled talent in Missouri’s advanced manufacturing industries.

Occupying a key site at the campus edge, the PMC will be a signature building that reflects OTC’s critical role in providing skilled talent for Missouri’s advanced manufacturing industries. Fronting one of Springfield’s main thoroughfares, the 500’ long high-bay space will offer views into PMC’s main programs including Industrial Systems, Precision Manufacturing, Collaborative Projects, and Industry Partner Space. Alongside the high-bay, a two-story wing accommodates other lab space including Network Technologies, Digital Design, and Rapid Prototyping. To enhance the visitor experience, a choreographed “parade route” will help OTC lead prospective students and industry recruiters through the facility.

Robert W. Plaster Center for Advanced Manufacturing

W. Plaster Center for Advanced Manufacturing

Robert W. Plaster Center for Advanced Manufacturing

W. Plaster Center for Advanced Manufacturing

The proposed building will serve as a testimonial to OTC’s role in nurturing talents and skills in Missouri’s advanced manufacturing industries.

Robert

Robert

― WHAT MAKES IT COOL

Commonwealth Center for Advanced Manufacturing

Prince Georges County, Virginia

Client: University of Virginia Foundation

Size: 63,000 square feet (5,853 square meters)

Completion Date: 2012

Awards:

Best of Best, Global Best Projects Awards, Engineering News Record, 2013 Design Excellence Award, Institutional, AIA Northern Virginia, 2014

The CCAM initiative is a non-profit institution, housed in a purpose-built facility, which promotes faster and more effective translation of laboratory discoveries into commercializable products and processes.

― WHAT IT IS

A new model for accelerating research breakthroughs into product development.

↑

We worked closely with CCAM’s founding partner, the University of Virginia, Virginia Tech, and the Rolls-Royce Corporation in programming and eventually designing the new facility.

←

In the world of high-tech industry, somewhere between basic discoveries in the laboratory and full-scale production of profitable and reliable products, lays a graveyard of promising ideas that lacked the right resources for successful translation into commercial reality.

― WHAT MAKES IT COOL The only collaboration of its kind in North America with member companies such as Rolls Royce, Siemens, and Canon.

Center for Advanced Manufacturing 56

Commonwealth

Our Team

Ed Cordes

Jeffrey Zynda

Kay Kornovich

Adana Johns

Jose Bofill

Andy Clinch

Jason Chan

Paul Harney

Ed Cordes

Jeffrey Zynda

Kay Kornovich

Adana Johns

Jose Bofill

Andy Clinch

Jason Chan

Paul Harney

58

Su Hong Chen

design

That’s why clients and communities on nearly every continent partner with us to design healthy, happy places in which to live, learn, work, play, and heal. We’re passionate about human-centered design, and committed to creating a positive impact in people’s lives through sustainability, resilience, well-being, diversity, inclusion, and research. In fact, Fast Company named us one of the World’s Most Innovative Companies in Architecture. Our global team of 2,700 creatives and critical thinkers provides integrated services in architecture, interior design, landscape architecture, and more. Our partners include Danish architects Schmidt Hammer Lassen; retail strategy and design consultancy Portland; sustainable transportation planning consultancy Nelson\Nygaard; and luxury hospitality design firm Pierre-Yves Rochon (PYR).

Since 1935, we’ve believed that

has the power to make the world a better, more beautiful place.

59

For more information, contact: scienceandtechnology@perkinswill.com

University of Waterloo Engineering Buildings 5 and 7

University of Waterloo Engineering Buildings 5 and 7

University of Michigan Nano-Mechanical Science and Engineering Center

University of Michigan Nano-Mechanical Science and Engineering Center

- Travis McCready, Massachusetts Life Sciences Center President and CEO

- Travis McCready, Massachusetts Life Sciences Center President and CEO

Lowell Francis College of Engineering Perry Hall

Lowell Francis College of Engineering Perry Hall

Client:

Fermilab―Integrated Engineering

Client:

Fermilab―Integrated Engineering

Robert W. Plaster Center for Advanced Manufacturing

W. Plaster Center for Advanced Manufacturing

Robert W. Plaster Center for Advanced Manufacturing

W. Plaster Center for Advanced Manufacturing

Robert

Robert

Ed Cordes

Jeffrey Zynda

Kay Kornovich

Adana Johns

Jose Bofill

Andy Clinch

Jason Chan

Paul Harney

Ed Cordes

Jeffrey Zynda

Kay Kornovich

Adana Johns

Jose Bofill

Andy Clinch

Jason Chan

Paul Harney