INDUSTRY NEWS MAINTENANCE GREEN PRODUCTION COMPANY PROFILE www.furnaces-international.com -DECEMBER 2022 + THE FURNACES INTERNATIONAL BUYERS’ GUIDE 2023

Furnaces International December 2022 www.furnaces-international.com 28 Editor: Nadine Bloxsome nadinebloxsome@quartzltd.com Tel: +44 (0) 1737 855115 Editorial Assistant: Zahra Awan Tel: +44 (0) 1737 855038 zahraawan@quartltd.com Production Editor: Annie Baker Sales Manager/Advertisement production: Esme Horn esmehorn@quartzltd.com Tel: +44 (0) 1737 855136 Subscriptions: Jack Homewood subscriptions@quartzltd.com Managing Director: Tony Crinnion Published by: Quartz Business Media Ltd, Quartz House, 20 Clarendon Road, Redhill, Surrey RH1 1QX, UK. Tel: +44 (0)1737 855000. Email: furnaces@quartzltd.com www.furnaces-international.com Furnaces International is published quarterly and distributed worldwide digitally © Quartz Business Media Ltd, 2022 www.furnaces-international.com -DECEMBER 2022 + THE FURNACES INTERNATIONAL BUYERS’ GUIDE 2023 C 82 FRONT COVER: Granco Clark 4 34

Welcome to the December issue of Furnaces International.

I can’t believe we are already at the end of the year and it has certainly been quite an interesting and challenging year for many.

I’m pleased to say that this issue is once again packed full of great technical articles and the Greener Furnaces section seems to grow each time, so there are clearly a lot of new projects and processes being implemented in the drive towards Net Zero manufacturing.

There is also a full round-up from Zahra Awan, Editorial Assistant, who attended the Furnaces North America show in October. It looked like a bustling event and with over 1200 attendees, I hope this can continue to thrive as live events get going again next year. On this theme, please keep an eye out for more details of the upcoming Glassman Conference and Exhibition taking place in February 2023, as there will be a dedicated Furnaces Technology session, in association with Furnaces International. Get in touch if you’d like the opportunity to present to the glass industry at this event.

1 Furnaces International December 2022 www.furnaces-international.com

© Quartz Business Media Ltd, 2022

All the best for a

Year! Nadine

CONTENTS AND COMMENT GLOBAL FURNACES 2 Global Furnaces News 4 Ametek Land:

inside 12 Event review: Furnaces North America attracts

attendees 14 Harnessing the Sun: A heat treat case study with General

LIFE OF A FURNACE 24 Life of a Furnace News 28 Precision press feed systems for efficient extrusion operations 34 Increasing refractory lifetime 50 Furnaces simulations to assist in daily operation GREENER FURNACES 60 Greener Furnaces News 64 The Turla RFK’s new heaters range 72 Regenerative burners and Low NOx injection technology 82 Enhancing carbon bake house furnace safety and efficiency

Happy New

Bloxsome, Editor, Furnaces International, nadinebloxsome@quartzltd.com

Peeking

over 1,200

Atomics

ArcelorMittal closing Bremen furnace, citing ‘soaring’ gas costs

ArcelorMittal has announced that it will switch off one of two furnaces at its steelworks in the German city of Bremen until further notice from September-end, citing the soaring cost of gas, weak market demand and a negative economic outlook.’

The steelmaker said it will also shut down the direct reduction plant at its Hamburg steel factory from the fourth quarter of this year, while keeping workers on shorter hours at both sites.‘’The high costs for gas and electricity are putting a heavy strain on our competitiveness.’’

Reiner Blaschek, chief executive of ArcelorMittal Germany

“The high costs for gas and electricity are putting a heavy strain on our competitiveness. On top of that, from October onwards, there will be the German government’s planned gas levy, which will further burden us,” Reiner Blaschek, chief executive of ArcelorMittal Germany, said in a

statement.‘’We see an urgent need for political action to get energy prices under control immediately.”

Reiner Blaschek, chief executive of ArcelorMittal Germany

“With a tenfold increase in gas and electricity prices, which we had to accept within a few months, we are no longer competitive in a market that is 25% supplied by imports. We see an urgent need for political action to get energy prices under control immediately,” he added.

ArcelorMittal said higher gas prices caused by the Russia-Ukraine conflict are impacting the work at the two facilities.

This is making the two plants ‘unprofitable’, according to a report by The Wall Street Journal.

ArcelorMittal has already reduced its gas consumption in Germany and produced around 70Mt of steel in total last year.

Bormioli Pharma completes Italian glassmaking

One of the leading Chinese aviation companies has announced a cooperation with SECO/WARWICK and placed an order for a Vector® vacuum furnace for carburizing (LPC) and gas quenching. The furnace will be used for the manufacture of hydraulic pump components and other machinery.

The vacuum furnace ordered by the aviation company will be used mostly for gas quenching parts sensitive to hardening deformations made from such types of steel as tool steel, stainless steel, structural steel, bearing steel or high-speed steel. The device de-

signed by SECO/WARWICK plans to feature the LPC option, which will be used for vacuum carburizing.

FineCarb and PreNitLPC are modern and economical methods for low pressure carburizing (LPC). By dosing a nitrogen medium during the controlled heating stage, the carburizing process can be performed under higher temperatures (1000°C and more) while ensuring the small-grain structure of the processed layer. This technology enables savings of process costs by shortening the carburizing cycle and reducing the consumption of process gases.

Maciej Korecki, VP, Vacuum Business Segment at the SECO/ WARWICK Group commented on this development,

“We are pleased that a Fortune Global 500 company has placed trust in us and commissioned the manufacturing of this technology,… Our furnace is a guarantee of the perfect quality of workpieces and of a highly repeatable and uniform carburizing process. We understand that the aviation industry is certainly very demanding. Meeting the strictest standards allows us to successfully cooperate with the largest companies in the aviation and automotive industries”

NEWS GLOBAL FURNACE 2 Furnaces International December 2022 www.furnaces-international.com

NEWS GLOBAL FURNACE

Verallia upgrades French glassmaking furnace

Verallia France has renovated its number three furnace at its SaintRomain-le-Puy (Loire) site. The renovation has enabled the maintenance of glass production and will reduce energy consumption at the site.

Fabien Marion, Industrial Director of Verallia France said: “On this partial repair, we prepared the furnace to change the energy mix towards more electricity and less fossil fuels, allowing us to reduce our environmental footprint.”

The furnace is one of 13 at the Saint-Romain-le-Puy site. The plant is also one of the only Verallia France sites to offer several shades of glass.

Fabrice Faure, Director of the Verallia plant in Saint-Romain-lePuy, said: “Oven number three was built in 2015 and was shut down on August 23 for partial reconstruction. 467 people from 82 different companies took turns [renovating the furnace] over 49 days.”

Isabelle Bardon, employee of the

site for 25 years, and client Rodolphe de Pins, President of Cru Lirac and owner of Château de Montfnone, had the honour of restarting the oven, as the godmother and godfather, in a traditional event known as the match ceremony. The ceremony requires the flame to be transferred from one oven to another. It was this gesture that

the godmother and the godfather followed: the fire of oven number two in operation was transferred to oven number three for its restart. The renovation is one of the many decarbonisation initiatives undertaken by the Verallia Group to achieve its target of a 46% reduction in CO 2 emissions (Scopes 1 and 2) by 2030.

glassmaking furnace upgrade

NEWS GLOBAL FURNACE 3

AMETEK LAND:

Peeking inside

Zahra Awan* spoke with Fiona Turner** on the ins and outs of AMETEK Land. With technological transitions, the thermal processes have become safer, more efficient and more technical. AMETEK Land is one of many companies assisting the industry with technology designed to enhance performance.

GLOBAL FURNACES 4

Furnaces International December 2022 www.furnaces-international.com

Fiona Turner

Role Global Head of Product Management, AMETEK Land

Could you give us a brief history behind AMETEK Land?

AMETEK Land is a world leader in industrial infrared non-contact temperature measurement, combustion efficiency and environmental pollutant emissions monitoring.

The company started as Land Instruments in 1947, effectively a spin-out company from Sheffield’s steelworks. Our eponymous founder, Tom Land, initially started making devices to measure temperature in his father’s steelworks. His company has gone from strength to strength, bringing state-of-the-art technology to industrial processes. We now have a proud 75-year history and can claim a number of industry firsts:

� Commercial infrared thermometer using silicon photodiode

* Editorial Assistant

** Global Head of Product Management, Ametek Land

GLOBAL FURNACES 5 Furnaces International December 2022 www.furnaces-international.com

AMETEK Inc. [has] transformed

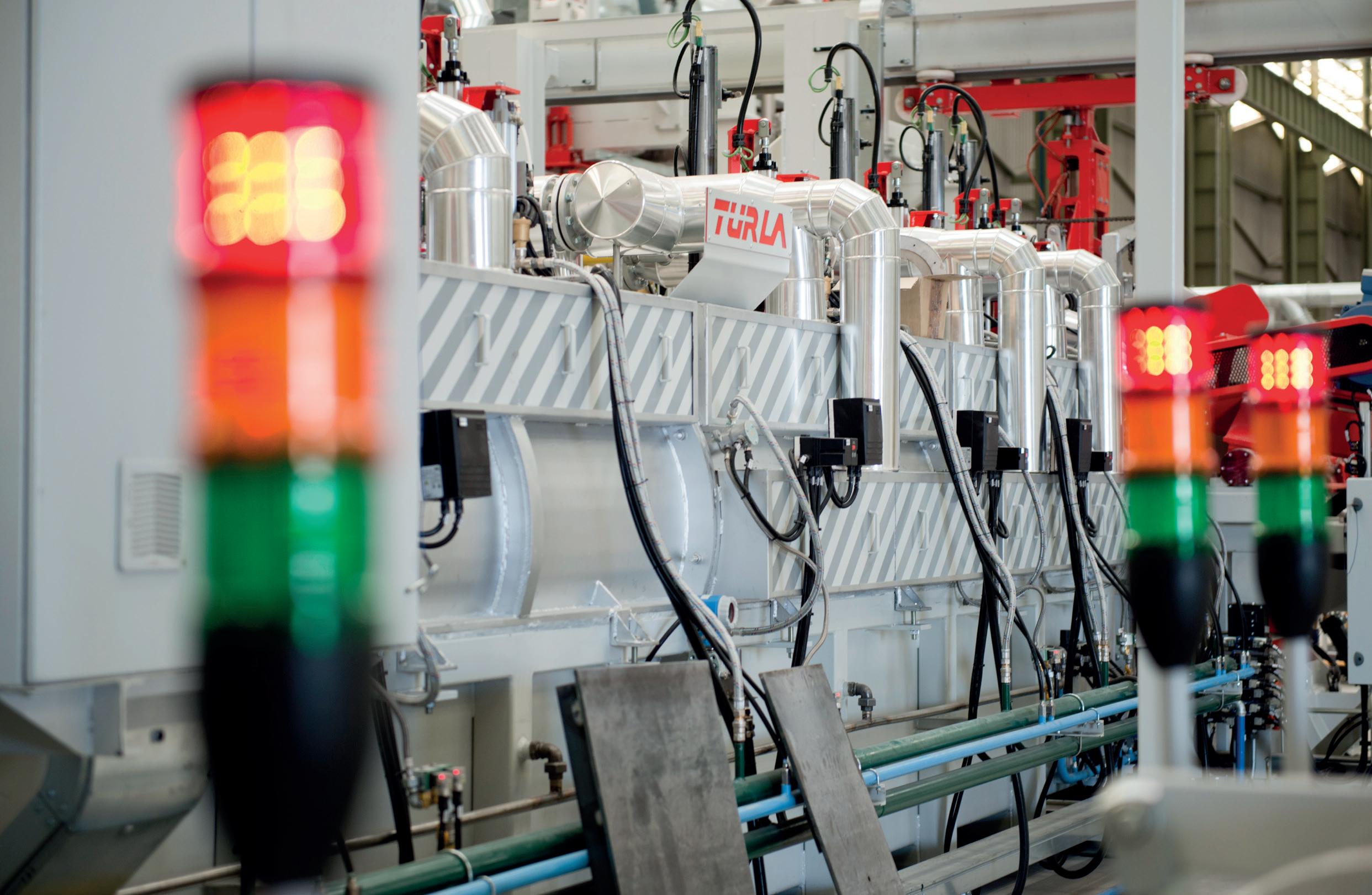

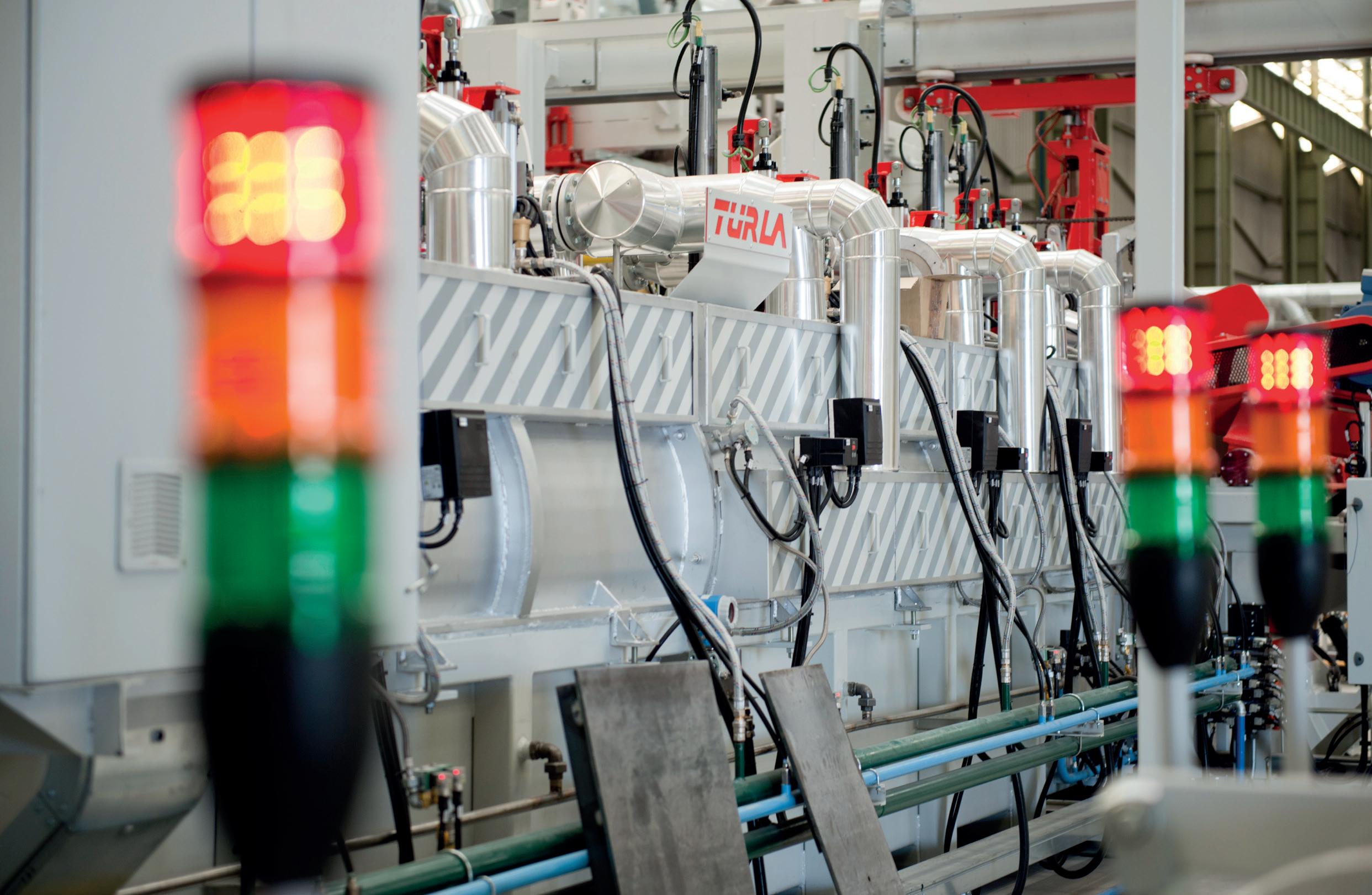

GLOBAL FURNACES 6 Furnaces International December 2022 www.furnaces-international.com

“

from a traditional, family-run business into a modern, global enterprise. ”

� Portable single-lens reflex infrared thermometer

� ISO9000-certified infrared thermometer manufacturer

� Production of in-flight infrared thermometer

� Utility gas turbine infrared thermometer

In 2006, Land Instruments was acquired by AMETEK Inc. and transformed from a traditional, family-run business into a modern, global enterprise. We retained our dedicated R&D centre and manufacturing facility in Sheffield, UK, and we now supply our world-leading pyrometers, scanners and thermal imagers to over 100 countries worldwide.

What are the main industries that AMETEK Land works with?

Metals, glass, hydrocarbon processing and power are the main market sectors we serve, but there are requirements for precision non-contact temperature monitoring instruments, often for high temperatures and harsh environments, in many other manufacturing industries. We also have customers in the medical, aerospace, automotive and plastics applications to name just a few. We supply products to over 100 countries worldwide.

Why technology? Where do you see technology leading the industries you work with?

Our whole function is technology. The alternative used to be operators attempting to judge temperature from the glowing colour of a piece of metal, or the emissions levels by how smoky the air looked! For centuries these were the only methods, and metal and glass were certainly manufactured, but the processes were dependent on skilled artisans and produced low volumes, inefficiently, with variable quality, significant levels of scrap and

GLOBAL FURNACES 7 Furnaces International December 2022 www.furnaces-international.com

complete disregard for emissions.

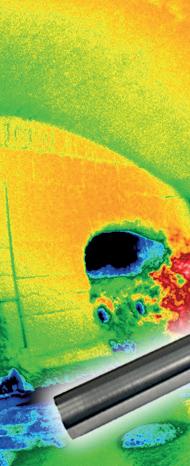

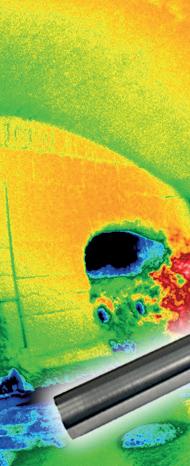

Our technology and products provide accurate temperature monitoring of substances and positions in the process that were previously un-measurable. Some even provide a detailed process view inside furnaces, using carefully selected wavelengths to effectively ‘see’ through smoke and flames.

For many of our customers, process temperature is the key parameter that determines product quality and efficiency. Too cold, and chemical reactions slow or stop, or solid products become less ductile resulting in damage at later processing stages.

Too hot, and unwanted chemical reactions may occur, emissions increase, the surface finish may be affected, infrastructure can be damaged and the process wastes energy. So our technology enables the precise temperature monitoring and control which leads to increased throughput of a higher quality product.

With the digitalisation and integration to Industry 4.0 technologies, how are AMETEK Land products being used? Where does AMETEK Land stand in this move?

At the forefront. Our products have always been enablers of automation, supplying live process temperature measurements to customer PLC and other plant control systems, over protocols as simple as 4-20mA and digital alarms and as advanced as Gbit industrial ethernet will allow. Whichever protocol is chosen, significant amounts of ‘big data’ can be amassed, and our dedicated software used to gain process insights and direction.

Over the last 10 years, our products have also been becoming smarter and smarter, with more advanced processing and I/O onboard, and embedded webservers for remote configuration.

For example, with our latest LWIR range, the full high-speed

8 Furnaces International December 2022 www.furnaces-international.com

GLOBAL FURNACES

thermal video can be viewed as required in a web browser, but there is no requirement for dedicated software or continuous operator monitoring. Once alarms have been configured on specific regions of interest using the webserver, the browser can be closed, with the operators safe in the knowledge that the camera will autonomously monitor the furnace shell for developing hotspots and trigger alarms instantly if required.

While connectivity is necessary, security is paramount for most of our customers, so our products operate within a limited part of the customer network, inside tight firewall protection, with server data kept on site.

What new projects are AMETEK Land working on?

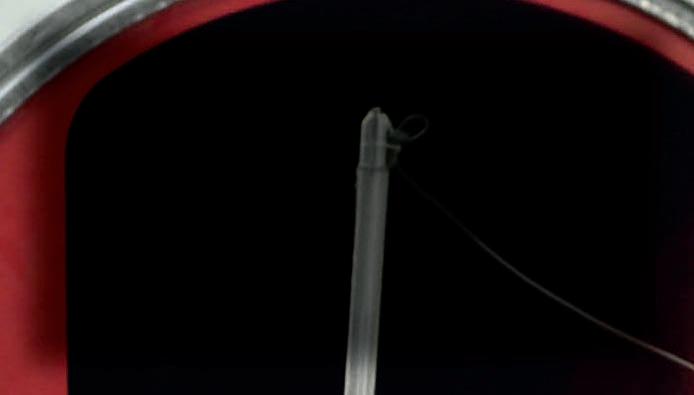

With a dedicated R&D function at our head office near Sheffield in the UK, we are continuously launching new products and improving our older models. Recent developments include the autonomous longwave camera I mentioned above for furnace shell monitoring, and a midwave infrared ‘borescope’ thermal imager that pokes through the refractory wall to give a wide-angle process view inside the furnace itself, even through flames and smoke. You can expect to see further products utilising this waveband in the future, and also an expansion of our Ex Hazloc / ATEX product range for hazardous atmospheres.

Could AMETEK Land products assist in reducing the impacts of the energy crisis on a company/industry?

Absolutely! So many of our instruments are for high temperature applications, that require huge amounts of energy to melt/soften/vapourise the product. Traditionally they would be heated until the product change occurred, with burner settings based on

GLOBAL FURNACES 9 Furnaces International December 2022 www.furnaces-international.com

CHALLENGES BEHIND GROWTH

historic process know-how. However, if you can precisely monitor the temperature, you can precisely control it. You don’t have to overheat it. Many of our customers report significant energy savings – as well as product quality benefits - from being able to tightly control process temperature.

What is the future of AMETEK Land? What future products or where do you see the technology moving to?

It is an exciting time to be working in product development at AMETEK Land.

New developments in semiconductor materials are leading to novel infrared detectors, and thereby to innovative new pyrometers, thermal imaging and scanning systems. The processing power of even the smallest chips is so impressive these days that we are implementing complex functionality onboard our instruments, that would previously have required a server and offline post-processing. We are following recent developments in artificial intelligence (AI) with great interest: AI has huge potential for the interpretation of big data such as thermal images, and could potentially identify trends that an expert plant operator might miss.

We are also involved in several collaborative long-term research projects with external academic and industrial partners. Several of these focus on energy conservation and decarbonisation which is of huge interest to many of our customers; I will be speaking about our infrared insight into hydrogen combustion at an Institute of Physics Conference at Rolls-Royce in Derby on 27th October. We also present at many other exhibitions and events throughout the year. In the meantime, keep up with our latest developments at www.ametek-land.com. �

10 Furnaces International December 2022 www.furnaces-international.com

GLOBAL FURNACES

GLOBAL FURNACES 11 Furnaces International December 2022 www.furnaces-international.com

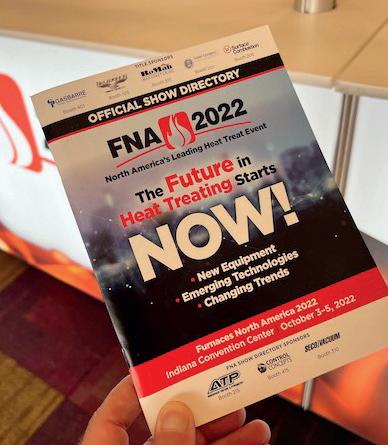

Furnaces North America attracts over

Furnaces North America 2022, North America’s premier trade show and technical conference in the heat treating industry, presented by the Metal Treating Institute, has announced that the event attracted over 1,200 attendees from across the world this week to the Indianapolis Convention Center. Over the three days, attendees experienced connection with over 125+ top suppliers in the heat treating industry, 35 educational sessions in 10 tracks, and two packed social networking events.

Attendees were full of energy and excitement as many stated it felt great to get back to an in-person meeting, and actually talk to people, as well as view equipment and products to help improve their business.

Exhibitors stated that the energy and quality of attendees on the show floor were amazing. Attendees were all about connecting with suppliers to hear how they could help them improve through the current challenges with supply chain issues, automa-

GLOBAL FURNACES 12

Furnaces International December 2022 www.furnaces-international.com

over 1,200 attendees: Event Review

tion, and labor shortages.

FNA Show Producer, Tom Morrison stated, “When the show doors opened up, it was so exciting the see the reconnection of supplier and customer. FNA is a big success because a lot of people including the Metal Treating Institute volunteers, sponsors, and management, who put their heart and soul into delivering a world class event. It was exciting to see that hard work payoff this week.”

It was unanimous that attendees, exhibitors, and speakers look forward to Furnaces North America 2024. The FNA Show Management announced it will host FNA 2024 will be held in Columbus, Ohio on October 14-16 at the Columbus Convention Center with the Hilton Columbus serving as the host hotel. � For more information, visit www.heattreat.net.

GLOBAL FURNACES 13

Furnaces International December 2022

www.furnaces-international.com

Harnessing the Sun: A heat treat case study with General HEAT TREAT TODAY

By Rafal Walczak*,

By Rafal Walczak*,

Imagine this: A huge lab facility nestled in the south of France. . . teams of scientists and technicians striving to bring carbon-free energy solutions to the world. . . “replicating the high-energy fusion reaction that powers the sun and stars.” To complete the project, what heat treat solution is needed? Read to find out.

Article first published on www.heattreattoday.com in September 2022.

*Product Manager, SECO/VACUUM

GLOBAL FURNACES 14

Furnaces International December 2022 www.furnaces-international.com

General Atomics TODAY

Introduction

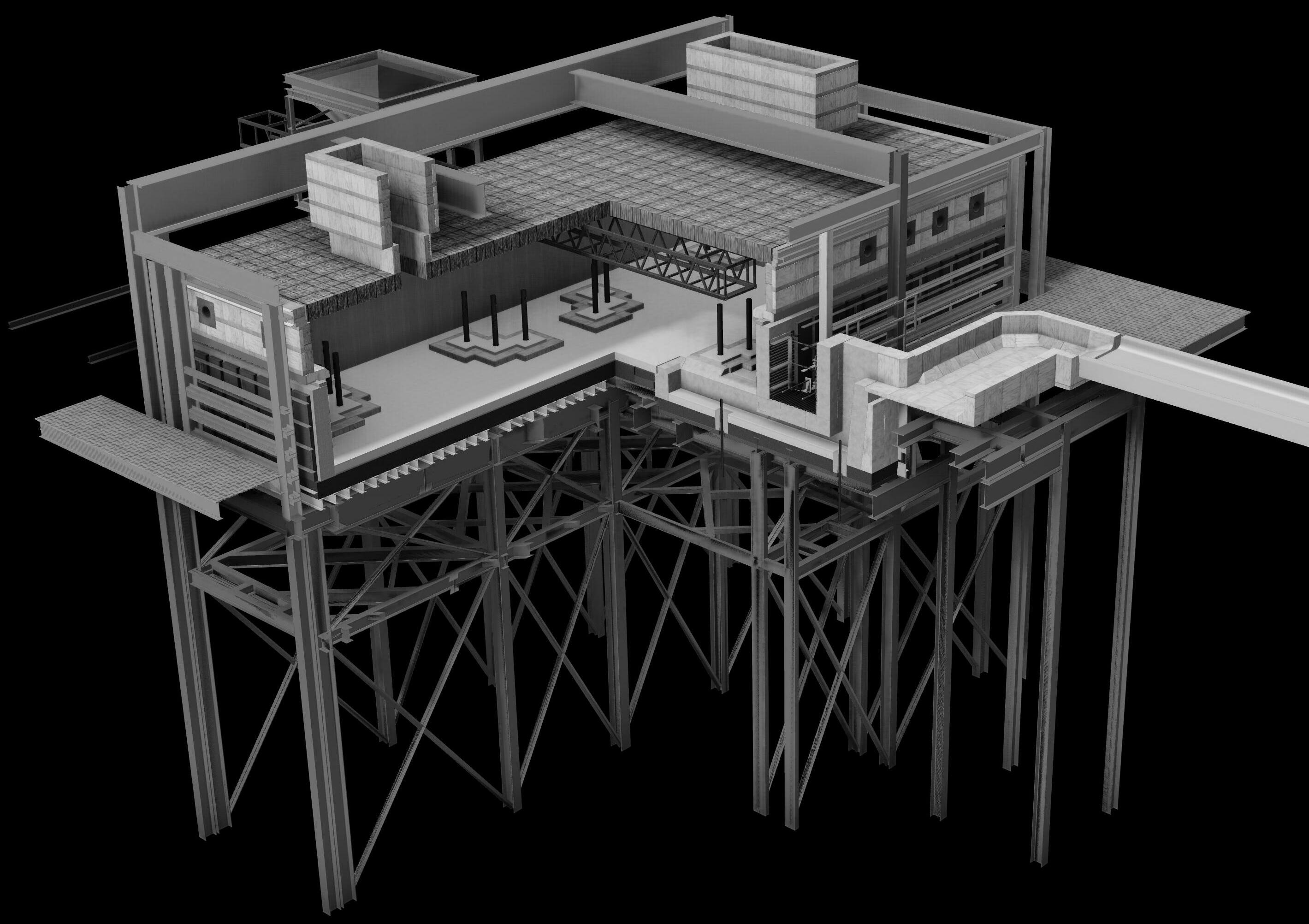

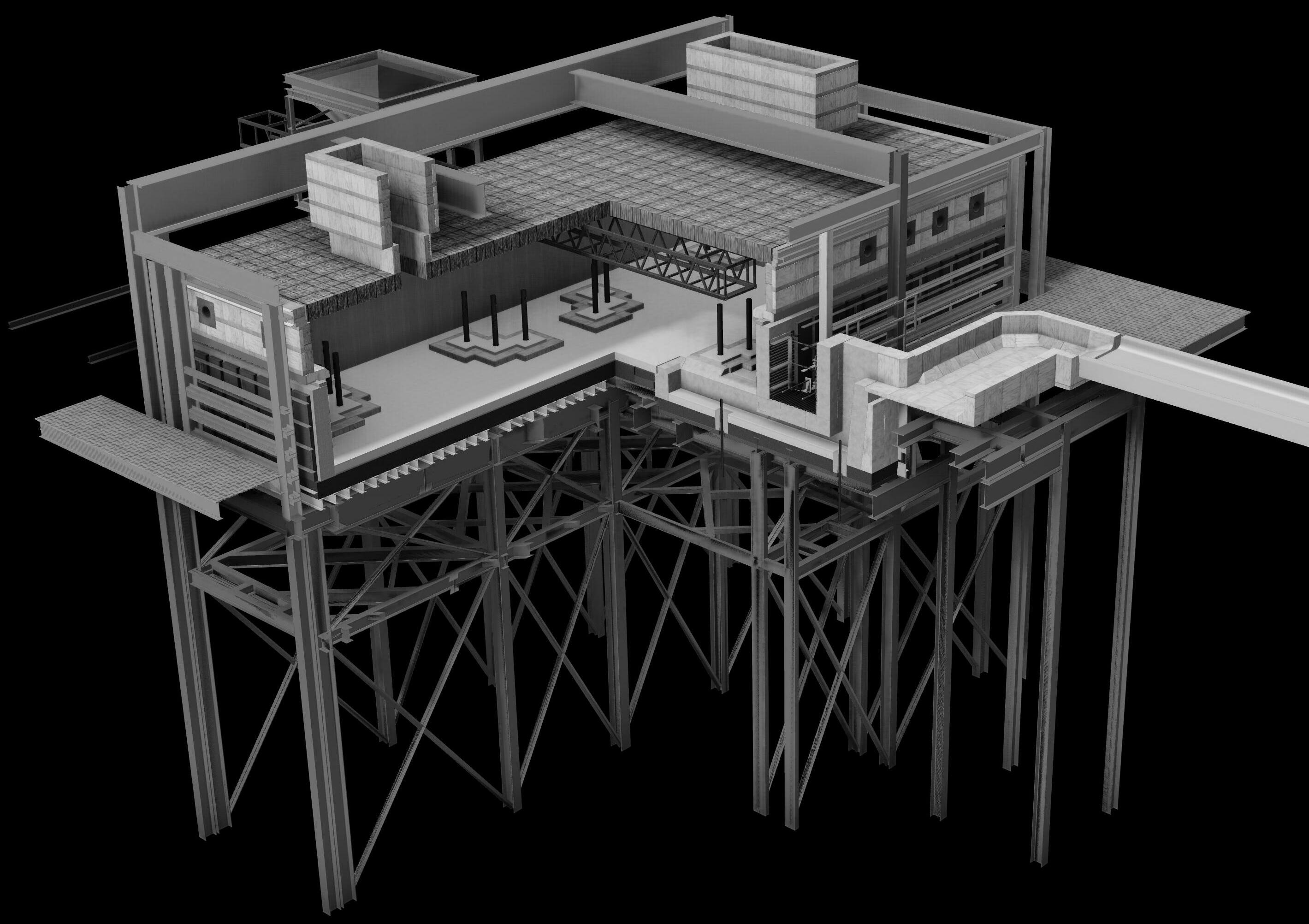

For this case study, we will discuss how SECO/VACUUM built a highly specialized custom heat treating furnace used in the construction of the central component of a large, multinational science experiment.

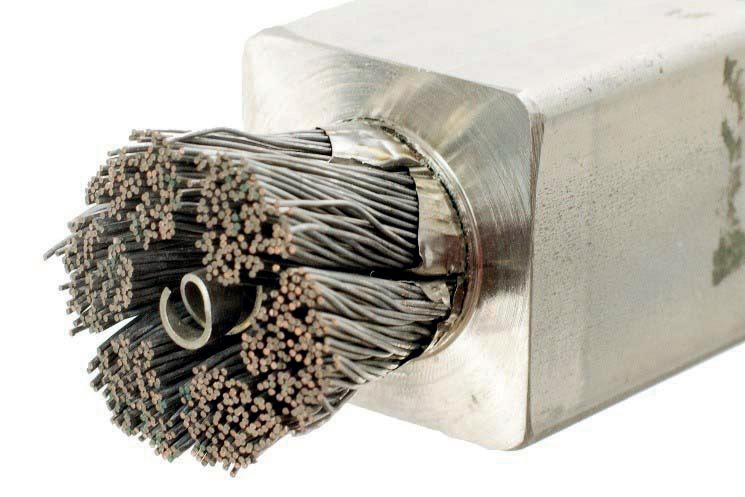

The Experiment ITER (standing for International Thermonuclear Experimental Reactor and meaning “the way” in Latin) is the largest high-energy science experiment ever conducted. At a giant lab facility in southern France, 35 countries, hundreds of vendors, and thousands of scientists and technicians are collaborating on a device to demonstrate the feasibility of clean, safe, carbon-free energy production by replicating the high-energy fusion reaction that powers the sun and stars. There are no solid materials that can touch, much less contain, such a high-energy reaction without

GLOBAL FURNACES 15 Furnaces International December 2022 www.furnaces-international.com

GLOBAL FURNACES

Figure 1. ITER Laboratory at the Cadarache researchcenter in southern France

Photo source: ITER Organization

Figure 2. ITER central solenoid and one isolated solenoid module

Photo source: General Atomics ITER Manufacturing

immediately vaporizing. Instead, this super-hot cloud of plasma must be contained by a special configuration of magnets called a tokamak, which can trap charged particles in a toroidal or donut-shape cloud. This tokamak has 10 times more plasma containment volume than any other tokamak ever built. The term “tokamak” comes to us from a Russian acronym that stands for “toroidal chamber with magnetic coils” (тороидальная камера с магнитными катушками).

General Atomics’ Magnet Technologies Center near San Diego, CA was contracted to build the ITER tokamak’s large central magnet, the most powerful superconducting magnet ever built, strong enough to lift an aircraft carrier. Other magnets in the tokamak serve to contain the plasma. The central solenoid is an oscillating magnet responsible for inducing current in the plasma cloud similar to how an induction stove heats a pan, except it is heating the plasma to 15 times

16 Furnaces International December 2022 www.furnaces-international.com

the temperature of the surface of the sun. Far too large to be constructed and transported in one piece, the 12-meter-tall, 4-meter-wide coil of wires must be built in six 2-meter-tall modules to be joined once they are all on site at the lab. A seventh module will be built as a spare.

Kenneth Khumthong, technical lead for final testing and fabrication certification for ITER Central Solenoid at GA, described the tests on each module of the magnet, saying, “We run a battery of tests on each and every module, subjecting them to voltages as high as 30,000 volts and powering them with as much current as 40,000 amps. This is done to ensure that every module meets all of ITER’s specifications prior to shipping them out to France.”

Embrittlement vs. Field Strength Tradeoff

Other superconducting electromagnets in the ITER tokamak will be made using coils of relatively durable niobium-titanium alloy. Past experiments have demonstrated that magnetic fields greater than 12 tesla disrupt the superconducting properties of Nb3Ti. The ITER central solenoid, however, must sustain magnetic field strengths above 13 tesla. For this reason, the central solenoid coils must instead use niobium-tin as its superconducting wire, which more reliably maintains superconducting properties in such high magnetic fields but is also more brittle and too fragile to bend after reaction to Nb3Sn. In order to accommodate for the brittle wire, General Atomics had to first coil the wire and jack-

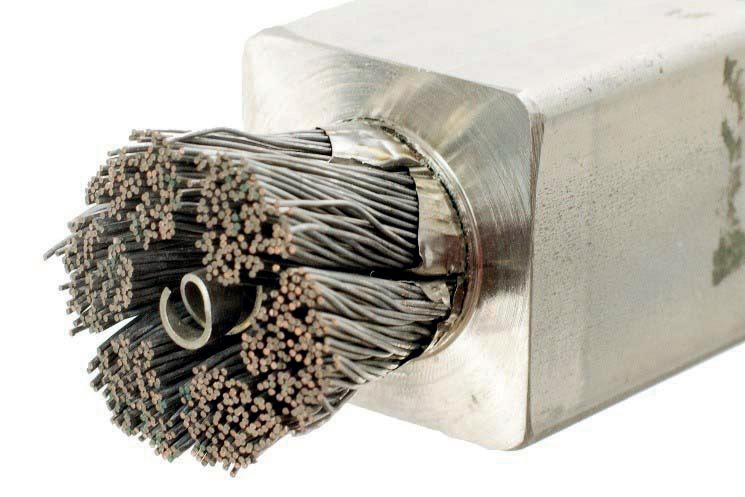

Figure 3. A dissection of the central solenoid conductor strands, central spiral, and structural jacket

Photo source: ITER Organization

GLOBAL FURNACES Furnaces International December 2022 www.furnaces-international.com

GLOBAL FURNACES

et into their final shape before heat treating the metals into their superconducting, albeit brittle, alloy Nb3Sn.

The Wire

� Niobium-tin wire strands react to become Nb3Sn.

� Copper strands serve as traditional conductors to safely dissipate stored energy when the superconductivity experiences a disruption. The copper strands do not react with the niobium-tin.

�

A central spiral maintains a hollow channel to circulate liquid helium to chill the Nb3Sn wires to 4°K, below their superconducting temperature of 12°K.

� Creating such strong magnetic fields inside a coil of wire will also tear apart the coil of wire itself if that wire is not supported inside a high strength jacket. The ITER central solenoid wire bundle is about 38.5 mm diameter, housed inside a 50 x 50 mm stainless steel jacket.

� Total maximum current in the superconductor wire is 48,000 amps.

� Worldwide niobium production increased six-fold for several years just to meet the niobium demands of the ITER project.

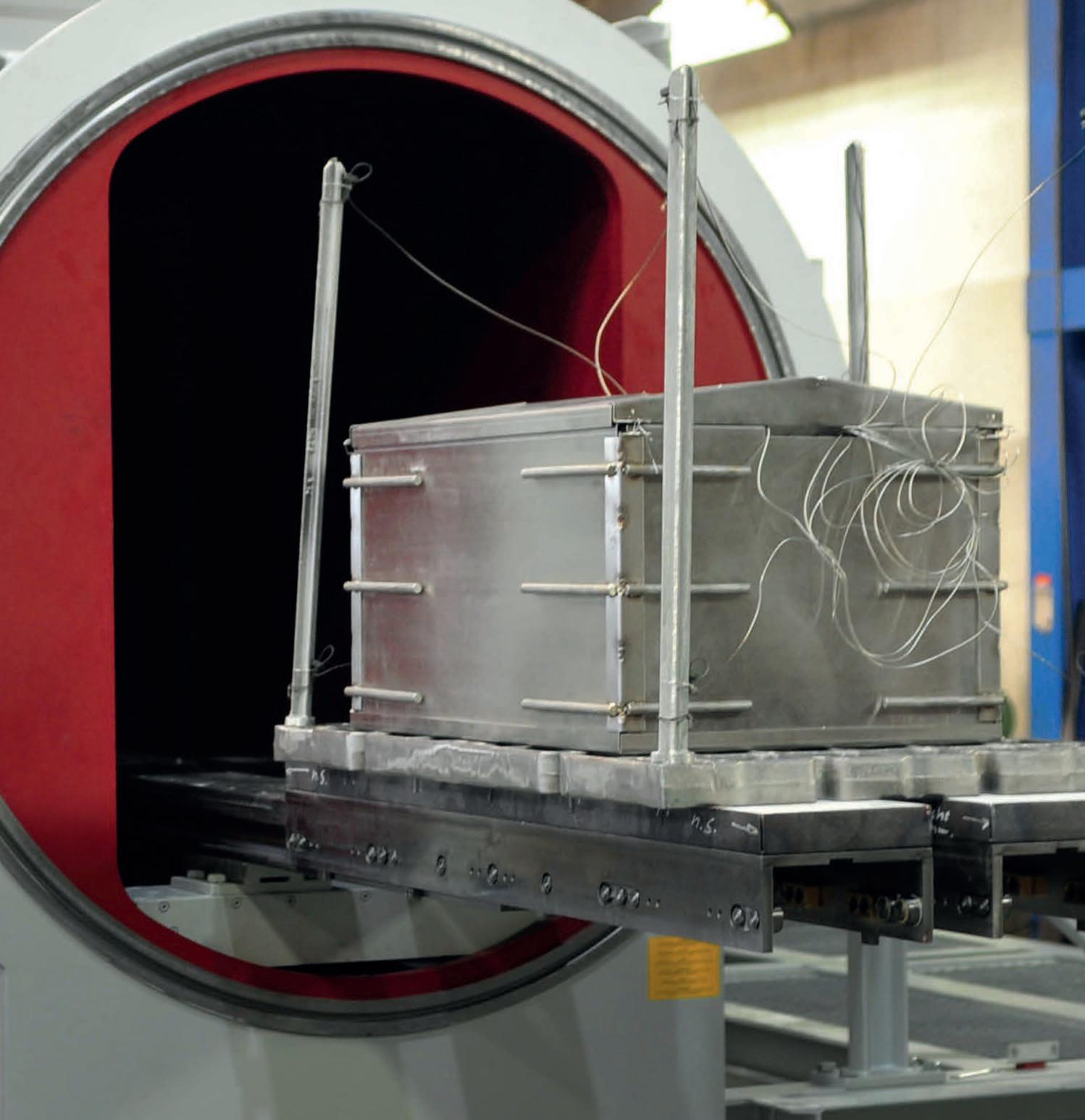

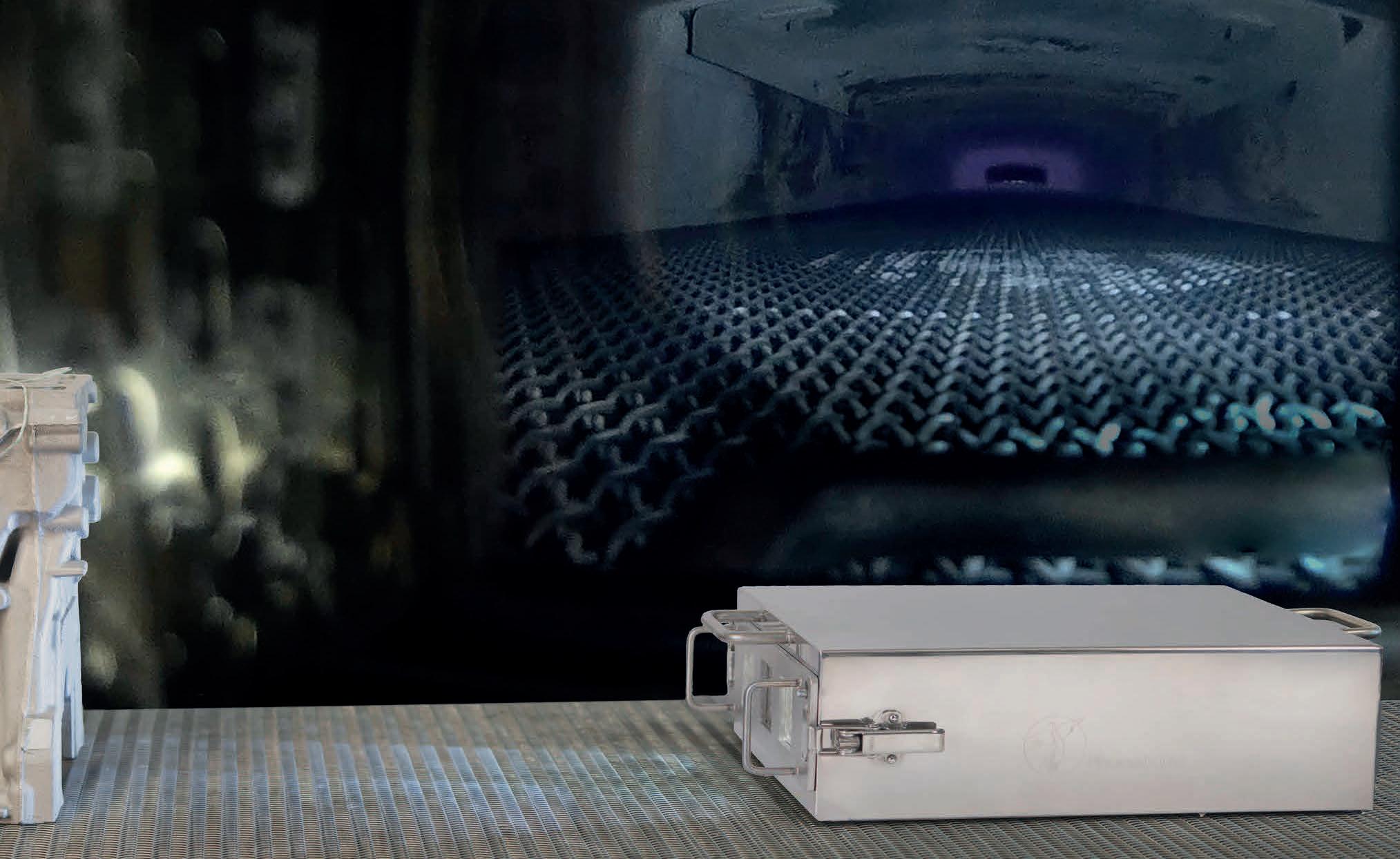

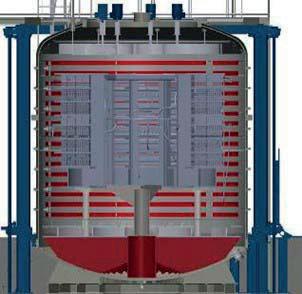

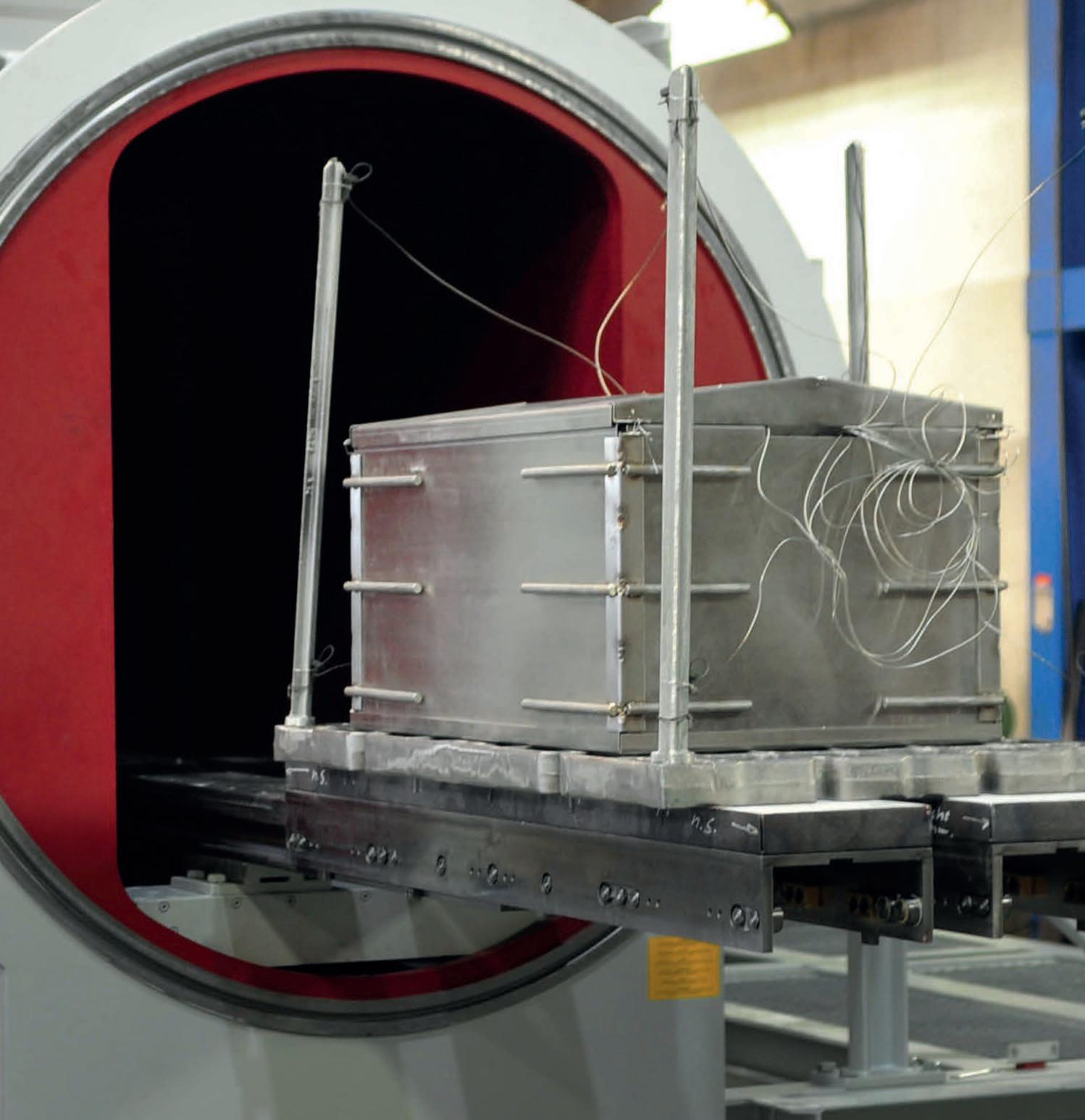

The Heat Treating Furnace

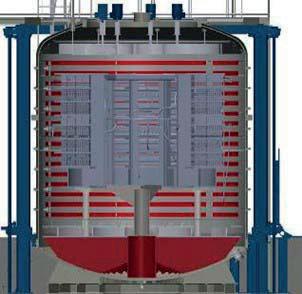

In order to convert the niobium-tin metal conductors into superconductors, each of these 4 meter by 2 meter 110 ton solenoid sections must be heat treated for five weeks, exceeding 1200°F (650°C) at its peak. The heat treatment serves to alloy the niobium and tin together into Nb3Sn, which becomes a superconductor when chilled with liquid helium to 4°Kelvin. No such heat treating furnaces existed, so General Atomics turned to SECO/

18 Furnaces International December 2022 www.furnaces-international.com

Figure 4. Technicians ensure proper placement before lowering heat treat furnace

Photo source: General Atomics ITER Manufacturing

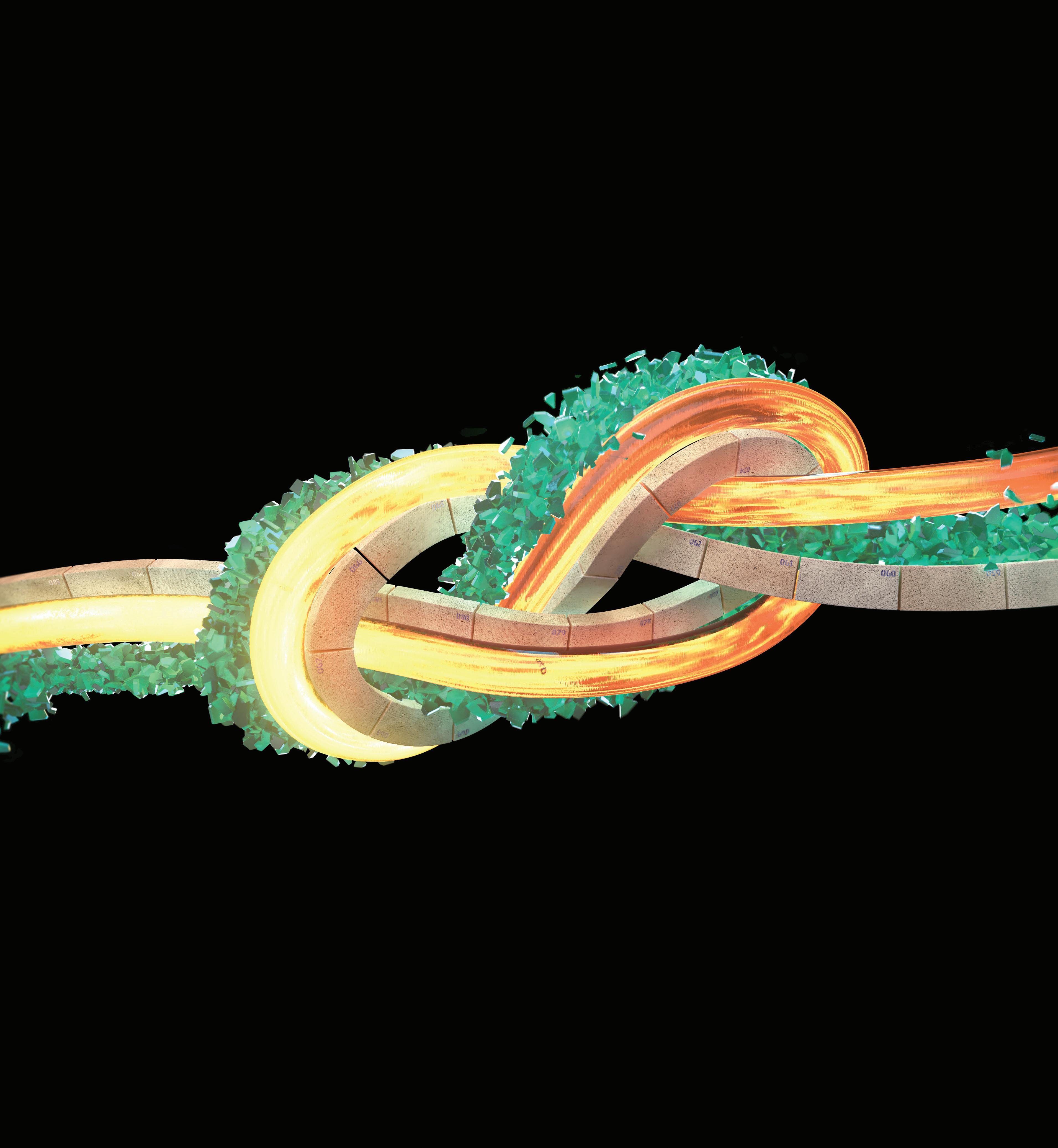

GLASS SERVICE Tying Technology Together Help the planet existing chnology educe CO2 with: l Boost l More boost l Electric forehearth l Superboost l Hybrid ur naces ble future from Glass Service and FIC The World,s Number One in Fur nace Technology FIC (UK) Limited Long Rock Industrial Estate, Penzance, Cornwall TR20 8HX, United Kingdom www.fic-uk.com +44 (0) 1736 366 962

GLOBAL FURNACES

Source: SECO/VACUUM

VACUUM to build a custom heat treating furnace large enough to fit these solenoids and packed with all the technology needed to meet the strict quality control standards of this monumental experiment.

Five inch wide metal band heaters ring around the walls of the furnace with nearly 900kW of heating power. Covering 50% of the walls, they provide a very uniform heat. This is brought about by the following seven steps.

The Heat Treating Sequence

In addition to alloying the niobium-tin wires, the furnace also serves to remove the stresses in the stainless steel jacket housing the superconducting wire and to bake off any residual contaminants prior to reaching reaction temperature.

1. Complete a quality control test: Vacuum seal the untreated solenoid coil in the room temperature furnace and charge the inside of the conductor jacket with 30 bar high pressure helium to test for leaks after forming and welding.

a. Monitor furnace atmosphere with ultra-high sensitivity mass-spectrometer helium detectors.

2. Purge with argon gas while slowly ramping up heat.

a. This drives off hydrocarbons and oxygen before the system reaches reaction temperatures.

b. Monitor furnace atmosphere with gas chromatograph to find impurities from residual oils and lubricants leftover from manufacturing process.

c. Monitor and control argon circula-

20 Furnaces International December 2022 www.furnaces-international.com

Figure 5. Cutaway illustration showing the furnace construction

tion and exchange with mass flow sensors and circulation blowers that penetrate the furnace lid with ferrofluidic feedthrough seals around the blower motor shafts.

3. Maintain at 1058°F (570°C) for about 10 days. Confirm stabilized temperature and pure atmosphere.

4. Proceed to 1202°F (650°C) for four days. This is the actual reaction phase that achieves the primary objective of converting the niobium-tin into the superconducting alloy Nb3Sn.

5. Very slowly and uniformly ramp back down to room temperature to avoid additional stresses in the coil.

6. Complete another quality control test: Evacuate the argon and once again vacuum seal the solenoid coil in the room temperature furnace and recharge with 30 bar high pressure helium to test for leaks after heat treating. Monitor atmosphere for the presence of helium, which would indicate a leak in the coil.

7. Only then is it ready for the post-heat treating stages of wrapping with insulation and encasing in epoxy resin for rigidity.

Options, Upgrades, Special Features

There was no room for error. SECO/VACUUM collaborated with the engineers at General Atomic to create a heat treat furnace that can assure temperature variation within the coil never varies by more than 18°F (10°C) anywhere in the furnace at any time in the five-week cycle and achieves near-perfect repeatability for all seven modules.

They accomplished this with quadruple-redundant control thermocouples and feeding temperature data from 150 points in the coil into the control computers. To shield against impurities, the furnace is first evacuated to a vacuum pressure of 0.001 Torr, and then purged with pure argon to drive out any residual

GLOBAL FURNACES 21 Furnaces International December 2022 www.furnaces-international.com

GLOBAL FURNACES

About the Author: Rafal Walczak is the product manager at SECO/VACUUM.

Rafal joined SECO/WARWICK Group as a service engineer in the Vacuum Furnaces Division soon after graduation from Technical University of Zielona Góra in Poland in 2002.

Since 2008, he has been involved in vacuum furnace sales in Europe and the USA. The combination of his technical background and field service experience help him provide outstanding support to his SECO/ VACUUM customers.

For more information: Contact Rafal at Rafal.Walczak@SecoVacUSA. com

oxygen or hydrocarbons that could contaminate the purity of the superconductor. Monitoring the argon atmosphere for impurities are redundant mass spectrometers. The argon is circulated by seven convection fans to heat the solenoid assembly evenly. Each of these fans must be driven through ferrofluidic feedthrough seals which allow the rotating shafts to operate through the furnace walls without compromising the vacuum seal of the furnace.

Consult, Collaborate, and Partner with SECO/VISORY

General Atomics first began discussing this project with Rafał Walczak, the product manager at SECO/VACUUM, in early 2010. Both teams spent over two years on conceptual discussions, preliminary designs, and process simulations before SECO was even awarded the contract. Once SECO was on board, it took another two years of design, fabrication, and installation before the furnace could be put into operation. SECO/VACUUM built it to handle a lifetime of use without error so they could be sure that it would work flawlessly for the seven cycles that it actually had to run.

The SECO/VISORY Heat Treat Advisory Council is a team of SECO/VACUUM heat treat experts and consultants with diverse thermal experience and process knowledge who are available to help companies solve their specific heat treat equipment challenges. �

22 Furnaces International December 2022 www.furnaces-international.com

THE POWER OF THREE

Good things always come in threes. From batch and cullet treatment to furnace building and equipment maintenance, the fluidity of the SORG Group’s three individual streams create one sustainable, smooth-flowing solution powered by the most advanced melting and conditioning technologies.

sks.net sorg.de

eme.de

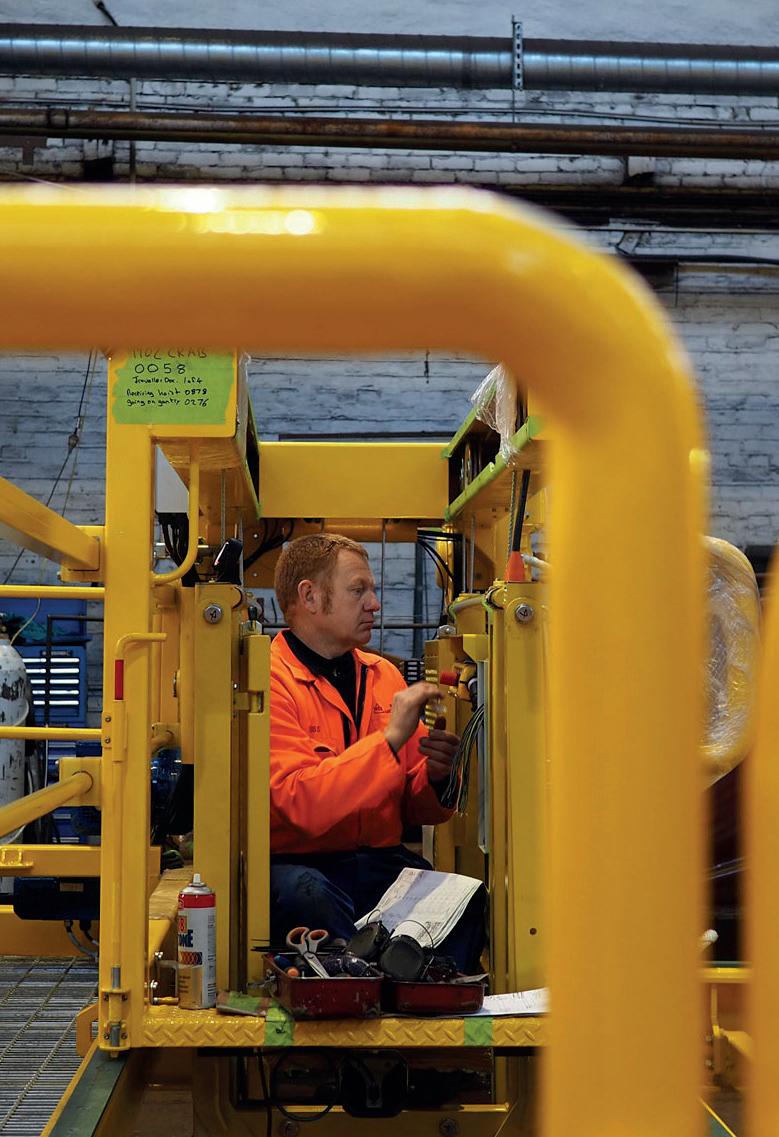

Robur acquires glass furnace inspection

Glass furnace inspection company

Franke Industrieofen Service has joined the Munich-based industry service specialist, Robur. It will now offer its furnace inspection and monitoring services under its new branding FIOS.

Dr. Norbert Pfitzner, founder, and CEO of Franke Industrieofen Service, said: “Operating in the glass and aluminium industry we are already well known in Germany and central Europe.

“Together with Robur we want to expand our reach and offer our services to more clients – together Robur partners and especially with our longtime friends at Excelsius.”

FIOS specialises in furnace inspection and monitoring services without stopping the production

process.

Using a self-developed mobile inspection camera system, FIOS delivers HD-quality insights into the furnace during the production process in temperatures up to 1,500ºC and gives feedback on the burning process.

This information can be used to make well-founded decisions on necessary furnace maintenance.

Dr Pfitzner explained the change in the branding: “In the past we have already been called FIOS by our international clients and this was inspiration for us to also pick up this name officially as our future brand.

“Based on our heritage and experience, we will expand our busi-

ness for our clients and, together with Robur, offer industrial service along the life cycle of our clients’ assets”.

The two groups were already known to each other through their cooperation with Excelsius.

“FIOS is the perfect extension of our hot work services” said Dr. Florian König, Senior Partner at Robur, and CEO of the Business Unit Process of the group.

“FIOS and Excelsius have already partnered in the past, are both companies of choice in the glass and aluminium industry and together have the ideal potential to expand into further industries to deliver their hot works expertise,” he added.

Bormioli Pharma completes Italian glassmaking furnace upgrade

Pharmaceutical glass manufacturer Bormioli Pharma has completed the refurbishment of its Bergantino, Italy furnace, which is dedicated to the production of type II glass containers.

The project, completed last month, is one of many initiatives the company has put in action in terms of industrial investments.

This new project strengthens the moulded glass production capabilities of the group, which have been recently integrated with tubular glass capabilities.

In the last three years, Bormioli Pharma has acquired two companies in Germany specialised in the production of pharmaceutical packaging and, among this, of tubular glass vials (Type I, II, III).

The result is a highly flexible glass productive platform, with back-up opportunities and multiple technologies.

The Bormioli Pharma plant in Bergantino employs about 350 people and more than 1.8 billion pieces are produced annually.

The use of advanced technologies and the high qualified systems used to improve product quality contribute to the continuous advancement of this Bormioli Pharma’s plant, which is one of the most important European centres to produce moulded glass for pharmaceutical use.

NEWS LIFE OF A FURNACE 24 Furnaces International December 2022 www.furnaces-international.com

inspection specialist

“Our philosophy at Robur has always been to bring specialists together and have them work collaboratively on finding solutions to the challenges our customers face.

“With a focus on digital transformation, supporting ecological change and the Robur partnership, we can offer our customers and partner companies the ideal basis for growing together and mastering the challenges of today collaboratively within a group of specialists.

“We are delighted that Norbert, together with his colleagues at FIOS, have chosen to shape this further growth in and with Robur.”

NEWS LIFE OF A FURNACE 25 Furnaces International December 2022 www.furnaces-international.com

Verallia sets date for Brazilian glass furnace lighting

Verallia has confirmed the date it plans to light the second furnace at its Jacutinga, Brazil glass production facility.

The CEO of the French-headquartered container glass manufacturer, Patrice Lucas, said the lighting would take place, as planned, on November 9 this year.

He made the announcement in its latest financial report where they said momentum in Latin America was ‘unprecedented’.

The company invested €60 million in the glass packaging plant expansion.

Revenue growth remained high despite the slight expected decline in volumes due to less available capacity.

The company renovated five furnaces in the second half of the year –four of those in Q3 alone- which limited production capacity.

Overall, revenue was up by 24.5% over nine months at €2,518 million, compared to the first nine months of 2021.

In Southern and Western Europe, sales were up over the first nine months of the year, despite a slight decline in volumes in the third quarter due to the simultaneous renovations of several furnaces.

Northern and Eastern Europe posted improved revenue for the first

nine months of the year.

Volumes were, however, also down slightly during the third quarter.

Verallia’s situation in Ukraine remained similar to during the first half of the year: one furnace was emptied and cooled in order to keep it in good condition, while the second is now mainly focused on producing food jars.

In Latin America, the excellent momentum seen during the first half continued in the region, in terms of both volumes and sales prices.

Thanks to higher year-end visibility, coupled with excellent third quarter results, the group has increased its adjusted EBITDA target for 2022 to above €820 million (compared to €750–800 million previously).

NEWS LIFE OF A FURNACE 26 Furnaces International December 2022 www.furnaces-international.com

ST. LOUIS, MISSOURI, USA 800 325 7075 | www.gillespiepowers.com | 314 423 9460 ✓SINGLE CHAMBER / MULTI CHAMBER FURNACES ✓SCRAP DECOATING SYSTEMS ✓TILTING ROTARY MELTING FURNACES ✓SCRAP CHARGING MACHINES ✓LAUNDER SYSTEMS ✓CASTING / HOLDING FURNACES ✓HOMOGENIZING OVENS ✓COOLERS ✓SOW PRE-HEATERS ✓REPAIR & ALTERATIONS

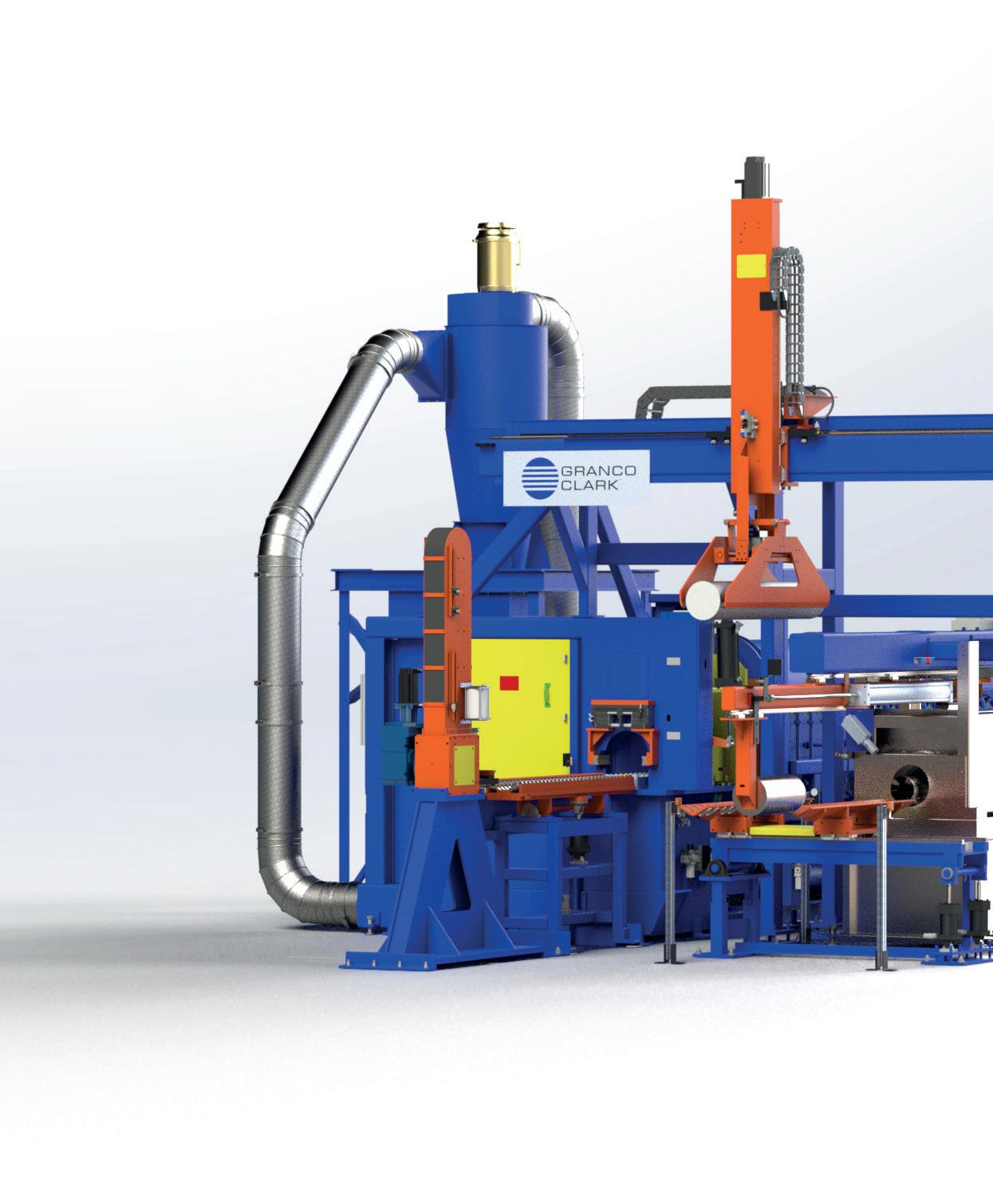

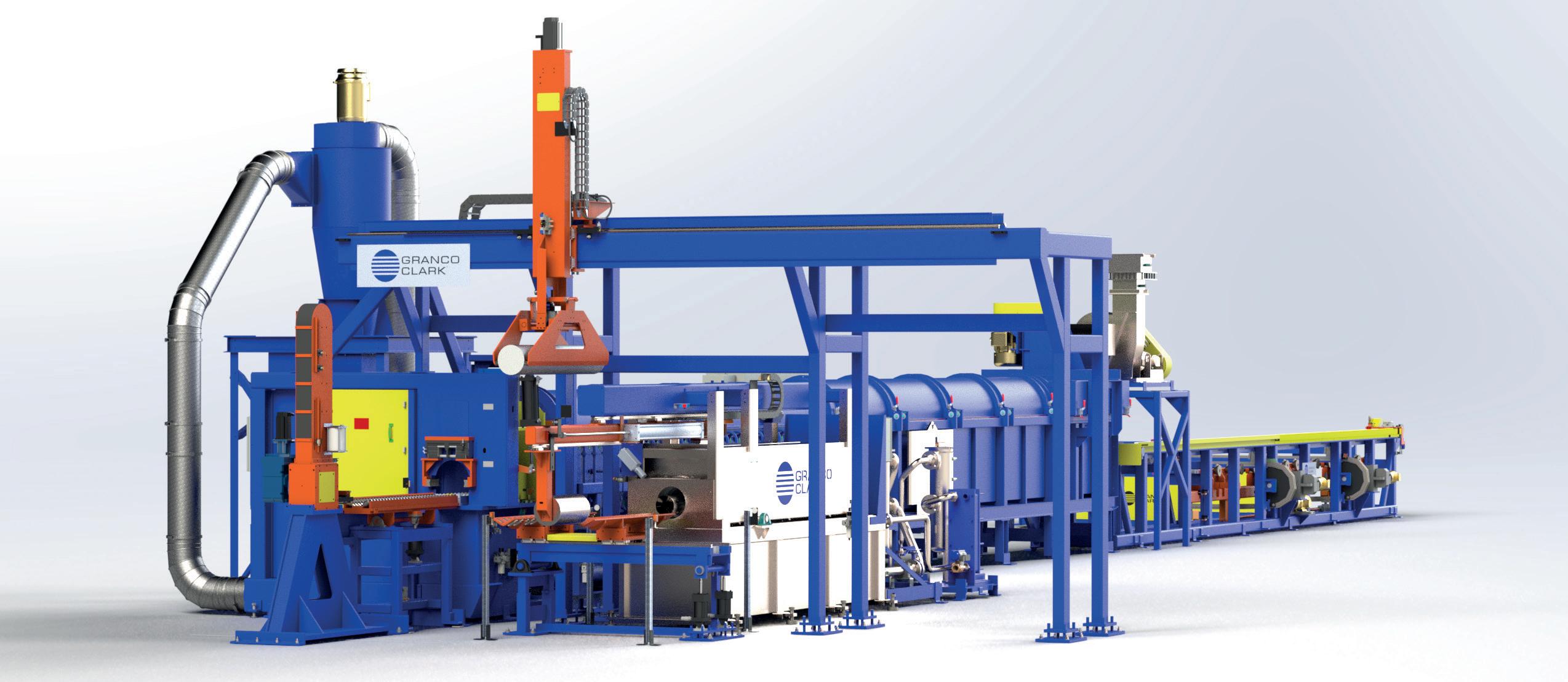

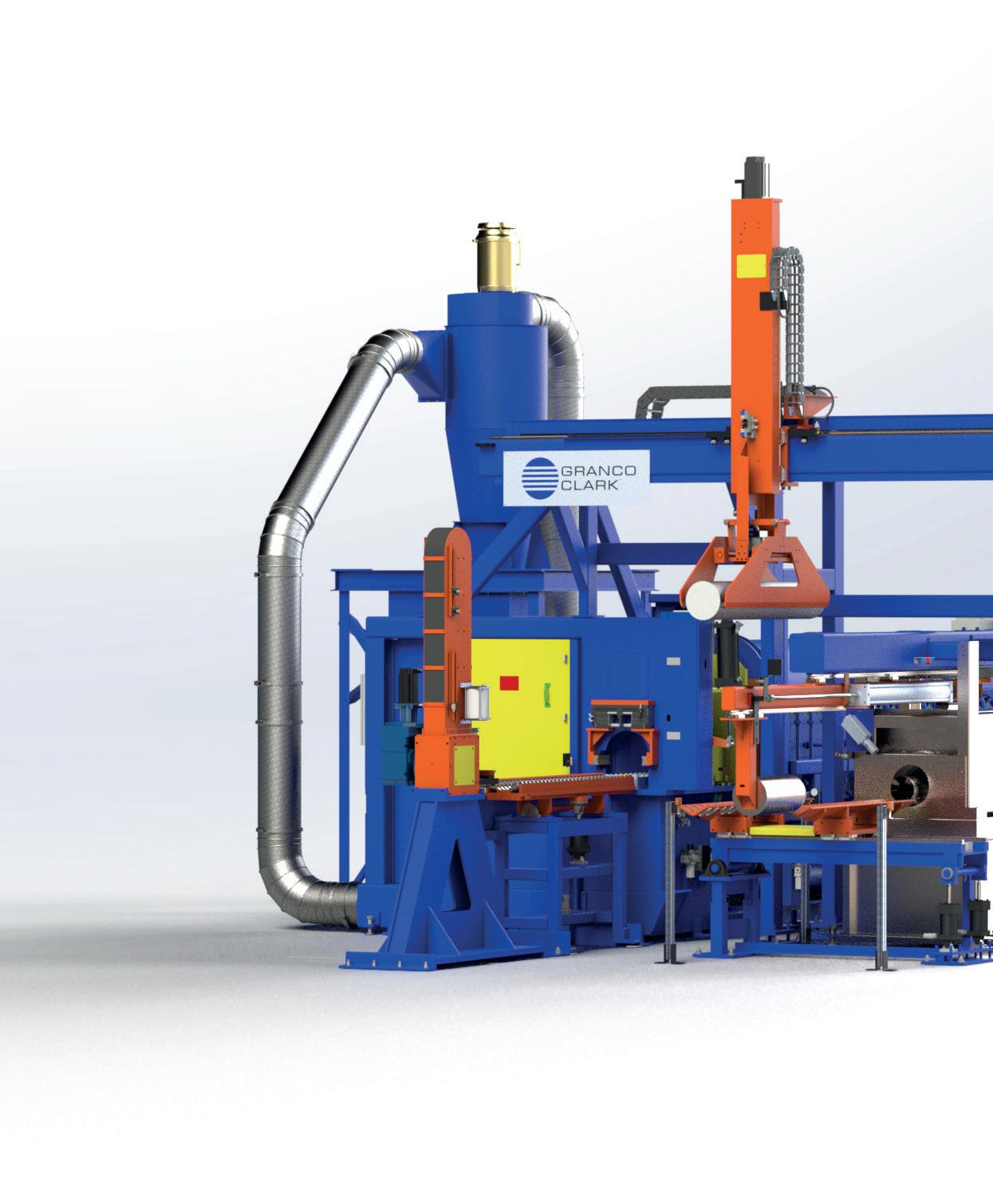

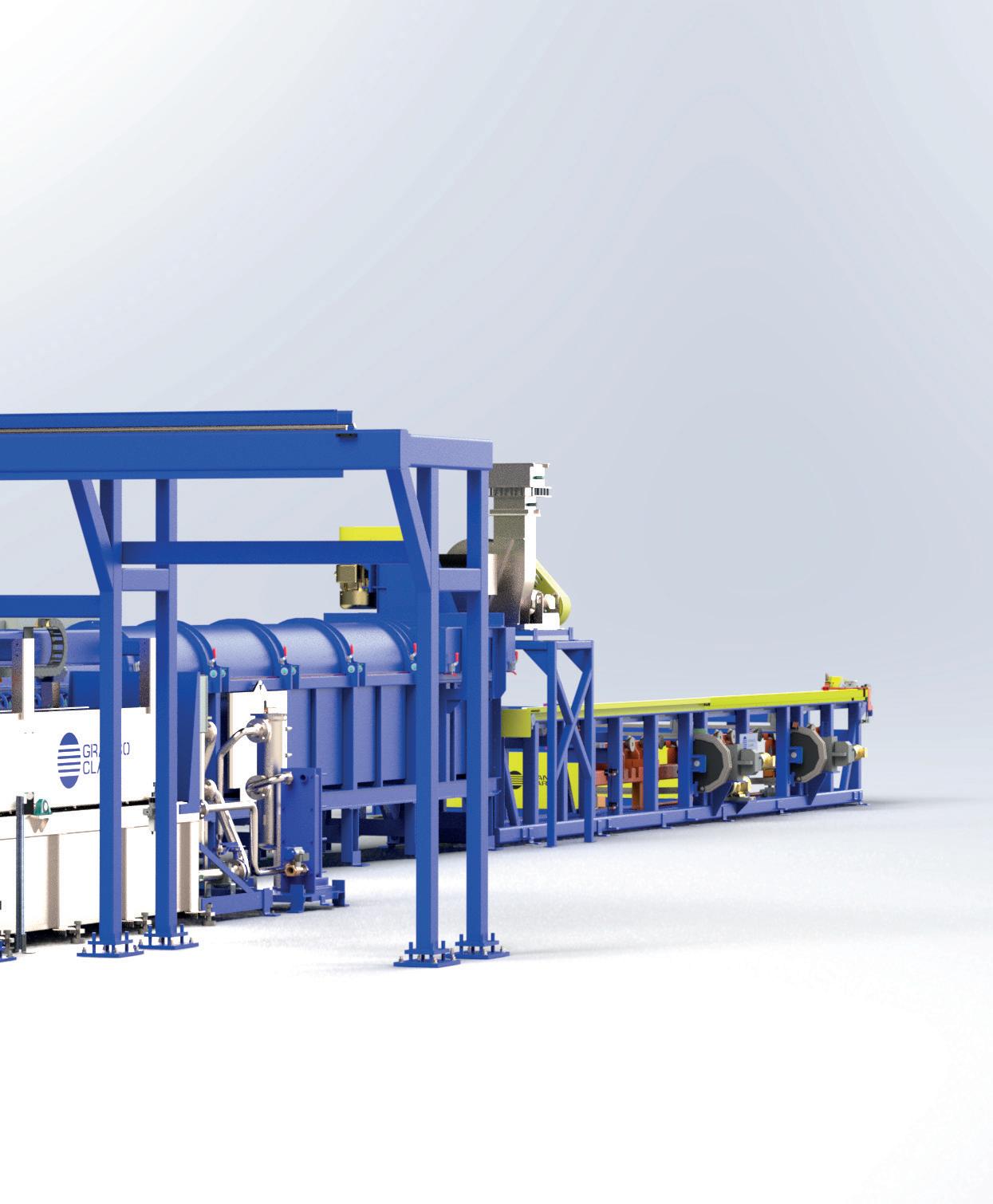

GC

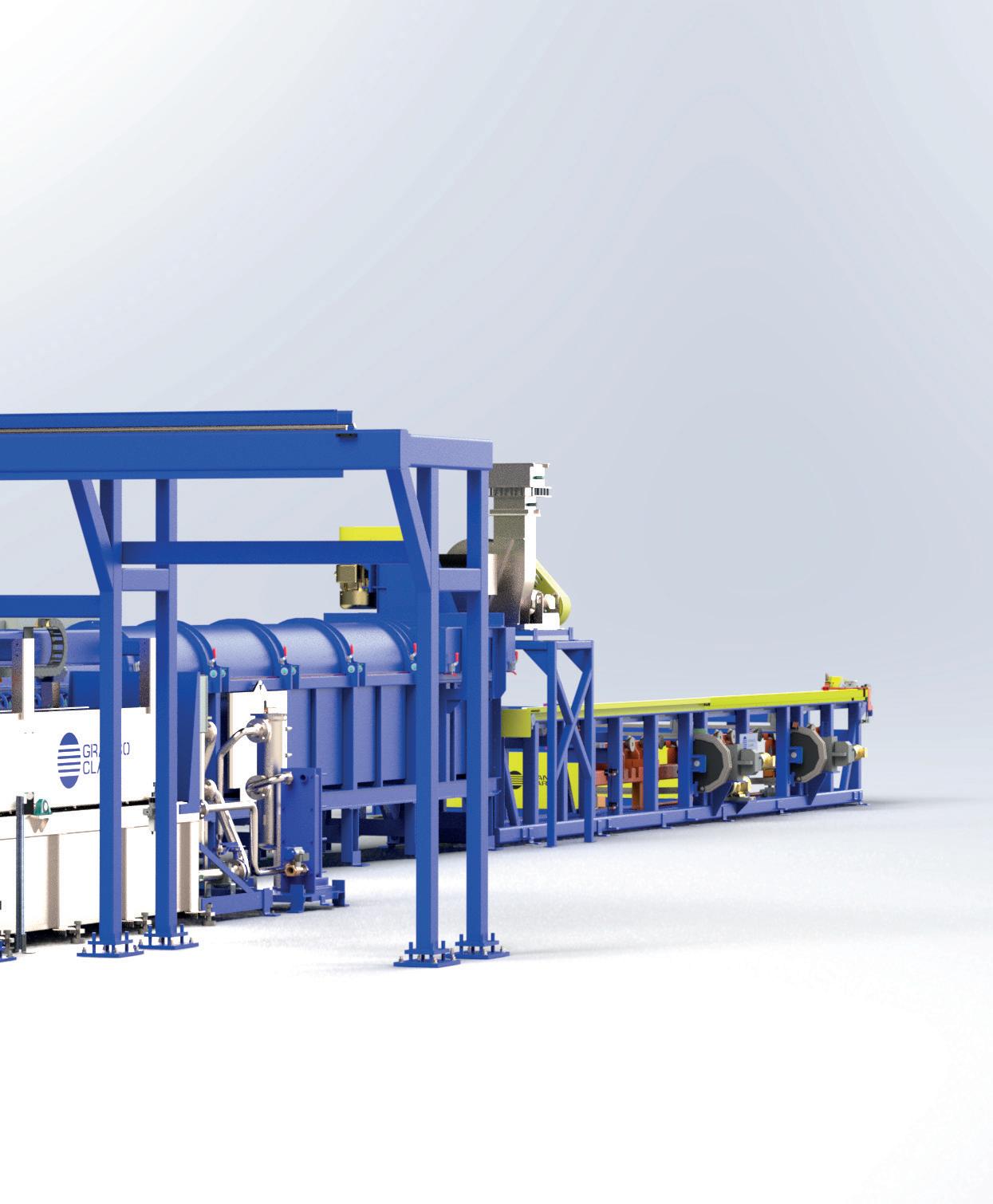

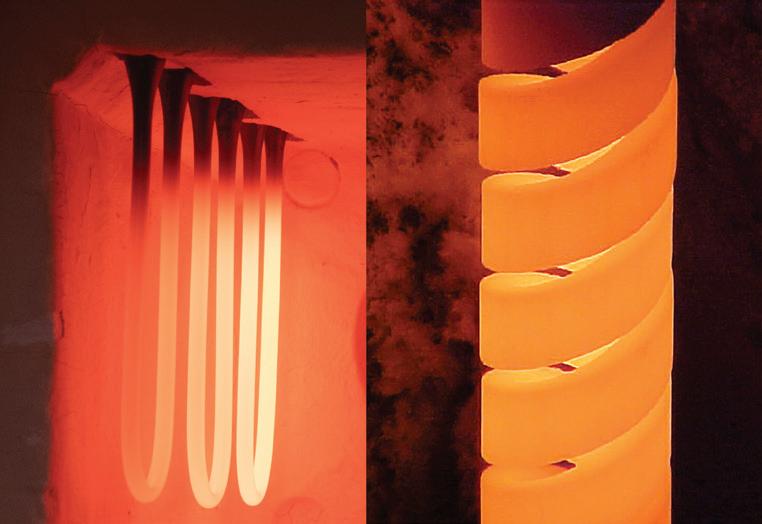

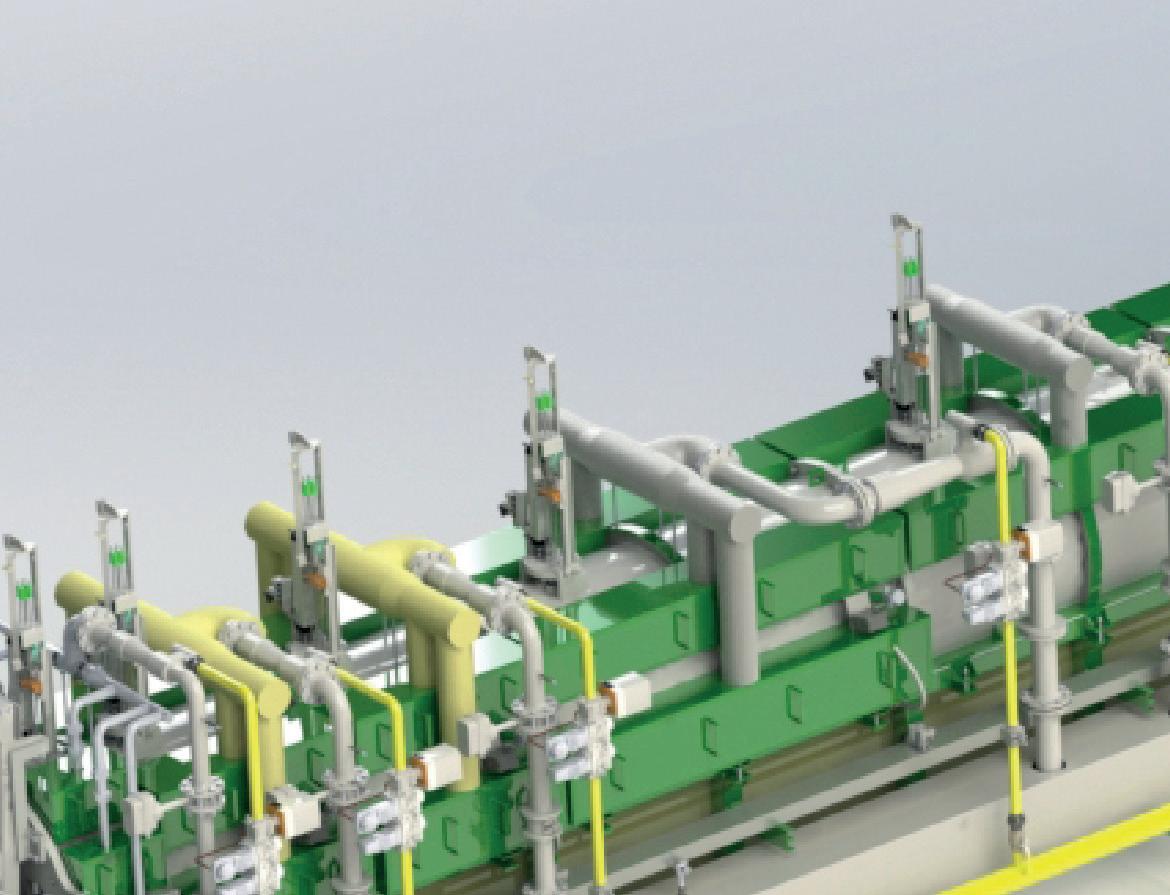

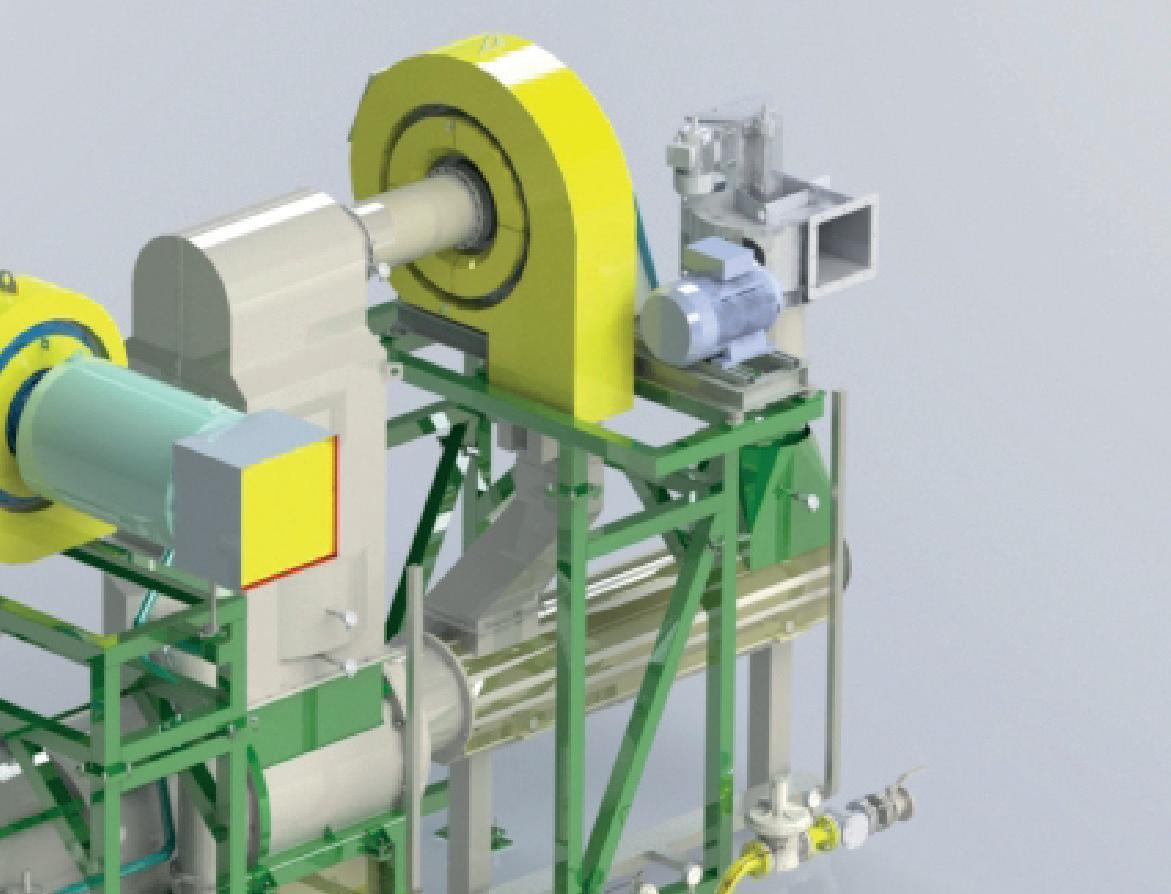

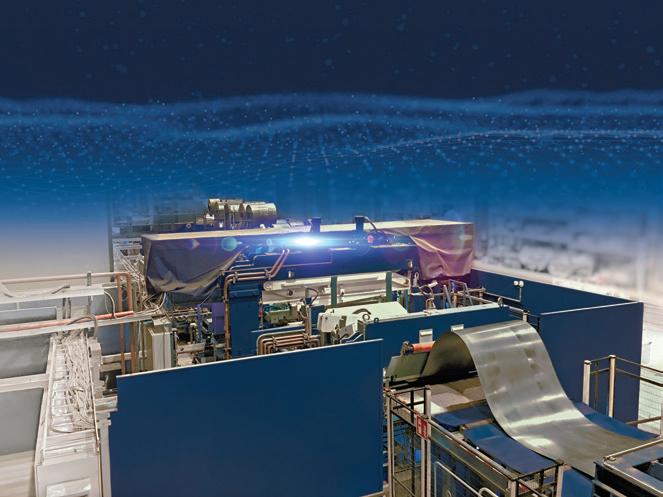

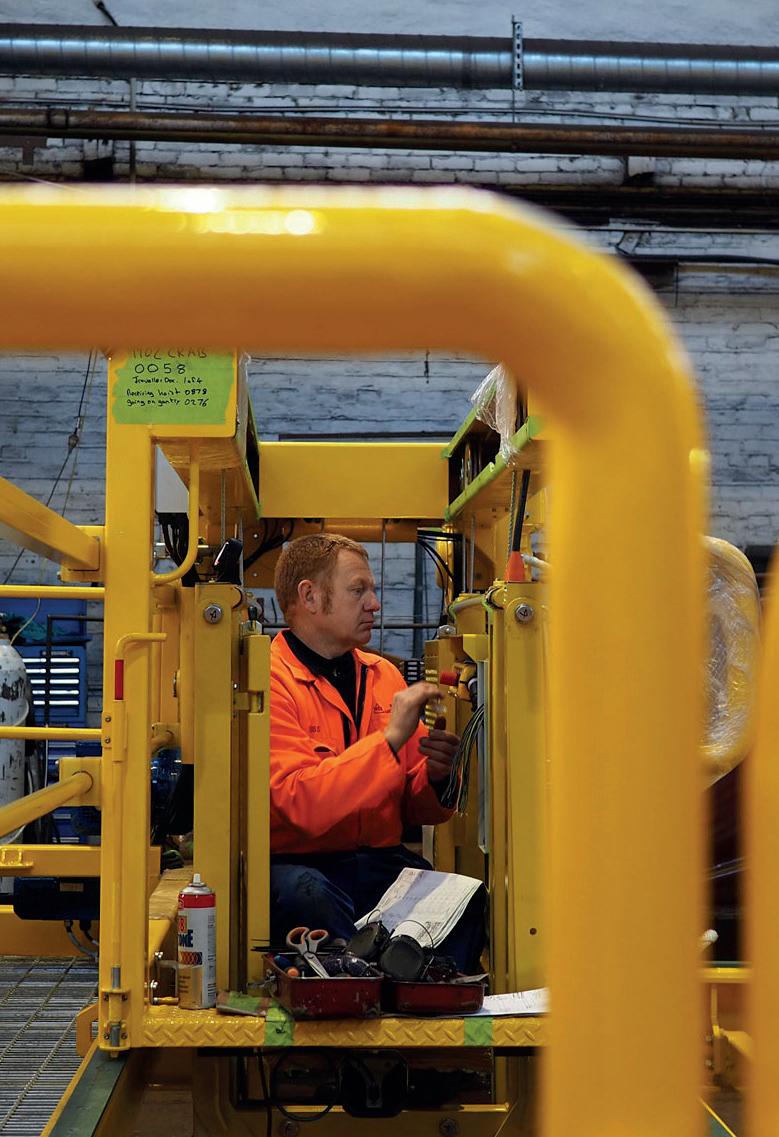

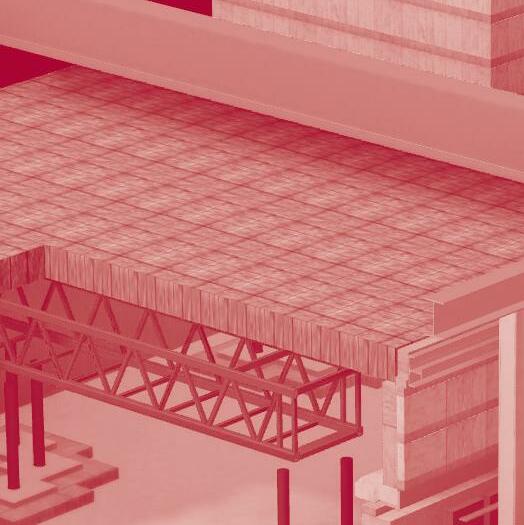

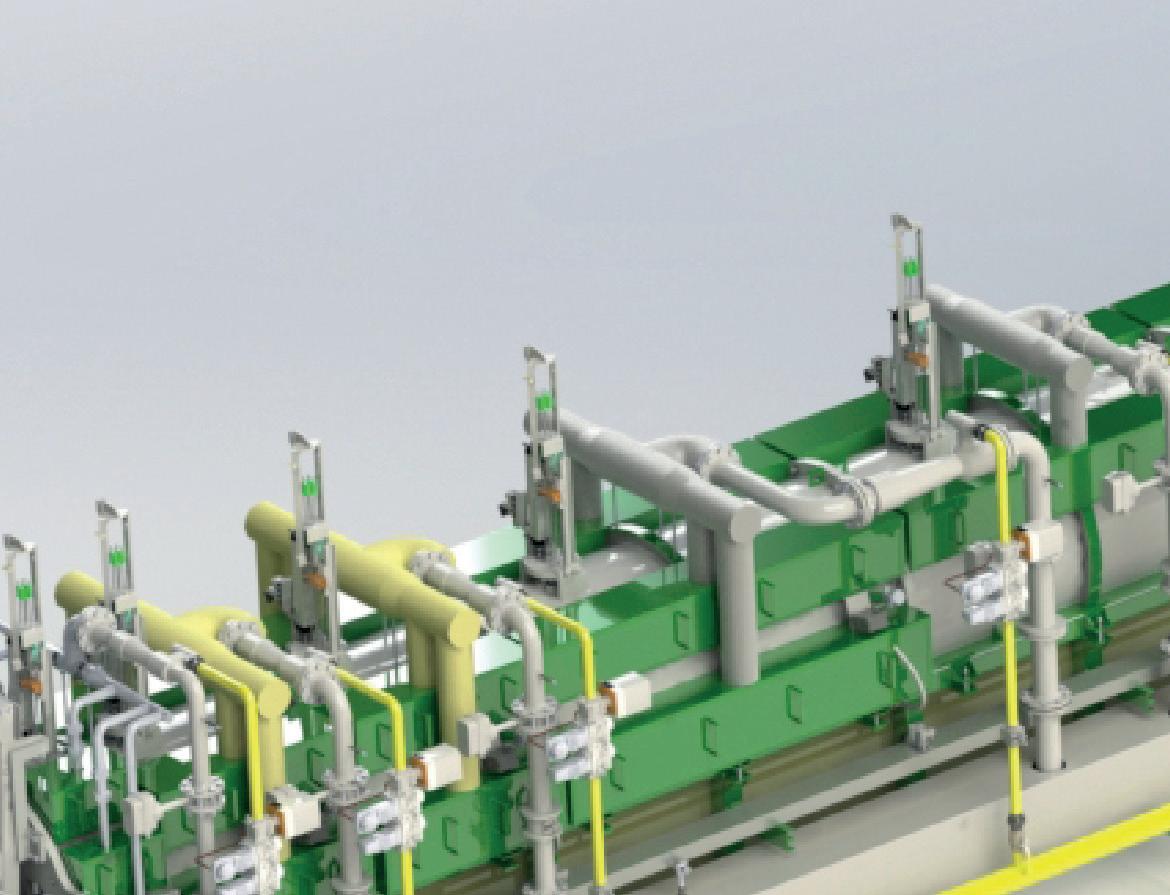

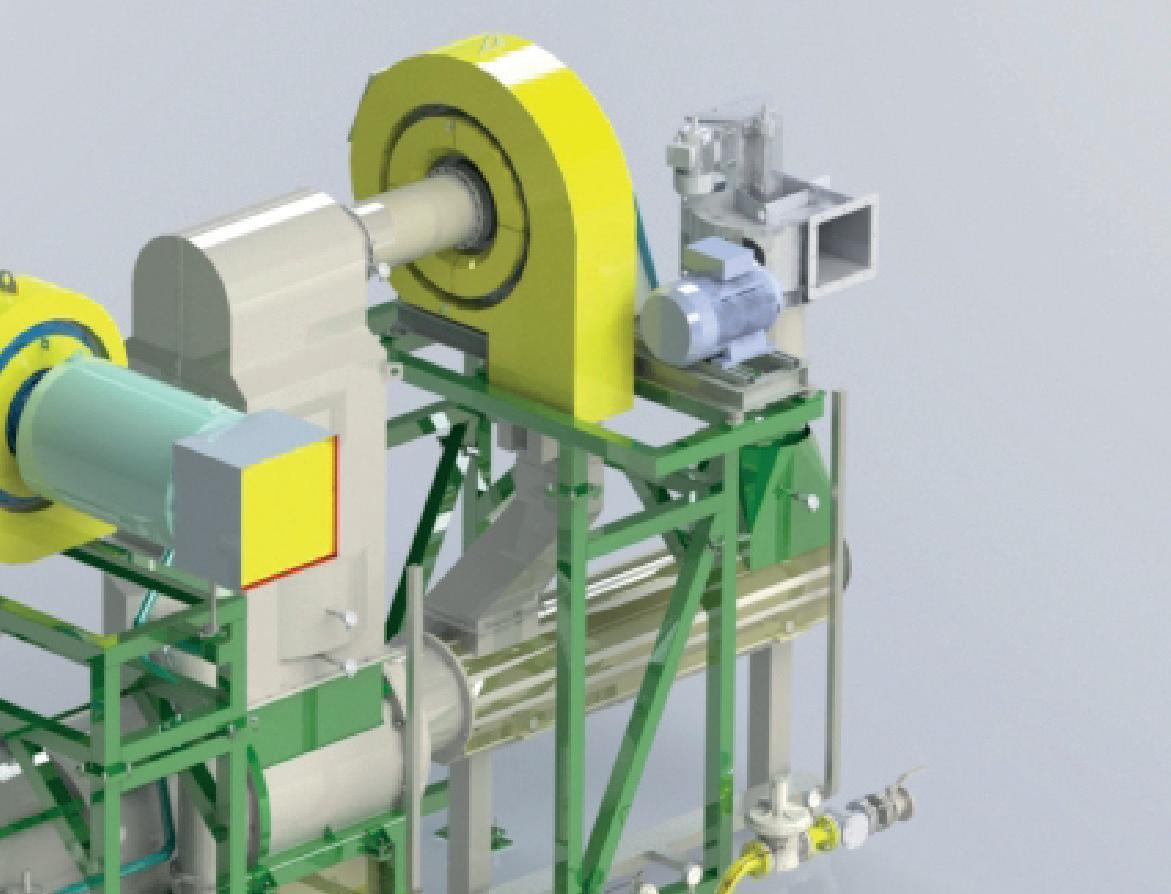

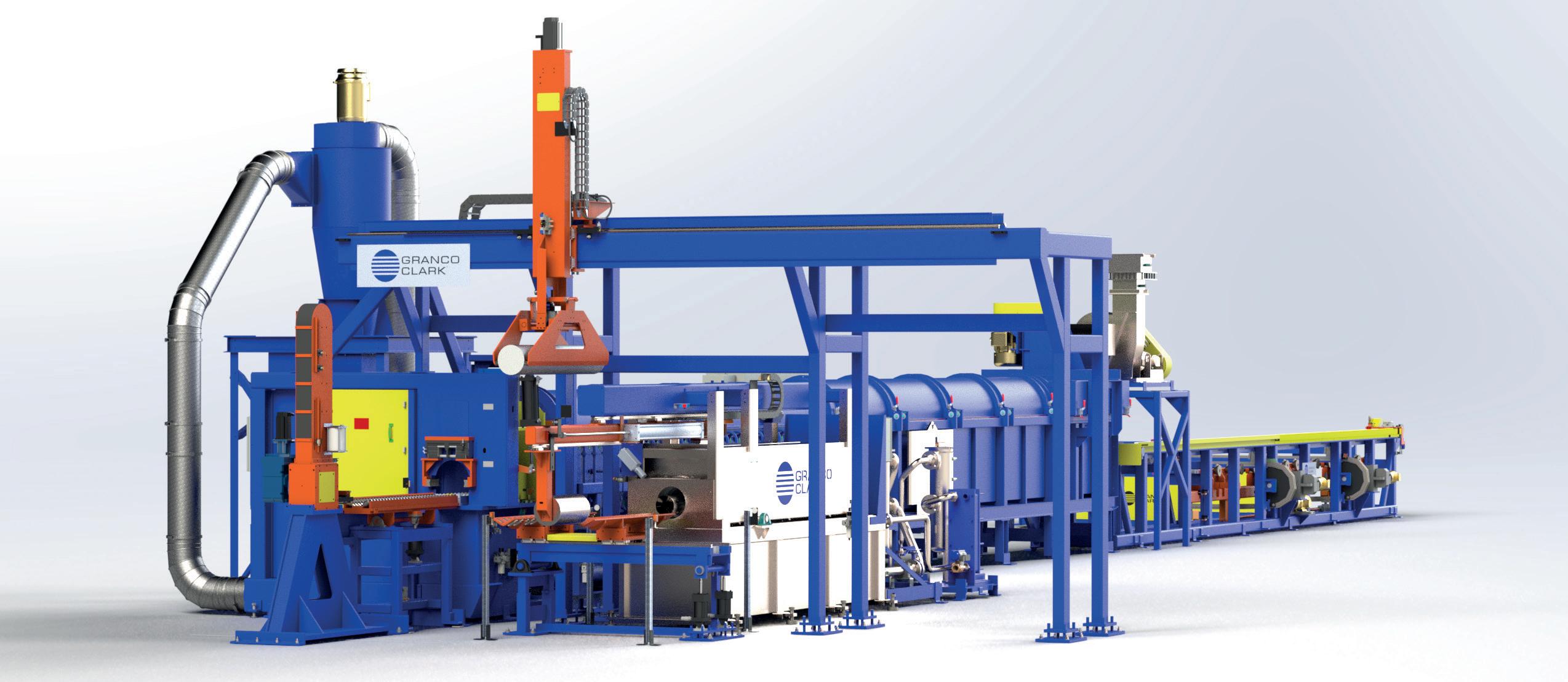

The heating and preparation of logs into billet prior to extrusion is a key aspect of achieving efficient production of high-quality profiles. Log processing includes several steps, including heating, cutting, and handling. Based in Belding, MI, Granco Clark has a long history of engineering and manufacturing efficient, reliable, high-precision equipment for the extrusion industry, including furnaces and machines designed to provide efficient and reliable log processing (Figure 1).

28

LIFE OF A FURNACE

Furnaces International December 2022 www.furnaces-international.com

Precision Press Feed Systems for Efficient Extrusion Operations

Log Furnace: Over 50 years ago, Granco Clark invented the flame-impingement furnace, the tunnel furnace, and the jet preheat furnace. These developments evolved into the energy-saving Hot Jet furnace, which delivers uniform temperature to the log. Over the years since the Hot Jet furnace was first introduced, the company has continued to make slight changes to the design in the spirit of continuous improvements—such as the introduction of using a large, long-life quiet roller system that provides easier maintenance.

The company’s newest generation of log heating furnace has been completely redesigned from entry to exit (including the doors). The furnace features a number of design characteristics that are aimed at taking billet/log heating to the next level in the extrusion industry. The first orders of the new generation furnace are currently being delivered to customers. More details about the new furnace will be announced at a later date.

Cutting and Bonding: Cutting hot logs into billets after the log furnace provides flexibility and significant advantages over precut billet heating. In addition, the days of cutting billets with hot log shears are mostly gone. Shears once served a purpose, but the benefit of having a perfectly square cut billet that has been precisely cut to length by a side-cut hot billet cut saw (HBCS) has gained preference by most extruders.

After cutting billets to length, there will always be a section of

Press Feed Systems

LIFE OF A FURNACE 29

Furnaces International December 2022 www.furnaces-international.com

LIFE OF A FURNACE

the billet remaining. This remaining piece may or may not be usable by itself. Some extruders have attempted to loosely load the short pieces into the press, hoping they will extrude smoothly during the extrusion process. However, the FusionBond system welds the remaining short piece to the next log in the furnace, thus making it completely usable and thereby reducing scrap.

30

Furnaces International December 2022 www.furnaces-international.com

The FusionBond system eliminates two-piece headaches, improves recovery, and avoids unnecessary cost due to risky twopiece billet handling malfunctions.

Billet Handling: Granco Clark offers many methods for transporting the billet from the heating system to the press, depend-

31 Furnaces International December 2022 www.furnaces-international.com

LIFE OF A FURNACE

LIFE OF A FURNACE

This article first appeared in Light Metal Age, April 22, www.lightmetalage.com.

ing on the extruder’s preference. These methods range from a simple transveyor to a servo-controlled overhead pick and place system. Tipoff transfers are often clumsy and can result in billets rolling uncontrollably, so a smooth delivery from the heating system to the press is paramount.

Isothermal Heating: On the way to the press, it is recommended that extruders process the billet to provide a precision temperature gradient in order to achieve isothermal and iso-pressure extrusion. The Taper Quench system ensures flexibility and control, allowing extruders to precisely adjust the temperature gradient of the billet while locking in a desirable grain structure.

The benefits of taper heating the billet in this way include faster and consistent extrusion speeds, increased throughput, and consistent die face pressures.

Conclusion

An excellent extrusion line is kicked off with a high-quality feed system that ensures the billet has been properly heated, cut, and handled before it even enters the extrusion press. Granco Clark’s press feed systems are just a small portion of the handling and processing systems that it provides, including high-performance extrusion quenching, fully automated extrusion handling, stacking systems with aging, and precision off-line extrusion cutting—nearly all of which are available with clean, quiet, and precise servo systems (as an alternative to hydraulics). No matter the equipment, the company implements the same precise and robust engineering approach to every extrusion equipment solution.

�

32 Furnaces International December 2022 www.furnaces-international.com

+1-800-918-2600 | sales@grancoclark.com | www.grancoclark.com A world of good wishes. It’s our joy this holiday season to say, thank you. Merry Christmas and Happy New Year. MADEIN

Increasing refractory lifetime

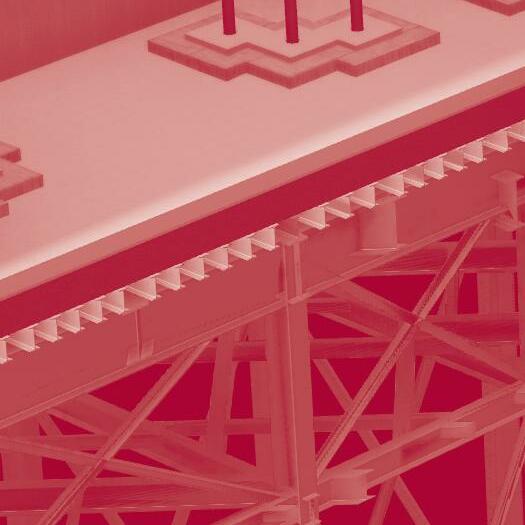

The average campaign life of the RH-OB vessel at SAIL’s Rourkela Steel Plant was almost doubled from an initial average of 88 heats, then 106 heats to 130 by greater attention to the weld joints between the snorkel legs and lower vessel, and by increasing the position of the refractory retainer plates 300mm higher up the vessel. By S Roy1, A Bhattacharyya2 , P Kumar Pedapudi1, and P R Padhee1

A number of steel vacuum technologies for secondary refining were developed for degassing in the 1950s. These included RH (Rurhstahl Heraeus) degassing, Vacuum Tank Degassing (VTD), Vacuum Arc Degassing (VAD), and Vacuum Induction Melting (VIM). Today, the demands of clean steels require even lower hydrogen and nitrogen content, ultra-low carbon and sulphur, and lower total oxygen. Vacuum treatment facilities play a crucial role in achieving this. The chosen vacuum degassing technique is dictated by the steel grade to be produced. The use of RH vacuum degassing is the most common, especially for large heat sizes. RH processing is an important tool for various metallurgical functions such as decarburisation, vacuum degassing and inclusion removal. It is also used successfully to produce ultra-low carbon steels, auto grade steels, pipeline steels, and silicon steels. RH degassing starts with sucking up the liquid steel from the ladle into a vacuum chamber via two snorkels (up-leg and down-leg) [1]. Then, a flow of steel is circulated between the vacuum chamber and ladle by blowing an inert gas into the liquid steel. The degassing process involves both a chemical reaction and a transport phenomenon in the liquid steel[1], inside splashes of metal in the vacuum chamber and at the surface of bubbles as they

34 Furnaces International December 2022 www.furnaces-international.com

LIFE OF A FURNACE

form[2,3]. Liquid steel flow characteristics play an important role in controlling the rate of degassing, decarburisation and inclusion removal. This complex process involves thermodynamics, kinetics, and multi-phase flow and mass transfer[4]. It has been proved that a lower vacuum pressure[5, 6], a deeper insertion depth of the snorkel[3, 7] and a higher gas flow rate[8-12] favour optimisation of the fluid flow within the RH vessel, although the circulation rate will reach a saturated value with the increasing gas flow rate[7, 13]. The RH-OB degasser is categorised as a ‘Re Circula-

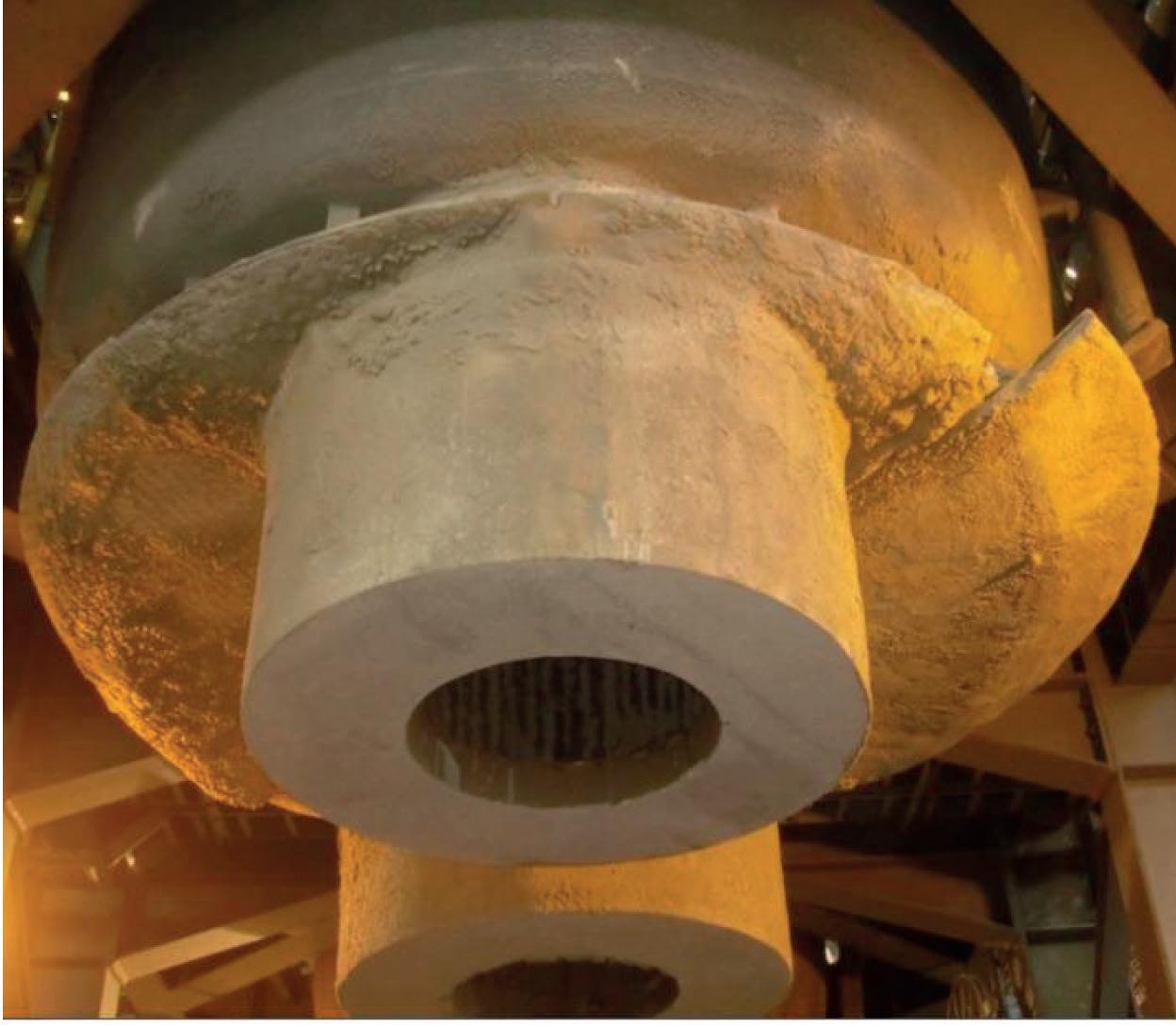

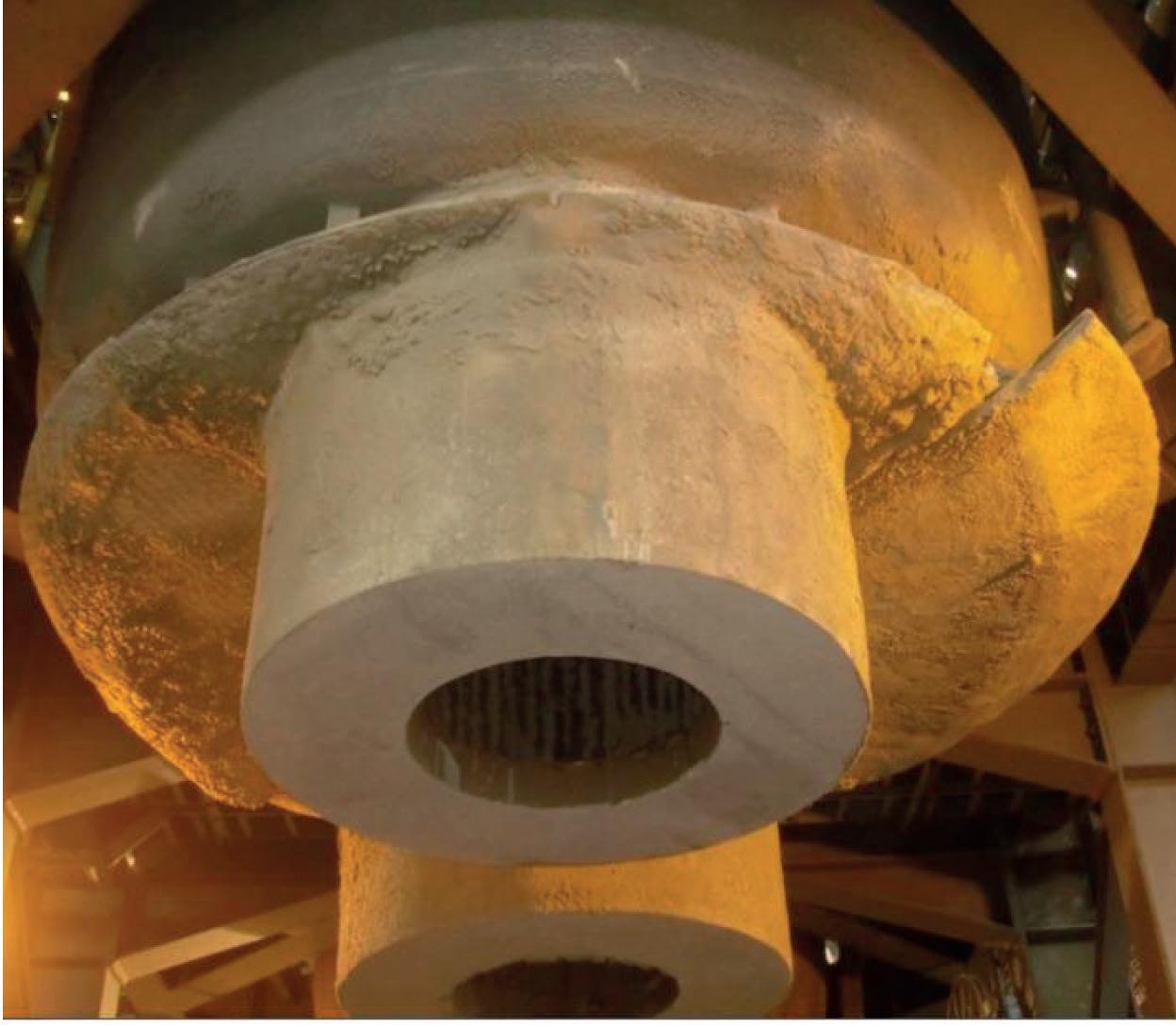

Figure 1. Refractory lining of RH-OB degasser

35 Furnaces International December 2022 www.furnaces-international.com

LIFE OF A FURNACE

tion Degassing’’ characterised by very high decarburisation and degassing with relatively little temperature loss, as compared to other degassing techniques. Further, the ability to blow oxygen in the RH-OB process compensates for any temperature loss during recirculation of the steel. No special slag measures and no additional ladle freeboard are required. Fast vessel changes and efficient ladle transport concepts increase the capacity and productivity of a plant.

Construction of the vessel

The RH degasser consists of a refractory lined vessel with two snorkels at the bottom and a gas off-take at the top along with a vacuum pumping system. Treatment starts by immersing the snorkels into the molten steel contained in a ladle either by lifting the ladle or by lowering the RH vessel. The steel rises into both snorkels by suction. One of the snorkels is equipped with argon or nitrogen gas injection pipes. This lift gas creates the steel circulation through the vessel back into the ladle via the outlet snorkel. The treatment time is defined as the duration between submersion and removal of the snorkels into the melt and varies between 15 and 45 minutes depending on the steel grade required.

Unplanned shutdowns risk

Usually, the lifetime prognosis for the refractories is based on operational experience and on the close co-operation with the refractory supplier. However, there is the risk of unplanned shutdowns that lead to low productivity and higher costs. The demand for RH-treated steel grades is increasing, which necessitates high plant availability and, therefore, high refractory

36 Furnaces International December 2022 www.furnaces-international.com

LIFE OF A FURNACE

AUTONOMOUS CHARGING & SKIMMING MACHINES

LIFE OF A FURNACE

Figure 2. Refractory lining of a new snorkel before campaign

lifetime. The reliability of the refractory is especially important when operating with a single RH degasser as a vessel change takes considerable time. To achieve a high refractory lifetime, it is essential to determine the main factors influencing refractory wear. This enables the maintenance of the RH vessel to be planned and avoids unscheduled shut downs. As a consequence, the productivity of the RH degasser can be optimised.

Steel Melting Shop No II at the Rourkela Steel Plant, was commissioned in 1996. The RH-OB facility was introduced during the expansion of the steelshop in 2013 but was not commissioned until 2016, in the final phase of the steelshop’s modernisation. All quality steel such as IF steel, automotive and deep drawing, alloy steel for pressure vessel, HIC resistant steels, line pipe, ball bearings and so forth can be produced. The following metallurgical benefits characterised in the RH-Treatment at Rourkela Steel Plant:

� Optimum decarburisation to less than 20ppm carbon;

38 Furnaces International December 2022 www.furnaces-international.com

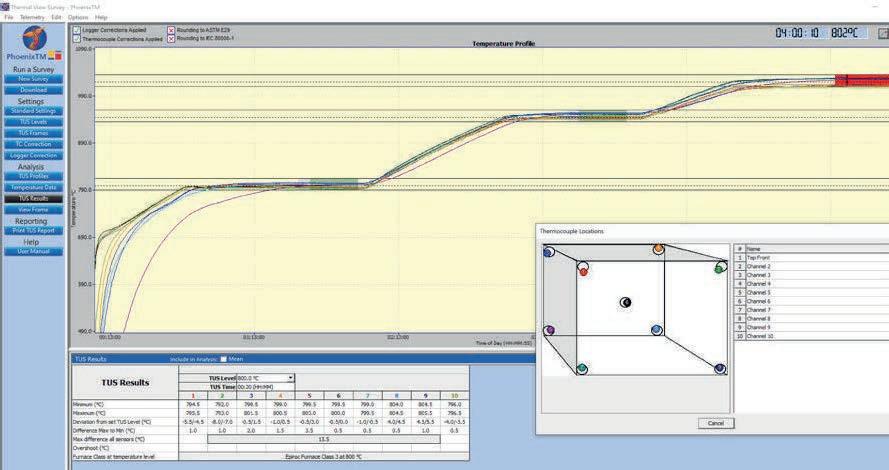

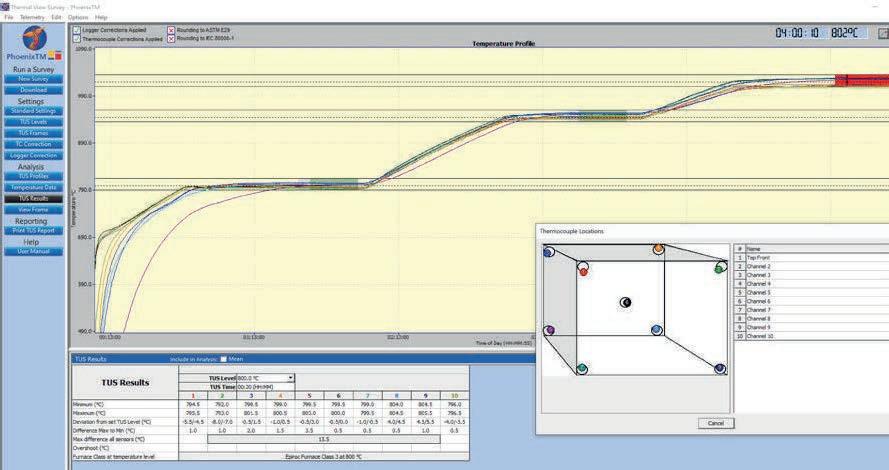

Temperature •Complete product temperature profile •Measure up to 20 points •No Trailing Thermocouples so quick, safe and cost effective •Custom systems to meet specific application challenges including Oil Quench! •Understand, control and improve your process TUS •Fully compliant to AMS2750 or CQI-9 •Live RF Telemetry TUS Data •Batch, Semi and Continuous Furnace Operation •Minimal Production Down Time •Quick easy TUS report generation Video •Inspect your furnace during live production •Find, fix and forget your furnace issues •Keep your furnace operational and productive . . . and Maintain ! Measure, Certify PhoenixTM GmbH Germany info@phoenixtm.de PhoenixTM Ltd UK sales@phoenixtm.com PhoenixTM LLC USA info@phoenixtm.com www.phoenixtm.com Visit us for more information: ... where experience counts ! Thru-process Temperature and Optical Monitoring

factors influencing

� Rapid reduction of hydrogen content to less than 1.5ppm;

� Removal of nitrogen under vacuum to less than 30ppm;

� Achievement of exact compositional values;

� Chemical heating of the melt is possible;

� Improved overall steel cleanliness.

As illustrated in the refractory lining depicted in Figure 1, the vessel along with the snorkel is lined with refractory bricks and castables. The snorkel is relined with bricks of 165mm thickness on the inside while the outer shell is covered with castable of 90mm thickness (Figure 2). The lower part of the leg consists of mag-chrome bricks 175mm thick and the upper part lined with bricks of 200 mm thickness. The lower vessel has 12 courses of direct bonded mag-chrome bricks of 250mm lining thickness and has a total height of 2000mm. There is a steel brick retainer plate 25mm thick between the lower vessel and middle vessel which supports the entire load of the latter. The brick retainer plate is covered with a special L-shaped brick[15] to prevent erosion of the retainer plate. The entire vessel is lined with mag-chrome bricks due to their high-volume stability, high hot strength to resist erosion by steel flow, high thermal shock resistance, high resistance to corrosion by steel and slag, high resistance to iron oxide attack and no carbon pick up of the steel from the refractory.

FURNACE 40 Furnaces International December 2022 www.furnaces-international.com

LIFE OF A

“To achieve a high refractory lifetime,

lifetime, it is essential to determine the main refractory wear”

From 88 to 130 heats

Initially, the life of the snorkel and lower vessel was approximately 88 heats and this increased to 130 heats after the first modifications. In the RH-OB vessel, gunning is carried out after every heat to minimise the erosion rate of the snorkel and to increase lifetime. Bricks in the lower vessel are changed after each campaign along with the snorkels.

The RH-OB was a new addition and the challenge, therefore, was to increase the life of the refractory to improve productivity, reduce the specific cost of refractories and, in turn, the cost of steel. In the present study, the abrupt failure of the snorkel and vessel refractory have been addressed which was adversely affecting steel processing in the RH-OB unit.

Identification of problems

Since its inception, the RH-OB operation had proved to be a bottleneck, due to the short campaign life of the snorkel and lower vessel refractory. Moreover, during the initial 50 campaigns, the vessel was down 15 times due to the shell being punctured and metal breakout from the snorkel and bottom junction, and once due to metal breakout from the lower and middle vessel retainer plate area. Also, during these 50 campaigns, the retainer plate had to be changed five times, leading to increased

FURNACE 41 Furnaces International December 2022 www.furnaces-international.com

LIFE OF A

LIFE OF A FURNACE

downtime of the vessel. This was adversely affecting productivity and the cost of production at the steel melting shop of RSP. To improve the campaign life, the two most vulnerable areas were identified after several case studies. These were: a) The weld joint between each snorkel and the vessel and; b) The retainer plate of the lower vessel.

Detailed inspection after every heat for three months, failure analysis and refractory post-mortem analysis led to identifying these main causes.

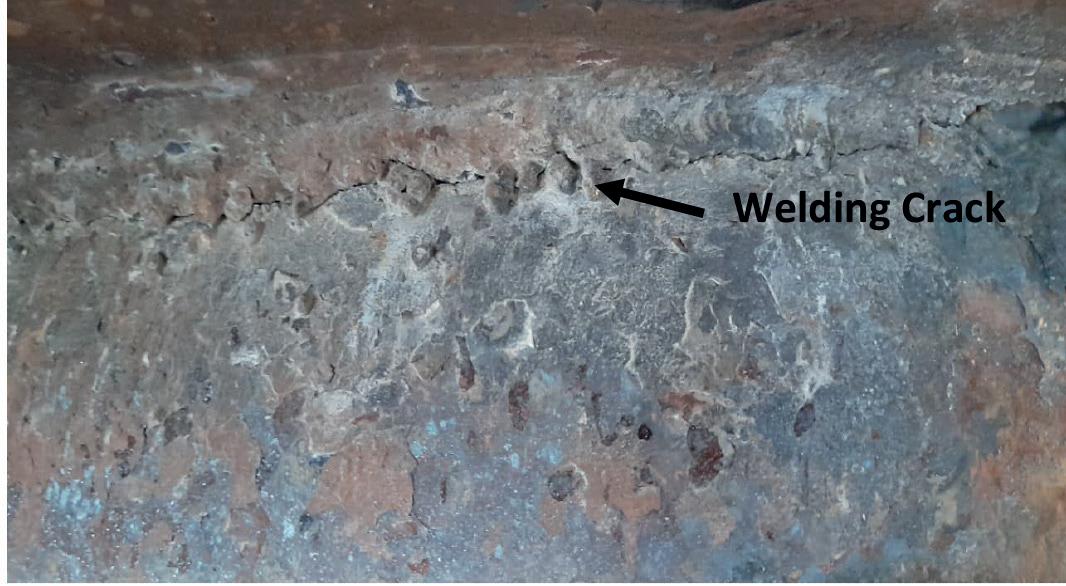

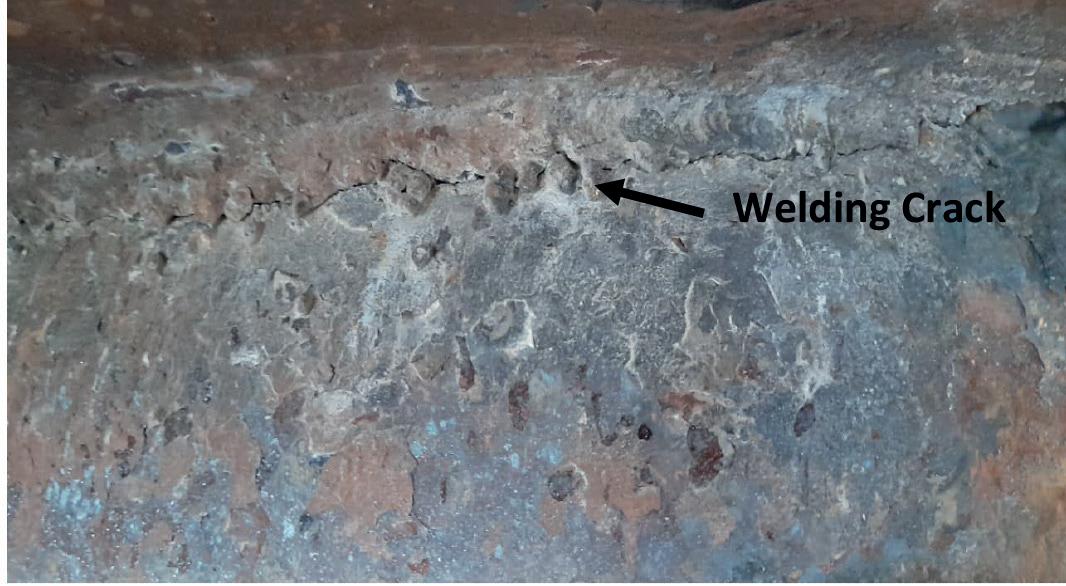

The snorkel

The snorkel consists of a metal cylinder lined with refractory inside and out. The metal part is welded to the lower vessel before the start of each campaign. This requires in-situ welding around the circumference of the cylinder from both inside and outside the joint after aligning the snorkel to the lower vessel. The weight of the snorkel and lack of space resulted in a poor weld quality which sometimes led to the creation of pinholes and cracks in the weld during operation (Figure 3). These small pin holes were sufficient for high velocity air ingress into the vacuum chamber which was evacuated to 1-2 mbar. The impact of this high velocity air on the refractory could cause sudden collapse of refractory in the impacted area. Falling refractory further exposed the steel heat being treated and the hole gradually became larger ultimately leading to metal breakout as depicted in Figure 4. As a result, the vessel had to be taken out of service for repair frequently.

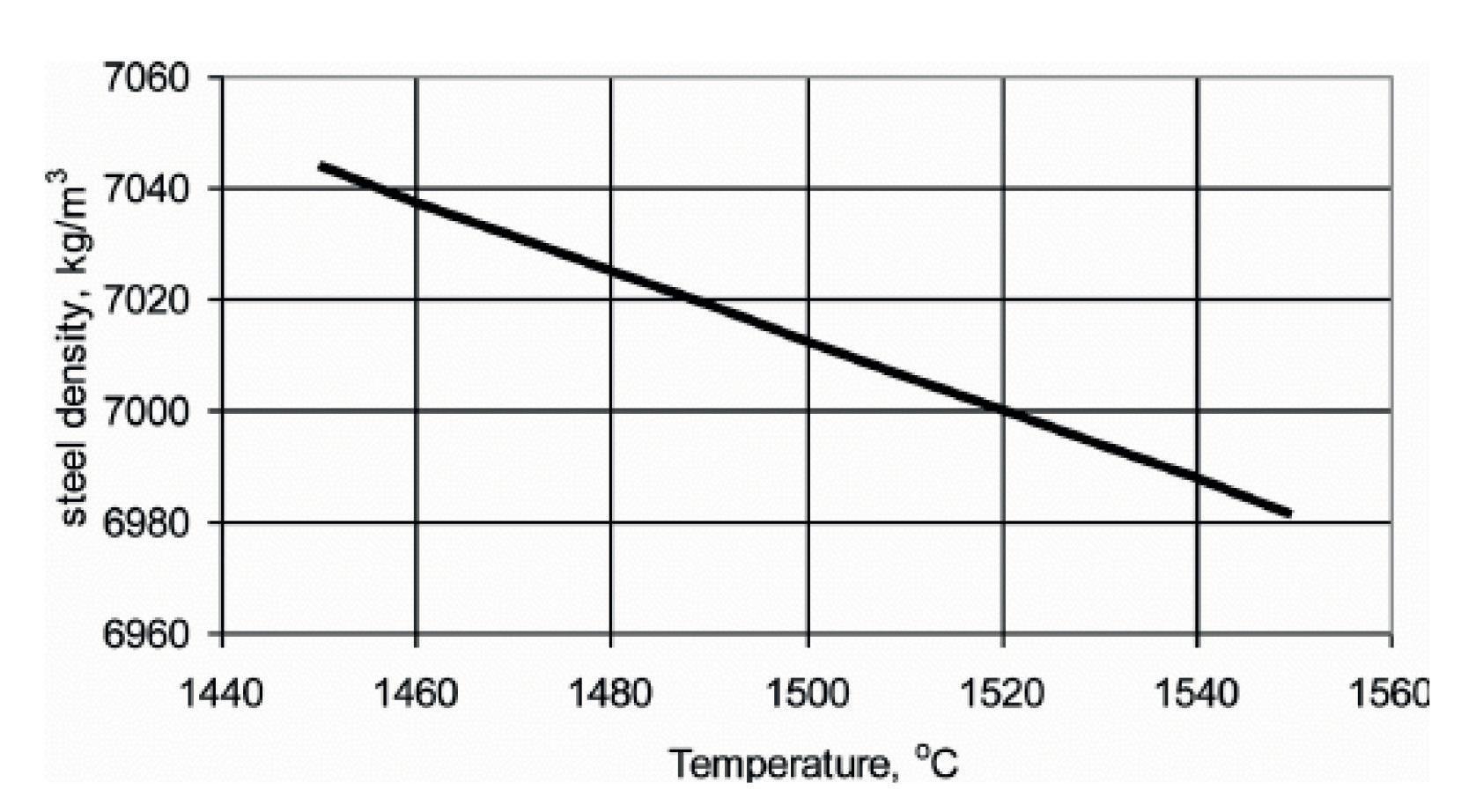

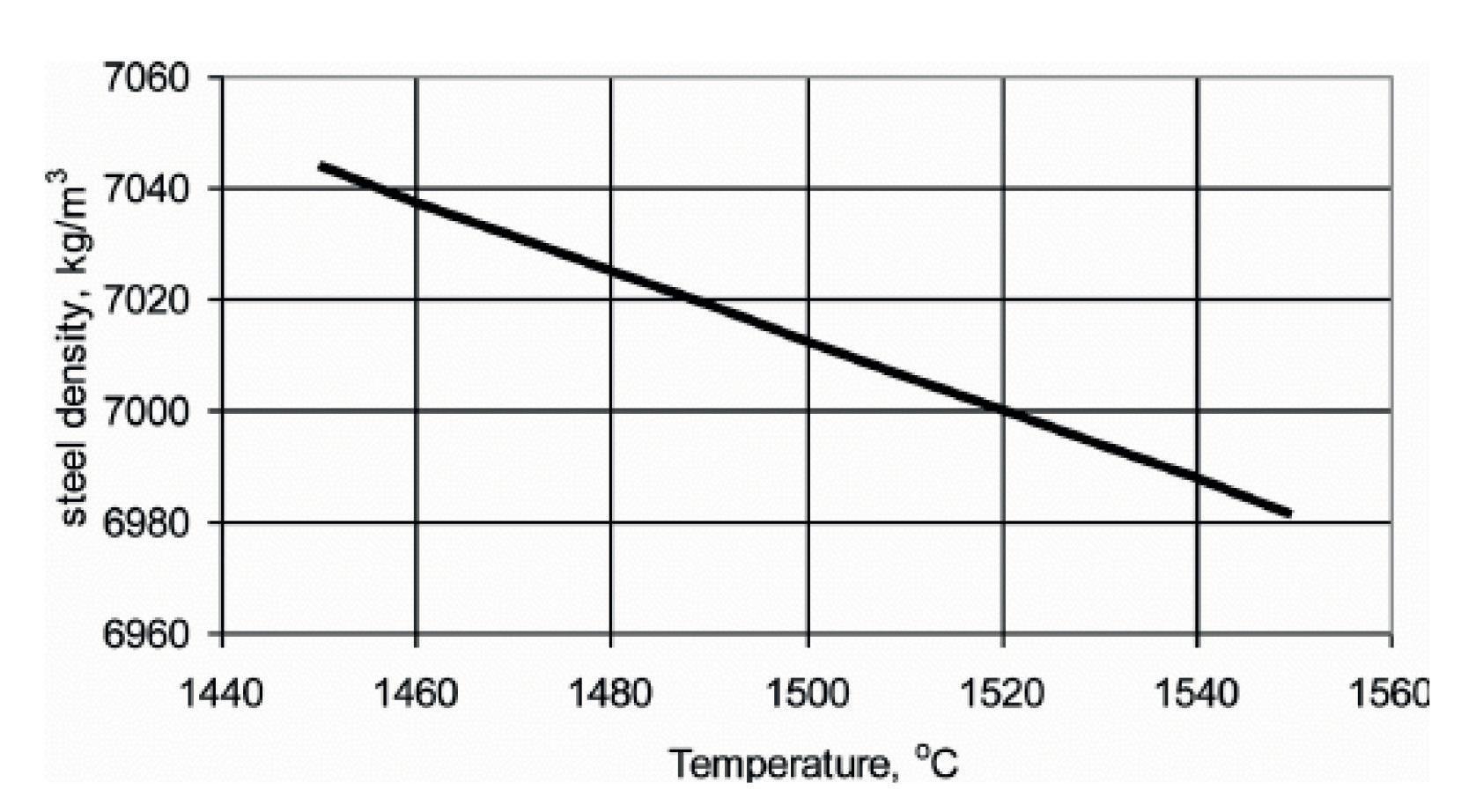

Apart from this, severe turbulence of liquid steel was occurring within the vessel during very low vacuum operation. This

42 Furnaces International December 2022 www.furnaces-international.com

was aggravated when the temperature of the steel charged was high – above 1640°C – and this elevated temperature decreased the density of the liquid steel (to around 6.9kg/cm3 Figure 5)[14] which caused a sharp rise of the height of the liquid steel above the recommended 1.47m design level required to produce steel splashing within the vessel during the deep degassing stage. This thermo-mechanical impact resulted in rapid erosion of the thin refractory lining on the bottom retainer plate area, which was only 140mm thick. Once erosion of this refractory was complete, the steel retainer plate was exposed and eroded due to the high velocity and impact of liquid steel. This resulted in the sudden collapse of refractory bricks once the retainer plate, which supported the refractory, failed and this in turn led to hole formation in the lower vessel, which resulted in a loss of vacuum and

43 Furnaces International December 2022 www.furnaces-international.com

LIFE OF A FURNACE

Figure 3a. Welding crack at the junction of vessel bottom and snorkel

Figure 3b. Detail of welding crack at snorkel

LIFE OF A FURNACE

stopped the operation.

The problem was verified using Bernoulli’s equation. The velocity of the air ingress into the vessel was calculated with real-time data and found to be above supersonic speed. According to Bernoulli’s equation:

p + 1/2ρV2 +ρgh = constant (1) where p is the pressure, ρ is the density, V is the velocity, h is the elevation and g is the gravitational acceleration. Now considering that the height is similar we get:

P1–P2= 1/2(ρ2V22–ρ1V12) (2) and, A1V1 = A2V2 (3) Therefore, from equations 2 and 3, it shows that decreasing the area of the hole or decreasing the pressure of the vacuum will increase the air velocity.

A2< A1, V2> V1

V2> V1, p2< p1

From the real time data, the air velocity with decreasing pressure is calculated for vacuum pressures of 1mbar and 10mbar, as shown in the box below, indicating that the velocity of air through a pin hole is much higher than supersonic speed and has

44 Furnaces International December 2022 www.furnaces-international.com

Figure 4. Vessel puncture and metal break out at welding joint between bottom and snorkel

WE ARE USING ALL OUR ENERGY DESIGNING YOUR FURNACE, SO YOU DON'T WASTE YOURS! INNOVATION AS STANDARD ® TOLEDO ENGINEERING / TECOGLAS / ZEDTEC / KTG ENGINEERING / KTG SYSTEMS / EAE TECH www.teco.com

Figure 5. Temperature vs steel density

sufficient momentum to dislodge the refractory lining resulting in leakage of metal.

Experimental

Several steps were taken to eliminate the weld joint problem. First, a channel in the form of a ‘V’ was prepared only on the outside joint of the snorkel to the lower vessel, as inside is covered with refractory. The ‘V’ was prepared with a 45° angle following the recommended procedure of the supplier.

Proper grinding was also ensured in the area. The root run weld and final sealing weld run was made using Tungsten Inert Gas (TIG) welding. Furthermore, in place of random ultrasonic testing of the weld, 100% ultrasonic testing was carried out to detect any weakness of the weld which was then repaired.

To address the increase in height of liquid steel inside the vessel because of a lower steel density at increased temperature, the inside of the vessel was inspected thoroughly after each campaign for five subsequent campaigns to ascertain the maximum height up to which metal splashing ocurred.

46 Furnaces International December 2022 www.furnaces-international.com

LIFE OF A FURNACE

Increased steel splashing

The higher level of steel resulted in increased steel splashing inside the vessel and thereby eroded the refractory and subsequently the brick retainer plate. To take care of the unacceptable high rise of liquid steel, the height of the retainer plate was increased by 300mm. Height increase protected the brick covering of the plate from becoming eroded which, in turn, increased the life of the retainer plate as well as that of the lower and middle vessels as shown in Figure 6. HA 90 dense castable was also used to patch the area to retard brick erosion in this vulnerable region.

In conclusion, during the initial 50 campaigns the average life was only 106 heats and there were 15 cases of metal breakout from the snorkel welded joints. After the necessary modifications, in the next 50 campaigns, metal breakout occurred on only three cases and that too after a high snorkel life. The average life was increased to 130 heats and there was no damage to the brick retainer plate as a result of a marked reduction in erosion of refractory in the area. Vessel down time was dramatically reduced as a result of the significantly fewer shell repairs required.�

References

J Pieprzyca, T Merder, M Saternus et al , ‘Physical Modelling of Steel Flow in RH Apparatus,’ Archives of Metallurgy and Materials, vol 60, No 3, pp 1859–1863, 2015

M Takahashi, H Matsumoto, and T Saito, ‘Mechanism of decarburization in RH degasser,’ ISIJ International, vol 35, No 12, pp 1452–1458, 2007

Y G Park, K W Yi, and S B Ahn, ‘Effect of operatingparameters and dimensions of the RH system on melt circulationusing nu-

47 Furnaces International December 2022 www.furnaces-international.com

LIFE OF A FURNACE

merical calculations,’ ISIJ International,vol 41, No 5, pp 403–409, 2001

Y Luo, C Liu, Y Ren, and L Zhang, ‘Modeling on the fluid flow and mixing phenomena in a RH steel degasser with oval downleg snorkel’ Steel Research International, vol 89, No 12, Article ID 1800048, 2018

L Lin, F Bao, L Q Zhang, and H L Ou, ‘Physical model of fluid flow characteristics in RH-TOP vacuum refining process ‘ International Journal of Minerals, Metallurgy, and Materials, vol 19, No 6, pp 483–489, 2012

H Ling, C Guo, A N Conejo et al , ‘Effect of snorkel shape and number of nozzles on mixing phenomena in the RH process by physical modelling’ Metallurgical Research & Technology, vol 114, No 111, pp 1–13, 2017

J H Wei, N W Yu, and Y Y Fan, ‘Study on flow and mixing characteristics of molten steel in RH and RH-KTB refining processes’ Journal of Shanghai University (English Edition), vol 6, No 2, pp 167–175, 2002

D Q Geng, H Lei, and J C He, ‘Numerical simulation of the multiphase flow in the Rheinsahl-Heraeus (RH) system’ Metallurgical and Materials Transactions B, vol 41, No 1 pp 234–247, 2010

X G Ai, Y P Bao, W Jiang, J H Liu, P H Li, and T Q Li, ‘Periodic flow characteristics during RH vacuum circulation refining’ International Journal of Minerals, Metallurgy, and Materials, vol 17, No 1, pp 17–21, 2010

L Zhang and F Li, ‘Investigation on the fluid flow and mixing phenomena in a Ruhrstahl-Heraeus (RH) steel degasser using physical modelling’ JOM, vol 66, No 7, pp 1227–1240, 2014

X G Ai, S L Li, N Wang, and N Lv, ‘Simulation of inclusions removal influenced by snorkel and blowing parameters in RH

refining’ Advanced Materials Research, vol 291, No 294, pp 155–158, 2011

P H Li, Q J Wu, W H Hu et al , ‘Mathematical simulation of behaviour of carbon and oxygen in RH decarburization, ‘Journal of Iron and Steel Research International, vol 22, No S1, pp 63–67, 2015

V Seshadri and S L Costa, ‘Cold model studies of R H degassing process’ Transactions of the Iron and Steel Institute of Japan, vol 26, No 2, pp 133–138, 1986

January 2014 Archives of Metallurgy and Materials 59(2):487-492, DOI:10 2478/ AMM-2014-0080

S Roy, P R Padhee, A Bhattacharyya and R K Singh, ‘Improving health and productivity of calcining kiln through several innovations in refractory maintenance practices at Rourkela Steel Plant’ Processing and Characterisation of Materials, vol 13, pp 245–254, 2021

48 Furnaces International December 2022 www.furnaces-international.com

LIFE OF A FURNACE

GLASS SERVICE Are you looking to the future for CO2 reduction? Then look no further than FIC... Tying Technology Together The eventual solution is hybrid fur naces operating at up to 80% electricity BUT small steps increase electric boost to reduce the CO2 then superboost. GS and FIC are THE companies to supply CFD modelling of your flexible future fur naces. FIC ...the pathway to a cleaner future www.fic-uk.com +44 (0) 1736 366 962 The World,s Number One in Fur nace Technology FIC (UK) Limited Long Rock Industrial Estate, Penzance, Cornwall TR20 8HX, United Kingdom

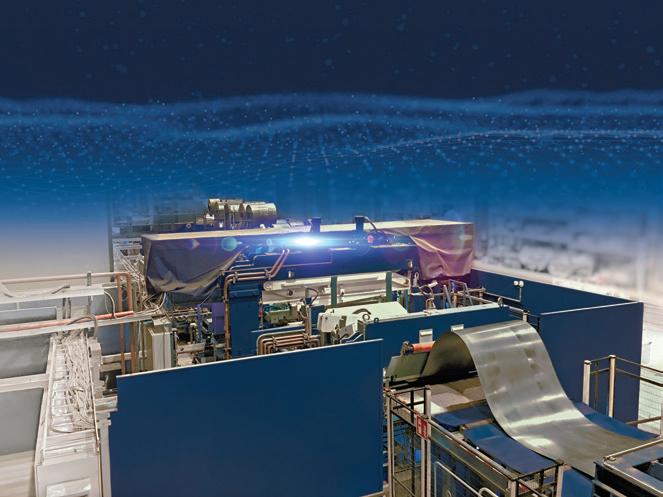

Furnace simulations to assist in daily operation

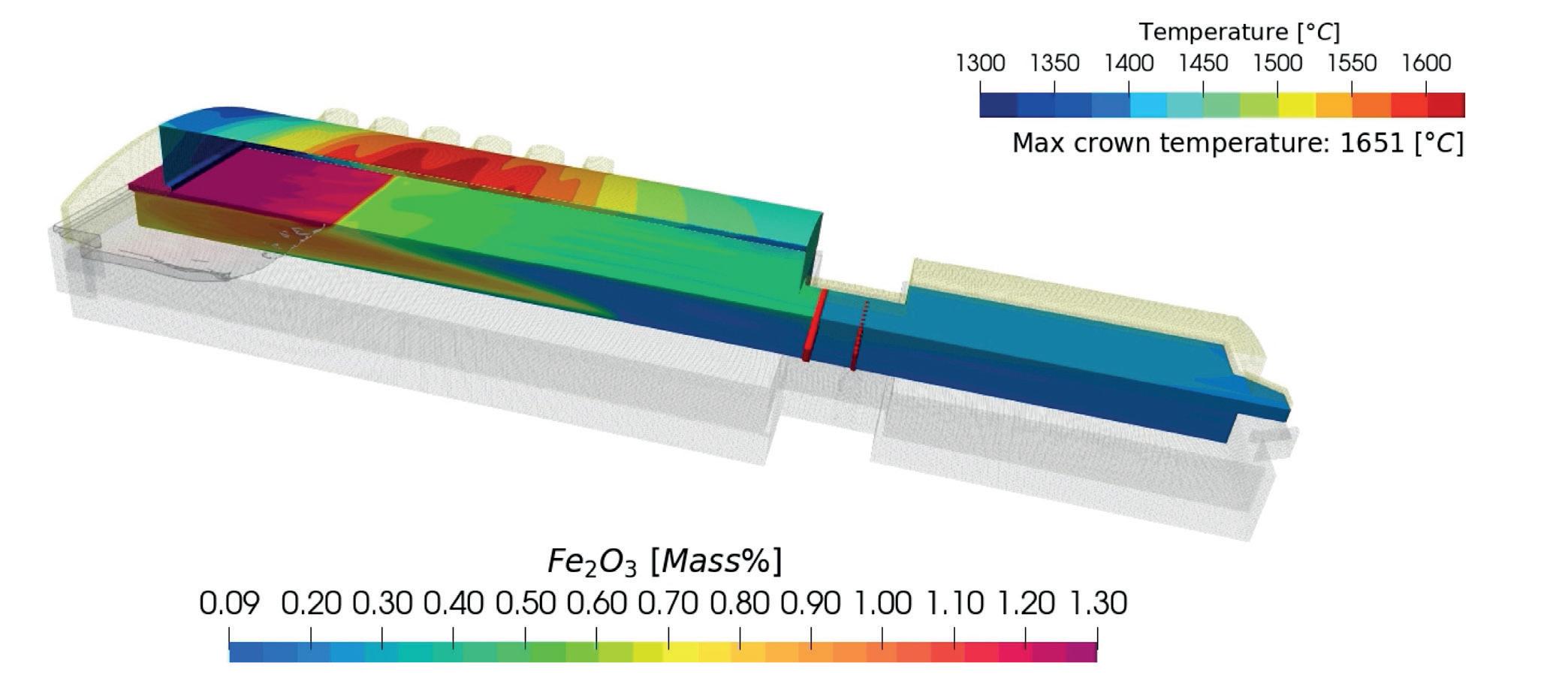

CelSian has developed a simulation software, GMT-X, for glass furnaces. Andries Habraken* outlines how the software’s dedicated models allow it to accurately describe the inside of a glass furnace.

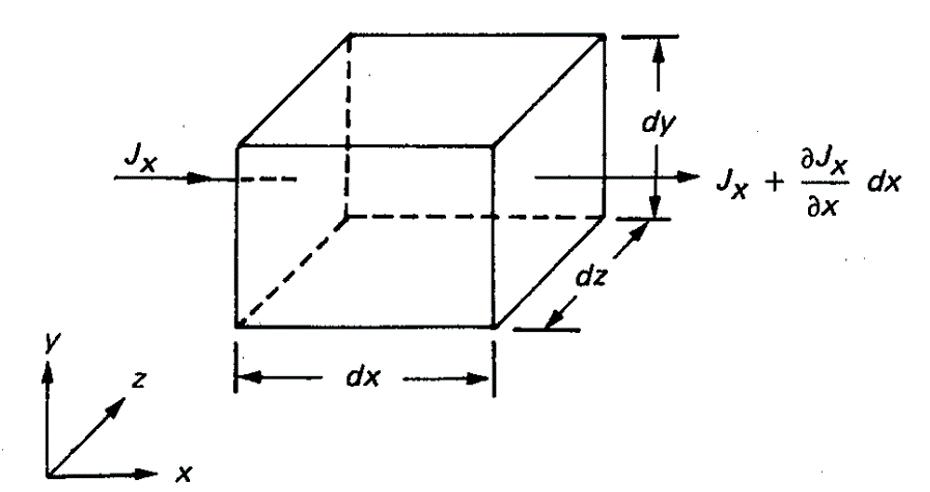

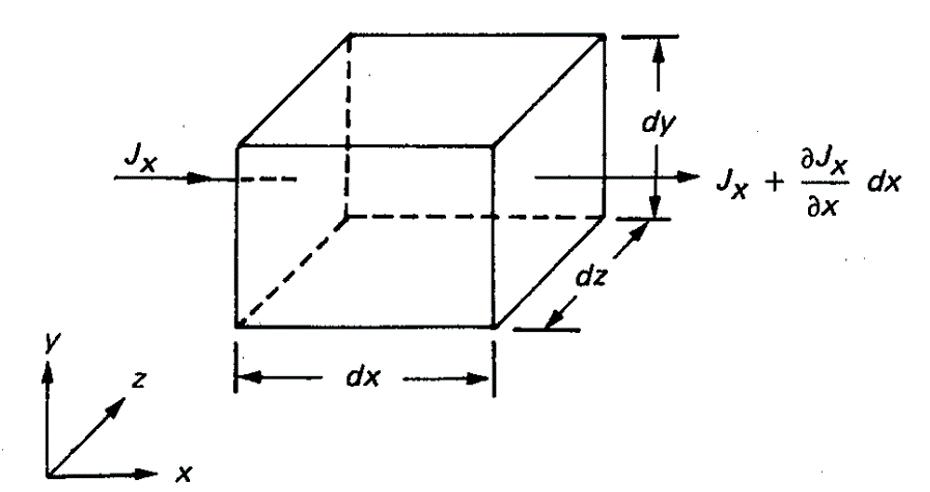

Computer simulation started its development in the previous century. The initial goal was to have a tool that could help understand and predict heat and mass transfer, fluid flow, chemical reactions, and other related processes that occur in engineering equipment, in the natural environment, and in living organisms.

The processes of heat transfer and fluid flow pervade many aspects of our life.

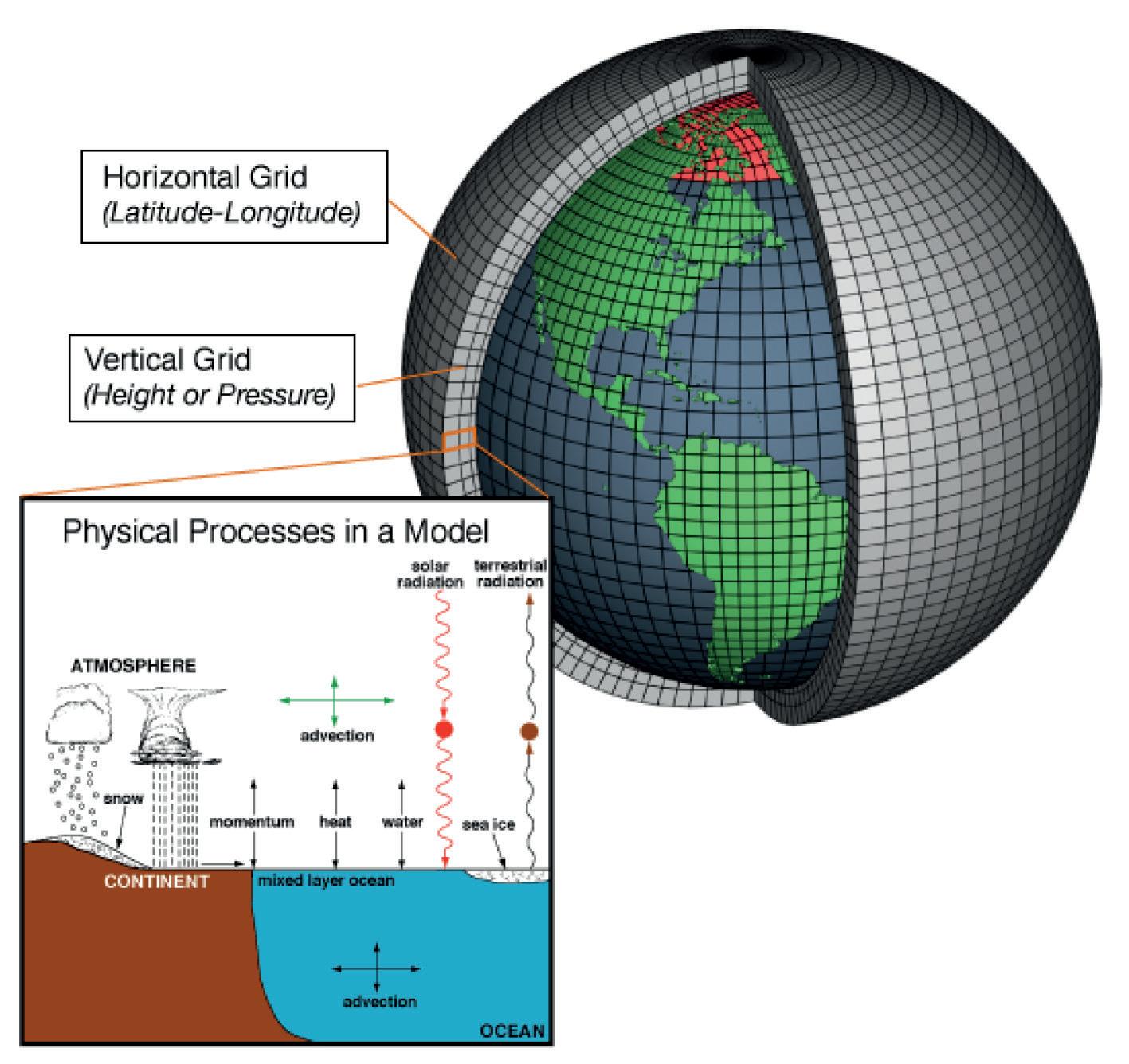

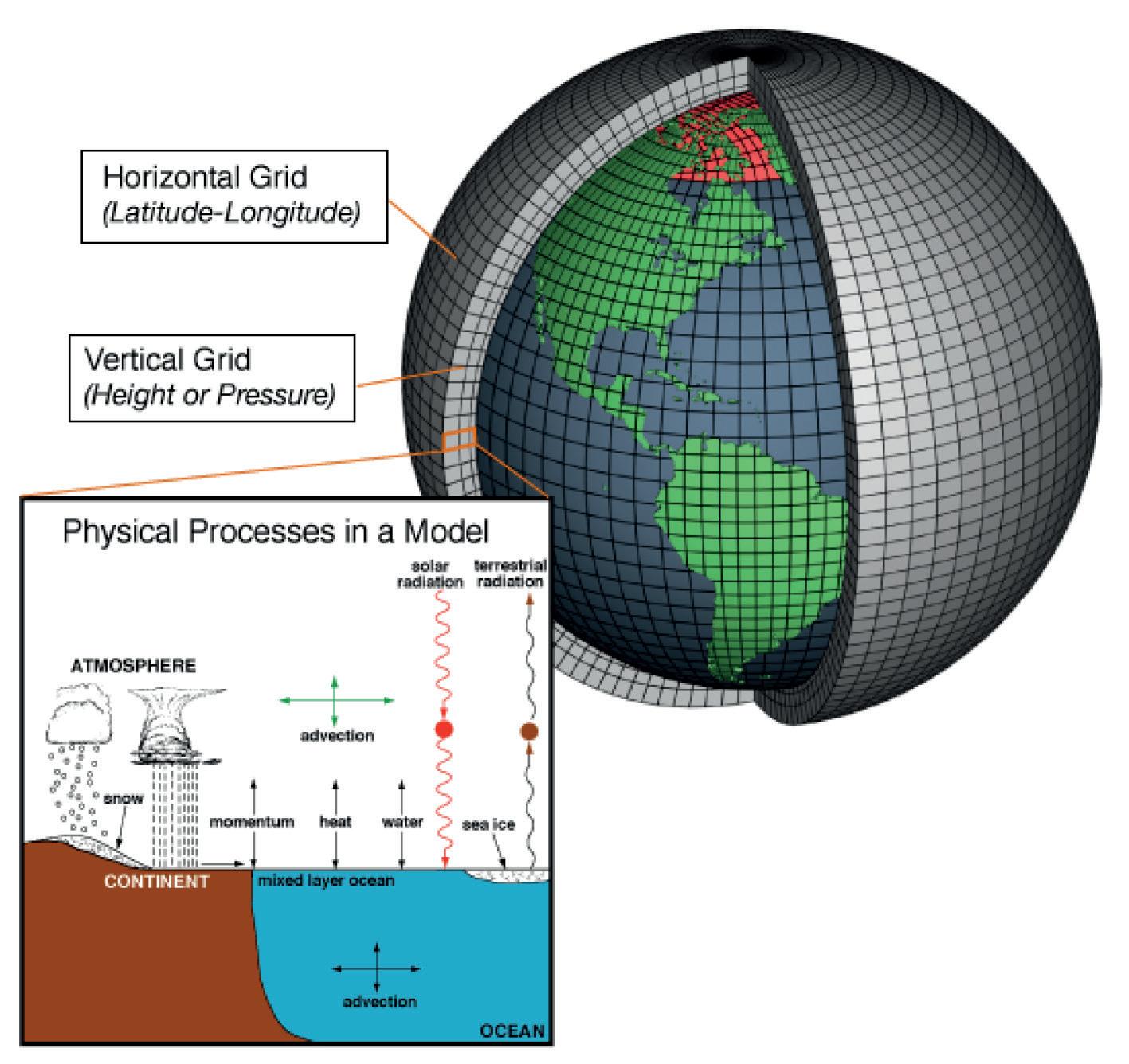

Like in real life, the best approach to solve a complex problem is to divide it into smaller pieces and try to solve it piece by piece. One of the first simulation methods described was based on this principle and worked as follows: a process is cut into many small boxes, and for each box, the laws of physics are calculated.[1] For the complete process, there is information exchange between the boxes. This is the principle of computational simulation tools as we know them today (Figure 1).

*Segment Leader of Process Optimisation, CelSian, Eindhoven, Netherlands www.celsian.nl

The weather forecast is a well-known example of a simulation tool that is used to predict wind, rain, and temperatures. Figure 2 shows an example of a climate model.[2] The Earth’s atmosphere is cut into a finite number of connecting blocks, and in each block, equations are solved to describe the local situation. The model includes all the basic components of the climate factors (atmosphere, ocean, land, and sea ice). The boundaries of this model lie in the energy coming from the sun and the heat losses toward the surrounding space.

Weather forecast models are incorporated into our daily life. We use them to schedule activities or decide how to commute

LIFE

A FURNACE 50

OF

Furnaces International December 2022 www.furnaces-international.com

to the office for instance.

Glass furnace simulation

CelSian developed simulation software for glass furnaces. This simulation software, named GTM-X, is similar to the software used for the weather forecast or the one used in the automotive and airplane industries, but it is equipped with dedicated models

Figure 1. Example of an energy flow balance over a control volume (Patankar).

LIFE OF A FURNACE

Figure 2. US NOAA, a model based on the ocean and atmosphere interactions

51 Furnaces International December 2022 www.furnaces-international.com

LIFE OF A FURNACE

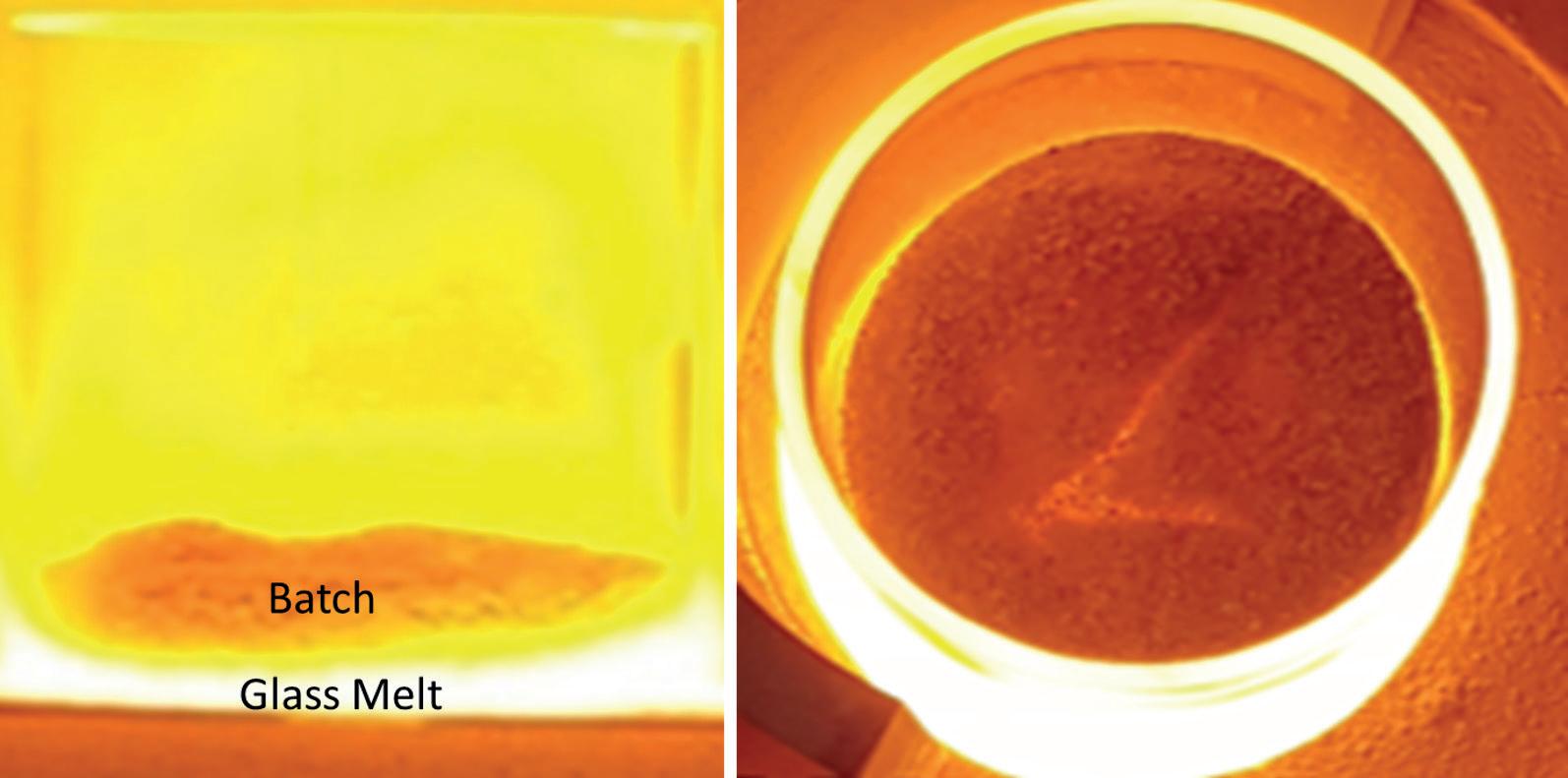

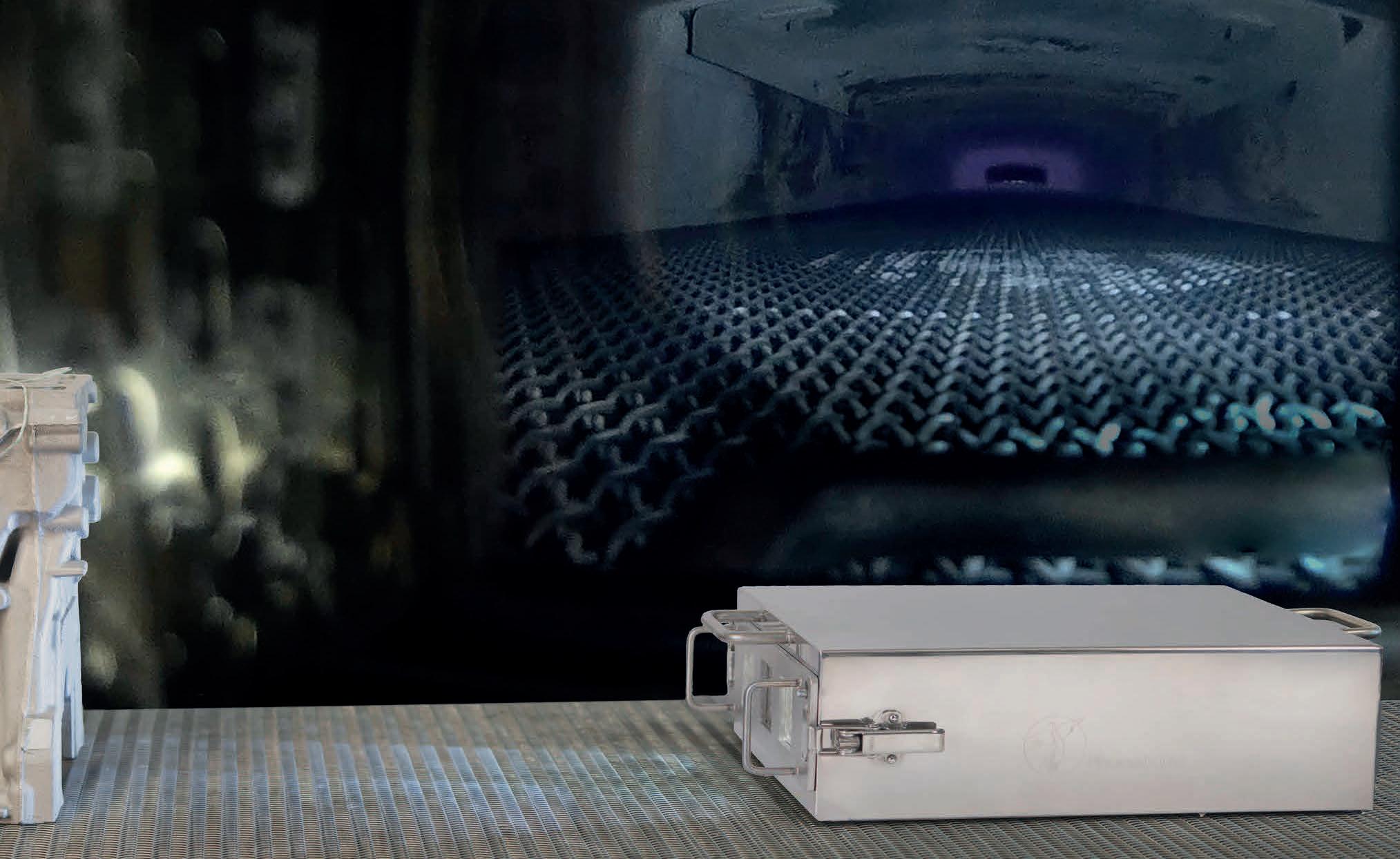

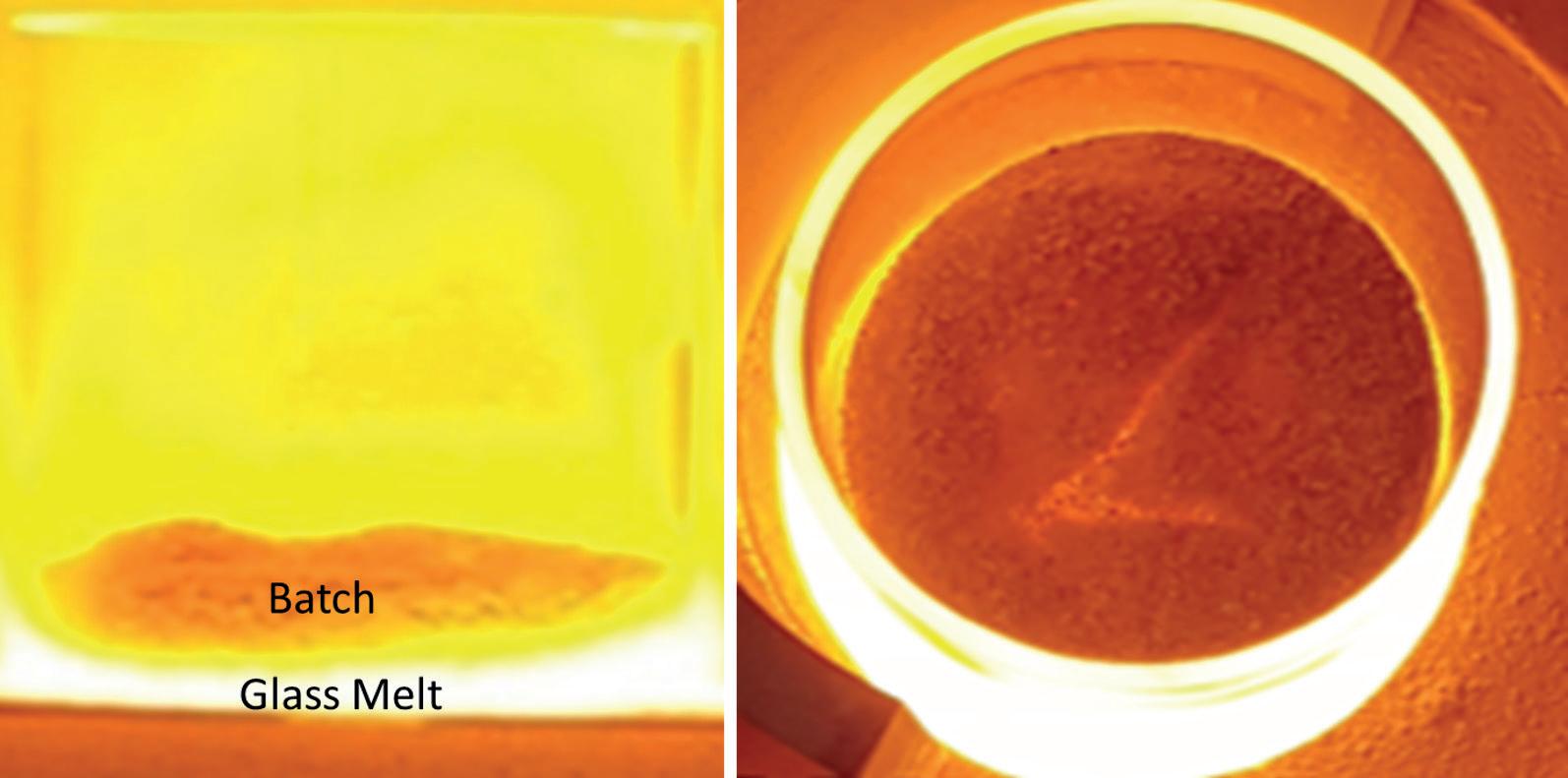

Figure 3. The cold top furnace experiment in CelSian’s laboratory.

that allow it to accurately describe the phenomena inside a glass furnace.

Figure

Data from laboratory experiments and many years of field experience is used to define and validate dedicated models like the model for the batch blanket[3] and the model to calculate the dissolution of sand grains.[4] CelSian’s laboratory is supporting the modelling of cold top furnaces, as the request for full electric furnace technology is rapidly increasing (Figure 3). This simulation software is used in-house by CelSian’s engineers to support process improvement projects, as well as by the engineering teams of several glass producers and furnace designers. Continuous developments are driven by feedback from the industry, like the implementation of a special radiation model needed for low iron glass melts.[6] Nearly all furnace designs are validated by mathematical furnace simulations. GTM-X is widely accepted simulation software and CelSian is proud that most furnace designers use GTM-X to improve current furnaces performances and work on new designs. The questions that GTM-X answers are related to

52 Furnaces International December 2022 www.furnaces-international.com

4. Example of a hybrid furnace design (courtesy of Fives Stein).

JOIN US IN TURKEY FOR GLASSMAN EUROPE

The Turkish glass industry is currently enjoying an unprecedented surge in demand, join us in Istanbul next February where the hollow glass industry does business. Meet exhibitors offering the latest innovative manufacturing solutions for energy efficiency, quality control, packaging, logistics and decoration. Sign up to be the first to hear about exhibitors, speakers and what’s on at our upcoming events.

(0)1737 855117

(0)1737

8-9

FEBRUARY Istanbul, Turkey

GET INVOLVED

NEW LOCATION FOR 2023 CONFERENCE PROGRAMME NETWORKING EVENTS

Join the

Group @glassmanevents BUSINESS MEDIA Official

partner:

EXHIBIT Ken Clark Sales Director +44

kenclark@quartzltd.com EXHBIT Manuel Martin Quereda International Sales Executive +44

855023 manuelm@quartzltd.com SPEAK Greg Morris Editor +44 (0)1737 855132 gregmorris@quartzltd.com

Glassman

media

Organised by: www.GlassmanEvents.com/Europe

“

Reducing carbon footprints is one of the largest challenges that new furnace designs will need to tackle

LIFE

A FURNACE 54 Furnaces International December 2022 www.furnaces-international.com

OF

”

low energy use, good product quality, low emissions, and a long furnace lifetime.

Future-proof furnaces

Reducing carbon footprints is one of the largest challenges that new furnace designs will need to tackle. Current initiatives focus on reducing energy use and investigating alternative energy sources like biofuel, electrical energy, and hydrogen. Although the best choice will most likely be driven by availability, technical challenges can be solved by computer modelling.

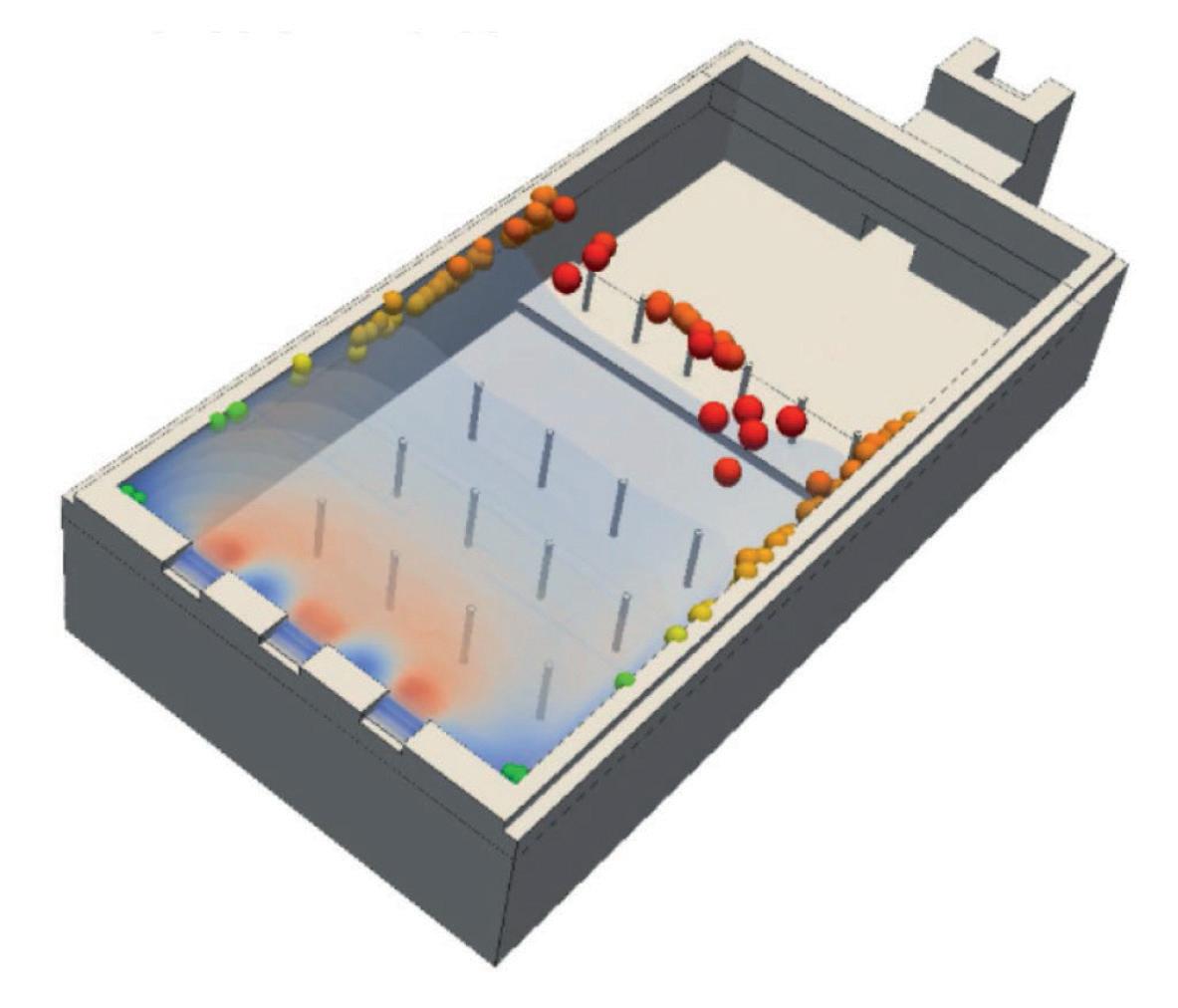

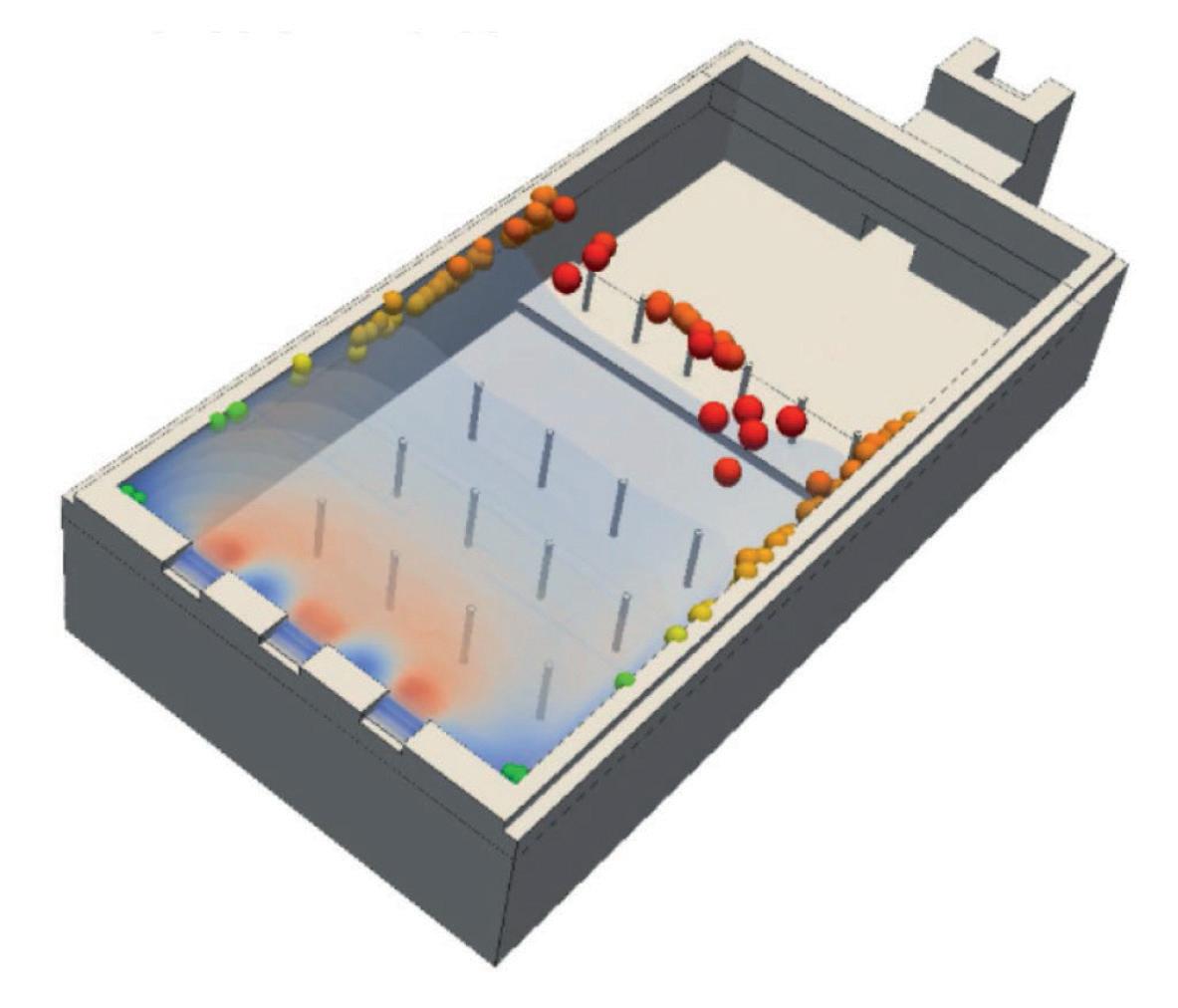

Increasing the amount of electrical boosting energy in a conventional furnace should not be done without carefully checking the impact on product quality. The flow of the glass melt is driven by temperature differences, and the wrong location of the electrodes can lead to production issues (Figure 4).

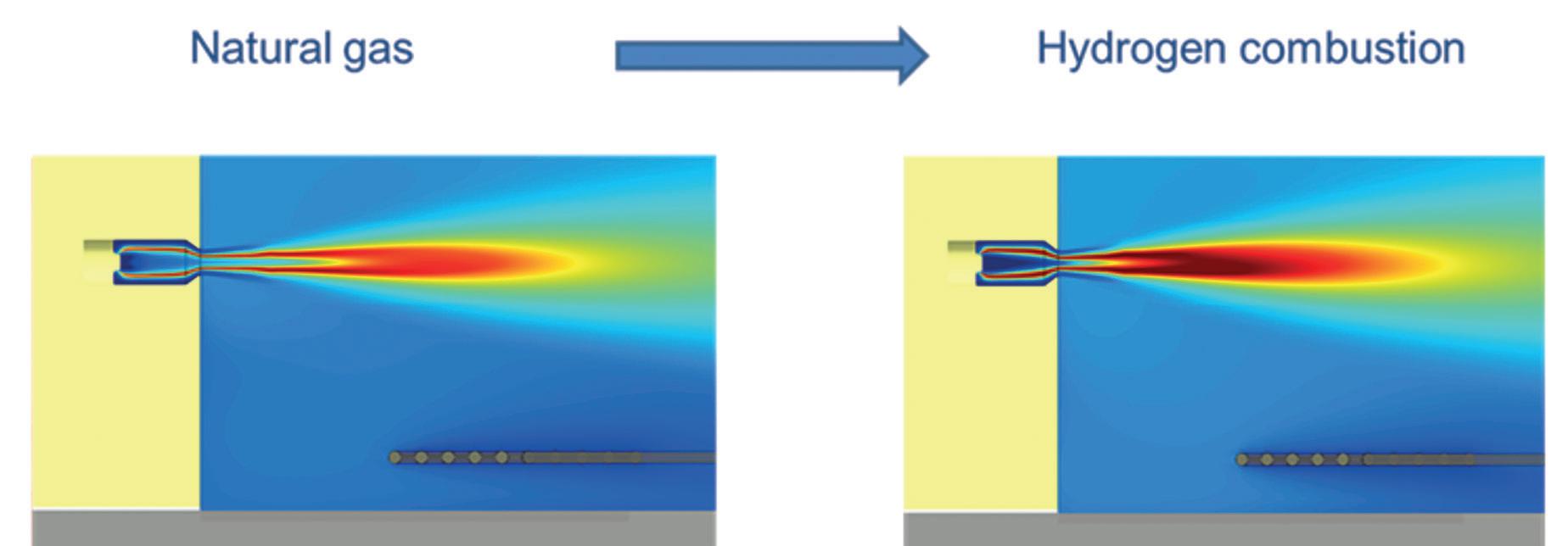

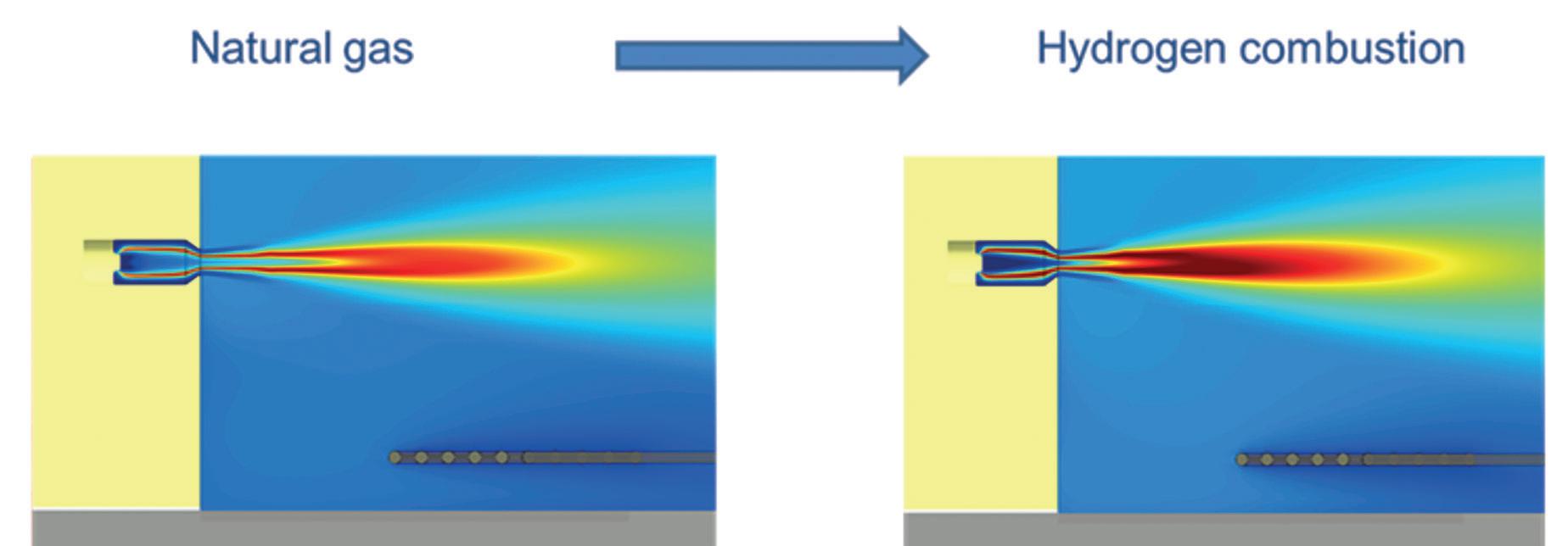

Using an alternative energy source like hydrogen leads to questions like burner design, the impact on product quality, and the consequence on the furnace’s lifetime. Figure 5 shows the result of a project in which modelling is combined with lab-scale testing to look at the impact of hydrogen combustion on heat transfer.

55 Furnaces International December 2022 www.furnaces-international.com

LIFE OF A FURNACE

Figure 5. Modelling and validation of hydrogen combustion.

LIFE OF A FURNACE

Support daily production

Solid inclusions, bubbles, and blisters are investigated in a laboratory, and their source of origin can be traced via computer modelling. Once the cause of a defect is known, possible solutions are safely tested in the computer model, leading to the safest and most promising solution to be applied in the real furnace. This approach has been proven in hundreds of projects.

For furnaces in which the product colour changes, it is profitable to reduce the time at which the product is out of the spec.

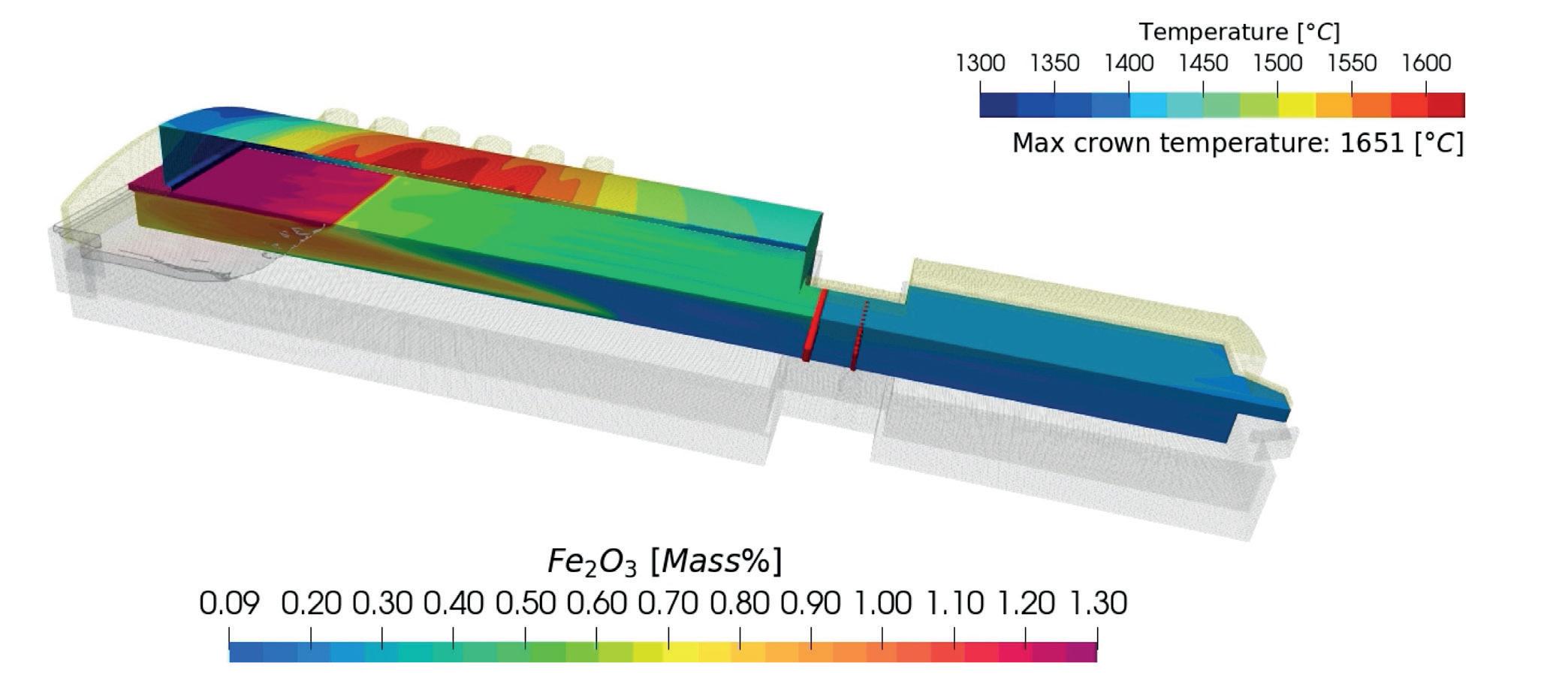

Figure 6 shows a model of a float furnace that is in the process of a colour change. The simulation reveals the change in iron oxide in the glass melt, which affects the product colour but also the radiative properties of the glass smelt. These properties are important to consider as they have an impact on the crown temperatures in the furnace. The simulation shows how the energy needs to be corrected to prevent overheating the crown.

Furnace control

Having a time changing computer model opens the road to other applications. The model predicts how and when changes oc-

56 Furnaces International December 2022 www.furnaces-international.com

Figure 6. Time transient modelling of a colour change and the impact on temperatures.

cur as a result of a change in the process. As the response of a glass furnace is very slow, it is difficult for a furnace operator to understand how the furnace responds. The dynamic computer model is a very helpful tool to support the operator. It is a digital twin of the real furnace, providing many virtual sensors beneath the melt surface.

The simulation as described above is almost as fast as in real-time, but still too slow to steer the glass furnace directly. For direct control of the furnace, a much faster model is created from the CFD model, by performing a series of step tests on the digital twin. This method is safe for the furnace, does not impact product quality, and results in a control model without information from unknown disturbances.

The reduced model can be used directly in an MPC to estimate glass melt temperatures in the furnace, and change the setpoints to keep these temperatures stable and within the allowed bounds. By using this technique, it has been proven that the standard deviation for average glass melt temperatures reduced from 1° C to 0.25 °C.

By using the controller, temperature stability is achieved and

57 Furnaces International December 2022 www.furnaces-international.com

LIFE OF A FURNACE

Figure 7. Using a detailed furnace simulation to generate a fast and accurate control model.

the unstable period after a large process change, like a job change, is reduced to a minimum.

If you are interested in the services and software CelSian offers, please contact us and we will find the best solution together. � References

1) Numerical heat transfer and fluid flow, Suhas V. Patankar, 1980, McGraw-Hill Book Company

2) National Ocean Service, a model based on ocean and atmosphere interactions, January 21, 2021.

3) A.J. Faber, R.G.C. Beerkens, H. de Waal: Thermal behaviour of glass batch on batch heating, Glastech. Ber. 65(7), 177–185 (1992)

4) R.G.C. Beerkens, H.P.H. Muijsenberg, T. van der Heijden: Modelling of sand grain dissolution in industrial glass melting tanks, Glastech. Ber. 67, 179–188 (1994)

5) R.G.C. Beerkens: Analysis of elementary process steps in industrial glass melting tanks – Some ideas on innovations in industrial glass melting, Ceram. Silik. 52(4), 206–217 (2008)

6) A.M. Lankhorst, L. Thielen, P.J.P.M. Simons, A.F.J.A. Habraken: Proper modeling of radiative heat transfer in clear glass melts. In: 73rd Conference on Glass Problems, ed. by S.K. Sundaram (Wiley, Chichester 2013) pp. 249–258

7) L. Huisman: Control of Glass Melting Processes Based on Reduced CFD Models, PhD Thesis (Technical University TU Eindhoven, Eindhoven 2005)

58 Furnaces International December 2022 www.furnaces-international.com

LIFE OF A FURNACE

Québec City, Canada

Future Aluminium Forum 2023: Meeting the Demand

With global aluminium demand projected to increase 40 per cent by 2030, the aluminium sector will need to produce an additional 33.3 Mt – a reality only possible through the inception of streamlined technologies, digital manufacturing and sustainable solutions across the supply chain.

Join us at the Future Aluminium Forum to meet manufacturers rising to the challenge, focus on the opportunities that growth will bring, and prioritize time for your own learning and networking.

To find out more about speaking contact:

Nadine Bloxsome, Conference Director nadinebloxsome@quartzltd.com +44 1737 855115

To find out more about stand and sponsorship opportunities contact: Nathan Jupp, Commercial Sales Director nathanjupp@quartzltd.com +44 1737 855027

In 2023, the Forum will return in a live format to Québec City, a region where the aluminium industry has existed for more than a century and is now seeing rapid change and collaboration between manufacturers, processors, suppliers and OEMs. Register

O cial media partners: Supported by:

your interest at www.FutureAluminiumForum.com

MAY 2023

@Alu_Forum

BUSINESS MEDIA LTD

Organised by:

Hong Kong’s only steel-rolling mill to produce recycled steel

Tenova Italimpianti has announced it has received a contract from Metalloinvest for the reconstruction of the Heating Furnace nr. 2 in the second rolling unit of Alexey Ugarov OEMK, in Russia.

As part of the reconstruction, the new Shiu Wing Steel, Hong Kong’s first and only steel-rolling mill, plans to produce recycled steel to meet growing demand created by China’s green ambitions in Hong Kong and other cities in the Greater Bay Area (GBA) development zone, according to a report by South China Morning Post.

The 65-year-old steelmaker plans to build an electric-arc furnace at its plant in Tuen Mun to produce 700kt of recycled steel a year by 2025 and expand its presence in the GBA, Dario Pong, Shiu Wing’s executive director, said in an interview.

The construction steel market in the development zone, which comprises Hong Kong, Macau and nine mainland Chinese cities in Guangzhou province, is estimated at 20 to 25Mt a year, a significantly higher amount compared to Hong Kong’s market of 1.2-1.5Mt a year.

“We hope to make the decision [to build the furnace] next year. We need about two years to build and then need about 10 years to recover that investment.”

Dario Pong, Shiu Wing’s executive director:

“We hope to make the decision [to build the furnace] next year. We need about two years to build and then need about 10 years to recover that investment,” Pong said.

Shiu Wing’s investment plan follows China’s decarbonization goals

set out at the 2020 United Nations General Assembly, where it pledged to peak carbon emissions before 2030 and reach carbon neutrality by 2060.

“We want to restart our [green] steelmaking business because we are seeing a new concept emerge – People are talking about green steel now,” Pong added. design of the walking hearth furnace includes the modification of the combustion system using the new technology burners with the aim to improve efficiency and reduce emissions.

The project aims also to eliminate the formation of a range of defects in the products, allowing the client to reduce costs and increase volumes of high quality long products (Special Bar Quality, SBQ).

NEWS GREENER FURNACES 0 Furnaces International December 2022 www.furnaces-international.com

NEWS GREENER FURNACES 60 Starbar® and Moly-D® elements are made in the U.S.A. with a focus on providing the highest quality heating elements and service to the global market. 58 years of service and reliability I Squared R Element Co., Inc. Phone: +1 (716) 542-5511 Email: sales@isquaredrelement.com www.isquaredrelement.com Industrial Heating Quarter Page 1 11/30/2021 2:43:23 PM PRINT + DIGITAL SUBSCRIPTIONS AVAILABLE ALUMINIUMTODAY.COM/SUBSCRIPTIONS Get the aluminium industry’s most informative read, direct to your inbox or letterbox. Subscriptions include six issues a year, the annual directory, two additional digital supplements and much more! AIT_Full_page_Portfolio_A4_Ad.indd 3 30/11/2022 11:18

Hatch to deliver hydrogen route for green steel project

Tata Steel has announced that Hatch will be part of the team to deliver the hydrogen route to make green steel at its lJmuiden plant in the Netherlands. Hatch has been selected to provide the engineering for the reducing electric furnace (REF) package, which, when coupled with a direct reduced iron (DRI) plant, will enable the production of green steel using hydrogen.

The hydrogen route project is part of Tata Steel’s commitment to produce steel with zero carbon emissions by 2045. To achieve that goal, Tata Steel will convert its steelmaking facilities from coal-based to hydrogen-based utilizing direct reduced ironmaking (DRI) technology, in which iron ore is directly reduced using natural gas, and progressively increasing amounts of hydrogen, and subsequently melted and refined in large and efficient rectangular electric smelting furnaces.

‘’We want to be CO 2 neutral before 2045 and we want to emit between 35 and 40% less CO2 before 2030. This will largely be done via the hydrogen route.’’

the building of a sustainable steel industry.’’

Joe Lombard, global managing director, metals, Hatch

“Efforts to reduce CO 2 emissions from iron and steel production are critical to mitigating the impacts of climate change. Transitioning to low-carbon emission steel production enables the building of a sustainable steel industry. We look forward to working together with Tata Steel on this landmark project and congratulate them for their leadership in accelerating this change,” shared Joe Lombard, global managing director, metals, Hatch.

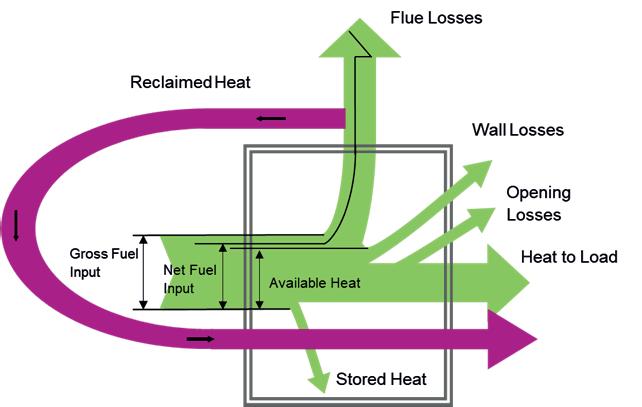

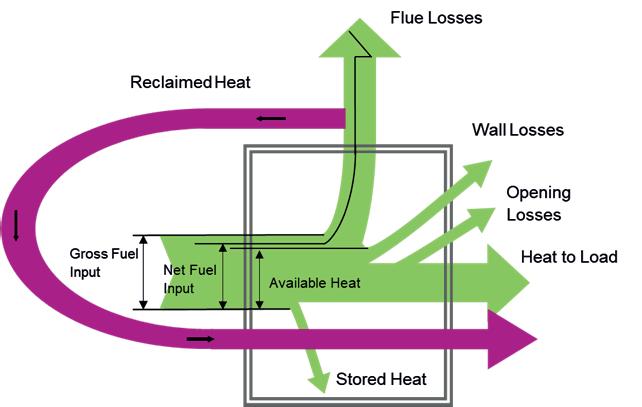

Tata Steel has engaged Hatch to develop basic engineering for the DRI reduction smelting complex,